Page 1

INSTRUCTION SHEET

DĆ3894Ć1

Dynamic Braking Kit

Model 34C473

For use with 5, 7Ć1/2 and 10 HP

General Purpose AĆC VKSR Drives

ThreeĆPhase Input

Before installing and/or adjusting this kit, the quali

fied electrical maintenance person who is familiar

with

this type of equipment and the hazards involved

should read this entire instruction sheet.

DESCRIPTION

The Reliance Electric Dynamic Braking (DB) Kit is deĆ

signed

and/or

to provide rapid

enable the AĆC V

150% intermittent braking to the motor. The kit dissiĆ

in the form of heat, the power regenerated by the

pates,

motor during deceleration or intermittent overhauling

The power is dissipated by resistors mounted in

loads.

the NEMA 1 side (right side) of the AĆC VKS Drive Con

cabinet.

troller

This kit also provides adjustable motoring and regenĆ

erative current limit circuitry. The adjustment range of

the motoring current control is approximately 40 to

of the drive controller fullĆload current (not of the

150%

motor

fullĆload current rating). The adjustment range of

the

regeneration current control is approximately 80 to

150% of the drive controller fullload current (not of the

motor fullĆload current rating). The use of this kit does

not affect the operation of the drive's instantaneous

electronic

trip current protection.

deceleration of the drive motor

KSR

Drive Controller to provide

Ć

The following are design specifications for this kit:

