Page 1

AEC

Absolute Encoder

Converter

(Cat. No. 4100-5.2)

Installation and Setup Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown

in this guide are intended solely for purposes of example. Since there

are many variables and requirements associated with any particular

installation, Allen-Bradley does not assume responsibility or liability

(to include intellectual property liability) for actual use based upon

the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole

or part, without written permission of Rockwell Automation, is

prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION

Identifies information about practices or

circumstances that can lead to personal injury or

death, property damage or economic loss

!

Attention statements help you to:

•

identify a hazard

•

avoid a hazard

•

recognize the consequences

IMPORTANT

Allen-Bradley is a trademark of Rockwell Automation

Identifies information that is critical for successful

application and understanding of the product.

Page 3

European Communities (EC) Directive Compliance

If this product has the CE mark it is approved for installation within

the European Union and EEA regions. It has been designed and

tested to meet the following directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC

Electromagnetic Compatibility (EMC) by applying the following

standards, in whole or in part, documented in a technical

construction file:

•

EN 50081-2 EMC — Generic Emission Standard, Part 2 —

Industrial Environment

•

EN 50082-2 EMC — Generic Immunity Standard, Part 2 —

Industrial Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low

Voltage, by applying the safety requirements of EN 61131-2

Programmable Controllers, Part 2 - Equipment Requirements and

Tests. For specific information required by EN 61131-2, see the

appropriate sections in this publication, as well as the Allen-Bradley

publication Industrial Automation Wiring and Grounding Guidelines

For Noise Immunity, publication 1770-4.1.

This equipment is classified as open equipment and must be

mounted in an enclosure during operation to provide safety

protection.

Page 4

Page 5

Table of Contents

Preface

Chapter 1

Read This Manual

Read This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Who Should Use this Manual. . . . . . . . . . . . . . . . . . . . . . . . . 1

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Contents of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Common Techniques Used in this Manual . . . . . . . . . . . . . . . 4

AEC Product Receiving and Storage Responsibility . . . . . . . . . 5

Allen-Bradley Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Local Product Support . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Technical Product Assistance . . . . . . . . . . . . . . . . . . . . . . 6

On the Web . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Overview

AEC Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

AEC Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

AEC Mechanical Specifications. . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 2

i Publication 4100-UM052B-EN-P - October 2001

Installation & Hook-Up

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installing the AEC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Complying with European Union Directives. . . . . . . . . . . . . 11

EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Mounting the AEC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Connecting the AEC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Connecting the AEC to the 1394 . . . . . . . . . . . . . . . . . . . 16

Connecting the AEC to the Compact. . . . . . . . . . . . . . . . 17

Connecting the AEC to the 1756-MO2AE. . . . . . . . . . . . . 19

Wiring the AEC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Wiring Cable Flying Leads to the Plugs . . . . . . . . . . . . . . 21

The SSI Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Page 6

ii

The Control Connector. . . . . . . . . . . . . . . . . . . . . . . . . . 24

Fault Relay 24

Analog Servo Command Pass Through (For Compact Only) . . . . 26

Power Supply Connector . . . . . . . . . . . . . . . . . . . . . . . . 27

Chapter 3

Chapter 4

Setup

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Setting the Rotary Switches . . . . . . . . . . . . . . . . . . . . . . . . . 29

Configuration Switch Tables . . . . . . . . . . . . . . . . . . . . . . . . 30

Configuration Switch A . . . . . . . . . . . . . . . . . . . . . . . . . 30

Configuration Switch B . . . . . . . . . . . . . . . . . . . . . . . . . 31

Powering the AEC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

AEC With GML Commander . . . . . . . . . . . . . . . . . . . . . . . . 32

Adding AEC to your Commander Diagram . . . . . . . . . . . 32

Setting the Transducer Resolution. . . . . . . . . . . . . . . . . . . . . . . . . 33

Selecting Homing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Aligning Absolute Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Operation

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Absolute Position Update . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Incremental Position Output . . . . . . . . . . . . . . . . . . . . . . . . 35

Position at Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Chapter 5

Appendix A

Publication 4100-UM052B-EN-P - October 2001

Fault Indication & Control Status

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Transducer Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Encoder Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Internal Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

No Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Specifications

Equivalent Circuit Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . 44

Page 7

iii

Appendix B

Index

Strobe Position For Applications Not Using the 1394 or Compact

Absolute Strobe Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Absolute Strobe Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Incremental Strobe Period . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Publication 4100-UM052B-EN-P - October 2001

Page 8

iv

Publication 4100-UM052B-EN-P - October 2001

Page 9

Preface

Read This Manual

Who Should Use this Manual

Read and understand this instruction manual. It provides the

necessary information to let you install, connect, and set up the AEC

for safe, reliable operation. This preface covers the following topics:

•

Who should use this manual

•

The purpose of this manual

•

Terms

•

Common techniques used in this manual

•

Allen-Bradley support

You should read this manual if you are responsible for the installation,

set up or operation of the AEC (Absolute Encoder Converter).

If you do not have a basic understanding of the products listed below,

contact your local Allen-Bradley representative for information on

available training courses before using this product.

•

S Class Compact motion controller

•

1394 GMC System module

•

GML (Graphic Motion Language) Commander software

Purpose of this Manual

This manual is an installation and set up guide for the AEC and

describes the procedures necessary to properly install and configure it

into your motion control system.

1 Publication 4100-UM052B-EN-P - October 2001

Page 10

Preface 2

Safety Precautions

The following general precautions apply to the AEC:

ATTENTION

!

Electric shock can kill. Make sure the AEC is safely

installed in accordance with the Installation and

Set-up chapters of this manual. Avoid contact with

electrical wires and cabling while power is on.

Only trained service personnel should open the

electrical cabinet.

This product contains stored energy devices. To

avoid hazard of electrical shock, verify that all

voltage on the capacitors has been discharged

before attempting to service, repair, or remove this

unit. You should only attempt the procedures in

this manual if you are qualified to do so and

familiar with solid-state control equipment and the

safety procedures in publication NFPA 70E and

BS-EN60204.

The system integrator is responsible for local safety

and electrical codes.

ATTENTION

!

An incorrectly applied or installed product can result

in component damage or a reduction in product life.

Wiring or application errors, such as undersizing or

inadequate DC supply, or excessive ambient

temperatures can result in a malfunction.

The AEC contains ESD (Electrostatic Discharge)

sensitive parts and assemblies. Static control

precautions are required when installing, testing,

servicing, or repairing this assembly. Component

damage can result if ESD control procedures are not

followed. If you are not familiar with static control

procedures, refer to Allen-Bradley publication

8000-4.5.2, Guarding Against Electrostatic Damage or

any other applicable ESD Protection Handbook.

