Page 1

LonWorks

Communication Option Module

for VTAC 7 Drives

M/N 2LW3000

Instruction Manual

D2-3498

Page 2

The information in this manual is subject to change without notice.

Trademarks not belonging to Rockwell Automation are

property of their respective companies.

Throughout this manual, the following notes are used to alert you to safety considerations:

ATTENTION:Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss.

!

Important: Identifies information that is critical for successful application and understanding of the product.

The thick black bar shown on the outside margin of this page will be used throughout this instruction manual to

signify new or revised text or figures.

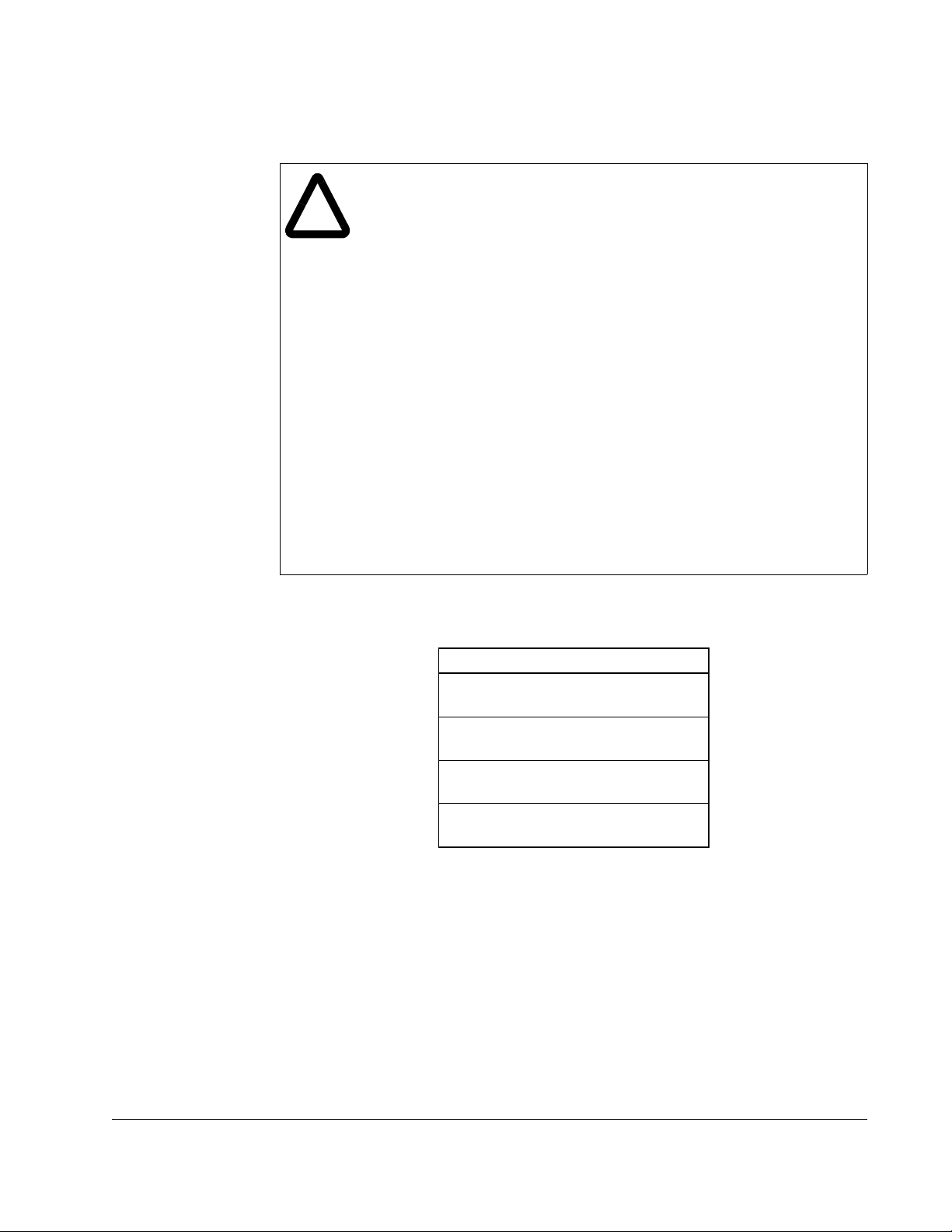

ATTENTION:Only qualified electrical personnel familiar with the construction and operation of

this equipment and the hazards involved should install, adjust, operate, or service this equipment.

!

Read and understand this manual and other applicable manuals in their entirety before

proceeding. Failure to observe this precaution could result in severe bodily injury or loss of life.

ATTENTION:Do not install modification boards with power applied to the drive. Disconnect and

lock out incoming power before attempting such installation. Failure to observe this precaution

could result in severe bodily injury or loss of life.

ATTENTION:DC bus capacitors retain hazardous voltages after input power has been

disconnected. After disconnecting input power, wait five minutes for the DC bus capacitors to

discharge and then check the voltage with a voltmeter to ensure the DC bus capacitors are

discharged before touching any internal components. Failure to observe this precaution could

result in severe bodily injury or loss of life.

ATTENTION:The user is responsible for conforming with all applicable local, national, and

international codes. Failure to observe this precaution could result in damage to, or destruction

of, the equipment.

ATTENTION:The drive contains ESD- (Electrostatic Discharge) sensitive parts and assemblies.

Static control precautions are required when installing, testing, servicing, or repairing the drive.

Erratic machine operation and damage to, or destruction of, equipment can result if this procedure

is not followed. Failure to observe this precaution can result in bodily injury.

AnyBus is a trademark of HMS.

LonWorks, and LonMaker are trademarks of Echelon Corporation.

Windows is a trademark of Microsoft Corporation.

VT AC 7 is a trademark of Rockwell Automation.

©2001 Rockwell Automation. All rights reserved.

Page 3

CONTENTS

Chapter 1 Introduction

1.1 Related Documentation ...................................................................................1-1

1.2 Getting Assistance from Rockwell Automation................................................ 1-1

Chapter 2 Getting Started

2.1 Required Equipment........................................................................................2-2

2.2 Installation Checklist........................................................................................ 2-3

Chapter 3 Installing the LonWorks Module in the Drive

3.1 Installing the Module in 1 to 5 HP@460 VAC Drives .....................................3-3

3.2 Installing the LonWorks Module in 7.5 to 10 HP @ 460 VAC Drives ..............3-7

3.3 Installing the LonWorks Module in 1 to 20 HP@230 VAC Drives.... ...... ....... 3-11

3.4 Installing the LonWorks Module in 30 to 100HP@230VAC and

75 to 200 @ 460VAC Drives3-15

3.5 Installing the LonWorks Module in 15 to 25 HP and 25 to 60 HP @ 460VAC

Drives3-20

3.6 Installing the LonWorks Module in 200 to 400 HP @ 460 VAC Drives .........3-26

Chapter 4 Connecting the Drive to the Network and Applying Power

4.1 Connecting the Drive to the Network............................................................... 4-1

4.2 Terminating the Network ................................................................................. 4-1

4.3 Applying Power................................................................................................4-2

Chapter 5 Programming the Drive for Network Communication

5.1 Setting the Control Source (P.000)..................................................................5-1

5.2 Setting the Network Connection Type (P.061) ................................................ 5-2

5.3 Setting the Communication Loss Response (P.062)....................................... 5-2

5.4 Setting the Speed Display Scale (P.028) ........................................................ 5-5

5.5 Setting the Network Output Register Sources (P.066 to P.069)......................5-5

Chapter 6 Installing the Drive as a Node in the Network

Chapter 7 Operating the Drive Using a LonMark Profile

7.1 Input Network Variables (NVIs) ....................................................................... 7-3

7.2 Output Network Variables (NVO) ....................................................................7-6

7.3 Configuration Properties (NCIs) ....................................................................7-10

Chapter 8 Conditions Required for Operation

8.1 General Guidelines.......................................................................................... 8-1

8.2 Starting the Drive.............................................................................................8-1

8.3 Stopping the Drive...........................................................................................8-2

8.4 Setting the Frequency ..................................................................................... 8-2

8.5 Writing Values to a VTAC 7 Register .............................................................. 8-2

8.6 Reading Values from VTAC 7 Registers ......................................................... 8-3

8.7 Resetting Faults...............................................................................................8-3

8.8 Priority of nciMinOutTm and nciSendHrtBt......................................................8-3

Contents

I

Page 4

Chapter 9 Troubleshooting the LonWorks Module and Network

9.1 Understanding the Status Indicators on the Module ........................................9-1

9.1.1 Module Status LED................................................................................9-2

9.1.2 Service LED...........................................................................................9-2

9.1.3 Wink LED...............................................................................................9-2

9.1.4 Communication Module Status LED......................................................9-2

9.2 Error Handling..................................................................................................9-3

Appendix A Technical Specifications........................................................................................... A-1

II

LonWorks Module for VTAC 7 Drives

Page 5

List of Figures

Figure 2.1 – Components of the LonWorks Module .................................................2-1

Figure 3.1 – DC Bus Voltage Terminals (1 to 5HP @ 460VAC) ..............................3-4

Figure 3.2 – LonWorks Module Location in 1 to 5 HP @ 460 VAC Drives..............3-5

Figure 3.3 – DC Bus Voltage Terminals (7.5 to 10 HP @ 460 VAC).......................3-8

Figure 3.4 – LonWorks Module Location in 7.5 to 10 HP Drives..............................3-9

Figure 3.5 – DC Bus Voltage Terminals (1 to 20 HP @ 230 VAC)........................3-12

Figure 3.6 – 1 to 20 HP @ 230 Volt Drive.............................................................3-14

Figure 3.7 – DC Bus Voltage Terminals (30 to 100 HP @ 230 VAC and 75 to 200 HP

@ 460 VAC)....................................................................................... 3-16

Figure 3.8 – Location of Terminal Cover and Regulator Board Cover in 30 to 100 HP

@ 230 VAC and 75 to 200 HP @ 460 VAC Drives ...........................3-17

Figure 3.9 – Regulator Board’s Connection to LonWorks Module, Keypad, and Base

Board..................................................................................................3-19

Figure 3.10 – DC Bus Voltage Terminals (15 to 25 HP @ 460 VAC) ....................3-21

Figure 3.11 – DC Bus Voltage Terminals (25 to 60 HP @ 460 VAC) ....................3-22

Figure 3.12 – LonWorks Module Location in 15 to 25 HP @ 460 VAC Drives.......3-23

Figure 3.13 – LonWorks Module Location in 25 to 60 HP @ 460 VAC Drives.......3-24

Figure 3.14 – LonWorks Module Location in 200 to 400HP @ 460VAC Drives .... 3-27

Figure 6.1 – Location of the Service Pin on the LonWorks Module.......................... 6-1

Figure 7.1 – Node Object..........................................................................................7-1

Figure 7.2 – Drive Object.......................................................................................... 7-2

Figure 9.1 – Status Indicators on the LonWorks Module.......................................... 9-1

Contents

III

Page 6

IV

LonWorks Module for VTAC 7 Drives

Page 7

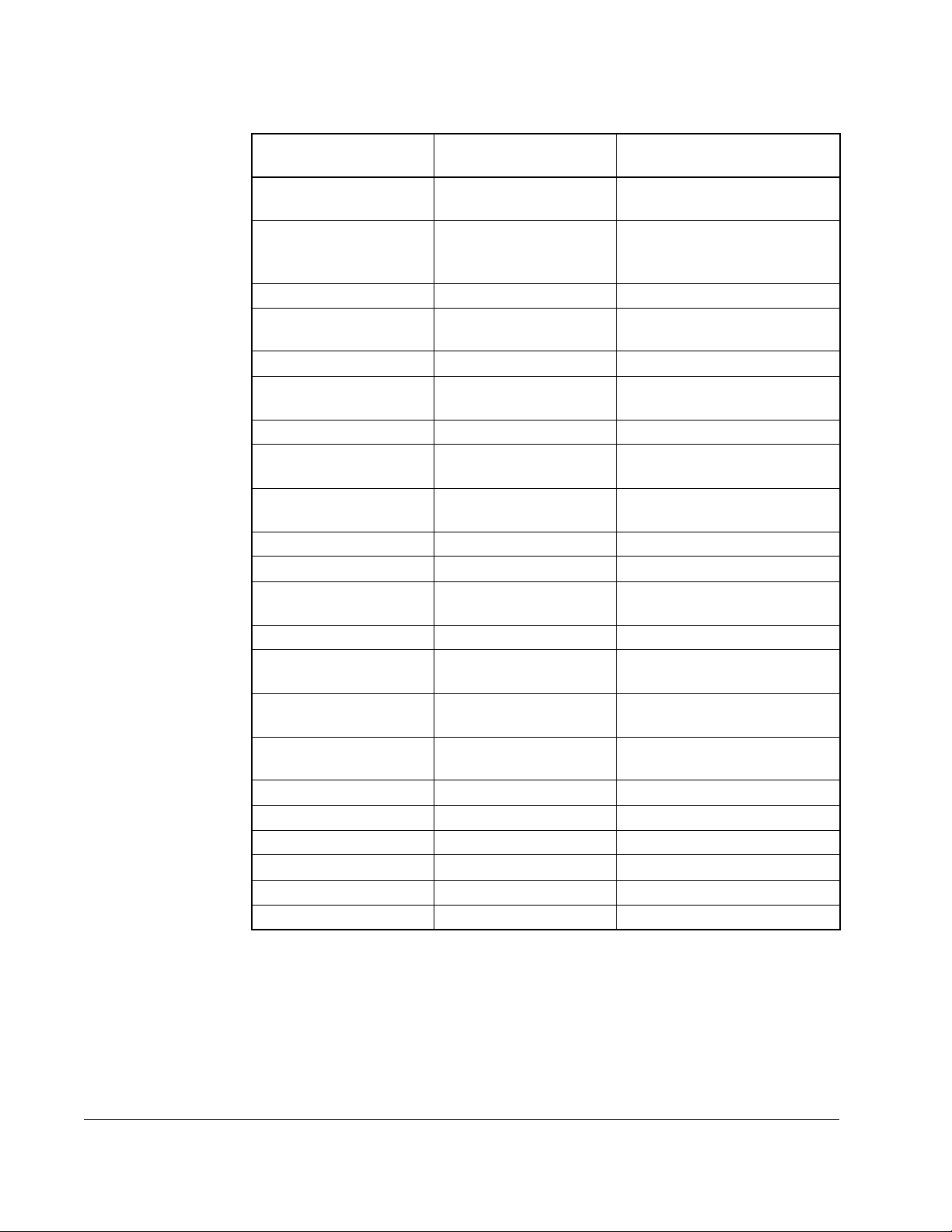

List of Tables

Table 2.1 – Equipment Shipped with the LonWorks Module....................................2-2

