Page 1

User Manual

ArmorStart® LT Distributed Motor Controller

Catalog Numbers 290D, 291D, 294D

Page 2

Important User Information

IMPORTANT

Because of the variety of uses for the products described in this publication, those responsible for the application and use of

this control equipment must satisfy themselves that all necessary steps have been taken to assure that each application and

use meets all performance and safety requirements, including any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in this guide are intended solely for purposes of

example. Since there are many variables and requirements associated with any particular installation, Rockwell Automation

does not assume responsibility or liability (to include intellectual property liability) for actual use based upon the examples

shown in this publication.

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (Publication SGI-1.1

local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

available from your

) describes some

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Page 3

General Precautions

In addition to the precautions listed throughout this manual, the following statements, which are general to the system,

must be read and understood.

ATTENTION: This manual is intended for qualified service personnel responsible for setting up and servicing these devices. The

user must have previous experience with and a basic understanding of electrical terminology, configuration procedures,

required equipment, and safety precautions.

WARNING: The National Electrical Code (NEC), NFPA79, and any other governing regional or local code will overrule the

information in this manual. Rockwell Automation cannot assume responsibility for the compliance or proper installation of the

ArmorStart LT or associated equipment. A hazard of personal injury and/or equipment damage exists if codes are ignored

during installation.

ATTENTION: The controller contains ESD (electrostatic discharge) sensitive parts and assemblies. Static control precautions are

required when installing, testing, servicing, or repairing the assembly. Component damage may result if ESD control

procedures are not followed. If you are not familiar with static control procedures, refer to Publication 8000-4.5.2

against Electrostatic Discharge, or any other applicable ESD protection handbooks.

, Guarding

ATTENTION: Only personnel familiar with the controller and associated machinery should plan or implement the installation,

startup, and subsequent maintenance of the system. Failure to do this may result in personal injury and/or equipment

damage.

Precautions for Bulletin 294D Applications

ATTENTION: Only qualified personnel familiar with adjustable frequency AC drives and associated machinery should plan or

implement the installation, startup, and subsequent maintenance of the system. Failure to do this may result in personal injury

and/or equipment damage.

Rockwell Automation Publication 290D-UM001A-EN-P - June 2012 3

Page 4

Software Requirements

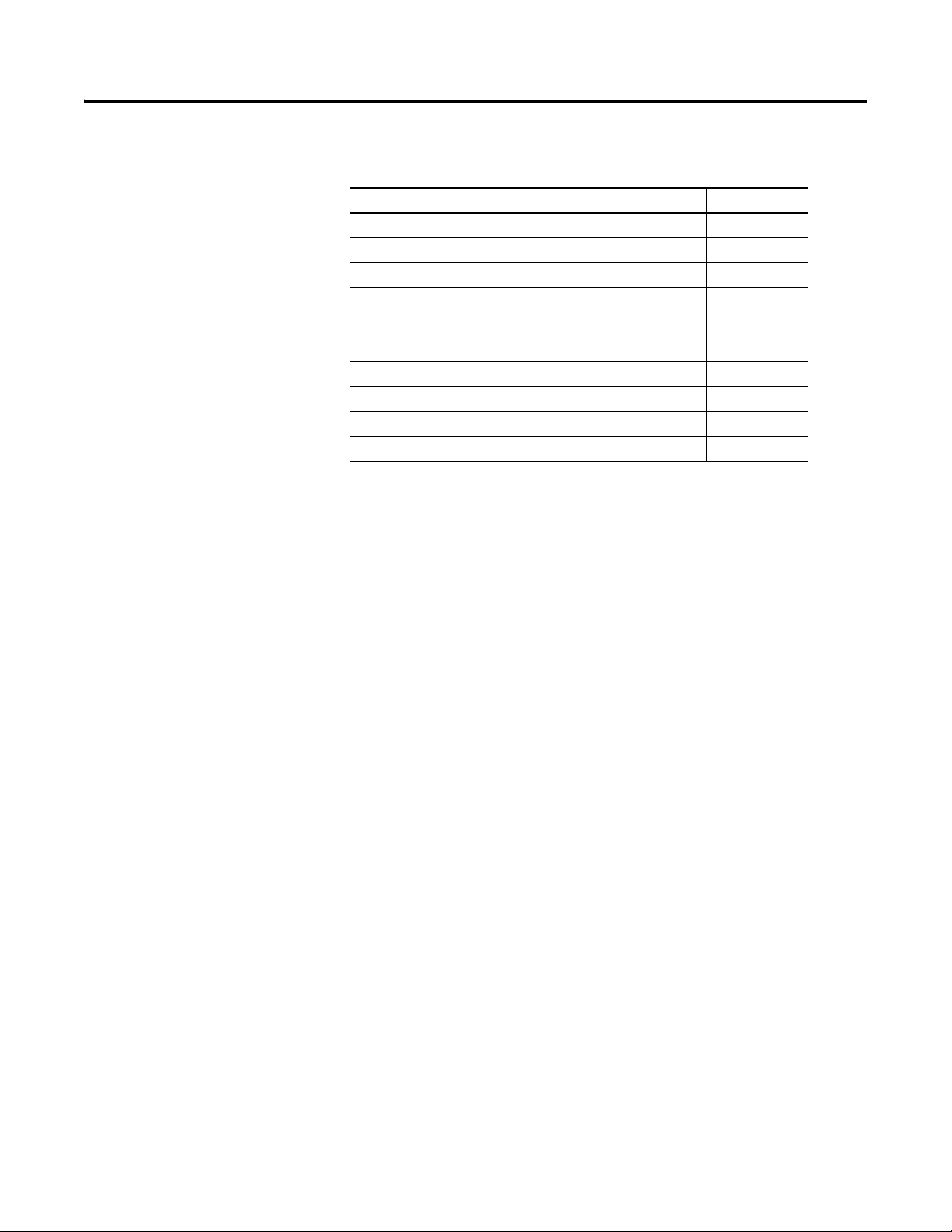

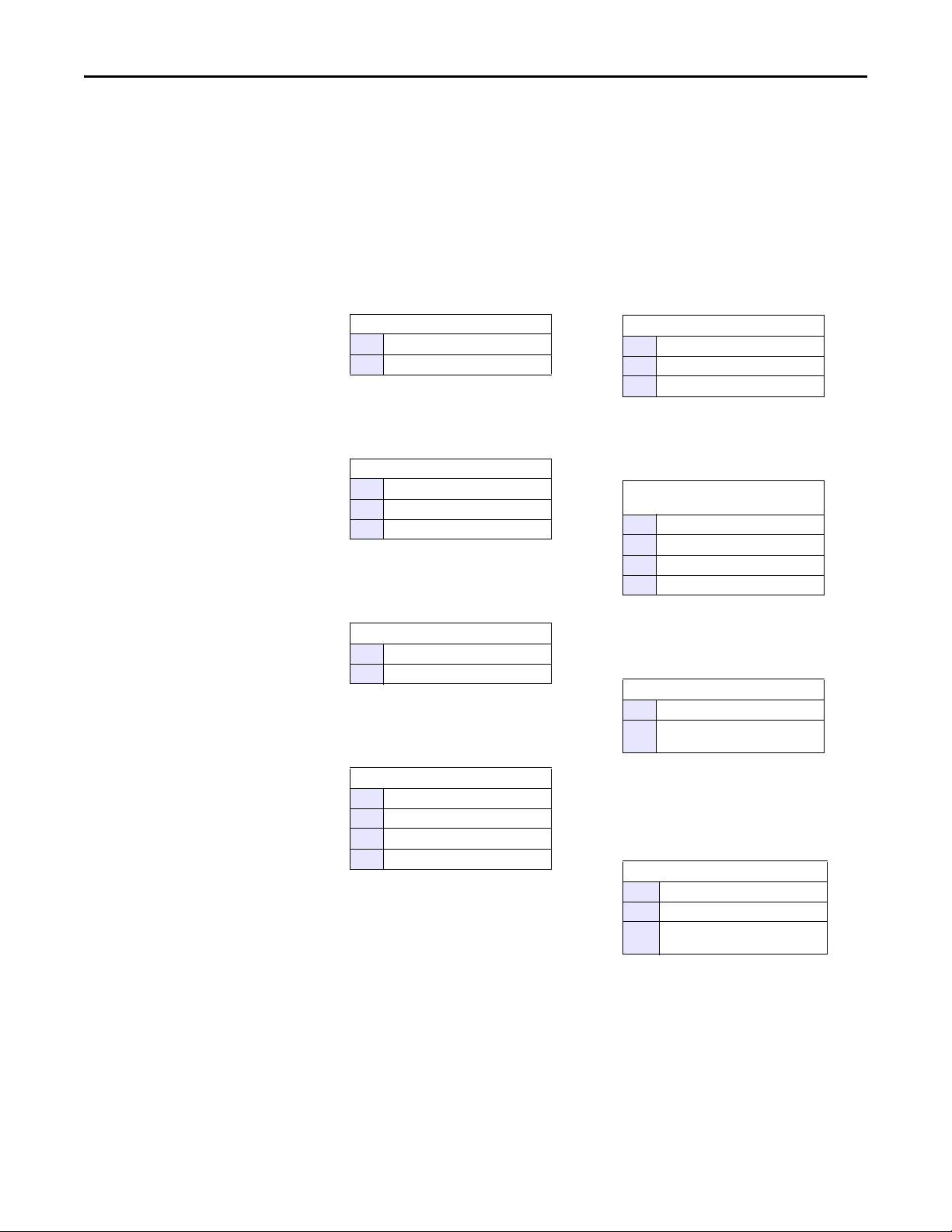

The table lists the versions of software that are required.

Software Version

RSLinx Classic 2.56 or later

RSLogix 5000 17.01 or later

RSNetworx 11 or later

Download the most current version of the Add-On Profile from

http://www.rockwellautomation.com/support/downloads.html.

Additional Resources

These documents and websites contain additional information concerning related Rockwell Automation products.

You can view or download publications at http:/www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or Rockwell Automation sales representative.

Table 1 - Rockwell Automation Industrial Network Resources

Resource Description

http://www.ab.com/networks/

http://www.rockwellautomation.com/services/networks/

http://www.rockwellautomation.com/services/security/

http://www.ab.com/networks/architectures.html Education series webcasts for IT and controls professionals

Industrial Automation Wiring and Grounding Guidelines, Publication 1770-4.1 Provides general guidelines for installing a Rockwell Automation industrial system.

Wiring and Grounding Guidelines, (PWM) AC Drives, Publication DRIVES-IN001 Describes wiring and grounding guidelines for Pulse Width Modulated (PWM) AC Drives

Product Certifications website,

http://www.rockwellautomation.com/products/certification

Table 2 - ODVA Resources

Resource Description

http://www.odva.org/

http://www.odva.org/default.aspx?tabid=54

Rockwell Automation networks and communication website

Rockwell Automation network and security services websites

Provides declarations of conformity, certificates, and other certification details.

Open DeviceNet Vendors Association (ODVA) website

The CIP Advantage website

• CIP features and benefits

• How to get started

Table 3 - Product Selection Resources

Resource Description

Industrial Controls catalog website,

http://www.ab.com/catalogs/

ArmorStart LT Distributed Motor Controller Selection Guide, Publication 290-SG001

4 Rockwell Automation Publication 290D-UM001A-EN-P - June 2012

Industrial Controls catalog website

Product selection g uide

Page 5

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using its products. At

http://www.rockwellautomation.com/support/

, you can find technical manuals, a knowledge base of FAQs, technical

and application notes, sample code and links to software service packs, and a MySupport feature that you can customize

to make the best use of these tools.

