Page 1

Installation Instructions

Bulletin 42CS Stainless Steel Photoelectric Sensors

SAVE THESE INSTRUCTIONS FOR FUTURE USE.

Refer to the product catalog pages for additional information.

Description

The 42CS family of sensors offers a wide range of sensing

modes in a smooth 316L stainless steel housing, designed for

food, beverage and pharmaceutical applications.

The ferromagnetic teach feature makes the sensor easy to

program by simply placing a ferromagnetic metal object on a

section of the sensors housing to initiate the teach process.

The smooth and clean design minimizes the collection and

accumulation of undesired particles and allows for a fast

cleanup.

Features

S Patented ferromagnetic teach for easy sensor

programming

S Extended temperature operating range

S Clean design minimizes the accumulation of undesired

particles allowing for a fast and easy cleanup

S 18 mm stainless steel 316L enclosure with laser etched

markings

S Two teach modes: standard and precision

S Complementary light and dark operate outputs

S Teach lockout feature prevents unauthorized users from

changing the settings

S Clear object detection models available

S Input to disable light source on transmitted beam emitter

S IP69K, ECOLAB and Johnson Diversey rated

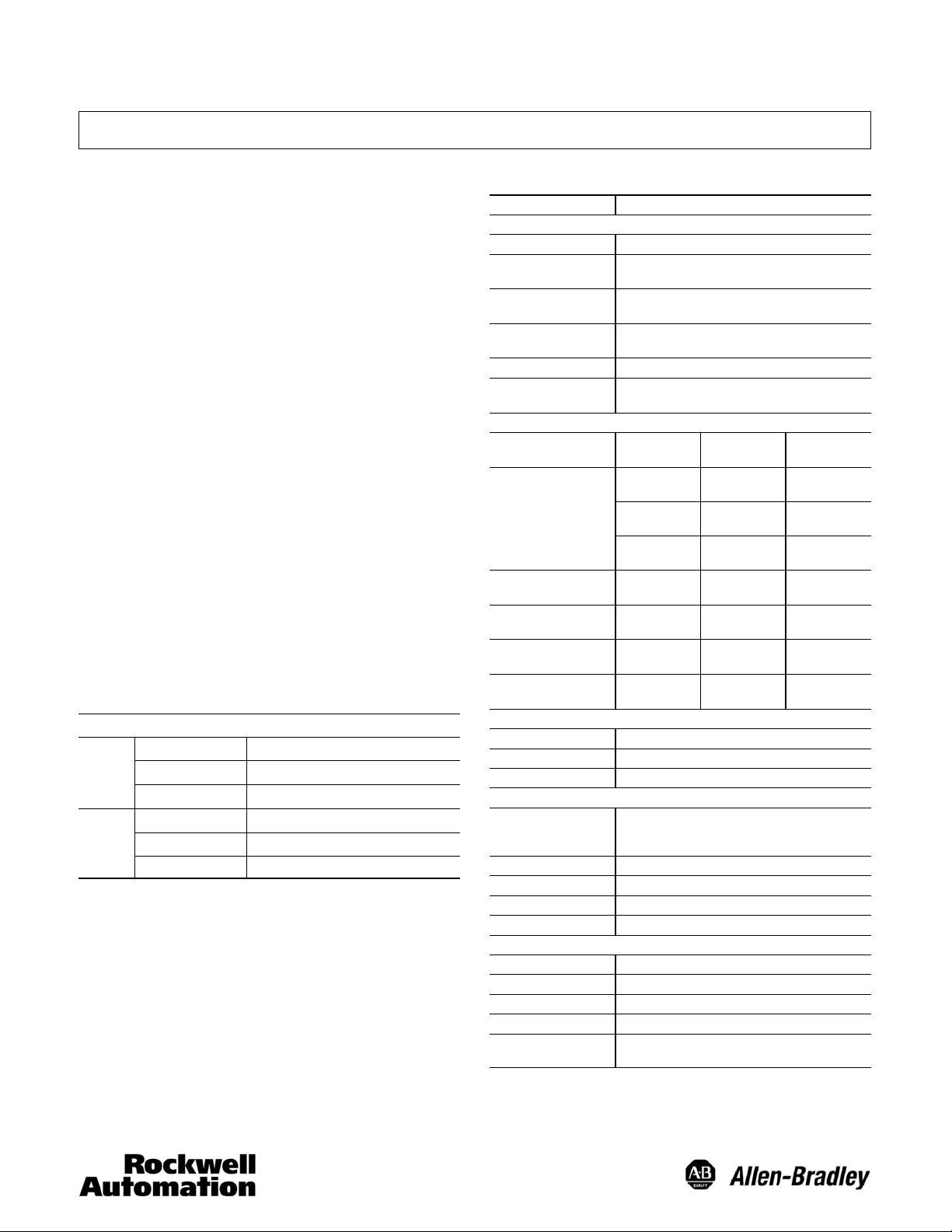

Sensor Indicators

LED Status

OFF Teach function is locked

Green

Yellow

Pin 4 of Micro (M12) QD. L.O for diffuse, background suppression. D.O for polarized

retroreflective and transmitted beam

ON Teach function is enabled

Flashing (8 Hz) Short Circuit

OFF

ON

Flashing (3 Hz)

Output de-energized

