Page 1

ALLEN-BRADLEY

Bulletin 2755

Hand-Held Scanner

with Wedge Option

(Catalog No. 2755-G3-W, 2755-G6-W)

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics

differing from those of electromechanical equipment.

“Application Guidelines for Application, Installation, and

Maintenance of Solid State Controls” (Publication

SGI-1.1) describes some important differences between

solid state equipment and hard–wired electromechanical

devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons

responsible for applying this equipment must satisfy

themselves that each intended application of this

equipment is acceptable.

In no event will the Allen-Bradley Company be

responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included

solely for illustrative purposes. Because of the many

variables and requirements associated with any particular

installation, the Allen-Bradley Company cannot assume

responsibility or liability for actual use based on the

examples and diagrams.

No patent liability is assumed by Allen-Bradley Company

with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in

part, without written permission of the Allen-Bradley

Company is prohibited.

Compaq is a registered trademark of Compaq Computer Corporation.

DEC and VT are registered trademarks of Digital Equipment Corporation.

Hewlett-Packard is a registered trademark of Hewlett-Packard Company.

IBM is a registered trademark of Internationa Business Machines Corporation

PC AT, PS/2 and PC XT are trademarks of International Business Machines Corporation

PHOTOSWITCH is a registered trademark of Allen-Bradley Company, Inc.

Page 3

Table of Contents

Hand-Held Scanner with Wedge Option

A–B

Using

this Manual

Overview

of Scanner

Chapter 1

Chapter Objectives 1–1. . . . . . . . . . . . . . . . . . . . . . . . . .

Contents of Package 1–1. . . . . . . . . . . . . . . . . . . . . . . . .

Intended Audience 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview of Manual 1–2. . . . . . . . . . . . . . . . . . . . . . . . .

Warning and Caution Symbols 1–3. . . . . . . . . . . . . . . .

Related Publications 1–3. . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2

Chapter Objectives 2–1. . . . . . . . . . . . . . . . . . . . . . . . . .

Function of Scanner 2–1. . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Modes 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hand-Held Mode 2–2. . . . . . . . . . . . . . . . . . . . . . . . .

Autosense Mode 2–2. . . . . . . . . . . . . . . . . . . . . . . . .

Setup Parameters 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keyboard Wedge 2–3. . . . . . . . . . . . . . . . . . . . . . . . .

General Setup 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Message Format 2–4. . . . . . . . . . . . . . . . . . . . . . . . . .

Symbology 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ordering a Scanner 2–5. . . . . . . . . . . . . . . . . . . . . . . . . .

Scanner Accessories 2–6. . . . . . . . . . . . . . . . . . . . . . . . .

Using

the Scanner

Chapter 3

Chapter Objectives 3–1. . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Description 3–1. . . . . . . . . . . . . . . . . . . . . . . . .

LED Indicators 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Labels 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scanning Ranges 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Scanner 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Beep 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Tips 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 4

Table of Contents

Hand-Held Scanner with Wedge Option

Setup

Instructions

General

Setup

Parameters

Chapter 4

Chapter Objectives 4–1. . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Wedge Interface 4–1. . . . . . . . . . . . . . . . . . . .

Connecting Scanner Interface Cable 4–2. . . . . . . .

Removing Scanner Interface Cable 4–3. . . . . . . . .

Connecting Wedge Interface Cable 4–4. . . . . . . . .

Connecting Optional Power Supply 4–5. . . . . . . . .

Terminal Power Up Sequence 4–5. . . . . . . . . . . . . .

Enabling Wedge Mode 4–6. . . . . . . . . . . . . . . . . . . . .

Selecting a T erminal Type 4–6. . . . . . . . . . . . . . . . . . .

Scanner Configuration Guidelines 4–8

Scanner Default Settings 4–10. . . . . . . . . . . . . . . . . . . . .

Resetting Factory Defaults 4–12. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

Chapter 5

Chapter Objectives 5–1. . . . . . . . . . . . . . . . . . . . . . . . . .

System Status 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Consumption 5–3. . . . . . . . . . . . . . . . . . . . . . . . .

Beeper Operation 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Capture Count 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spotter Beam 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Autosense Mode 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message

Format

Parameters

ii

Chapter 6

Chapter Objectives 6–1. . . . . . . . . . . . . . . . . . . . . . . . . .

Message Format 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prefix 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Suffix 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scanner Identifier 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Code Identifier 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preamble or Postamble 6–6. . . . . . . . . . . . . . . . . . . . . . .

Preamble 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Postamble 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intercharacter Delay 6–10. . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Table of Contents

Hand-Held Scanner with Wedge Option

Symbologies

Chapter 7

Chapter Objectives 7–1. . . . . . . . . . . . . . . . . . . . . . . . . .

Label Lengths 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Code 39 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modulo 43 Check Character 7–3. . . . . . . . . . . . . . .

Transmit Stop/Start Characters 7–3. . . . . . . . . . . . .

Minimum Length 7–4. . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Length 7–4. . . . . . . . . . . . . . . . . . . . . . . .

UPC (A and E) 7–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supplements 7–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Expanded UPC-E 7–5. . . . . . . . . . . . . . . . . . . . . . . .

Transmit Number System Digit 7–6. . . . . . . . . . . .

Transmit Check Digit 7–6. . . . . . . . . . . . . . . . . . . . .

UPC to EAN Translation 7–7. . . . . . . . . . . . . . . . . .

EAN/JAN 7–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supplements 7–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmit Number System Digit 7–9. . . . . . . . . . . .

Transmit Check Digit 7–9. . . . . . . . . . . . . . . . . . . . .

Interleaved 2 of 5 7–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Digit 7–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Minimum Length 7–11. . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Length 7–11. . . . . . . . . . . . . . . . . . . . . . . .

Standard 2 of 5 7–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Minimum Length 7–12. . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Length 7–12. . . . . . . . . . . . . . . . . . . . . . . .

Code 128 7–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Minimum Length 7–13. . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Length 7–13. . . . . . . . . . . . . . . . . . . . . . . .

Codabar 7–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmit Stop/Start Characters 7–14. . . . . . . . . . . . .

Minimum Length 7–15. . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Length 7–15. . . . . . . . . . . . . . . . . . . . . . . .

iii

Page 6

Table of Contents

Hand-Held Scanner with Wedge Option

Specifications

Chapter 8

Appendix A Bar Code Test Symbols

Appendix B Digit Selection Symbols

Appendix C Autosense Mode

Appendix D Maintenance

Appendix E Scanner Parameters

Glossary

Index

iv

Page 7

3.1

4.1

4.2

4.3

C.1

2.A

2.B

3.A

3.B

4.A

6.A

6.B

Table of Contents

Hand-Held Scanner with Wedge Option

Figures

Scanning Ranges 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keyboard W edge Interface Connections 4–1. . . . . . . .

Connecting Scanner Interface Cable 4–2. . . . . . . . . . . .

Removing Scanner Interface Cable 4–3. . . . . . . . . . . . .

Autosense Mode C–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tables

Wedge Interface Cables 2–6. . . . . . . . . . . . . . . . . . . . . .

Scanner Accessories 2–6. . . . . . . . . . . . . . . . . . . . . . . . .

LED Indicators 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scanning Ranges: Standard/Long Range Scanner 3–4

Scanner Default Settings 4–10

Code Identifier Characters 6–5. . . . . . . . . . . . . . . . . . . .

Hexadecimal Conversion Table 6–8. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

v

Page 8

Chapter

Using this Manual

1

A–B

Chapter Objectives

Contents of Package

Intended Audience

This chapter gives an overview of the manual

including:

• Contents of Package

• Intended Audience

• Overview of Manual

• Warnings and Cautions

• Related Publications

You should receive the following items when

ordering the Catalog No. 2755-G3-W or

2755-G6-W Scanner:

• Scanner

• Scanner Holder

• User Manual

No special knowledge is required to install,

configure, or operate the scanners as a keyboard

wedge interface. However, this manual does not tell

you how to use or generate an application program to

receive and store the data.

1–1

Page 9

Chapter 1

Using this Manual

Overview of Manual

This manual shows how to set up and use the scanner

as a keyboard wedge interface for non-contact scan-

ning applications. The contents of each chapter are:

Chapter Title Purpose

1 Using this Manual Provides an overview of this manual.

2 Overview of Scanner Gives an overview of scanner functions, oper-

ating modes, and scanner setup parameters.

3 Using the Scanner Provides basic instructions on how to use the

scanner for non-contact scanning.

4 Setup Instructions Shows how to setup the scanner as a

keyboard wedge interface and configure the

operating parameters of the scanner.

5 General

Setup Parameters

6 Message

Format Parameters

7 Symbologies Covers parameters that enable bar code

8 Specifications Details specifications of the scanners.

Covers parameters specific to the operation of

the scanner including beeper, power consumption, and capture count. Parameters are

selected by scanning bar code labels.

Covers parameters that control the format of

messages transmitted to the host computer or

terminal. Parameters are selected by scanning

bar codes.

symbologies the scanner is capable of reading. Symbologies are disabled or enabled by

scanning bar codes.

1–2

Page 10

Chapter 1

Using this Manual

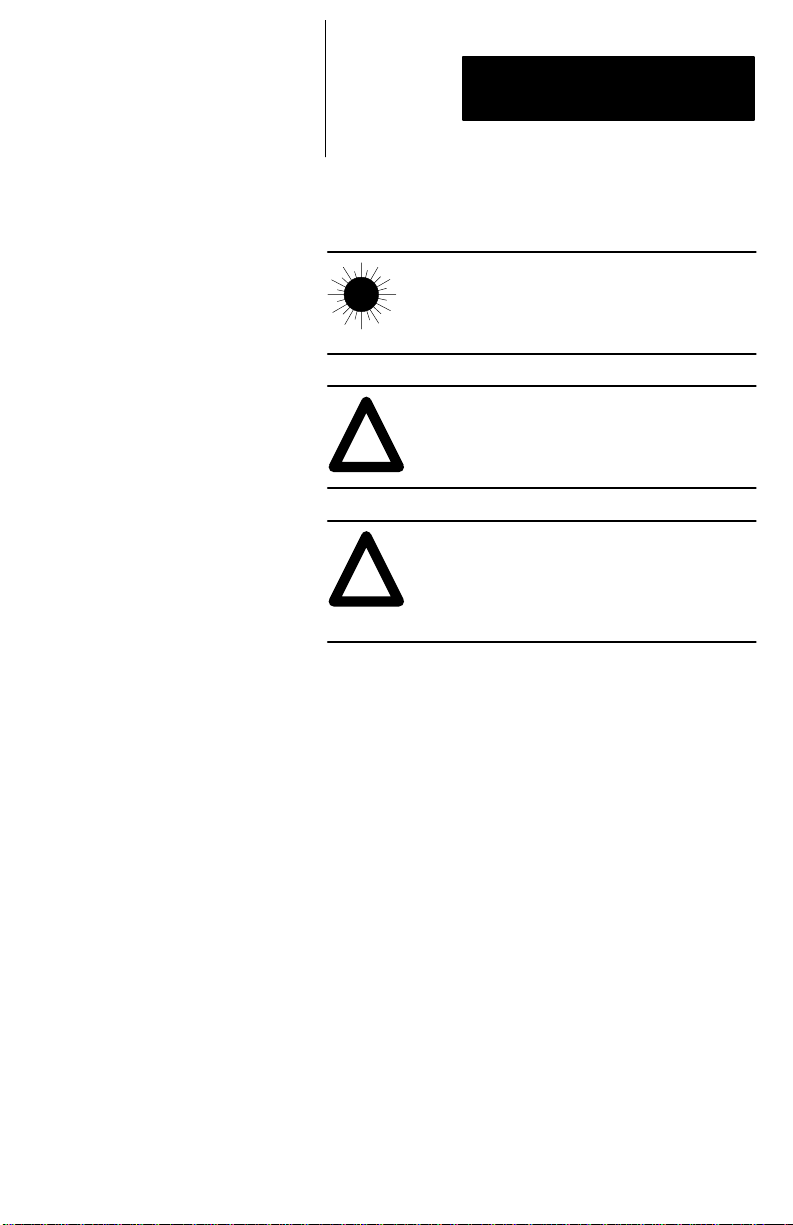

Warning and Caution Symbols

Related Publications

This manual contains the following caution and

warning symbols.

CAUTION:

A laser caution symbol that appears

where laser light is present.

WARNING:

A warning symbol means people might

!

be injured if procedures are not followed.

CAUTION:

A caution symbol is used when equip-

!

ment may be damaged if procedures are

not followed.

Below is a list of related publications you may need

to refer to when using the scanners.

• Publication No. 2755-921

Bar Code Basics

Describes bar code symbologies, equipment, and

typical applications.

• Publication No. 2755-2.44

Product Data for the family of

Visible Laser Diode Hand-Held Scanners

1–3

Page 11

Chapter

2

Overview of Scanner

A–B

Chapter Objectives

Function of Scanner

This chapter gives an overview of the scanner

including:

• Function of Scanner

• Operating Modes

• Scanner Setup Parameters

• Scanner Accessories

The scanner is a keyboard wedge interface that is

capable of scanning, decoding, and transmitting bar

code data to a host computer or terminal.

As a keyboard wedge interface you can use the

scanner with most manufacturer’s terminals. The

scanner connects between the keyboard and display

of the terminal. In this mode the scanner draws

power directly from the terminal.

The wedge translates scanned data so that it appears

as if it was entered at the keyboard. When the wedge

is transmitting scanned data, the computer ignores

data entered at the keyboard.

