Page 1

ArmorStart® Distributed Motor

Controller

USER MANUAL

Bulletin 280G/281G, 284G

Page 2

Page 3

3

ATTENTION

!

IMPORTANT

Important User Information

Because of the variety of uses for the products described in this publication,

those responsible for the application and use of this control equipment must

satisfy themselves that all necessary steps have been taken to assure that

each application and use meets all performance and safety requirements,

including any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in

this guide are intended solely for purposes of example. Since there are many

variables and requirements associated with any particular installation,

Rockwell Automation does not assume responsibility or liability (to include

intellectual property liability) for actual use based upon the examples shown

in this publication.

Rockwell Automation publication SGI-1.1, Safety Guidelines for the

Application, Installation and Maintenance of Solid-State Control (available

from your local Allen-Bradley sales office), describes some important

differences between solid-state equipment and electromechanical devices

that should be taken into consideration when applying products such as

those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or

part, without written permission of Rockwell Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

Identifies information about practices or circumstances

that can lead to personal injury or death, property damage

or economic loss

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

Identifies information that is critical for successful

application and understanding of the product.

Trademark List

ArmorStart and ControlLogix are registered trademarks of Rockwell Automation, Inc.

ArmorConnect, DeviceLogix, PLC, RSNetWorx, RSLogix 5000, and SLC are trademarks of Rockwell Automation,

Inc. DeviceNet and the DeviceNet logo are trademarks of the Open Device Vendors Association (ODVA). ControlNet

is a trademark of ControlNet International, LTD.

Page 4

4

European Communities (EC)

Directive Compliance

If this product has the CE mark it is approved for installation within the

European Union and EEA regions. It has been designed and tested to meet

the following directives.

Low Voltage and EMC Directives

This product is tested to meet Council Directive 73/23/EEC Low Voltage

and 89/336/EEC and Council Directive 89/336/EC Electromagnetic

Compatibility (EMC) by applying the following standard(s):

• Bulletin 280/281: EN 60947-4-1 — Low-voltage switchgear and

controlgear — Part 4-1:Contactors and motor-starters —

Electromechanical contactors and motor-starters.

• Bulletin 283: EN 60947-4-2 — Low-voltage switchgear and

controlgear — Part 4-2: AC semiconductor motor controllers and

starters.

• Bulletin 284: EN 61800-3 — Adjustable speed electronic power drive

systems — Part 3: EMC product standard including specific test

methods.

This product is intended for use in an industrial environment.

Page 5

Table of Contents

Table of Contents i

Chapter 1

Product Overview

Chapter 2

Installation and Wiring

Introduction ....................................................................................1-1

Description .....................................................................................1-1

Safety ArmorStart............................................................................1-1

Operation .......................................................................................1-2

Mode of Operation ..........................................................................1-2

Bulletin 280G/281G — Full-Voltage Start ................................1-2

Bulletin 284G — Sensorless Vector Control..............................1-2

Description of Features ..................................................................1-3

Overload Protection .................................................................1-3

LED Status Indication ..............................................................1-5

Fault Diagnostics .....................................................................1-5

Inputs ......................................................................................1-6

Gland Plate Entrance ...............................................................1-6

ArmorStart with DeviceNet Network Capabilities ......................1-6

DeviceLogix™ ........................................................................1-6

Peer to Peer Communications (ZIP) ..........................................1-6

EMI Filter..................................................................................1-6

Dynamic Brake Resistor ...........................................................1-7

Control Brake Contactor ..........................................................1-7

Receiving .......................................................................................2-1

Unpacking ......................................................................................2-1

Inspecting ......................................................................................2-1

Storing ...........................................................................................2-1

General Precautions .......................................................................2-2

Precautions for Bulletin 280G/281G Applications.............................2-2

Precautions for Bulletin 284G Applications ......................................2-2

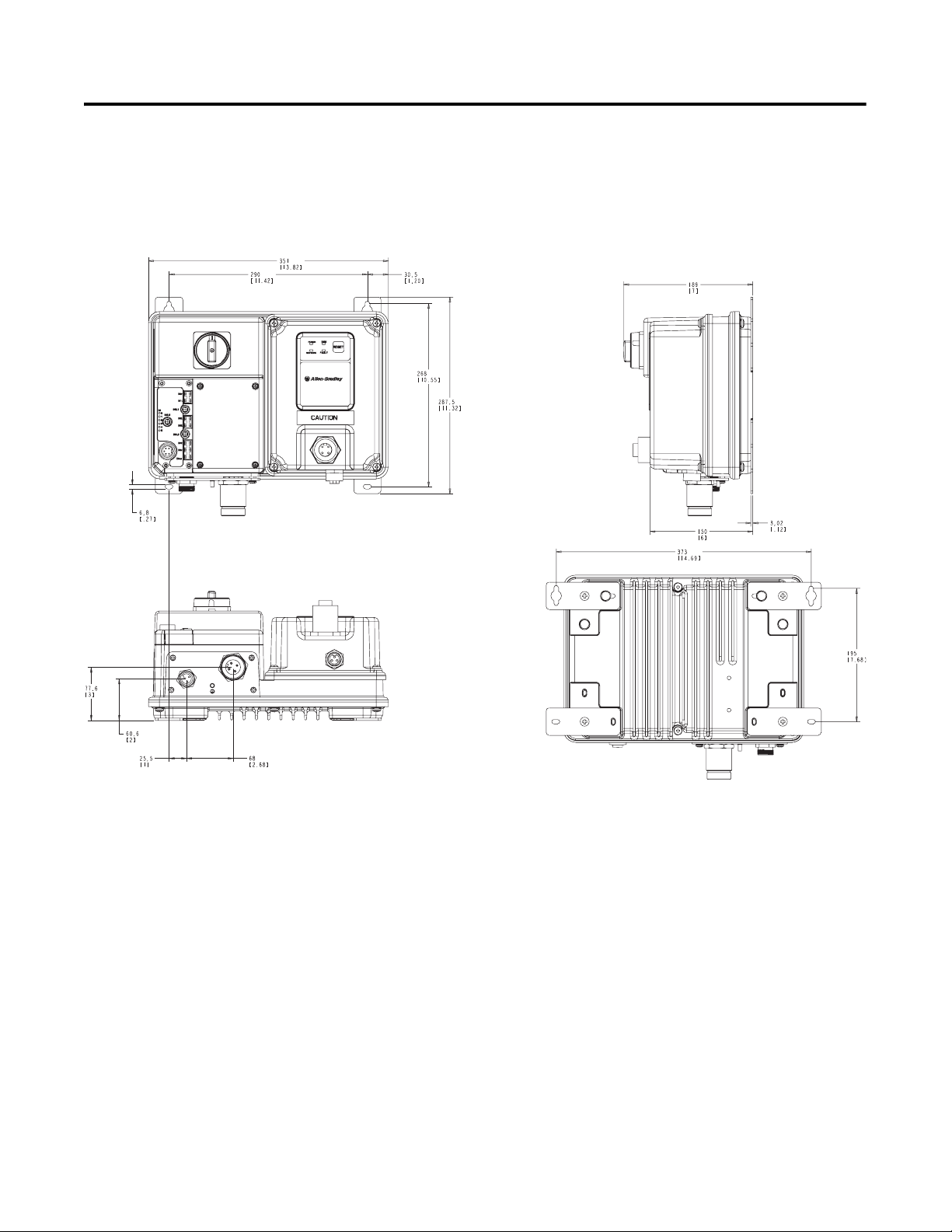

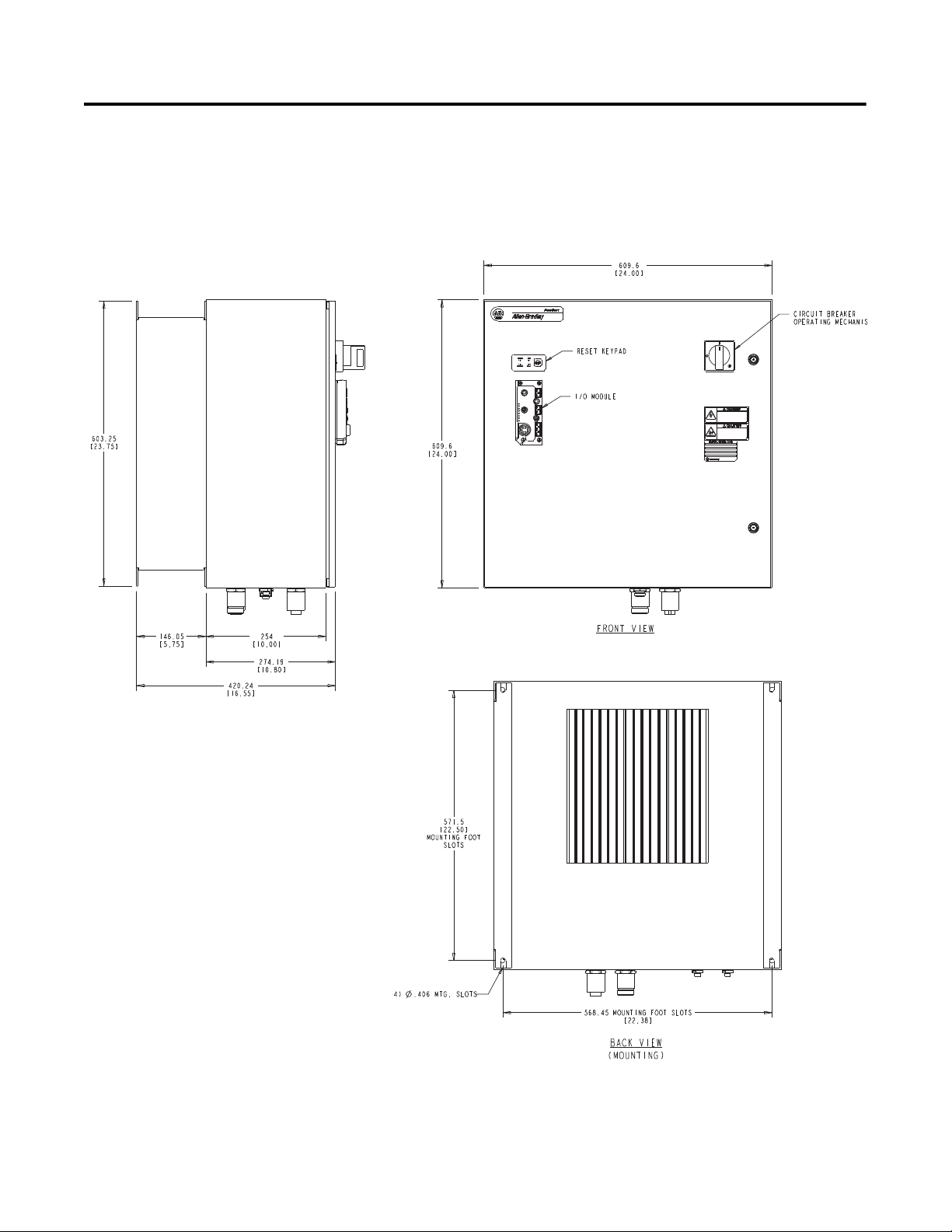

Dimensions ....................................................................................2-4

Bulletin 280G/281G..................................................................2-4

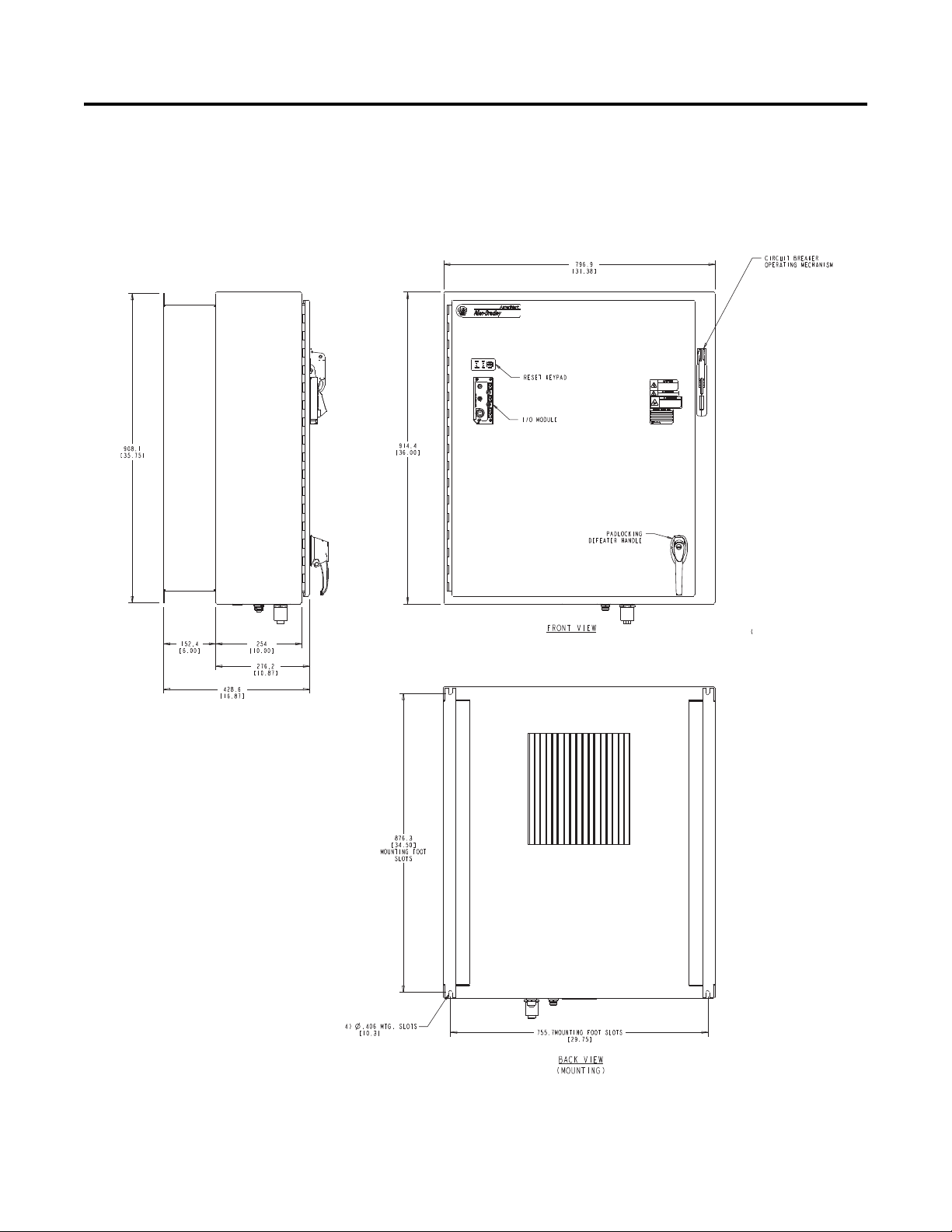

Bulletin 284G ...........................................................................2-6

Bulletin 1000............................................................................2-8

Wiring ..........................................................................................2-13

Power, Control, Safety Monitor Inputs, and

Ground Wiring ......................................................................2-13

Terminal Designations ..................................................................2-14

Dimensions for Safety Products.....................................................2-15

Bulletin 280G Safety Product..................................................2-15

Bulletin 281G Safety Product..................................................2-16

Bulletin 284G Safety Product..................................................2-17

Bulletin 1000 Safety Product ..................................................2-19

Safety Terminal Designations .......................................................2-26

ArmorConnect Power Media .........................................................2-29

Description ............................................................................2-29

ArmorStart with ArmorConnect Connectivity ..........................2-30

Terminal Designations............................................................2-30

ArmorStart Safety with ArmorConnect Connectivity ...............2-31

Terminal Designations............................................................2-31

ArmorConnect Cable Ratings .................................................2-31

Branch Circuit Protection Requirements for

ArmorConnect Three-Phase Power Media .............................2-32

Group Motor Installations for USA and Canada Markets ................2-32

Page 6

ii Table of Contents

Wiring and Workmanship Guidelines ............................................2-32

DeviceNet Network Installation .....................................................2-33

Other DeviceNet System Design Considerations ....................2-34

Electromagnetic Compatibility (EMC) ............................................2-35

General Notes (Bulletin 284G only) ........................................2-35

Grounding .............................................................................2-35

Wiring ...................................................................................2-35

Chapter 3

Bulletin 280G/281G

Programmable Parameters

Chapter 4

Bulletin 284G Programmable Parameters

for Sensorless Vector Controllers

Introduction ....................................................................................3-1

