Page 1

QUICK START

ARMORSTART® DISTRIBUTED

MOTOR CONTROLLER WITH

ARMORPOINT® BACKPLANE

Getting Started

BULLETIN 283A

Introduction This guide provides the basic information required to start up your

ArmorStart

and information regarding installing, programming, and ArmorPoint

Communication Backplane, are described here. For detailed

information on specific product features or configurations, refer to the

ArmorStart user manual, Publication 283-UM001*-EN-P.

This guide is intended for qualified service personnel responsible for

setting up and servicing these devices. You must have previous

experience with and a basic understanding of electrical terminology,

configuration procedures, required equipment, and safety precautions.

For Bulletin 283A devices, you should understand Bulletin 1738

ArmorPoint adapter and I/O products.

®

Distributed Motor Controller. Factory default settings

®

Page 2

2

Installation The ArmorStart Distributed Motor Controller is convection cooled.

Operating temperature must be kept between -20…40°C (-4…104°F).

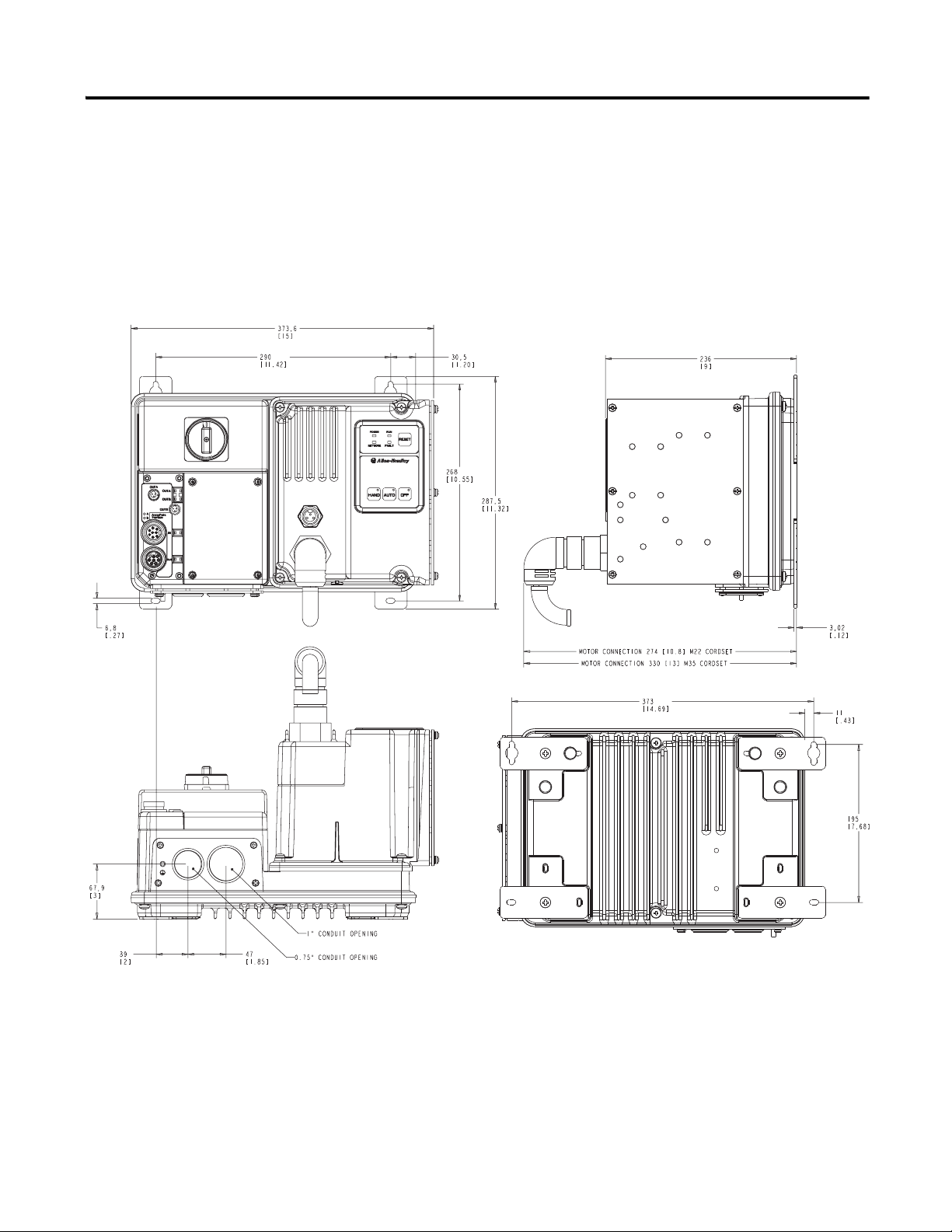

Dimensions Dimensions are shown in millimeters (inches). Dimensions are not intended

to be used for manufacturing purposes. All dimensions are subject to

change.

Figure 1 Dimensions for IP67/NEMA Type 4 with Conduit Entrance

Publication 283A-QS001C-EN-P - July 2006

Page 3

3

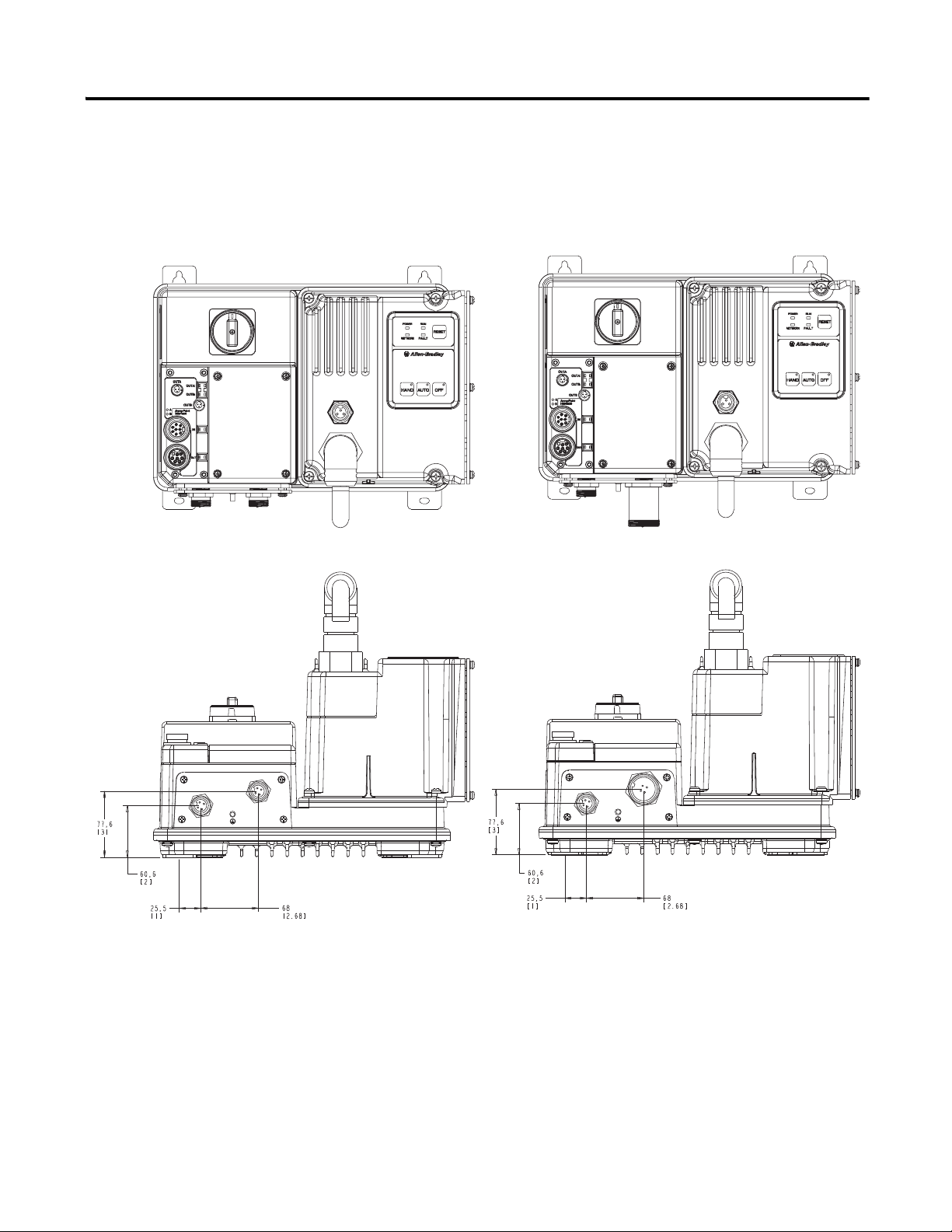

ArmorStart device with a 10 A short circuit protection rating ArmorStart device with a 25 A short circuit protection rating

Dimensions are shown in millimeters (inches). Dimensions are not intended

to be used for manufacturing purposes. All dimensions are subject to

change.

