Page 1

MobileView Guard

G750 Terminal

2727-G7P20D1P4

2727-G7P20D1P5

2727-G7P20D1Q6

2727-G7P20D3Q7

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (Publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://www.ab.com/manuals/gi) describes some important differences

between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for

solid state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is

acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

WARNING

!

ATTENTION

!

IMPORTANT

SHOCK HAZARD

Identifies information about practices or

circumstances that can cause an explosion in a

hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

Identifies information about practices or circumstances

that can lead to personal injury or death, property

damage, or economic loss.

Attentions help you:

• identify a hazard

• avoid a hazard

• recognize the consequence

Identifies information that is critical for successful

application and understanding of the product.

Labels may be located on or inside the drive to alert

people that dangerous voltage may be present.

Page 3

Table of Contents

Preface

Overview

Safety Precautions and Elements

Contents of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Intended Uses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

European Communities (EC) Directive Compliance . . . . . . P-2

Chapter 1

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

MobileView Guard Sample System Configuration . . . . . . . . 1-2

Hardware Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Membrane Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

MobileView Guard Configurations . . . . . . . . . . . . . . . . . . . 1-6

MobileView Guard Accessories . . . . . . . . . . . . . . . . . . . . . 1-7

Chapter 2

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Enabling Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Enabling Switch Operation. . . . . . . . . . . . . . . . . . . . . . 2-5

Connection Example with a Safety Control Relay. . . . . . 2-6

Switching Element Data . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Foreseeable Misuse of the Enabling Switch . . . . . . . . . . 2-8

Emergency Stop Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Handling of the MobileView Terminal . . . . . . . . . . . . . . . . 2-9

Chapter 3

Terminal Connections

i Publication 2727-UM002D-EN-P

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Mounting and Connecting the Junction Box . . . . . . . . . . . . 3-2

DIN Rail Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Connecting the MobileView to the Junction Box . . . . . . 3-4

Junction Box Pinout and Wiring . . . . . . . . . . . . . . . . . . 3-5

MobileView Connection Cable . . . . . . . . . . . . . . . . . . . 3-7

MobileView Junction Box Cable . . . . . . . . . . . . . . . . . . 3-8

Accessing/Wiring the MobileView Connection Compartment 3-9

Removing the Back Cover . . . . . . . . . . . . . . . . . . . . . . 3-9

Connection Compartment Details . . . . . . . . . . . . . . . . . 3-10

Attaching the MobileView Connection Cable. . . . . . . . . 3-11

Connecting a Computer using the RS-232 Serial Port. . . . . . 3-12

Making an Ethernet Connection. . . . . . . . . . . . . . . . . . . . . 3-13

Using the PC Card Slot . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Connecting a Keyboard / Printer Using the IrDA Interface . 3-15

Installing the Mounting Bracket . . . . . . . . . . . . . . . . . . . . . 3-16

Page 4

Table of Contents ii

Configuring the MobileView

Terminal

Chapter 4

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Using the MobileView Configuration Tool . . . . . . . . . . . . . 4-1

Calibrating the Potentiometer . . . . . . . . . . . . . . . . . . . . 4-2

Adjusting Display and Touch Screen Settings . . . . . . . . 4-3

Setting the Handwheel to Zero . . . . . . . . . . . . . . . . . . . 4-4

Configure Keypad Settings . . . . . . . . . . . . . . . . . . . . . . 4-5

Configuring Startup Settings . . . . . . . . . . . . . . . . . . . . . 4-5

Activating/Testing Pushbutton LEDs . . . . . . . . . . . . . . . 4-6

Loading a New Image File . . . . . . . . . . . . . . . . . . . . . . 4-7

Clearing the Registry . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Checking the Operating and Control Elements . . . . . . . . . . 4-10

Transferring Data with a Personal Computer . . . . . . . . . . . 4-11

Verifying Serial Port Availability . . . . . . . . . . . . . . . . . . 4-11

Installing Microsoft ActiveSync Software . . . . . . . . . . . . 4-12

Connecting the MobileView Terminal to a PC . . . . . . . . 4-12

Disconnecting Communication . . . . . . . . . . . . . . . . . . . 4-14

Installing Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Saving Registry Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Using RSView ME Station

Chapter 5

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Startup Options for RSView ME Station . . . . . . . . . . . . . . . 5-1

Starting RSView ME from the desktop . . . . . . . . . . . . . . . . 5-4

Screen Buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Input Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Loading an ME Application . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Running an Application. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Application Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Terminal Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Networks and Communications . . . . . . . . . . . . . . . . . . . . . 5-9

Diagnostic Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

File Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Font Linking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Print Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Startup Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Time/Date/Regional Settings . . . . . . . . . . . . . . . . . . . . . . . 5-25

Publication 2727-UM002D-EN-P

Page 5

CE Thin Client Operating

Instructions

Windows CE Applications

Maintenance and Troubleshooting

Table of Contents iii

Chapter 6

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Starting Up/Powering On the Terminal . . . . . . . . . . . . . . . 6-1

Setting Auto Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Configuring Ethernet Network Settings. . . . . . . . . . . . . . . . 6-2

Saving Registry Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Starting Terminal Services . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Shutting Down/Powering Off the Terminal . . . . . . . . . . . . 6-5

Setting the Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Chapter 7

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

MobileView Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Generating Programs for Windows CE . . . . . . . . . . . . . . . . 7-2

Virtual Channel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Chapter 8

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Cleaning the MobileView Guard Terminal . . . . . . . . . . . . . 8-1

Handling the MobileView Guard Terminal . . . . . . . . . . . . . 8-2

Troubleshooting the Terminal . . . . . . . . . . . . . . . . . . . . . . 8-3

Providing Technical Support Information . . . . . . . . . . . . . . 8-4

Appendix A - Specifications

Appendix B - Security Considerations

Appendix C - Available Fonts for Terminal Applications

Index

Publication 2727-UM002D-EN-P

Page 6

Table of Contents iv

Publication 2727-UM002D-EN-P

Page 7

This preface provides information on:

• manual contents

• terminology

• intended audience

• intended uses

• European Communities (EC) Directive Compliance

• standards and agency certifications

• Rockwell Automation Support

Preface

Contents of Manual

This manual is organized as follows:

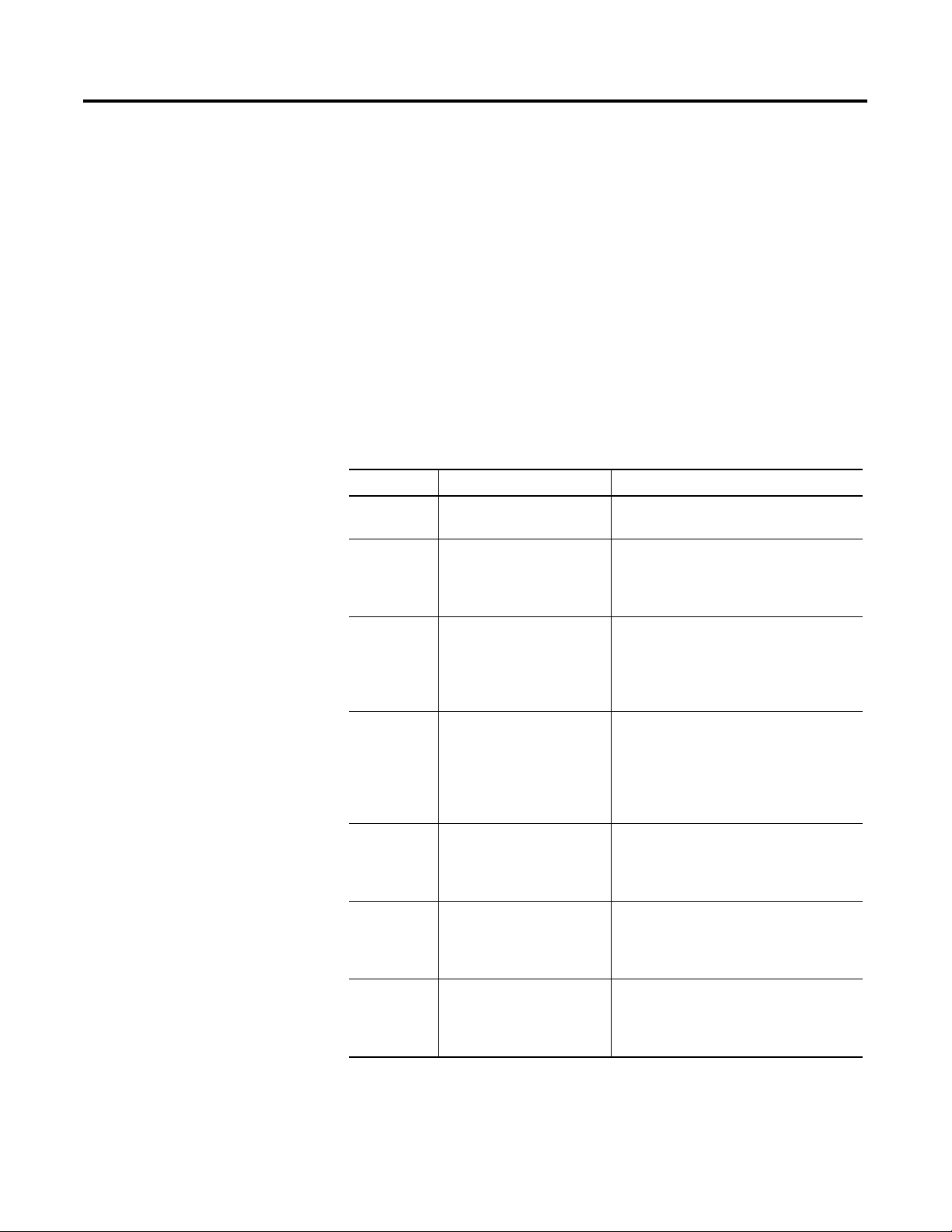

Chapter Title Description

1 Overview Gives a general overview of the

MobileView Guard G750 and its features.

