Page 1

Allen-Bradley

AdaptaScan

Software

User

(Cat. No. 2755-ASN)

Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. “Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls” (Publication SGI-1.1)

describes some important differences between solid state equipment and

hard–wired electromechanical devices. Because of this difference, and also

because of the wide variety of uses for solid state equipment, all persons

responsible for applying this equipment must satisfy themselves that each

intended application of this equipment is acceptable.

In no event will the Allen-Bradley Company be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, the Allen-Bradley Company cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Allen-Bradley Company with respect to use

of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of the Allen-Bradley Company is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage, or economic loss.

Attentions help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is especially important for successful

application and understanding of the product.

AdaptaScan is a trademark of Allen-Bradley Company, Inc.

Microsoft and MS-DOS are registered trademarks, and Windows is a trademark of Microsoft Corporation.

Page 3

Using this Manual

Installation

Working with Projects

Preface

What is AdaptaScan? P–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intended Audience P–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Package P–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents of Manual P–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conventions P–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications P–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Support P–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 1

Chapter Objectives 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Requirements 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing AdaptaScan Software 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2

Chapter Objectives 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Running AdaptaScan Software 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

What is a Database File? 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What is a Project? 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Opening a Project 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Project Window 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AdaptaScan Dialogs 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AdaptaScan Tools 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Saving a Project 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Closing a Project 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deleting a Project 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Cut, Copy and Paste 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Importing/Exporting Reader Configurations 2–15. . . . . . . . . . . . . . . . . .

Entering a Project Name, Description, and Baud Rate 2–17. . . . . . . . . . .

Preferences 2–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Help 2–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

toc–i

Page 4

Table of Contentstoc–ii

On-Line Communications

Getting Started

Chapter 3

Chapter Objectives 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Going On-Line 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Compare Tool 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Monitoring a Reader 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying LED Status 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying Counters 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying Bar Code Labels 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying Hardware Information 3–7. . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4

Chapter Objectives 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Description 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What You Need 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting Power 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the DL10 Slave 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Reader 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the Configuration Cable 4–5. . . . . . . . . . . . . . . . . . . . . . .

Power-up Sequence 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Running the AdaptaScan Software 4–6. . . . . . . . . . . . . . . . . . . . . . . .

Communications Setup 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating a Project 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating a New Reader Configuration 4–8. . . . . . . . . . . . . . . . . . . . . .

Downloading Firmware 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining the Label Setup 4–1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Scanner 4–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Decoder 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Discrete Outputs 4–17. . . . . . . . . . . . . . . . . . . . . . . . . .

Defining a Package 4–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the Timer 4–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the Serial Port 4–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Message Output 4–23. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Downloading the Configuration 4–25. . . . . . . . . . . . . . . . . . . . . . . . . . .

Monitoring Reader Operation 4–26. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dataliner Operation 4–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scanner Setup

Publication 2755-838

Chapter 5

Chapter Objectives 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Laser Caution 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scan Patterns 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scan Adjustments 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting up the Scanner 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Focus Options 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the Focus 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Table of Contents toc–iii

Defining Labels

Decoder Setup

Chapter 6

Chapter Objectives 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Helpful Hints 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What is a Label? 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What is a Label Setup? 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Managing Bar Code Labels 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining a Bar Code Label 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viewing Readers with the Same Bar Code Label Setup 6–7. . . . . . . . . .

Defining Symbols for a Bar Code Label 6–8. . . . . . . . . . . . . . . . . . . . .

Selecting Symbologies for a Bar Code Label 6–10. . . . . . . . . . . . . . . . .

Chapter 7

Chapter Objectives 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Helpful Hints 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Decoding Functions 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V alid Symbologies 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

When Decoding Occurs 7–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Indicator 7–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Capture Count 7–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Decode Parameters 7–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Performance Indicator 7–8. . . . . . . . . . . . . . . . . . . . . .

Viewing Readers with the Same Trigger Source 7–10. . . . . . . . . . . . . . .

Communication Port

Settings

Chapter 8

Chapter Objectives 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communication Ports 8–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DeviceNet 8–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS-422 / RS-485 Port 8–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS-232 Port 8–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Protocols 8–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminal 8–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DF1 8–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DH-485 8–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring DeviceNet Parameters 8–3. . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Serial Port 8–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Terminal Communications 8–8. . . . . . . . . . . . . . . . . . . . . .

Configuring DF1 Communications 8–10. . . . . . . . . . . . . . . . . . . . . . . . .

Configuring DH-485 Communications 8–11. . . . . . . . . . . . . . . . . . . . . .

Viewing Readers with the Same Serial Port Configuration 8–12. . . . . . . .

Publication 2755-838

Page 6

Table of Contentstoc–iv

Configuring Discrete

Inputs and Outputs

Defining Messages

Chapter 9

Chapter Objectives 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Helpful Hints 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Types of Outputs 9–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Types of Inputs 9–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Inputs and Outputs 9–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Discrete Inputs and the Package Detect 9–6. . . . . . . . . . . .

Configuring Discrete Outputs 9–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Timer 9–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Input Timers 1 and 2 9–10. . . . . . . . . . . . . . . . . . . . . . . . .

Configuring an ASCII Trigger 9–12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DeviceNet I/O 9–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring DeviceNet Inputs 9–15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring DeviceNet Outputs 9–16. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 10

Chapter Objectives 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What is a Message? 10–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message Samples 10–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining Messages 10–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Bar Code Contents of a Message 10–6. . . . . . . . . . . . . .

Configuring Optional Message Parameters 10–8. . . . . . . . . . . . . . . . . .

Configuring the Message Format 10–10. . . . . . . . . . . . . . . . . . . . . . . . .

DeviceNet Messages 10–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Pass-Through to DeviceNet 10–15. . . . . . . . . . . . . . . . . . . . . . . .

Using Match Tables

Chapter 11

Chapter Objectives 11–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Helpful Hints 11–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What is a Match Table? 1 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Match Table Applications 1 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Match Rules 1 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining a Package 11–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Auto-Load 11–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Match Tables 1 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Contents of Match Tables 1 1–9. . . . . . . . . . . . . . . . . . .

Configuring Match Table Outputs 11–11. . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Match Entry Counter 11–12. . . . . . . . . . . . . . . . . . . . . . .

Configuring a Package Definition 11–13. . . . . . . . . . . . . . . . . . . . . . . . .

Configuring a Package Using Match Table Entries 11–15. . . . . . . . . . . . .

Configuring Package Outputs 11–17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Package Counter 11–18. . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Auto-Load Trigger 1 1–19. . . . . . . . . . . . . . . . . . . . . . . . .

Viewing Readers with the Same Trigger Source 1 1–20. . . . . . . . . . . . . . .

Publication 2755-838

Page 7

Table of Contents toc–v

Downloading/Uploading

Configurations

Printing a Project

Dynamic Data Exchange

Chapter 12

Overview 12–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Helpful Hints 12–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Upload/Download Connections 12–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Cable 12–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Downloading a Configuration 12–2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Uploading a Configuration 12–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 13

Chapter Objectives 13–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting up a Printer 13–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printing a Project 13–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sending Project to a File 13–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printout Contents 13–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 14

Chapter Objectives 14–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 14–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DDE Syntax 14–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AdaptaScan DDE Topics 14–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read Performance in Excel 14–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read Count in Excel 14–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read LED Status in Excel 14–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read Label Data in Excel 14–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read Match or Package Count in Excel 14–5. . . . . . . . . . . . . . . . . . . . .

Writing Commands to a Reader 14–6. . . . . . . . . . . . . . . . . . . . . . . . . .

Excel Example 14–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DDE Through the AdaptaScan RS-232 Port 14–7. . . . . . . . . . . . . . . . . .

ASCII Character Set

Preset Read Ranges

Metacharacters

Transmission Check

Appendix A

Appendix B

Appendix C

Appendix D

Glossary

Index

Publication 2755-838

Page 8

What is

aptaScan

Intende

e

are Package

Preface

This manual is a reference guide for using the AdaptaScan Software.

It describes features and procedures for configuring the operation of

the AdaptaScan Bar Code Reader.

Because this is a reference manual it covers all the features of the

AdaptaScan Software. You may not use or need to use all the

features, so use the manual as needed.

If you’re just getting started, make sure you work through the

Getting Started chapter. It takes you through all the steps

required to get the Reader scanning and decoding bar code

symbols.

Softw

Ad

d Audienc

?

The AdaptaScan Bar Code Reader includes a scanner and decoder in

a single compact package. The Reader is configured using a

Microsoft Windows 95 or Windows NT based package that lets

you create, store and download applications. To simplify application

design, the AdaptaScan software uses menus, dialog boxes and tools

which are standard in Windows.

Applications are transferred between your computer and an

AdaptaScan Reader using a communication cable.

This manual is written for the individual responsible for designing

bar code applications. We assume you are familiar with bar code

terminology. A glossary is provided at the end of this manual if you

are not familiar with a word or acronym.

Because AdaptaScan software runs in Microsoft Windows, you

should know how to use a mouse, choose commands, and work with

Windows and dialog boxes. To learn basic windows techniques, read

the User’s Guide that came with your Microsoft Windows package.

The AdaptaScan Software package comes with:

• Two (3

• Software registration forms

• AdaptaScan Software manual

1

inch) installation disks

/2

Page 9

Using this ManualP–2

Contents of Manual

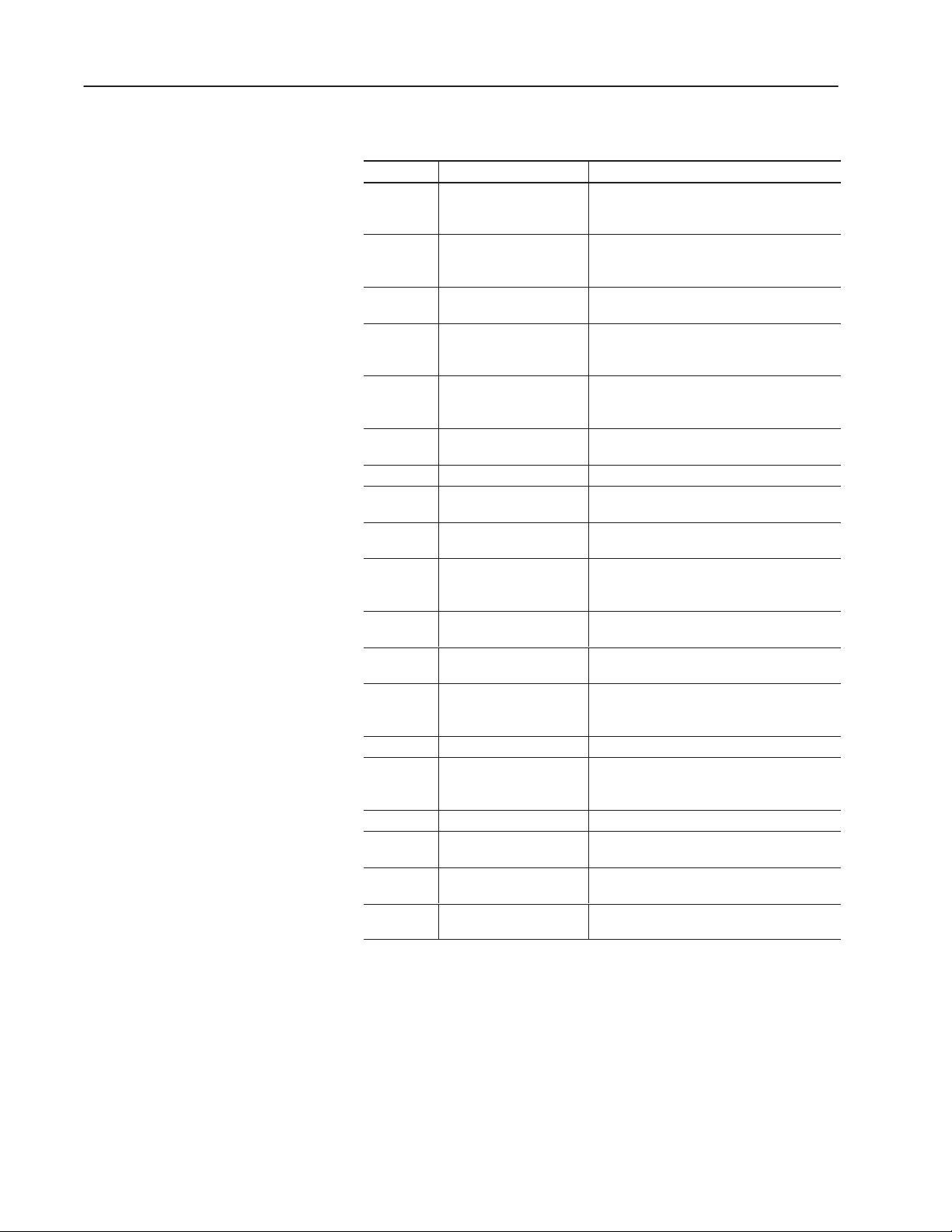

This manual is organized as follows:

Chapter Title Description

Preface Describes the purpose and contents of the

manual, the intended audience and conventions used.

1 Installation Explains how to install AdaptaScan Software

on a personal computer. Also describes how

to download new firmware to a Reader.

2 Working with Projects Covers some basics on using AdaptaScan

software.

3 On-Line Communications Describes how to go on-line, use compare,

obtain scanner metrics and perform other online functions.

4 Getting Started Provides step-by-step instructions that config-

ure the Reader to scan and decode a bar code

symbol.

5 Scanner Setup Describes how to configure the operation of

the Reader’s scan beam.

6 Defining Labels Describes how to create and use label setups.

7 Decoder Setup Describes how to configure the operation of

the Reader’s decoding functions.

8 Communication

Port Settings

9 Configuring Discrete

Inputs and Outputs

10 Defining Messages Explains how to define the content of the data

11 Using Match Tables Describes how to configure and use match

12 Downloading

Configurations

13 Printing a Project Describes how to printout a project.

14 Dynamic Data Exchange Describes how to exchange data with other

Appendix A ASCII Character Set ASCII conversion chart.