Table 2.2 – Required User-Supplied Equipment ...................................................... 2-2

Table 3.1 – Locating the Appropriate Installation Procedure....................................3-1

Table 3.2 – Model Numbers for 1 to 5 HP@460 VAC Drives.................................. 3-3

Table 3.3 – Model Numbers for 7.5 to 10 HP @ 460 VAC Drives............................3-7

Table 3.4 – Model Numbers for 1 to 20 HP@230 VAC Drives..............................3-11

Table 3.5 – Model Numbers for 30 to100 HP @ 230 VAC and 75 to 200 HP @ 460

VAC Drives .........................................................................................3-15

Table 3.6 – Model Numbers for 15 to 25 HP and 25 to 60 HP @ 460 VAC Drives3-20

Table 3.7 – Model Numbers for 200 to 400 HP @ 460 VAC Drives.......................3-26

Table 4.1 – Terminal Block Terminal Definitionst ..................................................... 4-1

Table 9.1 – Module Status LED: State Definitions....................................................9-2

Table 9.2 – Service LED: State Definitions...............................................................9-2

Table 9.3 – Wink LED: State Definitions...................................................................9-2

Table 9.4 – Communication Module Status LED: State Definitions..........................9-2

Contents

V

Page 8

VI

LonWorks Module for VTAC 7 Drives

Page 9

CHAPTER 1

Introduction

This manual is intended for qualified electrical personnel responsible for installing,

programming, and maintaining AC drives and LonWorks networks. It provides

information about the LonWorks Communication Option Module (2LW3000) and

using it with VTAC 7 drives.

The LonWorks Communication Option module consists of a LonWorks module

mounted on an AnyBus board. It is mounted in the VTAC 7 drive and receives its

required power from the drive and the network.

LonWorks networks consist of intelligent control devices, called nodes, that are

connected by one or more communications media and that communicate with each

other using a common protocol. A LonWorks network can consist of up to 32.385

nodes divided into 255 subnets (127 nodes/subnet).

Nodes on the network can be thought of as objects that respond to various inputs and

produce desired outputs. Linking the inputs and outputs of network objects enables

the network to perform applications. No central control or master-slave architecture is

required.

1.1 Related Documentation

Refer to the following publication as necessary for more information. This publication

is available from http://www.theautomationbookstore.com or

http://www.vtacdrives.com.

• VTAC 7 User's Guide (D2-3372)

1.2 Getting Assistance from Rockwell Automation

If you have any questions or problems with the products described in this instruction

manual, contact your local Rockwell Automation authorized HVAC representative.

For technical assistance, call 1-800-726-8112. Before calling, please the review the

troubleshooting section of this manual and check the VTAC drives website for

additional information. When you call this number, you will be asked for the drive

model number and this instruction manual number.

Introduction

1-1

Page 10

1-2

LonWorks Module for VTAC 7 Drives

Page 11

CHAPTER 2

Getting Started

This chapter provides:

• A description of the LonWorks module’s components

• A list of parts shipped with the module

• A list of user-supplied parts required for installing the module

• An installation checklist

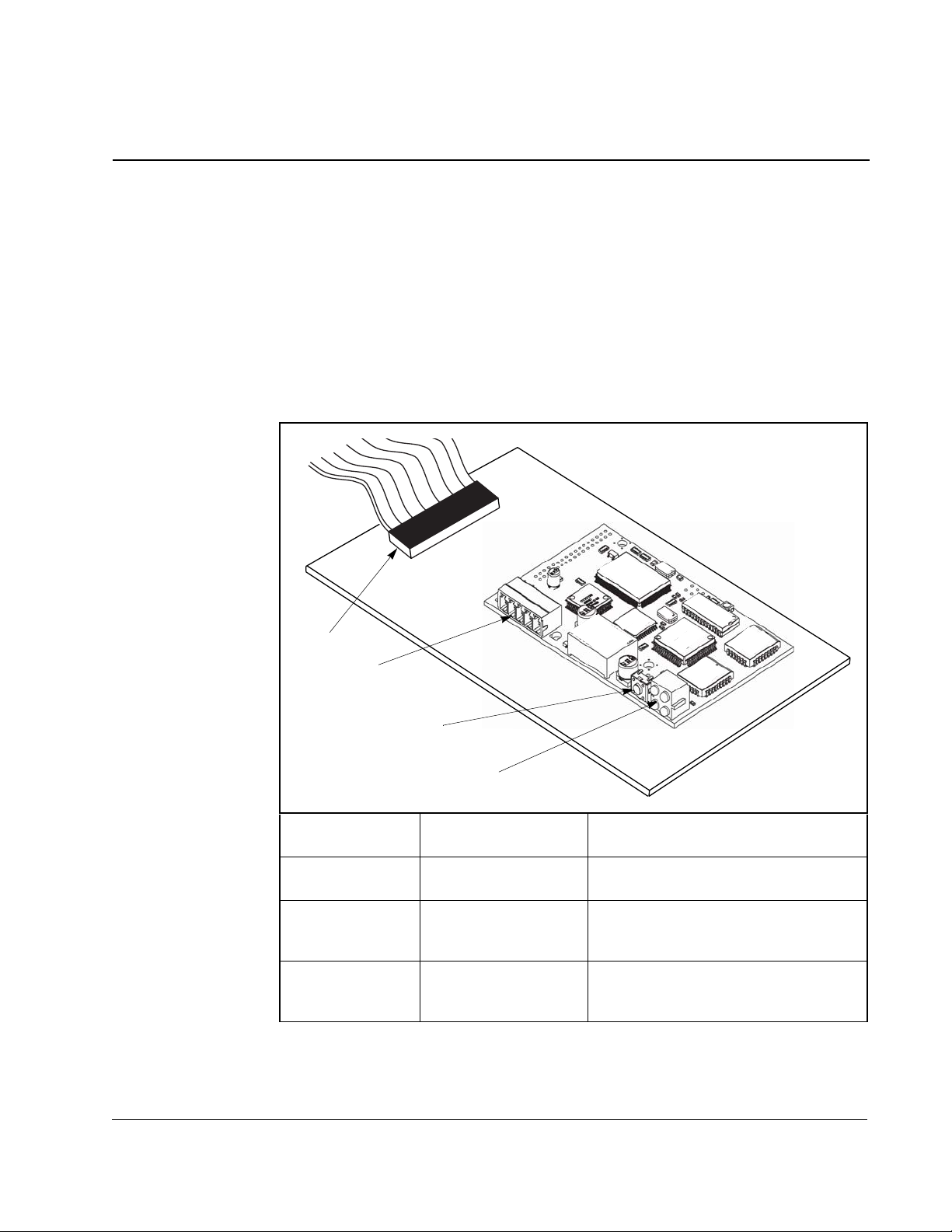

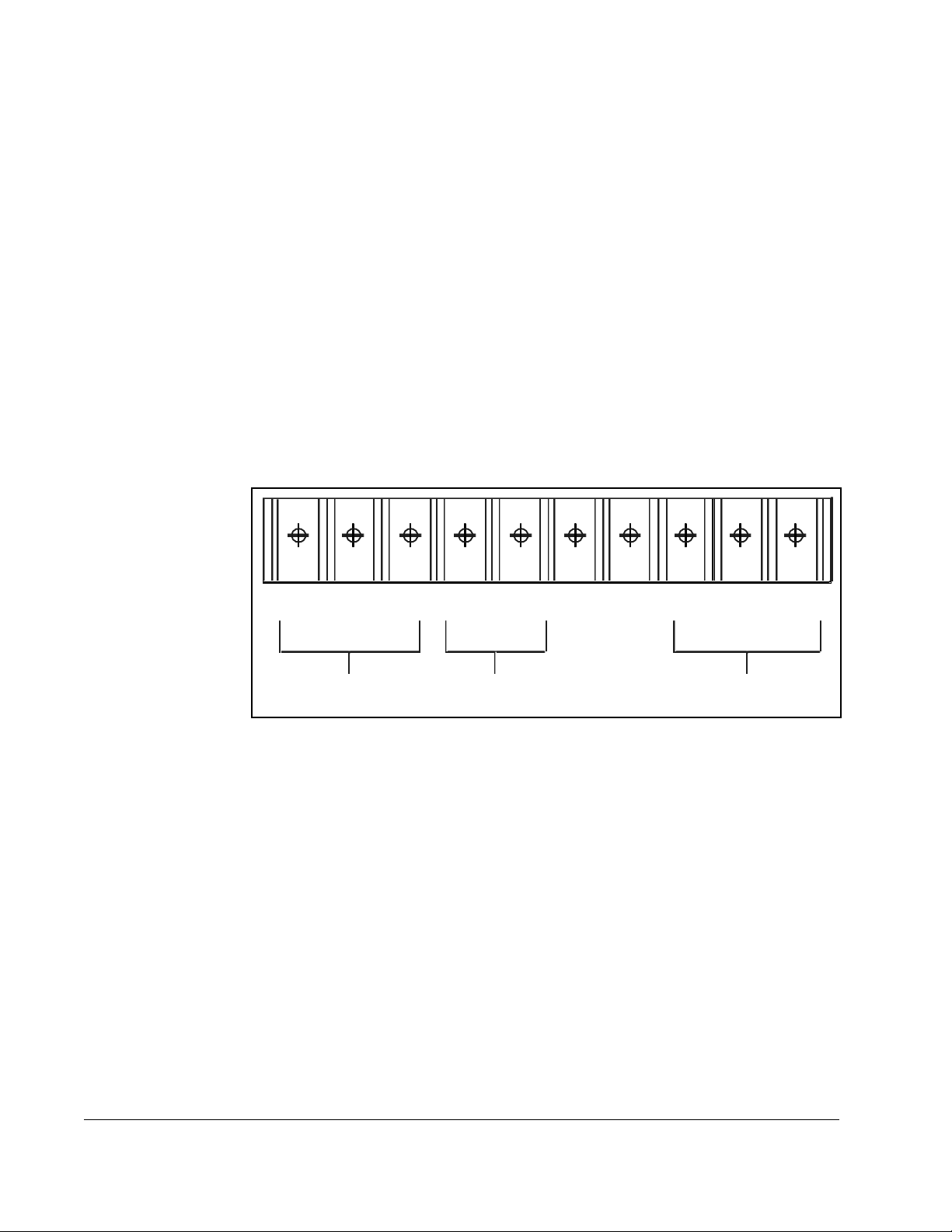

Ribbon Cable

Connector

Terminal Block A 5-screw terminal block connects the

Service Pin A pushbutton identifies the node during

Status Indicators Four LEDs indicate the status of the

Figure 2.1 – Components of the LonWorks Module

Connects the module to the drive.

module to the network.

installation. See chapter 5, Installing

the Drive on the Network.

connected drive, module, and network.

See chapter 7, Troubleshooting.

Getting Started

2-1

Page 12

2.1.Required Equipment

Table 2.1 lists the equipment shipped with the LonWorks module. When you unpack

the module, verify that the package includes all of these items.

Table 2.1 – Equipment Shipped with the LonWorks Module

LonWorks Communications Option module .

LonWorks Communication Option Module User Manual (D2-3498)

Diskette containing .XIF file

Table 2.2 lists user-supplied equipment also required to install and configure the

module.

Table 2.2 – Required User-Supplied Equipment

Phillips screwdriver

Network cable. Recommended cables:

• Belden 851 02, unsh ielded

• Belden 847 1, unsh ie lde d

Item Description

Item Description

• Level IV 22AWG, unshielded

• JY (St) Y 2x2x0.8, shielded

• TIA568A Cat.5 24AWG

For detailed information about recommended cables for a LonWorks network, see

the FTT-10 Free Topology User’s Guide (doc.id.078-0156-01F) at

http://www.echelon.com.

Any standard LonWorks installation tool (for example, LonMaker for Windows).

2-2

LonWorks Module for VTAC 7 Drives

Page 13

2.2 Installation Checklist

This section is designed to help experienced users start using the LonWorks module.

If you are unsure how to complete a step, refer to the referenced chapter

Step Action Refer to

❒

❒

❒

❒

❒

❒

❒

1 Review the safety precautions for the

module.

2 Verify that the drive is properly

installed.