Installation Assistance

If you experience a problem within the first 24 hours of installation, contact Customer Support.

United States or Canada 1.440.646.3434

Outside United States or

Canada

Use the Wo rldw ide L ocator at http://www.rockwellautomation.com/support/

americas/phone_en.html, or contact your local Rockwell Automation representative.

New Product Satisfaction Return

Rockwell Automation tests all of its products to ensure that they are fully operational when shipped from the

manufacturing facility. However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the

Outside United States Please contact your local Rockwell Automation representative for the return

phone number above to obtain one) to your distributor to complete the return process.

procedure.

Rockwell Automation Publication 290D-UM001A-EN-P - June 2012 5

Page 6

Notes:

6 Rockwell Automation Publication 290D-UM001A-EN-P - June 2012

Page 7

Summary of Changes

New and Updated Information

This table contains the changes made to this revision.

Top ic Pag e

Rockwell Automation Publication 290D-UM001A-EN-P - June 2012 7

Page 8

Summary of Changes

Notes:

8 Rockwell Automation Publication 290D-UM001A-EN-P - June 2012

Page 9

Preface

European Communities (EC) Directive Compliance

Low Voltage and EMC Directives

If this product has the CE mark it is approved for installation within the

European Union and European Economic Area (EEA). It has been designed and

tested to meet the following directives.

This product is tested to meet the European Union (EU) Council 2006/95/EC

Low Voltage Directive and the EU Council 2004/108/EC Electromagnetic

Compatibility (EMC) Directive by applying the following standard(s):

• Bulletin 290D_/291D_: EN 60947-4-1 — Low-voltage switchgear and

controlgear — Part 4-1: Contactors and motor-starters — Electromechanical

contactors and motor-starters.

• Bulletin 294D_: EN 61800-3 — Adjustable speed electronic power drive

systems — Part 3: EMC product standard including specific test methods

EN 61800-5-1:2003 — Adjustable speed electrical power drive systems —

Part 5-1: Safety requirements — Electrical, thermal and energy.

This product is intended for use in an industrial environment.

Rockwell Automation Publication 290D-UM001A-EN-P - June 2012 9

Page 10

Preface

Introduction

The ArmorStart LT is an integrated, pre-engineered, motor starting solution

designed for use in material handling applications. ArmorStart LT is the latest

addition to the ArmorStart portfolio. ArmorStart LT is a leader in the market

place given its compact size and high performance features in network, I/O, and

motor control. This manual will guide you through the features and functionality

when installing the product. Thank you for choosing ArmorStart LT for your

distributed motor control needs. If you have any questions please refer to the

“Support Section” for contact information.

10 Rockwell Automation Publication 290D-UM001A-EN-P - June 2012

Page 11

Table of Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Software Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

New Product Satisfaction Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Summary of Changes

New and Updated Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Preface

European Communities (EC) Directive Compliance. . . . . . . . . . . . . . . . . 9

Low Voltage and EMC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 1

Product Overview

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Feature Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Standard Features Across Product Familly . . . . . . . . . . . . . . . . . . . . . . 20

Network Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Factory Installed Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

ArmorStart LT Characteristics Bulletin 290D/291D . . . . . . . . . . . . . . . 22

Catalog Number Explanation Bulletin 290D/291D. . . . . . . . . . . . . . . . . 23

ArmorStart LT Characteristics Bulletin 294D . . . . . . . . . . . . . . . . . . . . . . 24

Catalog Number Explanation Bulletin 294D . . . . . . . . . . . . . . . . . . . . . . . .25

Basic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Group Motor Installations for USA and Canada Markets. . . . . . . . .26

Control Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Motor Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Local I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Overload Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Mode of Operation Bulletin 290D/291E. . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Full-Voltage Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Mode of Operation Bulletin 294D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Sensorless Vector Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Status LEDs and Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Electronic Data Sheet (EDS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Fault Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Protection Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Optional HOA Selector Keypad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Keypad Local Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Optional HOA Keypad Configuration (Bulletin 290D/291D only). . . 34

Rockwell Automation Publication 290D-UM001A-EN-P - June 2012 11

Page 12

Table of Contents

Optional HOA Selector Keypad

with Jog Function(Bulletin 294D only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Keypad Local Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Keypad and HOA Disable Parameter. . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Source Brake Contactor and Connector (Bulletin 294D only) . . . . . . . .37

Chapter 2

Installation and Wiring

Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Inspecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Storing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Installation Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Precautions for Bulletin 290D/291D Applications. . . . . . . . . . . . . . . . . . . 40

Precautions for Bulletin 294D Applications . . . . . . . . . . . . . . . . . . . . . . . . . 40

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Bulletin 290D/291D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Bulletin 294D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

ArmorStart LT Gland Plate Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Connection Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Internal Power, Control, and Ground Locations . . . . . . . . . . . . . . . . .43

Gland Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Wiring Terminal Detail. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Branch Circuit Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

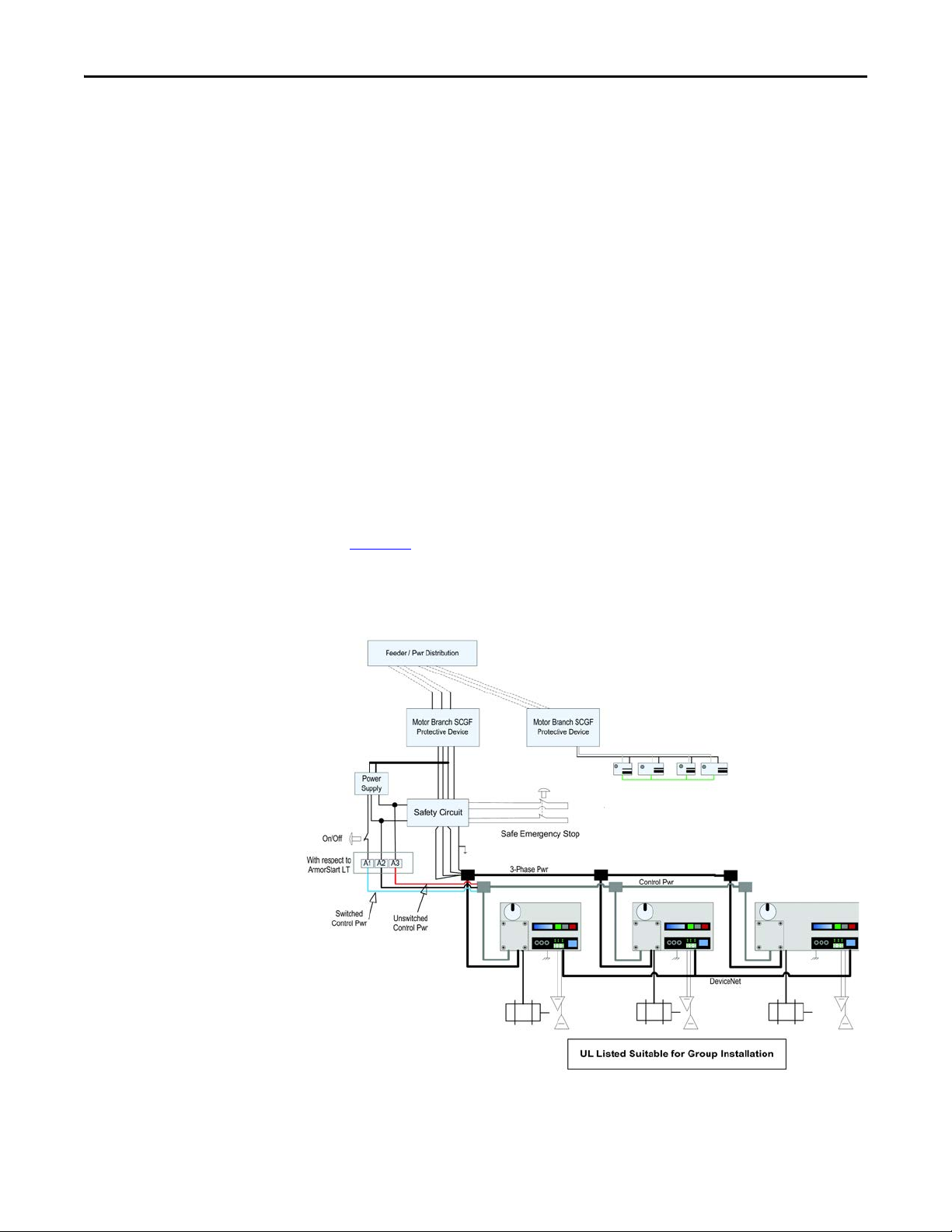

Typical System Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

ArmorConnect Power Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

ArmorConnect Cable Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Branch Circuit Protection Requirements for ArmorConnect

Three-Phase Power Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Group Motor Installations for USA and Canada Markets . . . . . . . . . . . .55

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Cable Workmanship Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Service Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Hand Operation (HOA) Considerations. . . . . . . . . . . . . . . . . . . . . . . . 56

General Wiring Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Grounding Safety Grounds. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Grounding PE or Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Grounding Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Power Distribution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Delta/Wye with Grounded Wye Neutral. . . . . . . . . . . . . . . . . . . . . . . .58

AC Line Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Line Reactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Bulletin 294D Motor Cable Considerations . . . . . . . . . . . . . . . . . . . . . . . . .59

Unshielded Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Shielded Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Recommended Cable Connectors/Glands . . . . . . . . . . . . . . . . . . . . . . .60

12 Rockwell Automation Publication 290D-UM001A-EN-P - June 2012

Page 13

Product Commissioning

Table of Contents

Recommended Cord Grips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Shield Terminating Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Electromagnetic Compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

General Notes (Bulletin 294D only) . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Ethernet, DeviceNet, and I/O Connections . . . . . . . . . . . . . . . . . . . . . . . . .63

ArmorConnect Power Media Receptacles . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Optional Locking Clip. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Chapter 3

Configuring DeviceNet Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Manually Configure the Network Address Switches . . . . . . . . . . . . . .67

DeviceNet Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Establishing a DeviceNet Node Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Node Commissioning using Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Node Commissioning using Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Registering an EDS File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Using the Node Commissioning Tool Inside RSNetworx

for DeviceNet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Bulletin 290E/291E/294E

Programmable Parameters

Chapter 4

Electronic Data Sheet (EDS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Basic Setup Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Parameter Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

ArmorStart LT DeviceNet Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Parameter Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Bulletin 290D/291D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Basic Status Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Trip Status Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Basic Configuration Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Starter Protection Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

User I/O Configuration Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Miscellaneous Configuration Group . . . . . . . . . . . . . . . . . . . . . . . . . . .105

Advanced Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

Bulletin 294D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Basic Status Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Trip Status Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

Motor and Control Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131

Speed Control Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .133

Starter Protection Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

User I/O Configuration Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

Miscellaneous Configuration Group . . . . . . . . . . . . . . . . . . . . . . . . . . .142

Advanced Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .143

Rockwell Automation Publication 290D-UM001A-EN-P - June 2012 13

Page 14

Table of Contents

Chapter 5

Diagnostics

Specifications

Appplying More Than One

ArmorStart LT Motor Controller

in a Single Branch Circuit

on Industrial Machinery

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .167

Status LEDs and Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .167

Fault Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .168

Protection Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .168

Quick Reference Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .170

Fault LED Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .170

Bulletin 290D/291D Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .170

Bulletin 294D Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .172

Chapter 6

Bulletin 290D/291D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

Motor Overload Trip Curves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .180

