Page 1

INSTALLATION INSTRUCTIONS PHOTOSWITCH

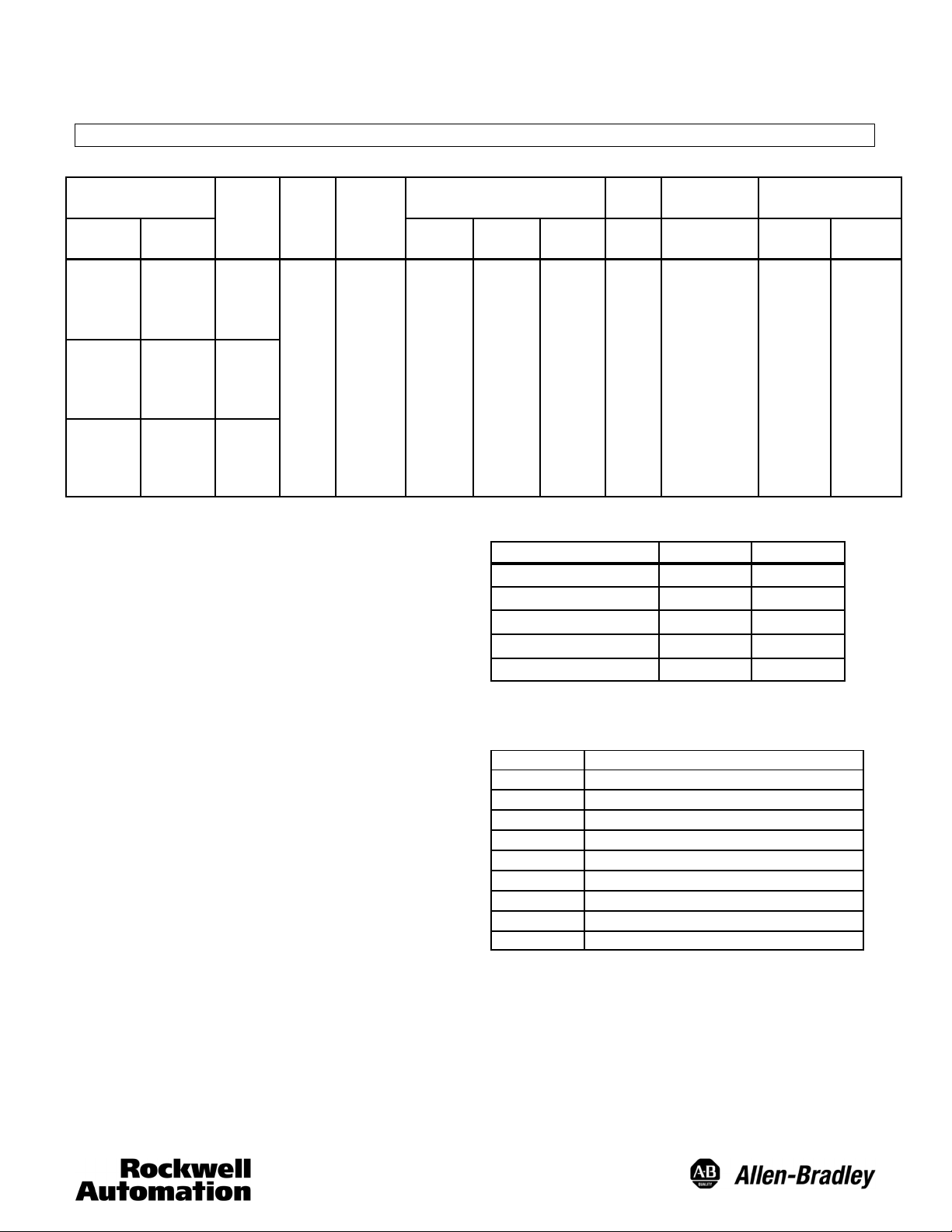

BACKGROUND SUPPRESSION CONTROL WITH TIMING, BULLETIN 42DBS-5100

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE. FOR ADDITIONAL INFORMATION REFER TO PUBLICATION PG-9000

BULLETIN NUMBER OPERATING

PHOTOHEAD POWERBASES

42DBS-5100 — TIMING

42DTB-5000 —

42DCB-5000 —

MODE

VOLTAGE

SUPPLY

10--30

VDC

CURRENT

SUPPLY

TYPE RATING LEAKAGE

40mA MAX NPN & PNP

SPECIFICATIONS:

Range Adjustment Fine and Coarse........................

o

Ambient Temperature Range -- 4 0

Fto150oF(--40oCto65oC)..

