Page 1

ALLEN-BRADLEY

Bulletin 2755 Industrial Medium and

High-Spped Bar Code Scanners

(Catalog Numbers 2755-L7SA, -L7RA, -L7SB, -L7RB,

-L7SC, -L7SD, -L7RD, -L9SA, -L9RA, -L9SB, -L9RB,

-L9SD, -L9RD)

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. “Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls” (Publication SGI-1.1)

describes some important differences between solid state equipment and

hard–wired electromechanical devices. Because of this difference, and also

because of the wide variety of uses for solid state equipment, all persons

responsible for applying this equipment must satisfy themselves that each

intended application of this equipment is acceptable.

In no event will the Allen-Bradley Company be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, the Allen-Bradley Company cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Allen-Bradley Company with respect to use

of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of the Allen-Bradley Company is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage, or economic loss.

Attentions help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is especially important for successful

application and understanding of the product.

PLC is a registered trademark of Allen-Bradley Company, Inc.

Pyramid Integrator, DTL and CVIM are trademarks of Allen-Bradley Company, Inc.

MicroVAX, VAX and DECnet are registered trademarks of Digital Equipment Corporation.

VAXstation, VAXcluster and DECwindows are trademarks of Digital Equipment Corporation.

Page 3

Table of Contents

A–B

Using This Chapter

Product Descriptions

Installation Considerations

Chapter 1

Chapter Objectives 1–1

Overview of This Manual 1–1

Intended Audience 1–2

Warnings and Cautions 1–2

Danger and Caution Labels 1–3

Chapter 2

Chapter Objectives 2–1

Overview 2–1

L7 Reading Ranges 2–2

L9 Reading Ranges 2–3

Features 2–4

Cabling 2–5

Accessories 2–6

Chapter 3

Installation

Chapter Objectives 3–1

How the Scan Head Operates 3–1

Positioning the Symbols Correctly 3–2

Usable Beam Length 3–5

Compensating for Pitched Symbols 3–6

Minimum Bar Width Adjustment 3–6

Code Element Distance 3–8

Chapter 4

Chapter Objectives 4–1

Warnings and Cautions 4–1

Before You Start 4–1

Tools You Will Need 4–1

Determining the Space Requirements 4–2

Mounting the Scan Head 4–2

Vibration Cautions 4–3

How to Install Swivel Mounting Base 4–3

Using the Flat Mounting Plate 4–4

Connecting Your Equipment 4–5

Installing the Package Detector Assembly 4–6

i

Page 4

Table of Contents

Operation

Maintenance and

Troubleshooting

Specifications

Chapter 5

Chapter Objectives 5–1

Warnings and Cautions 5–1

Laser On/Off Control 5–1

Scan Width Adjustment 5–2

Scan Width Adjustment Procedure 5–2

Raster Height Adjustment 5–3

Raster Height Adjustment Procedure 5–4

Chapter 6

Chapter Objectives 6–1

Maintaining the Equipment 6–1

Scan Window Removal 6–1

Cleaning the Glass Window 6–2

Cleaning the Plastic Window 6–3

Troubleshooting the System 6–4

Chapter 7

Scan Head 7–1

Glossary G–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index I–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

Page 5

Chapter

Chapter Objectives

Overview Of This Manual

A–B

1

Using This Manual

Read this chapter to familiarize yourself with the rest of the manual. You will learn

about:

• Contents of the manual.

• Intended audience.

• Warnings and cautions.

This manual is for Catalog Nos. 2755–L7SA, –L7SB, –L7SC, –L7SD,

–L7RA, –L7RB, –L7RC, –L7RD Industrial Medium–Speed Bar Code

Scanners and Catalog Nos. 2755–L9SA, –L9SB, –L9SD, –L9RA, –L9RB,

and –L9RD Industrial High–Speed Bar Code Scanners.

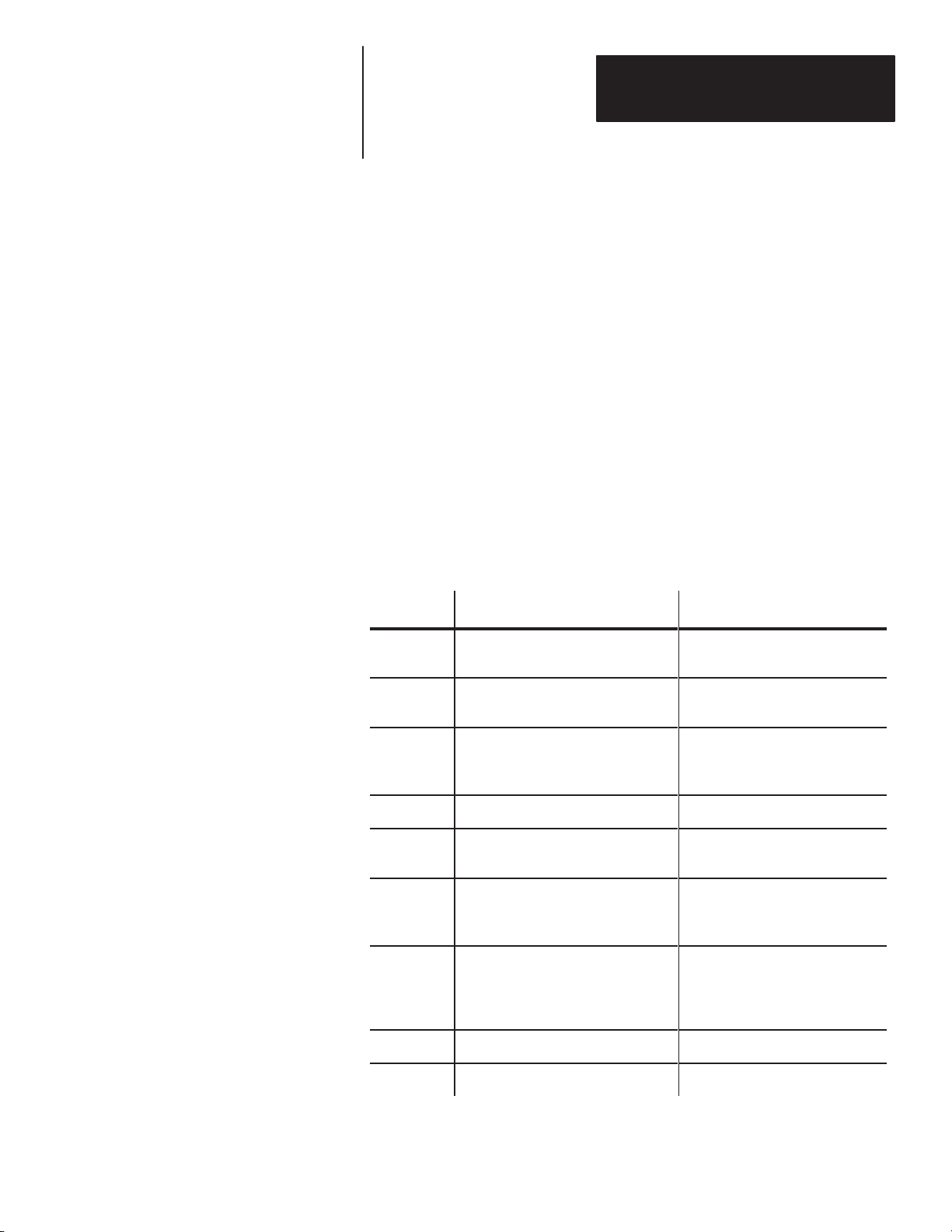

Chapter Title Purpose

1 Using This Manual

2 Product Description

3 Installation Considerations

4 Installation Installation procedures.

5 Operation

6

7 Specifications

- Glossary

Maintenance and

Troubleshooting

Provides an overview of the

manual.

Features and capabilities

are described.

Things you should know

and understand before

installing your scanner.

Operating procedures and

beam adjustments.

Maintenance and

Troubleshooting guidelines

are provided.

Electrical, mechanical,

environmental and

operational information is

listed.

- Index

1–1

Page 6

Chapter 1

Using this Manual

Intended Audience

Warnings And Cautions

No special knowledge is needed to read this manual and follow its directions.

If the system will be used to communicate with a higher level controller, we

assume you are familiar with communication terminology.

Both warnings and cautions are found in this manual and on the equipment.

The following symbols are used:

CAUTION: This laser caution symbol appears where

laser radiation is present.

WARNING: A warning symbol means people might

be injured if the procedures are not followed.

Danger and Caution Labels

CAUTION: A caution symbol is used when

machinery could be damaged if the procedures are not

followed.

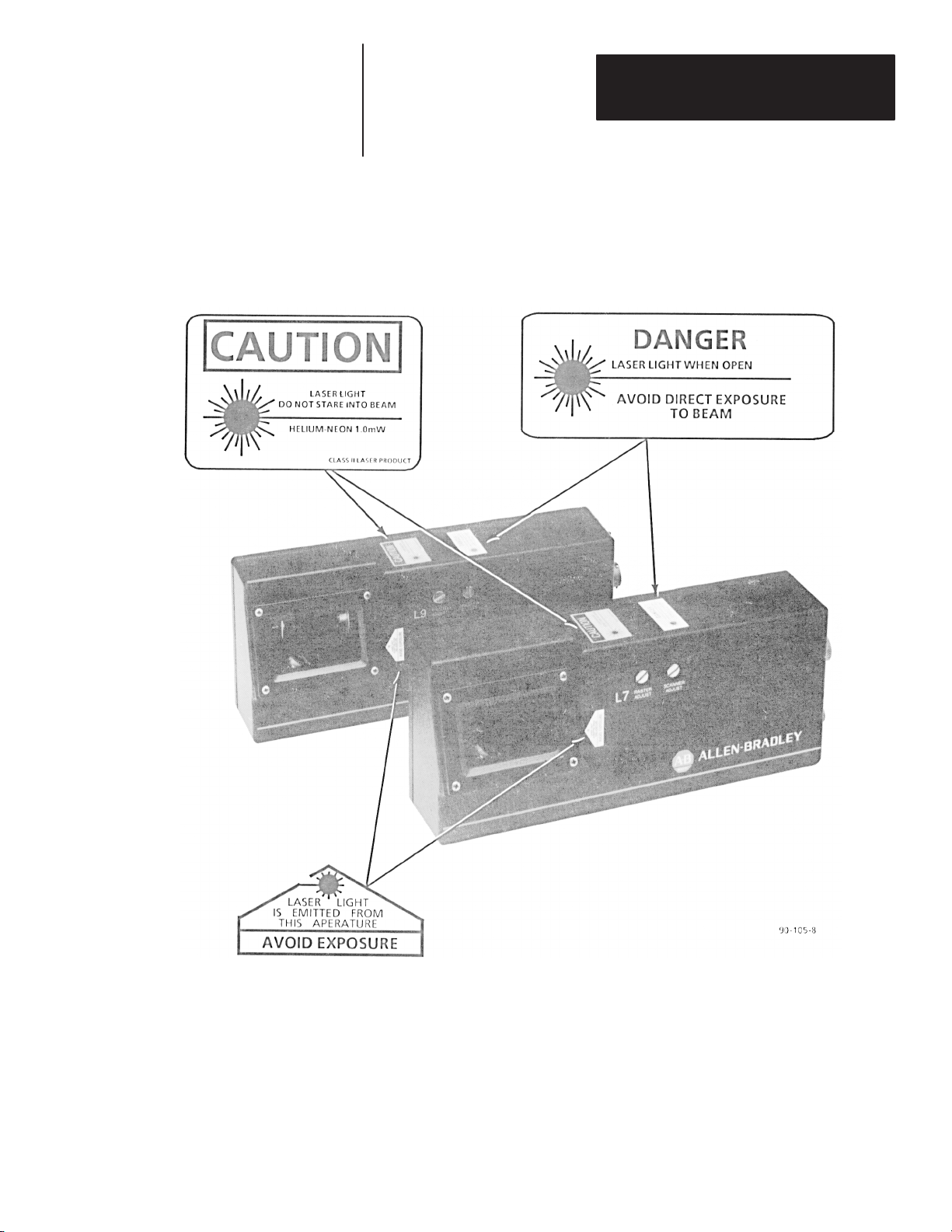

The scan head is labeled in accordance with federal regulations. If any label

is removed, lost, or becomes illegible, order a replacement from your

Allen–Bradley representative. Figure 1.1 shows location of the labels on the

scan head.