Publication 4100-UM052B-EN-P - October 2001

Page 11

Preface 3

Contents of this Manual

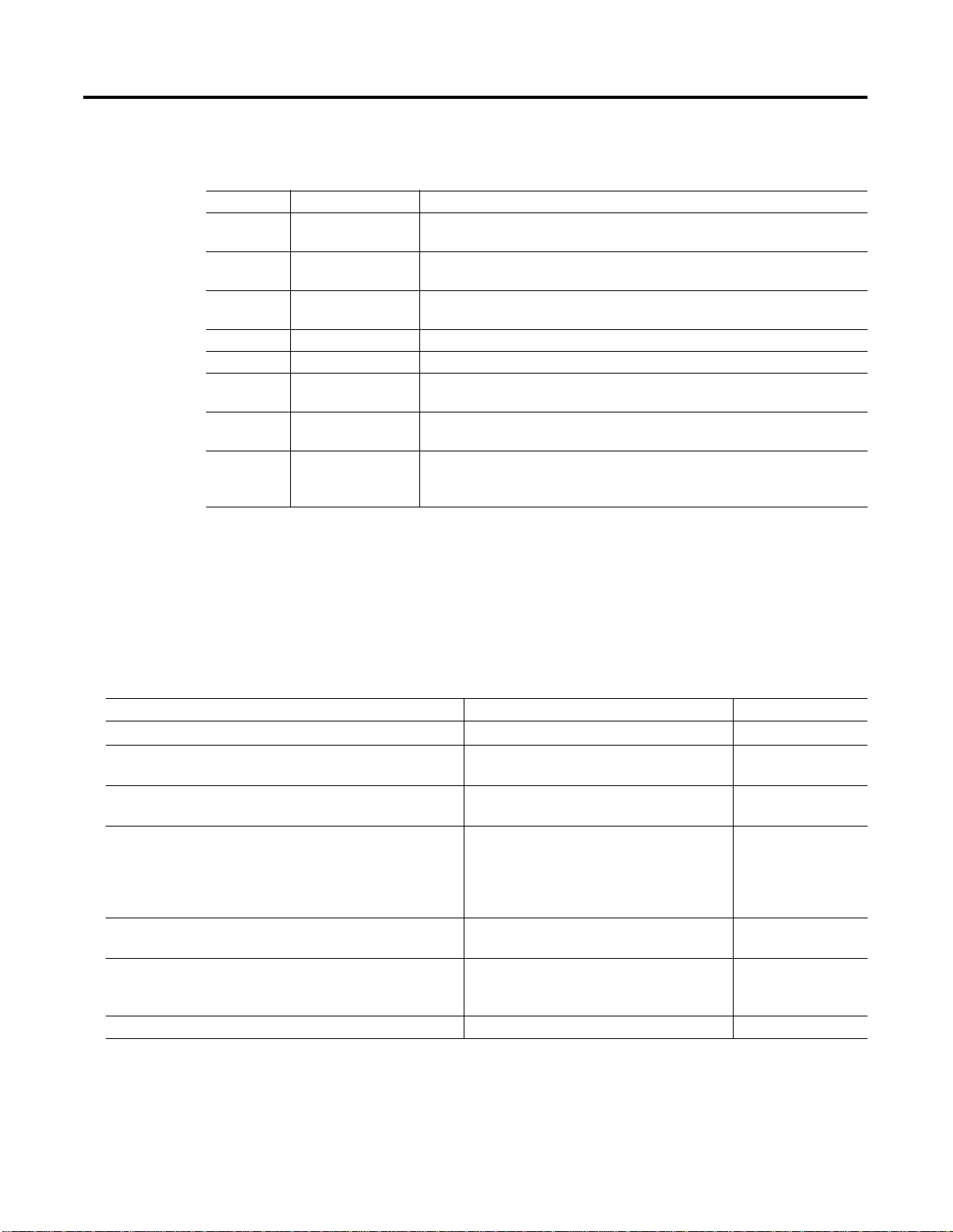

Chapter Title Contents

Preface Describes the purpose, background, and scope of this manual. Also specifies

the audience for whom this manual is intended.

1 Overview Provides a general description of the AEC, its features and mechanical

specifications.

2 Installation Provides the steps needed to successfully mount and wire the AEC to an SSI

device and the S Class Compact Motion Controller or the 1394 GMC system.

3 Set-Up Provides the guidelines for setting up and configuring the AEC.

4 Operation Provides information on Absolute and Incremental Position.

5 Fault Indication &

Control Status

Appendix A Specifications Provides physical, electrical, environmental, and functional specifications for

Appendix B Strobe Position Contains additional information about setting the strobe for those users

Provides information on fault and status indicators and types of faults.

the AEC.

connecting their AEC to a controller other than the S Class Compact Motion

Controller or the 1394 GMC system.

Related Documentation

The following documents contain additional information concerning

related Allen-Bradley products. To obtain a copy, contact your local

Allen-Bradley office or distributor.

For Read This Document Document Number

Programming Allen-Bradley motion controller with GML GML Commander Reference Manual GMLC-5.2

Instructions for installation and set-up for the 1394 GMC

system

Instructions for installation and set-up for the S Class

Compact motion controller

An article on wire sizes and types for grounding electrical

equipment (North American standards)

An article on wire sizes and types for grounding electrical

equipment (European standards).

A complete listing of current Allen-Bradley documentation,

including ordering instructions. Also indicates whether the

documents are available on CD-ROM or in multi-languages

A glossary of industrial automation terms and abbreviations Allen-Bradley Industrial Automation Glossary AG-7.1

1394 Digital, AC, Multi-Axis Motion Control

System User Manual

IMC S Class Compact Motion Controller

Installation and Set-up Manual

National Electrical Code Published by the

BS-EN 60204 Electrical Equipment of

Machines

Allen-Bradley Publication Index SD499

1394-5.0

999-122

National Fire

Protection

Association of

Boston, MA.

Published by British

Standards Institute

Publication 4100-UM052B-EN-P - October 2001

Page 12

Preface 4

Terminology

Common Techniques Used in this Manual

In order to avoid confusion, we have used the following general terms

in a specific manner within this manual. We define them as follows:

Transducer - the SSI device is considered a transducer for the

purposes of this manual.

Encoder - Refers to the AEC connector that goes to the 1394 GMC

System or the S Class Compact motion controller. The cable from the

controller attaches to the AEC at the Encoder connector.

For specific definitions of other terms used in industrial automation,

see the Allen-Bradley Industrial Automation Glossary (publication

number AG-7.1).

The following conventions are used throughout this manual:

•

Bulleted lists such as this one provide information, not

procedural steps.

•

Numbered lists provide sequential steps or hierarchical

information.

•

Words that you type or select appear in bold.

•

When we refer you to another location, the section name

appears in italics.

Publication 4100-UM052B-EN-P - October 2001

ATTENTION

!

IMPORTANT

The exclamation point inside of a triangle, followed

by the word “ATTENT ION” indicate circumstances

that can lead to personal injury, death, property

damage or economic loss.

Identifies information that is critical for successful

application and understanding of the product.

Page 13

Preface 5

AEC Product Receiving and Storage Responsibility

You, the customer, are responsible for thoroughly inspecting the

equipment before accepting the shipment from the freight company.

Check the item(s) you receive against your purchase order. If any

items are obviously damaged, it is your responsibility to refuse

delivery until the freight agent has noted the damage on the freight

bill. Should you discover any concealed damage during unpacking,

you are responsible for notifying the freight agent. Leave the shipping

container intact and request that the freight agent make a visual

inspection of the equipment.

Leave the product in its shipping container prior to installation. If you

are not going to use the equipment for a period of time, store it:

•

in a clean, dry location

•

within an ambient temperature range of 0 to 85° C (32 to 185° F)

•

within a relative humidity range of 5% to 95%, non-condensing

•

in an area where it cannot be exposed to a corrosive

atmosphere

•

in a non-construction area

Allen-Bradley Support

Allen-Bradley offers support services worldwide, with over 75 Sales/

Support Offices, 512 authorized Distributors and 260 authorized

Systems Integrators located throughout the United States alone, plus

Allen-Bradley representatives in every major country in the world.

Local Product Support

Contact your local Allen-Bradley representative for:

•

sales and order support

•

product technical training

•

warranty support

•

support service agreements

Publication 4100-UM052B-EN-P - October 2001

Page 14

Preface 6

Technical Product Assistance

If you need to contact Allen-Bradley for technical assistance, please

review the information in this manual first. Then call your local

Allen-Bradley representative. For the quickest possible response, we

recommend that you have the catalog numbers of your products

available when you call. See the Related Documentation section of

this chapter for the publication numbers of other manuals that can

help with this product.

The Rockwell Automation Technical Support number is:

1-603-443-5419

On the Web

For information about Allen-Bradley, visit the following World Wide

Web s ite :

http://www.ab.com/

Publication 4100-UM052B-EN-P - October 2001

Page 15

Overview

Chapter

1

AEC Description

The AEC is an absolute encoder converter. It receives the absolute

position sent by the SSI transducer and changes it to an incremental

quadrature signal that the 1394 GMC System module and the S Class

Compact motion controller can use.

The AEC is designed to accept outputs from absolute encoders, linear

displacement transducers, or any other measuring device, which

transmits its measured values over an SSI. Several devices are

supported with various combinations of counts per turn and number

of turns. These are defined in the Setup chapter of this manual.

Parallel output devices are not supported.

The AEC provides two independent channels from absolute to

incremental quadrature conversion. The resolution of each channel is

set via rotary switches and each one can operate with a transducer

using a different supply voltage. (Although the supply voltages may

be different, they are not isolated. The grounds must be of equal

potential.) Each channel can be individually strobed to obtain new

absolute or incremental position information.

7 Publication 4100-UM052B-EN-P - October 2001

Page 16

8 Overview

AEC Features

The AEC has the following features:

•

Two fully independent axes capable of absolute to incremental

quadrature conversion.

•

Each channel can support independent absolute transducer

input.

•

User selectable resolution.

•

Fixed transducer acquisition speed of 400 kHz.

•

Each axis provides one differential quadrature output.

•

Fixed quadrature output frequency of 800 kHz.

•

Independent +5 V DC, + 15 V DC, and +24 V DC transducer

voltages.

•

Selectable for incremental strobes or internal 1ms timebase.

•

Interfaces directly to Allen-Bradley 1394 GMC System and S

Class Compact motion controllers.

•

Normally open and normally closed status outputs for each axis.

•

Bicolor LED status indication for each axis.

•

An on-board reset switch that resets both axes.

•

Absolute Home request remotely clears corrected faults and

resets system on a per axis basis.

