Page 1

INSTRUCTION SHEET D2Ć3017Ć2

OUTPUT

F

or use with 300, 350, 400 and 500 HP

460 V

General Purpose or Variable Torque

CONT

ACTOR KIT

Models 36C47

AC, ThreeĆPhase Input

AĆC VLSR

Drives

WARNING

BEFORE INST

ALLING

AND/OR

OPERA

TING

THIS KIT, THE QUALIFIED ELECTRICAL

MAINTENANCE

PERSON WHO IS F

AMILIAR

WITH THIS TYPE OF EQUIPMENT AND THE

HAZARDS INVOLVED SHOULD READ THIS

ENTIRE INSTRUCTION SHEET. FAILURE

TO

OBSERVE THIS PRECAUTION COULD REĆ

SULT IN BODILY INJURY.

DESCRIPTION

The Reliance Electric Output Contactor Kit provides a

positive

AĆC VLSR Drive Controller and the Drive Motor. A

controller Start command will cause the contactor to be

energized.

the AĆC Contactor's auxiliary contact does not close (N"

auxiliary

the AĆC Contactor will drop out immediately if the

controller

speed is reached if the controller is set

will drop out after zero speed is reached if the controller is

set

(IET)

Upon

the

clean and dry area until ready to use. The ambient

temperature of the storage area must not exceed 65oC

(149oF) or go below -40oC (-40oF).

disconnect (contactor) between the output of the

The controller start sequence will be inhibited

signal). When the Stop rocker switch is pressed,

is set for coastĆtoĆrest or will drop

for rampĆtoĆrest. When an instantaneous electronic trip

occurs,

receiving, check the contents of the

contents as listed in Table 1. Store this equipment in a

the AĆC Contactor will drop out immediately

out after zero

for coastĆtoĆrest or

kit received with

if

INSTALLATION

NOTE:

mounted in a clean and dry environment. Maximum

ambient temperature must not exceed 40oC outside the

cabinet (55oC inside the cabinet).

WIRE SIZING NOTE: Care should be taken to see that all

interconnecting wiring is sized and installed in

All components of the Output Contactor Kit must be

conformance with the National Electric Code (NEC),

published by the National Fire Protection Association, or

the

Canadian Electrical Code (CEC),

local codes.

Table 1 Complete parts listing.

Description Qty. Part Number

Contactor

Auxiliary Contact (NO)

Connector

Control Transformer

Fuse Block

Fuse

Relay Socket

Relay

Cover

Wire Harness

Wire Harness

Wire Harness

Wire Assembly

Wire Assembly

Wire Assembly

Wire Assembly

Hex Washer Head Screw

.

ăă(5/16Ć18 x 1/2")

Hex Head Cap Screw

ăă(1/4Ć20 x 3/4")

Flat Washer (1/4")

Lock Washer (1/2")

Hex Head Cap Screw

ăă(1/2Ć13 x 1 1/4")

Flat Washer (1/2")

Lock Washer (1/2")

Taptite

Screw (10Ć32 x

Taptite Screw (8Ć32 x 1/2")

Taptite Screw (6Ć32 x 1/2")

Hex Head Cap Screw

ăă(1/4Ć20 x 1 1 /4")

Spacer

TyĆRap

1/2")

and other applicable

1

705310Ć9R

1

76624ĆX

3

610290Ć57A

1

417155ĆS

1

49454ĆA

1

64676Ć1P

1

600434Ć5R

1

600434Ć6R

1

705321Ć15R

1

705337Ć35R

1

801553Ć34R

1

801553Ć35R

1

608809Ć12SA

1

608809Ć12X

1

608809Ć12RX

1

608809Ć12SC

4

601741Ć73B

6

601741ĆC

8

601748Ć1E

8

601748Ć3J

3

601741Ć8AB

3

601748Ć1J

3

601748Ć3N

5

601741Ć63C

2

601741Ć62D

2

601741Ć61D

2

601741ĆAB

2

400684ĆB

10

69306Ć3D

Page 2

1. Disconnect all power to the AĆC VLS Drive before

installing this kit.