DB Resistor rating: 500 watts

2

WR

=

3: 6 starts/stops per minute from 1800 RPM

2

WR

=

6: 3 starts/stops per minute from 1800 RPM

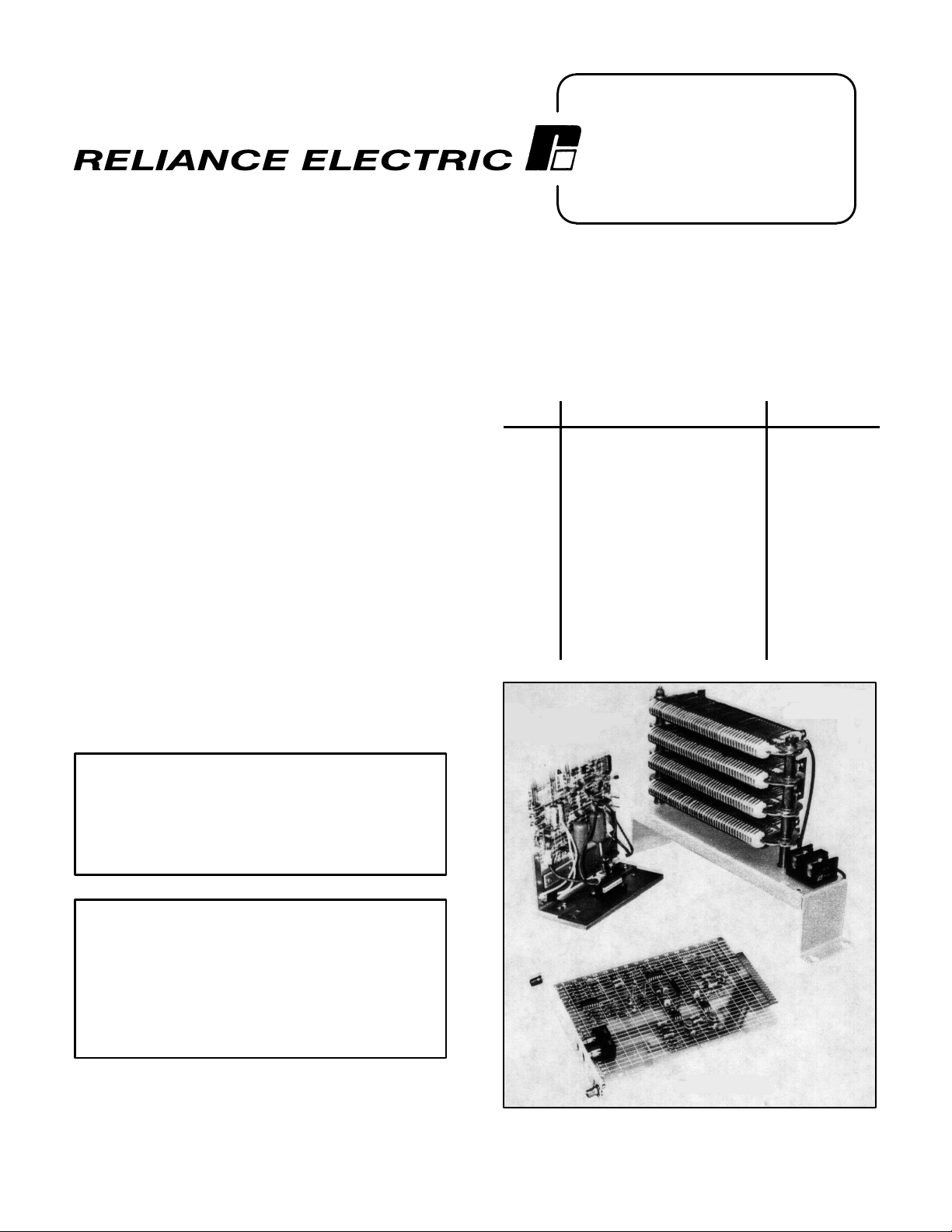

KIT CONTENTS

Qty. Description Part

1

DB

Resistor Assembly

DB Base Driver Assembly

1

W

1

1

1

Ć

2

2

4

2

2

ire Harness

W

ire Harness

W

ire Harness

Gasket

eps Nut

K

#10Ć32 x 3/8 T

#10 Internal T

Lock W

asher

aptite Screw

ooth

#10Ć32 x 3/8 Round Head

Machine Screw

CLSA Board

1

DB BASE DRIVER

ASSEMBLY

Number

801450Ć3R

77596Ć88R

705337Ć21R

608808Ć63TD

608808Ć63TC

417194Ć12C

401599Ć11E

601741Ć63B

601748Ć4J

601742Ć6E

0Ć52862

DB RESISTOR

ASSEMBLY

CAUTION:

set

below a particular motor's

Should the regenerative

minimum current lev

current limit be

el, the regenerative current limit circuitry may proĆ

the motor

hibit

from decelerating. Reset the regen

erative current limit as described under ADJUSTĆ

MENTS"

CAUTION: DO

DB

bly

age

ate

in this instruction sheet.

NOT

operate the controller with

Resistor Assembly and DB

Base Driver Assem

the

connected and the CLSA Board removed. Dam

to equipment will occur

. If it is desired to oper

the controller without dynamic braking, removal

of the threeĆpin plug (wire harness 608808Ć63TD)

from the DB Base Driver Assembly PC Board will

disable

The

diode

ing

At

high rates of deceleration, the LED will appear to be

ON

this kit.

DB Base Driver PC Board includes a light emitting

(LED) that indicates dynamic braking action. Dur

normal deceleration, the LED will cycle ON and OFF

continuously

.

Ć

Ć

Ć

Ć

Ć

CLSA BOARD

Ć

.

Figure 1. Kit contents.

Page 2

INSTALLATION

1. Disconnect

ler.

EQUIPMENT IS AT LINE VOLTAGE WHEN AĆC

POWER IS CONNECTED TO THE AĆC VKS

DRIVE CONTROLLER. ALL UNGROUNDED

CONDUCTORS

BE

DISCONNECTED FROM THE

BEFORE IT IS SAFE TO TOUCH ANY INTERNAL

PARTS

REMOVED, USE A VOLTMETER TO VERIFY

THAT THE DĆC BUS FILTER CAPACITORS ARE

DISCHARGED BEFORE TOUCHING ANY INĆ

TERNAL

all power to the AĆC VKS Drive Control

DANGER

OF THE AĆC POWER LINE

CONTROLLER

OF

THIS EQUIPMENT

P

ARTS OF THE CONTROLLER.