Output energized

Output energized (Margin < 2)

Specifications

Certifications cULus and CE marked for all applicable directives

Environmental

Operating Environment IP69K, ECOLAB and Johnson Diversey rated

Operating

Temperature [C (F)]

Vibration 10…55Hz, 1 mm amplitude; meets or exceeds IEC

Shock 30 g with 1 ms pulse duration, meets or exceeds IEC

Relative Humidity 5…95% (noncondensing)

Ambient Light Immunity 5000 Lux (Incandescent light) and 100000 Lux

Optical

Sensing Modes

Standard Diffuse

Background

Suppression

Polarized Retroreflective 4 m (13.12 ft) Visible Red

Clear Object Detection 1 m (3.2 ft) Visible red

Transmitted Beam 20 m (65.62 ft) Infrared

Electrical

Voltage 10…30V DC

Current Consumption 35 mA max

Sensor Protection Short circuit, transient noise, reverse polarity

Outputs

Response Time 1 ms (diffuse, polarized retroreflectived, clear object),

Output Type PNP or NPN by cat. no.

Output Mode Complementary light and dark operate

Output Current 100 mA

Output Leakage Current 10 µAmax.

Mechanical

Housing Material Stainless steel 316L

Lens Material PMMA

Connector Material Grilamid

Connection Types 4-pin DC micro (M12) QD

Supplied Accessories Stainless steel teach rod, mounting nuts (threaded

-- 2 5 …+85° (--13…185°)

60947--5--2

60947--5--2

(Sunlight)

Sensing

Range

100 mm

(3.94 in.)

400 mm

(15.75 in.)

800 mm

(31.5 in. )

60…100 mm

(2.36…3.94 in.)

1.25 ms (background suppression),

2 ms (transmitted beam)

models only)

Light Source

Visible Red

(660 nm)

Infrared

(880 nm)

Infrared

(880 nm)

Visible Red

(660 nm)

(660 nm)

(660 nm)

(880 nm)

