Page 1

Allen-Bradley

User’s Manual

PHOTOSWITCH

42CRC Color Registration Control

(Cat. No. 42CRC-4000, 4001)

Page 2

Table

of Contents

Title Page

Description 1,2............................................

Installation

a. Lens Location 2.....................................

b. Mounting 2.........................................

c. Wiring 3...........................................

Alignment

a. Opaque Web Material 3...............................

b. Opaque Non-Reflective Web Material 3...................

c. Transparent Web Material

with Dark Opaque Mark 4.............................

Operating Modes

a. Latch 5............................................

b. Non-Latch 5........................................

c. Light or Dark Mark Sensing 5..........................

d. Automatic Operation 5................................

e. Manual Operation 5..................................

f. Red and Green Light Sources 6.........................

Additional Features

a. Output Dwell 7......................................

b. Gated Operation 7....................................

c. Diagnostic Alarm Output 8.............................

d. Contrast Check 9.....................................

Operation 10.............................................

Maintenance 11...........................................

Specifications 11..........................................

a. Outline Dimensions 13.................................

b. Internal Schematic 13..................................

c. Diagnostic Resistor Selection 14.........................

d. Cable Color Coding 14.................................

e. Wiring Diagrams 15, 16...................................

f. Performance Curves 17.................................

Publication PA-8853 — February 1994

Page 3

42CRC Color Registration Control

1

Description

The Photoswitch Type 42CRC Series 4000 LED Color Registration Mark Control

with Automatic Gain Control (AGC) is a fixed focus diffuse-reflective scanning

device designed to detect pre-printed registration marks against contrasting

backgrounds. Detection of the marks is achieved by sensing the difference in the

gray-scale response to the mark and background.

This device has two sources of emitted light, a red and a green LED that

are selected by an operating-mode switch. The choice of a red or green

LED broadens the control’s capability of detecting a wide range of mark

and background colors.

A small light spot is projected on the material being scanned. The reflectivity of the material at the spot defines the level of the received signal.

Changes in the reflectivity, due to the contrast between the printed mark

and the background is recognized by the control, which provides an output.

This output can then be used by the packaging machine to properly cut,

seal, crimp, or fold packages or tubes.

The 42CRC Series 4000 also has a number of unique features that enhance

flexibility and reliability.

S An automatic gain sensitivity control permits fully automatic operation

eliminating the need for constant operator interface when mark to background colors change.

S A manual sensitivity selection mode enables the operator to fine tune the

control to detect poor quality marks.

S A built-in diagnostic system provides early-warning alarm indication of

gradual loss of operating margin due to changes in contrast, misalignment, or dust prior to loss of output signal, avoiding unexpected process

disruption.

S Custom microcircuitry for very high sensitivity and increased intelli-

gence in a small workable package.

S Fast 250 microsecond response time.

S Latch or automatic reset functions.

S Adjustable output dwell time.

S Selectable light or dark mark detection.

S Continuous output short circuit protection.

S Reverse polarity protection.

Page 4

2

42CRC Color Registration Control

Description

(Continued)

S An external gate input makes it possible to blind the control during por-

tions of the machine cycle, eliminating the possibility of false signals

between registration marks.

S Analog test points allow evaluation of mark contrast prior to running a

machine, and three LED status indicators provide setup ease and

accuracy.

S Quick Disconnect design for ease of installation, reduced downtime and

replacement cost.

S NPN or PNP outputs. Model 4000 has one NPN (sinking) output rated

100mA at 30 VDC. Model 4001 has one PNP (sourcing) output rated

100 mA at 30 VDC. Both models have a separate diagnostic NPN

(sinking) output rated 30 mA at 30 VDC.

S Rugged high impact housing is constructed of #380.0 cast aluminum,

anodized and epoxy coated for maximum corrosion resistance.

S Entire control is rated for NEMA 3, 4, 6P, 12 and 13, IP67 (IEC 529).

Installation

a. Lens Location

For increased flexibility the lens of the 42CRC is interchangeable with the

lens cap. Determine which lens location is best for your particular application, taking into consideration the accessibility to the control adjustments

and the visibility of the indication lights. When the lens location has been

determined, make sure to tighten the lens and cap to effectively maintain a

watertight rating.