Bulletin 100-K/104-K Life-Load Curves . . . . . . . . . . . . . . . . . . . . . . . . . . .181

Bulletin 294D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .182

Motor Overload Trip Curves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .188

Appendix A

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .189

ArmorStart LT Product Family . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190

Multiple-Motor Branch Circuits and Motor Controllers Listed

for Grooup Installation – General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .191

Maximum Fuse Ampere Rating According to 7.2.10.4(1)

and 7.2.10.4(2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .193

Complete Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .193

Explanatory Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .195

Input and Output Conductors of Bulletin 290D and 291D

Controllers (a) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .201

Input and Output Conductors of Bulletin 294D Controllers (b) . . . . .201

Combined Load Conductors (c). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .201

Appendix B

CIP Information

14 Rockwell Automation Publication 290D-UM001A-EN-P - June 2012

High Level Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .203

Product Code and Name Strings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .203

CIP Explicit Connection Behavior. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .204

EDS Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .204

CIP Object Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .204

Identity Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .205

CLASS CODE 0x0001 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .205

Message Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .206

CLASS CODE 0x0002 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .206

Assembly Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .206

CLASS CODE 0x0004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .206

I/O Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

Connection Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .216

Page 15

Table of Contents

CLASS CODE 0x0005 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .216

Discrete Input Point Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .219

CLASS CODE 0x0008 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .219

Discrete Output Point Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .220

CLASS CODE 0x0009 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .220

Discrete Output Point Object Special Requirements . . . . . . . . . . . .221

Analog Input Point Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .225

CLASS CODE 0x000A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .225

Analog Output Point Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .225

CLASS CODE 0x000B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .225

Parameter Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .226

CLASS CODE 0x000F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .226

Parameter Group Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .227

CLASS CODE 0x0010 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .227

Discrete Input Group Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .228

CLASS CODE 0x001D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .228

Discrete Output Group Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .228

CLASS CODE 0x001E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .228

Control Supervisor Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .229

CLASS CODE 0x0029 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .229

Overload Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .230

CLASS CODE 0x002C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .230

DPI Fault Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .231

CLASS CODE 0x0097 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .231

DeviceNet Interface Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .236

CLASS CODE 0x00B4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .236

Zip Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .238

CLASS CODE 0x032E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .238

ZIP Enable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .238

Attribute Symantics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .240

Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .242

Appendix C

Using DeviceLogix

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .245

DeviceLogix Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .246

Support and Feedback Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back Cover

Installation Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back Cover

New Product Satisfaction Return . . . . . . . . . . . . . . . . . . . . . . . . . . Back Cover

Documentation Feedback. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back Cover

Trademark List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back Cover

Rockwell Automation Publication 290D-UM001A-EN-P - June 2012 15

Page 16

Table of Contents

Notes:

16 Rockwell Automation Publication 290D-UM001A-EN-P - June 2012

Page 17

Chapter 1

Product Overview

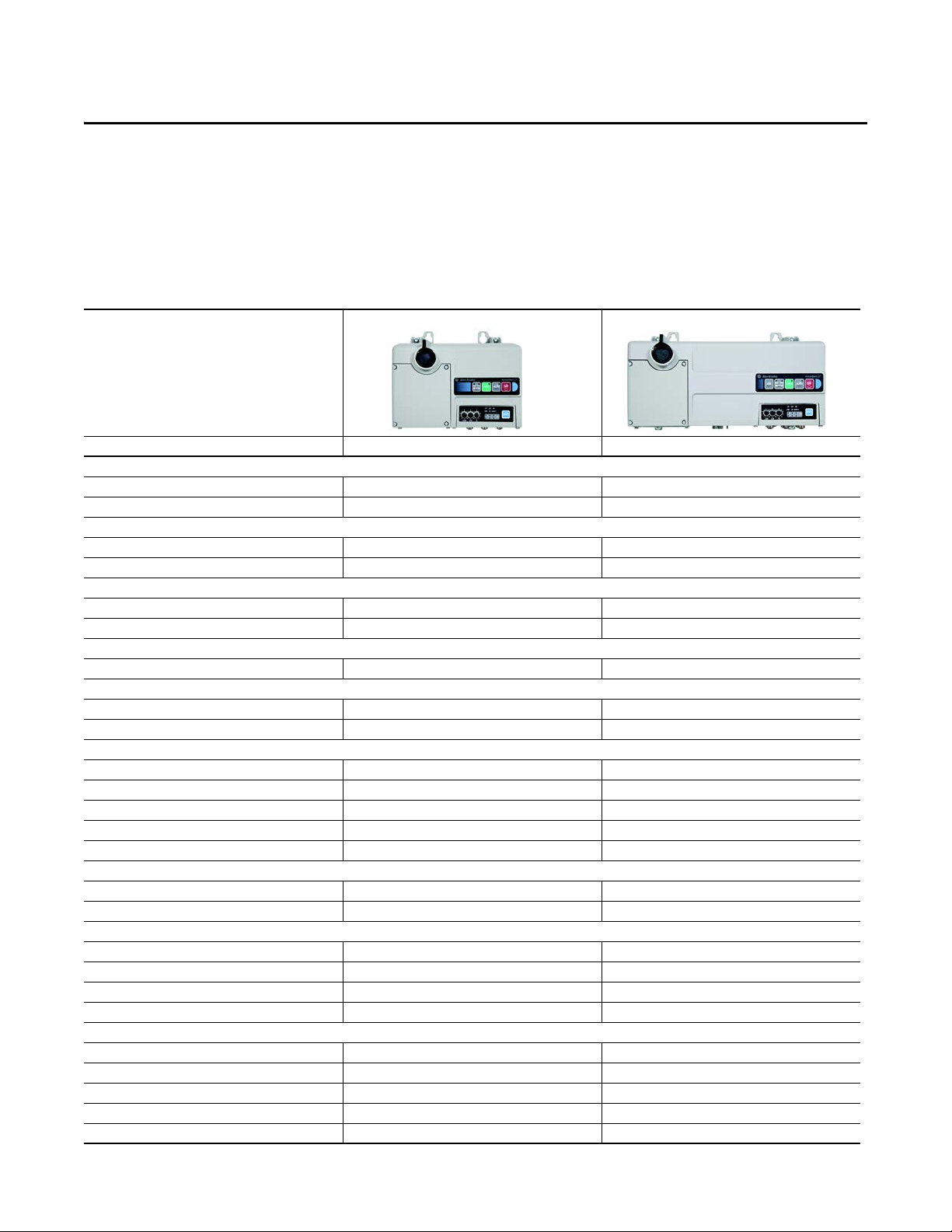

Bulletin 290/291 294

Network Communications:

EtherNet/IP

DeviceNet

Horsepower Range:

0.5…5 Hp (0.37…3.3 kW)

0.5…2 Hp (0.37…1.5 kW)

Starting Method:

Full-Voltage and Reversing

VFD (V/Hz) —

Environmental Rating:

IP66/UL Type 4/12

Control Voltage:

24V DC

Internal Power Supply (sourced from 3-phase)

Operational Voltage Ratings:

200…480V DC

380…480V DC —

Rated for Group Motor Installations

Local logic using DeviceLogic™

Peer-to -Peer (ZI P)

I/O Capability:

Six Self-Configurable Points

LED Status Indication

Gland Plate Entry:

Conduit Entrance

ArmorConnect® Power and Control Media (option)

Quick Disconnects: I/O and Communications

EMI Filter —

Factory Installed Options:

Manual-Auto-Off HOA Keypad

Source Brake Contactor —

Internal 24V DC Power Supply

Optional Motor Cables

ArmorConnect Gland

DeviceNet Version Only

—

—

—

DeviceNet Version Only

Rockwell Automation Publication 290D-UM001A-EN-P - June 2012 17

Page 18

Chapter 1 Product Overview

Description

ArmorStart LT is available with Full Voltage, Full Voltage Reversing, or Variable

Speed motor control performance. It comes equipped with a UL Listed At-motor

disconnect that supports a lock-out tag-out (LOTO) provision. ArmorStart LT

is listed as suitable for group installations per UL and can be applied with either

branch circuit breaker protection or fuse protection. It provides a robust IP66/

UL Type 4/12➊ enclosure suitable for water washdown environments in a single

box construction that will minimize inventory needs. All external connections

are made from the bottom of the unit minimizing accidental contact by moving

equipment. ArmorStart LT as a standard will come with quick disconnect

receptacles for the I/O and network connections. And finally, ArmorStart LT

will include DeviceLogix, a high-performing local logic engine when a fast I/O

response is critical to the application.

ArmorStart LT leverages the capabilities of the Rockwell Automation® Integrated

Architecture so you can achieve an unmatched level of integration and ease

of use. The architecture of ArmorStart LT allows Premiere Integration with

Allen-Bradley® ControlLogix® or CompactLogix™ line of Automation Controllers

and PLCs.

The ArmorStart LT is available with options that can further reduce installation

and commissioning time and cost

, such as:

• Quick disconnect receptacles for power, control, and motor connections

• Local Hand-Off-Auto keypad for manual control.

• Internal power supply (IPS) eliminating the need to run additional control

power to each unit

• Bulletin 294 can be ordered with an electromechanical brake connection

(source brake)

• EDS Tag Generator tool with RSLogix 5000

➊ The G2 gland option is rated IP66/ UL Type 4

18 Rockwell Automation Publication 290D-UM001A-EN-P - June 2012

Page 19

Product Overview Chapter 1

IMPORTANT

Features

The ArmorStart LT provides many features and benefits that are unsurpassed in

the market place:

• Robust IP66, UL Type 4/12 enclosure

• UL Listed, Suitable for Group Motor Applications

• UL Listed, At-motor disconnect switch

• Native support for DeviceNet

• 6 user configurable I/O points

• DeviceLogix

• Zone interlock protocol (ZIP)

• Optional internal power supply

• Optional electromechanical brake contactor

• Optional local control via Hand-Off-Auto keypad

• Optional quick disconnect for power and motor connections

Not all options are available for Bulletin 290D/291D/294D. Refer to the catalog

configurator for details.

Rockwell Automation Publication 290D-UM001A-EN-P - June 2012 19

Page 20

Chapter 1 Product Overview

Feature Description

Standard Features Across Product Family

UL Listed “Suitable for Group Motor Applications” — Where NFPA 70

(NEC) or 79 are required installation standards, this Listing allows two or more

motors to be connected to the same branch circuit without individual motor

branch short circuit or ground fault protection. Refer to Appendix A for details.

At-motor disconnect switch — ArmorStart LT offers a local ON/Off motor

disconnecting means with lockout-tagout provision. Industrial standards require

a local at-motor disconnect to be within eye sight of the motor for maintenance

or other shutdown reasons. Refer to your installation code for details.

User configurable I/O — ArmorStart LT offers 6 user configurable I/O points

to be used with sensors and actuators. By default all 6 points are configured as

sinking 24V DC inputs. The user has the option to select any point as a sourcing

24V DC output.

DeviceNet Network Capabilities

The ArmorStart Distributed Motor Controller delivers advanced capabilities to

access parameter settings and provides fault diagnostics, and remote start-stop

control.