WARNING: No user maintenance of the scan head is required.

Do not open the enclosure!

!

WARNING: Improperly controlling, adjusting, or operating the

scan head can result in hazardous radiation exposure.

1–2

Page 7

Chapter 1

Using this Manual

Figure 1.1

Location of Warning and Caution Labels on the Scan Head

1–3

Page 8

Chapter

Chapter Objectives

Overview

A–B

2

Product Description

The capabilities of the scan head are described when connected to a Catalog

No. 2755–DM9 Decoder.

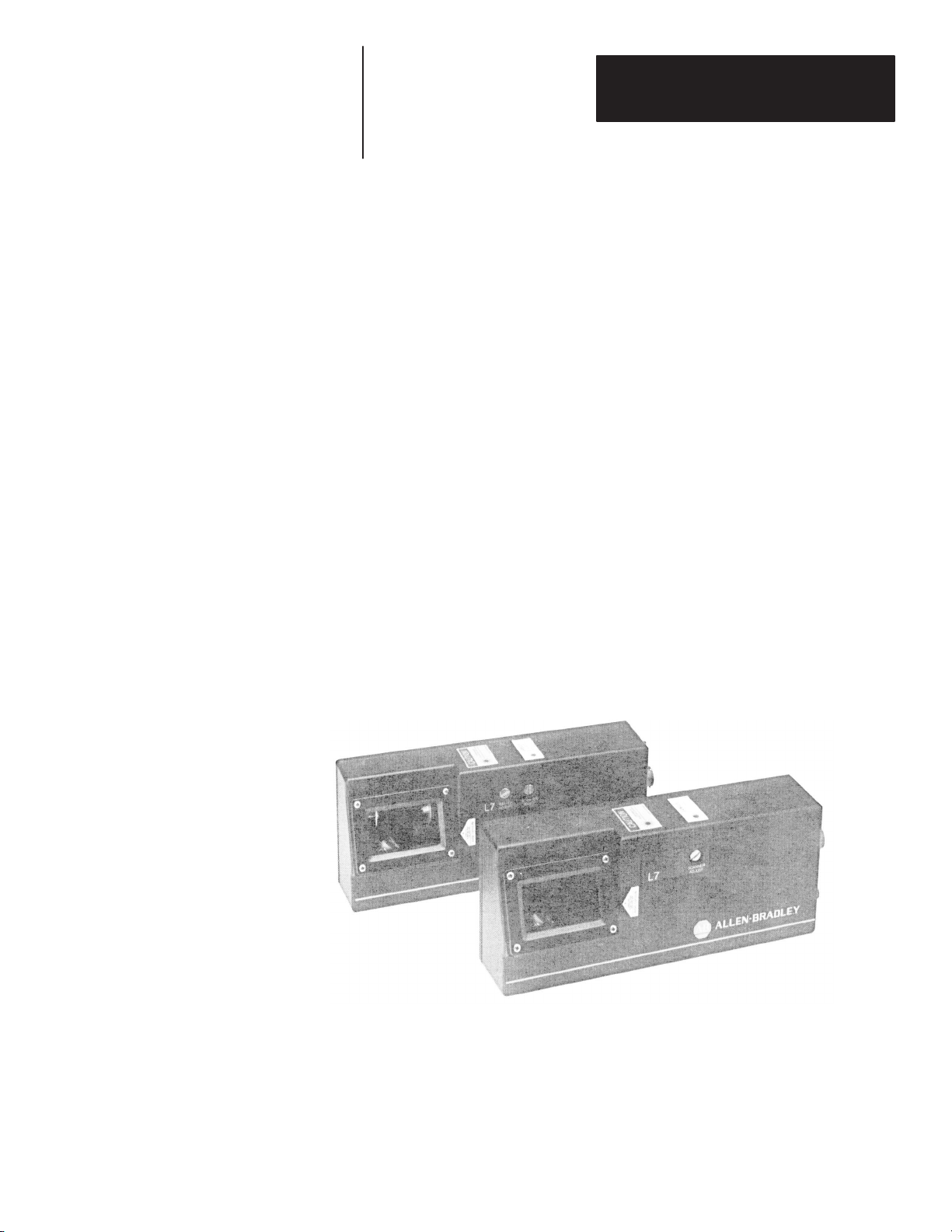

The Industrial Medium and High Speed Bar Code Scanners are moving

beam, bar code scan heads designed for use with the Catalog No. 2755–DM9

Decoder. The scanners are available as shown:

• Side scanning (Catalog No. 2755–L7Sx①, –L9Sx①)

• Side Raster scanning (Catalog No. 2755–L7Rx①, –L9Rx①)

① The x stands for the different range selections of each scanner. Refer to Figures 2.2 and 2.3.

Scanning is bidirectional at approximately 350 scans per second with an L7,

Industrial Medium–Speed Bar Code Scanner and 800 scans per second with

an L9, Industrial High–Speed Bar Code Scanner. Depending on the scanner

used, symbols can be scanned as near as 3.5 inches (8.9 cm) and as far as 50

inches (127 cm) away.

Figure 2.1

Side Scanning and Raster Scanning

90–105–9

The side scanning model reflects the scanning beam out of the side of the

NEMA 4 case.

The raster scanning model uses a stepping raster motor to project what

appears to be a number of parallel beams out the side of the unit. This type

of scan head is useful when attempting to scan poor quality labels, or labels

that may not always be in exactly the same place.

2–1

Page 9

Chapter 2

Product Description

L7 Reading Ranges

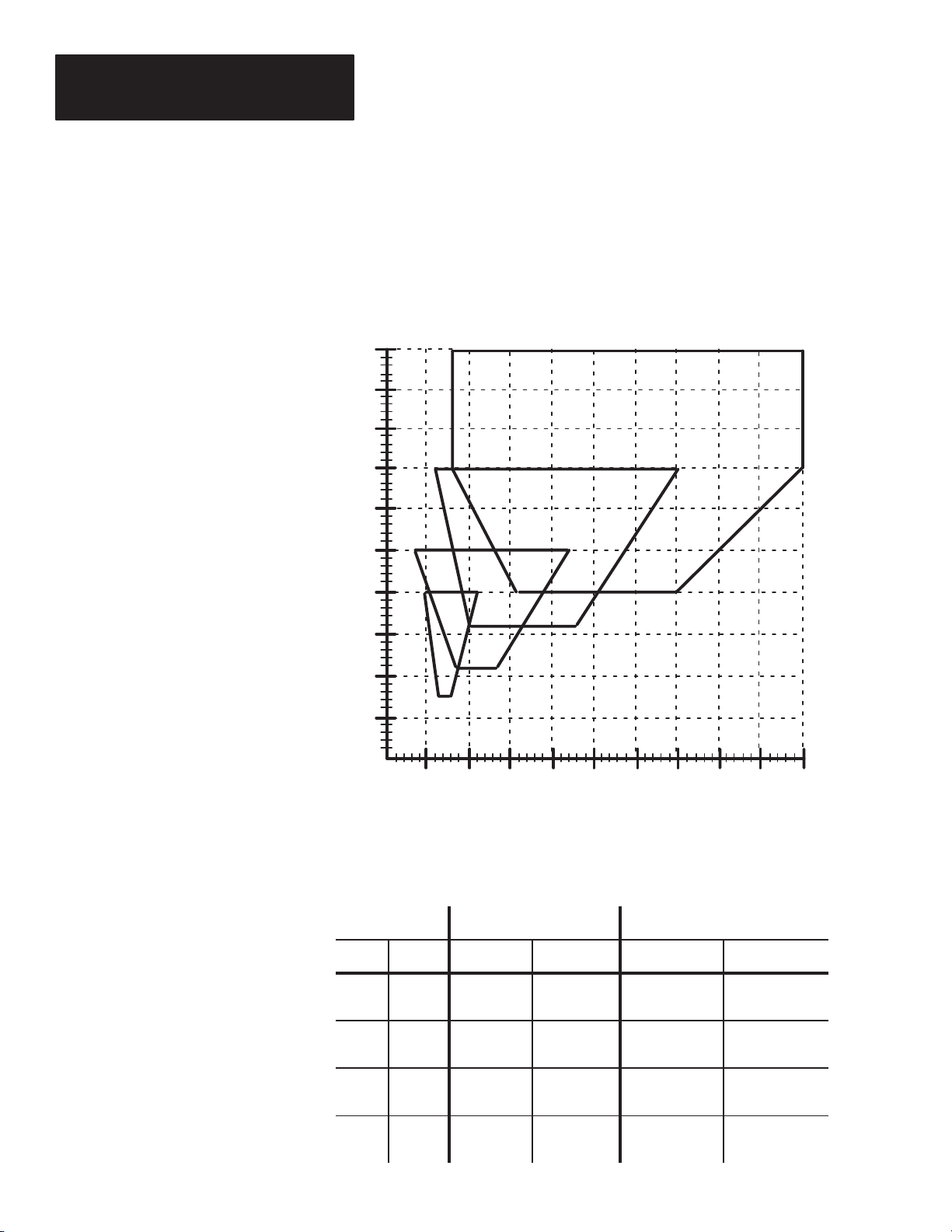

Figure 2.2 illustrates the average reading ranges, relative to the symbol’s

minimum bar width, that you should expect when using an L7 scanner with

your Catalog No. 2755–DM9 Decoder.

Figure 2.2

Average Scan Range vs. Minimum Bar Width for L7 Scanner

Minimum Bar Width

Mils

Millimeters

50

1.27

45

1.14

40

1.02

35

.89

30

.76

25

.64

20

.51

15

.38

10

.25

5

.13

2755–L7SC

2755–L7RC

2755–L7SD

2755–L7RD

2755–L7SB

2755–L7RB

2755–L7SA

2755–L7RA

2–2

Inches

Centimeters

12.7

① Scan Range will vary with symbol quality, pitch and skew. This application was based on no more than 5 ° pitch and 30° skew, with full scan beam

(Figure 5.3). Refer to Chapter 3, Installation Considerations when reading labels with more than 20° pitch.

10

5

38.1

25.4

Scan Range (from face of scanner)

15

20

50.8

63.5

25

30

76.2

88.9

35

①

40

101.6

114.3

45

50

127.0

The following table compares the minimum bar width to the scan range of

each catalog number.

Minimum Bar

Width

Mils mm Inches Centimeters Side Scanning

7.5

10

20

11

20

25

16

25

35

20

35

50

① When using ‘‘A’’ range scanners to read labels with high paper noise, increasing the skew to 25 will enhance performance.

.19

.25

.51

.28

.51

.64

.41

.64

.89

.51

.89

1.27

Scan Range

6.5 – 8.5

6.0 – 9.0

5.0 – 11.0

8.5 – 13.5

5.5 – 19.0

3.5 – 22.0

10 – 23

8 – 29

6 – 35

16 – 35

8 – 50

8 – 50

① Catalog Number

16.5 – 21.6

15.2 – 22.9

12.7 – 27.9

21.6 – 34.3

14.0 – 48.3

8.9 – 55.9

25.4 – 58.4

20.3 – 73.7

15.2 – 88.9

40.6 – 88.9

20.3 – 127

20.3 – 127

2755–L7SA① 2755–L7RA①

2755–L7SB 2755–L7RB

2755–L7SD 2755–L7RD

2755–L7SC 2755–L7RC

Raster

Scanning

Page 10

Chapter 2

Product Description

L9 Reading Ranges

Figure 2.3 illustrates the average reading ranges, relative to the symbol’s

minimum bar width, that you should expect when using an L9 scanner with

your Catalog No. 2755–DM9 Decoder.

Figure 2.3

Average Scan Range vs. Minimum Bar Width for L9 Scanner

35

.89

30

.76

25

.64

20

.51

15

.38

10

.25

5

.13

2755–L9SD

2755–L9RD

2755–L9SB

2755–L9RB

2755–L9SA

2755–L9RA

Minimum Bar Width

Mils

Millimeters

Inches

Centimeters

① Scan Range will vary with symbol quality, pitch and skew. This application was based on no

more than 5°pitch and 30° skew, with full scan beam (Figure 5.3). Refer to Chapter 3, Installation

Considerations when reading labels with more than 20° pitch.