4 Install the module in the drive.

Verify that the drive and the network are

not powered. Then, connect the module

to the drive. Use the captive screws to

secure and ground the module to the

drive.

5 Connect the drive to the network. Chapter 4

6 Apply power to the drive and

network.

Verify that the module and network are

installed correctly and then apply power

to them. The module receives power

from the drive and network.

7 Program the drive for network

communication.

8 Install the drive as a node in the

network.

Use a network tool for LonWorks (such

as LonMaker) to install the drive as a

node in the network.

Throughout

this manual

VTAC 7 AC

Drive User

Manual

(D2-3372)

Chapter 3

Chapter 4

Chapter 5

Instruction

manual for

LonWorks

installation

tool

Getting Started

When to press service pin?

2-3

Page 14

2-4

LonWorks Module for VTAC 7 Drives

Page 15

CHAPTER 3

Installing the LonWorks Module

in the Drive

The LonWorks module installation procedure differs depending on the drive type. Use

table 3.1 to locate the appropriate procedure for your drive.

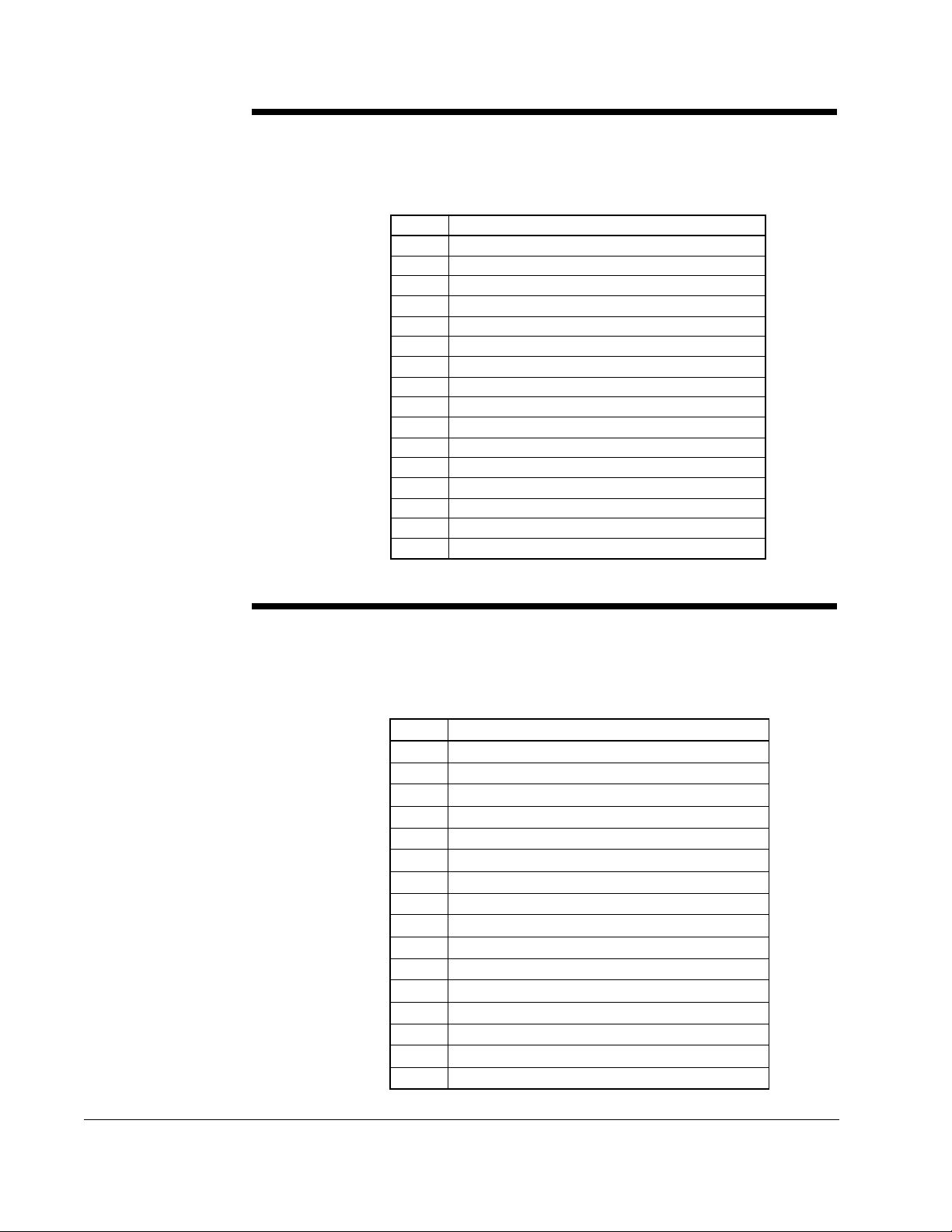

Table 3.1 – Locating the Appropriate Installation Procedure

Horsepower Rating

1

1

2

2

3

3

5

5

7.5

7.5

10

10

15

15

20

Drive Model Number

1H21xx

1H22xx

1H41xx

1H42xx

2H21xx

2H22xx

2H41xx

2H42xx

3H21xx

3H22xx

3H41xx

3H42xx

5H21xx

5H22xx

5H41xx

5H42xx

7H21xx

7H22xx

7H41xx

7H42xx

10H21xx

10H22xx

10H41xx

10H42xx

15H21xx

15H22xx

15H41xx

15H42xx

20H21xx

20H22xx

Use the Procedure in

Section …

3.3

3.1

3.3

3.1

3.3

3.1

3.3

3.1

3.3

3.2

3.3

3.2

3.3

3.5

3.3

Installing the LonWorks Module in the Drive

3-1

Page 16

Table 3.1 – Locating the Appropriate Installation Procedure (Continued)

Horsepower Rating

20

25

30 30W21xx 3.4

30

40 40W21xx 3.4

40

50 50W21xx 3.4

50

60

60 60W21xx 3.4

75 75W21xx 3.4

75

100 100H21xx 3.4

100

125

150

200 200W41xx 3.4

200 200H41xx 3.6

250 250H41xx 3.6

300 300H41xx 3.6

350 350H41xx 3.6

400 400H41xx 3.6

Drive Model Number

20H41xx

20H42xx

25H41xx

25H42xx

25W21xx

30H41xx

30H42xx

40H41xx

40H42xx

50H41xx

50H42xx

60H41xx

60H42xx

75H41xx

75W41xx

100H41xx

100W41xx

125H41xx

125W41xx

150H41xx

150W41xx

Use the Procedure in

Section …

3.5

3.5

3.5

3.5

3.5

3.5

3.4

3.4

3.4

3.4

3-2

LonWorks Module for VTAC 7 Drives

Page 17

3.1 Installing the Module in 1 to 5 HP@460 VAC Drives

ATTENTION:Only qualified electrical personnel familiar with the

construction and operation of this equipment and the hazards involved

!

should install, adjust, operate, or service this equipment. Read and

understand this manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution could result in

severe bodily injury or loss of life.

ATTENTION:The drive is at line voltage when connected to incoming

AC power. Disconnect, lock out, and tag all incoming power to the drive

before performing the following procedure. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:DC bus capacitors retain hazardous voltages after input

power has been disconnected. After disconnecting input power, wait five

minutes for the DC bus capacitors to discharge and then check the

voltage with a voltmeter to ensure the DC bus capacitors are discharged

before touching any internal components. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:The drive contains ESD- (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

when installing, testing, servicing, or repairing the drive. Erratic machine

operation and damage to, or destruction of, equipment can result if this

procedure is not followed. Failure to observe this precaution can result

in bodily injury.

Use this procedure to install the module in the drives listed in table 3.2.

Table 3.2 – Model Numbers for 1 to 5 HP@460 V AC Drives

VTAC 7 Model Numbers

1H41xx

1H42xx

2H41xx

2H42xx

3H41xx

3H42xx

5H41xx

5H42xx

Refer to figure 3.2 as you perform the procedure.

If the drive is panel-mounted, this procedure will be easier to perform if the drive is

removed from the panel.

Unless otherwise indicated, keep all hardware that is removed. You will need it for

reassembly. This includes screws, lock washers, and rivets.

Important: Read and understand the warning labels on the outside of the drive

before proceeding.

Installing the LonWorks Module in the Drive

3-3

Page 18

Step 1. Shut Down the Drive

Step 1.1 Disconnect, lock out, and tag all incoming power to the drive.

Step 1.2 Wait five minutes for the DC bus capacitors to discharge.

Step 1.3 Remove the cover by loosening the four cover screws.

Important: Read and understand the warning labels on the inside of the drive before

proceeding.

Step 2. Verify That the DC Bus Capacitors are Discharged

Step 2.1 Use a voltmeter to verify that there is no voltage at the drive’s AC input

power terminals (R/L1, S/L2, T/L3).

Step 2.2 Ensure that the DC bus capacitors are discharged. To check

DC bus potential:

a. Stand on a non-conductive surface and wear insulated gloves.

b. Use a voltmeter to measure the DC bus potential at the DC bus power

terminals as shown in figure 3.1.

R/L1 T/L3

S/L2 10V 10 COM

AC Power

Input Leads

Figure 3.1 – DC Bus Voltage Terminals (1 to 5HP @ 460VAC)

+

–+

DC Bus

Volts

Step 3. Remove the Keypad Bracket from the Drive

Step 3.1 Record connections to the Regulator board terminal strip if they must be

disconnected to remove the keypad bracket.

Step 3.2 Use a magnetic screwdriver to remove the three M4 x 10 screws that fasten

the bottom of the keypad support bracket to the drive heat sink.

Important: The keypad support bracket is connected to the drive by wiring. Do not lift

the bracket out completely, because this can damage or pull out wiring.

Step 3.3 S pread the retaining clips on the 26-conductor Regulator board ribbon cable

connector to disconnect it from the Current Feedback board. The Current

Feedback board is located on the right below the keypad.

Step 3.4 Move the keypad support bracket aside.

–

W/T3V/T2U/T1

Motor Leads

3-4

Step 3.5 Pinch the retaining clip that is through the center of the Current Feedback

board and carefully pull out the Current Feedback board.

Step 3.6 Unplug the internal fan assembly power connector (CONN7) from the drive.

LonWorks Module for VTAC 7 Drives

Page 19

Step 4. Install the LonW orks Module in the Keypad Bracket

ATTENTION:The drive contains ESD- (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

!

when installing, testing, servicing, or repairing the drive. Erratic machine

operation and damage to, or destruction of, equipment can result if this

procedure is not followed. Failure to observe this precaution can result

in bodily injury.

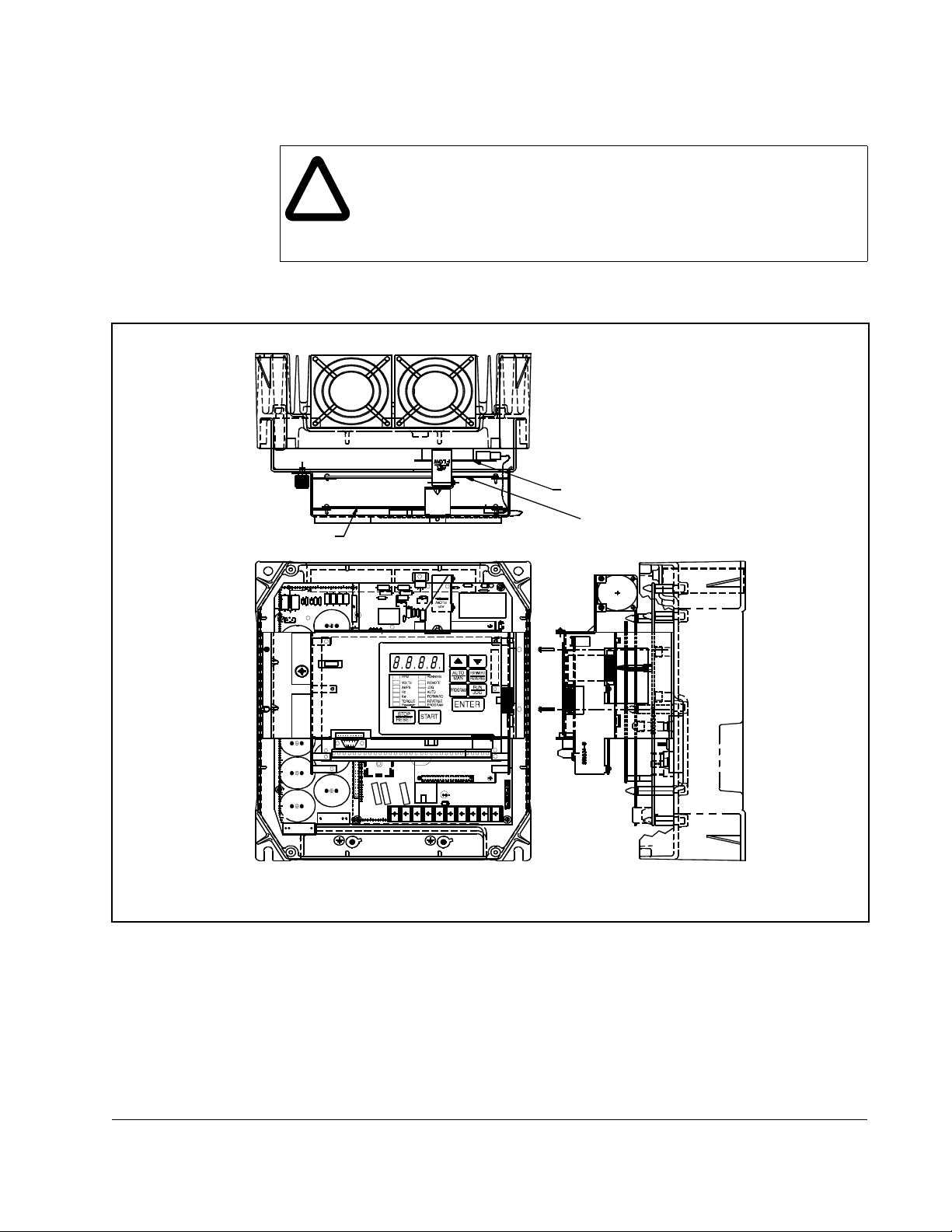

Refer to figure 3.2 for component locations.

