Page 1

Installation/Configuration Instructions for 42DR

Intrinsically Safe Sensor

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

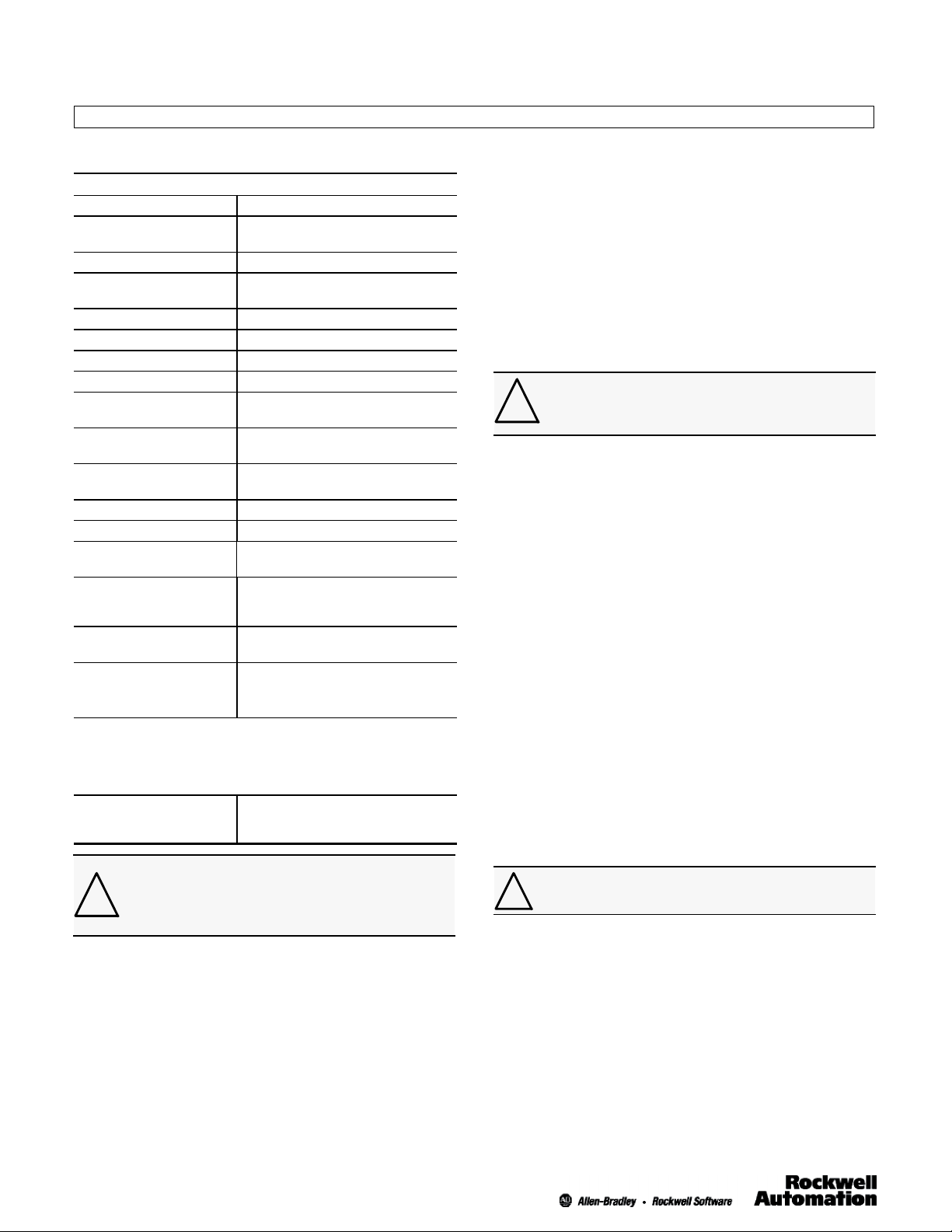

Specifications

Normal Operation Requirements

Voltage Supply 13--29.5V DC

Supply Current 26mA max (output energized) at 13V DC

Response Time 1ms

Dual Outputs 1 NPN open collector (current sink)

Output Ratings 20mA, 29.5V DC maximum

Turn On Pulse Suppression Yes

Light/Dark Energized Option Yes

Reverse Polarity Protection Ye s

Output Overvoltage

Protection w/ Barriers

Field of View Type 42DRU Reflex 2.5

Sensitivity Adjustment Selectable by LOW (L)—HIGH (H) switch.

Ambient Temperature -- 4 0 F to 150F(--40Cto65C)

Relative Humidity 90%

Rated Operating Distances

42DRU- 5500 3 Dia. Reflector #92--39 1 to 30

42DRU- 5700 3 Dia. Reflector #92--39 6 to 15

42DRP- 5500

White Paper

Distance Discrimination Range

Distance differential between surface to be detected and background is defined

as the increase in distance required to de-energize the output, measured from the

point of energization:

Min. differential 10% 6 to 16

Min. differential 20% 2 to 5

42DRA- 5500 Operating distance depended on the choice

30mA max (output energized) at 29.5V DC

1 PNP open collector (current source)

Yes

Type 42DRP Proximity 3

Covers full range of operating distances.