You configure the scanner for keyboard wedge mode

by modifying scanner setup parameters. Parameters

are selected based on the terminal type and the types

of bar codes used in your application.

The scanner is easily configured by scanning the

appropriate bar code labels in Chapters 4 through 7 of

this manual. When a configuration label is scanned,

the scanner sends a 1 or 2 line acknowledgement

message to your terminal display.

Important: It is your responsibility to provide the

appropriate application program on the host

computer/terminal to receive and store the data.

2–1

Page 12

Chapter 2

Overview of Scanner

Operating Modes

The scanner functions in one of two operating modes:

Hand-Held Mode or Autosense Mode.

Hand-Held Mode

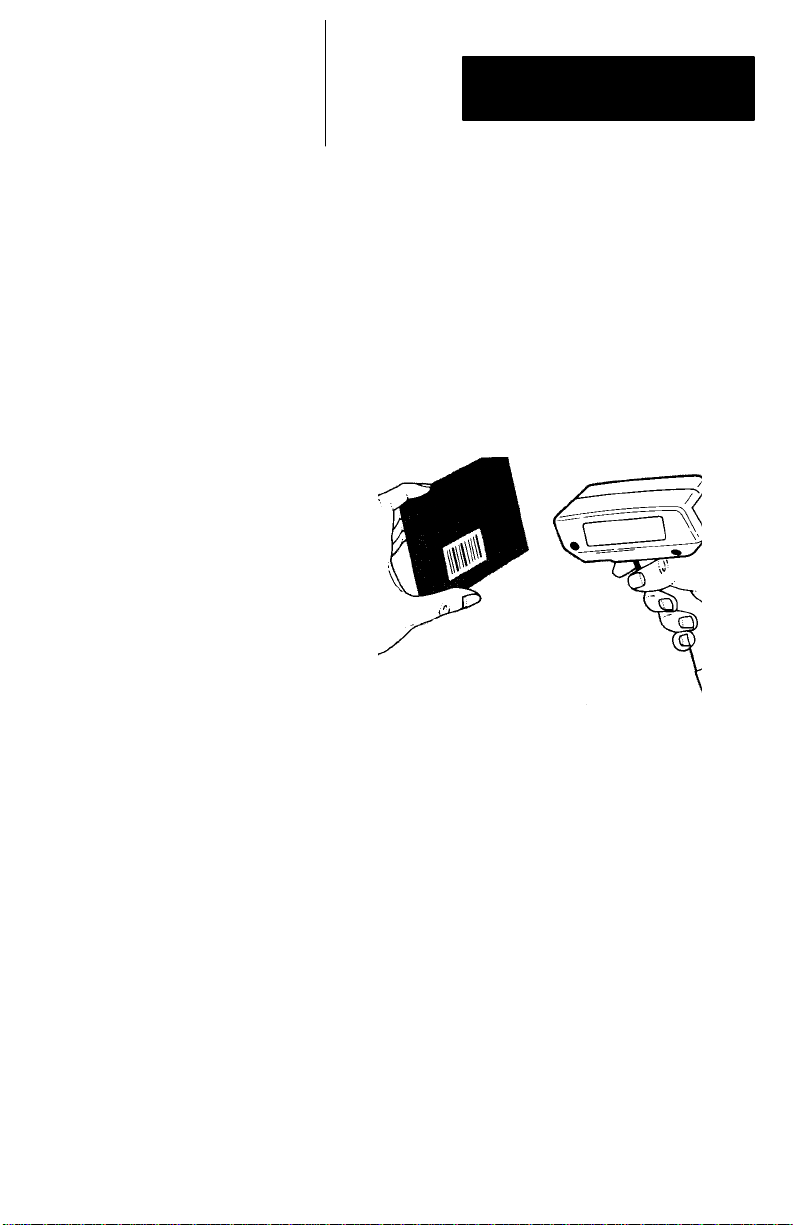

In hand-held mode, you hold the scanner in your

hand and press the trigger every time you want to

scan a bar code symbol.

Chapter 3 provides details on using the scanner in

hand-held mode.

Autosense Mode

In this mode the scanner operates in an optional

Autostand (Catalog No. 2755-NS2) for hands-free

operation. The scanner uses a low level laser beam as

an internal object sensor.

When the scanner is placed in the stand it becomes

immediately active for reading any bar code label

presented to it. The scanner is triggered when a bar

code label breaks the scan beam path (between the

reflector on the stand and the scanner).

You also have the option of removing the scanner

from the stand and using it as a conventional

hand-held scanner. The low level beam will not

interfere with hand-held use of the scanner.

2–2

When replaced in the stand the scanner reverts

automatically to the Autosense mode.

Note: Autosense mode can also be set up using a

PHOTOSWITCH reflector. See Accessories.

Page 13

Chapter 2

Overview of Scanner

Setup Parameters

The built-in setup parameters of the scanner fall into

four general categories:

• Keyboard Wedge

• General Setup

• Message Format

• Symbologies

Each category controls parameters that relate to

specific functions of scanner operations and its

operation in wedge mode.

Keyboard Wedge Parameters

Parameters that configure the scanner to operate in

keyboard wedge mode include:

• Enable Wedge Mode

• Select T erminal Type

Chapter 4 shows how to enable the scanner to operate

in wedge mode with a specific terminal type.

General Setup Parameters

General setup parameters are basic to the operation

of the scanner. These parameters control:

• System Status Display

• Power Consumption

• Beeper Operation

• Capture Count

• Spotter Beam

• Autosense Mode

General parameters are set by scanning bar code

labels in Chapter 5.

2–3

Page 14

Chapter 2

Overview of Scanner

Message Format Parameters

Parameters that control the format and speed of

messages transmitted to the host include:

• Prefix

• Suffix

• Scanner Identifier

• Code Identifier

• Preamble

• Postamble

• Intercharacter Delay

Message format parameters are enabled or disabled

by scanning bar codes in Chapter 6.

Symbology Parameters

The scanner can be configured to read the following

bar code symbologies:

2–4

• Code 39

• UPC

• EAN/JAN

• Interleaved 2 of 5

• Standard 2 of 5

• Code 128

• Codabar

Symbologies are selected based on the requirements

of the application.

You enable or disable symbologies by scanning bar

codes in Chapter 7.

Page 15

Chapter 2

Overview of Scanner

Ordering a Scanner

The following figure shows the catalog number

breakdown for ordering a scanner.

2755 - G 3 - W

Bulletin Number

Device TypeDevice Type

G = Gun

Scan Range

3 = Standard Range

6 = Long Range

Decoder Type

W = Wedge

2–5

Page 16

Chapter 2

Overview of Scanner

Scanner Accessories

Table 2.A lists the wedge interface cables available

for the supported terminal types. Included with each

catalog number is an 8 foot (2.4 meter) coiled

scanner interface cable.

Table 2.A

Wedge Interface Cables

Catalog No. T erminal Description

2755-NC20 IBM-PC, -XT, -AT

Allen-Bradley 6120, 6121

Alen-Bradley 1784-T35, -T50, -T60

Allen-Bradley 2706-DL40 (AT or XT Mode)

Compaq DeskPro, Compaq 286

2755-NC21 IBM PS/2 (50, 55, 60, 80)

Compaq 386

2755-NC22 IBM 3151, 3472

2755-NC24 DEC VT220, VT240, VT320, VT340,

VT420, VT1000

1

Requires Catalog No. 2755-PW1 Power Supply

Table 2.B lists other accessories for the scanners.

Table 2.B

Scanner Accessories

1

2–6

Catalog No. Description

2755-NS1 Scanner Holder (included with scanner).

2755-NS2

Autostand

2

2755-GB1 Holster Belt

2755-GH5 Scanner Holster (functions on belt or sling)

2755-PW1 5V Power Supply, 110 VAC, 60 Hz

2755-NT1 Reflective Tape, 2 inch (50.8 mm) square

3

92-39

92-47

2

Reflective tape is supplied with Autostand. Additional reflective

Circular Reflector, 3 inch (76.2 mm) diameter

3

Circular Reflector, 1 1/4 inch (31.8 mm) diameter

tape is available by ordering Catalog No. 2755-NT1.

3

Allen-Bradley PHOTOSWITCH part number.

Page 17

Chapter

Using the Scanner

3

A–B

Chapter Objectives

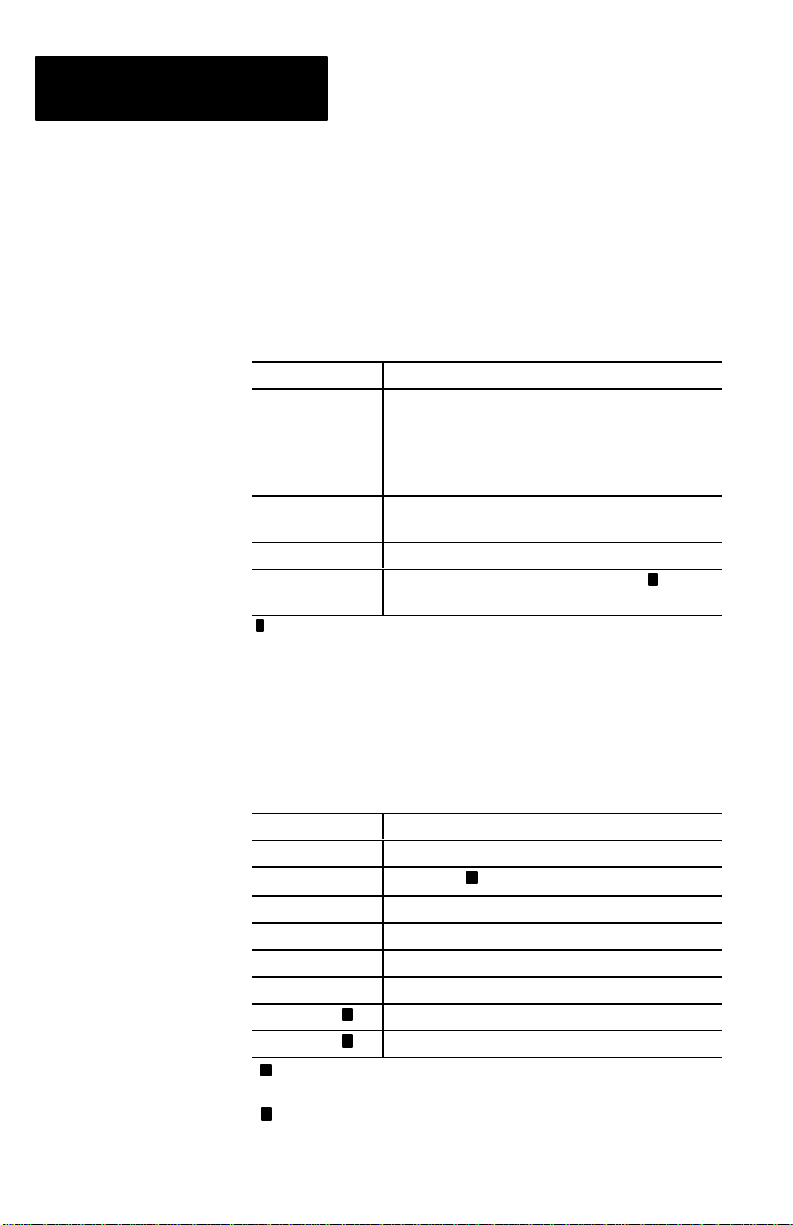

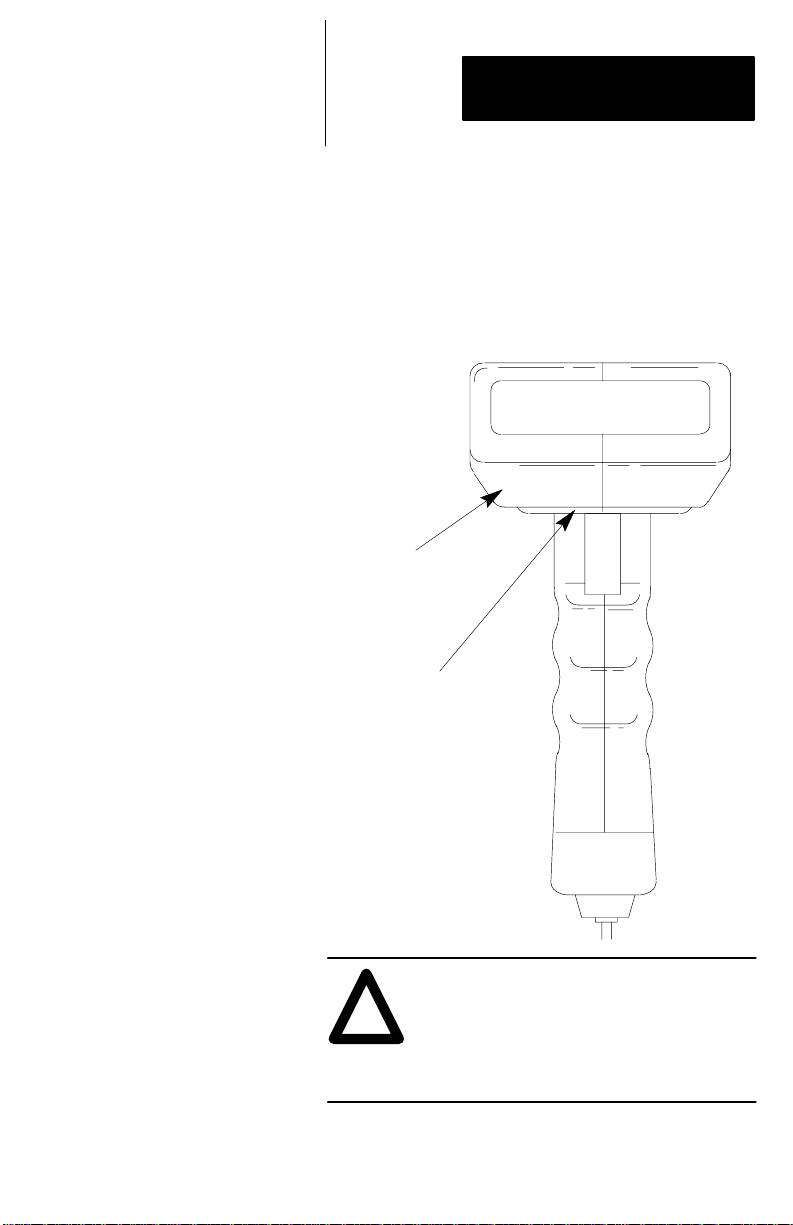

Physical Description

This chapter covers some basic topics on the

operation and use of the scanner including:

• Physical Description

• LED Indicators

• Safety Labels

• Scanning Ranges

• Operating Scanner

• Beep

• Operating Tips

• Troubleshooting

The scanners use a low power visible laser diode light

source for non-contact scanning applications.

