Page 1

INSTALLATION INSTRUCTIONS PHOTOSWITCH

DIFFUSE/ANALOG CONTROL, BULLETIN 42DRP-5400

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE. FOR ADDITIONAL INFORMATION REFER TO PUBLICATION PG-9000

BULLETIN NUMBER

PHOTOHEAD POWERBASE

VOLTAGE

SUPPLY

42DRP- 5400 — — —

SUPPLY

CURRENT

TYPE RATING LEAKAGE

Analog Voltage 1--10VDC —

Analog Current 1--20mA —

Two Adjustable Set

Points NPN

42DTB-5000

TERMINAL

42DCB-5000

CABLE

22--28

VDC

70mA

SPECIFICATIONS:

Voltage Supply to Analog Output (Terminal 2):

Current Output 40VDC Max............................

Voltage Output 0V....................................

Output Indicators

Setpoint A Red LED...................................

Setpoint B Green LED.................................

Setpoint Adjustment Ye s................................

Setpoint Output Differential 15%.........................

Slope Selectable Positive or Negative.......................

Reverse Polarity Protection Ye s...........................

Transient Noise Protection Ye s...........................

Short Circuit Protection Analog Output only................

Analog Output Calibration Ye s...........................

Sensing Range Adjustment Ye s...........................

Temperature Compensation Yes..........................

Field of View 3........................................

Transmitting LED Infrared, 880nm........................

Operating Environment: NEMA 3, 4, 12, 13, and IP66 (IEC529)

Approvals UL Listed and CSA Certified....................

Housing Material High impact chemically resistant Valox

Ambient Temperature Range -- 4 0

.....

o

Fto150oF(--40oCto65oC)..

Relative Humidity 90%.................................

Te rm i na t io n s

Cable Base: Supplied with 10 (3m) of 5-conductor,..........

flexible, vinyl-covered cable

Terminal Base: Supplied with #6/32 nickel plated brass.......