All operating distances are with LOW (L)—

HIGH (H) switch in the HIGH (H) position.

1.25 Dia. Reflector #92--47 1 to 20

0.625 Dia. Reflector #92--46 1 to 15

1.25 Dia. Reflector #92--47 6 to 8

Short Range (SR) Long Range (LR)

1 5

5 to 16 16 to 5

of lens or Fiber Optic Cable. See Bulletin

PA- 8306, PA- 8307, and PA- 8401.

Features (continued)

S Photohead and terminal base are specially keyed to

prevent improper installation of non-intrinsically safe

equipment in a hazardous location.

S Terminal base for input voltages 13 to 29.5V DC eliminates

needs for separate junction box.

S Entity approval:

-- Vmax = 29.5V

-- Imax = 107mA

-- C i = 0 F

-- L i = 0 H

Attention: These parameters must be adhered to. If

!

not, injury may be caused to person or

property.

S Control input parameters

-- Supply voltage 13 to 29.5V DC

-- Supply current, 26mA max. at 13V DC, 30mA max. at

29.5V DC

S Plug-in Photohead contains functional electronics and

optics.

S Thick film microcircuitry for quality and reliability.

S Adjustable input sensitivity.

S RF interference protected.

S No false turn-on pulse.

S Synchronous detection circuitry avoids ambient

interference.

S Switch selection for light or dark operation.

S Dual open collector outputs provide current sink (NPN) and

current source (PNP) capabilities.

-- Load voltage 29.5V DC max.

-- Load current 20mA max.

S Response Time: 1ms

S LED alignment indicator: Visible 360

S NEMA 4X corrosion resistant, high impact housing.

S UL Listed.

Attention: Installation in hazardous environment

locations shall be made according to

!

ANSI/ISA -- RP 12.6 and other applicable

codes and standards.

Features

S For use in Class I, II, III; Division 1, 2; Group A, B, C, D, E,

F, G hazardous locations with Intrinsic Safety Zener Diode

Barriers.

S Reflex, polarized reflex, proximity, and special function

control models.

S Rated operating ranges

-- R e f l e x 1 to 30 (0.03m to 9m)

-- Polarized Reflex 6 to 15 (0.15m to 4.5m)

-- Proximity 0 to 5 (0 to 1.5m).

S Quick-Disconnect (QD) reduces downtime. No disruption of

alignment or wiring.

Attention: Substitution of components may impair

!

intrinsic safety.

Why Intrinsically Safe

Explosion prevention is a prime cons ideration in plants and facilities containing

hazardous atmospheres where “explosion-proof” housings are used.

The main fault with the “explosion-proof” housing system is that a single human

error could create a light explosion probability. Such occurrences as, failing to

tightly replace covers on “explosion-proof” housings, failing to shut off the power

before removing the cover of such a housing, and damaging the machined

surfaces of such covers are all prime examples.

Intrinsically Safe systems are now recognized as a more highly desirable

means of providing automated control functions in explosive environments. The

technique relies on the inherent parameters of electronic circuits, so that no

energy can be released under normal or abnormal operating conditions, of

sufficient magnitude to ignite a specified atmospheric mixture.

Page 2

To design an effective Intrinsically Safe system, energy sources that enter the

hazardous area must be limited. For electronic controls, energy limiting is

accomplished by controlling the voltages and currents that may enter the

hazardous area. In addition, stored electrical energy in the controls is limited to

levels that cannot cause ignition of a given atmosphere.

An Intrinsically Safe system overcomes the shortcomings of the

“explosion-proof” system and virtually eliminates the probability of explosion by

properly installing Intrinsic Safety Zener Diode Barriers in the safe area.

Intrinsic Safety Zener Diode Barriers must be installed in the power supply

line,theload supply line and when using the current source (PNP) open

collector of the Series 5500,inthesignal return line.

Summary of Hazardous Locations

(For full and complete definitions, consult the National Electric Code

publication NFPA No. 70-- 78.)

Class I Locations in which flammable gases or vapors

are or may be present in the air in quantities

sufficient to produce explosive or ignitable

mixtures.

Class II Locations which are hazardous because of the

presence of combustible dust.

Class III Locations which are hazardous because of the

presence of easily ignitable fibers or flyings, but

in which such fibers or flyings are not likely to be

suspended in air concentrations sufficient to

produce ignitable mixtures.

Division I Locations which are hazardous concentrations

in the air exist continuously, intermittently, or

periodically under normal operating conditions.

Division 2 Locations which are hazardous concentrations

are handled, processed, or used but are

normally within closed containers or closed

systems from which they can escape only in

case of accidental rupture or breakdown.

Group A Atmospheres containing acetylene.

Group B Atmospheres containing hydrogen, or gases or

vapors of equivalent hazard, such as

manufactured gas.

Group C Atmospheres containing ethyl-ether vapors,

ethylene, or cyclo-propane.

Group D Atmospheres containing gasoline, hexane,

naptha, benzine, butane, propane, alcohol,

acetone, benzol, laquer solvent vapors, or

natural gas.

