Page 1

User Manual

ArmorStart® Distributed Motor Controller with EtherNet/IP™

Catalog Numbers

280E, 281E, 284E

Page 2

Important User Information

IMPORTANT

Because of the variety of uses for the products described in this publication, those responsible for the application and use of

this control equipment must satisfy themselves that all necessary steps have been taken to assure that each application and

use meets all performance and safety requirements, including any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in this guide are intended solely for purposes of

example. Since there are many variables and requirements associated with any particular installation, Rockwell Automation

does not assume responsibility or liability (to include intellectual property liability) for actual use based upon the examples

shown in this publication.

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (Publication SGI-1.1

local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

available from your

) describes some

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may

lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or

economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage

may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach

dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Page 3

Trademark List

Allen-Bradley, ArmorConnect, ArmorStart, DeviceLogix, RSLogix 5000, RSNetWorx, StepLogic, RSLinx, On-Machine and ControlLogix are trademarks of Rockwel l Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

European Communities (EC) Directive Compliance

If this product has the CE mark it is approved for installation within the European Union and EEA regions. It has been

designed and tested to meet the following directives.

Low Voltage and EMC Directives

This product is tested to meet Council Directive 2006/95/EC Low Voltage Directive and Council Directive

2004/108/EC Electromagnetic Compatibility (EMC) by applying the following standard(s):

• Bulletin 280E/281E: EN 60947-4-1 — Low-voltage switchgear and controlgear — Part 4-1: Contactors and motorstarters — Electromechanical contactors and motor-starters.

• Bulletin 284E: EN 61800-5-1 — Adjustable speed electronic power drive systems — Part 5-1: Safety requirements

— Electrical, thermal and energy.

• Bulletin 284E: EN 61800-3 — Adjustable speed electronic power drive systems — Part 3: EMC product standard

including specific test methods.

This product is intended for use in an industrial environment.

Page 4

Page 5

Table of Contents

European Communities (EC) Directive Compliance. . . . . . . . . . . . . . . . . . 3

Low Voltage and EMC Directives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 1

Product Overview

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Mode of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Bulletin 280E/281E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Full-Voltage Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Bulletin 284E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Sensorless Vector Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Description of Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Overload Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Embedded Switch Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Switched vs. Unswitched

Control Power Input/Output

(I/O) Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

EtherNet/IP™ Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Embedded Web Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

E-mail Notification Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

EtherNet/IP LED Status Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Control Module LED Status

and Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Electronic Data Sheet (EDS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Fault Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Protection Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Gland Plate Entrance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Motor Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

DeviceLogix™. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Factory-Installed Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Optional HOA Keypad Configuration (Bulletin 280E/281E only) 25

Optional HOA Selector Keypad with Jog Function

(Bulletin 284E only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Source Brake Contactor and Connector (Bulletin 284E only) . . . . 26

EMI Filter (Bulletin 284E only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Dynamic Brake Connector (Bulletin 284E only) . . . . . . . . . . . . . . . . 26

IP67 Dynamic Brake Resistor (Bulletin 284E only). . . . . . . . . . . . . . 26

Output Contactor (Bulletin 284E only) . . . . . . . . . . . . . . . . . . . . . . . . 27

Shielded Motor Cable (Bulletin 284E only). . . . . . . . . . . . . . . . . . . . . 27

Rockwell Automation Publication 280E-UM001B-EN-P - July 2012 5

Page 6

Table of Contents

ArmorStart® EtherNet/

IP Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Notes: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Chapter 2

Installation and Wiring

Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Inspecting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Storing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Precautions for Bulletin 280E/281E Applications . . . . . . . . . . . . . . . . . . . 32

Precautions for Bulletin 284E Applications . . . . . . . . . . . . . . . . . . . . . . . . . 32

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Conduit Gland Entrance Bulletin 280E/281E . . . . . . . . . . . . . . . . . . 33

Conduit Gland Entrance Bulletin 284E . . . . . . . . . . . . . . . . . . . . . . . . 34

ArmorConnect® Gland Connectivity Bulletin 280E/281E . . . . . . . 35

ArmorConnect Gland Connectivity Bulletin 284E . . . . . . . . . . . . . . 36

Mount Orientation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Power, Control, Safety Monitor Inputs, and Ground Wiring . . . . . 37

Terminal Designations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Control Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

24V DC Control Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

ArmorStart with

EtherNet/IP Internal Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Recommended Cord Grips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

AC Supply Considerations for Bulletin 284E Units . . . . . . . . . . . . . . . . . 43

Ungrounded and High Resistive Distribution Systems . . . . . . . . . . . 43

Disconnecting MOVs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Group Motor Installations for USA and Canada Markets . . . . . . . . 45

Wiring and Workmanship Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Other System Design Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Electromagnetic Compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

General Notes (Bulletin 284E only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Grounding Safety Grounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Grounding PE or Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Grounding Motors. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . 48

ArmorConnect Power Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

ArmorConnect Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

ArmorConnect Cable Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6 Rockwell Automation Publication 280E-UM001B-EN-P - July 2012

Page 7

Table of Contents

Branch Circuit Protection Requirements for ArmorConnect

Three-Phase Power Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Ethernet and I/O Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Optional Locking Clip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Chapter 3

Introduction to EtherNet/IP and

Device Level Ring Technology

Product Commissioning

Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Introduction to EtherNet/IP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Linear Network Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Device Level Ring (DLR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Number of Nodes on a

DLR Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Ethernet Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Ethernet Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

EtherNet/IP General

Wiring Guideline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Requested Packet

Interval (RPI). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Chapter 4

IP Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Gateway Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Subnet Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Configuring EtherNet/

IP Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Manually Configure the Network Address Switches . . . . . . . . . . . . . 68

Use the Rockwell Automation BootP/DHCP Utility . . . . . . . . . . . . . . . 70

Save the Relation List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

DHCP IP Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Using the Rockwell Automation Embedded

Web Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Internal Web Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Network Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Parameter Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

E-mail Notification Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Device Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Chapter 5

Rockwell Automation Publication 280E-UM001B-EN-P - July 2012 7

Page 8

Table of Contents

Adding an ArmorStart to RSLogix

5000

Optional HOA Keypad Operation

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Connect and Configure ArmorStart with Add-On-Profile (AOP). . . . 82

Offline Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

General Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Connection Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Parameters Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Online Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Parameters Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Module Info Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Internet Protocol Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Port Configuration Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Network Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Auto-Generated Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Notes: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Chapter 6

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Keypad Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Keypad and HOA Disable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Notes: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Bulletin 280E/281E/284E

Programmable Parameters

Chapter 7

Basic Setup Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Parameter Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

ArmorStart EtherNet/IP Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Parameter Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Bulletin 280E/281E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Basic Status Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Produced Assembly Config Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Starter Protection Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

User I/O Configuration Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Miscellaneous Configuration Group. . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Starter Display Group (Bulletin 280E/281E only) . . . . . . . . . . . . . . 130

Starter Setup Group (Bulletin 280E/281E only). . . . . . . . . . . . . . . . 132

Bulletin 284E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Basic Status Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Produced Assembly Config Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Starter Protection Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

User I/O Configuration Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Miscellaneous Configuration Group. . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Drive I/O Configuration Group (Bulletin 284E only) . . . . . . . . . . 152

8 Rockwell Automation Publication 280E-UM001B-EN-P - July 2012

Page 9

Table of Contents

Drive Display Group (Bulletin 284E only). . . . . . . . . . . . . . . . . . . . . 154

Drive Setup Group (Bulletin 284E only) . . . . . . . . . . . . . . . . . . . . . . 160

Drive Advanced Setup Group (Bulletin 284E only). . . . . . . . . . . . . 164

Clear a Type 1 Fault and Restart the Drive. . . . . . . . . . . . . . . . . . . . . 175

Clear an Overvoltage, Undervoltage, or Heatsink OvrTmp Fault

without Restarting the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

How StepLogic Works. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

StepLogic Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Linear List of Parameters

for Bulletin 280E/281E and Bulletin 284E . . . . . . . . . . . . . . . . . . . . . . . . 193

Chapter 8

How to Configure an Explicit

Message

Diagnostics

Programming ControlLogix® Explicit Message . . . . . . . . . . . . . . . . . . . . . 203

Explicit Messaging with ControlLogix . . . . . . . . . . . . . . . . . . . . . . . . 203

Setting Up the MSG Instruction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Formatting an Explicit Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Performing Explicit Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Chapter 9

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Protection Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Fault Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Clear Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Fault Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Fault Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Short Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Overload Trip. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Phase Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Phase Short . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Ground Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Stall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Control Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

I/O Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Over Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Phase Imbalance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Over Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

A3 Power Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Internal Communication Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

DC Bus Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Electrically Erasable Programmable Read-Only Memory

EEPROM Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Hardware Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Rockwell Automation Publication 280E-UM001B-EN-P - July 2012 9

Page 10

Table of Contents

Restart Retries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Miscellaneous Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

EtherNet/IP LED Status Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Control Module LED

Status and Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Control Module Fault

LED Indications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Fault 11 Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Resetting Device to

Factory Defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Chapter 10

Troubleshooting

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Bulletin 280E/281E Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Bulletin 284E Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Fault Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

DB1 Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Operation and Troubleshooting of the DB1 - Dynamic Brake . . . 225

DB1 Resistor Overtemperature Fault. . . . . . . . . . . . . . . . . . . . . . . . . . 226

DB1 Overcurrent Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

DB1 Undercurrent Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

DB1 Switch Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

DB1 Open Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

DB1 VBus Link Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

DB1 Comm Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

DB1 Thermal Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Internal Drive Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