2 Safety Precautions and

Elements

3 Terminal Connections Shows how to connect the MobileView

4 Configuring the MobileView

Terminal

5 CE Thin Client Operating

Instructions

6 Windows CE Applications Describes the Windows CE software

Describes safety precautions and safety

elements (enabling switch, emergency

stop switch) of the MobileView Guard

G750.

Guard G750 to the Junction Box, make

Ethernet, serial, and IrDA (keyboard and

printer) connections, use the PC Card slot,

and install the optional mounting bracket.

Provides details on how to use the

MobileView Configuration Tool to

calibrate operating elements. It also

provides details on how to transfer data

between the MobileView terminal and PC,

and install programs.

Gives instructions on how to start up,

configure Ethernet settings, and power off

the MobileView Guard. It also gives

details on how to start terminal services.

installed in the MobileView terminal,

generation of Windows CE programs, and

the MobileView Guard virtual channel.

7 Using RSView ME Station Describes the RSView ME Station

software installed in the MobileView

2727-G7P20D1Q6 and 2727-G7P20D3Q7

terminals.

1 Publication 2727-UM002D-EN-P

Page 8

Preface 2

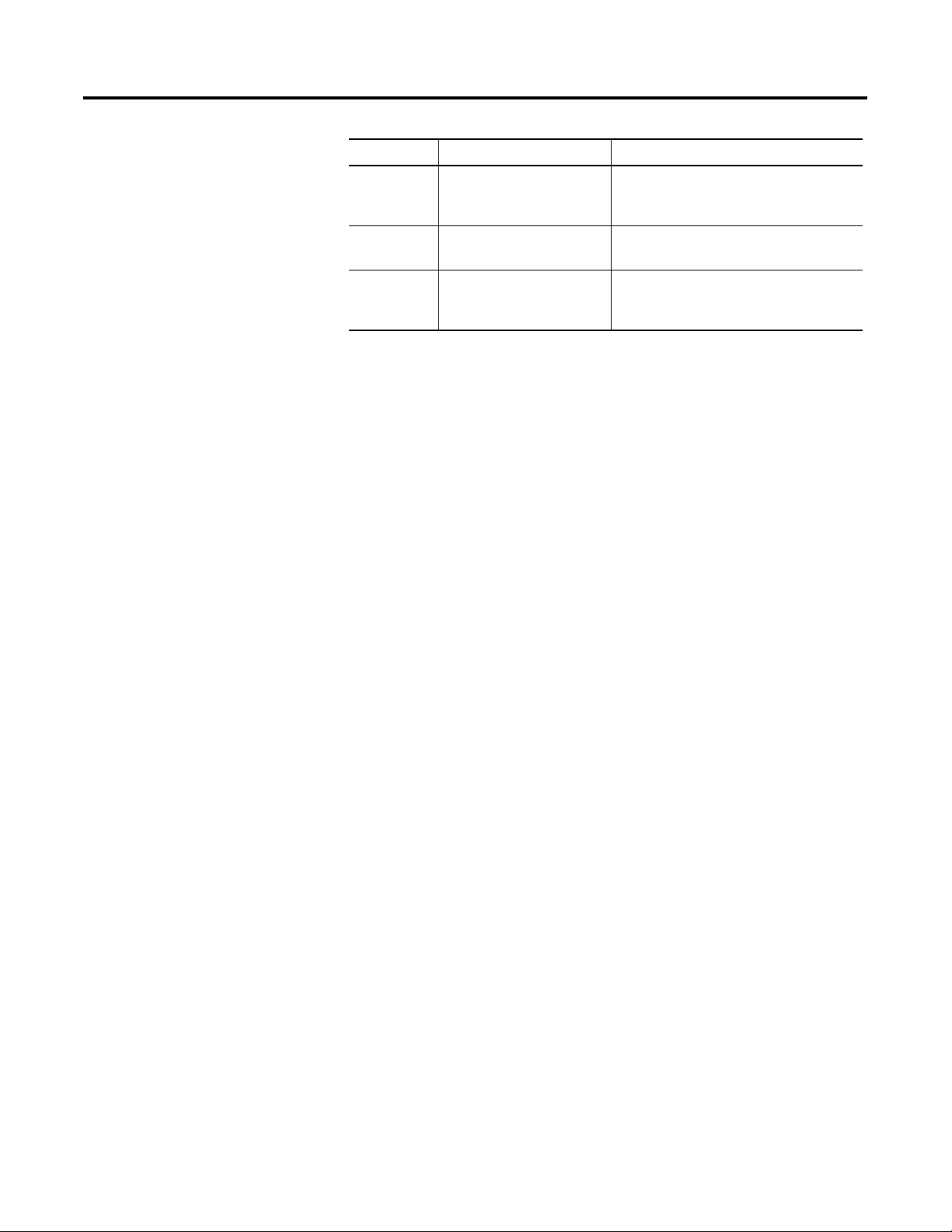

Chapter Title Description

8 Maintenance and

Troubleshooting

A Specifications Gives specifications for the MobileView

Provides information on cleaning, handling

and troubleshooting the MobileView

Guard G750 terminal.

Guard G750 terminal.

Terminology

Intended Audience

Intended Uses

B Available Fonts for Terminal

Applications

The MobileView Guard G750 is referred to as the MobileView terminal

throughout this manual.

This manual is for the individuals responsible for installing,

configuring, troubleshooting, and operating the MobileView Guard

G750 in an industrial environment.

The MobileView Guard G750 may only be used for the types of use

described in this manual. This terminal has been developed,

manufactured, tested and documented in accordance with ergonomic

guidelines and the appropriate safety standards. If you follow the

instructions and safety precautions relating to the intended use are

properly observed, the MobileView Guard G750 does not, under

normal circumstances, represent a danger to the health of personnel

or a risk of damage to other property or equipment.

Provides information on pre-installed fonts

and available fonts for download for the

MobileView terminals.

European Communities (EC) Directive Compliance

Publication 2727-UM002D-EN-P

Observe national regulations for disposing of electronic components.

The product has the CE mark and is approved for installation within

the European Union and EEA regions. It has been designed and tested

to meet the following directives. In addition, the device meets the

Council Directive 98/37/EC as a safety component.

Page 9

Preface 3

EMC Directive

This product is tested to meet the Council Directive 89/336/EC

Electromagnetic Compatibility (EMC) by applying the following

standards, in whole or in part, documented in a technical construction

file:

• EN 61000-6-4:2001 EMC - Generic Emission Standard, Part 2 -

Industrial Environment

• EN 61000-6-2:2001 EMC - Generic Immunity Standard, Part 2 -

Industrial Environment

• EN 61131-2 - Programmable Controllers Part 2 - Equipment

Requirement and Tests

This product is intended for use in an industrial environment.

Safety of Machinery Standards

The MobileView Guard G750 meets the following council directives:

• EN 954-1:1996 Safety-related parts of control systems

• EN 292-1:1991 - Basic concepts, general principles for design

• EN 292-2: 1991/A1:1995 - Technical principles and specifications

• EN418:1992 - Emergency stop equipment, function aspects, principles

of design

• EN 60204-1:1997 - Electrical equipment of machines, general

requirements

A Declaration of Conformity is available upon request.

Publication 2727-UM002D-EN-P

Page 10

Preface 4

Publication 2727-UM002D-EN-P

Page 11

Overview

Chapter

1

Chapter Objectives

Overview

This chapter covers the following topics:

• overview

• hardware description

• membrane keypad

• touch screen

• terminal configurations

• terminal accessories

The MobileView products are a family of human machine interface

devices with a rugged design and Windows-CE compatible

electronics. The MobileView Guard G750 is specifically designed for

safety applications with features, including:

• multiple 3-position enable switches

• emergency stop switch (option)

These features allow operator access to the machine’s safety system as

well as the general interface to its control system.

Using a high-performance Intel StrongARM processor and providing

an Ethernet interface, the MobileView Guard G750 is ideal for a

variety of applications including:

• operator panel for machines and plants

• teach and programming panel for robots

• test, maintenance, and startup

All tasks can be solved graphically and in color. Operation is intuitive,

using a touch screen with symbol-controlled sequences.

Instead of a floppy or hard disk drive, which are not suitable for harsh

environmental conditions, the MobileView Guard G750 uses scalable

FLASH and RAM banks. Functionality is easily expanded using PC

cards Type I, II, and III.