DeviceLogix — ArmorStart LT offers local programmable logic via

DeviceLogix. DeviceLogix is a stand-alone program that resides within the

ArmorStart LT. It is programmed locally using the Add-On-Profile and

implements operations such as, AND, OR, NOT, Timers, Counters, Latches,

and Analog operations. DeviceLogix can run as a stand-alone application,

independent of the network or collaboratively with the PLC. However,

unswitched control power must be maintained for DeviceLogix to operate.

Zone Interlock Protocol (ZIP) — The zone control capabilities of ArmorStart

LT is ideal for motored conveyors. Zone Interlocking Parameters (ZIP) allow one

ArmorStart to receive data directly, from up to four other DeviceNet nodes,

without going through a network scanner. These direct communications

between conveyor zones are beneficial in a merge, diverter, or accumulation

conveyor application.

Quick disconnect for I/O and network — ArmorStart LT offers quick

disconnect connectors for I/O and communications.

DeviceNet node address — ArmorStart LT offers external accessible address

switches for device node address configuration. The address can be set statically

or dynamically.

EMI filter — ArmorStart LT for VFD application (Bulletin 294) provides an

internal EMI filter and is CE compliant. For CE compliant installations refer to

the recommended EMI/RFI cord grip accessory. For availability of the quick

20 Rockwell Automation Publication 290D-UM001A-EN-P - June 2012

Page 21

Product Overview Chapter 1

disconnect shielded motor cable contact your local sales representative for

details.

Local and remote status and diagnostics — ArmorStart LT offers

comprehensive status and diagnostics for I/O, Network, and device health via 12

LEDs found on the electronic control module (ECM). If a fault occurs a local

fault reset button allows the user to quickly get the process started after corrective

action is taken. The user can also configure the embedded web server to send an

e-mail when a fault or warning occurs.

Gland plate entrance — ArmorStart LT offers different methods of connecting

three-phase, control power, and motor. ArmorStart LT has conduit entrance

openings, as standard.

Factory-Installed Options

Internal power supply (IPS) — ArmorStart LT offers the user an optional

24V DC internal power supply. The internal power supply provides all control

and I/O power needs and is sourced from the incoming 3-phase power. This

eliminates the need to run separate control power to each unit, reducing

installation time and cost. The local at-motor disconnect will remove power

from the motor terminals and outputs when in the OFF condition.

Hand/Off/Auto (HOA) keypad — ArmorStart LT offers an optional local

Hand-Off-Auto keypad. This key pad allows local start/stop motor control

regardless of PLC status. This option can be used for troubleshooting or

maintenance operations. The HOA can also be disabled when local control

is not allowed, using parameter 67.

Source brake — ArmorStart LT provides an optional, internally-controlled

electromechanical motor brake contactor. The motor brake power is sourced

from 3-phase power, L1 and L2.

Quick disconnect gland — ArmorStart LT offers a plug -n- play solution that

simplifies wiring and installation. These factory installed quick disconnect

receptacles provide connectivity to ArmorConnect® media for three-phase,

control, and motor connections. The cables are ordered separately.

Rockwell Automation Publication 290D-UM001A-EN-P - June 2012 21

Page 22

Chapter 1 Product Overview

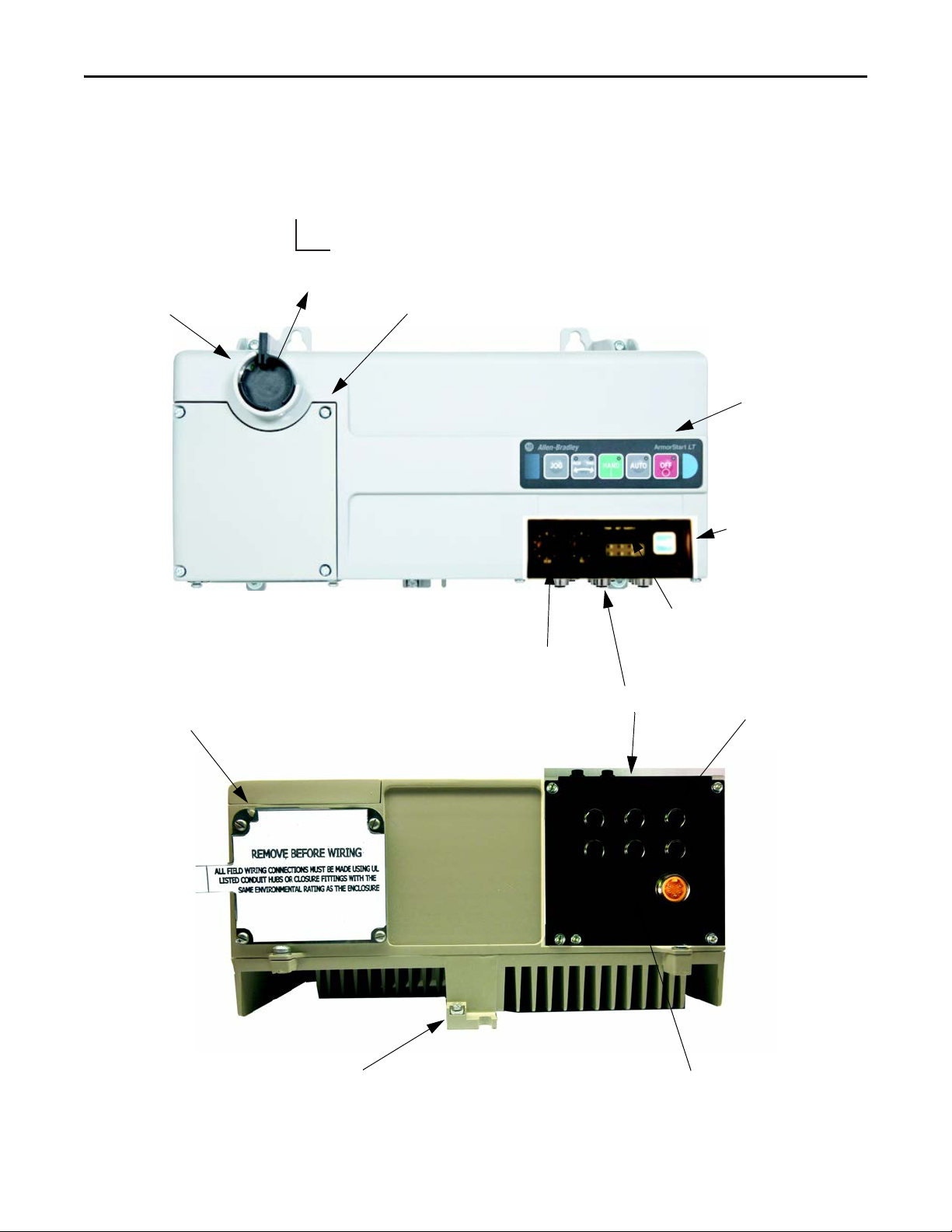

6 Configurable I/Os

LockOut/TagOut Provision

Wiring Access

Reset

IP Address Switches

On/Off Switch

HOA Keypad (optional)

Gland Plate – Conduit/Cord Grip or

ArmorConnect

®

Media (optional)

Status and Diagnostic LEDs

DeviceNet Connector

ECM (Electronic

Control Module)

Protective Earth (PE)

ArmorStart LT Characteristics

0

O

1

On

Figure 1 - Bulletin 290D/291D ArmorStart LT

22 Rockwell Automation Publication 290D-UM001A-EN-P - June 2012

Page 23

Product Overview Chapter 1

➊ IP66/UL Type 4 is available with all gland option s. UL Type 4/12 is available with G1 an d G3 gland option.

➋ See selection guide 290-SG001_-EN-P Accessories section for gland configurations and ordering

➌ Leave blank unless there is a customer-specific opt ion defined by the factory.

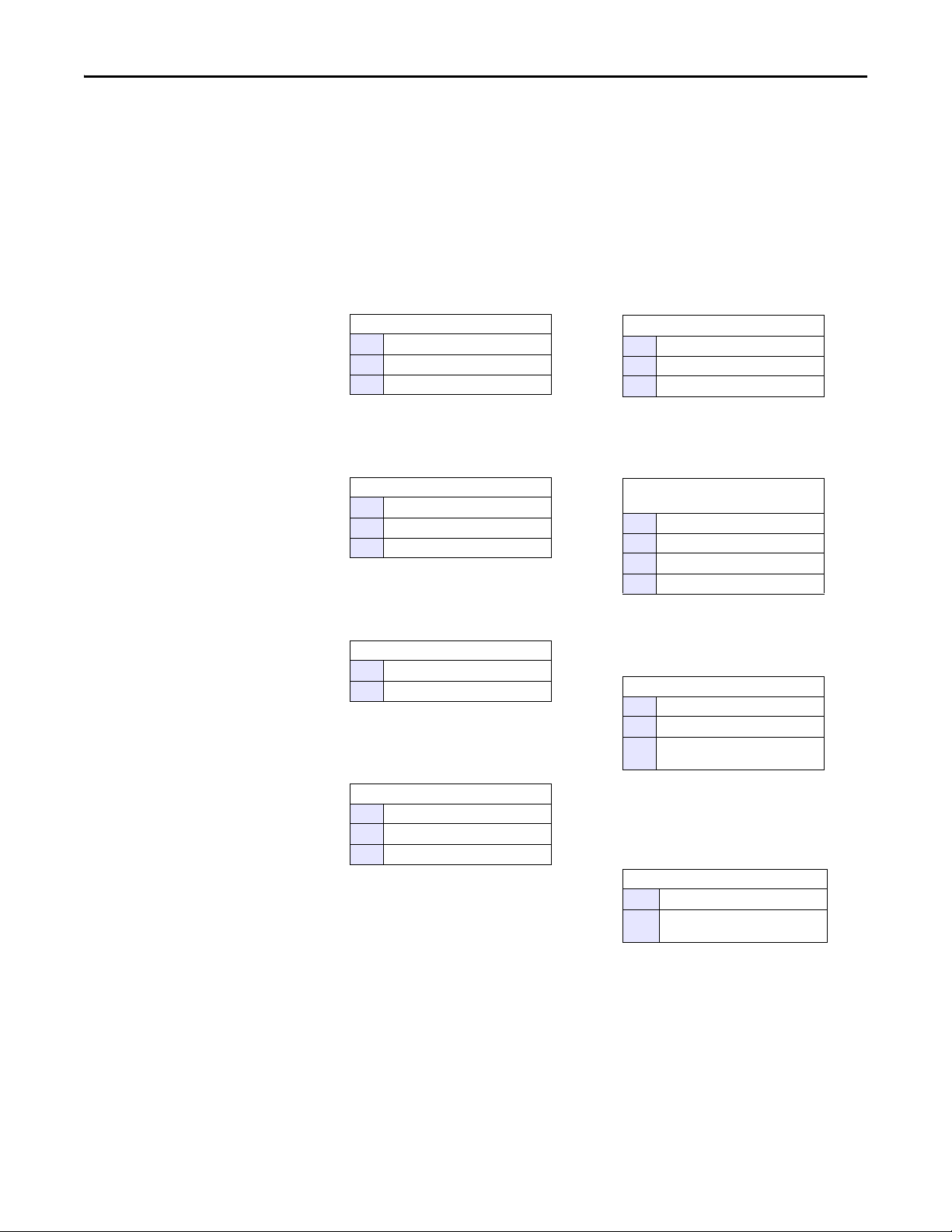

Catalog Number Explanation

Examples given in this section are for reference purposes. This basic explanation

should not be used for product selection; not all combinations will produce a

valid catalog number.