Relative Humidity 90%.................................

Turn on Pulse Suppression Ye s...........................

Reverse Polarity Protection Ye s...........................

Output Overload and Short Circuit Protection Ye s...........

Field of View 3

........................................

Transmitting LED Infrared, 880nm........................

Margin and Alignment Indicator with 3 Indicating Modes

-- R e d Output Energized................................

-- Green 2XMargin...................................

-- F l a s h i n g G r e e n Over Current..........................

Lens Material Acrylic...................................

Operating Environment NEMA,3,4,12,13andIP66(IEC529).

Approvals UL Listed and CSA Certified....................

Housing Material High impact chemically resistant VALOX

...

Cable Base Suppliedwith10 (3m) of 5 conductor, flexible,.....

vinyl-covered cable.

Te rm i na t io n Supplied with #6/32 nickel plated brass..........

pressure type materials

OUTPUT CHARACTERISTIC RESPONSE

(OFF STA TE)

100mA AT

10--30 VDC

1A 5ms

TIME

Timing Ranges

TIMING RANGE (SECONDS) SHORT LONG

On/Off Delay 0--1.5 0--15

On Delay 0--1.5 0--15

Off Delay 0--1.5 0--15

o

One Shot 0--1.5 0--15

Delayed One Shot 0--1.5 0--15

ACCESSORIES

Optional Mounting Assemblies

PAR T NU MB ER DESCRIPTION

60-1577 Armored Cable Adapter

60-1785 Universal Mounting Assembly

60-1748 Heavy Duty Mounting Assembly

60-1840 Right Angle Mirror

60-2014 Flexi-mount Mounting Assembly

60-2072 PHOTOcountSWITCH Totalizer

60-2083 Photoguard Heavy Duty Protection

60-2213 Conduit Mounting Adapter

60-2230 Limit Switch Type Mounting Assembly

SUPPRESSION POINT

ADJUSTMENT RANGE

2.5-- 1 2

(6.3cm--30.5cm)

TYPICAL SUPPRESSION QUALITY

WHITE BACK-

GROUND

CONTROL OFF

2.5

(6.35cm)

4

(10.1cm)

6

(15.2cm)

8

(20.3cm)

10

(25.4cm)

12

(30.5cm)

BLACK

TARG ET CON -

TROL ON

2.3

(5.89cm)

3.9

(9.9cm)

5.8

(14.7cm)

7.7

(19.5cm)

9.5

(24.1cm)

10.5

(26.6cm)