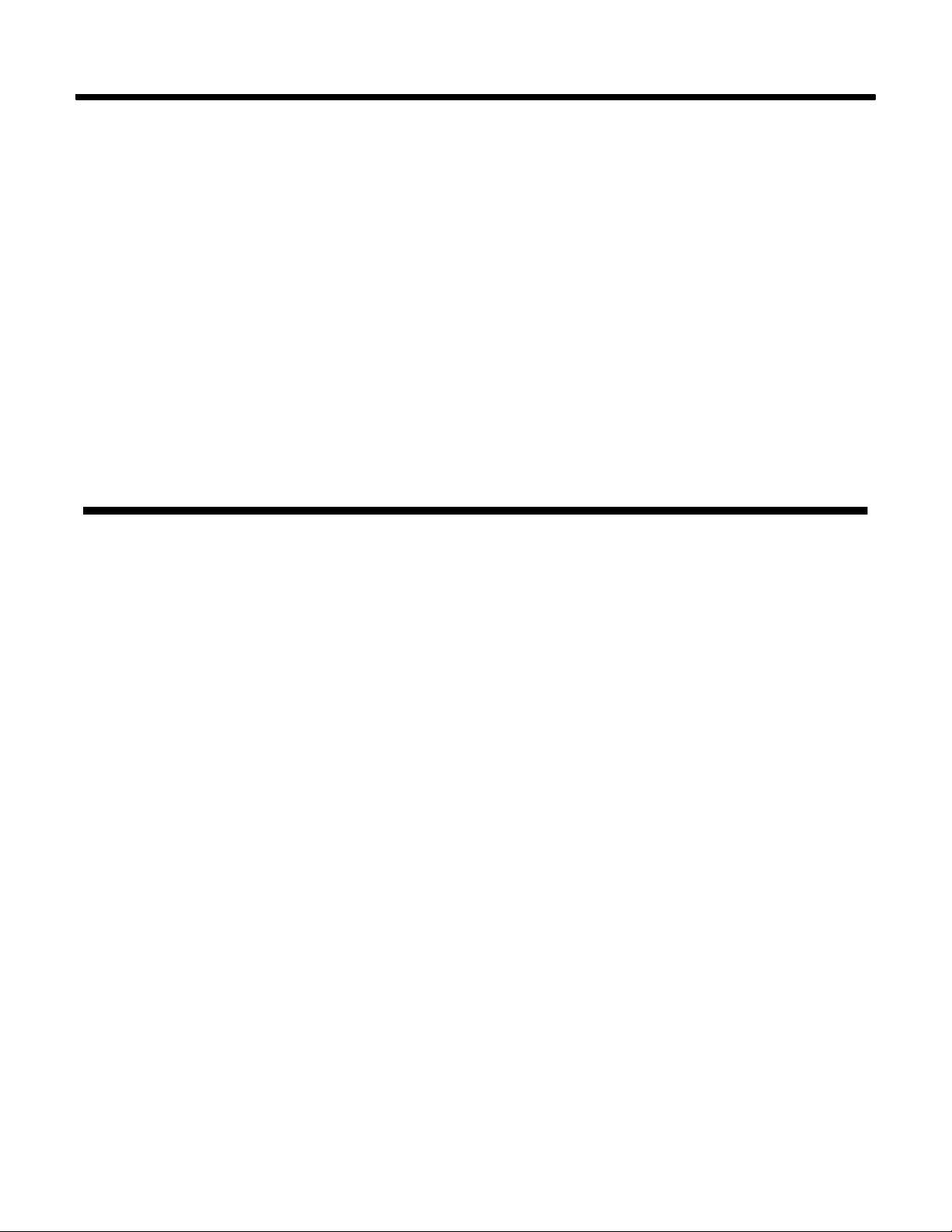

b. Mounting

The control must be mounted on a firm stable surface or support. A mounting which is subject to excessive vibration or shifting may cause unreliable

operation.

This control is designed to detect a mark at a fixed distance from the lens.

Mount the control .5 inches (13 mm) from the web to the center of the face

of the lens, with the light spot centered on the mark. Web flutter must be

held to a minimum to maintain the sensing distance within the +/-- .08 (2

mm) depth of field. To ensure reliable operation, mount the control where

the web material travels smoothly over a plate or roller with little flutter

and where there are no web creases or wrinkles. See Page 3, Figure 1.

Page 5

42CRC Mounting

42CRC Color Registration Control

42CRC

WEB MATERIAL

MOUNT THE 42CRC OVER A PLATE OR ROLL TO

PREVENT FALSE SIGNALS DUE TO WEB FLUTTER

FIGURE 1

3

Installation

(Continued)

Alignment

c. Wiring

For proper wiring the 42CRC requires a Photoswitch Cable Assembly

#60-2292 ordered separately. The control operates on 10-30 VDC @ 70

mA max. See pages 11 and 12 for complete specifications. All external

wiring should conform to the National Electric Codes and applicable

local Codes. See wiring diagrams beginning on page 15 for external

connections.

The 42CRC is designed to perform reliably on many different types of web

material. However, once the device is mounted and wired, it should be

aligned to the particular web material for optimum performance and

reliability.

Most marks can be detected by using the following mounting and alignment methods. Difficult mark colors and some foil material may require

the use of the Test Points on the control to determine the best position for

maximum mark to background contrast (see Page 9, d., Contrast Check).