The trigger in the handle of the scanner turns on the

light beam. The beam exits the window on the front

of the scanner.

LED Indicators

Cable Connection

Note: If your scanner is enabled for Autosense

mode, the internal object sensor is automatically

triggered when bar codes are presented to it.

Scanning Window

Trigger

3–1

Page 18

Chapter 3

Using the Scanner

Light, reflected off the bar code symbols, passes back

through the window and is detected by light sensors.

When a label is read, the laser is automatically turned

off until the next pull of the trigger.

The laser beam looks like a narrow red line of light. It

is actually a tiny spot of light traveling very fast. The

laser spot moves across the bar code symbol at

approximately 35 scans/second. The bar code is

scanned many times in a short period of time.

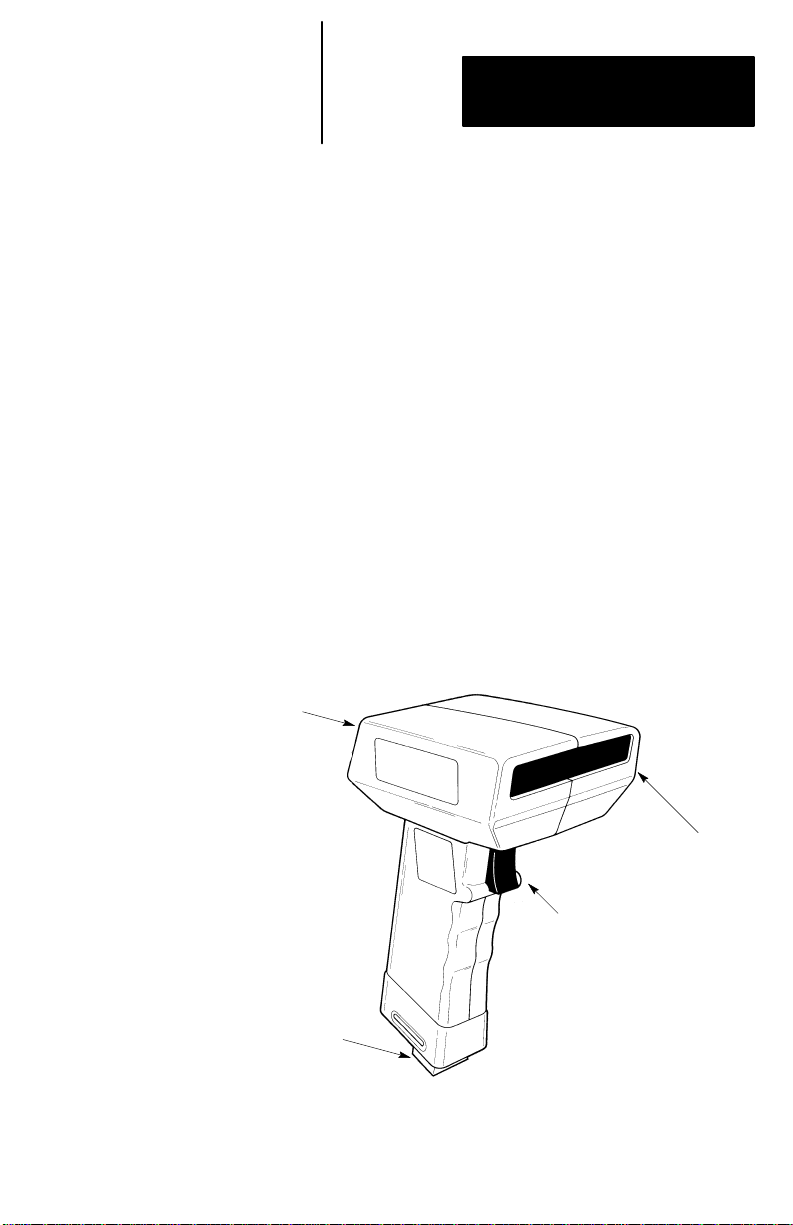

LED Indicators

The rear of the scanner has two indicators that

provide a visual indication of scanner operation.

GOOD READ

SCANNING

Table 3.A defines the color and function of each

LED indicator.

Table 3.A

LED Indicators

LED Label Color Function

The GOOD READ light momentarily turns on

GOOD READ Green

SCANNING Yellow The SCANNING light turns on when the

(and you will hear a beep) when a bar code

symbol has been successfully decoded.

device is scanning.

3–2

Page 19

Chapter 3

Using the Scanner

Safety Labels

The scanners use a low power visible laser diode. As

with any bright light source, such as the sun, you

should avoid staring directly into the beam.

Momentary exposure to a CDRH Class II laser is not

known to be harmful.

The following figure shows the location of all safety

labels as they appear on the scanner.

CAUTION:

Use of controls, adjustments, or perform-

!

ance of procedures other than those

specified herein may result in hazardous

visible light exposure.

3–3

Page 20

Chapter 3

Using the Scanner

Scanning Ranges

The scanners can read bar code labels at various

distances depending on the bar code width (width of

narrowest element in bar code, either bar or space).

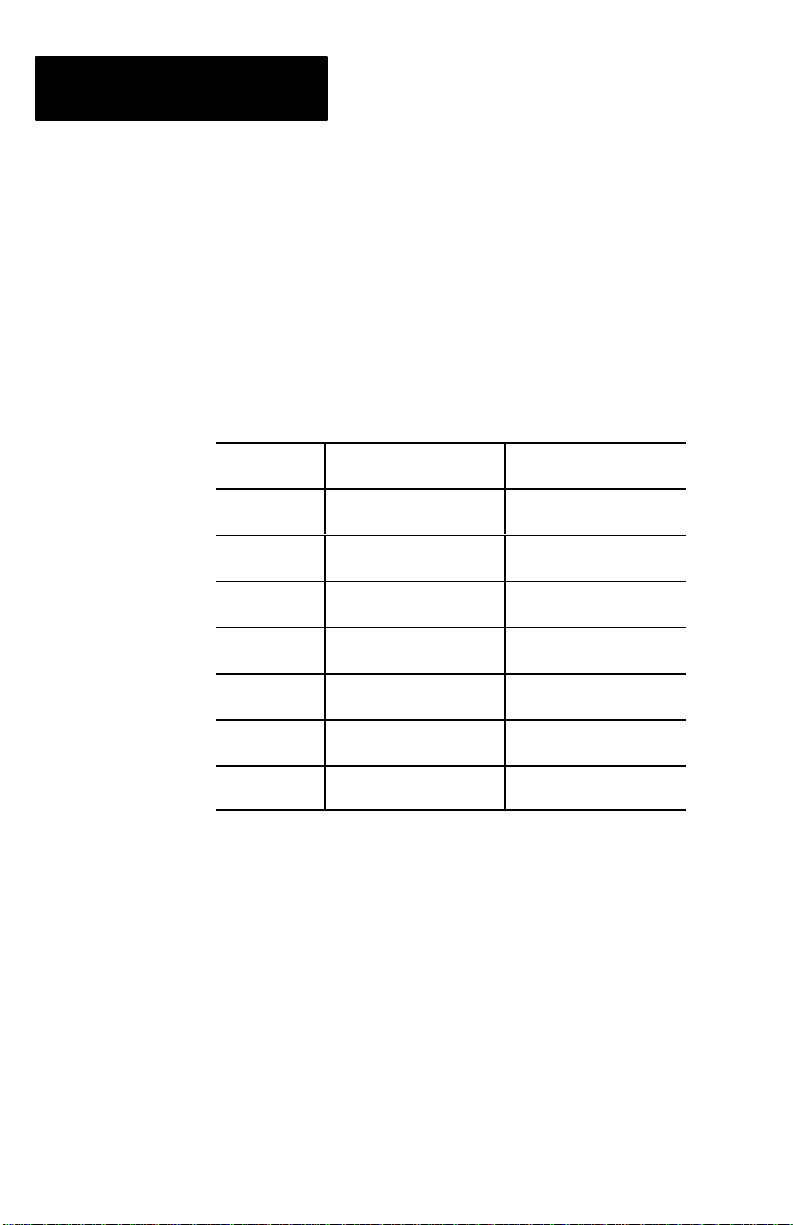

T able 3.B defines the scanning ranges for both the

standard and long range scanner. Scanning ranges are

listed for symbols with bar code widths from 6.0 mil

to 55.0 mil (.15 mm to 1.40 mm).

Table 3.B

Scanning Ranges: Standard and Long Range Scanners

Bar Code

Width

6.0 mil

(.15 mm)

7.5 mil

(.19 mm)

10.0 mil

(.25 mm)

15.0 mil

(.38 mm)

20.0 mil

(.51 mm)

40.0 mil

(1.02 mm)

55.0 mil

(1.40 mm)

Standard Range

(2755-G3-W)

3.0 in - 5.0 in

7.6 cm - 12.7 cm

2.5 in - 7.5 in

6.4 cm - 19.0 cm

1.0 in - 10.0 in

2.5 cm - 25.4 cm

1.5 in - 14.0 in

3.8 cm - 35.6 cm

2.5 in - 18.0 in

6.4 cm - 45.7 cm

9.0 in - 25.0 in

22.9 cm - 63.5 cm

12.0 in - 30.0 in

30.5 cm - 76.2 cm

Long Range

(2755-G6-W)

N.A.

N.A.

N.A.

8.0 in - 22 in

20.3 cm - 55.9 cm

12 in - 36 in

30.5 cm - 91.4 cm

23 in - 60 in

58.4 cm - 152.4 cm

23 in - 66 in

58.4 cm - 167.6 cm

3–4

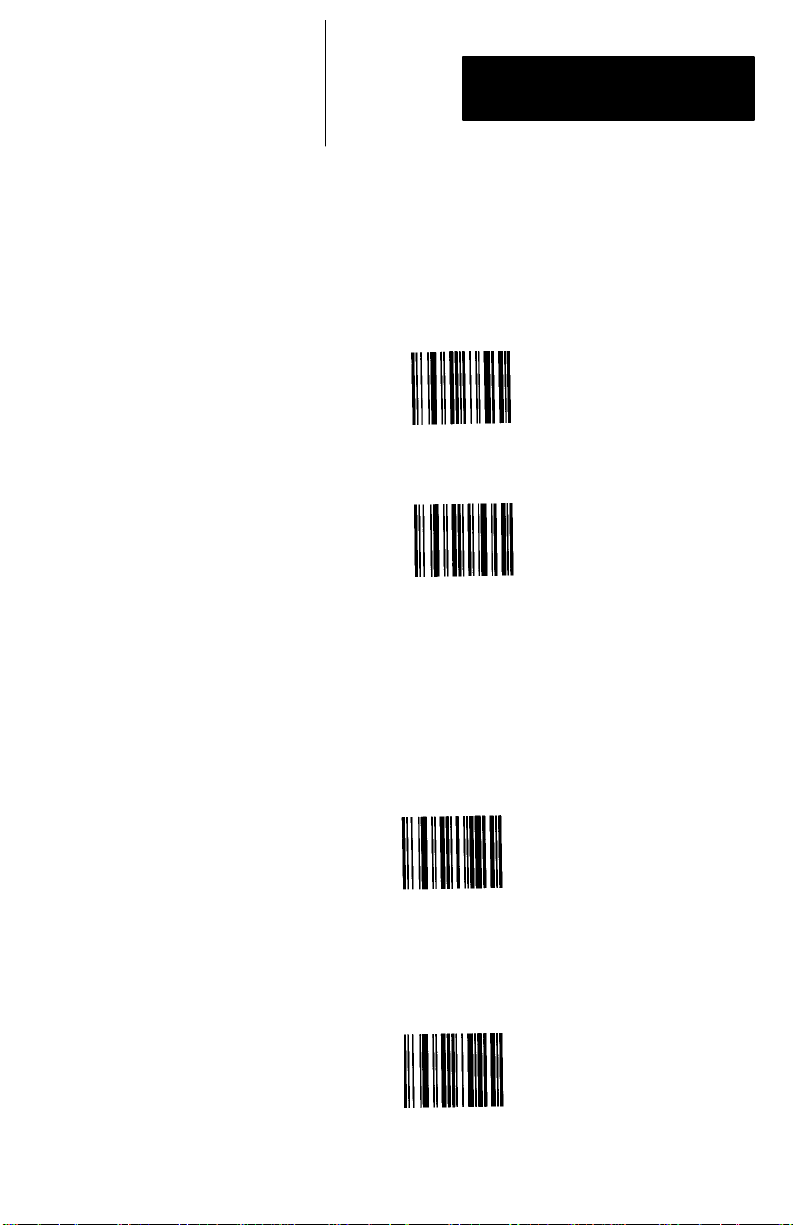

Figure 3.1 illustrates the scanning ranges in graphic

form. The figure shows that the scanning range of

the standard range scanner for a 40.0 mil (1.02 mm)

bar code width is 9.0 - 25.0 inches (22.9 - 63.5 cm).