5

12.7

10

25.4

Scan Range (from face of scanner)

15

38.1

20

50.82563.53076.23588.9

①

The following compares the minimum bar width to the scan range of each

catalog number.

Minimum Bar Width Scan Range② Catalog Number

Mils mm Inches Centimeters

7.5

10

20

11

20

25

16

25

35

② Scan range will vary with symbol quality. This application was based on no more than 5° pitch and 30° skew with

full scan beam (Figure 5.3). Refer to Chapter 3, Installation Considerations when reading labels with more than 20°

pitch.

③ Scan range may be reduced when using low contrast labels.

.19

.25

.51

.28

.51

.64

.41

.64

.89

6.5 – 8.5

6.0 – 9.0

5.0 – 11.0

10 – 13.5

9 – 16

8.5 – 18

10.5 – 21.5

9.0 – 25.5

7.5 – 30③

16.5 – 21.6

15.2 – 22.9

12.7 – 27.9

25.4 – 34.3

22.9 – 40.6

21.6 – 45.7

26.7 – 54.6

22.9 – 64.8

19.1 – 76.2③

Side

Scanning

2755–L9SA① 2755–L9RA①

2755–L9SB 2755–L9RB

2755–L9SD 2755–L9RD

Raster

Scanning

2–3

Page 11

Chapter 2

Product Description

Features

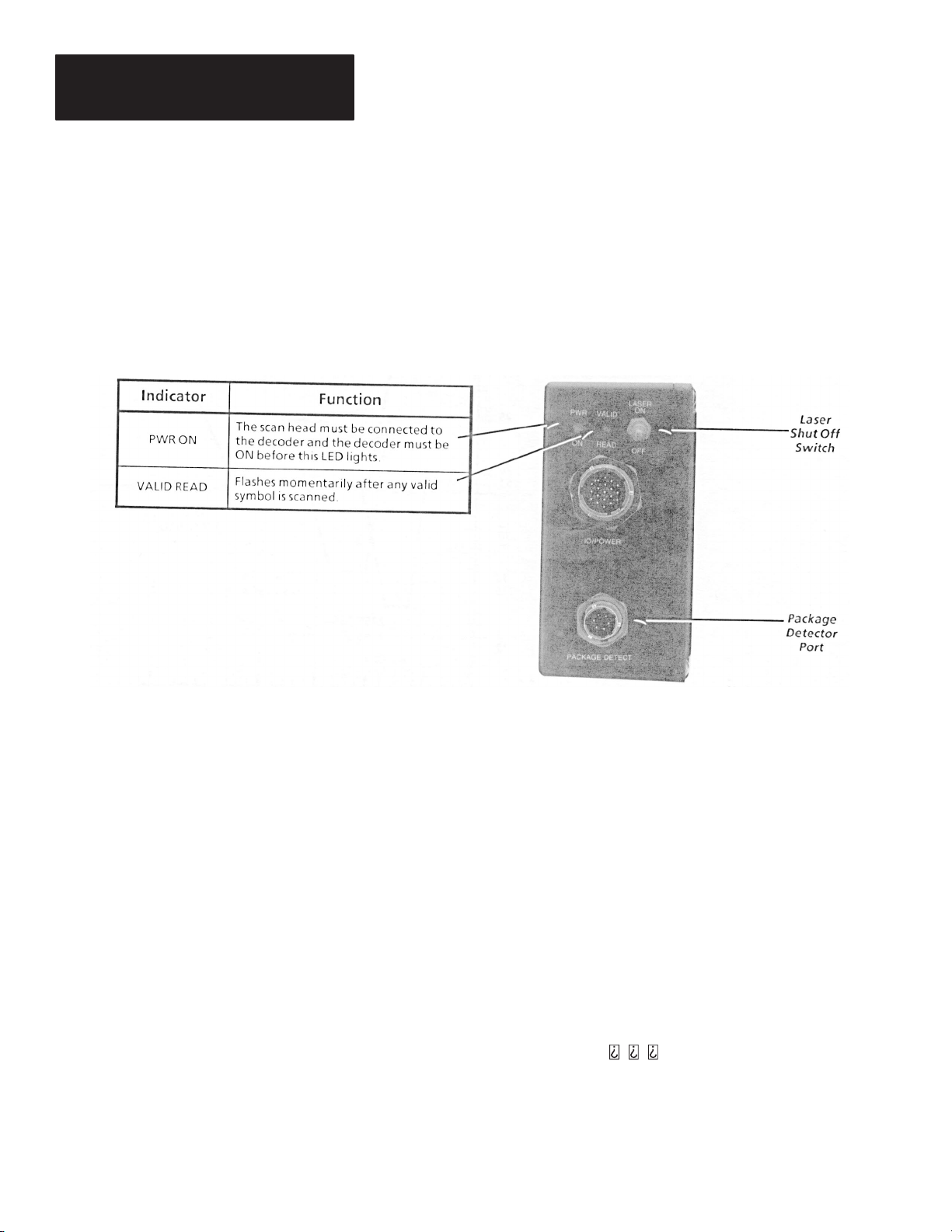

Laser Shut Off – Use this switch to enable/disable the laser beam without

interrupting power. The upward position (ON) enables the laser, the

downward position (OFF) disables the laser beam. The use of this feature is

covered in Chapter 5, Operation.

LED indicators – There are two LEDs on the back of the scan head, Power

On and Valid Read. They are defined in Figure 2.4.

Figure 2.4

Scan Head Features

2–4

NEMA 4 Case – Both the L7 and L9 scan heads are housed in gasketed,

NEMA 4, aluminum cases.

Replaceable Scan Windows – You can easily remove and replace the scan

windows. Both the L7 and L9 scan heads are shipped with coated, optical

quality, glass windows. Coated, low loss, optical quality, plastic windows

are also available for special applications, or when required by FDA

regulations. The use of this feature is covered in Chapter 6, Maintenance

and Troubleshooting.

Package Detector Port – Connect the optional Package Detector Assembly

(Catalog No. 2755–NP3, or NP5) to this port to allow the scan head to be

turned on only when there is a package present.

The use of this feature is

covered in Chapter 4, Installation.

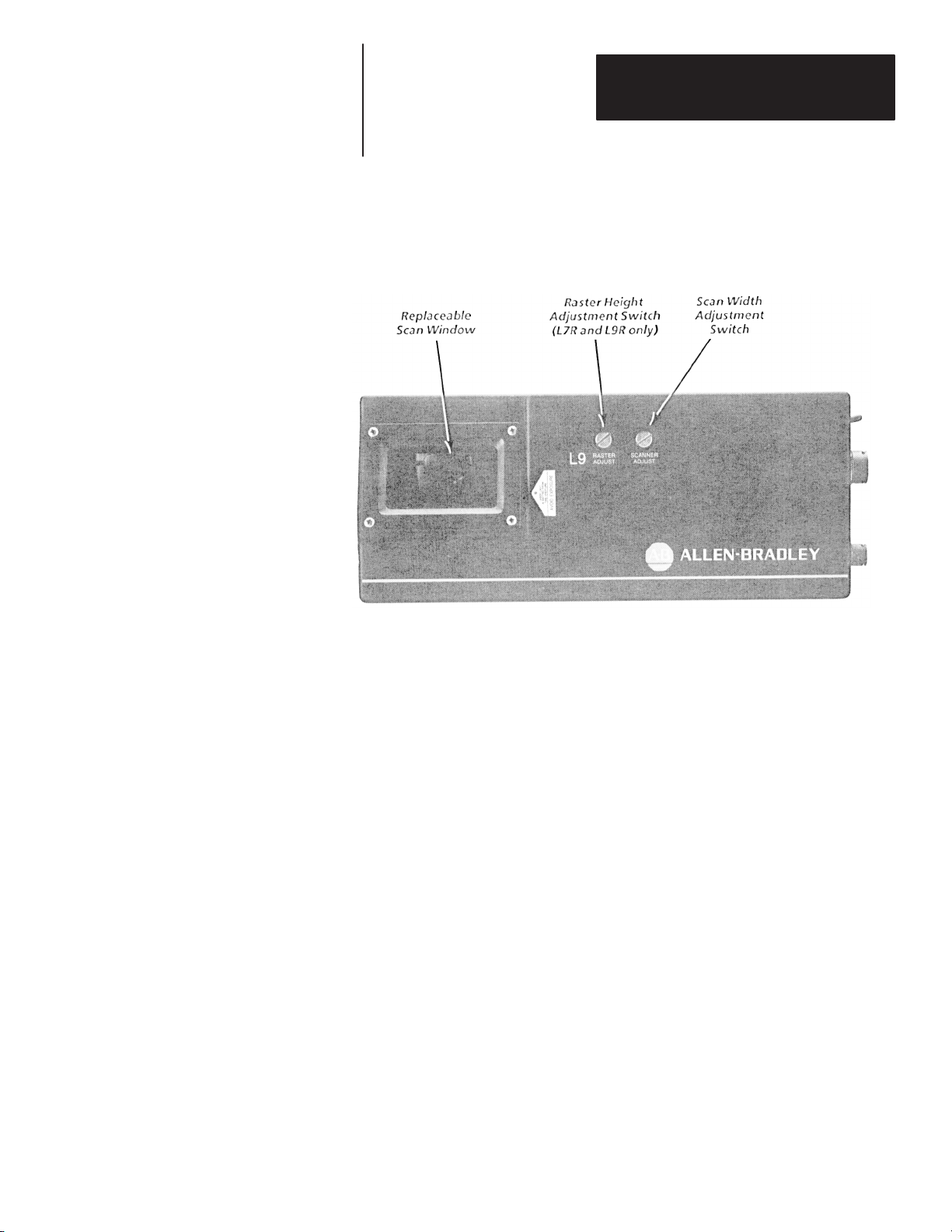

Scan Width Adjustment – This four position switch is located behind a

gasketed 1/4–20 screw. Rotate this switch, using the supplied tool, to set the

scan width to one of four settings: full,

, , .

Examples of this feature are

covered in Chapter 5, Operation.

Raster Height Adjustment – This four position switch is located behind a

gasketed 1/4–20 screw. Rotate this four position switch to increase/decrease

the height of your raster scanning pattern (on L7R and L9R only). Examples

of this feature are covered in Chapter 5, Operation.

Page 12

Figure 2.5

Scan Head Features

Chapter 2

Product Description

Cabling

Accessories

Scanner to Decoder cables are sold separately. Refer to Table 2.C for

information necessary to order the proper cable.

Several accessories are available to provide installation and operational

flexibility, including:

• Package Detector Assembly – This assembly consists of a Package

Detector Switch and a reflector. This switch indicates to the decoder that

a package is present.

• Mounting hardware – A swivel ball mounting base is available for use

with a flat mounting plate or “T” Mounting plate.

• Replaceable Windows – Replaceable, optical quality, glass and plastic

windows are available.

2–5

Page 13

Chapter 2

Product Description

The following table lists system accessories.

Catalog

Number

2755–NP3

2755–NP5

2755–NC9

Long Range Package

Detector Assembly

Short Range Package

Detector Assembly

Package Detector Port

Connector

2755–NM1 Swivel Mounting Base

Item Description

An infrared photoelectric switch and reflector. For the

detection of packages up to a maximum of 18 feet

(5.5 m) away.

A visible red photoelectric switch and reflector. For the

detection of packages up to a maximum 10 feet (3 m) away.

Connects user–supplied photoelectric switch to scan head.

Accepts cables with .190 to .312 inches

(4.8 to 7.9 mm) outer jacket diameter.

Universal swivel ball mount for greater installation flexibility.

Must be used with “T” Mounting Plate or Flat Mounting Plate.

2755–NM2 “T” Mounting Plate

Mounts Swivel Mounting Base (Catalog No. 2755–NM1) to

scan head.

Attach this plate to scan head in order to use your own

2755–NM3 Flat Mounting Plate

brackets, or to use the Swivel Mounting Base (Catalog No.

2755–NM1) when you want the swivel ball close to the base

of the scan head.

2755–CL10 10 foot (3 meter) Cable Connects scanner to Catalog No. 2755–DM9 Decoder.

