Page 1

Installation Instructions

IF2 I/O Interface to PDM

(Catalog Number 4100-IF2)

The IF2 I/O Interface to PDM is a printed circuit board intended for

use with the positioning drive modules (PDM). The purpose of this

board is to reverse the polarity of the I/O circuit to remove the

problem of compatibility that may arise from connecting any

external control conductors to the I/O.

.

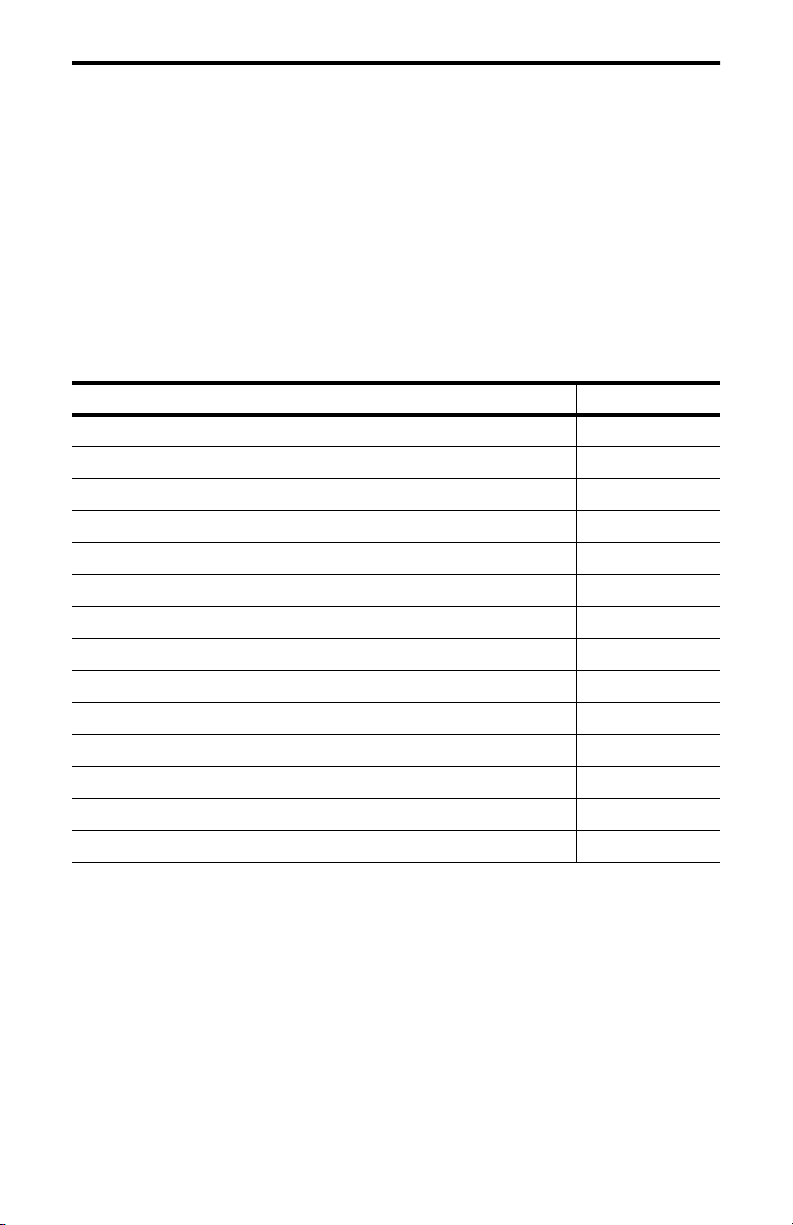

See page:

Important User Information 2

Allen-Bradley Support 3

Compliance to the European Union Directive 4

Low Voltage Directive 4

Preventing Electrostatic Discharge 5

Overview 6

Installation 7

Mounting 7

Wiring 8

Wiring Cable Flying Leads to the Plugs 8

Wiring the P1 Connector 10

Wiring Diagram 10

Wiring the P2 User Connector 11

Cables 11

Publication 4100-IN001A-EN-P- February 2001

Page 2

2 IF2 I/O Interface to PDM

Important User Information

Those responsible for the application and use of this product must

satisfy themselves that all necessary steps have been taken to assure

that the application and use of this product meets all performance

and safety requirements, including all applicable laws, regulation

codes, and standards.

The illustrations, charts, sample programs, and layout examples

shown in this manual are intended solely for purposes of example.