pressure type terminals

ACCESSORIES

Optional Mounting Assemblies

PAR T NU MBER DESCRIPTION

60-1577 Armored Cable Adapter

60-1785 Universal Mounting Assembly

60-1748 Heavy Duty Mounting Assembly

60-2014 Flexi-mount Mounting Assembly

60-2083 Photoguard Heavy Duty Protection

60-2213 Conduit Mounting Adapter

60-2230 Limit Switch Type Mounting Assembly

61--5540 NEMA 7 & 9 Enclosure

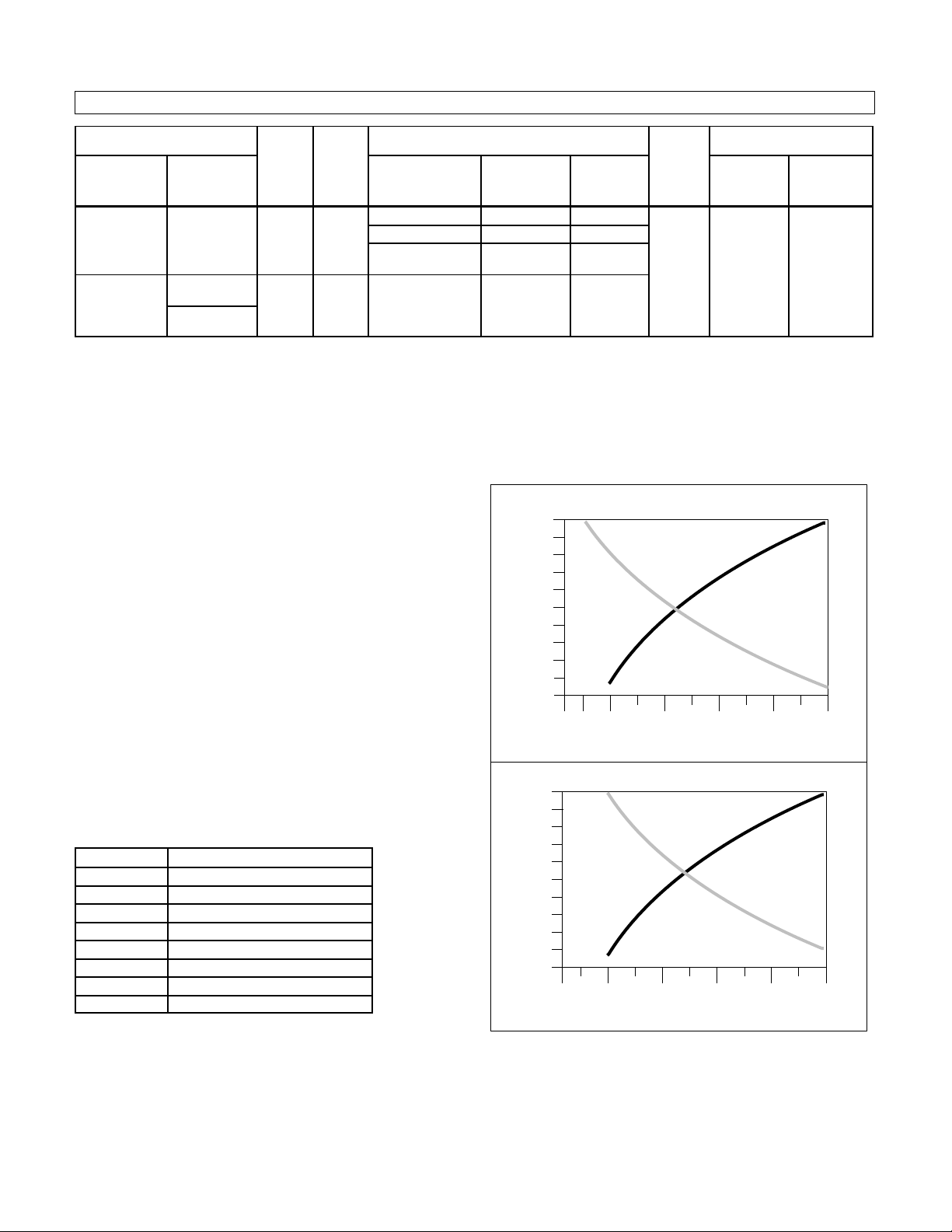

OUTPUT CHARACTERISTIC

(OFF STATE)

RESPONSE

TIME

100ms 2-- 1 5

WHITE PAPER

15 X15

(.38 X .38)

(.61m--4.57m)

OPERATING DISTANCE

WITH

100mA 10A

OPERATING DISTANCE SELECTION

The maximum operating distance is based on installing the control in a relatively clean environment. Normal industrial environment

actually ranges from moderately Dusty to extremely Dirty.

Greater operating margin (excess gain) may be required, which

can be obtained by reducing the operating distance of the control.

TYPICAL RESPONSE CURVES

CURRENT OUTPUT SLOPE

20

18

16

14

POSITIVE

SLOPE

12

10

8

6

DC CURRENT (mA)

4

2

0

6”

0

(15.24cm)

(.3m)

1’

(.6m)

2’

(.9m)

3’

OPERATING DISTANCE

10

DC VOLTAGE

9

8

7

6

5

4

3

2

1

0

0

VOLTAGE OUTPUT SLOPE

POSITIVE

SLOPE

(.3m)

1’

(.6m)

2’

(.9m)

3’

OPERATING DISTANCE

NEGATIVE

SLOPE

4’

(1.2m)

NEGATIVE

SLOPE

4’

(1.2m)

LINEAR

RESPONSE

5-- 1 3

(1.22m--4.27m)

5’

(1.5m)

5’

(1.5m)

CALIBRATION PROCEDURES

Before starting the calibration procedures for Analog Output or

Setpoint Output, be sure the control is at the same temperature as it’s

environment; it adjusts after approximately 15 minutes. Setpoint Calibration is best performed after calibration of the Analog Output has

been completed.

Page 2

Calibration of Analog Output

Calibration of the Analog Output is done with a Voltmeter or an

Ammeter. When calibrating the Voltage Output, connect the Voltmeter between Terminal 2 (+) and the negative power supply, terminal 1

(--). Select the Voltmeter Scale for 10VDC. When calibrating the Current Output, install the Ammeterbetween Terminal2 (--) and the positive power supply Terminal (+), or the positive of a separate power

supply when used. Select the Ammeter scale for 20mA (DC).

1. With Selector Switches 1 and 2, select Analog Current or Voltage

Output.

2. With Selector Switches3 and 4, selectPositive or Negative Slope

operation.