Parameter Programming .........................................................3-1

Parameter Group Listing .................................................................3-2

DeviceLogix™ Group .....................................................................3-2

DeviceNet Group ............................................................................3-7

Starter Protection Group ...............................................................3-10

User I/O ........................................................................................3-14

Misc. Group .................................................................................3-14

ZIP Parameters ............................................................................3-16

Starter Display .............................................................................3-23

Starter Setup ................................................................................3-24

Introduction ....................................................................................4-1

Parameter Programming .........................................................4-1

Parameter Group Listing .................................................................4-2

DeviceLogix™ Group .....................................................................4-3

DeviceNet Group ............................................................................4-8

Starter Protection Group ...............................................................4-12

User I/O ........................................................................................4-15

Miscellaneous Group ....................................................................4-16

Drive DeviceNet Group ..................................................................4-18

Display Group................................................................................4-20

Basic Program Group ....................................................................4-25

Advanced Program Group..............................................................4-28

Clear Type 1 Fault and Restart ......................................................4-42

Clear an Overvoltage, Undervoltage, or Heatsink OvrTmp Fault

without Restarting the Drive..........................................................4-42

How Step Logic Works .................................................................4-55

Step Logic Settings .......................................................................4-55

Chapter 5

DeviceNet™ Commissioning

Establishing a DeviceNet Node Address ..........................................5-1

Node Commissioning using Hardware ............................................5-1

Node Commissioning using Software .............................................5-2

Building and Registering an EDS File ..............................................5-3

Page 7

Table of Contents iii

Using the Node Commissioning Tool Inside RSNetWorx

for DeviceNet ................................................................................. 5-5

System Configuration ................................................................... 5-6

Using Automap feature with default Input and Output (I/O)

Assemblies (Bulletin 280G/281G).................................................... 5-7

Default Input and Output (I/O) Assembly Formats

(Bulletin 280G/281G) ...................................................................... 5-7

Setting the Motor FLA and Overload Trip Class

(Bulletin 280G/281G) ...................................................................... 5-8

Using Automap feature with default Input and Output (I/O)

Assemblies (Bulletin 284G)............................................................. 5-9

Default Input and Output (I/O) Assembly Formats (Bulletin 284G) .... 5-9

Setting the Motor FLA (Bulletin 284G) ........................................... 5-10

193-DCNT Product Overview........................................................ 5-11

User Manual .......................................................................... 5-11

Bill of Material ....................................................................... 5-11

Accessories........................................................................... 5-11

Tools Menu............................................................................ 5-12

Node Comissioning................................................................ 5-12

Chapter 6

Explicit Messaging on DeviceNet™

Chapter 7

Using DeviceLogix™

Chapter 8

ArmorStart® ZIP Configuration

Logic Controller Application Example with Explicit

Messaging ..................................................................................... 6-1

Programming the 1747-SLC .......................................................... 6-2

I/O Mapping ............................................................................ 6-2

Explicit Messaging with SLC .......................................................... 6-3

Setting up the Data File ................................................................. 6-4

Sequence of Events ....................................................................... 6-5

Programming the 1756-ControlLogix ............................................. 6-8

I/O Mapping ............................................................................ 6-8

Explicit Messaging with ControlLogix ............................................. 6-9

Setting Up the MSG Instruction ...................................................... 6-9

DeviceLogix Programming ............................................................. 7-1

DeviceLogix Programming Example ............................................... 7-2

ArmorStart Fault Bit, Status Bit, Outputs and Produced Network Bits in

the DeviceLogix Ladder Editor ....................................................... 7-5

Overview ....................................................................................... 8-1

ZIP Parameter Overview ................................................................ 8-1

Data Production ............................................................................. 8-3

Data Consumption ......................................................................... 8-3

Mapping Consumed Data to the DeviceLogix Data Table. ............... 8-3

Finding ZIP bits in Device Logix Editor........................................... 8-12

Page 8

iv Table of Contents

Chapter 9

Diagnostics

Overview ........................................................................................9-1

Protection Programming ..........................................................9-1

Fault Display ..................................................................................9-1

Clear Fault .....................................................................................9-2

Fault Codes ....................................................................................9-2

Fault Definitions .............................................................................9-3

Short Circuit ............................................................................9-3

Overload Trip ...........................................................................9-3

Phase Loss ..............................................................................9-3

Phase Short..............................................................................9-3

Ground Fault ............................................................................9-3

Stall .........................................................................................9-3

Control Power ..........................................................................9-3

I/O Fault ..................................................................................9-3

Over Temperature ...................................................................9-3

Phase Imbalance .....................................................................9-3

Over Current.............................................................................9-4

DeviceNet™ Power Loss .........................................................9-4

Internal Communication Fault...................................................9-4

DC Bus Fault ............................................................................9-4

EEPROM Fault .........................................................................9-4

Hardware Fault ........................................................................9-4

Restart Retries .........................................................................9-4

Miscellaneous Faults................................................................9-4

Chapter 10

Troubleshooting

Appendix A

Specifications

Appendix B

Bulletin 280G/281G CIP Information

Introduction ..................................................................................10-1

Bulletin 280G/281G Troubleshooting .............................................10-2

Bulletin 284G Troubleshooting.......................................................10-5

Fault Definitions .....................................................................10-5

Operation and Troubleshooting of the DB1- Dynamic Brake....10-7

Internal Drive Faults .............................................................10-10

DeviceNet Troubleshooting Procedures ......................................10-14

Control Module Replacement (Bulletin 280G/281G) .....................10-15

Control Module Replacement (Bulletin 284G)...............................10-16

Base Module Replacement (Bulletin 280G/281G).........................10-17

Base Module Replacement (Bulletin 284G) ..................................10-19

Bulletin 280G/281G Specifications ..................................................A-1

Bulletin 284G Specifications............................................................A-6

ArmorConnect™ Three-Phase Power Media ................................A-11

Patchcords ............................................................................A-11

Power Tees & Reducer ..........................................................A-12

Power Receptacles ................................................................A-13

Electronic Data Sheets ...................................................................B-1

DOL Type Product Codes and Name Strings ...................................B-1

DOL Reversing Type Product Codes and Name String .....................B-2

DeviceNet Objects ..........................................................................B-2

Page 9

Table of Contents v

Identity Object — CLASS CODE 0x0001 .........................................B-3

Identity Objects ..............................................................................B-3

Message Router — CLASS CODE 0x0002 ......................................B-3

DeviceNet Object — CLASS CODE 0x0003 .....................................B-4

Assembly Object — CLASS CODE 0x0004 .....................................B-5

Custom Parameter Based

“Word-wise” I/O Assemblies ..........................................................B-5

“Word-wise” Bit-Packed Assemblies ..............................................B-6

Standard Distributed Motor Controller I/O Assemblies .....................B-7

Standard Distributed Motor Controller Output

(Consumed) Assemblies ..........................................................B-7

Standard Distributed Motor Controller Input

(Produced) Assemblies ............................................................B-8

Connection Object — CLASS CODE 0x0005 .................................B-10

Discrete Input Point Object — CLASS CODE 0x0008 ...................B-14

Discrete Output Point Object — CLASS CODE 0x0009 ..................B-15

Discrete Output Point Object Special Requirements ......................B-16

DOP Instances 1 and 2 Special Behavior ...............................B-16

Parameter Object — CLASS CODE 0x000F ..................................B-18

Parameter Group Object — CLASS CODE 0x0010 ........................B-19

Discrete Input Group Object — CLASS CODE 0x001D ..................B-20

Discrete Output Group Object — CLASS CODE 0x001E ................B-21

Control Supervisor Object -CLASS CODE 0x0029 ..........................B-22

Acknowledge Handler Object — CLASS CODE 0x002b .................B-23

Overload Object — CLASS CODE 0x002c .....................................B-24

DeviceNet Interface Object -CLASS CODE 0x00B4 ........................B-25

Appendix C

Bulletin 284G CIP Information

Electronic Data Sheets ...................................................................C-1

VFD Type Product Codes and Name Strings ....................................C-1

DeviceNet Objects ..........................................................................C-2

Identity Object — CLASS CODE 0x0001 .........................................C-2

Identity Objects ..............................................................................C-3

Message Router — CLASS CODE 0x0002 ......................................C-3

DeviceNet Object — CLASS CODE 0x0003 .....................................C-4

Assembly Object — CLASS CODE 0x0004 .....................................C-5

Custom Parameter Based

“Word-wise” I/O Assemblies ..........................................................C-6

“Word-wise” Bit-Packed Assemblies ..............................................C-6

Standard Distributed Motor Controller I/O Assemblies .....................C-8

Standard Distributed Motor Controller Output

(Consumed) Assemblies ..........................................................C-8

Standard Distributed Motor Controller Input

(Produced) Assemblies ............................................................C-9

Inverter Type Distributed Motor Controller Input

(Produced) Assemblies...........................................................C-10

PowerFlex Native Assemblies.................................................C-11

Connection Object — CLASS CODE 0x0005 .................................C-13

Discrete Input Point Object — CLASS CODE 0x0008 ...................C-18

Discrete Output Point Object — CLASS CODE 0x0009 ..................C-19

Page 10

vi Table of Contents

Discrete Output Point Object Special Requirements ......................C-20

DOP Instances 3 and 4 Special Behavior ...............................C-20

DOP Instances 1, 2, 9, and 10 Special Behavior ....................C-22

Parameter Object — CLASS CODE 0x000F ..................................C-24

Parameter Group Object — CLASS CODE 0x0010 ........................C-25

Discrete Input Group Object — CLASS CODE 0x001D ..................C-26

Discrete Output Group Object — CLASS CODE 0x001E ................C-27

Control Supervisor Object -CLASS CODE 0x0029 ..........................C-28

Acknowledge Handler Object — CLASS CODE 0x002b .................C-29

DeviceNet Interface Object -CLASS CODE 0x00B4 ........................C-30

Appendix D

Group Motor Installations

Appendix E

Accessories

Appendix F

Safety I/O Module and TÜV

Requirements

Appendix G

Renewal Parts

Appendix H

PID Setup

Application of ArmorStart® Controllers in Group Installation ...........D-1

IP67 Dynamic Brake Resistor ..........................................................E-3

ArmorStart Safety-Related Parts...................................................... F-1

ArmorBlock Guard I/O Modules .......................................................F-2

Specifications ..........................................................................F-2

ArmorBlock Guard I/O Recommended Compatible

Cables and Connectors....................................................................F-3

Safety-Related Specifications..........................................................F-6

Maintenance and Internal Part Replacement....................................F-6

Troubleshooting ..............................................................................F-7

Renewal Parts.................................................................................G-1

Exclusive Control.............................................................................H-1

Trim Control....................................................................................H-2

PID Reference and Feedback...........................................................H-3

PID Deadband .................................................................................H-3

PID Preload .....................................................................................H-4

PID Limits .......................................................................................H-4

PID Gains ........................................................................................H-4

Guidelines For Adjusting PID Gains..................................................H-5

Appendix I

Step Logic, Basic Logic and Timer/

Counter Functions

Step Logic Using Timed Steps.......................................................... I-2

Step Logic Using Basic Logic Functions............................................ I-3

Timer Function.................................................................................I-4

Counter Function.............................................................................. I-4

Step Logic Parameters.....................................................................I-5

Page 11

Chapter 1

Product Overview

Introduction This chapter provides a brief overview of the features and

functionality of the Bulletin 280G/281G and 284G ArmorStart®

Distributed Motor Controllers.

Description The ArmorStart Distributed Motor Controllers are integrated, pre-

engineered, starters with Bulletin 280G/281G for full-voltage and

reversing applications and Bulletin 284G for variable frequency AC

drives applications. The ArmorStart offers a robust IP67/NEMA Type

4 enclosure design, which is suitable for water wash down

environments.

The modular “plug and play” design offers simplicity in wiring the

installation. The quick disconnects for the I/O, communications, and

motor connections reduce the wiring time and eliminate wiring errors.

The ArmorStart offers as standard, six DC inputs to be used with

sensors for monitoring and controlling the application process. The

ArmorStart’s LED status indication and built-in diagnostics

capabilities allow ease of maintenance and troubleshooting.

The ArmorStart Distributed Motor Controller offers short circuit

protection per UL508 and IEC 60947. The ArmorStart is rated for

local-disconnect service by incorporating the Bulletin 140 Motor

Protector as the local-disconnect, eliminating the need for additional

components. The ArmorStart Distributed Motor Controllers are

suitable for group motor installations.

Safety ArmorStart The safety version of the ArmorStart provides a safety solution

integrated into DeviceNet Safety installations. The Bulletin 280/281/

284 Safety ArmorStart achieves Category 4 functionality by using

redundant contactors. The Safety ArmorStart offers a quick connects

via the gland plate to the 1732DS-IB8XOBV4 safety I/O module. The

Bulletin 1732DS Safety I/O inputs will monitor the status of the

safety rated contactors inside the ArmorStart. The Bulletin 1732DS

Safety I/O outputs to provide 24V DC power for control power to the

ArmorStart.

Note: The Bulletin 280/281/284 Safety ArmorStart is suitable for

safety applications up to Safety Category 4PL e (TÜV

assessment per ISO 13849-1:2008). T

available upon request.

Note: For additional information regarding the

1732DS-IB8XOBV4 safety I/O module, see publication

1791DS-UM001*-EN-P.

ÜV compliance letter is

Page 12

1-2 Product Overview

00%

ge

)

Operation The ArmorStart Distributed Motor Controllers can operate three-

phase squirrel-cage induction motors as follows:

Bulletin 280G/281G: up to 10 Hp (7.5 kW) @ 460VAC, 50/60 Hz.

Bulletin 284G: up to 5 Hp (3.0 kW) @ 460V AC.

Bulletin 1000: 7.5 Hp (5.5 kW), 10 Hp (7.5 kW) and 15 Hp (11 kW)

@ 460VAC, 50/60 Hz.

The ArmorStart Distributed Motor Controller will accept a control

power input of 120VAC.

Mode of Operation Bulletin 280G/281G

Full-Voltage Start

This method is used in applications requiring across-the-line starting,

in which full inrush current and locked-rotor torque are realized. The

ArmorStart Bulletin 280G offers full-voltage starting and the Bulletin

281G offers full-voltage starting for reversing applications.

1

Percent

Volta

Time (seconds

Bulletin 284G

Sensorless Vector Control

• Sensorless Vector Control provides exceptional speed regulation

and very high levels of torque across the entire speed range of the

drive

• The Autotune feature allows the Bulletin 284G ArmorStart

Distributed Motor Controller to adapt to individual motor

characteristics.

• To select this method of operation, select V for the Mode of

Operation listed in the catalog structure. See

Publication 280-SG001*.