The scanning range of the long range scanner for the

40.0 mil (1.02 mm) bar code width is 23 - 60 inches

(58.4 - 152.4 cm).

Page 21

Standard Range Scanner

Catalog No. 2755-G3-W

Narrow

Bar Width

Scanner

0.006 in

(0.15mm)

0.0075 in

(0.19mm)

inches

centimeters

0

Figure 3.1

Scanning Ranges

0.010 in

(0.25mm)

0.015 in

(0.38mm)

0.020 in

(0.51mm)

10 20 30

5

25.4 50.8 76.2

12.7

Chapter 3

Using the Scanner

0.040 in

(1.02 mm)

(1.40 mm)

15

38.1

Depth of Field

0.055 in

63.5

10

5

Width

of

0

Scanning

Beam

(inches)

5

10

25

Long Range Scanner

Catalog No. 2755-G6-W

Scanner

Narrow

Bar Width

0

inches

centimeters

15.0 mil

(0.38 mm)

20.0 mil

(0.51mm)

40.0 mil

(1.02 mm)

55.0 mil

(1.40 mm)

25.4 50.8 76.2 101.6 127.0

2010

Depth of Field

10

5

Width

of

0

Scanning

Beam

(inches)

5

10

504030

60 70

152.4 177.8

3–5

Page 22

Chapter 3

Using the Scanner

Operating

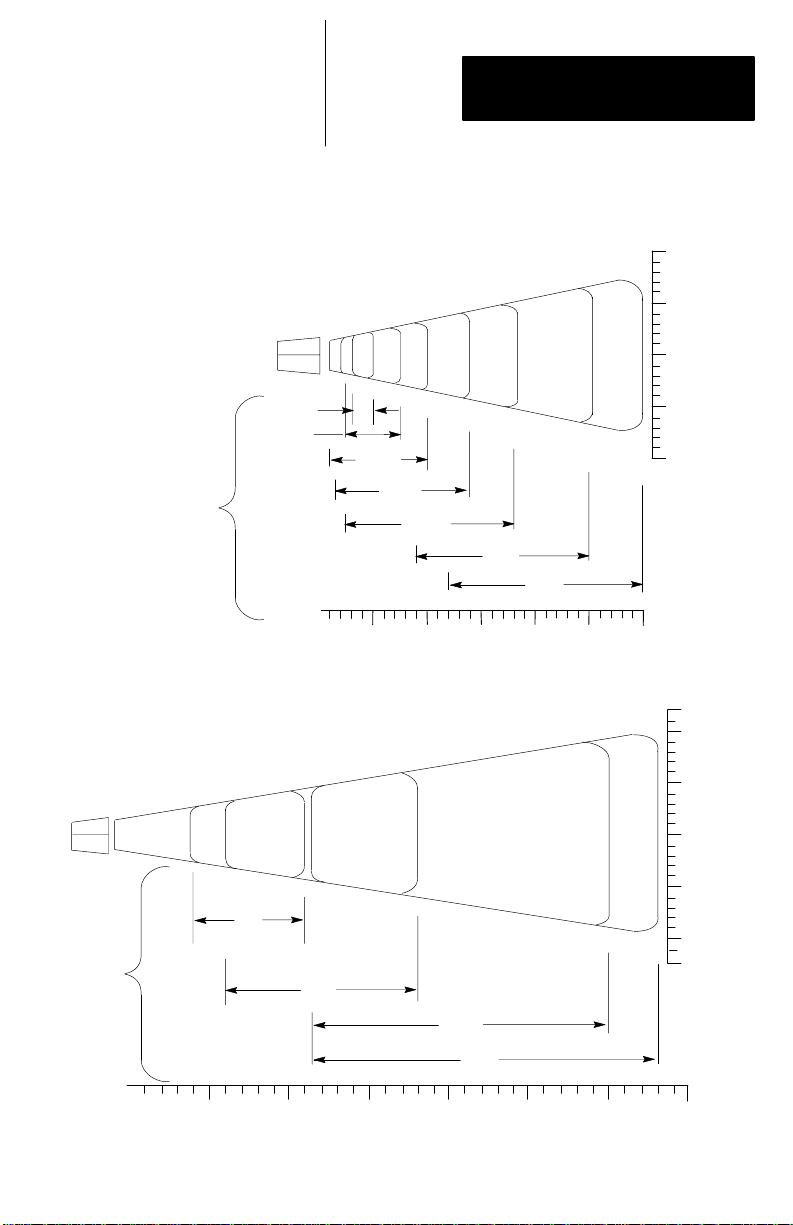

Follow these basic steps to operate scanner.

Scanner

1. Check

Before using the scanner, check

all cable connections to make

sure they are secure.

Chapter 4 defines the wedge

interface connections for

the scanner.

2. Test

Aim the scanner at the work

surface and press the trigger.

You should see the red beam on

the work surface, and the SCANNING indicator on the back of

the unit should be on.

2. Scan

Aim the scanner at the bar code and

press the trigger. Adjust the scanner

position so the beam is centered on the

bar code and overlaps it on both sides.

When the scanner has read the symbol:

• You will hear a beep and/or ...

• The GOOD READ light will

turn on momentarily.

• The red beam will turn off.

If you fail to scan, see the Trouble-

shooting section.

3–6

Page 23

Chapter 3

Using the Scanner

Beep

Operating Tips

RIGHT

When scanning a bar code symbol, listen for one

short, high tone. It means the bar code has been

decoded successfully.

Hold at an Angle

Do not hold the scanner directly over the bar code. In

this position light can bounce back into the scanner

and prevent decoding. Angle the scanner slightly.

Scan the Entire Symbol

• Move the scanner so the beam crosses every bar

and space on the symbol.

• The larger the symbol the farther away you should

hold the scanner.

• Hold the scanner closer for symbols with bars that

are close together.

• If you have difficulty reading a label hold the

scanner beyond the recommended range in Figure

3.B and then move the scanner closer.

WRONG

3–7

Page 24

Chapter 3

Using the Scanner

Troubleshooting

This section provides a list of things to check if you

are having problems scanning.

Note: Scanning problems are most often caused

by poor quality bar code symbols. If scanning

problems arise test your bar code system using the

high quality bar code test symbols supplied in

Appendix A.

• Make sure the scanner is configured to read the

the type of bar codes you are trying to scan.

• Check if the bar code symbol is worn or damaged.

• Verify that you are holding the scanner at an angle.

• Make sure the beam crosses every bar and space

on the symbol.

• Check for loose cable connections.

• Check that there is power to the scanner and the

host computer or terminal.

If you perform these checks and the symbol still does

not scan, contact your Allen-Bradley representative.

3–8

Page 25

Chapter

Setup Instructions

4

A–B

Chapter Objectives

Installing Wedge Interface

This chapter provides setup instructions including:

• Installing the Wedge Interface

• Enabling Wedge Mode

• Selecting T erminal Type

• Scanner Configuration Guidelines

• Scanner Default Settings

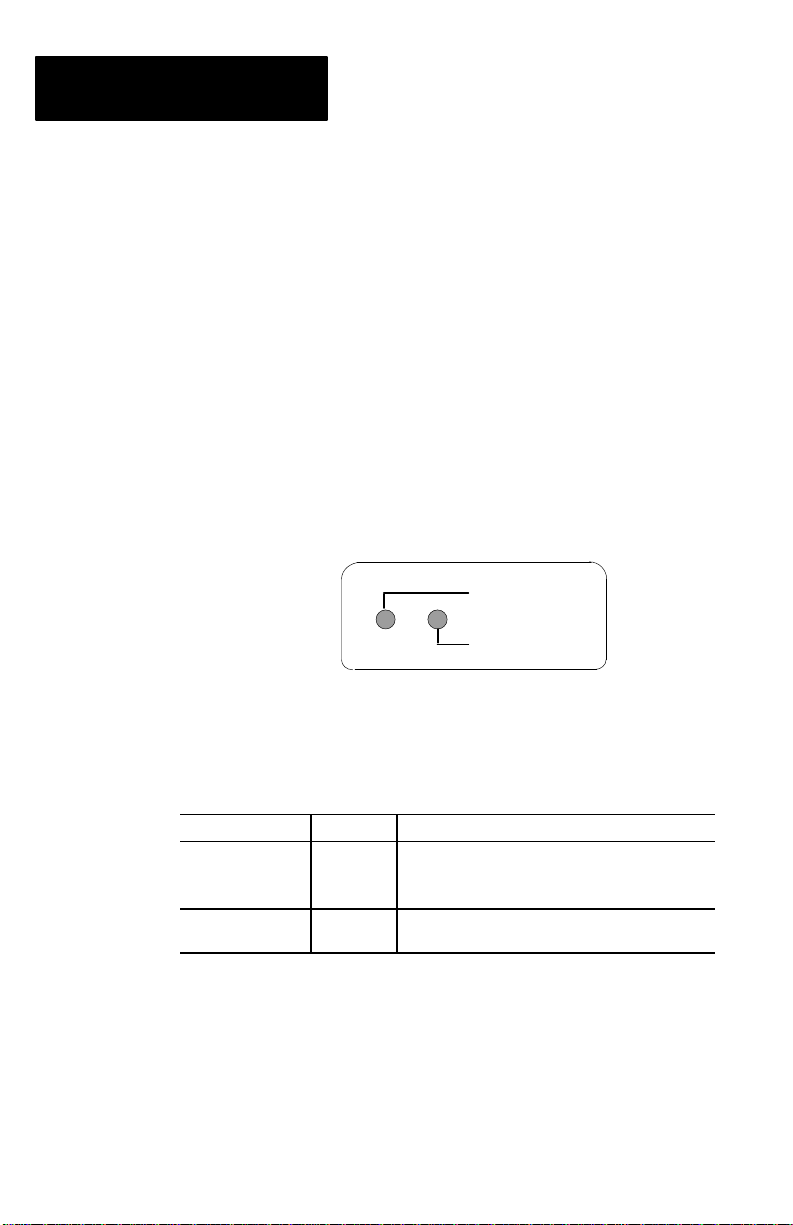

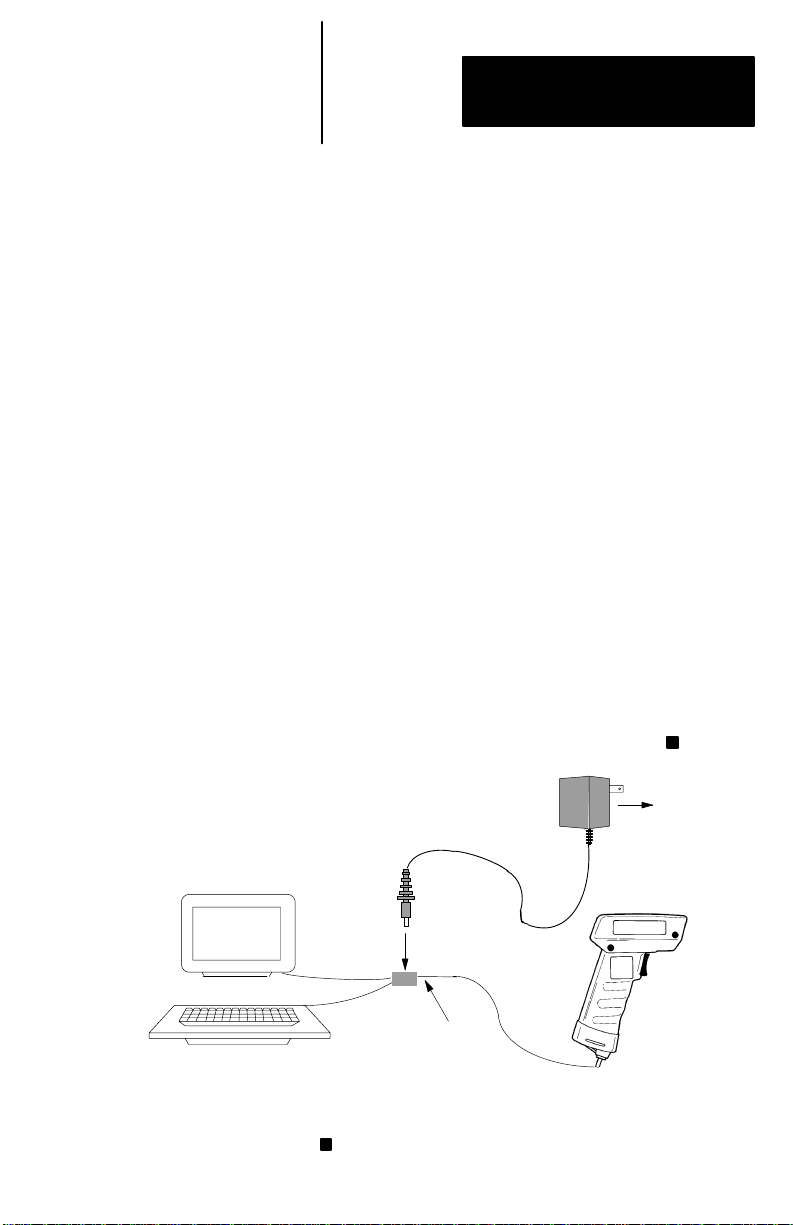

Figure 4.1 shows the basic connections for installing

the scanner as a keyboard wedge interface. The

installation uses two cables: the scanner interface

cable and the wedge interface cable. Cables for the

different terminal types are listed in Table 2.A.