Group E Atmospheres containing metal dust, including

aluminum, magnesium, and their commercial

alloys, and other metals of similarly hazardous

characteristics.

Group F Atmospheres containing carbon black, coal or

cake dust.

Group G Atmospheres containing flour, starch, or grain

dusts.

Typical Class I Locations

S Petroleum refineries and gasoline storage and dispensing

areas.

S Industrial firms that use flammable liquids in dip tanks for

parts cleaning or other operations.

S Petrochemical companies that manufacture chemicals from

gas and oil.

S Dry cleaning plants where vapors from cleaning fluids can

be present.

S Companies that have s praying areas where they coat

products with paint or plastics.

S Aircraft hangars and fuel servicing areas.

S Utility gas plants, and operations involving storage and

handling of liquified petroleum gas or natural gas.

Typical Class II Locations

S Grain elevators, flour, and feed mills.

S Plants that manufacture, use, or store magnesium of

aluminum powders.

S Plants that have chemical or metallurgical processes,

producers of plastics, medicines, and firewoods, etc.

S Producers of starch or candies.

S Spice-grinding plants, sugar plants, and cocoa plants.

S Coal preparation plants and other carbon-handling or

processing areas.

Typical Class III Locations

S Textile mills, cotton gins, cotton seed mills, and flax

processing plants.

S Any plant that shapes, pulverizes or cuts wood and creates

sawdust or flyings.

Note: Fibers and flyings are not likely to be suspended in the

air, but can collect around machinery or on lighting fixtures

and where heat, a spark or hot metal can ignite them.

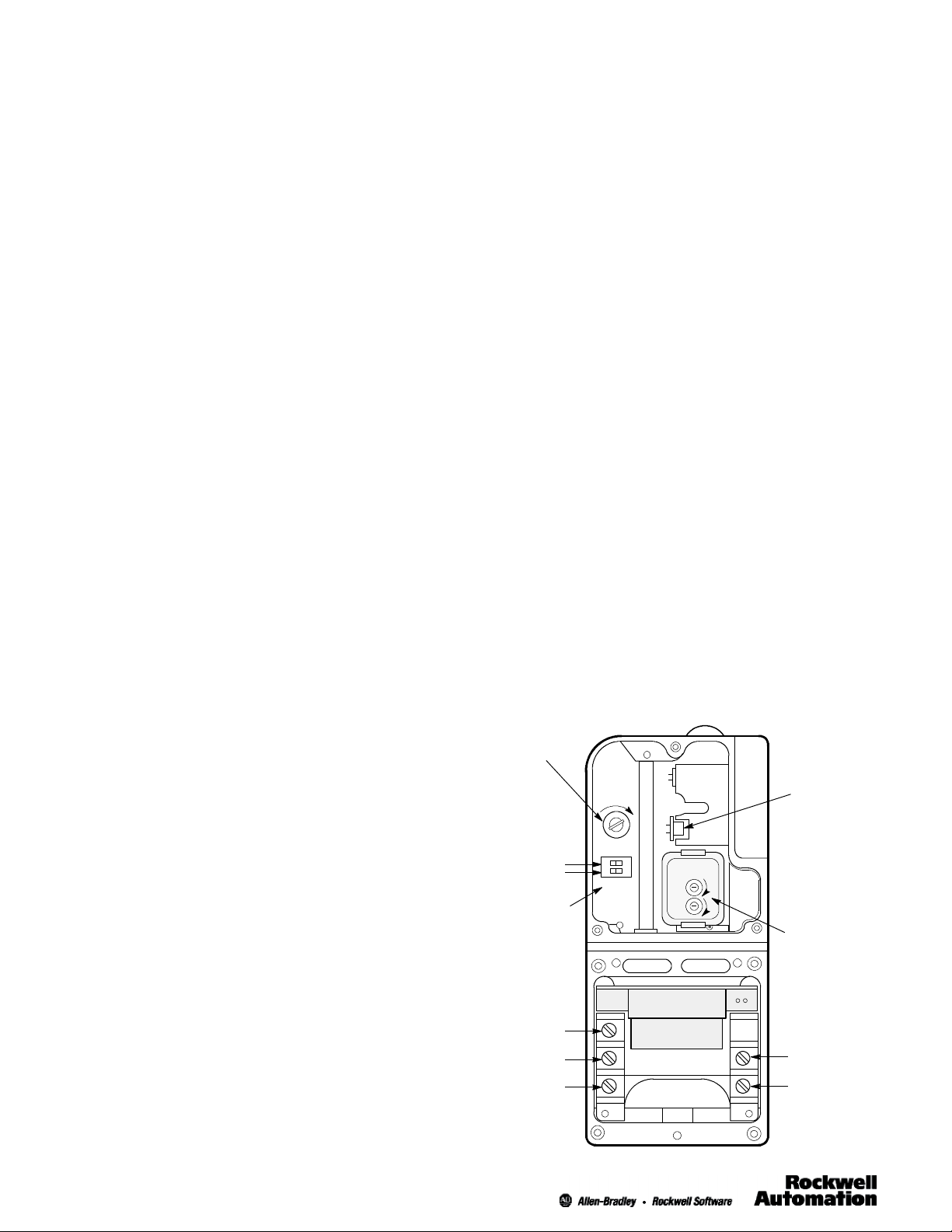

Series 5500 Type 42DRP Photohead and

42DTB Power Base with Covers Removed

Sensitivity

Adjustment

Low - High

Sensitivity

Switch

Light/Dark

Switch

SENS

LO HI

DK LT

TWO - WAY

TIME DELAY

O

N

O

F

F

Visible

Alignment

Indicator

Short Range

Long Range

Shutter

(on 42DRP

only)

PNP & NPN

Output

Circuitry

3

2

1

See page 7, for actual connection diagrams.