•

Single 18-36 V DC input voltage power requirement.

•

A rugged steel case for greater protection. The case has

pre-drilled mounting tabs.

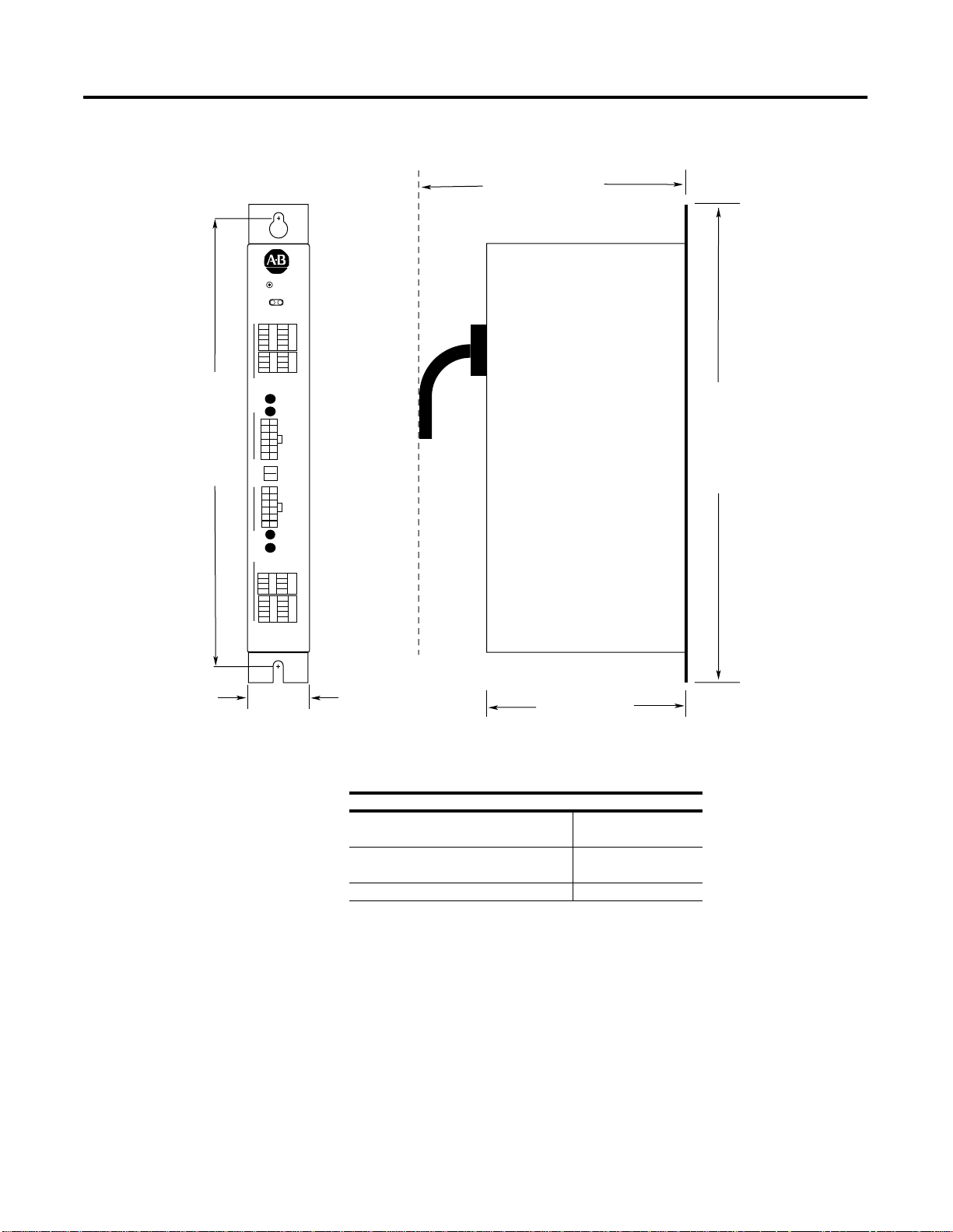

AEC Mechanical Specifications

The following figure shows the placement and labeling of major items

on the AEC front panel.

Publication 4100-UM052B-EN-P - October 2001

Page 17

Reset

Axis 0 Axis 1

AB

5

10

4

9

3

8

2

7

1

6

4

8

3

7

2

6

1

5

A

Axis 0

B

Overview 9

Figure 1 AEC front panel

203.2 mm (8.0 in.) with

cable clearance

Use 1/4 -20 or M6

bolt (typical 2 places)

SSIControl

ConfigurationConfiguration

330.2 mm (13.0 in.)

2

1

A

B

Axis 1

8

7

6

5

10

9

8

7

6

AB

AEC

Encoder EncoderPower

4

3

2

1

5

4

3

2

1

Switches Switches

SSI Control

44.45 mm (1.75 in.)

152.4 mm (6.0 in.)

Package Specifications

Package size

mm and (in.)

Product weight

kg and (lbs.)

342.9 x 152.4 x 44.45

(13.5 x 6.0 x 1.75)

2.27

(5.0)

Material Painted Steel

342.9 mm (13.5 in.)

Publication 4100-UM052B-EN-P - October 2001

Page 18

10 Overview

Publication 4100-UM052B-EN-P - October 2001

Page 19

Installation & Hook-Up

Chapter

2

Chapter Objectives

Installing the AEC

Read this entire chapter before beginning to mount, connect, or wire

any of the components to the AEC. It is the responsibility of the

installer to see that the installation conforms to the directions in this

manual and local codes and procedures. This chapter covers the

following topics.

•

European Union Compliance

•

Mounting the AEC

•

Connecting the AEC to the 1394 GMC system

•

Connecting the AEC to the Compact motion controller

•

Connecting the AEC to the 1746-MO2AE

•

Wiring the SSI transducer to the AEC

•

Wiring the Control connector

•

An example of a Fault relay

•

Wiring the Power connector

The AEC is designed to mount in an electrical cabinet using the

flanges on its back panel. This installation method should be observed

for all applications. Before powering the AEC, make sure it has been

configured correctly and that the transducer(s) and control devices

(controller) are connected to it correctly.

Complying with European Union Directives

11 Publication 4100-UM052B-EN-P - October 2001

The information contained in this document pertains to the Absolute

Encoder Converter (AEC), an Allen-Bradley product. If the AEC is

installed within the European Union or EEA regions and has the CE

mark, the following regulations apply.

Page 20

12 Installation & Hook-Up

EMC Directive

The AEC is tested to meet Council Directive 89/336 Electromagnetic

Compatibility (EMC) in accordance with Article 10 (1). The following

directives apply:

•

EN 50081-2 EMC-Generic Emission Standard, Part 2-Industrial

Environment.

•

EN 50082-2 EMC-Generic Immunity Standard, Part 2-Industrial

Environment.

The AEC, as described in this document, is intended for use in an

industrial environment and is not intended for use in a residential,

commercial, or light industrial environment.

To meet CE requirements, the following are required:

•

The AEC must be mounted in an IP 54 rated metal enclosure on

a metal panel.

•

All equipment must be bonded.

•

You must use the specified Allen-Bradley cables.

•

The AEC is designed to function without maintenance when

operated in the environment specified in this manual.

•

Under normal conditions, the AEC should not require any

periodic maintenance. However, if conditions are less than ideal

and any superficial dust has accumulated on the controller over

time, remove the dust carefully. Also, it is recommended to

periodically inspect all cables for abrasion and all connectors for

proper seating.

Mounting the AEC

Publication 4100-UM052B-EN-P - October 2001

Before mounting the AEC, verify that the 1394 GMC System or the S

Class Compact motion controller is installed correctly. Refer to the

1394 Digital AC Multi-Axis Motion Control System User Manual

(publication 1395-5.0) or the IMC 23/x Installation and Set-up Manual

(publication 999-122) for installation instructions.

The AEC must be properly grounded to the metal enclosure panel.

The following diagram shows how to ground the AEC to the panel.

Page 21

Figure 2 Mounting and Grounding Diagram

#10 AWG to

Ground Bus

AEC Mounting Tab

Ground

Lug

Installation & Hook-Up 13

Internal Star Washers

Scrape paint off panel to insure

electrical connection between

chassis and grounded metal plate.

Mount the AEC next to a 1394 GMC system or an S Class Compact

motion controller on a metal enclosure panel using two 1/4 -20 or M6

bolts. Refer to the Mechanical Specifications in the Overview chapter

of this manual for mounting dimensions. Figures 3 and 4 in this

chapter show where to mount the AEC.

Size 1/4 - 20 or M6

Hardware

Tapped Hole

(Minimum of 3 Threads)

Metal Panel

(Must be connected to

earth ground.)