Figure 2 Dimensions for IP67/NEMA Type 4 with ArmorConnect™ Connectivity

Publication 283A-QS001C-EN-P - July 2006

Page 4

4

Primaries

Secondaries

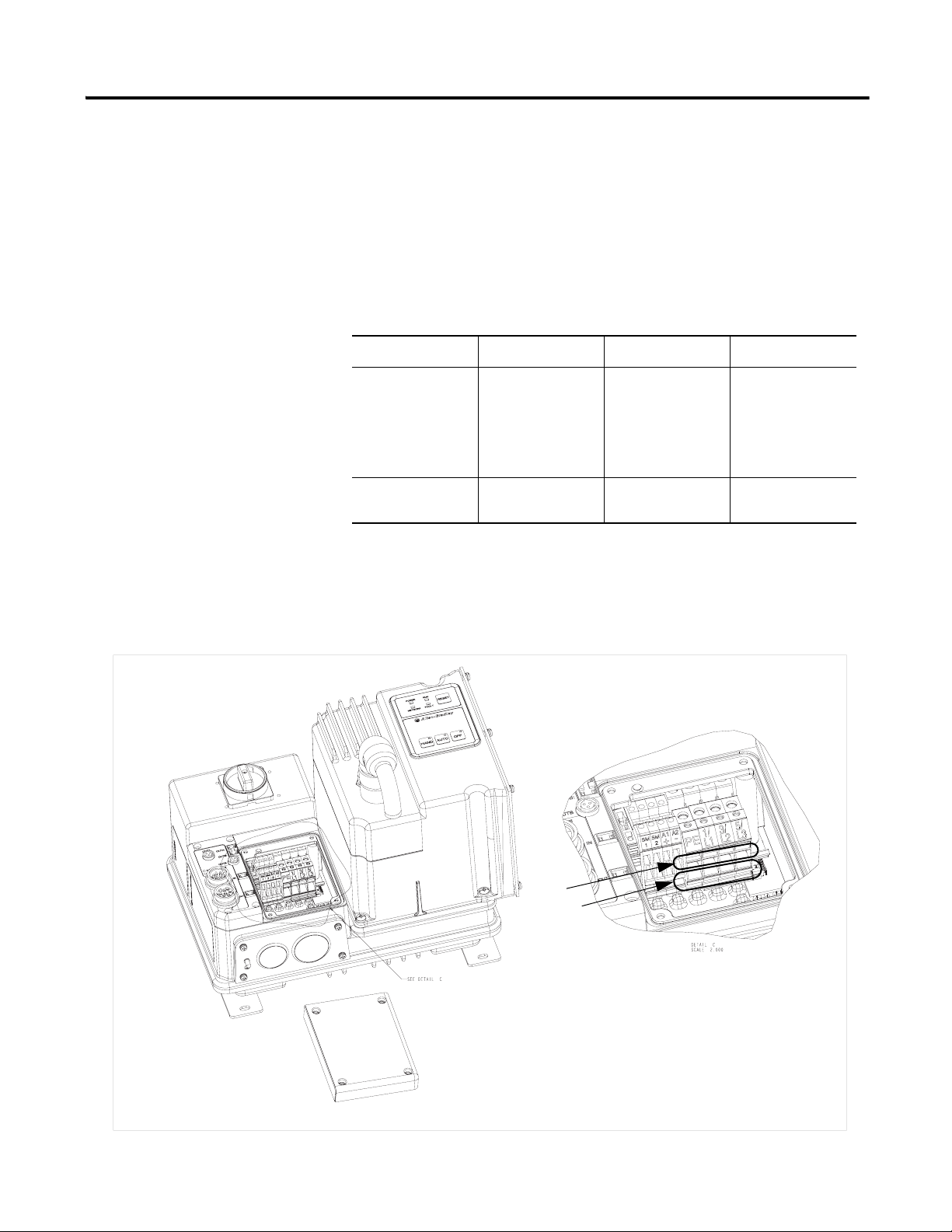

Wiring Power, Control, Safety Monitor Inputs, and Ground Wiring

Table 1 provides the power, control, safety monitor inputs, ground wire

capacity and the tightening torque requirements. The power, control,

ground, and safety monitor terminals will accept a maximum of two wires

per terminal.

Table 1 Power, Control, Safety Monitor Inputs, Ground Wire Size, and Torque

Specifications

Terminals Wire Size Torque Wire Strip Length

Primary Terminal:

10.6…21.6 lb.-in.

(1.2…2.4 N•m)

Secondary Terminal:

5.3…7.3 lb.-in

(0.6…0.8 N•m)

5.0…5.6 lb.-in

(0.6 N•m)

0.35 in. (9 mm)

0.35 in. (9 mm)

Power

and

Ground

Control and Safety

Monitor Inputs

Primary/Secondary

Terminal:

1.0…4.0 mm

(#18 …#10 AWG)

2

0.34mm

…4.0 mm2

(#22…#10 AWG)

2

Terminal Designations As shown in Figure 3, the ArmorStart Distributed Motor Controller contains

terminals for power, control, safety monitor inputs, and ground wiring.

Access can be gained by removing the terminal access cover plate.

Figure 3 ArmorStart Power, Control, and Safety Monitor Terminals

Publication 283A-QS001C-EN-P - July 2006

Page 5

Table 2 Power, Control, and Ground Terminal Designations

Terminal Designations No. of Poles Description

SM1 ➊ 2 Safety Monitor Input

SM2 ➊ 2 Safety Monitor Input

A1 (+) 2 Control Power Input

A2 (-) 2 Control Power Common

PE 2 Ground

1/L1 2 Line Power Phase A

3/L3 2 Line Power Phase B

5/L5 2 Line Power Phase C

➊ Only available with the Safety Monitor option.

5

Publication 283A-QS001C-EN-P - July 2006

Page 6

6

ArmorConnect Power Media Description

The ArmorStart Power Media offers both three-phase and control power

cable system of cordsets, patchcords, receptacles, tees, reducers and

accessories to be utilized with the ArmorStart Distributed Motor Controller.

These cable system components allow quick connection of ArmorStart

Distributed Motor Controllers and reduce installation time. They provide

for repeatable, reliable connection of the three-phase and control power to

the ArmorStart Distributed Motor Controller and motor by providing a plug

and play environment that also avoids system mis-wiring. When specifying

power media for use with the ArmorStart Distributed Motor Controllers

(Bulletins 280, 281, 283, and 284) use only Bulletin 280 ArmorConnect™

power media.

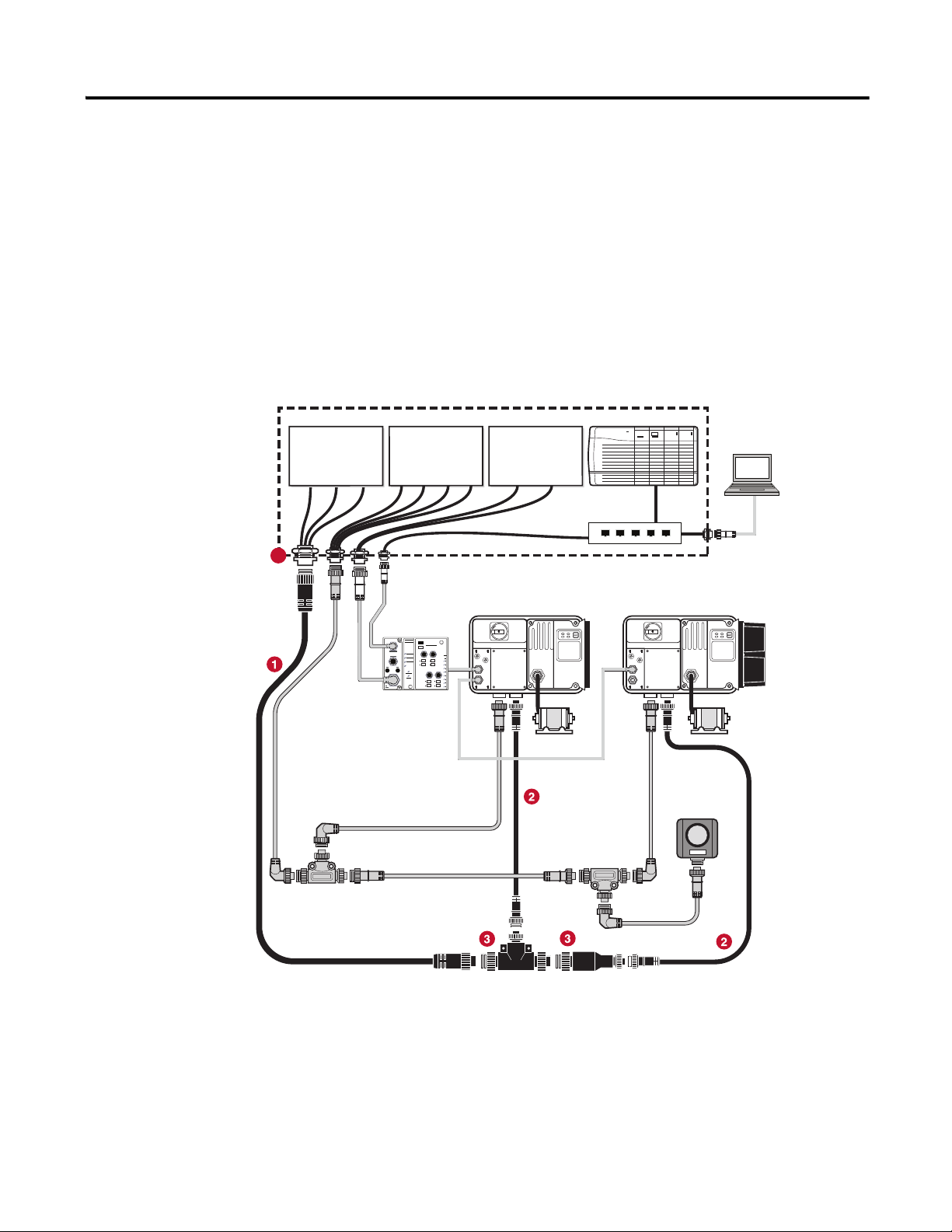

Figure 4 Three-Phase Power System Overview

Enclosure

Bulletin 1492FB

Branch Circuit

Protective Device

Bulletin 1606

Bulletin 1606

PLC

Ethernet

Computer

Terminal

4

Bulletin 283

ArmorStart

ArmorPoint

➊ Three-Phase Power Trunk- PatchCord cable with integral female or male connector on each end

Example Part Number: 280-PWR35A-M*

➋ Three-Phase Drop Cable- PatchCord cable with integral female or male connector on each end

Example Part Number: 280-PWR22A-M*

➌ Three-Phase Power Tees and Reducer -

Tee connects to a single drop line to trunk with quick change connectors – Part Number: 280-T35

Reducing Tee connects to a single drop line (Mini) to trunk (Quick change) connector – Part Number: 280-RT35

Reducer connects from quick change male connector to mini female connector– Part Number: 280-RA35

➍ Three-Phase Power Receptacles -

Female receptacles are a panel mount connector with flying leads – Part Number: 280-M35F-M1