290 E - F A Z - G1 - Option 1 - Option 2

—————— —— ——

abcde f g h

a

Bulletin Number

Code Description

290 Full-Voltage Starter

291 Reversing Starter

b

Communications

Code Description

E EtherNet/IP

D DeviceNet

Code D escrip tion

Z External 24V DC control power

PInternal power supply

Code D escrip tion

G1 Conduit entry

G2 ArmorConnect

G3 Gland Kit➋

e

Control Voltag e

f

Gland Plate Options

(Power and Motor)

c

Enclosure Type

Code Description

F UL Type 4/12 ➊

d

Overload Selection

Code Description

A 0.25…3.5 A

B 1.1…7.6 A

g

Option 1

Code D escrip tion

3 Hand/Off/Auto selector keypad

3FR Hand/Off/Auto selector keypad with

Code Desc ription

blank

➌

Forw ard/Reve rse

h

Option 2

No option

Rockwell Automation Publication 290D-UM001A-EN-P - June 2012 23

Page 24

Chapter 1 Product Overview

Bottom View

1

On

0

O

Protective Earth (PE)

DeviceNet connector

LockOut/TagOut Provision

Gland Plate – Conduit/Cord Grip or

ArmorConnect Media (optional)

Reset

IP Address Switches

ECM (Electronic Control Module)

Hand-Off-Auto Keypad

(optional)

On/Off Switch

Status and Diagnostic LEDs

Wiri ng Acces s

6 Configurable I/Os

ArmorStart LT Characteristics

Figure 2 - Bulletin 294D ArmorStart LT

24 Rockwell Automation Publication 290D-UM001A-EN-P - June 2012

Page 25

Product Overview Chapter 1

➊ IP66/UL Type 4 is available with all gland options. UL Type 4/12 is available with G1 and G3 gland option.

➋ Leave blank unless there is a customer-specific option defined by the factory.

Catalog Number Explanation

Examples given in this section are for reference purposes. This basic explanation

should not be used for product selection; not all combinations will produce a

valid catalog number.

294 E - F D1P5 Z - G1 - Option 1 - Option 2

——————————

abc d ef g h

a

Bulletin Number

Code Description

294 VFD Starter

b

Communications

Code Description

E EtherNet/IP

D DeviceNet

Code D escrip tion

Z External 24V DC control power

PInternal power supply

Code D escrip tion

G1 Conduit entry

G2 ArmorConnect

G3 Gland Kits ➋

e

Control Voltag e

f

Gland Plate Options

(Power and Motor)

c

Enclosure Type

Code Description

F UL Type 4/12 ➊

d

Output Current

Code Description

D1P5 1.5 A (0.4 kW), 0.5 Hp

D2P5 2.5 A (0.75 kW), 1.0Hp

D4P2 3.6 A (1.5 kW), 2.0Hp

g

Option 1

Code D escrip tion

3 Hand/Off/Auto selector keypad with Jog

Code Desc ription

SB S ource Brake

blank

➌

function

h

Option 2

No option

Rockwell Automation Publication 290D-UM001A-EN-P - June 2012 25

Page 26

Chapter 1 Product Overview

Outputs

Inputs

EtherNet

Comms

A3

A1

A2

O

Switched Control Power

Unswitched Control Power

Motor

Control

Motor

Controller

Class 2

External

24VDC Power

Supply

Disconnect

24VDC

+

-

L1 L2

L3

T1 T2

T3

* Control power output is determined by disconnect status

*

ArmorStart LT

L

N

Basic Operation

Group Motor Installations for USA and Canada Markets

The ArmorStart LT Distributed Motor controllers are listed for use with each

other in group installations per NFPA 79, Electrical Standard for Industrial

Machinery and NFPA 70, the National Electrical Code. When applied according

to the group motor installation requirements, two or more motors are permitted

on a single branch circuit. Group Motor Installation has been successfully used

for many years in the USA and Canada.

Note: For additional information regarding group motor installations with the

ArmorStart LT Distributed Motor Controller, see Appendix A

.

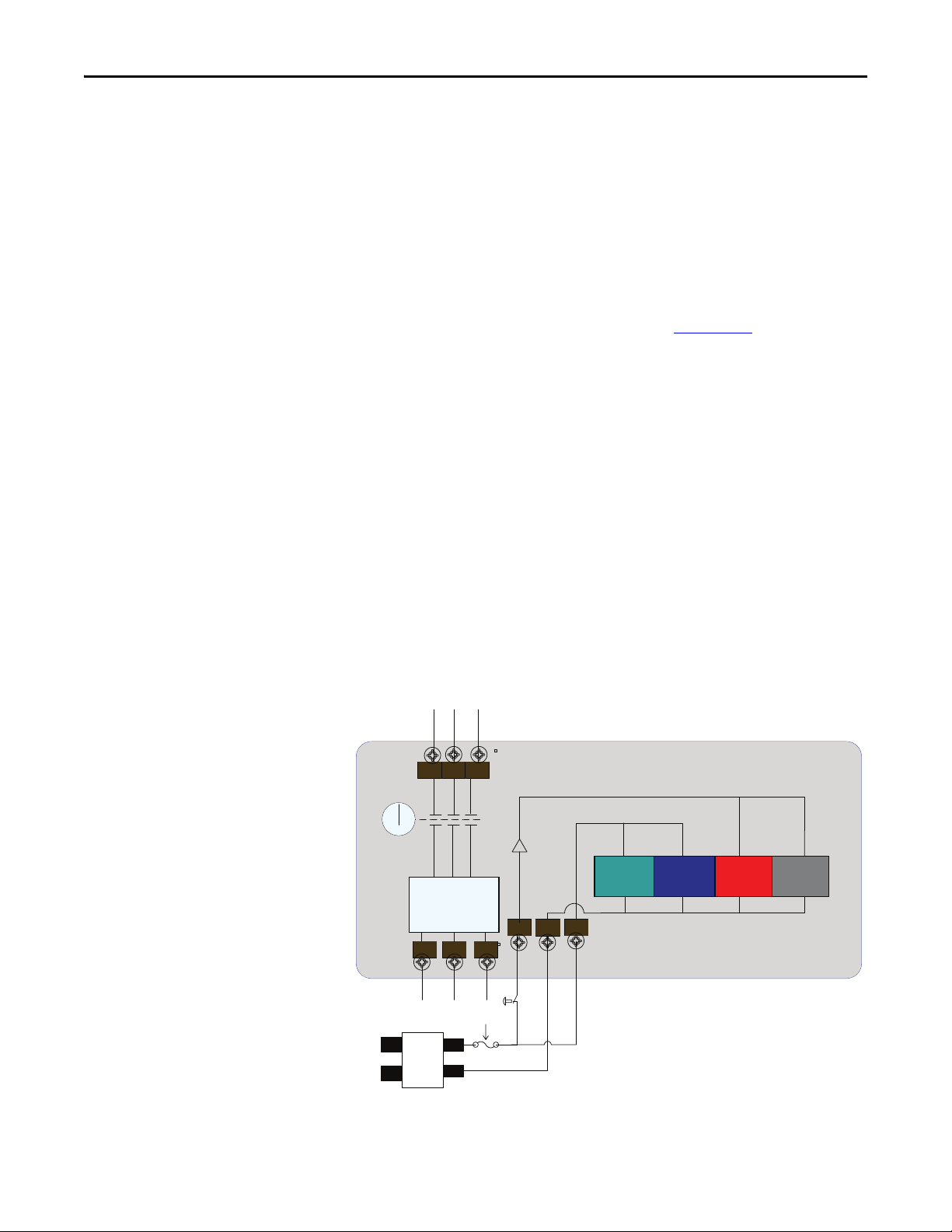

Control Circuit

ArmorStart LT accepts a 24V DC Class 2 input power supply for switched

and unswitched power. The control voltage provides power to the inputs

(unswitched) and outputs (switched). Unswitched control voltage is used to

ensure no loss of network connectivity, sensor, or other field input status under

normal operation. The control power terminal connections are labeled A1, A2,

and A3. Switched power is identified as (+A1) (-A2). Unswitched power is

identified as (+A3) (-A2).

As an option, ArmorStart LT can be supplied with an internal power supply

(IPS) eliminating the need for an external control power. The IPS is sourced from

the line side of 3-phase power and is not impacted by the status of the local atmotor disconnect switch.