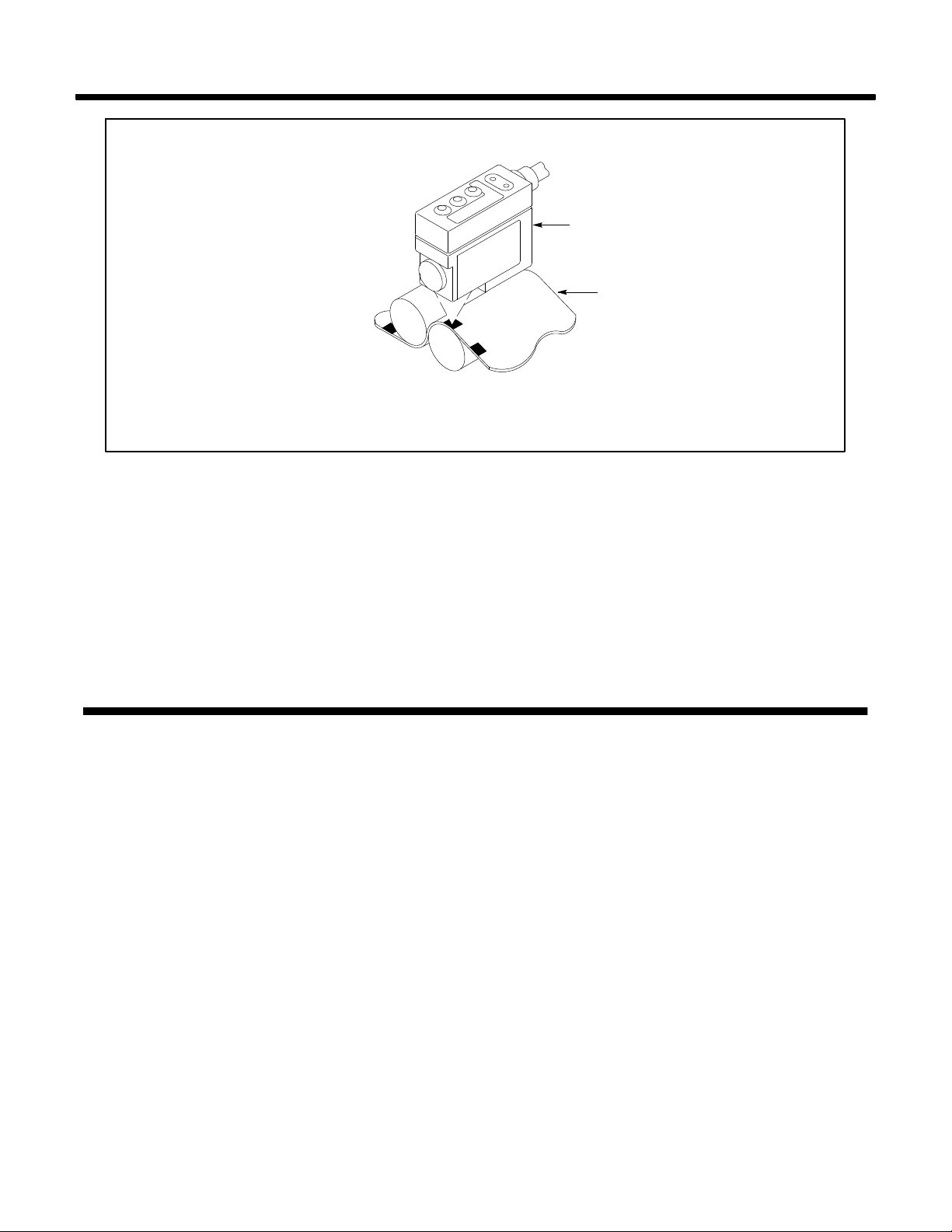

a. Opaque Reflective Web Material

For sensing light or dark registration marks on opaque reflective surfaces,

mount the control .5 (13 mm) above the surface of the material. If the surface is shiny or reflective, angle the control about 10 to 15 degrees to the

perpendicular (75 to 80 from the control to the web surface). See Figure

2, Page 4.

b. Opaque Non-Reflective Web Material

For sensing light or dark registration marks on material with non-reflective

surfaces, mount the control .5 (13 mm) from the surface and perpendicular (90) to the web. See Figure 3, Page 4.

Page 6

4

42CRC Color Registration Control

Alignment

c. Transparent Web Material With Dark Opaque Mark

(Continued)

For this type of material, mount the control .5 (13 mm) above the web

surface and at a 10 to 15 degree angle to the perpendicular (75 to 80 from

the control to the web surface). A light colored plate or roller must be

mounted directly behind the transparent web material.

The control will see through the transparent web, sense the light colored

background providing the required contrast to the dark opaque registration

mark. See Figure 4.

42CRC Alignment

OPAQUE REFLECTIVE WEB MATERIAL

WITH LIGHT OR DARK REGISTRATION MARKS

42CRC

SCANNING DISTANCE

.5 (13mm)

75 TO 80

OPAQUE NON-REFLECTIVE WEB MATERIAL

WITH LIGHT OR DARK REGISTRATION MARKS

42CRC

SCANNING

DISTANCE

90

.5 (13mm)

WEB MATERIAL

PLATE

MOUNT THE 42CRC AT A 10 TO 15 DEGREE ANGLE

FOR REFLECTIVE (SHINY) WEB SURFACES.

FIGURE 2 FIGURE 3

TRANSPARENT WEB MATERIAL WITH DARK

OPAQUE REGISTRATION MARKS

75 TO 80

PLATE

MOUNT THE 42CRC AT A 10 TO 15 DEGREE ANGLE.

MOUNT A PLATE MADE OF A LIGHT COLORED MATERIAL

BEHIND THE TRANSPARENT WEB MATERIAL.