Appendix B Preset Read Ranges

A, B, C, and C+

Appendix C Metacharacters Describes metacharacters and how they are

Appendix D Transmission Check Describes LRC and checksum transmission

Provides instructions on how to configure the

Reader’s communication ports.

Describes how to configure the operation of

the Reader’s discrete input and output mod-

ules.

messages sent by the Reader.

tables.

Provides instructions on how to setup and

download applications to a single or multiple

Reader(s).

Windows applications supporting DDE such as

Microsoft Excel.

Read range charts and tables for the four pre-

set read ranges.

used.

checks.

Page 10

Using this Manual P–3

Technical Support

Conventions

Related Publications

The following conventions are used throughout this manual:

• Reader refers to the AdaptaScan Bar Code Reader

• Windows refers to Microsoft Windows 95 or Windows NT

• A hand followed by italicized text in the left margin gives helpful

hints:

☞ Use the Monitor dialog to verify read percentages while

adjusting the scan beam.

The following table lists publications related to the AdaptaScan

Software and the AdaptaScan Bar Code Reader.

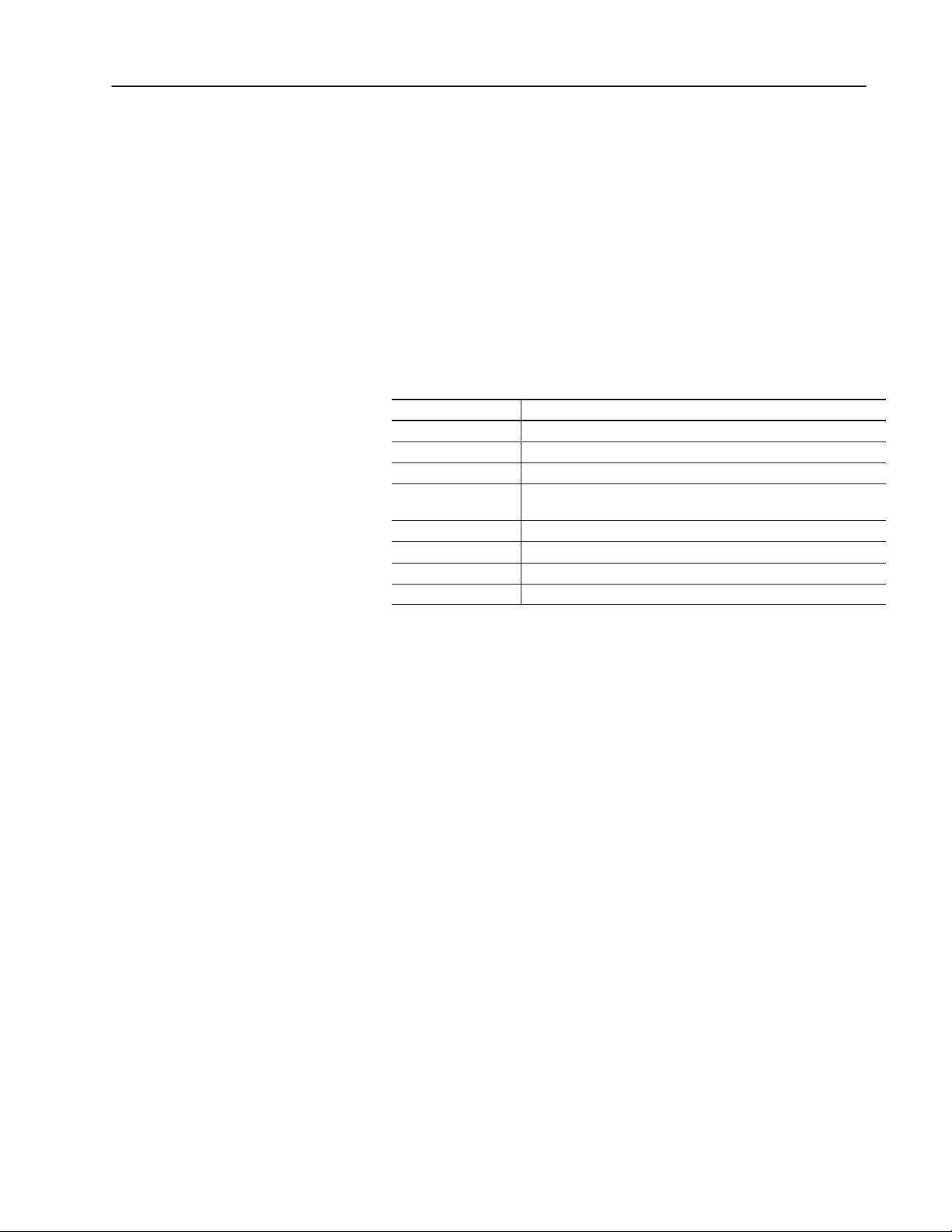

Publication Number Description

2755-837 AdaptaScan Bar Code Reader User Manual

2755-6.8 Application Guide for AdaptaScan Bar Code Readers

1485-6.7.1 DeviceNet Cable System Planning and Installation Manual

1770-6.2.2

1787-6.5.3 DeviceNet Manager Software (Catalog No. 1787-MGR) User Manual

1749-6.5.5 DeviceNet Adapter Module (Catalog No. 1749-ADN) User Manual

1747-6.5.2 DeviceNet Scanner (Catalog No. 1747-SDN) Configuration Manual

1771-6.5.118 DeviceNet Scanner (Catalog No. 1771-SDN) Configuration Manual

Data Highway / Data Highway Plus / Data Highway-485 Cable

Installation Manual

If you should require assistance or need additional information on

operating the AdaptaScan Reader, Configuration Software, or

accessories, you can:

• access technical support and other information at the

Allen-Bradley web site http://www.ab.com/

• use the Technical Support Fax Back system (available 24 hrs a

day) at 1-440-646-6701

• send a fax describing the problem / question to 1-440-646-6890

for technical support

• call 1-440-646-6800 between 8AM and 5PM (EST), Monday

through Friday to talk to a technical support representative

• write to Allen-Bradley Technical Support

1 Allen Bradley Drive

Mayfield Heights

Ohio 44124-6118

Page 11

Chapter Objectives

System Requirements

Chapter

1

This chapter contains these sections:

Section Page

System Requirements 1–1

Installing AdaptaScan Software 1–2

Downloading Firmware 1–5

The minimum hardware and software requirements for installing and

running AdaptaScan software are:

Hardware

• Personal computer (486/25 MHz minimum)

8 MB of memory (RAM), VGA or higher resolution, with mouse

• 3.5 inch high-density (1.44 MB) disk drive

• Hard disk with 2 MB of free space

• Configuration cable (Catalog No. 2755-NC48 for Series B

Reader, 2755-NC43 for Series A Reader) to connect the personal

computer to the Reader.

Software

• AdaptaScan Software (Catalog No. 2755-ASN)

• Microsoft Windows 95 or Windows NT

Optional Equipment

• A printer for project printouts.

Page 12

1–2 Installation

Installin

aptaScan

Software

g Ad

This section shows how to install the AdaptaScan Configuration

software.

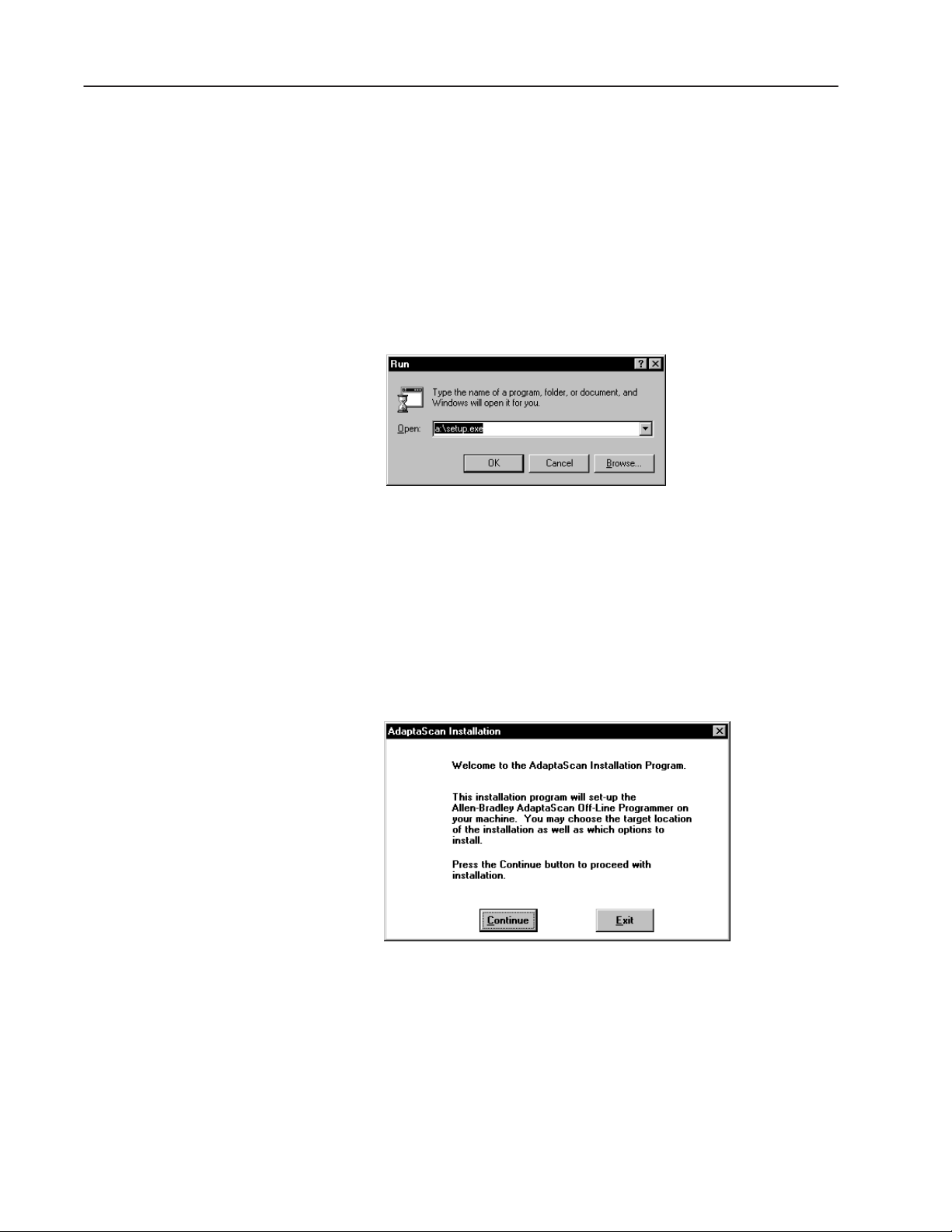

To install the AdaptaScan Configuration software:

1. Insert the AdaptaScan disk #1 in the appropriate floppy disk

drive.

2. In the Program Manager window, choose Run from the File

menu.

The Run dialog opens.

3. In the command line box, type the drive letter of the drive

containing the AdaptaScan diskette followed by a colon and the

word setup.

For example, type a:setup

Then click OK or press

The installation begins. You are prompted to continue or exit the

installation.

ENTER.

Publication 2755-838

Page 13

1–3Installation

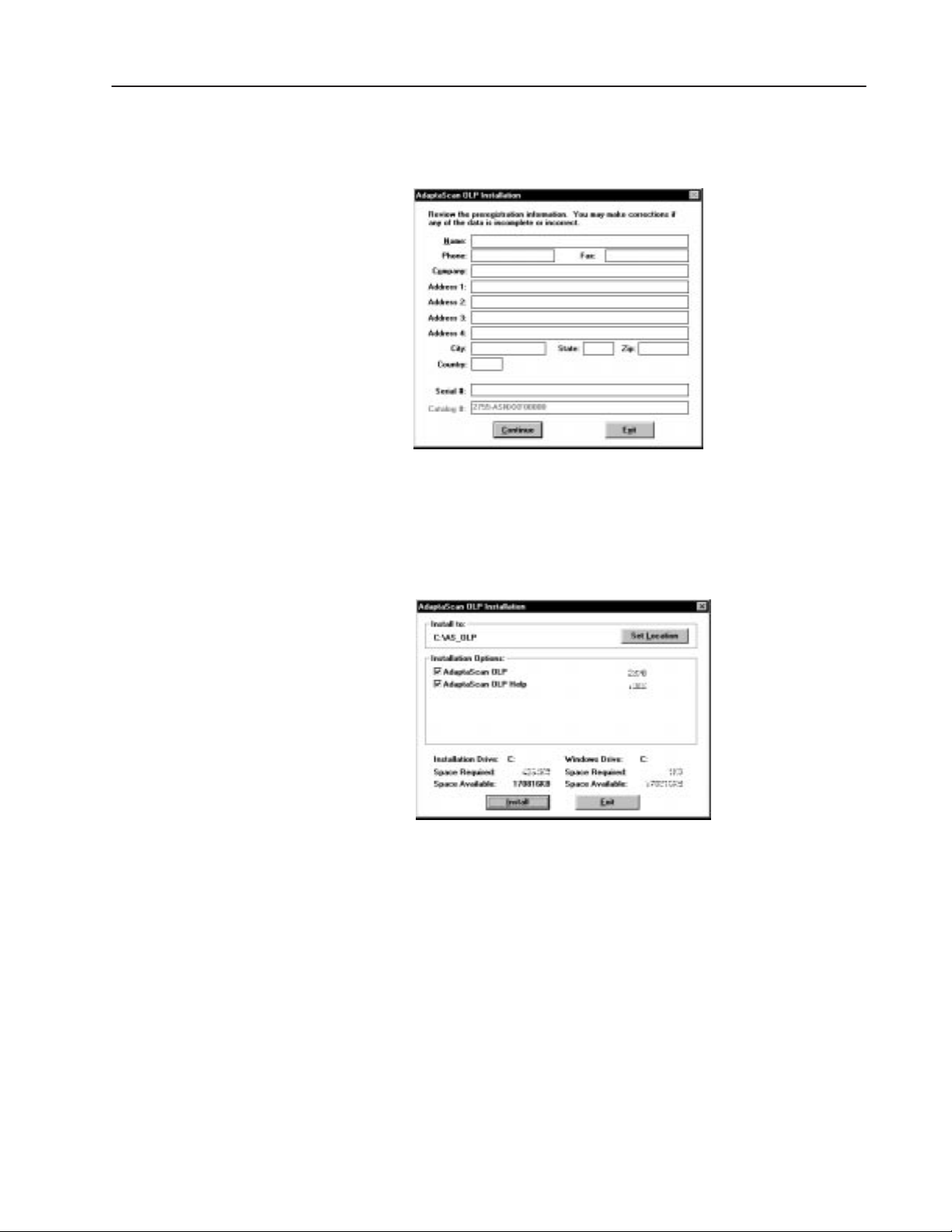

4. Click Continue to proceed with the installation.

You are prompted to verify/provide registration information.