. AF

TER POWER IS

MUST

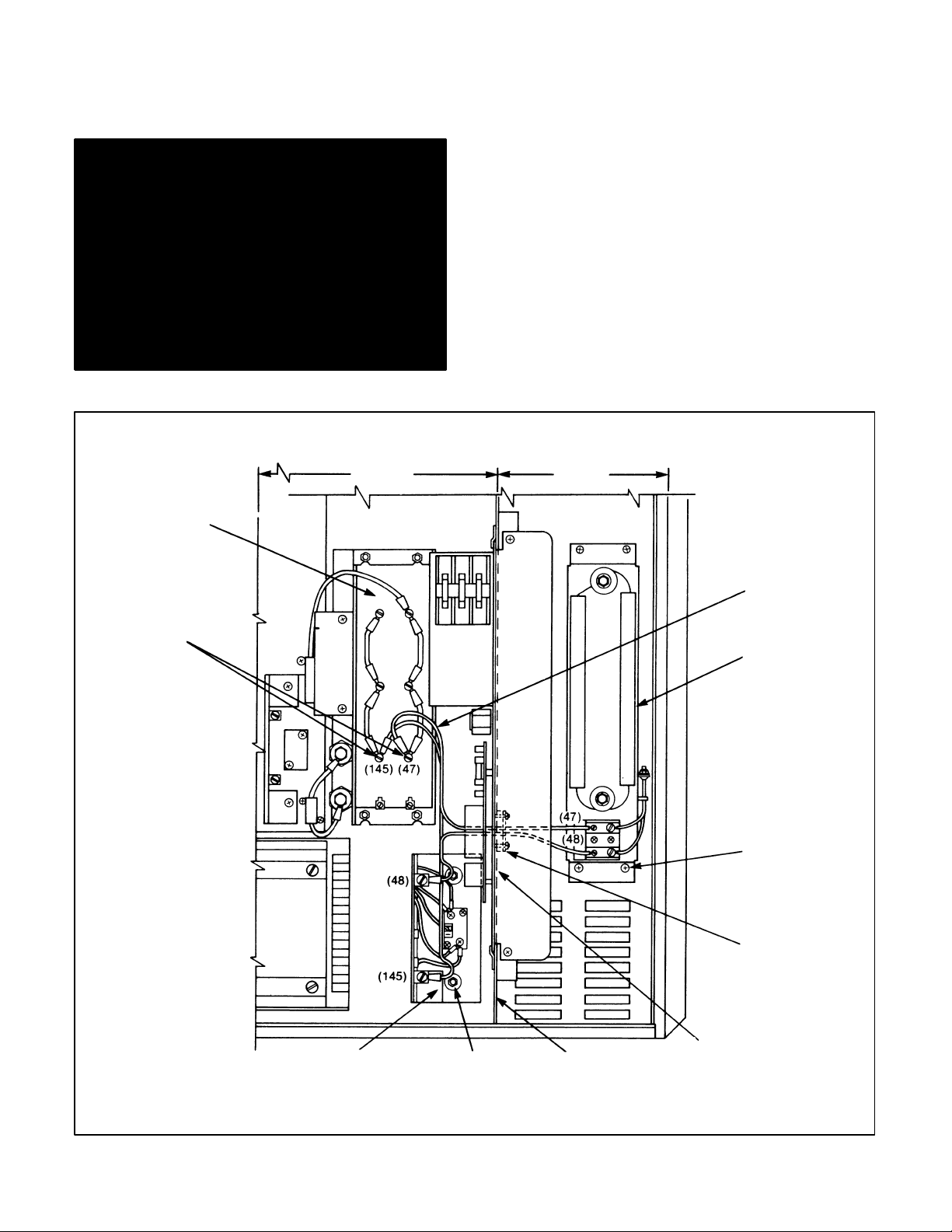

2. Using an 11/32'' wrench, remove the lower cover

plate and gasket from the vertical barrier on the

1 side (Figure 2). Discard the gasket.

Ć

NEMA

NOTE: This cover plate and gasket are behind the

Variable

oltage D

ĆC Supply (S

Ć3 Assembly). At the

V

user's discretion, the Variable Voltage DĆC Supply

can be removed to gain access to this area.

3. Install

over the studs on the vertical barrier the two

supplied gaskets (part 417194Ć12C).

4. ReĆinstall

the cover

plate with hardware removed in

Step 2.

5. Install the nonĆlugged ends of wire harness pair)

705337Ć21R (the only harness not of twisted pair)

thru the gasket and cover plate from the NEMA 12

side

(left side) by pushing lead 47 thru the top hole

in the gasket and lead 48 thru the bottom hole.

two leads will be connected later in this pro

These

Ć

cedure.

CAPACITOR

COVER REMOVED

CAPACITOR

TERMINALS

NEMA 12

NEMA 1

WIRE HARNESS

705337Ć21R

DB RESISTOR

ASSEMBLY

TAPTITE

SCREW

DB BASE DRIVER

Figure 2. Initial installation details.

ASSEMBLY

STUD WITH

KEPS NUT

VERTICAL

BARRIER

COVER PLATE

AND GASKET

VARIABLE

VOLTAGE

DĆC SUPPLY

Page 3

6. Remove

itor

the filter capacitor cover and locate

capac

terminals 145 (bottom left) and 47 (bottom right)

(Figure 2).