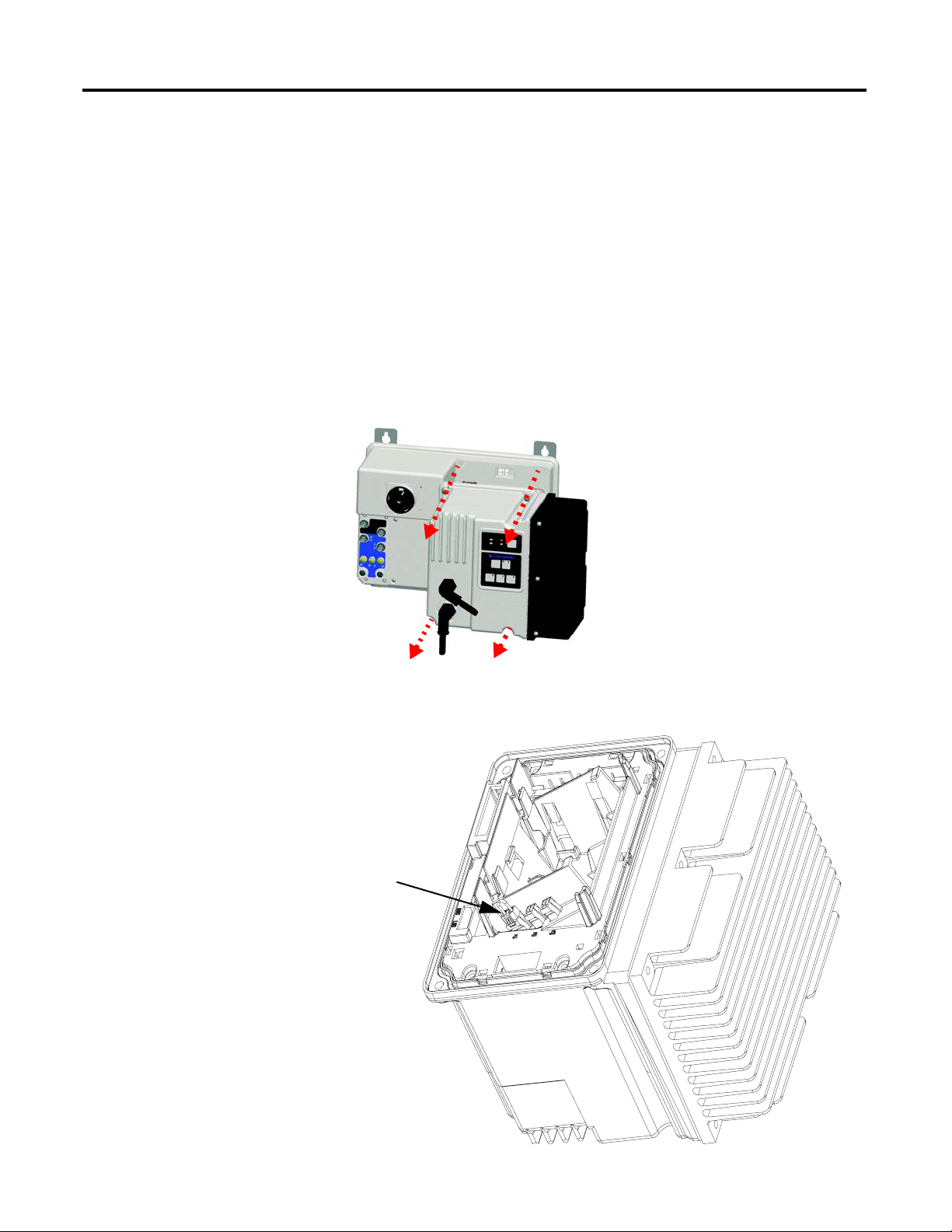

Control Module Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Installation of Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Troubleshoot and General Solutions for Linear or DLR Networks. . . 235

Specific Issues on Your DLR or Linear Network. . . . . . . . . . . . . . . . 235

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Chapter 11

Specifications for EtherNet/IP

Bulletin 280E/281E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Motor Overload Trip Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Contactor Life Load Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Bulletin 284E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Sensorless Vector Control (SVC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Motor Overload Trip Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Chapter 12

10 Rockwell Automation Publication 280E-UM001B-EN-P - July 2012

Page 11

Table of Contents

Accessories Industrial Ethernet Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

D Code Connectivity (M12) – 1585D . . . . . . . . . . . . . . . . . . . . . . . . 253

Sensor Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Sensor Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Motor and Brake Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Sealing Caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Other . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Dynamic Braking Resistors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Sensorless Vector Control (SVC) Minimum Resistance and

Recommended Modules for Option DB . . . . . . . . . . . . . . . . . . . . . . . 259

Bulletin 284E Option (-DB) – IP20 Resistor . . . . . . . . . . . . . . . . . . 260

Sensorless Vector Control (SVC) Recommended Dynamic Brake

Modules for Option DB1 (IP67 Resistor) . . . . . . . . . . . . . . . . . . . . . 261

Appendix A

Applying More Than One

ArmorStart

Motor Controller in a Single

Branch Circuit

on Industrial Machinery

CIP Information

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

ArmorStart LT Product Family . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Multiple-Motor Branch Circuits and Motor Controllers Listed for Group

Installation – General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Maximum Fuse Ampere Rating According to 7.2.10.4(1) and 7.2.10.4(2)

267

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Complete Text 267

Explanatory Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Input and Output Conductors of Bulletin 290E and 291E Controllers (a)

275

Input and Output Conductors of Bulletin 294E Controllers (b) . . . . 275

Combined Load Conductors (c). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Appendix B

High Level Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Product Codes and Name Strings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

CIP Explicit Connection Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

EDS Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

CIP Object Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Identity Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

CLASS CODE 0x0001 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Assembly Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

CLASS CODE 0x0004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

I/O Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Connection Manager Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

CLASS CODE 0x0006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Class 1 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Rockwell Automation Publication 280E-UM001B-EN-P - July 2012 11

Page 12

Table of Contents

Exclusive Owner Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Listen Only Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Class 3 CIP Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Discrete Input Point Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

CLASS CODE 0x0008 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Discrete Output Point Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

CLASS CODE 0x0009 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Parameter Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

CLASS CODE 0x000F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Parameter Group Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

CLASS CODE 0x0010 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Discrete Input Group Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

CLASS CODE 0x001D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Discrete Output Group Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

CLASS CODE 0x001E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Control Supervisor Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

CLASS CODE 0x0029 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

Overload Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

CLASS CODE 0x002C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Device Level Ring (DLR) Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

CLASS CODE 0x0047 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Qos Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

CLASS CODE 0x0048 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

DPI Fault Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

CLASS CODE 0x0097 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

DPI Alarm Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

CLASS CODE 0x0098 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Interface Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

CLASS CODE 0x00B4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

TCP/IP Interface Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

CLASS CODE 0x00F5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

Ethernet Link Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

CLASS CODE 0x00F6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Appendix C

Using DeviceLogix

12 Rockwell Automation Publication 280E-UM001B-EN-P - July 2012

DeviceLogix Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

DeviceLogix Programming Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

Import and Export. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 314

Bulletin 284 - VFD Preset Speed Example . . . . . . . . . . . . . . . . . . . . . . . . . 314

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

DeviceLogix Ladder Editor Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

ArmorStart 280 and 281 Status Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

Bulletin 280 and 281 ArmorStart Fault Bits. . . . . . . . . . . . . . . . . . . . 321

Bulletin 280 and 281 ArmorStart Outputs. . . . . . . . . . . . . . . . . . . . . 322

Page 13

Table of Contents

Bulletin 280 and 281 ArmorStart Produced Network Bits . . . . . . 322

Bulletin 284 ArmorStart Status Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . 323

Bulletin 284 ArmorStart Fault Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

Bulletin 284 ArmorStart Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

Bulletin 284 ArmorStart Produced Network Bits . . . . . . . . . . . . . . 325

Appendix D

PID Setup

StepLogic, Basic Logic and Timer/

Counter Functions

PID Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

Exclusive Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

Trim Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

PID Reference and Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

PID Deadband . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

PID Preload. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

PID Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

PID Gains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

Guidelines for Adjusting the PID Gains . . . . . . . . . . . . . . . . . . . . . . . 331

Notes:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

Appendix E

StepLogic Using Timed Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

StepLogic Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

StepLogic Using Basic Logic Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

Timer Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

Counter Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

StepLogic Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

Renewal Parts

Appendix F

Bulletin 280E/281E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

Control Module Renewal Part Product Selection. . . . . . . . . . . . . . . 341

Base Module Renewal Part Product Selection . . . . . . . . . . . . . . . . . . 342

Bulletin 284E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344

Control Module Renewal Part Product Selection. . . . . . . . . . . . . . . 344

Base Module Renewal Part Product Selection . . . . . . . . . . . . . . . . . . 345

Rockwell Automation Publication 280E-UM001B-EN-P - July 2012 13

Page 14

Table of Contents

14 Rockwell Automation Publication 280E-UM001B-EN-P - July 2012

Page 15

Chapter 1

Product Overview

Bulletin 280E/281E 284E

Type EtherNet/IP™

Horsepower Range:

0.5…10 Hp (0.37…7.5 kW) ✓ —

0.5…5 Hp (0.4…3.0 kW) — ✓

Starting Method:

Full-Voltage and Reversing ✓ —

Sensorless Vector Control — ✓

Environmental Rating:

IP67/NEMA Type 4 ✓✓

Control Voltage:

24V DC ✓✓

Operational Voltage Ratings:

200…480V AC ✓ —

380…480V AC — ✓

Rated for Group Motor Installations ✓✓

Local logic using DeviceLogix™ ✓✓

I/O Capability:

Four Inpu ts ✓✓

Two Out put s ✓✓

Network Communications:

EtherNet/IP™ ✓✓

LED Status Indication ✓✓

Gland Plate Entry:

Conduit Ent rance ✓✓

ArmorConnect Power Media ✓✓

Quick Disconnects (I/O, Communications, Motor

Connection, Three-Phase and Control Power

Extended Length Motor and Brake Cables ✓✓

Factory Installed Options:

HOA Keypad ✓✓

Source Brake Contactor — ✓

Dynamic Brake Connector — ✓

Output Contactor — ✓

EMI Filter — ✓

Shielded Motor Cable — ✓

✓✓

Rockwell Automation Publication 280E-UM001B-EN-P - July 2012 15

Page 16

Chapter 1 Product Overview

Introduction

Description

This chapter provides a brief overview of the features and functionality of the

ArmorStart

Bulletin 280E, 281E, and 284E.