Figure 4.1

Keyboard Wedge Interface Connections

Optional Power Supply

Catalog No. 2755-PW1

1

AC

Power Source

Computer

or T erminal

Power Supply

Receptacle

Wedge

Interface Cable

1

Optional power supply required for DEC terminals.

Scanner

2755-G3-W or

2755-G6-W

4–1

Page 26

Chapter 4

Setup Instructions

Connecting Scanner Interface Cable

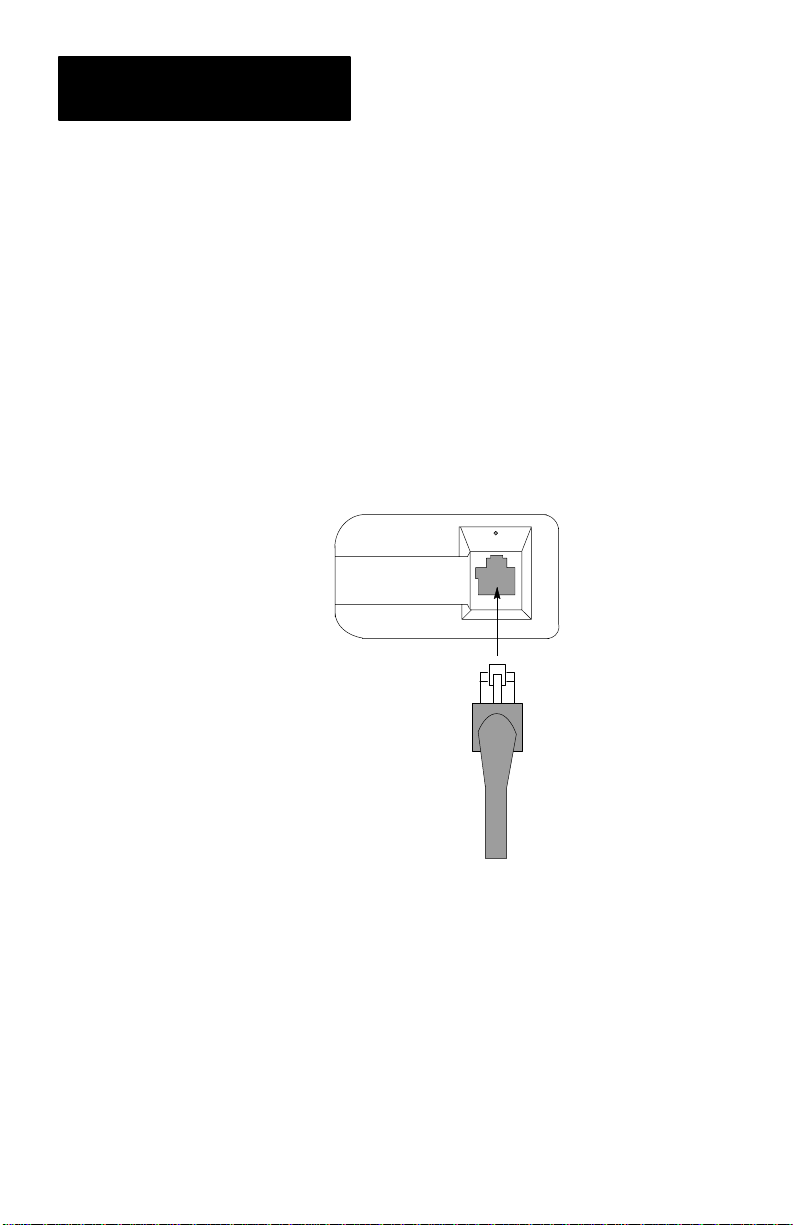

The scanner interface cable has a modular plug

(resembling a telephone connector) on one end and a

DB9 squeeze-to-release connector on the other end.

T o install the interface cable:

Insert the modular plug into the opening at the

bottom of the scanner’s handle (Figure 4.2). The

modular plug is keyed to insure proper insertion.

Press firmly until the plug clicks into place.

Figure 4.2

Connecting Scanner Interface Cable

4–2

Page 27

Chapter 4

Setup Instructions

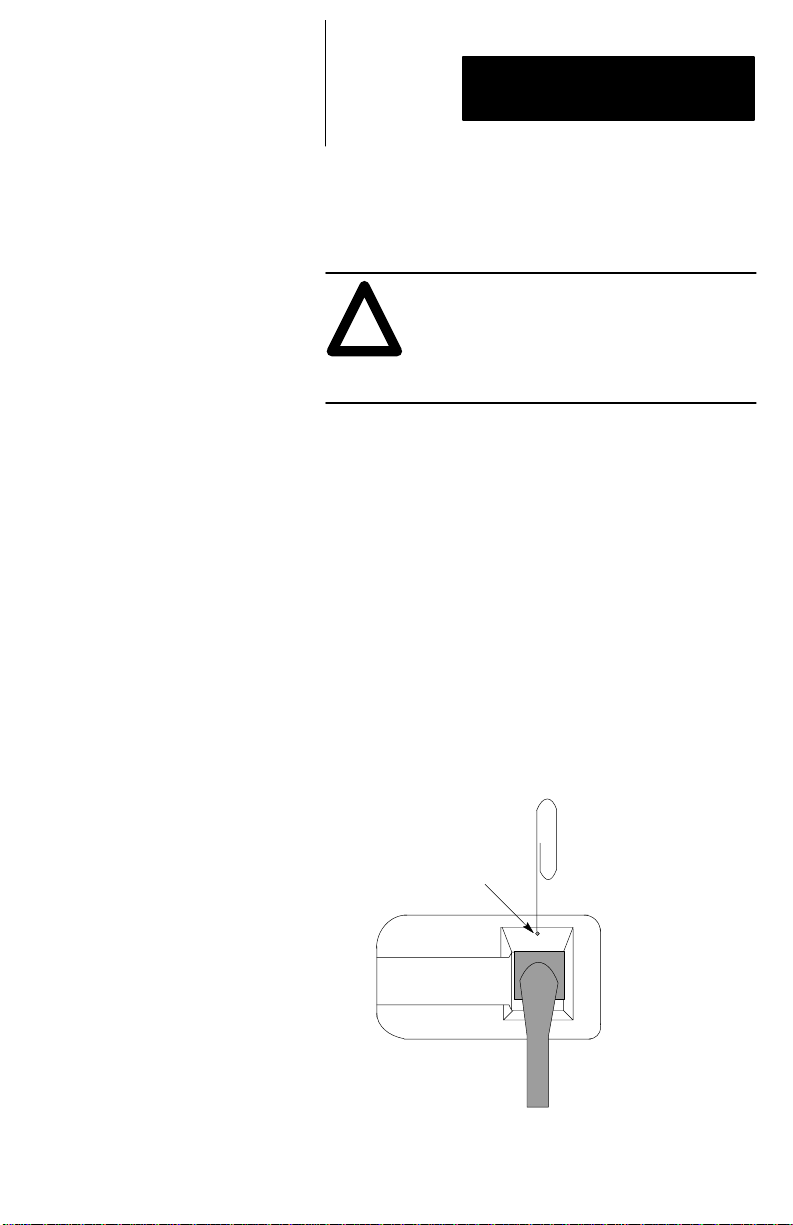

Removing Scanner Interface Cable

At some point you may have to replace the interface

cable with another cable.

CAUTION:

Do not remove the scanner interface cable

!

until the host computer/terminal is turned

off. Failure to do this could result in

damage to the scanner.

T o remove the interface cable, follow these steps.

1. Turn power to computer/terminal off.

2. Disconnect optional power supply from AC

power source.

3. Disconnect scanner from wedge interface cable.

4. Insert a straightened paper clip into the cable

release hole as shown in Figure 4.3.

5. Press down firmly on the paper clip to release the

retainer and gently pull the connector out of the

scanner.

Figure 4.3

Removing Interface Cable

Cable Release Hole

4–3

Page 28

Chapter 4

Setup Instructions

Connecting Wedge Interface Cable

The wedge interface cable connects the scanner to the

terminal keyboard and the terminal. You select a

wedge interface cable based on the the terminal you

are using. The available cables are listed in T able 2.A.

The wedge interface cable has a connector housing

and a ”Y” cable. The housing contains 1 or 2

plug-in sockets for the scanner and an optional power

supply . The two legs of the ”Y” cable connect to the

terminal keyboard and the terminal.

CAUTION:

Do not connect scanner to terminal until

!

power to the terminal is off. Failure to do

this could result in damage to the scanner.

T o connect the wedge interface cable:

1. Turn off power to the computer/terminal to which

the scanner will be connected.

4–4

2. Plug the DB9 squeeze-to-release connector

of the scanner interface cable into the

connector housing of the wedge interface cable.

3. Unplug the keyboard from the terminal and replug

the keyboard into the short leg of the ”Y” cable.

4. Plug the remaining long leg of the ”Y” cable into

the terminal where the keyboard was connected.

5. Arrange the fully connected unit so that all cables

run freely.

Page 29

Chapter 4

Setup Instructions

Connecting Optional Power Supply

Some terminal interfaces require an external power

supply . One end connects to a standard AC

receptacle supplying the appropriate voltage level.

The other end plugs into a receptacle located on the

housing connector of the wedge interface cable.

CAUTION:

The Catalog No. 2755-PW1 Power Supply

!

has the following polarity:

+

+5 V Ground

If using another power supply, the polarity

must be the same.

T o install the power supply:

1. Power to the terminal must be turned off.

CAUTION:

Do not connect power supply until the

!

terminal is turned off. Failure to follow

this caution could result in damage to the

scanner or terminal.

2. Plug the circular connector of the power supply

into the receptacle on the housing connector of

the wedge interface cable.

3. Plug the power supply into a standard AC

power source.

Terminal Power Up Sequence

Turn on the power to the terminal to which the

scanner is connected. The unit will issue a series of

beeps which are intentional and indicate that the

terminal/keyboard power-on reset routines have

been completed.

4–5

Page 30

Chapter 4

Setup Instructions

Enabling Wedge Mode

Selecting a Terminal Type

CF

After installing the keyboard wedge interface you

need to enable the scanner to operate in wedge mode.

If this is a first time installation you must enable

the scanner to operate in wedge mode.

T o enable wedge mode, scan label CE and listen for

two short beeps.

CE Enable

Wedge Mode *

You now need to identify the type of terminal that the

wedge interface is connected to. Scan the appropriate

label below and listen for two short beeps.

First time installations require you to program the

scanner for use with the connected terminal.

PC-AT *

PS/2 and 50/60/80

Allen-Bradley 6121

Allen-Bradley 1784-T50, -T60

Allen-Bradley 2706-DL40

Allen-Bradley 1784-T35 (AT mode)

Compaq 386, 286

1

2

PC-XT

CG

1

Can be used in AT or XT mode depending on the internal jumper. See DL40 User Manual.

2

Can be used in AT or XT mode depending on the DIP switch setting. See User Manual for 1784-T35.

4–6

Allen-Bradley 6120, 2706-DL40

Allen-Bradley 1784-T35 (XT mode)

Compaq Deskpro

1

2

Page 31

Chapter 4

Setup Instructions

CH

CI

IBM 3151

3472

,

DEC VT220

VT240, VT320, VT340,

VT420, VT1000

You have now completed the process of installing and

configuring the scanner to operate in wedge mode.

The rest of the manual covers additional

parameters that can be set for the scanner and

your application. Review the configuration

guidelines and factory default settings in the

following sections to determine if changes are

required.

4–7

Page 32

Chapter 4

Setup Instructions

Scanner Configuration Guidelines

Configuration is the process of enabling or disabling

certain scanner operating parameters. The host

computer/terminal and the types of bar codes that will

be encountered will determine which parameters

should be enabled or disabled.

Follow three basic steps to configure your scanner:

1. Review the rest of the manual to familiarize

yourself with each group of scanner parameters.

2. Review the requirements of your application

This will enable you to determine if the factory

defaults must be changed.

3. Enable or disable the relevant parameters by

scanning the bar codes in Chapters 4 through 7.

The section that follows describes this process.

All configuration bar code labels in this manual

are Code 128, Character Set B.

Scanning Menu Labels

The scanner does not have a distinct configuration

mode. Instead, it automatically recognizes and reacts

to labels you scan. You do not scan an enter or exit

label to begin or exit configuration mode.

Most parameters are set by scanning one label. For

example, assume your application uses Codabar

labels. By default, this symbology is disabled.

T o select the Codabar symbology, locate the Codabar

menu in Chapter 7 and scan the label to the left of

Enable Codabar. The correct label is shown below.

4–8

VB

A successful scan is indicated by two short-high

beeps. An unsuccessful scan produces no beeps

and requires you to rescan the Codabar label.

Most parameters are modified in this way. When you

are finished with modifications you can resume

normal bar code scanning.

Enable

Codabar

Page 33

Chapter 4

Setup Instructions

Note: When enabling or disabling a parameter, be

sure the scanner beam illuminates only one symbol at

a time. The layout of this manual minimizes the

accidental scanning of multiple labels.