(+)

(- )

2

Page 3

Description

Type 42DR Series 5500 QD Intrinsically Safe miniature self-contained

Photoelectric controls each consist of a combination modulated LED light

source, high speed silicon photodetector and dual open collector sold state

outputs which can be used to interface with programmable controllers,

computers, digital control systems or E-M control relays via Intrinsic Safety

Zener Diode Barriers.

The Type 42DR Series 5500 controls are modular in design and consist of two

components—a plug in photohead and a power base which are selected to

suit your functional requirements and assembled together at the point of

installation. The photohead includes a unique Quick-Disconnect feature so that

it can be quickly mounted to or removed from the power base by simply turning

one screw, without disrupting control wiring or alignment. This capability reduces

production downtime and replacement cost and precludes the need for adding

plug and cable assemblies for field disconnect purposes.

Please note that the Series 5500 photoheads and the Series 5500 power base

are keyed so that no other photohead other than the Series 5500 can be

mounted to the Series 5500 power base in a hazardous location. The user

must disconnect the power before removing the quick-disconnect

photoheads or covers.

All Type 42DR Series 5500 (5700) Photoelectric controls must be used

with Intrinisic Safety Zener Diode Barriers.

Photoheads

There are four different photoheads available. For reflex operation (with

retroreflective target), use Type 42DRU Model 5500 which provides an

operating range from 1 to 30.Forpolarized reflex operation (with corner

cube type retroreflective target), use Type 42DRU Model 5700 which provides

an operating range from 6 to 15.Forproximity operation (diffuse reflection

off the object itself), specify Type 42DRP Model 550 which offers an operating

range from 0 to 5. The design of Type 42DRA Model 5500 special function

photohead increases the application capabilities of the control line in difficult

environmental conditions by use of fiber optics and special lens assemblies.

In all models, the photohead contains all the functional electronics and optics. It

includes synchronous detection circuitry which tends to restrict the control to

operate only with its own pulsed LED source. Adjustable input sensitivity

broadens control application capability to those involving translucent and even

transparent materials, such as plastic films and glass. A switch is provided to

assure sensitivity adjustment over the entire control operating range.

With a flick of a switch, the Type 42DR control provides operation in either a

light energized (beam break) or dark energized (beam make) mode.

An optical shutter on the Type 42DRP proximity control permits the use of a

single control for both short- and long-range proximity applications. With the

shutter in the short range (SR) position, the maximum operating distance is 1.

The very sharp drop off in operating margin as shown in the Type 42DRP

response curve on page 6 helps to ignore backgrounds that are close to the

object being detected.

The dual open collector outputs, one an NPN open collector for current sink

and the other a PNP open collector to provide current source, are included in all

Type 42DR controls to maximize customer logic interconnection capabilities.

Therefore, these controls provide the opportunity for simultaneous connection to

relay loads or opto-coupler drives and TTL logic outputs. Seepage7for

connection diagrams.