5. Enter the registration data. Verify the software serial and catalog

number with the label on the software diskette. Click Continue

to proceed with the installation.

You are prompted for the location of files to be installed.

We recommend that you use the default installation path. To

change the installation drive or file name, click the Set Location

button.

6. Click the Install button to proceed with the installation

You are shown the progress of the installation. Insert disk #2

when requested.

A message indicates when the installation is complete.

Publication 2755-838

Page 14

1–4 Installation

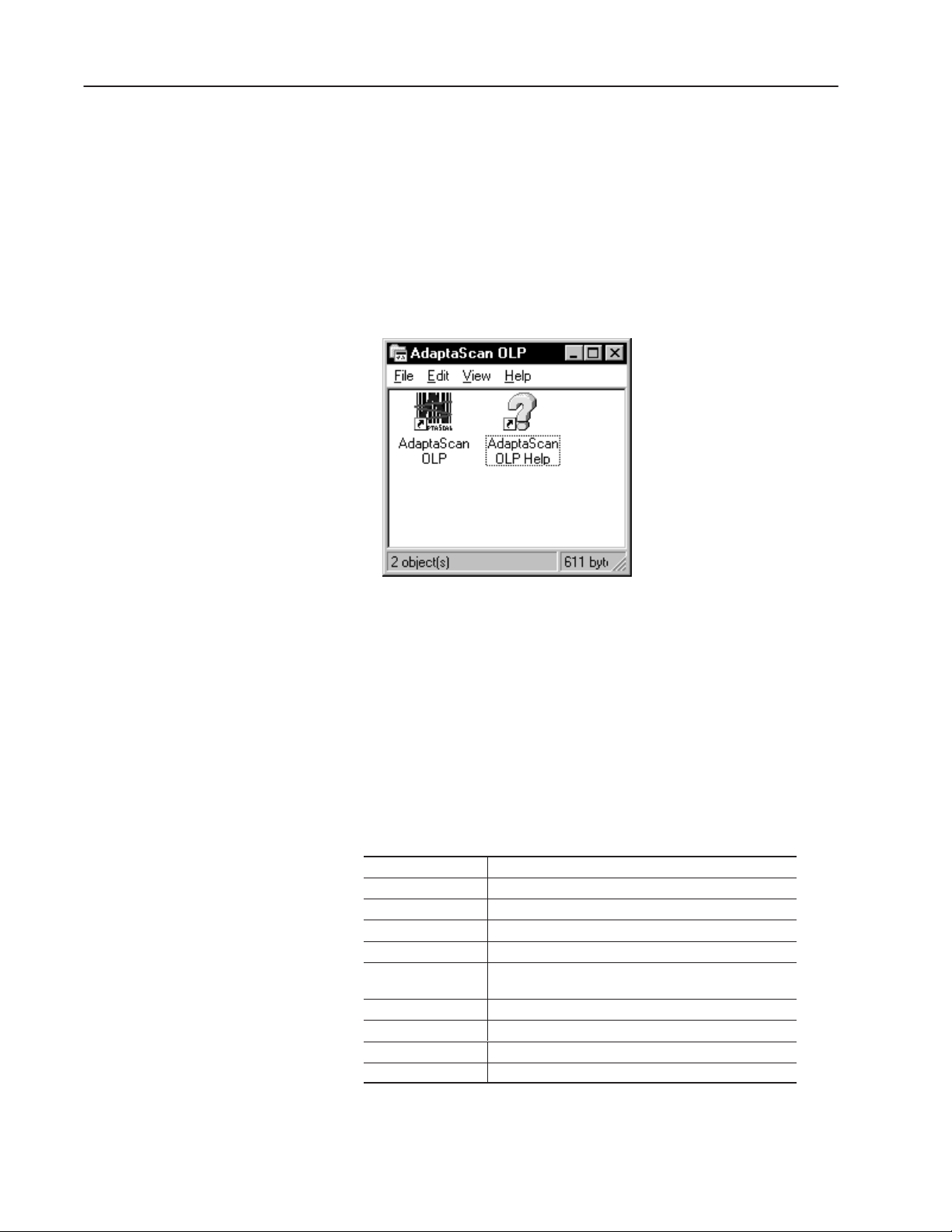

AdaptaScan Installation Summary

The default AdaptaScan installation:

• Copies files to disk under the target drive and directory

(C:\AS_OLP) or the location specified during installation.

• Adds ”AdaptaScan Off–Line Programmer” to registry

• Adds AdaptaScan OLP to the Windows Start menu

• Creates an AdaptaScan group containing icons for AdaptaScan

software and the Windows help file.

Registering AdaptaScan Software

Please take time to complete and send in the registration card you

received with AdaptaScan software. Registering entitles you to:

• automatic notification of upgrades and revisions to AdaptaScan

software

• technical assistance

AdaptaScan Installation Files

File Function

AB.SYS User information provided during installation.

ADAPTASC.HLP AdaptaScan help system.

ADAPTASC.CNT AdaptaScan help contents.

ADPTSCN1,2,3.EDS Contains product information for DeviceNet Manager.

APPGUIDE.DBF Database containing example projects from the

AdaptaScan Application Guide.

APPGUIDE.ID1 Index for database.

OLP.EXE AdaptaScan software executable.

SNEXxxxx.BIN Contains firmware code for Reader.

SNEXxxxx.INI Reader firmware update file.

Publication 2755-838

Page 15

1–5Installation

Downloading Firmware

Each Reader is shipped with manufacturing firmware installed.

You must download the release firmware prior to programming the

Reader. All the devices on the same network must have the same

firmware installed.

Note: Download firmware with a computer connected directly to

the Reader configuration port.

ATTENTION: Do not download firmware while the

scanner is on a DeviceNet master/slave network or you

!

will cause unrecoverable damage to the scanner.

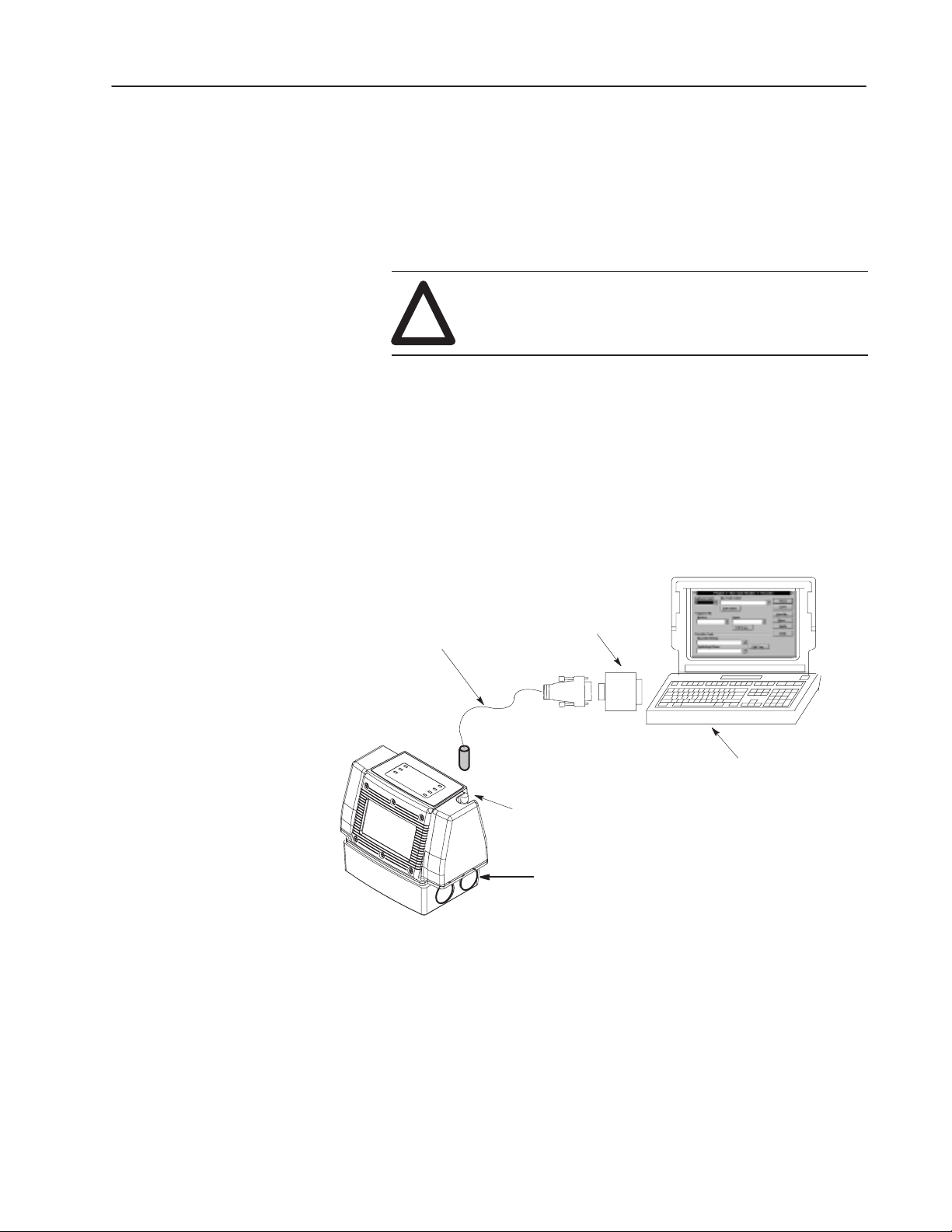

Connect Configuration Cable

The configuration cable connects the configured communications

port (see Preferences, page 2–18) of the computer running

AdaptaScan software to the Configuration Port Connector of the

Reader. Downloads may also be done through the the Reader serial

communication ports when scanner protocol is selected (see page

8–6).

Configuration Cable

(Catalog No. 2755-NC48 Series B Reader

2755-NC43 Series A Reader)

Circular Connector

Make Power Connections

After connecting the configuration cable, you can connect power to

the wiring base. The Reader User Manual (Publication 2755-837)

contains wiring diagrams and instructions.

D Connector

4 Pin Female

Configuration

Port Connector

9 to 25 Pin Adapter

may be required

9 Pin Male

Personal Computer

Connect power, refer to Reader

User Manual (Publication 2755-837)

Publication 2755-838

Page 16

1–6 Installation

Verify DeviceNet Address

The Reader is shipped with a default DeviceNet address of 63.

Verify that the DeviceNet address is still set at 63.

1. From the Windows Start menu, select Programs>AdaptaScan

OLP>AdaptaScan OLP.

The database dialog opens.

2. Click the New button.

The AdaptaScan project window opens.

Publication 2755-838

Page 17

3. From the Communications menu, select Go-Online.

The Reader will be detected (if properly connected) and displayed

in the project window.

Note: The Query dialog may be displayed when you go on-line

(depending on your preference settings). Refer to page 2–19.

1–7Installation

4. If the address displayed is not 63, change the Reader address by

clicking the Device button.

The Device dialog opens showing the current address.

If the Device is online but not in the project

database, the following dialog is displayed:

5. Change the address and click Apply.

If the Device is online and in the current project

database, the following dialog is displayed:

Publication 2755-838

Page 18

1–8 Installation

Download the Firmware to the Reader

1. Check that Reader is properly connected to your computer (using

configuration cable) and has power applied (refer to page 1–5).

2. Select Preferences from the View menu.

SNEXaaaa.ini

3. Make sure the communications channel is set to Configuration

Port.

4. From the Communications menu, select Go-Online.

The Reader will be detected (if properly connected) and displayed

in the project window.

Note: The Query dialog may be displayed when you go on-line

(depending on your preference settings). Refer to page 2–19.

5. From the Project window (see page 1–6), highlight the Reader

name and then click the Firmware button.

The Open dialog is displayed allowing you to enter or browse to

the firmware file you want to download.

Select .ini

Firmware File

aaaa = Version Number

SNEXaaaa.ini

6. Select the firmware file you want to download and click OK.

The following messages appear as the firmware is downloaded.

Downloading will take several minutes. During this time the

Module LED will flash red.

Publication 2755-838

Resetting. Please Wait . . .

Sending. Please Wait . . .

7. The messages disappear when the download is complete.

You are ready to create a Reader configuration.