7. Remove the #10 screws from capacitor terminals

and 47. Connect leads 145 and 47

145

of wire har

ness part 705337Ć21R to capacitor terminals 145

and

47, respectively

8.

ReĆinstall the filter capacitor cover

. Reinstall the #10 screws.

.

9. Locate the four preĆdrilled holes in the back of the

1 side (right side)

NEMA

of the enclosure. Start the

four supplied #10Ć32 x 3/8'' taptite screws into

holes but do not tighten fully (Figure 2).

these

10. Position the keyhole slots of the DB Resistor AsĆ

sembly (part 801450Ć3R) over the taptite screws.

Tighten

11. Connect

er

nals

sembly

12. Connect

all four screws.

the leads pushed thru the gasket and

plate in Step 5. Connect leads

47 and

48, respectively

47 and 48 to termi

, on the DB Resistor As

(Figure 2).

one end of wire harness part 60880863T

cov

(the single orange and black twisted pair) to the

SNUBBER

ON" connections on

the regulator mo

therboard (Figure 3). Polarity is Important. The

orange

lead connects to the plus (+)

and the black

Ć

lead

connects

to the minus (-). Let the other end of

the harness rest along the enclosure floor unconĆ

nected

13. Locate

Ć

side (left side) of the enclosure (Figure 2). W

until connection later in this procedure.

the studs in

the lower back of the NEMA 12

ith the

PC board on the left, position the Base Driver AsĆ

sembly

provided

bly

(part 77596Ć88R) over the studs. Using the

keps nuts,

install the Base Driver Assem

on the studs.

