Rockwell Automation 440N-Z21U16A, 440N-Z21U16B, 440N-Z21U16H, 440N-Z21U16J, 440N-Z21U26A User Manual

...Page 1

SensaGuard™ 18 mm Plastic Barrel Unique Coding

IMPORTANT

WARNING

440N-Z21U16*, 440N-Z21U26*

Installation Instructions

Original instructions in English

Operating Characteristics

SAVE THESE INSTRUCTIONS FOR FUTURE USE.

ENGLISH:

GERMAN:

FRENCH:

ITALIAN:

SPANISH:

PORTUGUESE:

POLISH:

This instruction sheet is available in multiple languages at www.rockwellautomation.com/literature. Se lect

publication language and type "SensaGuard" in the search field.

Dieses Instruktio nsblatt kann in mehreren Sprachen unter ww w.rockwellautomation.com/ literature gelesen

werden. Bitte Ihre Sprache anwähl en und "SensaGuard" im Suchfeld eintippen.

Ces instructions sont disponibles dans différentes langues à l'adresse suivante www.rockwellautomation.com/

literature. Sélectionner la langue puis taper “SensaGuard” dans le champ de recherche.

La presente scheda d'istruz ione è disponibile in varie lingue sul sito w ww.rockwellautomation.com/literature.

Selezionare la lingua desiderata e digitare "SensaGuard" nel campo di ri cerca.

Puede encontrar esta hoja de i nstrucciones en varios idiomas en www.rockwel lautomation.com/literature.

Seleccione el idioma de pu blicación y escriba "SensaGuard" en el campo de búsque da.

Esta folha de instruções está disponível em várias línguas em www.rockwell automation.com/literature.

Seleccione a língua de publicação e entre com "SensaGuard" no espaço de busca.

Ta kartka z instrukcjami jest dostepna w wielu jezykach na stronie: www.rockwellautomation.com/literature

Wybierz jezyk publikacji i wpisz w polu poszukiwania "SensaGuard".