2755–CL25 25 foot (7.6 meter) Cable Connects scanner to Catalog No. 2755–DM9 Decoder.

W77121–800–01①

W77121–800–02①

W77121–802–01①

W77121–802–02①

① Replacement part number.

2–6

Replacement Glass

Window Kit

Replacement Plastic

Window Kit

Caution & Warning Label

Kit (English Only)

Caution & Warning Label

Kit (Alternate Language)

Anti–reflective, optical glass replacement window.

Hard coated, anti–reflective, optical quality, plastic

replacement window.

2755–L7, L9 - 5 sets per package.

2755–L7, L9 - 1 set each in German, French, Italian,

Spanish.

Page 14

Chapter

Chapter Objectives

How thw Scan Head Operates

A–B

3

Installation Considerations

The operation of the scan head is briefly described. In addition, the

importance of proper symbol positioning and the effect pitch has upon a

symbol is also discussed.

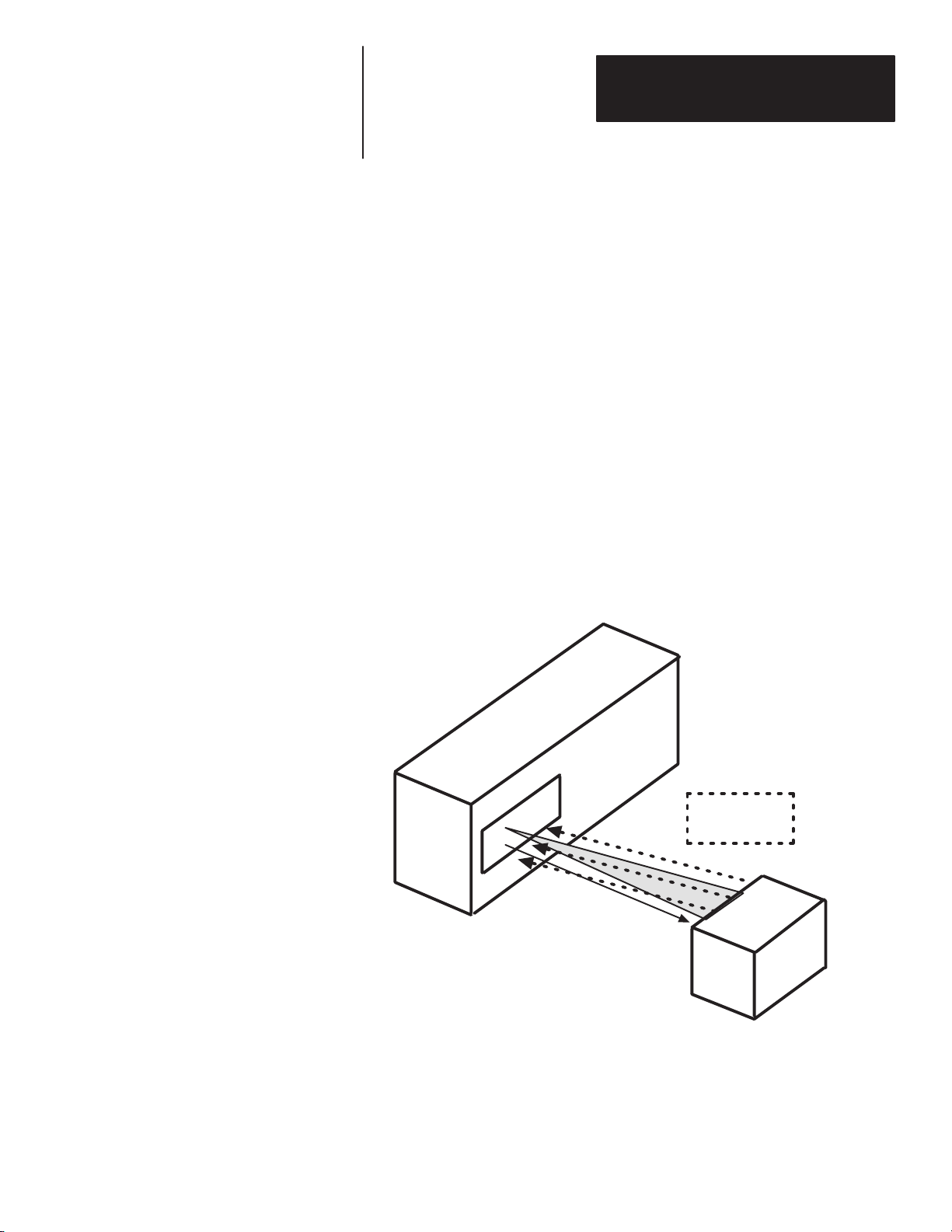

Inside the scan head is the laser, the lens and mirror system and the

electronics. The laser generates a small, concentrated light beam that is

focused and projected through a window. This light is reflected by a symbol

and returned to the scan head for processing. The signal is then sent to the

decoder for further processing. Refer to Figure 3.1.

Figure 3.1

How the Scan Head Operates

T o Label

Reflected light

from symbol

(Diffuse Return)

3–1

Page 15

Chapter 3

Installation Considerations

Positioning the Symbols Correctly

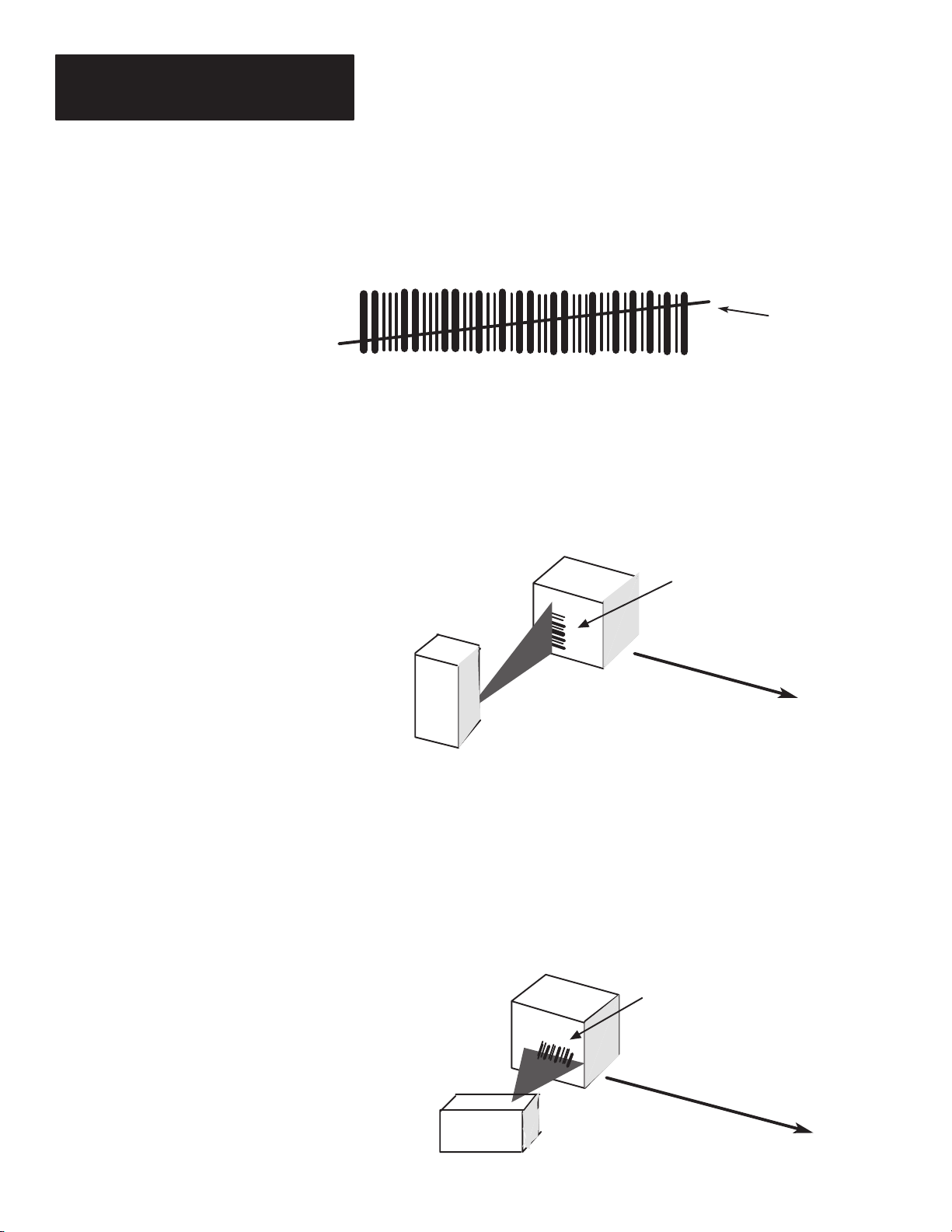

As the symbols move past the scan head, they must be correctly oriented.

The laser’s line of light must cut through all the bars and spaces in one

sweep.

Laser’s line of light

cuts through the

entire symbol

For example, if the scan head is mounted so the laser beam is in the vertical

direction, then the symbol must also be mounted vertically, commonly

known as the step ladder orientation. Figure 3.2 illustrates the step ladder

orientation.

Figure 3.2

Step Ladder Orientation

Label

Conveyor

Direction

3–2

If the scan head is mounted so the beam is in the horizontal direction, the

symbol must also be in the horizontal direction. This is termed picket fence

orientation.

Refer to Figure 3.3 for an example of the scan head and symbol in a picket

fence orientation.

Figure 3.3

Picket Fence Orientation

Label

Conveyor

Direction

Page 16

Chapter 3

Installation Considerations

When setting up your scanner, you should attempt to have the laser line of

light nearly perpendicular to the bars and spaces of the symbol. For optimal

performance mount the scan head in a skewed position, 10° to 20° angle off

normal from the symbol, as shown in Figure 3.4.

Figure 3.4

Proper Mounting of Scan Head

Symbol

20°

10

°

Optimal angles

for scanning

beam

10°

20°

90°

20

90°

°

10°

10°

20°

Optimal angles for scanning

beam

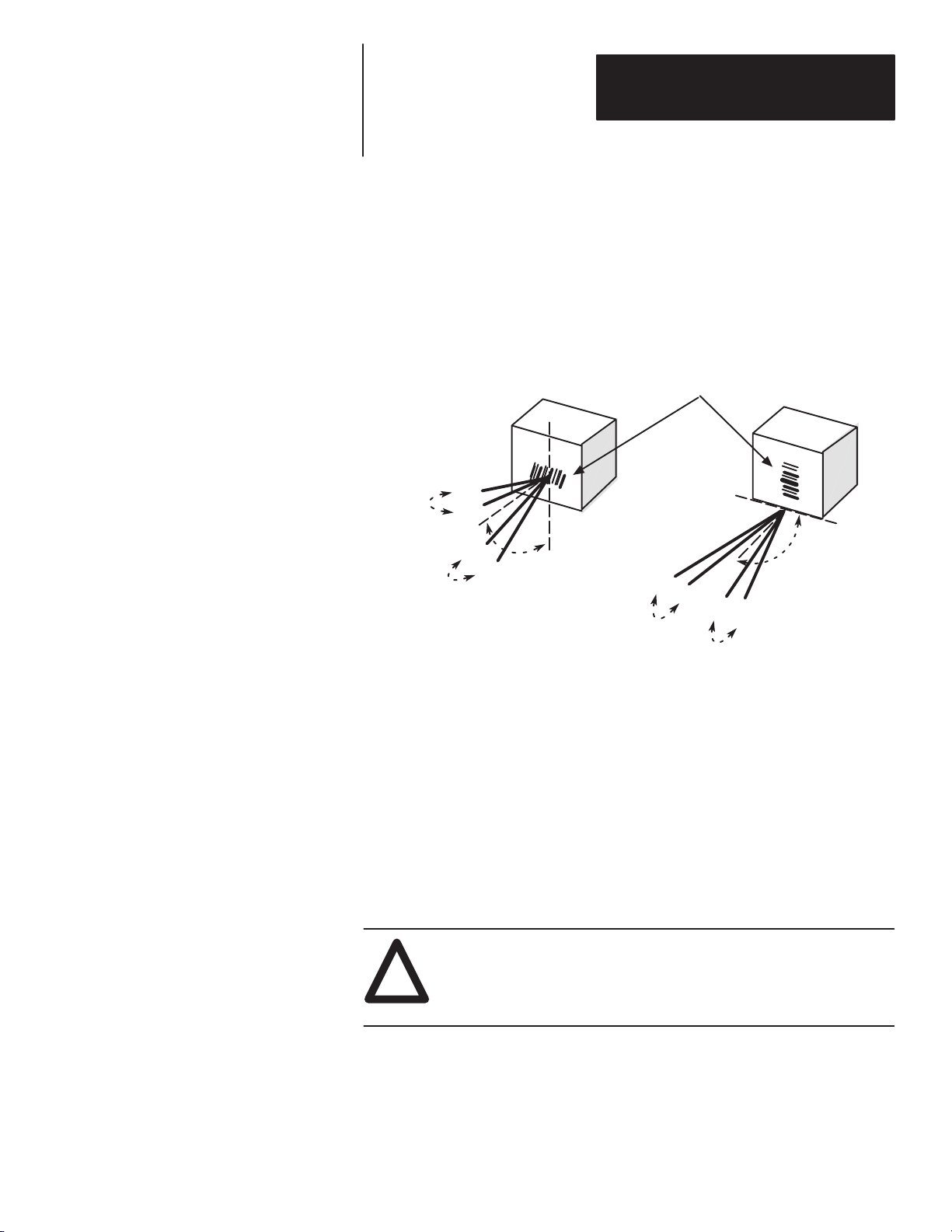

The scan head can successfully decode symbols that are out of alignment,

provided that the projected, or apparent, bar element widths are within the

minimum widths shown in Tables 2.A and 2.B.