1

Page 2

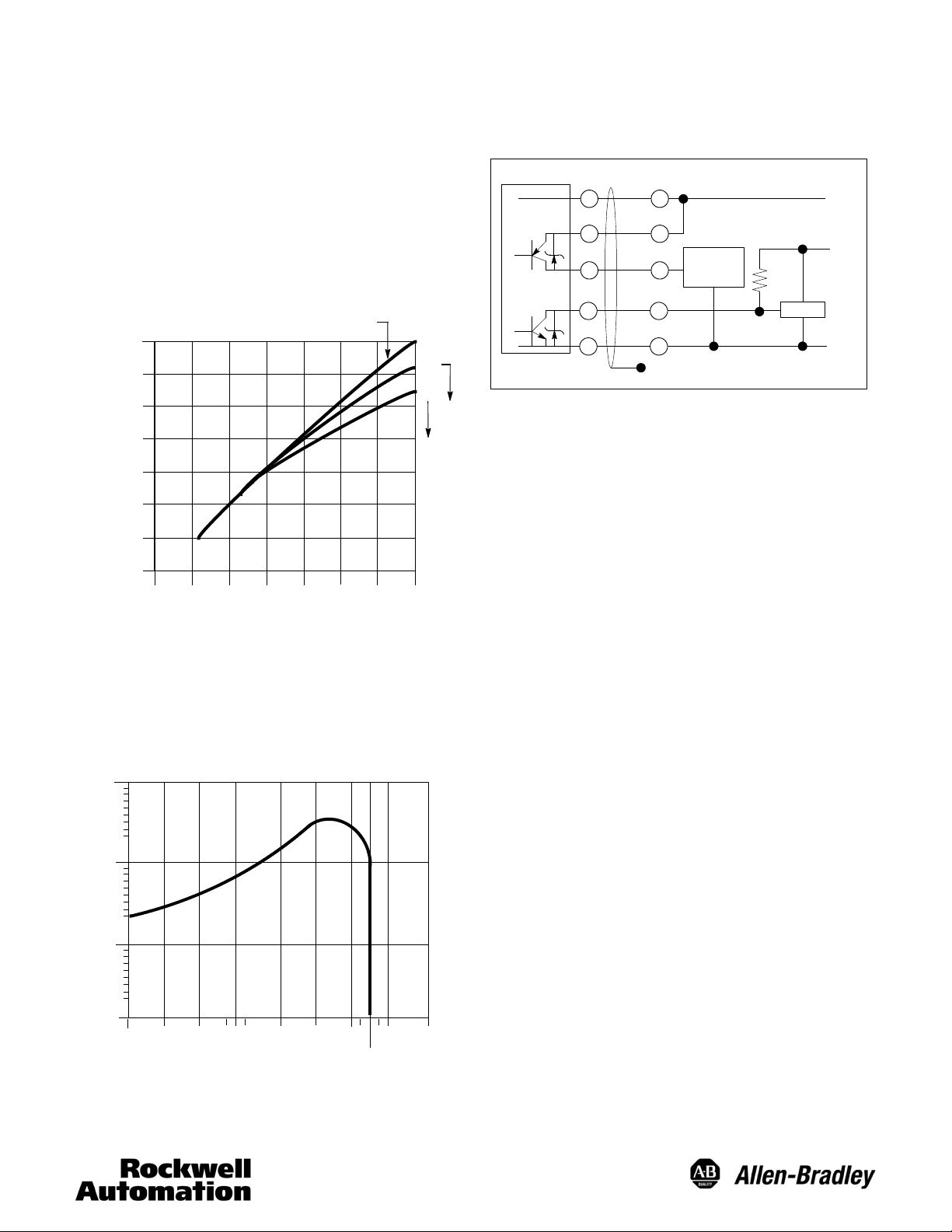

OPERATING MARGIN

1. The operating margin is parenthesis are for diffuse white surfaces

that fill the control’s field of view.

2. 6.1% and 2.6% designate dark colored surfaces having diffuse re-

flectance of 6.1% and 2.6% respectively compared to diffuse white.

3. The 2.6% surface is Krylon # 1602 Ultra flat black.

TYPICAL SUPPRESSION CURVE

WHITE PAPER

14

(35.5cm)

12

(30.5cm)

10

(25.4cm)

8

(20.3cm)

6

(15.2cm)

(10.1cm)

(5.08cm)

4

2

0

0 2

(5.08cm)4(10.1cm)6(15.2cm)8(20.3cm)

10

(25.4cm)

12

(30.5cm)

DISTANCE TO SENSED OBJECT

14

(35.5cm)

6.1%

2.6%

(OPERATING MARGIN) M - 38

DISTANCE TO BACKGROUND OBJECT

TYPICAL RESPONSE CURVE

SUPPRESSION SET FOR 8 (20.3CM)

1000x

100X

10X

OPERATING MARGIN

1X

.1”

(.254cm)

.3”

(.762cm)

.5”

(1.27cm)

.8”

(2.032cm)2”(5.08cm)4”(10.16cm)6”(15.24cm)

OPERATING DISTANCE

8”

(20.3cm)

10”

(25cm)

12”

(30cm)

WIRING

All external wiringshould conformto theNational ElectricCode and

applicable local codes. See wiring diagrams for external connections.