LonWorks

Module

Regulator

Board

LonWorks

Module

Top View

Current Feedback

Board

AUTO

STAR T

RUNNING

REMOTE

JOGAMPS

AUTO

FORWARD

REVERSE

PROGRAMPROGRAM

20

ENTER

Forward

Reverse

RUN

JOG

Side View

RPM

VOLTS

Hz

Kw

TORQUE

Password

STOP

RESET

16

Front View

Figure 3.2 – LonWorks Module Location in 1 to 5 HP @ 460 VAC Drives

Step 4.1 Remove the LonWorks module from its anti-static wrapper. Align the key on

the Regulator board’s 34-conductor ribbon cable connector with the slot in

the LonWorks module’s connector. Press the ribbon cable connector in until

it locks into position.

Step 4.2 Route the 26-conductor ribbon cable for the Current Feedback board out of

Step 4.3 Align the LonWorks module on the four mounting tabs on the keypad

Installing the LonWorks Module in the Drive

the side of the keypad bracket.

bracket. Make sure that the ribbon cable is not pinched between the keypad

bracket and the LonWorks module.

3-5

Page 20

Step 4.4 Fasten the LonWorks module to the right side of the keypad bracket using

the two metal M3 screws and lock washers for proper grounding. Fasten the

left side using the two 6-32 screws and lock washers for proper grounding.

Important:

Step 5. Reinstall the Keypad Bracket in the Drive

Step 5.1 Reconnect the internal fan assembly power connector (CONN7) to the

!

Step 5.2 Reinstall the Current Feedback board. Carefully align the two sets of

Step 5.3 Inspect the Current Feedback board connector thoroughly for bent or

Step 5.4 Align the keypad support bracket with the mounting holes in the drive heat

You must use the lock washers to properly ground the LonWorks module.

Improper grounding of the LonWorks module can result in erratic operation

of the drive.

drive. Align the key on the connector with the slot in the receptacle. Press

the connector into position.

ATTENTION:Proper alignment of the Current Feedback board is critical.

Verify that the connector pins on the Current Feedback board are

correctly aligned with their corresponding connectors on the drive.

Failure to observe this precaution can result in bodily injury.

connector pins on the Current Feedback board with their matching

connectors on the drive. Gently press the board into place. The board

should go in easily. If you feel resistance, a pin might be bent or misaligned.

Recheck alignment and retry installation.

misaligned pins.

sink. Fasten the bracket with the three M4 x 10 screws removed earlier.

Step 5.5 Align the Regulator board’s 26-conductor ribbon cable connector with the

Current Feedback board connector. Press it in until it locks into position.

Step 5.6 Reconnect any wiring that was removed from the Regulator board terminal

strip. Refer to the terminal connections documented in step 3.1 or to the

appropriate instruction manuals for the devices being used.

Step 5.7 NEMA 4X/12 drives only: Before installing the cover , check that the gaskets

on the cover are flat and within the gasket channels.

Step 5.8 Reinstall the cover. Align all cover screws into the heat sink before

tightening any of them.

To maintain the integrity of NEMA 4X/12 drives, sequentially tighten the

cover screws to ensure even compression of the gaskets. Do not exceed

2.2 Nm (20 in-lb) of torque on these screws.

3-6

LonWorks Module for VTAC 7 Drives

Page 21

3.2 Installing the LonWorks Module in

7.5 to 10 HP @ 460 VAC Drives

ATTENTION:Only qualified electrical personnel familiar with the

construction and operation of this equipment and the hazards involved

!

should install, adjust, operate, or service this equipment. Read and

understand this manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution could result in

severe bodily injury or loss of life.

ATTENTION:The drive is at line voltage when connected to incoming

AC power. Disconnect, lock out, and tag all incoming power to the drive

before performing the following procedure. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:DC bus capacitors retain hazardous voltages after input

power has been disconnected. After disconnecting input power, wait five

minutes for the DC bus capacitors to discharge and then check the

voltage with a voltmeter to ensure the DC bus capacitors are discharged

before touching any internal components. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:The drive contains ESD- (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

when installing, testing, servicing, or repairing the drive. Erratic machine

operation and damage to, or destruction of, equipment can result if this

procedure is not followed. Failure to observe this precaution can result

in bodily injury.

Use this procedure to install the LonWorks module in the drives listed in table 3.3.

Table 3.3 – Model Numbers for 7.5 to 10 HP @ 460 VAC Drives

Refer to figure 3.4 as you perform this procedure.

If the drive is panel-mounted, this procedure will be easier to perform if the drive is

removed from the panel.

Unless otherwise indicated, keep all hardware that is removed. You will need it for

reassembly. This includes screws, lock washers, and rivets.

Important: Read and understand the warning labels on the outside of the drive

before proceeding.

Step 1. Shut Down the Drive

Step 1.1 Disconnect, lock out, and tag all incoming power to the drive.

Step 1.2 Wait five minutes for the DC bus capacitors to discharge.

VTAC 7 Model Numbers

7H41xx

7H42xx

10H41xx

10H42xx

Installing the LonWorks Module in the Drive

3-7

Page 22

Step 1.3 Remove the cover by loosening the four cover screws.

Important: Read and understand the warning labels on the inside of the drive before

proceeding.

Step 2. Verify That the DC Bus Capacitors are Discharged

Step 2.1 Use a voltmeter to verify that there is no voltage at the drive’s AC input

power terminals (R/L1, S/L2, T/L3).

Step 2.2 Ensure that the DC bus capacitors are discharged. To check

DC bus potential:

a. Stand on a non-conductive surface and wear insulated gloves.

b. Use a voltmeter to measure the DC bus potential at the DC bus power

terminals shown in figure 3.3.

R/L1 T/L3

S/L2 10V 10 COM

AC Power

Input Leads

Figure 3.3 – DC Bus Voltage Terminals (7.5 to 10 HP @ 460 VAC)

+

–+

DC Bus

Volts

Step 3. Remove the Keypad Bracket from the Drive

Step 3.1 Record connections to the Regulator board terminal strip if they must be

disconnected to remove the keypad bracket.

Step 3.2 Loosen the thumb screw on the left side of the keypad bracket. Hold the

bracket on the left and lift the bracket up and to the left to separate it from

the keypad support bracket.

Important: The keypad support bracket is connected to the drive by wiring. Do not lift

the bracket out completely, because this can damage or pull out wiring.

Tie up or support the bracket to prevent damage to the wiring.

Step 3.3 S pread the retaining clips on the 26-conductor Regulator board ribbon cable

connector to disconnect it from the Current Feedback board. The Current

Feedback board is located on the right below the keypad.

–

W/T3V/T2U/T1

Motor Leads

3-8

LonWorks Module for VTAC 7 Drives

Page 23

Step 4. Install the LonW orks Module in the Keypad Bracket

ATTENTION:The drive contains ESD- (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

!

Refer to figure 3.4 for component locations.

Regulator Board

when installing, testing, servicing, or repairing the drive. Erratic machine

operation and damage to, or destruction of, equipment can result if this

procedure is not followed. Failure to observe this precaution can result

in bodily injury.

Current Feedback Board

LonWorks Module

LonWorks Module

Top View

Figure 3.4 – LonWorks Module Location in 7.5 to 10 HP Drives

Step 4.1 Remove the LonWorks module from its anti-static wrapper. Align the key on

Step 4.2 Route the 26-conductor ribbon cable for the Current Feedback board out of

Installing the LonWorks Module in the Drive

Front View

the Regulator board’s 34-conductor ribbon cable connector with the slot in

the LonWorks module’s connector. Press the ribbon cable connector in until

it locks into position.

the side of the keypad bracket.

Side View

3-9

Page 24

Step 4.3 Align the LonWorks module on the four mounting tabs on the keypad

bracket. Make sure that the ribbon cable is not pinched between the keypad

bracket and the LonWorks module.

Step 4.4 Fasten the LonWorks module to the right side of the keypad bracket using

the two metal M3 screws and lock washers for proper grounding. Fasten the

left side using the two 6-32 screws and lock washers for proper grounding.

Important: Y ou must use the lock washers to properly ground the LonWorks module.

Improper grounding of the LonWorks module can result in erratic

operation of the drive.

Step 4.5 Reconnect the keypad bracket to the keypad support bracket by inserting

the mounting tabs into the slots in the keypad support bracket and tightening

the thumb screw.

Step 4.6 Align the Regulator board’s 26-conductor ribbon cable connector with the

Current Feedback board connector. Press it in until it locks into position.

Step 5. Reassemble the Drive

Step 5.1 Reconnect any wiring that was removed from the Regulator board terminal

strip. Refer to the terminal connections documented in step 3.1 or to the

appropriate instruction manuals for the devices being used.

Step 5.2 NEMA 4X/12 drives only: Before installing the cover , check that the gaskets

on the cover are flat and within the gasket channels.

Step 5.3 Reinstall the cover. Align all cover screws into the heat sink before

tightening any of them.

To maintain the integrity of NEMA 4X/12 drives, sequentially tighten the

cover screws to ensure even compression of the gaskets. Do not exceed

2.2 Nm (20 in-lb) of torque on these screws.

3-10

LonWorks Module for VTAC 7 Drives

Page 25

3.3 Installing the LonWorks Module in

1to20HP@230VAC Drives

ATTENTION:Only qualified electrical personnel familiar with the

construction and operation of this equipment and the hazards involved

!

should install, adjust, operate, or service this equipment. Read and

understand this manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution could result in

severe bodily injury or loss of life.

ATTENTION:The drive is at line voltage when connected to incoming

AC power. Disconnect, lock out, and tag all incoming power to the drive

before performing the following procedure. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:DC bus capacitors retain hazardous voltages after input

power has been disconnected. After disconnecting input power, wait five

minutes for the DC bus capacitors to discharge and then check the

voltage with a voltmeter to ensure the DC bus capacitors are discharged

before touching any internal components. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:The drive contains ESD- (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

when installing, testing, servicing, or repairing the drive. Erratic machine

operation and damage to, or destruction of, equipment can result if this

procedure is not followed. Failure to observe this precaution can result

in bodily injury.

Use this procedure to install the LonWorks module in the drives listed in table 3.4.

Table 3.4 – Model Numbers for 1 to 20 HP@230 VAC Drives

VTAC 7 Model Numbers

1H21xx

1H22xx

2H21xx

2H22xx

3H21xx

3H22xx

5H21xx

5H22xx

7H21xx

7H22xx

10H21xx

10H22xx

15H21xx

15H22xx

20H21xx

20H22xx

Refer to figure 3.6 as you perform this procedure.

Installing the LonWorks Module in the Drive

3-11

Page 26

If the drive is panel-mounted, this procedure will be easier to perform if the drive is

removed from the panel.

Unless otherwise indicated, keep all hardware that is removed. You will need it for

reassembly. This includes screws, lock washers, and rivets.

Important: Read and understand the warning labels on the outside of the drive

before proceeding.

Step 1. Shut Down the Drive

Step 1.1 Disconnect, lock out, and tag all incoming power to the drive.

Step 1.2 Wait five minutes for the DC bus capacitors to discharge.

Step 1.3 Remove the cover by loosening the four cover screws.

Important: Read and understand the warning labels on the inside of the drive before

proceeding.

Step 2. Verify That the DC Bus Capacitors are Discharged

Step 2.1 Use a voltmeter to verify that there is no voltage at the drive’s AC input

power terminals (R/L1, S/L2, T/L3).

Step 2.2 Ensure that the DC bus capacitors are discharged. To check

DC bus potential:

a. Stand on a non-conductive surface and wear insulated gloves.

b. Use a voltmeter to measure the DC bus potential at the DC bus power

terminals shown in figure 3.5.

+

R/L1 T/L3

Step 3. Remove the Keypad Bracket from the Drive

Step 3.1 Record connections to the Regulator board terminal strip if they must be

disconnected to remove the keypad bracket.

S/L2

AC Power

Input Leads

Figure 3.5 – DC Bus Voltage Terminals (1 to 20 HP @ 230 VAC)

DC Bus

Volts

–

W/T3V/T2U/T1

Motor Leads

3-12

Step 3.2 Use a magnetic screwdriver to remove the M4 x 10 screws that fasten the

bottom of the keypad support bracket to the drive.

LonWorks Module for VTAC 7 Drives

Page 27

Step 3.3 Spread the retaining clips on the Regulator board ribbon cable (on the right

side) to disconnect it from the Base Board.

Step 3.4 Remove the keypad bracket. Place it with the keypad down on a flat surface.

If you cannot lay it flat, tie it up to prevent damage to wiring.

Step 4. Install the LonW orks Module in the Keypad Bracket

Refer to figure 3.6 for component locations.

Step 4.1 Remove the LonWorks module from its anti-static wrapper. Align the key on

the Regulator board’s 34-conductor ribbon cable connector with the slot in

the LonWorks module’s connector. Press the ribbon cable connector in until

it locks into position.