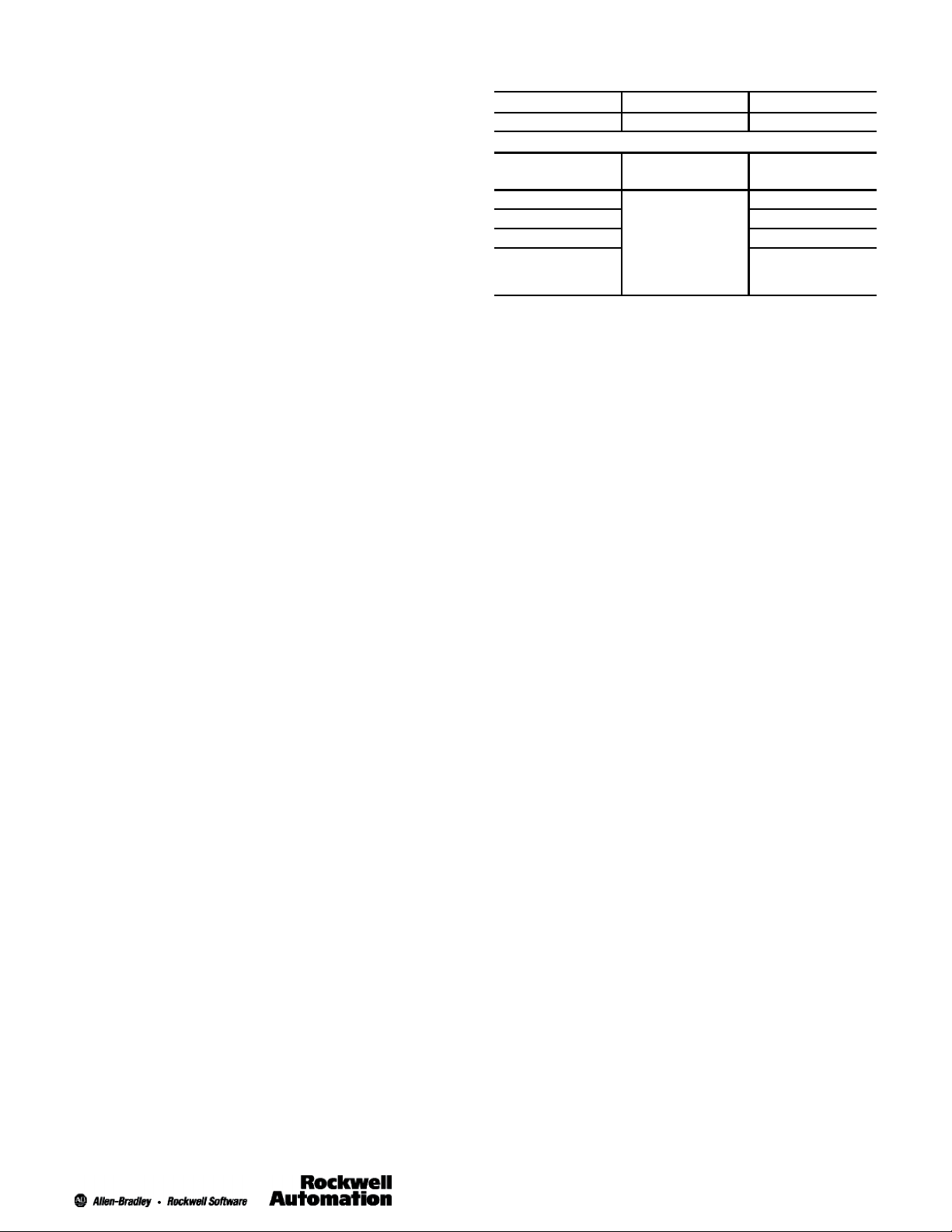

Ordering Instructions

1. Select Power Base

Base Type

Terminal 13 to 29.5V DC 42DTB- 5500

2. Select Photohead

Operating Mode

Reflex

Polarized Reflex 42DRU- 5700

Proximity 42DRP- 5500

Fiber Optic

Wide Angle

Fixed Focus

3. Select Mounting Assembly

#60--1785 Universal, general purpose, 360 adjustment.

#60--1748 Heavy Duty, for mechanical protection.

#60--2014 Flexi-Mount, for Unistrut mounting on conveyor rails.

#60--2083 Photoguard, #12 gauge cold rolled steel heavy duty protection.

4. Select Intrinsic Safety Zener Diode Barriers

Select Control Drawing on page 7 for wiring diagrams of sourcing and

sinking output configurations. Barrier selection is described below for

each Control Drawing configuration. For installations, to ensure safety

each Barrier must comply with the entity parameters indicated on the

Control Drawing.

In selecting the Intrinsic Safety Zener Diode Barriers, it is important to consider

the resistance of the barrier to ensure operational characteristics in the midst of

inherent barrier voltage drop.

Voltage Supply Type & Model

Output

Characteristics

NPN (Current Sink)

and

PNP (Current Source)

Type & Model

42DRU- 5500

42DRA- 5500

Power Base

Type 42DRU, 42DRP, and 42DRA Intrinsically Safe models 5500 and 5700

Photoheads can be plugged only into a terminal base Type 42DTB Model

5500 suitable for voltage inputs of 13 to 29.5V DC.

The Type 42DTB Model 5500 Terminal Base allowstheusertomakehis

incoming and outgoing connections directly to the control thereby eliminating the

need of a separate junction box. Wiring connections are made to easy-to-wire

pressure type terminals with nonrotating clamps on the screws capable of

handling up to two #14AWG wires.

3

Page 4

Power Supply Barrier

V

Intrinsic safety zener diode barrier #897H-- S120 is recommended for FM

Approved and UL Listed locations. See page 8 for barrier details.

Alternatively, the user must select his own power supply barrier. It should be

noted that the Series 5500 control must have at least 13V DC at the + and -terminals of the power base, Type 42DTB Model 5500. The supply current at

13V DC is 26mA. The maximum barrier resistance is then determined by the

following formula: Vs -- 13

Rb max =

0.026

where:

Rb max = Maximum Barrier Resistance

Vs = Voltage Supply

13 = Minimum Voltage Supply to Control

0.026 = Supply Current (26mA max. at 13V DC)

Load Supply Barrier

Intrinsic Safety Zener Diode Barrier #897H-- S120 is recommended for FM

Approved and UL Listed locations. See page 8 for barrier details.