Page 13

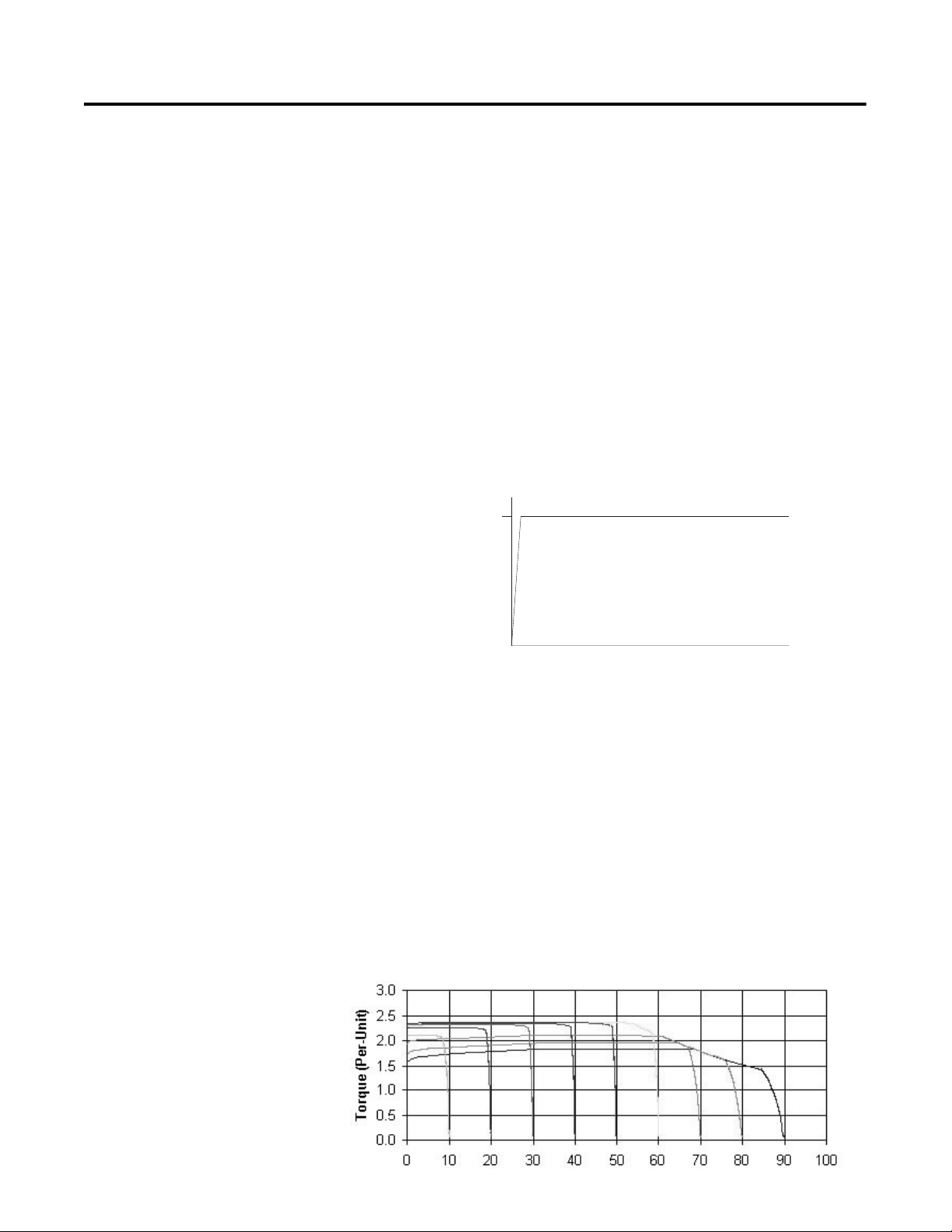

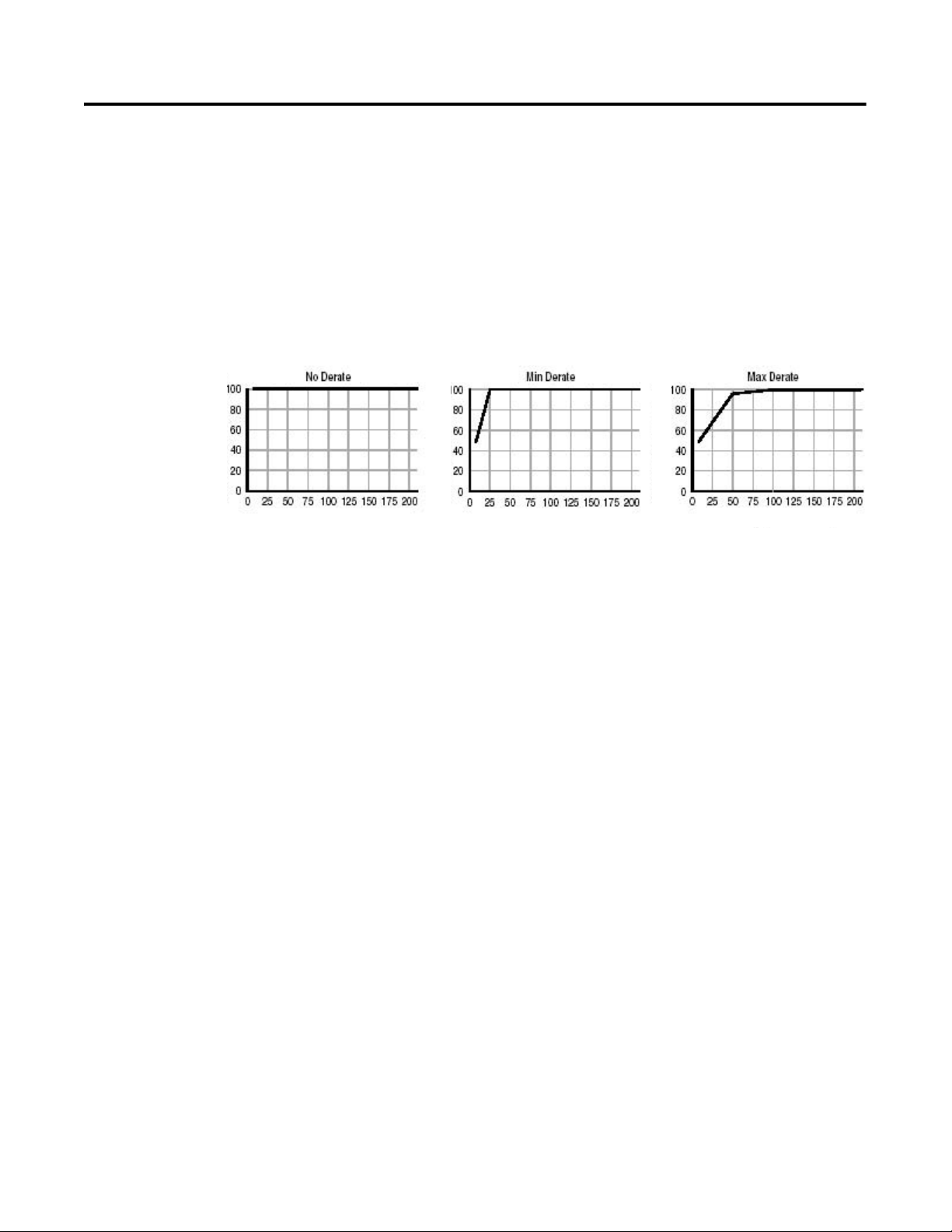

Description of Features Overload Protection

Class 15 Overload Curves

1

100

10000

0 100 200 300 400 500 600 700

Multiples for Full Load Current

Approximate Trip Time (sec)

Cold

Hot

Class 10 Ove rload Curv es

1

10

100

1000

10000

0 100 200 300 400 500 600 700

Multiples of Full Load Current

Approximate Trip Time (sec)

Cold

Hot

Class 20 Ove rload Curv es

1

100

10000

0 100 200 300 400 500 600 700

Multiples of Full Load Current

Approximate Trip Time (sec)

Cold

Hot

Class 10

Class 15

Class 20

%

%

of

%

The ArmorStart Distributed Motor Controller incorporates, as

standard, electronic motor overload protection. This overload

protection is accomplished electronically with an I

ArmorStart’s overload protection is programmable via the

communication network, providing the user with flexibility.

The Bulletin 280G/281G overload trip class can be selected for class

10, 15, 20 protection. Ambient insensitivity is inherent in the

electronic design of the overload.

Figure 1.1 Overload Trip Curves

Product Overview 1-3

2

t algorithm. The

Page 14

1-4 Product Overview

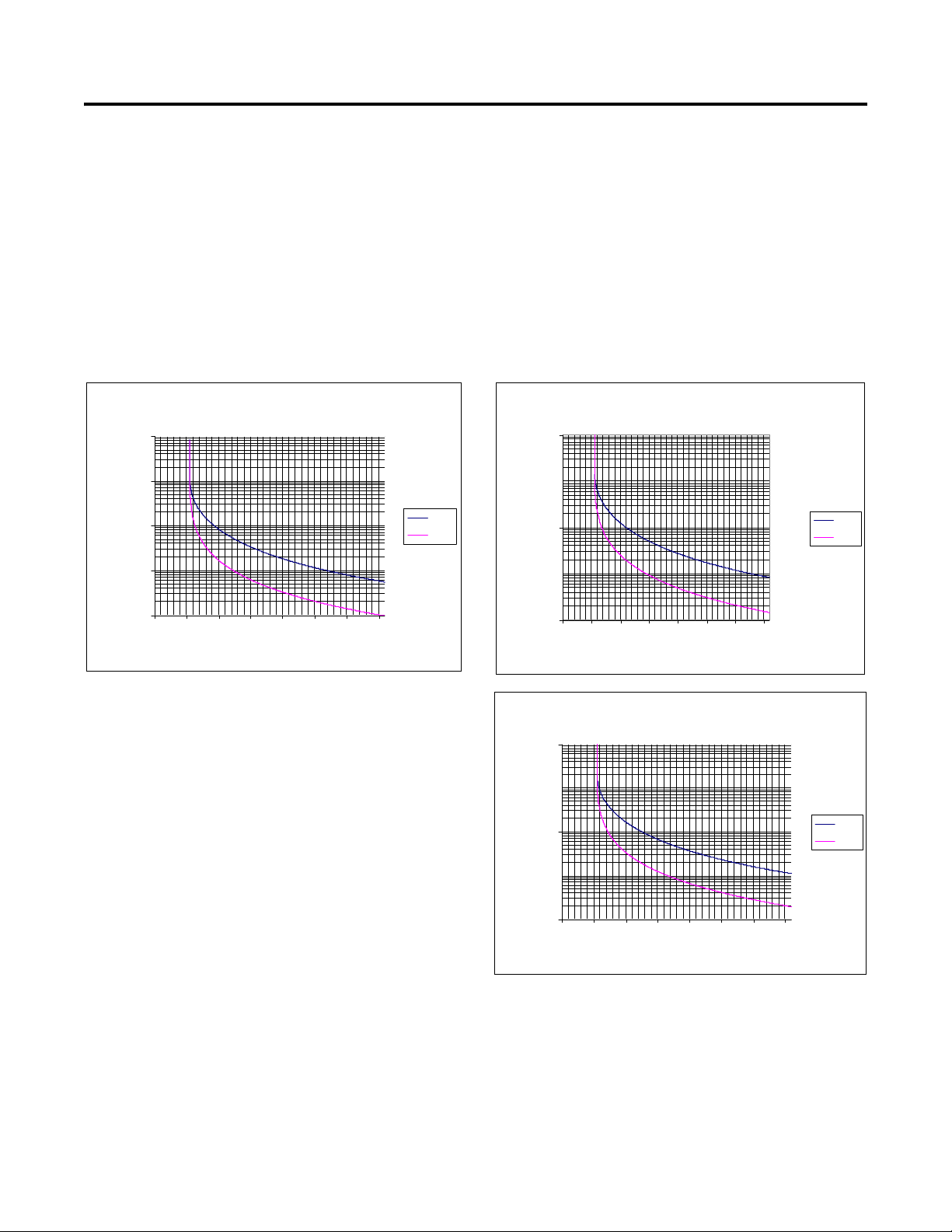

% of P132 (Motor NP Hertz) % of P132 (Motor NP Hertz)

% of P132 (Motor NP Hertz)

% of P133 (Motor OL Current)

% of P133 (Motor OL Current)

% of P133 (Motor OL Current)

The Bulletin 284G ArmorStart Distributed Motor Controller

incorporates, as standard, electronic motor overload protection. This

2

overload protection is accomplished electronically with an I

t

algorithm. The ArmorStart’s overload protection is programmable via

the communication network providing the user with flexibility.

Programming the Motor OL Current parameter provides class 10

overload protection for the Bulletin 284G Distributed Motor

Controller. Ambient insensitivity is inherent in the electronic design

of the overload.

Figure 1.2 Overload Trip Curves

Page 15

Product Overview 1-5

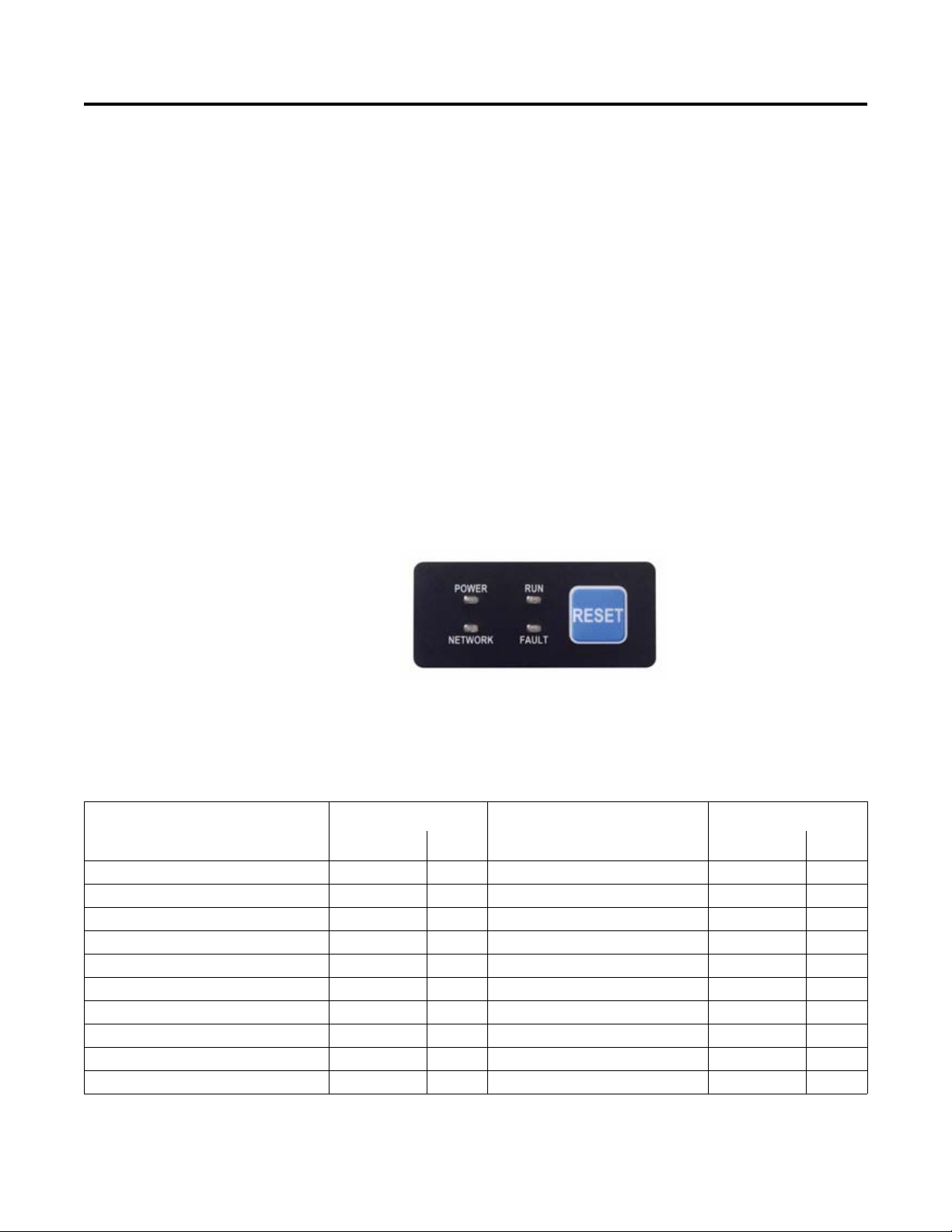

LED Status Indication

The LED Status Indication provides 4 status LEDs and a Reset

button. The LEDs provide status indication for the following:

•POWER LED

The LED is illuminated solid green when control power is present

and with the proper polarity

• RUN LED

This LED is illuminated solid green when a start command and

control power are present

•NETWORK LED

This bi-color (red/green) LED indicates the status of the

communication link

•FAULT LED

Indicates Controller Fault (Trip) condition

The “Reset Button” acts as a local trip reset.

Figure 1.3 Status Indication and Reset

Fault Diagnostics

Fault diagnostics capabilities built in the ArmorStart Distributed

Motor Controller help you pinpoint a problem for easy

troubleshooting and quick re-starting.

Fault Indication

• Short Circuit X X • Phase Imbalance X

• Overload X X • Miscellaneous Fault X

• Phase Loss X X • Brake Fuse Detection X

• Control Power Loss X X • Internal Comm. Fault X

• Control Power Fuse Detection X X • DC Bus Fault X

• I/O Fault X X • Ground Fault X

• Over Temperature X X • Overcurrent X

• DeviceNet™ Power Loss X X • Restart Retries X

• EEprom Fault X X • Stall X

• Hardware Fault X X • Phase Short X

Available on Bulletin:

Fault Indication

280G/281G 284G 280G/281G 284G

Available on Bulletin:

Page 16

1-6 Product Overview

Inputs

The inputs are single-keyed (2 inputs per connector), which are

sourced from DeviceNet power (24V DC), with LED status

indication.

Gland Plate Entrance

The ArmorStart product offers connectivity to the ArmorConnect™

power media. Receptacles are provided for connectivity to both threephase and control power media.