Symbols that are pitched or tilted up to ±45°, are still readable. Skewed

symbols can also be read as long as the misalignment is less than ±50°.

Figure 3.5 shows a correctly placed symbol as well as misaligned symbols.

Note: When using “A” range scanners to read labels with high paper noise,

increasing the skew to 25° will enhance performance.

WARNING: If at any time during operation an intense dot of

light is reflected onto a symbol instead of a line of light, turn the

!

scanner OFF with the toggle switch on the back of the scanner.

Then turn the decoder OFF.

3–3

Page 17

Chapter 3

Installation Considerations

Figure 3.5

Positioning Terminology

Skewed package

and symbol

Pitched package

and symbol

Tilted, over square

symbol

Correctly positioned

symbol and package

3–4

When setting up a raster scanner, the raster pattern can either overlap the

entire symbol, or be restricted to cover only a portion of the symbol.

Overlapping the symbol helps to aid in the scanning of misaligned symbols.

Restricting, or dithering the raster pattern is helpful when scanning symbols

of poor quality. Refer to Figure 3.6.

Figure 3.6

Raster pattern

Page 18

Chapter 3

Installation Considerations

Usable Beam Length

To estimate the Usable Beam

Width:

1. Determine the distance from

the face of the scanner to the

center of the bar code symbol.

This distance is your Reading

Distance.

2. Locate your Reading

Distance on the L7 or L9

diagram (the Reading

Distances are displayed across

the top of each scale).

3. Displayed across the bottom

of each scale are the nominal

Usable Beam Lengths.

Figure 3.7 shows the size and shape of the scanning window. The black area

is a no read are area.

The Usable Beam Length (bottom of chart) is compared to the the Reading

Distance (top of chart). The Usable Beam Length is slightly less than the

projected beam length. The reading distance is measured from the scan

window to the center of the symbol.

Figure 7

Usable Beam Length

5

0

Inches

Centimeters

Inches

Centimeters

12.71025.41538.12050.82563.53076.23588.9

0

5.2

NA

13.2

NA

Inches

Centimeters

8.7

22.1

0

0

L7 Reading Distance

Reading Distance

12.2

15.6

19.1

31.0

39.6

48.5

22.6

57.4

26.1

66.3

①

40

101.645114.3

29.6

75.2

Usable Beam Length (nominal)

L9 Reading Distance

12.7

5

10

25.4

38.1

①

15

20

50.82563.53076.2

33.0

83.8

50

127.0

36.5

92.7

Usable

Beam

Length

Inches

Centimeters

NA

NA

2.9

7.4

4.8

12.2

Reading Distance

6.7

17.0

8.6

21.8

10.6

26.9

12.5

31.8

Usable

Beam

Length

Usable Beam Length (nominal)

① Measured from the face of the scanner to the center of bar code symbol.

3–5

Page 19

Chapter 3

Installation Considerations

Compensating for Pitched Symbols

When attempting to read a symbol that is pitched, two things must be

considered:

• The adjusted minimum bar width

• The nearest and farthest code elements must be within the scanners

reading range

Minimum Bar with Adjustment

When a symbol is pitched, the bars appear to be narrowerand closer to one

another. This apparent element width is a reduction of the actual element

width. Before you attempt to position your scanner using Figures 2.2 and 2.3

found in Chapter 2, you must determine your symbol’s adjusted minimum

bar width.

Figure 3.8 shows two boxes, each having the same bar code symbol printed

on them. Below each box is an exaggerated view of 5 elements (3 black, 2

white) as seen from the top down.

Figure 3.8

Actual versus Apparent Element Width

Actual Element Width 21 mil (.53

mm) 0° pitch

Apparent Element Width 18mil (.46

mm) because of 30 ° pitch, elements

appear narrower

3–6

Actual Element Widths

21 mil

Pitched 30

30°

°

Actual Element Widths

21 mil

Apparent Element Widths

18 mil

Page 20

Chapter 3

Installation Considerations

For example, a 21 mil (.53mm) symbol with 0° pitch can be successfully

scanned at 27 inches (68.6 cm) with a Catalog. No. 2755–L7SC scanner. If

you pitch the symbol 30° and determine the adjusted minimum bar width

using the formula below, you will realize that you are attempting to read an

18 mil (.46 mm) symbol.

Adjusted Minimum Bar Width = Actual Bar Width * cos [pitch angle]

In our example, the following conditions apply:

Actual Bar Width = 21 mil (.53 mm)

Pitch Angle = 30°

Minimum Bar Width

Inches

Millimeters

25

.64

20

.51

15

.38

10

.25

5

.13

Therefore: 21

cos [30] = 18.2 mil (.46 mm)

*

The minimum recommended bar width that the L7SC can read is 20 mil (.54

mm). Because of the pitch of the symbol, you will have to use a different

scanner, such as the L7SD. However, you will also have to decrease the

distance between the scanner and the symbol. The Catalog No.

2755–L7SD’s maximum read range with a 18 mil (.46 mm) symbol is 24

inches (61 cm). The farthest element of the symbol including the quiet zone

must not exceed 24 inches (61 cm).

In summary, increasing the pitch of the symbol decreases the minimum bar

width. Figure 3.9 is an excerpt from Figure 2.2, which illustrates this

example.

Figure 3.9

Pitch Effecting Scan Range

2755–L7SC

2755–L7SD

2755–L7SB

2755–L7SA

21 mil (.53mm) long

symbol with 0° pitch

21 mil (.53mm) long

symbol with 30°

pitch yields adjusted

minimum bar width

of 18 mil (.46mm).

Symbol to scanner

distance has also

been compensated so

symbol can be read

(see next page).

Inches

Centimeters

5

12.7

10

25.4

15

38.1

Scan Range ( from scan window)

20

50.82563.53076.23588.9

3–7

Page 21

Chapter 3

Installation Considerations

Code Elelment Distance

The pitched symbol’s nearest and farthest elements must be within the

minimum and maximum reading distance of your scanner.

Centering your symbol within the scanner’s minimum and maximum scan

range can help guard against pitched symbols exceeding the scan range

limits. However , you could exceed the scan range with a pitched symbol, as

shown in Figures 3.10 and 3.11.

Figure 3.10

Scan Range and Symbol Resolution at 0° Pitch

3” (7.6 cm) long

symbol pitched 0°.

The center of the

symbol is positioned

10” (25.4 cm) from the

face of the scanner.

Scan Range equals

10” (25.4cm).

2755–L7SA

10 ”

3 ”

Symbol’s Nearest and

Farthest Elements

10”

Minimum Bar Width

Mils

Millimeters

25

.64

20

.51

15

.38

10

.25

5

.13

Centimeters

Inches

5

12.7

2755–L7SD

2755–L7SB

2755–L7SA

10

25.4

Scan Range (from face of scanner)

15

38.1

20

50.82563.53076.23588.9

2755–L7SC

The center of the 3”

(7.6 cm) long symbol,

pitched 0°, is

positioned 10” (25.4

cm) from the face of

the scanner.

As you can see, the

2755–L7SA scanner

can be effectively

used for this

application.

3–8

Page 22

2755–L7SA

Chapter 3

Installation Considerations

Figure 3.11 further illustrates how the pitched symbol changed the Scan

Range enough to require a different scanner.

Figure 3.11

Scan Range And Symbol Resolution Changed By Pitch

11.5 ”

10 ”

3 ”

In this example, a 3

inch (7.6 cm) symbol

pitched 30° will

require the scanning

beam to extend an

additional 1.5 inches

(3.8 cm).

Minimum Bar Width

Mils

Millimeters

25

.64

20

.51

15

.38

10

.25

5

.13

Centimeters

Inches

5

12.7

2755–L7SB

2755–L7SA

10

25.4

Scan Range (from face of scanner)

15

38.1

20

50.82563.53076.23588.9

1.5 ”

Symbol’s

Nearest

Element

10”

2755–L7SC

2755–L7SD

Symbol’s

Farthest

Element

11.5”

This was the the

Scan Range and

element width at 0°

pitch.

This is the new Scan

Range.

Pitching the symbol

changed the bar

width and extended

the scan range.

The L7SA scanner is

not recommended for

this application.

Instead, use the

L7SB.

A pitched symbol will always change the minimum bar width and scan range

of the symbol. The amount of the change depends on the pitch of the

symbol.

3–9

Page 23

Chapter

W

Chapter Objectives

arning and Cautions

A–B

4

Installation

Carefully read this chapter before installing the system. We list rules and

recommendations for installing and connecting your scanner.

• WARNING: Do not make any other adjustments to the

equipment than those specified in this manual.

!

• WARNING: If at any time during operation an intense dot

of light is generated instead of a thin line of light,immediately

turn the laser off, using the toggle switch on the back of the

scanner, then remove power to the decoder.

Before You Start

Tools You Will Need

CAUTION: Do not look directly into the laser beam. It could

damage your eyes.

WARNING: No user maintenance of the hardware is required.

!

The angle and distance between the scan head and the label is an important

consideration. These considerations, orientation and alignment, are

described in Chapter 3, Installation Considerations.

Normally, the only tools you will need for installation will be the adjustment

tool supplied with your scanner. If the optional Swivel Mounting Base and

Plate are used (Catalog No. 2755–NM1 and 2755–NM2), you will also need

a screwdriver and a

Do not open the unit’s housing!

3

/16–inch Allen wrench.

4–1

Page 24

Chapter 4

Installation

Determining the Space Requirements

10–32UNF–2B

x .31

4.75 in

12.07 cm

Back View

3.00 in

7.62 cm

The decoder and scan head are separate units that can be mounted in different

locations. A 10 foot (3 meter) or 25 foot (7.6 meter) cable is used to connect

the two units. Figure 4.1 illustrates the dimensions of the scan head.

Figure 4.1

Mounting Dimensions of the Scan Head

2.69 in

6.83 cm

5.38 in

13.67 cm

2.69 in

6.83 cm

4.75 in

12.07 cm

3.19 in

8.05 cm

2.69 in

6.83 cm

2.20 in

5.59 cm

4.75 in

12.07 cm

Front View

3.00 in

7.62 cm

12.5 in

31.75 cm

Bottom View

10–32UNF–2B

x .31

1.357 in

3.45 cm

1.33 in

3.38 cm

4.75 in

12.07 cm

Mounting the Scan Head

4–2

Before installing the scan head, review the following information:

• Determine the optimum position of the scan head relative to the labels

that are to be read. Refer to Chapter 3 for positioning information.

• If you are using the optional swivel base or brackets, add their dimensions

into your positioning calculations.

