Page 1

4 or 8 Way Encoder

Buffer Unit

(Cat. Nos. 4100-EF04, 4100-EF08)

Installation and Setup Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown

in this guide are intended solely for purposes of example. Since there

are many variables and requirements associated with any particular

installation, Allen-Bradley does not assume responsibility or liability

(to include intellectual property liability) for actual use based upon

the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole

or part, without written permission of Rockwell Automation, is

prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

WARNING

Identifies information about practices or

circumstances that can lead to personal injury or

death, property damage or economic loss

!

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

IMPORTANT

Allen-Bradley is a trademark of Rockwell Automation

Identifies information that is critical for successful

application and understanding of the product.

Page 3

European Communities (EC)

Directive Compliance

If this product has the CE mark it is approved for installation within

the European Union and EEA regions. It has been designed and

tested to meet the following directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC

Electromagnetic Compatibility (EMC) by applying the following

standards, in whole or in part, documented in a technical

construction file:

• EN 50081-2 EMC — Generic Emission Standard, Part 2 —

Industrial Environment

• EN 50082-2 EMC — Generic Immunity Standard, Part 2 —

Industrial Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low

Voltage, by applying the safety requirements of EN 61131-2

Programmable Controllers, Part 2 - Equipment Requirements and

Tests. For specific information required by EN 61131-2, see the

appropriate sections in this publication, as well as the Allen-Bradley

publication Industrial Automation Wiring and Grounding Guidelines

For Noise Immunity, publication 1770-4.1.

This equipment is classified as open equipment and must be

mounted in an enclosure during operation to provide safety

protection.

Page 4

Page 5

Table of Contents

Preface

Chapter 1

Using This Manual

Read This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Who Should Use this Manual. . . . . . . . . . . . . . . . . . . . . . . P-1

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Contents of this Manual . . . . . . . . . . . . . . . . . . . . . . . . P-3

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . P-3

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-3

Common Techniques Used in this Manual . . . . . . . . . . . . . P-4

Product Receiving & Storage Responsibility . . . . . . . . . . . . P-5

Allen-Bradley Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-5

Local Product Support . . . . . . . . . . . . . . . . . . . . . . . . . P-5

Technical Product Assistance . . . . . . . . . . . . . . . . . . . . P-6

On the Web . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-6

Overview

Encoder Buffer Unit Description . . . . . . . . . . . . . . . . . . . . 1-1

Encoder Buffer Unit Principal Features . . . . . . . . . . . . . 1-1

Encoder Buffer Unit Principal Specifications. . . . . . . . . . . . 1-2

Mechanical Specifications. . . . . . . . . . . . . . . . . . . . . . . 1-2

Environmental Specifications . . . . . . . . . . . . . . . . . . . . 1-2

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Power Input Specifications . . . . . . . . . . . . . . . . . . . . . . 1-2

Encoder Power Supply (master socket). . . . . . . . . . . . . 1-3

Follower Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

8 Way Encoder Buffer Unit Mechanical Drawing . . . . . . 1-4

4 Way Encoder Buffer Unit Mechanical Drawing . . . . . . 1-4

Chapter 2

i Publication 4100-IN054B-EN-P -January 2001

Installation

Mounting the Encoder Buffer Unit . . . . . . . . . . . . . . . . . . . 2-2

Typical Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Page 6

ii

Chapter 3

Appendix A

Operation

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Master Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Follower-1 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Follower-2 to 4 or 8 Outputs . . . . . . . . . . . . . . . . . . . . 3-2

Configuration Links. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Encoder Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Encoder Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Follower Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Accessories

Principle Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Index

Publication 4100-IN054B-EN-P -January 2001

Page 7

Preface

Read This Manual

Who Should Use this

Manual

Read and understand this instruction manual. It provides the

necessary information to let you install, connect, and set up the

Encoder Buffer Unit for safe, reliable operation. This preface covers

the following topics:

• Who should use this manual

• The purpose of this manual

• Terminology

• Common techniques used in this manual

• Allen-Bradley support

You should read this manual if you are responsible for the installation

or set up of the Encoder Buffer Unit in either its 8 or 4 way

configuration.

If you do not have a basic understanding of the products listed below,

contact your local Allen-Bradley representative for information on

available training courses before using this product.

Purpose of this Manual

• S Class Compact motion controller

• 1394 GMC System module

This manual is an installation and set up guide for the Encoder Buffer

Unit in both its 8 and 4 Way configurations. It describes the

procedures necessary to properly install and configure it into your

motion control system. Apart form the number of outputs both units

are identical and the information in this manual applies equally to

both. Where it is necessary to differentiate between them, this is

clearly indicated in the text.

1 Publication 4100-IN054B-EN-P - January 2001

Page 8

Preface P-2

Safety Precautions

The following general precautions apply to the Encoder Buffer Unit:

WARNING

!

Electric shock can kill. Make sure the Encoder Buffer

Unit is safely installed in accordance with the

Installation and Set-up chapters of this manual. Avoid

contact with electrical wires and cabling while power

is on. Only trained service personnel should open

the electrical cabinet.

This product contains stored energy devices. To

avoid hazard of electrical shock, verify that all

voltage on the capacitors has been discharged before

attempting to service, repair, or remove this unit. You

should only attempt the procedures in this manual if

you are qualified to do so and familiar with

solid-state control equipment and the safety

procedures in publication NFPA 70E and

BS-EN60204.

The system integrator is responsible for local safety

and electrical codes.

WARNING

!

An incorrectly applied or installed product can result

in component damage or a reduction in product life.

Wiring or application errors, such as undersizing or

inadequate DC supply, or excessive ambient

temperatures can result in a malfunction.

The Encoder Buffer Unit contains ESD (Electrostatic

Discharge) sensitive parts and assemblies. Static

control precautions are required when installing,

testing, servicing, or repairing this assembly.

Component damage can result if ESD control

procedures are not followed. If you are not familiar

with static control procedures, refer to Allen-Bradley

publication 8000-4.5.2, Guarding Against Electrostatic

Damage or any other applicable ESD Protection

Handbook.