ArmorStart with DeviceNet Network Capabilities

The ArmorStart Distributed Motor Controller delivers advanced

capabilities to access parameter settings and provides fault

diagnostics, and remote start-stop control. DeviceNet is the

communication protocol, provided with the ArmorStart Bulletin

280G/281G or 284G Distributed Motor Controller.

DeviceLogix™

DeviceLogix is a stand-alone Boolean program that resides within the

ArmorStart Distributed Motor Controller. DeviceLogix is

programmed using Boolean math operations, such as, AND, OR,

NOT, Timers, Counters, and Latches. DeviceLogix can run as a standalone application, independent of the network. However, 24V DC

must be supplied at the DeviceNet connector to power the inputs.

Peer to Peer Communications (ZIP)

The zone control capabilities of ArmorStart Distributed Motor

Controllers is ideal for large horsepower (0.5…15 Hp) motored

conveyors. The ArmorStart Distributed Motor Controllers have builtin DeviceNet communications, DeviceLogix technology, and the

added Zone Interlocking Parameters (ZIP) which allow one

ArmorStart to receive data directly, from up to four other DeviceNet

nodes, without going through a network scanner. These direct

communications between conveyor zones are beneficial in a merge,

diverter, or accumulation conveyor application.

EMI Filter (Bulletin 284G only)

The EMI Filter is required if the Bulletin 284G ArmorStart

Distributed Motor Controller must be CE-compliant. A shielded

4-conductor patchcord or cordset no longer than 14 meters, must be

used to comply with the CE requirement.

Page 17

Product Overview 1-7

Dynamic Brake Resistor (Bulletin 284G only)

The IP67 Dynamic Brake Resistor plug and play design offers

simplicity in writing and installation. The factory installed option of

DB1 must be selected in order to have the quick disconnect

connectivity. The cable length of the IP67 Dynamic Brake Resistor is

available in two lengths, 0.5 meter and 1 meter. See Appendix G,

Accessories, for available IP67 Dynamic Brake Resistors.

Note: The IP67 Dynamic Brake Resistor is used only with the -DB1

factory-installed option.

Control Brake Contactor

An internal contactor is used to switch the electromechanical motor

brake On/Off. The motor brake is powered from the control voltage

circuit.

Page 18

1-8 Product Overview

Notes:

Page 19

Chapter 2

Installation and Wiring

Receiving It is the responsibility of the user to thoroughly inspect the equipment

before accepting the shipment from the freight company. Check the

item(s) received against the purchase order. If any items are damaged,

it is the responsibility of the user not to accept delivery until the

freight agent has noted the damage on the freight bill. Should any

concealed damage be found during unpacking, it is again the

responsibility of the user to notify the freight agent. The shipping

container must be left intact and the freight agent should be requested

to make a visual inspection of the equipment.

Unpacking Remove all packing material, wedges, or braces from within and

around the starter. Remove all packing material from device(s).

Inspecting After unpacking, check the nameplate catalog number(s) against the

purchase order.

Storing The controller should remain in its shipping container prior to

installation. If the equipment is not to be used for a period of time, it

must be stored according to the following instructions in order to

maintain warranty coverage.

• Store in a clean, dry location.

• Store within an ambient temperature range of –25…+85 °C

(–13…+185 °F).

• Store within a relative humidity range of 0…95%,

noncondensing.

• Do not store equipment where it could be exposed to a corrosive

atmosphere.

• Do not store equipment in a construction area.

Page 20

2-2 Installation and Wiring

ATTENTION

!

ATTENTION

!

ATTENTION

!

ATTENTION

!

ATTENTION

!

General Precautions In addition to the precautions listed throughout this manual, the

following statements, which are general to the system, must be read

and understood.

The controller contains ESD (electrostatic

discharge)-sensitive parts and assemblies. Static

control precautions are required when installing,

testing, servicing, or repairing the assembly.

Component damage may result if ESD control

procedures are not followed. If you are not familiar

with static control procedures, refer to Publication

8000-4.5.2, Guarding against Electrostatic

Discharge, or any other applicable ESD protection

handbooks.

An incorrectly applied or installed controller can

damage components or reduce product life. Wiring

or application errors, such as undersizing the motor,

incorrect or inadequate AC supply, or excessive

ambient temperatures, may result in malfunction of

the system.

Precautions for Bulletin 280G/281G

Applications

Only personnel familiar with the controller and

associated machinery should plan or implement the

installation, startup, and subsequent maintenance of

the system. Failure to do this may result in personal

injury and/or equipment damage.

To prevent electrical shock, open disconnect prior

to connecting and disconnecting cables. Risk of

shock - environment rating may not be maintained

with open receptacles.

Only qualified personnel familiar with adjustable

frequency AC drives and associated machinery

should plan or implement the installation, startup,

and subsequent maintenance of the system. Failure

to do this may result in personal injury and/or

equipment damage.

Page 21

Precautions for Bulletin 284G

ATTENTION

!

ATTENTION

!

Applications

Installation and Wiring 2-3

The drive contains high voltage capacitors which

take time to discharge after removal of mains

supply. Before working on drive, ensure isolation of

mains supply from line inputs (R, S, T [L1, L2, L3]).

Wait three minutes for capacitors to discharge to

safe voltage levels. Failure to do so may result in

personal injury or death. Darkened display LEDs

are not an indication that capacitors have discharged

to safe voltage levels. Risk of shock-environment

rating may not be maintained with open receptacles.

Only qualified personnel familiar with adjustable

frequency AC drives and associated machinery

should plan or implement the installation, startup,

and subsequent maintenance of the system. Failure

to do this may result in personal injury and/or

equipment damage.

Page 22

2-4 Installation and Wiring

Dimensions for Bulletin 280G/281G Dimensions are shown in millimeters (inches). Dimensions are not

intended to be used for manufacturing purposes. All dimensions are

subject to change.

Figure 2.1 Dimensions for IP67/NEMA Type 4 with ArmorConnect

Connectivity

Page 23

Installation and Wiring 2-5

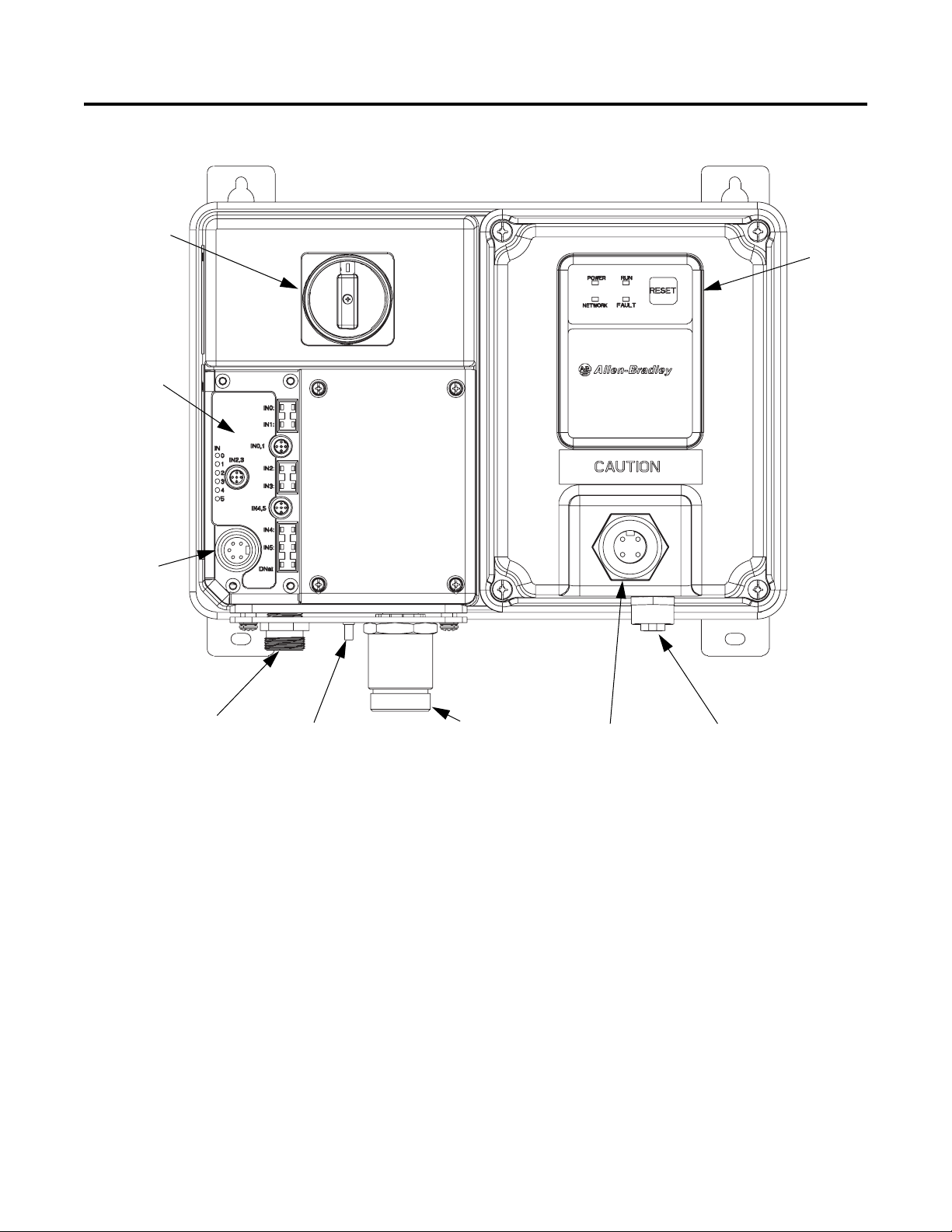

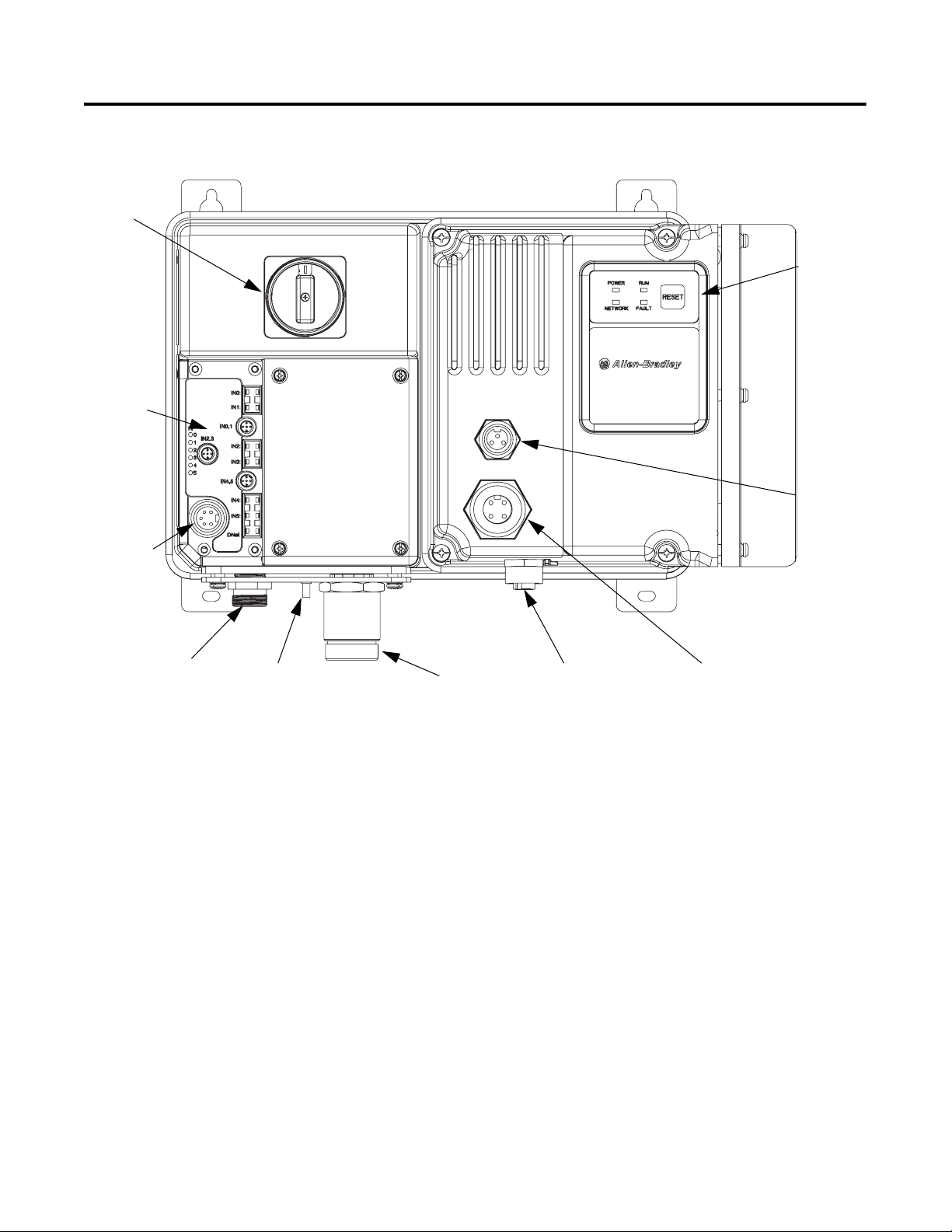

Motor

Connection

DeviceNet

Connection

(Mini/M18)

Local Disconnect

6 Inputs

(Micro/M12)

Ground Terminal

Control Brake

Control Power

Receptacle

3-Phase Power

Receptacle

LED Status

Indication

Figure 2.2 Bulletin 280G/281G ArmorStart® with DeviceNet™

Communication Protocol

Page 24

2-6 Installation and Wiring

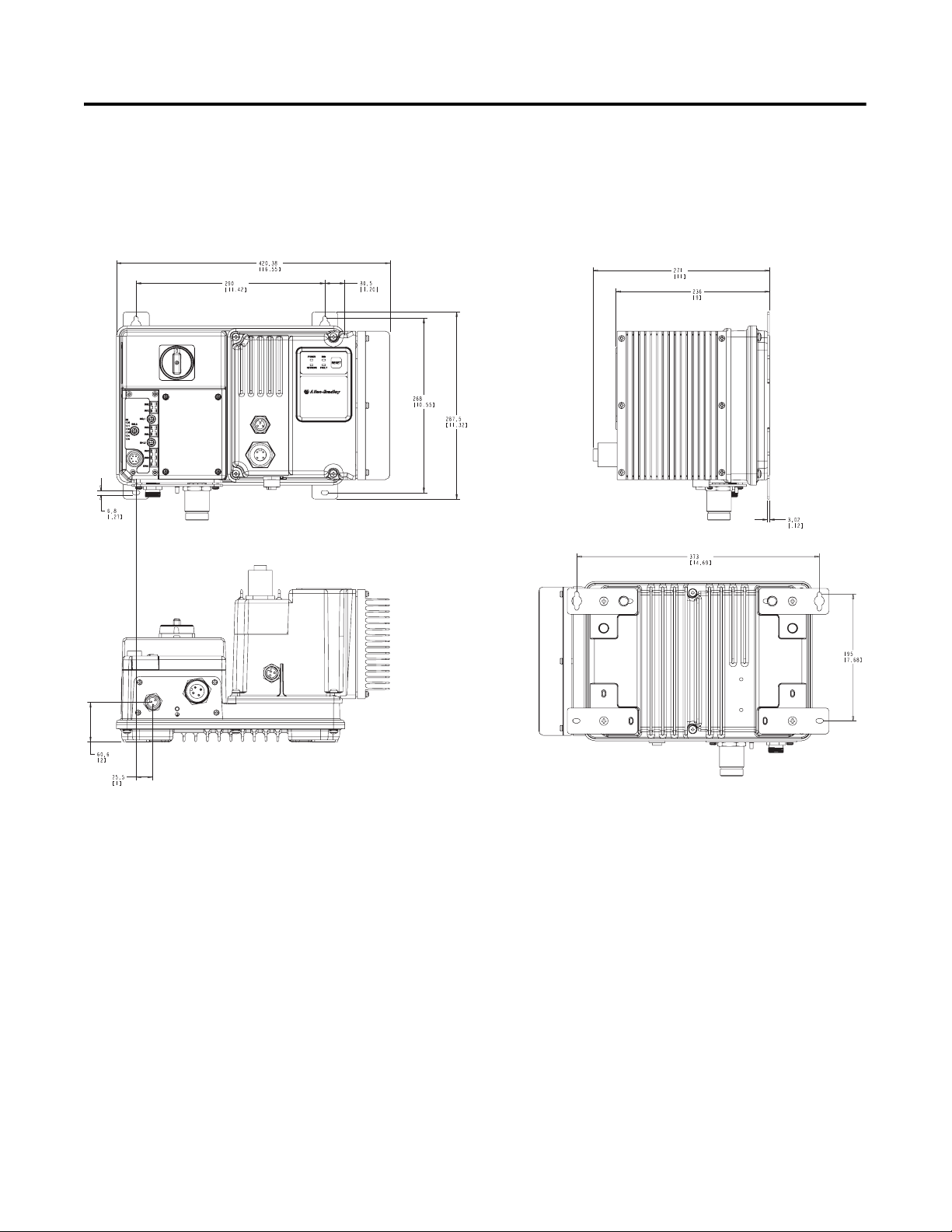

Dimensions for Bulletin 284G Dimensions are shown in millimeters (inches). Dimensions are not

intended to be used for manufacturing purposes. All dimensions are

subject to change.