Since there are many variables and requirements associated with

any particular installation, Allen-Bradley does not assume

responsibility or liability (to include intellectual property liability) for

actual use based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation, and Maintenance of Solid State Control

(available from your local Allen-Bradley office), describes some

important differences between solid state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Throughout this documentation we use notes to make you aware of

safety considerations:

WARNING

Identifies information about practices or

circumstances that can lead to personal injury or

death, property damage, or economic loss.

!

Warning statements help to:

• Identify a hazard.

• Avoid a hazard.

• Recognize the consequences.

IMPORTANT

Publication 4100-IN001A-EN-P- February 2001

Identifies information that is critical for successful

application and understanding of the product.

Page 3

IF2 I/O Interface to PDM 3

Allen-Bradley Support

Allen-Bradley offers support services worldwide, with over 75 Sales/

Support Offices, 512 authorized Distributors and 260 authorized

Systems Integrators located throughout the United States alone, plus

Allen-Bradley representatives in every major country in the world.

Local Product Support

Contact your local Allen-Bradley representative for:

• sales a nd o r der suppor t

• product technical training

• warranty support

• support service agreements

Technical Product Assistance

If you need to contact Allen-Bradley for technical assistance, please

review the information in this manual first. Then call your local

Allen-Bradley representative. For the quickest possible response, we

recommend that you have the catalog numbers of your products

available when you call. See the Related Documentation section of

this chapter for the publication numbers of other manuals that can

help with this product.

The Rockwell Automation Technical Support number is:

1-952-914-3990

On the Web

For information about Allen-Bradley, visit the following World Wide

Web si te:

http://www.ab.com/

Publication 4100-IN001A-EN-P- February 2001

Page 4

4 IF2 I/O Interface to PDM

Compliance to the European Union Directive

This product doesn’t bear the CE mark because it has been defined

as a component. It has been tested as part of a system and is

included in the declaration of conformance for the system It has

been designed and tested to meet the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards:

•

EN 50081-2EMC - Generic Emission Standard, Part 2 Industrial Environment

•

EN 50082-2EMC - Generic Immunity Standard, Part 2 Industrial Environment

This product is intended for use in an industrial environment.

Heavy Industrial Environment

The IF2 I/O Interface to PDM is intended for use in a heavy

industrial environment and is not to be used in a domestic or office

environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low

Voltage, by applying the safety requirements of EN 60204 Safety of

machinery - Electrical equipment of machines.

Publication 4100-IN001A-EN-P- February 2001

Page 5

IF2 I/O Interface to PDM 5

For specific information required by EN 60204, see the appropriate

sections in this publication, as well as the following Allen-Bradley

publications:

•

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

•

Automation Systems Catalog, publication B111

This equipment is classified as open equipment and must be

installed (mounted) in an enclosure during operation as a means of

reducing user exposure to hazards.

Preventing Electrostatic Discharge

Electrostatic discharge can damage the interface

ATTENTION

board if you touch the circuitry or connector pins

without taking precautions. Follow these

guidelines when you handle the interface board:

!

•

Touch a grounded object to discharge potential

static.

•

Wear an approved grounding wrist strap.

•

Do not touch the connector or connector pins

on the servo board.

•

Do not touch circuit components inside the

servo board.

•

If available, use a static-safe work station.

Publication 4100-IN001A-EN-P- February 2001

Page 6

6 IF2 I/O Interface to PDM

Overview

The IF2 I/O Interface to PDM is a printed circuit board intended for

use with the positioning drive modules (PDM).

Figure 1 Front View of I/O Interface Board

These drives are built with output stages which source current to

their loads, and input stages which require a current sinking input to

operate. The 24 volt supply from the drive to the input/output (I/O)

is floating, and if the negative side is connected to safety ground

there is a possibility that an earth fault on a control wire would

cause the I/O to go to an active state resulting in an unexpected

action from the drive. In order to comply with EN60204-1: 1993, it is

necessary to connect the 24 volt positive circuit to ground if any

external control conductors (i.e outside the control enclosure) are

connected to the I/O. This can create compatibility problems with

some programmable logic controllers, and the purpose of this board

is to reverse the polarity of the I/O circuit to remove the problem of

compatibility.

Publication 4100-IN001A-EN-P- February 2001

Page 7

IF2 I/O Interface to PDM 7

Installation

The interface is a DIN rail mounting unit which has a terminal strip

2

(1.5 mm

Mounting

The Interface board has 2 mounting feet on the back to attach it to

the DIN rail.

Figure 2 DIN Rail Mounting Feet

screw clamp type) down each side.