Page 19

Chapter Objectives

Working with Projects

This chapter contains the following sections:

Section Page

Running AdaptaScan Software 2–2

What is a Database File? 2–3

What is a Project? 2–3

Opening a Project 2–3

Project Window 2–4

AdaptaScan Dialogs 2–8

Saving a Project 2–12

Closing a Project 2–13

Deleting a Project 2–13

Entering Project Name, Description, and Baud Rate 2–17

Selecting Preferences 2–18

Help 2–20

Chapter

2

Page 20

2–2 Working with Projects

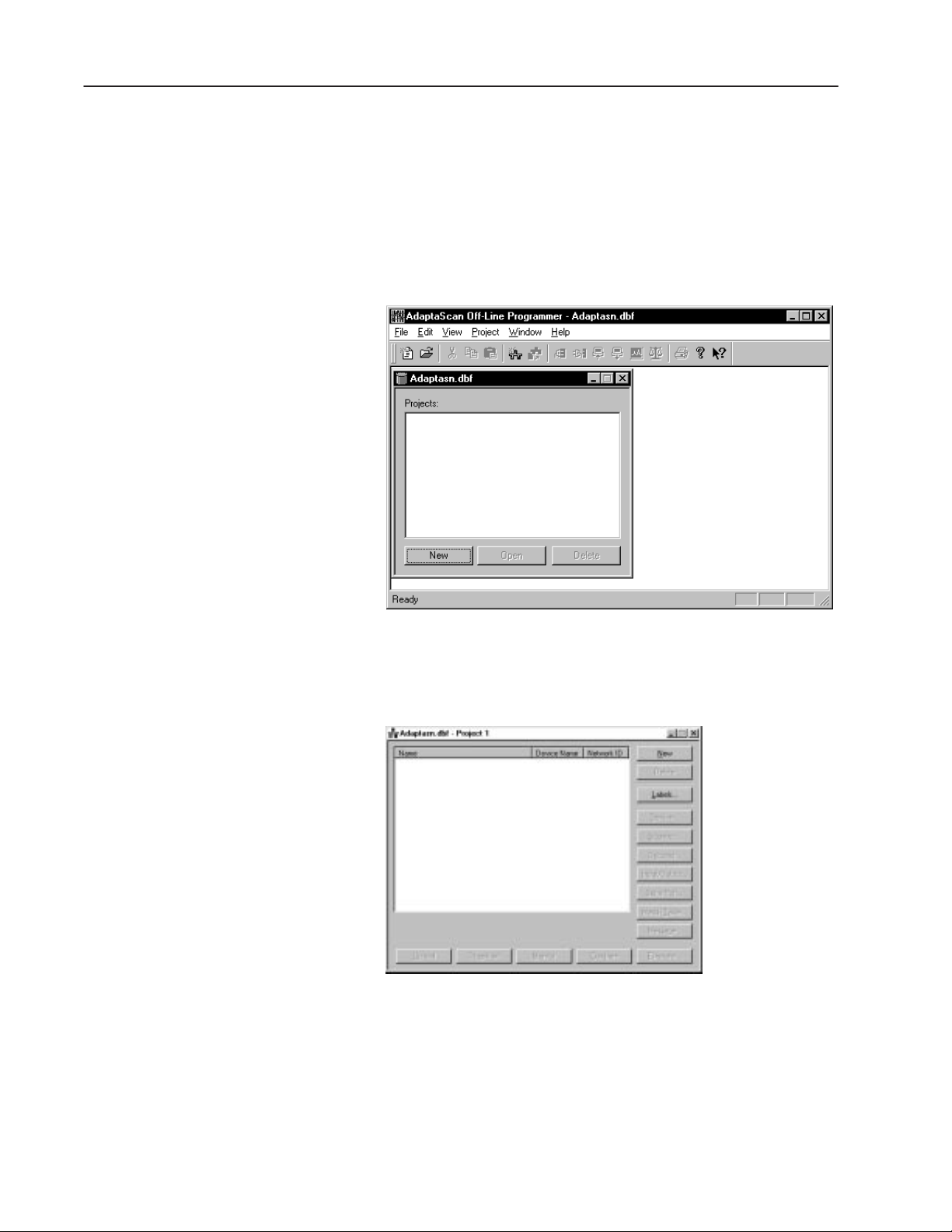

Running AdaptaScan Software

AdaptaScan software opens like any other Windows 95 application.

To start AdaptaScan software:

1. From the Windows Start menu, select Programs>AdaptaScan

OLP>AdaptaScan OLP or double-click the AdaptaScan OLP

icon.

The AdaptaScan window opens with the database dialog:

The AdaptaScan Off-Line Programmer window is your workspace

for creating projects.

Publication 2755-838

Page 21

2–3Working with Projects

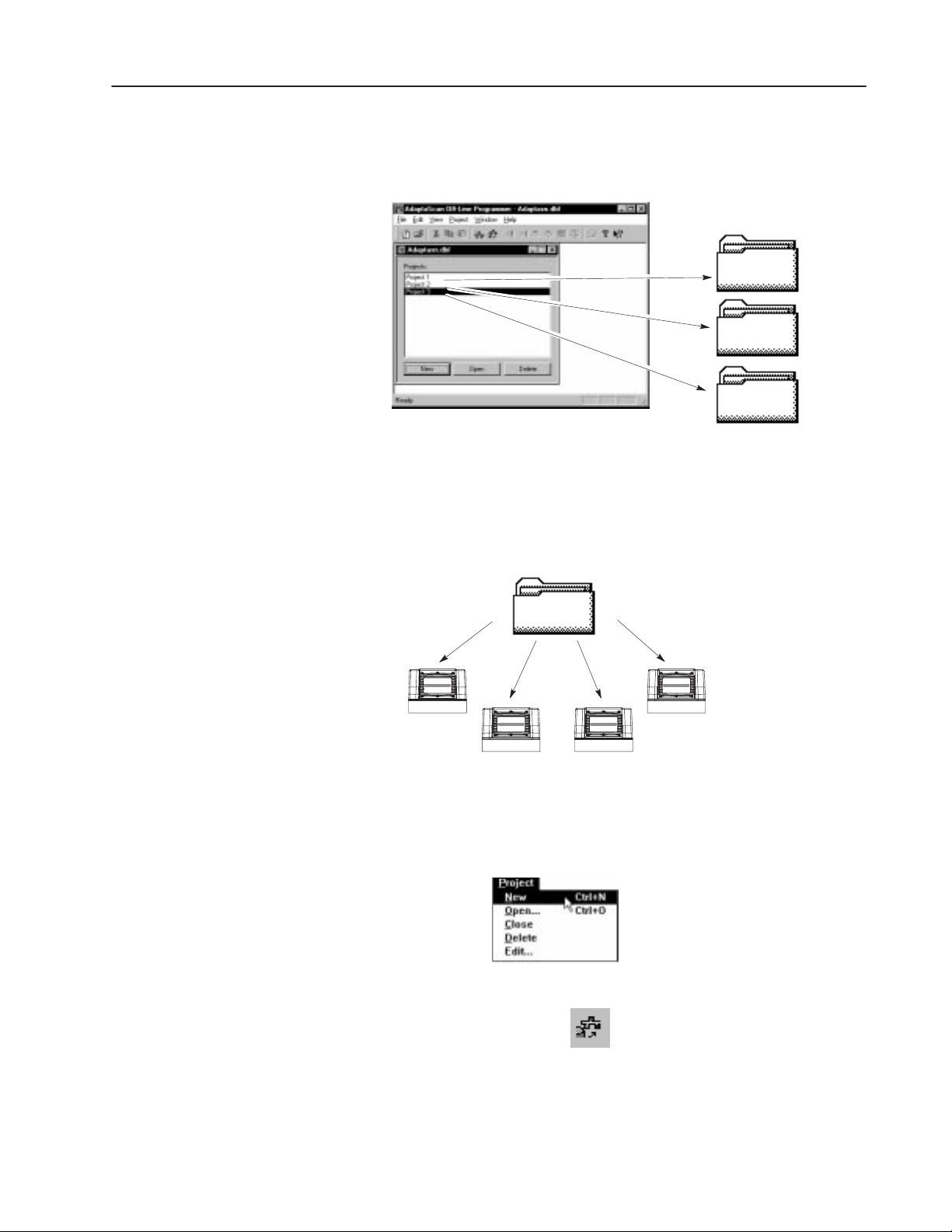

What is a Database File?

What is a Project?

A database file provides a method of organizing projects. Each

database file may contain one or more projects. From the File menu

you can open existing or create new database files.

Project File

Project File

Project File

Each Reader configuration is associated with a project. Each project

contains one or more Reader configurations. If using DeviceNet or

DH-485 communications, each project also defines one DeviceNet or

DH-485 network.

Opening a Project

Project File

Reader 1

Reader 2 Reader 3

Reader 4, . . .

There are two methods of creating a new project.

• From the Project menu, select New.

• Click the New Project tool on the tool bar.

The Project window opens allowing you to define a Reader

configuration.

Publication 2755-838

Page 22

2–4 Working with Projects

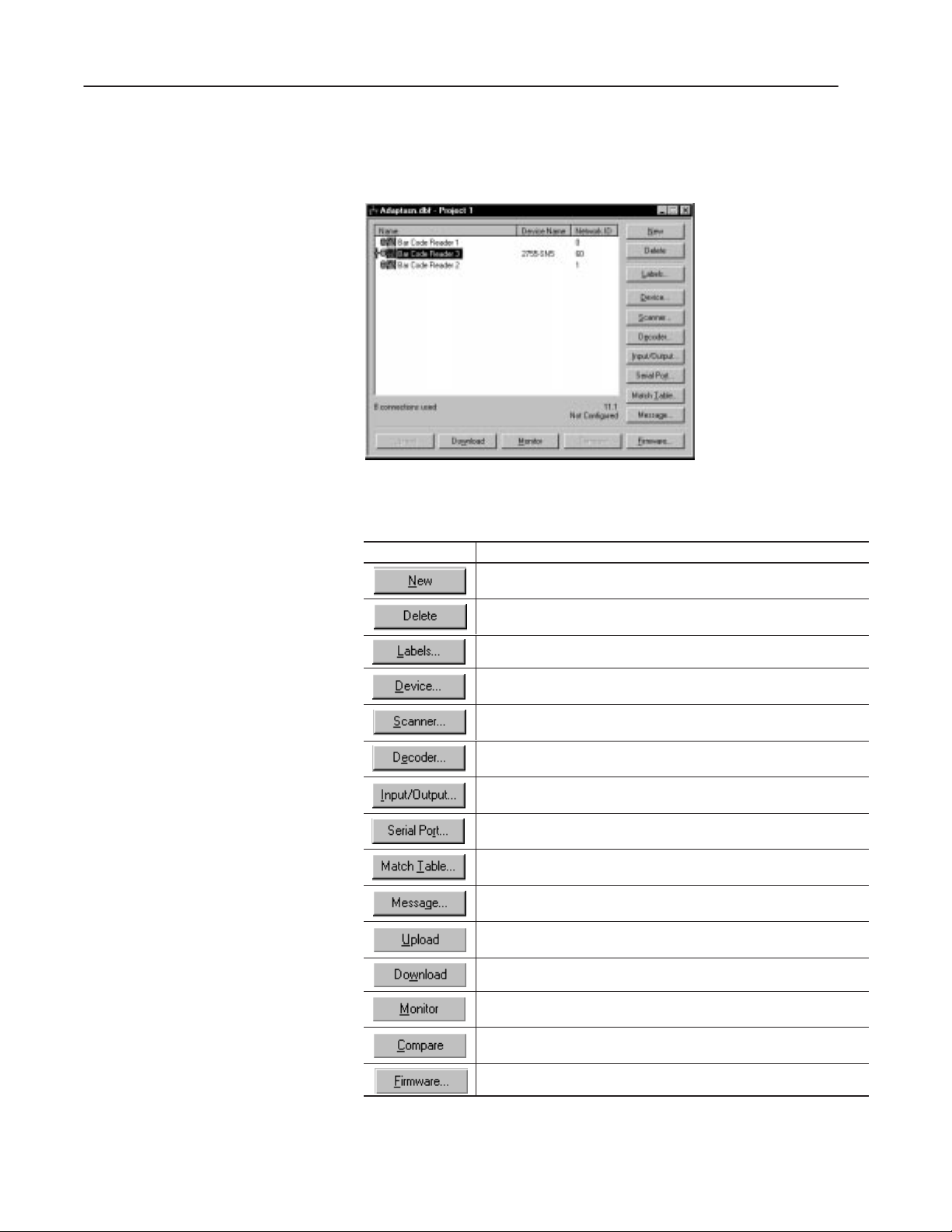

Project Window

Creating a Reader configuration starts with the Project window.

All of the basic configuration options are accessed from buttons.

Selecting a button opens the corresponding dialog.

The buttons on the Project window are defined below.

Select: To:

Create a new Bar Code Reader configuration (Bar Code Reader 1, Bar

Code Reader 2, Bar Code Reader 3, ...) in the Project window.

Delete the selected Bar Code Reader configuration from the Project window.

Define label setups and symbologies for Reader operation.

Define a unique name and enter a description for the Reader. Also de-

fines a DeviceNet address for the Reader.

Specify linear or raster scanning, how scanning is triggered, and accesses

the focus function.

Define when the Reader decodes data and what label is decoded. Also

defines the inter-symbol timer and performance indicator parameters.

Define the operation for package detector, discrete inputs, discrete out-

puts, timer and ASCII trigger commands.

Define communication parameters (RS-232, RS-485/RS422) and proto-

cols (ASCII, DH-485, DF1) for the Reader’s communication ports.

Define match table, package and counter functions for decoded

bar code data.

Define the format and content of messages sent to the host after bar

codes are decoded.

Transfer the configuration stored in a Reader to the currently opened

project in the AdaptaScan Software.

Downloads the highlighted configurations to the device or network.

View the operation of a single Reader or another Reader on the same

network.

Compare the Reader configuration within the project with the on–line

device.

Download new firmware to a selected Reader.