ATTENTION

!

To avoid a shock hazard, remove all power to the

system panel before mounting the AEC.

The 1394 contains stored energy devices. To avoid the

hazard of electrical shock, verify tha t all voltages are

zero (0.00) before proceeding.

Publication 4100-UM052B-EN-P - October 2001

Page 22

14 Installation & Hook-Up

Optional

Second

AEC for

Axis 2 and

Axis 3

Figure 3 Mounting the AEC next to a 1394 GMC on a system panel

Wireway

1394

AEC

Reset

Axis 0 Axis 1

AB

10

9

8

7

6

8

7

6

5

A

Axis 0

B

2

1

A

B

Axis 1

8

7

6

5

10

9

8

7

6

AB

AEC

5

4

3

SSIControl

2

1

4

3

2

1

ConfigurationConfiguration

Encoder EncoderPower

Switches Switches

4

3

2

1

5

4

3

2

SSI Control

1

GMC System

Publication 4100-UM052B-EN-P - October 2001

IMPORTANT

The AEC can only be mounted on the left side (when

look ing directly at th e mounted 1394) of the 1394 GMC

System. This is due to cable specifications and module

expansion of the 1394.

Page 23

The AEC

can also

be placed

to the left

of the

Compact

Installation & Hook-Up 15

Figure 4 Mounting the AEC next to an S Class Compact motion controller.

S Class

Compact

Allen –Bradley IMC S Class

Axis 0

Axis 1

Servo &

Servo &

Feedback

Feedback

Wireway

AEC

Reset

Axis 0 Axis 1

AB

10

9

8

7

6

8

7

6

5

Axis 0

2

1

Axis 1

8

7

6

5

10

9

8

7

6

AB

5

4

3

SSIControl

2

1

4

3

2

1

Optional

A

B

ConfigurationConfiguration

Second

AEC for

Axis 2

and

Axis 3

Encoder EncoderPower

A

B

Switches Switches

4

3

2

1

5

4

3

2

SSI Control

1

AEC

Connecting the AEC

IMPORTANT

The AEC can be mounted on either side of the S Class

Compact motion controller on the system panel.

The following section details how to connect the AEC encoder

connectors to the 1394 GMC System and the S Class Compact motion

controller.

ATTENTION

Do not attempt to make any electrical connections to the

AEC while power is applied. Doing so risks damage to

the AEC, peripheral equipment, and your health and

safety.

!

Publication 4100-UM052B-EN-P - October 2001

Page 24

16 Installation & Hook-Up

ATTENTION

The AEC does not support the r emoval or the i nsertion of

any connectors when under power. The power

disturbance can result in unintended machine motion,

loss of proc es s co n t rol, o r a n el ect ri cal arc that can ca use

an explosion in a hazardous environment.

!

Connecting the AEC to the 1394

Connect the AEC to a 1394 GMC System using the encoder cable

(catalog number 1394-GR04) for each axis. This is a four foot cable

that connects Axis 0 Encoder or Axis 1 Encoder connector on the AEC

to the J3, J4, J5, or J10 encoder feedback connector on the 1394.

IMPORTANT

This cable is polarity sensitive.

IMPORTANT

The 1394 interface circuitry requires 0.325A to operate. Any additional

devices connected to the 1394, such as incremental encoders, can

require an additional 0.2A per device (check your device for the

precise requirements).

To connect the encoder cables:

1. Insert the 12-pin plug labeled “REC/AEC” in the Axis 0 Encoder

or Axis 1 Encoder connector on the AEC.

2. Insert the 12-pin plug labeled “1394” in the J3, J4, J5, or J10

encoder feedback connector on the 1394.

3. Wire the remaining auxiliary power labeled “ENC. PWR” to the

5V DC power supply. The red wire is +5V and the black is a +5

common.

The AEC does not require power from the 1394 to

operate nor doe s it provide power to the 1394. However,

the 1394 requires a separate 5V power supply to run its

interface circuitry.

Publication 4100-UM052B-EN-P - October 2001

Page 25

Installation & Hook-Up 17

Axis 0 Encoder Connector

Axis 1 Encoder Connector

5V DC

Power

Supply

IMPORTANT

When using multiple Encoder devices, we recommend

you wi re all o f the au xi liary power cabl e s to the same 5 V

DC power supply.

Figure 5 Connecting the Encoder Cables and the 5V Power Supply to the 1394

Wireway

1394

GMC System

AEC

Reset

Axis 0 Axis 1

AB

5

10

4

9

3

8

SSIControl

2

7

1

6

4

8

3

7

6

5

Axis 0

2

1

Axis 1

8

7

6

5

10

9

8

7

6

AB

2

1

A

B

ConfigurationConfiguration

Encoder EncoderPower

A

B

4

3

2

1

5

4

3

2

1

AEC

1394-GR04

Switches Switches

SSI Control

IMPORTANT

Anchor the c able so that no more than 2 feet of cable is

left unsupported. The excessi ve weight of an unanchored

cable could pull the plug out of the connector

Connecting the AEC to the Compact

To connect the AEC to the S Class Compact motion controller, use the

encoder cable (catalog number 4100-RCS3T) for each axis. This three

foot cable connects the Axis 0 Encoder or the Axis 1 Encoder

connector on the AEC to the Axis 0, 1, 2, or 3 servo and feedback

connector on the Compact. The Compact sends the drive servo output

Publication 4100-UM052B-EN-P - October 2001

Page 26

18 Installation & Hook-Up

signal through the 4100-RCS3T cable. The following figure shows

where to connect the encoder cable to the AEC and the Compact.

IMPORTANT

This cable is NOT polarity sensitive.

To connect the Encoder cable:

1. Insert one 12-pin plug in the Axis 0 Encoder or Axis 1 Encoder

connector on the AEC.

2. Insert the remaining 12-pin plug in the Axis 0, 1, 2, or 3 servo

and feedback connector on the Compact.

Figure 6 Connecting the Encoder Cables to the Compact

S-Class

Compact

Allen –Bradley IMC S Class

Wireway

4100-RCS3T

AEC

Reset

Axis 0 Axis 1

AB

10

9

8

7

6

8

7

6

5

A

Axis 0

B

5

4

3

2

1

4

3

2

1

ConfigurationConfiguration

SSIControl

Axis 0

Servo &

Feedback

IMPORTANT

2

1

Encoder EncoderPower

A

B

Switches Switches

Axis 1

4

8

3

7

2

6

1

5

5

10

4

9

3

8

2

7

Axis 1

Servo &

Feedback

Axis 2

Servo &

Feedback

Axis 3

Servo &

Feedback

6

AB

AEC

SSI Control

1

Anchor the cable so that no more than 2 feet of cable is

left unsupported. The excessi ve weight of an unanchored

cable could pull the plug out of the connector.

Publication 4100-UM052B-EN-P - October 2001

Page 27

Connecting the AEC to the 1756-MO2AE

Installation & Hook-Up 19

TIP

See Application Note, publication number 4100-2.7 for

more detailed information regarding using the AE C with

the 1756-MO2AE.

To connect the AEC to the 1756-MO2AE, use the pre-made encoder

cable (4100-CCS15F) for each axis. This 15 foot cable connects the

Axis 0 Encoder or Axis 1 Encoder connector on the AEC to the

1756-MO2AE. The 4100-CCS15F is a 15 foot cable with a 12-pin plug

on one end and the flying leads on the other end.

IMPORTANT

This cable is NOT polarity sensitive.

To connect the 4100-CCS15F Encoder cable:

1. Insert the end with the 12-pin plug to either the Axis 0 Encoder

or Axis 1 Encoder connector on the AEC.

2. Connect the flying leads to the appropriate pin locations on the

1756-MO2AE using the pin locations as shown in the following

diagram.

1756-MO2AE Pins for Connecting AEC

Pin Number Pin Value Wire Color

1 V REF+ Red

3 V REF- Black

11 Chassis Black

25 A+ White

27 A- Black

29 B+ Green

31 B- Black

33 Z+ Blue

35 Z- Black

Publication 4100-UM052B-EN-P - October 2001

Page 28

20 Installation & Hook-Up

AEC

The wires for Strobe+ and Strobe- must be run through the DC Output

card. The pin locations are designated in the following table.

DC Output 1756-OB16I/A Pins for Connecting the AEC Strobe

Pin Number Pin Value Wire Color

2 Strobe + Yellow

1 Strobe - Black

The following diagram shows the 4100-CCS15F cable connecting the

AEC to the 1756-MO2AE.