Some parameters require that you scan multiple

labels to modify a setting. An example is the

Intercharacter Delay parameter. To set the

intercharacter delay to 5 milliseconds (msec):

1. Scan the Intercharacter Delay (GB) label and

listen for one short beep.

GB

+

Intercharacter Delay=xx msec

The dotted boxes to the right of the label indicate

that you must scan two additional labels; one for

the digit 0 and the second for the digit 5.

2. After the beep, scan the bar code beside 0 in

Appendix B, and listen for one short-high beep.

3. Scan the bar code beside 5 in Appendix B and

listen for two short beeps. The two beeps indicate

that you scanned the last parameter argument.

If you scan the

Intercharacter Delay (GB) label and

then scan a normal data label (instead of 0 and 5), a

normal tone is emitted in response to the data label,

and the programming command is ignored. No exit

code is required to resume normal operations.

Note: Any parameter that requires multiple scans

will display dotted boxes to the right of the primary

label. The number of dotted boxes indicates the

number of additional labels to be scanned.

4–9

Page 34

Chapter 4

Setup Instructions

Scanner Default Settings

Parameter

Wedge Mode Enable or Disable Enable

Terminal Type PC-AT, PS/2, 50/60/80

PC-XT

IBM 3151

DEC VT220

Parameter Options Default

Power Consumption Enable Continuous Full Power

Enable Standby

Beeper Operation Beeper Off

Beeper On; Volume Low

Beeper On; Volume Medium

Beeper On; Volume Loud

Capture Count 1 or 2 1

Spotter Beam Enable or Disable Disable

Autosense Mode Enable or Disable Disable

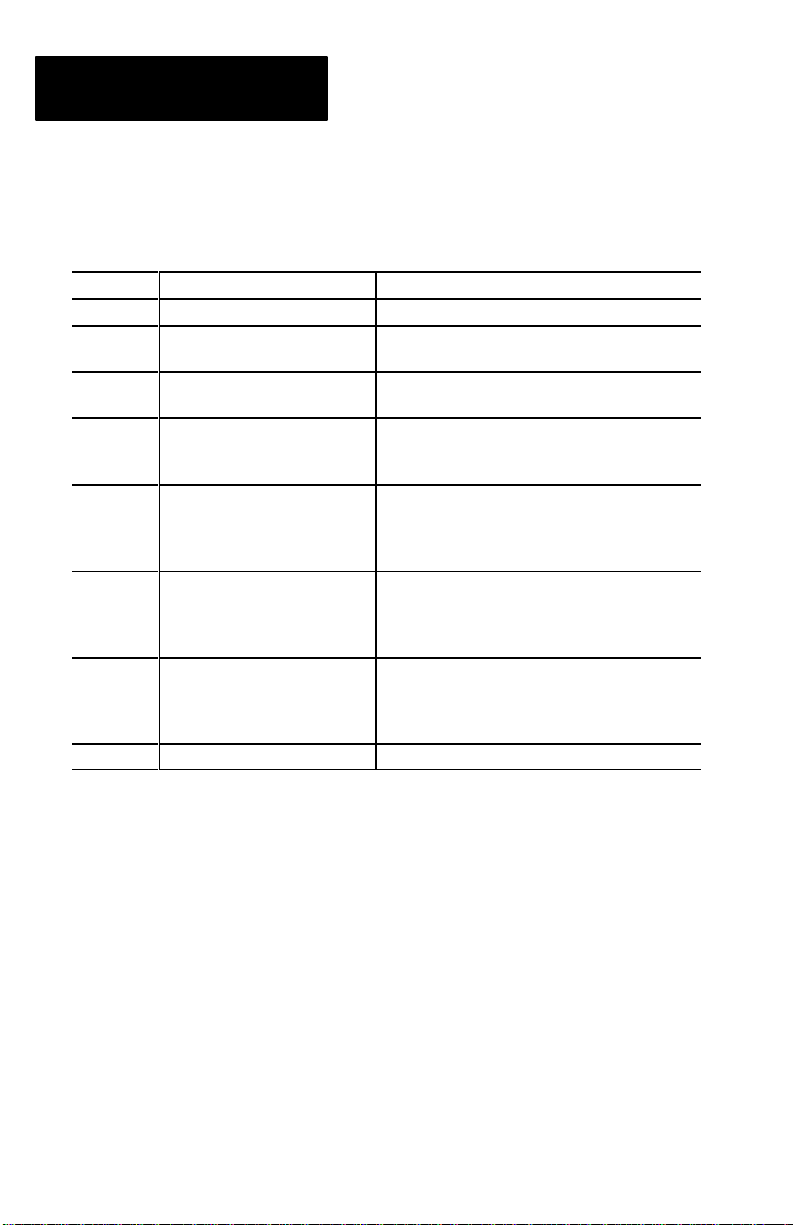

T able 4.A lists the factory default settings for each

group of scanner parameters.

Table 4.A

Scanner Default Settings

Keyboard Wedge

Options Default

PC-AT, PS/2, 50/60/80

General Scanner Setup

Continuous Full Power

Beeper On; Volume Loud

4–10

Page 35

Chapter 4

Setup Instructions

Table 4.A (continued)

Scanner Default Settings

Message Format

Parameter

Prefix None, STX, or SOH None

Suffix None, ETX, CR, LF, HT, or

CR and LF

Scanner Identifier Disable or a number (01- 99) Disable

Code Identifier Disable or Enable Disable

Preamble None or 1-4 characters None

Postamble None or 1-4 characters None

Intercharacter Delay User Defined Delay (in msec) or

No Intercharacter Delay

Code

Code 39 Disable

Enable Standard Code 39

Enable Full ASCII Code 39

Enable or Disable Modulo 43

Check Character

Enable or Disable Transmission

of Start/Stop Character

Minimum Length 1

Maximum Length 32

UPC (A and E) Disable

Enable with 2 or 5 digit supplements

Enable without 2 or 5 Digit Supplements

Enable/Disable Expanded UPC-E Disable

Enable/Disable Transmission

of Number System Chararacter

Enable/Disable Transmission

of Check Digit

Enable/Disable UPC to EAN Translation Disable

Options Default

None

No Intercharacter Delay

Symbologies

Options Default

Enable Standard Code 39

Disable

Disable

Enable without 2 or 5

Digit Supplements

Enable

Enable

4–11

Page 36

Chapter 4

Setup Instructions

Table 4.A (continued)

Scanner Default Settings

Symbologies

Code

EAN/JAN (8 or 13 digit) Disable

Enable with 2 or 5 Digit Supplements

Enable without 2 or 5 Digit Supplements

Enable or Disable Transmission

Number System Chararacter

Enable or Disable Transmission

of Check Digit

Interleaved 2 of 5 Disable

Enable without Check Digit

Enable with Check Digit

Minimum Length 2

Maximum Length 32

Standard 2 of 5 Enable or Disable Disable

Minimum Length 4

Maximum Length 32

Code 128 Enable or Disable Enable

Minimum Length 1

Maximum Length 32

Codabar Enable or Disable Disable

Enable or Disable Transmission

Number System Chararacter

Minimum Length 1

Maximum Length 32

Options Default

Disable

Enable

Enable

Disable

Disable

Resetting Factory Defaults

4–12

To reset the scanner to the factory default settings

(listed in T able 4.A) scan label ZA.

ZA

Reset to

Factory Defaults

Note: Scanning this label produces a bi-level tone.

Page 37

Chapter

5

General Setup Parameters

A–B

Chapter Objectives

System Status

This chapter describes parameters specific to the

operation of the scanner including:

• System Status

• Power Consumption

• Beeper Operation

• Capture Count

• Spotter Beam

• Autosense Mode

T o set specific operating parameters, scan the

appropriate bar code labels in each section.

Note: Throughout this chapter, default settings for

parameters are flagged by an asterisk (* ).

The labels in this section allow you to examine the

configuration of your system.

T o send a list of currently programmed parameters to

the display device, scan option ZB. A sample display

is shown on the top of the next page.

Note: Scanning ZB may interfere with your terminal

software, depending on your application.

ZB

Display Configuration

5–1

Page 38

Chapter 5

General Setup Parameters

Display Configuration Example (ZB Command)

Model 5317

Power

Data Bits

Char Delay

Scanner ID

Preamble

Code ID Char

Serial Buffr

*

Armed

ASCII

*

Addendum

Xmit S/S

Check Ch

Send Sys #

Send Ck Ch

UPCE Expand

Limits

Redundant Scan=Capture Count, Armed=Enabled, Addendum=Supplements

*

Shaded parameters are not supported in this product.

Always On

7

00

None

None

No

Full

39Parameter

Yes

No

–

No

No

–

–

–

01–32

UPC

Yes

–

No

–

–

Yes

Yes

No

–

Beeper

Parity

Protocol

Prefix

Postamble

Labels

Display Duplex Half

Symbology

EAN

No

–

No

–

–

Yes

Yes

–

–

I 2/5

No

–

–

–

No

–

–

–

02–32

Loud

None

Off

Off

None

Full

S 2/5

No

04–32

128

Yes

–

–

–

–

–

–

–

–

–

–

–

–

–

–

01–32

Version

Baud Rate

Stop Bits

RTS

Suffix

*

Redundant Scan

Label Delay

Auto Label Bfr Off

Codabr

No

–

–

No

–

–

–

–

01–32

Scan option ZC to send the program version number

followed by carriage return-line feed (CR-LF) to the

display device. The version number is sent in the

form ##.## (1.00, for example).

2.51

9600

1

Rcv Rdy+

Off

No

00

5–2

ZC

Transmit Version Number

Scan option @C to send an identification code which

verifies the specific program type of the scanner to

the display device.

@C Transmit Program ID

Note: Options ZC and @C are used for

troubleshooting to identify the scanner.

Page 39

Chapter 5

General Setup Parameters

Power Consumption

You can select one of two power consumption modes

for the scanner. Option @A supplies full power to the

scanner at all times. Option @B allows the scanner to

revert to standby mode after a successful read. This

mode is a power conservation feature whereby the

scanner uses extremely low power (microwatts) from

the host terminal.

T o supply full power to the scanner at all times, scan

label @A.

@A

Enable Continuous

Full Power *

Note: The scanner automatically uses full power

when configured to operate in Autosense mode.

To allow the scanner to revert to standby mode after a

successful read, scan label @B.

@B

Enable

Standby Power

5–3

Page 40

Chapter 5

General Setup Parameters

Beeper Operation

To disable or set the volume of the beeper, scan the

appropriate option below.

AA

Beeper Off

AB Beeper On;

Volume Low

AC Beeper On;

Volume Medium

AD

Beeper On;

Volume Loud *

5–4

Page 41

Chapter 5

General Setup Parameters

Capture Count

Capture Count determines the number of successful,

identical decodes that must occur for a valid read.

You can use the capture count to enhance the security

of the bar code reader.

Option BC sets the capture count to 1 which requires

one successful decode.

BC

Capture Count = 1 *

Scan option BD to set the capture count to 2. Two

identical decodes must occur for a valid read.

BD

Capture Count = 2

Because the laser scans a label many times a second,

you will notice little or no change in the speed of the

decode.

5–5

Page 42

Chapter 5

General Setup Parameters

Spotter Beam

You can enable the scanner to use a spotter beam

which helps when aiming the scanner. Each time you

press the trigger, the scanner generates a bright laser

spot for a fixed duration, after which the scanner

beam is activated.

The spotter beam is recommended for long range

applications.

Scanning label NP disables the spotter beam. Hold

the trigger for two seconds after scanning.

NP

Disable

Spotter Beam *

T o enable the spotter beam, scan label NQ, then scan a

digit from 0 – 9 (Appendix B), holding the trigger

for two seconds after scanning the digit. Each

digit enables the spotter beam for a specified duration

as shown in the table below. For example, to enable

the spotter beam for 200 milliseconds, scan the NQ

label, then scan code 3 in Appendix B.

NQ

+

5–6

Enable Spotter Beam=xx msec

This Digit Enables Spotter Beam for:

0 50 ms

1 100 ms

2 150 ms

3 200 ms

4 250 ms

5 300 ms

6 350 ms

7 400 ms

8 450 ms

9 500 ms

Note: Spotter Beam and Autosense Mode are

mutually exclusive parameters. Only one of these

parameters can be enabled at a time.

Page 43

Chapter 5

General Setup Parameters

Autosense Mode

In Autosense mode, the scanner has an internal object

sensor allowing you to operate the scanner in an

optional Autostand (Catalog No. 2755-NS2) for

hands-free operation.

When the scanner is placed in the Autostand it

becomes immediately active for reading any bar code

label presented to it. The scanner is triggered when a

bar code label breaks the scan beam path between the

reflective label on the stand and the scanner.

T o activate Autosense mode, scan the Enable

Autostand (NO) label. You must hold the trigger

down for two seconds after scanning the label.

NO

Enable

Autosense Mode

The scanner will respond by emitting a continuous,

low level, red beam of light.

Note: The scanner is automatically configured to use

full power (not standby power) in Autosense mode.

For details on how to set up the scanner to operate in

the optional Autostand, see Appendix C.

T o deactivate Autosense mode, scan the Disable

Autostand symbol (NN). You must hold the trigger

down for two seconds after scanning the label.

NN

Disable

Autosense Mode *

Note: Spotter Beam and Autosense Mode are

mutually exclusive parameters. Only one of these

parameters can be enabled at a time.