Bulletin 284

ArmorStart

Bulletin 800F

Emergency Stop

Pushbutton

Publication 283A-QS001C-EN-P - July 2006

Page 7

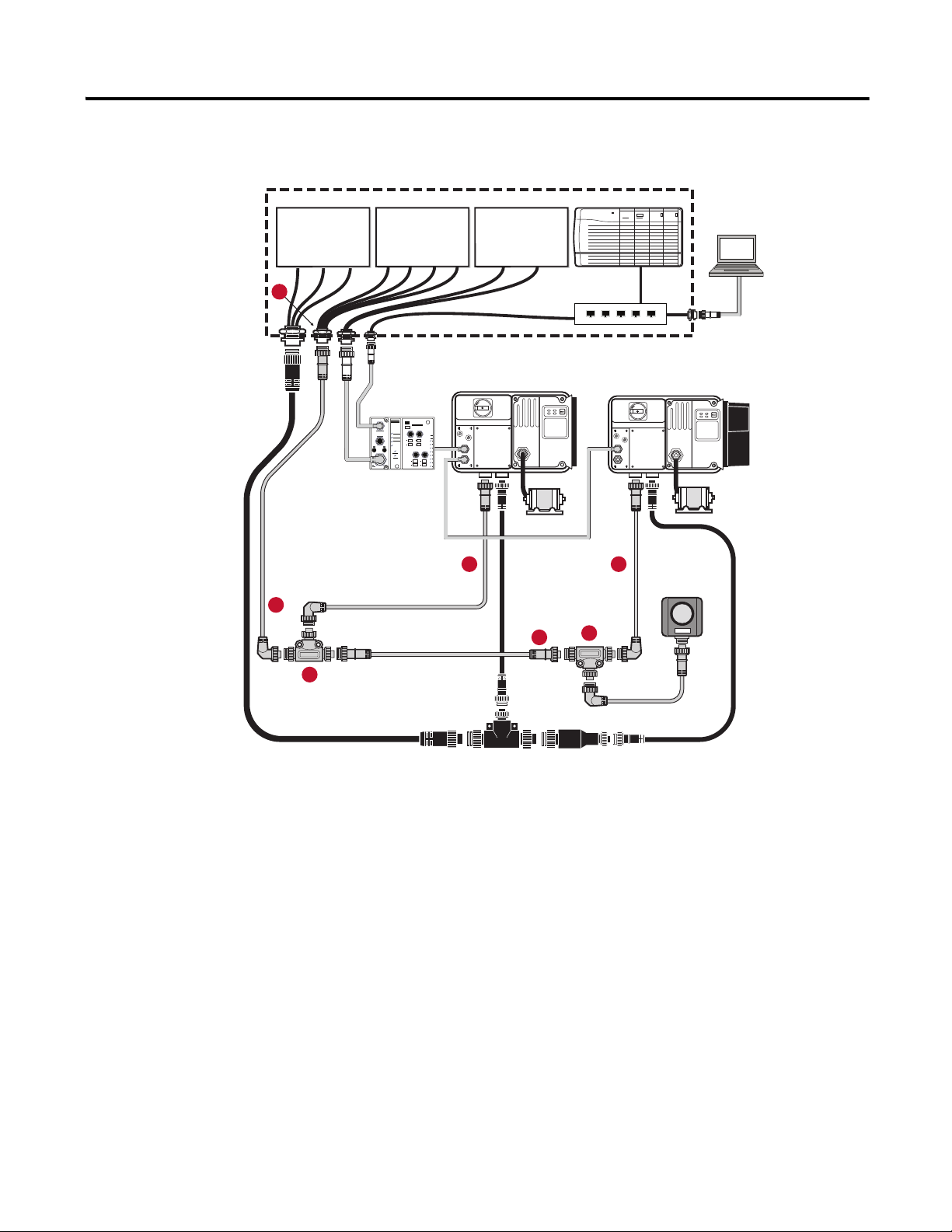

Figure 5 Control Power Media System Overview

Bulletin 283

ArmorStart

ArmorPoint

Bulletin 284

ArmorStart

Ethernet

PLC

Bulletin 1492FB

Branch Circuit

Protective Device

Enclosure

Bulletin 1606

Bulletin 1606

Bulletin 800F

Emergency Stop

Pushbutton

8

6

6

6

6

7

7

Computer

Terminal

7

➏ Control Power Media Patchcords - PatchCord cable with integral female or male connector on each end

Example Part Number: 889N-F65GFNM-*

➐ Control Power Tees - The E-stop In Tee (Part Number: 898N-653ES-NKF) is used to connect to the Bulletin 800F On-Machine E-Stop station using a

control power media patchcord. The E-stop Out tee (Part Number: 898N-653ST-NKF) is used with cordset or patchcord to connect to the ArmorStart

Distributed Motor Controller.

➑ Control Power Receptacles - Female receptacles are a panel mount connector with flying leads –

Part Number: 888N-D65AF1-*

Publication 283A-QS001C-EN-P - July 2006

Page 8

8

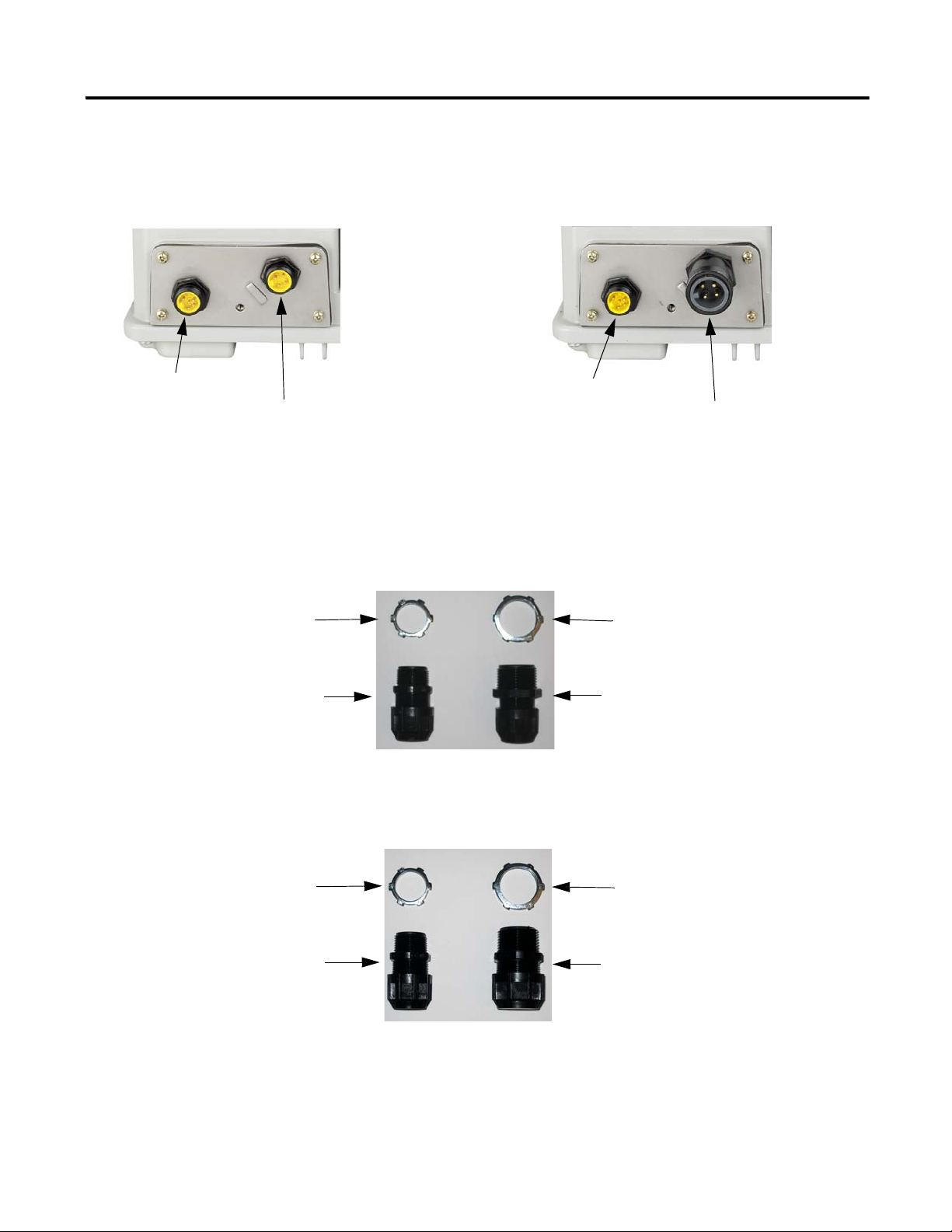

Control Power Receptacle

Three-Phase Power Receptacle

Control Power Receptacle

Three-Phase Power Receptacle

ArmorStart devices with 10 A short

circuit protection rating

ArmorStart devices with 25 A short

circuit protection rating

3/4 in. Lock Nut 1 in. Lock Nut

Thomas & Betts Cord Grip

Part Number: 2931NM

3/4 in. Stain Relief Cord Connector

Cable Range: 0.31…0.56 in.

Used with Control Power Media

Cordset - Example Part Number:

889N-M65GF-M2

Thomas & Betts Cord Grip

Part Number: 2940NM

1 in. Stain Relief Cord Connector

Cable Range: 0.31…0.56 in.

Used with Three-Phase Power

Media Cordset - Example Part

Number: 280-PWR22G-M1

Cord Grips for ArmorStart Devices with 10 A short circuit protection rating

3/4 in. Lock Nut 1 in. Lock Nut

Thomas & Betts Cord Grip

Part Number: 2931NM

3/4 in. Stain Relief Cord Connector

Cable Range: 0.31…0.56 in.

Used with Control Power Media

Cordset - Example Part Number:

889N-M65GF-M2

Thomas & Betts Cord Grip

Part Number: 2942NM

1 in. Stain Relief Cord Connector

Cable Range: 0.70…0.95 in.