Alternatively, the user may select his own load supply barrier. When using the

NPN (current sink) open collector output of the Series 5500 Intrinsically Safe

controls, a load supply barrier must be selected in addition to the power supply

barrier. The maximum load supply barrier resistance can be determined by

using the following the formula. The user must provide values for the load

voltage drop, V

Rb max =

max): Vs -- V

, and the load current, I

load

-- 3 . 4

load

I

load

load

(20mA

where:

Rb max = Maximum Barrier Resistance

Vs = Voltage Supply

V1 = Load Voltage Drop

3.4 = Output Cir. Voltage Drop (3.4V)

I

load

= Load Current (20mA max.)

Note: The NPN and output configuration is not approved for

use in hazardous locations classified as Class I, Division 1,

Groups A or B.

where:

Rbps = Max. Power Supply Barrier Resistance

Rbrs = Max. Signal Return Barrier Resistance

Vs = Voltage Supply

load

= Load Voltage Drop

V

13 = Min. Voltage Supply to Control (13V)

0.026 = Supply Current (26mA max. at 13V)

I

load

V

0.4 = Output Switch Voltage Drop (0.4V)

brs

= Load Current (10mA max.)

= Signal Return Barrier Voltage Drop

Installation of Adjacently Mounted Units

Type 42DR Series 5500 Photoheads are supplied to operate at one of two

different frequency ranges, permitting Photoheads to be mounted close to each

other without generating interfering signals.

Units in open frequency range are marked with a dot (S). Units in the other

frequency range have no dot.

Accordingly, when two Type 42DR Series 5500 controls are mounted close

together and/or face each other, select Photoheads so that one is marked with a

dot (S) and the other has no dot.

Alignment

Alignment of the Type 42DR LED control can be accomplished by visually

sighting the control at the reflector using reflex operation or at the object using

proximity until the visible LED indicator on the top lights with switch in the “LT”

position or goes out when the switch is in “DK” position.

To insure that the beam is centered on the reflector, in Reflex or on the object

using proximity, sweep the beam across the reflector or object in the horizontal

plane and determine at what points the indicator light goes on and then goes off.

Set the beam half way between both points. Do the same in the vertical plane.

Signal Return Barrier for Source (PNP) Output Only

Intrinsic Safety Zener Diode Barrier #897H-- S140 is recommended for FM

Approved and UL Listed locations. See page 8 for barrier details.

Alternatively, the user may select his own signal return barrier when the PNP

(current source) open collector output of the Series 5500 Intrinsically Safe

controls. For PNP output applications in hazardous locations not classified as

Class I, Division 1, Groups A and B, signal barrier must be selected in addition

to the power supply barrier and the load supply barrier. For reference, see

Control Drawing for the three barrier PNP output configurations. The sum of the

maximum signal return barrier resistance and the maximum load supply barrier

resistance can be determined using the following the formula. The user must

provide values for the load voltage drop, V

max):

Rbls + Rbrs =

Vs -- (V

load+Vbrs

I

load

+0.4)

, and the load current, I

load

load

(20mA

where:

Rbls = Load Supply Barrier Resistance

Rbrs = Signal Return Barrier Resistance

Vs = Voltage Supply

load

brs

= Load Voltage Drop

= Signal Return Barrier Voltage Drop

= Load Current (20mA max.)

, and the load current, I

is 10mA max in this configuration.

load

Vs -- 13

I

+ 0.026

load

load

Rbps + Rbrs =

I

load

brs

+ 0.026

.

load

+

)

load

V

V

0.4 = Output Switch Voltage Drop (0.4V)

I

load

For PNP output applications in hazardous locations classified as Class I,

Division 1, Groups A and B, signal return barrier must be selected in addition to

the power supply barrier. For reference, see Control Drawing for the two barrier

PNP output configurations. The signal return barrier resistance and the power

supply barrier resistance must satisfy the following two formulas. The user must

provide values for the load voltage drop, V

Please note that I

Rbps = Vs -- (o.4 + V

4

Page 5

Dimensions

ToRemove

Terminal Style Power Base

Photohead

0.109

(2.7)

1.437

(36.5)

1.031

(8.7) Min.

2.797

(71.0)

2.594

(65.8)

2.186

(55.5)

1.437

(36.5)

2.186

(55.5)

Top View Bottom View

Quick

Disconnect

Screw

LED

Indicator

Note: Hardware included with sensor: two (2)

nickel plated 10--32 mounting screws.

0.765

(19.4)

Control with Universal Mounting Assembly #60 -- 1785

Material

#11 GA CRS

1.750

Dia.