Figure 3 - Control Circuit Wiring Diagram — Single External Power Supply

26 Rockwell Automation Publication 290D-UM001A-EN-P - June 2012

Page 27

Product Overview Chapter 1

Outputs

Inputs

EtherNet

Comms

A3

A1

A2

O

Switched Control Power

Unswitched Control Power

Motor

Control

Motor

Controller

Class 2

External Switched

24VDC Power Supply

Disconnect

24VDC

+

-

L

N

L1 L2

L3

24VDC

+

-

L

N

Class 2

External Unswitched

24VDC Power Supply

* Control power output is determined by disconnect status

*

T1 T2

T3

ArmorStart LT

Outputs

Inputs

EtherNet

Comms

O

Motor

Control

Motor

Controller

Disconnect

Internal Power

Supply

*

* Control power output is determined by disconnect status

T1 T2

T3

ArmorStart LT

*

L2L3L1

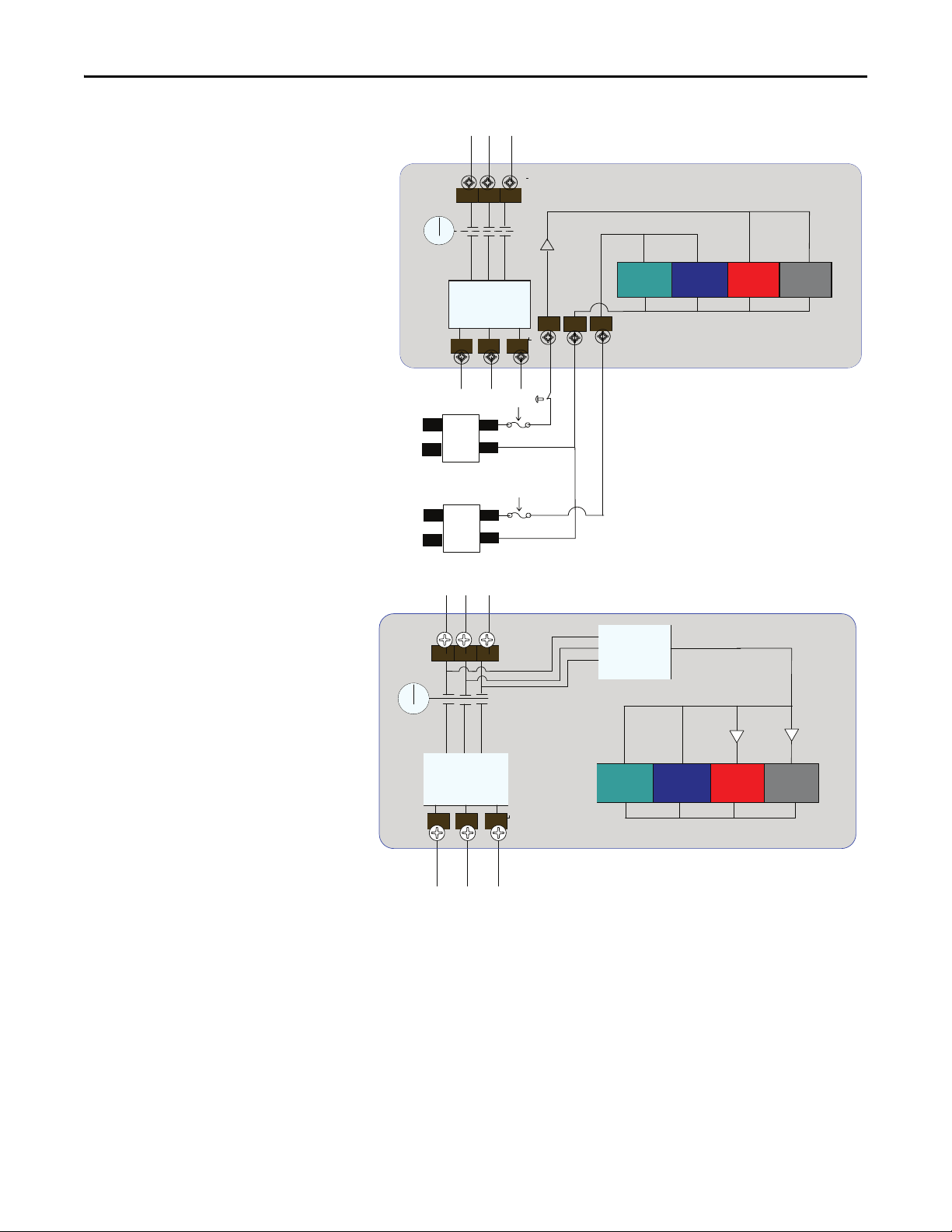

Figure 4 - Control Circuit Wiring Diagram — Multiple External Power Supplies

Figure 5 - Control Circuit Wiring Diagram — Internal Power Supply (optional)

Rockwell Automation Publication 290D-UM001A-EN-P - June 2012 27

Page 28

Chapter 1 Product Overview

Motor Circuit

The ArmorStart LT Distributed Motor Controllers are rated to operate the

following types of three-phase squirrel-cage induction motors:

Bulletin 290D/291D:

0.5 Hp (0.37 kW) to 5 Hp (3 kW) @ 480/277V AC

Bulletin 294D:

0.5 Hp (0.37 kW) to 2 Hp (1.5 kW) @ 480/277V AC

Local I/O

The ArmorStart LT provides as standard, 6 user configurable I/O points. By

default, all points are configured as an Input. The user will need to refer to

parameter 49 [IOPointConfiguration], to define an output point.

Overload Protection

Mode of Operation Bulletin 290D/291D

The ArmorStart LT Distributed Motor Controller incorporates, as standard,

electronic motor overload protection. This overload protection is accomplished

2

electronically with an I

programmable via the communication network, providing the user with greater

flexibility.

The Bulletin 290D/291D includes programmable overload Class 10, 15, and 20

protection. The Bulletin 294D provides overload protection: 150% for 60 s and

200% for 3 s.

Refer to Chapter 6

t algorithm. The ArmorStart LTs overload protection is

, Specifications, for additional information.

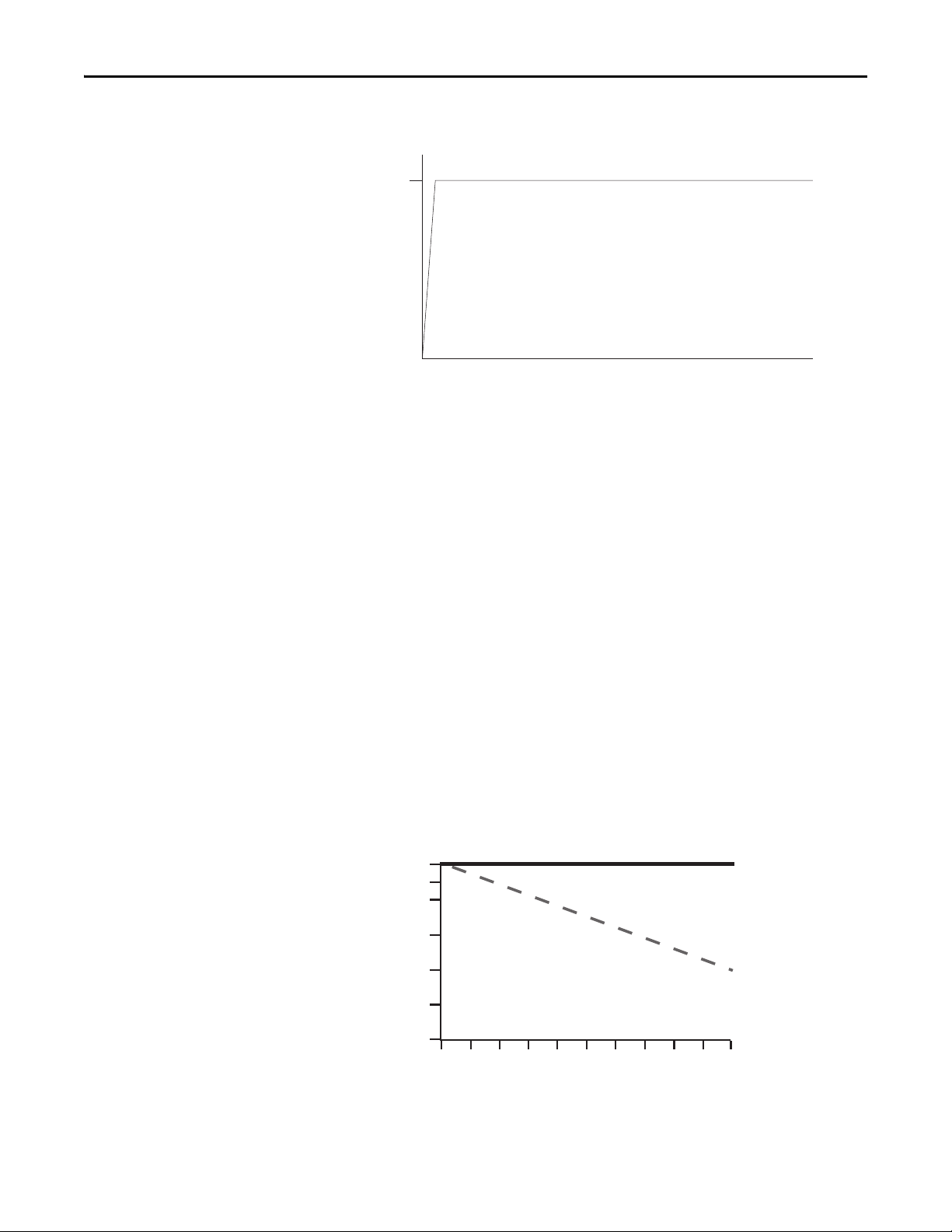

Full-Voltage Start

This method is used in applications requiring across-the-line starting, in which

full inrush current and locked-rotor torque are realized. The ArmorStart LT

Bulletin 290D offers full-voltage starting and Bulletin 291D offers full-voltage

starting for reversing applications, from 0.5 Hp (0.37 kW) to 5 Hp (3 kW) at

480Y/277V AC, 3-phase power.

28 Rockwell Automation Publication 290D-UM001A-EN-P - June 2012

Page 29

Figure 6 - Full-Voltage Start

100%

Percent Voltage

Time (seconds)

% of speed

% of load

With Slip

Compensation

Without Slip

Compensation

100

99

98

97

96

95

0 102030405060708090100

Product Overview Chapter 1

Mode of Operation Bulletin 294D

Sensorless Vector Performance

Using a distributed AC drive to operate mechanical equipment at optimum

speed helps reduce energy costs and eliminates mechanical wear and tear that can

occur in the mechanical parts. The advance monitoring found in ArmorStart LT

protects critical equipment against unplanned downtime with advanced

diagnostics and notification of irregular operating parameters. ArmorStart LT

provides open-loop speed regulation (V/Hz) with slip compensation. This

provides excellent speed regulation and high levels of torque across the entire

speed range of the drive, and improved speed regulation as loading increases.

Open Loop Speed Regulation with Slip Compensation allows the VFD to

automatically adjust the output frequency to compensate for speed changes due

to motor loading. This feature utilizes an open loop, current feedback, slip

compensation circuit. Slip Compensation works as an open loop speed regulator

that increases the output frequency of the drive as the load is increased, or

decreases the frequency as the load drops. This feature is used where the motor

must run at a relatively constant speed regardless of torque output.

Rockwell Automation Publication 290D-UM001A-EN-P - June 2012 29

Page 30

Chapter 1 Product Overview

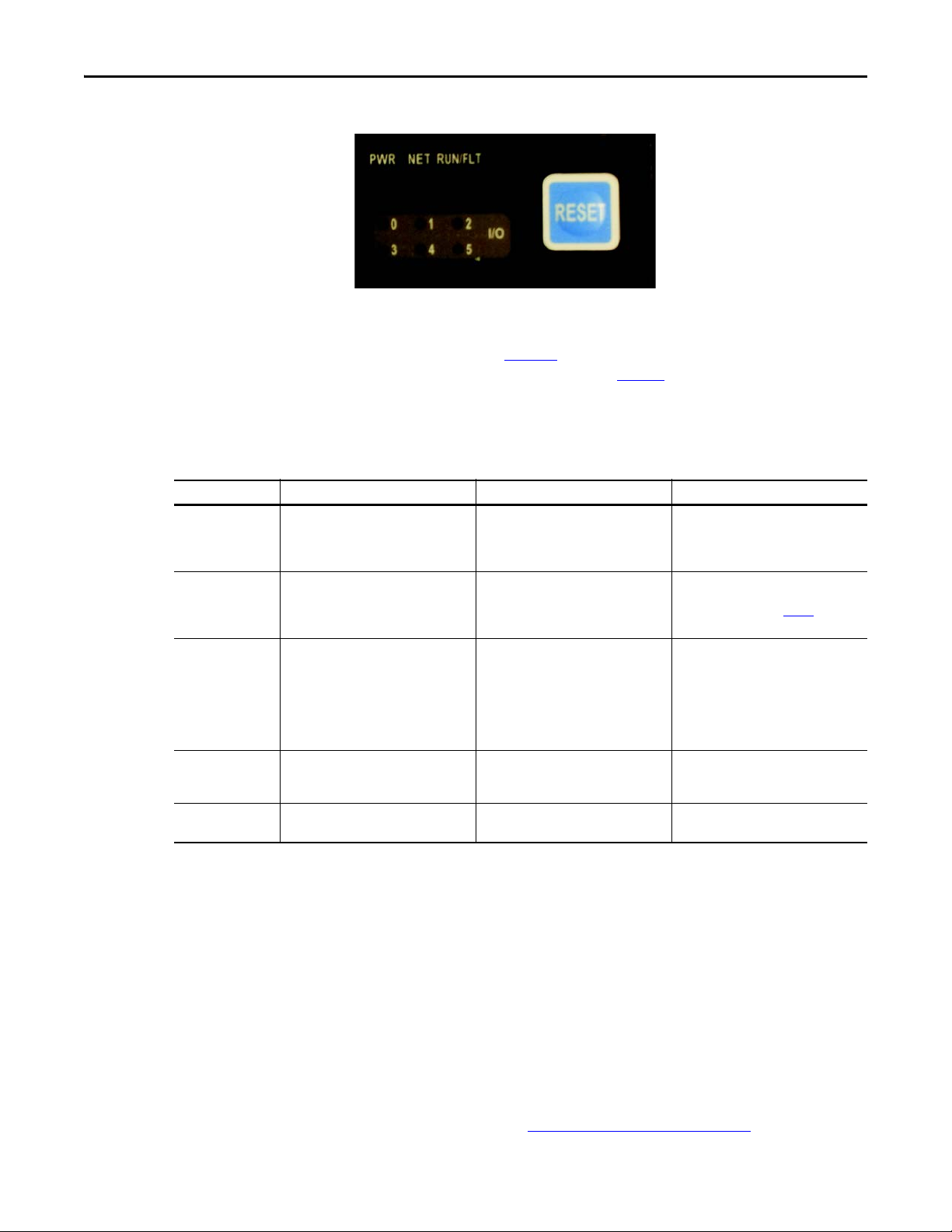

Status LEDs and Reset

Indicator Description Color_1 Color_2

PWR LED The bicolor (green/yellow) LED shows the

RUN/FLT LED The bicolor (green/red) LED combines the

NET – Network Status

LED

I/O Status

Enunciators 0…5

LEDs

Reset Button The blue reset button will cause a

Figure 7 - Status, Diagnostic LEDs, and Reset

ArmorStart LT provides comprehensive status and diagnostics via 12 individually

marked LEDs shown in Figure 7

local reset is provide for clearing of faults. Ta b l e 4

status LEDs.