WEB MATERIAL

PLATE

MOUNT THE 42CRC PERPENDICULAR TO THE WEB

FOR NON-REFLECTIVE (MATTE) WEB SURFACES

42CRC

SCANNING DISTANCE

.5 (13mm)

TRANSPARENT

WEB MATERIAL

FIGURE 4

Page 7

42CRC Color Registration Control

5

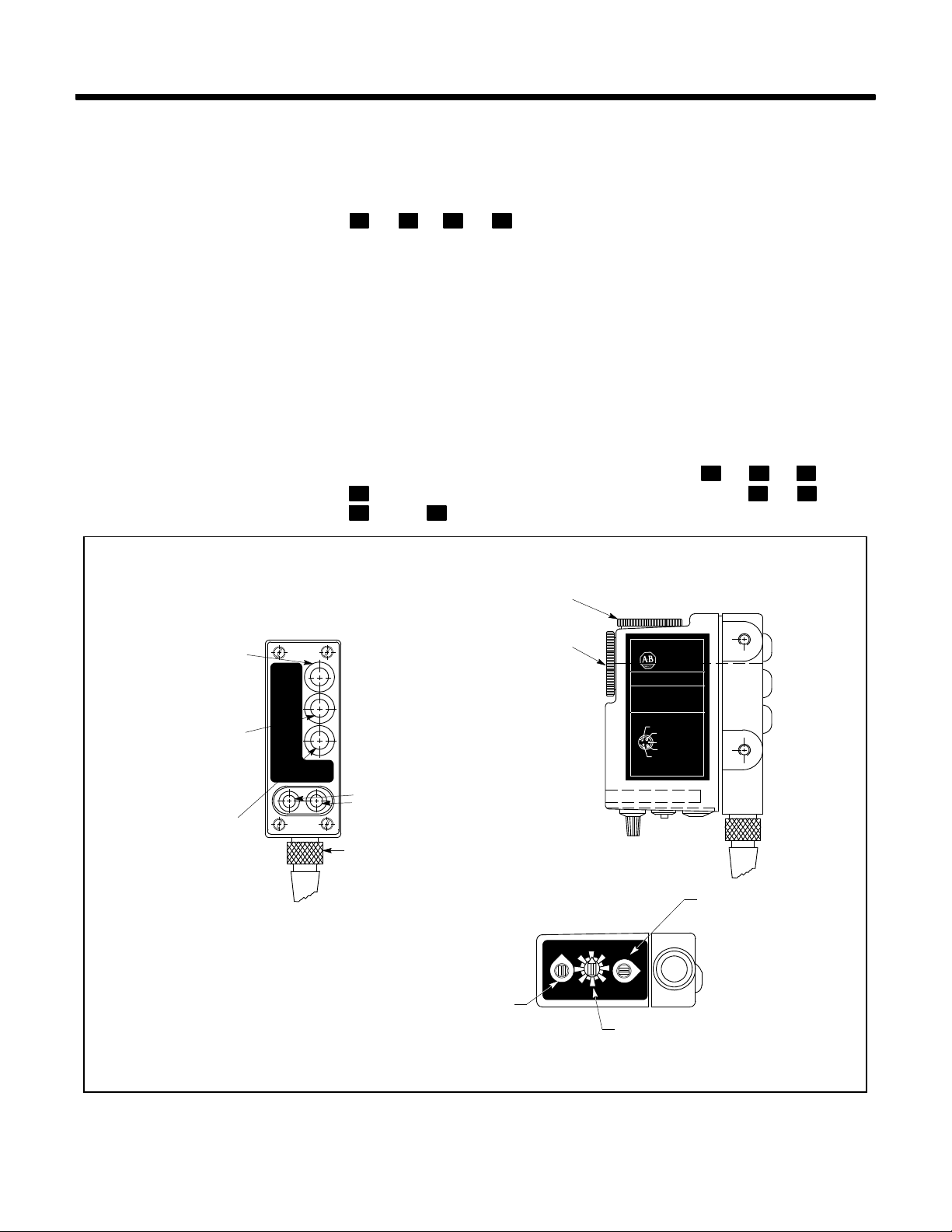

Operating Modes

After the control has been installed and aligned, it must be set for the

particular operation. An important feature of the control is that it gives the

user complete flexibility to select any combination of the four major

operating modes listed below via a convenient external function selector

switch. See Figures 5, 6, and 7.

a. Latch Operation

This function allows the user to latch the switched output “ON” for an indefinite period when a mark is detected. The output is reset by applying a

positive 4 to 30 VDC to the “white” GATE/RESET input lead or by simply

switching this lead to the B+ supply. Electromechanical or solid state contacts can be used to reset the control. This function enables the output duration to be extended, and the output reset later in the machine cycle. The

“Latch” switch positions are “A” through “D”.

b. Non-Latch

In the non-latch mode, detection of a mark turns the switched output “ON”

for an adjustable dwell time of up to 250 milliseconds. After the dwell

time, the output will automatically reset. This mode is similar to an adjustable one-shot. Non-latch positions are “E through H”.

c. Light and Dark Mark Sensing

The 42CRC can be set to energize on the leading edge of light marks on a

dark background or the leading edge of dark marks on a light background.

The alphabetic positions on the function switch have letters with white

backgrounds and letters with black backgrounds. Select white background

positions for light mark sensing and black background positions for dark

mark sensing.

d. Automatic Operation

“Automatic” mode provides stable, adjustment-free sensing for most applications. The 42CRC automatically adjusts the sensitivity, compensating

for variations in background colors and lens contamination. It also provides

additional gain for the low contrast marks on dark backgrounds and scanning of glossy surfaces at an angle.

