Page 1

Bulletin 2755

High Speed Decoder

(Catalog Numbers 2755-DM9 & -DM9E)

User Manual

ALLEN-BRADLEY

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. “Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls” (Publication SGI-1.1)

describes some important differences between solid state equipment and

hard–wired electromechanical devices. Because of this difference, and also

because of the wide variety of uses for solid state equipment, all persons

responsible for applying this equipment must satisfy themselves that each

intended application of this equipment is acceptable.

In no event will the Allen-Bradley Company be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, the Allen-Bradley Company cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Allen-Bradley Company with respect to use

of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of the Allen-Bradley Company is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage, or economic loss.

Attentions help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is especially important for successful

application and understanding of the product.

PLC is a registered trademark of Allen-Bradley Company, Inc.

Pyramid Integrator, DTL and CVIM are trademarks of Allen-Bradley Company, Inc.

VAX is registered trademark of Digital Equipment Corporation.

Page 3

Table of Contents

A–B

Using This Chapter

Description of Hardware

Chapter 1

Chapter Objectives 1–1

Overview of This Manual 1–1

Intended Audience 1–2

Conventions Used 1–2

Warnings and Cautions 1–3

Nomenclature 1–3

Related Publications 1–3

Chapter 2

Chapter Objectives 2–1

Differences Between DM9 and DM9E 2–1

Features of the Decoder 2–1

Laser Scan Heads 2–2

Physical Description 2–2

Indicators 2–3

Communications Ports 2–5

Output Modules 2–6

Power and Scan Head Connectors 2–8

Accessories 2–9

How the Decoder Operates

Configuring Your Decoder

Chapter 3

Chapter Objectives 3–1

How the Decoder Operates 3–1

Communications 3–4

RAM and EEPROM Memory 3–7

Operating Modes 3–9

Trigger Ending Conditions 3–10

Response Modes 3–10

Chapter 4

Chapter Objectives 4–1

Initial Programming of the Decoder 4–1

Programming Terminal Cable 4–2

Menu and Setup Screens 4–2

Start–up Procedure 4–4

Select Operation Menu 4–5

Using and Editing the Configuration (Setup) Screens 4–11

Command Bar 4–15

i

Page 4

Table of Contents

Configuring Your Decoder

Installing the Decoder

Chapter 4

Setup Screen #1 4–17

Setup Screen #1 Fields 4–20

Message Format 4–20

Data Check Characters 4–23

Host Communications 4–24

Package Detect Input 4–27

Setup Screen #2 4–28

Setup Screen #2 Fields 4–31

Bar Code Types 4–31

Code Lengths 4–31

Scanner Control 4–33

Match Code Table 4–40

Outputs 4–41

Input 4–43

Programming Example 4–45

Chapter 5

Chapter Objectives 5–1

Equipment You Will Need 5–1

Electrical Precautions 5–2

How to Handle Excessive Noise 5–2

Grounding Recommendations 5–3

Determining Space Requirements 5–3

Installing the Decoder 5–4

How to Connect Your Equipment 5–5

Installing and Wiring Modules 5–7

Communicating With a Host

ii

Chapter 6

Chapter Objectives 6–1

Host Port 6–1

RS–232 Interface 6–2

RS–422 Interface 6–4

RS–485 Interface 6–5

Message Format 6–7

Example Data Messages 6–9

Host Commands 6–10

Page 5

Table of Contents

Host Commands Using a

RS-232 or RS-422 Interface

Chapter 7

Chapter Objectives 7–1

RS–232/RS–422 ASCII Command Protocol 7–1

Single Character Commands 7–1

Two Character Commands 7–2

Responses to Commands 7–3

Host Commands 7–4

1. Set Code 39, I 2–of–5, and Codabar Check Characters 7–5

2. Clear Output Counter 7–6

3. Enable/Disable Bar Code Type 7–6

4. Set Configuration to Default Values 7–7

5. Set Host Communications 7–7

6. Write Header Message 7–8

7. Set Package Detect Input Filter and Sense 7–9

8. Write Source Identification Message 7–10

9. Read Output Counter 7–10

10. Set Message Format 7–11

11. Read Match Code Table 7–12

12. Write Match Code Table 7–13

13. Clear No–Read Count 7–14

14. Write No–Read Message 7–15

15. Read No–Read Count 7–16

16. Set Output Condition and Duration 7–16

17. Clear Package Count 7–17

18. Read Package Count 7–17

19. Reset Decoder 7–18

20. Set Configuration to Default Values, Save to EEPROM & Restart 7–18

21. Save New Configuration to EEPROM and Restart 7–19

22. Save New Configuration to EEPROM (No Restart) 7–19

23. Set Scanner Control 7–20

24. Set Bar Code Specific Length 7–21

Host Commands Using the

RS-485 Interface

Chapter 8

Chapter Objectives 8–1

RS–485 Command Protocols 8–1

RS–485 ASCII Command Protocol 8–1

RS–485 PCCC Command Protocol 8–2

PCCC Command Format 8–2

PCCC Commands 8–5

Unprotected Read Command 8–5

Unprotected Read Command Structure 8–6

Unprotected Read Reply Format 8–7

Unprotected Read Example 8–9

iii

Page 6

Table of Contents

Unprotected Write Command 8–10

Unprotected Write Command Structure 8–10

Unprotected Write Command Cont.

Unprotected Write Reply Format 8–12

Writing to the Command Area of Memory 8–13

Communication Link Diagnostic Commands 8–16

Link Diagnostic Command Structure 8–16

Diagnostic Link Reply Format 8–17

Read Diagnostic Counters Reply 8–18

Read Diagnostic Status Reply 8–19

Diagnostic Loop Reply 8–21

Reset Counters Reply 8–21

Maintenance and

Troubleshooting

Specificatuions

Setting Up the Programming

Terminal

Default Parameters Of the

Decoder

ASCII Conversion Table

Configuration Area of

Memory

Chapter 9

Chapter Objectives 9–1

Maintaining the Decoder 9–1

Power Input Fuse Replacement 9–1

Module Fuse Replacement 9–2

Troubleshooting 9–3

Chapter 10

Decoder 10–1

Appendix A A–1

Appendix B B–1

Appendix C C–1

Appendix D D–1

Protocol Selection Chart

Transmission Check Codes

iv

Appendix E E–1

Appendix F F–1

Glossary G–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index I–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 7

Table of Contents

Figures

2.1 Catalog No. 2755–DM9, –DM9E Decoder 2–3. . . . . . . . . . . . . . . . . . . .

2.2 LED Indicators 2–4. . .

2.3 Communications Ports 2–5. . .

2.4 Output Modules 2–6. . .

2.5 Input power and Scan Head Connectors 2–8. . .

3.1 Catalog No. 2755–DM9, –DM9E Decoder 3–1. . .

3.2 DC Output Module Application 3–3. . .

3.3 AC Output Module Application 3–3. . .

3.4 Input Module Auto Load Application 3–4. . .

3.5 Communications Interface Examples 3–5. . .

3.6 Decoder Memory 3–8. . .

4.1 Setup Screen #1 4–17. .

4.2 Setup Screen #2 4–28. .

4.3 Package Detect Signal 4–34. .

4.4 Internal Timer Trigger 4–35. .

4.5 Setting Inter–Scan Timer 4–39. .

4.6 Auto Load Feature 4–44. .

5.1 Mounting Dimensions of the Decoder 5–3. . .

5.2 Fasteners Used to Mount the Decoder 5–4. . .

5.3 Connecting Equipment to the Decoder’s Ports 5–5. . .

5.4 Modules and Connectors 5–7. . .

5.5 Module Connections 5–8. . .

6.1 Host Port Pin Numbers 6–2. . .

6.2 Communications With RS–232 Host Device 6–4. . .

6.3 Communications With RS–422 Host Device 6–5. . .

6.4 Communications In an RS–485 Network 6–6. . .

6.5 Message Format 6–7. . .

9.1 Power Input Fuse 9–1. . .

9.2 Output Module Fuse 9–2. . .

A.1 Connections for Cable Used With an ADM 3E Terminal A–1. . .

A.2 Connections for Cable Used With DEC–VT100 Terminal A–2. . .

A.3 One Possible Setup for DEC–VT100 Terminal A–2. . .

A.4 Connections for Cable Used With 1784–T45 Terminal A–3. . .

A.5 Connections for Cable Used With a Televideo 955 Terminal A–4. .

A.6 Connections for Cable Used With 1770–T1, –T2, or –T3 Terminals A–5

v

Page 8

Chapter

Chapter Objectives

Overview of this Manual

A–B

1

Using This Manual

Read this chapter to familiarize yourself with the rest of the manual. You will learn

about:

• Contents of the manual.

• Intended audience.

• Conventions useed.

• Warnings and cautions.

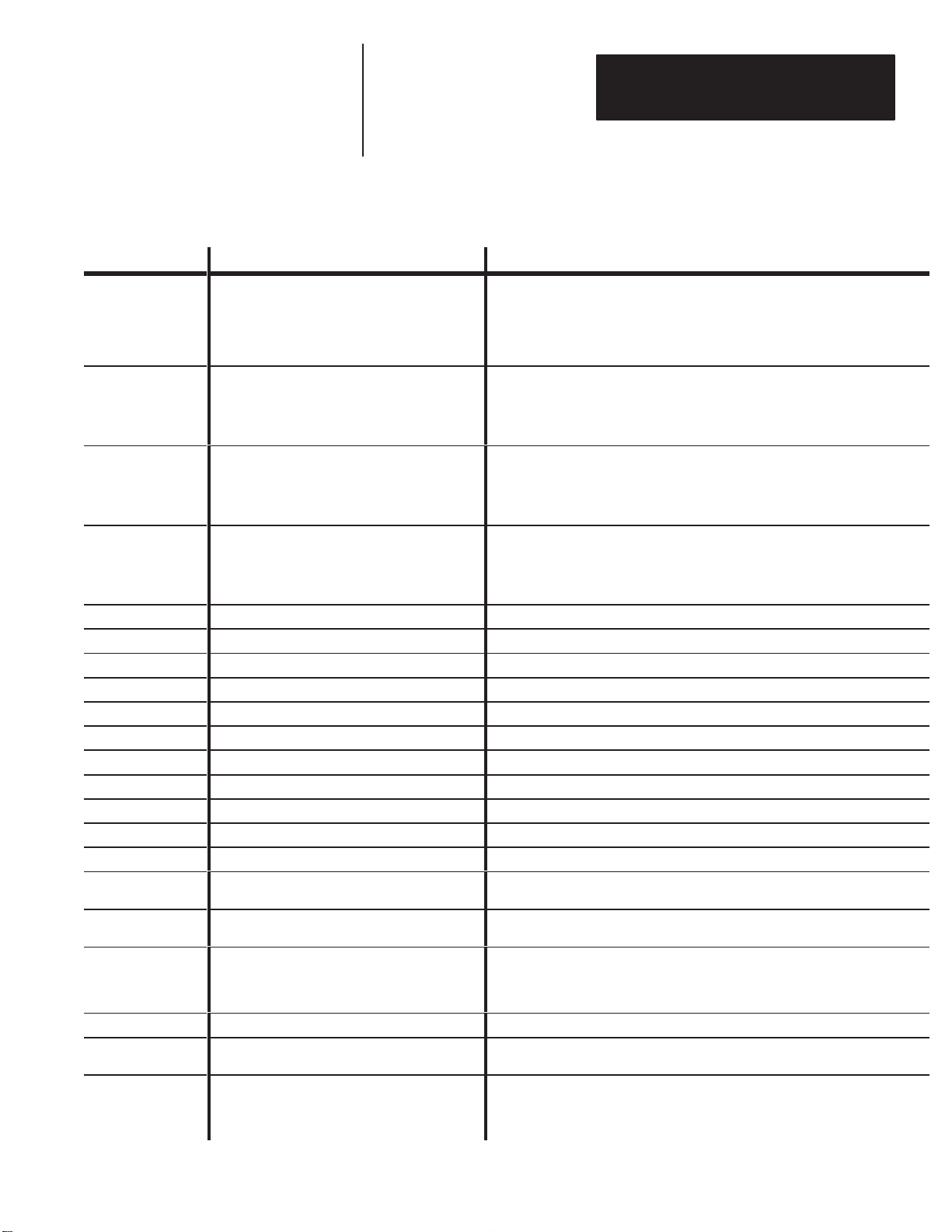

This manual describes how to use the Catalog No. 2755–DM9 and DM9E

High Speed Decoders. This manual contains the following chapters:

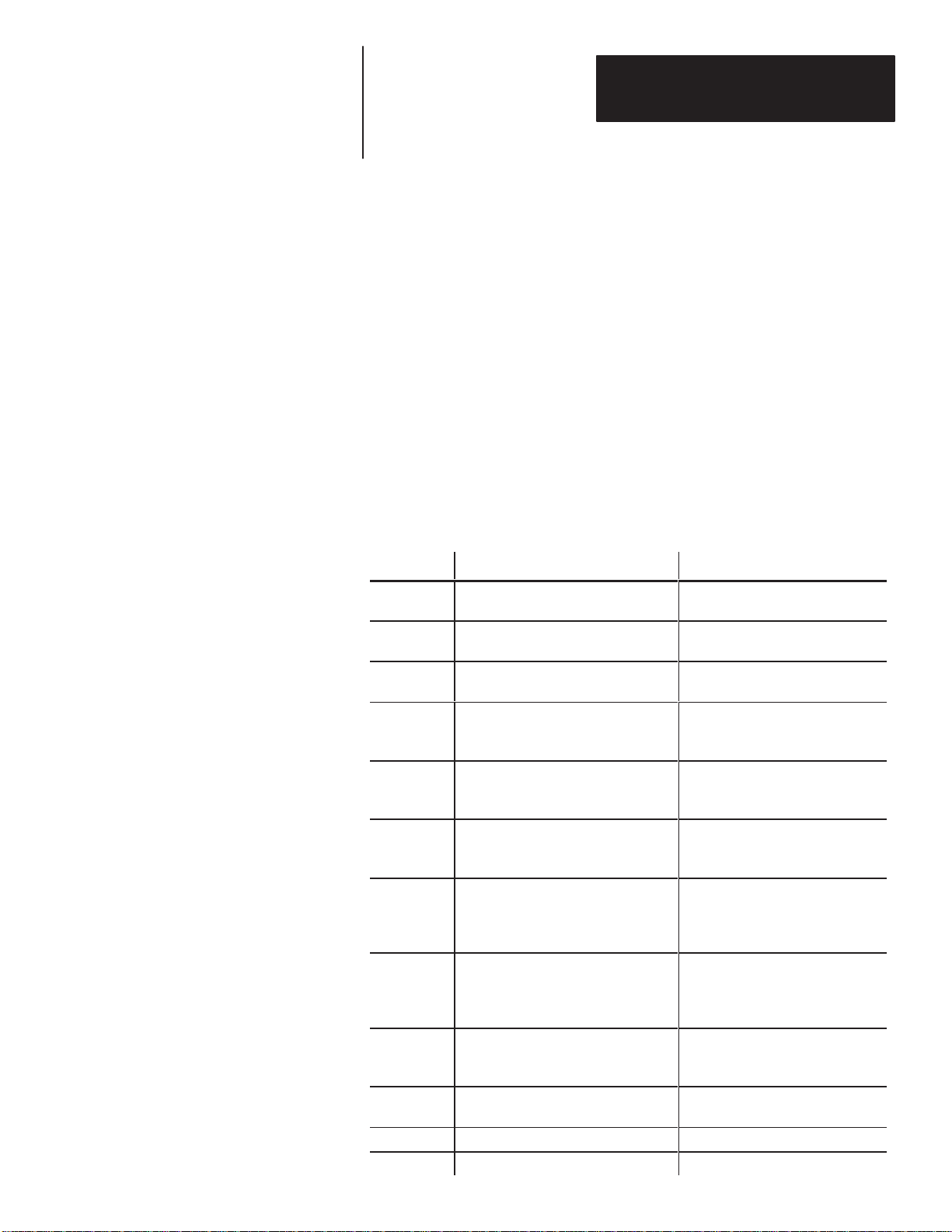

Chapter Title Purpose

1 Using This Manual

2 Description of the Hardware

3 How the Decoder Operates

4 Configuring Your Decoder

5 Installing the Decoder

6 Communicating With a Host

7

8

9

10 Specifications

- Appendices Includes glossary of terms.