1 Publication 2727-UM002D-EN-P

Page 12

1-2 Overview

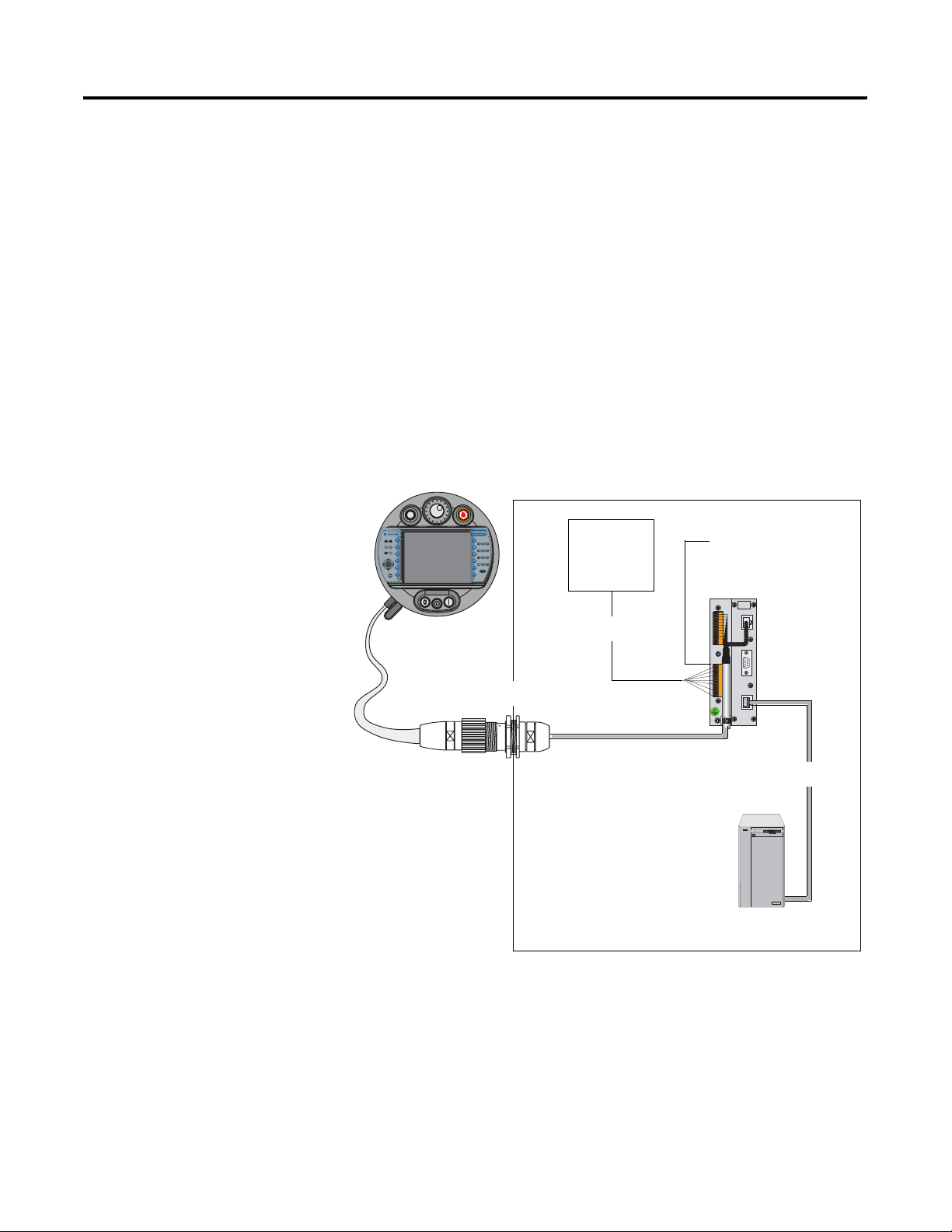

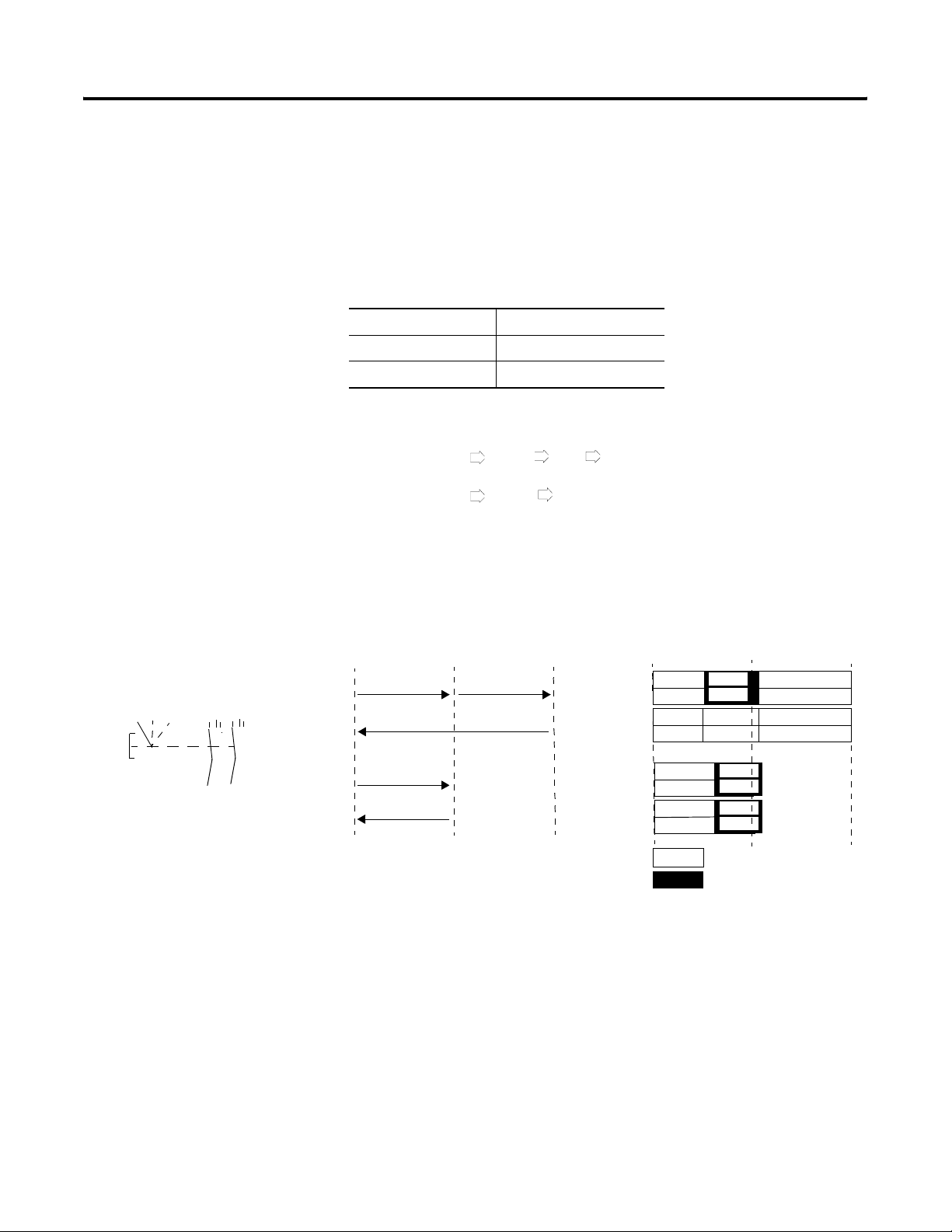

MobileView Guard Sample System Configuration

The MobileView Guard G750 connects as a client to a Windows NT or

Windows 2000 server. It also provides a Windows CE platform for

applications generated with common visualization tools, Visual Basic,

Visual C++, and the CE 4.x Software Developers Kits (SDK) included

on the product CD.

The MobileView Guard G750 Catalog Numbers 2727-G7P20D1Q6 and

2727-G7P20D3Q7 support RSView Machine Edition Software.

The MobileView Guard G750 easily adapts to specific applications

using configurable operating and control elements.