Step 4.2 Route the other ribbon cable out of the side of the keypad bracket.

Step 4.3 Align the LonWorks module on the four mounting tabs on the keypad

bracket. Make sure that the ribbon cable is not pinched between the keypad

bracket and the LonWorks module.

Step 4.4 Fasten the LonWorks module to the right side of the keypad bracket using

the two metal M3 screws and lock washers for proper grounding. Fasten the

left side using the two 6-32 screws and lock washers for proper grounding.

Important: Y ou must use the lock washers to properly ground the LonWorks module.

Improper grounding of the LonWorks module can result in erratic

operation of the drive.

Step 5. Reinstall the Keypad Bracket in the Drive

Step 5.1 Place the keypad support bracket back into position. Use a magnetic

screwdriver to fasten it to the drive with the screws removed in step 3.2.

Step 5.2 Realign the 26-conductor ribbon cable connector with the connector inside

the slot in the keypad support bracket. Carefully press the ribbon cable

connector in until the retaining clips lock into place.

Step 5.3 Reconnect any wiring that was removed from the Regulator board terminal

strip. Refer to the terminal connections documented in step 3.1 or to the

appropriate instruction manuals for the devices being used.

Step 5.4 NEMA 4X/12 drives only: Before installing the cover , check that the gaskets

on the cover are flat and within the gasket channels.

Installing the LonWorks Module in the Drive

3-13

Page 28

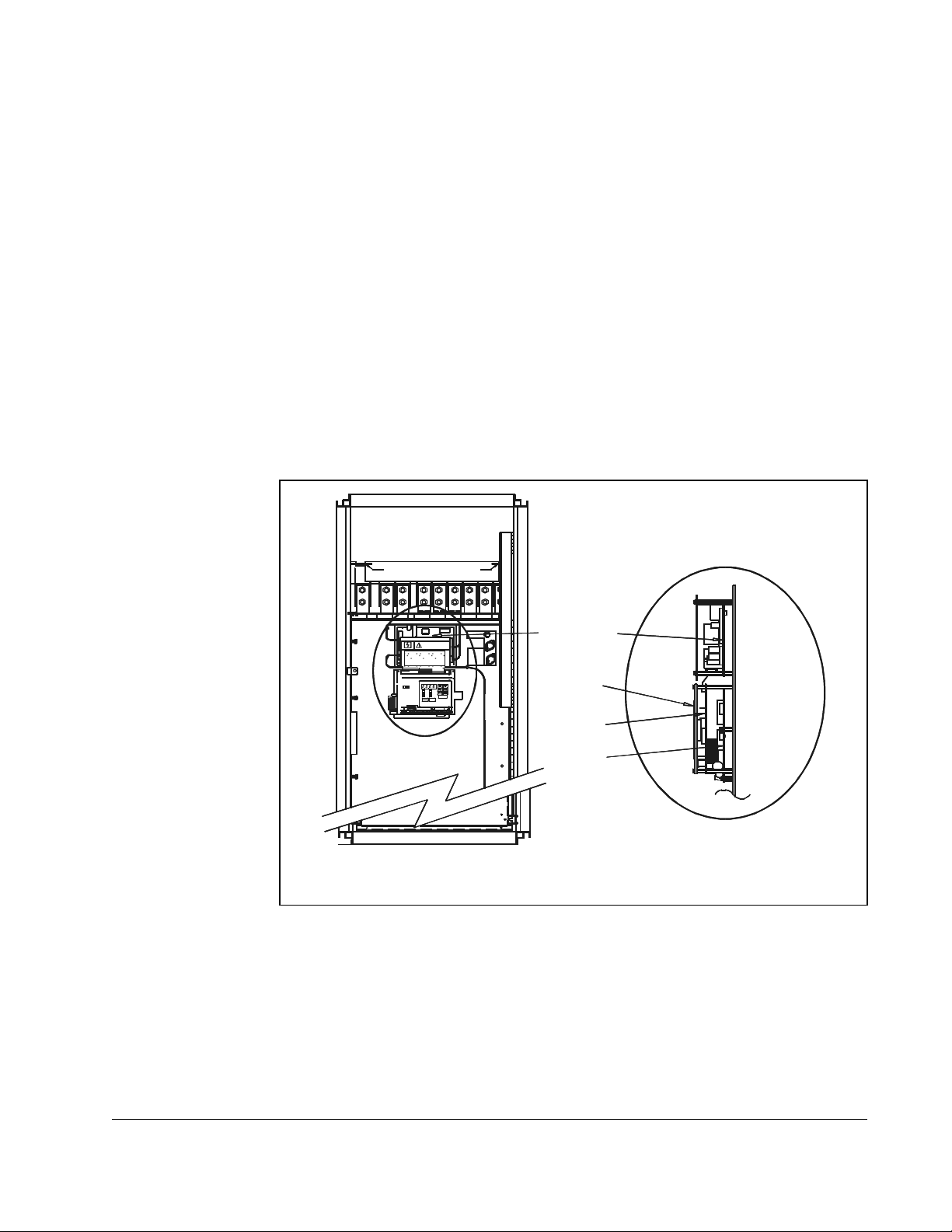

Keypad Bracket

Regulator Board

Terminal Strip

Power Term inal

Strip

Figure 3.6 – 1 to 20 HP @ 230 Volt Drive

Step 5.5 Reinstall the cover. Align all cover screws into the heat sink before

tightening any of them.

To maintain the integrity of NEMA 4X/12 drives, sequentially tighten the

cover screws to ensure even compression of the gaskets. Do not exceed

2.2 Nm (20 in-lb) of torque on these screws.

3-14

LonWorks Module for VTAC 7 Drives

Page 29

3.4 Installing the LonWorks Module in

30 to 100HP@230 VAC and 75 to 200 @ 460VAC

Drives

ATTENTION:Only qualified electrical personnel familiar with the

construction and operation of this equipment and the hazards involved

!

should install, adjust, operate, or service this equipment. Read and

understand this manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution could result in

severe bodily injury or loss of life.

ATTENTION:The drive is at line voltage when connected to incoming

AC power. Disconnect, lock out, and tag all incoming power to the drive

before performing the following procedure. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:DC bus capacitors retain hazardous voltages after input

power has been disconnected. After disconnecting input power, wait five

minutes for the DC bus capacitors to discharge and then check the

voltage with a voltmeter to ensure the DC bus capacitors are discharged

before touching any internal components. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:The drive contains ESD- (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

when installing, testing, servicing, or repairing the drive. Erratic machine

operation and damage to, or destruction of, equipment can result if this

procedure is not followed. Failure to observe this precaution can result

in bodily injury.

Use this procedure to install the LonWorks module in the drives listed in table 3.5.

Table 3.5 – Model Numbers for 30 to100 HP @ 230 VAC and 75 to 200 HP @ 460 VAC Drives

VTAC 7 Model Numbers

30 to 100HP @

230VAC

30W21xx

50W21xx

60W21xx

75W21xx

100H21xx

Refer to figures 3.8 and 3.9 as you perform the procedure.

Unless otherwise indicated, keep all hardware that is removed. You will need it for

reassembly. This includes screws, lock washers, and rivets.

Important: Read and understand the warning labels on the outside of the drive

before proceeding.

75 to 200HP @

460VAC

75H41xx

75W41xx

100H41xx

100W41xx

125H41xx

125W41xx

150H41xx

150W41xx

200W41xx

Installing the LonWorks Module in the Drive

3-15

Page 30

Step 1. Shut Down the Drive

Step 1.1Disconnect, lock out, and tag all incoming power to the drive.

Step 1.2 Wait five minutes for the DC bus capacitors to discharge.

Step 1.3 Open the drive’s outer cabinet door.

Step 1.1 Read and understand the warning labels on the inside of the drive before

proceeding.

Step 2. Verify That the DC Bus Capacitors are Discharged

Step 2.1 Use a voltmeter to verify that there is no voltage at the drive’s AC input

power terminals (R/L1, S/L2, T/L3 or U/T1, V/T2, W/T3).

Step 2.2 Ensure that the DC bus capacitors are discharged. To check

DC bus potential:

a. Stand on a non-conductive surface and wear insulated gloves.

b. Use a voltmeter to measure the DC bus potential at the DC bus power

terminals shown in figure 3.7.

DC Bus

P (+)

R

S

Volts

T

N (-)

3-16

U (T1)

W (T3)

Figure 3.7 – DC Bus Voltage Terminals (30 to 100 HP @ 230 VAC and 75 to 200 HP @ 460 VAC)

GND

V (T2)

LonWorks Module for VTAC 7 Drives

Page 31

Step 3. Remove the Keypad Bracket from the Drive

Step 3.1 Remove the Power Module from the drive cabinet.

Step 3.2 If the drive has:

•

A Regulator bo ard and te rminal co ver: Re move the th ree M4 sc rews from the

cover plate over the Regulator board. Remove the cover. See figure 3.8.

•

A terminal cover only: If you have this type of drive, this procedure is easier

to perform if you lay the drive on its side. Remove the side cover from the

drive. Use a long magnetized screwdriver to unfasten the four screws that

hold the keyp ad bracket in.

Step 3.3 Remove the terminal cover, which is below the keypad and fastened with

two M4 screws. See figure 3.8.

Figure 3.8 – Location of Terminal Cover and Regulator Board Cover in 30 to 100 HP @ 230 VAC and 75 to 200 HP @ 460 VAC Drives

Step 3.4 Record connections to the Regulator board terminal strip if they must be

disconnected to remove the keypad bracket.

Step 3.5 Remove the anodized inner cover by removing the two M3 roundhead

screws.

Step 3.6 Pull the keypad assembly partly out of the drive. Spread the retaining clips

on the Regulator board ribbon cable (on the right side) to disconnect it from

the Base Board. See figure 3.9.

Step 3.7 Remove the keypad bracket. Place it with the keypad down on a flat surface.

If you cannot lay it flat, tie it up to prevent damage to wiring.

Installing the LonWorks Module in the Drive

3-17

Page 32

Step 4. Install the LonW orks Module in the Keypad Bracket

ATTENTION:The drive contains ESD- (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

!

Refer to figures 3.8 and 3.9 for component locations.

Step 4.1 Remove the LonWorks module from its anti-static wrapper. Align the key on

Step 4.2 Route the other ribbon cable out of the side of the keypad support bracket.

Step 4.3 Align the LonWorks module on the four mounting tabs on the keypad

Step 4.4 Fasten the LonWorks module to the right side of the keypad bracket using

when installing, testing, servicing, or repairing the drive. Erratic machine

operation and damage to, or destruction of, equipment can result if this

procedure is not followed. Failure to observe this precaution can result

in bodily injury.

the Regulator board’s 34-conductor ribbon cable connector with the slot in

the LonWorks module’s connector. Press the ribbon cable connector in until

it locks into position.

bracket. Make sure that the ribbon cable is not pinched between the keypad

bracket and the LonWorks module.

the two metal M3 screws and lock washers for proper grounding. Fasten the

left side using the two 6-32 screws and lock washers for proper grounding.

Important:

Step 5. Reinstall the Keypad Bracket in the Drive

Step 5.1 Align the Regulator board ribbon cable connector with the connector to the

Step 5.2 Place the keypad bracket back into position.

Step 5.3 Reattach the anodized inner cover.

Step 5.4 If the drive has:

Step 5.5 Reconnect any wiring that was removed from the Regulator board terminal

You must use the lock washers to properly ground the LonWorks module.

Improper grounding of the LonWorks module can result in erratic operation

of the drive.

Base board. Carefully press the ribbon cable connector in until the retaining

clips lock into place.

•

A Regulator board cover and a terminal cover: Replace the Regulator board

cover. Fasten it using the three M4 screws removed in earlier.

•

Only a terminal cover: Use a long magnetized screwdriver to fasten the four

screws that hold the keypad bracket. Replace the side cover.

strip. Refer to the terminal connections documented in step 3.4 or to the

appropriate instruction manuals for the devices being used.