- Index Alphabetical index.

Host Commands Using the

RS-232 or RS-422 Interface

Host Commands Using the

RS–485 Interface

Maintenance and

Troubleshooting

Provides an overview of the

manual.

Describes features and

design of the decoder.

Describes how the decoder

operates.

Provides step-by-step

instructions on how to

configure the decoder.

Provides general rules and

recommendations for

installing the decoder.

Describes how a host

device can communicate

with a decoder.

Describes how to send host

commands and receive

data using the RS-232 and

RS-422 interfaces.

Describes how to send

commands and receive

data on an RS-485 Local

Area Network.

Describes basic

troubleshooting and fuse

replacement procedures.

Provides basic decoder

specifications.

1–1

Page 9

Chapter 1

Using this Manual

Intended Audience

Conventions Used

You do not require any special knowledge to read this manual and follow its

instructions. If the decoder will be used to communicate with a computer or

TM

PLC

communication devices, communications standards (RS–232, RS–422,

RS–485), and communications terminology. In this manual, we describe the

commands that a host device can transmit to the decoder and the command

responses sent by the decoder. We do not describe how to create PLC or

computer programs for generating the commands.

Some chapters in this manual contain examples of how to enter data or

commands. The following conventions are used:

programmable controller, we assume you are familiar with

• A symbol or word in brackets represents a single key you would press.

These include keys such as [RETURN], [SHIFT] or [A].

• Punctuation, such as commas, and symbols such as “/” would be entered

as shown.

• ASCII codes are represented by either their mnemonic (CR, ETX, LF,

etc.) or their decimal number equivalent (CR =13, S=83, etc.). Refer to

Appendix C for a listing of the ASCII codes.

Note: When the [RETURN] key is specified, this is the carriage return

function of your keyboard. This key may also be labeled ENTER or use

some other symbol.

1–2

We have included numerous examples of CRT displays. All CRT displays

are shown inside a box with a double lined border. We have reproduced

these screens as accurately as possible. However, due to legibility and space

requirements we have modified some of the spacing.

When describing the programming terminal used to configure the decoder,

we make reference to arrow keys. If you use an Allen–Bradley Industrial

Terminal (Catalog No. 1770–T1, –T2, or –T3), you do not have arrow keys.

Use the [CTRL] and [U], [D], [L], or [R] keys for the U

ight cursor functions, respectively.

R

p, Down, Left, or

Page 10

Chapter 1

Using this Manual

Warnings And Cautions

Nomenclature

Related Publications

Description Title Purpose of Publication

Catalog Number

2755-ND002②

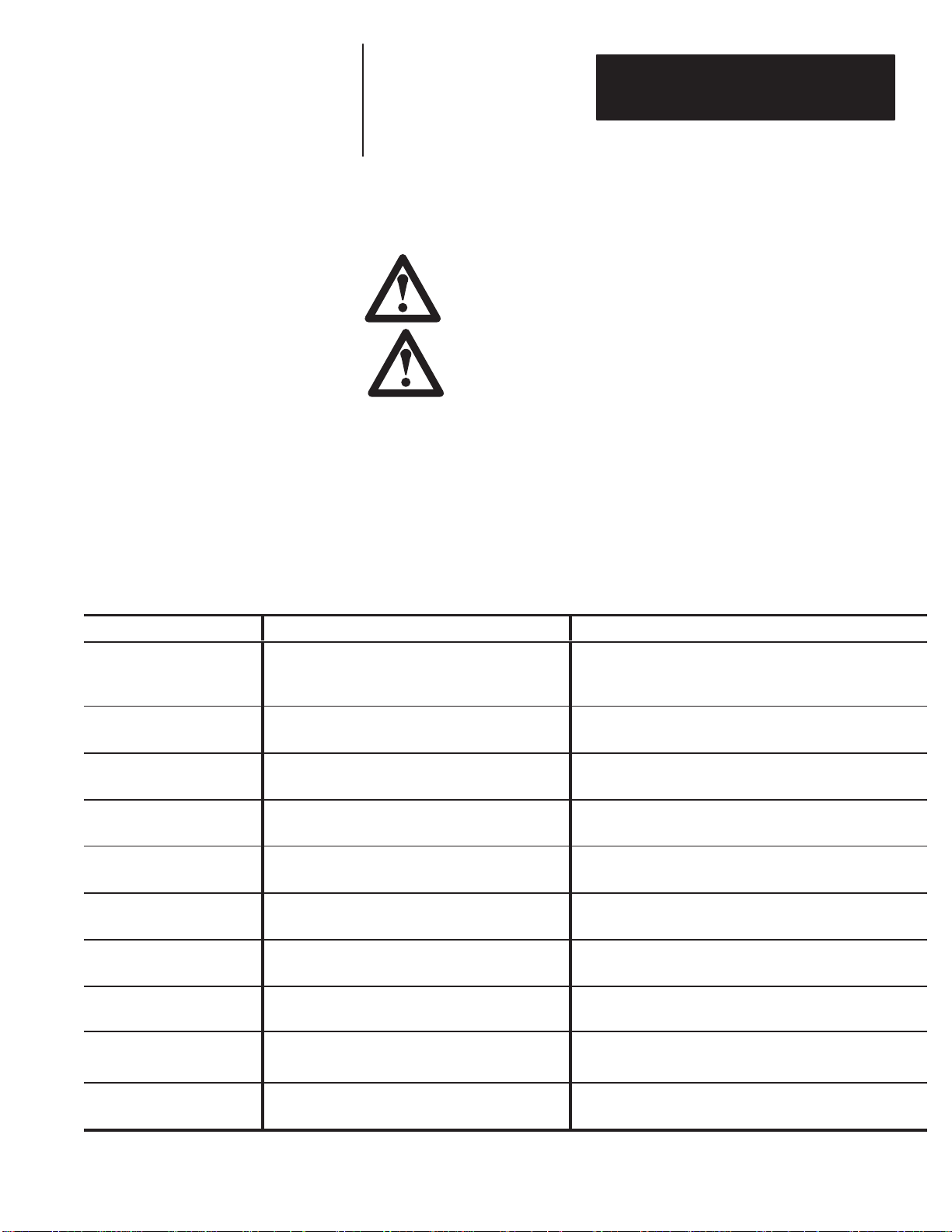

Both warnings and cautions are found in this manual and on the equipment.

The following symbols are used:

WARNING: A warning symbol means people might be

injured if the procedures are not followed.

CAUTION: A caution symbol is used when machinery could

be damaged if the procedures are not followed.

This manual may contain some terms that you are not familiar with. We

have provided a glossary of terms at the back of this manual (Appendix G) to

assist you.

The following table lists related publications that you may require to install

and operate the decoder.

User’s Manual for Bulletin 2755 Industrial

Medium and High Speed Bar Code

Scanners.

Provides information on the Catalog Number

2755-L7 and -L9 scan heads①.

Publication 2755-829②

Publication 2755-826②

Publication 2755-801②

Publication 2760-812

Publication 2760-822

Publication 2760-823

Publication

1771-6.5.34

Publication

1771-6.5.15

Publication

1771-6.5.13

① We have provided only a partial catalog number since there are various configurations available for these scan heads.

② Additional scan heads may be available for use with the Catalog Number 2755-DM9 decoder. Refer to your Allen-Bradley representative for more information.

User’s Manual for Bulletin 2755 Enhanced

Medium Speed Scan Heads

User’s Manual for Bulletin 2755 Medium

Speed Material Handling Scanners

User’s Manual for Bulletin 2755 Modular

Bar Code Scanners

User’s Manual for Bulletin 2760–RB

Flexible Interface Module

Protocol Cartridge Programming Manual Provides instruction on using the RS-232/RS-422

Protocol Cartridge Programming Manual Provides instruction on using the RS-485

BASIC Module User’s Manual Provides information on the Catalog Number

User’s Manual for 1771–KE and 1771–KF Provides information on the Catalog Number

ASCII I/O Module User’s Manual Provides information on the Catalog Number

Provides information on the Catalog Number

2755-L4F and -L4R enhanced scan heads①.

Provides information on the Catalog Number

2755-L4F and -L4R scan heads①.

Provides information on the Catalog Number

2755-L4 and -L5 scan heads①.

Provides information on the Catalog Number

2760-RB Flexible Interface Module.

protocol cartridge for the 2760-RB module.

protocol cartridge for the 2760-RB module.

1771-DB BASIC module.

1771-KE and -KF Communications Controllers.

1771-DA ASCII I/O module.

1–3

Page 11

Chapter

Chapter Objectives

Differences between Catalog

Number 2755-DM9 & 2755-DM9E

A–B

2

Description of Hardware

This chapter provides an overview of the Catalog Number 2755-DM9,

-DM9E Bar Code Decoder. We also provide descriptions of the major

features.

Note: In this chapter and in subsequent chapters, we will refer to the Catalog

Number 2755-DM9, -DM9E High Speed Decoder as the decoder.

• Catalog Number 2755-DM9 decoder includes a 120 VAC power cord, and

an English language manual. An LED label in English is attached to the

decoder.

Features

• Catalog Number 2755-DM9E decoder includes an unterminated 220 VAC

line cord and information for ordering User’s Manuals in English and

other languages. LED labels in English, French, German, Italian, and

Spanish are packaged with the decoder. Operation of the 2755-DM9 and

DM9E decoders is identical.

The decoder acquires video data from a separate laser scan head and then

decodes this data. The decoder can then:

• Send the decoded data to another device such as a host computer,

auxiliary terminal, or programmable controller.

• Compare the decoded data to previously stored data and use the results of

this comparison to operate up to eight discrete outputs (match code

operation).

Note: The decoder also maintains counters for package count, no-reads, and

discrete outputs.

The decoder is capable of decoding the following types of bar code symbols:

• Code 39. • UPC-A and E

• Interleaved 2 of 5. • EAN-8 and 13

• Codabar. • Code 128.

2–1

Page 12

Chapter 2

Description of Hardware

You can program many of the operating parameters of the decoder. This

programming capability allows you to adapt the decoder to a specific

application. You can:

• Specify decoder operating modes.

• Select types and lengths of symbols to be read.

• Select communications protocols used when communicating with a

computer or programmable controller.

• Enter up to eight match codes.

• Specify up to eight discrete outputs.

• Specify up to eight discrete outputs.

You can select continuous scanning or you can define what event will trigger

the label reading process. You can specify the trigger to be:

• A signal from the package detector connected to the laser scan head.

• A command received from a host computer.

• The decoder’s internal timer.

The decoder can communicate with a host computer using the following

standards:

Laser Scan Heads

Physical Description

• RS-232.

• RS-422.

• RS-485 (Multi-drop Network using Allen-Bradley DH485 protocol).

The decoder will operate with the following scan heads:

• Catalog No. 2755-L7 and -L9 Medium and High Speed, Industrial Bar

Code Scanners.

• Catalog No. 2755-L4F, -L4R, and -L5R Medium Speed, Enhanced,

Material Handling Scanners.

Note: We have not listed complete catalog numbers for the scan heads.

These scan heads are available in a variety of configurations.

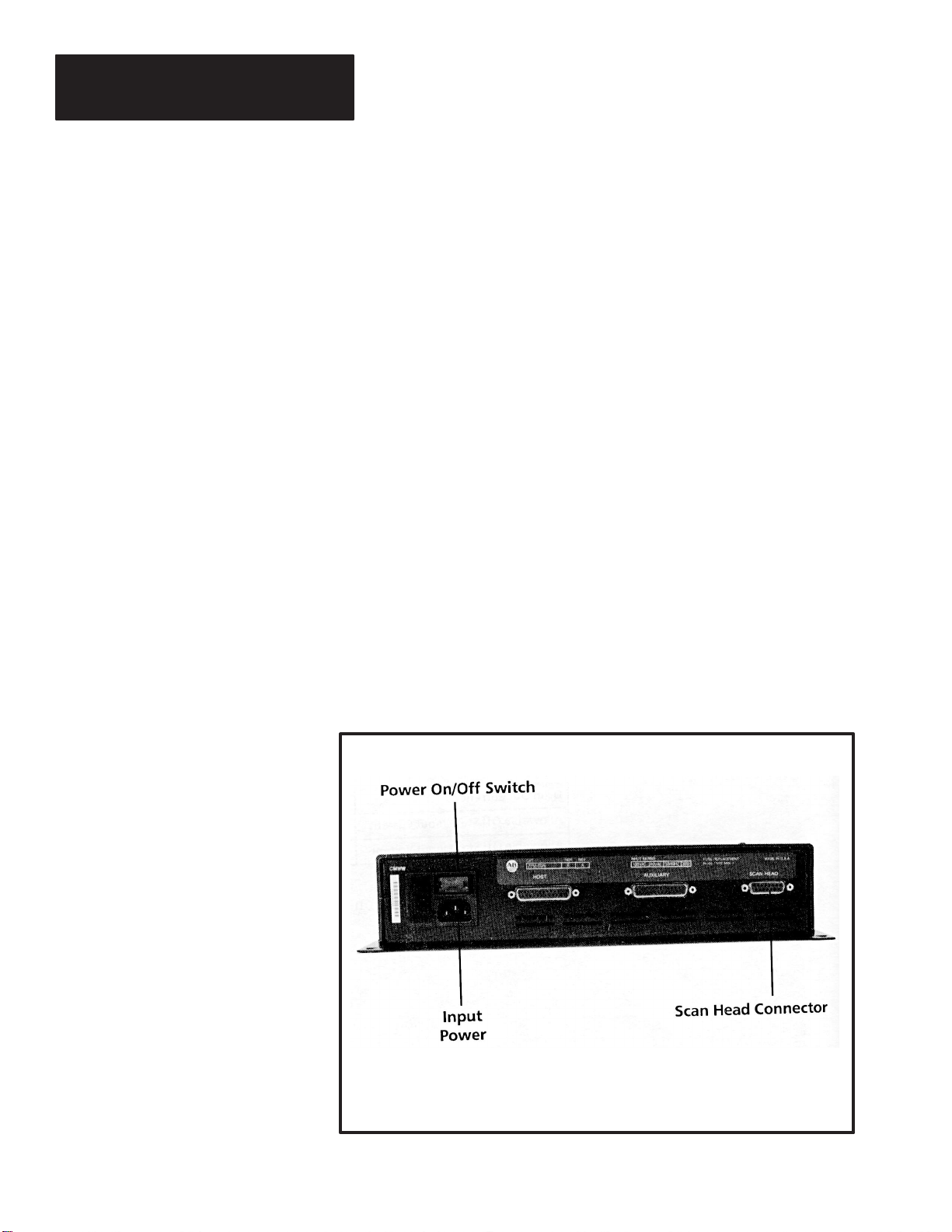

Figure 2.1 shows the decoder. The decoder is housed in a steel enclosure

(NEMA 1 rating). The decoder enclosure is 14” wide, 2.81” tall, and 10.75”

deep (refer to Chapter 5 for installation drawing). On top of the decoder are

fourteen indicator LEDs which indicate the status of the decoder and the

outputs (refer to Indicator Section in this chapter). On the back of the

decoder are the communications ports (refer to Communications Port Section

in this chapter). A separate removable cover allows for easy access to the

discrete output modules and fuses (refer to Output Module Section in this

chapter). Connectors are also provided for the laser scan head and power

line connector cables.