5–7

Page 44

Chapter

6

Message Format Parameters

A–B

Chapter Objectives

Message Format

Prefix Scanner Identifier Code Identifier Data Postamble SuffixPreamble

This chapter defines parameters that control the

format of transmitted bar code messages including:

• Prefix and Suffix

• Scanner Identifier

• Code Identifier

• Preamble and Postamble

In addition to these parameters, you can program an

intercharacter delay to prevent data overruns with

your host computer/terminal or wedge.

A message transmitted from the scanner upon a

successful decode has the following format:

Some of these message parameters may not be

required or may vary from one host system to

another. You select parameters based on the

requirements of your application and the host system.

T o select message parameters, you scan the

appropriate bar code labels in each section.

Note: Throughout this chapter default settings for

parameters are flagged by an asterisk (*).

6–1

Page 45

Chapter 6

Message Format Parameters

Prefix

A prefix is a subset of the preamble normally

formatted to some industry standard. It is represented

by a specific ASCII code. An example of a prefix is

the STX (Start of Transmission) code.

Scan the appropriate prefix label.

IA

Prefix=None *

IB Prefix=STX

PrefIC Prefix=SOH

6–2

Page 46

Chapter 6

Message Format Parameters

Suffix

A suffix is a subset of the postamble. Like the prefix,

it is normally assigned to a specific ASCII code.

Examples of suffixes are CR (Carriage Return) and

LF (Line Feed).

Scan the suffix appropriate for your application.

MA

Suffix=None *

MB Suffix=ETX

MC

MD

Suffix=CR

Suffix=LF

ME Suffix=HT

MF Suffix=CR and LF

6–3

Page 47

Chapter 6

Message Format Parameters

Scanner Identifier

Scanner ID characters are used to identify individual

scanners when more than one scanner is interfaced

with the host system. Options available are none

(Disabled) or digits 01 through 99.

Scanning label JA disables the scanner identifier.

JA

Disable

Scanner Identifier *

To enter a scanner ID, scan label JB and then two

separate digits from Appendix B. The ID characters

cannot exceed 99.

JB

+

Enable Scanner Identifier

plus two characters

For example, to enter a scanner ID of 01, scan the JB

label, then scan codes 0 and 1 in Appendix B.

6–4

Page 48

Chapter 6

Message Format Parameters

Code Identifier

A single-character code identifier may optionally be

transmitted with a message. This option allows the

host computer to identify the type of bar code

scanned, as well as the encoded information.

Scan option FA to disable the code identifier.

FA

Disable

Code Identifier *

Scan option FB to enable the code identifier.

FB

Enable

Code Identifier

T able 6.A shows the code identifier character

assignments.

Table 6.A

Code Identifier Characters

Symbology Code Identifier

Code 39 a

Interleaved 2 of 5 b

Standard 2 of 5 c

UPC/EAN/JAN d

Code 128 f

Codabar h

6–5

Page 49

Chapter 6

Message Format Parameters

Preamble or Postamble

Preambles and postambles consist of up to four

ASCII characters. Each ASCII character is encoded

as two hexadecimal characters. Use T able 6.B,

Hexadecimal Conversion Table, to look up the

hexadecimal equivalent.

T o use the conversion table:

1. Find each ASCII character in the table and locate

the corresponding bold hexadecimal equivalent

character in the top row and the left column of the

table. For example, the ASCII character ”Q” is

represented by the hexadecimal numbers 5 (top)

and 1 (left).

2. Scan the bar code symbols that correspond to the

hexadecimal equivalent characters. First scan the

bar code symbol that corresponds to the bold hex

character at the top. Then scan the bar code

symbol that corresponds to the bold hex character

at the left.

For example, for the ASCII character ”Q”, first

scan the bar code symbol labeled 5, then scan the

bar code symbol labeled 1. If your preamble or

postamble contains an ”N”, first scan 4 and then E.

3. Repeat this procedure for each ASCII character

you want to enter.

6–6

Note: If you select a preamble or postamble you

must scan four ASCII characters, even if the

preamble or postamble is less than four characters in

length. Do this by scanning null (NUL) characters

for the additional characters.

For example, if your preamble is ”AB” (in ASCII

code), enter A, B, and two null characters by

scanning the hexadecimal characters 4,1 4,2 0,0 0,0.

Because each ASCII character is represented by two

hexadecimal characters, you need eight

scans.

Page 50

Chapter 6

Message Format Parameters

Preamble

Postamble

KB

A preamble is a string of characters that prefixes a

message that is transmitted to the host. The preamble

may be used to identify the scanner that sent the

message. The maximum preamble length is four

ASCII characters.

KA

Preamble=None *

To enter a preamble, scan the KB label, then refer to

Table 6.B to enter the four ASCII characters. The

procedure on the previous page explains how to enter

preamble characters.

+

Preamble = 4 ASCII (8 Hex) characters

A postamble is similar to a preamble, except it is

appended to the message which is transmitted to the

host. Its maximum length is four ASCII characters.

LB

LA

Postamble=None *

T o enter a postamble, scan the LB label, then refer to

Table 6.B to enter the four ASCII characters. The

procedure on the previous page explains how to enter

preamble characters.

+

Postamble = 4 ASCII (8 Hex) Characters

6–7

Page 51

Chapter 6

Message Format Parameters

0

1

2

3

4

5

Table 6.B

Hexadecimal Conversion Table

0 1 2 3

0 NUL DLE SP 0

1 SOH DC1 ! 1

2 STX DC2 ” 2

3 ETX DC3 # 3

4 EOT DC4 $ 4

5 ENQ NAK % 5

6 ACK SYN & 6

7 BEL ETB ’ 7

8 BS CAN ( 8

9 HT EM ) 9

A LF SUB * :

B VT ESC + ;

C FF FS , <

D CR GS – =

E SO RS . >

F SI US / ?

6

6–8

7

Page 52

Table 6.B (continued)

Hexadecimal Conversion Table

4 5 6 7

0 @ P ‘ p

1 A Q a q

2 B R b r

3 C S c s

4 D T d t

5 E U e u

6 F V f v

7 G W g w

8 H X h x

9 I Y i y

A J Z j z

B K [ k {

C L \ l |

D M ] m }

E N ^ n ~

F O _ o DEL

Chapter 6

Message Format Parameters

8

9

A

B

C

D

6–9

E

F

Page 53

Chapter 6

Message Format Parameters

Intercharacter Delay

Certain terminals and computers require an

intercharacter delay to simulate the effects of

keystroke delays. Selecting an intercharacter delay

causes the characters to be sent at the slower rate

required by the device to which you are interfacing.

Scanning label GA disables intercharacter delay .

GA

No Intercharacter

Delay *

T o set Intercharacter Delay to a value other than zero,

scan label GB, then two separate digits from

Appendix B. The intercharacter delay cannot

exceed 31 milliseconds.

GB

+

Intercharacter Delay=xx msec

For example, to set the delay to 15 milliseconds, scan

the GB label, then scan codes 1 and 5 in Appendix B.

6–10

Page 54

Symbologies

Chapter

7

A–B

Chapter Objectives

This chapter shows how to enable bar code symbologies the scanner is capable of reading including:

• Code 39

• UPC-A and UPC-E

(with optional 2 or 5-digit supplements)

• EAN-8 and EAN-13

(with optional 2 or 5-digit supplements)

• Interleaved 2 of 5

• Standard 2 of 5

• Code 128

• Codabar

T o disable or enable specific bar code symbologies,

scan the appropriate bar code labels in each section.

Note: We recommend that you disable all

symbologies not used by your application.

Throughout this chapter, the default symbology

selections are flagged by an asterisk (*).

Label Lengths

The minimum label lengths are set to 1 character,

except for Interleaved 2 of 5 which is set to 2

characters and Standard 2 of 5 which is set to 4

characters. The maximum label length for all

symbologies is set to 32 characters. You can set

minimum and maximum label lengths.

Note: The minimum length must be less than or

equal to the maximum length for scanning to occur.

7–1

Page 55

Chapter 7

Symbologies

Code 39

T o disable Code 39, scan label OA.

OA

Disable Code 39

T o enable Code 39, scan option OB or OC. After

enabling Code 39, make any additional required

selections from options OD through OI.

OB

Enable Standard Code 39 *

OC Enable Full ASCII Code 39

7–2

Page 56

Chapter 7

Symbologies

Modulo 43 Check Character

Options OD and OE allow you to enable or disable the

Modulo 43 check character for Code 39. T o enable

the Modulo 43 check character, scan label OE. To

disable the Modulo 43 check character, scan label OD.

OD

Disable Modulo 43 *

Check Character

OE Enable Modulo 43

Check Character

Transmit Start/Stop Characters

You can transmit or suppress the Start and Stop

characters in Code 39. T o suppress transmission of

the Start and Stop characters, scan label OF.

OF

Do Not Transmit *

Start and Stop

T o enable transmission of the Start and Stop

characters, scan label OG.

OG

Transmit

Start and Stop

7–3

Page 57

Chapter 7

Symbologies

Code 39

(continued)

Minimum Length

The minimum length of Code 39 is set by scanning

label OH and then two digits (01 - 32) in Appendix B.

OH

+

Minimum Length

(Specified by two digits 01-32)

For example, to enter a minimum length of 05, scan

the OH label, then scan codes 0 and 5 in Appendix B.

Maximum Length

The maximum length of Code 39 is set by scanning

label OI and then two digits (01 - 32) in Appendix B.

OI

+

Maximum Length

(Specified by two digits 01-32)

7–4

For example, to enter a maximum length of 05, scan

the OI label, then scan codes 0 and 5 in Appendix B.

If the minimum and maximum lengths are set

equal, only codes of that exact length are read.

Page 58

Chapter 7

Symbologies

UPC (A and E)

T o disable all UPC labels, scan label QA.

QA

Disable UPC (A and E)

Supplements

Option QB or option QC enable both UPC-A and

UPC-E. T o enable scanning of UPC labels with the 2

or 5 Digit supplements, scan label QB.

Enable UPC

QB

with 2 or 5 Digit

Supplement Enabled

To enable scanning of UPC labels with the 2 or 5

Digit supplements disabled, scan label QC.

QC

Enable UPC *

with 2 or 5 Digit

Supplement Disabled

Expanded UPC-E

You can enable/disable expansion of E labels to A

labels. T o disable expanded UPC-E, scan label QH.

QH

Disable *

Expanded UPC-E

T o enable expansion of E labels to A labels, scan

label QI.

QI

Enable

Expanded UPC-E

7–5

Page 59

Chapter 7

Symbologies

UPC (A and E)

(continued)

Transmit Number System Digit

You can enable or disable the transmission of the first

character in a UPC symbol (the number system

character). T o disable transmission of the first

character in a UPC symbol, scan label QD.

QD

Disable Transmission

Number System Digit

T o enable transmission of the first character in a UPC

symbol (the number system character), scan label QE.

QE

Enable Transmission *

Number System Digit

Transmit Check Digit

You can enable or disable the transmission of the last

character in a UPC symbol (the check digit). T o

disable transmission of the check digit in a UPC

symbol, scan label QF.

7–6

QF

Disable Transmission

of Check Digit

T o enable transmission of the check digit in a UPC

symbol, scan label QG.

QG

Enable Transmission

of Check Digit *

Page 60

Chapter 7

Symbologies

UPC to EAN Translation

You can cause UPC labels to be transmitted as

EAN-13 labels. T o enable UPC to EAN translation,

scan label QJ.

QJ

Enable UPC to EAN

Translation

T o disable UPC to EAN translation, scan label QK.

QK

Disable UPC to EAN

Translation *

7–7

Page 61

Chapter 7

Symbologies

EAN/JAN

Scan label RA to disable EAN/JAN (8 or 13 digit).

RA

Disable EAN/JAN *

(8 or 13 digit)

Supplements

Option RB or option RC enables both EAN 8-digit

and EAN 13-digit. EAN/JAN labels can be read with

or without supplements. T o enable scanning of

EAN/JAN labels with the 2 or 5 digit supplements,

scan label RB.

Enable EAN/JAN

RB

with 2 or 5 Digit

Supplement Enabled

T o enable scanning of EAN/JAN labels with the 2 or

5 Digit supplements disabled, scan label RC.

7–8

RC

Enable EAN/JAN

with 2 or 5 Digit

Supplement Disabled

Page 62

Chapter 7

Symbologies

Transmit Number System Digit

You can enable or disable the transmission of the first

character in an EAN/JAN symbol (the number system

character). T o disable transmission of the first

character in an EAN/JAN symbol, scan label RD.

RD

Disable Transmission

Number System Digit

T o enable transmission of the first character in an

EAN/JAN symbol, scan label RE.

RE

Enable Transmission *

Number System Digit

Transmit Check Digit

You can enable or disable the transmission of the last

character in an EAN/JAN symbol (the check digit).

T o disable transmission of the check digit in an

EAN/JAN symbol, scan label RF.

RF

Disable Transmission

of Check Digit

T o enable transmission of the check digit in an

EAN/JAN symbol, scan label RG.

RG

Enable Transmission

of Check Digit *

7–9

Page 63

Chapter 7

Symbologies

Interleaved 2 of 5

Scan label PA to disable Interleaved 2 of 5.

PA

Disable

Interleaved 2 of 5 *

Check Digit

You can enable Interleaved 2 of 5 with or without the

check digit. T o enable Interleaved 2 of 5 without the

check digit, scan label PB.

Enable

PB

Interleaved 2 of 5

without Check Digit

To enable Interleaved 2 of 5 with the check digit,

scan label PC.