Figure 2.3 Dimensions for 2 Hp (1.5 kW) and below @ 460V AC, IP67/NEMA

Type 4 with ArmorConnect connectivity

Page 25

Installation and Wiring 2-7

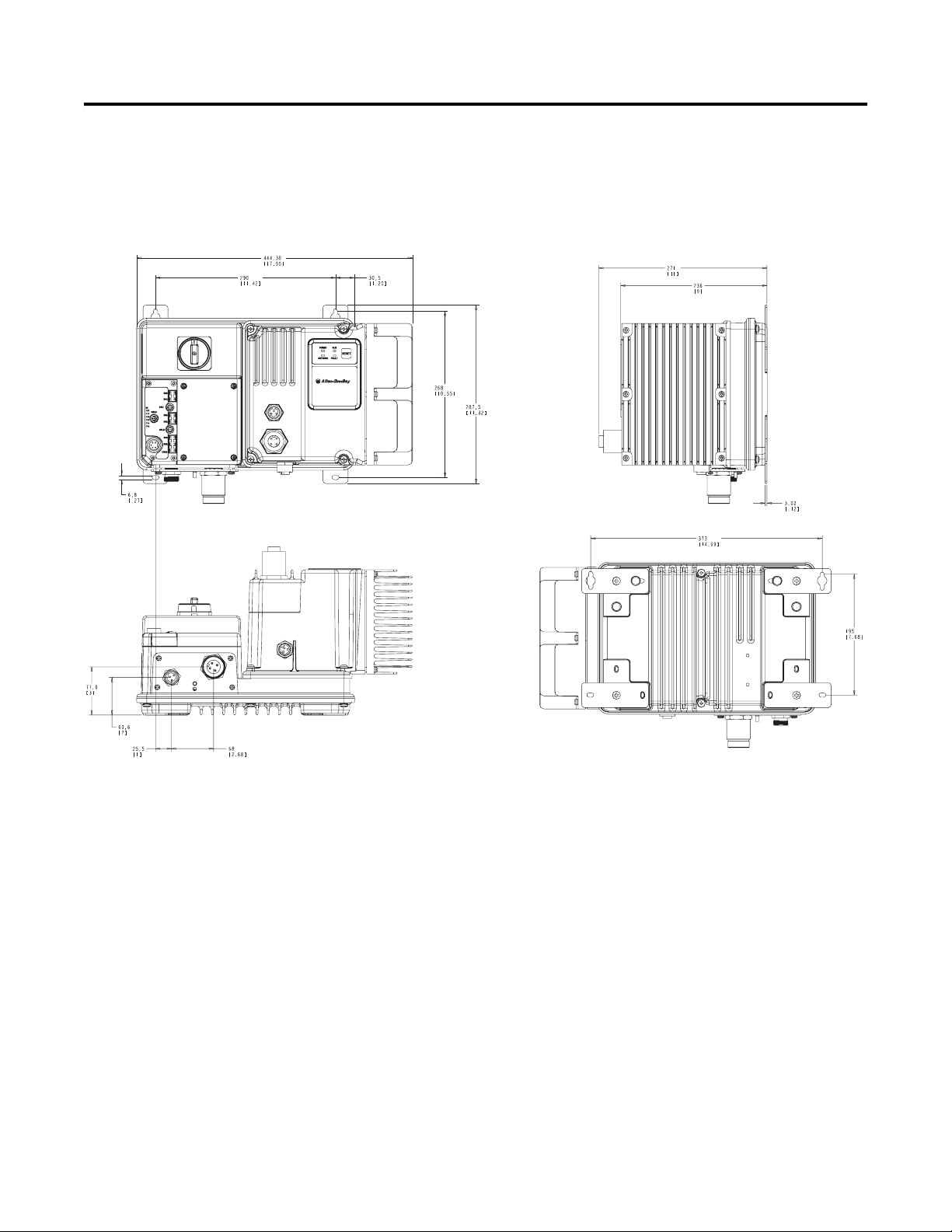

Dimensions for Bulletin 284G,

Continued

Dimensions are shown in millimeters (inches). Dimensions are not

intended to be used for manufacturing purposes. All dimensions are

subject to change.

Figure 2.4 Dimensions for 3 Hp (2.2 kW) and above @ 460V AC, IP67/NEMA

Type 4 with ArmorConnect connectivity

Page 26

2-8 Installation and Wiring

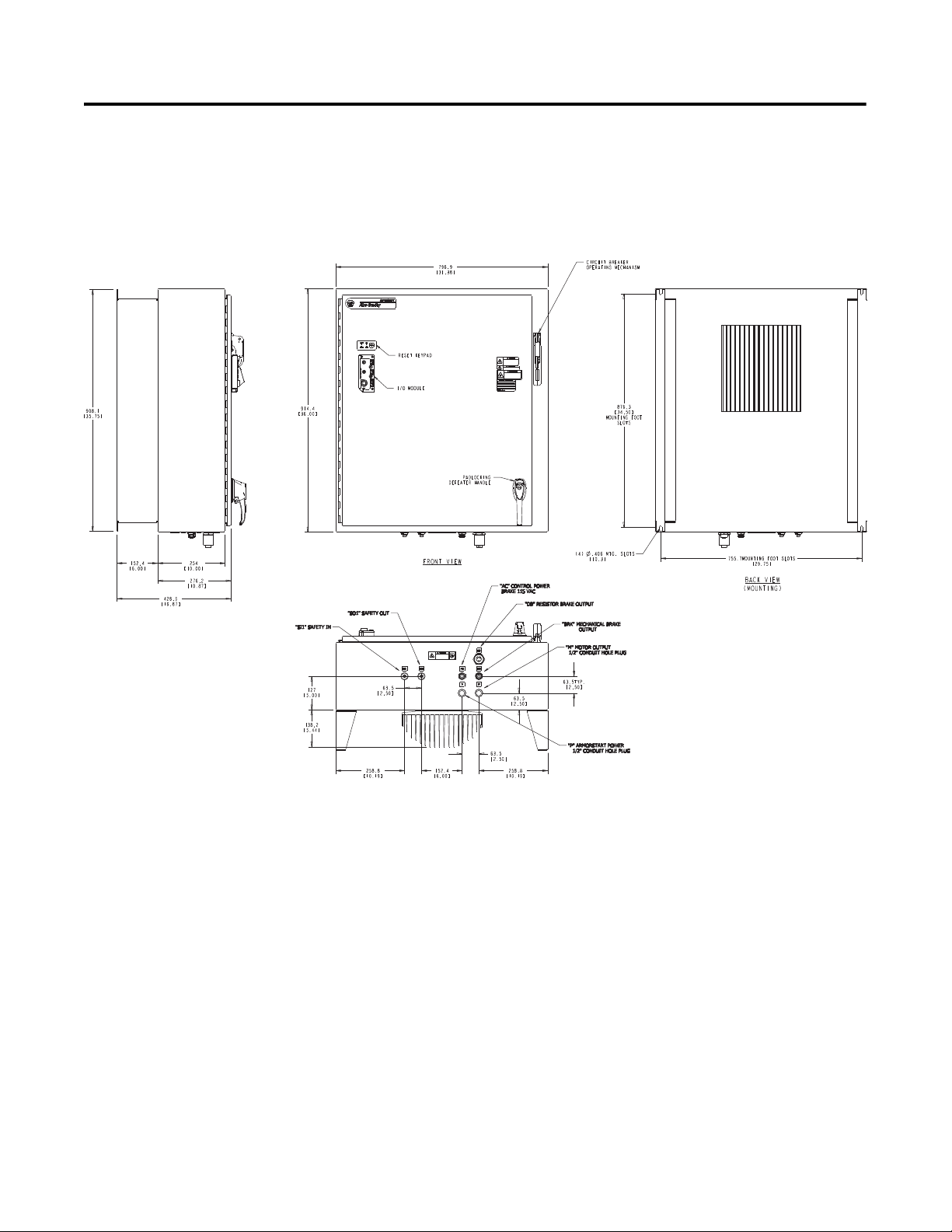

Dimensions for Bulletin 1000 Dimensions are shown in millimeters (inches). Dimensions are not

intended to be used for manufacturing purposes. All dimensions are

subject to change.

Figure 2.5 Dimensions for 7.5 Hp (5.5 kW) and 10 Hp (7.5 kW) @ 460V AC,

IP67/NEMA Type 4 with ArmorConnect Connectivity

Page 27

Installation and Wiring 2-9

Dimensions for Bulletin 1000,

Continued

Dimensions are shown in millimeters (inches). Dimensions are not

intended to be used for manufacturing purposes. All dimensions are

subject to change.

Figure 2.6 Dimensions for 15 Hp (11 kW) @ 460V AC, IP67/NEMA Type 4 with

ArmorConnect Connectivity

Page 28

2-10 Installation and Wiring

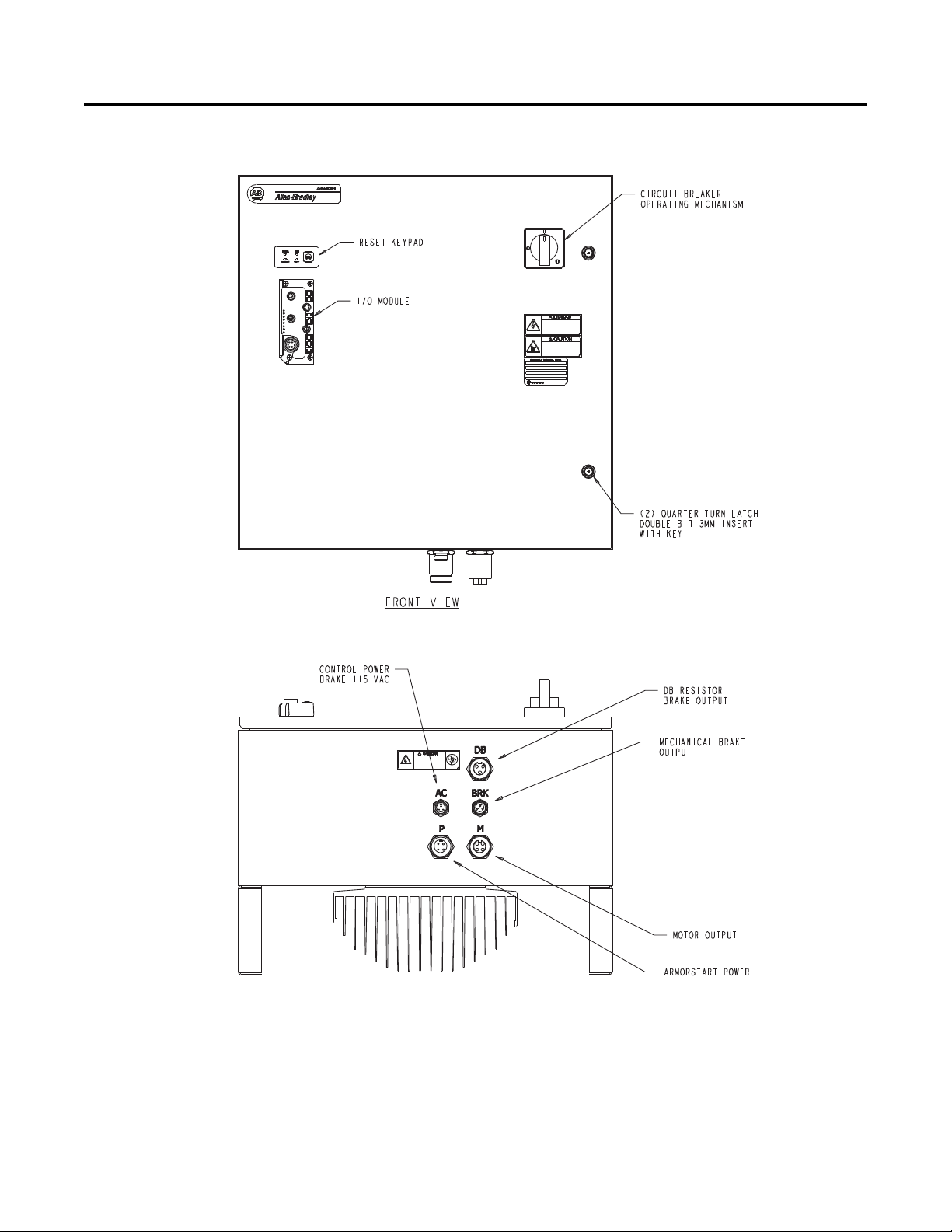

LED Status

Indication

Motor

Connector

Dynamic

Brake Connector

Control Brake

Connector

Ground

Te r mi n a l

3-Phase

Receptacle

Control Power

Receptacle

DeviceNet

Connection

(Mini/M18)

Local Disconnect

6 Inputs

(Micro/M12)

Figure 2.7 Bulletin 284G ArmorStart

Page 29

Figure 2.8 Bulletin 1000 ArmorStart

Installation and Wiring 2-11

Page 30

2-12 Installation and Wiring

Figure 2.9 Bulletin 1000 ArmorStart

Page 31

Wiring Power, Control, and Ground Wiring

Table 2.1 provides the power, control, safety inputs, and ground wire

capacities, and the tightening torque requirements. The power,

control, ground, and safety monitor terminals will accept a maximum

of two wires per terminal.

Table 2.1 Power, Control, Safety Input, Ground Wire Size, and Torque

Specifications

Terminals Wire Size Torque Wire Strip Length

Installation and Wiring 2-13

Power

and

Ground

Control and Safety

Inputs

Primary/Secondary

Terminal:

1.5…4.0 mm

(#16 …#10 AWG)

1.0 mm

(#18…#10 AWG)

2

…4.0 mm2

2

Primary Terminal:

Secondary Terminal:

10.8 lb.-in.