Used with Three-Phase Power

Media Cordset - Example Part

Number: 280-PWR35G-M1

Cord Grips for ArmorStart Devices with 25 A short circuit protection rating

ArmorStart with ArmorConnect Connectivity

Installing ArmorConnect Power Media using Cord Grips

Publication 283A-QS001C-EN-P - July 2006

Page 9

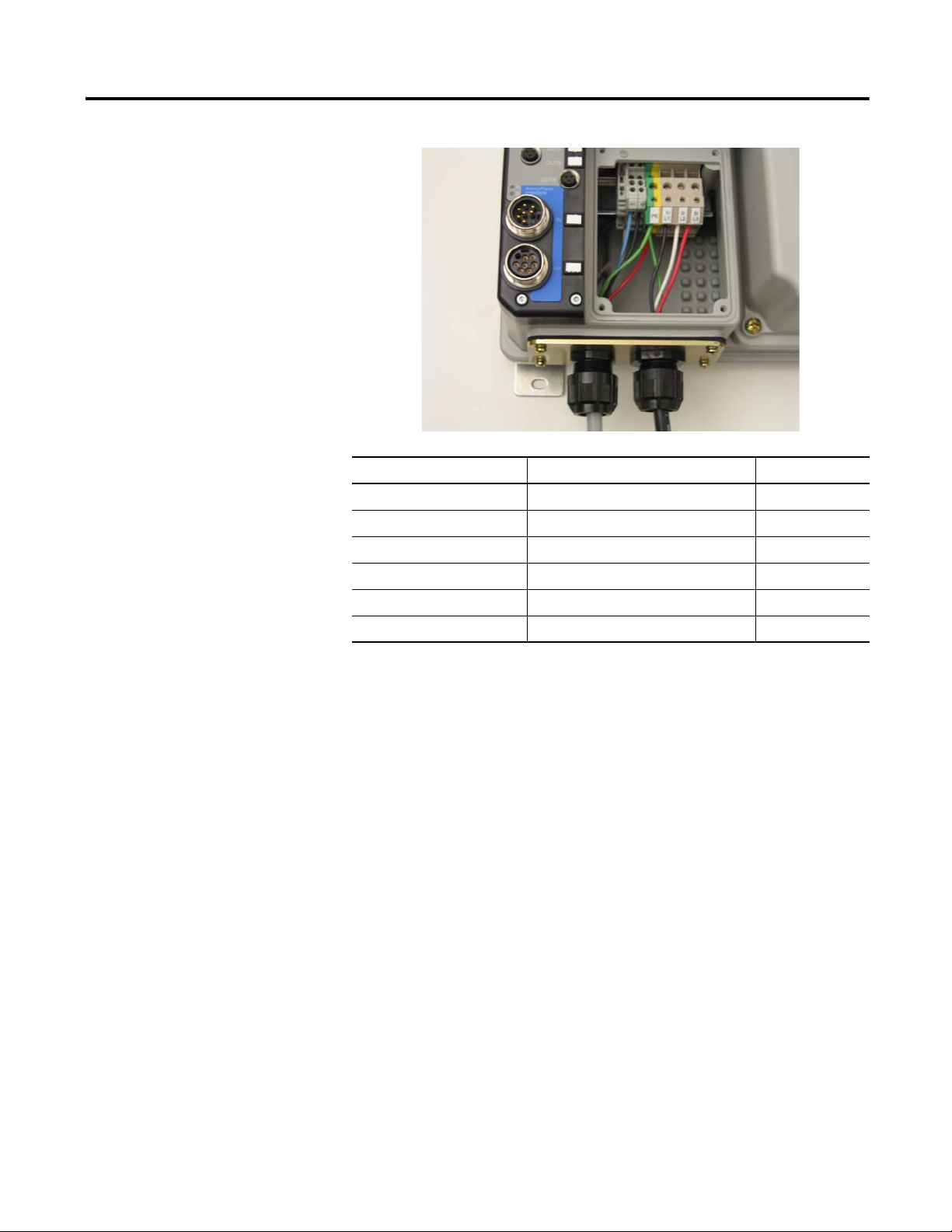

Terminal Designations Description Color Code

A1 (+) Control Power Input Blue

A2 (-) Control Power Common Black

9

PE Ground Green/Yellow

1/L1 Line Power - Phase A Black

2/L2 Line Power - Phase B White

3/L3 Line Power - Phase C Red

ArmorConnect Cable Ratings

The ArmorConnect Power Media cables are rated per UL Type TC

600V 90 °C Dry 75 °C Wet, Exposed Run (ER) or MTW 600V 90 °C or

STOOW 105 °C 600V - CSA STOOW 600V FT2. For additional

information regarding ArmorConnect Power Media see the ArmorStart

User Manual.

Branch Circuit Protection Requirements for ArmorConnect™

Three-Phase Power Media

When using ArmorConnect Three-Phase Power Media, only fuses can be

used for the motor branch circuit protective device, for the group motor

installations. The recommended fuse types are the following: Class CC, T,

or J type fuses. For additional information, see the ArmorStart User

Manual.

Publication 283A-QS001C-EN-P - July 2006

Page 10

10

Group Motor Installations for USA and Canada Markets

The ArmorStart Distributed Motor controllers are listed for use with each

other in group installations per NFPA 79, Electrical Standard for Industrial

Machinery. When applied according to the group motor installation

requirements, two or more motors, of any rating or controller type, are

permitted on a single branch circuit. Group Motor Installation has been

successfully used for many years in the USA and Canada.

Wiring and Workmanship Guidelines

In addition to conduit and seal-tite raceway, it is acceptable to utilize cable

that is dual rated Tray Cable, Type TC-ER and Cord, STOOW, for power

and control wiring on ArmorStart installations. In the USA and Canada

installations, the following guidance is outlined by the NEC and NFPA 79.

In industrial establishments where the conditions of maintenance and

supervision ensure that only qualified persons service the installation, and

where the exposed cable is continuously supported and protected against

physical damage using mechanical protection, such as struts, angles, or

channels, Type TC tray cable that complies with the crush and impact

requirements of Type MC (Metal Clad) cable and is identified for such use

with the marking Type TC-ER (Exposed Run)* shall be permitted between

a cable tray and the utilization equipment or device as open wiring. The

cable shall be secured at intervals not exceeding 1.8 m (6 ft) and installed in

a “good workman-like” manner. Equipment grounding for the utilization

equipment shall be provided by an equipment grounding conductor within

the cable.

Publication 283A-QS001C-EN-P - July 2006

*Historically cable meeting these crush and impact requirements were

designated and marked “Open Wiring”. Cable so marked is equivalent to the

present Type TC-ER and can be used.

While the ArmorStart is intended for installation in factory floor

environments of industrial establishments, the following must be taken into

consideration when locating the ArmorStart in the application: Cables,

including those for control voltage including 24V DC and communications,

are not to be exposed to an operator or building traffic on a continuous

basis. Location of the ArmorStart to minimize exposure to continual traffic

is recommended. If location to minimize traffic flow is unavoidable, other

barriers to minimize inadvertent exposure to the cabling should be

considered. Routing cables should be done in such a manner to minimize

inadvertent exposure and/or damage.

Additionally, if conduit or other raceways are not used, it is recommended

that strain relief fittings be utilized when installing the cables for the control

and power wiring through the conduit openings.

Page 11

11

The working space around the ArmorStart may be minimized as the

ArmorStart does not require examination, adjustment, servicing or

maintenance while energized. In lieu of this service, the ArmorStart is

meant to be unplugged and replaced after proper lockout/tag-out procedures

have been employed.

Since the ArmorStart is available with a factory installed HOA keypad

option this may require the ArmorStart to be selected and installed as

follows if the application requires frequent use of the hand operated

interface by the equipment operator:

1. They are not less than 0.6 m (2 ft) above the servicing level and are

within easy reach of the normal working position of the operator.

2. The operator is not placed in a hazardous situation when operating

them.

3. The possibility of inadvertent operation is minimized.

If the operated interface is used in industrial establishments where the

conditions of maintenance and supervision ensure that only qualified

persons operate and service the ArmorStart's operator interface, and the

installation is located so that inadvertent operation is minimized then other

installation locations with acceptable access can be provided.

Publication 283A-QS001C-EN-P - July 2006

Page 12

12

LED Status Indication The LED Status Indication provides 4 status LEDs and a Reset button. The

LEDs provide status indication for the following:

• POWER LED

The LED is illuminated solid green when control power is present and

with the proper polarity

•RUN LED

This LED is illuminated solid green when a start command and control

power are present

• NETWORK LED

This bi-color (red/green) LED indicates the status of the

communication link

• FAULT LED

Indicates Controller Fault (trip) condition

The “Reset Button” as a local trip reset.

Figure 6 LED Status Indication and Reset

Publication 283A-QS001C-EN-P - July 2006

Page 13

ArmorStart with ArmorPoint ArmorStart for the ArmorPoint Backplane

The Bulletin 283A ArmorStart Distributed Motor Controller allows

connectivity to the ArmorPoint backplane. The ArmorPoint I/O system can

communicate using DeviceNet™, ControlNet™, or EtherNet

communication protocols. In addition to the other network communication

protocols; the ArmorPoint Distributed I/O products allow the I/O capability

to be expanded beyond the standard two outputs. Two dual-key output

connectors are provided standard. The outputs are sourced from control

voltage power (A1, A2). LED status indication is also provided, as standard

with the ArmorPoint. When using ArmorPoint, a maximum of two

ArmorStart Distributed Motor Controllers can be connected to the

ArmorPoint Distributed I/O products.

ArmorStart to ArmorPoint Connectivity

Figure 7 Connectivity Diagram for one ArmorStart Distributed Motor Controller

13

When connecting to the Bulletin 1738 ArmorPoint Distributed I/O product,

a network adapter and at least one ArmorPoint Digital Output, Digital Input,

Analog, AC and Relay product, or Specialty product must be selected. The

ArmorPoint Distributed I/O product can accommodate up to 63 modules per

network node. The cable that connects the ArmorPoint Distributed I/O to

the ArmorStart Distributed Motor Controller is the Bulletin 280A-EXT1.

The 280A-EXT1 includes an ArmorPoint bus extension cable and a

network terminating resistor. The network terminating resistor must be

connected to the “ArmorPoint Interface Out” connector.

Figure 8 Connectivity Diagram for two ArmorStart Distributed Motor Controllers

If an additional ArmorStart Distributed Motor Controller is to be connected,

the Bulletin 280A-EXTCABLE will be required. A maximum of two

ArmorStart Distributed Motor Controllers can be connected to the Bulletin

1738 Distributed I/O. The Bulletin 280A-EXTCABLE is connected from

the “ArmorPoint Interface Out” on the first unit, to the “ArmorPoint

Interface In” on the second unit. The network terminating resistor is

connected to the “ArmorPoint Interface Out” on the second unit.

Publication 283A-QS001C-EN-P - July 2006

Page 14

14

ArmorPoint Backplane Commissioning

Establishing a Backplane Node Address

Backplane node addresses are established automatically by the ArmorPoint

system on power up. Node addresses for the backplane modules are

allocated from left to right, starting at address 1.

Note: The rotary address switches on the starter module are ignored

when using the ArmorPoint backplane.

Note: When using RSNetWorx for DeviceNet with the 283A

ArmorStart Distributed Motor Controllers, DO NOT use the

node commissioning outlined in Chapter 5 of the User Manual.

Details on Using the “ArmorStart Ladder Logic Configurator”

The ArmorStart Ladder Logic Configurator is a ladder logic routine (File

Name: ArmorStart_Configurator.ACD) designed so that under program

control, the entire product family of the ArmorStart Distributed Motor

Controllers can be configured easily from a Logix based controller. The

family of ArmorStart Distributed Motor Controllers includes the following

Bulletin Numbers: 280A, 281A, 283A and 284A. The ArmorStart

Distributed Motor Controllers can be networked over ControlNet or

EtherNetIP, when on the appropriate ArmorPoint backplane. The ladder

logic file is designed to be merged into an existing ladder logic file or it can

be used as the basic program and other logic can be added to it. This

document assumes that the reader has an average knowledge of the use of

RSLogix™5000 and Logix based controllers. Device configuration is done

inside the Controller tag editor under the Monitor Tags tab.