DANGER

EQUIPMENT IS AT LINE VOLTAGE WHEN

INPUT DISCONNECT IS ON. THE

THE

INPUT

DISCONNECT MUST BE OFF BEFORE IT IS

TO TOUCH ANY INTERNAL P

SAFE

ARTS

OF

THIS EQUIPMENT. AFTER POWER IS

REMOVED, THE COMMUTATION CAPACIĆ

TORS CAN REMAIN CHARGED. ALLOW

TWO MINUTES BEFORE TOUCHING ANY

INTERNAL PARTS OF THE CONTROLLER.

FAILURE TO OBSERVE THESE PRECAUĆ

TIONS COULD RESULT IN FATAL INJURY.

NOTE: If the Output Contactor Kit and the Control Circuit

Transformer Kit are to be installed, mount the Output

Contactor

Kit normally occupies the same location as the Output

Contactor Kit. The Control Circuit Transformer

relocated as defined in Instruction Sheet D2Ć3014.

2. Disconnect

Kit first because the

Control Circuit T

ransformer

Kit must be

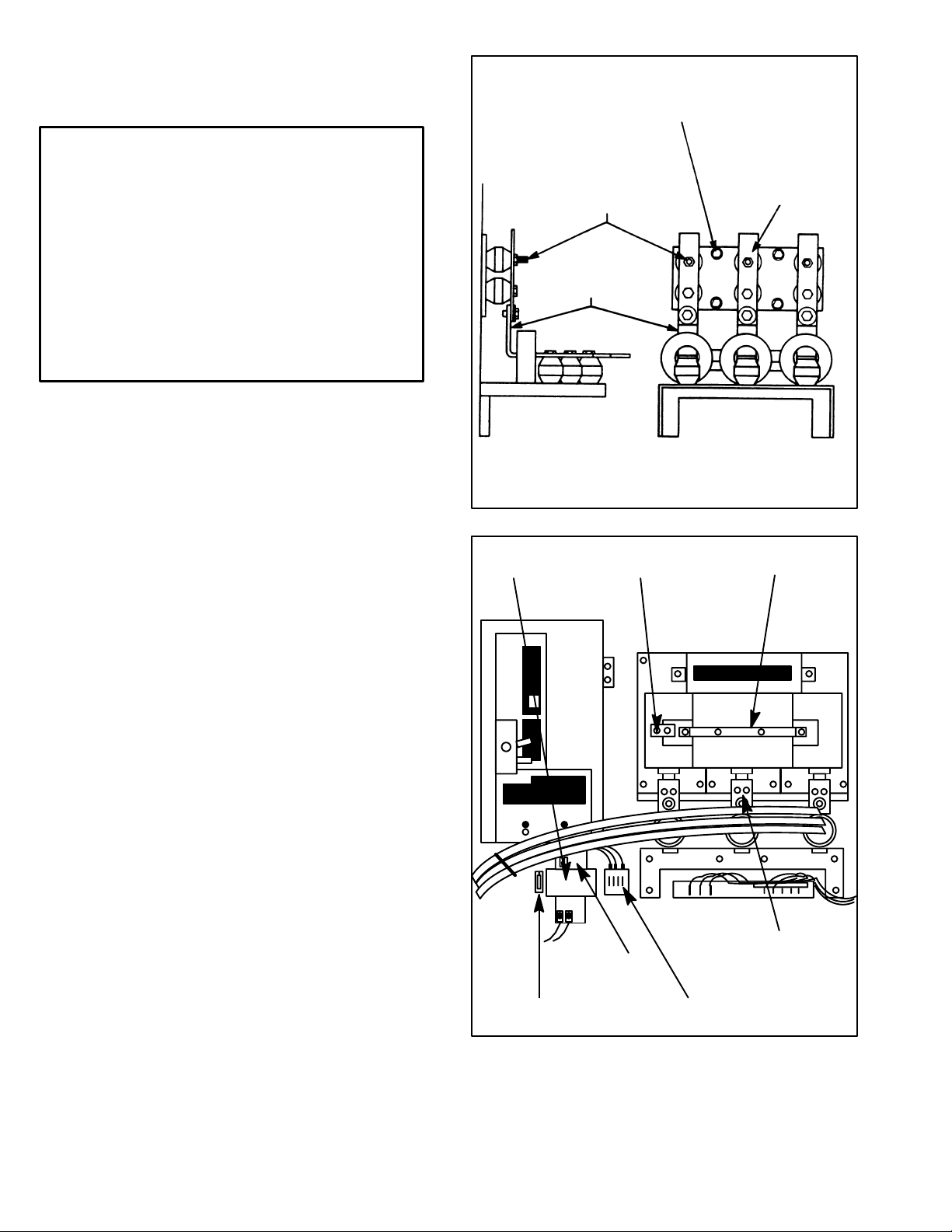

motor leads T1, T2 and T3 from the output

bus bar assembly (Figure 1). Disconnect bus bars

601, 602 and 603 from the output bus bar assembly

(Figure 1). Remove the output bus bar assembly by

removing the four taptite screws. This assembly will

not

be used while the Output Contactor

Kit is installed.

TAPTITE

SCREW (4)

DISCONNECT MOTOR

LEADS T1, T2, T3

BUS BARS

601, 602, 603

SIDE VIEW

OUTPUT

FRONT VIEW

BUS BAR

ASSEMBLY

Figure 1. Removing output bus bar assembly.

CONTROL

TRANSFORMER

AUXILIARY

CONTACT

CONTACTOR

3.

Snap the Auxiliary Contact (76624Ć

X) into the cavity on

the front left of the Contactor (Figure 2). Secure with

the captive lock screw provided.