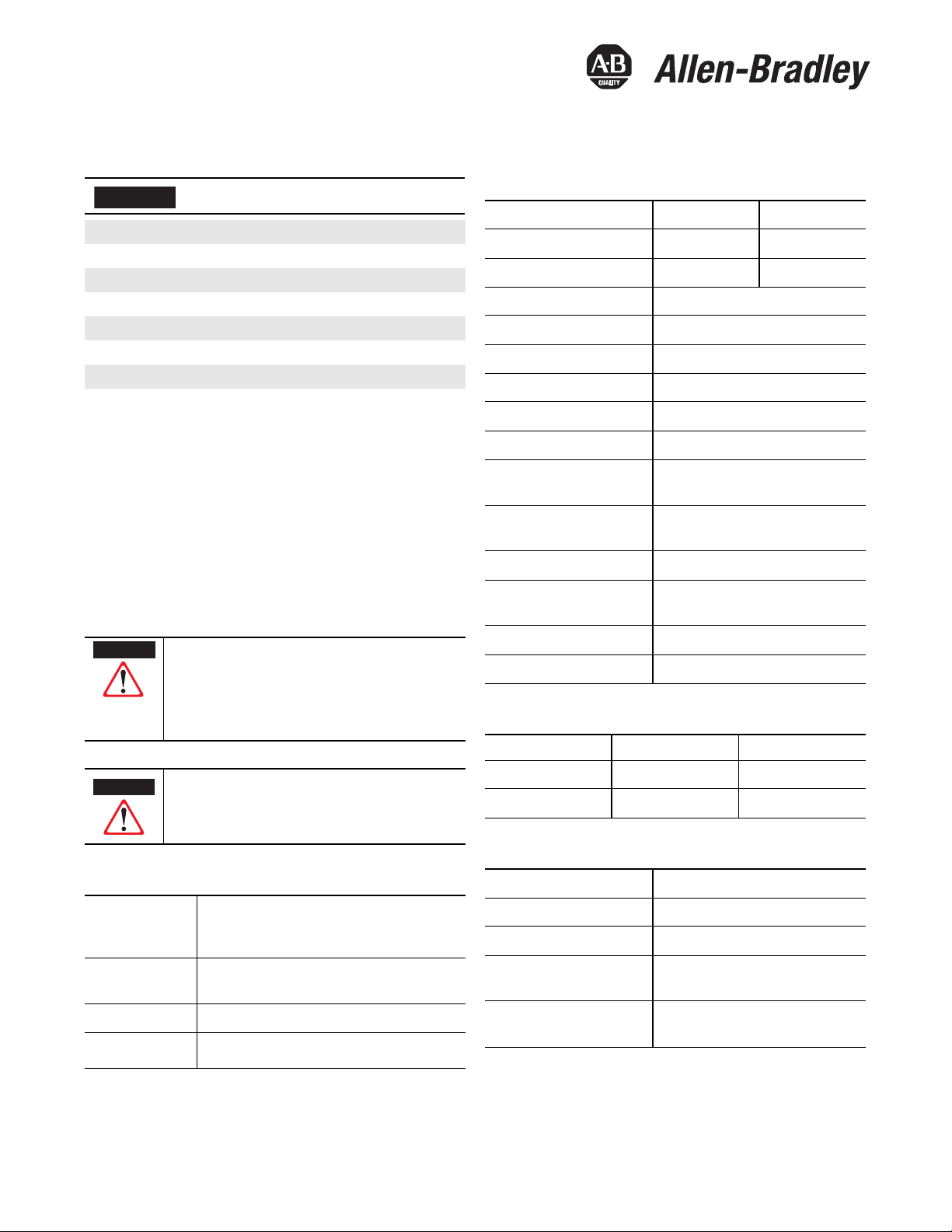

Sensing Distance 18 mm Actuator 30 mm Actuator

Assured Make 15 mm 25 mm

Assured OFF 25 mm 35 mm

Typical Misalignment (±7 mm in both axes)

Repeat Accuracy 10% of sensing range

Max. output current (all outputs) 200 mA

Input Current 50 mA (no load supply current)

Installation Instructions

Installation must be in accordance with the following steps and

stated specifications and should be carried out by suitable

competent personnel. The unit is not to be used as a mechanical

stop. Guard stops and guides must be fitted. Adherence to the

recommended maintenance instructions forms part of the

warranty.

This device is intended to be part of the safety related control

system of a machine. Before installation, a risk assessment should

be performed to determine whether the specifications of this

device are suitable for all foreseeable operational and

environmental characteristics of the machine to which it is to be

fitted. Refer to Technical Specifications below for certification

information and ratings.

ATTENTION

The presence of spare actuators compromise the

integrity of the safety systems. Personal injury or

death, property damage or economic loss can

result. Appropriate management controls, working

procedures and alternative protective measures

should be introduced to control their use and

availability.

Do not defeat, tamper, remove or bypass this unit.

Severe injury to personnel could result. The sensor

MUST be connected to a Class 2 SELV 24V DC,

+10%/-15% power supply.

Technical Specifications

Type 4 Interlocking Device per ISO 14119 (High Coding)

Safety Classification

Standards

Certifications TÜV, CE Marked for all applicable directives, cULus

Functional Safety Data

PLe, Cat 4 per ISO 13849-1

SIL CL3 per IEC 62061 and IEC 61508

ISO 14119, IEC 60947-5-3, IEC 61508, IEC 62061, ISO138491, UL 508, CSA 22.2 No. 14

-9

: 1.12 - 10

PFH

D

Operational Current, Min. 1 mA DC

Off-state Current <0.5 mA DC

Max. no. of switches, connected in

series

Operating Voltage

Unlimited. See Unit Response Time section on

page 5.

24V DC +10%/-15%

Class 2 SELV power supply

Frequency of operating cycle 1 Hz

Response Time (Off )

54 ms first switch,

18 ms for each additional switch

Case Material Polycarbonate

Actuator Material Polycarbonate

Outputs (guard door closed, actuator in place)

Outputs Description Status

Safety 2 x PNP, 0.2 A max. ON (+24V DC)

Auxiliary 1 x PNP, 0.2 A max. OFF (0V DC)

Environmental

Operating Temperature [C (F)] -10…+55° (14…131°)

Operating Humidity 5…95% relative

Washdown Rating NEMA 3, 4X, 12, 13, IP69k

Shock & Vibration

Radio Frequency

IEC 68-2-27 30 g, 11 ms/IEC 68-2-6

10…55 Hz

IEC 61000-4-3

IEC 61000-4-6

Rockwell Automation 440N-IN013A-EN-P—October 2014

Page 2

2 SensaGuard™ 18 mm Plastic Barrel Unique Coding

Sensor

18 mm Actuator

67.06

[2.640]

2.03

[.080]

M18X1

36.47

[1.436]

13.72

[0.54]

15.87

[0.625]

36.47

[1.436]

13.72

[0.54]

15.87

[0.625]

4.57

[0.180]

DIA

19.81

[0.78]

3.17

[0.125]

15.42

[0.607]

2 PLACES

18 mm Actuator

75 mm

Sensor

1

Sensor

2

30 mm Actuator

100 mm

Sensor

1

Sensor

2

IMPORTANT

Protection

Short-circuit Incorporated

Current Limitation Incorporated

Overload Incorporated

False Pulse Incorporated

Tra nsi ent Noi se In cor por ated

Reverse Polarity Incorporated

Overvoltage Incorporated

Thermal Shutdown/Restart Incorporated

Electrical Life

10 x 10

Dimensions [mm (in.)]