• Allow a minimum clearance of 8 inches (20.3 cm) at the rear of the scan

head so you can attach the cables to the various ports.

• Securely mount the scan head to a rigid surface to ensure proper operation

of the scanning mechanism.

The thickness of your mounting surface determines the length of the screws

or bolts required. You will need two 10–32 screws, with flat and split

washers. Select a length that equals the thickness of the mounting surface,

thickness of the washers plus the depth of the screw holes,

mm).

3

/8–inch (9.5

Page 25

V

ibration Cautions

Chapter 4

Installation

The raster scanning models may occasionally experience raster rollover.

This condition is caused by jarring the scanner, excessive vibration, and will

occasionally occur upon power up.

The stepping of the raster motor is controlled by an incremental shaft

encoder, which has the ability to reset itself if one of the above conditions is

met.

Note: If the scanner is jarred during operation, labels may not be

scanned while the raster is resetting. In high speed operations, some

objects may not be scanned.

4–3

Page 26

Chapter 4

Installation

How to Install the Swivel

Mounting Base (Catalog No.

2755-NM1 and 2755-NM2)

3.19 (8.10)

2.812 (7.14)

2.00

1.625

(5.08)

(4.13)

.187

(4.75)

7/16–20

UNF–2A

For greater installation flexibility, you can attach the scan head to an optional

Swivel Mounting Base. The installation dimensions of the Swivel Base and

its associated “T” Mounting Plate are shown in Figure

4.2.

Figure 4.2

Mounting Dimensions of Swivel and “T” Mounting Plate

Inches (Centimeters)

.75

(19.05)

3.63

(9.22)

3.75

(9.53)

1.500

(3.81)

.180 (4.57)

4 places

.19 (4.83)

1.88 (4.78)

.30 (7.62)

1.00

(2.54)

5.50

(13.97)

.25

(6.35)

3.000

(7.62)

0.213 Dia.

2 Holes

1.50 (38.1)

.38 (9.65)

1.25 (3.18)

1.00 (2.54)

7/16–20 UNF–2B

5/8 Deep

.13 (3.3)

Swivel Mounting Base Catalog No. 2755–NM1

“T” Mounting Plate Catalog No. 2755–NM2

4–4

Page 27

Chapter 4

Installation

Using the Flat Mounting Plate

(Catlaog No. 2755-NM3 Series B)

A Flat Mounting Plate is also available. By attaching this plate to the bottom

of your scan head, you can position the swivel mounting ball close to the

base of the scan head. Make sure the Allen nut on the mounting ball is tight.

You may also use the Flat Mounting Plate when you want to mount the scan

head with brackets of your own design. Whenever possible, mount the

scanner on its wide side as shown on page 4–3. The dimensions are shown

in Figure 4.3.

Figure 4.3

Mounting Dimensions of the Flat Plate Inches (Centimeters)

2.25 (5.71)

.38 (0.96)

3.000

(7.62)

2.812

3.50

(8.89)

.25 (0.64)

Flat Mounting Plate with Mounting Screws Catalog No. 2755–NM3 Series B

(7.14)

.093 (0.24)

.31 (0.79)

1.500 (3.31)

.750

(1.91)

1.625

(4.13)

0.204 (0.52)

& Countersunk

80

°

0.390 (0.99)

2 Places

6–32

UNC–2B

4 Places

.25

(0.64)

Connecting Your Equipment

Connect your equipment using the appropriate cables. Follow the

step–by–step procedure described below.

Step 1 With the power to the decoder OFF, connect your scanner to the port

labeled Scan Head on the back of the decoder.

Step 2 Connect the configuration terminal to the decoder’s Auxiliary port.

Step 3 The initial configuration should be done at this time, if it was not

done earlier (refer to the User’s Manual supplied with your decoder).

Step 4 If a host computer will be used, connect it to the port labeled Host on

your DM9 decoder.

Step 5 If output devices will be used, connect them to the decoder (refer to

the User’s Manual supplied with your decoder).

Step 6 If a package detector will be used, connect it to the small port on the

scan head.

Step 7 Refer to Chapter 5 for scanner operation.

4–5

Page 28

Chapter 4

Installation

Installing the Package Detector Assembly

When installing the Package Detector Assembly, we recommend you observe

the following guidelines:

• Install the Package Detector Switch at an angle to the label to minimize

the light reflecting off the label.

• Install the reflector so the Package Detector’s operating range is not

exceeded.

• The Package Detector’s beam must be broken before the label is in

position.

Figure 4.4

Recommended Placement of Package Detector Switch and Reflector.

Reflector①

4–6

Scan Head

The laser beam must not strike the reflector, or you may get inaccurate reads

①

Package Detector

Switch

Figure 4.5 specifies which pins on the Package Detector Port Connector

(Catalog No. 2755–NC9) are used.

Figure 4.5

Pins Used on Package Detector Connector

Package Detector Input ①

A

Common

B

+ 12V

C

Package

Detector Port

① The package detector input is used to trigger the decoder to start decoding information. The package detect LED

on the Decoder will light when the package detect input is active.

Note: If you have programmed the decoder to turn the laser ON only upon a

package detect, the laser will be OFF until the package detector is triggered.

Refer to the User’s Manual for your decoder.

Page 29

Chapter

W

Chapter Objectives

arning and Cautions

A–B

5

Operation

Guidelines on how to operate the scanners are described when connected to a

Catalog Number 2755-DM9 Decoder.

• WARNING: Do not make any other adjustments to the

equipment than those specified in this manual.

!

• WARNING: If at any time during operation an intense dot

of light is generated instead of a thin line of light,immediately

turn the laser off, using the toggle switch on the back of the

scanner, then remove power to the decoder.

CAUTION: Do not look directly into the laser beam. It could

damage your eyes.

Laser On/Off Control

As shown in Figure 5.1, a toggle switch is used to enable and disable the

laser beam that exits the enclosure.

Figure 5.1

Laser On/Off Toggle Switch

5–1

Page 30

Chapter 5

Operation

Scan Width Adjustment

As shown in Figure 5.2, all scan heads come equipped with a 4 position

switch used for scan width adjustment. The switch is covered by a gasketed

1/4–20 screw.

Figure 5.2

Scan Width Adjustment Switch

To avoid an unnecessarily long beam, rotate this switch clockwise. The scan

width will reduce from full to approximately 3/4, 1/2 and 1/4. Figure 5.3

shows the scan width relative to the switch position. In each case, the usable

scan beam will be 80% of the actual beam width.

Figure 5.3

Scan Width Adjustment Switch Positions

5–2

Full scan beam

1/2

scan beam

3/4 scan beam

Factory Setting

1/4 scan beam

Reducing the scan width will often improve the scanner’s performance while

reading UPC, Code 128 and other high density labels at short ranges.

Increasing the scan width may improve the readability of low contrast labels

at maximum ranges.

Page 31

Chapter 5

Operation

Scan Width Adjustment Procedure

Raster Head Adjustment

1. Remove power to the scan head. In doing so, you will avoid harmful

direct eye contact with the beam.

2. Remove the gasketed 1/4–20 screw to expose the scan width

adjustment screw.

3. Using the adjustment tool provided with the scanner, carefully rotate

the switch to the desired position.

4. Replace the gasketed 1/4–20 screw.

5. Apply power to the scan head.

Raster scan heads are equipped with stepping raster motors designed to move

in synchronization with the scan sweep. The raster motor takes one step on

each reverse scan. Each step deflects the scan beam by approximately .3°.

The approximate spacing between the raster lines can be expressed as:

N (Lines/Inch) = 191/D

D = Distance from scan head to Label. For maximum accuracy,

measure from the label center to the scan window, then add

1.28 inches (3.25 cm).

Figure 5.4 shows the Raster Height Adjustment Switch, which is covered by a

gasketed 1/4–20 screw.

Figure 5.4

Raster Height Adjustment Switch

5–3

Page 32

Chapter 5

Operation

This switch selects the number of steps, or increments, the raster motor

makes. To reduce the number of steps, rotate this switch counterclockwise.

The raster heights are shown, relative to the switch positions, in Figure 5.4.

Figure 5.4

Raster Height Adjustment Switch Positions

Raster Height Adjustment Procedure

30° Raster Sweep

8° Raster Sweep

15° Raster Sweep

3° Raster Sweep

Factory Setting

1. Remove power to the scan head. In doing so, you will avoid harmful

direct eye contact with the beam and scanner rollover (explained on

page 4–3 under Vibration Cautions).

2. Remove the gasketed 1/4–20 screw to expose the Raster Height

Adjustment Switch.

5–4

3. Using the adjustment tool provided with the scanner, carefully rotate

the switch to the desired position.

4. Replace the gasketed 1/4–20 screw.

5. Apply power to the scan head.

Page 33

Chapter

Eq

Chapter Objectives

Maintaining the

Scan Window Removal

uipment

A–B

6

Maintenance and Troubleshooting

Maintenance procedures are stated and troubleshooting charts are provided in

this chapter.

WARNING: No user maintenance of the scan head is required.

Do not open the enclosure.

!

The scan window fits into an opening on the side of the scan head. A

gasketed cover is then tightly secured over the window to ensure a NEMA 4

rating.

To remove the scan window:

1. Remove the four Phillips head screws from the cover.

2.Lift the cover away from the scan head. Make sure the scan window does

not fall out. Handle the scan window by the edges to avoid finger prints.

Refer to Figure 6.1.

Figure 6.1

Scan Window Removal

6–1

Page 34

Chapter 6

Maintenance and Troubleshooting

Cleaning the Glass Window

Do not use abrasive materials, such as disposable paperwipes, to clean the

glass scan window. Most disposable wipes, or paper towels, use glass fibers

which will scratch and cloud the window. Instead, use the following

materials:

Air: Optics rated clean air

Solvent: Optics rated cleaning solution for use on coated lenses

Wipe: Optics quality lens cleaning paper and cotton–tipped swabs.

Use the following procedure to clean the glass scan window:

CAUTION: Do not use abrasive materials, such as disposable

paper wipes, to clean the glass scan window. In most cases, they

!

contain glass fibers that will scratch and cloud the window.

Step 1 Turn the decoder OFF.

Step 2 Check that the PWR ON indicators on both the decoder and scan head

are OFF.

Step 3 Use the lens cleaning paper to wipe any dust or foreign material from

the window. Be careful not to scratch the window with any grit that might be

on the window.

Step 4 Dust off the scan window and adjacent areas with optics rated air.

Step 5 Remove the scan window. Figure 6.1 illustrates the removal.

CAUTION: Do not touch the internal mirrors! Smudge from

finger prints will diffuse the beam.

!

Step 6 Clean the window using the optics rated cleaning solution,

cotton–tipped swabs and lens cleaning paper. To avoid smearing film and

fingerprints, rotate the cotton–tipped swab, while it’s on the glass, nearly one

full turn. Then, discard it.

Step 7 Replace the scan window.

Step 8 Turn the decoder ON. The PWR ON indicators on both the decoder

and scan head should be ON.

6–2

When the window is clean, you will barely be able to see the reflection of the

laser beam on the clear glass.

Page 35

Chapter 6

Maintenance and Troubleshooting

Cleaning the Plastic Window

Do not use abrasive materials, such as disposable paper wipes, to clean the

plastic scan window. Most disposable wipes, or paper towels, use glass

fibers which will scratch and cloud the window. Instead, use the following

materials:

Air: Optics rated clean air

Solvent: Optics rated cleaning solution for use on coated lenses

Wipe: Optics quality lens cleaning paper and cotton–tipped swabs.

Use the following procedure to clean the glass scan window:

CAUTION: Do not use organic solvents or abrasive materials,

such as disposable paper wipes, to clean the plastic scan window.

!

In most cases, they contain glass fibers that will scratch and cloud

the window.

Step 1 Turn the decoder OFF.

Step 2 Check that the PWR ON indicators on both the decoder and scan head

are OFF.

Step 3 Use the lens cleaning paper to wipe any dust or foreign material from

the window. Be careful not to scratch the window with any grit that might be

on the window.

Step 4 Dust off the scan window and adjacent areas with optics rated air.

Step 5 Remove the scan window. Figure 6.1 illustrates the removal.