TYPICAL WIRING DIAGRAMS

(OPERATING MARGIN) M- 16

TERMINAL BASE

ALIGNMENT

+

3

2

1

--

CABLE BASE

Red

Orange

Grey

Blue

Black

Floating Shield

Programmable

Controller

DC Interface

1. Loosen lock to allow sensing range adjustment.

2. Adjust “Coarse” sensing range adjustment to the maximum position (full counterclockwise position)

3. Set “Light Energized” (LT)/“Dark Energized” (DK) switch to the

Light Energized position.

4. Select short (0--1.5sec) or Long (0--15sec) “off delay” (one-shot)

switch.

5. Select short (0--1.5sec) or Long (0--15sec) “on delay” (one-shot)

switch.

6. Select “Time delay” (TD) or “One-Shot” (OS) operation switch .

7. Set the on time to minimum, with the on-timing pot. (full counter

clockwise)

8. Set the off-time to maximum, with the off-timing pot, when in

short-off mode (full clockwise) or to at least 2--3 seconds, when

in long-off mode.

9. Turn “coarse” sensing range adjustmentto the minimum position

(full clockwise).

10. Position the control in its application and increase the sensing

range until the control senses the background. The Red LED indicator will turn On. The Green LED (2X margin indicator) will

probably turn On.

11. With the “fine” adjustment, decrease the sensing range until the

Green LED turns Off.

12. Place the object to be detected in front of the control at the expected sensing distance. Both red and green LED’s should turn

On. Remove the target.

13. Time Delay Operation -- If after the off delay has elapsed the

Red LED indicator turns Off, the control has the correct adjustments and settings should be locked with the lock screw. If

the Red LED does not turn Off, slightly reduce the sensing

range with the fine sensingrange adjustmentand repeat steps

12 and 13.

14. One-Shot Operation -- Replace the target in front of the control

after the one shot time has elapsed. If the Red LED turnsOn,

the settingsare correctand can be locked with the lock screw.

If the Red LED does not turn On, slightly reduce the sensing

range with the fine sensingrange adjustmentand repeat steps

12 and 14.

(+)

10--30VDC

+5VDC

TTL Logic

(--)

22

Page 3

15. Select Light or Dark operate mode with switch.

16. Adjust for the desired delays with the On and Off timing pots.

17. Tighten the lockscrew after adjusting the sensing range. A slight

increase in sensing distance may occur. Typically .25 (.63cm) at

12 (30.5cm), .12 (30.5cm) at a 6 (15.2cm) and .062 (1.57cm)

at 3 (7.62cm), for both background and target. If necessary,

sensing range variation can be compensated for by adjusting to

11.75 (29.8cm) for a 12 (30.5cm) suppression point, 5.875

(14.9cm) for a 6 (15.2cm) suppression point, and 2.95

(7.46cm) for a 3 (7.62cm) suppression point. Repeat steps 5 and

6 to verify the range after the lockscrew is tightened.

APPLICATION PRECAUTIONS

To obtain the high sensitivity and sharp cut-off required in a background suppression control, two photodetectors are used. One detector senses objects in close, the other detector will sense further out.

If the further out signal (background) is greater than or equal to

the close in signal, the control remains Off, if the close signal is greater than the background signal, the control output will turn On.

This interdependence of the two photodetectors and overlapping

sensing areas require that the object being sensed passes by the sensor

in certain directions or false operation could occur. Therefore, an object always should travel on an x-axis perpendicular with the control.

See figures below.

CLOSE SENSING

AREA

FIELD OF VIEW

OVERLAP

Direction

of travel

SUPPRESSION

POINT

OBJECT

SUPPRESSED

FAR SENSING

AREA

TO BE

WRONG DIRECTION OF TRAVEL CORRECT DIRECTION OF TRAVEL

INSTALLATION

The control must be securely mounted on a firm, stable surface or

support. A mounting which is subject to excessive vibration or shifting may cause intermittent operation.