16.84

[0.663]

3.17

[0.125]

22.22

[0.875]

48.92

30.40

[1.197]

[1.926]

19.81

[0.78]

Mounting Information

Use non-removable screws, bolts, or nuts to mount the switch and

actuator. Do not over torque the mounting hardware.

Position the switch and actuator so they are aligned with each

other.

Mount the switch and actuator to removable guard, door, or gate.

Keep the switch and actuator within the sensing range below.

This switch is not meant to be fully embedded in metal. Use the

stainless steel version (440N-Z21S17* or 440N-Z21U17*) for

embedding.

Nut Torque Specification

Plastic Barrel Switch: 2.26 N•m (20 in•lb)

Plastic Actuators: 2.26 N•m (20 in•lb)

6

4.57

[0.18]

2 places

Dia.

Minimum Distance Between Sensors

19.81

[0.78]

22.22

[0.875]

30 mm Actuator

48.92

[1.926]

Mode of Operation

Status indicators:

• “Power/Fault” LED illuminates green: Door/guard closed,

safety outputs active.

• “Power/Fault” LED illuminates red: Door/guard open,

safety outputs off.

• “Power/Fault” LED flashes red: Unit failure. See Diagnostic

section on page 3.

• “Power/Fault” LED flashes green: Safety inputs off.

Misalignment Curve

18 mm Unit with 18 mm Target

25

20

OFF OFF

15

10

Face to Face Distance—mm

5

Side Lobe Side Lobe

0

-25

(-0.98)

-20

(-0.787)

-15

(-0.59)

Lateral Misalignment Tolerance—mm (in)

There must be a minimum spacing of 4 mm

(0.157in.) if actuator and sensor face approaches

laterally. This will prevent false triggering due to

the side lobe areas.

Assured Sensing

Assured Sensing

-10

(-0.39)-5(-0.19)

Distance

OFF

Distance

ON

0

5

(0.19)10(0.39)15(0.59)

20

(0.787)25(0.98)