MobileView Guard Terminal

running as CE Thin Client and/or

Custom CE Applications

n

u

7 8 9

4 5

1 2 3

. 0 -

ESC

6

R

KETOP

5, 10, 15, 20 meter mobile

Connection Cable

Discrete/Ethernet

ror

r

E

Connection

Typical System Control Cabinet

PILZ PST 1

Safety Relay

Discrete

Connections

24V dc Power

MobileView

Junction Box

24V DC

ONLY

+24V

TERM INAL IN

GND

ES1+

ES1-

ES2+

ES2-

ED1+

ED1-

ED2+

ED2-

RS422 OUT

+24V

GND

ES1+

ES1-

ES2+

ES2-

ED1+

ED1-

ED2+

ED2-

ETHERNET OUT

Publication 2727-UM002D-EN-P

Ethernet

Connection

Local or Remote

Windows NT or 2000 Server

Page 13

Overview 1-3

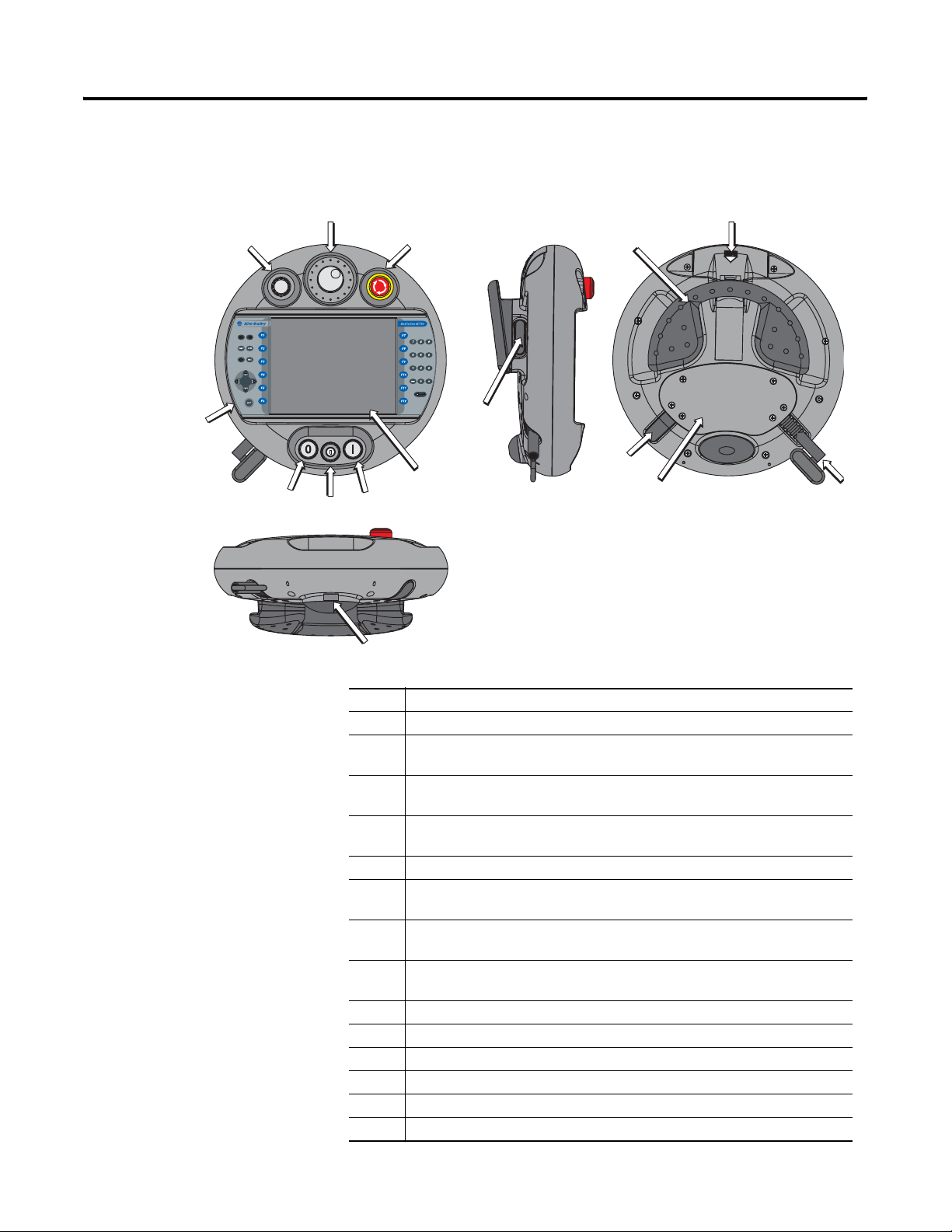

Hardware Description

1

4

The following illustration shows the location of key hardware

components.

2

3

9

8

5

7

6

11

15

14

12

13

10

1 Potentiometer with 0-127 linear resolution (option)

2 Electronic handwheel with 50 pulses/rev, -32768 to +32768 (option)

3 Emergency stop switch, twin-circuit, N/C contacts, 24V dc, 500mA max

(option)

4 Membrane keypad with tactile feedback - standard Windows keyboard

operation

5 Illuminated momentary push button, normally open, OFF marking, yellow LED

(option)

6 3-position key switch (option)

7 Illuminated momentary push button, normally open, ON marking, yellow LED

(option)

8 7.7 inch VGA (640 x 480 pixels) passive matrix color LCD display with analog

resistive touch screen

9 3-position, twin circuit, enabling switch (one each side of handle) for safety

interface

10 IrDA keyboard/printer interface, 9600 or 115.2K baud

11 Handle for left or right-hand operation

12 Single slot PC card interface for Type I, II and III cards (option)

13 Strain relief for connection cable (shipped with cable)

14 Back cover to connection compartment

15 Plug for cable outlet when not used (meets degree protection IP54)

Publication 2727-UM002D-EN-P

Page 14

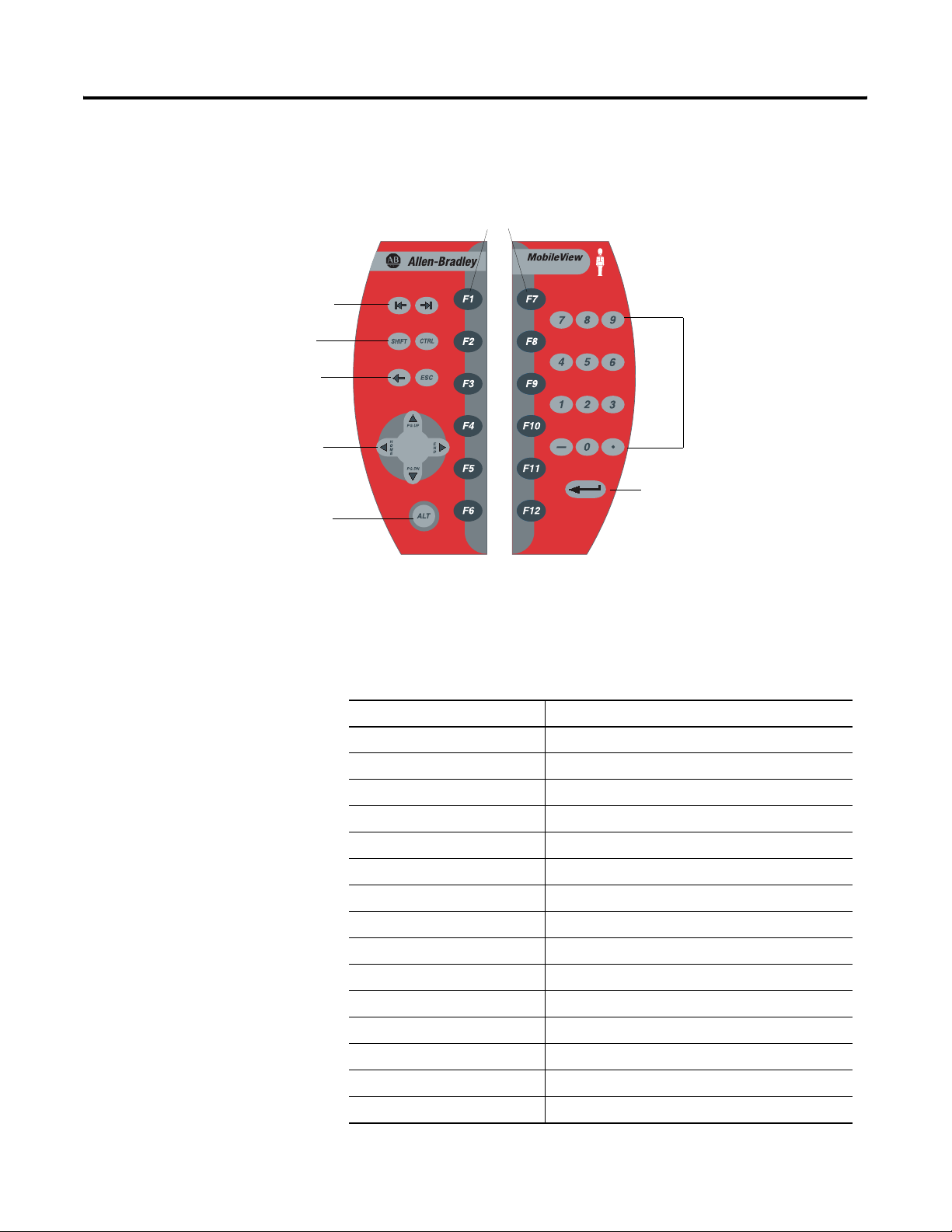

1-4 Overview

Membrane Keypad

Tab Left/Right Keys

Shift and Ctrl Keys

Backspace and Esc Key

Page Up/Down

Home/End

Alt Key

The MobileView terminal has a membrane keypad with stainless steel

dome switches for tactile feedback.

Function Keys

F1 - F12

Guard

G750

Numeric,

Period,

Minus

Keys

Enter Key

The keys on the keypad operate identically to a Windows PC

keyboard with the exception of Tab Left and the ALT-Arrow key

combinations. Most standard 2-key combinations are supported

including some 3-key combinations. The table below shows the

Windows virtual key codes for each key.

Keypad Key Windows Virtual Key Code

Numeric keys 0 - 9 VK_NUMPAD0 through VK_NUMPAD9

. (period) VK_DECIMAL

- (minus) VK_SUBRACT

Arrow (left/right/up/down) VK_LEFT/VK_RIGHT/VK_UP/VK_DOWN

Enter VK_RETURN

Backspace VK_BACK

ALT+Up arrow (PG UP) VK_PRIOR

ALT+Down arrow (PG DN) VK_NEXT

ALT+Left arrow (PG HOME) VK_HOME

ALT+Right arrow (PG END) VK_END

Tab Left key VK_LSHIFT+VK_TAB

Tab Right key VK_TAB

SHIFT key VK_LSHIFT

CTRL VK_LCONTROL

F1 - F12 function keys VK_F1 through VK_F12

Publication 2727-UM002D-EN-P

Page 15

Keypad Key Windows Virtual Key Code

ESC VK_ESCAPE

ALT key VK_MENU

Options:

Illuminated push button, left

Key switch, left

Key switch, right

Illuminated push button, right

VK_F13

VK_F14

VK_F15

VK_F16

Overview 1-5

Touch Screen

The touch screen is calibrated before shipment. No further calibration

is required.

ATTENTION

Do not use a sharp object, such as a screw driver to

operate the touch screen. Using sharp objects may

damage the touch screen.

!