2–2

(Continued)

Page 13

Figure 2.1

Catalog Number 2755-DM9, -DM9E

Chapter 2

Description of Hardware

Indicators

90-061-1

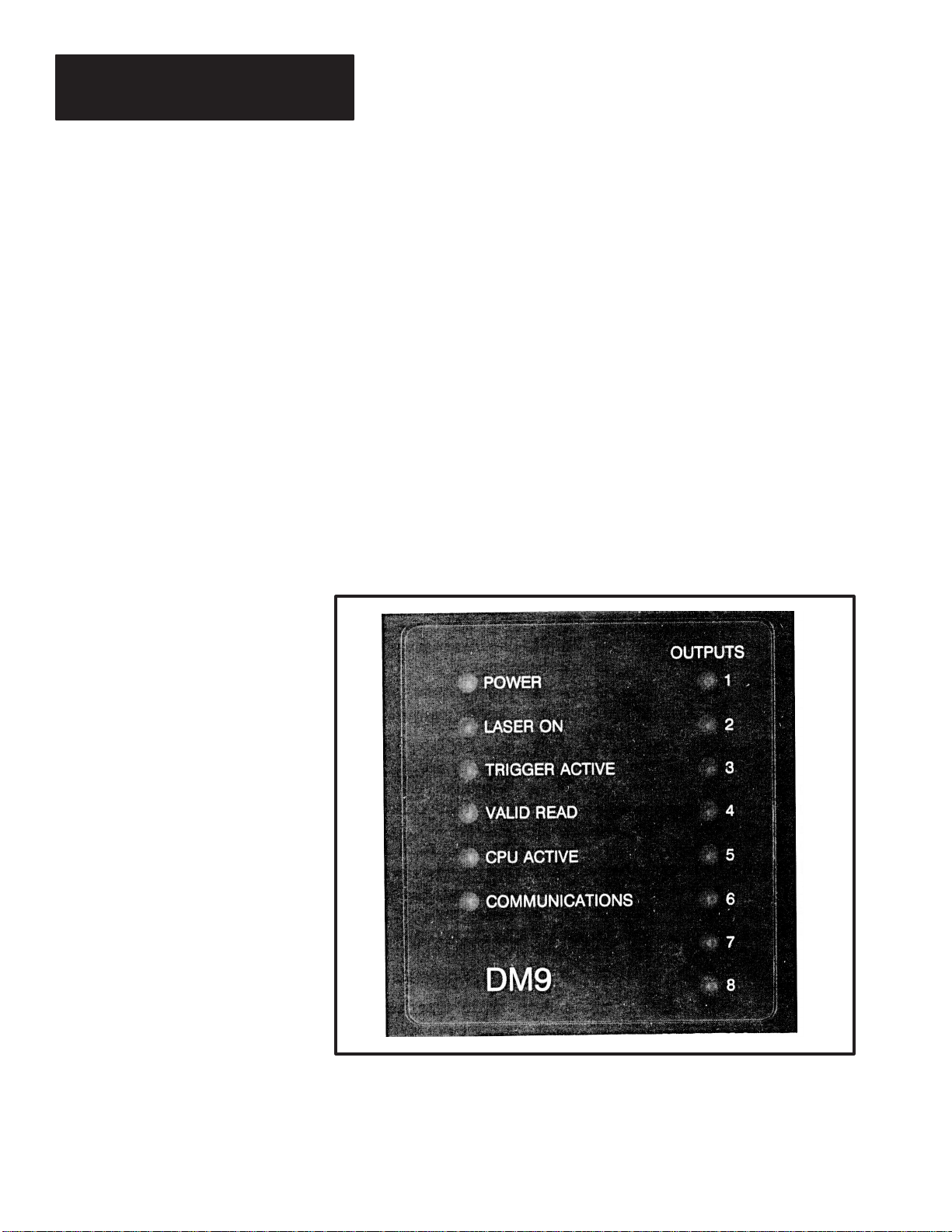

Fourteen LED indicators (Figure 2.2) provide an indication of the decoder

status. The indicators provide the following indications:

• POWER - This green indicator illuminates when power is applied to the

decoder.

• LASER ON - This red indicator illuminates when the decoder has enabled

the scan head to turn on the laser light source. The LED may illuminate

even if the scan head is disconnected or the “Laser On” switch for the

Catalog No. 2755-L7 or -L9 scan heads is in the OFF position.

• TRIGGER ACTIVE - This yellow indicator illuminates when the decoder

is in the triggered mode and scanning has been triggered by:

1. The package detector connected to the scan head.

2. A Start Scan command sent by the host.

3. The internal timer.

The LED remains on until a trigger OFF command is received.

• VALID READ - This green indicator illuminates momentarily whenever

the decoder has met the fields per scan and capture count parameters.

2–3

Page 14

Chapter 2

Description of Hardware

Note: This LED may not correspond to a read output condition (refer to page

4-41). In the triggered mode, the read output condition must meet the fields

per package parameter.

• CPU ACTIVE - This green indicator is continuously illuminated under

normal operation. Failure of the CPU ACTIVE indicator to illuminate is

an indication of a hardware failure.

• COMMUNICATIONS - This yellow indicator illuminates momentarily

whenever data is sent to or received at either of the communications ports.

• OUTPUTS 1 through 8- Each of these red indicators indicate the status

of the output modules. When an output module is turned on, the

respective indicator illuminates.

Note: If you have a Catalog No. 2755-DM9 decoder, the LED label is

attached. If you have a Catalog No. 2755-DM9E decoder, the LED label is

not attached. Apply the appropriate language label supplied with the

decoder.

Figure 2.2

LED Indicators

2–4

90-061-5

Page 15

Chapter 2

Description of Hardware

Communications Ports

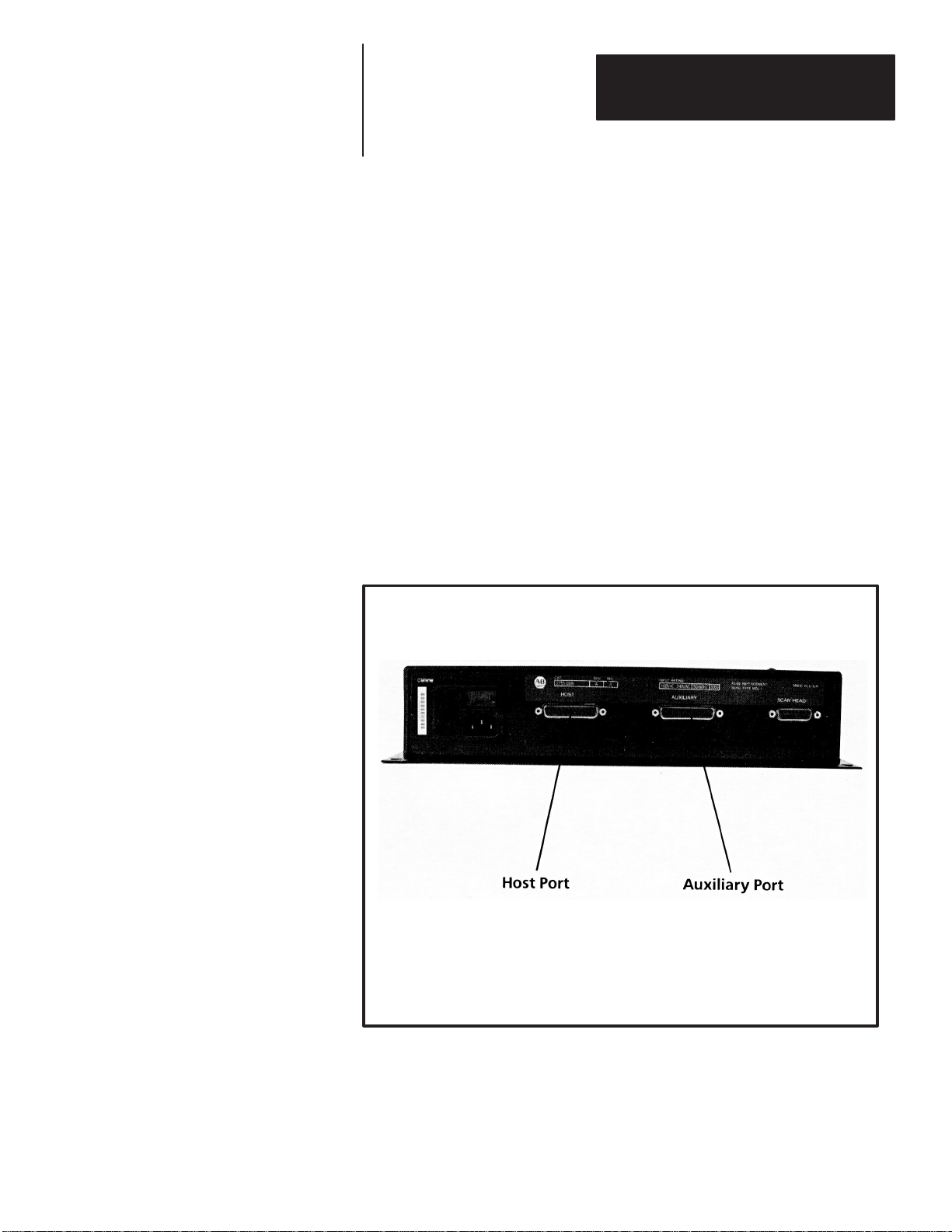

There are two communication port connectors on the decoder:

• HOST port connector. The HOST port connector supports RS-232,

RS-422, and RS-485 communication interfaces. Through this port, you

can link the decoder to a host computer or programmable controller. Both

commands and data may be sent to/from the host device.

Note: The RS-485 interface allows the decoder to be installed as part of a

multi-drop network. Refer to Chapter 3 for a more detailed description.

• AUX port connector. The AUX or auxiliary port connector allows you to

program and monitor the decoder using one of the following CRTs:

Allen-Bradley Industrial Data Terminal (Catalog No. 1770-T1, -T2, and

-T3), Allen-Bradley T45 Laptop Terminal (Catalog No. 1784-T45),

Digital VT100, Televideo 955, Lear Siegler ADM 3E, or a

terminal/computer that emulates one of the terminals listed.

Figure 2.3

Communication Ports

90-061-2

2–5

Page 16

Chapter 2

Description of Hardware

Output Modules

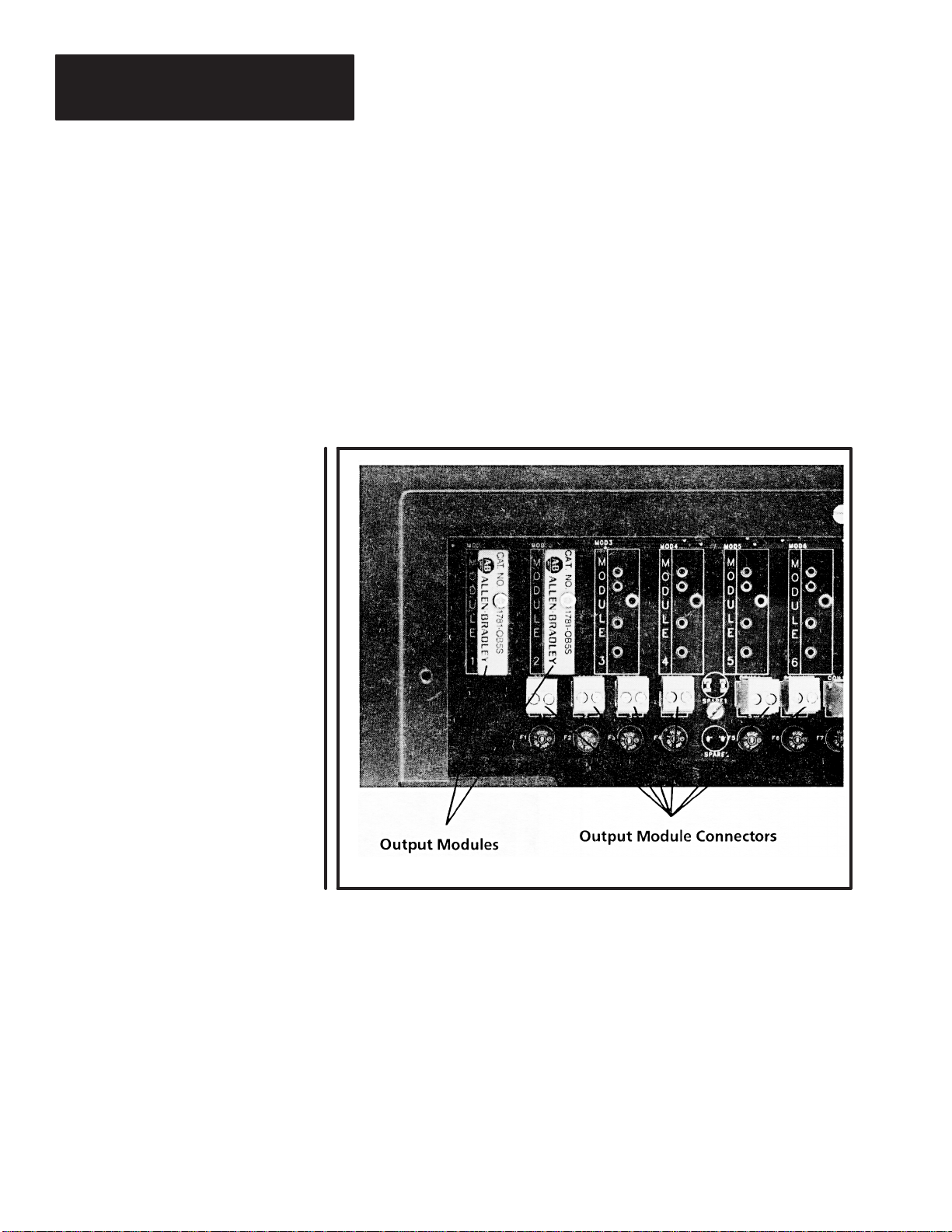

Two DC output modules (Catalog No. 1781-OB5S) are provided with the

decoder. You can add up to six more AC or DC output modules for a total of

eight. Module location #8 can also accept an input module for auto loading

match codes (refer to Chapters 3 and 4). All output module types can be

installed in any of the eight module slots. You can program the decoder to

turn on these output modules based upon the conditions you specify during

configuration of the decoder. Use these outputs to operate electromechanical

devices such as relays, alarms, etc. Fuses protect the decoder from power

overloads.

Figure 2.4

Output Modules

2–6

90-061-4

Page 17

Chapter 2

Description of Hardware

The following output modules are available.