Rockwell Automation 440N-IN013A-EN-P—October 2014

Page 3

SensaGuard™ 18 mm Plastic Barrel Unique Coding 3

IMPORTANT

476

8

1

5

2

3

Brown

White

Blue

Pink

Grey

Green

Red

Yellow

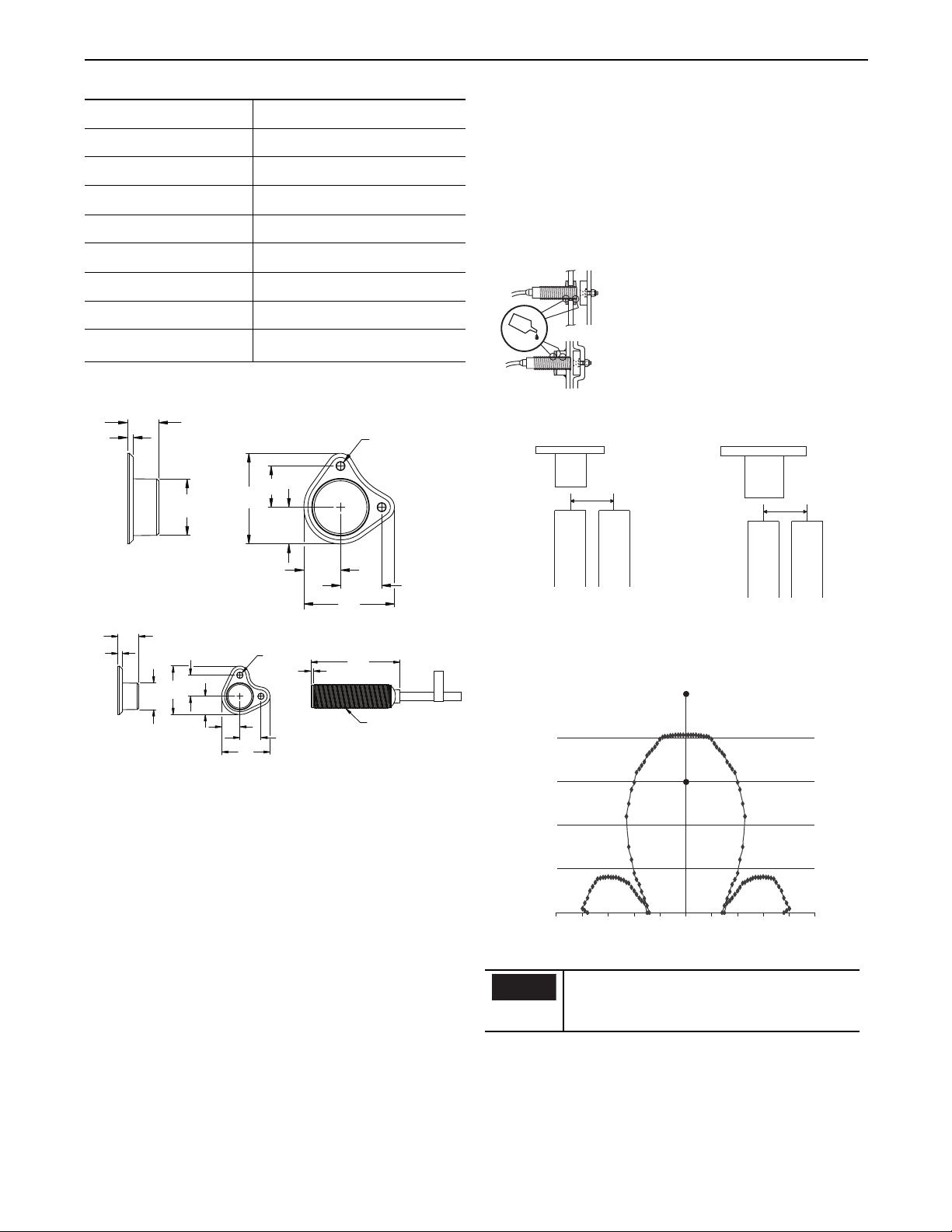

18 mm Unit with 30 mm Target

35

30

25

OFF OFF

20

15

10

Face to Face Distance—mm

Side Lobe Side Lobe

5

0

-30

(-1.18)

-20

(-0.787)

(-0.39)

Lateral Misalignment Tolerance—mm (in)

There must be a minimum spacing of 7 mm

(0.275in.) if actuator and sensor face approaches

laterally. This will prevent false triggering due to

the side lobe areas.

Assured Sensing

Distance

Assured Sensing

Distance

-10

OFF

ON

010

(0.39)20(0.787)30(1.18)

Wiring Diagram

8-Pin Unit

Pin Number Wire Color Signal

1 White Aux. Outputs

2 Brown +24V

3 Green NA

4 Yellow OSSD 2, +24V Input

5 Grey OSSD 1

6 Pink OSSD 2

7Blue0V

8 Red OSSD 1, +24V Input

Recommended mating cable, 2 m (6.5 ft)—889D-F8AB-2.

Replace the 2 with 5 (5 m) or 10 (10 m) for standard cable lengths.

5-Pin Unit

Pin Number Signal

1+24V

2 OSSD 1

30V

4 OSSD 2

5Aux.

Recommended cordset, 2m (6.5 ft) - 889D-F5AC-2. Replace the

2 with 5 (5 m) or 10 (10 m) for standard cable lengths.

Note: If the user does not require the Auxiliary signal, a 4-pin

cordset (889D-F4AC-2) can be used.

Recommended patchcord for use with ArmorBlock® Guard

Safety I/O, 2 m (6.5 ft) - 889D-F4ACDM-2. Replace the 2 with

0M3 (0.3 m), 1 (1 m), 5 (5 m), or 10 (10 m) for standard cable

lengths.

Note: Do not use a 5-pin patchcord with the ArmorBlock.

2

15

3

4

Diagnostic

Unit Indicators (per IEC 60073)

State Status Troubleshooting

Off Not Powered NA

Red Not Safe, OSSD not active NA

Green Safe, OSSD active NA

Device

Output

LED

Green

Flash

Flash

Power up test or OSSD inputs

not valid

Red

1 Hz Flash Recoverable Fault

4 Hz Flash Non-recoverable Fault

Check 24V DC or OSSD inputs

(yellow and red wire)

Recoverable fault —check

OSSD outputs are not shorted

to GND, 24V DC or each other.

Cycl e pow er.