Publication 4100-IN054B-EN-P - January 2001

Page 9

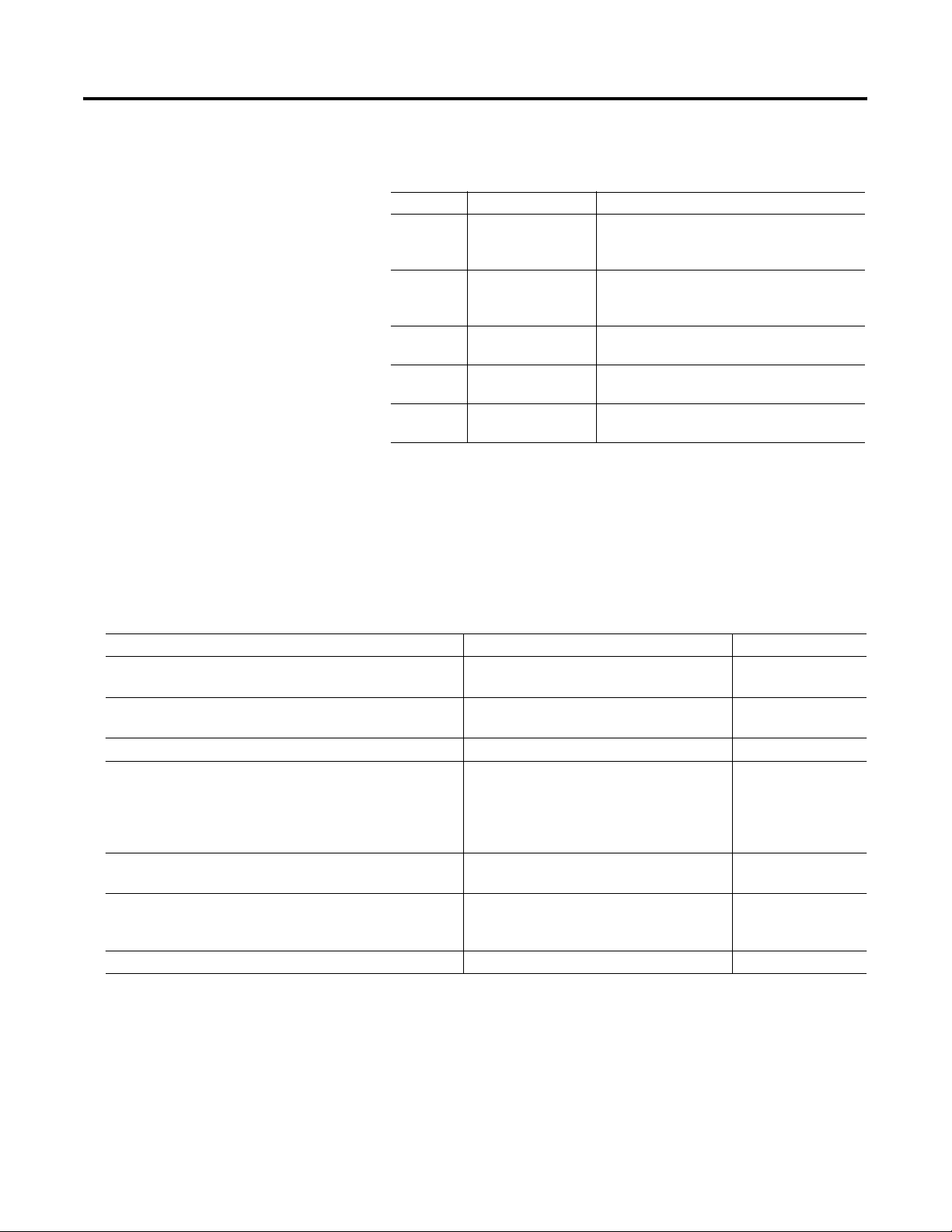

Contents of this Manual

Chapter Title Contents

Preface Describes the purpose, background, and scope

1 Overview Provides a general description of the Encoder

2 Installation Provides the steps needed to successfully

3 Operation Provides information on using the Encoder

Appendix A Accessories Contains a list of principle accessories

Related Documentation

Preface P-3

of this manual. Also specifies the audience for

whom this manual is intended.

Buffer Unit, its features and mechanical

specifications.

mount and wire the Encoder Buffer Unit.

Buffer Unit.

available for use with the Encoder Buffer Unit

The following documents contain additional information concerning

related Allen-Bradley products. To obtain a copy, contact your local

Allen-Bradley office or distributor.

For Read This Document Document Number

Instructions for installation and set-up for the 1394 GMC

system

Instructions for installation and set-up for the S Class

Compact motion controller

Instructions for using the Ultra Plus 1398 Ultra plus User Manual 1398-5.1

An article on wire sizes and types for grounding electrical

equipment (North American standards)

An article on wire sizes and types for grounding electrical

equipment (European standards).

A complete listing of current Allen-Bradley documentation,

including ordering instructions. Also indicates whether the

documents are available on CD-ROM or in multi-languages

A glossary of industrial automation terms and abbreviations Allen-Bradley Industrial Automation Glossary AG-7.1

1394 Digital, AC, Multi-Axis Motion Control

System User Manual

IMC S Class Compact Motion Controller

Installation and Set-up Manual

National Electrical Code Published by the

BS-EN 60204 Electrical Equipment of

Machines

Allen-Bradley Publication Index SD499

1394-5.0

999-122

National Fire

Protection

Association of

Boston, MA.

Published by British

Standards Institute

Terminology

In order to avoid confusion, we have used the following general terms

in a specific manner within this manual. We define them as follows:

Encoder Buffer Unit - Refers to the product in general terms where the

information applies to both the 8 Way and 4 Way configurations.

Publication 4100-IN054B-EN-P - January 2001

Page 10

Preface P-4

ESRS - Refers to the Encoder Signal Reference Simulator.

Way - Refers to the number of channels on the Encoder Buffer Unit.

8 Way- Refers to the Encoder Buffer Unit when configured for 8

follower outputs.

4 Way- Refers to the Encoder Buffer Unit when configured for 4

follower outputs.

System Control Encoder - Is used interchangeably with Master

Encoder.

For specific definitions of other terms used in industrial automation,

see the Allen-Bradley Industrial Automation Glossary (publication

number AG-7.1).

Common Techniques Used

in this Manual

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not

procedural steps.

• Numbered lists provide sequential steps or hierarchical

information.

• When we refer you to another location, the section name

appears in italics.

• An Important Table as shown below provides information that

is necessary to successful use and understanding of the product.

IMPORTANT

• The exclamation point inside of a triangle indicates

circumstances that can lead to personal injury, death, property

damage or economic loss. See example below.

Identifies information that is critical for successful

application and understanding of the product.

Publication 4100-IN054B-EN-P - January 2001

WARNING

!

Failure to observe these warnings may cause damage

to the unit, unexpected and/or uncontrolled

movement of peripheral equipment, and your health

and safety.

Page 11

Preface P-5

Product Receiving &

Storage Responsibility

You, the customer, are responsible for thoroughly inspecting the

equipment before accepting the shipment from the freight company.

Check the item(s) you receive against your purchase order. If any

items are obviously damaged, it is your responsibility to refuse

delivery until the freight agent has noted the damage on the freight

bill. Should you discover any concealed damage during unpacking,

you are responsible for notifying the freight agent. Leave the shipping

container intact and request that the freight agent make a visual

inspection of the equipment.

Leave the product in its shipping container prior to installation. If you

are not going to use the equipment for a period of time, store it:

• in a clean, dry location

• within an ambient temperature range of 0 to 85° C (32 to 185° F)

• within a relative humidity range of 5% to 95%, non-condensing

• in an area where it cannot be exposed to a corrosive

atmosphere

• in a non-construction area

Allen-Bradley Support

Allen-Bradley offers support services worldwide, with over 75 Sales/

Support Offices, 512 authorized Distributors and 260 authorized

Systems Integrators located throughout the United States alone, plus

Allen-Bradley representatives in every major country in the world.

Local Product Support

Contact your local Allen-Bradley representative for:

• sales and order support

• product technical training

• warranty support

• support service agreements

Publication 4100-IN054B-EN-P - January 2001

Page 12

Preface P-6

Technical Product Assistance

If you need to contact Allen-Bradley for technical assistance, please

review the information in this manual first. Then call your local

Allen-Bradley representative. For the quickest possible response, we

recommend that you have the catalog numbers of your products

available when you call. See the Related Documentation section of

this chapter for the publication numbers of other manuals that can

help with this product.

The Rockwell Automation Technical Support numbers are:

For Europe: (+44) 1270 580142

For North America: 1-603-443-5419

On the Web

For information about Allen-Bradley, visit the following World Wide

Web s ite:

http://www.ab.com/

Publication 4100-IN054B-EN-P - January 2001

Page 13

Overview

Chapter

1

Encoder Buffer Unit

Description

The Encoder Buffer Unit is a DIN rail mounting module designed to

duplicate the master incremental quadrature pulse train with index.

The device accepts the master incremental signals at connector P2,

buffers them, and makes a duplicate of them available on all follower

outputs.

Provided the format of the signal at the master input is TTL level

RS422, the Encoder Buffer Unit is not concerned about its source.

Therefore, an encoder (the master encoder) can be connected to this

input or other hardware items such as an ESRS (Encoder Signal

Reference Simulator) can be used.

Encoder Buffer Unit Principal Features

• Selectable “As Master” or “Reversed” of quadrature A & B phases

to provide an electrical reverse at the buffer outputs.