3. Set retroreflective target at 2 (.61m). Adjust the Analog Output

Calibration pot. for 10VDC or 20mA (2%) when in Negative

Slope operation to 1VDC or 1mA (10%) when in Positive Slope

operation.

4. Set the retroreflective target at the desired range. 15 (4.57m)

maximum, 5 (1.52m) minimum. Adjust the Sensing Range Adjustment pot. for 1VDC or 1mA (10%) when using Negative

5. Bring the object to be detected at 1 (.3m). Re-adjust the Analog

Output Calibration pot. for 10VDC or 20mA (2%) when using

Negative Slope operation or to 1VDC or 1mA when using Positive Slope operation if necessary.

6. Place the object to be detected at the desired range. Re-adjust the

Sensing Range Adjustment pot. for 1VDC or 1mA (10%) when

using Negative Slope operation or to 10VDC or 20mA (2%)

when using Positive Slope operation if necessary.

The Analog Output is now calibrated.

Calibration of Setpoint Outputs

1. Place the object at the distance where the Setpoint Output A is to

come on.

2. Adjust the Setpoint pot. A to turn on Output A at this point. (Red

LED turns on.)

3. Place the object at the distance where the Setpoint Output B is to

come on.

4. Adjust the Setpoint B to turn on Output B at this point. (Green

LED turns on.)

This completes the calibration of Setpoint Outputs.

Slope operation or to 10VDC or 20mA (2%) when using Positive Slope operation.