4. Using the four furnished 5/16Ć18 x 1/2" hex washer

head

screws, mount

the Contactor (705310Ć9R) in the

controller as shown in Figure 2. The mounting holes

are preĆdrilled in the back panel.

5. Using the six furnished 1/4Ć20 x 3/4" hex head cap

screws and six 1/4" flat washers and 1/4" lock

washers, install the three identical Connectors

(610290Ć57A) to the line side of the Contactor. See

Figure 2.

6. Using

the three furnished 1/2Ć13 x

1 1/4" hex head cap

screws and the three 1/2" flat washers and 1/2" lock

washers, attach the Connectors to the 601, 602 and

603 bus bars.

7. Using

four of the furnished 10Ć32 x 1/2" taptite screws,

mount the Control Transformer (417155ĆS) to the left

of

the motor overload relay block as shown in Figure 2.

The

mounting holes are preĆdrilled in

the back panel.

(It might be helpful to preĆthread the screws in the

mounting holes.)

8. connect the metal jumper supplied with the

transformer

H2)

on the input side of the transformer

between the two center

terminals (H

. See Figure

3

and

2.

CONNECTOR (3)

METAL

JUMPER

FUSE

IN FUSE BL

OCK

MOTOR OVERL

RELA

Y BL

OCK

Figure 2. Controller right bay components.

OAD

Page 3

ă9. Using the two furnished 8Ć32 x 1/2" taptite screws,

mount the Fuse Block (49454ĆA) to the left of the

Control Transformer. See Figure 2. The mounting

holes are preĆdrilled in the back panel. Insert the 3.2

F

use (64676Ć1P), 250Ćvolt, UL Class RK5) into the

amp

Fuse Block.