(1.2 N•m)

4.5 lb.-in

(0.5 N•m)

6.2 lb.-in

(0.7 N•m)

0.35 in. (9 mm)

0.35 in. (9 mm)

Page 32

2-14 Installation and Wiring

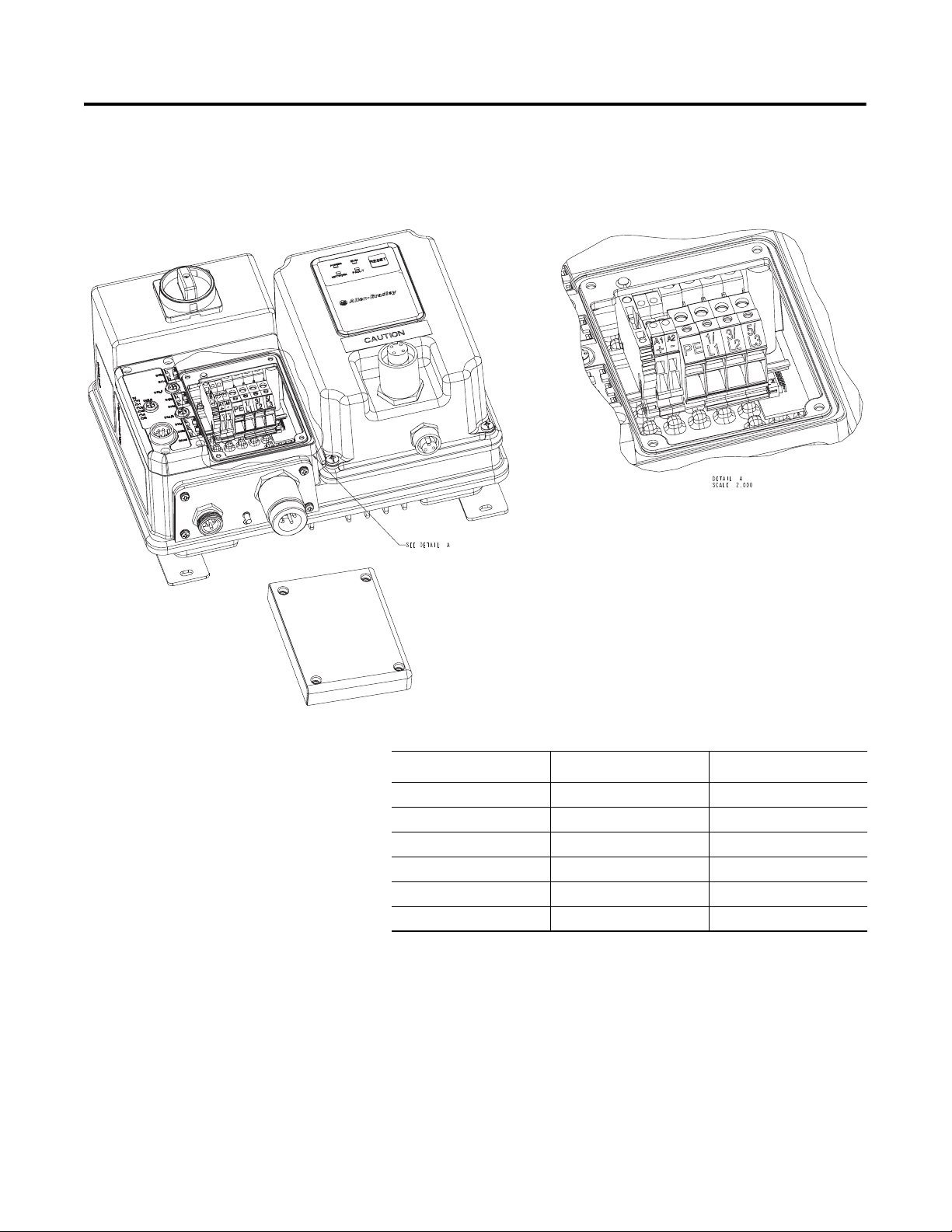

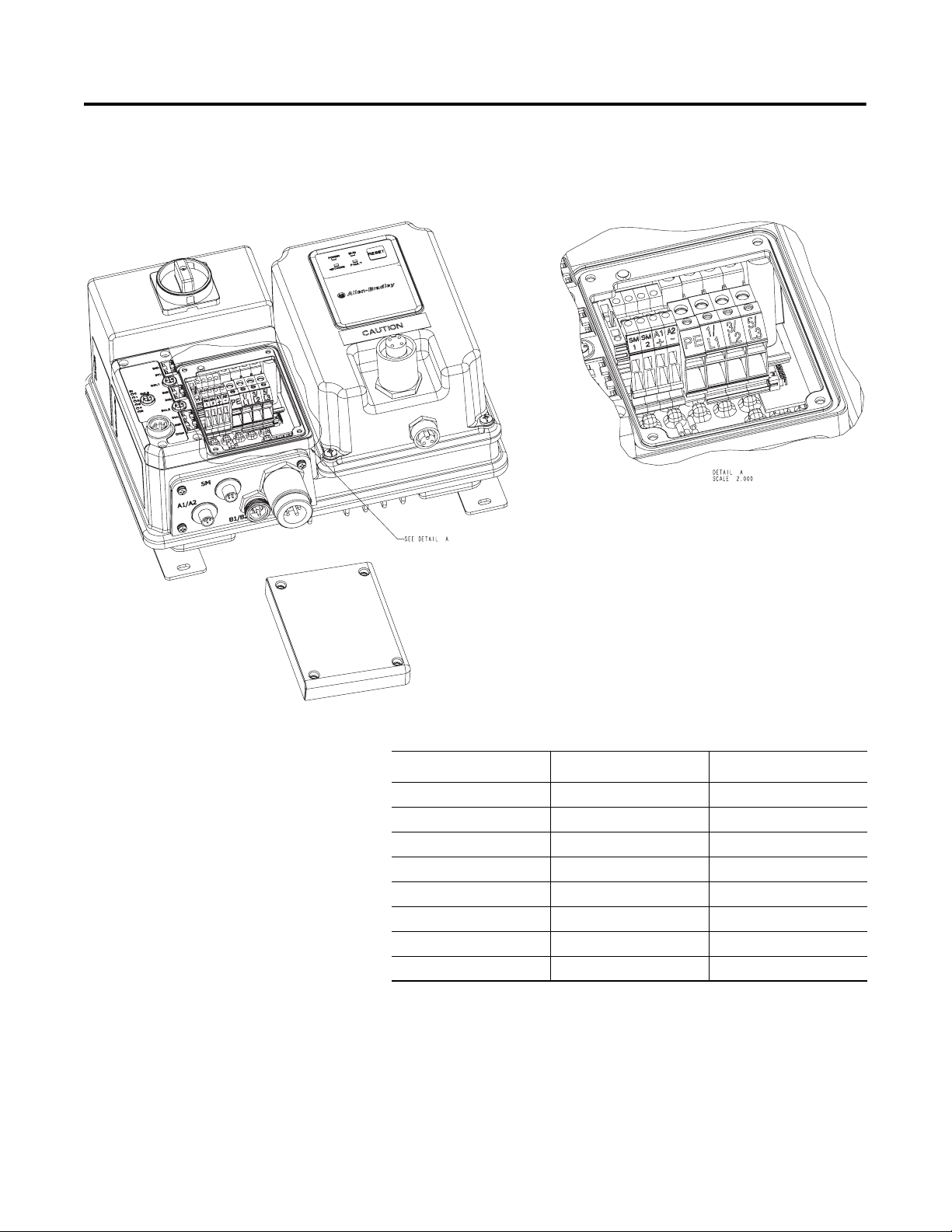

Terminal Designations for Bulletins

280G, 281G, and 284G

As shown in the next figure, the ArmorStart Distributed Motor Controller

contains terminals for power, control, and ground wiring. Access can be

gained by removing the terminal access cover plate.

Figure 2.10 ArmorStart Power, Control and Terminals

Table 2.2 Power, Control, and Ground Terminal Designations

Terminal Designations No. of Poles Description

A1 (+) 2 Control Power Input

A2 (-) 2 Control Power Common

PE 2 Ground

1/L1 2 Line Power Phase A

3/L3 2 Line Power Phase B

5/L5 2 Line Power Phase C

Page 33

Installation and Wiring 2-15

Dimensions for Bulletin 280G

Safety Product

Dimensions are shown in millimeters (inches). Dimensions are not

intended to be used for manufacturing purposes. All dimensions are

subject to change.

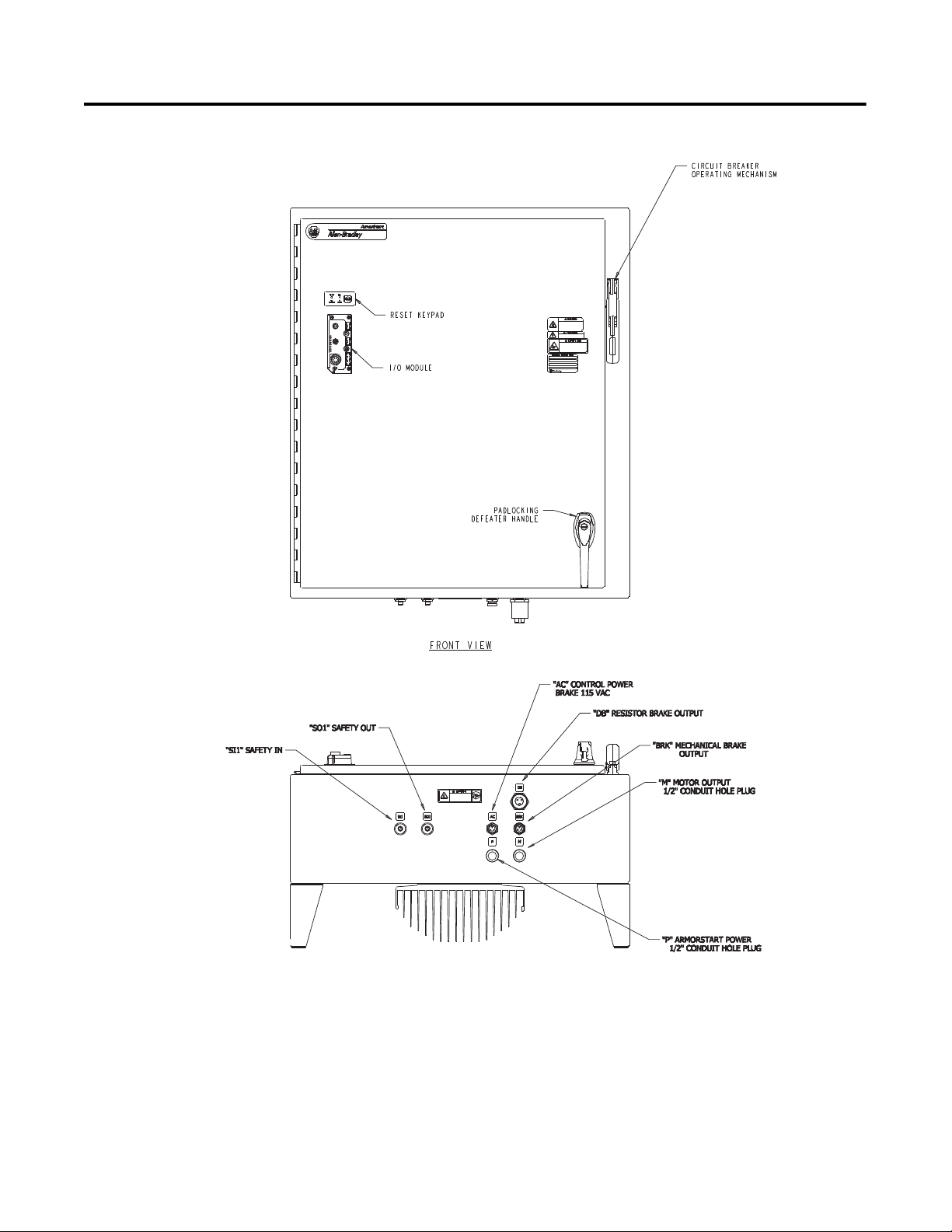

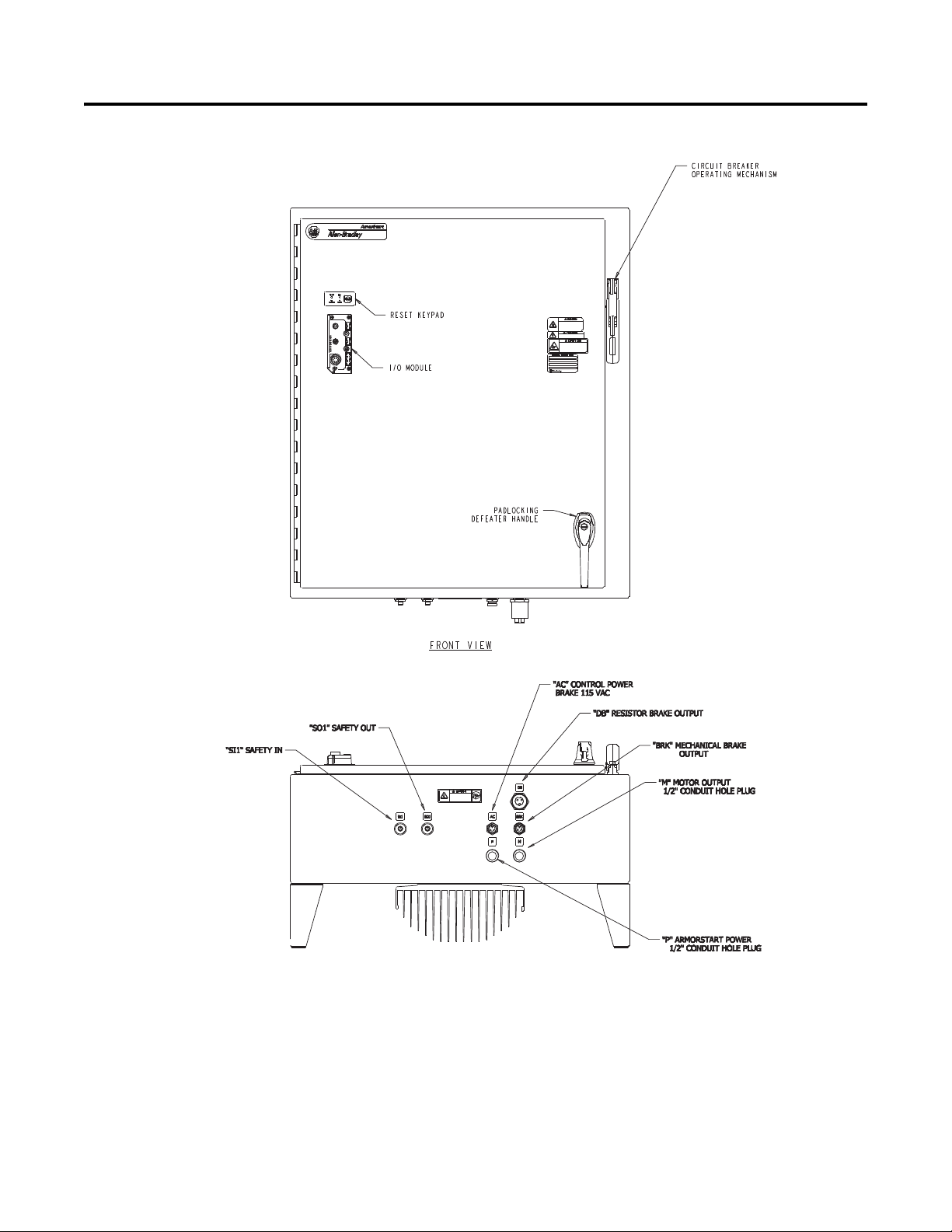

Figure 2.11 Dimensions for Bulletin 280G Safety Product

Page 34

2-16 Installation and Wiring

Dimensions for Bulletin 281G

Safety Product

Dimensions are shown in millimeters (inches). Dimensions are not

intended to be used for manufacturing purposes. All dimensions are

subject to change.

Figure 2.12 Dimensions for Bulletin 281G Safety Product

Page 35

Installation and Wiring 2-17

Dimensions for Bulletin 284G

Safety Product

Dimensions are shown in millimeters (inches). Dimensions are not

intended to be used for manufacturing purposes. All dimensions are

subject to change.

Figure 2.13 Dimensions for 2 Hp (1.5 kW) and below @ 460V AC, IP67/NEMA

Type 4 with ArmorConnect connectivity

Page 36

2-18 Installation and Wiring

Dimensions for Bulletin 284G

Safety Product, Continued

Dimensions are shown in millimeters (inches). Dimensions are not

intended to be used for manufacturing purposes. All dimensions are

subject to change.

Figure 2.14 Dimensions for 3 Hp (2.2 kW) and 5 Hp (3.0 kW) and below @

460V AC, IP67/NEMA Type 4 with ArmorConnect connectivity

Page 37

Installation and Wiring 2-19

Dimensions for Bulletin 1000

Safety Product

Dimensions are shown in millimeters (inches). Dimensions are not

intended to be used for manufacturing purposes. All dimensions are

subject to change.

Figure 2.15 Dimensions for 7.5 Hp (5.5 kW) and 10 Hp (7.5 kW) @ 460V AC,

IP67/NEMA Type 4 with ArmorConnect Connectivity

Page 38

2-20 Installation and Wiring

Dimensions for Bulletin 1000

Safety Product, Continued

Dimensions are shown in millimeters (inches). Dimensions are not

intended to be used for manufacturing purposes. All dimensions are

subject to change.