Publication 283A-QS001C-EN-P - July 2006

Note: The ArmorStart Ladder Logic Configurator (File Name:

ArmorStart_Configurator.ACD) is provided on the CD shipped

with every ArmorStart product with the ArmorPoint

Communications protocol.

Theory of Operation

It is possible to connect an ArmorStart product to the Point I/O based subnet

of the ArmorPoint I/O system. This allows the ArmorStart to be connected

to EtherNetIP and ControlNet, along with the original DeviceNet. The

easiest way to program these ArmorStarts, is to use RSNetWorx for

DeviceNet software, bridging through the appropriate network. This

ladder logic has been developed as an alternate method of configuration.

Once the appropriate device configuration is done to a User Defined

Structure in the ladder logic file, a bit will need to be turned on in the logic

to trigger a system wide read of the system. This system wide read, goes out

and reads certain attributes of every parameter of every ArmorStart in the

system and stores the information into a large data array. The first attribute

Page 15

15

is a flag word that tells the ladder logic if the parameter is read only. If the

read only bit is set, then the ladder logic will skip the additional attribute

reads and will go to the next parameter. If the parameter is writable, then the

logic will read the size, min. allowed value, max. allowed value, the

parameter name, help string and the raw data of each parameter. These

attributes are stored in the data array for use later when the configuration is

written to each ArmorStart. The logic requires that a system wide read

function be completed prior to a system wide write function being

requested.

Note: A system wide read function should be done anytime that a new

ArmorStart is added to the system or an ArmorStart is updated

with a more recent version. This assures that the data array in

the logic matches the total system.

Once a system wide read is done, the raw data of the individual parameters

in the data array can be modified and a system wide write function activated

from a bit in the ladder logic. Only parameters that changed will be written

to the ArmorStart devices, and after a write is done the parameter is read

back and stored in the data array for comparison. If the write and reread

value do not match, an Error Report is generated.

If an error occurs for any reason, during a system wide read or write, an

error report will be logged, containing the device and parameter it occurred

on. Also the status and extended status of the message block is logged in

case the error originated there.

I/O Tree Overview

In order to transfer I/O information, the ArmorStart needs to be added to the

I/O tree of the Logix processor. The details of doing this are outside of the

scope of these instructions, but screen captures of the completed

configuration are included below for reference. The configuration below

shows the EtherNetIP card in the Logix chassis slot 1. The 1738-AENT

module is always located at slot zero in the subnet and the ArmorStart

device is located in slot 2 on the subnet. These slots are circled below for

you reference.

Figure 9 Logix Processor I/O Tree

Publication 283A-QS001C-EN-P - July 2006

Page 16

16

The only configuration that the user needs to be concerned with for the

ArmorPoint communication adapter is either the EtherNet IP address or the

ControlNet node address.

Since there currently is no profile for an ArmorStart device in the I\O Tree,

the 1738-MODULE profile needs to be used as a generic profile. The

standard configuration for an ArmorStart 283A, using this profile is shown

below.

Figure 10 ArmorStart Configuration using 1738-MODULE Profile

Logic Configuration Details

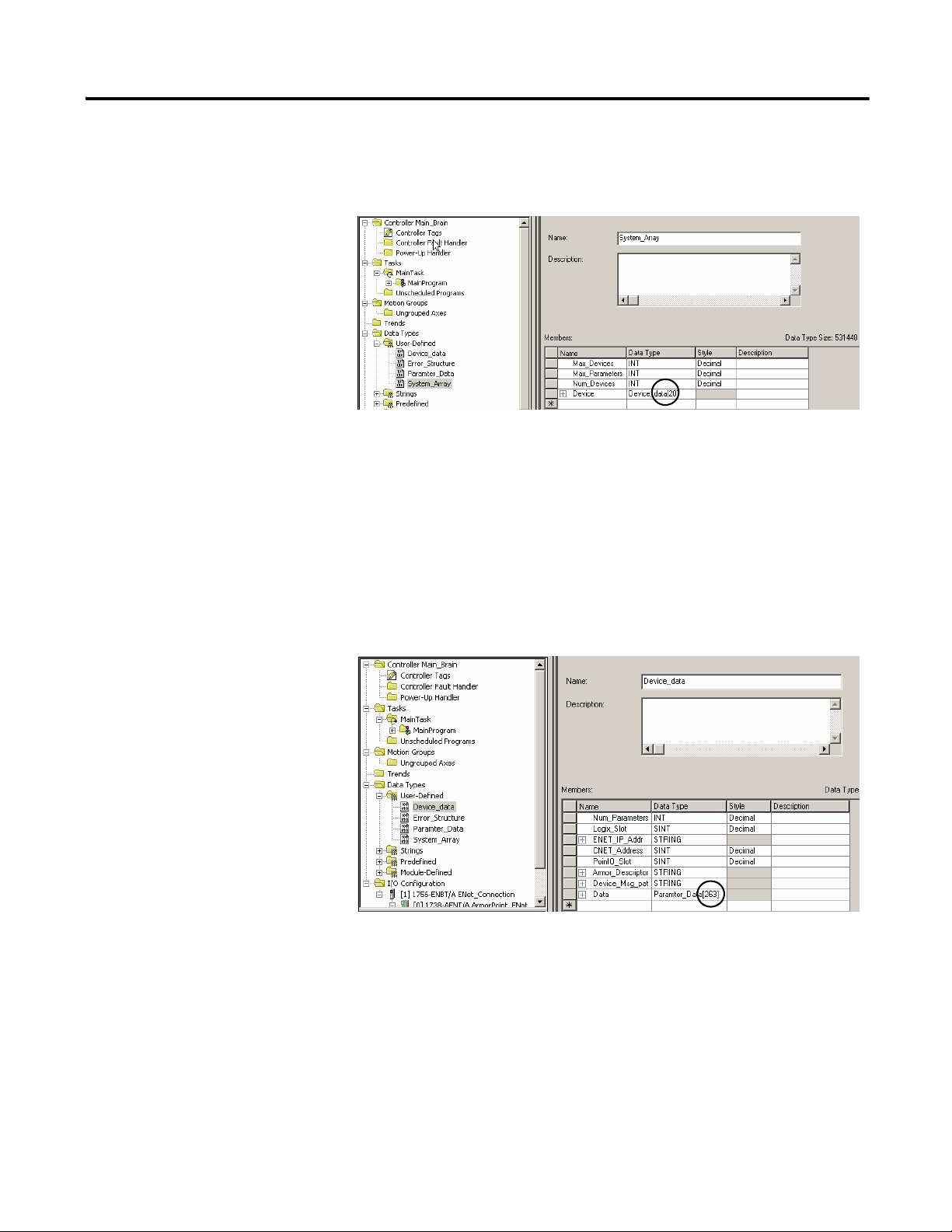

Inside the Configurator file is a large User Defined structure called

Armor_Start_System, which contains all of the data for both the

configuration of the routine, and also storage space for all of the ArmorStart

parameters. With 20 devices, the total memory needed to hold this structure

in the Logix controller is 195K bytes. The diagram below shows the upper

part of the structure and 3 important elements.

Figure 11 Configurator File — Armor_Start_System

Armor_Start_System.Max_Devices defaults to 20; because the total

number of devices that the structure is designed to hold initially, is 20. This

amount can be easily changed, but doing so will also necessitate a

change to the size of the System Array structure to match exactly.

Note: The Logix memory that contains the structure will also change

size proportionally.

Publication 283A-QS001C-EN-P - July 2006

Page 17

17

Shown below is the array size that will also need to be changed to match the

Armor_Start_System.Max_Devices value.

Figure 12 System Array Size

Armor_Start_System.Max_Parameters defaults to 262, because the

maximum number of parameters in any existing ArmorStart product is 262

or less. This amount can be easily be changed, and doing so will also

proportionally change the size of the System Array structure and the Logix

memory that holds it. Shown below is the array size that will also need to

be changed to be 1 greater than the

Armor_Start_System.Max_Parameters value. This is because the

parameters are stored by parameter number, and since there is no parameter

0, that storage location is unused.

Figure 13 Array Size Parameter

Armor_Start_System.Num_Devices defaults to zero and is defined as the

total number of ArmorStart products connected to the control system that

need to be configured. It is important that this value be set before the

configuration routine is executed.

It is to the users best advantage to trim the structures down to the minimum

values that match their system because this will save a considerable amount

of Logix processor memory. However, some room should be left in the

structures to handle any future additions of ArmorStart devices to the

system.

Publication 283A-QS001C-EN-P - July 2006

Page 18

18

Adding Devices to the Configuration Structure

Once the three major System level parameters are entered, it is up to the

user to enter in, each of the ArmorStart devices configuration information.

These parameters are defined by the slot in the Logix chassis where the

EtherNetIP or ControlNet communication card resides. The next parameter

is the EtherNetIP IP or ControlNet node address of the 1738 communication

adapter containing the ArmorStart. Lastly, the slot number on the

ArmorPoint subnet where the ArmorStart is connected also needs to be

entered. An optional parameter is a string that can be entered with a

description of the function of the ArmorStart device. Each device will be

configured by entering its data into a different block of the

Armor_Start_System.Device[] array.

The Following shows the configuration for a communication card in the

Logix chassis 2, AENT IP address 192.168.1.10 and Point I/O slot 3. The

logic determines whether the network is EtherNetIP or ControlNet

depending on whether the ENET_IP_Addr field is blank or the

CNET_Address is zero. One of these two fields must be filled out for the

logic to work correctly. The Armor_Descriptor field is optional and is used

to more easily identify the ArmorStart as to its function in the system.

Figure 14 Communication Card Configuration

Note: To easily edit an ASCII string, click on the string value field and

a small icon with three dots appears.

Figure 15 String Browser Box

Publication 283A-QS001C-EN-P - July 2006

Page 19

19

Click on the three dots icon and a String Browser box appears. Modify the

text to what is desired and click on Apply, then click on OK. This works for

ALL strings throughout the entire data array.

Figure 16 String Browser Box

Modifying Parameter Data for an ArmorStart

The last configuration that will need to be done eventually, is the writing of

a parameter configuration change for an ArmorStart. This is done by first

equating a particular ArmorStart to a device number in the data array.

Again, this device number is determined by the Logix slot of the

communication card, ETherNetIP or CNet address of the communication

adapter and subnet slot of ArmorStart. The optional, Armor_Descriptor

field is extremely handy for doing a functional lookup of the device number.