115

VOL

T

TERMINAL B

RELA

RELA

OARD

Y IN

Y SOCKET

OUTLET AIR

DUCT REMOVED

SIDE W

OPENINGS

ALL

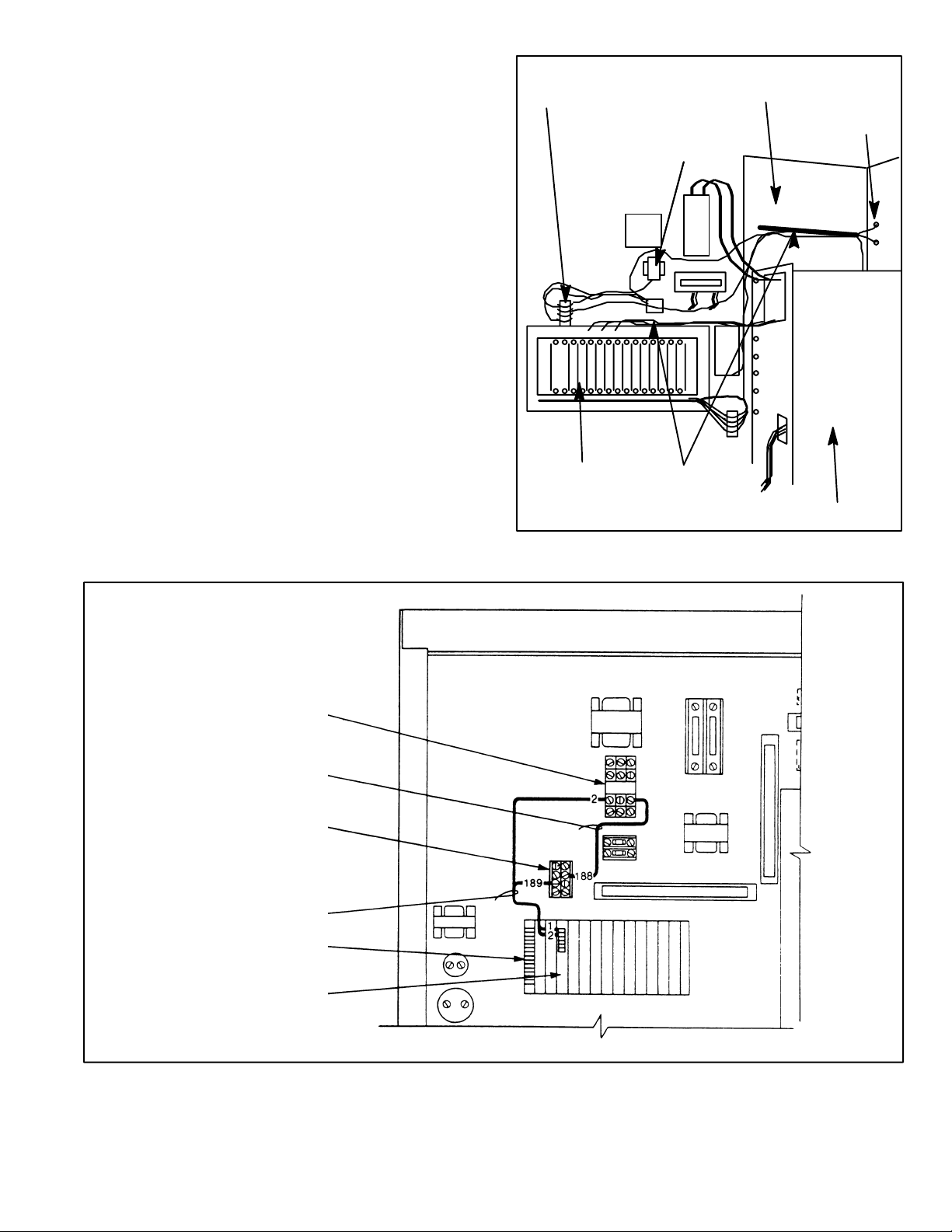

10. Using

two

furnished 6Ć32 x 1/2" taptite screws, mount

the Relay Socket (600434Ć5R) in the left bay of the

controller as shown in Figure 3. The mounting holes

are preĆdrilled in the back panel. Insert the Relay

(600434Ć6R) into the Relay Socket.

11. Remove

the outlet air duct (Figure 3) by loosening the

nine hex head cap screws. Set aside for later

reĆinstallation.

12. Remove

the factory

Ćinstalled wiring between

terminals

43 and 53 on TB1 and terminals 1 and 2 on the

faceplate of the CSS-* card. See Figure 4.

13. Connect Wire Harness 705337Ć35R. Connect leads

189 and 2 to terminals 1 and 2, respectively, on the

faceplate

of the CSS- card. Connect the other end of

lead 189 to the 115Ćvolt terminal board and the other

end

of the lead 2 to the Relay

* The

fourth letter of this regulator PC board designation indicates a difference in the PC board.

Refer to the specific controller to identify the fourĆletter PC board designation.

. See Figures 3, 4 and 7.

CS

S -*CARD

FACEPLATE

CHANNELS

POWER MODULE

Figure 3. Controller left bay components.

RELAY

WIRE

AS

SEMBLY

608809Ć12SA

115 VOL

TERMINAL

WIRE HARNES

705337Ć35R

CSS-*CARD

FACEPLATE

* The fourth letter of this regulator PC board designation indicates a difference in the PC board. Refer to the specific controller to identify the fourĆletter PC board designation .