Figure 7 Connecting the Encoder Cable to the 1756-MO2AE and DC Output

DC Output Module

(1756-OB16I/A)

1756-MO2AE

2

4

6

8

10

12

14

16

18

20

22

+OK

24

26

28

30

32

34

36

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

1

+OUT-1

3

-OUT-1

5

+ENABLE-1

7

-ENABLE-1

9

DRVFLT-1

11

CHASSIS

13

IN_COM

15

HOME-1

17

REG24V-1

19

REG5V-1

21

-OK

23

CHASSIS

25

+CHA-1

27

-CHA-1

29

+CHB-1

31

-CHB-1

33

+CHZ-1

35

-CHZ-1

Strobe+

(Yellow)

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

+OUT-0

-OUT-0

+ENABLE-0

-ENABLE-0

DRVFLT-0

CHASSIS

IN_COM

HOME-0

REG24V-0

REG5V-0

CHASSIS

+CHA-0

-CHA-0

+CHB-0

-CHB-0

+CHZ-0

-CHZ-0

4100-CCS15F

Axis 0 Encoder Connector

Strobe(Black)

AEC

Reset

Axis 0 Axis 1

AB

5

10

4

9

3

8

2

7

1

6

4

8

3

7

2

6

1

5

A

Axis 0

B

2

1

A

B

Axis 1

4

8

3

7

2

6

1

5

5

10

4

9

3

8

2

7

1

6

AB

AEC

SSIControl

ConfigurationConfiguration

Encoder EncoderPower

Switches Switches

SSI Control

Publication 4100-UM052B-EN-P - October 2001

Page 29

Installation & Hook-Up 21

Wiring the AEC

There are several connectors on the front of the AEC. All are

duplicated for each axis except the power input connector. Each axis

has two five-pin plugs for connecting the SSI transducer and two

four-pin plugs for connecting a control. In the center is a 2-pin plug

for the power cable. The flying leads wire directly to the screw

terminals on the plugs.

Wiring Cable Flying Leads to the Plugs

To wire the cable leads to the plug:

1. Look at the plug to make sure the terminal is open. The

following figure shows both an open and a closed terminal.

Figure 8 Terminal diagram

Terminal open

Clamping screws

Terminal closed

2.

Terminal Steps

If the terminals are: Do this:

Not open Go to step 3

Open Go to step 4

3. Using a small, flat-head screwdriver, turn the clamping screw

counter-clockwise several times.

4. Using a proper stripping tool, strip the wire insulation back on

the cable lead.

IMPORTANT

All terminals accommodate a maximum of 14 gauge

wire.

5. Trim the cable lead so that 0.275 inches of metal wire is

exposed.

6. Insert the cable lead in the appropriate terminal. Refer to the

proper figures for their locations.

Publication 4100-UM052B-EN-P - October 2001

Page 30

22 Installation & Hook-Up

7. Use the screwdriver to tighten the clamping screw to the proper

torque (0.25 N-m/2.2 in-lb.).

8. Verify that the cable lead does not pull out of the terminal.

9.

Cable Leads

If the cable lead: Do this:

Pulls out of the terminal Repeat steps 3 through 9

again

Does not pull out of the

terminal

Repeat steps 3 through 9 for

the next terminal

The function of these connectors, their pinouts, and names are

defined in the following sections.

The SSI Connector

The SSI connectors are used to connect the absolute transducer to the

AEC. The pin layout and functionality for this connector are as

follows.

SSI Connector Pin Functions

SSI Input

Pin Number Pin Function

1 Transducer Power +24V DC

2 Transducer Power +15V DC

Publication 4100-UM052B-EN-P - October 2001

3 Transducer Power +5V DC

4 Data -

5Clock -

6Shield

7 Transducer Power Return

8Shield

9 Data +

10 Clock +

Page 31

Installation & Hook-Up 23

The following is the connector pin numbering scheme for the SSI

connector as viewed with the AEC mounted in its normal position.

SSI Connector Pin Numbering

AB

10 5

94

83

72

61

ATTENTION

!

IMPORTANT

Wiring t he connec tor f or the wro ng tra nsducer power can

result in imp ro p er operation o r dama ge to the position

transducer.

Pins 1 through 3 are reserved for transducer power

output. Only one of these can be in use at a time. It is

your responsibility to determine the power requirement

of the tr ansducer you are connecting to the AEC and to

use the pin that corresponds to that requirem ent.

Publication 4100-UM052B-EN-P - October 2001

Page 32

24 Installation & Hook-Up

Plug A

10

9

8

7

6

Plug B

5

4

3

2

1

Figure 9 Wiring Diagram for SSI Connector

Clock +

Data +

Return

Shield

Clock Data +5V DC

+15V DC

+24V DC

IMPORTANT

IMPORTANT

Maximum cable length between SSI Device and the

AEC is 100 feet.

Anchor the cable so that no more than 2 feet of cable is

left unsupported. The excessi ve weight of an unanchored

cable can pull the plug out of the connector.

The Control Connector

The control connectors let you connect the AEC to an application fault

string to indicate an AEC related fault condition to the controlling

hardware. The connector also has an analog command pass through

signal pair for connecting a servo amplifier.

Fault Relay

To provide safe operation (opening the fault string if a fault occurs or

power to the AEC is lost) the control status relay outputs must be

Publication 4100-UM052B-EN-P - October 2001

Page 33

24V DC

Installation & Hook-Up 25

connected appropriately. The control status relay N/O contact is held

energized when the AEC has not detected a fault.

There is one control status relay per axis. Each relay provides one

normally open and one normally closed pair that is voltage free and

isolated from each other and the ground.

Figure 10 An example of a Normally Open Fault status contact

DC

AEC Fault contact

located at Axis 0,1

Control connector

Common

Start/Stop String

Fault String

Start

Stop

7

3

CR1

CR1

ATTENTION

The Fault Contacts are NOT intended to be used for an

emergency stop string. They are intended for fault

indication only.

!

The diagram shows an example of connecting the AEC fault contact

into a system fault string. Since the status relay is energized when the

AEC is indicating no faults, the contact is closed.

A typical fault detection scheme may require additional circuitry when

used in applications where the AEC fault contacts do not have

sufficient capacity to drive a fault detection circuit directly.

Publication 4100-UM052B-EN-P - October 2001

Page 34

26 Installation & Hook-Up

The pin layout and functionality for the Control connector is as

follows:

Control Connector Pin Functions

Control

Pin Number

1Shield

2 Fault N/C Relay Contact

3 Fault N/O Relay Contact

4 Reference -

5Shield

6 N/C Relay Common Contact

7 N/O Relay Common Contact

8 Reference +

Pin Function

The following table displays the connector pin numbering scheme, as

seen with the AEC mounted in its normal position.

Control Connector Pin Numbering

AB

84

73

62

51

Analog Servo Command Pass Through (For Compact Only)

There is one analog command pass through signal pair (Reference +

and Reference -) per axis. The 4100-RCS3T encoder cable between the

AEC and the Compact (see Connecting the AEC to a Compact section

of this chapter) passes the analog command signal from the Compact,

through the AEC, and out to the servo amplifier, if connected.

Publication 4100-UM052B-EN-P - October 2001

Page 35

Plug A

8

7

6

5

Plug B

4

3

2

Reference +

Shield

Reference -

Installation & Hook-Up 27

Figure 11 Wiring diagram for connecting a Servo Amplifier

to the Control Connector

To Servo Amplifier

1

IMPORTANT

Anchor the c able so that no more than 2 feet of cable is

left unsupported. The excessi ve weight of an unanchored

cable could pull the plug out of the connector.

Power Supply Connector

The power supply connector is used to connect power to the AEC.

There is one power input connector for the AEC. The input power is

used to operate the AEC and attached transducers.

The AEC operates within the voltage range of 18-36V DC. The power

source must be able to supply 21W of power continuously.

Publication 4100-UM052B-EN-P - October 2001

Page 36

28 Installation & Hook-Up

The pin layout and functionality for this connector are shown in the

following table.

Power Supply Pin Functions

Power Supply

Pin Number Pin Function

1 Supply Common

2 Supply +

The following table shows the power supply connector pin

numbering, as seen with the AEC mounted in its normal position.

Power Supply Pin Numbering

Power

2

1

The following diagram illustrates the power connections for the AEC.

Figure 12 Wiring diagram for connecting the power cable to the connector

2

1

Supply +

Supply Return

IMPORTANT

To 18-36V DC

Power Supply

Anchor the cable so that no more than 2 feet of cable is

left unsupported. The excessi ve weight of an unanchored

cable could pull the plug out of the connector.