• Selectable 5V or 12V Master encoder supply.

• Individually selectable 5V power to follower outputs.

• Individual 5V and 12V power supply OK indicators.

• Product housed in a rugged DIN rail mounting PCB tray with

integral mounting feet.

• Powered from a single +24V DC supply.

1 Publication 4100-IN054B-EN-P - January 2001

Page 14

1-2 Overview

Encoder Buffer Unit

Principal Specifications

Mechanical Specifications

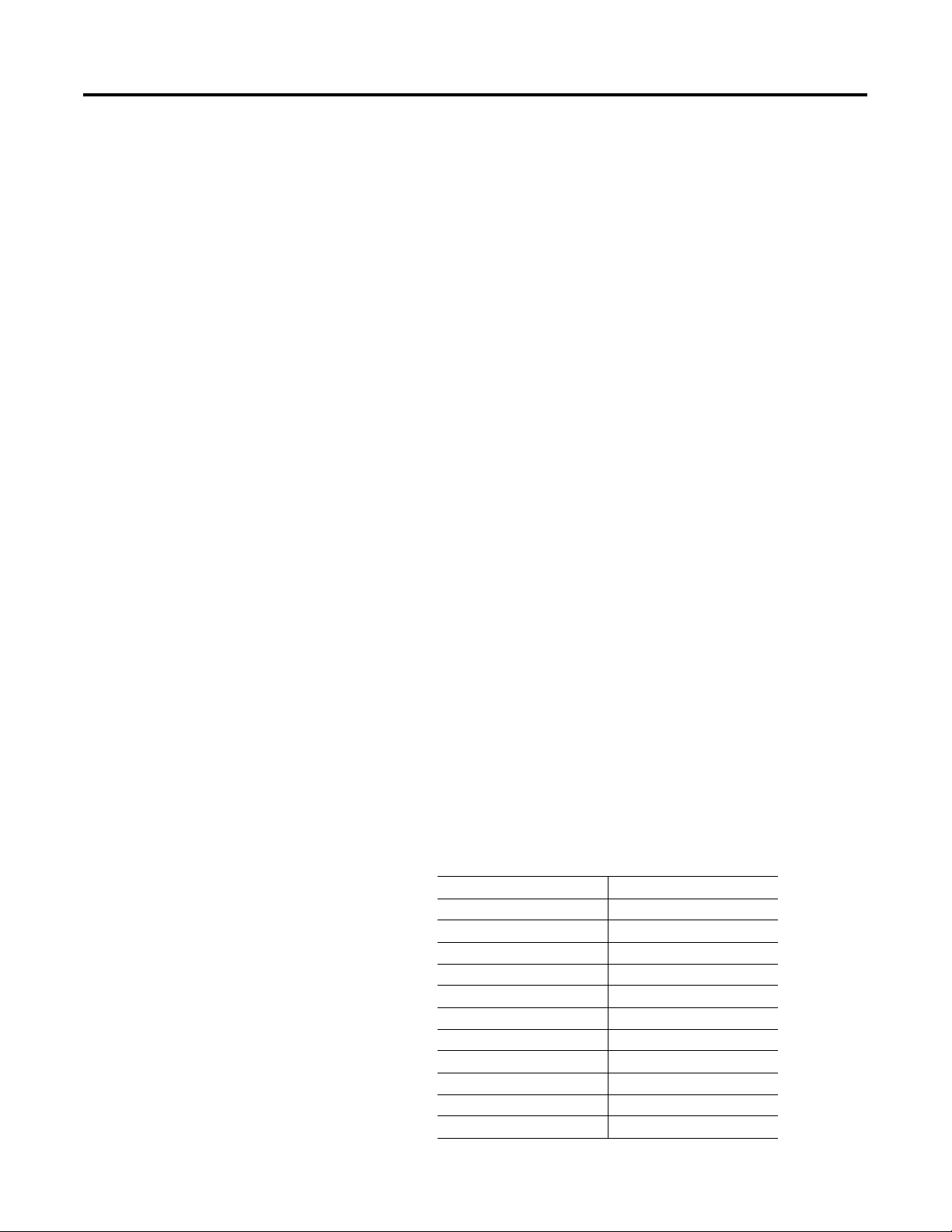

Table 1.A Mechanical Specifications

Enclosure Type Plastic DIN rail mounting tray with integral feet.

Enclosure Size, 8 Way English (inch)

16.90 x 3.00 x 2.50

Enclosure Size, 4 Way English (inch)

11.6 x 3.00 x 2.50

Metric (mm)

430 x 76 x 64

Metric (mm)

294 x 76 x 64

Environmental Specifications

Table 1.B Environmental Specifications

Operating Storage

Temperature

Humidity

o

C -40 to 70oC

0 to 60

95% non condensing @ 60

o

C

Power Supply

Power Input Specifications

Table 1.C Power Specifications Input

Input Voltage Range +18 to +36V DC.

Reverse Polarity Protection Yes

Maximum Input Current, 8 Way Approx. 1.1A at 18V Supply

Approx. 0.80A at 24V Supply

Approx. 0.70A at 36V Supply

Maximum Input Current, 4Way Approx. 0.70A at 18V Supply

Approx. 0.60A at 24V Supply

Approx. 0.50A at 36V Supply

Inrush Approx. 5 times maximum input current

Note: The above input currents are drawn when full rated current is

drawn from the master and all outputs.