CAUTION: Do not touch the internal mirrors! Smudge from

finger prints will diffuse the beam.

!

Step 6 Clean the window using the optics rated cleaning solution,

cotton–tipped swabs and lens cleaning paper. To avoid smearing film and

fingerprints, rotate the cotton–tipped swab, while it’s on the glass, nearly one

full turn. Then, discard it.

Step 7 Replace the scan window.

Step 8 Turn the decoder ON. The PWR ON indicators on both the decoder

and scan head should be ON.

When the window is clean, you will barely be able to see the reflection of the

laser beam on the clear glass.

6–3

Page 36

Chapter 6

Maintenance and Troubleshooting

Troubleshooting the System

Problem Probable Cause Possible Solution

PWR ON indicators on

both scan head and

decoder do not light.

PWR ON indicator on

scan head does not light,

but PWR ON indicator on

decoder is lit.

No laser beam emitted

from window of scan head

Decoder is not turned ON.

Improper connection to power supply.

Line fuse on decoder is blown.

Faulty power cord or switch.

No incoming power.

Interconnect cable between decoder and

scan head is loose.

Interconnect cable is defective.

Scan head or decoder is defective.

Laser ON/OFF toggle switch is in OFF

position.

No scan trigger signal.

Improperly positioned labels.

Turn decoder ON.

Reconnect power cord to source.

Replace fuse on decoder.

Check that voltage is present at service

outlet.

Check that voltage is present at service

outlet.

Reconnect cable and check connections.

Replace cable.

Replace scan head.

Check Laser ON/OFF toggle switch

position.

Verify sending of scan trigger by either

package detect or trigger from decoder.

Check that reading distance is correct and

orientation of labels to scan head is correct.

Unable to read a label.

Laser beam expands and

contracts.

Warning!

Laser beam is an intense

dot of light.

6–4

Poor quality labels.

Laser ON/OFF toggle switch is in OFF

position.

Decoder is improperly programmed.

Loose cables or connections.

Scan Window is dirty

Scan head is not securely mounted. Improve mounting.

Laser scanning mechanism is not operating

correctly.

Check that labels are good quality and

within specifications.

Check Laser ON/OFF toggle switch

position.

Refer to the appropriate User’s Manual.

Check cables and connections.

Clean window . Refer to Chapter 6

Turn laser OFF using toggle switch on back

of scanner, then turn decoder OFF.

Page 37

Chapter

Scan Head

(Catalog Number 2755-L7 and L9

10–32UNF–2B

x .31

A–B

7

Specifications

Electrical Receives power from decoder.

Mechanical

Enclosure Cast aluminum NEMA 4

LED Indicators Power On

Valid Read

Weight 6.5 lbs. (2.95 kg)

Dimensions (H x W x D) 5.38” x 12.5” x 2.69”

2.69 in

6.83 cm

5.38 in

13.67 cm

2.69 in

6.83 cm

4.75 in

12.07 cm

Back View

3.00 in

7.62 cm

4.75 in

12.07 cm

3.19 in

8.05 cm

2.69 in

6.83 cm

2.20 in

5.59 cm

4.75 in

12.07 cm

Front View

3.00 in

7.62 cm

12.5 in

31.75 cm

10–32UNF–2B

x .31

1.357 in

3.45 cm

1.33 in

3.38 cm

4.75 in

12.07 cm

Bottom View

Environment Ambient temperature range, 32° to 131°F (0°

to 55°C)

CDRH Standards Meets Class II standards

7–1

Page 38

Chapter 7

Specifications

Optical

Light Source Focused helium–neon (He–Ne) laser

(632.8nm)

Power 1.5 mW max.

Fixed Scan Rate L7 – 350 scans/second, ± 5%

L9 – 800 scans/second, ± 5%

Scan sweep angle L7 47°

L9 27°

Scan Range L7 3.5” to 50” (8.89 cm to 127 cm) from

scan window. ①

L9 5” to 30” (12.7 cm to 76.2 cm) from

scan window ①

Depth of Field L7 3.5” to 50” (8.89 cm to 127 cm) from

scan window ①

L9 5” to 30” (12.7 cm to 76.2 cm) from

scan window ①

Label Skew L7 5° to 50° from normal ②

L9 5° to 50° from normal ②

Label Pitch L7 5° to 45° from normal ②

L9 5° to 45° from normal ②

Package Detect

Min. OFF–State Voltage 11 VDC

Max.

ON–State Voltage 2 VDC

Depending on the model selected

①

② Depending on label quality

7–2

Page 39

Glossary

A–B

A

AIM

Acronym for Automatic Identification Manufacturers.

alignment

The relative position of a scanner or light source to the target or the receiving

element.

alphanumeric or alphameric

The character set which contains letters, digits, and other characters such as

punctuation marks.

aspect ratio

The ratio of height to width of a bar code symbol. A code twice as high as

wide would have an aspect ratio of 2; a code twice as wide as high would

have an aspect ratio of

attended system

A scanner/decoder combination that must be activated, or attended, by an

operator.

or 0.5.

G

average background reflectance

Expressed as a percent, this is the simple arithmetic average of the

background reflection reading from at least five different points on a sheet.

average edge

An imaginary line bisecting the irregularities of the character edge.

B

background

The area surrounding a printed symbol.

bar

The dark element of a printed symbol.

bar code

The vertical bars and spaces found in a bar code symbol.

bar code density

The number of characters which can be represented in a lineal inch.

bar code label

A label that carries a bar code and is suitable to be affixed to an article.

bar code reader

A device used to identify and read a bar code symbol. Also know as a

decoder

bar code symbol

A group of vertical bars ,that represents a character or group of characters

whose spacing is determined by a specific set of rules. In most cases, human

readable characters are also printed below the bars.

G–1

Page 40

Glossary

bar length

The bar dimension perpendicular to the bar width.

bar width

The thickness of a bar measured from the edge closest to the symbol’s start

character to the trailing edge of the same bar.

bidirectional symbol

A bar code symbol that can be read in complementary (two) directions.

binary code

A power–of–two code; each bit position has a weighted value.

bit

An acronym for Binary Digit. The smallest unit of information in the binary

numbering system. Represented by the digits 0 and 1.

C

CCD

Acronym for Charge Couple Device; a linear image sensor that scans at high

speeds (approximately 4,000 times per second) and detects the presence or

absence of marks passing under the device.

character

A single group of bars and spaces representing an individual number, letter

or punctuation mark. A graphic shape representing a letter, number or

symbol.

character alignment

The vertical or horizontal position of characters with respect to a given

reference line.

character density

The dimension, in linear inches, required to encode one character.

character reading

Reading of alpha or numeric characters,and/or symbols, by optical means.

character set

Those characters available for encoding purposes.

G–2

character skew

See skew.

character spacing

The horizontal distance between two adjacent characters.

check digit

A digit included within a symbol whose value is based mathematically on

other characters included in the symbol. It is used to mathematically check

the accuracy of the read.

Page 41

Glossary

clear area

A clear space, containing no dark marks, that precedes the start character of a

symbol and follows the stop character. That region of a document reserved

for OCR characters and the required clear space around these characters.

code

A set of rules governing how the bars and spaces of the symbol will represent

characters and groups of characters. bar code.

code medium

The material used to construct a machine readable code. Such materials may

be retroreflective or opaque.

code reader or scanner

A device that examines a spatial pattern, one part after another, and generates

analog or digital signals corresponding to the pattern.

contact scanner

A code reader that requires physical contact with the code medium.

continuous code

A bar code or symbol that does not use an intercharacter gap between

characters in the code. Code 128 is an example of intercharacter gap.

D

decoder

An unattended device used to decode, or make usable, a digital or analog

signal transmitted from a scanning device.

decoder logic

The electronic package which receives the signals from the scanner,

interprets the signals into meaningful data and provides the interface to other

devices.

depth of field

The distance between the maximum and minimum plane where a symbol can

be read.

diffuse reflection

Reflection of light in all directions. Diffuse reflection occurs from

non–glossy surfaces. (Also see specular reflection)

dirt

In paper, refers to the presence of relatively non–reflective foreign particles

embedded in the sheet. The size and lack of reflectance of the particles may

cause the optical scanner to mistake the dirt for inked areas.

discrete code

A bar code or symbol where the space between characters, intercharacter

gap, are not part of the code; as with Code 39. (Also see continuous code)

G–3

Page 42

Glossary

diverging beam

A beam of light that is optically controlled so the light extends in different

directions from the source.

E

EAN

Acronym for European Article Numbering System, the international standard

bar code for retail food packages.

edge error

Irregularities with respect to the average edge of an element.

element

1) A single binary position in a character. 2) Dimensionally the narrowest

width in a character, bar or space.

encoded area

The total linear dimension consisting of all the characters of a code pattern,

including start/stop characters and data.

extraneous ink

Ink in a scan area not intended to be there.

F

first read rate

The first read rate is the percentage of bar code symbols that are read with the first

pass of the bar code wand under ideal conditions. Bar code symbols should have a

first read at least 90% of the time. A first read rate of less than 90% usually means

that either the bar code symbols or scanning device need some type of adjustment or

modification. This does not mean that a system which has a first read rate of less

than 90% is unacceptable.

G

guard bars

The bars at the ends and center of a UPC and EAN symbol. They ensure a

complete scan of the bar code.

G–4

H

hand held scanner

Refers to any scanning device that must be held over the bar code symbol.

height–of–scan

The maximum vertical scanning dimension of a moving beam scanner at a

specific distance from the face of the scanner.

Page 43

Glossary

helium neon laser

The type of laser most commonly used in bar code scanners. Because the

laser beam is bright red, bars must not be printed with red ink since they

would be indistinguishable from the background.

I

incandescent light source

Intense white light used to illuminate an object as it passes under a CCD

camera.

intercharacter gap

The space between two adjacent bar code characters. For example, the white

space between two characters in AIM USS–39.

interleaved bar code

A bar code in which characters are paired together using bars to represent the

first character and spaces to represent the second; as in USS–I 2/5

K

key mark or trigger

A code bit(s) that provides the scanner with the instruction that the code is in

a position to be read; used in some fixed beam readers.

L

ladder orientation

See step ladder orientation

laser scanner

An optical bar code reading device using a low energy laser light beam as the

source of illumination.

Light Emitting Diode (LED)

A semiconductor diode generally made from gallium arsenide, that can serve

as a near infrared light source when voltage is applied continuously or in

pulses. LED’s have extremely long lifetimes when properly operated; being

solid–state, they are very resistant to shock and vibration.

light operated

Condition in which the control operates when the light beam in

uninterrupted.

M

mis–encodation

When the characters which were to be represented in symbol form are not

correctly encoded. Example: desired number is 1,2, 3, 4; the encoded

number is 1, 2, 5, 4.

G–5

Page 44

Glossary

misread

A condition which occurs when the data output of a reader does not agree

with the encoded data presented. See substitution error.

module

A group of elements.The term module is used by the Uniform Product Code Council

in it descriptions of the UPC code. A module is the narrowest unit of measure in the

code. A module may be “black” or “white”. Contiguous modules are used to form

bars or spaces that are wider than one unit.

modulo check digit or character

A calculated character within a data field used for error detection. The

calculated character is determined by applying a code algorithm to the data

field contents.

modulus 43 check character

Used in Code 39 for data security in addition to the built–in self–checking

characters. The check–character is the modulus 43 sum of all of the

character values in a given message and is the last character in the code

moving beam scanner

A device which dynamically searches for a bar code pattern by sweeping a

moving optical beam through a field of view.

N

nanometer

Unit of measure used to define the wavelength of light. 10

no–read, non–read, non–scan

9

meters.

The absence of data at the scanner output after an attempted scan due to no

code, defective code, scanner failure or operator error.

nominal size

The standard size for a bar code symbol. Most codes can be used over a range of

magnifications from 0.80 to 1.20, nominal.

numeric

A machine vocabulary that includes only the numbers as contrasted to

alphanumeric which includes both letters and numerals.

O

G–6

OCR

Acronym for Optical Character Reader. An information processing device

that scans and decodes human readable OCR symbols.

OCR–A

An abbreviation commonly applied to the character set contained in ANSI

Standard x3.17–1974.