OUTLINE DIMENSIONS

Control

Top Vi ew

Suppression

Point

Direction

of travel

OBJECT

TO BE

SUPPRESSED

Both

sensing ranges

overlap

61/64

(24.2)

15/16

(33.3)

15/32

(11.9)

39/64

(15.4)

5 33/64

(139.5)

QUICK

DISCONNECT

SCREW

LED

INDICATOR

1/2--14

NPSM

15/64

(27.3)

10--32 UNF

2HOLES

49/64

(19.4)

35/64

(13.8)

17/16

(36.5)

11/2

(38.1)

21/64

(8.3)

25/32

(54.7)

1 17/16

(36.5)

25/32

(54.7)

TO REMOVE SCANNER

11/32

(8.7)MIN.

7/64

(2.7)

2 51/64

(71.0)

2 19/32

(65.8)

25/32

(54.7)

21/64

(8.3)

11/2

(38.1)

3/4

(19.0

)

TERMINAL BASE CABLE BASE

33

10-32 UNC

15/64

(27.3)

2HOLES

1/4-18

NPSM

39/64

(15.4)

1/4-18

NPSM

15/32

(11.9)

27/8

(73.0)

61/64

(24.2)

3 63/64

(101.2)

7/64

(2.7)

10’ (3m)

CABLE

Page 4

MOUNTING ASSEMBLIES

w

39/64

(15.4)

.280

(7.10)

15/32

(11.9)

27/8

(73.0)

GENERAL PURPOSE MOUNTING

60-1785

MATERIAL

#11 GA CRS

61/64

(24.2)

(50.8)

2 21/32

(67.5)

11/3 2

(8.73)

4.0

(101.6)

57/16

(138.1)

CLEARANCE FOR

#1/4- -20 HDW

3/4

(19.0)

2

.325

(8.26)

2 57/64

(73.42)

13/4

DIA.

3/4

(19.0)

39/64

(15.4)

.280

(7.10)

15/32

(11.9)

(106.5)

41/4

61/64

(24.2)

2

(50.8)

2 21/32

(67.5)

11/ 32

(8.73)

5 25/64

(136.9)

1 11/16

(42.9)

.325

(8.26)

39/64

(15.4)

15/32

(11.9)

2 27/32

(72.3)

(54.7)

5/32

21/64

(8.3)

61/64

(24.2)

FOR #10-32 HDW

2

11/2

(38.1)

CLEARANCE

11/2

(38.1)

1/4 (6.3)

1 14/32

(61.9)

HEAVYDUTYMOUNTING

60-1748

11/3 2

(8.73)

1 53/64

(46.43)

47/64

(104.4)

1

(25.4)

21/2

(63.5)

CLEARANCE

FOR #10-32 HDW

21/2

(63.5)

15/32

(11.9)

39/64

(15.4)

#10-32

THREAD

2HOLES

11/4

(31.7)

21/64

(8.3)

1/4

(6.3)

11/2

(38.1)

61/64

(24.2)

1/4 (6.3)

1 14/32

(61.9)

11/3 2

(8.73)

(25.4)

1

4 11/32

(110.3)

59/64

(23.4)

25/32

(54.7)

5 24/32

(146.4)

21/2

(63.5)

Control with Cable Base

Control with Terminal Base

Control with Cable Base Control with Terminal Base

ww.rockwellautomation.com

Power, Control and Information Solutions Headquarters

Americas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414.382.2000, Fax: (1) 414.382.4444

Europe/Middle East/Africa: Rockwell Automation NV, Pegasus Park, De Kleetlaan 12a, 1831 Diegem, Belgium, Tel: (32) 2 663 0600, Fax (32) 2 663 0640

Asia Pacific: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel: )852) 2887 4788, Fax: (852) 2508 1846

Publication PA--9168(A)

March 1992

44

Loading...

Loading...