Note: Output modules function as a switch, not as a power source.

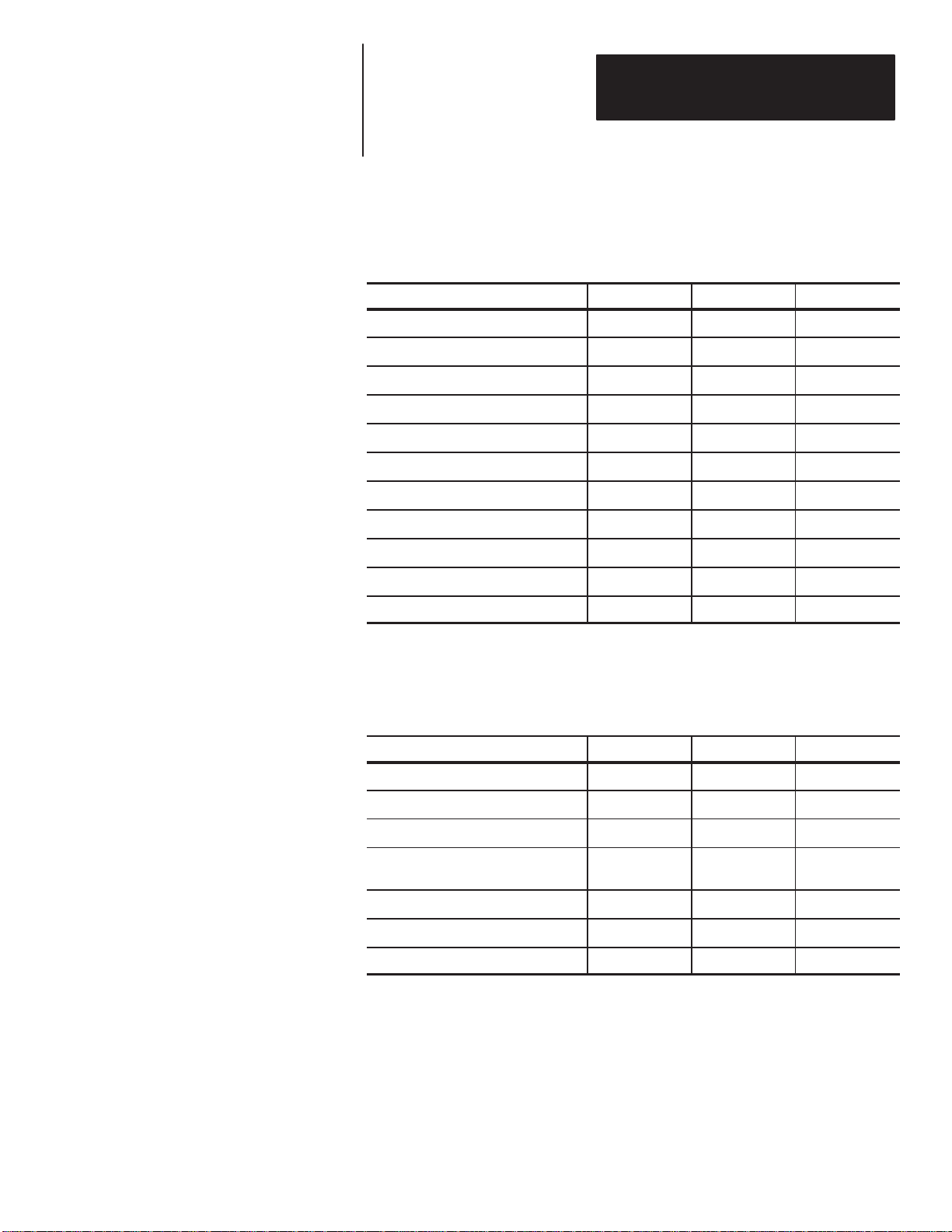

Catalog No. 1781-0B5S 1781-0A5S 1781-OM5S

Nominal Line Voltage

-- 120 VAC 240 VAC

Maximum Line Voltage

Minimum Line Voltage 3.0 VDC 12 VAC 24 VAC

Maximum Peak Off State Voltage 60 VDC

Maximum Off-State Leakage

Static off-state dv/dt -- 200 V/ usec 200 V/ usec

Maximum On-State Current

Minimum On-State Current 10 mA DC 50 mA RMS 50 mA RMS

Maximum 1 Cycle Surge -- 4.0 A Peak 4.0 A Peak

Maximum 1 Second Surge

Peak On-State Voltage 1.5 V DC

60 VDC 140 VAC 280 VAC

400 V Peak 600 V Peak

1.0 mA 2.5 mA RMS 4.0 mA RMS

0.5 A DC 0.5 A RMS 0.5 A RMS

1.5 A DC -- --

1.6 V Peak 1.6 V Peak

The following input modules are available (for position No. 8 only). See

Chapters 3 and 4.

Note: The input modules require a voltage source for activation.

Catalog No. 1781-IB5S 1781-IA5S 1781-IM5S

Maximum Input Voltage 32 VDC 140V RMS/AC 280 V RMS/AC

Minimum Input Voltage

Input Resistance 1k ohm - Maximum Input Current 32mA DC @

Drop Out Current

Allowable Off State Input Current 1.0 mA DC 3.0 mA RMS 2.0 mA RMS

Allowable Off State Input V oltage

3.3 VDC 90V RMS/AC 180 V RMS/AC

10mA RMS @

32 VDC

1.0 mA DC 2.5 mA RMS 1.5 mA RMS

2.0 VDC 50 VRMS/AC 120 VRMS/AC

140 VRMS

8mA RMS @

280 VRMS

Note: Note polarity when connecting DC Input and Output modules.

2–7

Page 18

Chapter 2

Description of Hardware

Power and Scan Head Connectors

The decoder will accept line voltages from 85 to 264 volts AC at a frequency

of 47 to 63 Hz without any adjustments. The Catalog No. 2755-DM9

decoder is supplied with a 120VAC rated power cord. If you are powering a

2755-DM9 decoder with a supply voltage greater than 120 VAC, you must

obtain a suitable power cord.

Note: Catalog No. 2755-DM9E is supplied with an unterminated power cord.

Attach a suitable connector using the diagram provided in Chapter 5.

A 15 pin D connector is provided on the decoder for connecting the laser

scan head. You can connect the decoder to the scan head using one of the

following:

• For Catalog No. 2755-L7 and -L9 scan heads use-

10 foot (3.05 meter) cable (Catalog No. 2755-CL10)

25 foot (7.62 meter) cable (Catalog No. 2755-CL25)

• For Catalog No. 2755-L4 and -L5 scan heads use-

10 foot (3.05 meter) cable (Catalog No. 2755-CK10)

25 foot (7.62 meter) cable (Catalog No. 2755-CK25)

Note: The scan head is powered by the decoder through the cable. The scan

heads do not require a separate power source.

Figure 2.5

Input Power and Scan Head Connectors

90-061-4

2–8

Page 19

Chapter 2

Description of Hardware

Accessories

The following table lists the accessories that you may require for use with the

decoder.

Catalog Number Item Description

Raster and side scanning devices that operate at 350 scans per

second. Raster scanners scan both vertical and horizontal directions

2755-L7①

2755-L9①

2755-L4F①

-L4R①

2755-L5R①

1781-OB5S DC Output Module 3 to 60 VDC output at 0.5 amperes.

1781-OA5S AC Output Module 12 to 140 VAC output at 0.5 amperes.

1781-OM5S AC Output Module 24 to 280 VAC output at 0.5 amperes.

1781-IB5S DC Input Module 3.3 to 32 VDC

1781-IA5S AC Input Module 90 to 140 VRMS/VDC

1781-IM5S AC Input Module 180 to 280 VRMS/VDC

2760-A485 RS-485 Connector Use these connectors to create cables for an RS-485 network.

2755-CL10 10-ft (3.05 meters) Scan Head Cable

2755-CL25 25-ft (7.62 meters) Scan Head Cable

2755-CK10 10-ft (3.05 meters) Scan Head Cable

2755-CK25 25-ft (7.62 meters) Scan Head Cable

W77104-899-01

Purchased

Locally

Package

Detector

Assembly

User Created Host Port Communications Cable For connecting host device to the decoder, refer to Chapter 6.

User Created Auxiliary Port Communications Cable

W77121-801-01

W77121-801-02

Industrial Medium Speed Bar Code

Scanner

Industrial High Speed Bar Code Scanner

Enhanced Medium Speed Scanner

Enhanced Medium Speed Raster Scanner

Replacement Fuse- Power Output

Modules

Replacement Fuse- Line Input Power 250V ( 1 amp, slow blow), 5 x 20 mm or 3AG

2755-NP3

2755-NP5

2755-NP1

2755-NP4

Power Cords -

120 V AC

220 V AC- Unterminated one end

simultaneously. Some of these scan heads have a maximum read

distance of 50” (1.27 meters) depending upon symbol size and

quality. Scanners can read Case Code symbols (symbols directly

printed on kraft paper/cardboard boxes).

Raster and side scanning devices that operate at 800 scans per

second. Raster scanners scan both vertical and horizontal directions

simultaneously. Some of these scan heads have a maximum read

distance of 30”

(76 cm) depending upon symbol size and quality .

Front or side scanners that operate at 200 scans per second. Some

of these scan heads have a maximum read distance of 50” (1.27

meter) depending upon symbol size and quality . Scanners can read

Case Code symbols (symbols directly printed on kraft

paper/cardboard boxes).

Raster scanners that operate at 200 scans per second. This scan

head has a maximum read distance of 45” (1.14 meters) depending

upon symbol size and quality . Scan head scans both vertical and

horizontal directions simultaneously. Scanner can read Case Code

symbols (symbols directly printed on kraft paper/cardboard boxes).

Use to connect decoder to Catalog No. 2755-L7 or -L9 scan head.①

Use to connect decoder to Catalog No. 2755-L7 or -L9 scan head.①

Use to connect decoder to Catalog No. 2755-L4 or -L5 scan head.①

Use to connect decoder to Catalog No. 2755-L4 or -L5 scan head.①

Plug-in type fuses provide overload protection for the decoder.

Optional, for 2755-L7, -L9 Scan Heads

Optional, for 2755-L7, -L9 Scan Heads

Optional, for 2755-L4, -L5 Scan Heads

Optional, for 2755-L4, -L5 Scan Heads

For connecting programming terminal to the decoder. Refer to

Appendix A.

Replacement power cord.

User must provide suitable connector.

① We have not provided the complete catalog number since these heads are available in a variety of configurations.

2–9

Page 20

Chapter

Chapter Objectives

How the Decoder Operates

A–B

3

How the Decoder Operates

This chapter provides a brief description of how the decoder operates. We

also provide a brief description of how the decoder communicates with host

devices.