Publication 4100-UM052B-EN-P - October 2001

Page 37

Setup

Chapter

3

Chapter Objectives

Setting the Rotary Switches

The AEC is used in conjunction with the 1394 GMC System or the S

Class Compact motion controller and SSI transducers. It is not a

stand-alone product and must be configured to work with the

hardware connected to it. This involves specific steps that are

determined by the make and model of the hardware connected to the

AEC. This manual assumes that the GML Commander v4.01 or higher

software is used.

This chapter covers :

•

Explanation of the Rotary switch settings

•

Powering the AEC

•

Configuring the AEC with the GML Commander software

•

Homing Procedure

•

Aligning Absolute Device

Setting the rotary switches located on the front panel, configures the

AEC.

Before you apply power to the AEC you must configure each axis to

suit the transducer connected to it. A total of four parameters per axis

must be configured. For each axis, determine the following:

1. Transducer resolution in counts/turn (this is in counts/stroke for

linear displacement transducers). Parameter 1 is set by

configuration switch “A”. The table “Configuration Switch A” lists

all the options supported by the AEC. Use this table to select the

switch setting that matches the value for your transducer.

IMPORTANT

2. Whether the transducer is a single or multi turn device.

3. Whether Grey or Binary is used for transducer data.

4. The operation mode. Locked or free running.

29 Publication 4100-UM052B-EN-P - October 2001

Configuration switc h “B” is used for setting the next

three parameter s. You must find the sett ing that meets the

combination of values for all thr ee parameters.

Page 38

30 Setup

Configuration Switch Tables

ATTENTION

The Compact and 1394 motion controllers must use the

LOCKED mode of operation.

!

Configuration Switch A

Transducer Resolutions

Transducer Resolution

Switch Setting Counts/Turn Bits/Turn

0128

1256

2512

31024

42048

54096

68192

7 16384

8 32768

9 65536

A 131072

B 262144

C 2097152

D 4194304

E 16777216

F 33554432

7

2

8

2

9

2

10

2

11

2

12

2

13

2

14

2

15

2

16

2

17

2

18

2

21

2

22

2

24

2

25

2

Publication 4100-UM052B-EN-P - October 2001

IMPORTANT

All Allen-Bradley 842A Encoders must have

Configuration Switch A set to E.

Page 39

Configuration Switch B

Transducer Turns, Data Format, & Operation Mode

Transducer Turns, Data Format, & Operation Mode

Switch Setting Turns Data Code Operation Mode

0SingleGreyLocked

1 Reserved for future use

2 Single Grey Free Run

3 Reserved for future use

4 Single Binary Locked

5 Reserved for future use

6 Single Binary Free Run

7 Reserved for future use

8 Multi Grey Locked

9 Reserved for future use

Setup 31

A Multi Grey Free Run

B Reserved for future use

C Multi Binary Locked

D Reserved for future use

E Multi Binary Free Run

F Reserved for future use

IMPORTANT

ATTENTION

All Allen-Bradley 842A Encoders set for grey output

must have Configuration Switch B set to 0. All

Allen-Bradley 842A Encoders set for binary output

must have Configuration Switch B set to 4.

The Compact and 1394 motion controllers must use the

LOCKED mode of operation.

!

Publication 4100-UM052B-EN-P - October 2001

Page 40

32 Setup

Powering the AEC

The AEC has reverse polarity protection. However, always take care to

observe correct polarity when you connect the power to your unit. If

power is connected with the wrong polarity, no damage is done. The

AEC simply does not function until the polarity is corrected. There is

no warning or indication of an incorrect polarity connection.

The AEC also has over current protection provided by a fuse on the

printed circuit board. The fuse is a 2 amp/250V, 5mm radial. A spare

fuse is located on the lower left portion of the printed circuit board

and is clearly marked “Spare Fuse”. If the fuse blows, always

determine and correct the reason it blew before installing the new

fuse.

ATTENTION

Never replace the fuse with the unit under power. When

replacing the fuse, make sur e it is of the proper rating.

!

AEC With GML Commander

IMPORTANT

The AEC can only be used with GML Commander version 4.01 or

higher. There are several steps that must be taken in GML Commander

before the AEC can be used within a GML Commander diagram. This

section outlines the necessary steps. For more detail about individual

steps, see the GML Commander Reference Manual (publication

number GMLC-5.2), the “Configuring Axis Use” chapter, “Defining

Feedback” section.

Before powering the AEC, make sure that it has been

properly installe d and configured according to the

instructions contained in this manual.

Adding AEC to your Commander Diagram

To add the AEC to your GML Commander diagrams go to GML

Commander and do the following:

1. Select the Configure menu option from the opening GML

Commander screen.

Publication 4100-UM052B-EN-P - October 2001

Page 41

2. Select Axis Use from the Configure pull-down menu.

3. Select the axis to configure for the AEC from the Axis Use

pull-down. The Configure Axis Use screen displays.

4. At the General screen, select the Axis Type.

5. Go to the Position Mode field select either rotary or linear.

6. Select the Feedback Tab from the Configure Axis Use screen.

7. Select AEC for the Transducer Type field.

8. Check the Transducer Loss Detection box.

Setting the Transducer Resolution

Setup 33

1. Enter the Transducer Resolution Conversion Constant.

2. Enter a value for the External Conversion Constant. (1394 series

only.)

3. Enter the value for the Unwind Constant (rotary axis only).

4. Enter the Unwind Reference (rotary axis only). This defines the

point where the Unwind returns at each cycle.

For more information about the above fields, see the GML

Commander Reference Manual (publication number GMLC-5.2).

Selecting Homing Procedure

The AEC only uses the Absolute Serial procedure for Homing the axis.

1. Select the Homing tab from the Configure Axis Use screen.

2. Select Absolute Serial from the pull down list of the Procedure

option box.

For more information on Homing procedures, refer to the GML

Commander Reference Manual (publication number GMLC-5.2), the

“Configuring Axis Use” chapter, “Defining Homing” section.

Publication 4100-UM052B-EN-P - October 2001

Page 42

34 Setup

ATTENTION

!

Aligning Absolute Encoder

Once the hardware is wired and the configuration steps have been

taken, it is important to align the Absolute Encoder. The alignment

process aligns the absolute device to the zero position of the axis, and

updates both the working and power-up home position values. It also

changes the Position setting in the Homing page of the Configure Axis

Use dialog box. This is done from the Hookups section of the

Configure Axis Use screen in GML Commander.

To align the devices:

1. Make sure all external components are connected.

When executing the Homing or Alignment procedure on

a servo axis, feedback is momentarily disabled and then

re-enabled (if the error checking fe atur es do not detect an

error) in the motion controller. If the axis has stored

energy or the ability to move during the time feedback is

disabled, you have to apply a breaking mechanism to the

axis before you execute the procedure.

2. Make sure All Configured Axis Use information is entered. (Refer

to previous steps in this chapter.)

3. Download the Configured Axis information.

4. Select the Hookups tab from the Configure Axis Use screen.

5. Click on the Align Absolute Device button.

6. In response to the Commander message box, move the axis to

its minimum travel position and click on OK.

7. The alignment procedure runs.

For more information about alignment, see the GML Commander

Reference Manual (publication number GMLC-5.2), the “Configuring

Axis Use” chapter, “Verifying Hookups” section.

Publication 4100-UM052B-EN-P - October 2001

Page 43

Operation

Chapter

4

Chapter Objectives

Absolute Position Update

This chapter provides an overview of how the AEC determines

position. This chapter covers the following topics:

•

Absolute Position Update

•

Incremental Position Output

•

Position at Start-up

Absolute position information can be requested from the transducer

via the AEC at any time. When the AEC interprets the strobe pulse

train to be an absolute update request from the controlling hardware,

it interrogates the transducer’s absolute position and incrementally

streams the position to the awaiting controller.

IMPORTANT

During an absolute position update, the quadrature

encoder output stream is always positive: A leads B. S ee

the Incremental Position Output section of this manual

for more details.

Incremental Position

Output

35 Publication 4100-UM052B-EN-P - October 2001

The AEC checks for the transducer position periodically. In the

Locked mode of operation, this process is triggered and synchronized

by the strobe input. In the Free-running mode of operation, the

th

position is sampled, calculated, and transmitted every 1/1000

second, based on the internal time of the AEC. The AEC compares the

newly sampled absolute position against the last. It calculates the

difference between the new and the old positions and transmits the

difference through the encoder port in an incremental fashion.