Publication 4100-IN054B-EN-P - January 2001

Page 15

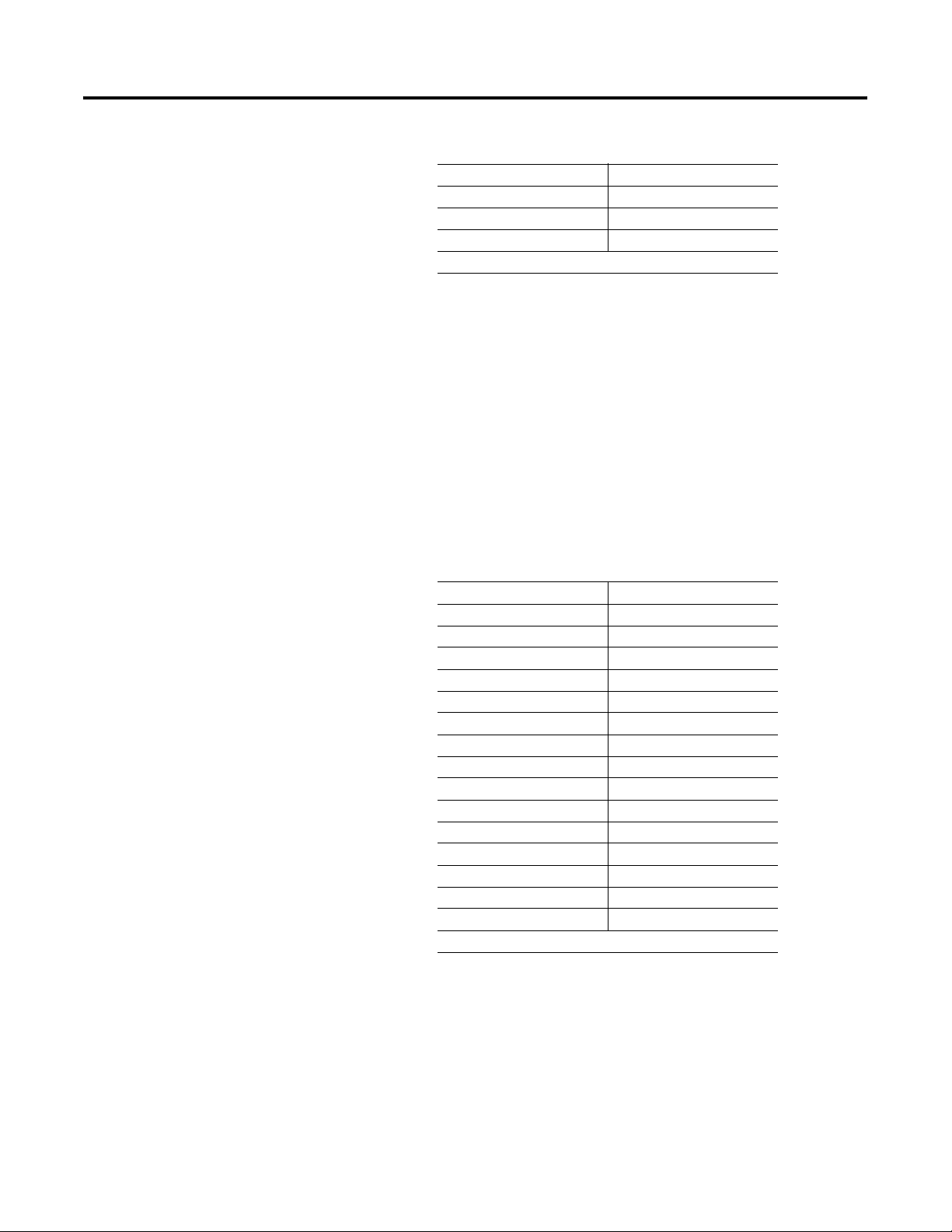

Encoder Power Supply (master socket)

Table 1.D Encoder Power Supply (master socket)

Overview 1-3

Output Voltages +5V or +12V DC. Both

Maximum Output Current 0.75A DC 5V DC Selected

0.25A DC 12V DC Selected

Overcurrent Protection Both supplies are short circuit and over

temperature protected.

± 7.5%.

Follower Outputs

Table 1.E Follower Outputs

Number of follower outputs. 8 or 4

Output data type. RS422 TTL Levels

Output phase definitions. “As Master” is defined as the A & B

phases from the master input remaining

unchanged at the follower outputs.

“Reversed” is defined as the A & B

phases from the master input being

reversed at the follower outputs.

Power Output 5V DC

follower output

± 7.5% at 0.2A maximum per

Publication 4100-IN054B-EN-P - January 2001

Page 16

1-4 Overview

8 Way Encoder Buffer Unit Mechanical Drawing

(Part Number 4100-EF08 series B)

Figure 1.1 8 Way Encoder Buffer Unit

430 mm MAX

77 mm

ENCODER DIRECTIONLK-DIRLK-VOLTS ENC VOLTAGE

MASTER

+12V +5V

HEALTHY

P1

FLWR-1

P2 P3 P4 P5 P6 P7 P8 P9 P10

FLWR-2 FLWR-3 FLWR-4 FLWR-5 FLWR-6 FLWR-7 FLWR-8

8 Channel Encoder Buffer

FOLLOWER POWER LK-5V-FX

LK-5V-F4LK-5V-F1 LK-5V-F2 LK-5V-F3 LK-5V-F5 LK-5V-F6 LK-5V-F7 LK-5V-F8

4 Way Encoder Buffer Unit Mechanical Drawing

(Part Number 4100-EF04 series B)

Figure 1.2 4 Way Encoder Buffer Unit

+12V +5V

77 mm

HEALTHY

P1

Publication 4100-IN054B-EN-P - January 2001

295 mm MAX

LK-Volts ENC VOLTAGE LK-DIR ENCODER DIRECTION

MASTER

P2 P3 P4 P5 P6

FLWR-1 FLWR-2 FLWR-3 FLWR-4

LK-5V-F1 LK-5V-F2 LK-5V-F3 LK-5V-F4

4 Channel Encoder Buffer

FOLLOWER POWER LK-5V-FX

Page 17

Chapter

2

Installation

The Encoder Buffer Unit is designed to be mounted in an electrical

cabinet via its integral mounting feet. For all applications, this

installation method should be observed. Before powering up your

Encoder Buffer Unit, make sure it has been configured correctly and

that all peripheral equipment has been correctly connected to it.

WARNING

!

WARNING

!

A feedback loop must not be closed via the

Encoder Buffer Unit. Use of this Buffer in the

feedback path of a position controller disables any

"encoder loss" detection function which can cause a

runaway condition.

Failure to observe these warnings will cause

unexpected and/or uncontrolled movement of

peripheral equipment. This may cause damage to the

equipment and to your health and safety.

Do not apply power to your Encoder Buffer Unit

when it is part of a control system without first

establishing that this will not have any adverse

effects.

Do not make or break any electrical connections to

your Encoder Buffer Unit while power is applied.

Do not change any selection link settings on your

Encoder Buffer Unit while power is applied.

Failure to observe the above warnings may cause

damage to the follower unit, unexpected and/or

uncontrolled movement of peripheral equipment

and your health and safety.

1 Publication 4100-IN054B-EN-P - January 2001

Page 18

2-2 Installation

The following safety points must be observed when installing the unit:

• The 24V DC supplies must be electrically isolated from all other

supplies with higher potentials.

• The 0V (common) side of the 24V DC supply must be connected

to a safety ground.

• The unit is intended for installation and use within an electrical

control cabinet in a normal industrial environment.

Mounting the Encoder

Buffer Unit

IMPORTANT

The Encoder Buffer Unit is mounted onto a DIN rail using the

mounting feet on the back of the board.

Figure 2.1 Encoder Buffer Unit DIN Rail Mounting Foot

System designers should take care to avoid long

encoder cable runs when using a 5V encoder. If

cable volt drop is a problem, the use of a 12V

encoder is recommended.

64 mm

Typical Applications

Publication 4100-IN054B-EN-P - January 2001

This section illustrates some typical applications for the Encoder

Buffer Unit. Although the 4 channel unit is shown in the diagrams, all

applications apply equally to the 8 channel unit. A range of cables and

other accessories are available for use with this product – see the table

in Appendix B - Accessories.