The ArmorStart EtherNet/IP™ Distributed Motor Controllers are integrated,

pre-engineered, motor starting solutions. Bulletins 280E and 281E are used for

full-voltage and reversing applications, respectively. Bulletin 284E is used in

variable frequency applications where more precise motor control is needed. The

ArmorStart EtherNet/IP controller offers a robust IP67/UL Type 4/12

enclosure design, which is suitable for water wash down environments.

ArmorStart EtherNet/IP includes an embedded dual port switch that supports

device level ring (DLR) applications. It supports IEEE 1588 end-to-end

transparent clock. This allows synchronization within a distributed network of

devices. Transparent clocks in combination with enhanced or managed Ethernet

switches are able to adjust for network introduced timing delays and improve the

performance of motion applications.

The ArmorStart EtherNet/IP network address can be configured dynamically or

statically via the embedded Web Server. In addition, the controller’s IP address

can be manually set via three IP address switches found on the I/O section of the

device.

® EtherNet/Industrial Protocol (IP) Distributed Motor Controllers,

The controller’s embedded Web Server allows the user to check status,

diagnostics and perform simple device configuration using a standard web

browser. It also supports SMTP protocol which allows the user to configure the

device to send an alert e-mail of potential issues.

The ArmorStart Distributed Motor Controller is a modular “plug and play”

design that offers simplicity in wiring and installation. The quick disconnects for

the I/O, communications, and motor connections reduce the wiring time and

eliminate wiring errors. The controller offers, as standard, four configurable

(sink/source) DC inputs and two sourcing solid state outputs, to be used with

sensors and actuators respectively, for monitoring and controlling the application

process. The ArmorStart’s light-emitting diode (LED) status indication and

built-in diagnostics capabilities allow ease of maintenance and troubleshooting.

The optional Hand/Off/Auto (HOA) keypad configuration allows local start/

stop control.

An Add-on profile for ControlLogix® is available. Add-on profiles streamline the

programming and installation by eliminating the task of individually configuring

the device tags.

The copy and paste function allows easy configuration of multiple ArmorStarts

Controllers. RSLogix™ 5000 revision 17.01 or later is required to implement addon profile support.

16 Rockwell Automation Publication 280E-UM001B-EN-P - July 2012

Page 17

Product Overview Chapter 1

280 E – F 12Z – 10 C – CR – Option 1

a

a

b

c

d

bcde

e

fg

g

f

h

h

Bulletin Number

Overload Selection Current Range

Enclosure Type

Code Description

Description

280

281

Full Voltage Starter

Reversing Starter

Contactor Size/Control Voltage

24V DC

12Z

23Z

Short Circuit Protection

(Motor Circuit Protection)

Code Description

Description

10

25

10 A Rated Device

25 A Rated Device

Code

E EtherNet/IP

Description

Code

F IP67/ UL Type 4/12

Code

A 0.24…1.2 A

B 0.5…2.5 A

C 1.1…5.5 A

D 3.2…16 A

Control and 3-Phase Power Connections/Motor Cable Connection

(CR: Conduit/Round Media) or (RR: Round/Round Media)

CR

3 m, unshielded cordset

male 90°

Round Media (Male

Receptacle)

Round Media (Male

Receptacle)

Round Media (Male

Receptacle)

Round Media (Male

Receptacle)

No cable

3 m, unshielded cordset

male 90°

No cable

Motor Cable3-Phase Power

Description

Conduit Entrance

Conduit Entrance

Conduit Entrance

Conduit Entrance

Control Power

Code

blank

CR W*

* Refer to the Industrial Controls Catalog for extended motor cable lengths.

RR blank

RR W*

DescriptionCode

Description

Option 1

3

3FR

Hand/Off/Auto Selector Keypad

Hand/Off/Auto Selector Keypad with

Forward/Reverse

The Armorstart controller and associated motor cable have been evaluated as a

system by UL and is suitable for group installation. Armorstart controllers

contain a UL listed disconnect which in many applications eliminates the need

for additional components.

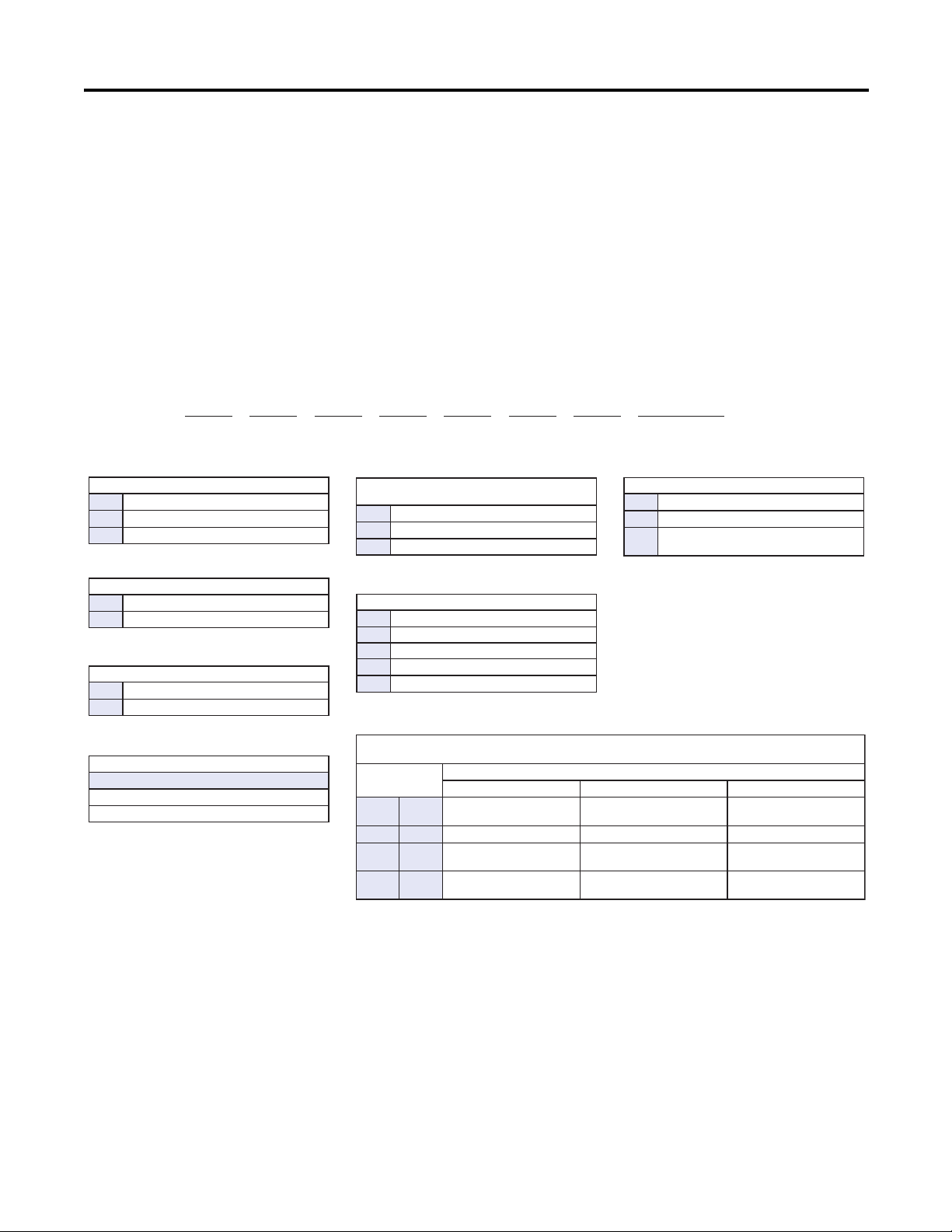

Catalog Number Explanation

Examples given in this section are for reference purposes. This basic explanation

should not be used for product selection because not all combinations will

produce a valid catalog number.