Publication 2755-838

Page 23

2–5Working with Projects

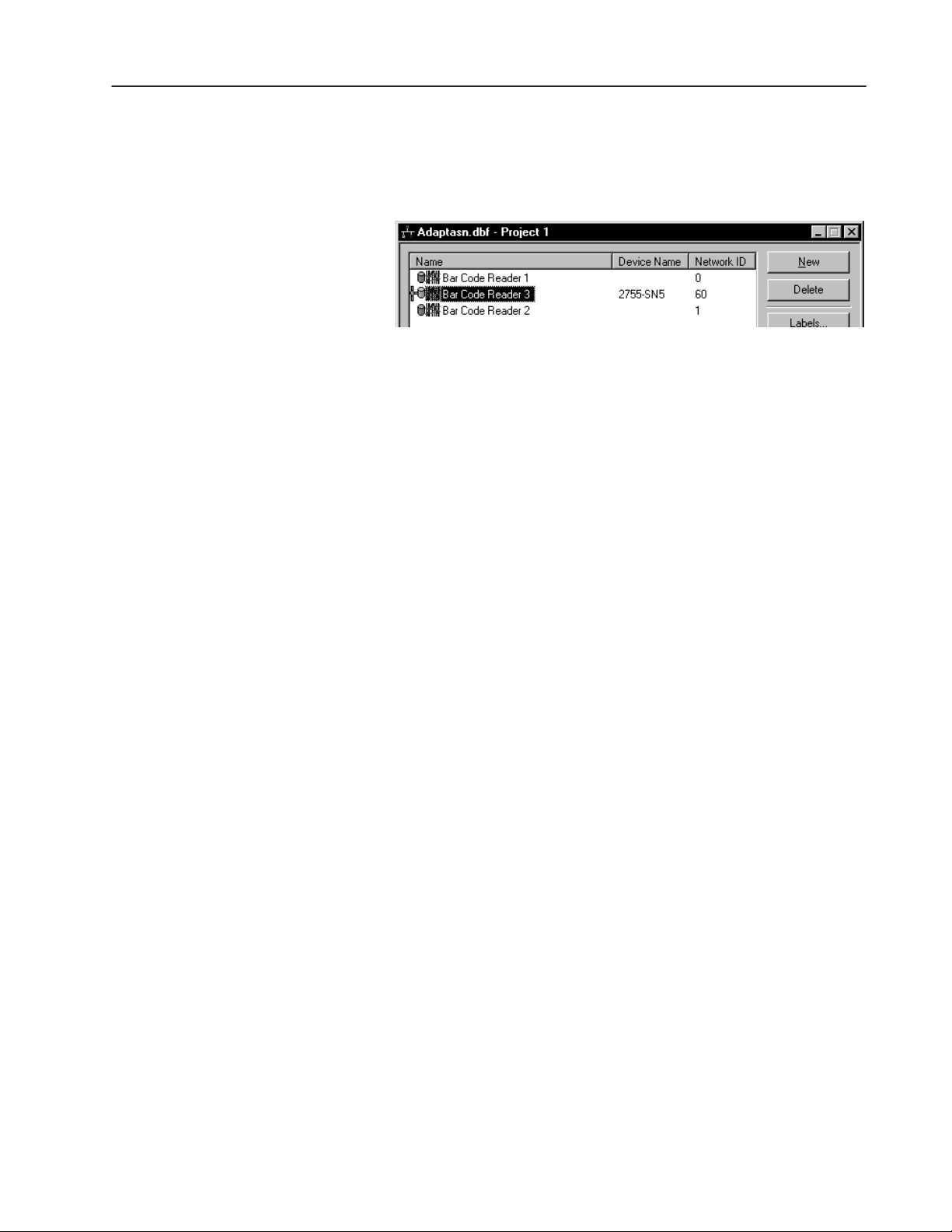

Existing Configurations

Any existing Reader configurations within the project are displayed

in the project window:

This display shows:

• Name - Reader name as specified on the Device dialog.

AdaptaScan software provides a default name of Bar Code

Reader 1, Bar Code Reader 2, etc.

• Device Name - read only field that displays the internally

configured name of the DeviceNet device (typically the catalog

number).

• Network ID - the node address of the device on the DeviceNet

network

Note: When you go on-line with the software, any devices that are

not part of the configuration but are present on the network will be

added to the display. Refer to Chapter 3 for a description of the

on-line functions.

Publication 2755-838

Page 24

2–6 Working with Projects

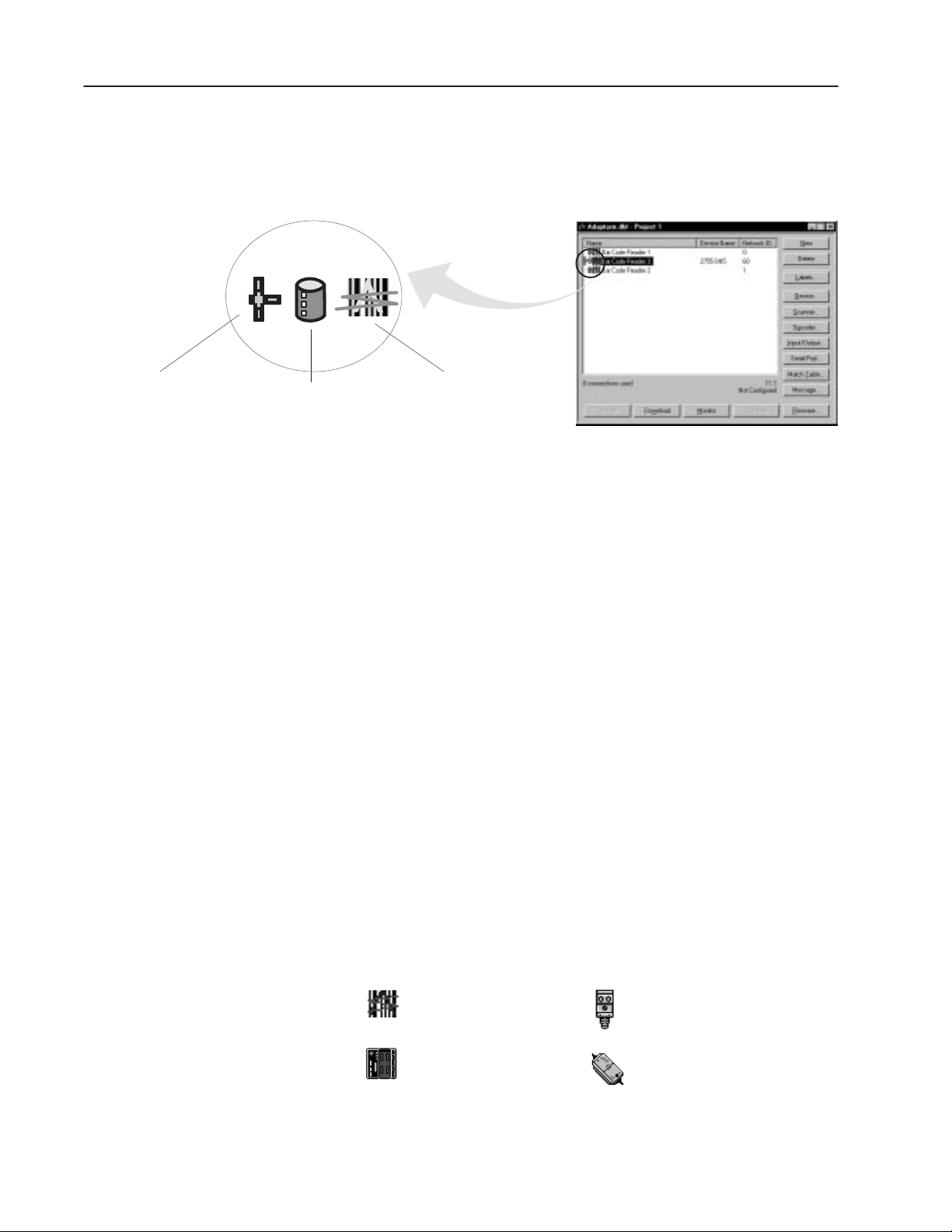

Status

The project window status icons display the status of the Reader

connections and configurations.

Connection

Indicates device is on-line

Database

Indicates Configuration

is stored in the database

Connection

When displayed, indicates a connection was made to the device:

• Yellow (default) indicates that the AdaptaScan software does not

• Green appears after a Compare operation (see page 3–4) was

• Red appears after a Compare operation (see page 3–4) was

Database

When displayed, indicates that a database configuration exists for the

Reader. The color indications are the same as for the Connection

icon (see descriptions above) except the database icon will remain

yellow if a compare operation did not match the database.

Device Icon

Graphic representing

the type of device

have the information required to determine whether the device’s

configuration matches the configuration in the software database.

performed and the configuration of the on-line device matches the

database configuration.

performed and the configuration of the on-line device does not

match the database configuration.

Publication 2755-838

Device Icon

Displays the icon associated with the device. Here are some

common device icons:

= AdaptaScan Reader

= SDN Scanner Card

= PhotoEye photo-electric detector

= KFD DeviceNet Personal

Computer Interface

Page 25

2–7Working with Projects

Information Lines

There are two areas on the project window that provide information

about a highlighted Reader configuration.

Connections per Reader / Description Field Version Number / Compare Status

Connections Per Reader / Description

The total number of connections is displayed on the project dialog

along with a device description. The description displayed is entered

on the Device dialog description field.

Each Reader has a minimum of 7 and a maximum of 64 connections.

A connection is an AdaptaScan object that moves data both

internally and between Readers. For example, when Package Detect

is specified as the decode trigger, a connection moves data from the

package detect input to the decoder. If the Package Detect is from

another Reader, each of the Readers use the connection object.

Important: You will not be allowed to download a configuration

with more than 64 connections in a Reader. A warning message is

displayed. However, you can still read old databases with more than

64 connections. You will need to reduce the number of items that

use connections before downloading the configuration. Some items

that use connections are match fields, inputs and outputs.

Version Number / Compare Status

The first line shows the firmware version number of the Reader. The

second line shows the compare status in a text format and matches

the status shown by the connection and database status icons (see

previous page).

Publication 2755-838

Page 26

2–8 Working with Projects

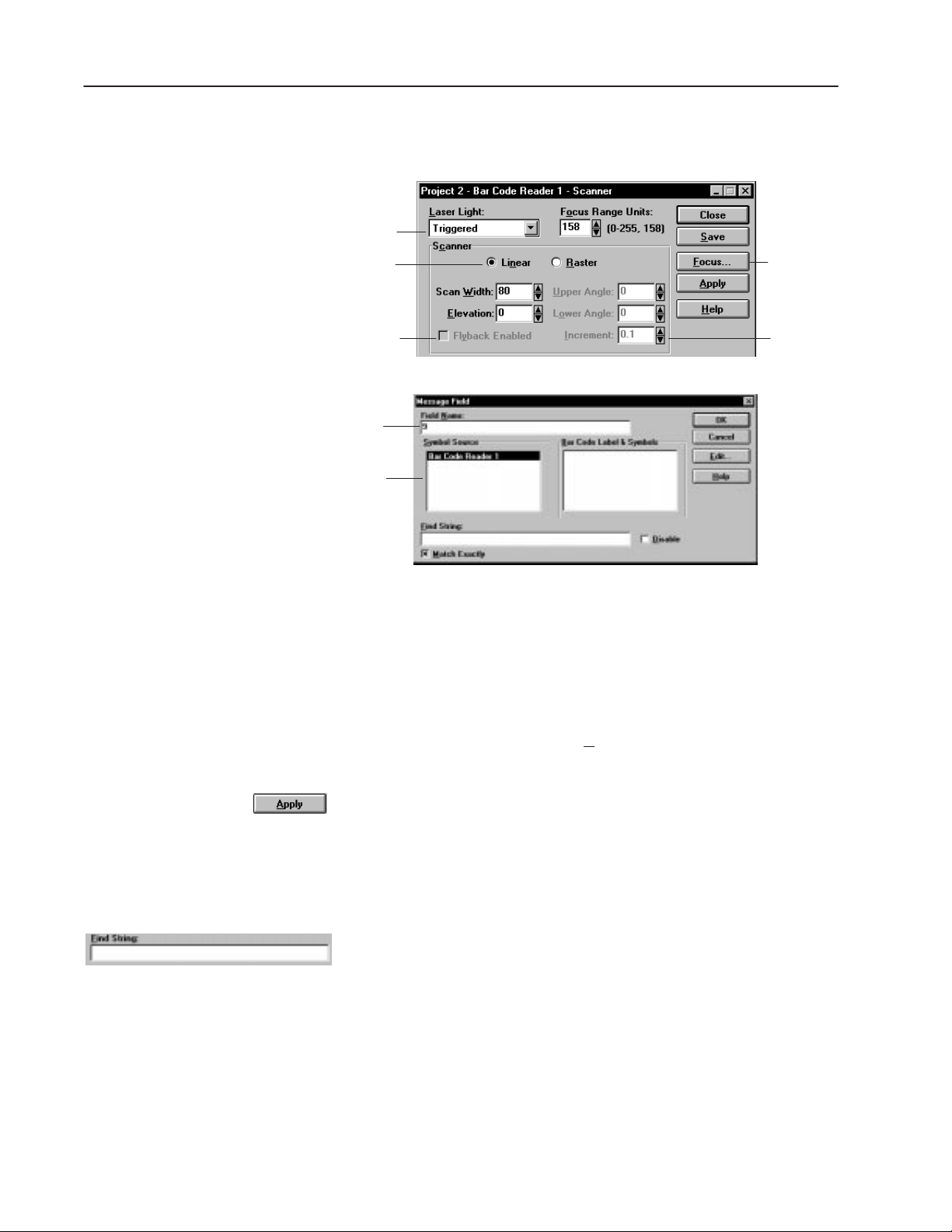

AdaptaScan Dialogs

AdaptaScan software uses dialog boxes to request information and

set operating parameters.

Drop-down List Box

Radio Button

Check Box

Text Box

List Box

Command

Button

Spin Control

To move around a dialog box:

• Move the mouse pointer to field and click the left mouse button.

• Or press TAB to move forward through fields and SHIFT+TAB to

move backward through fields.

• Or press the ALT key and the underlined letter of a field name.

For example, to move to the L

aser Light field, press ALT+L.

Command Buttons

Rectangular areas in the dialog box that look like buttons you can

push. When you click a command button, it presses like a real push

button.

Text Boxes

Text boxes are rectangular boxes in which you type text. Sometimes

these boxes contain text or a value, sometimes they’re empty.

The mouse pointer changes to an

box. Place the pointer where you want to start typing and click the

left mouse button. To replace all text, double-click in the text box

and type the new text.

I-beam when positioned over a text

Publication 2755-838

Page 27

2–9Working with Projects

List Boxes

This is a box with a list of items. To select an item from a list, click

on the item. A scroll bar appears beside the list box if there are more

items than can fit inside the box.