In this position the orange LED marked “AUTO” is “ON” and the manual

sensitivity adjustment is NOT functional. Switch positions for this mode

are A,

A

,C,C,E,E,G,G.

e. Manual Operation

This operating mode extends the control’s sensing capability for very low

contrast marks (e.g., pastel colors) on light backgrounds. Signal processing

in the 42CRC continually corrects for variations in background signal

level. The result is a mark detection system that has a more stable threshold

Page 8

6

42CRC Color Registration Control

Operating Mode

(Continued)

level, and is easier to set up in the manual operation mode. The control

must be set in the manual mode when the “test points” are used to check

for sufficient sensing contrast (see “Contrast Check” on page 9.) In this

position the orange LED marked “AUTO” will be “OFF” and the manual

sensitivity adjustment is functional. Switch positions for this mode are B,

B

,D,D,F,F,H,H.

f. Red or Green Light Sources

The 42CRC Control has both a red and a green LED light source. The

function switch permits selection of one or the other LED. The LED selection guide, Figure 8 on page 9, lists which LED to use with some basic

mark and background color combinations.

To select the proper light source for colors not listed in Figure 8, make a

Contrast Check as described on page 13. Test the mark/background with

each LED and select the one that provides the maximum mark to background voltage change.

The red LED corresponds with switch positions A,

F

. The Green LED corresponds with switch positions C,C,D,D,G,

G

,andH,H.

A

,B,B,E,E,andF,

AUTOMATIC/MANUAL

INDICATOR

ORANGE LED

“ON” IN AUTOMATIC

MODE

MARGIN INDICATOR

GREEN LED

“ON” WHEN OPERATING

MARGIN IS AT

LEAST 2 TO 1

OUTPUT INDICATOR

RED LED

“ON” WHEN THE CONTROL

OUTPUT IS “ON”

AUTO

MARGIN

SIGNAL

TEST POINTS

INTERCHANGE

LENS AND CAP

TO CHANGE

SENSING DIRECTION

TEST POINTS

TO CHECK

MARK CONTRAST

QUICK-DISCONNECT

Cable Assembly

SENSITIVITY

ADJUSTMENT

(MANUAL MODE)

5

4

3

SENS

PHOTOSWITCH

COLOR

REGISTRATION

CONTROL

42CRC--4000

SUPPLY

4D30vDC 70MA MAX

OUTPUT

100MA30VDC MAX

N.O.NP N51NK

20MA30VDC MAX

ALARM

SCANNING

WHITE-GATE (-) / RESET (+)

ORANGE-DIAG. ALARM

BLACK-NEGATIVE

RED-POSITIVE

BLUE-OUT PUT

OUTPUT DWELL TIME

ADJUSTMENT

(NON-LATCH MODE)

MODE

7

8

6

9

0

2

1

2

A

A

1

H

3

B

H

0

4

B

G

C

G

F

F

E

E

D

D

C

9

DWELL

5

6

7

8

FUNCTION SELECTOR SWITCH

FIGURE 5

Page 9

42CRC Color Registration Control

Function Selector Switch Operating Modes

7

NON-LATCHED OUTPUT

DARK MARK

MANUAL SENSITIVITY

GREEN LED

NON-LATCHED OUTPUT

LIGHT MARK

MANUAL SENSITIVITY

GREEN LED

NON-LATCHED OUTPUT

DARK MARK

AUTOMATIC SENSITIVITY

GREEN LED

NON-LATCHED OUTPUT

LIGHT MARK

AUTOMATIC SENSITIVITY

GREEN LED

NON-LATCHED OUTPUT

LIGHT MARK

MANUAL SENSITIVITY

RED LED

NON-LATCHED OUTPUT

LIGHT MARK

MANUAL SENSITIVITY

RED LED

NON-LATCHED OUTPUT

DARK MARK

AUTOMATIC SENSITIVITY

RED LED

LATCHED OUTPUT

LIGHT MARK

AUTOMATIC SENSITIVITY

RED LED

A

H

H

G

G

F

F

E

E

NON-LATCHED OUTPUT

LIGHT MARK

AUTOMATIC SENSITIVITY

RED LED

A

D

B

D

LATCHED OUTPUT

DARK MARK

AUTOMATIC SENSITIVITY

RED LED

B

C

C

LATCHED OUTPUT

DARK MARK

MANUAL SENSITIVITY

GREEN LED

LATCHED OUTPUT

LIGHT MARK

MANUAL SENSITIVITY

RED LED

LATCHED OUTPUT

DARK MARK

MANUAL SENSITIVITY

RED LED

LATCHED OUTPUT

LIGHT MARK

AUTOMATIC SENSITIVITY

GREEN LED

LATCHED OUTPUT

DARK MARK

AUTOMATIC SENSITIVITY

GREEN LED

LATCHED OUTPUT

LIGHT MARK

MANUAL SENSITIVITY

GREEN LED

NOTE: ALL WHITE LETTERS ON

BLACK BACKGROUNDS INDICATE THE

DARK ENERGIZE (MARK) POSITION.

ALL BLACK LETTERS ON WHITE

BACKGROUNDS INDICATE THE LIGHT

ENERGIZE (MARK) POSITION.

Additional Features

FIGURE 6

a. Output Dwell Time Control

The Dwell Control (Figure 6) extends the “ON” time of the control output

to a definable time limit. Typical applications would be controlling an operation that requires a well-defined time period (e.g., a pause for a product

filling, cutting, or sealing operation). The output dwell time is linearly adjustable up to 250 milliseconds. The longer “In” time of either the mark

presence or dwell control setting defines the “On” duration of the

control output.

b. Gated Operation

Gating or “blinding” the control is possible by simply switching the white

Gate/Reset lead to ground. It is desirable that the scanning area is free of

any printing except the registration marks. If other markings are in the scan

area, the control will detect them as registration marks.