Figure 1 - Catalog Number Explanation for 280E/281E

Rockwell Automation Publication 280E-UM001B-EN-P - July 2012 17

Page 18

Chapter 1 Product Overview

g

Short Circuit Protection (Motor

Circuit Protector)

Code Description

10 10 A Rated Device

25 25 A Rated Device

a

Bulletin Number

Code Description

284 VFD Starter

d

Torque Performance Mode

Code Description

V

Sensorless Vector Control

and Volts per Hertz

i

Option 1

Code Description

3

Hand/Off/Auto Selector

Keypad with Jog Function

h

Control and 3-Phase Power Connections / Motor Cable Connection

(CR: Conduit/Round Media) or (RR: Round/Round Media)

Code

Description

Control Power 3-Phase Power Motor Cable

CR blank Conduit Entrance Conduit Entrance

3 m, unshielded

cordset male 90°

CR N Conduit Entrance Conduit Entrance

3 m, shielded

cordset male 90°

CR

W

Conduit Entrance Conduit Entrance No cable

RR blank

Round Media

(Male Receptacle)

Round Media

(Male Receptacle)

3 m, unshielded

cordset male 90°

RR N

Round Media

(Male Receptacle)

Round Media

(Male Receptacle)

3 m, shielded

cordset male 90°

RR

W

Round Media

(Male Receptacle)

Round Media

(Male Receptacle)

No cable

284 E – F V D2P3 D – 10 – CR – Option 1 – Option 2 – Option 3

ab cd e f g h i j k

b

Communications

Code Description

E EtherNet/IP

c

Enclosure Type

Code Description

F Type 4 (IP67)

e

Output Current

380…480V

Code Description

D1P4 1.4 A, 0.4 kW, 0.5 Hp

D2P3 2.3 A, 0.75 kW, 1.0 Hp

D4P0 4.0 A, 1.5 kW, 2.0 Hp

D6P0 6.0 A, 2.2 kW, 3.0 Hp

D7P6 7.6 A, 3.3 kW, 5.0 Hp

j

Option 2

Code Description

DB blank DB Brake Connector

DB1 blank

Connectivity to IP67

DB Resistor

SB blank

Source Brake

Contactor

SB

W

No cable

k

Option 3

Code Description

EMI EMI Filter

OC Output Contactor

f

Control Voltage

Code Description

Z 24V DC

Figure 2 - Catalog Number Explanation for 284E

Operation

18 Rockwell Automation Publication 280E-UM001B-EN-P - July 2012

The ArmorStart Distributed Motor Controllers can operate three-phase squirrelcage induction motors as follows:

Bulletin 280E/281E: up to 10 Hp (7.4 kW) at 480V AC

Bulletin 284E: up to 5 Hp (3.0 kW) at 480V AC

ArmorStart EtherNet/IP Controllers accept 24V DC control voltage. The

control voltage will provide power to inputs (unswitched) and outputs

(switched). Unswitched control voltage is used to ensure no loss of sensor or

other field input status under normal operation.

Page 19

Product Overview Chapter 1

00%

ge

)

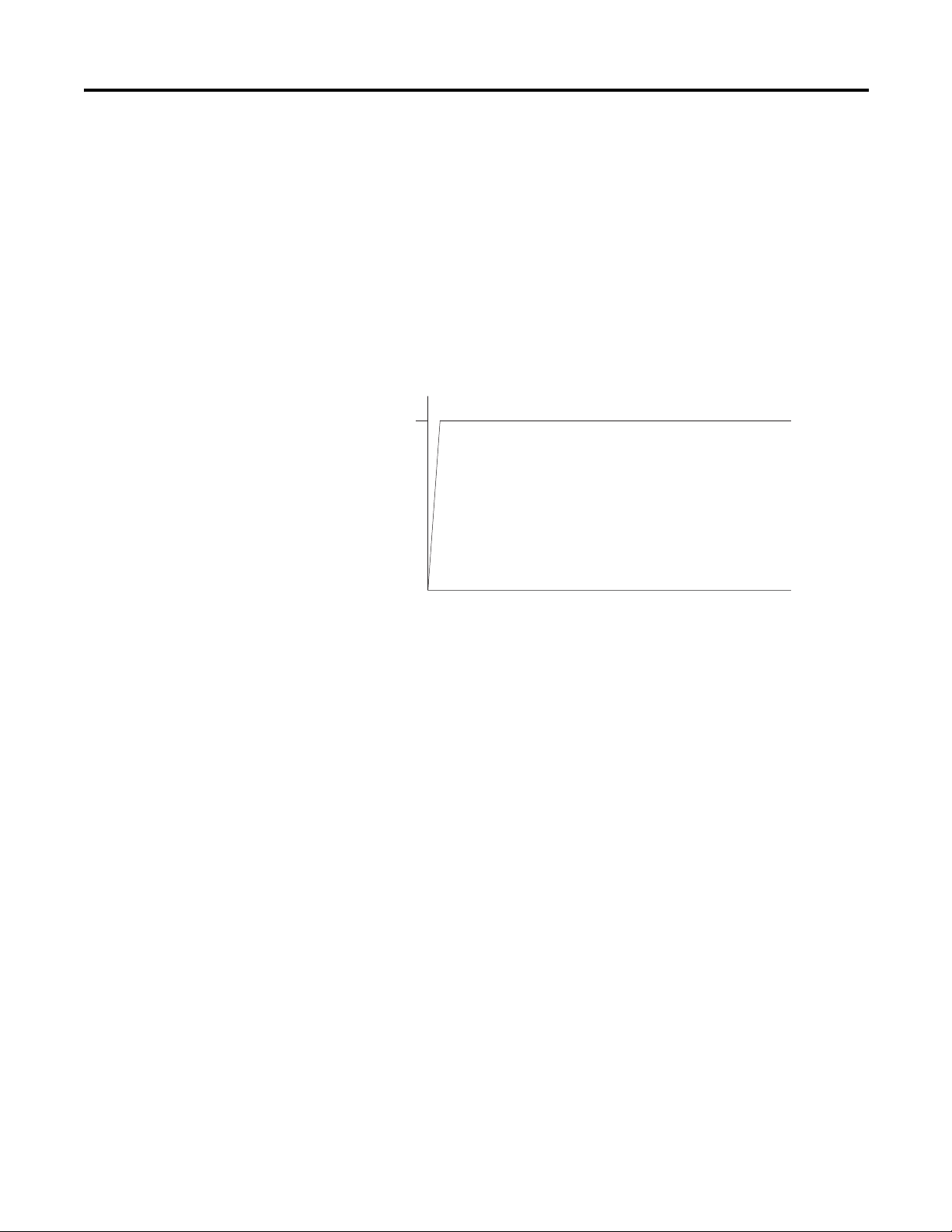

Mode of Operation

Bulletin 280E/281E

Full-Voltage Start

This method is used in applications requiring across-the-line starting, in which

full inrush current and locked-rotor torque are realized. The ArmorStart Bulletin

280E offers full-voltage starting and the Bulletin 281E offers full-voltage starting

for reversing applications.

Figure 3 - Full-Voltage Start

1

Percent

Volta

Time (seconds

Bulletin 284E

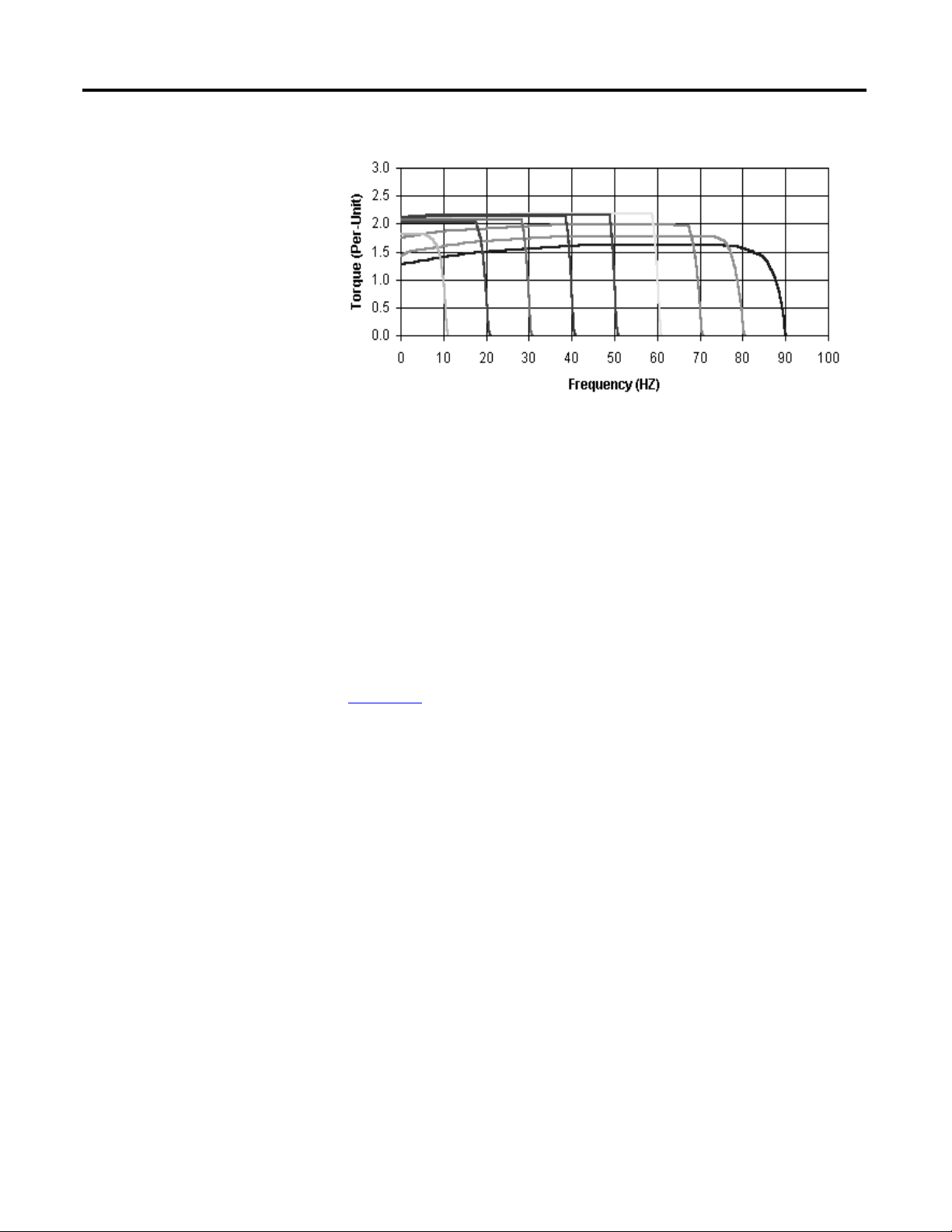

Sensorless Vector Control

Sensorless vector control provides exceptional speed regulation and very high

levels of torque across the entire speed range of the drive. Features include:

• Autotune feature allows the Motor Controller to adapt to individual

motor characteristics.