Rockwell Automation 440N-IN013A-EN-P—October 2014

IMPORTANT

Refer to Technical Specifications (page 1) for

certification information and ratings.

Page 4

4 SensaGuard™ 18 mm Plastic Barrel Unique Coding

IMPORTANT

IMPORTANT

IMPORTANT

IMPORTANT

Commissioning

Power the Sensor

Connect the sensor to 24V DC. See "Typical Wiring Diagram"

section for help.

The sensor "Status/Diag" LED will begin to blink

Green eight times then repeat, indicating that

the sensor has not yet learned an actuator.

The sensor can be commissioned to either have the ability to

learn another actuator or be locked for a one time learn only. See

“Teaching in the Actuator” section.

Teaching in the actuator (ability to learn an additional

actuator)

Quick Start

1. Power up the sensor and bring an actuator into the sensing

range.

2. Leave the actuator in the sensing field for two minutes or

longer.

3. Learn is complete.

The sensor can learn a new actuator up to eight

times. The "Status/Diag" LED will blink the

number of actuators left that a sensor can learn.

Initially teaching in the actuator

The sensor will automatically start the learning process as soon as

an actuator is brought into the sensing range.

The actuator must not be removed from the

sensing field during the learning procedure or

the ability to learn additional actuators will be

disabled.

Learning Sequence

1. Target present: "Status/Diag" LED blinking Green 1 Hz rate

2. Verifying actuator: "Status/Diag" LED blinking Green/RED 1 Hz rate (15sec)

3. Program sensor: "Status/Diag" LED blinking Green/RED 4 Hz rate (15sec)

4. Program complete: "Status/Diag" LED blinking Green (# of learns left) (15 sec)

5. Ready state: "Status/Diag" LED solid Green

6. Learn is complete

Teaching in the Actuator (one time learn only; unit

locked)

Initially teaching in the actuator

The sensor will automatically start the learning process as soon as

an actuator is brought into the sensing range.

Learning Sequence

1. Target present: "Status/Diag" LED blinking Green 1 Hz rate

2. Verifying actuator: "Status/Diag" LED blinking Green/RED 1 Hz rate (15 sec)

3. Program Sensor: "Status/Diag" LED blinking Green/RED 4 Hz rate (15 sec)

4. Program Locking: "Status/Diag" LED blinking Green (# of learn left) (15 sec)

During the Program Locking Stage, perform the following steps:

a. Remove the actuator from the sensing field, until the

"Status/Diag" LED changes to solid red.

b. Replace the actuator back into the sensing field and the

"Status/Diag" LED will continue blinking green (number of

learns remaining).

5. Ready state: "Status/Diag" LED solid green

6. Learn is complete

Learning a new actuator:

To learn a replacement actuator, bring the actuator to be taught

into the sensing range of the safety switch.

The learn sequence is the same as the sequence for

commissioning the first actuator.

IMPORTANT

A sensor can not re-learn a previously learned actuator or a

standard SensaGuard actuator.

The sensor will only recognize the most recently learned actuator.

Unique Coded Diagnostic:

Error codes for learning process. Repeat until the unit is power

cycled.

Status/Diag LED—Flashes (4 Hz) Error Code

Green OSSD inputs not valid

A sensor can be locked so it can not learn

another actuator by removing the actuator from

the sensing field during the 15 second "Program

Complete" sequence.

A sensor can be locked so it can not learn

another actuator; see teaching in the actuator

(one time learn only) section.