Publication 2727-UM002D-EN-P

Page 16

1-6 Overview

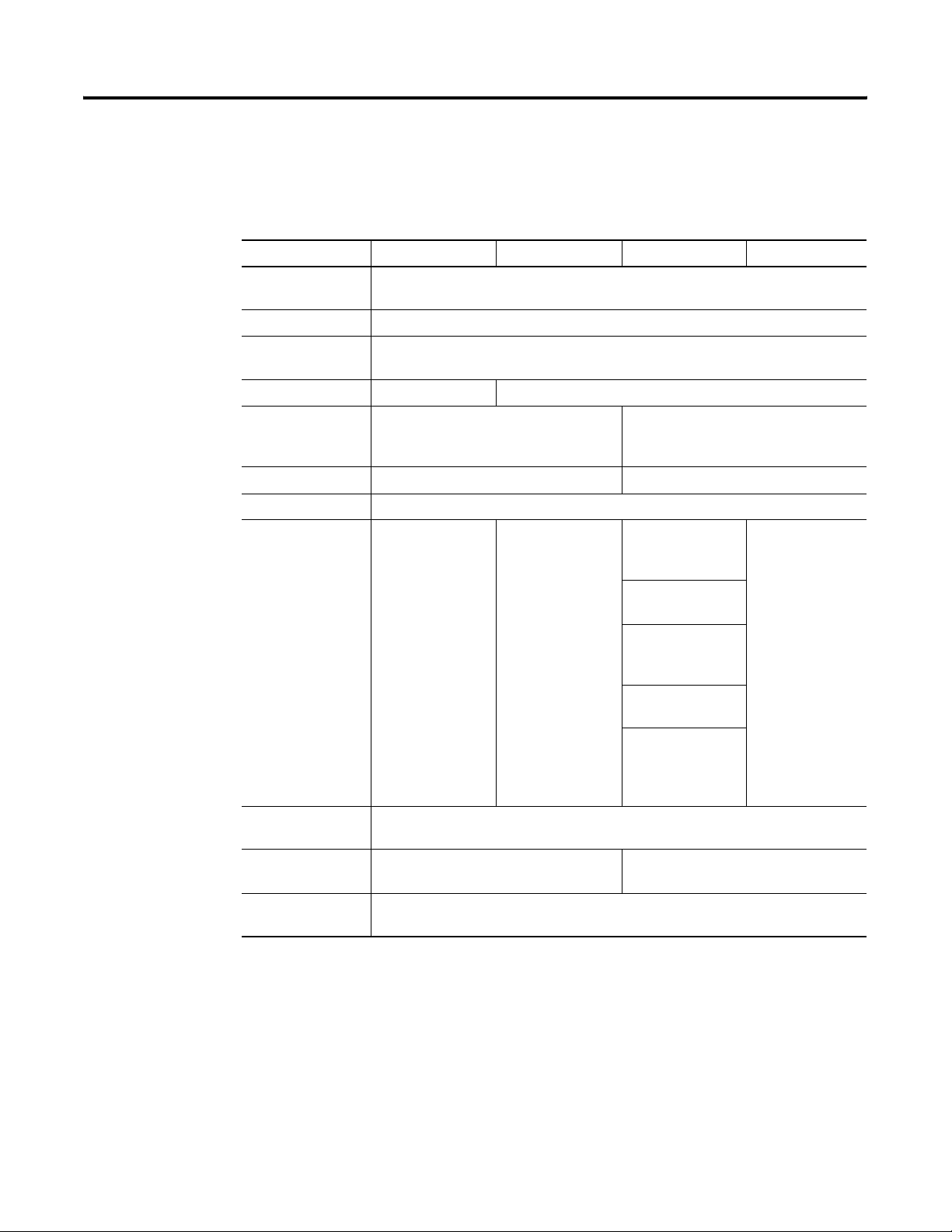

MobileView Guard Configurations

Features 2727-G7P20D1P4 2727-G7P20D1P5 2727-G7P20D1Q6 2727-G7P20D3Q7

7.7 Inch VGA

Display

IrDA Interface Yes

3-Position Enable

Switch

2-Circuit E-Stop No Yes

Memory 16MB RAM

PC Card Slot No Yes

Communications 10Base-T Ethernet

Operating

Elements

The MobileView Guard terminal is available in 4 configurations. The

table below lists each configuration by catalog number and the

included features.

Yes

Yes

64MB RAM

32MB Flash

Push Button with

OFF Marking Position 5

Key Switch Position 6

64MB Flash

Windows CE

Operating System

RSView Machine

Edition

Thin Client

Application

No No

No

Push Button with

ON marking Position 7

Potentiometer Position 1

Electronic

Handwheel -

Position 2

Yes

Yes

No

Yes

Publication 2727-UM002D-EN-P

Page 17

Overview 1-7

MobileView Guard

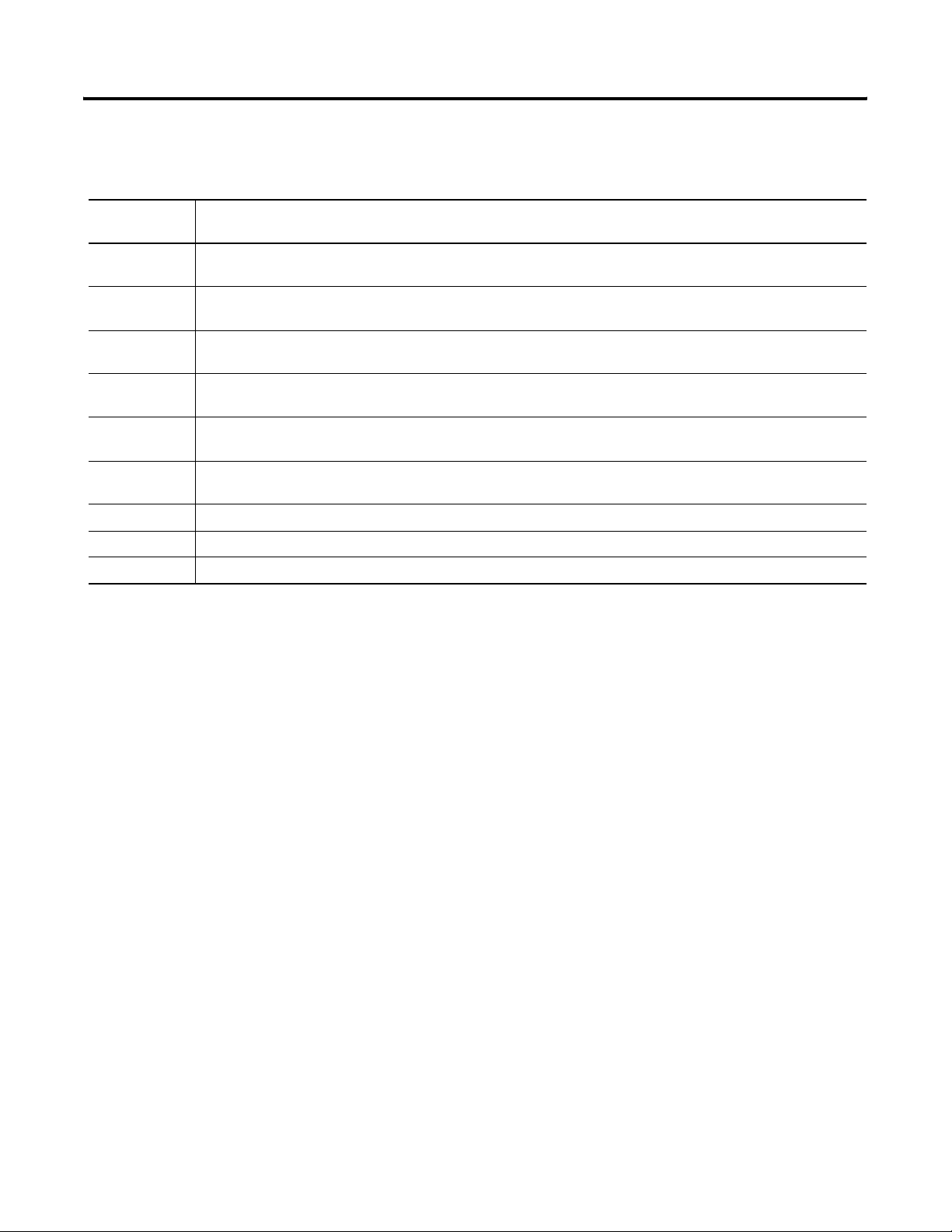

The following accessories are available for the MobileView terminal.

Accessories

Catalog

Number

2727-MRT5 MobileView Guard Connection Cable (5 meter /16.4 ft) - connects the MobileView Guard terminal to the Junction Box

2727-MRT10 MobileView Guard Connection Cable (10 meter /32.8 ft) - connects the MobileView Guard terminal to the Junction

2727-MRT15 MobileView Guard Connection Cable (15 meter /49.2 ft) - connects the MobileView Guard terminal to the Junction

2727-MRT20 MobileView Guard Connection Cable (20 meter/65.6 ft) - connects the Mobileview Guard terminal to the Junction Box

2727-MRJB1 MobileView Guard Junction Box - provides controller, Ethernet, power supply, emergency stop switch, and enabling

2727-MREX1 MobileView Guard Junction Box Cable (2 meter / 6.5 ft) - connects the MobileView Guard Connection Cable to the

2727-MRC1 MobileView Download Cable (4 meter /13.1 ft) - connects between the MobileView Guard terminal to a PC.

2727-MRMB1 MobileView Guard Mounting Bracket for stationary operation or storing the MobileView Guard terminal.

2727-MRSDK1 MobileView Guard SDK file set for WIndows CE development.

Description

Cable.

Box Cable

Box Cable.

cable.

switch connections.

Junction Box.

Publication 2727-UM002D-EN-P

Page 18

1-8 Overview

Publication 2727-UM002D-EN-P

Page 19

Safety Precautions and Elements

Chapter

2

Chapter Objectives

General Safety

This chapter provides information on general safety precautions in

addition to important information on:

• power supply

• enabling switches

• emergency stop switch

• handling of the MobileView terminal

The MobileView Guard G750 may only be used for the types of use

described in this manual. The MobileView Guard G750 has been

developed, manufactured, tested and documented in accordance with

ergonomic guidelines and the appropriate safety standards.

When disposal of MobileView terminals is required, please observe

the national regulations for disposing electronic components.

It is important to follow the instructions in this manual in all

circumstances. Failure to do so could result in potential sources of

danger or the defeating of safety features integrated in the terminal.