• Able to develop high torque over a wide speed range and adapts to

individual motor characteristics.

• Embedded Variable Frequency Drive (VFD) control includes the Timer,

Counter, Basic Logic and StepLogic® functions which can reduce hardware

design costs and simplify control schemes.

• Integral PID (proportional, integral, differential) functionality enhances

application flexibility.

Rockwell Automation Publication 280E-UM001B-EN-P - July 2012 19

Page 20

Chapter 1 Product Overview

Figure 4 - Sensorless Vector Control

Description of Features

Embedded Switch Tech nology

Overload Protection

The ArmorStart Distributed Motor Controller incorporates, as standard,

electronic motor overload protection. This overload protection is accomplished

2

electronically with an I

programmable via the communication network, providing the user with

flexibility.

The Bulletin 280E/281E overload trip class can be selected for class 10, 15, 20

protection. The Bulletin 284E overload trip class is Class 10 only. Ambient

insensitivity is inherent in the electronic design of the overload (refer to

Chapter 11

ArmorStart EtherNet/IP includes embedded switch technology as standard.

Each ArmorStart EtherNet/IP will consume one Common Industrial Protocol

(CIP) connection. The ArmoStart will consume a Class 3 connection when

RSLogix 5000 software displays the AOP.

In general, for a DLR or linear network keep individual segments to 50 nodes

or less. In addition, it is important to reserve a minimum of 10% of available

bandwidth to allow for processing of explicit messages.

for the specification for overload trip curves).

t algorithm. The ArmorStart’s overload protection is

Common features are:

• Designed according to the ODVA specification for EtherNet/IP.

ODVA specification found at http://www.odva.org/

• Embedded switch technology is designed to enable end devices to form

linear and ring network topologies

• Supports Device Level Ring (DLR) protocol

20 Rockwell Automation Publication 280E-UM001B-EN-P - July 2012

Page 21

Product Overview Chapter 1

• Supports IEEE 1588 transparent clock for CIP Motion™ and CIP Sync™

applications

• Supports the management of network traffic to ensure timely delivery of

critical data, that is, QoS and IGMP protocols are supported

Note: DLR ports cannot be used as two network interface cards (NICs)

connected to two different subnets.

Switched vs. Unswitched Control Power Input/Output (I/O) Connections

The voltage at terminals A1/A2 supplies power to the Armorstart outputs.

Removing this power or placing the Armorstart disconnect in the “OFF”

position will disable the outputs.

The unswitched power A3/A2 supplies power to the input and communication

module. This power is not affected by the state of the disconnect switch. This

ensures that anytime the controller can communicate, the state of the inputs

is correct.

Figure 5 - Input and Output Configuration

EtherNet/IP™ Ports

ArmorStart EtherNet/IP includes a dual port Ethernet switch that supports

10/100 Mbps It utilizes a sealed D-coded micro (M12) style Ethernet connector.

Dynamic Host Configuration Protocol (DHCP) is enabled as the factory

default. Before using your adapter in an EtherNet/IP network you may need

to configure an IP address or set the address statically.

ATTENTION: To avoid unintended operation, the adapter must be assigned a fixed IP

address. If a DHCP server is used, it must be configured to assign a fixed IP address for

your adapter.

Failure to observe this precaution may result in unintended machine motion or loss

of process control.

Rockwell Automation Publication 280E-UM001B-EN-P - July 2012 21

Page 22

Chapter 1 Product Overview

IMPORTANT

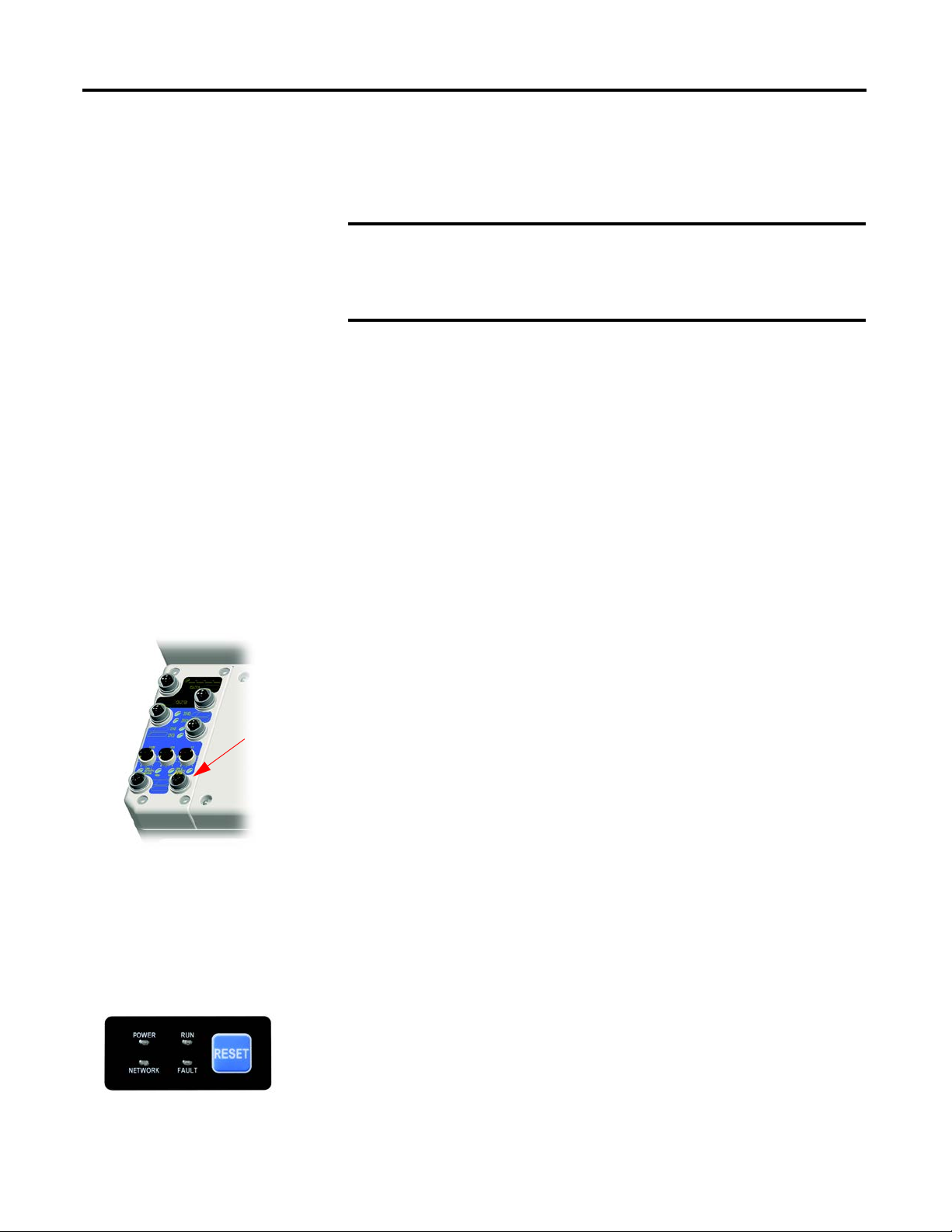

Figure 6 - EtherNet/IP LED

Figure 7 - LED Status

Indication and Reset

Embedded Web Server

EtherNet/IP LED Status Indication

The embedded web server allows the user to view information and configure the

ArmorStart via a web browser. The default Login is “Administrator”. There is no

password set by default.

Caution: The user should set the password to a unique value for authorized

personnel. If the Login and password are lost you will need to reset the device to

factory defaults via the Programmable Logic Controller (PLC). Note: The

configuration will be lost.

E-mail Notification Configuration

The embedded web server supports configuration of the Simple Mail Transfer

Protocol (SMTP). Once properly configured, the motor controller will e-mail

the user with specific fault/trip messages.

EtherNet/IP LED status and diagnostics consists of four LEDs.

Control Module LED Status and Reset

• Link Activity/Status LEDS

– Ethernet Link1 Activity/Status (Port 1) – LED Color: Bicolor

(Green/Yellow)

– Ethernet Link2 Activity/Status (Port 2) – LED Color: Bicolor

(Green/Yellow)

• “MOD” LED – Bicolor Red/Green represents the Ethernet Module status

• “NET” LED – Bicolor Red/Green represents the Ethernet Network status

The Control Module LED status and diagnostics consists of four status LEDs

and a Reset button.

• POWER LED

The LED is illuminated solid green when switched (+A1/A2) control

power is present and with the proper polarity.

22 Rockwell Automation Publication 280E-UM001B-EN-P - July 2012

Page 23

Product Overview Chapter 1

• RUN LED

This LED is illuminated solid green when a start command and control

power are present.

• NETWORK LED

This bicolor (red/green) LED indicates the status of the internal

communication link.

• FAULT LED

This indicates a Controller Fault (trip) condition.

The “Reset Button” is a local trip reset.

Electronic Data Sheet (EDS)

Fault Diagnostics

EtherNet/IP devices have electronic data sheets (EDS). These are specially

formatted text files, as defined by the CIP™ Specifications, which represent the

object model of the device. EDS files contain details about the readable and

configurable parameters of the EtherNet/IP device. They also provide

information about the I/O connections the device supports and the content

of the associated data structures. EDS are used by EtherNet/IP device

configuration tools, such as RSNetWorx™ for EtherNet/IP, and data servers

such as RSLinx® Classic.

EDS files for all ArmorStart EtherNet/IP devices can also be uploaded directly

from the device via the web server interface. Rockwell Automation product EDS

files are also available on the internet at: http://www.ab.com/networks/eds.