PC

Enable

Interleaved 2 of 5

with Check Digit

7–10

Page 64

Chapter 7

Symbologies

Minimum Length

To set a minimum length (other than two) for

Interleaved 2 of 5, scan label PD and then two digits

(02-32) in Appendix B. The value of the number

you scan must be even. Odd numbers are ignored.

PD

+

Minimum Length

(Specified by two digits 02-32)

For example, to enter a minimum length of 12, scan

the PD label, then scan codes 1 and 2 in Appendix B.

Maximum Length

To set a maximum length for Interleaved 2 of 5, scan

label PE and then two digits (02-32) in Appendix B.

The value of the number you scan must be even.

PE

+

Maximum Length

(Specified by two digits 02-32)

For example, to enter a maximum length of 12, scan

the PE label, then scan codes 1 and 2 in Appendix B.

If the minimum and maximum lengths are set

equal, only codes of that exact length are read.

7–11

Page 65

Chapter 7

Symbologies

Standard 2 of 5

Scan label PF to disable Standard Code 2 of 5.

PF

Disable *

Standard 2 of 5

To enable Standard Code 2 of 5, scan label PG.

PG

Enable

Standard 2 of 5

Minimum Length

To set a minimum length (other than 4) for Standard

Code 2 of 5, scan label PH and then two digits

(04-32) in Appendix B.

PH

+

Minimum Length

(Specified by two digits 04–32)

7–12

Maximum Length

To set a maximum length for Standard Code 2 of 5

messages, scan label PI and then two digits (04-32) in

Appendix B.

PI

+

Maximum Length

(Specified by two digits 04–32)

If the minimum and maximum lengths are set

equal, only codes of that exact length are read.

Page 66

Chapter 7

Symbologies

Code 128

Scan label TA to disable Code 128.

TA

Disable Code 128

Scan option TB to enable Code 128.

TB

Enable Code 128 *

Minimum Length

To set a minimum length for Code 128, scan label TC,

then two digits (01-32) in Appendix B.

TC

+

Minimum Length

(Specified by two digits 01-32)

Maximum Length

To set a maximum length for Code 128, scan TD, then

two digits (01-32) in Appendix B.

TD

+

Maximum Length

(Specified by two digits 01-32)

If the minimum and maximum lengths are set

equal, only codes of that exact length are read.

7–13

Page 67

Chapter 7

Symbologies

Codabar

Scan label VA to disable Codabar.

VA

Disable Codabar *

Scan option VB to enable Codabar.

VB

Enable Codabar

Transmit Start/Stop Characters

You can enable or disable the transmission of the

Start and Stop characters in Codabar. To disable

transmission of the Start and Stop characters, scan

label VC.

VC

Disable Transmission *

Start/Stop Characters

7–14

T o enable transmission of the Start and Stop

characters, scan label VD.

VD

Enable Transmission

Start/Stop Characters

Page 68

Chapter 7

Symbologies

Minimum Length

T o set a minimum length for Codabar messages, scan

label VE and then two digits (01-32) in Appendix B.

VE

+

Minimum Length

(Specified by two digits 01-32)

For example, to enter a minimum length of 05, scan

the VE label, then scan codes 0 and 5 in Appendix B.

Maximum Length

T o set a maximum length for Codabar messages, scan

label VF, and then two digits (01-32) in Appendix B.

VF

+

Maximum Length

(Specified by two digits 01-32)

For example, to enter a minimum length of 05, scan

the VF label, then scan codes 0 and 5 in Appendix B.

If the minimum and maximum lengths are set

equal, only codes of that exact length are read.

7–15

Page 69

Chapter

Specifications

8

A–B

Hand Held Scanners

Catalog No. 2755-G3-W

Catalog No. 2755-G6-W

Optical

Nominal Scan Rate 35 scans/second

Wavelength (nominal) 670 nm

Maximum Pitch ±55 degrees

Maximum Skew ±65 degrees

Scanning Range

Minimum

Bar Width

6.0 mil

(.15 mm)

7.5 mil

(.19 mm)

10.0 mil

(.25 mm)

15.0 mil

(.38 mm)

20.0 mil

(.51 mm)

40.0 mil

(1.02 mm)

55.0 mil

(1.40 mm)

Standard Range

(2755-G3-W)

3.0 in - 5.0 in

7.6 cm - 12.7 cm

2.5 in - 7.5 in

6.4 cm - 19.0 cm

1.0 in - 10.0 in

2.5 cm - 25.4 cm

1.5 in - 14.0 in

3.8 cm - 35.6 cm

2.5 in - 18.0 in

6.4 cm - 45.7 cm

9.0 in - 25.0 in

22.9 cm - 63.5 cm

12.0 in - 30.0 in

30.5 cm - 76.2 cm

Long Range

(2755-G6-W)

N.A.

N.A.

N.A.

8.0 in - 22 in

20.3 cm - 55.9 cm

12 in - 36 in

30.5 cm - 91.4 cm

23 in - 60 in

58.4 cm - 152.4 cm

23 in - 66 in

58.4 cm - 167.6 cm

Scanning Range

Autosense Mode 36 in (91.4 cm) maximum

(to reflective label or tape)

Electrical

Supply Voltage 4.75 to 14 VDC

Current Consumption

While Scanning 200 mA maximum

Standby Power 100 mA maximum

Continuous Full Power 200 mA maximum

1

Autosense mode automatically uses continuous full power.

1

8–1

Page 70

Chapter 8

Specifications

Mechanical

Dimensions

Inches 4.0(L) x 2.8(W) x 6.6(H)

Millimeters 102(L) x 71(W) x 168(H)

Weight 8.0 oz (0.23 kg)

LED Indicators

Good Read Green

Scanning Yellow

Environmental

Operating T emperature 0° to 122° F

-18° to

+50° C

Storage T emperature -40° to 158° F

-40° to

+70° C

Relative Humidity 5 to 95% (noncondensing)

Electrostatic Discharge 15kv to any

external surface

Drop T est 5 feet (1.27 meter)

on concrete

Dust and Rain MIL STD 810D

Sections 510.2I & 506.2II

8–2

Interface

Keyboard Wedge

Certification

Dept. of Health and Class II laser product.

Human Services (DHHS) Complies with DHHS

radiation performance

standards, 21 DFR

subchapter J.

Page 71

Appendix

A

A–B

Bar Code Test Symbols

Use the following labels to insure that your scanner is functioning

properly. The only label the long range scanner can read below is

the Interleaved 2-of-5 (15 mil) label.

A–1

Page 72

Appendix

B

Digit Selection Symbols

A–B

B–1

Page 73

Appendix

C

A–B

Autosense Mode

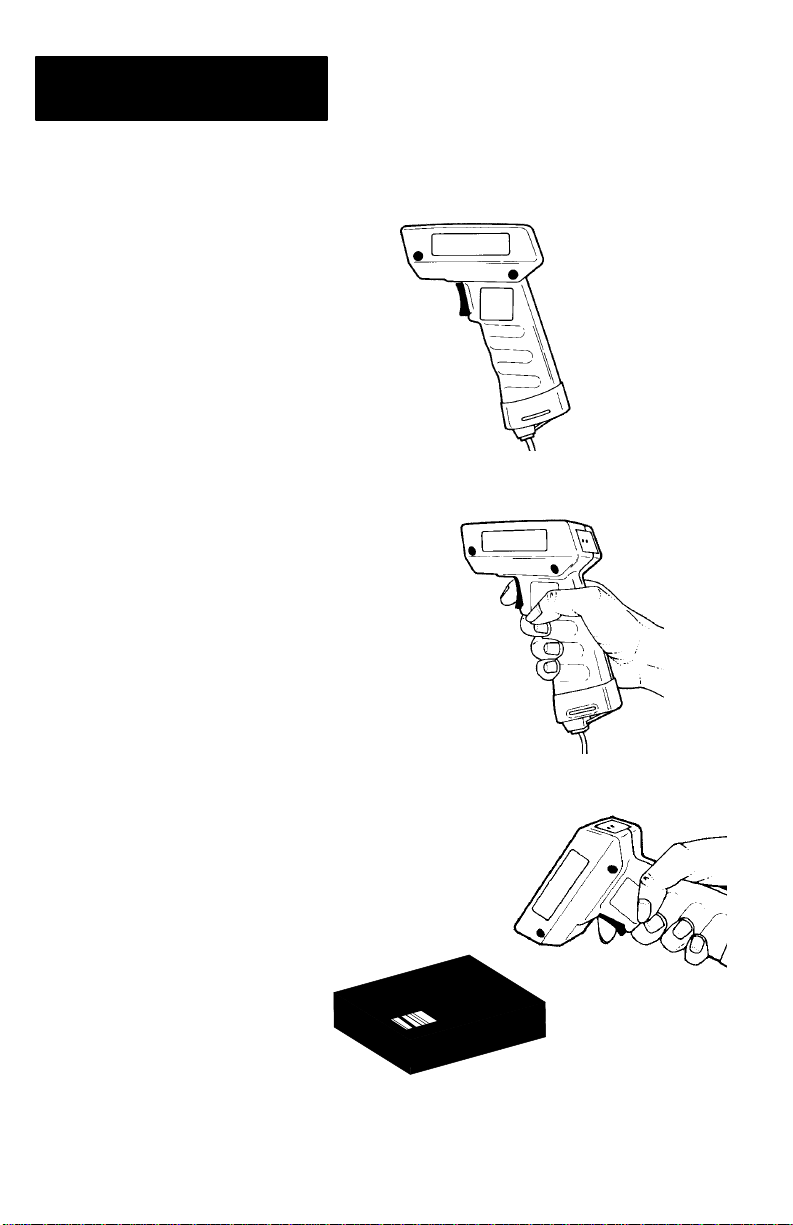

T o set up the scanner to operate in Autosense mode

using the optional Autostand follow the steps below

while referring to Figure C.1.

1. Enable the scanner to operate in Autosense mode

by scanning the Enable Autosense (NO) label in

Chapter 5.

2. Attach the Stand Riser to the Stand Base

using two of the supplied #6-32 thumb screws.

. Attach the Scanner Holder to the top of the Stand

3

Riser using the other two #6-32 thumb screws.

4. Verify that the reflective label is affixed to the

Stand Base.

5. Place the scanner in the stand as shown in

Figure C.1.

6. Check that the red beam of light is aimed at the

reflective label on the stand.

The Autostand is now ready to read bar code labels

presented to it.

While the scanner is activated in Autosense mode

you are able to remove the scanner from its holder

and use it for hand-held applications. When the

scanner is removed from the Autostand the scanning

beam is turned on automatically to read a bar code

label. If the scanner does not see a label the scanning

beam will turn off after four seconds. Scanning is

re-initiated by manually pulling the trigger. The

scanner can then be placed into the stand once again

and it will function in Autosense mode.

C–1

Page 74

Appendix C

Autosense Mode

#6-32 Thumb Screws

Figure C.1

Autostand

Scanner

Scanner Holder

Stand Riser

#6-32 Thumb Screws

Stand Base

Important: When the scanner is to be powered from

a battery such as in a hand-held terminal, you should

disable Autosense mode. In this application, you may

need to use the power conservation mode of the

scanner when drawing power from a battery. Autosense mode will function only in full power mode.

1

Reflective tape is supplied with the autostand. Additional reflective tape is

available by ordering Catalog No. 2755-NT1.

Reflective

1

Label

C–2

Page 75

Appendix

D

Maintenance

This appendix provides general maintenance

information for your scanner.

A–B

Cleaning Window

Inspecting Cables

You may need to clean the window of the scanner.

Carefully clean the window by first removing loose

particles of dirt with clean air. Then use a soft, lint

free cloth moistened with an optical quality cleaning

fluid for plastic lenses and wipe the window in a

single direction (don’t wipe cloth back and forth

across window). Do not leave streaks.

CAUTION:

Do not use abrasive material or sol-

!

vents (e.g., alcohol or acetone) on the

window . These items may damage

the window or finish on the scanner.

WARNING:

The scanner has no serviceable parts.

!

Do not open the housing of the scanner.

Periodically inspect the cable on the scanner for wear

and other signs of damage. A worn or damaged cable

may interfere with the operation of the scanner.

Contact your Allen-Bradley representative to order

replacement cables.

D–1

Page 76

Appendix

E

Scanner Parameters

Each bar code label in this manual is preceded by two

characters. The following tables list the two character

mnemonic for each scanner parameter and the page

location of the corresponding label.

General Scanner Setup Parameters

Mnemonic

ZA Set Scanner to Factory Defaults 4-10

ZB Display Scanner Configuration 5-1

ZC Transmit Program Version Number 5-2

@C Transmit Program ID 5-2

@A Enable Full Continuous Power 5-3

@B Enable Standby Power 5-3

AA Beeper Off 5-4

AB Beeper On; Volume Low 5-4

AC Beeper On; Volume Medium 5-4

AD Beeper On; Volume Loud 5-4

BC Capture Count=1 5-5

BD Capture Count=2 5-5

NP Disable Spotter Beam 5-6

NQ Enable Spotter Beam 5-6

NO Enable Autosense Mode 5-7

NN Disable Autosense Mode 5-7

Function Page #

A–B

E–1

Page 77

Appendix E

Scanner Commands

Mnemonic

CE Enable Wedge Mode 4-6

CF Terminal Type = PC-AT, PS/2 and 50/60/80,

CG Terminal Type = PC-XT,

CH Terminal Type = IBM 3151, 3472 4-7

CI Terminal Type = DEC VT220, VT240, VT320,

Mnemonic

IA Prefix = None 6-2

IB Prefix = STX 6-2