Once the device number is determined, the parameter number to be

modified, must be obtained. The best way to do this, is to go to the

ArmorStart user manual and get the parameter number of the value to be

modified. The parameter numbers all start with 1 and are numbered

sequentially to the last parameter number. The user manual is important

because it will thoroughly describe each parameter, for example, whether or

not a parameter is writable and what the parameter limits/interpretation are.

Once the device and parameter number is obtained, the next step is to

modify the configuration data for that parameter. The following screen

capture shows the data array and particularly, the parameter 8 for Device 0.

Publication 283A-QS001C-EN-P - July 2006

Page 20

20

Figure 17 Data Array

The value to be modified is the .data element of the structure. For reference,

the Min_value, Max_value, and Name_String for the parameter is also in

the structure, so that the user knows what the minimum and maximum

allowable values are for the data. It is important to realize that the data is in

a raw format. In other words, this data could be considered a Boolean, a bit

mask, an ASCII string, an integer, a byte, etc., depending on the definition

of the parameter in the ArmorStart. Also, there could be an implied decimal

point, scaling, and different units involved. It is important that the user

fully understand and verify the raw data value being modified with the

user manual, so that it is correctly interpreted by the ArmorStart or

undesired operation in the ArmorStart may occur.

Publication 283A-QS001C-EN-P - July 2006

Once the data is written, during a System Wide Write function, the ladder

logic will read it back and put into the .Last_Read_Value of the structure.

This will be a handy visual verification that the data was written correctly.

Page 21

21

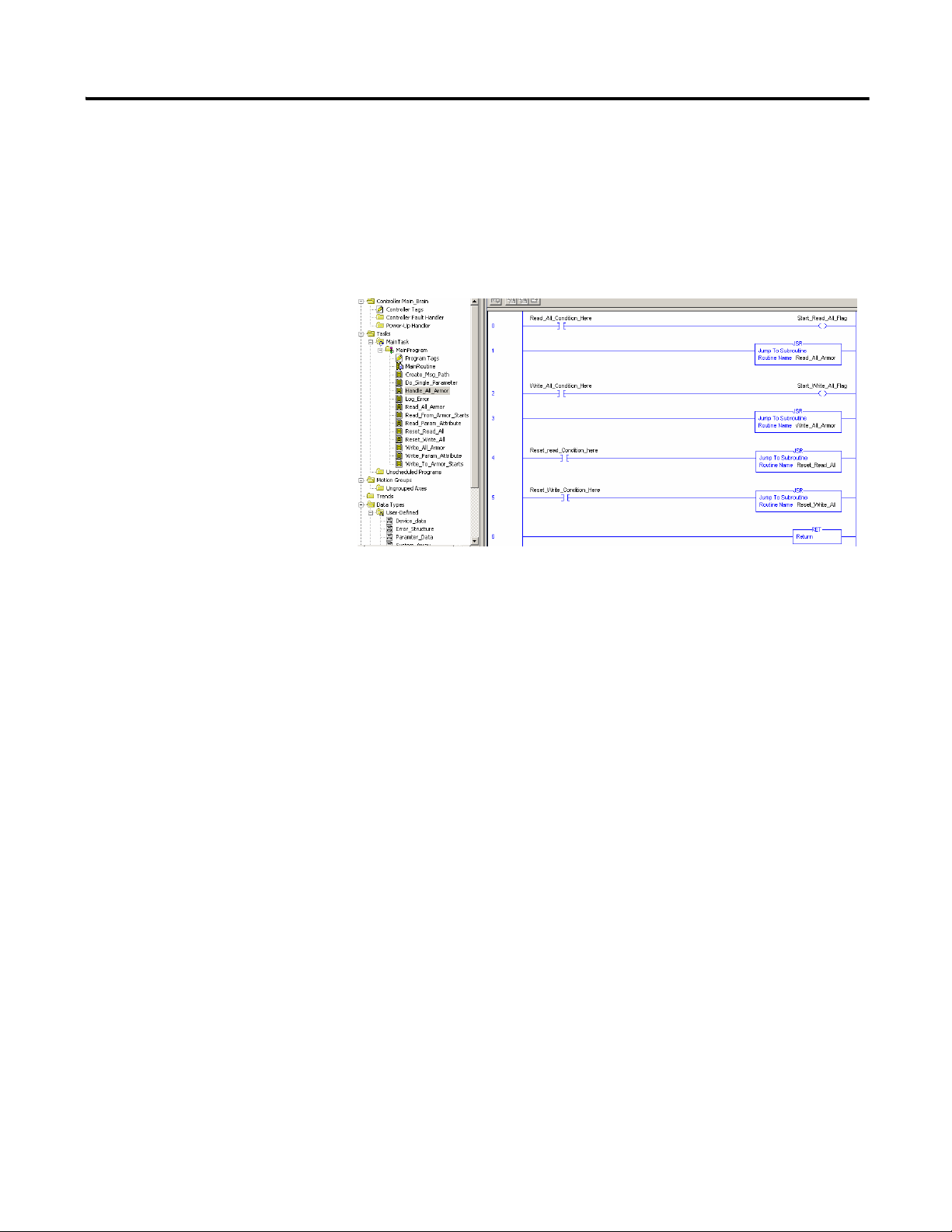

Triggering a System Wide Read

Once the system configuration has been done, a System Wide Read must be

initiated. The logic to trigger both a System Wide Read and Write is

contained in a subroutine called Handle_All_Armor. The rungs are shown

below for reference.

Figure 18 Handle_All_Armor Rungs

To trigger the system wide read, the contact Read_All_Condition_Here

needs to be energized in the ladder logic. This can be done through

additional logic or simply by energizing the bit, on-line, in the

RSLogix™5000 software, Controller Tag monitor screen. The

Read_All_Condition_Here is handled as a one shot inside the logic, but

should be de-energized at a later time. This is so a system wide read is not

triggered after every Logix power cycle or for each transition from Program

to RUN mode. When the read finishes successfully, the

Read_All_System_Done_Flag bit energizes in the logic. However, if an

error occurs during the read, the Read_All_System_Error_Flag bit

energizes and the error will be logged into the structure called

Error_Report.

Triggering a System Wide Write

Once a successful System Wide Read has been initiated and the

Read_All_System_Done_Flag bit is energized, a System Wide Write can

be triggered. To trigger the system wide write, the contact

Write_All_Condition_Here needs to be energized in the ladder logic. This

can be done through additional logic or simply by energizing the bit on-line,

in the RSLogix5000 software, Controller Tag monitor screen. The

Write_All_Condition_Here is handled as a one shot inside the logic, but

should be de-energized at a later time. This is so a System Wide Write is not

triggered after every Logix power cycle or for each transition from Program

to RUN mode. When the write finishes successfully, the

Write_All_System_Done_Flag bit energizes in the logic. If an error occurs

during the write, the Write_All_System_Error_Flag bit energizes and the

error will be logged into the structure called Error_Report.

Publication 283A-QS001C-EN-P - July 2006

Page 22

22

Interpreting the Error Report

If an error occurs during the operation of the ladder logic, either the

Write_All_System_Error_Flag or Read_All_System_Error_Flag bits will

energize depending on which function was being triggered. Information will

be logged inside the data structure Error_Report, that will aid in

troubleshooting the problem. The format of this structure is shown below.

Figure 19 Error Report

The first element of this structure is .Local_Error and will contain a

number corresponding to an error interpretation. The error numbers are

described in the next table.

Table 3 Error Definitions

Error

No.

0 Success. Function completed successfully.

1 Read Number Parameter Error. Num_Devices element in the configuration is either 0 or

greater than the Max_Devices element.

2 Read Message Block Error. The Message block doing the data reads returned back an

error. Look at the Msg_Error and Msg_Ext_Error fields for the errors reported by the

message.

3 Write Data out of Limits. The value of the data to be written is either less than the

Min_value or greater than the Max_value.

4 Write Message Block Error. The Message block doing the data writes returned back an

error. Look at the Msg_Error and Msg_Ext_Error fields for the errors reported by the

message.

5 Write Disallowed. The System Wide Write attempted without a successful System Wide

Read done first.

6 Data Write Error. The data read back after a parameter write, does not match.

7 Number of Parameters Error. The number of parameters read from an ArmorStart is

greater than the Max_Devices element in the structure.

Error Description

Publication 283A-QS001C-EN-P - July 2006

Page 23

23

Quick Reference

Troubleshooting

There are four LEDs on the front of the ArmorStart that can provide an

indication as to the health of the device. The following is a brief explanation

of the operation of each LED.

Table 4 LED Status Indication

LED Definition

Power

Run

Network

Fault

Table 5 Network LED Status Indication

Network Status LED Definition Possible Causes

Off The device has not completed the initialization, is not on an

active network, or may not be powered up.

Flashes green-red-off While waiting to detect the network baud rate, the LED will

flash this pattern about every 3 seconds.

Solid Green The device is operating in a normal condition, and is

communicating to another device on the network.

Flashing Green The ArmorPoint module cannot successfully establish a

connection on the backplane.

Flashing Red The ArmorPoint module has stopped communicating over

the backplane with ArmorStart.

Solid Red Backplane media issue. Check backplane media and ArmorStart backplane cable

Flashing Red and Green The device is in a communication faulted state. Power cycling the device may resolve the problem;

This LED will be illuminated solid green when control power is present and

with the correct polarity.

This LED will be illuminated solid green when a start command and control

power are present.

This bi-color LED is used to indicate the status of the communications

network. See the Network Status LED table below for additional information.

This LED is used to indicate the fault status of the ArmorStart. When the unit is

faulted, the unit will respond with a specific blink pattern to identify the fault.

See the Fault LED table below for additional information.

Check to make sure the product is properly wired and

configured on the network.

If the product stays in this state it means that there is no set

baud rate. Insure that at least one device on the network

has a set baud rate.

No action required.

The wrong connection parameter for the ArmorStart was

entered in the “Module Properties” page in RSLogix5000 or

the I/O Tree was not properly configured.

Check control power connections to the ArmorPoint Module

and ArmorStart.

connections.

however, if the problem continues, it may be necessary to

contact Technical Support.

Publication 283A-QS001C-EN-P - July 2006

Page 24

24

Fault LED indications for

Bulletin 283A ArmorStart

Distributed Motor Controllers

Table 6 Controller Fault LED Definitions

Blink

Pattern

1

2

3

4

5

6

7 I/O Fault This error indicates a blown output fuse.

8 Over Temperature This fault is generated when the operating temperature has been exceeded. This fault cannot be disabled.