2.891

(73.42)

0.953

(24.2)

1.312

(33.3)

0.609

(15.4)

1/2--14

NPSM

0.469

(11.9)

4.250

(106.5)

1.093

(27.7)

0.469

(11.9)

0.453

(15.4)

4.250

(106.5)

10-- 32 UNF

2 Holes

0.953

(24.2)

5.516

(139.5)

0.344

(8.73)

5.391

(136.9)

0.547

(13.8)

1.5

(38.3)

0.328

(8.3)

7.031

(178.59)

Control with Terminal Style Power Base

0.953

2.500

(63.5)

Clearance for

#10-32 HDW

0.469

(11.9)

0.609

(15.4)

#10-32 Thread 2

Holes

1.250

(31.7)

0.250

(6.3)

1.500

(38.1)

0.328

(8.3)

(24.2)

0.250 (6.3)

1.437

(61.9)

0.344

(8.73)

1

(25.4)

(110.3)

0.922

(23.4)

2.156

(54.7)

4.344

5.750

(146.4)

2.500

(63.5)

0.750

(19.0)

0.280

(7.10)

2

(50.8)

2.656

(67.5)

1.687

(42.9)

0.325

(8.26)

5

Page 6

Typical Response Curves

42DRU--5500 Retroreflective

200X

100X

80X

40X

20X

10X

8X

4X

Operating Margin

2X

1X

3

1

(7.62cm)

(2.54cm)

42DRU--5700 Polarized Retroreflective

40X

20X

10X

8X

4X

3X

2X

Operating Margin

1X

0.1

(0.254cm)

1

(2.54cm)

42DRP--5500 Standard Diffuse

100X

80X

40X

20X

10X

8X

4X

Short

Range

0.625 (16mm)

Reflector

1.25 (32mm)

Reflector

6

1

(15.24cm)

(0.3m)

Operating Distance

6

2

(15.24cm)

(5.08cm)

OperatingDistance

2

(0.6m)

(1.5m)

1.25

(32mm)

Reflector

1

(0.6m)

(0.3m)5(1.5m))

5

2

10

(3m)

3 (78mm)

Reflector

20

(6.1m)

(78mm)

Reflector

10

(3m)

8 15

Long

Range

3

20

(6.1m)

50

(15.24m)

(15.24m)

42DRA--5500 Fixed Focus Diffuse

1000

100

10

Operating Margin

1

0.5

(1.27cm)

1

(2.54cm)

5

(12.7cm)

Operating Distance

42DRA--5500 Wide Angle Diffuse

100

0

100

10

Operating Margin

1

0.5

50

(1.27cm)1(2.54cm)

Operating Distance

10

(25.4cm)

20

(50.8cm)

Note 1:

For reliable service in dusty and dirty industrial environments, higher optical

operating margins may be required, resulting in reduced operating range for the

control. Use curves as approximate applications guide only.

Note 2:

42DRA-- 5500 Typical Response curves with glass and plastic fiber optic cables.

See PA--8306.

2X

Operating Margin

1X

0.1

(0.254cm)

1

(2.54cm)

6

(15.24cm)

2

1

(0.6m)

(0.3m)5(1.5m)

10

(3m)

20

(6.1m)

50

(15.24m)

Operating Distance

6

Page 7

Installation Wiring Diagrams for Series 5000 Intrinsically Safe Version

Class I, II, III, Division 1, Group C, D, E, F, G

Class I, II, III, Division 2, Group A, B, C, D, F, G

Photoheads Terminal Base

42DRA-- 5500, 42DRU--5500

42DRP-- 5500, 42DRU--5700

NPN Open Collector Connections (Sinking)

(2 Barriers Required)

Vmax = 29.5V

Imax = 107mA

Sink Wiring

PNP Open Collector Connections (Sourcing)

Vmax = 29.5V

Imax = 107mA

Source Wiring

Ci = 0F

Li = 0H

(3 Barriers Required)

Ci = 0F

Li = 0H

42DTB -- 5500

Terminal BasePhotohead

Terminal BasePhotohead

(+)

(1)

(--)

(+)

(3)

(2)

(--)

Barrier Entity Parameters

AB #897H--S120

Out

Gnd

AB #897H--S120

Out

Gnd

Barrier Entity Parameters

AB #897H--S120

Out

Gnd

AB #897H--S120

Gnd

Out

AB #897H--S140

In

Zener Diode Barriers

Barrier Bus

(less than 1 ohm)

Barrier Bus

(less than 1 ohm)

Nonhazardous LocationHazardous Location

In

Gnd

Earth Ground

In

Gnd

In

Gnd

Earth Ground

Gnd

In

Out

Power Supply

& Load Circuits

Power Supply

Supply Return

Power Supply

Load Supply

Load

Supply Return

Load

24V DC 8%

Load

Supply

( +5V DC)

TTL

Device

Signal

Return

(+)

(+)

(+)

(--)

24V DC 8%

(+)

(+)

(--)

Gnd

Class I, II, III, Division 1, Group A, B, C, D, E, F, G

Class I, II, III, Division 2, Group A, B, C, D, F, G

PNP Open Collector Connections (Sourcing)

(2 Barriers Required)

Vmax = 29.5V

Imax = 107mA

Source Wiring

Notes:

Installation must be in accordance with the National Electrical CodeR (NFPA 70, Article 504), ANSI/ISA--RP12.6, and the manufacturer ’s instructions.

Barrier entity parameters: Voc 29.5V; Isc 107mA; Ca Ccable; La Lcable; recommended barriers are indicated on the above wiring diagram.

If the electrical parameters of the cable used are unknown, the following values may be used: Capacitance -- 60pF /ft.; Inductance -- 0.20H/ft.