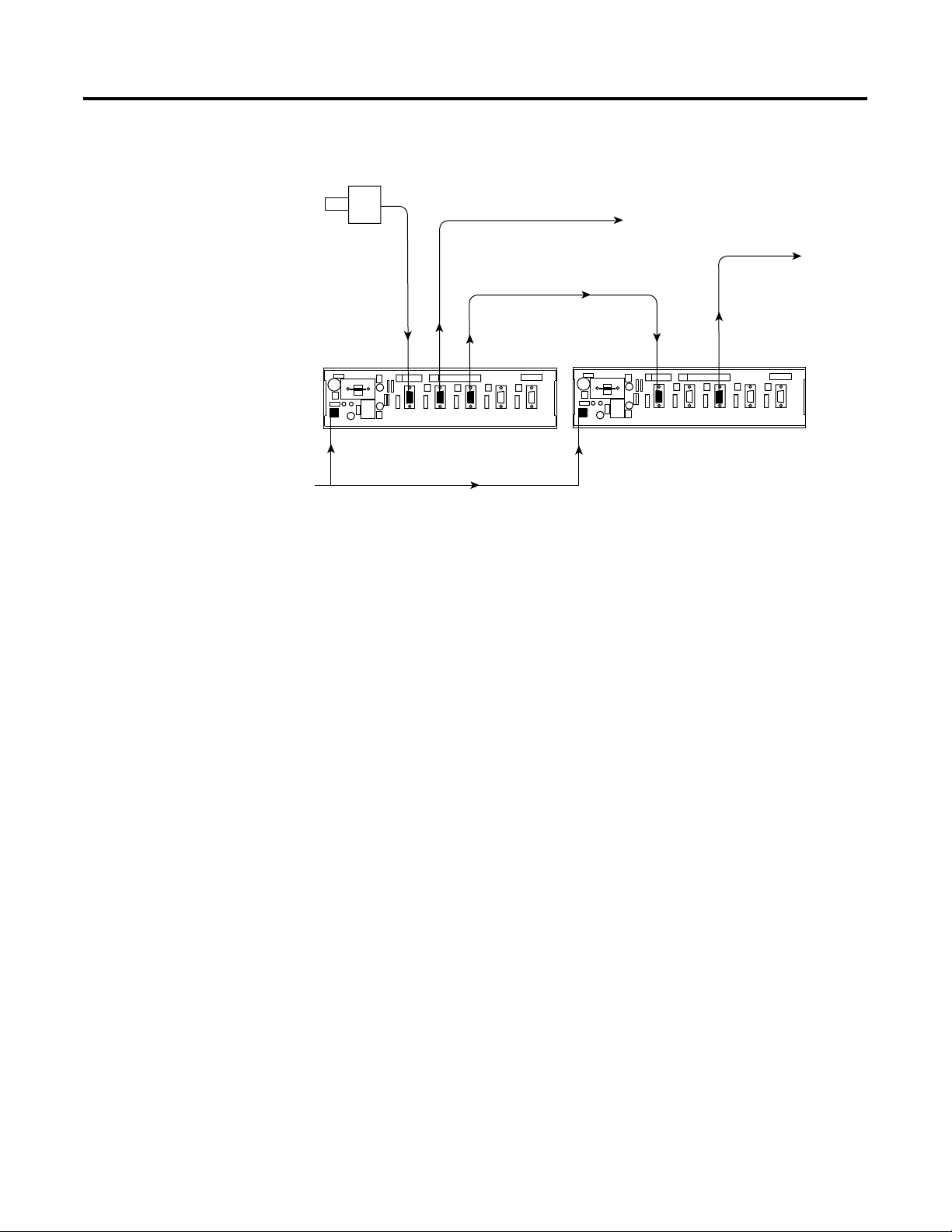

The following diagram shows two units connected in cascade. The

cable, which connects P4 (first unit) to P2 (second unit), must join

only the following pins: 1, 2, 3, 4, 5, 6, 10 &15.

Page 19

Figure 2.2 EBU Units Connected in Cascade

System Control Encoder

Installation 2-3

To additional Encoder Buffer Units

LK-Volts ENC VOLTAGE LK-DIR ENCODER DIRECTION

MASTER

FLWR-1 FLWR-2 FLWR-3 FLWR-4

+12V +5V

HEALTHY

P1

LK-5V-F1 LK-5V-F2 LK-5V-F3 LK-5V-F4

P2 P3 P4 P5 P6

FOLLOWER POWER LK-5V-FX

4 Channel Encoder Buffer

+12V +5V

HEALTHY

P1

4 Channel Encoder Buffer Unit

LK-Volts ENC VOLTAGE LK-DIR ENCODER DIRECTION

MASTER

FLWR-1 FLWR-2 FLWR-3 FLWR-4

LK-5V-F1 LK-5V-F2 LK-5V-F3 LK-5V-F4

P2 P3 P4 P5 P6

Second 4 Channel Encoder Buffer Unit

FOLLOWER POWER LK-5V-FX

4 Channel Encoder Buffer

24V DC Power

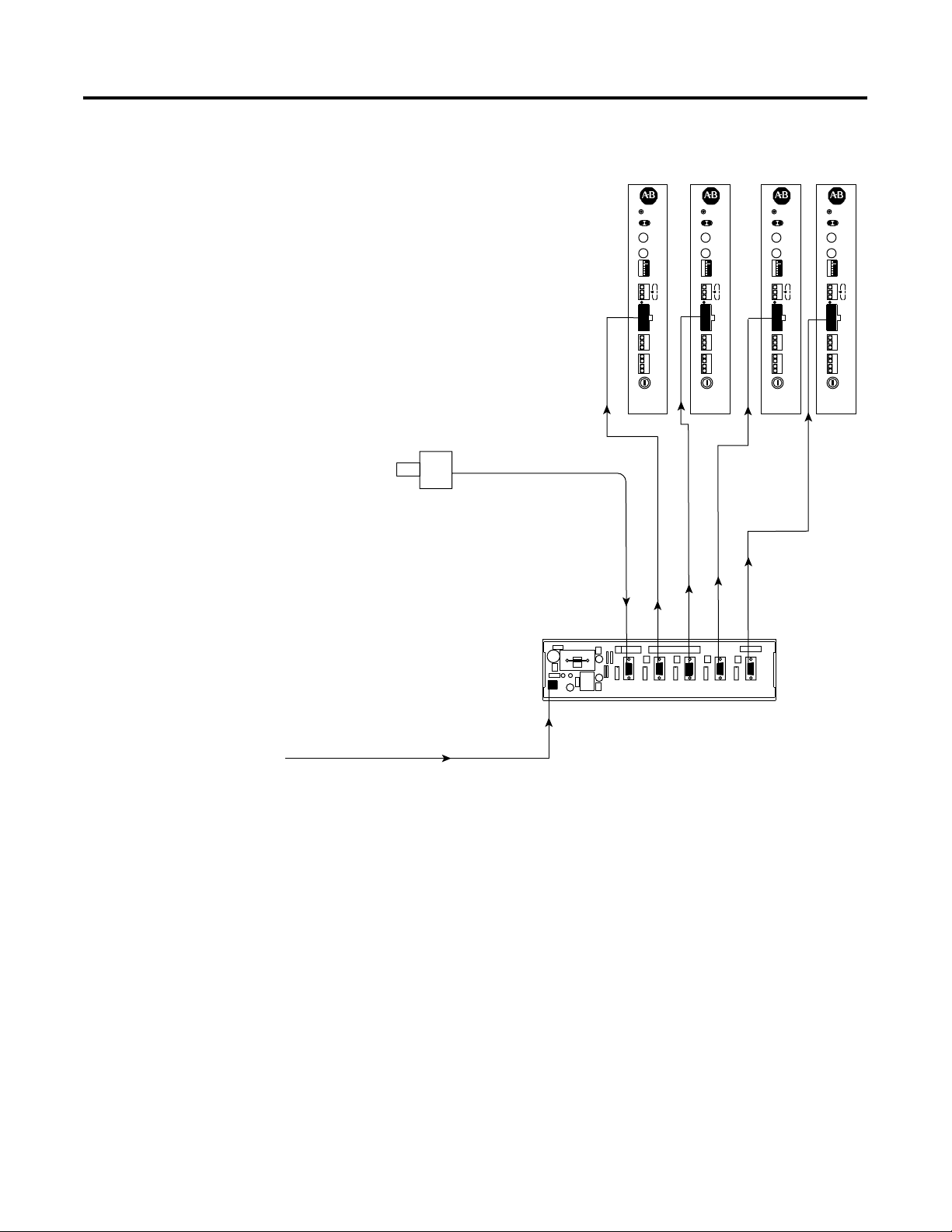

This diagram shows a system control encoder, in the stand-alone

mode, connected to the master input of the 4 Channel Encoder Buffer

and an ALEC module being driven off each follower output.