Figure 2.16 Dimensions for 15 Hp @ 460V AC, IP67/NEMA Type 4 with

ArmorConnect Connectivity

Page 39

Figure 2.17 Bulletin 280G Safety ArmorStart

Motor

Connection

DeviceNet

Connection

(Mini/M18)

Local Disconnect

6 Inputs

(Micro/M12)

A1/A2

Control Brake

Control Power

Receptacle

3-Phase Power

Receptacle

LED Status

Indication

SM

Installation and Wiring 2-21

Page 40

2-22 Installation and Wiring

Motor

Connection

DeviceNet

Connection

(Mini/M18)

Local Disconnect

6 Inputs

(Micro/M12)

3-Phase Power

Receptacle

LED Status

Indication

A1/A2

Control Power

SM

Control Brake

Figure 2.18 Bulletin 281G Safety ArmorStart

Page 41

Figure 2.19 Bulletin 284G Safety ArmorStart

Motor

Connection

DeviceNet

Connection

(Mini/M18)

Local Disconnect

6 Inputs

(Micro/M12)

Dynamic Brake

3-Phase Power

Receptacle

LED Status

Indication

A1/A2

Control Power

SM

Control Brake

Installation and Wiring 2-23

Page 42

2-24 Installation and Wiring

Figure 2.20 Bulletin 1000 Safety ArmorStart

Page 43

Figure 2.21 Bulletin 1000 ArmorStart

Installation and Wiring 2-25

Page 44

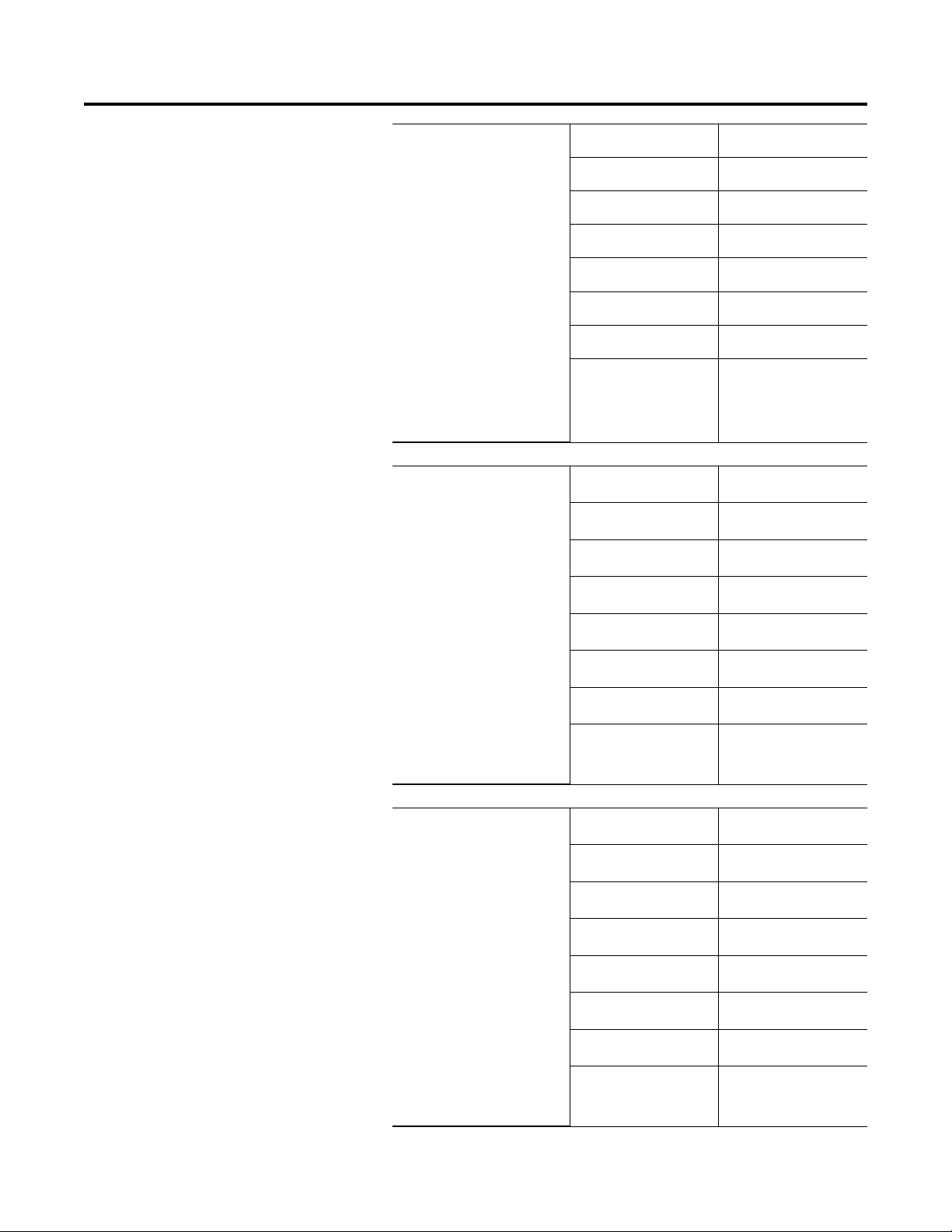

2-26 Installation and Wiring

Safety Terminal Designations As shown in the next figure, the ArmorStart Distributed Motor Controller

contains terminals for power, safety I/O inputs, control, and ground wiring.

Access can be gained by removing the terminal access cover plate.

Figure 2.22 Bulletin 280G ArmorStart Safety Power, Control and Terminals

Table 2.3 Power, Control, Safety Monitor, and Ground Terminal Designations

Terminal Designations No. of Poles Description

SM1 2 Safety I/O Input

SM2 2 Safety I/O Input

A1 (+) 2 Control Power Input

A2 (-) 2 Control Power Common

PE 2 Ground

1/L1 2 Line Power Phase A

3/L3 2 Line Power Phase B

5/L5 2 Line Power Phase C

Page 45

Installation and Wiring 2-27

Safety Terminal Designations,

Continued

As shown in the next figure, the ArmorStart Distributed Motor Controller

contains terminals for power, safety I/O inputs, control, and ground wiring.

Access can be gained by removing the terminal access cover plate.

Figure 2.23 Bulletin 281G ArmorStart Safety Power, Control and Terminals

Table 2.4 Power, Control, Safety Monitor, and Ground Terminal Designations

Terminal Designations No. of Poles Description

SM1 2 Safety I/O Input

SM2 2 Safety I/O Input

A1 (+) 2 Control Power Input

A2 (-) 2 Control Power Common

PE 2 Ground

1/L1 2 Line Power Phase A

3/L3 2 Line Power Phase B

5/L5 2 Line Power Phase C

Page 46

2-28 Installation and Wiring

Safety Terminal Designations,

Continued

As shown in the next figure, the ArmorStart Distributed Motor Controller

contains terminals for power, safety I/O inputs, control, and ground wiring.

Access can be gained by removing the terminal access cover plate.

Figure 2.24 ArmorStart Safety 2 Hp Power, Control and Terminals

Table 2.5 Power, Control, Safety Monitor, and Ground Terminal Designations

Terminal Designations No. of Poles Description

SM1 2 Safety I/O Input

SM2 2 Safety I/O Input

A1 (+) 2 Control Power Input

A2 (-) 2 Control Power Common

PE 2 Ground

1/L1 2 Line Power Phase A

3/L3 2 Line Power Phase B

5/L5 2 Line Power Phase C

Page 47

ArmorConnect Power Media Description

Encl

The ArmorConnect power media offers both three-phase and control

power cable system of cord sets, patch cords, receptacles, tees,

reducers and accessories to be utilized with the ArmorStart

Distributed Motor Controller. These cable system components allow

quick connection of ArmorStart Distributed Motor Controllers, there

by reducing installation time. They provide for repeatable, reliable

connection of the three-phase and control power to the ArmorStart

Distributed Motor Controller and motor by providing a plug-and-play

environment that also avoids system mis-wiring. When specifying

power media for use with the ArmorStart Distributed Motor

Controllers (Bulletin 280G/281G and 284G) use only the Bulletin

280 ArmorConnect power media.

Figure 2.25 Three-Phase Power System Overview

osure

Bulletin 1492FB

Branch Circuit

Protective Device

Bulletin 1606

Power Supply

1606-XLSDNET4

DeviceNet

Power Supply

Installation and Wiring 2-29

PLC

Bulletin 280/281

ArmorStart

RESET

Bulletin 280/281

ArmorStart

RESET

➊ Three-Phase Power Trunk- PatchCord cable with integral female or male connector on each end

Example Part Number: 280-PWR35A-M*

➋ Three-Phase Drop Cable- PatchCord cable with integral female or male connector on each end

Example Part Number: 280-PWR35A-M*

➌ Three-Phase Power Tee and Reducer -

Tee connects to a single drop line to trunk with quick change connectors – Part Number: 280-T35

Reducing Tee connects to a single drop line (Mini) to trunk (Quick change) connector – Part Number: 280-RT35

➍ Three-Phase Power Receptacles -

Female receptacles are a panel mount connector with flying leads – Part Number: 280-M35F-M1

Bulletin 284

ArmorStart

Page 48

2-30 Installation and Wiring

RESET

Bulletin 280/281

ArmorStart

Bulletin 284

ArmorStart

RESET

Bulletin 280/281

ArmorStart

PLC

Bulletin 1492FB

Branch Circuit

Protective Device

Enclosure

Bulletin 1606

Power Supply

1606-XLSDNET4

DeviceNet

Power Supply

Figure 2.26 Control Power Media System Overview

➏ Control Power Media Patchcords - PatchCord cable with integral female or male connector on each end

Example Part Number: 889N-F3AFNU-*F

➐ Control Power Tees - The Control Power tee (Part Number: 898N-33PB-N4KF) is used with a patchcord to connect to the ArmorStart Distributed Motor

Controller.

➑ Control Power Receptacles - Female receptacles are a panel mount connector with flying leads –

Part Number: 888N-D3AF1-*F

Page 49

Installation and Wiring 2-31

Control Power

Receptacle

Ground

Term in al

Three-Phase

Power

Receptacle

Term in al

Designations

Description Color Code

A1 (+) Control Power Input Black

A2 (-) Control Power Common White

PE Ground Green/Yellow

1/L1 Line Power - Phase A Black

3/L2 Line Power - Phase B White

5/L3 Line Power - Phase C Red

ArmorStart with ArmorConnect Connectivity

Terminal Designations

ArmorConnect Cable Ratings

The ArmorConnect power media cables are rated per UL Type TC

600V 90 °C Dry 75 °C Wet, Exposed Run (ER) or MTW 600V 90 °C

or STOOW 105 °C 600V - CSA STOOW 600V FT2.

Page 50

2-32 Installation and Wiring

Ground

Termi na l

Three-Phase

Power

Recepale

120V AC

Aux. Powr

for

Conto Brake

Safety Monitor

Input from

1732DS Safey

I/O Module Inpt

A1/A2 -24V DC

Control Power rm

1732DS Safety

I/O Module Outu

Term in al

Designations

Description Color Code

SM1 Safety Monitor Input Brown

SM2 Safety Monitor Input White

A1 (+) Control Power Input Brown

A2 (-) Control Power Common Blue

PE Ground Green/Yellow

1/L1 Line Power - Phase A Black

3/L2 Line Power - Phase B White

5/L3 Line Power - Phase C Red

ArmorStart Safety with ArmorConnect Connectivity

Terminal Designations

ArmorConnect Cable Ratings

The ArmorConnect power media cables are rated per UL Type TC

600V 90 °C Dry 75 °C Wet, Exposed Run (ER) or MTW 600V 90 °C

or STOOW 105 °C 600V - CSA STOOW 600V FT2.

Page 51

Installation and Wiring 2-33

Branch Circuit Protection Requirements for ArmorConnect

Three-Phase Power Media

When using ArmorConnect three-phase power media, fuses can be

used for the motor branch circuit protective device, for the group

motor installations. The following fuse types are recommended: Class

CC, T, or J type fuses. A 100 A circuit breaker (Allen-Bradley140

H-Frame) can be used for the motor branch protective device, for the

group motor installations when using only the following

ArmorConnect Power Media components: 280-M35M-M1,

280-M35F-M1, 280-T35, and 280-PWRM35*-M*.

Maximum Ratings

Voltage (V) 480Y/277

Sym. Amps RMS 65 kA

Fuse 100 A

Circuit Breaker 100 A

Group Motor Installations for USA

and Canada Markets

Wiring and Workmanship

Guidelines

The ArmorStart Distributed Motor Controllers are listed for use with

each other in group installations per NFPA 79, Electrical Standard for

Industrial Machinery. When applied according to the group motor

installation requirements, two or more motors, of any rating or

controller type, are permitted on a single branch circuit. Group Motor

Installation has been successfully used for many years in the USA and

Canada.

Note: For additional information regarding group motor

installations with the ArmorStart Distributed Motor

Controller, see Appendix D.

In addition to conduit and seal-tite raceway, it is acceptable to utilize

cable that is dual rated Tray Cable, Type TC-ER and Cord, STOOW,

for power and control wiring on ArmorStart installations. In the USA

and Canada installations, the following guidance is outlined by the

NEC and NFPA 79.

Page 52

2-34 Installation and Wiring

In industrial establishments where the conditions of maintenance and

supervision ensure that only qualified persons service the installation,

and where the exposed cable is continuously supported and protected

against physical damage using mechanical protection, such as struts,

angles, or channels, Type TC tray cable that complies with the crush

and impact requirements of Type MC (Metal Clad) cable and is

identified for such use with the marking Type TC-ER (Exposed

Run)* shall be permitted between a cable tray and the utilization

equipment or device as open wiring. The cable shall be secured at

intervals not exceeding 1.8 m (6 ft) and installed in a “good workmanlike” manner. Equipment grounding for the utilization equipment

shall be provided by an equipment grounding conductor within the

cable.

*Historically cable meeting these crush and impact requirements

were designated and marked “Open Wiring”. Cable so marked is

equivalent to the present Type TC-ER and can be used.

While the ArmorStart is intended for installation in factory floor

environments of industrial establishments, the following must be

taken into consideration when locating the ArmorStart in the

application: Cables, including those for control voltage including

24V DC and communications, are not to be exposed to an operator or

building traffic on a continuous basis. Location of the ArmorStart to

minimize exposure to continual traffic is recommended. If location to

minimize traffic flow is unavoidable, other barriers to minimize

inadvertent exposure to the cabling should be considered. Routing

cables should be done in such a manner to minimize inadvertent

exposure and/or damage.

Additionally, if conduit or other raceways are not used, it is

recommended that strain relief fittings be utilized when installing the

cables for the control and power wiring through the conduit openings.

The working space around the ArmorStart may be minimized as the

ArmorStart does not require examination, adjustment, servicing or

maintenance while energized. In lieu of this service, the ArmorStart is

meant to be unplugged and replaced after proper lockout/tag-out

procedures have been employed.

DeviceNet Network Installation The ArmorStart Distributed Motor Controller contains the equivalent

of 30 in. (0.76 m) of DeviceNet drop cable's electrical characteristics

and therefore 30 in. of drop cable must be included in the DeviceNet

drop cable budget for each ArmorStart in addition to actual drop cable

required for the installation.

Other DeviceNet System Design Considerations

The separation of the control power and DeviceNet power is

recommended as a good design practice. This minimizes the load on

the DeviceNet supply, and prevents transients which may be present

on the control power system from influencing the communication

controls.

Page 53

Installation and Wiring 2-35

Electromagnetic Compatibility

(EMC)

The following guidelines are provided for EMC installation

compliance.

General Notes (Bulletin 284G only)

• The motor Cable should be kept as short as possible in order to

avoid electromagnetic emission as well as capacitive currents

• Conformity of the drive with CE EMC requirements does not

guarantee an entire machine installation complies with CE EMC

requirements. Many factors can influence total machine/

installation compliance.

• Using an EMI filter with any drive rating, may result in relatively

high ground leakage currents. Therefore, the filter must only be

used in installations and solidly grounded (bonded) to the

building power distribution ground. Grounding must not rely on

flexible cables and should not include any form of plug or socket

that would permit inadvertent disconnection. Some local codes

may require redundant ground connections. The integrity of all

connections should be periodically checked.

Grounding

Connect a grounding conductor to the terminal provided as standard

on each ArmorStart Distributed Motor Controller. Refer to Table 2.2

for grounding provision location. There is also an externally available

ground terminal. Refer to Figure 2.2 and Figure 2.7.

Wiring

Wire in an industrial control application can be divided into three

groups: power, control, and signal. The following recommendations

for physical separation between these groups is provided to reduce the

coupling effect.

• Minimum spacing between different wire groups in the same tray

should be 6 in. (16 cm).

• Wire runs outside an enclosure should be run in conduit or have

shielding/armor with equivalent attenuation.

• Different wire groups should be run in separate conduits.

• Minimum spacing between conduits containing different wire

groups should be 3 in. (8 cm).

Page 54

2-36 Installation and Wiring

Notes:

Page 55

Chapter 3

Bulletin 280G/281G Programmable

Parameters

Introduction This chapter describes each programmable parameter and its

function.