The position and direction information is encoded and sent using the

industry standard (A and B) channels in quadrature (90 degree

phasing). Each channel is driven differentially for improved noise

immunity. When moving in the positive direction, the phase of the

quadrature pulse train is A leading B. When moving in the negative

direction, the phase of the quadrature pulse train is B leading A. The

output frequency of both channels is fixed at 800kHz. One transducer

position count is represented by one edge transition (either positive or

negative) of the quadrature pulse train. This encoding scheme is

defined as 4X. Your position controller must support the 4X decode of

the AEC encoder output.

of a

Page 44

36 Operation

Position at Start-up

In locked mode, the AEC sends incremental position after receiving

incremental strobe pulses. The AEC, when configured for free-running

mode for controlling hardware other than the Compact or 1394, sends

the incremental position at start-up. In this mode, the AEC behaves

like an incremental encoder. Neither mode requires an absolute

update to begin transmitting positional information.

Publication 4100-UM052B-EN-P - October 2001

Page 45

Fault Indication & Control Status

Chapter

5

Chapter Objectives

This chapter covers the AEC operation status. Fault states are

separated into four basic categories:

•

Transducer

•

Encoder

•

Internal

•

No Fault

Faults can be attributed to:

•

Improper installation

•

Improper AEC switch configuration

•

Faulty hardware (i.e. broken cable)

•

Improper application

It is the responsibility of the user to make sure that the application is

safe. Understanding the capabilities of the AEC can help you achieve

this goal.

The AEC provides bicolor LED fault indication for each axis. The color

and pattern of these LEDs provide “at-a-glance” indication of the

status of each axis.

Although the AEC is equipped with a Reset button, it is not a

recommended form of fault resolution. If the non-offending axis is

running fine, pressing the reset button could result in a hazardous

situation.

ATTENTION

Pressing the Re set Button or Powering Off the AE C

results in both axes being reset. This can cause problems

if one axis is running in a no-faul t condition and either of

these procedures is followed to correct a fault on the

other axis.

!

37 Publication 4100-UM052B-EN-P - October 2001

Page 46

38 Fault Indication & Control Status

Transducer Faults

Transducer faults detected by the AEC are indicated by a flashing RED

LED for the offending axis. In a fault condition, the quadrature output

is inhibited and the fault relay is de-energized. The following table

displays a list of probable causes to investigate.

Transducer Faults

Transducer Faults and Causes

Fault Possible Cause

Configuration error Configuration switches are set to an

illegal combination.

SSI Line Break AEC detected loss of data signal. This is

the normal state for an unused SSI.

SSI Time-out Transducer position not received after

100ms.

Encoder Faults

Encoder faults are strobe cycle errors. The strobe is an input to the

AEC through the Encoder connector. When detected by the AEC, the

offending axis’s LED alternately flashes RED-GREEN. This causes the

quadrature output to default to free-running mode and the fault relay

is de-energized. The following table lists faults and possible causes

when Encoder faults are indicated.

Encoder Faults

Encoder Faults & Causes

Fault Possible Cause

Incremental Strobe Loss The AEC is in locked mode & stopped

receiving incremental strobe pulses.

Absolute Strobe Loss AEC did not receive the second

absolute strobe pulse in time.

Strobe Timing Violations Incremental or Absolute strobe

update timing has been violated.

In the case of an incremental strobe loss or move error, sending an

Absolute Home command may reset the fault.

Publication 4100-UM052B-EN-P - October 2001

Page 47

Fault Indication & Control Status 39

Internal Faults

Internal faults are internal hardware errors detected by the AEC. For

both axes, indication is solid RED, quadrature output is inhibited, and

the fault relay is de-energized. In the case of a Global Hardware fault,

where both LEDs are solid red, Call Allen-Bradley Technical Support.

No Faults

In this state, the AEC has detected no errors. The indication per axis is

either flashing or solid GREEN. FLASHING GREEN indicates that the

AEC has not yet detected a strobe. When configured for locked mode,

the AEC is waiting for either an absolute strobe cycle or incremental

strobe. When configured for free-running mode, the AEC is waiting

for an absolute strobe cycle. Regardless of the selected mode, the AEC

is operating in free-running mode. When the LEDs are SOLID GREEN,

the AEC has received a strobe and is operating in its program mode.

There is no fault action and the relay is energized.

Publication 4100-UM052B-EN-P - October 2001

Page 48

40 Fault Indication & Control Status

Publication 4100-UM052B-EN-P - October 2001

Page 49

AEC

Specifications

Appendix

A

Figure 13

AEC Front

Panel

Reset

Axis 0 Axis 1

AB

5

10

4

9

3

8

2

7

1

6

4

8

3

7

2

6

1

5

A

Axis 0

B

ConfigurationConfiguration

2

1

SSIControl

Figure A.1 shows the connector locations for the AEC. The following

tables provide the pin numbers and their respective descriptions.

SSI Connector

Plug A Plug B

10 = Clock + 5 = Clock -

9 = Data + 4 = Data -

8 = Shield 3 = Transducer Power +5V DC

7 = Transducer Power Return 2 = Transducer Power +15V DC

6 = Shield 1 = Transducer Power +24V DC

Control Connector

Plug A Plug B

8 = Reference + 4 = Reference -

7 = N/O Fault Relay Contact 3 = N/O Fault Relay Contact

6 = N/C Fault Relay Contact 2 = N/C Fault Relay Contact

5 = Shield 1 = Shield

Encoder Connector

Plug A Plug B

12 = Z - 6 = Z + (Blue)

11 = B - 5 = B + (Green)

10 = A - 4 = A + (White)

9 = Strobe - 3 = No Connection

8 = Reference Shield Input 2 = Strobe +

A

B

Axis 1

8

7

6

5

10

9

8

7

6

AB

Encoder EncoderPower

4

3

2

1

5

4

3

2

1

Switches Switches

SSI Control

7 = Reference - Input 1 = Reference + Input

AEC

41 Publication 4100-UM052B-EN-P - October 2001

Page 50

42 Specifications

Power Connector

2 = Supply +

1 = Supply -

Mechanical Specifications

Specification Description

Enclosure Type Steel case with integral mounting tabs

Enclosure Size 295 x 343 x 43 mm (11.6 x 13.5 x 1.7 in)

Environmental Specification

Specification Description

Operating Temperature 0 to 60 o C

o

Storage Temperature -40 to 85

C

Humidity 95% non condensing @ 60

Supported Devices

Manufacturer Model

Allen-Bradley All series 842A Encoders

Stegmann: AG661, AG626

Heidenhain: ROC424 & 417

BEI: MT40 Multi-Turn,

BEI RAS25 Single Turn

Temposonics III: Model PA and Model RH

IVO: GM 400, GM 401

o

C

Publication 4100-UM052B-EN-P - October 2001

Page 51

Specification Description

Number of Axes 2

Specifications 43

Module Specifications

Transducer Resolution

Counts/Turn

Number of Turns

Transducer Interface

Protocol

Acquisition Frequency

Data Format

Line Driver (Clock)

Line Receiver (Data)

Minimum Data Voltage

Maximum Rate of Position Change

(Delta Count)

Input

Isolation

Voltage Range

Power

Fuse

Transducer Output Power

Isolation

Voltage

Current

7

- 218 and 221 - 225

2

25

1 - 2

except 219, 220, 223

SSI

400 kHz

Binary or Gray Code

RS-422 (IC 26LS31)

RS-422 (IC 26LS33)

+/- 3.0V measured from Data+ to

DataMust be lesser of:

1/2 (Counts/Turn) per 1/1000

th

second

or

2048 counts per 1/1000

th

second

Chassis Common

18 to 36 V

21 Watts maximum

2 A/250V, 5mm Radial

Wickmann # 19372-057-K, ABLeb.#

515-038

Chassis Common

5, or 15, or 24V DC

300mA maximum

Fault Contact Outputs

Ty pe

Isolation

Coil-Contact

Open Contact

Rating

AC

DC

Encoder Ouputs

Channel Frequency

Driver Type

Strobe Inputs:

Type

Source Impedance

Maximum active Voltage

Minimum Inactive Voltage

NO/NC contact set per axis

1000V AC

750 V AC

AC/DC

125V AC @ 10mA - 0.6A

110V DC @ 10mA - 0.6A

30V DC @ 10mA - 2.0A

4X quadrature encoding

800kHz fixed (3.2 Meg cnts/sec)

RS-422 (IC26LS31)

Current Sourcing Active Low

10k Ohm

0.6V DC

2.2V DC

Publication 4100-UM052B-EN-P - October 2001

Page 52

44 Specifications

Equivalent Circuit Diagrams

Encoder

The following diagrams detail the equivalent circuits for the Strobe

Input, Transducer Data Input, the SSI Clock Output, and the Encoder

Output.