Publication 4100-IN054B-EN-P - January 2001

Page 20

2-4 Installation

Figure 2.3 4 Way EBU and ALEC

ALEC 1 ALEC 2 ALEC 3 ALEC 4

QUALITY

Reset

AL

CPU OK

Mode

AxisLink

Address

123456

12V/5V

Extd Node On/Off

Enc. Fault On/Off

Extd Length On/Off

Extd Term 1 On/Off

Extd Term 2 On/Off

1

2

AxisLink

Encoder OK

Incremental

Registration

Input

Common

24V DC

Fault Power

Relay Input

Fuse

Encoder Input

QUALITY

Reset

AL

CPU OK

Mode

AxisLink

Address

123456

12V/5V

Extd Node On/Off

Enc. Fault On/Off

Extd Length On/Off

Extd Term 1 On/Off

Extd Term 2 On/Off

1

2

AxisLink

Encoder OK

Incremental

Encoder Input

Registration

Input

Common

24V DC

Fault Power

Relay Input

Fuse

QUALITY

Reset

AL

CPU OK

Mode

AxisLink

Address

123456

12V/5V

Extd Node On/Off

Enc. Fault On/Off

Extd Length On/Off

Extd Term 1 On/Off

Extd Term 2 On/Off

AxisLink

Encoder OK

Registration

Input

Common

24V DC

Fault Power

Relay Input

Fuse

1

2

Incremental

Encoder Input

QUALITY

Reset

AL

CPU OK

Mode

AxisLink

Address

12

12V/5V

Extd Node On/Off

3

Enc. Fault On/Off

45

Extd Length On/Off

Extd Term 1 On/Off

6

Extd Term 2 On/Off

AxisLink

Encoder OK

Registration

Input

Common

24V DC

Fault Power

Relay Input

Fuse

1

2

Incremental

Encoder Input

ALEC

ALEC

ALEC

ALEC

System Control Encoder

LK-Volts ENC VOLTAGE LK-DIR ENCODER DIRECTION

MASTER

FLWR-1 FLWR-2 FLWR-3 FLWR-4

+12V +5V

HEALTHY

P1

LK-5V-F1 LK-5V-F2 LK-5V-F3 LK-5V-F4

P2 P3 P4 P5 P6

FOLLOWER POWER LK-5V-FX

4 Channel Encoder Buffer

4 Channel Encoder Buffer Unit

24V DC Power

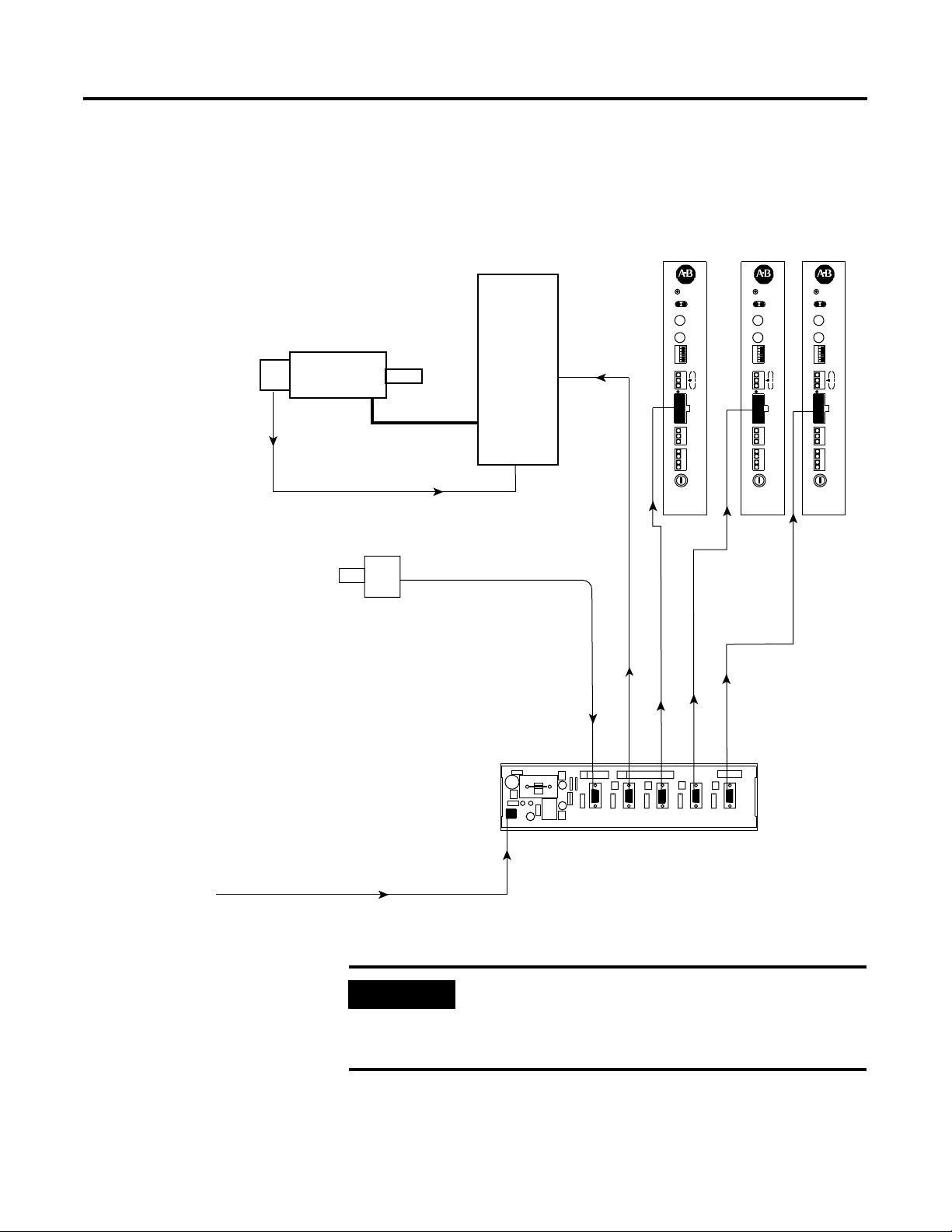

This diagram shows a system control encoder used in the stand-alone

mode and connected to the master input of the 4 Channel Encoder

Buffer Unit. One follower output is connected to the “Master Encoder”

input on a follower drive (this drive must be in the encoder follower

mode). With this arrangement, the follower encoder follows the

system control encoder, taking into account any gearing, etc.

configured in the drive.

Publication 4100-IN054B-EN-P - January 2001

Page 21

Follower

Encoder

Installation 2-5

ALEC units are also shown connected to other follower outputs

demonstrating that a combination of ALEC modules and follower

drives is permissible.

Figure 2.4 4 Way EBU with Follower Drive

FOLLOWER DRIVE

Motor

Master

Encoder

Powe r

Follower

Encoder

ALEC 1 ALEC 2 ALEC 3

QUALITY

Reset

AL

CPU OK

Mode

AxisLink

Address

123456

12V/5V

Extd Node On/Off

Enc. Fault On/Off

Extd Length On/Off

Extd Term 1 On/Off

Extd Term 2 On/Off

1

2

AxisLink

Encoder OK

Incremental

Encoder Input

Registration

Input

Common

24V DC

Fault Power

Relay Input

Fuse

QUALITY

Reset

AL

CPU OK

Mode

AxisLink

Address

123456

12V/5V

Extd Node On/Off

Enc. Fault On/Off

Extd Length On/Off

Extd Term 1 On/Off

Extd Term 2 On/Off

1

2

AxisLink

Encoder OK

Incremental

Encoder Input

Registration

Input

Common

24V DC

Fault Power

Relay Input

Fuse

QUALITY

Reset

AL

CPU OK

Mode

AxisLink

Address

123456

12V/5V

Extd Node On/Off

Enc. Fault On/Off

Extd Length On/Off

Extd Term 1 On/Off

Extd Term 2 On/Off

1

2

AxisLink

Encoder OK

Incremental

Encoder Input

Registration

Input

Common

24V DC

Fault Power

Relay Input

Fuse

System Control Encoder

24V DC Power

LK-Volts ENC VOLTAGE LK-DIR ENCODER DIRECTION

MASTER

+12V +5V

HEALTHY

P1

P2 P3 P4 P5 P6

4 Channel Encoder Buffer Unit

ALEC

FLWR-1 FLWR-2 FLWR-3 FLWR-4

LK-5V-F1 LK-5V-F2 LK-5V-F3 LK-5V-F4

FOLLOWER POWER LK-5V-FX

4 Channel Encoder Buffer

ALEC

ALEC

IMPORTANT

P3 is the only output to which the motor thermal

information and analog position reference are

brought out. Only this output should be used to

complete the encoder feedback loop.