Page 45

Glossary

OCR–B

An abbreviation commonly applied to the character set contained in ANSI

Standard x3.49–1975.

off–line

Refers to devices that operate independently of a central processing unit.

on–line

An operation in which peripheral devices are connected directly to the

computer central processor unit.

opacity

1) The property of paper that minimizes the show through of printing from

the back side or the next sheet.

2) The ratio of the paper reflectance with a black backing to the paper

reflectance with a white backing.

scanning range

The sum of the scan head’s optical throw and depth–of–field.

optical throw

The distance from the face of the scanning device to the center of the depth

of field.

orientation

The alignment of bars and spaces to the scanner. Often referred to as vertical

(picket fence) or horizontal (ladder).

P

parallel beam

A beam of light that is optically controlled so the light travels in a parallel

path. Generally used when the object is larger than the lens diameter.

parallel code

A code configuration that is optically scanned in its entirety at one time.

Since all codes marks are read simultaneously, the code can move pass the

reader in either direction.

parity bar, parity bit, parity module

A parity bit is added to a binary array to make the sum of all the bits always

odd or always even; a fundamental check.

permanent code

A code which is indefinitely reused in a bar code application.

picket fence orientation

A bar code or symbol presented in such a manner that its overall length

dimension is parallel to the horizon. The bars look like a picket fence.

G–7

Page 46

Glossary

pitch

1) Rotation of a code pattern about the X axis.

2) The normal distance between the centerline or adjacent characters.

pre–printed symbol

A symbol which is printed in advance of application either on a label or on

the article to be identified.

Print Contrast Signal (PCS)

A measurement of contrast (brightness difference) between the bars and

spaces of a symbol. A minimum PCS value is needed for a symbol to be

scannable.

PCS = (R

)/ RL, where R

L–RD

is the reflectance factor of the light

L

background and R

is the reflectance factor of the

D

dark bars. PCS values can be calculated and

displayed automatically on suitable instruments.

print quality

The complete analysis of a printed symbol with regard to reflectance

properties as well as bar and space resolution with regard to symbol

specification. The inter–relationship of printed material and imprinted

material that affects the optimum performance of the scanner.

proximity sensor

A method of object detection in which the source and detector are located on

the same side; the detector senses energy from the source which is bounce

back by the object being detected.

Q

quiet zone, quiet area

An area preceding and following a bar code symbol that contains no printing.

R

G–8

raster scanner

Also available as an optional raster assembly. Raster scanners are similar to

standard scanners. The beam still travels from left to right, but it now does

so in a sinusoidal, or top to bottom, pattern. This allows the scanner to see

different scan paths so if a bar is deformed or soiled in one place it may still

be read due to the sinusoidal sweep of the beam.

raster rollover

A reset of the raster mechanism that causes the rastering scan beam to

rollover, or continue its sweep, as much as 360° until it resets.

Page 47

Glossary

read

A successful scan of a bar code symbol.

reflectance

The amount of light returned from an illuminated surface.

reflectance, absolute

The ratio of the total reflectance by a document to the total light incident on

the document.

reflectance, diffuse

Reflected light whose angle of reflection varies from the angle of incidence

of the illuminating light; such as reflection from a non–glossy surface.

reflectance, specular

Reflected light whose angle of reflection is equal, or nearly equal, to the

angle of incidence of the illuminating light, as in reflection from a mirror.

reflex

A method of object detection in which the source and detector are located on

the same side; a retroreflector on the far side returns the energy from the

source to the detector.

resolution

1) The measure of the ability of a lens, a photographic material or a photographic

system to distinguish detail under certain specific conditions.

2) The dimension of the smallest element which can be printed employing a

particular technique.

3) The narrowest element dimension which can be distinguished by a particular

reading device.

retroreflective

Characteristic of material causing it to reflect light back to its source

regardless of angle of incidence.

retroreflector

A reflector, specially constructed, which reflects energy back to the source

from which it came. It is also known as a “corner reflector”.

reverse image

A symbol in which the normal dark areas are represented in the light areas.

S

scan

The search for a symbol or marks which are to be optically recognized.

scan head, scanner

A device that optically scans bar code symbols and converts the optical

information into digital or analog form and sends it to a decoder.

G–9

Page 48

Glossary

scanning curtain

The effective reading area (width x height) of a moving beam scanner, which

is equal to its depth–of–field and height–of– scan at a specific operating

range.

scanning range

The combined distance of optical throw and depth of field.

self–checking

A bar code or symbol using a checking algorithm which can be applied to

each character to guard against undetected errors. Non–self–checked codes

may employ a check digit or other redundancy in addition to the data

message.

serial code

A bar code symbol typically used with a fixed beam scanner where the

scanning action is caused by the motion of the symbol past the scanning

head. The bits of the symbol are evaluated one at a time (serially).

skew

Rotation about the Y axis. Rotational deviation from correct horizontal and

vertical orientation may apply to a single character, line or the entire encoded

item.

space

The lighter element of a bar code

space encoding

See interleaved bar code.

special symbol/character

In a character set, a character that is neither a numeral, letter, or a blank: for

example, @ $ % ¢ & *.

spectral response

The variation in sensitivity of a device to light of different wavelengths.

specular reflection

Reflection of light from a surface at an angle equal but opposite to the angle

of incidence. See reflectance, specular.

spots

Ink or dirt spots within the spaces or clear area of a bar code which may

reduce first read rate.

G–10

start/stop character

A bar code character that provides the scanner with start and stop reading

instructions as well as code orientation.

step ladder orientation

A code pattern in which the overall coded area from start to stop is

perpendicular to the horizon. The individual bars appear as rungs of a

ladder.

Page 49

Glossary

substitution error

This error can be seen in a mis–encodation, mis–read, or human operator

error. Characters are substituted with erroneous information. Example:

correct data is 1, 2, 3; substitution is 1, 2, 5. Substitution errors are usually

the result of bar code labels with printing defects. Substitution errors are

extremely difficult to determine and are usually not found until the data has

been processed and an obvious data error is noticed.

symbol

A combination of characters including start/stop characters and check

characters, as required, which form a complete scannable entity.

symbol density

The number of characters per linear inch.

symbol length

The length of the symbol measured from the beginning of the quiet area

adjacent to the start character to the end of the quiet area adjacent to a stop

character.

U

unattended system

A Scanner/decoder combination that is triggered, or activated, by an external

source such as a computer, PLC or mechanical switch.

UPC

Universal Product Code. The standard bar code symbol for retail food

packaging in the United States.

V

valid read

A scan that when processed by a decodder, satifies the follwowing

parameters:

• Belongs to an enabled symbology

• Field length (number of characters)

• Fields per scan

• Capture count

G–11

Page 50

Glossary

valid read indicator

An indicator on the:

scan head that indicates a scan has been processed by the decoder and at

least one label has been read.

decoder that indicates a processed scan meets the capture count and fields

per scan for at least one label.

output module that indicates a processed scan meets the capture count,

fields per package, and fields per scan for at least one label.

void(s)

The absence of ink within printed bars. The absence of ink within the

confines of a character.

W

wand

A hand held scanning device used as a contact bar code or OCR reader.

white zone – see quiet zone

G–12

Page 51

A–B

Index

A

Abrasive materials on scan

windows 6-2–6-3

Accessories

2-6–2-7

Alignment, symbol

3-3, G-2, G-6

Aluminum case

2-4, 6-1

Ambient temperature

7-1

Apparent bar width

3-3, 3-6, 5-4

Anti-reflective scan window

2-7

Attaching mounting plates

4-5

B

Ball, mounting

2-6–2-7, 4-5

Beam width, usable

3-5, 5-2, G-3

Brackets

2-7, 4-3, 4-5

C

Cabling

2-6

Caution

1-1–1-3, 4-1, 4-4, 5-1, 5-4,

6-2–6-3

CDRH

6-1

Centering label within scan range

3-8

Clearance, cable

4-3

Compensating for pitched symbols

3-6

Connector, package detect port

2-7, 4-6

Cleaning scan windows

6-2–6-3

D

Danger

1-3

Default scanner settings

5-2, 5-4

Diffuse

3-1, 6-2–6-3, G-3, G-8

Disable laser

2-4, 5-1

Dithering the raster pattern

3-4

DM9

4-2

E

EAN

G-4

Element

3-3, 3-6–3-9, G-4, G-8–G-9

Emitted laser light

1-3

Enclosure

1-3, 2-6, 6-1

Encoder

4-4

Exceeding scan range limits

3-8

F

FDA

2-4

Finger prints (on scan window)

6-1–6-3

G

Gasketed cover

2-4–2-5, 5-2–6-1

H

He-Ne (Helium-neon laser)

6-2

I

Improperly positioned label

1-3, 6-4

Incremental encoder

4-4

Indicators, LED

2-4, 6-2–7-1

Infrared laser

2-7, G-5

Installation

4-1, 4-4, 4-6

Intended audience

1-2

L

Laser on/off control

5-1

LEDs

2-4

M

Maintenance

1-1, 1-3, 2-4, 6-1

Minimum bar width

2-2–2-3, 3-7–3-9

Misaligned symbols

3-3–3-4

O

Optics quality cleaner

6-2–6-3

Optimum scan angles

3-3, 4-3, G-7

P

Package Detector

2-6–2-7, 4-6

Picket fence

3-2, G-4

Pitched symbols, compensating for

3-6 - 3-9

Positioning symbols

3-1–3-4, 3-8, 4-3, 6-4

PWR

2-4–2-5, 6-2–6-4

R

Raster

height adjustment

5-3 - 5-4

scanner

2-5, 3-4, 4-4, G-8

I–1

Page 52

Index

rollover

4-4, 5-4, G-9

Reading Distance

3-5

Replaceable windows

2-4–2-6

Reset

4-4

Resolution

3-9, G-7–G-8

Rollover, raster

4-4, 5-4, G-9

S

Scan

angles

3-3, 4-3, G-7

range

2-2–2-3, 3-8–3-9, G-6, G-9

width adjustment

5-2 - 5-3

Scan Window

2-5, 6-1, 6-4

Cleaning

6-2–6-3

Removal/replacement

6-1–6-3

Skew

2-2–2-3, 3-3–3-4, 6-2, G-2, G-9

Solvents, use of

6-2–6-3

Specifications

7-1

Step Ladder position

3-2, G-5–G-6, G-10

Swivel mounting base

2-6–2-7, 4-3–4-5

T

Terminology

1-2, 3-4

Toggle switch

3-3, 4-1, 5-1, 6-4

Troubleshooting

2-4, 6-1, 6-4

U

UPC

5-2, G-4–G-5, G-10

Usable beam width

3-5, 5-2, G-3

W

Warning

1-1–1-3, 3-3, 4-1, 5-1, 6-1, 6-4

Widths, apparent element

3-3, 3-6, 5-4

I–2

Page 53

Allen-Bradley has been helping its customers improve productivity and quality for 90 years.

A-B designs, manufactures and supports a broad range of control and automation products

worldwide. They include logic processors, power and motion control devices, man-machine

interfaces and sensors. Allen-Bradley is a subsidiary of Rockwell International, one of the

world’s leading technology companies.

With major offices worldwide.

Algeria • Argentina • Australia • Austria • Bahrain • Belgium • Brazil • Bulgaria • Canada • Chile • China, PRC • Colombia • Costa Rica • Croatia • Cyprus • Czech

Republic • Denmark • Ecuador • Egypt • El Salvador • Finland • France • Germany • Greece • Guatemala • Honduras • Hong Kong • Hungary • Iceland • India •

Indonesia • Israel • Italy • Jamaica • Japan • Jordan • Korea • Kuwait • Lebanon • Malaysia • Mexico • New Zealand • Norway • Oman • Pakistan • Peru • Philippines

• Poland • Portugal • Puerto Rico • Qatar • Romania • Russia–CIS • Saudi Arabia • Singapore • Slovakia • Slovenia • South Africa, Republic • Spain • Switzerland •

Taiwan • Thailand • The Netherlands • Turkey • United Arab Emirates • United Kingdom • United States • Uruguay • Venezuela • Yugoslavia

World Headquarters, Allen-Bradley, 1201 South Second Street, Milwaukee, WI 53204 USA, Tel: (1) 414 382-2000 Fax: (1) 414 382-4444