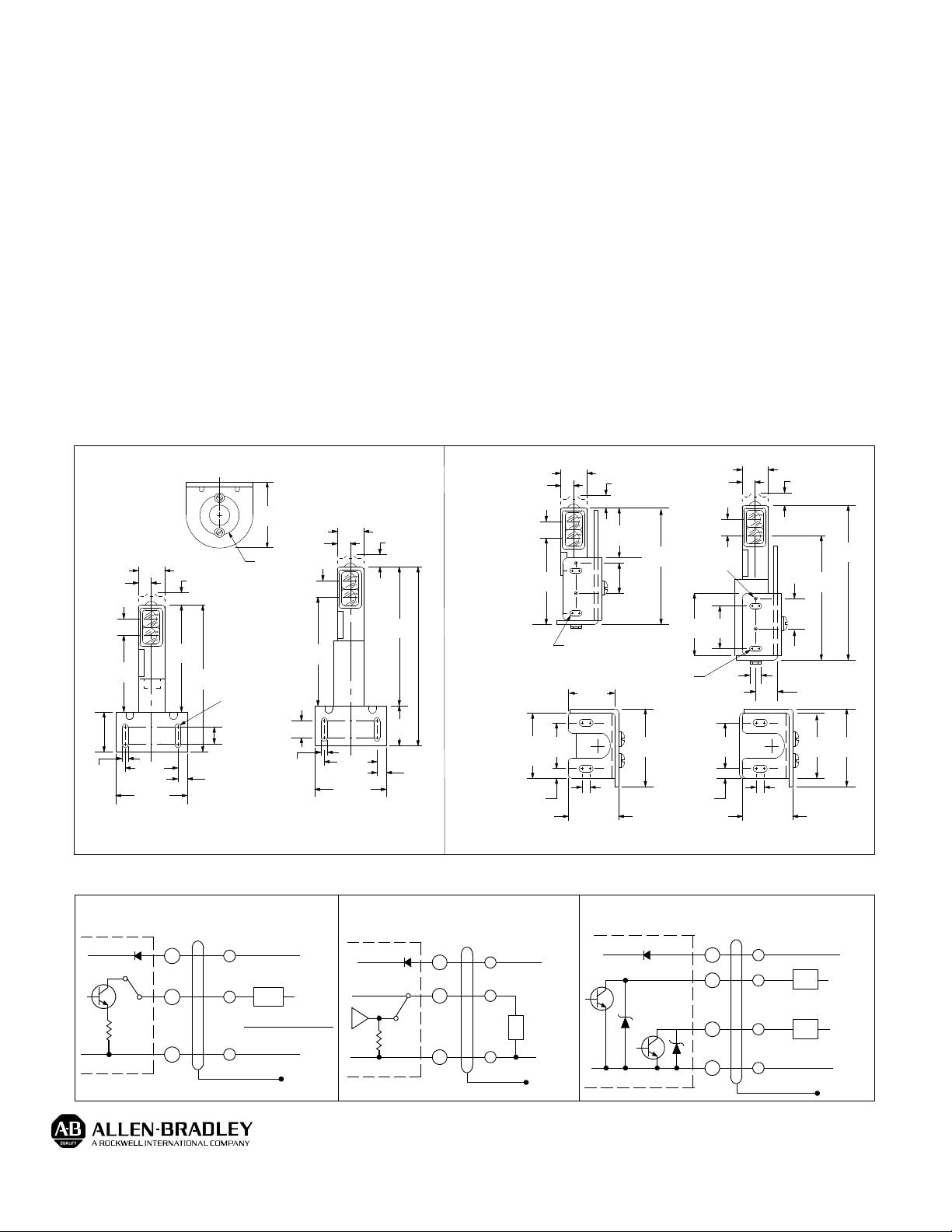

INSTALLATION

The control must be securely mounted on a firm, stable surface or support. A mounting

which is subject to excessive vibration or shifting may cause intermittent operation.

OUTLINE DIMENSIONS

GENERAL PURPOSE

MOUNTING

60-1785

(7.10)

Control with Cable Base

39/64

(15.4)

.280

15/32

(11.9)

27/8

(73.0)

MATERIAL

#11 GA CRS

61/64

(24.2)

2

(50.8)

2 21/32

(67.5)

4.0

(101.6)

11/ 32

(8.73)

57/16

(138.1)

.325

(8.26)

2 57/64

(73.42)

13/4

DIA.

CLEARANCE FOR

#1/4--20 HDW

3/4

3/4

(19.0)

(19.0)

61/64

39/64

(15.4)

.280

(7.10)

15/32

(11.9)

(106.5)

41/4

(24.2)

(50.8)

2 21/32

(67.5)

11/3 2

(8.73)

5 25/64

(136.9)

1 11/16

(42.9)

2

Control with Terminal Base

.325

(8.26)

HEAVY DUTY

MOUNTING

60-1748

39/64

(15.4)

61/64

15/32

(11.9)

2

5/32

(54.7)

21/64

(8.3)

2 27/32

(72.3)

11/2

(38.1)

(24.2)

FOR #10-32 HDW

CLEARANCE

11/2

(38.1)

1/4 (6.3)

1 14/32

(61.9)

11/3 2

(8.73)

1 53/64

(46.43)

47/64

(104.4)

1

(25.4)

CLEARANCE

FOR #10-32 HDW

21/2

(63.5)

39/64

(15.4)

#10-32

THREAD

2HOLES

21/2

(63.5)

21/64

(8.3)

Control with Cable Base Control with Terminal Base

15/32

(11.9)

11/4

(31.7)

1/4

(6.3)

11/2

(38.1)

61/64

(24.2)

1/4 (6.3)

1 14/32

(61.9)

11/3 2

(8.73)

(25.4)

1

59/64

(23.4)

WIRING

All external wiring should conform to the National Electric Code and applicable local codes. See wiring diagrams for external connectins.

ANALOG CURRENT OUTPUT CONNECTIONS

TERMINAL

BASE

CABLE BASE

RED

+

GRAY

2

RMAX =

BLACK

--

(+) 22 -- 28

VDC

CURRENT

SENSOR

(+) 40 VDC

SUPPLY VOLTAGE --

20MA

FLOATING

SHIELD

ANALOG VOLTAGE OUTPUT CONNECTIONS

TERMINAL

BASE

+

MAX

10V

(--)

2

--

CABLE BASE

RED

GRAY

BLACK

(+) 22--28

VDC

VOLTAGE

SENSOR

R=3k

Ohm MIN

(--)

FLOATING

SHIELD

NPN SET POINT OUTPUT CONNECTIONS

TERMINAL

BASE

+

3

1

--

CABLE BASE

RED

ORANGE

BLUE

BLACK ( --)

LOAD

100mA MAX

LOAD

100mA MAX

4 11/32

(110.3)

25/32

(54.7)

(+)22--28

5 24/32

(146.4)

21/2

(63.5)

VDC

(+)10--30

VDC

(+)10--30

VDC

(--)

FLOATING

SHIELD

Publication PA--9171(A)

September 1992

Loading...

Loading...