Red-Red-Red-Green

Can not learn a standard SensaGuard

Actuator

Red-Red-Red-Green-Green Actuator already learned

Red-Red-Red-Green-Green-Green Bad RFID; Target moved out of range

Red-Red-Red-Green-Green-Green-Green Exceeded learning 8 actuators

Red-Red-Red-Green-Green-Green-GreenGreen

Unit locked: Can not learn another

actuator

Rockwell Automation 440N-IN013A-EN-P—October 2014

Page 5

SensaGuard™ 18 mm Plastic Barrel Unique Coding 5

Yel

Red

Brown

Gray

Pink

Blue

24VDC

Power

Supply

1606

-XL120D

Switch 1

+24

RTN

Switch 2

White

White

Yel

Red

Brown

Gray

Pink

Blue

Actuator 1

Actuator 2

Switch 3

White

Yel

Red

Brown

Gray

Pink

Blue

Actuator 3

Switch 4

White

Yel

Red

Brown

Gray

Pink

Blue

Actuator 4

Switch 5

White

Yel

Red

Brown

Gray

Pink

Blue

Actuator 5

+24 V

+24 V

+24 V

+24 V

+0 V

+0 V

+0 V

+0 V

+0 V

+0 V

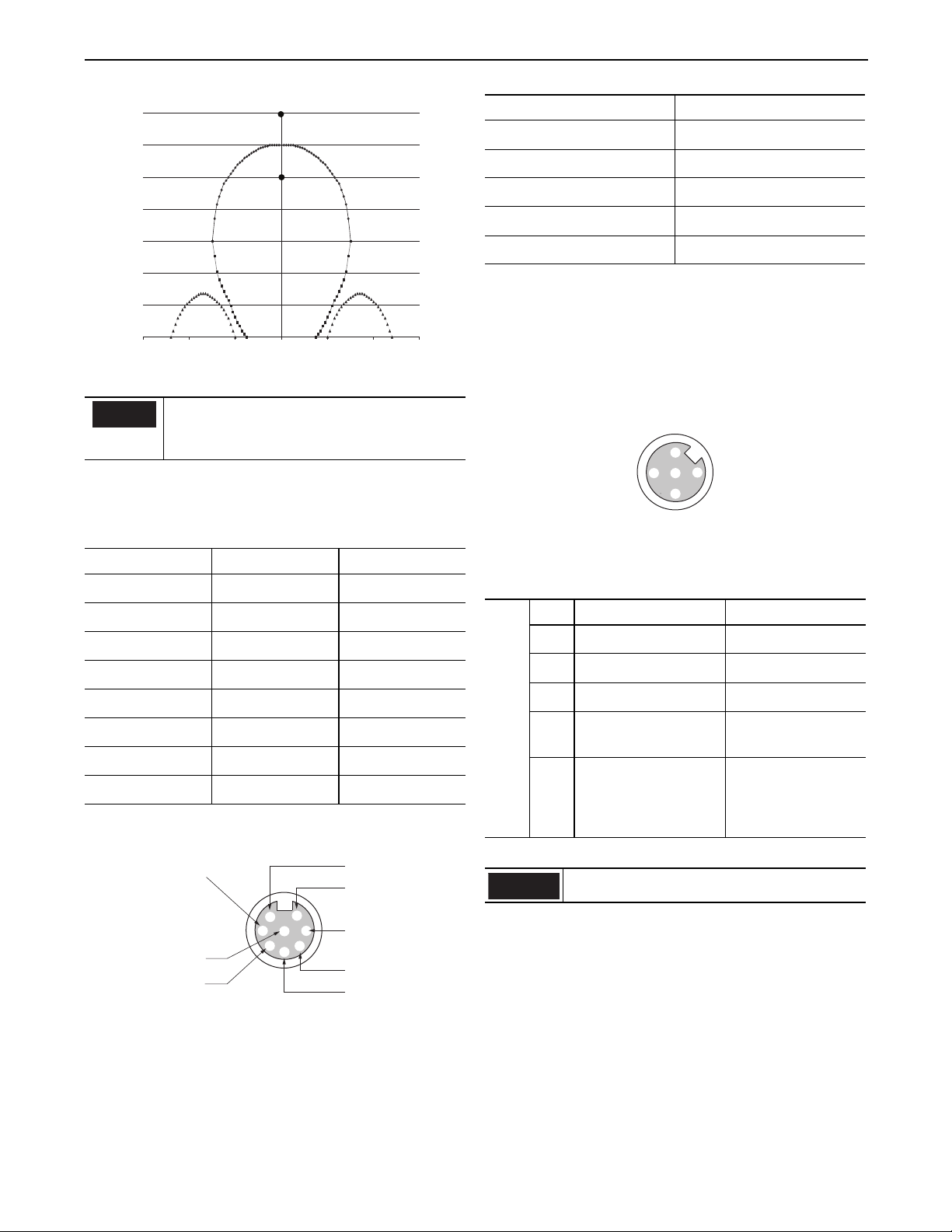

Actuator 2 is in sensing range.

Switch

2 is functioning properly

OSSDs are energize to 24 V

Green LED is ON.

Actuator 3 is in sensing range.

Switch

3 has fault.

See Table Above—Red LED is flashing

Actuator 1 is in sensing range.

Switch

1 is functioning properly

OSSDs are energize to 24 V

Green LED is ON.

Actuator 4 is in sensing range.

Switch

4 is functioning properly.

Series inputs are 0 V.

OSSDs are de-energized to 0V .

Green LED is Flashing to indicate

Series inputs are not 24V.

Actuator 5 is in sensing range.

Switch

5 is functioning properly .