You can also use the arrow keys to select an item in the list. Press

TAB until you get into the list box. Then, press the UP or DOWN

ARROW

keys to select the item you want.

Some list boxes let you select multiple items. To select

non-consecutive items, click the first item, press and hold down the

CTRL key, then click the next item(s). To select consecutive items,

click the first item, press and hold down the

SHIFT key, then click the

last item. To deselect a range, click the first item in the list.

Drop-down List Boxes

These are text boxes with an underlined down-arrow beside them. If

you click inside the text area or click on the down-arrow, the list

drops down. When you select an item from the list, the list

disappears.

Check Boxes

Square boxes that contain an X or are blank. Check boxes are used

to select or clear an option. An X in the box means the option is

selected. A blank box means the option is not selected (it’s cleared).

Click the box to toggle the option on or off.

Radio Buttons

Circles that contain a solid dot or are blank. Radio buttons come in a

group. When you click one button in a group, it clears any other

option that was selected. A solid dot in the button means the option

is selected. When an option is not selected, the radio button is clear

(no dot).

Spin Controls

Small text boxes with up-down arrows at the right. Spin controls are

used to select sequential numbers. Click the up arrow to increase the

number or click the down arrow to decrease the number. Or you can

click in the box and enter a number.

Publication 2755-838

Page 28

2–10 Working with Projects

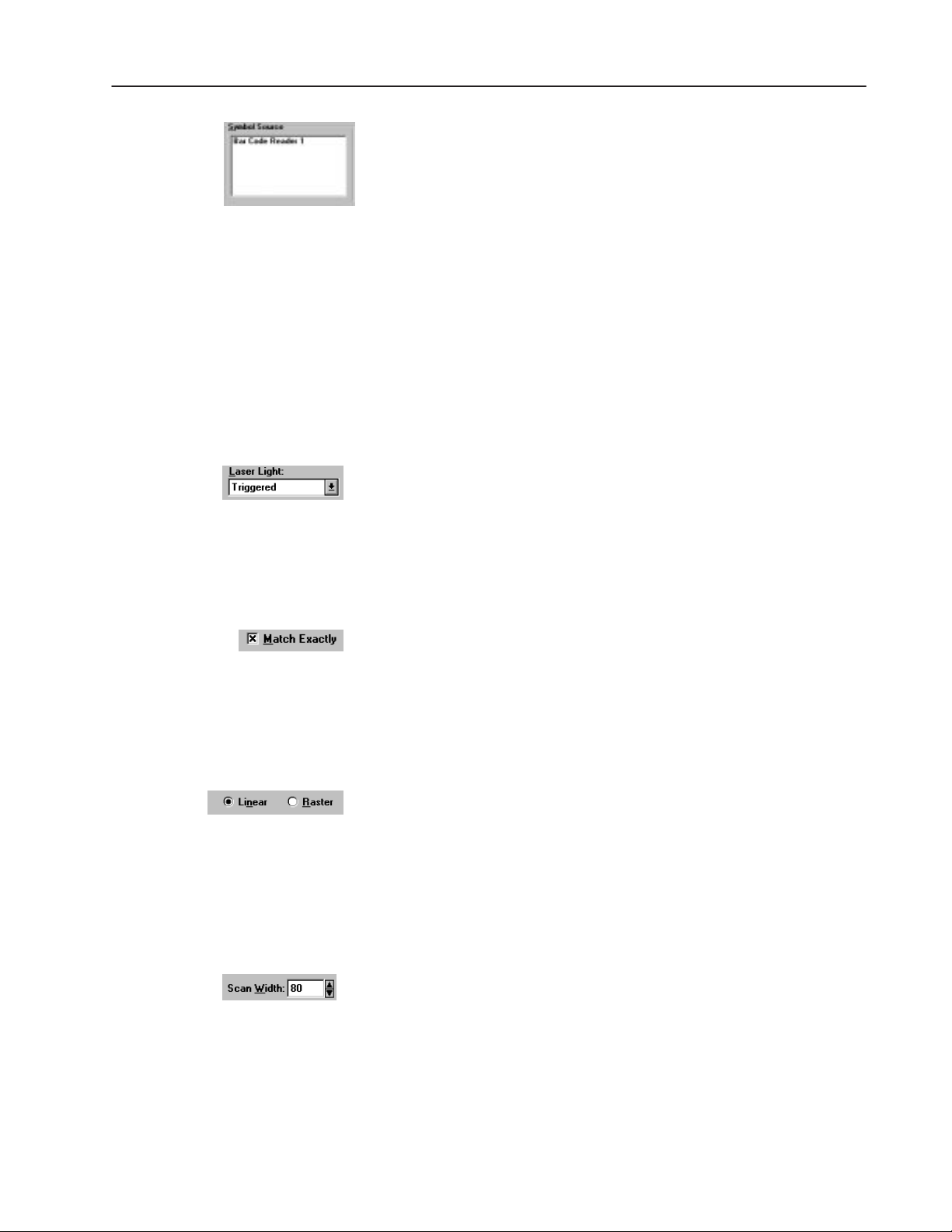

AdaptaScan Tools

Turn the tool bar view on or off from the View menu.

The tool icons provide shortcuts to the following menu items:

Move the toolbar to any side of the window or detach the toolbar and

place anywhere on your screen by clicking on and holding down the

mouse key while dragging the toolbar.

Detached

Default Position

Bottom Position

Side Window

Publication 2755-838

Page 29

Tool Summary

The following provides a brief summary of the AdpataScan tools.

2–11Working with Projects

Tool

Create New Database File >New

Open Existing Database File >Open

Open Selected Project Project >Open

Create New Project Project >New

Go On-Line On-Line Tools >Go On-Line

Go Off-Line On-Line Tools >Go Off-Line

Upload Selected

Configuration into Project

Download Selected

Configurations to Network

Icon

On-Line Tools >Upload

On-Line Tools >Download

or Select

from menu:

Description

Creates a database file that will contain

project configuration files.

Opens window allowing you to select an

existing database file (.dbf) containing

project configuration files.

Opens the project currently selected in

the AdaptaScan database file window.

Creates a new project within the

currently open database file (.dbf).

Connects the programming computer to

the network.

Disconnects the programming computer

from the network.

Uploads the configuration stored in the

selected device to the current project.

Downloads the selected Reader

configuration(s) to the Readers on the

network.

For additional

information,

see page:

2–3

2–3

2–3

2–3

3–2

3–2

12–3

12–5

Open Monitor Window On-Line Tools >Monitor Opens on-line monitor window. 3–5

Compare Project

Configuration with

On-Line Device

Cut Selection to Clipboard Edit >Cut

Copy Selection to Clipboard Edit >Copy

Paste Clipboard Contents Edit >Paste

Print File >Print

About AdaptaScan Software Help >About Off-Line Programmer

On-Line Context Help Help >Contents

On-Line Tools >Compare

Compares the configuration database of

the currently selected Reader to the

actual configuration stored within the

Reader.

Removes the currently selected item

from the dialog or window and places

the item on the clipboard.

Copies the currently selected item from

the dialog or window and places the

copy on the clipboard.

Pastes the last item placed on the

clipboard to the currently selected

location.

Opens the print dialog that allows you to

print out an application report.

Opens a dialog showing the software

revision and serial numbers along with

other software information.

When selected, displays a pointer. this

pointer may be moved to an area on a

dialog or menu and clicked for help

about the item.

3–4

2–14

2–14

2–14

13–2

2–20

Publication 2755-838

Page 30

2–12 Working with Projects

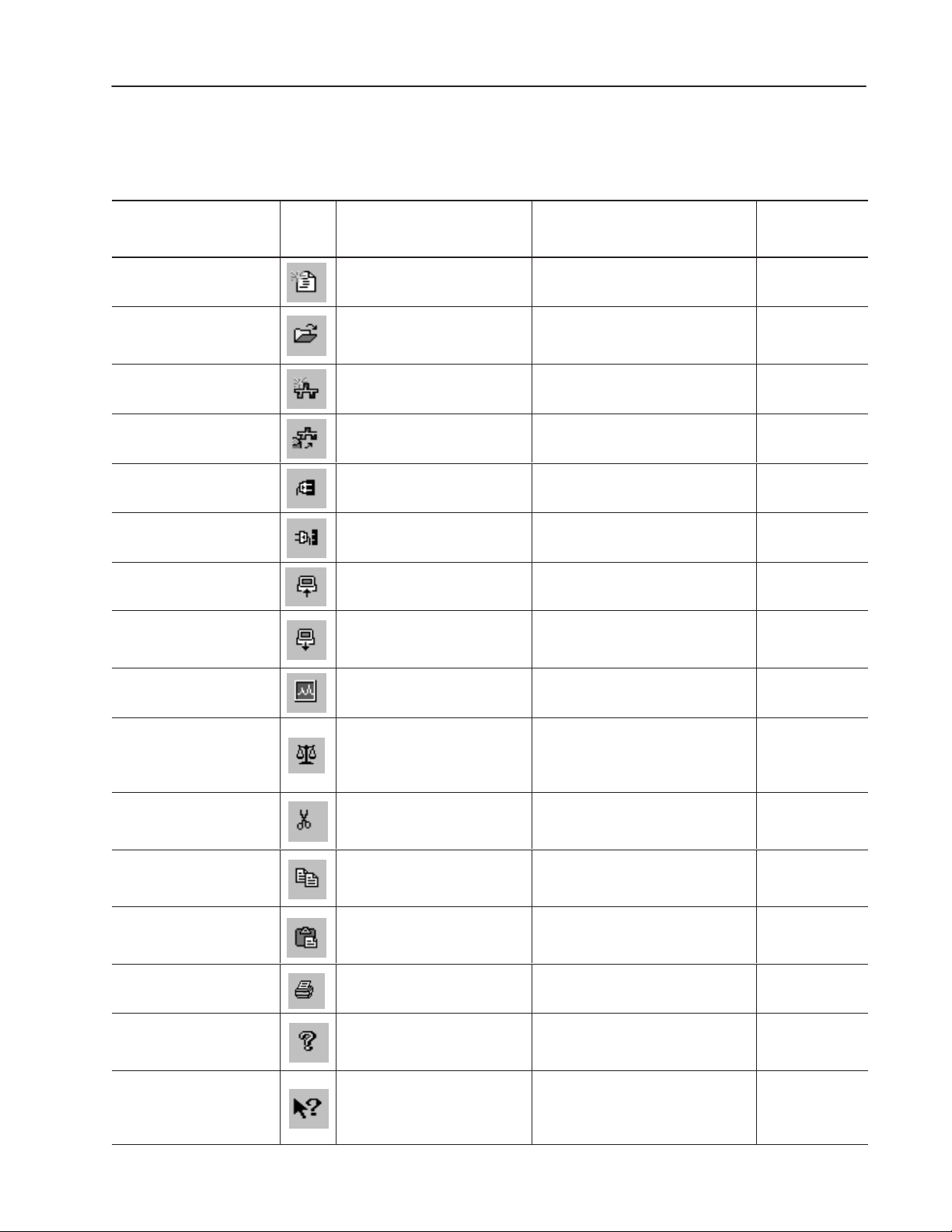

Saving a Project

Project information is saved as you configure each dialog box.

AdaptaScan dialog boxes have one or more of the following buttons.

Save Button

Saves the dialog information. If you close a dialog without saving,

you are prompted:

Changes have been made. Do you want to save these changes

before closing?

If you select No, all changes to the dialog (and associated dialogs

accessed from the dialog) are deleted. Selecting Yes saves changes.

Apply Button

Sends the dialog data to the specified Reader. Use Apply when

making changes to the Scanner or Device dialogs while online.

OK Button

Accepts the data within the dialog box. The dialog information is

saved on the previous dialog (after selecting OK).

Publication 2755-838

Page 31

2–13Working with Projects

Closing a Project

This section shows how to close a project. When closing a project,

use one of the following methods. You are prompted to save

information if changes were made but not saved.

• With the project you want to close as the active window (or icon),

select Close from the Project menu.

• Or select Close from the control menu on the project window.

Control Menu Box

The Project window closes but the AdaptaScan Off-Line

Programmer window remains open.

Deleting a Project

With the project you want to delete as the active window (or icon),

select Delete from the Project menu.

You are prompted:

Are you sure you want to delete (Project Name).

After deletion, there is no way to recover it.

Select Yes to delete the project. When a project is deleted, all project

data is deleted from the program database and cannot be restored.

Select No to cancel the delete function.

Publication 2755-838

Page 32

2–14 Working with Projects

Using Cut, Copy and Paste

The following items may be cut, copied and pasted within and

between database files:

• projects

• Reader configurations

• match functions

• message fields

• labels

• symbols (can’t be copied)

The cut, copy, and paste icons and menu selections will only be

available where they can be used. Otherwise the icons will appear

grayed out.

Important: Cutting or copying and then pasting a Reader

configuration is different from importing/exporting Reader

configurations.

When an individual Reader configuration is pasted into a project,

only the original Reader’s configuration dialog boxes are copied and

recreated in the new project. Connections to and from the original

configuration are not recreated using Paste. Paste is useful when you

need to make a configuration similar to an existing configuration in

the currently open project or another project.

When you need to make an exact copy of a configuration, copy and

paste the entire project in the AdaptaScan database dialog or use the

import/export functions (see next page).

Publication 2755-838

Page 33

2–15Working with Projects

Importing/Exporting Reader Configurations

Using the import/export functions you can transfer exact copies of

Reader configurations between projects. The imported/exported

configurations maintain the internal and external connections (see

page 2–7 for a description of connections).

To import a Reader configuration into a project:

1. Open the project you want to import the configuration file into.

2. From the File menu, select Import.

The Import Configuration dialog is displayed.

3. Enter the path>filename of the Reader configuration you want to

import (.cfg file).

4. Click Open to import the Reader configuration into the project.

Publication 2755-838

Page 34

2–16 Working with Projects

To export a Reader configuration from a project:

1. Open the project that contains the file being exported.

2. Highlight the Reader configuration you want to export.

3. From the File menu, select Export.

The Export Configuration dialog is displayed.