In addition to the safety instructions in this manual, you must also use

safety precautions and accident prevention measures appropriate to

the situation.

1 Publication 2727-UM002D-EN-P

Page 20

2-2 Safety Precautions and Elements

ATTENTION

!

• Make sure interrupted processes can be properly

restarted after power failures or power dips. No

dangerous operating conditions must be allowed

to occur, even temporarily.

• In situations where faults occurring within the

automation system could cause personal injury or

significant damage to machinery and equipment,

take additional external safety measures to ensure

the system remains in a safe operating condition.

• Make sure unauthorized persons are not allowed

to adjust settings or make memory modifications

that could lead to dangerous situations.

• Test the functionality of safety-related parts

(E-stop and enabling switches) on a regular basis.

• If the MobileView terminal and controller do not

communicate using a point-to-point connection,

keypad data, for example, may transmit with a

delay. Use of an Ethernet switch between the

MobileView terminal and controller is

recommended for a higher speed connection.

• Test safety-relevant parts after strong shocks to

the terminal (for example, if terminal is dropped

on ground).

• When the MobileView terminal is used to operate

the machine/plant, ensure that the MobileView is

the single point of operation (C.F. ANSI/RAI

15.06).

• If you use a PC card with the MobileView, always

make sure the PC card is properly loaded. After a

strong impact, the PC card cover remains closed.

Verify the card is properly loaded to maintain a

good electrical contact.

• When the MobileView is used in manual mode

(for example, teaching of robot), ensure the robot

moves at a slower speed (C.F. ANSI/RAI 15.06).

Publication 2727-UM002D-EN-P

Page 21

Power Supply

ATTENTION

!

Safety Precautions and Elements 2-3

• The device meets the safety class III in

accordance with EN 61131-2 and EN 50178. The

24V power supply for the equipment must

provide appropriate isolation between the

safety-extra-low-voltage circuits and

dangerous-contact voltage circuits (for example,

by safety transformers or similar facilities).

• The power supply circuit must be protected with

a 3.15 A fuse.

• The nominal supply voltage of the MobileView

terminal (without MobileView Connection Cable)

is 24V dc (supply voltage range: 18-32V dc).

• Typical current consumption is:

- 300 mA at 24V dc

- 400mA at 18V dc

• When planning the power supply, consider the

voltage drop in the connection cable.

Specifications of power supply lines in the

connection cable are:

- Cross section: AWG24 (0.24mm2)

- Material: zinc-coated copper strand

- Line resistance: <90 Ohm/km (<145 Ohm/mile)

Enabling Switches

The enabling switches are in accordance with EN 60204-1 in safety

categories according to EN 954-1 (Safety related parts of control

system). There are two parallel switched, potential-free, normally

open contacts for connecting external peripherals, nominal voltage

24V dc (safety-extra-low voltage in accordance with EN 61131-2 and

EN 50178), typical current 500 mA dc.

The electronic enabling switch realizes the enabling equipment as a

safety function for machines in special operating modes. The enabling

switch is part of the MobileView terminal.

Each machine features a normal operating mode and a special

operating mode.

• In normal operating mode, guards and/or operative protection

devices are used to prevent access and guarantee safety. Special

operating modes are used to maintain the normal operating

mode.

Publication 2727-UM002D-EN-P

Page 22

2-4 Safety Precautions and Elements

• In special operating mode, safety must be guaranteed in other

ways since the operator must enter dangerous areas of the

machine, and targeted movements must be possible. In this

case, a reduced speed of the machine must be defined by means

of the risk assessment. A movement will only be possible if an

enabling device is actuated. The user must be trained and must

know the details of the intended use. The safety related parts of

the control for reducing speed and for the enabling device must

be constructed so that they meet the safety category 3 according

to EN 954-1, defined by the risk assessment.

To meet safety category 3 in accordance with EN 954-1, the enabling

switch must be implemented with 2 circuits.

EN 60204-1 describes the functioning of the enabling device. Due to

the latest findings of analysis of accidents and since technical solutions

are available, the 3-position enabling switch became state of the art.

The positions 1 and 3 of the enabling switch are OFF functions. Only

the central position is used for enabling. The EN 60204-1 is identical

with IEC 60204-1. So the 3-position enabling switch is of international

relevance.

The enabling switch consists of a 3-position operating element and

separated evaluation electronics. Essential features are continuous

two-channel circuits between the actuating elements and the

connecting terminals. For the evaluation circuits, different

technologies and circuits are used. Because of the electronic switching

contacts, their lifetime does not depend on the load as long as the

nominal values of the load (ohmic, inductive and capacitive) are not

exceeded.

ATTENTION

!

• Enabling switches may only be used if the

operator activating the switch recognizes the

dangerous situation in time to take immediate

action if necessary.

• The enabling switch is only used to enable

commands for performing dangerous

movements. The commands must be activated by

a separate operating element (key on terminal).

Only persons allowed to activate the enabling

switch are allowed to work in the dangerous

area.

• On the MobileView Guard terminal, the enabling

switches always feature 2 circuits.

Publication 2727-UM002D-EN-P

Page 23

Safety Precautions and Elements 2-5

Enabling Switch Operation

The actuating element consists of two symmetrically arranged slides.

The position of these slides is detected by electrical switches and

transmitted to the evaluation electronics.

Positions of Enabling Switch

Home Position (1) enabling outputs are open

Enabling (2) enabling outputs are closed

Panic (3) enabling outputs are open

For the enabling switch, the following switch sequences are possible:

A. Home position enabling panic home position (1-2-3-1)

B. Home position enabling home position (1-2-1)

x

x

u v

y

The pushing of the actuating elements directly into the panic position

is evaluated in a way that the enabling position is skipped when the

actuating elements are released.

Contact Travel Diagram

123

2

2

3

3

1

1

ZT1, ZT2

a)

ZT1, ZT2

ZT1, ZT2

b)

ZT1, ZT2

x

v

x

y

u

b)

123

Circuit 1

ZT1

Circuit 2

ZT2

a)

ZT1

ZT2

ZT1

ZT2

ZT1

ZT2

Circuit 1

Circuit 2

Circuit 1

Circuit 2

Circuit 1

Circuit 2

Circuit 1

Circuit 2

Circuit 1

Circuit 2

Circuit 1

Circuit 2

Circuit 1

Circuit 2

Circuit 1

Circuit 2

Circuit 1

Circuit 2

Circuit X = open

Circuit X = closed

Publication 2727-UM002D-EN-P

Page 24

2-6 Safety Precautions and Elements

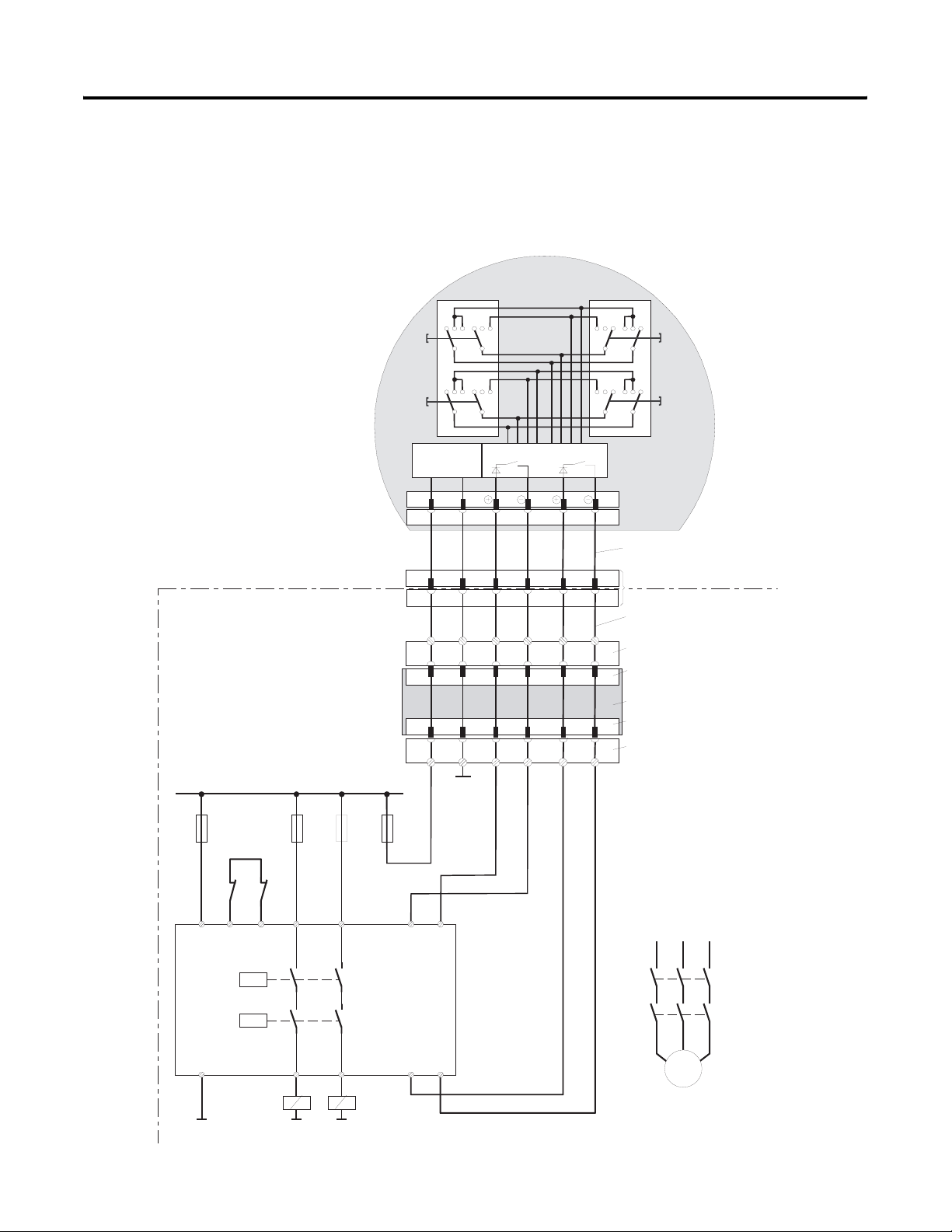

Connection Example with a Safety Control Relay

The diagram below shows suggested wiring for enabling switches

using a PILZ PST safety control relay to meet safety category 3. Refer

to PILZ PST documentation for additional information.