Page 10

8

42CRC Color Registration Control

Additional Features

(Continued)

To avoid detecting the unwanted marks, the control can be disabled

“gated” during the times the unwanted marks appear (see Figure 9). The

control can be “gated” by using electromechanical or solid state contacts

synchronized with the machine cycle.

c. Diagnostic Alarm Output

This feature provides for advanced remote (via CRT or control panel alarm

indication) warning of gradual loss of signal strength due to misalignment,

dust or drift in mark contrast prior to loss of a control output signal,

avoiding unexpected process disruption.

The diagnostic alarm is a normally closed NPN output. This output goes to

the open (indicating) state when the signal margin drops below 1.5.X for

seven consecutive marks (this is to avoid a false alarm) of any period or

duration. The diagnostic output also goes to the indicating state when the

cable is severed or disconnected or when the power supply to the

control fails.

The first occurrence of a signal margin 1.7X, indicative of correction of a

fault condition resets the diagnostic alarm. Since the diagnostic alarm

feature is not time-based, its operation is not affected by operations

employing indefinite pauses.

Function Selector Switch

Operating Modes

PHOTOSWITCH

COLOR

REGISTRATION

CONTROL

42CRC-4000

OUT

SPOT MODE MARK

SWITCH

POSITION

A

A

B

B

C

C

D

D

E

E

F

F

G

G

H

H

RED

LATCH

NON-LA.

GREEN

AUTO

MANUAL

LIGHT

55-5080A

DARK

Two function switch selection charts are provided with

each registration control, one is attached to the control, the

other chart with adhesive backing can be mounted on the

machine for easy reference.

The selection chart makes it easy to select the proper operation mode on the function switch shown in Figure 6.

Example: The operating mode required is as follows:

1. Output — Non-Latch

2. Spot (LED) Color-Green

3. Operating Mode — Automatic

4. Mark Color — Dark

Select a switch position which has a white dot in each of

the above columns.

The correct switch position for this application is

G

.

FIGURE 7

Page 11

42CRC Color Registration Control

9

Additional Features

(Continued)

Led Light Source

Selection

d. Contrast Check

Test Points are provided on the back cover of the control (see Figure 5,

Page 6) to determine if sufficient contrast exists between the mark and the

background for reliable operation. The test point contacts are made of nickel plated stainless steel and can be immersed in water or short circuited

without affecting the operation of the control.

To check contrast, set the control in the manual mode. Set the web stationary with the light spot of the control on the background. Using a DC voltmeter (100K ohm/volt), connect the test probes to the test points. Note the

reading and repeat the measurement with the light spot centered on the

mark. If the difference between the two readings is in excess of 300 mV,

there is sufficient contrast for reliable operation.

Check the mark/background with both the green and red LEDs. Use the

LED that provides the maximum voltage difference. By making this contrast check, you can also determine the correct mounting angle (Figures 2,

3, and 4) by adjusting the scanning angle to obtain the maximum voltage

difference.

BACK-

GROUND

COLOR

WHITE

BLUE

GREEN RED

YELLOW

ORANGE GREEN

RED

WHITE BLUE GREEN YELLOW ORANGE RED BLACK

RED

OR

GREEN

RED

OR

GREEN

GREEN

REGISTRATION MARK COLOR

RED

OR

GREEN

RED

OR

GREEN

RED

OR

GREEN

RED

OR

GREEN

RED RED GREEN GREEN RED

RED

RED

OR

GREEN

RED

OR

GREEN

RED

OR

GREEN

RED

OR

GREEN

RED

OR

GREEN

RED

OR

GREEN

RED

OR

GREEN

GREEN GREEN

RED

OR

GREEN

RED

OR

GREEN

RED

OR

GREEN

RED

RED GREEN

GREEN GREEN

GREEN RED

GREEN

GREEN

RED

OR

RED

OR

BLACK

RED

OR

GREEN

RED

OR

GREEN

GREEN GREEN RED RED

FIGURE 8

Page 12

10

42CRC Color Registration Control

Operation

After the control has been properly installed and the chosen operating

mode has been selected, set the dwell and the sensitivity controls to the full

counter-clockwise position. Apply power to the control and set the web in

motion. THE WEB MUST BE MOVING AT LEAST 2 INCHES (51 mm)

PER SECOND FOR PROPER CONTROL FUNCTION.

Automatic, Non-Latch

In this setting no sensitivity adjustment is required and the sensitivity

control is inoperative. Set the dwell control to the desired output dwell by

rotating the adjustment clockwise toincreasethetimetoamaximumof

250 milliseconds.

Automatic, Latch

No sensitivity or dwell time adjustments are required and both controls are

inoperative.

Manual, Non-Latch

Rotate the sensitivity control clockwise until the “Green Margin Light”

illuminates with the presence of a moving mark. This setting provides the

correct signal for reliable operation. If output dwell time is required, rotate

the dwell control clockwise to the appropriate duration.

Manual, Latch

Gating

WEB

MATERIAL

42CRC-4000

NPN OUTPUT

NO-GATING

42CRC-4001

PNP OUTPUT

NO-GATING

GATING

SIGNAL

42CRC-4001

NPN OUTPUT

GATED

42CRC-4001

PNP OUTPUT

GATED

Set the sensitivity control as described above. The dwell time is

inoperative.