Barrier bus must be insulated from other grounded metal. Use DIN Rail Mounting Kit, Allen-Bradley #64--136.

Maximum nonhazardous area voltage must not exceed 250V.

An approved dust tight seal is required for Class II, III applications.

The output circuits of Zener Diode Barriers shall be in separate cables or separated from each other per NEC 504--30.

No revision to drawing without prior UL approval.

Ci = 0F

Li = 0H

(+)

(3)

(2)

(--)

Terminal BasePhotohead

Barrier Entity Parameters

AB #897H--S120

Out

Gnd

AB #897H--S140

In

Gnd

Barrier Bus

Gnd

In

Gnd

Earth Ground

(less than 1 ohm)

Out

Gnd

Power Supply

Supply Return

Load

10mA Max.

24V DC 8%

Signal

Return

(+)

(--)

Allen-Bradley Control Drawing #133--451(Ver 08)

7

Page 8

#897H--S120 and #897H--S140 Intrinsic Safety Zener

w

Diode Barrier Information Specifications

Environmental Conditions

Operating Temperatures -- 4 0 to 122F(--40Cto+50C)

Storage Temperature -- 4 0 F to 167F(--40Cto+75C)

Relative Humidity 5% to 95% noncondensation

Vibration Resistance

Vibration Frequency 55Hz

Vibration Amplitude +1.5mm (+0.062in)

Shock Resistance 20g

Operational Data, Safety Barrier #897H- S120

Input Voltage—Rated

Internal Resistance—Typical

—Tolerance

Replaceable Fuse

#23- 155 Rating

Leakage Current Micro A

Short Circuit Protection Yes

Division 1, 2

Groups AtoG

Operational Data, Safety Barrier #897H- S140

Input Voltage—Rated

Voltage Drop Resulting from

Internal Impedance—Typical

—Tolerance

Replaceable Fuse

#23- 156 Rating

Leakage Current 10A

Short Circuit Protection Yes

Division 1, 2

Groups AtoG

Mounting Accessories

#63- 112 Plastic Mounting Adaptor for Barriers #897H - S120 and #897H- S140

to fit #64- 134 or other EN50022/DIN46277 Mounting Rail.

#64- 134 1m (3.3ft) prepunched zinc plated and chromated steel Mounting Rail

per EN50022/DIN46277 (TS35)

+24V

—Max

+26V

302

+16

80mA

Class I, II, III

+24V

—Max

+26V

1V

1V @ < 22mA

2V @ > 22mA

100mA

Class I, II, III

Description

Intrinsic Safety Zener Diode Barriers #897H-- S120 and #897H--S140)are

passive protective interface assemblies to isolate intrinsically safe circuits from

non-intrinsically safe circuits as defined in FM Class No. 3610.

Intrinsically safe connections are suitable for hazardous locations classified as:

Class I, II, III

Division 1 or 2

Groups A, B, C, D, E, F, G.

The Intrinsic Safety Zener Diode Barrier offer economical solutions for

instrumentation and control systems in hazardous locations defined by NEC

Article 500.

Principle of the Replaceable Keyed Fuse Assemblies

For the Intrinsic Safety Zener Diode Barriers #897H --S120 & #897H--S140, the

principle of a keyed fuse assembly has been employed. In case of a fault due to

overvoltage, polarity misconnection or transients, only the protective keyed fuse

assembly needs to be replaced. Disassembly, disconnection of the wiring, or

even disposing of the entire barrier is eliminated, thus providing a very

economical solution for application of Intrinsic Safety Zener Diode Barriers.

The protective fuse is securely embedded in a keyed fuse assembly. This keyed

assembly is coded for a defined fuse rating. Only the properly rated keyed fuse

assembly is able to be inserted in the appropriate barrier.

The replacement of the fuse assembly can be done by the user at the job site.

The barriers do not have to be returned to the manufacturer for replacement.

See Operational Data for #897H-- S120 and #897H--S140 in Specifications for

proper Replaceable Fuse selection.

12

#897H--S120 or #897H--S140

Intrinsic Safety

Zener Diode Barrier

with Replaceable Fuse

(102)

160mA

160mA

160mA

4

160mA

Intrinsic

Safety

Barrier

34

0.5

(12.5)

2.1875 (56)

DIN Rail Mounting Hole Spacing

4

(102)

2.75

(70)

3.75

(93.5)

#64--134 TS35 DIN Mounting Rail

ww.rockwellautomation.com

Power, Control and Information Solutions Headquarters

Americas: Rockwell Automation,1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414.382.2000, Fax: (1) 414.382.4444

Europe/MiddleEast/Africa: Rockwell Automation, NV,Pegasus Park, De Kleetlaan 12a, 1831 Diegem, Belgium, Tel: (32) 2 663 0600, Fax(32) 2 663 0640

Asia Pacific: Rockwell Automation, Level 14, Core F, Cyberport 3,100 CyberportRoad, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

Publication 42DR-- IN001A--EN--P

July 2013

E 2013 Rockwell Automation, Inc. All rights reserved. Printed in USA.

PA--8701(Ver 06)

8

Loading...

Loading...