Publication 4100-IN054B-EN-P - January 2001

Page 22

2-6 Installation

Publication 4100-IN054B-EN-P - January 2001

Page 23

Operation

Chapter

3

General

Indicators

Inputs and Outputs

Your Encoder Buffer Unit is fitted with a range of indicators, I/O ports

and links to allow easy configuration and use. This section explains

the function and operation of these and provides additional technical

data where appropriate.

Two green LED indicators are provided on the Encoder Buffer Unit

front panel to give you at-a-glance information regarding the status of

the Encoder Buffer Unit. When they are both lit the encoder power

supply are healthy.

The following digital I/Os are provided with the Encoder Buffer unit.

The only difference between the 4 Way and the 8 Way is the number

of Follower Outputs available.

Master Input

The Master input (P2) receives the signal from the master encoder or

other peripheral equipment. It has a 15 way male high density D

socket that connects the Master Encoder cable to the Encoder Buffer

Unit.

The following table shows the pin outs for the connector.

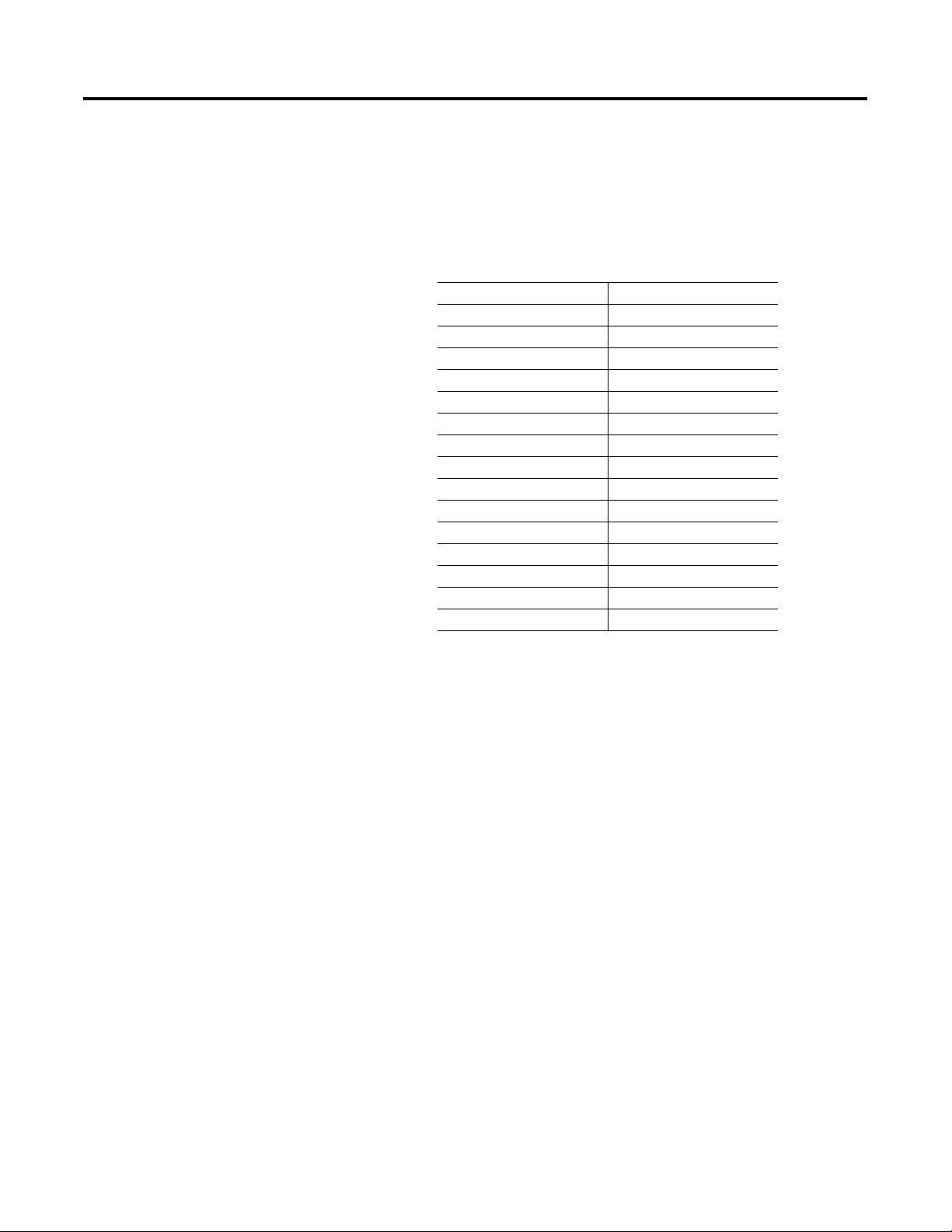

Table 3.A Master Connector Pin Layout

Pin Number Signal Name

1A+

2A3B+

4B5 I+ (Z+)

6 Encoder Return

7 Encoder Return

8 Encoder Supply

9 Encoder Supply

10 I- (Z-)

11* Motor Thermal

1 Publication 4100-IN054B-EN-P - January 2001

Page 24

3-2 Operation

Table 3.A Master Connector Pin Layout

12* Motor Thermal

13* Absolute Position

14 No Connection

15 Shield

* This pin configuration is for IQ and Ultra Plus drives only.

Follower-1 Output

The Follower-1 Output (P3) allows the user to connect a follower

drive or other peripheral equipment to the Encoder buffer Unit. The

connector is a 15 way male high density D plug.

Note: The Motor Thermal and analog position reference are brought

out through this follower connector.

Table 3.B Follower-1 Output Connector Pin Layout

Pin Number Signal Name

1A+

2A3B+

4B5 I+ (Z+)

6 Encoder Return

7 Encoder Return

8 No Connection

9 5V DC (optional)

10 I- (Z-)

11* Motor Thermal

12* Motor Thermal

13* Absolute Position

14 No Connection

15 Shield

* This pin configuration is for IQ and Ultra Plus drives only.

Publication 4100-IN054B-EN-P - January 2001

Follower-2 to 4 or 8 Outputs

The Follower-2 through Follower-4 (4 Way unit) or Follower-2

through Follower-8 (8 Way unit) outputs let you connect to follower

drives or other devices. The connector is a 15 way male high density

D plug.

Page 25

Operation 3-3

Note: The Motor Thermal and analog position reference are NOT

brought out to these follower connectors.

The pin layout for these connectors is illustrated in the following

table.

Table 3.C Follower-2 through 4 (or 8) Pin Layout

Pin Number Signal Name

1A+

2A3B+

4B5 I+ (Z+)

6 Encoder Return

7 Encoder Return

8 No Connection

9 5V DC (optional)

10 I- (Z-)

11 No Connection

12 No Connection

13 No Connection

14 No Connection

15 Shield

Configuration Links

Configuration links have been provided on the Encoder Buffer Unit to

let you set the Encoder Supply Voltage, Encoder Direction, and

Follower Power. The Configuration Links are a series of pins and

two-way jumpers. The required configuration is set by connecting the

pins with the two-way jumpers as specified in the following

directions.

Encoder Supply Voltage

The Encoder Buffer Unit lets you set the Encoder Supply voltage to

either +5V DC or +12V DC. This is done through the three-way link

marked LK-VOLTS . Where you place the two-way jumper determines

the supply voltage.

The Encoder Supply Voltage is set by placing the two-way jumper so

that is connects the link pins in the following sequence:

For a 12V Encoder Supply, Link 1- 2.

For a 5V Encoder Supply, Link 2 – 3

Publication 4100-IN054B-EN-P - January 2001

Page 26

3-4 Operation

The following diagram shows the layout of the links that select

encoder supply voltage.