9

10 Reserved Not Used

11

12

13

Definitions Possible Causes or Remedies

Short Circuit The motor circuit protector has tripped, or the internal wiring protection algorithm has detected an unsafe

current range. Try to reset the protector if tripped. If the condition continues, check the power wiring. This

fault cannot be disabled.

Overload trip The load has drawn excessive current and based on the trip class selected, the device has tripped. Verify

that the load is operating correctly and the ArmorStart is properly set-up. This fault cannot be disabled.

Phase Loss The ArmorStart has detected a missing phase. Verify that three-phase voltage is present at the line side

connections. This fault can be disabled and is disabled by default.

Shorted SCR Prior to every start, the unit will check all SCRs for shorts and unit load connections to the motor. If there is

a shorted SCR in the SMC-3 and/or open load, the start will be aborted and a shorted SCR/open load fault

will be indicated. This prevents damage from phase imbalance. This fault cannot be disabled.

Phase Rotation When enabled, 3-phase input power will be verified before starting. If input power phasing is detected to

be incorrect, the start will be aborted and a fault indicated. This fault can be disabled and is disabled by

default.

Control Power The ArmorStart has detected a loss of the control power voltage. Check control voltage, wiring, and proper

polarity. Also check and replace the control voltage fuse, if necessary. This fault can be disabled and is

disabled by default.

Phase Imbalance The ArmorStart has detected a voltage imbalance. Check the power system and correct if necessary. This

fault can be disabled and is disabled by default.

Internal Communication This fault occurs when communication between the main board and the SMC-3 is lost. This fault cannot be

disabled.

Heatsink Over

temperature/JAM

EEPROM Fault This is a major fault, which renders the ArmorStart inoperable. Possible causes of this fault are transients

This fault indicates either an over temperature fault or a JAM fault. The heatsink is monitored by

thermistors and the SCR temperature is tracked by an algorithm. When a maximum temperature is reached

by either, the microcomputer switches off the SMC and indicates a fault code of 12. A fault code of 12

could also indicate a JAM fault. This fault cannot be disabled.

induced during EEprom storage routines. If the fault was, initiated by a transient, power cycling should

clear the problem otherwise replacement of the ArmorStart may be required. This fault cannot be disabled.

Hardware Fault This fault indicates that a serious hardware problem exists. Check for a base/starter module mismatch. If

14

16 Miscellaneous Fault This fault cannot be disabled.

Publication 283A-QS001C-EN-P - July 2006

no mismatch exists, the ArmorStart may need to be replaced. (Hdw Flt is the factory-enabled default

setting.) This fault cannot be disabled.

Page 25

Bulletin 283 Parameters

Table 7 Starter Display and Parameter Settings

Parameter Name String Path (hex) Min Max Dflt Type Value

SMC Display

101 Phase A Current 002C – 01 – 08 0 32767 — INT xxx.x Amps

102 Phase B Current 002C – 01 – 09 0 32767 — INT xxx.x Amps

103 Phase C Current 002C – 01 – 0A 0 32767 — INT xxx.x Amps

104 Average Current 002C – 01 – 05 0 32767 — INT xxx.x Amps

105 % Therm Utilized 002C – 01 – 07 0 100 — USINT xxx %

SMC Settings

106 FLA Setting 002C – 01 – 03 See Table 8 below Min I INT xxx.x Amps

107 OL Trip Class 002C – 01 – 04 0 3 1 BYTE 1 = 10

108 OL Reset Level 0029 – 01 – 131 0 100 75 BYTE xxx %

109 Start Time 000F - 06D - 01 1 45 10 USINT sec

110 Start Mode 000F - 06E - 01 0 1 0 BOOL

111 Current Limit 000F - 06 - 01 150 600 350 UINT

112 Initial Torque 000F - 070 - 01 0 90 60 USINT % LRT

113 Soft Stop Time 000F - 071 - 01 0 90 0 USINT sec

114 Kick Start 000F - 072 - 01 0.0 1.5 0.0 USINT sec

115 SCR Temp Reset Mode 000F - 073 - 01 0 1 0 BOOL

116 Phase Rotation 000F - 074 - 01 0 1 0 BOOL

0 = Current Limit

1 = Soft Start

Display multiplier of 10.

SMC is looking for values

between 15 and 60.

0 = Manual

1 = Auto Reset

0 = Disable

25

xxx % FLA

1 = Enable

Table 8 FLA Setting Ranges and Default Values (with indicated setting precision)

FLA Current Range (A)

Minimum Value Maximum Value

1.1 3.0 1.1

3.0 5.5 3.0

5.3 7.6 5.3

6.3 16.0 6.3

Default Value

Publication 283A-QS001C-EN-P - July 2006

Page 26

26

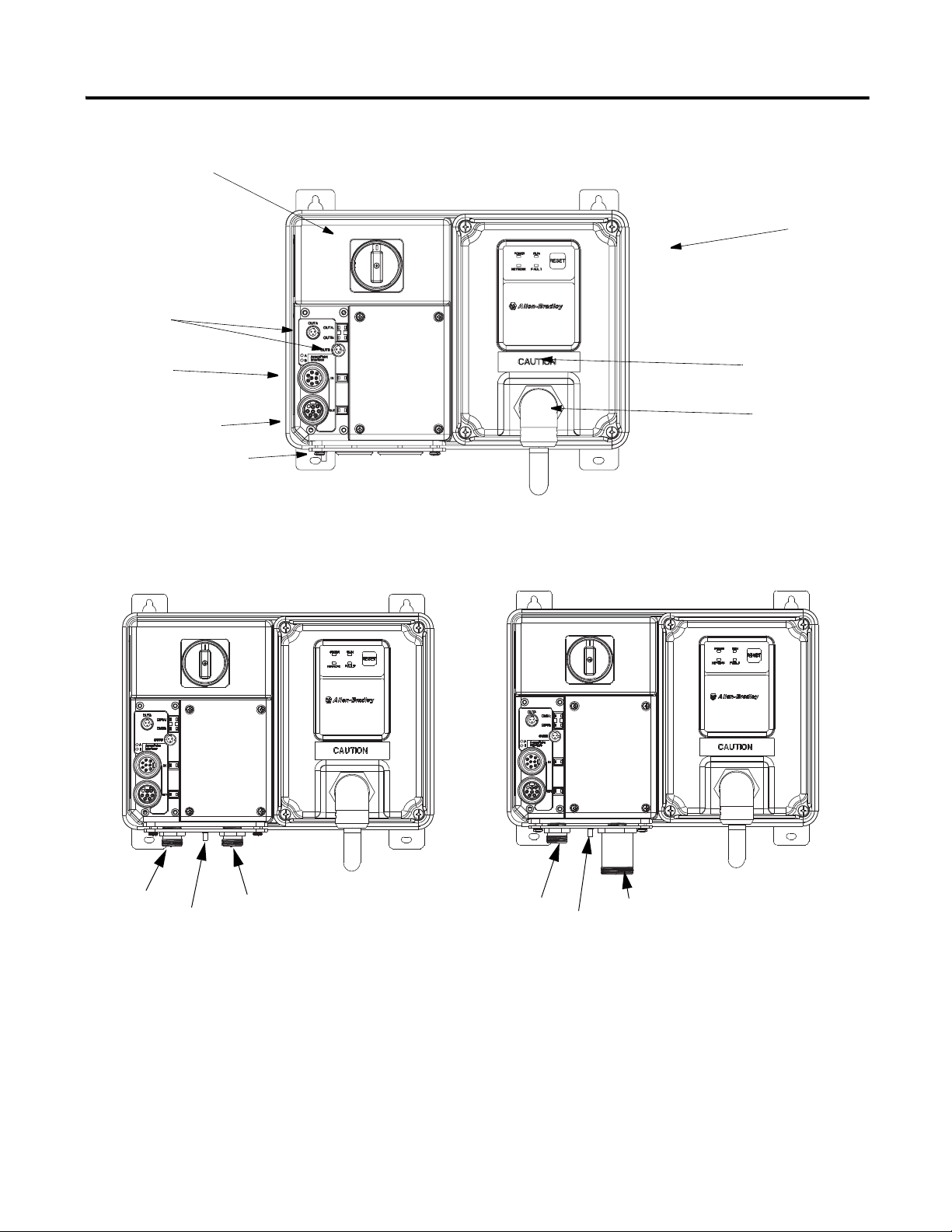

LED Status

Indication

Motor

Connection

ArmorPoint

Local Disconnect

2 Outputs

(Micro/M12)

ArmorPoint

Source Brake

Connector

Interface

(IN)

Interface

(OUT)