Ć

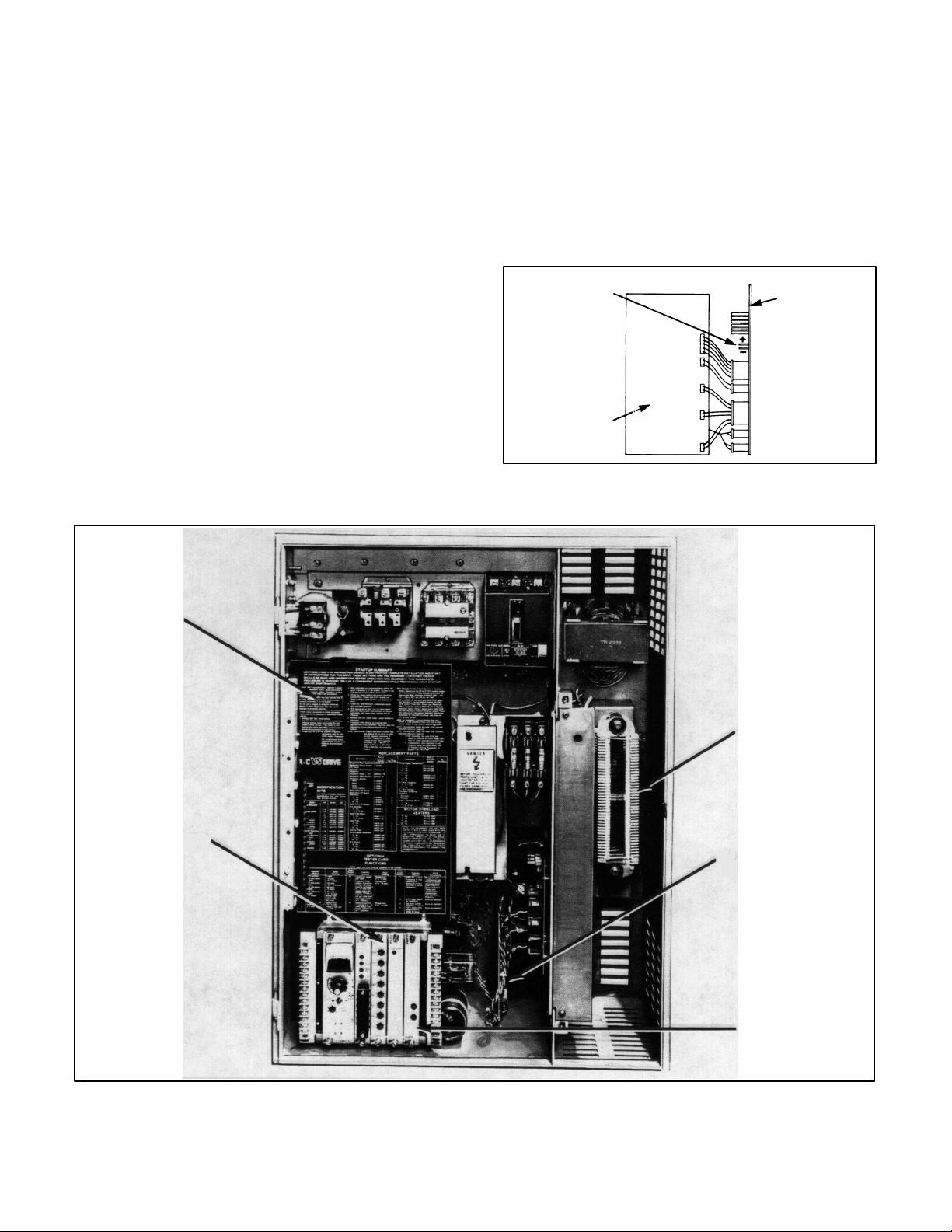

14. Remove the phase module cover (Figure 4).

Connect

SNUBBER ON"

CONNECTION

one end of wire harness part 608808Ć63TD

MOTHERBOARD

(+) ORANGE

(-) BLACK

Ć

Ć

Ć

C

Ć

PSPC BOARD ON

RIGHT SIDE OF

REGULATOR

Figure 3. Location of SNUBBER ON" connections

on motherboard.

PHASE

MODULE

COVER

VSAA BOARD

DB RESISTOR

ASSEMBLY

DB BASE DRIVER

ASSEMBLY

CLSA BOARD

Figure 4. Dynamic Braking Kit installed.

Page 4

to the top set of three pins on the lower right Base

PC Board. Connect the other end

Driver

ness

to the top set of three pins on the DB Base

Assembly PC Board (Figure 5).

er

plugs

is not important.

ule cover

15.

Connect the end of wire harness 608808Ć63T

unconnected

Base

.

in Step 12 to the pair of pins on the DB

Driver Assembly PC Board (Figure 5).

ReĆinstall the phase mod

Polarity

of the har

Driv

of these

C left

Install

the plug with the orange wire aligning with the

top pin.

16. Connect the end of wire harness 705337Ć21R left

unconnected in Step 5 to the DB Base Driver AsĆ

sembly

PC Board. Using the

supplied internal tooth

lock washers and #10Ć32 x 3/8 round head maĆ

chine screws, connect leads 48 and 145 to termiĆ

nals 48 and 145, respectively (Figure 5).

NOTE: If the Variable Voltage DĆC Supply was reĆ

moved

LOWER RIGHT

BASE DRIVER

PC BOARD

in Step 2, it must be reĆinstalled

at this time.

Ć

Ć

Ć

CAUTION: The DB Resistor Assembly and DB

Base Driver Assembly are now installed. DO NOT

operate

0Ć52862)

namic

harness

the controller

installed. If it is desired to disable the

Braking Kit, remove the threeĆpin plug

608808Ć63TD) from the DB Base Driver

without the CLSA Board (part

Dy

(wire

As

Ć

Ć

sembly PC Board (installed in Step

17. Install

the CLSA Board in the far right slot of the reg

ulator

(Figure 4).

Ć

18. ReĆapply power to the AĆC VKS Drive. The LED on

DB Base Driver Assembly PC

the

Board should be

off. If the LED is on, check the wire harness

608808Ć63TC connections between the motherĆ

board

and the DB Base Driver

Assembly PC Board.

TOP SET OF

3 PINS

BOTTOM SET

OF 3 PINS

WIRE HARNESS

608808Ć63TC

BOTTOM SET

OF 3 PINS

WIRE HARNESS

608808Ć63TD

(POLARITY NOT

IMPORTANT)

WIRE HARNESS

705337Ć21 R

48

DB BASE DRIVER

ASSEMBLY

145

Figure 5. DB Base Driver Assembly Installation details.

Page 5

ADJUSTMENTS

DANGER

ADJUSTMENTS ARE MADE WITH POWER ON.

EXERCISE EXTREME CAUTION WHEN PERĆ

FORMING THESE ADJUSTMENTS AS HAZĆ

ARDOUS VOLTAGE EXISTS.

the acceleration rate

5. If

the Accel Rate potentiometer on the VSAA Board

about 1/4th turn counterclockwise and check the

acceleration according to Step 3. Continue to reĆ

peat this procedure until the desired acceleration

is reached.

rate

Setting the Regen Current Limit

of the motor is too fast, adjust

Dynamic

able.

of

motoring and regenerative current.