LK-VOLTS ENC VOLTAGE

n 1

Link 1 – 2 = 12V

n 2

Link 2 – 3 = 5V

n 3

The default setting is for +5V DC.

Encoder Direction

The Encoder Direction is set with the Configuration Link marked

LK-DIR. This is four links arranged in a square with 2 two-way

jumpers. The direction can be set to either As Master or Reversed.

When the configuration link is set in the As Master position, the

quadrature pulse train at the follower outputs are in phase with those

produced by the encoder.

When the configuration link is set in the Reversed position, it changes

the A&B phases produced by the Master encoder such that, when

viewed at a follower output, the encoder appears to be rotating in the

opposite direction (i.e. Reversed produces an electrical direction

reverse.) The Index pulse gating is not affected. All follower outputs

are reversed simultaneously.

To set the Encoder Direction to As Master, move the 2 two-way

jumpers to link 1- 2 & 3 - 4.

To set the Encoder Direction to Reversed, move the 2 two-way

jumpers to link 1 - 3 & 2 - 4

The following diagram shows the layout of the links that select

encoder direction as laid out on the Encoder Buffer Unit.

LK-DIR ENCODER DIRECTION

1 n n 2

Link 1 – 2 & 3 – 4 = As Master

Publication 4100-IN054B-EN-P - January 2001

3 n n 4

Link 1 – 3 & 2 – 4 = Reversed

Page 27

The default setting is As Master.

Operation 3-5

WARNING

A feedback loop must not be closed via the

Encoder Buffer Unit. Use of this Buffer in the

feedback path of a position controller disables any

"encoder loss" detection function which can cause a

runaway condition.

!

Failure to observe these warnings will cause

unexpected and/or uncontrolled movement of

peripheral equipment. This may cause damage to the

equipment and to your health and safety.

Follower Power

The Follower Power configuration link sets the follower output to

either unpowered or powered. There is one Configuration Link for

each follower channel, marked LK-5V-F1 etc. These are three-way

links with two-way jumpers. In the powered state, the follower

supplies +5V output power.

To set the Follower output to unpowered, link 1- 2 with the two-way

jumper.

To set the Follower output to powered, Link 2 - 3 with the two-way

jumper.

The following diagram shows the layout of the links that select

encoder supply voltage. These are located to the left of the Follower

Output that they effect and are numbered accordingly.

LK-5V-FX

n 1

n 2

n 3

The following diagram shows the text indicating the selection options

for the Follower Outputs. It is located in one location near the top of

the board.

Publication 4100-IN054B-EN-P - January 2001

Page 28

3-6 Operation

FOLLOWER POWER

LK-5V-FX

Link 1 – 2 = OFF

Link 2 – 3 = ON

The default setting is unpowered (OFF).

Publication 4100-IN054B-EN-P - January 2001

Page 29

Accessories

Appendix

A

Principle Accessories

Table 0.A Principle Accessories

Crimped flying leads to 15 way high density D socket.

Supplied with loose 12 way AMP connector shell which

can be used for 1394 or ALEC. User connection drawing

for 1394 & ALEC included. Red and Black wires for the

1394 5V encoder supply included.

Un-crimped flying leads to 15 way high density D plug

compatible with EF08/04 Master socket. Allows

customers to connect non-standard encoder to EFO08/4.

Data sheet defining pin-out and color included. Has

encoder power connected to pin 9.

This section lists the principle accessories available for use with this

product. It includes cables for connecting the Encoder Buffer Unit to

Master Encoders and other devices.

Crewe Part number 44-0268-XXX

Crewe Description 8 or 4 Channel Buffer to 1394 or

ALEC

Passport No. 4100-EFCCXXX

Passport Description Encoder Fanout Board to 1394

cable

Crewe Part number 44-0269-XXX

Crewe Description Flying lead to 8/4 Channel Buffer

I/P

Passport No 4100-EFCEXXX

Passport Description Encoder Fanout Board to Encoder

Flying leads.

MIL spec 10way (18-1) socket to 15 way high density D

plug compatible with EF08/04 Master socket. Connects

845 encoder (or equivalent) to EF08/04. Has encoder

power connected to pin 9.

Fitted 12 way AMP connector to 15 way high density D

socket. Dedicated for 1394 only and supplied with user

sheet for external 5V connection.

1 Publication 4100-IN054B-EN-P - January 2001

Crewe Part number 44-0192-XXX

Crewe Description 5V & 12V encoder to 8/4 Channel

Buffer I/P

Passport No. N/A

Passport Description N/A

Crewe Part number 44-0254-XXX

Crewe Description 8/4 Channel Follower to 1394 only

Passport No. N/A

Passport Description N/A

Page 30

A-2 Accessories

Table 0.A Principle Accessories

Fitted 12 way AMP connector to15 way high density D

socket. Dedicated for ALEC only. No other data supplied

as it is not required

15 way high density D socket to 15 way high density D

plug compatible with EF08/04 Master socket. Cable

connects EF08/04 to ESRS or to IQ2000 or UltraPlus.

This unit generates a variable frequency bi-directional

quadrature pulse train with index at selectable counts.

The unit excepts an external speed command, produces a

commanded velocity output and provides a square wave

strobe locked to the index pulse. Same size as the AEC

and REC.

Crewe Part number 44-0249-XXX

Crewe Description 8/4 Channel Buffer to ALEC only

Passport No. N/A

Passport Description N/A

Crewe Part number 44-0280-XXX

Crewe Description IQ2000 to ESRS

Passport No. 4100-EFCS

Passport Description Encoder Fanout Board to ESRS

Crewe Part number 9103-0170

Crewe Description ESRS

Passport No. 4100-ESRS

Passport Description Encoder Simulator

Publication 4100-IN054B-EN-P - January 2001

NOTE: In the Crewe part numbers for cables, XXX defines the cable

length in feet.

Page 31

Index

A

Accessories A-1

Principle Accessories A-1

Allen-Bradley Support P-5

C

Configuration Links 3-3

Encoder Direction 3-4

Encoder Supply Voltage 3-3

Follower Power 3-5

Contents of this Manual P-3

D

Definitions P-3

encoder, P-4

Drawing

4 Way EBU Mechanical

8 Way EBUMechanical 1-4

1-4

E

EBU

Description

Overview 1-1

Principal Features 1-1

Encoder Direction 3-4

Encoder Supply voltage 3-3

1-1

F

Follower Power 3-5

Follower-1 Output 3-2

Follower-2 through Follower-4 3-2

I

Input

Master Input

Installation 2-1

4 Way EBU and ALEC 2-4

4 Way EBU with Follower Drive 2-5

EBU Units Connected in Cascade 2-3

Mounting 2-2

3-1

M

Master input 3-1

O

ollower-2 through Follower-8 3-2

Operation 3-1

General 3-1

Indicators 3-1

Inputs 3-1

Outputs 3-1

Output

Follower-1 Output

Follower-2 to 4 or 8 Outputs 3-2

3-2

P

Principle Accessories A-1

Product Receiving P-5

Purpose of this Manual P-1

R

Read This Manual P-1

Related Documentation P-3

S

Safety Precautions P-2

Specifications

Power Supply

Encoder 1-3

Follower Outputs 1-3

Input 1-2

Storage Responsibility P-5

Support

Allen-Bradley,

local product, P-5

technical product assistance, P-6

support

On the Web

P-5

P-6

T

Typical Applications 2-2

W

Who Should Use this Manual P-1

World Wide Web site P-6

Publication 4100-IN054B-EN-P -January 2001

Page 32

Back Cover

Publication 4100-IN054B-EN-P - January 2001 1 PN 4100-IN054B

Supersedes Publication 4100-IN054A - November 2000 © 2001 Rockwell International Corporation. Printed in the U.S.A.

Loading...

Loading...