Fault diagnostics capabilities built in the ArmorStart Distributed Motor

Controller are designed to help you pinpoint a problem for easy troubleshooting

and quick re-starting.

Protection Faults

Protection Faults are generated when potentially dangerous or damaging

conditions are detected. Protection Faults are also known as “Trips.”

Rockwell Automation Publication 280E-UM001B-EN-P - July 2012 23

Page 24

Chapter 1 Product Overview

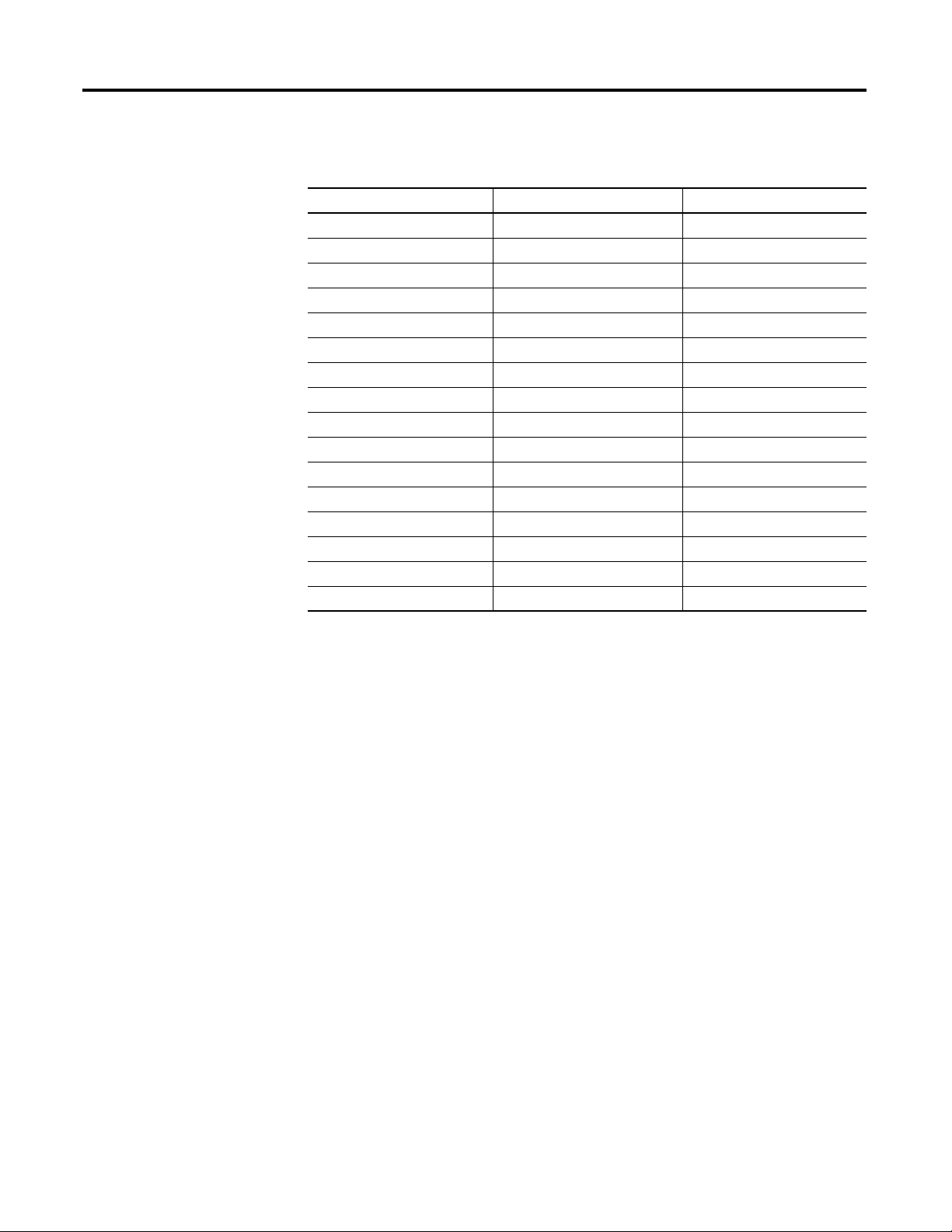

Table 1 - Protection Faults

Bulletin 280E/281E Trip Status Bulletin 284E Trip Status PowerFlex 40 Fault Codes

Short Circuit Short Circuit —

Overload Overload (Drive Codes 7 and 64)

Phase Loss Phase Short (Drive Codes 38…43)

Reserved Ground Fault (Drive Code 13)

Reserved Stall (Drive Code 6)

Control Pwr Loss Control Pwr Loss —

Input Fault Input Fault —

Over Temperature Over Temperature —

Phase Imbalance Over Current (Drive Codes 12 and 63)

A3, Unswitched Power Loss A3, Unswitched Power Loss —

Reserved Internal Comm (Drive Code 81)

Reserved DC Bus Fault (Drive Codes 3, 4 and 5)

EEprom EEprom (Drive Code 100)

Hdw Flt Hdw Flt (Drive Codes 70 and 122)

Reserved Restart Retries (Drive Code 33)

Reserved Misc. Fault (Drive Codes 2, 8, 29, 48 and 80)

Standard Features

Parameter Group “Start Protection,” Parameter 24 “PrFault Enable” is used to

enable and disable the above protection faults. Refer to Parameter 61

“LastPR Fault” for additional details of the last protection fault.

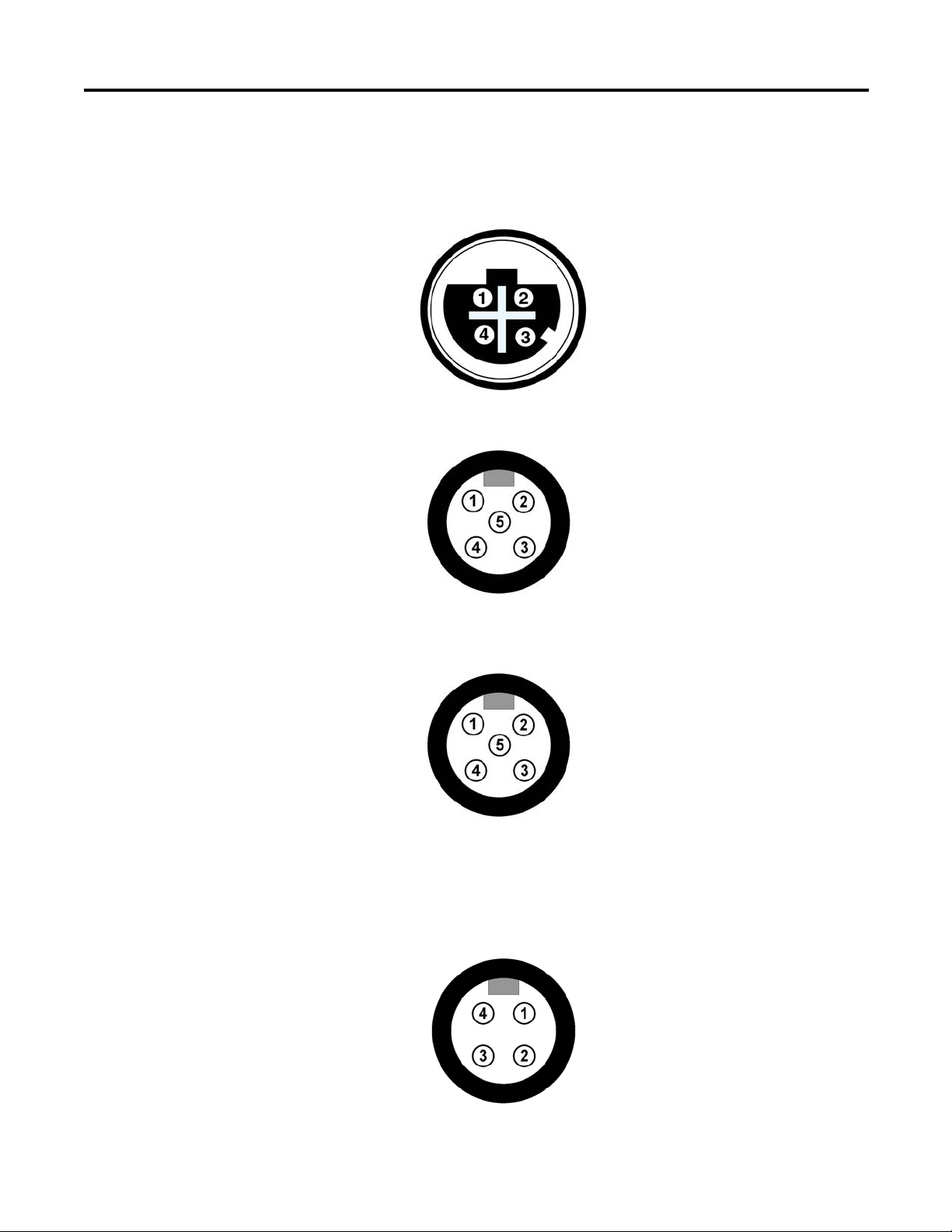

Inputs

The EtherNet/IP version includes four 24V DC inputs that are single keyed (two

inputs per connector) sourced from A3/A2 control power. The inputs use two

M12 Connectors. Each input has an LED status indication. They are

configurable as sinking or sourcing.

Outputs

The EtherNet/IP version includes two self-protected solid state outputs that are

single keyed (one per connector), sourced from A1/A2 control power. Outputs

are sourcing type with a maximum current per output point of 0.5 A DC. The

outputs use one M12 connectors per output, each having LED status indication.