Parameter Programming

Each Distributed Motor Controller type will have a common set of

parameters followed by a set of parameters that pertain to the

individual starter type.

Refer to Chapter 5, DeviceNet™ Commissioning for instructions in

using RSNetWorx™ for DeviceNet to modify parameter settings.

Important: Resetting the Factory Default Values Parameter 47,

Set to Defaults, allows the installer to reset all parameters

to the factory default values. It also resets the MAC ID to

its factory default after DeviceNet Power is cycled if

switches are set >63.

Important: Parameter setting changes downloaded to the

ArmorStart™ take effect immediately, even during a

“running” status.

Important: Parameter setting changes made in a configuration tool

such as RSNetWorx for DeviceNet do not take effect in

the ArmorStart until the installer applies or downloads

the new settings to the device.

Page 56

3-2 Bulletin 280G/281G Programmable Parameters

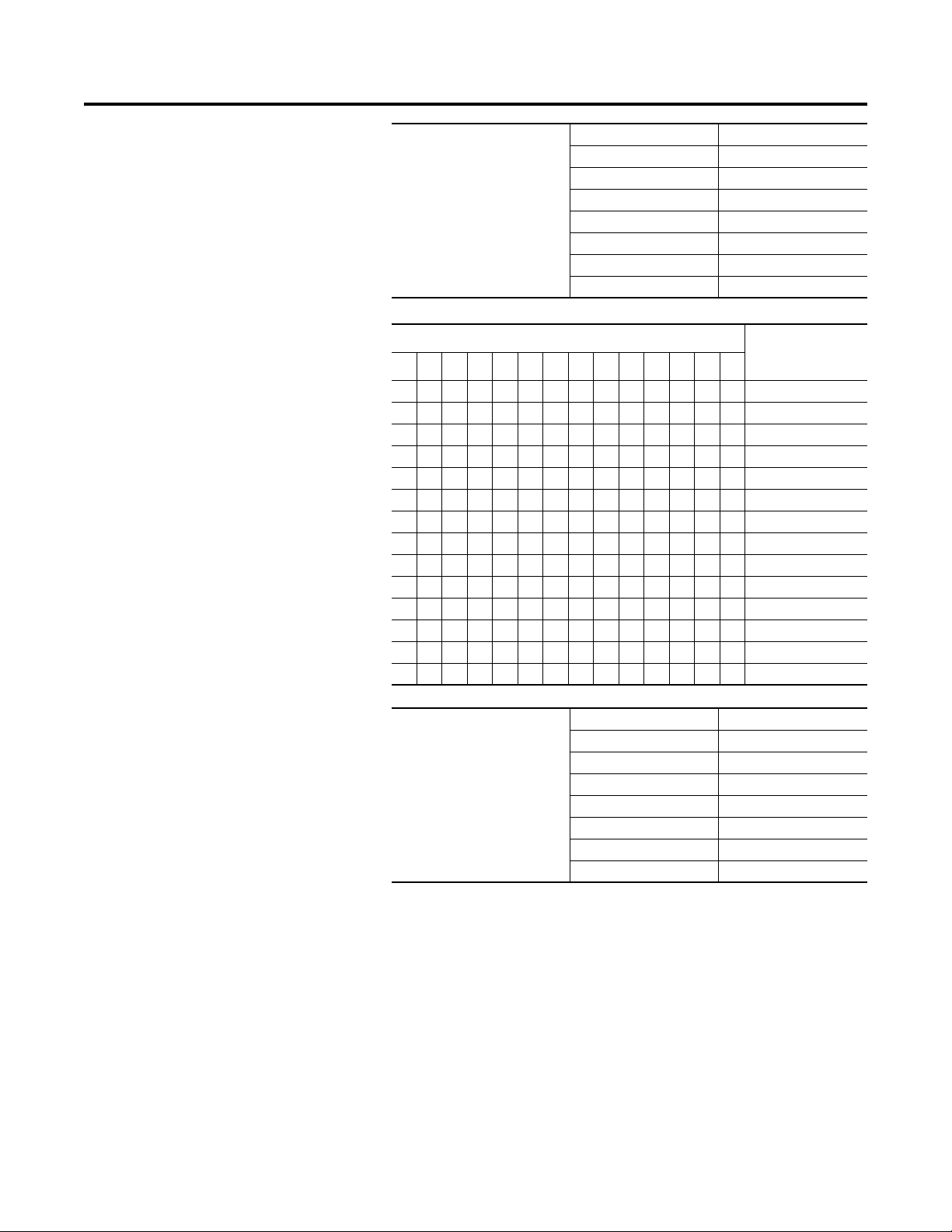

Parameter Group Listing The Bulletin 280G/281G ArmorStart contains eight parameter

groups. The parameters shown in the DeviceLogix, DeviceNet,

Starter Protection, User I/O, Misc. Parameter, ZIP Parameters, Starter

Display and Starter Setup, are discussed in this chapter.

Table 3.1 Parameter Group Listing

DeviceLogix DeviceNet

1 Hdw Inputs 10 Autobaud Enable 22 Breaker Type 30 Off-to-On Delay 45 Keypad Mode 67 AutoRun Zip 101 Phase A Current 106 FLA Setting

2 Network Inputs 11 Consumed IO Assy 23 PrFltResetMode 31 On-to-Off Delay 46 Keypad Disable 68 Zone Produced EPR 102 Phase B Current 107 Overload Class

3 Network Outputs 12 Produced IO Assy 24 Pr Fault Enable 32 In Sink/Source 47 Set To Defaults 69 Zone Produced PIT 103 Phase C Current 108 OL Reset Level

4 Trip S tat us 13 Prod Assy Word 0 25 Pr Fault Reset 56 Base Enclosure 70 Zone #1 MacId 104 Average Current

5 Starter Status 14 Prod Assy Word 1 26 StrtrDN FltState 57 Base Option 71 Zone #2 MacId 105% Therm Utilized

6 DNet Status 15 Prod Assy Word 2 27 StrtrDN FltValue 58 Wiring Option 72 Zone #3 MacId

7 Starter Command 16 Prod Assy Word 3 28 StrtrDN IdlState 59 Starter Enclosure 73 Zone #4 MacId

8 Network Override 17 Consumed IO Size 29 StrtrDN IdlValue 60 Starter Options 74 Zone #1 Health

9 Comm Override 18 Produced IO Size 61 Last PR F

19 Starter COS Mask 62 W

20 Net Out COS Mask 77 Zone #4 Health

21 DNet Voltage 78 Zone #1 Mask

Starter

Protection

ault 75 Zone #2 Health

arning Status 76 Zone #3 Health

User I/O Misc. ZIP Parameters Starter Display Starter Setup

79 Zone #2 Mask

80 Zone #3 Mask

81 Zone #4 Mask

82 Zone #1 Offset

83 Zone #2 Offset

84 Zone #3 Offset

85 Zone #4 Offset

86 Zone #1 EPR

87 Zone #2 EPR

88 Zone #3 EPR

89 Zone #4 EPR

90 Zone #1 Control

91 Zone #2 Control

92 Zone #3 Control

93 Zone #4 Control

94 Zone #1 Key

95 Zone #2 Key

96 Zone #3 Key

97 Zone #4 Key

98 Device Value Key

99 Zone Ctrl Enable

DeviceLogix™ Group

Hdw Inputs

This parameter provides status of

hardware inputs

Parameter Number 1

Access Rule GET

Data Type WORD

Group DeviceLogix

Units —

Minimum Value 0

Maximum Value 15

Default Value 0

Page 57

Bulletin 280G/281G Programmable Parameters 3-3

Bit

543210

————— XInput 0

———— X —Input 1

— — — X — — Input 2

—— X ———Input 3

— X ————Input 4

X —————Input 5

Network Inputs

This parameter provides status of

network inputs

1514131211109876543210

——————————————— X Net Input 0

—————————————— X — Net Input 1

————————————— X —— Net input 2

———————————— X ——— Net Input 3

——————————— X ———— Net Input 4

—————————— X ————— Net Input 5

————————— X —————— Net Input 6

———————— X ——————— Net Input 7

——————— X ———————— Net Input 8

—————— X ————————— Net Input 9

————— X —————————— Net Input 10

———— X ——————————— Net Input 11

——— X ———————————— Net Input 12

—— X ————————————— Net Input 13

— X —————————————— Net Input 14

X ——————————————— Net Input 15

Parameter Number 2

Access Rule GET

Data Type WORD

Group DeviceLogix

Units —

Minimum Value 0

Maximum Value 65535

Default Value 0

Bit

Function

Function

Network Outputs

This parameter provides status of

network outputs

Parameter Number 3

Access Rule GET

Data Type WORD

Group DeviceLogix

Units —

Minimum Value 0

Maximum Value 32767

Default Value 0

Page 58

3-4 Bulletin 280G/281G Programmable Parameters

Bit

Function

14131211109876543210

—————————————— X Net Output 0

————————————— X — Net Output 1

———————————— X —— Net Output 2

——————————— X ——— Net Output 3

—————————— X ———— Net Output 4

————————— X ————— Net Output 5

———————— X —————— Net Output 6

——————— X ——————— Net Output 7

—————— X ———————— Net Output 8

————— X ————————— Net Output 9

———— X —————————— Net Output 10

——— X ——————————— Net Output 11

—— X ———————————— Net Output 12

— X ————————————— Net Output 13

X —————————————— Net Output 14

Trip Status

Parameter Number 4

Access Rule GET

This parameter provides trip

identification

Data Type WORD

Group DeviceLogix Setup

Units —

Minimum Value 0

Maximum Value 16383

Default Value 0

Bit

Function

131211109876543210

————————————— X Short Circuit

———————————— X — Overload

——————————— X —— Phase Loss

—————————— X ——— Reserved

————————— X ———— Reserved

———————— X ————— Control Power

——————— X —————— I/O Fault

—————— X ——————— Over Temperature

————— X ———————— Phase Imbalance

———— X ————————— Dnet Power Loss

——— X —————————— Reserved

—— X ——————————— Reserved

— X ———————————— EEprom

X ————————————— HW Fault

Page 59

Bulletin 280G/281G Programmable Parameters 3-5

Starter Status

This parameter provides the

status of the starter

131211109876543210

————————————— X Tripped

———————————— X — Warning

——————————— X —— Running Fwd

—————————— X ——— Running Rev

————————— X ———— Ready

———————— X ————— Net Ctl Status

——————— X —————— Reserved

—————— X ——————— At Reference

————— X ———————— Reserved

———— X ————————— Reserved

——— X —————————— Reserved

—— X ——————————— Keypad Hand

— X ———————————— HOA Status

X ————————————— 140M On

Parameter Number 5

Access Rule GET

Data Type WORD

Group DeviceLogix

Units —

Minimum Value 0

Maximum Value 16383

Default Value 0

Bit

Function

DNet Status

This parameter provides status of

the DeviceNet connection

Parameter Number 6

Access Rule GET

Data Type WORD

Group DeviceLogix

Units —

Minimum Value 0

Maximum Value 32, 767

Default Value 0

Page 60

3-6 Bulletin 280G/281G Programmable Parameters

Bit

1514131211109876543210

——————————————— X Explicit Connection

—————————————— X — I/O Connection

————————————— X —— Explicit Fault

———————————— X ——— I/O Fault

——————————— X ———— I/O Idle

———————— X X X ————— Reserved

——————— X ———————— ZIP 1 Cnxn

—————— X ————————— ZIP 1 Flt

————— X —————————— ZIP 2 Cnxn

———— X ——————————— ZIP 2 Flt

——— X ———————————— ZIP 3 Cnxn

—— X ————————————— ZIP 3 Flt

— X —————————————— ZIP 4 Cnxn

X ——————————————— ZIP 4 Flt

Starter Command

The parameter provides the

status of the starter command.

Parameter Number 7

Access Rule GET

Data Type WORD

Group DeviceLogix

Units —

Minimum Value 0

Maximum Value 255

Default Value 0

Function:

Bit

76543210

——————— X Run Fwd

—————— X — Run Rev

————— X —— Fault Reset

———— X ——— Reserved

——— X ———— Reserved

—— X ————— Reserved

— X —————— Reserved

X ——————— Reserved

Network Override

This parameter allows for the

local logic to override a Network

fault

0 = Disable

1 = Enable

Parameter Number 8

Access Rule GET/SET

Data Type BOOL

Group DeviceLogix

Units —

Minimum Value 0

Maximum Value 1

Default Value 0

Function:

Page 61

Bulletin 280G/281G Programmable Parameters 3-7

DeviceNet Group

Comm Override

This parameter allows for local

logic to override the absence of

an I/O connection

0 = Disable

1 = Enable

Autobaud Enable

When this parameter is enabled,

the device will attempt to

determine the network baud rate

and set its baud rate to the same,

provided network traffic exists.

At least one node with an

established baud rate must exist

on the network for autobaud to

occur.

0 = Disable

1 = Enable

Parameter Number 9

Access Rule GET/SET

Data Type BOOL

Group DeviceLogix

Units —

Minimum Value 0

Maximum Value 1

Default Value 0

Parameter Number 10

Access Rule GET/SET

Data Type BOOL

Group DeviceNet

Units —

Minimum Value 0

Maximum Value 1

Default Value 1

Consumed I/O Assy

This parameter selects the

format of the I/O data consumed.

Enter a Consumed I/O assembly

instance number to select a data

format.

Produced I/O Assy

This parameter selects the

format of the I/O data produced.

Enter a Produces I/O assembly

instance number to select a data

format.

Parameter Number 11

Access Rule GET/SET

Data Type USINT

Group DeviceNet

Units —

Minimum Value 0

Maximum Value 187

Default Value 160

Parameter Number 12

Access Rule GET/SET

Data Type USINT

Group DeviceNet

Units —

Minimum Value 0

Maximum Value 190

Default Value 161

Page 62

3-8 Bulletin 280G/281G Programmable Parameters

Prod Assy Word 0

This parameter is used to build

bytes 0-1 for produced assembly

120

Produced Assy Word 1

This parameter is used to build

bytes 2-3 for produced assembly

120

Prod Assy Word 2

This parameter is used to build

bytes 4-5 for produced assembly

120

Parameter Number 13

Access Rule GET/SET

Data Type USINT

Group DeviceNet

Units —

Minimum Value 0

Maximum Value 108

Default Value 1

Parameter Number 14

Access Rule GET/SET

Data Type USINT

Group DeviceNet

Units —

Minimum Value 0

Maximum Value 108

Default Value 4

Parameter Number 15

Access Rule GET/SET

Data Type USINT

Group DeviceNet

Units —

Minimum Value 0

Maximum Value 108

Default Value 5

Prod Assy Word 3

This parameter is used to build

bytes 6-7 for produced assembly

120

Consumed I/O Size

This parameter reflects the

consumed I/O data size in bytes.

Parameter Number 16

Access Rule GET/SET

Data Type USINT

Group DeviceNet

Units —

Minimum Value 0

Maximum Value 108

Default Value 6

Parameter Number 17

Access Rule GET

Data Type USINT

Group DeviceNet

Units —

Minimum Value 0

Maximum Value 8

Default Value 1

Page 63

Bulletin 280G/281G Programmable Parameters 3-9

Produced I/O Size

This parameter reflects the

produced I/O data size in bytes.

Starter COS Mask

This parameter allows the

installer to define the change-ofstate conditions that will result in

a change-of-state message

being produced

➊ Bulletin 280G products.

➋ Bulletin 281G products.

Parameter Number 18

Access Rule GET

Data Type USINT

Group DeviceNet

Units —

Minimum Value 0

Maximum Value 8

Default Value 2

Parameter Number 19

Access Rule GET/SET

Data Type WORD

Group DeviceNet

Units —

Minimum Value 0

Maximum Value 16383

Default Value

16149 ➊

16157 ➋

Bit

Function

13 12 11 10 9 8 7 6 5 4 3 2 1 0

————————————— X Tripped

———————————— X — Warning

—————————— X —— Running Fwd

—————————— X ——— Running Rev

————————— X ———— Ready

———————— X ————— NET Ctl Status

——————— X —————— 140M On

—————— X ——————— Reserved

————— X ———————— Input 0

———— X ————————— Input 1

——— X —————————— Input 2

—— X ——————————— Input 3

— X ———————————— Input 4

X ————————————— Input 5

Page 64

3-10 Bulletin 280G/281G Programmable Parameters

Net Out COS Mask

This parameter sets the bits that

will trigger a COS message when

network outputs change state.