Ground Terminal

Control Power

Control Power

Three-Phase Power

Three-Phase Power

Ground Terminal

Ground Terminal

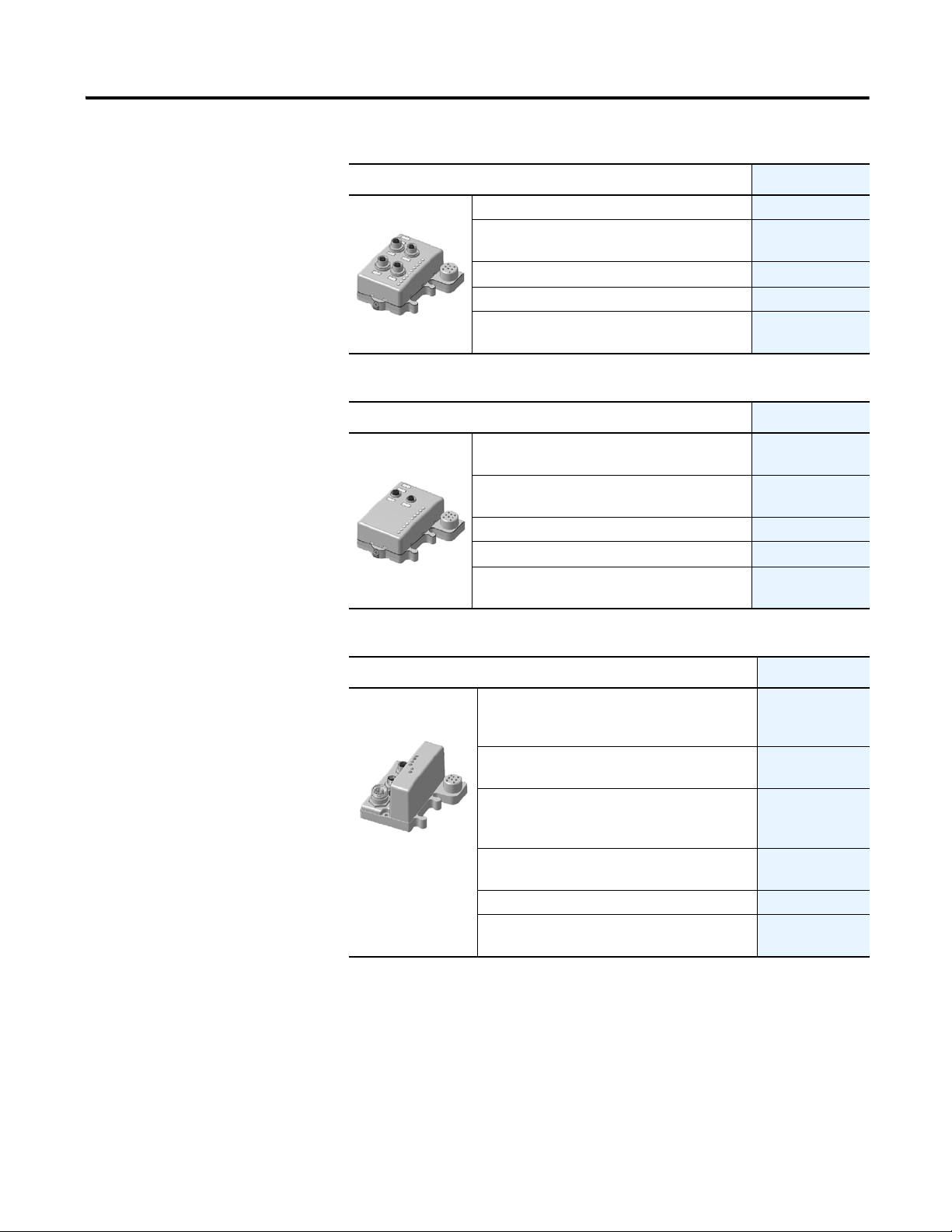

Figure 20 Bulletin 283 ArmorStart

Figure 21 Bulletin 283 ArmorStart with ArmorConnect

Publication 283A-QS001C-EN-P - July 2006

Page 27

27

Table 9 DeviceNet Media

➊

Description Length m (ft) Cat. No.

Sealed

KwikLink pigtail drops are Insulation

Displacement Connector (IDC) with integral Class

1 round cables for interfacing devices or power

supplies to flat cable

1 m (3.3) 1485P-P1E4-B1-N5

2 m (6.5) 1485P-P1E4-B2-N5

3 m (9.8)

1485P-P1E4-B3-N5

6 m (19.8) 1485P-P1E4-B6-N5

DeviceNet Mini- T-Port Tap

Right Keyway

Left Keyway

1485P-P1N5-MN5NF

1485P-P1N5-MN5KM

Connector Cat. No.

Gray PVC Thin Cable

Thick Cable

Mini Straight Female

Mini Straight Male

Mini Straight Female

Mini Right Angle Male

Mini Right Angle Female

Mini Straight Male

Mini Right Angle Female

Mini Straight Male

Mini Straight Female

Mini Straight Male

Mini Straight Female

Mini Right Angle Male

Mini Right Angle Female

Mini Straight Male

Mini Right Angle Female

Mini Straight Male

1485G-P➋N5-M5

1485G-P➋W5-N5

1485G-P➋M5-Z5

1485G-P➋W5-Z5

1485C-P➌N5-M5

1485C-P➌W5-N5

1485C-P➌M5-Z5

1485C-P➌W5-Z5

➊

See publication M116-CA001A-EN-P for complete cable selection information.

➋

Replace symbol with desired length in meters (Example: 1485G-P1N5-M5 for a 1 m cable). Standard cable lengths: 1 m, 2 m, 3 m, 4 m, 5 m, and 6 m.

➌

Replace symbol with desired length in meters (Example: 1485C-P1N5-M5 for a 1 m cable). Standard cable lengths: 1 m, 2 m, 3 m, 4 m, 5 m, 6 m, 8 m, 10 m, 12 m,

18 m, 24 m, and 30 m.

NOTE: Stainless steel versions may be ordered by adding an “S” to the cat. no. (Example: 1485CS-P1N5-M5)

Publication 283A-QS001C-EN-P - July 2006

Page 28

28

DC Micro Patchcord

DC Micro V-Cable

DC Micro Y-Cable

AC Micro Patchcord

Table 10 Sensor Media

Description

0

ArmorStart I/O

Connection

➊

Pin Count Connector Cat. No.

Straight Female

Straight Male

889D-F4ACDM-

➋

Input 5-Pin

Straight Female

0

0

Right Angle Male

Straight Female

889D-F4AACDE-

879D-F4ACDM-

➋

➋

Input 5-pin

0

Right Angle Male

0

Input 5-pin

0

Straight Female

Right Angle Male

879D-R4ACM-

879D-F4ACTE-

➋

➋

Straight Female

Straight Male

Output 3-pin

Straight Female

Right Angle Male

See Publication M116-CA001A-EN-P for complete cable selection information.

➊

Replace symbol with desired length in meters (Example: 889D-F4ACDM-1 for a 1 m cable). Standard cable lengths: 1 m, 2 m, 5 m, and 10 m.

➋

NOTE: Stainless steel versions may be ordered by adding an “S” to the cat. no. (Example: 889DS-F4ACDM-1)

Table 11 Sealing Caps

➌

Description Used on I/O Connection Catalog Number

Plastic Sealing Cap (M12) Input

Aluminum Sealing Cap Output

➌

To achieve IP67 rating, sealing caps must be installed on all unused I/O connections.

Table 12 ArmorPoint Media

Description Length m (ft) Cat. No.

0

ArmorPoint Bus Extension Cable including

Terminating Resistor

Extension Cable to connect two ArmorStart

Distributed Motor Controllers to ArmorPoint

communication protocol

1 (3.3)

1 (3.3)

889R-F3AERM-

899R-F3AERE-

1485A-M12

889A-RMCAP

280A-EXT1

280A-EXTCABLE

➋

➋

Publication 283A-QS001C-EN-P - July 2006

Page 29

Bulletin 1738 ArmorPoint Distributed I/O Products

Table 13 Digital I/O Products

Description Cat. No.

0

Table 14 Digital Input Products

24V DC 8 Source Output w/ 8 M12 connectors 1738-OB8EM12

24V DC 8 Source Output w/ 8 M8 connectors 1738-OB8EM8

24V DC 4 Source Output w/ 4 M12 connectors 1738-OB4EM12

24V DC 4 Source Output w/ 4 M8 connectors

24V DC 2 Source Output w/ 2 M12 connectors 1738-OB2EM12

24V DC 2 Source Output - 2 A Prot. w/ 2 M12

connectors

24V DC 4 Sink Output w/ 4 M12 connectors

29

1738-OB4EM8

1738-OB2EPM12

1738-OV4EM12

0

Table 15 Analog Products

0

24V DC Analog Current Input w/ 2 M12 connectors 1738-IE2CM12

24V DC Analog Voltage Input w/ 2 M12 connectors

24V DC Analog Current Output w/ 2 M12 connectors

24V DC Analog Voltage Output w/ 2 M12 connectors

Description

24V DC 8 Sink Input w/ 4 M12 connectors,

2 points per connector

24V DC 8 Sink Input w/ 8 M8 connectors

24V DC 8 Sink Input w/ 1 M23 connector

Cat. No.

1738-IB8M12

1738-IB8M8

1738-IB8M23

24V DC 4 Sink Input w/ 4 M12 connectors 1738-IB4M12

24V DC 4 Sink Input w/ 4 M8 connectors 1738-IB4M8

24V DC 2 Sink Input w/ 2 M12 connectors

1738-IB2M12

24V DC 4 Source Input w/ 4 M12 connectors 1738-IV4M12

Description

Cat. No.

1738-IE2VM12

1738-OE2CM12

1738-OE2VM12

24V DC 2 Thermocouple Input

24V DC 2 RTD Input

1738-IT2IM12

1738-IR2M12

Table 16 Power Supply Products

Description

0

POINT I/O Field Potential Distributor Module 1738-FPD

24V DC Expansion Power Supply

Cat. No.

1738-EP24DC

Publication 283A-QS001C-EN-P - July 2006

Page 30

30

Table 17 AC and Relay Products

Description Cat. No.

0

24V DC Coil N.O. DPST Relay w/ 2 M12 connectors 1738-OW4M12

24V DC Coil N.O. DPST Relay w/ 2 AC M12

120V AC 2 Input w/ 2 AC 4 pin M12 connectors

120V AC 2 Input w/ 2 AC 3 pin M12 connectors

120/230V AC 2 Output w/ 2 AC 3 pin M12

Table 18 Specialty Products

connectors

connectors

1738-OW4M12AC4

1738-IA2M12AC4

1738-IA2M12AC3

1738-OA2M12AC3

0

ArmorPoint I/O RS-232 ASCII Serial Interface

ArmorPoint I/O RS-485 ASCII Serial Interface

ArmorPoint Synchronous Serial Interface Module

Table 19 Adapter Products

0

ArmorPoint DeviceNet Adapter Module, Drop or

ArmorPoint DeviceNet Adapter Module, Drop only,

ArmorPoint DeviceNet Adapter Module, Drop or

ArmorPoint DeviceNet 24V DC Adapter Module with

ArmorPoint Redundant ControlNet Adapter Module

ArmorPoint Ethernet/IP 10/100 Mbps Adapter

Description

Module

Module

24V DC Very High Speed Counter Module

Cat. No.

1738-232ASCM12

1738-485ASCM12

1738-VHSC24M23

ArmorPoint 5V Encoder/Counter Module 1738-IJM23

with Absolute Encoder

1738-SSIM23

Description Cat. No.

Pass-through, with male and female M12

1738-ADN12

connectors

with male M18 connector

Pass-through, with male and female M18

1738-ADN18

1738-ADN18P

connectors

subnet expansion

1738-ADNX

1738-ACNR

Module

1738-AENT

Publication 283A-QS001C-EN-P - July 2006

Page 31

Notes:

31

Publication 283A-QS001C-EN-P - July 2006

Page 32

Registered Trademark List

ArmorPoint and ArmorStart are registered trademarks of Rockwell Automation, Inc.

Tr ademark List

ArmorConnect, RSLogix5000, PLC, RSNetWorx, and SLC are trademarks of Rockwell Automation, Inc. ControlNet is a trademark of ControlNet

International, LTD. DeviceNet and the DeviceNet logo are trademarks of the Open Device Vendors Association (ODVA).

Publication 283A-QS001C-EN-P — July 2006 41053-384-06

Superecedes Publication 283A-QS001B-EN-P — September 2005 Copyright ©2006 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.

Loading...

Loading...