24 Rockwell Automation Publication 280E-UM001B-EN-P - July 2012

Page 25

Product Overview Chapter 1

Gland Plate Entrance

The ArmorStart product offers two different methods of connecting incoming

three-phase and control power to the device. One method offered is the

traditional conduit entrance with a 3/4 in. and a 1 in. conduit hole opening. The

second method offers connectivity to the ArmorConnect® power media. Factoryinstalled receptacles are provided for connectivity to both three-phase and

control power media.

Motor Cable

With every ArmorStart Distributed Motor Controller, a 3-meter unshielded

4-conductor cordset is provided with each unit as standard. If the optional

Electromagnetic Interference (EMI) Filter is selected for Bulletin 284E units, a

shielded 4-conductor cordset is provided with each unit as standard.

Factory-Installed Options

DeviceLogix™

DeviceLogix is a stand-alone Boolean program that resides within the

ArmorStart Distributed Motor Controller. DeviceLogix is programmed locally

using the Add-On Profile and implements Boolean math operations, such as,

AND, OR, NOT, Timers, Counters, and Latches. DeviceLogix can run as a

stand-alone application, independent of the network. However, 24V DC via A3

unswitched control power, must be maintained.

Optional HOA Keypad Configuration (Bulletin 280E/281E only)

The ArmorStart offers two optional factory-installed Hand/Off/Auto (HOA)

configurations: Standard and Forward/Reverse HOA.

Figure 8 - Optional HOA Configuration (Bulletin 280E left, 281E right)

Rockwell Automation Publication 280E-UM001B-EN-P - July 2012 25

Page 26

Chapter 1 Product Overview

Optional HOA Selector Keypad with Jog Function (Bulletin 284E only)

The HOA Selector Keypad with Jog Function allows for local start/stop control

with capabilities to jog in forward/reverse motor directions.

Figure 9 - Optional HOA with Jog Function Configuration

Source Brake Contactor and Connector (Bulletin 284E only)

An internal contactor is used to switch the electromechanical motor brake On/

Off. The motor brake contactor is powered from the main power circuit. The

configuration of the R1 relay controls the function of the brake. A customer

accessible 2.5 A fuse is provided to protect the brake cable. Included is a 3-meter

3-pin cordset for connection to the motor brake as standard.

EMI Filter (Bulletin 284E only)

The EMI filter is required to be CE compliant. When selected, a 3-meter

shielded 4-conductor motor cordset is provided as standard. This is only available

with sensorless vector control.

Dynamic Brake Connector (Bulletin 284E only)

The user selectable DB Option includes a 3-meter, 3-pin cordset for connection

to a IP20 dynamic brake module. See Chapter 11

modules.

Note: The IP67 Dynamic Brake Resistor cannot be used with the -DB

factory-installed option.

for available dynamic brake

IP67 Dynamic Brake Resistor (Bulletin 284E only)

The IP67 Dynamic Brake Resistor design offers simplicity in wiring and

installation. The user selectable DB1 option provides the quick connector and an

26 Rockwell Automation Publication 280E-UM001B-EN-P - July 2012

Page 27

Product Overview Chapter 1

internal resistor monitoring circuit board. The cable length available is 0.5 m and

1.0 m. The IP67 Dynamic Brake is separately ordered. See Chapter 11

available IP67 Dynamic Brake Resistors.

Note: The IP67 Dynamic Brake Resistor is used only with the -DB1

factory-installed option. Only the specified IP67 Dynamic Brake resistor

can be used based on the VFD horsepower. Connecting resistors other than those

specified will result in a DB1 fault.

for

Output Contactor (Bulletin 284E only)

An internal contactor is sourced from the 24V DC (A1/A2) control voltage

to isolate the load side of the Bulletin 284E ArmorStart Distributed Motor

Controller. When control power is applied to A1/A2, the output contactor will

close. When control power is removed, the output contactor will open. There is

no other switching element that allows alternate control of the output contactor.

A sequenced stop involving the output contactor cannot be performed.

Shielded Motor Cable (Bulletin 284E only)

If the EMI Filter is selected, a 3-meter shielded 4-conductor cordset is provided

as standard.

Rockwell Automation Publication 280E-UM001B-EN-P - July 2012 27

Page 28

Chapter 1 Product Overview

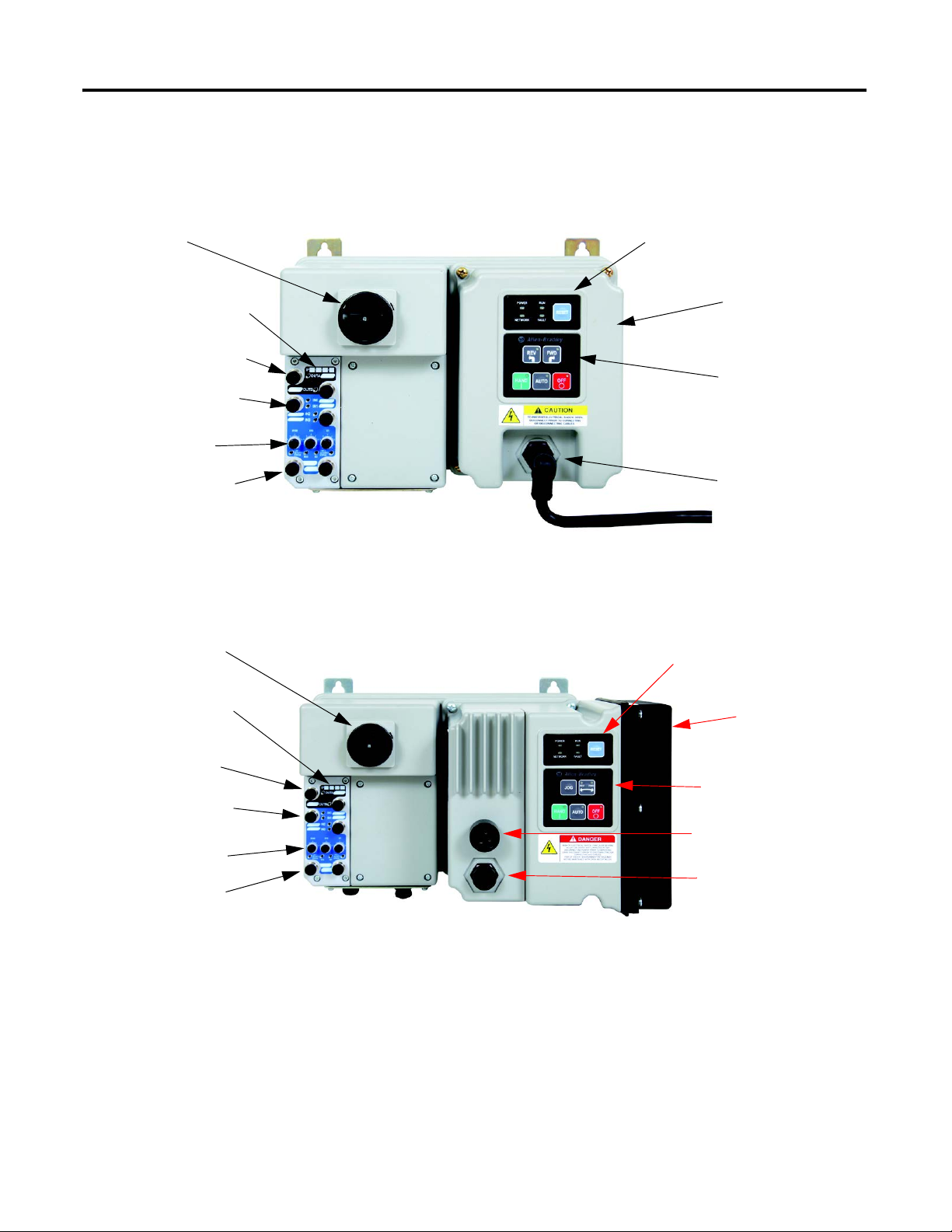

LED Status

Indication and Reset

Motor Connection

4 Inputs (Micro/M12)

IP Address Notation Area

Local Disconnect

2 Outputs (Micro/M12)

Hand-Off-Auto Keypad

IP Address Switches

Control Module

Ethernet Ports (DLR)

LED Status

Indication and Reset

Motor Connection

Source Brake Connection

4 Inputs (Micro/M12)

Ethernet Ports (DLR)

IP Address Switches

IP Address Notation Area

Hand-Off-Auto Keypad

Control Module

Local Disconnect

2 Outputs (Micro/M12)

ArmorStart® EtherNet/ IP Features

Figure 10 - Bulletin 280E/281E ArmorStart with EtherNet/IP™

Communication Protocol

28 Rockwell Automation Publication 280E-UM001B-EN-P - July 2012

Figure 11 - Bulletin 284E ArmorStart with EtherNet/IP Communication Protocol

Page 29

Notes:

Product Overview Chapter 1

Rockwell Automation Publication 280E-UM001B-EN-P - July 2012 29

Page 30

Chapter 1 Product Overview

30 Rockwell Automation Publication 280E-UM001B-EN-P - July 2012

Page 31

Installation and Wiring

IMPORTANT

Chapter 2

Receiving

Unpacking

Inspecting

It is the responsibility of the user to thoroughly inspect the equipment before

accepting the shipment from the freight company. Check the item(s) received

against the purchase order. If any items are damaged, it is the responsibility of the

user not to accept delivery until the freight agent has noted the damage on the

freight bill. Should any concealed damage be found during unpacking, it is again

the responsibility of the user to notify the freight agent. The shipping container

must be left intact and the freight agent should be requested to make a visual

inspection of the equipment.