LIGHT MARK

XY XY XY

DARK MARK

FIGURE 9

Page 13

42CRC Color Registration Control

11

Maintenance

Specifications

Clean the lens surface periodically. With a non-abrasive cleaning solution

(mild soap) and a soft cloth. Do not use strong chemicals on the plastic

lens.

Page 14

12

42CRC Color Registration Control

Voltage Supply: 10V to 30VDC.................................

Current Consumption 70mA Max................................

Output: Model 4000 Open Collector..............................

NPN (Current Sink)

Model 4001 Open Collector..............................

PNP (Current Source)

Output Rated Load Current (On-State) 100mA.....................

Output Rated Load Voltage (Off-State) 30VDC.....................

Output Short Circuit Protection Continuous........................

Response Time at Maximum Contrast

(Black & White) 250 Microseconds............................

Minimum Web Velocity 2 Inches per sec...........................

(51mm per second)

Maximum Output Dwell 250 Milliseconds min.....................

Minimum Output Dwell

(Overridden by Signal Duration) 250 Microseconds...............

Transmitter LED’s

(Selectable Red or Green) Visible Red, 630 nm...................

Visible Green, 570 nm

Minimum Useable Mark to Background Voltage

Change (Measured at Test Points in Manual Mode)

Manual Mode 250 Millivolts D.C..............................

Automatic Mode 500 Millivolts D.C............................

Scanning Distance 0.5 (13mm).................................

Depth of Field +/-- .08 (2mm).................................

Min. Size of Mark

at Scanning Distance 0.08 X.10 (2mm X 2.5mm)................

False Pulse Suppression Yes....................................

Reverse Polarity Protection Yes.................................

External Gating Mode Yes.....................................

Latching Output Mode with External Reset Yes....................

Diagnostic Alarm Following seven successive marks............

below margin of 1.5 X, or loss of power.

Diagnostic Alarm Output N.C. Open collector NPN output,......

30mA max., 30VDC max.

Operating Environment Housing made of #380.0 cast aluminum.......

Anodized and epoxy coated for

corrosion resistance.Rated forNEMA 3,

4, 6P, 12, and 13. IP67 (IEC 529)

Test Points for Contrast Check Yes..............................

Page 15

42CRC Color Registration Control

13

Specifications

(Continued)

Dimensions 3.80 L X 2.95 H X 1.31 D........................

(97mmLX75mmHX33mmD)

Weight 12 oz (350 g).........................................

Storage Temperature --13F(--25C) to 167F(75C)................

Operating Ambient Temp. Range 32F(0C) to 158F(70C).........

Max Relative Humidity 95%...................................

Cable Assembly #60-2292

(Order Separately) 10 Feet (3m) 5 conductor with shield,........

#22 AWG (26 X 36) Stranded. Flexible

mount PVC jacket 260 nominal O.D.

rated UL 2661 — 150C 300volts. 5 pin

(female) watertight connector.

Agency Approvals UL listed, CSA certified.......................

Page 16

14

2.357

(59.87)

42CRC Color Registration Control

Outline Dimensions (mm between brackets)

2.500

(63.50)

(10.64)

PHOTOSWITCH

COLOR

REGISTRATION

CONTROL

42CRC--4000

SUPPLY

4D30vDC 70MA MAX

OUTPUT

100MA30VDC MAX

N.O. NPN51NK

20MA30VDC MAX

ALARM

SCANNING

WHITE-GATE (-) / RESET (+)

ORANGE-DIAG. ALARM

BLACK-NEGATIVE

RED-POSITIVE

BLUE-O UTPUT

1.10

(27.94)

1.10

(27.94)

.415

(10.54)

.830

(21.08)

1.312

(33.32)

.656

(16.62)

1.437

(36.50)

3.375

(85.73)

Using Optional

Lens Position

Focal

Points

(Scanning

Distance)

.432

(10.97)

.419

.470

(11.94)

1.875

(47.63)

.250 (6.35) Max. thread depth

.375

(9.53)

M5 X 0.8 Thread

2places

1.930

(49.02)

#60-2292

Cable Assembly

Internal Schematic

Photo Detector Board

Optics

M5 X 0.8 Thread

.250 (6.35) Max. thread depth

4places

FIGURE 10

Microcircuit

Pulse

Amp

Manual

Sensitivity

Adjustment

Integrator

and Analog

Amplifier

6

5

4

3

2

SENS

(75.06)

7

8

1

2.955

MODE

H

H

9

G

G

F

F

0

E

(71.12)

A

A

B

B

C

D

D

E

Margin

Comp.

2.800

1

0

C

9

DWELL

2

3

4

5

6

7

8

(+)

Margin

Indicator

Green LED

Signal

Comp.

Overload

Protection

Indicator

Red LED

Output

NPN or

PNP

LED’S

Red Green

Pulse

Generator

Operating

Mode Logic

FIGURE 11

Auto Mode

Indicator

Orange

LED

Dwell

Time

Diagnostic

Alarm

Gate/Reset

(--)

Diagnostic

Output

NPN

Page 17

Diagnostic Alarm

Minimum Resistor

Value Selection

(OHMS)

MINIMUM

RESISTANCE

1000

833

667

500

333

42CRC Color Registration Control

15

(USE 1/2 WATT RESISTOR)

Color Coding

#60-2292 Cable Assembly

30252015100

VOLTAGE

(D.C.)