3-18

LonWorks Module for VTAC 7 Drives

Page 33

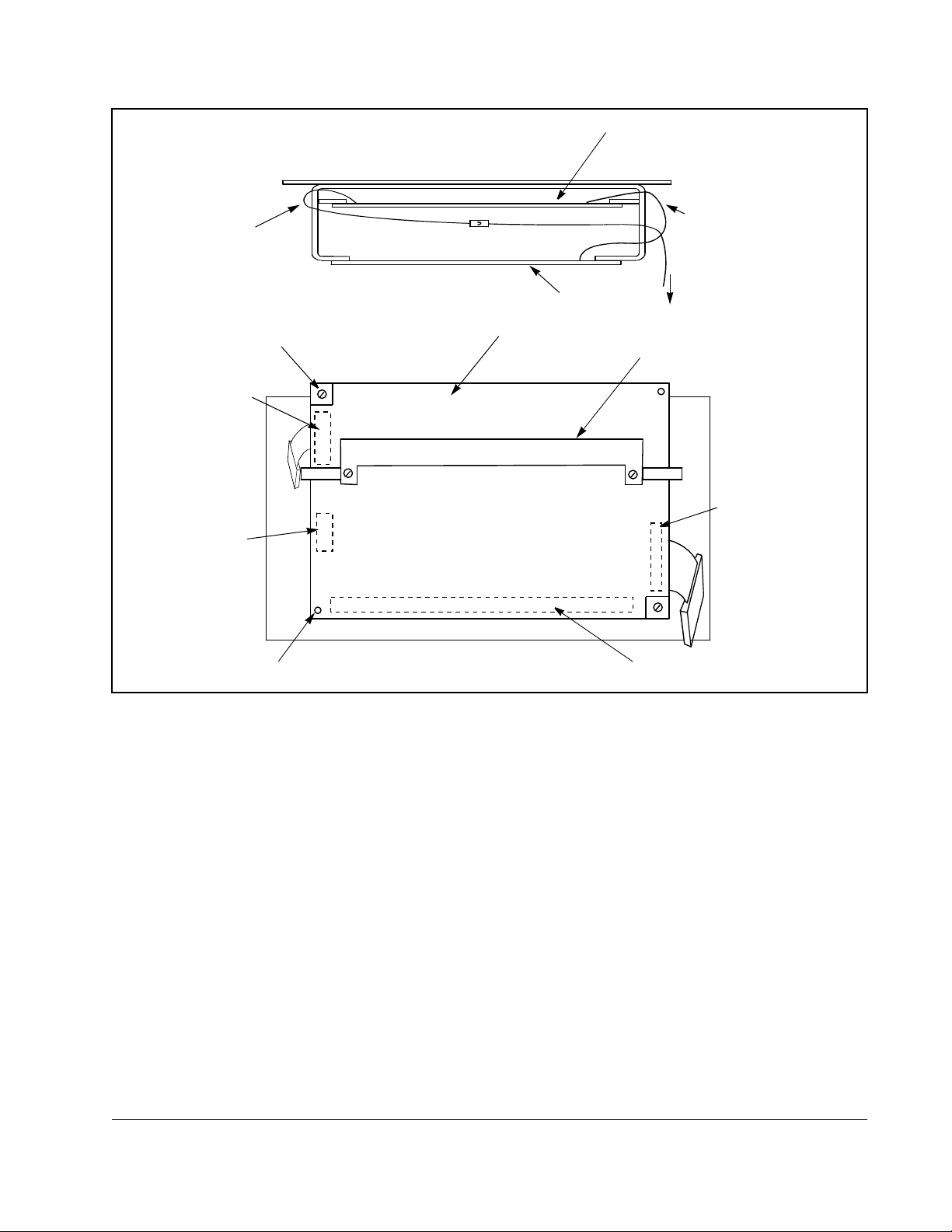

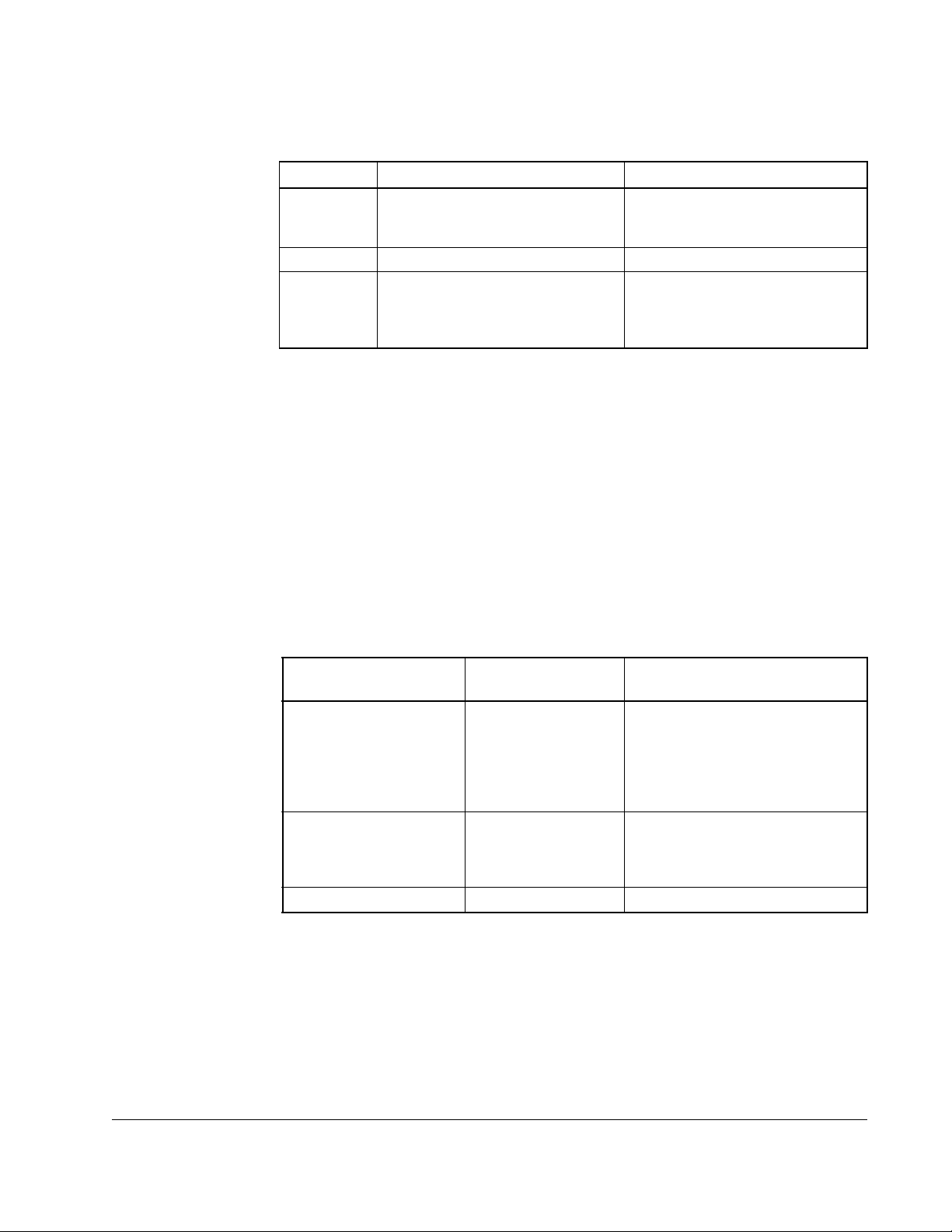

Ribbon Cable

Connecting

Regulator Board and

Base Board

Front

Top View

Regulator Board

LonWorks

Ribbon Cable

Connecting

Regulator Board

and LonWorks

Module

To Base Board

Metal Screw

Ribbon Cable

Connector to

Connect Base

Board

Ribbon Cable

Connector to

Connect Keypad

Plastic Rivet

Figure 3.9 – Regulator Board’s Connection to LonWorks Module, Keypad, and Base Board

Back Side of

Regulator Board

Insulator

Ribbon Cable

Connector to

Connect

LonWorks

Module

Rear View of Regulator Board

Terminal Strip

Step 5.6 Replace the terminal cover (below the keypad). Fasten it using the M4

screws removed earlier.

Step 5.7 Reinstall the Power Module in the drive cabinet.

Step 5.8 Close the outer cabinet door.

Installing the LonWorks Module in the Drive

3-19

Page 34

3.5 Installing the LonWorks Module in 15 to 25 HP and

25 to 60 HP @ 460VAC Drives

ATTENTION:Only qualified electrical personnel familiar with the

construction and operation of this equipment and the hazards involved

!

should install, adjust, operate, or service this equipment. Read and

understand this manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution could result in

severe bodily injury or loss of life.

ATTENTION:The drive is at line voltage when connected to incoming

AC power. Disconnect, lock out, and tag all incoming power to the drive

before performing the following procedure. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:DC bus capacitors retain hazardous voltages after input

power has been disconnected. After disconnecting input power, wait five

minutes for the DC bus capacitors to discharge and then check the

voltage with a voltmeter to ensure the DC bus capacitors are discharged

before touching any internal components. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:The drive contains ESD- (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

when installing, testing, servicing, or repairing the drive. Erratic machine

operation and damage to, or destruction of, equipment can result if this

procedure is not followed. Failure to observe this precaution can result

in bodily injury.

Use this procedure to install the LonWorks module in the drives listed in table 3.6.

Table 3.6 – Model Numbers for 15 to 25 HP and 25 to60 HP @ 460 VAC Drives

Model Numbers for 15 to 25 HP

VTAC 7 Drives

15H41xx

15H42xx

20H41xx

20H42xx

25H41xx

25H42xx

Refer to figure 3.12 or 3.13 as you perform the procedure.

Unless otherwise indicated, keep all hardware that is removed. You will need it for

reassembly. This includes screws, lock washers, and rivets.

If the drive is panel-mounted, this procedure will be easier to perform if the drive is

removed from the panel.

Model Numbers for 25 to 60 HP

VTAC 7 Drives

25W21xx

30H41xx

30H42xx

40H41xx

40H42xx

50H41xx

50H42xx

60H41xx

60H42xx

3-20

LonWorks Module for VTAC 7 Drives

Page 35

Important: Read and understand the warning labels on the outside of the drive

before proceeding.

Step 1. Shut Down the Drive

Step 1.1 Disconnect, lock out, and tag all incoming power to the drive.

Step 1.2 Wait five minutes for the DC bus capacitors to discharge.

Step 1.3 Remove the cover by loosening the four cover screws.

Important: Read and understand the warning labels on the inside of the drive before

proceeding.

Step 2. Verify That the DC Bus Capacitors are Discharged

Step 2.1 Use a voltmeter to verify that there is no voltage at the drive’s AC input

power terminals (R/L1, S/L2, T/L3).

Step 2.2 Ensure that the DC bus capacitors are discharged. To check

DC bus potential:

a. Stand on a non-conductive surface and wear insulated gloves.

b. Use a voltmeter to measure the DC bus potential at the DC bus power

terminals as shown in figures 3.10 (15 to 25 HP @ 460 volts) and 3.11

(25 to 60 HP @ 460 volts).

U/T1 T/L3

Installing the LonWorks Module in the Drive

V/T2

Motor Leads

Figure 3.10 – DC Bus Voltage Terminals (15 to 25 HP @ 460 VAC)

+

DC Bus

Volts

–

R/L1W/T3

S/L2

AC Power

Input Leads

3-21

Page 36

Figure 3.11 – DC Bus Voltage Terminals (25 to 60 HP @ 460 VAC)

Step 3. Remove the Keypad Bracket from the Drive

See figure 3.12 (15 to 25 HP @ 460 VAC) or 3.13 (25 to 60 HP @ 460 VAC) for part

locations.

Step 3.1 Record connections to the Regulator board terminal strip if they must be

disconnected to remove the keypad bracket.

Input WiringDC Bus Volts

Step 3.2 Loosen the thumb screw on the left side of the keypad bracket. Hold the

bracket on the left and lift the bracket up and to the left to separate it from

the keypad support bracket.

Important: The keypad support bracket is connected to the drive by wiring. Do not lift

the bracket out completely, because this can damage or pull out wiring.

Tie up or support the bracket to prevent damage to the wiring.

Step 3.3 Disconnect the 26-conductor Regulator board ribbon cable from the Power

Supply board (located on the right side below the keypad). You can see the

connector through the slot on the keypad support bracket. Use a small

screwdriver inserted through the slot to spread the retaining clips on the

connector to release it.

3-22

LonWorks Module for VTAC 7 Drives

Page 37

Step 4. Install the LonW orks Module in the Keypad Bracket

ATTENTION:The drive contains ESD- (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

!

Step 4.1 Remove the LonWorks module from its anti-static wrapper. Align the key on

when installing, testing, servicing, or repairing the drive. Erratic machine

operation and damage to, or destruction of, equipment can result if this

procedure is not followed. Failure to observe this precaution can result

in bodily injury.

the Regulator board’s 34-conductor ribbon cable connector with the slot in

the LonWorks module’s connector. Press the ribbon cable connector in until

it locks into position.

Regulator Board

Top ViewFront View

Figure 3.12 – LonWorks Module Location in 15 to 25 HP @ 460 VAC Drives

LonWorks

Module

Installing the LonWorks Module in the Drive

3-23

Page 38

Regulator Board

LonWorks

Module

Front View

Figure 3.13 – LonWorks Module Location in 25 to 60 HP @ 460 VAC Drives

Step 4.2 Align the LonWorks module on the four mounting tabs on the keypad

bracket. Make sure that the ribbon cable is not pinched between the keypad

bracket and the LonWorks module.

Step 4.3 Fasten the LonWorks module to the right side of the keypad bracket using

the two metal M3 screws and lock washers for proper grounding. Fasten the

left side using the two 6-32 screws and lock washers for proper grounding.

Important:

You must use the lock washers to properly ground the LonWorks module.

Improper grounding of the LonWorks module can result in erratic operation

of the drive.

Step 4.4 Realign the 26-conductor ribbon cable connector with the Power Supply

board connector inside the slot in the keypad support bracket. Carefully

press the ribbon cable connector in until the retaining clips lock it into place.

Step 5. Reinstall the Keypad Bracket in the Drive

Step 5.1 Reconnect the keypad bracket to the keypad support bracket by inserting

the mounting tabs into the slots in the keypad support bracket and tightening

the thumb screw.

Step 5.2 Reconnect any wiring that was removed from the Regulator board terminal

strip. Refer to the terminal connections documented in step 3.1 or to the

appropriate instruction manuals for the devices being used.

Top View

3-24

Step 5.3 NEMA 4X/12 drives only: Before installing the cover , check that the gaskets

on the cover are flat and within the gasket channels.

Step 5.4 Reinstall the cover. Align all cover screws into the heat sink before

tightening any of them.