Remove all packing material, wedges, or braces from within and around the

Armorstart distributed motor controller. Remove all packing material from the

device(s). Check the contents of the package. Contact your local Allen-Bradley

representative if any items are missing.

Before the installation and start-up of the drive, a general inspection of mechanical

integrity (i.e. loose parts, wires, connections, packing materials, etc.) must be made.

After unpacking, check the item(s) nameplate catalog number(s) against the

purchase order. See Chapter 1

which will aid in nameplate interpretation.

for an explanation of the catalog numbering system

Storing

The controller should remain in its shipping container prior to installation. If the

equipment is not to be used for a period of time, it must be stored according to

the following instructions in order to maintain warranty coverage.

• Store in a clean, dry location.

• Store within an ambient temperature range of –25°C…+85°C

(–13°F…+185°F).

• Store within a relative humidity range of 0…95%, noncondensing.

• Do not store equipment where it could be exposed to a corrosive

atmosphere.

• Do not store equipment in a construction area.

Rockwell Automation Publication 280E-UM001B-EN-P - July 2012 31

Page 32

Chapter 2 Installation and Wiring

General Precautions

Precautions for Bulletin 280E/281E Applications

In addition to the precautions listed throughout this manual, the following

statements, which are general to the system, must be read and understood.

ATTENTION: The controller contains ESD (electrostatic discharge) sensitive

parts and assemblies. Static control precautions are required when installing,

testing, servicing, or repairing the assembly. Component damage may result

if ESD control procedures are not followed. If you are not familiar with static

control procedures, refer to Publication 8000-4.5.2

Electrostatic Discharge, or any other applicable ESD protection handbooks.

ATTENTION: An incorrectly applied or installed controller can damage

components or reduce product life. Wiring or application errors, such as

undersizing the motor, incorrect or inadequate AC supply, or excessive

ambient temperatures, may result in malfunction of the system.

ATTENTION: Only personnel familiar with the controller and associated

machinery should plan or implement the installation, startup, and

subsequent maintenance of the system. Failure to do this may result in

personal injury and/or equipment damage.

ATTENTION: To prevent electrical shock, open the disconnect switch prior to

connecting and disconnecting cables. Risk of shock – environment rating

may not be maintained with open receptacles.

, Guarding against

Precautions for Bulletin 284E Applications

WARNING: The drive contains high voltage capacitors which take time to

discharge after removal of mains supply. Before working on a drive, ensure

isolation of mains supply from line inputs (R, S, T [L1, L2, L3]). Wait three

minutes for capacitors to discharge to safe voltage levels. Failure to do so may

result in personal injury or death. Darkened display LEDs are not an indication

that capacitors have discharged to safe voltage levels. Risk of shock –

environment rating may not be maintained with open receptacles.

ATTENTION: Only qualified personnel familiar with adjustable frequency AC

drives and associated machinery should plan or implement the installation,

startup, and subsequent maintenance of the system. Failure to do this may

result in personal injury and/or equipment damage.

32 Rockwell Automation Publication 280E-UM001B-EN-P - July 2012

Page 33

Installation and Wiring Chapter 2

290

11.42[]

287,5

11.32[]

268

10.55[]

6,8

.27[]

39

2[]

47

1.85[]

67,9

3[]

3,02

.12[]

373

14.69[]

11

.43[]

195

7.68[]

189

7[]

OR CONNECTION 185 [7.3] M22 CORDSETMOT

MOTOR ECTION 243 [9.57] M35 CORDSETCONN

150

6[]

351

13.82[]

0.75 in. CONDUIT OPENING

1 in. CONDUIT OPENING

Dimensions

Dimensions are shown in millimeters (inches). Dimensions are not intended to

be used for manufacturing purposes. All dimensions are subject to change.

Conduit Gland Entrance Bulletin 280E/281E

Figure 12 - Dimensions for Bulletin 280E/281E

Rockwell Automation Publication 280E-UM001B-EN-P - July 2012 33

Page 34

Chapter 2 Installation and Wiring

290

11.42[]

287,5

11.32[]

268

10.55[]

6,8

.27[]

39

2[]

47

1.85[]

67,9

3[]

3,02

.12[]

373

14.69[]

11

.43[]

195

7.68[]

236

9[]

2HP or less 420.38 [16.55]

3HP or greater 444.38 [17.50]

R CONNECTION 266.9 [10.51]MOTO

0.75 in. CONDUIT OPENING

1 in. CONDUIT OPENING

Conduit Gland Entrance Bulletin 284E

Figure 13 - Dimensions for Bulletin 284E

34 Rockwell Automation Publication 280E-UM001B-EN-P - July 2012

Page 35

Installation and Wiring Chapter 2

203.2

[8]

CABLE

KEEP OUT

203.2

[8]

CABLE

KEEP OUT

68

2.68[]

60,6

2[]

77,6

3[]

25,5

1[]

351

13.82[]

290

11.42[]

287,5

11.32[]

268

10.55[]

6,8

.27[]

25,5

1[]

68

2.68[]

60,6

2[]

77,6

3[]

351

13.82[]

290

11.42[]

268

10.55[]

287,5

11.32[]

6,8

.27[]

10 Hp @ 480V AC

3 Hp and less @ 480V AC

25 A Short Circuit

Protection (M35)

10 A Short Circuit

Protection (M22)

ArmorConnect® Gland Connectivity Bulletin 280E/281E

Figure 14 - Dimensions for Bulletin 280E/281E

Rockwell Automation Publication 280E-UM001B-EN-P - July 2012 35

Page 36

Chapter 2 Installation and Wiring

68

2.68[]

60,6

2[]

77,6

3[]

25,5

1[]

419,53

16.52[]

290

11.42[]

287,5

11.32[]

268

10.55[]

6,8

.27[]

25,5

1[]

68

2.68[]

60,6

2[]

77,6

3[]

444,38

17.50[]

290

11.42[]

30,4

1[]

287,5

11.32[]

268

10.55[]

6,8

.27[]

3 Hp or greater at 480V

2 Hp or less at 480V

25 A Short Circuit

Protection (M35)

10 A Short Circuit

Protection (M22)

ArmorConnect Gland Connectivity Bulletin 284E

Figure 15 - Dimensions for Bulletin 284E

36 Rockwell Automation Publication 280E-UM001B-EN-P - July 2012

Page 37

Installation and Wiring Chapter 2

IMPORTANT

Mount Orientation

The recommended mounting orientation of ArmorStart EtherNet/IP is the

vertical configuration. This is especially important for the Bulletin 284. This

ensures proper air flow over the heat sink. Improper mounting or debris build up

will reduce air flow and increased internal temperatures. This may reduce the

overall life of the product. For alternate mounting contact your local sales

representative.

For proper heat dissipation and product operation, mount in the vertical orientation

as shown.

Operation

Wiring

The ArmorStart Distributed Motor Controllers can operate three-phase

squirrel-cage induction motors as follows:

Bulletin 280E/281E: 0.24…16 A; 200V AC, 230V AC, 460V AC; 50/60 Hz.

Bulletin 284E: up to 5 Hp (3.0 kW) @ 480V AC

The ArmorStart EtherNet/IP Distributed Motor Controller will accept a control

power input of 24V DC.

Power, Control, Safety Monitor Inputs, and Ground Wiring

Table 2 provides the power, control, and ground wire capacity and the tightening

torque requirements. The power, control, ground, and safety monitor terminals

will accept a maximum of two wires per terminal.

Table 2 - Power, Control, Safety Monitor Inputs, Ground Wire Size, and Torque Specifications

Terminals Wire Size Torque Wire Strip Length

Primary Terminal:

10.8 lb-in.

(1.2 N•m)

Secondary Terminal:

4.5 lb-in.

(0.5 N•m)

6.2 lb-in.

(0.7 N•m)

0.35 in. (9 mm)

0.35 in. (9 mm)

Power

and

Ground

Control Inputs

Primary/Secondary

Ter min al :

1.5…4.0 mm

(#16 …#10 American Wire

Gage (AWG))

1.0 mm

(#18…#10 AWG)

2

…4.0 mm2

2

Rockwell Automation Publication 280E-UM001B-EN-P - July 2012 37

Page 38

Chapter 2 Installation and Wiring

See Detail A

Detail A

Terminal Designations

As shown in Figure 16, the ArmorStart Distributed Motor Controller contains

terminals for power, control, and ground wiring. Access can be gained by

removing the terminal access cover plate.

Figure 16 - ArmorStart Power and Control Terminal Connections

(applies to Bulletin 280E/281E and Bulletin 284E)

Control Power Wiring

Table 3 - Power, Control and Ground Terminal Designations

Terminal Designations No. of Poles Description

A1 (+) 2 Control Power Input

A2 (–) 2 Control Power Common

A3 (+) 2 Unswitched 24V Control

PE 2 Ground

1/L1 2 Line Power Phase A

3/L3 2 Line Power Phase B

5/L5 2 Line Power Phase C

ArmorStart EtherNet/IP utilizes 24V DC control power for communications

and I/O. The control power terminal connections are labeled A1, A2, and A3.

Switched power will supply the outputs. Unswitched power will supply logic

power and sensor inputs.

38 Rockwell Automation Publication 280E-UM001B-EN-P - July 2012

Page 39

Installation and Wiring Chapter 2

24V DC Control Power

• 24V DC (–15%, +10%)

• A1 = Switched +V

• A2 = Common for both switched and unswitched (–V)

• A3 = Unswitched +V

Input and Output Characteristics

• 5-pin female connectors (M12)

• 4 fixed inputs (two per connector) – software selectable sink or source

• 2 sourcing outputs DC (solid-state) – (one per connector)

Input and Output Power Connection

• Sensor Power will be sourced from +24V supplied from A3(+) and A2(–).

•