Spot Size @

max. distance

10 mm @

100 mm

50 mm @

400 mm

120 mm @ 1 m

12 mm @

120 mm

100 mm @

3 mm

50mm@1m

600 mm @

20 m

1

Page 2

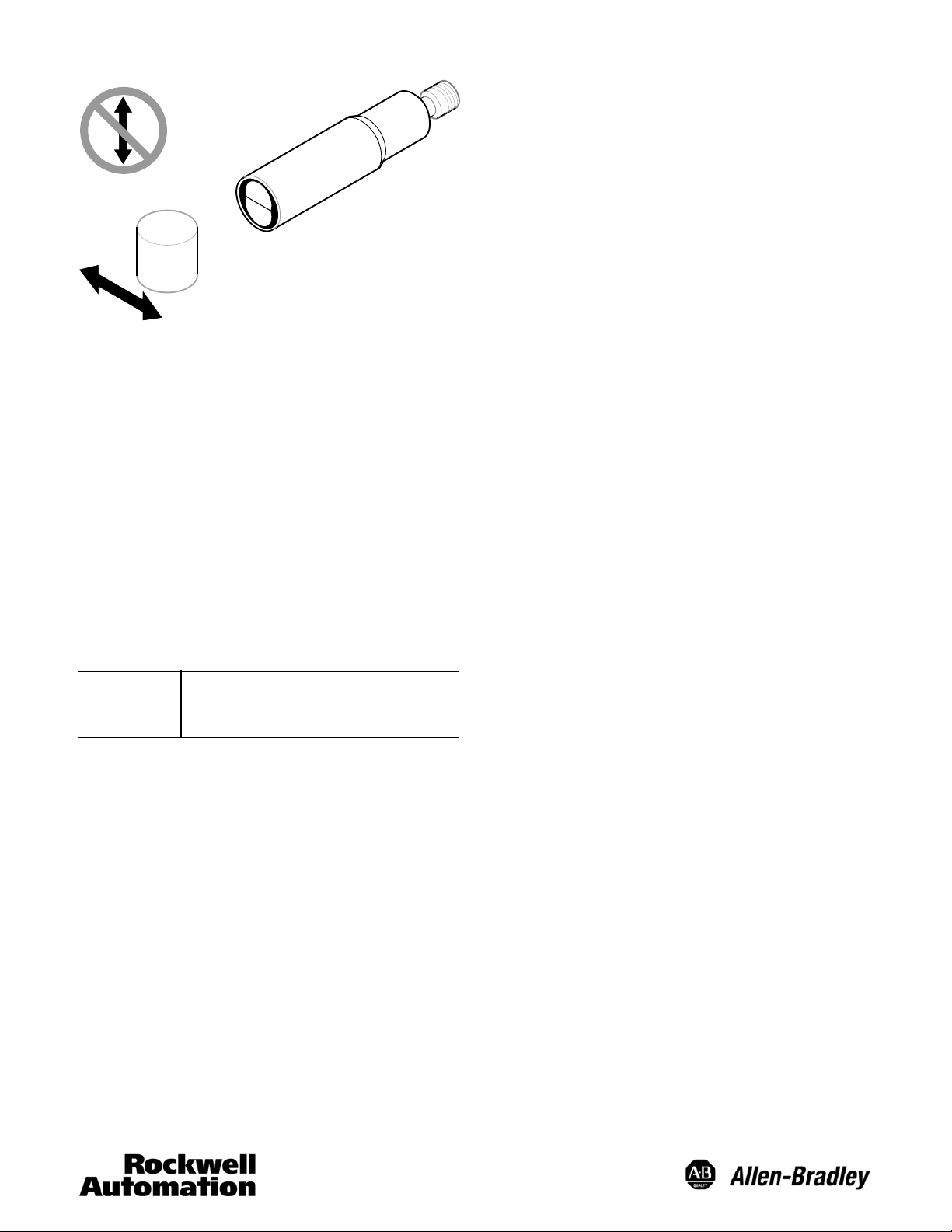

Background Suppression Sensors

Target

Application Note

Due to the detection method, targets traveling horizontal to

the sensor’s optics are detected. Targets traveling vertically

may not be accurately detected. For reliable background

suppression, a minimum separation distance of 6 mm is

recommended between the target and the background.

Sensor Alignment

1. Pan the sensor left, right, up, and down to center the beam

on the sensed object (for diffuse), reflector (for polarized

retroreflective) or transmitter (for transmitted beam).

2. Fix the sensor position when the green LED is ON

(flashing) and the yellow output LED is ON (light sensed

and L.O. output energized). This set up assures a good

margin and that the signal received is greater than twice

the signal required to energize the L.O. output. The yellow

LED is on when the L.O. output is conducting.