LonWorks Module for VTAC 7 Drives

Page 39

To maintain the integrity of NEMA 4X/12 drives, sequentially tighten the

cover screws to ensure even compression of the gaskets. Do not exceed

2.2 Nm (20 in-lb) of torque on these screws.

Installing the LonWorks Module in the Drive

3-25

Page 40

3.6 Installing the LonWorks Module in 200 to 400 HP @

460 VAC Drives

ATTENTION:Only qualified electrical personnel familiar with the

construction and operation of this equipment and the hazards involved

!

should install, adjust, operate, or service this equipment. Read and

understand this manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution could result in

severe bodily injury or loss of life.

ATTENTION:The drive is at line voltage when connected to incoming

AC power. Disconnect, lock out, and tag all incoming power to the drive

before performing the following procedure. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:DC bus capacitors retain hazardous voltages after input

power has been disconnected. After disconnecting input power, wait five

minutes for the DC bus capacitors to discharge and then check the

voltage with a voltmeter to ensure the DC bus capacitors are discharged

before touching any internal components. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:The drive contains ESD- (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

when installing, testing, servicing, or repairing the drive. Erratic machine

operation and damage to, or destruction of, equipment can result if this

procedure is not followed. Failure to observe this precaution can result

in bodily injury.

Use this procedure to install the LonWorks module in the drives listed in table 3.7.

Table 3.7 – Model Numbers for 200 to 400 HP @ 460 VAC Drives

Refer to figure 3.14 as you peform the procedure.

Unless otherwise indicated, keep all hardware that is removed. You will need it for

reassembly. This includes screws, lock washers, and rivets.

Important: Read and understand the warning labels on the outside of the drive

before proceeding.

Step 1. Shut Down the Drive

Step 1.1 Disconnect, lock out, and tag all incoming power to the drive.

Step 1.2 Wait five minutes for the DC bus capacitors to discharge.

Important: Read and understand the warning labels on the inside of the drive before

proceeding.

VTAC 7 Model Numbers

200H41xx

250H41xx

300H41xx

350H41xx

400H41xx

3-26

LonWorks Module for VTAC 7 Drives

Page 41

Step 2. Verify That the DC Bus Capacitors are Discharged

Step 2.1 Open the drive’s outer cabinet door.

Step 2.2 Lower the plastic terminal strip shield at the top of the drive.

Step 2.3 Use a voltmeter to verify that there is no voltage at the drive’s AC input

power terminals, R, S, and T.

Step 2.4 Replace the plastic terminal strip shield.

Step 2.5 Ensure that the DC bus capacitors are discharged. To check

DC bus potential:

a. Stand on a non-conductive surface and wear insulated gloves. (600 V)

b. Use a voltmeter to check the DC bus potential at the Voltmeter Test

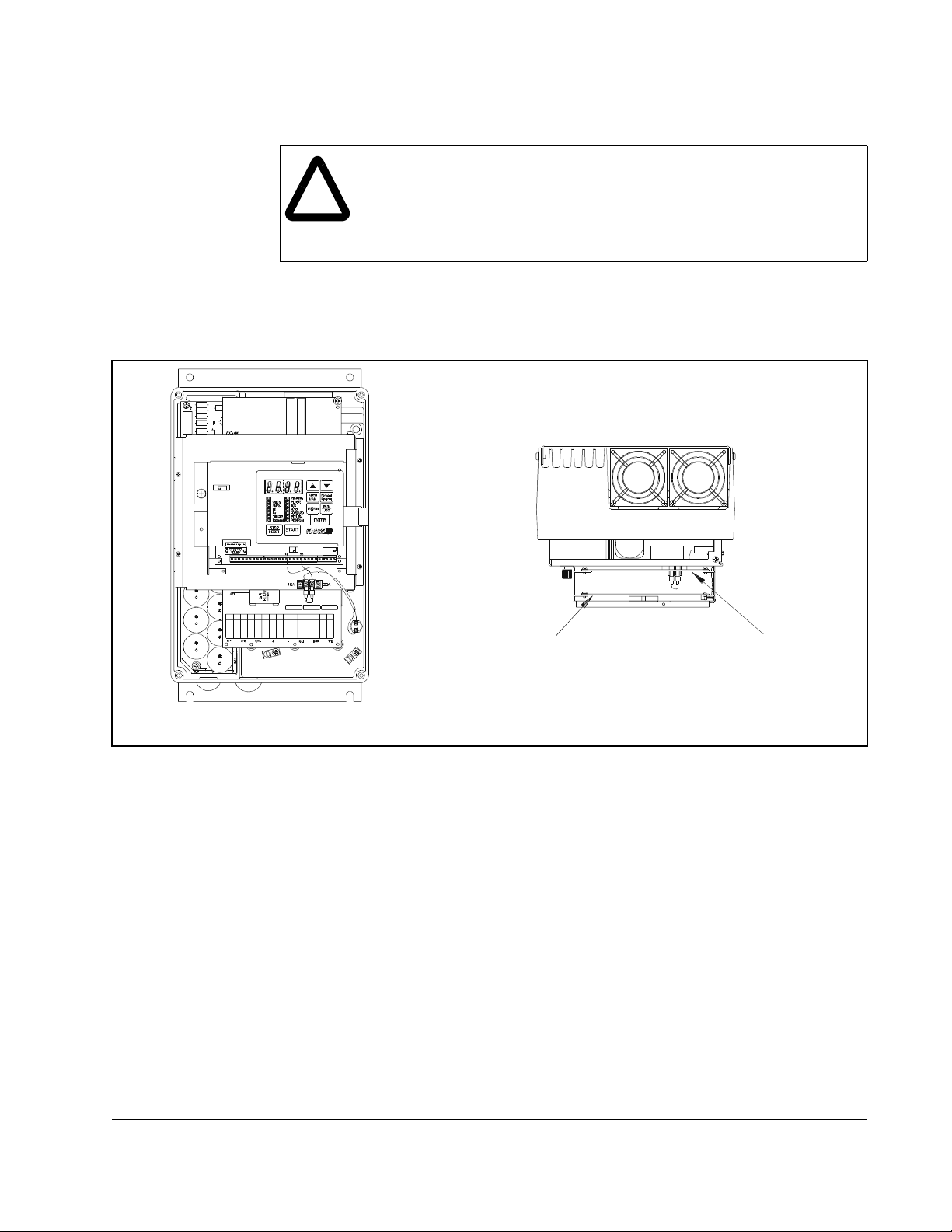

Points on the Power Module Interface board. See figure 3.14.

Step 3. Remove the Keypad Bracket from the Drive

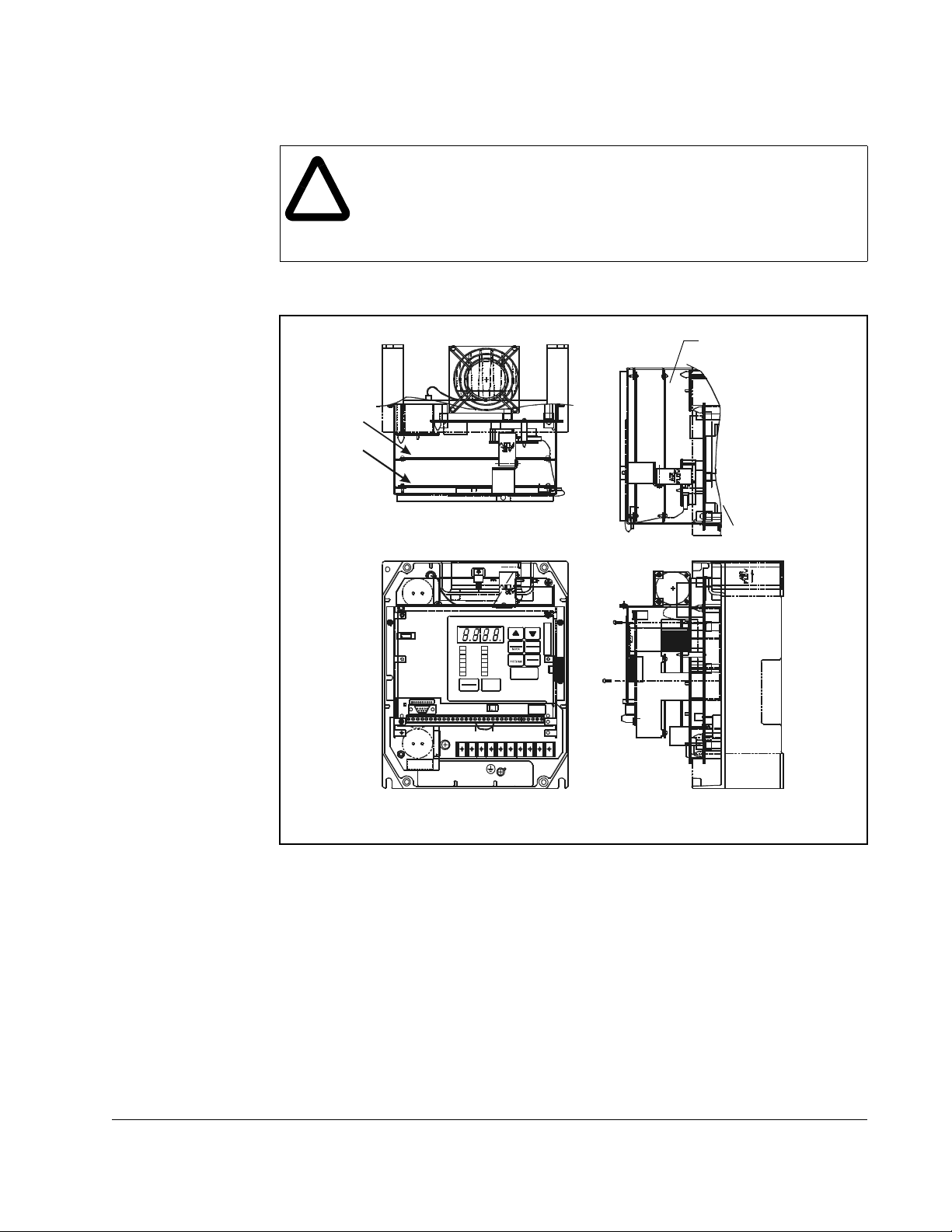

Refer to figure 3.14 for component locations.

POWER CONNE CTIONS

POWER CONNE CTIONS

FULL SHIELD TABS IN AND ROTATE SHIELD OUT

FULL SHIELD TABS IN AND ROTATE SHIELD OUT

CONNE C T USI NG 360MCM TW O HOLE TE RM IN AL LUG S

CONNE C T USI NG 360MCM TW O HOLE TE RM IN AL LUG S

TORQUE TO 32 5IN-LB

TORQUE TO 32 5IN-LB

Wiring Tray

DC–

DC–

GND

GND

GND

GND

WT1 WT2VRL1WWT3

WT1 WT2VRL1WWT3

DC+

DC+

U

U

DC+

DC+

DC–

DC–

DANGER

DANGER

SL2 T

SL2 T

RST

RST

Wiring Tray

Power Module

Interface Board

RUNNING

RPM

RUNNING

RPM

REMOTE

VOLTS

REMOTE

VOLTS

JOG

AMPS

JOG

AMPS

Hz

Hz

AUTO

AUTO

FORWARD

Kw

FORWARD

Kw

REVERSE

TORQUE

REVERSE

TORQUE

PROGRAM

Password

PROGRAM

Password

ENTER

ENTER

STOP

STOP

START

START

RESET

RESET

Keypad

Regulator

Board

LonWorks

Side View

(Enlarged)

Front View

Figure 3.14 – LonWorks Module Location in 200 to 400HP @ 460VAC Drives

Step 3.1 Record connections to the Regulator board terminal strip if they must be

disconnected to remove the keypad bracket.

Step 3.2 Use a magnetic screwdriver to remove the four screws and lock washers

that fasten the keypad bracket to the hinged mounting panel. Hold the

keypad bracket as you remove the screws.

Step 3.3 Disconnect the Regulator board ribbon cable from the Power Module

Interface board.

Installing the LonWorks Module in the Drive

3-27

Page 42

Step 4. Install the LonWorks Module

ATTENTION:The drive contains ESD- (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

!

Step 4.1 Remove the LonWorks module from its anti-static wrapper. Align the key on

Step 4.2 Align the LonWorks module’s four mounting holes with the four standoffs on

Step 4.3 Fasten the board to the drive with four 7/32″ nuts. Metal nuts must be used

Step 4.4 Remove the LonWorks module from its anti-static wrapper. Align the key on

when installing, testing, servicing, or repairing the drive. Erratic machine

operation and damage to, or destruction of, equipment can result if this

procedure is not followed. Failure to observe this precaution can result

in bodily injury.

the Regulator board’s 34-conductor ribbon cable connector with the slot in

the LonWorks module’s connector. Press the ribbon cable connector in until

it locks into position.

The LonWorks module mounts on four standoffs behind the Regulator

board.

the hinged mounting panel of the drive.

for proper grounding of the LonWorks module.

the Regulator board’s 34-conductor ribbon cable connector with the slot in

the LonWorks module’s connector. Press the ribbon cable connector in until

it locks into position.

Step 5. Reinstall the Keypad Bracket in the Drive

Step 5.1 Align the key on the connector from the Regulator board with the key of the

connector on the Power Module Interface board. Press the ribbon cable

connector in until it locks into position.

Step 5.2 Reconnect the keypad bracket to the hinged mounting panel using the four

screws removed earlier.

Step 5.3 Reconnect any wiring that was removed from the Regulator board terminal

strip. Refer to the terminal connections documented in step 3.1 or to the

appropriate instruction manuals for the devices being used.