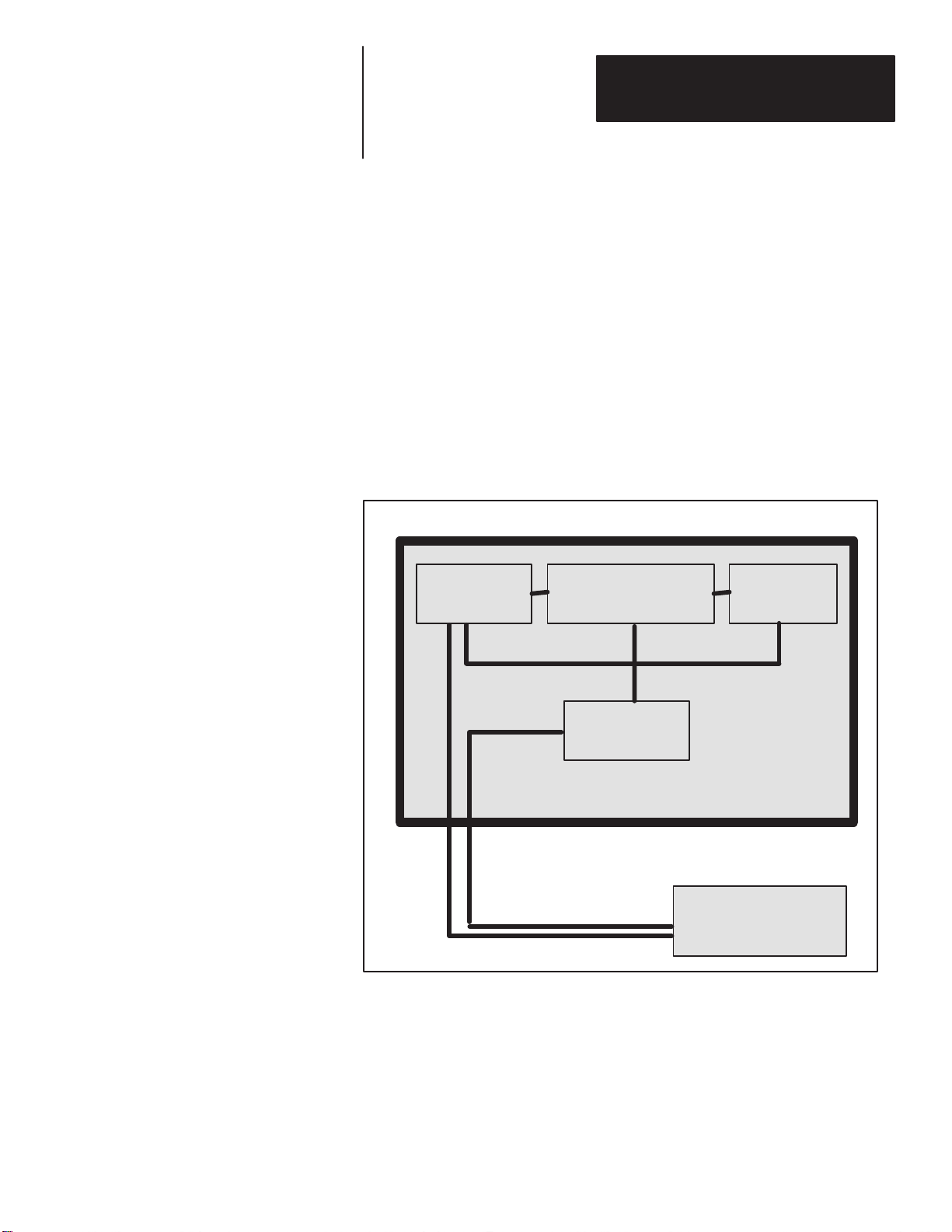

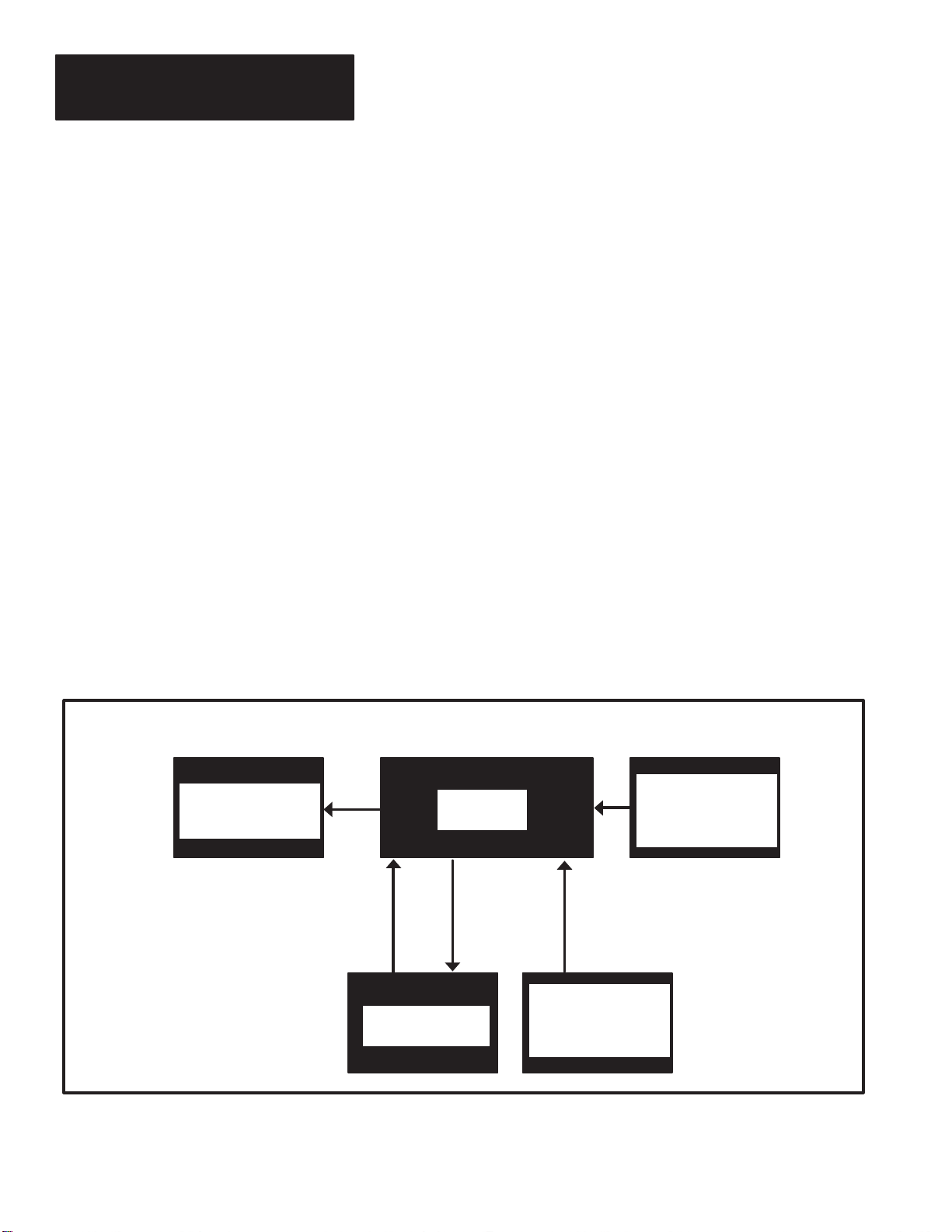

Figure 3.1 is a block diagram of the decoder.

Figure 3.1

Catalog Number 2755-DM9 Decoder

DECODER

DATA

ACQUISITION

POWER SUPPLY - An internal power supply provides power for both the

laser scan head and internal circuitry of the decoder. As stated earlier, the

source voltage may range from 85 to 264 volts AC. The power supply will

automatically adjust to the input voltage.

MICROPROCESSOR

POWER

SUPPLY

I/O

LASER SCAN HEAD

DATA ACQUISITION CIRCUIT - The data acquisition circuitry of the

decoder receives both video and synchronization signals from the laser scan

head. The data acquisition circuitry filters and stores blocks of data received

from the scan head in the Random Access Memory (RAM) of the decoder.

3–1

Page 21

Chapter 3

How the Decoder Operates

MICROPROCESSOR - The microprocessor reads the information obtained

by the data acquisition circuit, processes the information, and then makes

decisions on what to do with the decoded data based upon your programming

instructions.

I/O - A single 25 pin connector (HOST PORT) provides three different

interfaces (RS-232, RS-422, and RS-485) for communications with a host

computer or programmable controller. The I/O section of the decoder

supports asynchronous data transmission at baud rates of up to 38,400 bits

per second.

Another 25 pin connector (AUX PORT) provides an RS-232 interface for

programming and monitoring of the decoder using a programming terminal.

Refer to Chapter 2 for a listing of the terminals that can be used for

programming or monitoring.

Up to eight modules can be plugged into the circuit board of the decoder.

Refer to Chapter 2 for a description of the input and output modules that can

be used. Output modules function as switches, not as power sources (refer to

Figures 3.2 and 3.3).

Note: Outputs are initially turned off (open) when power is first applied to

the decoder and when the decoder is turned off.

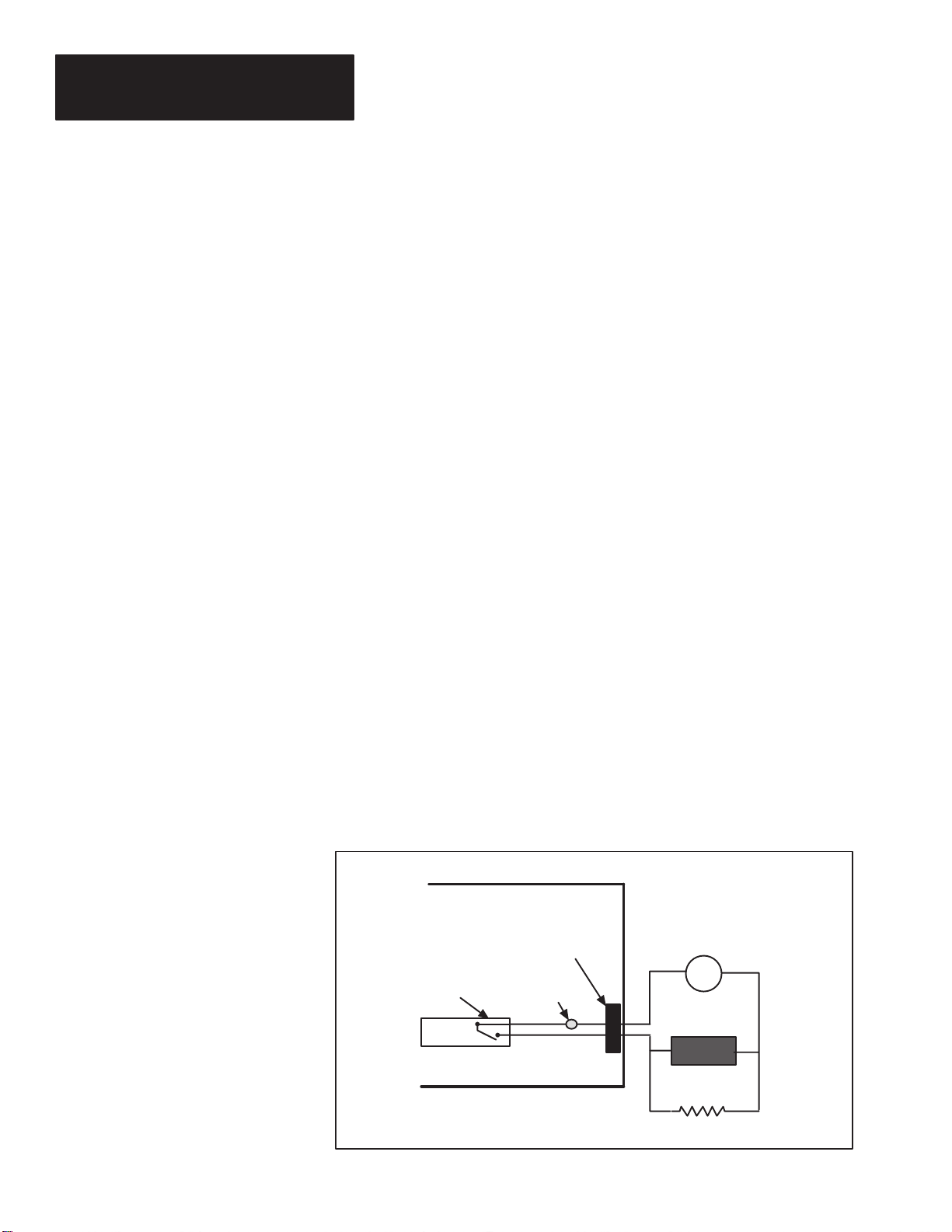

DC Output Module Application

Figure 3.2 illustrates a typical DC output module application. When using

high impedance loads, you may have to add an additional resistor (Rx) in

parallel with the load. Select a value for Rx that maintains a minimum

current of 10 mA through the output module in the on state. Typical values

for Rx range from 300 to 6,000 ohms depending upon the source voltage.

Figure 3.2

DC Output Module Application

DECODER

DC SOURCE 3-60 VDC

+

_

LOAD

_

+

DC OUTPUT MODULE

CONNECTOR BLOCK

FUSE

3–2

Rx

Page 22

Chapter 3

How the Decoder Operates

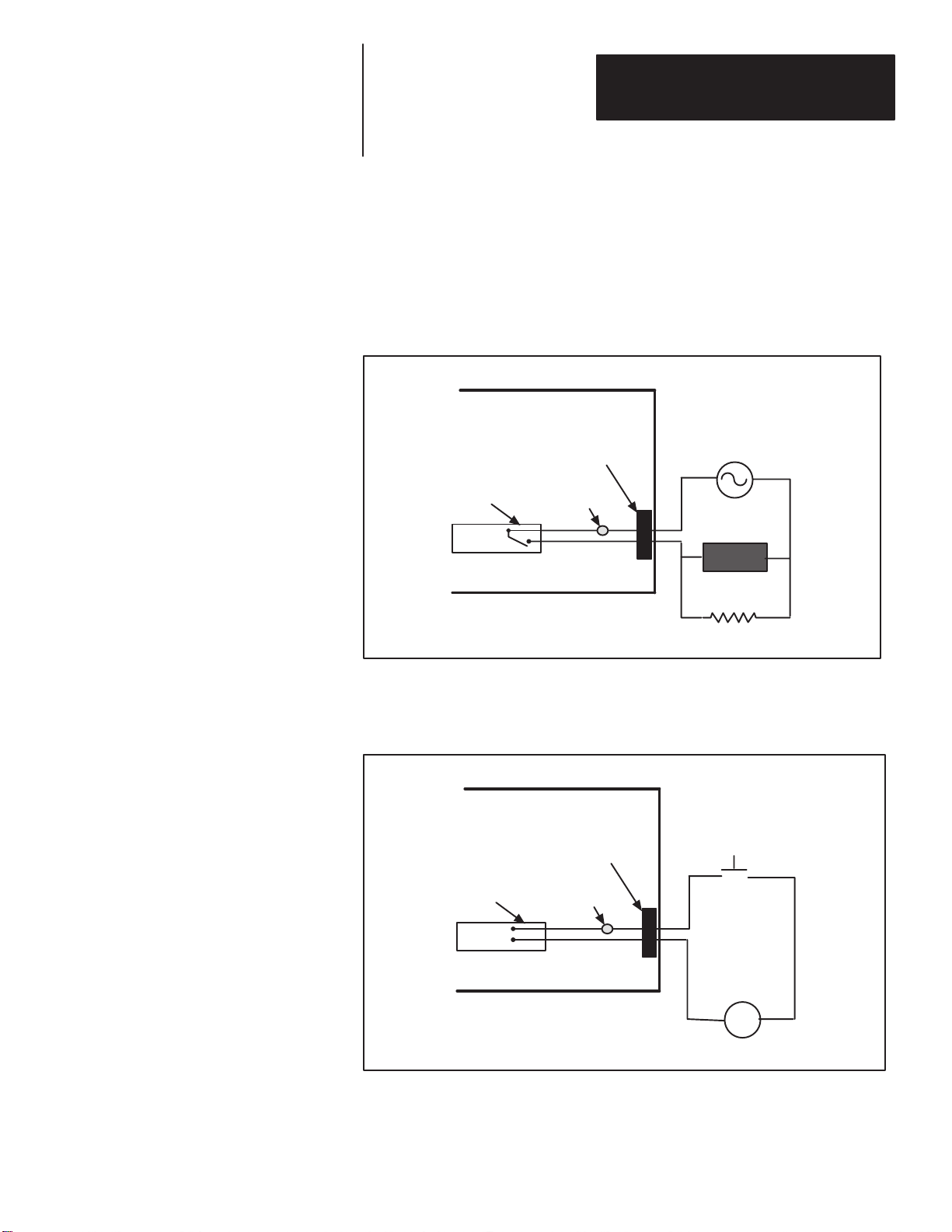

AC Output Module Application

Figure 3.3 illustrates a typical AC output module application. When using

high impedance loads, you may have to add an additional resistor (Rx) in

parallel with the load. Select a value for Rx that maintains a minimum

current of 50 mA RMS through the output module in the on state.

Figure 3.3

AC Output Module Application

DECODER

AC SOURCE

LOAD

Rx

AC OUTPUT MODULE

CONNECTOR BLOCK

FUSE

Input Module Auto Load Application

Figure 3.4 illustrates the auto load input module application.

Figure 3.4

Typical Input Module Auto Load Application

DECODER

Auto Load

CONNECTOR BLOCK

INPUT MODULE

AC or DC

MODULE LOCATION #8 ONLY

FUSE

Pushbutton

+

-

Communications

AC or DC SOURCE

As stated earlier the decoder can transmit decoded bar code information to a

host computer or programmable controller. The three communications

3–3

Page 23

Chapter 3

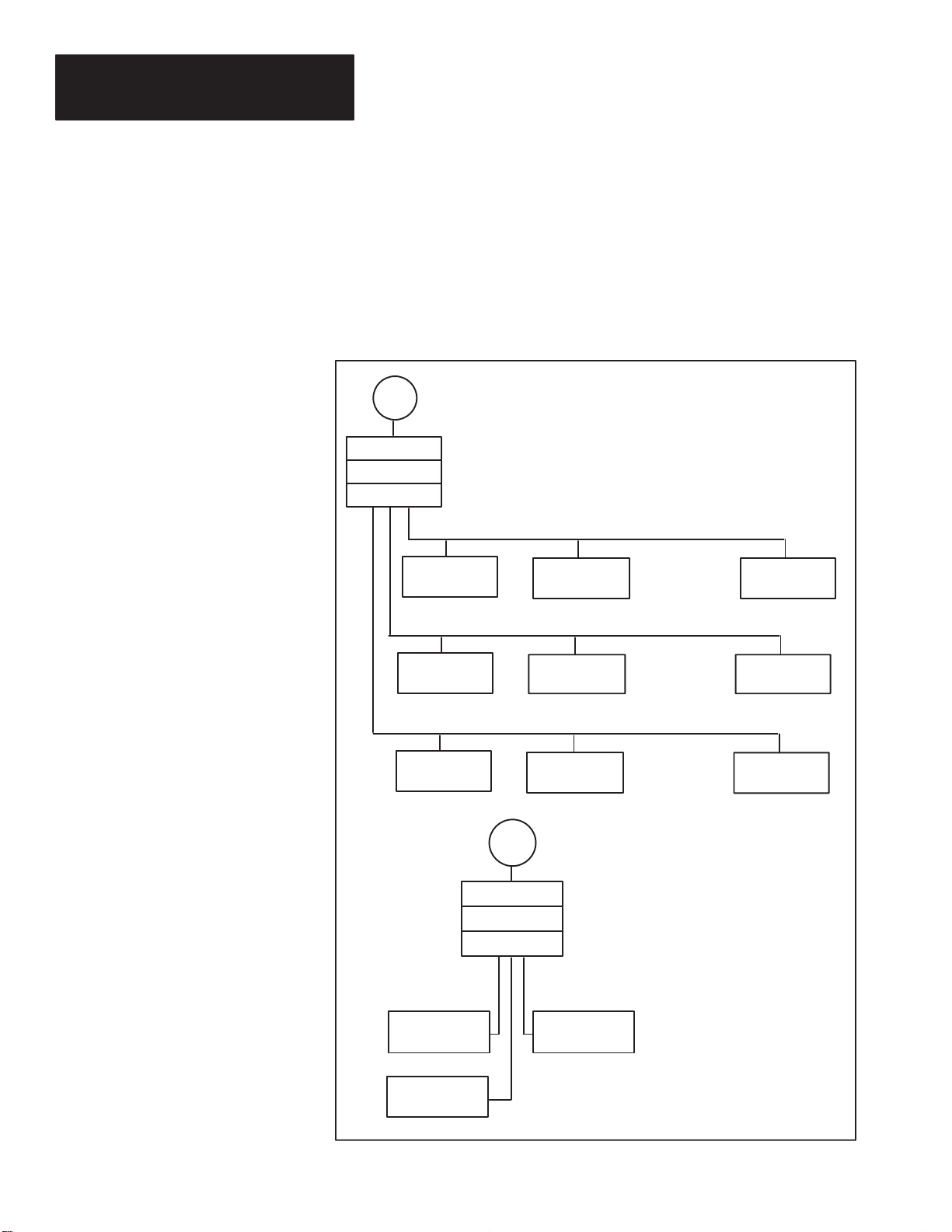

How the Decoder Operates

interfaces (RS-232, RS-422, and RS-485) provide a variety of ways to

accomplish communications with a host. Figure 3.5 illustrates some of the

possible host interfaces.