Mounting the Sensor

Installing sensors on equipment running

IMPORTANT

Securely mount the sensor on a firm, stable surface or

support. A mounting which is subject to excessive vibration or

shock may cause intermittent operation. Mounting brackets

are available for a various installations. See accessories

section for an example.

above the indicated vibration and shock

specification may cause intermittent

operation.

Sensitivity Adjustment Modes

Two types of sensitivity adjustment modes are possible on the

42CS diffuse and polarized retroreflective: Standard Teach

and Precision Teach.

The Standard Teach is recommended for general purpose

detection of opaque targets, large objects or the absence of a

background that could interfere with the teach process. For

this teach process, the threshold levels are set at 50% of the

detected signal.

The Precision Teach is suited for the detection of small

targets or semi transparent objects, where a smaller variation

in gain needs to be sensed. For this teach process, the

threshold levels are set at below the hysteresis levels of the

detected signal.

Diffuse, Polarized Retroreflective and Clear Object

To teach the 42CS using the Standard Teach mode:

1. Place the target within the sensing range.

2. Enter teach mode by placing a ferromagnetic metal object

in the notch until the green LED flashes once. Note that the

green LED flashes while the teach process is active.

3. When the teach process is complete the green LED turns

solid ON. The yellow LED also turns solid ON when the

target is detected with at least twice the minimum amount

of light needed (Margin >= 2) for standard operation. A

flashing yellow LED indicates that the sensor operates with

a margin below the recommended 2X (1 < Margin < 2).

4. The sensor is now ready to operate (yellow LED is on

when the target is present)

To teach the 42CS using the Precision Teach mode:

1. Place the target within the sensing range.

2. Enter teach mode by placing a ferromagnetic metal object

in the notch until the green starts flashing. Note that the

green LED blinks multiple times while the teach process is

active.

3. When the teach process is complete the green LED turns

solid ON. The yellow LED also turns solid ON when the

target is detected with at least twice the minimum amount

of light needed (Margin >= 2) for standard operation. A

flashing yellow LED indicates that the sensor operates with

a margin below the recommended 2X (1 < Margin < 2).

4. The sensor is now ready to operate (yellow LED is on

when the target is present).

Background Suppression

To teach the 42CS background suppression:

1 Place the target within the sensing range.

2 Enter teach mode by placing a ferromagnetic object in the

notch until the green LED starts flashing. Note that the

green LED blinks multiple times while the teach process is

active.

3 When the teach process is complete the green LED turns

solid ON. The yellow LED also turns solid ON when the

target is detected.

4 The sensor is now ready to operate (yellow LED is on

when the target is present).

Teach Lock/Unlock

The 42CS teach is used to prevent unauthorized users from

changing teach settings and avoid interference from any

metal objects that could be in proximity of the teach notch

while in operation.

To lock the sensor:

Place a ferromagnetic metal object in the notch until the

green LED turns OFF. The sensor is now locked.

To unlock the sensor:

Place a ferromagnetic metal object in the notch until the

green LED turns ON. The sensor is now unlocked.

2

Page 3

Wiring Diagrams

Quick disconnect connection is shown in the following

diagrams. Pin numbers correspond to an M12 male connector

on the sensor connected to an 889DS--F4AC--2 cordset

Approximate Dimensions [mm (in.)]

98.3

(3.87)

15.8

(0.63)

11. 5

(0.45)

6

(0.24)

82.5

(3.25)

65

(2.56)

Diffuse and Background Suppression

PNP Models with

Complementary Outputs

Brown (1)

Black (4)

LO

DO

White (2)

Blue (3)

Load

Load

+

–

NPN Models with

Complementary Outputs

Brown (1)

White (2)

DO

LO

Black (4)

Blue (3)

Load

Load

+

–

Polarized Retroreflective, Clear Object and

Transmitted Beam Receiver

PNP Models with

Complementary Outputs

DO

LO

Brown (1)

Black (4)

White (2)

Blue (3)

Load

Load

+

–

1

2

M12 Male

Transmitted Beam Emitter

Brown (1)

White (2)

Blue (3)

For normal operation, white wire (pin 2) needs no connection. To disable light source, connect

white wire (pin 2) to --V.