Table 4 - ArmorStart LT Status and Diagnostics Indicators

state of the control voltage. When LED is

off, switched and/or unswitched power is

not present.

functions of the Run and Fault LEDs.

The bicolor (green/red) LED indicates the

status of the CIP network connection. See

Network Status Indicator for further

information.

Flashing bicolor (red/green) indicates a

self-test on power up.

Six yellow LEDs are numbered 0…5 and

indicate the status of the input/output

connectors. One LED for each I/O point.

protection fault reset to occur.

, located on the ECM module. In addition, a

Solid green is illuminated when switched

and unswitched control power is within its

specified limits and has the proper polarity.

Solid green is illuminated when a Run

command is present.

Flashing green indicates an IP address is

configured, no CIP connections are

established, and an Exclusive Owner

connection has not timed out.

Steady green indicates at least one CIP

connection is established and an Exclusive

Owner connection has not timed out.

Yellow is illuminated when input is valid or

output is on.

——

details the diagnostic and

Solid yellow is illuminated when switched

or unswitched control power is outside its

specified limits or has incorrect polarity.

The LED will blink red in a prescribed fault

pattern when a protection fault (trip)

condition is present. See Tab le 5 for fault

blink patterns.

Flashing red indicates the connection has

timed out. Steady Red indicates a duplicate

IP Address detected.

Off when input is not valid or the output is

not turned on.

Electronic Data Sheet (EDS)

ArmorStart LT EtherNet/IP has an embedded electronic data sheet. An EDS

consists of specially formatted text files, as defined by the CIP™. EDS files contain

details about the readable and configurable parameters of the device. They also

provide information about the I/O connections that the device supports and the

content of the associated data structures. EDS are used by device configuration

tools, such as RSNetWorx™, and data servers such as RSLinx® Classic.

EDS files for all ArmorStart LT devices can be uploaded directly from the device

via the web server interface. Rockwell Automation product EDS files are also

available on the internet at: http://www.ab.com/networks/eds

30 Rockwell Automation Publication 290D-UM001A-EN-P - June 2012

.

Page 31

Product Overview Chapter 1

Fault Diagnostics

Fault diagnostics capabilities built in the ArmorStart LT Distributed Motor

Controller are designed to help you pinpoint a problem for easy troubleshooting

and quick re-starting.

Protection Faults

Protection faults will be generated when potentially dangerous or damaging

conditions are detected. Protection faults are also known as “trips” or “faults”.

These faults will be reported in multiple formats, including:

• Bit enumeration in the TripStatus parameter 16 in DeviceLogix

• In the ArmorStart LT web server for ArmorStart EtherNet/IP version

• As a sequence of LED flashes on the ECM

Table 5 - Protection Faults

LED Flash Bit Enumeration 290D/291D Trip Status Bits 294D Trip Status Bits

10OverloadTrip ➊ OverloadTrip ➊

2 1 PhaseLossTrip PhaseLShortTrip

32UnderPowerTrip ➊ UnderPowerTrip ➊

4 3 SensorShor tTrip ➊ SensorShortTrip ➊

5 4 PhaseImbalTrip OverCurrentTrip

65NonVolMemoryTrip ➊ NonVolMemoryTrip ➊

76reserved ParamSyncTrip ➊

8 7 JamTrip DCBusOrDiscnnct ➊

98StallTrip StallTrip ➊

10 9 U nderloadTr ip OverTemperature ➊

11 10 reserved GroundFault ➊

12 11 reserved RestartRetries

13 12 reserved DriveHdwFault ➊

14 13 OutputShortTrip ➊ OutputShortTrip ➊

15 14 UserDefinedTrip UserDefinedTrip

16 15 HardwareFltTrip ➊ Hardwa reFltTrip ➊

➊ Cannot be disabled.

Rockwell Automation Publication 290D-UM001A-EN-P - June 2012 31

Page 32

Chapter 1 Product Overview

Protection Warnings

ArmorStart LT supports fault warnings. Refer to the WarningStatus parameter

(param 17).

The following describes the warning conditions for 290D/291D units:

Bit Number

14

15 ConfigWarning

Bit Enumeration Description

0 OverloadWarning This warning is generated when the value of %ThermalUtilized (param n5)

2UnderPowerWarn

4 PhaseImbalWarn This warning is generated in firmware by monitoring the relative levels of the

7 JamWarning This warning is generated in firmware when RMS current is greater than the

9 UnderloadWarning This warning is generated in firmware when RMS current is less than the

UnswitchedPwrWarn

becomes greater than the value of the OLWarningLevel parameter (param 69).

This warning is generated when switched power dips below 19.2 V for more than 4 ms.

three phase currents. When the % imbalance becomes greater than the hard

coded warning limit, the warning is generated.

JAMWarningLevel (param 73) after the JamInhibitTime (param 70) has expired.

ULWarningLevel (param 79) after the ULInhibitTime (param 76) has expired.

This warning is generated when unswitched power dips below 19.2 V for 4 ms.

This warning is generated when parameter configuration values that are inconsistent

with certain device options are written. This warning may not be disabled.

The following describes the warning conditions for 294D units:

Bit Number

12 FanWarning This warning indicates that either the fan is running between 62% and 70% of

14

15 ConfigWarning

Bit Enumeration Description

2UnderPowerWarn

6 DriveParamInit This warning is generated when a Full Control Module to Drive parameter sync is in

UnswitchedPwrWarn

This warning is generated when switched power dips below 19.2 V for more than 4 ms.

progress, either on power up, or after an internal comms loss has been remedied.

rated RPM or that the “kick start” was needed to turn on the fan.

This warning is generated when unswitched power dips below 19.2 V for 4 ms.

This warning is generated when parameter configuration values that are inconsistent

with certain device options are written. This warning may not be disabled.

32 Rockwell Automation Publication 290D-UM001A-EN-P - June 2012

Page 33

Product Overview Chapter 1

Table 6 - Configuration Warnings

The following conditions will result in a configuration warning being generated:

Warning Type Warning Code Description

BrakeConfig 41 If Param 89 (BrakeMode) is set to anything other than

IOPointConfig 42 If Param 58 (Input00Function) thru Param 63 (Input05Function)

ZIPConfig 43 If Param 114 (Zone1PtMask) thru Param 121 (Zone4PtOffset)

JamConfig 44 If Param 72 (JamTripLevel) is less than Param 73

UnderLoadConfig 45 If Param 78 (ULTripLevel) is greater than Param 79

0=NoBrakeControl when brake hardware not present OR

If Param 89 (BrakeMode) is set to 1=AboveFrequency and

Param 90 (BrakeFreqThresh) is set to a value above Param

35 (MaximumFreq) OR

If Param 89 (BrakeMode) is set to 2=AboveCurrent and Param

91 (BrakeCurrThresh) is set to a value above Param 31

(Curren tLimit)

are set to 5=BrakeRelease and no brake is present OR

If Param 58 (Input00Function) thru Param 63 (Input05Function)

are set t0 anything other than 0=NoFunction while the

corresponding bit in Param 49 (IOPointConfigure) is set to

configure it as an output.

are set to have a mapping overlap, and Param 143

(ZoneCtrlEnable) set to Enabled OR

If Param 122 (Zone1AnalogMask) thru Param 129

(Zone4AnOffset) are set to have a mapping overlap, and Param

143 (ZoneCtrlEnable) set to Enabled

(JamWarningLevel)

(ULWarningLevel)

Rockwell Automation Publication 290D-UM001A-EN-P - June 2012 33

Page 34

Chapter 1 Product Overview

Optional HOA Selector Keypad

Keypad Local Control

The HOA Selector Keypad allows for local start/stop/jog control in forward/

reverse motor direction. If two buttons are pressed simultaneously, this action is

ignored by the device unless one of the buttons is the Off button. If the Off

button is pressed at any time, the unit will go to the off state. When local Hand

mode is entered, speed reference is switched to Internal Frequency. When in

“Auto” mode the unit the speed reference is switched to the mode specified in

parameter 33 “SpeedReference”.

HAND The Hand key will initiate starter operation

AUTO

OFF

DIR Arrow

JOG

The Auto key allows for Start/Stop control via the

communications network

If the starter is running, pressing the OFF key will cause the

starter to stop.

The Dir arrow selects the direction of the motor, either forward

or reverse.

When pressed, JOG will be initiated if no other control devices

are sending a stop command. Releasing the key will cause the

drive to stop, using selected stop mode.

Optional HOA Keypad Configuration (Bulletin 290D/291D only)

The ArmorStart LT offers optional factory-installed Hand/Off/Auto (HOA)

configurations: Standard (Bulletin 290D) and Forward/Reverse (Bulletin

291D).

Figure 8 - Bulletin 290D Standard HOA

Figure 9 - Bulletin 291D Forward/Reverse HOA

E

34 Rockwell Automation Publication 290D-UM001A-EN-P - June 2012

Page 35

Product Overview Chapter 1

Bulletin 290D

With the KeypadMode parameter (parameter 66) set to 1 = Maintained, pressing

the buttons reacts like a maintained switch.

Current Mode

Key Press

AUTO Auto Mode — Motor Off — —

HAND If no fault, Motor On — —

OFF — Motor turns Off Motor turns Off

FAULT PRESENT — Motor turns Off Motor turns Off

With the KeypadMode parameter (parameter 66) set to 0 = Momentary,

pressing the buttons reacts like a momentary switch.

Key Press

NO KEY PRESSED — Motor Off —

AUTO Auto Mode — Motor Off — —

HAND If no fault, Motor On — —

OFF — Motor Off Motor Off

PROTECTION FAULT PRESENT — Motor Off —

OFF HAND AUTO

Current Mode

OFF Key HAND AUTO Key

Bulletin 291D

With the KeypadMode parameter (parameter 66) set to 1 = Maintained, pressing

the buttons reacts like a maintained switch.