Note: You can also use the decoder as a stand-alone device using the discrete

outputs for control.

Figure 3.5

Communications Interface Examples

PLC

1771 I/O Rack

2760-RB

2760-SFC2

2755-DM9

2755-DM9

Decoder

2755-DM9

Decoder

Decoder

1

1

1

PLC TO DECODER USING

A FLEXIBLE INTERFACE

MODULE (RS-485)

2755-DM9

Decoder

2

2755-DM9

Decoder

2

2755-DM9

Decoder

2

PLC

PLC TO DECODER USING A

FLEXIBLE INTERFACE

MODULE (RS-232, RS-422)

• • • • • •

• • • • • •

• • • • • •

2755-DM9

Decoder

31

2755-DM9

Decoder

31

2755-DM9

Decoder

31

3–4

2755-DM9

Decoder

2755-DM9

Decoder

1771 I/O Rack

2760-RB

2760-SFC1

RS-232 or RS-422

2755-DM9

Decoder

Catalog No. 2760-RB is a Flexible Interface

Catalog No. 2760-SFC1, -SFC2 are Protocol Cartridges

Page 24

Chapter 3

How the Decoder Operates

Figure 3.5

Communications Interface Examples (Continued)

PLC TO DECODER USING

AN ASCII MODULE

PLC

1771 I/O Rack

1771-DA

RS-232

2755-DM9

Decoder

COMPUTER TO

DECODER

Host Computer

RS-232 or RS-422

2755-DM9

Decoder

PLC TO DECODER USING A

BASIC MODULE

PLC

1771 I/O Rack

1771-DB

RS-232

2755-DM9

Decoder

Catalog No. 1771-DB is a BASIC I/O Module

Catalog No. 1771-DA is an ASCII I/O Module

ALLEN-BRADLEY LOCAL-AREA NETWORK - Using the Catalog No.

2760-RB Flexible Interface Module with the 2760-SFC2 protocol cartridge

and the DM9 in the RS-485 mode, you can multi-drop up to 31 devices on

each port of the 2760-RB module.

PROGRAMMABLE CONTROLLERS - You can connect the decoder to a

programmable logic controller in one of three ways:

• Through the Allen-Bradley Data Highway.

• Through a Flexible Interface Module (Catalog No. 2760-RB). This

module can be used to create an RS-485 Local Area Network or

point-to-point communications using the RS-232 or RS-422

communications interfaces.

• Directly, using a Catalog No. 1771-DB BASIC module or 1771-DA

ASCII I/O module.

HOST COMPUTERS- In most cases, you can directly connect your host

computer to the decoder using the RS-232 or RS-422 interface. The decoder

can also communicate with an industrial computer through the Allen-Bradley

Data Highway.

3–5

Page 25

Chapter 3

How the Decoder Operates

RAM and EEPROM Memory

Before you try to change the operating configuration of the decoder, you

should understand how configuration parameters are stored. The decoder has

two types of memory:

• EEPROM- Electrically Erasable Programmable Read Only Memory

contains the “non-volatile” operating configuration of the decoder. The

term “non-volatile” means that the memory is not lost when you turn the

power off or restart the decoder.

• RAM- Random Access Memory contains the current operating

configuration of the decoder. Any changes made to the the operating

configuration of the decoder are made to the decoder’s RAM. All

information stored in the RAM is erased when the power to the decoder is

turned off. When the decoder is turned back on (rebooted), the

configuration parameters are copied from non-volatile memory

(EEPROM) to the RAM.

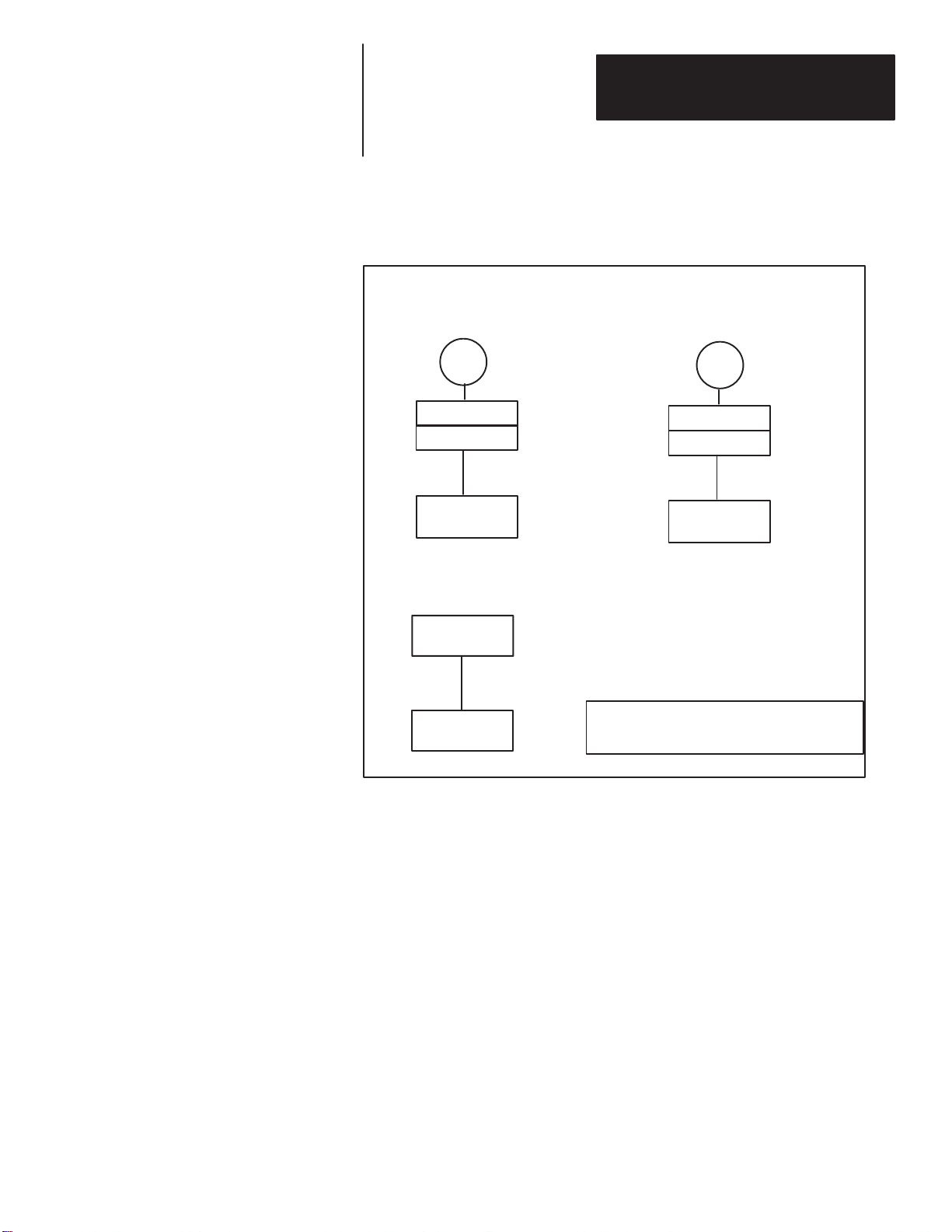

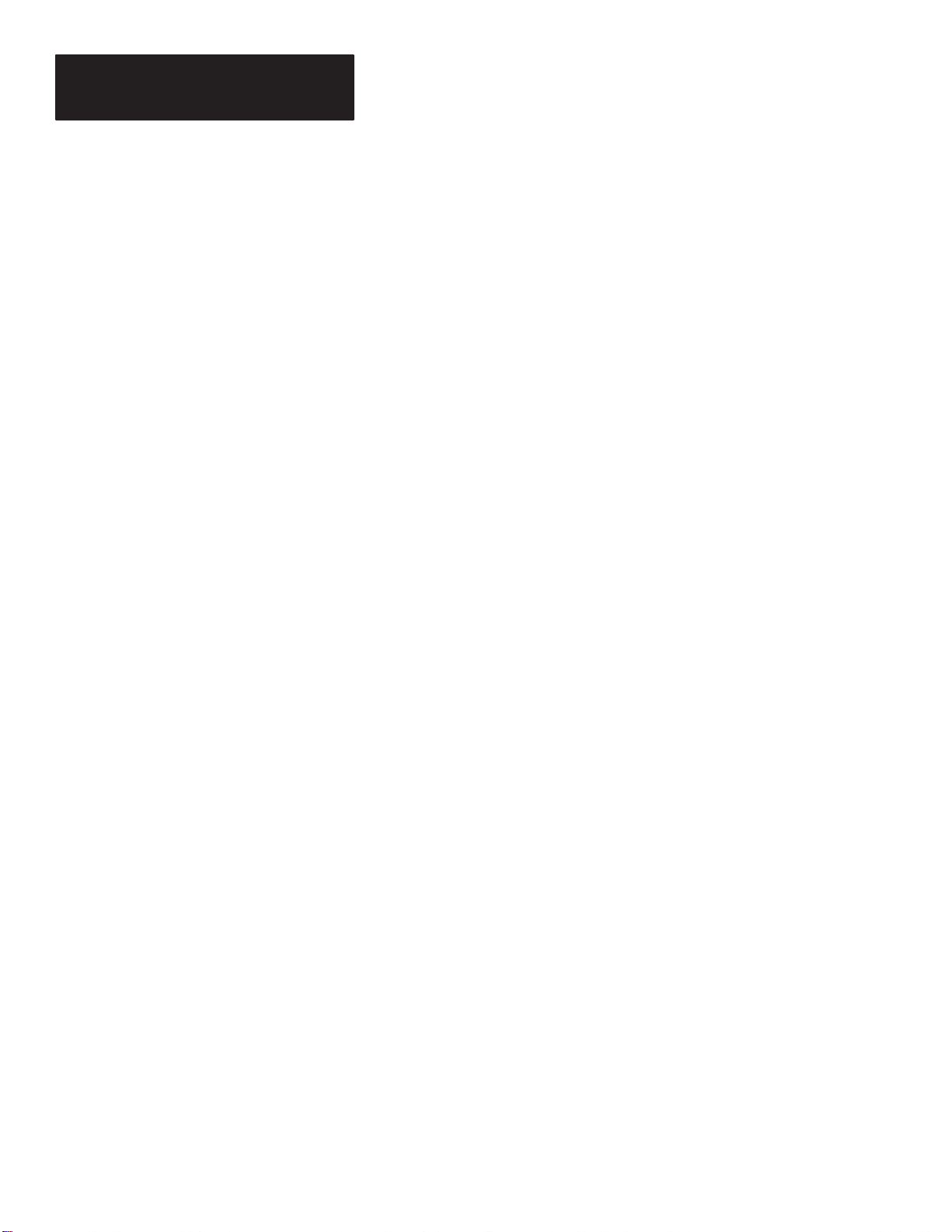

Figure 3.6 illustrates the relationship between the RAM and EEPROM

memory. Notice that the user interface is with the RAM memory. Also,

notice that the decoder transfers the contents of the RAM to the EEPROM

during a SAVE operation and copies the same contents from the EEPROM to

RAM during startup.

Note: The configuration in RAM determines the decoder performance

(operating characteristics).

Figure 3.6

Decoder Memory

3–6

Decoder

Performance

User Interface

RECALL

START-UP

RESTART

RAM

EEPROM

SAVE

DEFAULT

Default

Configuration

Settings

-Programmer

-Host

When you change the operating configuration of the decoder, you are

changing the configuration stored in the decoder’s RAM. Since the decoder

takes its current operating instructions from RAM, any changes you make

Page 26

Chapter 3

How the Decoder Operates

will become effective immediately (except for host communications

parameters listed below). If you want to enter changes into the decoder’s

permanent memory (EEPROM), you must use the SAVE command. When

the decoder is restarted, the operating parameters of the EEPROM are

transferred into RAM. If you don’t transfer the contents of the RAM to the

EEPROM (SAVE function), any changes made to the operating configuration

stored in RAM will be erased when the power is turned off.

Note: Unlike the other decoder operating parameters, changes to the

following parameters will not take effect until you SAVE the changes and

then restart the decoder.

• HOST PROTOCOL

• DEVICE ADDRESS

• ACK and NAK CHARACTERS①

Operating Modes

• BAUD RATE

• NUMBER OF DATA & STOP BITS

• PARITY

① Changes to ACK NAK characters will take effect immediately if you are in the ACK/NAK mode.

The decoder also stores the original factory set operating parameters in

EPROM. This type of memory cannot be changed by the user, and is always

available in case of a programming error. When you use a DEFAULT

command (described in next chapter), the decoder transfers the factory set

default parameters to the RAM. Once installed in RAM, the default

parameters control the operation of the decoder. If you want to save the

default parameters into the EEPROM, you must use the SAVE command.

A RECALL command (described in next chapter) transfers the previously

SAVED configuration from the EEPROM to the decoder’s RAM. Once

installed into RAM, the recalled configuration is displayed and controls

operation of the decoder.

When you configure the operation of the decoder, you will be required to

provide a variety of operating parameters. You should have an understanding

of the decoder’s operating modes prior to configuring the decoder (Chapter

4). The decoder operates in one of two modes:

• Continuous mode - In this mode, the decoder will continuously attempt to

decode data. Use this mode for initial scan head adjustments and

positioning.

• Triggered mode - In this mode, the decoder will only attempt to decode

data after receiving a trigger.

3–7

Page 27

Chapter 3

How the Decoder Operates

In the triggered mode of operation, there are three possible trigger sources:

• Host command - The command is generated by a host computer or

programmable controller.

• Package detect - A package detector connected to the scan head is the

source for the trigger.