Series inputs are 0V .

OSSDs are de-energized to 0V.

Green LED is Flashing to indicate

Series inputs are not 24V.

OSSD’s are OFF

Recoverable fault

IMPORTANT

Yel

Red

White

Gray

Pink

Blue

24V DC

Power

Supply

1606

Sensor 1

+24

RT

Sensor 2

Brown

Brown

Gray

Pink

White

Yel

Red

Blue

Sensor 3

Brown

Yel

Red

White

Gray

Pink

Blue

A1

S21

S11 41332313S12S52

42342414A2S34S22

MSR127TP

Actuator 1

Actuator 2

Actuator 3

Initial Conditions:

All actuators are in sensing

distance.

Actuator 1 is moved out of

sensing range.

Sensor 2 drops the 24 volts

(red and yellow) from Sensor 1

OSSD outputs.

Green LED flashes.

Sensor 3 drops the 24 volts

(red and yellow) from Sensor 2

OSSD outputs.

Green LED flashes.

0 ms

54 ms 72 ms 90 ms

Actuator 1 is out of sensing

range.

Actuator 2 and 3 are in

sensing range.

Actuator 1 is moved into sensing

range.

Sensor 1 OSSD outputs are

energized.

Sensor 2 OSSD inputs (red and yellow)

transition to 24V DC from Sensor 1

OSSD outputs.

Sensor 2 OSSD outputs are energized

Sensor 3 OSSD inputs (red and

yellow) transition to 24V DC from

Sensor 2 OSSD outputs.

Sensor 3 OSSD outputs are

energized.

0 ms

360 ms 378 ms 396 ms

OFF

ON

IMPORTANT

Troubleshooting

Series Circuit

Refer to Technical Specifications (page 1) for

certification information and ratings.

Unit Response Time (does not include safety control system response time)

Refer to Technical Specifications (page 1) for

certification information and ratings.

Rockwell Automation 440N-IN013A-EN-P—October 2014

Page 6

6 SensaGuard™ 18 mm Plastic Barrel Unique Coding

K1

+24V DC

MSR127RP with 1 sensor, monitored manual reset, driving 100S or 700S safety controllers.

A1 S11

S52 S121323 33

41

S21

S22

S34A214 24 34 42

MSR127RP

Reset

GND

Blue

Gray

Pink

Yellow

Red

Brown

SensaGuard

Unit 1

K2

+24V DC

GND

MSR127RP with 3 sensors in series, monitored manual reset, driving 100S or 700S safety controllers

Blue

Gray

Pink

Yellow

Red

Brown

SensaGuard

Unit 1

SensaGuard

Unit 2

SensaGuard

Unit 3

K1

A1 S11

S52 S121323 33

41

S21 S22 S34 A2 14 24 34 42

MSR127RP

Reset

K2

Blue

Gray

Pink

Yellow

Red

Brown

Blue

Gray

Pink

Yellow

Red

Brown

MSR127RP with 3 sensors and 1 440L light curtain in series, monitored manual reset, driving 100S or 700S safety relays.

Note: Light curtain must be last (farthest from MSR127).

GND

A1 S11

S52 S121323 33

41

S21 S22 S34 A2 14 24 34 42

MSR127RP

Reset

K1

K2

+24V DC

Blue

Gray

Pink

Yellow

Red

Brown

SensaGuard

Unit 1

SensaGuard

Unit 2

SensaGuard

Unit 3

GuardShield

Blue

Gray

Pink

Yellow

Red

Brown

Blue

Gray

Pink

Yellow

Red

Brown

Blue

Gray

Pink

Brown

A1 S11

S52 S121323 33

41

S21

S22

S34A214 24 34 42

MSR127TP

GND

MSR127RP with 1 sensor, automatic reset, driving 100S or 700S safety controllers

+24V DC

SensaGuard

Unit 1

K1

K2

Blue

Gray

Pink

Yellow

Red

Brown

MSR127TP with 3 sensors in series, automatic reset, driving 100S or 700S relays.

MSR127TP

+24V DC

GND

Blue

Gray

Pink

Yellow

Red

Brown

SensaGuard

Unit 1

K1

A1 S11

S52 S121323 33

41

S21 S22 S34 A2 14 24 34 42

K2

Blue

Gray

Pink

Yellow

Red

Brown

Blue

Gray

Pink

Yellow

Red

Brown

SensaGuard

Unit 3

SensaGuard

Unit 2

MSR127TP with 3 sensors and 1 440L light curtain in series, automatic reset, driving 100S or 700S safety contactors.