4. Select the directory in which you want to place the Reader

configuration.

5. Click Save to export the Reader configuration. The file will

appear in the directory with a .cfg extension.

Publication 2755-838

Page 35

2–17Working with Projects

Entering a Project Name, Description, and Baud Rate

AdaptaScan software creates projects with a default name (Project 1,

Project 2, ...) and a default DeviceNet baud rate of 125K. To rename

a project, enter a project description or change the baud rate, open

the project you want to edit. With the project as the currently active

window, select Edit from the Project menu.

The Project dialog opens.

Enter a new project name and description. Select a baud rate that is

compatible with the DeviceNet network on which the Readers are

communicating.

Publication 2755-838

Page 36

2–18 Working with Projects

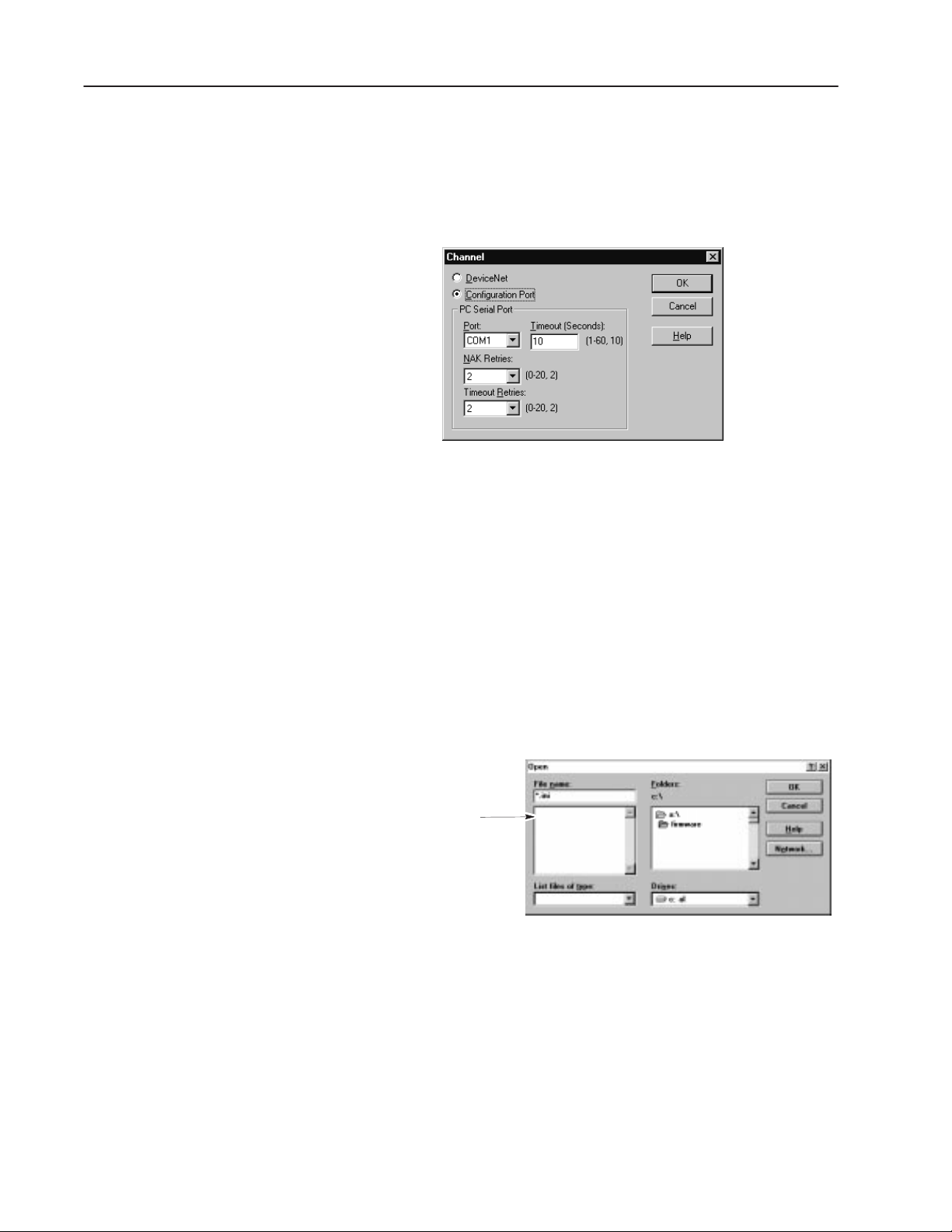

Preferences

The Preferences dialog allows you to specify options related to

computer communications. With the project as the currently active

window, select Preferences from the View menu.

The Preferences dialog opens.

Select: To:

DeviceNet

Configuration Port Specify a direct connection to a Reader’s configuration port.

Port Specify the communications port on your computer used to

Timeout

(Seconds)

NAK Retries Enter the number of times your computer will accept a NAK

Timeout Retries Enter the number of times your computer will attempt to estab-

Select DeviceNet to communicate with a Reader through a

DeviceNet network. A DeviceNet communications card and

driver software must be installed on your computer.

This is the default setting.

configure the Reader. The options are COM1 through COM9.

Enter the amount of time your computer will wait for a response

before a timeout occurs. Enter a value between 1 and 60, the

default is 10.

(negative acknowledgement) before a communications fault

occurs. Enter a value from 0-20, the default is 2.

lish communications after a timeout. Enter a value from 0-20,

the default is 2.

Publication 2755-838

Page 37

2–19Working with Projects

Network Query Preferences

The Query dialog specifies the network addresses that are checked

when the AdaptaScan software checks the network. By specifying

just the addresses that need to be read, you can speed up network

operations.

The Query dialog is displayed when you:

• select Query from the View menu

• select Go On-Line from the Communications menu

• select Refresh from the Communications menu

Specify the network address you want to check:

Select To:

All

Displayed Check only the connections displayed in the project window

Selected Check only the connections displayed and highlighted in the

Specified Check only the addresses listed.

Check all addresses (0 to 63).

(see page 2–4).

project window (see page 2–4).

To disable the Query dialog from displaying when you use on-line

tools, uncheck the checkbox on the bottom of the dialog. You can

still access the dialog from the View menu after unchecking the box.

Publication 2755-838

Page 38

2–20 Working with Projects

Help

Both general and context sensitive Help is available. Access general

Help topics by choosing Contents from the Help menu.

Help feature How to use it

Contents Tab

Index Tab Choose to see an alphabetical list of topics.

Find Tab Choose to search for topics by keywords.

Choose to display the help content books.

Access context sensitive help by choosing the Help button available

on all dialogs. Or click the Help tool

and then the item you

want help for.

Publication 2755-838

Page 39

Chapter Objectives

Chapter

3

On-Line Communications

This chapter describes AdaptaScan online communications and tools.

Section Page

Going On-Line 3–2

Using the Compare Tool 3–4

Monitoring a Reader 3–5

Displaying LED Status 3–6

Displaying Counters 3–7

Displaying Scanner Performance 3–7

Displaying Bar Code Labels 3–9

Displaying Hardware Information 3–9

Page 40

3–2

Going On-Line

Go On-Line

The Go On-Line command establishes communications between the

AdaptaScan software and DeviceNet network using the

communication channel specified on the Preferences dialog (see

page 2–18).

To go on-line with AdaptaScan software:

1. Click the Go On-Line icon or select Go On-Line from the

Communications menu.

The project window will display the devices on the network along

with their catalog number and address.

Note: The Query dialog may be displayed when you go on-line

(depending on your preference settings). Refer to page 2–19.

Note: If you are connected to the DeviceNet network using the

Reader configuration cable, only AdaptaScan Readers on the

network are identified and displayed. When connecting using a

DeviceNet communications card and driver software on your

computer, all DeviceNet nodes on the network are identified and

displayed.

2. Highlight individual readers in the list to display the currently

loaded firmware revision and their configuration status.

Publication 2755-838

Page 41

3–3

When going on-line:

•

You can only be on-line with one project at a time. Use the Go

Off-Line command (Communications menu) when you want to

switch to another project.

• Upload, Download, Monitor and Compare functions are only

available for AdaptaScan Readers having the same major version

number as the AdaptaScan software (firmware version 11.XX or

greater)

• The Firmware button, for downloading firmware to a Reader, is

only available when the communications channel is set for

Configuration Port (direct connection using configuration cable).

• Use Refresh (Communications menu) to query the network and

update the display.

• Use Query (View menu) to display the Query dialog. The Query

dialog allows you to specify the network addresses read when

on-line functions are used. Refer to page 2–19. By only

checking the addresses that are required, you can increase the

speed at which network operations occur.

Publication 2755-838

Page 42

3–4

Using the Compare Tool

Go On-Line

Compare

The compare tool compares the calculated Cyclic Redundancy

Check (CRC) of the configuration stored in the project database with

the CRC of the configuration stored in the Reader. Compare is

useful when checking if a Reader’s configuration has been changed

to determine if an upload or download is necessary.

Note: Reader configurations cut and copied between projects may

not match when compared due to differences in the label

configurations between projects.

To use compare:

1. Make sure the software is on-line by clicking the Go On-Line

icon or by selecting Go On-Line from the Communications

menu.

Note: The Query dialog may be displayed when you go on-line

(depending on your preference settings). Refer to page 2–19.

2. Select the Reader configuration you want to compare with the

actual configuration stored within the Reader.

3. Click the Compare tool icon or select Compare from the

Communications menu.

Connection Icon Database Icon

If the Reader configuration has been compared and does not match

the configuration stored in the Reader, the connection icon appears

red.

If the Reader configuration has been compared and matches the

configuration stored in the Reader, the database and connection icons

appear green.

If a Reader configuration has not been compared to the configuration

stored in a Reader, the database and connection icons appear yellow.

Publication 2755-838

Page 43

The Monitor window displays the current operational status of a

Monitoring a Reader

Reader.

To monitor a reader:

3–5

Go On-Line

☞ The more information

monitored (the more check

boxes selected) the slower the

monitor window is updated.

1. Make sure the software is on-line by clicking the Go On-Line

icon or by selecting Go On-Line from the Communications

menu.

2. Open the monitor dialog by selecting the Monitor button on the

main Project dialog or by selecting Monitor from the

Communications menu.

The monitor window is displayed:

Package 1:90

Match1: 30

7003063081

7003063081

7003063081

Starts and Stops monitoring.

Resets counter to configured initial value.

Displays hardware information about Reader.

3. Select the items you want to monitor.

Closes the dialog.

Publication 2755-838

Page 44

3–6

Displaying LED Status

The LEDs area of the monitor display shows the status of specific

Reader operations. Select the LEDs check box to display the status

of Reader operations. The following tables show the LED

conditions and their meanings.

ATTENTION: Depending upon the amount of

information being monitored and network response

!

times, the LED status indicators may not reflect the

current status of the Reader. Do not rely on these

status indicators for important operating decisions.

On Symbol

Condition

Yellow Bar code symbol is being scanned and decoded.

Flashing Bar code symbol is being read at less than 100% rate.

Off Not reading a bar code symbol.

Trigger/Read

Condition

Yellow Decoder trigger is on.

Green Valid bar code symbol read.

Off No trigger or valid bar code symbol read.

Indication

Indication

I/O 1 and I/O 2

Condition

Yellow Corresponding input or output is in an On (closed contact) state.

Off Corresponding input or output is in Off (open contact) state.

Network

Condition

Green Normal DeviceNet operating state.

Flashing Green Communication link established but no data transfer.

Red DeviceNet communication fault detected.

Flashing Red One or more DeviceNet devices are not responding. Reader may

not be able to perform all of its configured functions.

Off No DeviceNet communications established.

Laser On

Condition

Yellow The scanning beam is On (active).

Off The scanning beam is Off (inactive).

Module

Condition

Green Normal operating condition. Power is applied to the Reader and no

faults have been detected.

Flashing Green Power-up initialization sequence or Reader is not configured.

Red

Flashing Red Minor fault (recoverable). Occurs when downloading new firmware.

Off

➀ For reference only. These indicators will not be visible if the condition causing them

occurs.

Processor fault (unrecoverable).➀

No power applied to Reader.➀

Indication

Indication

Indication

Indication

Publication 2755-838

Page 45

☞ Click the Reset Counters

Displaying Counters

Displayin

button to reset counters to

initial value.

3–7

The Counter area of the monitor display shows the values stored in

the package and match entry counters. Select the Counters check

box to display the counter values.

g

Scanner Metrics

The metrics area of the monitor display shows either:

• the decode margin (see definition below).

• the number of decodes during a trigger period (Counts)

Select either Dial or History

Select either Margin or Counts

You can display the Margin or Count parameters in either a Dial or

History format.

Dial

History

Scanner metrics are useful during:

• Initial Setup for making minor adjustments to the scan beam on

the Scanner dialog.

• Normal operation to identify small decreases in performance.

For example, if the number of reads drops significantly, label

quality may have degraded or the scan window may require

cleaning.

Publication 2755-838

Page 46

3–8

Margin

The scanner metric for margin is a measure of how clearly

distinguishable the different element sizes (bars and spaces) are in a

symbol. Margin is calculated every time a symbol is decoded. The

margin result is the tolerance remaining before the AdaptaScan can

no longer differentiate between wide and narrow elements.

Several factors affect the margin, including how well the

AdaptaScan is focused and the quality of the symbol. Assuming that

the AdaptaScan is properly focused, margin can be used for an

indication of trends in label quality. This is especially true for ink jet

symbols on cardboard cartons where low margins can occur because

of increasing ink spread.

Margin values may be returned in a host message (see page 10–2) or

used to trigger an output if the margin value falls below a user

defined level (see page 7–8).

Publication 2755-838

Page 47

3–9

Displayin

Labels

Displayin

g Bar Code

g

Hardware Information

Select the Bar Code Labels check box to display labels as they are

decoded. The data from each label displays on a separate line. Any

data formatting is not displayed.

123098

456987

051997

051997

071996

Select the Hardware Info button to display information about the

Reader such as series/revision, firmware version, boot version, and

catalog numbers of Reader and AdaptaScan software.