• Internal timer - The internal timer cycles the trigger from on to off based

on a timed interval.

Trigger Ending Coditions

Response Modes

When a trigger on is received, the decoder will continuously attempt to

decode bar codes until one of the following trigger ending conditions occurs:

(a) The number of fields (bar codes) per package count is satisfied.

(b) A trigger off command is sent by a host device.

(c) Package detect signal is no longer present.

(d) The internal timer (No-Read timer) times out.

In the triggered mode of operation there are two options which determine

when the decoder will send bar code information to a host and/or operate

discrete outputs:

• After Valid Package - A valid package is a package that has valid bar

code symbols and meets the fields (bar codes) per package count

(condition

(a) listed above).

• End of Trigger - Refer to trigger ending conditions (b, c, d) listed above.

3–8

Page 28

Chapter

Chapter Objectives

Initial Programming of the Decoder

A–B

4

Configuring Your Decoder

Because the decoder can be used many ways, you will need to configure the

decoder to meet the requirements of your application. To do this, you must

make some decisions. We will show you how to use the menus and setup

screens that appear on a programming terminal to select the options you

need.

You must configure the decoder to meet the requirements of the application.

You can configure the decoder either before or after installation. If you

change the configuration while a triggered decode is in progress, there is

the possibility of missing a package and/or losing data.

Note: The default parameters for the decoder are given in Appendix B. If

these settings meet your requirements, you will not have to program the

decoder.

You will need the following equipment:

1. Decoder with power cable.

2. One of the following programming terminals:

• Allen-Bradley Industrial Terminal (Catalog No.1770-T1, -T2, or -T3).

• Allen-Bradley T45 Laptop Terminal (Catalog No. 1784-T45).

• Lear Siegler 3E.

• Televideo 955.

• DEC VT-100.

• A terminal or personal computer that accurately emulates one of the

above.

3. A cable to connect your programming terminal to the decoder.

Note: Prior to configuring your decoder, we suggest that you review the

description of how the decoder stores configuration data (refer to Chapter 3,

RAM and EEPROM Memory descriptions).

Note: Refer to Appendix A for programming terminal setup. The

programming terminal you use must be configured with the following

parameters:

Number of data bits: 8

Number of stop bits: 1

Baud rate: 9600

Parity: None

Flow Control: XON / XOFF

4–1

Page 29

Chapter 4

Configuring Y our Decoder

Programming Terminal Cable

Menus and Setup Screens

Programming of the decoder is done through the AUX connector on the back

of the decoder.

female, D type connector. Depending upon your programming terminal,

most standard RS-232 communications cables will work. If you need to

create a communications cable, refer to Appendix A.

You can program and/or monitor the operation of the decoder using the

following CRT screens:

The AUX port connector on the decoder is a standard 25 pin,

• Select Language Screen - Use this screen to select English, French,

German, Italian, or Spanish language screens.

• CRT Select Menu - You use this menu to select the type of programming

terminal being used.

• Select operation Menu - Using this menu, you select one of six

operations:

1) Display Labels Screen- Displays bar code labels as they are decoded.

2) System Status Screen- Displays the status of the decoder.

3) Setup Screens Setup Screen 1- Use this screen to configure the host interface which

includes host message format, host communications parameters and

protocol, and filtering of the package detect input.

Start-up Procedure

4–2

Setup Screen 2- Use this screen to configure the decoder for the bar

code symbologies, bar code lengths, scan head operation, match code

settings, and configuration of output modules.

4) Reset Status and Counters

5) Restart System

6) Select Language Screen- This screen allows you to reselect one of the

following languages:

• English

• French

• German

• Italian

• Spanish

After you have connected the programming terminal to the decoder and

attached the power cord:

Step 1 - Turn ON the programming terminal and configure the terminal for

communications with the decoder. Appendix A provides information on

setting up the programming terminal.

Page 30

Chapter 4

Configuring Y our Decoder

Step 2 - Turn the decoder ON. The green LEDs, labeled POWER ON and

CPU ACTIVE, will light.

Step 3 - When the following screen appears, press the key that corresponds

to the language you are using. All of the remaining screens will appear in the

selected language.

SELECT LANGUAGE CHOIX DU LANGAGE WAEHLE SPRACHE

1) English 1) Anglais 1) Englisch

2) French 2) Francais 2) Franzoesisch

3) German 3) Allemand 3) Deutsch

4) Italian 4) Italien 4) Italienisch

5) Spanish 5) Espagnol 5) Spanisch

Press 1, 2, 3, 4, 5, or ESC Appuyer 1, 2, 3, 4, 5 ou ESC Drueck

e 1, 2, 3, 4, 5, oder ESC

SELEZIONARE LINGUA SELECCIONAR LENGUA

1) Inglese 1) Ingles

2) Francese 2) Frances

3) Tedesco 3) Aleman

4) Italiano 4) Italiano

5) Spangnolo 5) Castellano

Premere 1, 2, 3, 4, 5 o ESC Pulsar 1, 2, 3, 4, 5, o ESC

Step 4 - After selecting the language, the decoder will display the CRT select

screen. Press the key (1, 2, 3, 4, or 5) that corresponds to the terminal you

are using. Pressing the [ESC] key, will return you to the language selection

screen.

2755-DM9 Bar Code Reader VX.XX

Copyright 1990 Allen-Bradley Company, Inc.

SELECT CRT TYPE

1 - Allen-Bradley 1770 Industrial Terminal

2 - Allen-Bradley T45 Portable Terminal

3 - Lear Siegler ADM 3E

4 - Televideo 955

5 - Digital VT100

Press 1, 2, 3, 4, 5 or ESC

Step 5 - After selecting the CRT type, the decoder will display the select

operation menu. The remaining displays that you will see depends upon the

operation that you select.

4–3

Page 31

Chapter 4

Configuring Y our Decoder

Select Operation Menu

After selecting the CRT type, the following Select Operation menu will

appear:

2755-DM9 Bar Code Reader VX.XX

Copyright 1990 Allen-Bradley Company, Inc.

SELECT OPERATION

1) Display Bar Code Labels

2) Display Status and Counters

3) Display/Change Configuration

4) Reset Status and Counters

5) Restart

6) Select Language

Press 1, 2, 3, 4, 5, 6, or ESC

The following are explanations of each operation listed on the Select

Operation menu:

1) Display Bar Code Labels - This operating mode allows you to monitor

bar code labels as they are being scanned. After selecting this operation by

pressing the [1] key, bar code labels will be displayed as they are decoded.

The display will scroll up as new labels appear on the bottom of the screen.

If more than one label is decoded on the same scan, the labels will be

displayed on the same line separated by a space. If a no-read condition

occurs, the decoder will display the no-read message that you enter as part of

the decoder configuration. Pressing the [ESC] key will exit this function.

The following is an example of how the display bar code labels screen might

appear:

4–4

Page 32

(Continued)

Chapter 4

Configuring Y our Decoder

19876367 3456721

59874292

45763019

56474821

10945280

45674895 7689577

87599039

35426881

11987454

54664778

87997070

56400982

54664747

09585746 7563778

53647747

87745646

35647465

6545456

2) Display Status and Counters - After selecting this operation by pressing

the [2] key at the select operations menu, the decoder will display the

following:

• Decoder Performance - The percentage of decodable scans over a 100

scan sample. The 100 scan sample is not made up of the raw scans from

the scan head. Instead, the 100 scan sample is made up of scans which

have passed through a “qualifier” circuit in the data acquisition circuitry.

The “qualifier” circuit acts as a pre-filter that discards empty, partial, or

noisy scans before decoding is attempted. Because of this, it is possible

to have a high decoder performance even though only a small percentage

of the scans are crossing the label (such as when a raster scan head is used

or the label is moving). This display is only available if continuous

trigger mode is selected and fields per package parameter (entered as part

of configuration programming) is anything but “any”.

Note: You can use the decoder performance monitor during:

Installation. By monitoring the percentage of good reads, you will be able to

determine the optimum location for the scan head in relation to the label(s)

being read.

Operation. If the percentage of good reads drops significantly below what it

was during installation, the scan head window may require cleaning or the

label quality may have degraded.

• No-Read Counter - The number of No-Reads. This counter is

incremented each time a package start trigger is generated and a stop

trigger occurs without a valid package. No-reads also occur when the

decoder does not decode the correct number of fields on a package as

4–5

Page 33

Chapter 4

Configuring Y our Decoder

specified by the fields per package configuration parameter. Data that is

lost due to an overflow of the buffer does not increment this counter.

• Package Counter- The number of packages detected. This counter is

incremented each time a package trigger is generated by the scan head

package detector, a host command, or the internal timer.

• Output Counters 1 through 8 - The number of times an output condition

has occurred.

The following is an example of how the display status and counters screen

may appear:

2755-DM9 Bar Code Reader VX.XX

Copyright 1990 Allen-Bradley Company, Inc.

Decoder Performance : 100%

No-Read Counter : 10

Package Counter : 300

Output Counter 1 : 44

Output Counter 2 : 45

Output Counter 3 : 56

Output Counter 4 : 5

Output Counter 5 : 33

Output Counter 6 : 23

Output Counter 7 : 40

Output Counter 8 : 67

ESC to Exit

This screen is updated approximately once per second.

Press the [ESC] key to exit the function.

3) Display/Change Configuration- Pressing the [3] key at the operation

menu will allow you to change the operating configuration of the decoder.

Two setup screens are used to configure the decoder. Before entering the

setup screens, the decoder will display a message asking you if you want the

outputs disabled during configuration:

4–6

Page 34

Chapter 4

Configuring Y our Decoder

CAUTION

Configuration changes may cause the discrete outputs to switch.

If outputs are to remain ENABLED, press ESC.

Otherwise press any other key to continue. Outputs

will be DISABLED until the device is restarted.

Note: We recommend that you disable the outputs while configuring the

decoder. This will prevent the outputs from being turned on unintentionally

during changes to the configuration.

If you press any key other than the [ESC] key, the outputs will be disabled

(off) during configuration. The outputs will remain disabled until you restart

(refer to restart operation) or cycle the power off and then back on

(remember to SAVE configuration first). If you press the [ESC] key, the

outputs will remain enabled during configuration. After responding to the

above message, the decoder will display the first of two setup screens:

------- MESSAGE FORMAT ------- ------- HOST COMM -------

_______________________________________

Commands: ESC Change: SPACE Cursor Control: ARROWS

_______________________________________

SEND BAR CODE DATA: Yes BAUD RATE: 9600

SEND PACKAGE COUNT: No BITS/CHAR: 8 Data, 1 Stop

SEND BAR CODE TYPE: No PARITY: None

SEND SOURCE IDENTIFIER: No

SEND HEADER MESSAGE: No ACK CHAR: None

SEND NO-READ MESSAGE: No NAK CHAR: None

START SCAN CHAR: None

EXPAND UPC-E: Yes STOP SCAN CHAR: None

SOURCE IDENTIFIER: LARGE BUFFER: No

LABEL DELIMITER: None RESPONSE MODE: End of Trigger

START CHAR: None HOST PROTOCOL: RS232

END MESSAGE: CRLF DEVICE ADDRESS: 01

TRANSMISSION CHECK: None

HEADER MESSAGE:

NO-READ MESSAGE:

CODE 39 CHECK CHAR: No SEND: No ---PACKAGE DETECT INPUT---

I 2-OF-5 CHECK CHAR: No SEND: No FILTER: No

CODABAR CHECK CHAR: No SEND: No SENSE: LO = Package

If you press the [ESC] key to select the command bar, you will notice that

the NEXT PAGE command is highlighted in reverse video on the bottom of

the screen. Press the [RETURN] key to enter the command. The decoder

will then display the second setup screen, which looks like this:

4–7

Page 35

Chapter 4

Configuring Y our Decoder

-- SYMBOLOGY -- -------- LENGTHS -------- -------- SCANNER CONTROL -------CODE 39: Yes 00 00 00 00 00 00 00 00 LASER-ON MODE: Continuous

I 2-OF-5: No 00 00 00 00 00 00 00 00 DECODE TRIGGER: Package Detect

CODE 128: No 00 00 00 00 00 00 00 00 CAPTURE COUNT: 2 (scans)

CODABAR: No 00 00 00 00 00 00 00 00 FIELDS/SCAN: 1

UPC-A: No FIELDS/PACKAGE: 1

UPC-E: No NO-READ TIMER: 0000 (msec)

EAN-8: No INTER-SCAN TIMER: 0000 (msec)

EAN-13: No MATCH COMPLETE: 1

---------MATCH CODE TABLE-------------- ----------- OUTPUTS [DISABLED]--------

1) CODE 39 N None 0000

2) CODE 39 N None 0000

3) CODE 39 N None 0000

4) CODE 39 N None 0000

5) CODE 39 N None 0000

6) CODE 39 N None 0000

7) CODE 39 N None 0000

8) CODE 39 N None 0000

_______________________________________

Commands: ESC Change: SPACE Cursor Control: ARROWS

_______________________________________

Note: The two setup screens display the current operating parameters of the

decoder. Any changes made to the configuration will become effective

immediately with the exception of the host communication parameters. In

order for changes to the host port baud rate, stop bits, parity, host protocol, or

device address to take effect, you must save the changes to the decoder’s

EEPROM (SAVE command) and then restart. You can restart the decoder by

pressing the [5] key (Restart System) at the Select Operation menu, through a

host command, or by turning the power off and then back on.

In the following sections of this chapter we will provide a description of all

the options available on the two setup screens. We will also provide a

step-by-step programming example.

4) Reset Status and Counters- Pressing the [4] key at the operations menu

will reset the package counter, no-read counter, and output counters. Prior to

resetting the counters, the decoder will display a confirmation prompt:

RESET STATUS AND COUNTERS . . . Confirm (Y/N)

Press the [Y] key to confirm the reset. Pressing the [N] key will cancel the

reset function.

4–8

5) Restart System- Pressing the [5] key at the select operation menu will

reboot the decoder. This has the same effect as turning the power off and

then back on. Prior to restarting the system, the decoder will display a

confirmation prompt:

Page 36

Chapter 4

Configuring Y our Decoder

RESTART SYSTEM . . . Confirm (Y/N)

Press the [Y] key to confirm the restart. Pressing the [N] key will cancel the

restart function.

6) Select Language- Pressing the [6] key at the operations select menu will

display the following menu:

SELECT LANGUAGE CHOIX DU LANGAGE WAEHLE SPRACHE

1) English 1) Anglais 1) Englisch

2) French 2) Francais 2) Franzoesisch

3) German 3) Allemand 3) Deutsch

4) Italian 4) Italien 4) Italienisch

5) Spanish 5) Espagnol 5) Spanisch

Using and Editing the Configuration (Setup) Screens

Press 1, 2, 3, 4, 5, or ESC Appuyer 1, 2, 3, 4, 5 ou ESC Drueck

e 1, 2, 3, 4, 5, oder ESC

SELEZIONARE LINGUA SELECCIONAR LENGUA

1) Inglese 1) Ingles

2) Francese 2) Frances

3) Tedesco 3) Aleman

4) Italiano 4) Italiano

5) Spangnolo 5) Castellano

Premere 1, 2, 3, 4, 5 o ESC Pulsar 1, 2, 3, 4, 5, o ESC

Press the key that corresponds with the language you want to use. After

selecting the language, the decoder will return you to the CRT selection

screen. All of the other screens will appear in the selected language.