Mounting Feet

Mounting Feet

Publication 4100-IN001A-EN-P- February 2001

Page 8

8 IF2 I/O Interface to PDM

Wiring

The flying leads from the PDM drive is wired to the IF2 I/O Interface

to PDM board using the connector marked P1. The flying leads from

the external controller are wired to the connector marked P2 User.

Each set of connectors have 26 slots available and the wiring is a 1

to 1 set up. The IF2 I/O Interface should be mounted as close as

possible to the associated PDM. The wires from the PDM to the IF2

should be in the same railway and should not contain any power

leads.

Due to the positioning of the screws on the inside of the connectors,

it is easier to wire the connectors by first removing them and then

running the flying leads to the appropriate slots. It is recommended

that you remove only one connector at a time to avoid confusion

and reduce the possibility of error in matching the flying leads to the

correct slot on the connector.

Wiring Cable Flying Leads to the Plugs

To wire the cable leads to the plug:

1. Look at the plug to make sure the terminal is open. Figure 3

shows both an open and a closed terminal.

Figure 3 Terminal diagram

Terminal open

Clamping screws

Terminal closed

2. Terminal Steps

If the terminals are: Do this:

Not open Go to step 3

Publication 4100-IN001A-EN-P- February 2001

Page 9

IF2 I/O Interface to PDM 9

If the terminals are: Do this:

Open Go to step 4

3. Using a small, flat-head screwdriver, turn the clamping screw

counter-clockwise several times.

4. Using a proper stripping tool, strip the wire insulation back on

the cable lead.

IMPORTANT

All terminals accommodate a maximum of 14 gauge

wire.

5. Trim the cable lead so that 0.275 inches of metal wire is

exposed.

6. Insert the cable lead in the appropriate terminal. Refer to the

proper figures for their locations.

7. Use the screwdriver to tighten the clamping screw to the

proper torque (0.25 N-m/2.2 in-lb.).

8. Verify that the cable lead does not pull out of the terminal.

9.

If the cable lead: Do this:

Pulls out of the terminal Repeat steps 3 through 9 again

Does not pull out of the terminal Repeat steps 3 through 9 for the

next terminal

The function of these connectors, their pinouts, and names are

defined in the following sections.

Publication 4100-IN001A-EN-P- February 2001

Page 10

10 IF2 I/O Interface to PDM

Wiring the P1 Connector

The PDM side is designed to connect directly on a 1 for 1 basis to

the I/O connectors on the PDM drive, as shown in the following

diagram.

Figure 4 Wiring Diagram.

24 V Common

Input 1

Input 2

Input 3

Input 4

PDM Drive

Input 5

Input 6

Input 7

Input 8

Input 9

Input 10

Input 11

Input 12

Input 13

Input 14

Input 15

Output 1

Output 2

Input 16

Output 3

Output 4

Output 5

Output 6

Output 7

Output 8

+24 V

Safety Ground

Input 1

Input 2

Input 3

Input 4

Input 5

Input 6

Input 7

Input 8

Input 9

Input 10

External Controller

Publication 4100-IN001A-EN-P- February 2001

Input 11

Input 12

Input 13

Input 14

Input 15

Input 16

Output 1

Output 2

Output 3

Output 4

Output 5

Output 6

Output 7

Output 8

+24 V (Fused)

Page 11

IF2 I/O Interface to PDM 11

Conductor size must not be greater than 1.5 mm2. The I/O circuits in

the PDM drive are protected by a 1 amp fuse contained in the drive.

Wiring the P2 Connector

The P2 User I/O requires a separate clean 24 volt nominal DC

supply. There is no galvanic connection from one side to the other,

and the user 24 volt supply must be grounded on the negative side

to the protective earth system. The supply should be between 20

and 30 volts DC, and should be capable of supplying the loads

imposed by the output loading plus 8 mA for each input used. It

must be fused adequately to protect the cable used. Output loads

must be connected between the output and 24 volt ground, and

must be 470 ohms or more impedance. The interface outputs are

rated at 50 mA. Cabling should be 1.5 mm maximum.

The inputs must be supplied by the users input circuit from the user

24 volt positive and each input sinks 8 mA when active.

Cables

An optional interface cable 44-0141-xxx is available which has a

shield termination eyelet for customer connection. The xxx at the

end of the cable part number defines the length of the cable in feet.

For example: 44-0141-010 is the cable in a 10 foot length. The

maximum cable length is 100 feet.

Publication 4100-IN001A-EN-P- February 2001

Page 12

Publication 4100-IN001A-EN-P- February 2001 957464-20

Supersedes Publication 68 -0060 – January 1997 2001 Rockwell Internat ional. All Rights Reserved. Printed i n USA

Loading...

Loading...