1. Adjust

2. Adjust

Setting the Motoring Current Limit

3. Turn

4. If the acceleration rate of the motor is not fast

braking action is automatic and is not

Current limit controls are provided for adjustment

both the Motoring

gen Current Limit potentiometers on the CLSA

Board

to the approximate

o'clock

tentiometers on the VSAA Board fully clockwise

(max

ator's Control Station fully clockwise (max speed)

and

eration

rent Limit is adjusted properly. If the acceleration

rate

to Step 5.

enough,

motor to stop. Adjust the Motoring Current Limit

1/8th turn clockwise and, with the Speed Setting

potentiometer still at maximum speed, press the

Start rocker switch. Continue to repeat this proceĆ

dure

NOTE:

and

been turned too far clockwise. (The Motoring CurĆ

rent

ic Trip [IET] current setting of the controller.) Reset

the drive by depressing the Stop rocker switch on

the

ing Current Limit a little counterclockwise and reĆ

peat the procedure described in Step 3.

position).

both the Accel Rate and the Decel Rate po

rate) (Figure 4).

the Speed Setting potentiometer on the Oper

press

the Start rocker switch. If the rate of accel

of the

motor is as desired, the Motoring Cur

is not fast enough, go to Step 4; if too fast, go

press the Stop rocker switch and allow the

until the desired acceleration

If a point is reached where the drive shuts off

coasts to a stop, the Motoring Current Limit

Limit

has exceeded the Instantaneous Electron

Operator's Control Station. Then turn the Motor

Current Limit and the Re

center of their ranges (12

rate is reached.

adjust

has

CAUTION:

set

Ć

Ć

Ć

Ć

Ć

Ć

Ć

Ć

below a particular motor's

el, the regenerative current limit circuitry may proĆ

hibit

erative

6. Set

tor's Control Station fully clockwise (max speed)

and

turn the Speed Setting potentiometer fully

clockwise

the

adjusted correctly. If the deceleration rate is too

long,

NOTE:

tended

controller to provide long deceleration times.

7. If the deceleration rate of the motor is too long, inĆ

crease the Regen Current Limit adjustment 1/8th

turn

in

Step 6. Continue this procedure until the

deceleration

NOTE:

and coasts to a stop, the Regen Current Limit has

been

Limit has exceeded the Instantaneous Electronic

Trip

drive by depressing the Stop rocker switch on the

Operator's Control Station. Then turn the Regen

Current Limit a little counterclockwise and repeat

the procedure described in Step 6.

8. If

the deceleration rate

just

about

celeration according to Step 6. Continue to repeat

this procedure until the desired deceleration is

reached.

Should the regenerative

the motor

current limit as described below

the Speed Setting potentiometer on the Opera

run the drive at maximum speed. Then quickly

motor is as desired, the Regen Current Limit

go to Step 7; if too short, go to Step 8.

clockwise and repeat the procedure

turned too far clockwise.

[IET] current setting of the controller

the Decel Rate potentiometer on the

from decelerating. Reset the regen

(min speed). If the rate of deceleration of

The Regen Current Limit adjustment is not in

to replace the Decel Rate adjustment on the

time is reached.

If a point is reached where the drive shuts off

of the motor is too short, ad

1/4 turn counterclockwise and check the de

current limit be

minimum current lev

.

counter

described

desired

(The Regen Current

.) Reset the

controller

Ć

Ć

Ć

Ć

is

Ć

Ć

Ć

Page 6

DB THRESHOLD

VSAA PIN 35

VSAA PIN 12

VSAA PIN 41

CURRENT

SHUNT

COMPARATOR

WITH

HYSTERESIS

JAM VOLTAGE

CONTROL

DB SIGNAL TO

SNUBBER BASE

DRIVER SWITCH

LVTU JAM

VSAA PIN 42

LVTU CLAMP

VSAA PIN 43

PSPC ISOLATED

POWER FOR

CURRENT LIMIT

Figure 6. Functional block diagram.

CLSA B/M 0Ć52862

Page 7

Page 8

U.S. Drives Technical Support

Tel: (1) 262.512.8176, Fax: (1) 262.512.2222, Email: support@drives.ra.rockwell.com, Online: www.ab.com/support/abdrives

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication D-3894-1 – 1992 Copyright © 1992 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.

Loading...

Loading...