T

BOARD

S

TB1

Figure 4. Connecting Wire Harness 705337Ć35R and Wire Assembly 608809Ć12SA.

14. Connect Wire Assembly 608809Ć12SA (labeled 188)

between the 115Ćvolt terminal board and the Relay.

See Figures 4 and 7.

15. Connect Wire Assembly 608809Ć12X (the green

ground wire labeled 289) to the Control Transformer.

Using the remaining 10Ć32 x 1/2" taptite screw,

Page 4

connect the other end to the hole preĆdrilled in the

back panel below the Control Transformer. See

Figures 2, 5 and 7.

16. Connect Wire Assembly 608809Ć12RX (labeled 288)

between the Fuse and the Control Transformer. See

figures 2, 5 and 7.

17. Connect Wire Assembly 608809Ć12SC between

terminals 1 and 3 on the Contactor terminal board.

See Figure 5.

18. Referring

to Figures 6 and 7 and T

able

2, connect W

ire

Harness 801553Ć34R beginning in the left bay of the

controller. Route the harness thru the back channel

located above the power module, thru the bottom

opening at the top of the side wall, thru the back

vertical channel to the respective connection points.

Note that leads 11 and 289 will route thru the back

channel located above the Control Transformer.

Harness

Lead

Numbers

(both ends)

388

ă11

381

383

289

Control T

Control T

Control T

From To

Fuse

Relay

ransformer H

ransformer H

ransformer X

1

4

2

Relay

L1 on Contactor

T

ransformer Line F

T

ransformer Line F

L2 on Contactor

use

use

19. Referring to Figures 6 and 7, connect Wire Harness

801553Ć35R to the Auxiliary Contact installed in Step

3. Route the harness in the

front channel (outermost)

located above the Control Transformer, up the front

vertical channel,

thru the top opening at the top of the

side wall, thru the front channel located above the

power module, down the front vertical channel, thru

the

horizontal channel located above the regulator

, to

terminals 43 and 53 on TB1 of the regulator.

20. Support the wire harnesses and assemblies as

necessary with the furnished tyĆraps.

CONTROL

TRANSFORMER

FUSE

WIRE

AS

SEMBLY

608809Ć12RX

WIRE AS

SEMBLY

608809Ć12X

WIRE AS

608809Ć12SC

CONTACTOR

SEMBLY

Figure 5. Connecting Wire Assemblies 608809Ć12X, Ć12RX and Ć12SC.

Page 5

21.

Replace the outlet air duct over the nine loosened

head

cap screws making sure all wiring is clear of

hex

the

duct. Tighten the screws.

22. Using the hardware supplied with the Contactor,

reconnect

motor leads T1, T2 and T3 to terminals 1T1,

1T2, and 1T3, respectively, on the load side of the

Contactor.

23. Using the two supplied spacers, the two 1/4Ć20 x 1

1/4"

hex head cap screws, and the two remaining 1/4"

flat washers and 1/4" lock washers; install the Cover

(705321Ć15R) on the Contactor.

24. ReĆapply power the AĆC VLS Drive.

WIRE HARNES

801553Ć35R

S

CONTACTOR

WIRE

HARNES

801553Ć34R

TB1

REGULATOR

RELAY

Figure 6. Connecting Wire Harnesses 801553Ć34R and Ć35R.

S

FUSE

TRANSFORMER

CONTROL

AUXILIARY

CONTACT

Page 6

TO

TB1

REGULATOR

TO 115Ć

VOLT

TERMINAL

BOARD

TO

TRANSFORMER

LINE

FUSES

* The fourth letter of this regulator PC board designation indicates a difference in the PC board. Refer to the specific controller to identify the fourĆletter PC board designation .

Figure 7. Electrical diagram.

Page 7

Page 8

U.S. Drives Technical Support

Tel: (1) 262.512.8176, Fax: (1) 262.512.2222, Email: support@drives.ra.rockwell.com, Online: www.ab.com/support/abdrives

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication D2-3017-2 – July 1990 Copyright © 1990 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.

Loading...

Loading...