When programming the decoder, use the two configuration (setup) screens to

set operating parameters. There are two types of fields that you can change

on the configuration screens:

• SELECT Fields - In the select fields, you have fixed selections such as

YES or NO. Pressing the [SPACE] bar multiple times will step through

the selections available. Pressing the [RETURN] key will enter the

selection.

• EDIT Fields - In the edit fields, you can enter strings of ASCII character

codes, numeric values, or text. Pressing the [SPACE] bar will open the

field for changes and clear the current values. You can then enter new

data. Pressing the [RETURN] key will close the field and enter the data

Pressing the [ESC] key will cancel any changes, return the values back to

the original contents when the field was opened, and close the field.

4–9

.

Page 37

Chapter 4

Configuring Y our Decoder

To do this: You must: Comments

Depending upon the type of field (select or edit) that you are configuring, use

the commands listed in Table 4.A:

Return to SELECT OPERA TION

menu.

Change any field. Press [SPACE] bar.

Enter a new or different value. Press [RETURN] key.

Move to a different field.

Move to next menu.

Transfer new parameters into the

Decoder’s memory (EEPROM).

Recall previously set parameters

from the Decoder’s memory

(EEPROM–User Definable).

Reset decoder to factory set

parameters (EPROM–Defaults).

SAVE

RECALL

DEFAULT

Press the [ESC] key to select the

command bar and then press the [ESC]

key again.

Press [RETURN] key or arrow keys.① See note ① below.

Press [ESC] key to select the command

bar and press the [RETURN] key.

Press [ESC] key to select command bar.

Use [SPACE] bar to select SA VE and

press the [RETURN] key. Press [Y] key

at confirmation prompt.

Press [ESC] key to select command bar.

Use [SPACE] bar to select RECALL and

press the [RETURN] key. Press [Y] key

at confirmation prompt.

Press [ESC] key to select command bar.

Use [SPACE] bar to select DEFAULT

and press the [RETURN] key. Press [Y]

key at confirmation prompt.

In select fields, next option is

displayed.

In edit fields, field is cleared and new

data can be entered.

New value is highlighted in reverse

video.

New configuration parameters are

transferred to the decoder’s

EEPROM.

Previously set parameters are

displayed.

Refer to Appendix B for factory set

parameters.

① Allen-Bradley Industrial Terminals (Catalog Number 1770-T1, -T2, or -T3) do not have arrow keys. Use the [CTRL] and U, D, L or R keys for Up, Down, Left or Right cursor

movement.

EDIT FIELDS - There are three types of data that can be entered or

modified in an edit field:

1) ASCII character codes-(decimal values 0 to 255)

2) Numeric values

3) Text strings

To open an edit field for a change, press the [SPACE] key. The cleared field

will appear as a block in reverse video and the decoder will display the edit

keys you can use at the bottom of the screen. All other keys will be ignored:

EDIT -- Cancel:ESC Enter:RETURN Erase Char: BACKSPACE

4–10

Page 38

Chapter 4

Configuring Y our Decoder

Type in the new data and press the [RETURN] key to close the field and

enter the data.

Note: Pressing the [ESC] key while you are entering data in an edit field will

return the contents of the field back to the original contents prior to editing.

When you enter a value in a field that requires an ASCII decimal value, you

have three options:

1) You can enter the decimal (numeric) equivalent value (refer to Appendix

C). After entering the decimal value, the selected ASCII character will be

displayed.

2) You can enter the ASCII character (non-numeric only) such as “T”. The

decoder will automatically enter the decimal equivalent value (T = 84).

3) If you press the [RETURN] key when the field is empty, “NONE” is

displayed (no ASCII value is defined). A decimal value of 255 is also

interpreted as “NONE”.

You can enter non-printable ASCII control characters into the following edit

fields:

• Source Identification Message

• Header Message

• No-Read Message

• Match Table Entry

To enter non-printable ASCII control characters (ASCII 0 through 31) into a

text string, refer to Table 4.B. For example: to enter carriage return and line

feed control characters, you would enter %M%J. The decoder will interpret

%M%J as the ASCII control characters CR and LF. The % character is

equivalent to ASCII 37 (decimal). Non-printable control characters are

always entered as a two character sequence and the second character must be

listed in Table 4.B. To enter the character %, you must use %%.

Note: Some fields have restrictions on the type of data that you can enter.

For example: numeric values only are allowed in the inter-scan timer field.

If you attempt to enter an invalid character, you will hear a beep. Numeric

values are also checked for range (min and max values) when the [RETURN]

key is pressed. An audible beep indicates a value is out of the specified

range. To correct an entry, you can either:

• Delete the incorrect entry by using the backspace, left arrow, [CTRL] [L],

or rubout keys.

• Press the [ESC] key once to return the field back to its original contents.

4–11

Page 39

Chapter 4

Configuring Y our Decoder

ASCII Control

Character

NUL %@ VT %K SYN %V

SOH %A FF %L ETB %W

STX %B CR %M CAN %X

ETX %C SO %N EM %Y

EOT %D SI %O SUB %Z

ENQ %E DLE %P ESC %[

ACK %F DC1 %Q FS %\

BEL %G DC2 %R GS %]

BS %H DC3 %S

HT %I DC4 %T US %

LF %J NAK %U

Enter:

ASCII Control

Character

Enter:

ASCII Control

Character

RS

SELECT FIELDS- To change the contents of a select field, press the

[SPACE] key. After pressing the [SPACE] key, he next option is displayed

and the decoder will display the control keys you can use at the bottom of the

screen. All other keys are ignored:

SELECT -- Cancel:ESC Change:SPACE Enter:RETURN

Enter:

∧

%

_

Command Bar

4–12

Press the [SPACE] key again until the option you want is displayed. Press

the [RETURN] key to enter the selected option.

When you first enter either setup screen you will observe the following at the

bottom of the display:

Change:SP ACE Cursor Control: ARROWSCommands : ESC

Notice that the command bar display provides a quick reference to the

commands used to edit the setup screen. If you select the command bar by

pressing the [ESC] key, the following will be displayed:

COMMAND - - Exit: ESC Select: RETURN Next Command: SPACE

NEXT PAGE

THIS PAGE RECALL SAVE DEFAULT

After selecting the command bar, you will notice that the first command

option NEXT PAGE is highlighted in reverse video. To display the other

Page 40

Chapter 4

Configuring Y our Decoder

(next) setup screen you would press the [RETURN] key. To select another of

the displayed commands, press the [SPACE] key until the desired command

is highlighted and then press the [RETURN] key. Pressing the [ESC] key

after selecting the command bar will return you to the select operation menu.

The following are explanations of each command in the command bar:

• NEXT PAGE - Selecting this command will display the other setup

screen. Remember that there are two setup screens used to configure the

decoder.

• THIS PAGE - Selecting this command will return you to the top of the

current setup screen.

• RECALL - Selecting this command will recall all the previously SAVED

configuration parameters from the decoder’s Electrically Erasable

Programmable Read Only Memory (EEPROM) to the decoder’s Random

Access Memory (RAM). Once moved into the decoder’s RAM, the

recalled configuration is displayed and controls the operation of the

decoder.

• SAVE - Selecting this command will save all the configuration parameters

to the decoder’s EEPROM. You must use the save function after

programming, or the decoder’s operating configuration will revert back to

the original configuration after a restart (or power loss) of the decoder.

• DEFAULT - Selecting this command will change the setup to the factory

default selections. Refer to Appendix B for the default parameters. If the

default values meet the requirements of your application, you do not have

to program the decoder.

4–13

Page 41

Chapter 4

Configuring Y our Decoder

Setup Screen #1

Figure 4.1 shows the first setup screen. The first setup screen configures the

communication parameters and host protocol. We have used lowercase

letters to indicate fields of the configuration data. These letters are keyed to

Table 4.C, listing the options available for each field type. Following the

table is a short description of the effect each option has on the decoder

operation.

Figure 4.1

Setup Screen #1

----------- MESSAGE FORMAT ----------- ----------- HOST COMM -----------

SEND BAR CODE DATA: a BAUD RATE: u

SEND PACKAGE COUNT: b BITS/CHAR: v

SEND BAR CODE TYPE: c PARITY: w

SEND SOURCE IDENTIFIER: d

SEND HEADER MESSAGE: e ACK CHAR: x

SEND NO-READ MESSAGE: f NAK CHAR: y

START SCAN CHAR: z

EXPAND UPC-E: g STOP SCAN CHAR: aa

SOURCE IDENTIFIER: h LARGE BUFFER: bb

LABEL DELIMITER: i RESPONSE MODE: cc

START CHAR: j HOST PROTOCOL: dd

END MESSAGE: k DEVICE ADDRESS: ee

TRANSMISSION CHECK: l

HEADER MESSAGE: m

NO-READ MESSAGE: n

CODE 39 CHECK CHAR: o SEND: p ---PACKAGE DETECT INPUT---

I 2-OF-5 CHECK CHAR:

CODABAR CHECK CHAR: s SEND: t SENSE: gg

q SEND: r FILTER: ff

4–14

Commands: ESC Change: SPACE Cursor Control: ARROWS

Page 42

Chapter 4

Configuring Y our Decoder

Reference

Letter

a

b

c

d

e

f

g

h

i

j

k

Description

Send bar code field data to host.

Send package count to host.

Send bar code type indicator to host.

Send source identification string to host.

Send header message to host. Select Yes or No N/A

Send no–read message to host, if

no–read.

Expand UPC–E bar codes. Select Yes or No N/A

Source identification message. Edit N/A Up to four ASCII

Label delimiter character. Edit N/A Numeric ASCII code ( 0 to

Start character. Edit N/A Numeric ASCII code ( 0 to

End of message. Select None, CRLF, CR, LF,

Field

T ype

Select Yes or No N/A

Select Yes or No N/A

Select Yes or No N/A

Select Yes or No N/A

Select Yes or No N/A

Options (Select Field

Only)

ETX

Valid Entries (Edit Field

Only)

characters.①

255) 255 = None. Refer

to Appendix C.

255) 255 = None. Refer

to Appendix C.

N/A

l

m

n

o

p

q

r

s

t

① You can enter non-printable characters in these fields, refer to the table on page 4-12.

Transmission check method. Select None, LRC,

Header message. Edit N/A Up to 32 ASCII

No–read message. Edit N/A Up to 32 ASCII

Employ check character for Code 39. Select Yes or No N/A

Send Code 39 check character. Select Yes or No N/A

Employ check character for Interleaved

2–of–5.

Send Interleaved 2–of–5 check

character.

Employ check character for Codabar. Select Yes or No N/A

Send Codabar check character. Select Yes or No N/A

N/A

Checksum–LSB,

Checksum–MSB

characters.①

characters.①

Select Yes or No N/A

Select Yes or No N/A

4–15

Page 43

Chapter 4

Configuring Y our Decoder

Reference

Letter

u

v

w

x

y

z

aa

bb

cc

Description

Host port–baud rate. Select 300, 1200, 2400, 4800,

Host port–number of data and stop bits. Select

Host port–parity. Select None, Odd, or Even N/A

Host port–ACK character. Edit N/A Numeric ASCII code ( 0 to

Host Port–NAK character. Edit N/A Numeric ASCII code ( 0 to

Host port–start scan character. Edit N/A Numeric ASCII code ( 0 to

Host port–stop scan character. Edit N/A Numeric ASCII code ( 0 to

Enable host port buffer (8k bytes). Select Yes or No N/A

Response mode. Select

Field

T ype

Options (Select Field

Only)

9600, 19200, 38400

8 data, 1 stop

8 data, 2 stop

7 data, 1 stop

7 data, 2 stop

End of Trigger, or After

V alid Package.

Valid Entries (Edit Field

Only)

N/A

N/A

255) 255 = None.②

255) 255 = None.②

255) 255 = None. ②

255) 255 = None.②

N/A

dd

ee

ff

gg

① Refer to Chapter 6 for a description of the RS-232 modes 3 and 4. Both of these modes use the modem control lines (RTS, CTS and DTR). However, there are differences in

how these control lines are used.

② Refer to Appendix C for ASCII conversion chart.

4–16

Host protocol. Select RS232 No flow control

RS232 XON/XOFF

RS232 RTS/CTS–1①

RS232 RTS/CTS–2①

RS422 No flow control

RS422 XON/XOFF

RS485 PCCC–1

PCCC with write

replies

RS485 PCCC–2

PCCC without write

replies

RS485 ASCII–1 ASCII

Commands with

command responses

RS485 ASCII–2 ASCII

Commands without

command responses

Device address for Class 1 node. Edit N/A 00 through 31

Enable package detect filter. Select Yes or No N/A

Package detect polarity (sense). Select LO = Package

HI = Package

N/A

N/A

Page 44

Chapter 4

Configuring Y our Decoder

Setup Screen #1 Fields

The following are detailed explanations of the fields on setup screen #1. We

have provided reference letters (a through gg) which are keyed to Table 4.C

and Figure 4.2.

Note: Fields with reference letters (a) through (t) control the format of bar

code data that is sent to a host device. Refer to Figure 6.5 for an illustration

of the data format. Table 6.A provides a short explanation of each field in a

data message.

Message Format

SEND BAR CODE DATA (a) - Selecting YES for this field will enable the

decoder to transmit the bar code data message to the host (refer to Figure

6.5). The bar code data message will not be sent to a host if you select NO.

SEND PACKAGE COUNT (b) - Selecting YES for this field will enable

the decoder to transmit the contents of the package counter to the host.

Package counts will not be sent if NO is selected. Refer to Figure 6.5, item

#14.

SEND BAR CODE TYPE (c) - Selecting YES for this field will enable the

decoder to transmit the type of code being decoded (Codabar, Code 39, etc)

to the host. Bar code type will not be sent if NO is selected. Bar code type is

transmitted as a 2 digit code, refer to Table 6.A. Figure 6.5, item #5

illustrates the position of the data in the data message.

SEND SOURCE IDENT (d) - Selecting YES for this field will enable the

decoder to transmit the contents of the SOURCE IDENT field to the host.

Source identification will not be sent if NO is selected. Refer to Figure 6.5,

item #2.

SEND HEADER MESSAGE (e) - Selecting YES for this field will enable

the decoder to transmit the contents of the HEADER MESSAGE field to the

host. Header message will not be sent if NO is selected. Refer to Figure 6.5,

item #3.

SEND NO-READ MESSAGE (f) - Selecting YES for this field will enable

the decoder to transmit the contents of the NO-READ MESSAGE field to the

host whenever a no-read occurs. The no-read message will not be sent if NO

is selected. Refer to Figure 6.5, item #8.

EXPAND UPC-E (g) - Selecting YES for this field will result in UPC-E

being transmitted in a 12 digit (expanded) format. UPC-E will be

transmitted in a 6 digit (compressed) format if NO is selected.

SOURCE IDENT (h) - You can enter one of two options:

1) The identification label you want sent to a host with each communication

(Send Source Ident selected). This entry is limited to 4 ASCII characters.

Refer to Figure 6.5, item #2.

2) Leave field blank.

4–17

Page 45

Chapter 4

Configuring Y our Decoder

LABEL DELIMITER (i) - You can enter one of two options:

1) The label delimiter characters being used. These characters indicate the

beginning and end of bar code label information. Refer to Table 6.A for a

more detailed description. Refer to Figure 6.5, items #4,#12, and #13. The

host can use this character as a marker between fields to sort out the data.

2) 255 = None.