FIGURE 12

WHITE-GATE (--) / RESET (+)

ORANGE-DIAG. ALARM

BLACK-NEGATIVE (--)

RED-POSITIVE (+)

BLUE-OUTPUT

FIGURE 13

Page 18

16

42CRC Color Registration Control

Wiring Diagrams

NPN OUTPUT 42CRC -- 4000

Latched Output -- Function Switch Positions

“A” Through “D” with or without External Gating

External Connections

42CRC-4000

Control

Output

(NPN)

Sink

Diagnostic

Output

(NPN)

Sink

Connector

Blue--NPN Output

Orange-NPN Diagnostic Alarm

White-Gate (--)/Reset (+)

Black (--)

*WARNING DO NOT CLOSE THE RESET AND

GATING SWITCHES SI MULTANEOUSLY

Cable Assembly #60-2292

Red (+)

Reset* Switch

(close to unlatch)

Bare-Shield

FIGURE 14

Load

(+) Supply

10-30VDC

Resistor by customer (if remote

diagnostic indicator is used.)

SeeFigure12

for resistor

selection.

30mA max,

remote diagnostic

indicator by

customer (if used)

Gating Switch

close to inhibit

(if used)

NPN will sink

0.3 mA

(--) Supply

External Connections

42CRC-4000

Control

Output

(NPN)

Sink

Diagnostic

Output

(NPN)

Sink

Connector

NPN OUTPUT 42CRC -- 4000

Non-Latched Output -- Function Switch Positions

“E” Through “H” with or without External Gating

Cable Assembly #60-2292

Red (+)

Blue-NPN Output

Orange-NPN Diagnostic Alarm

White-Gate (--)/Reset (+)

Black (--)

Bare-Shield

Load

(+) Supply

10-30VDC

Resistor by customer (if remote

diagnostic indicator is used.)

SeeFigure12

for resistor

selection.

30mA max,

remote diagnostic

indicator by

customer (if used)

Gating Switch

(--) Supply

Page 19

Wiring Diagrams

External Connections

42CRC-4001

Control

Output

(PNP)

Source

Diagnostic

Output

(NPN)

Sink

42CRC Color Registration Control

(Continued)

Connector

PNP OUTPUT 42CRC -- 4001

Latched Output -- Function Switch Positions

“A” Through “D” with or without External Gating

Cable Assembly #60-2292

Red (+)

Blue-PNP Output

Orange-NPN Diagnostic Output

White-Gate (--)/Reset (+)

Black (--)

Bare-Shield

Load

Reset* Switch

(close to unlatch)

(+) Supply

10-30VDC

Resistor by customer (if remote

diagnostic indicator is used.)

SeeFigure12

for resistor

selection.

30mA max,

remote diagnostic

indicator by

customer (if used)

17

(--) Supply

External Connections

42CRC-4001

Control

Output

(PNP)

Source

Diagnostic

Output

(NPN)

Sink

*WARNING DO NOT CLOSE THE RESET AND

GATING SWITCHES SI MULTANEOUSLY

FIGURE 16

PNP OUTPUT 42CRC -- 4001

Non-Latched Output -- Function Switch Positions

“E” Through “H” with or without External Gating

Connector

Blue-PNP Output

Orange-NPN Diagnostic Output

White-Gate (--)/Reset (+)

Black (--)

Cable Assembly #60-2292

Red (+)

Bare-Shield

*Gating Switch

close to inhibit

(if used)

NPN will sink

0.3mA

Load

(+) Supply

10-30VDC

Resistor by customer (if remote

diagnostic indicator is used.)

SeeFigure12

for resistor

selection.

30mA max,

remote diagnostic

indicator by

customer (if used)

(--) Supply

Gating Switch

Page 20

18

42CRC Color Registration Control

Performance Curves

Relative Sensitivity Vs Web Speed

1.1

1

.6

.4

Relative Sensitivity

.2

2100070010070107

(Metric Conversion 1 = 25.4mm)

(Automatic Mode)

Speed (In/Sec.)

FIGURE 18

Relative Sensitivity Vs Web Speed

(Manual Mode)

1.1

1

.8

.6

.4

Relative Sensitivity

.2

.5 1000700100701051.7

Speed (In/Sec.)

(Metric Conversion 1 = 25.4mm)

FIGURE 19

Page 21

GuardShield™ Safety Light Curtain User Manual

R

40

Original instructions

Page 22

GuardShield™ Safety Light Curtain User Manual

R

40

Original instructions

Page 23

GuardShield™ Safety Light Curtain User Manual

R

40

Original instructions

Page 24

PHOTOSWITCH is a registered trademark of Rockwell Automation.

www.rockwellautomation.com

Power, Control and Information Solutions Headquarters

Americas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414.382.2000, Fax: (1) 414.382.4444

Europe/Middle East/Africa: Rockwell Automation NV, Pegasus Park, De Kleetlaan 12a, 1831 Diegem, Belgium, Tel: (32) 2 663 0600, Fax (32) 2 663 0640

Asia Pacific: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel: )852) 2887 4788, Fax: (852) 2508 1846

Publication PA--8853 February 1994

Supersedes Publication PA--8853 February 1989 Copyright 1994 Rockwell Automation. Printed in USA

Loading...

Loading...