Step 5.4 Close and secure the outer cabinet door of the drive.

3-28

LonWorks Module for VTAC 7 Drives

Page 43

CHAPTER 4

Connecting the Drive to the Network

and Applying Power

ATTENTION:The drive may contain high voltages that can cause injury

or death. Remove all power from the drive, then verify power has been

!

4.1 Connecting the Drive to the Network

Before connecting the drive to the network, verify that the module has been installed

in the drive according to the instructions provided in chapter 3. Then use the following

procedure to connect the drive to the network:

Step 1. Verify that po wer is removed from the network and drive.

Step 2. Use static control procedures.

removed before installing or removing a LonWorks module. Failure to

observe these precautions could result in severe bodily injury or loss of

life.

Step 3. Route the network cable through the bottom of the drive (or as described in

the VTAC 7 User Manual). Refer to table 2.2 in chapter 2 for recommended

network cables.

Step 4. Connect the network cable to the 5-screw terminal block on the LonWorks

module. Refer to table 4.1 for the terminal definitions.

Table 4.1 – Terminal Block Terminal Definitions

Pin Name Function

1 SHIELD Shield connection

2 NC Not used

3 NC Not used

4 NET A LonWorks NET A connection

5 NET B LonWorks NET B connection

4.2 Terminating the Ne twork

The LonWorks module does not provide built-in termination. Refer to the FTT-10A

Free Topology Transceiver User’s Guide (doc.id078-0156-01F) for more information

about terminating a LonWorks network (available at http://www.echelon.com).

Connecting the Drive to the Network and Applying Power

4-1

Page 44

4.3 Applying Power

ATTENTION:Unpredictable operation may occur if parameter settings

and switch settings are not compatible with your application. Verify that

!

Step 1. Close the drive cover or re-install the cover on the drive.

Step 2. Apply power to the drive. The module receives its power from the connected

Step 3. Apply power to the other devices on the network.

When to press service pin?

setting are compatible with your application before applying power to the

drive. Failu re to obse rve thes e precaut ions cou ld result in severe bo dily

injury or loss of life.

drive.

(Check LEDs on VTAC?)

4-2

LonWorks Module for VTAC 7 Drives

Page 45

CHAPTER 5

Installing the Drive as a Node

in the Network

ATTENTION:This procedure requires power be applied to the drive and

the network while the cover is off of the drive. The user is responsible

!

The module is installed as a node in the LonWorks network using a standard

LonWorks installation tool such as LonMaker for Windows. Refer to the tool-specific

instruction manual for more information.

for ensuring safe conditions for operating personnel. Failure to observe

this precaution could result in severe bodily injury or loss of life.

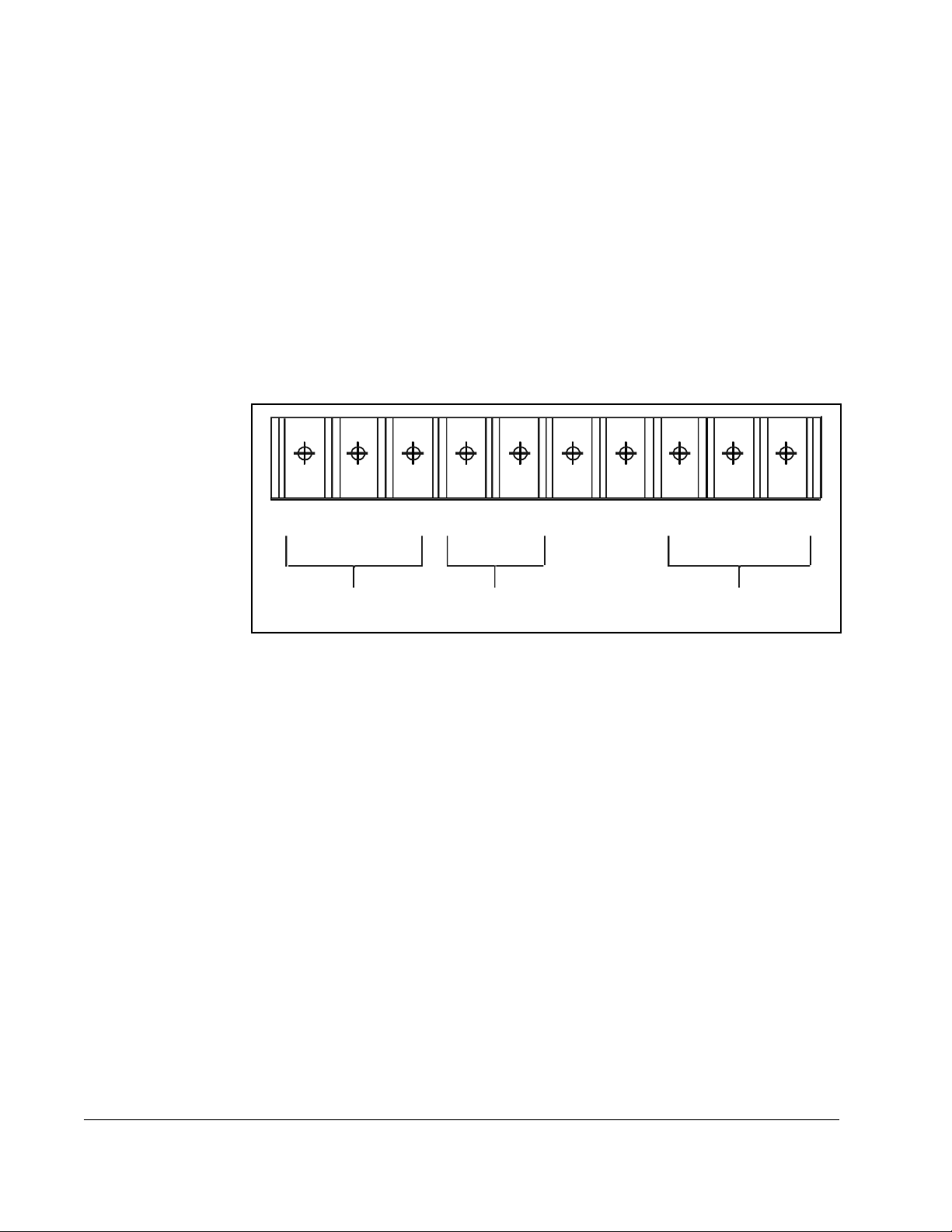

To identify the drive to the network, press the service pin shown in figure 5.1.

do this? Should this be part of chapter 4? How do you verify the results of

pressing the pin?)

When you have completed this procedure, re-install the drive cover.

Service Pin

Figure 5.1 – Location of the Service Pin on the LonWorks Module

(When to

Installing the Drive as a Node in the Network

5-1

Page 46

5-2

LonWorks Module for VTAC 7 Drives

Page 47

Programming the Drive

for Network Communication

This section describes how to configure a VTAC 7 drive for use with an LonWorks

network. The sections that follow describe the VTAC 7 parameters related to

LonWorks network operation. For other drive parameter descriptions, refer to the

VTAC 7 User Manual.

6.1 Setting the Control Source (P.000)

Parameter Range: LOCL = Local keypad/display

rE = Terminal strip remote inputs

OP = Option port

SErL = Serial port (CS3000 or OIM)

Default Setting: LOCL

Parameter Type: Configurable

CHAPTER 6

Parameter P.000 (Control Source) selects the source of control information for the

drive (start, jog, direction, etc.). To start and stop the drive over the network,

parameter P.000 must be set to OP. This parameter can be written over the network

only when the drive is stopped.

After parameter P.000 is set to OP, the Remote LED on the keypad should turn on to

show the network is in control of the drive. Note that parameter P.000 does not

prevent the drive from communicating on the network; it only allows the drive to be

controlled and the reference to be supplied from the network.

not have to be set to OP to modify or read drive parameters. True?

Parameter P.000 does

Programming the Drive for Network Communication

6-1

Page 48

6.2 Setting the Network Connection Type (P.061)

Parameter Range: 0 = Basic drive connection

1 = Full drive connection

Default Setting: 0

Parameter Type: Configurable

Refer also to paramete rs: N/A

Parameter P.061 (Network Connection Type) selects the type of network connection.

Setting P.061 = 1 provides full drive control from the network. Any drive data that has

been assigned a network register is transferred over the network. Parameter P.061

must be set to 1 to configure the drive over the network and have access to most

parameters, operating variables, and diagnostic information. The LonWorks module

will fault the drive if P.061 is not set to 1.

6.3 Setting the Commu nication Loss Response (P.062)

Parameter Range: 0 = IET fault

1 = Hold last reference

2 = Use terminal strip reference

Default Setting: 0

Parameter Type: Tunable

Refer also to paramete rs: P.000 Control Source

Parameter P.062 (Communication Loss Response) specifies how the drive responds

to a network communication loss when the Control Source (P.000) parameter is set to

OP (Option port).

If the option port is not in control of the drive, but is only monitoring drive operation,

then loss of network communications has no effect on drive operation. In all cases, the

LonWorks module, upon loss of communication with the network, will attempt to

re-establish the communication link.

T o eliminate extraneous fault conditions when a drive configured for network operation

is powered up, the drive will delay for approximately 20 seconds after power up before

annunciating a fault condition. A fault condition will be annunciated if network

communication is not established before the 20-second power-up timer expires, or if

network communication was established and then lost.

If the drive loses communication with the network, overspeed protection for the drive

will be in effect under all circumstances. you program overspeed protection in H.022.

When the motor goes above the overspeed limit, the drive faults and stops.

6-2

LonWorks Module for VTAC 7 Drives

Page 49

P.062 Option Port: Communication Loss Response

If P.062 = 0

The drive will consider a loss of network communication to be a drive fault, resulting in

an IET-type stop sequence.

When P.062 is set to IET fault (0) and communication is lost:

(continued)

• The drive latches a fault condition and performs a coast stop.

• The network communication loss fault is generated (nCL is displayed).

• The front panel REMOTE LED blinks, indicating that the network is inactive.

When network communication is re-established, you must reset the fault before the

drive can be re-started. See the VTAC 7 User Manual for information on resetting

faults. (A fault reset does not clear the error log.)

If P.062 = 1

The drive continues to operate, using the last reference received from the network.

ATTENTION:In volts/hertz regulation, if P .000 (Control Source) is set to

OP (Option Port), and P .062 is set to 1 (hold last reference), and the drive

!

loses communication with the network, the drive will maintain the last

frequency command sent to it. Ensure that drive machinery , all drive-train

mechanisms, and application material are capable of safe operation at

the maximum operating speed of the drive. Failure to observe this

precaution could resu lt in bodily inj ur y.

ATTENTION:When P.055 is set to

functional only from the selected control source. As a safety precaution,

Rockwell Automation recommends that an emergency stop pushbutton

be located near the drive in an easily accessible location. As a further

safety precaution, the user should post a warning on the drive to alert

personnel that the

this precaution could result in severe bodily injury or loss of life.

STOP/RESET key is not functional. Failure to observe

ON, the STOP/RESET key is

The response to network communication loss is:

• The drive continues to operate, using the last reference received from the network

master.

• An entry is made into the drive’s error log for each active-to-inactive transition of

network communicat ion status .

• The front panel REMOTE LED blinks, indicating that the network is inactive.

If network communication is re-established, the drive will again follow the reference

and sequencing control inputs supplied by the network. Note that if P.054 = ON and

the start and stop inputs are on (1), the drive will start.

Note that in this configuration, it might not always be possible to stop the drive over

the network.

Programming the Drive for Network Communication

6-3

Page 50

P.062 Option Port: Communication Loss Response

If P.062 = 2

The drive gets its speed/torque reference from the terminal strip analog input and its

stop input from the terminal strip stop input. All other inputs are held at the last values

received from the network.

This allows the network to continue controlling the drive reference with a direct-wired

analog output to input, and to stop the drive with a direct-wired digital output to input.

Note that if P.054 (Level Sense Start Enable) = OFF and the drive is stopped while in

this mode, it cannot be re-started until network communication is re-established or the

Control Source (P.000) is changed.

ATTENTION:If P.062 = 2 and P.054 (Level Sense Start Enab le) = ON

and network communication is lost while the drive is running, the terminal

!

Note that in this configuration, it might not always be possible to stop the drive over

the network.

strip stop input will function as a STOP/RUN input. If the terminal strip

stop input is opened, the drive will stop. If the terminal strip stop input is

closed, the drive will re-start. Failure to observe this precaution could

result in severe bodily injury or loss of life.

(continued)

The response to network communication loss is:

• The drive continues to operate, using the analog input from the Regulator board

terminal strip.

• An entry is made into the drive’s error log for each active-to-inactive transition of

network communicat ion status .

• The front panel REMOTE LED blinks, indicating that the network is inactive.

If network communication is re-established, the drive will again follow the reference

and sequencing control inputs supplied by the network. Note that if P.054 = ON and

the start and stop inputs are on (1), the drive will start.

ATTENTION:The drive is not equipped with a coast-stop pushbutton.

You must install a hardwired operator-accessible pushbutton that

!

provides a positive interrupt and shuts down the drive. See the drive

hardware instruction manual for wiring information. Failure to obser ve

this precaution could result in bodily injury.

6-4

LonWorks Module for VTAC 7 Drives

Page 51

6.4 Setting the Speed Display Scale (P.028)

Parameter Range: 10 to 9999

Default Setting: Synchronous speed based on H.001 (assuming a

4-pole motor)

Parameter Type: Tunable