Figure 14 Strobe Input Equivalent Circuit

+5V DC

22 k

Strobe +

Strobe -

2

SN74F14

9

Figure 15 Transducer Data Input Equivalent Circuit

Data+

9

SSI 500* Ω

Data -

4

*Impedance includes loss detection circuit

Figure 16 SSI Clock Output Equivalent Circuit

DS26LS31CN

Clock

220 Ω

k Ω

kΩ

µ F

180pF

180pF

10

5

+

-

SSI

Data

Publication 4100-UM052B-EN-P - October 2001

Page 53

QUAD A

QUAD B

Figure 17 Encoder Output Equivalent Circuit

DS26LS31CN

DS26LS31CN

Encoder

10

5

10

Specifications 45

5

DS26LS31CN

Z

IMPORTANT

Do not wire to the Z signals. The Z channel is not

supported at this time. Allen-Bradley reser ves the right to

10

5

use this signal for futur e purposes.

Publication 4100-UM052B-EN-P - October 2001

Page 54

46 Specifications

Publication 4100-UM052B-EN-P - October 2001

Page 55

Appendix

B

Strobe Position For Applications Not Using the 1394 or Compact

Absolute Strobe Cycle

When the AEC is connected to controlling hardware other than the

1394 or Compact, the setup must be capable of generating Absolute

Strobe pulses as outlined in this appendix. An Absolute Strobe cycle

is required to obtain the absolute position from the transducer.

The absolute position is transmitted to the controller as a stream of

incremental quadrature pulses on the rising edge of an Absolute

Strobe pulse. The absolute position is transmitted in a two strobe

pulse train sequence. This lets the controller determine the position

of the controlled hardware.

The phase of the encoder output pulses for an absolute strobe is

always positive as defined by A leading B. The absolute position is

transmitted with a sequence of two encoder pulse streams. With the

first absolute strobe (Strobe 1), the lower 16 bits of the transducer

position is transmitted. On the second absolute strobe (Strobe 2), the

9 most significant bits of the transducer position is transmitted (9 bits

of actual data transmitted since only 25 bits are supported). After

completing an absolute update cycle, the position can be calculated

by summing the least significant count with the most significant count

multiplied by 65536 (2

counts which can be transmitted is 33554431

25

- 1).

(2

16

). The total maximum number of transducer

IMPORTANT

ATTENTION

!

47 Publication 4100-UM052B-EN-P - October 2001

Regardless of the n umber of transduc er bit s, two abso lute

strobe pulses must be sent to the AEC to complete an

absolute position update.

Issuing an Absolute Strobe causes the AEC to stream

position inf ormation from the transducer. During this

time, if servo action is enabled by the controlling

hardware, m otion can occur. Place your system in a safe

state and disable servo action before performing an

Absolute position update.

Page 56

48 Strobe Position For Applications Not Using the 1394 or Compact

Absolute Strobe Timing

This section defines the timing requirements for the two-strobe pulse

train required for absolute position updates. The AEC must receive

two strobe pulses to initiate and complete an absolute position update

transfer. These are referred to as Ts1 and Ts2 in the data transfer

protocol diagram. The following diagram and table outline the

parametric requirements for an absolute position update cycle.

Figure 18 Absolute Position Transfer Protocol

Absolute Position Transfer Timing

Parameter Locked Mode Free-Running Mode

Min Max Min Max

Tabs (absolute update cycle) = (Ts1s2 + Ts2 + Ts2hpe) 3001ms

Ts1 (Strobe1 active pulse width) 100ms 1000ms 100ms 1000ms

Ts2 (Strobe2 active pulse width) 5ms 1000ms 5ms 1000ms

Ts1s2 (time from Strobe1 inactive to strobe2 active) Ts1+Ts1hpe+2 2000ms Ts1+Ts1hpe+2 2000ms

Tph (time from Strobe1 inactive edge to encoder state hold) 30ms 30ms

Ts1hpe (time from Strobe1 inactive to end of encoder stream) 0 25ms 0 25ms

Ts2hpe (time from Strobe2 inactive to end of encoder stream) 0 1ms 0 1ms

Tpei (*time from MSW pulse train end to incremental updating) 0 indefinite N/A N/A

Thold N/A N/A 500ms 500ms

*Operation mode dependent: Locked or Free-Running

An absolute position request is an asynchronous event initiated by

the controlling hardware. The first strobe starts the absolute position

update cycle. The first strobe (Ts1) must be active for a minimum of

100ms, but for less than 1000ms to be valid. A strobe is sourcing

Publication 4100-UM052B-EN-P - October 2001

Page 57

Strobe Position For Applications Not Using the 1394 or Compact 49

input on the AEC. Internally the AEC, holds it high when inactive and

to activate, it must be connected and pulled low. Within 30ms (tph)

of the strobe going active, the encoder output A and B signals are

held at their current state (any incremental updating is prohibited).

On Ts1 going inactive, the lower 16 bits of the absolute position is

transmitted. Anywhere from 0 to 65535 counts can be transmitted. It

can take up to 25ms (Ts1hpe) to transmit the least significant word

(LSW) of the transducer position. After the LSW has been transmitted,

the second strobe (Ts1s2) is brought active.

When the second strobe goes inactive (ts2), it triggers the

transmission of the most significant word (MSW). Anywhere from 0 to

511 counts can be transmitted. This completes an absolute position

update cycle. Once the MSW has been sent(Tpei), the AEC begins

sending incremental changes (Free-Running) or the Encoder output

remains inactive as the AEC waits for an incremental strobe pulse

(Locked).

Incremental Strobe Period

Strobe

Quadrature

Pulse T rain

When using controlling hardware other than the 1394 or Compact, it is

recommended that you set the Configuration Switch B for Free Run

operation (see Chapter 3, Setup). In this mode position, changes from

th

the transducer are sent every 1/1000

second by the AEC via the

encoder port (see Chapter 4, Operation at Startup). If synchronization

of incremental position updates is required by your application, the

controller hardware must be capable of generating periodic strobe

pulses as described in this section. The following diagram and table

outline the parametric requirements for an incremental strobe period.

Figure 19 Incremental Strobe Period Protocol

Tinc

Ts1

Ts1s1

Ts1pe

Position Increment

Delta Counts

Publication 4100-UM052B-EN-P - October 2001

Page 58

50 Strobe Position For Applications Not Using the 1394 or Compact

Incremental Strobe Timing Period

Parameter Min Max

Tinc (Incremental strobe period = Ts1 + Ts1s1) 1ms 60ms

Ts1 (Strobe1 active pulse width) 0.005ms 10ms

Ts1s1 (Time from Strobe inactive to next active strobe) Ts1pe 30000 - Ts1

Ts1pe (Time from Strobe inactive edge to end of position increments) *Maximum Delta Count

* Position increment must not exceed the maximum Delta Count rate during Ts1s1.

The count rate is equal to the encoder channel frequency times four (4X encode).

The Strobe (Ts1) must be active for a minimum of 5µs, but less than

5ms to be a valid incremental strobe. When the strobe goes inactive,

the AEC interrogates the transducer position and sends any

incremental change from the previous sample. The time (Ts1pe) to

transmit the incremental position is dependent on the size of the

position increment. The position increment must not exceed the

maximum delta count allowed between consecutive incremental

strobe pulses (Tinc). The period (Tinc) of the strobe must be greater

than 1ms, but less than 10ms. This period is constrained by the

incremental strobe active time (Ts1) and the time to send the position

(Ts1pe).

Publication 4100-UM052B-EN-P - October 2001

Page 59

Index

A

Absolute Position Update,

Absolute Strobe Cycle,

Absolute Strobe Timing,

AEC Product Receiving and Storage Responsibility

Allen-Bradley Support

35

47

48

5

C

CE requirements,

Common Techniques Used in this Manual

Configuration

GML Commander

Adding to a Commander Diagram, 32

Aligning Absolute Encoder, 34

Selecting Homing Procedure, 33

Setting the Transducer Resolution, 33

Configuration Switch Tables

Connecting the AEC

to the 1394,

to the 1756-MO2AE,

to the Compact,

Contents of this Manua

12

4

30

16

19

17

3

D

Definitions

encoder,

transducer,

Description,

4

4

7

E

European Union Directives

EMC Directive,

12

F

Fault Indication

Encoder Faults,

Internal Faults,

No Faults,

Transducer Faults,

Features,

Fuse,

8

32

38

39

39

38

I

Incremental Position Output,

Incremental Strobe Period,

35

49

5

M

Mounting the AEC

next to a 1394,

next to a Compact,

14

15

P

Pin Functions

Control Connector,

Power Supply,

SSI Connector,

Pin Numbering

Control Connector,

Power Supply,

SSI Connector,

Position at Start-up,

Powering the AEC,

Purpose of this Manual

26

28

22

26

28

23

36

34

1

R

Read This Manual

Related Documentation

Rotary Switches

Setting,

Switch A,

Switch B,

1

3

29

30

31