Current Mode

Key Press

FWD/REV FWD LED Set REV LED

AUTO Auto Mode — Motor Off — —

HAND If no fault, Motor On — —

OFF Ignore Motor Off Motor Off

PROTECTION FAULT PRESENT Ignore Motor Off —

With the KeypadMode parameter (parameter 66) set to 0 = Momentary,

pressing the buttons reacts like a momentary switch.

Key Press

NO KEY PRESSED — Motor Off —

FWD/REV FWD LED Set REV LED

AUTO Auto Mode — Motor Off — —

HAND If no fault, Motor On — —

OFF — Motor Off Motor Off

PROTECTION FAULT PRESENT — Motor Off —

OFF HAND AUTO

REV LED Set FWD LED

OFF HAND AUTO

REV LED Set FWD LED

——

Current Mode

——

Rockwell Automation Publication 290D-UM001A-EN-P - June 2012 35

Page 36

Chapter 1 Product Overview

IMPORTANT

Optional HOA Selector Keypad with Jog Function (Bulletin 294D only)

The HOA Selector Keypad with Jog function allows for local start/stop control

with capabilities to jog in forward/reverse motor directions.

Figure 10 - Bulletin 294D Jog/Forward/Reverse HOA

Keypad Local Control

With the KeypadMode parameter (parameter 66) set to 1 = Maintained, pressing

the buttons reacts like a maintained switch.

Current Mode

Key Press

NO KEY PRESSED — — Motor Off —

FWD/REV FWD LED Set REV LED

JOG If no fault, Jog Motor — — —

AUTO Auto Mode — Motor O ff — — —

HAND If no fault, Motor On — — —

OFF — Motor Off Motor Off Motor Off

PROTECTION FAULT PRESENT — Motor Off Motor Off —

OFF HAND JOG AUTO

REV LED Set FWD LED

FWD LED Set REV LED

REV LED Set FWD LED

——

With the KeypadMode parameter (parameter 66) set to 0 = Momentary,

pressing the buttons reacts like a momentary switch.

Current Mode

Key Press

NO KEY PRESSED — Motor Off Motor Off —

FWD/REV FWD LED Set REV LED

JOG If no fault, Jog Motor — — —

AUTO Auto Mode — Motor O ff — — —

HAND If no fault, Motor On — — —

OFF — Motor Off Motor Off Motor Off

PROTECTION FAULT PRESENT — Motor Off Motor Off —

OFF HAND JOG AUTO

REV LED Set FWD LED

FWD LED Set REV LED

REV LED Set FWD LED

——

If multiple buttons are pressed at the same time, the software interprets this as

a “no button pressed” condition. The only exception to this rule is if multiple

buttons are pressed and one of them is the Off button. If the Off button is

pressed in combination with any combination of other buttons, the processor

will behave as if the Off button were pressed by itself.

36 Rockwell Automation Publication 290D-UM001A-EN-P - June 2012

Page 37

Product Overview Chapter 1

Keypad Disable Parameter

“Keypad Disable”, parameter 67, only inhibits the “HAND”, “FWD”, “REV” and

“JOG” buttons on the HOA keypad. The “OFF” and “AUTO” buttons are

always enabled, even if parameter 67 is set to “1=Disable”. The keypad OFF

button can not be disabled.

Source Brake Contactor and Connector (Bulletin 294D only)

An internal contactor is used to switch the electromechanical motor brake

On/Off. The motor brake contactor is actuated via the internal power which

supplies L1 and L2 voltage to the mechanical brake in the motor. The source

brake can be configured for independent control via parameter configuration.

The internal contactor, electromechanical motor brake, and associated motor

branch cable are protected by the branch circuit protective device. There is no

resettable or replaceable protective device in ArmorStart LT.

WARNING: If the branch circuit protective device trips, the user must ensure

that the Source Brake function is still operational prior to putting the

equipment back in service. If the source brake function is not working properly,

loss of brake function or motor damage can occur.

Rockwell Automation Publication 290D-UM001A-EN-P - June 2012 37

Page 38

Chapter 1 Product Overview

Notes:

38 Rockwell Automation Publication 290D-UM001A-EN-P - June 2012

Page 39

Installation and Wiring

IMPORTANT

Chapter 2

Receiving

Unpacking

It is the responsibility of the user to thoroughly inspect the equipment before

accepting the shipment from the freight company. Check the item(s) received

against the purchase order. If any items are damaged, it is the responsibility of the

user not to accept delivery until the freight agent has noted the damage on the

freight bill. Should any concealed damage be found during unpacking, it is also

the responsibility of the user to notify the freight agent. The shipping container

must be left intact and the freight agent should be requested to make a visual

inspection of the equipment.

Remove all packing material, wedges, or braces from within and around the

ArmorStart LT distributed motor controller and other device(s). Check the

contents of the package to see if all contents are included. Contact your local

Allen-Bradley representative if any items are missing.

Before the installation and start-up of the drive, a general inspection

of mechanical integrity (i.e. loose parts, wires, connections, packing

materials, etc.) must be made.

Inspecting

Storing

After unpacking, check nameplate catalog number(s) of the item(s) against the

purchase order. See Chapter 1

which will aid in nameplate interpretation.

The controller should remain in the shipping container prior to installation.

If the equipment is not to be used for a period of time, it must be stored according

to the following instructions in order to maintain warranty coverage.

• Store in a clean, dry location.

• Store within an ambient temperature range of –25…+85 °C

(–13…+185 °F).

• Store within a relative humidity range of 0…95%, noncondensing.

• Do not store equipment where it could be exposed to a corrosive

atmosphere.

• Do not store equipment in a construction area.

Rockwell Automation Publication 290D-UM001A-EN-P - June 2012 39

for an explanation of the catalog numbering system

Page 40

Chapter 2 Installation and Wiring

Installation Precautions

Precautions for Bulletin 290D/291D Applications

The following statements must be read and understood.

ATTENTION: The earth ground terminal shall be connected to a solid earth

ground via a low-impedance connection.

ATTENTION: Copper ground conductors are recommended. The ArmorStart LT

external protective earth (PE) pad is aluminum. Refer to your local electrical

installation standard for proper bonding and protection when dissimilar metals

are used.

ATTENTION: An incorrectly applied or installed controller can damage

components or reduce product life. Wiring or application errors, such as

undersizing the motor, incorrect or inadequate AC supply, or out of range

ambient temperatures, may result in malfunction of the system.

SHOCK HAZARD: To prevent electrical shock, open appropriate machine

disconnect switch prior to connecting and disconnecting cables. Risk of shock —

environment rating may not be maintained with open receptacles.

Precautions for Bulletin 294D Applications

Dimensions

SHOCK HAZARD: The drive contains high voltage capacitors which take time

to discharge after removal of mains supply. Before working on drive, ensure

isolation of mains supply from line inputs (L1, L2, L3). Wait three minutes

for capacitors to discharge to safe voltage levels. Failure to do so may result

in personal injury or death.

ArmorStart LT consists of three components that are non-replaceable. The

Electronic Control Module (ECM); a gland plate for wire entry; and the

aluminum alloy enclosure which makes up the back cover, top housing, and

wiring access door. The ECM includes communications, discrete I/O, status and

diagnostic LEDs, and the node address switches. All mating surfaces are sealed

using foam in place gasket or o-ring.

40 Rockwell Automation Publication 290D-UM001A-EN-P - June 2012

Page 41

Installation and Wiring Chapter 2

Front View

Right Side View

Conduit Gland Entrance

ArmorConnect Internal Power

Supply Gland Plate (optional)

ArmorConnect Media

Gland Entrance (optional)

ArmorConnect Source Brake

Gland Plate (optional)

Line

Control

Motor

Line

Motor

Control

Line

Motor

Source Brake

260

[10.2]

170

[6.7]

217,83

[8.6]

130

[5.1]

65

[2.6]

202,05

[8.0]

38,49

[1.5]

57,13

[2.3]

37

[1.5]

24,25

[1.0]

48,5

[1.9]

0.75" CONDUIT OPENING

1" CONDUIT OPENING

IMPORTANT

For proper heat dissipation and product operation, mount the ArmorStart LT in the

vertical orientation as shown.

Dimensions

Dimensions are shown in millimeters (inches). Dimensions are not intended

to be used for manufacturing purposes. All dimensions are subject to change.

Figure 11 - Dimensions for Bulletin 290D/291D

Rockwell Automation Publication 290D-UM001A-EN-P - June 2012 41

Page 42

Chapter 2 Installation and Wiring

IMPORTANT

For proper heat dissipation and product operation, mount the ArmorStart LT in the

vertical orientation as shown.

Figure 12 - Dimensions for Bulletin 294D

381

[15.0]

240

[9.4]

219,32

206,43

[8.1]

120

[4.7]

Front View

37

[1.5]

[8.6]

170

[6.7]

92,9

[3.7]

38,49

[1.5]

24,25

Line

Motor

[1.0]

48,5

[1.9]

0.75" CONDUIT OPENING

Conduit Gland Entrance - Bottom View

ArmorConnect Internal Power

Supply Gland Plate (optional)

1" CONDUIT OPENING

Line

ArmorConnect Media Gland

Entrance (optional)

Control

Motor

Right Side View

Line

Motor

ArmorConnect Gland Entrance

with Source Brake (optional)

Control

Source Brake

42 Rockwell Automation Publication 290D-UM001A-EN-P - June 2012

Page 43

Dimensions are shown in millimeters (inches). Dimensions are not intended

to be used for manufacturing purposes. All dimensions are subject to change.

Figure 13 - ArmorStart LT Gland Plate Matrix

No Internal Power Supply

No Source Brake

Source Brake

No Internal Power Supply

Internal Power Supply

No Source Brake

Internal Power Supply

and Source Brake

1.00 in.

(25.4 mm)

0.75 in.

(19.05 mm)

0.75 in.

(19.05 mm)

1.00 in.

(25.4 mm)

0.75 in.

(19.05 mm)

1.00 in.

(25.4 mm)

0.75 in.

(19.05 mm)

G1 Conduit G2 Media

Standard

U.S. Trade Knock-outs

Dia. 25.5 mm

Dia. 20.5 mm

Dia. 25.5 mm

Dia. 20.5 mm

Dia. 25.5 mm

Dia. 20.5 mm

Dia. 25.5 mm

Dia. 20.5 mm

Installation and Wiring Chapter 2

G3 Conduit

Daisy Chaining

IP66 Metric Fittings

45°

Cat. No.

290-G3-A2

290-G3-A3

290-G3-A4

290-G3-A5

Connection Locations

User Modied

Gland Plate Clearances

Modications are not permitted in the keepout region. Fitting(s) should be oriented

so that they do not interfere with the enclosure when the gland plate is installed.

Torque the gland mounting screws to 12…14 in•lb (1.3…1.6 N•m).

Figure 14 - Internal Power, Control, and Ground Locations

66.1 mm

10.1 mm

91.3 mm

290-G3-A1

80.7 mm

11.8 mm

Rockwell Automation Publication 290D-UM001A-EN-P - June 2012 43

Page 44

Chapter 2 Installation and Wiring

Conduit Entry (Standard)

External PE

connection

Inputs/Outputs

Network

Optional ArmorConnect Quick

Disconnect Feature

Three-Phase

Power