Publication 2755-838

Page 48

Chapter Objectives

Chapter

4

This chapter provides step-by-step instructions on how to configure

the Reader to scan and decode UPC-A symbols. This section

acquaints you with basic configuration and operation of the Reader

by stepping through a sample configuration.

Section Page

Configuration Description 4–1

What You Need 4–2

Connecting Power 4–3

Connecting the DL10 4–3

Installing the Reader 4–5

Connecting the Configuration Cable 4–5

Running the AdaptaScan Software 4–6

Downloading Firmware 4–9

Setting Up the Communication Port 4–7

Creating a New Project 4–8

Creating a New Reader Configuration 4–8

Defining the Label Setup 4–11

Configuring the Scanner 4–13

Positioning the Reader 4–13

Focusing the Reader 4–15

Configuring the Decoder 4–16

Configuring the Discrete Outputs 4–17

Setting the Timer 4–21

Setting the Serial Port 4–22

Defining a Package 4–19

Configuring Message Output 4–23

Downloading the Configuration 4–25

Monitoring Reader Operation 4–26

Dataliner Operation 4–26

Configuration Description

The sample configuration reads UPC-A labels. The Reader will

activate outputs 1 and 2.

• Output 1 energizes when a label is read.

• Output 2 energizes when a no-read occurs.

The monitor display shows the status of the Reader operation.

An optional Dataliner DL10 display receives and displays decoded

bar code data from the Reader’s RS-232 port.

Page 49

4–2 Getting Started

What You Nee

d

Personal Computer

Running Windows 95 or Windows NT

Configuration Cable

(Catalog No. 2755-NC48 Series B Reader,

2755-NC43 Series A Reader)

The sample configuration requires the following items. The

Datalinert DL10 and cable are optional. The DL10 is a slave

message display that displays any ASCII data that it receives from

the Reader. You can use the configuration software monitor function

to view decoded data if a DL10 or other display device is

unavailable.

AdaptaScan Bar Code Reader

(Catalog No. 2755-SN3, -SN5, -SN8)

9-to-25 Pin Adapter

Required for Computers with

25 Pin Communication Port.

(Purchase Locally)

AdaptaScan Wiring Base

(Catalog No. 2755-NB40, -NB41)

Test Bar Code Symbols

(Publication No. 2755-940)

Provided with this Manual

AdaptaScan Software

(Catalog No. 2755-ASN)

DL10 Communication Cable

2 Conductor Shielded Cable

(Belden 8303 or Equivalent)

Power Supply

(Catalog No. 2755-PW46, -PW47)

Dataliner

(DL10 with

120V Power Cord)

Optional Items

Wire & Small Slotted Screwdriver

For Connecting Power Supply

Publication 2755-838

Page 50

4–3Getting Started

Connectin

er

g Pow

230V AC Desktop

Power Supply

(Catalog No. 2755-PW47)

Before configuring the Reader, you must connect the

communications cable and provide power.

Power Connections

Connect the power supply to the Reader wiring base as shown below.

Note: This example uses unshielded wires for power connections.

Make sure you use shielded cable for the final installation as

described in the AdaptaScan Bar Code Reader user manual.

120V AC Wallmount

Power Supply

(Catalog No. 2755-PW46)

GND

+

-

V+

Can_H

Shield

Can_L

V-

Reader Wiring Base

Verify the connection by applying power to the wiring base and

observing the polarity LED. The LED should be green. If the LED

is red, the polarity needs to be reversed. Disconnect power from the

wiring base until the Reader is installed.

Publication 2755-838

Page 51

4–4 Getting Started

Connecting the

DL10 Slave

Use a two conductor shielded cable to connect the DL10 data display

to the RS-232 port of the Reader. The DL10 is optional. If you

don’t have a DL10, you can still view decoded data using the

configuration software monitor function.

Note: The data viewed on the monitor window does not necessarily

correlate with the data sent out of the serial port. The monitor

window displays unformatted data while the serial port data may be

formatted to contain other data such as replacement strings, source

ID, etc.

Dataliner DL10

Message Display

Dataliner

Communications Port

Connect to 120 VAC

Power Source

Publication 2755-838

Use Belden 8303

or equivalent

Tx

GND

RS-232 Port

Reader Wiring Base

Page 52

Installing the Reader

Connecting the

Configuration Cable

ower-up Sequence

4–5Getting Started

Carefully position the Reader on the wiring base. You don’t need to

tighten the screws for this sample application.

Screws

4 Locations

Don’t Tighten Screws

Wiring Base

Insulating

Cover

Use the configuration cable (Catalog No. 2755-NC48 Series B,

2755-NC43 Series A) provided with the AdaptaScan software to

connect the computer’s communication port to the Reader’s

configuration port. If the computer has a 25-pin connector, you need

a 9-to-25 pin adapter.

9-to-25 Pin Adapter

Configuration Cable

(Catalog No. 2755-NC48 or -NC43)

4 Pin Female

Circular Connector

P

Apply power to the Reader. On initial powerup, the Reader performs

may be required

9 Pin Male

D Connector

Personal Computer

Configuration

Port Connector

Power source required

See Reader user manual

(Publication No. 2755-837)

a series of self-diagnostic tests and LED tests (all LEDs flash).

Refer to table page 3–6 for a description of the LED indicators.

When the Module LED flashes and turns a steady or flashing green,

the powerup sequence is complete. The complete powerup sequence

takes a few seconds.

Publication 2755-838

Page 53

4–6 Getting Started

Running the

AdaptaScan Software

If you haven’t already done so, install the AdaptaScan software.

Software installation procedures are described in Chapter 1.

After installing the software, the AdaptaScan OLP group icon

appears in the Program Manager window.

To run the AdaptaScan software:

1. From the Windows Start menu, select Programs>AdaptaScan

OLP>AdaptaScan OLP.

The AdaptaScan window opens.

2. All configurations occur within the AdaptaScan window. Use the

dialog buttons and/or menu selections to access the AdaptaScan

software operations.

Publication 2755-838

Page 54

4–7Getting Started

Communications Setup

The Reader configuration port is set for 9600 Baud and cannot be

changed. This port is set by default to communicate with the first

port that is available on your computer.

If your computer is using a different communication port, change the

port by selecting Preferences from the View menu.

To change communication port settings:

1. Select Preferences from the View menu.

The Preferences dialog opens.

2. Select the communications port connected to the Reader.

3. Make sure that Configuration Port connection is selected.

4. Click OK to save changes.

Note: The Reader can also be connected to a Reader through a

DeviceNet network connection. A DeviceNet communications card

and driver software must be installed on your computer. If you are

using DeviceNet Manager Software (Catalog No. 1787-MGR) to

connect to an AdaptaScan Reader in a network, refer to the user

manual (Publication No. 1771-2.29). Select DeviceNet connection

on the Preferences dialog when using a DeviceNet network

connection.

Publication 2755-838

Page 55

4–8 Getting Started

Creating a Project

Creating a Ne

Reader configuration dialogs are accessed from the Project menu.

To create a project:

Select New from the Project menu or click New on the AdaptaScan

window.

The Project window opens with the default name of Project 1.

w

Reader Configuration

To create a Reader configuration:

From the Project 1 window, click the New button.

An application is created with the default name Bar Code

Reader 1. Applicable dialog buttons are enabled.

Publication 2755-838

Page 56

4–9Getting Started

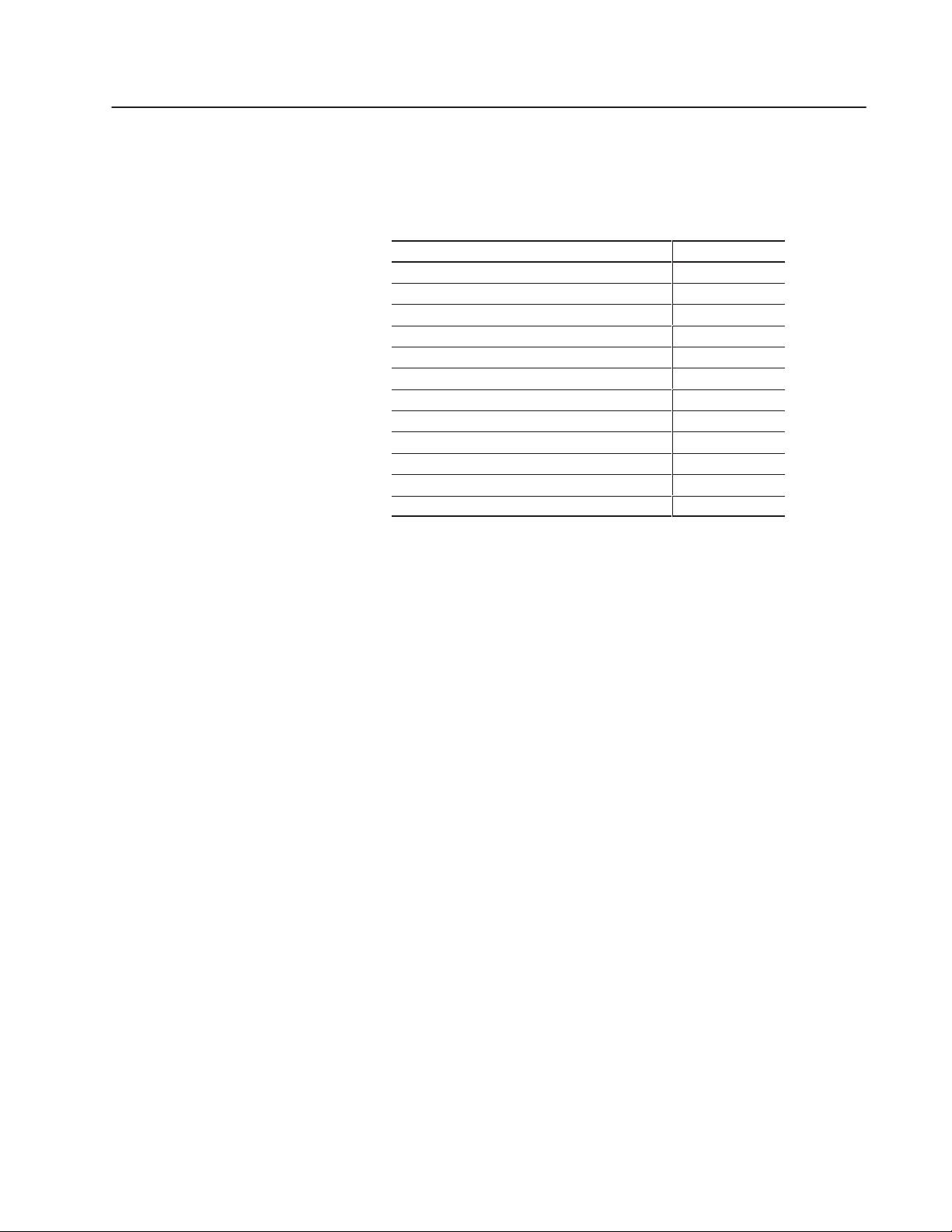

Downloadin

are

g Firmw

If the Reader is being operated for the first time (out of the box), you

must download operating firmware.

The Reader is shipped with a default DeviceNet address of 63.

To download operating firmware to the Reader:

1. From the Communications menu, select Go-Online.

The reader will be detected (if properly connected) and displayed

in the project window.

Note: The Query dialog may be displayed when you go on-line

(depending on your preference settings). Refer to page 2–19.

Note Address

2. From the Project window, highlight the Reader name and then

Select .ini

Firmware File

aaaa = Version Number

click the Firmware button.

The Open dialog is displayed allowing you to enter or browse to

the firmware file you want to download.

SNEXaaaa.ini

Publication 2755-838

Page 57

4–10 Getting Started

3. Select the firmware file you want to download and click OK.

The following messages appear as the firmware is downloaded.

Downloading will take several minutes. During this time the

Module LED will flash red.

Resetting. Please Wait . . .

Sending. Please Wait . . .

4. The messages disappear when the download is complete.

You are ready to create a Reader configuration.

Publication 2755-838

Page 58

4–11Getting Started

Defining the Label Setup

This section shows how to specify what type of label(s) the Reader is

expected to decode. For the sample configuration, the Reader is

expected to decode an UPC-A symbol.

To define the bar code label setup:

1. From the Project 1 window, click the Labels button.

The Bar Code Labels dialog opens.

2. Click New to define a new label.

The Bar Code Labels dialog opens with a default name of Label

1 for the label setup.

3. Click the New button to specify the symbols the Reader expects

to find on a label.

Publication 2755-838

Page 59

4–12 Getting Started

The Bar Code Label Symbol dialog opens.

4. Make changes as shown below and then click OK.

1. Change

Name to UPC-A

2. Select

UPC-A

The Bar Code Label dialog shows UPC-A in the Symbols list. If

other symbologies were expected on the label, you would define

them in the same way.

3. Click OK

Publication 2755-838

5. Click OK to save the label definition.

The bar code label, Label 1, appears in the Bar Code Labels list.

6. Click Save and then Close to save and close the label definition.

You return to the Project 1 window.

Page 60

4–13Getting Started

Con

the

anner

figuring

Sc

This section configures the Reader for linear scanning.

Configure the scanner:

1. From the Project 1 window, click the Scanner button.

The Scanner dialog opens.

Select

Always On

Select

Linear

2. Select Always On from the Laser Light list.

Note: Only use the Always On setting for initial setup. When

installed in an application, you should set Laser Light to

Triggered.

3. Select Linear under Scanner options.

Before using the focus function, you must position the Reader so

that the scan beam crosses a UPC–A label. You can use the test

card (Publication 2755-940).

Publication 2755-838

Page 61

4–14 Getting Started

Position the Reader:

1. Place the test symbol approximately 12 inches (.3 meter) in front

of the Reader so that the scan beam crosses the symbol.

Observe

On Symbol

LED

Test Card

Make sure symbol

is slightly skewed.

2. Observe the ON Symbol LED on top of the Reader. When the

LED is illuminated, the Reader is scanning an enabled

symbology.