+

–

NPN Models with

Complementary Outputs

Brown (1)

White (2)

LO

Black (4)

DO

Blue (3)

4

3

Load

Load

+

–

M12 x 1

M12 x 1

LED

LED

15.8

(0.63)

11. 5

(0.45)

(0.24)

6

(0.87)

2.2

(0.87)

2.2

71

(2.80)

98.3

(3.87)

82.5

(3.25)

65

(2.56)

71

(2.80)

Accessories

60-BCS-18B—Mounting bracket for smooth barrel

M18 x 1

17.5

(0.69) Dia.

60- 2656—Straight mounting bracket for threaded models

60- 2657—Right angle mounting bracket for thread models

Typical Response Curves

Standard Diffuse (100 mm)

1000

100

10

Operating Margin

1

0 1 10 100 1000

90% white

paper

18% grey

(0.03) (0.39) (3.9) (39.37) (1.9)

Distance [mm (in.)]

Standard Diffuse (400 mm) Beam Pattern (400 mm)

1000

100

10

Operating Margin

1

0 1 10 100 1000

18% grey

(0.03) (0.39) (3.9) (39.37) (1.9) (3.8) (5.9) (7.8) (9.8) (11.8) (13.7) (15.7)

Distance [mm (in.)]

90% white

paper

Beam Pattern (100 mm)

15

10

5

0

-- 5

18%

-- 1 0

Beam Diameter (mm)

-- 1 5

10 100

0 2030405060708090

(0.39) (3.9)

30

20

10

0

-- 1 0

-- 2 0

Beam Diameter (mm)

-- 3 0

0 50 100 150 200 250 300 350 400

90% white

paper

Distance [mm (in.)]

90% white

paper

18% grey

Distance [mm (in.)]

3

Page 4

Standard Diffuse (800 mm) Beam Pattern (800 mm)

1000

10

Operating Margin

1

0 1 10 100 1000

18% grey

(0.03) (0.39) (3.9) (39.37)

Distance [mm (in.)]

90% white

paper

200

100

0

--100

Beam Diameter (mm)

--200

0 100 200 300 400 500 600 700 800

(3.8) (19.6)

Distance [mm (in.)]

700 800

(31.5)

Polarized Retroreflective (4 m)

100

10

Operating Margin

1

0.01 0.10 1.00 10.00

(0.03) (0.32) (3.28) (32.8) (32.8) (65.6) (98.4) (131.2)

92--39

92--47

Distance [m (ft)]

Beam Pattern (4 m)

50

40

30

20

10

0

-- 1 0

-- 2 0

-- 3 0

Beam Diameter (mm)

-- 4 0

-- 5 0

010203040

Distance [m (ft)]

Clear Object (1 m) Beam Pattern (1 m)

100

10

Operating Margin

1

0.01 0.10 1.00 10.00

(0.03) (0.32) (3.28) (32.8)

Distance [m (ft)] Distance [m (ft)]

50

40

30

20

10

0

-- 1 0

-- 2 0

-- 3 0

Beam Diameter (mm)

-- 4 0

-- 5 0

02

1

(3.28

Transmitted Beam (20 m) Beam Pattern (20 m)

10000

1000

100

10

Operating Margin

1

0

0 1 10 100

(0.03) (0.39) (3.9)

Distance [m (ft)]

250

200

150

100

50

0

-- 5 0

--100

--150

Beam Diameter (mm)

--200

--250

0102030

5

(16.4)

(32.8) (65.6) (98.4)

15

(49.2)

Distance [m (ft)]

25

(82)

(6.56)

10000096921Ver 00

4

March 2010

Loading...

Loading...