Note: Light curtain must be last (farthest from MSR127)

MSR127TP

GND

A1 S11

S52 S121323 33

41

S21 S22 S34 A2 14 24 34 42

K1

K2

+24V DC

Blue

Gray

Pink

Yellow

Red

Brown

Blue

Gray

Pink

Yellow

Red

Brown

Blue

Gray

Pink

Yellow

Red

Brown

Blue

Gray

Pink

Brown

GuardShield

SensaGuard

Unit 1

SensaGuard

Unit 3

SensaGuard

Unit 2

IMPORTANT

Application Wiring Examples

Refer to Technical Specifications (page 1) for

certification information and ratings.

Rockwell Automation 440N-IN013A-EN-P—October 2014

Page 7

SensaGuard™ 18 mm Plastic Barrel Unique Coding 7

A1

S11

S21

S12

S22

S32

L11 Y32L121314

S42

2324S34

A2

DI

440R-D22R2

0

1

2

3

4

56

7

8

LOGIC

K1

K2

SensaGuard

SensaGuard

+24V DC

K1

K2

Reset

889D-F4AC-*

889D-F5AC-*

24V Com

Brown

Blue

Black

White

Brown

Blue

Grey

Black

White

Gate

Open

889D-F5AC-*

K1

K2

S11

S12

S21

S22

S34 A1 13

L11 A2 142324Y32

SI

440R-S12R2

RESET

0

MM

AM

24V DC

24V DC Com

Brown

Blue

White

Black

SensaGuard Integrated Latch

Reset

Gate

Open

Grey

IMPORTANT

889D-F8AB-*

A1

S11

S21

S12

S22

S32

L11 Y32L121314

S42

2324S34

A2

DI

440R-D22R2

0

1

2

3

4

56

7

8

LOGIC

K1

K2

K1

K2

S11

S12

S21

S22

S34 A1 13

L11 A2 142324Y32

SI

440R-S12R2

RESET

0

MM

AM

SensaGuard

SensaGuard

+24V DC

K1

K2

Reset

889D-F8AB-*

889D-F8AB-*

24V Com

Note: The Green wire is connected to the housing of the Stainless Steel

SensaGuard only; it has no connection for plastic SensaGuard.

Brown

Yellow

Yel lo w

Red

Red

Blue

Pink

Grey

Pink

Grey

Brown

Blue

Green

White

Green

White

Gates

Open

24V

D

C

24V DC Com

Brown

Yellow

Red

Blue

White

Pink

SensaGuard Integrated Latch

Reset

Gate

Open

Grey

Green

Application Wiring Examples

Rockwell Automation 440N-IN013A-EN-P—October 2014

Refer to Technical Specifications (page 1) for

certification information and ratings.

Page 8

8 SensaGuard™ 18 mm Plastic Barrel Unique Coding

List of Recommended

Safety Control Interfaces

GSR DI, GSR DIS, GSR SI, CR30, MSR126, MSR127, MSR131,

MSR138, MSR211, MSR221, MSR121, MSR320, SmartGuard™,

1791DS/ES CompactBlock™ Guard Safety I/O, 1732DS/ES

ArmorBlock Guard Safety I/O. Relay must have OSSD (light

curtain) inputs.

Check the machine is

isolated and stopped

whenever the interlocked

guard door is open.

IMPORTANT: After

installation and

commissioning, the

actuator, switch and switch

lid fixing screws should be

coated with tamper evident

varnish or similar compound.

Maintenance

Monthly

Check the correct operation of the switching circuit. Also check

for signs of abuse or tampering. Inspect the switch casing for

damage.

Repair

If there is any malfunction or damage, no attempts at repair

should be made. The unit should be replaced before machine

operation is allowed.

Declaration of Conformity

This is to declare that the products shown in this document

conform with the Essential Health and Safety Requirements

(EHSRs) of the European Machinery Directive. These products also

conform to EN60947-5-3, EN ISO 14119, and have third-party

approval.

For a comprehensive certificate please visit: www.ab.com/safety.

Rockwell Automation maintains current product environmental information on its website at

http://www.rockwellautomation.com/rockwellautomation/about-us/sustainability-ethics/product-environmental-c ompliance.page

Allen-Bradley and Rockwell Automation are trademarks of Rockwell Automation, Inc. Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication 440N-IN013A-EN-P—PN-243710—10000979536 Ver 00—October 2014

Copyright © 2014 Rockwell Automation, Inc. All rights reserved. Printed in the USA.

Loading...

Loading...