MobileView

(2 enabling switches with

3 positions and 2 circuits each)

123 123 321 321

ZT1

L

123 123 321 321

ZT2

L

ZT1

ZT2

R

R

Control cabinet

+24 VD C

F1

1A

Feedback

contro l loop

KA KB

4A(t)

6A(f)

S19:

K3:

DC/DC

converter

67

67

Evaluation electronics

C ircuit 1 Circu it 2

12 34

12 34

ZTxy ....... enabling switch x

y

Connection cable

MobileView

K1:

7 8 12 17K1: 1 2

7 8 12 1712

17-pin

coinvers jack

Intermediate cable

MobileView

+24V GND ED1+ ED1- ED2+ ED2-

K3:

X1

Terminal block socket K3 on

connection box

Male connector X1 on

connection box

Connection box

X2

+24V GND ED1+ ED1- ED2+ ED2-K4:

GND

F2

F3

4A(t)

or

6A(f)

F4

3,15A

or

Male connector X2 on

connection box

Terminal block socket K4 on

connection box

X1 X2

A1(+) 2 3 S11

K1

PILZ

PST1

K2

A2(-)

GND

Publication 2727-UM002D-EN-P

13

14 24 S23 S24

KA KB

GND GND

S12

L1 L2 L3

KA

Enabling of dangerous

movement

KB

M

Note: All contacts of KA and KB must be forced-guided!

Page 25

Safety Precautions and Elements 2-7

• Only if both channels of ZTL or ZTR are activated

“simultaneously” will both output relays K1 and K2 energize and

the output contacts 13-14 and 23-24 close.

• The output relays K1 and K2 will not energize if:

– only one enabling channel is activated,

– the tolerance value for the simultaneity period is exceeded,

– the feedback control loop X1-X2 is open.

• If one enabling channel is released after being simultaneously

activated, the output relays K1 and K2 will return to their initial

position. The forced-guided output contacts 13-14 and 23-24 will

open. The output relays will only energize again after both

enabling channels have been released and operate

simultaneously again.

In this way, the enabling switches avoid that one single error making

the safety function inoperable. A single error will be recognized at the

next cycle at the latest.

Switching Element Data

Nominal voltage 24V dc (typical)

32V dc (maximum)

Nominal current 500 mA (typical)

Short-circuit current circuit 1; maximum 1.9 A

circuit 2: maximum 600 mA

Max. inductive load (at 500 mA) circuit 1: >1H

circuit 2: maximum 320 mH

Max. capacitive load circuit 1: no limit since the transistor is

protected thermally

circuit 2: maximum 500 µF

The switching elements of the enabling switches are protected against

reversed polarity. The outputs of both circuits are protected against

short circuits and excess load.

• Circuit 1: thermal protective circuit

• Circuit 2: fold back protective circuit

Publication 2727-UM002D-EN-P

Page 26

2-8 Safety Precautions and Elements

Foreseeable Misuse of the Enabling Switch

Foreseeable misuse means not allowing the enabling switch to be

fixed in the enabling position. Misuse of the enabling switch must be

restricted. The following measures are recommended, which cause

the machine to stop in manual mode.

• Inquiry of the enabling switch when turning on the

machine/plant and inquiry of the enabling switch when

changing the operating mode from automatic to manual. (The

enabling switch must not be in the enabling position.)

• The enabling switch must be released within a defined period of

time and pushed into the enabling position again. The length of

time must be defined according to the activity.

Emergency Stop Switch

The emergency stop switch of the MobileView terminal meets the

requirements of EN 418. It must be designed as an emergency stop of

category 0 or category 1 (see EN 60204-1, chapter 9.2.5.4.2) on the

basis of the risk assessment for the machine. The connection of the

force-guided contacts to an appropriate monitoring system must meet

the safety category which is defined by means of the risk assessment

(in accordance with EN 954-1) of the machine.

The emergency stop has 2, potential-free, normally closed contacts for

connecting external peripherals, a nominal operating voltage of 24V

(Safety Extra Low Voltage in accordance with EN 61131-2 and EN

50178), and a maximum operating current of 500 mA.

ATTENTION

!

• When the emergency stop switch is not wired

into the emergency stop circuit, the MobileView

terminal must be stored where it is not available

to operators.

Consider that the operator might activate the

nearest emergency stop in case of danger. This

could have fatal consequences if the emergency

stop does not function.

• Emergency stop functions must remain

operational in all operating modes. Resetting an

activated emergency stop must not result in

uncontrolled startup of machines or installations.

• The emergency stop switch does not replace

other safety devices.

Publication 2727-UM002D-EN-P

Page 27

Safety Precautions and Elements 2-9

Risk Assessment of Machinery

For the risk assessment, the following standards must be applied:

• EN 292-1 “General principles for design of machinery”

• EN 1050 “Principles for risk assessment of machinery”

• EN 954-1“Safety-related parts of control systems”

• ANSI/RIA 15.06-1999 “For Industrial Robots and Robot Systems -

Safety Requirements (Section 9)

• ANSI B11.TR3-2000 “Risk Assessment and Risk Reduction - A

guide to estimate, evaluate and reduce risks associated with

machine tools”

The safety categories (B, 1, 2, 3, 4) define the structure of

safety-related parts of a machine and are derived from this risk

assessment.

Page 2-6 shows how the MobileView terminal meets safety category 3

using a PILZ PST1 safety control relay with the enabling switches. The

entire control system must be designed according to the principles of

safety category 3.

Handling of the MobileView Terminal

The MobileView terminal is a high-quality device that is equipped

with state-of-the-art electronics.

To avoid malfunctions or damage through improper handling, follow

these instructions during operation.

Publication 2727-UM002D-EN-P

Page 28

2-10 Safety Precautions and Elements

ATTENTION

!

• Do not operate the terminal if the cable is

damaged or pinched. To avoid damaging the

cable, do not place the cable over or around

sharp objects.

• When the terminal is not in use, hang the

terminal in the mounting bracket or place inside

a cabinet or enclosure.

• To avoid dropping the terminal, do not set the

terminal on unstable surfaces and keep the cable

clear of high traffic areas.

• To avoid damaging the operating elements, do

not set the terminal on its operating side.

• If the terminal falls to the ground, test the

emergency stop switch and enabling switch, and

verify that the PC card cover closes properly

before operating machine/plant.

• Do not set the terminal near heat sources and

avoid direct sunlight.

• Avoid exposing the terminal to mechanical

vibrations, excessive dust, humidity or strong

magnetic fields.

• Use a soft, damp cloth with 50% water and 50%

isopropyl alcohol to clean the operating panel

and operating elements. Do not use solvents,

scouring agents, or scrubbing sponges.

• Prevent foreign objects or liquids from getting

into the terminal. Check the protective covers of

the device regularly. Make sure all screws are

firmly tightened and that the housing and cable

entrance is not damaged.

• Turn off the power supply before removing the

back cover of the MobileView terminal. When the

back cover is removed, the terminal is sensitive to

electrostatic discharge (ESD).

• If the terminal exhibits any defect, have the unit

thoroughly and fully tested by the manufacturer

or authorized repair dealer before operating

terminal again.

• Do not use sharp objects, such as a screw driver,

on the touch screen. Sharp objects may damage

screen.

Publication 2727-UM002D-EN-P

Page 29

Terminal Connections

Chapter

3

Chapter Objectives

This chapter shows how to connect devices to the MobileView

terminal, including:

• mounting and connecting the MobileView Junction Box

• accessing and wiring the MobileView connection compartment

• connecting a computer using the RS-232 Port

• making an Ethernet connection

• using the PC card slot

• connecting a keyboard/printer using the IrDA interface

• installing the MobileView Mounting Bracket

1 Publication 2727-UM002D-EN-P

Page 30

3-2 Terminal Connections

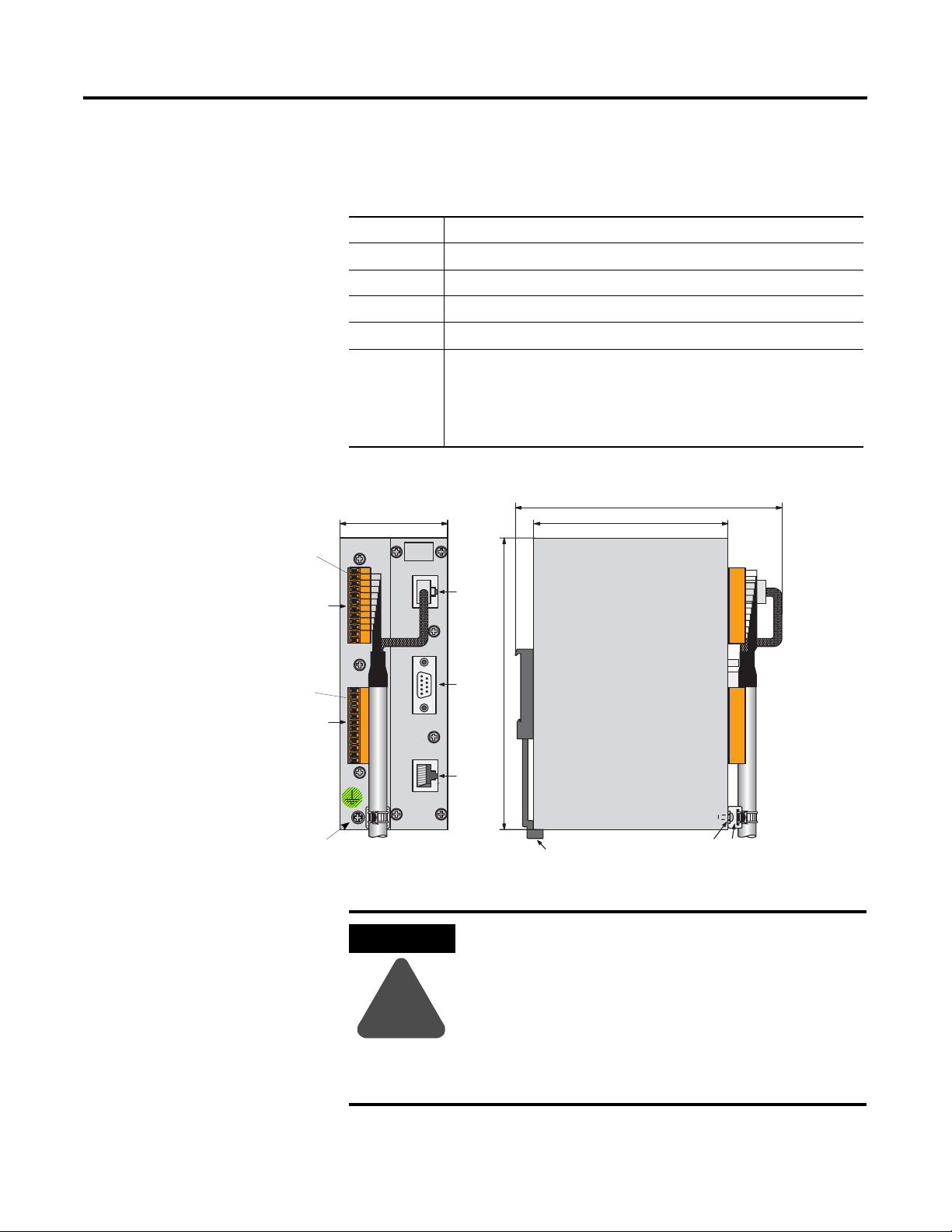

Mounting and Connecting the Junction Box

Pin 1, 24V dc

X1

(with Female

Terminal Block

Connector K3)

Pin 1, 24V dc

X2

(with Female

Terminal Block

Connector K4)

The MobileView Junction Box (2727-MRJB1) integrates the

MobileView terminal into the control system. It mounts on a DIN rail

inside an enclosure and has the following connectors:

Connectors Description

S1 RJ-45 jack for connecting the MobileView data lines.

S2 9-pin DSUB female connector (for future use).

S3 RJ-45 jack to Ethernet network.

X1 12-pin male connector for connecting the Junction Box Cable.

X2 12-pin male connector (shipped with a female terminal block connector)

for connecting the:

• 24V dc power supply

• emergency stop switch

• enabling switches

Junction Box

60 mm (2.36 in)

+24V

GND

ES1+

ES1-

ES2+

ES2-

ED1+

ED1-

ED2+

ED2-

+24V

GND

ES1+

ES1-

ES2+

ES2-

ED1+

ED1-

ED2+

ED2-

24V DC

ON LY

TER M INAL IN

RS 422 OUT

ETHERNET OUT

S1

S2

162 mm (6.4 in.)

S3

150 mm (5.91 in)

108 mm (4.25 in)

Publication 2727-UM002D-EN-P

Grounding Screw

ATTENTION

!

DIN Rail Latch

Grounding Screw

Strain Relief

for Cable

The MobileView Junction Box and the MobileView

terminal meet the safety class III in accordance with

EN 61131-2 and EN 50178.

When connecting the terminal, make sure all

voltages connected to the MobileView terminal are

safety extra low voltages and isolated from the low

voltage supply system by a safety transformer or a

similar safety component.

Page 31

Terminal Connections 3-3

DIN Rail Mounting

Mount the MobileView Junction Box inside an enclosure using a DIN

rail (not shipped with terminal).

To install the Junction Box on a DIN rail:

1. Mount the DIN rail.

2. Hook the top slot over the DIN rail.

3. While pressing the Junction Box against the DIN rail, snap the

Junction Box into position.

To remove the Junction Box from the DIN rail:

1. Place a screwdriver in the DIN rail latch at the bottom of the

Junction Box.

2. Holding the Junction Box, pry downward on the latch until the

Junction Box is released from the DIN rail.

Publication 2727-UM002D-EN-P

Page 32

3-4 Terminal Connections

Connecting the MobileView to the Junction Box

MobileView Terminal

ESC

7 8 9

5 6

4

3

1 2

.

-

0

un

R

KETOP

Dust Cover

Control Cabinet

Pin 1, 24V dc

r

o

r

Er

MobileView

Terminal Connections

Pin 1, 24V dc

X2/K4

Safety Equipment

Connections

MobileView Junction Box

+24V

GND

X1/K3

ES1+

ES1-

ES2+

ES2-

ED1+

ED1-

ED2+

ED2-

+24V

GND

ES1+

ES1-

ES2+

ES2-

ED1+

ED1-

ED2+

ED2-

24V DC

ONLY

TERMINAL IN

RS422 OUT

ETHERNET OUT

S1

S2

S3

maximum wall

thickness 5 mm (0.2 in)

Junction Box Cable

2 meter (6.5 ft)

Use Grounding Screw

to connect Earth

10 Base-T Connection

to Ethernet Network

Ground to Junction Box.

Junction Box Cable

Tie Wi re

24 mm

(0.94 in)

25 mm (±0.1)

±0.0039)

(0.98 in

130mm (5.12 in)

Connection Cable

Cable Clearance on both sides of Enclosure Wall

100 mm (3.94 in)

K1

Connection

Junction Box Cable

Publication 2727-UM002D-EN-P

Page 33

MobileView

S19

Junction Box Pinout and Wiring

K3

6

7

8

9

10

11

1

2

3

4

5

MobileView

Connection Cable

pink

black

green-brown

white-green

grey-pink

red-blue

brown

yellow

green

grey

violet

Junction Box

K1

1

2

3

4

5

6

7

8

12

17

11

9

10

Cable

pink

black

green-brown

white-green

grey-pink

red-blue

brown

yellow

green

grey

violet

Terminal Connections 3-5

MobileView

Junction Box

K4

X1

K3

1

24V dc

2

GND_IN

E-Stop, circuit 1, pos.

3

4

E-Stop, circuit 1, neg.

5

E-Stop, circuit 2, pos.

6

E-Stop, circuit 2, neg.

7

Enabling Sw. circuit 1, pos.

8

Enabling Sw. circuit 1, neg.

9

Enabling Sw. circuit 2, pos.

10

Enabling Sw. circuit 2, neg.

Not Used

11

Not Used

12

X2

+24V

1

2

GND

ES1+

3

4

ES1-

5

ES2+

6

ES2-

7

ED1+

8

ED1-

9

ED2+

10

ED2-

11

12

S4

K2

1

2

3

6

blue

white

orange

red

13

14

15

16

blue

white

orange

red

K2

S1

1

2

3

4

5

6

7

8

S2

1

2

3

4

Future Use

5

6

7

8

9

S3

1

TD+

2

TD-

3

RD+

4

To Ethernet Network

RD-

5

6

7

8

Publication 2727-UM002D-EN-P

Page 34

3-6 Terminal Connections

Power Supply Requirements

Electrical Specifications

24V dc Power Supply Use a 24V dc Safety Extra Low Voltage power

supply.

Supply Voltage Range: 18V dc to 32V dc

Current Consumption: 300mA at 24V dc

Peak Inrush Current: 5.6 A maximum

Grounding Connect Earth Ground to the Junction Box using

the Earth Ground Screw (shown on previous

page 3-4).

ATTENTION

!

• The device meets the safety class III in

accordance with EN 61131-2 and EN 50178. The

24V power supply for the equipment must

provide appropriate isolation between the

safety-extra-low-voltage circuits and

dangerous-contact voltage circuits (for example,

by safety transformers or similar facilities).

• The power supply circuit must be protected with

a 3.15 A fuse.

• The nominal supply voltage of the MobileView

terminal (without MobileView Connection Cable)

is 24V dc (supply voltage range: 18-32V dc) with

a typical input current of 300 mA.

When planning the power supply, consider the

voltage drop in the connection cable.

Specifications of power supply lines in the

connection cable are:

- Cross section: AWG24 (0.24mm

- Material: zinc-coated copper strand

- Line resistance:

<90 Ohm/km (<145 Ohm/mile)

2

)

Publication 2727-UM002D-EN-P

Page 35

Terminal Connections 3-7

MobileView Connection Cable

The Mobile Connection Cable (2727-MRTxx) connects the MobileView

terminal to the MobileView Junction Box Cable (2727-MREX1). The

Connection Cable is 5, 10, 15, or 20 meters (6.4, 32.8, 49.2 or 65.6 ft).

This cable withstands water, cleaning agents, motor oil, drilling oils,

grease, lubricants and condensates containing hydrochloric acid.

K1

17-pin Circular

Connector Pin #

MobileView

Connection Cable

Wire Color

1pink

2black

3 green-brown

4 white-green

5 grey-pink

6 red-blue

7brown

8yellow

12 green

17 grey

9 bridge to pin 10

10 bridge to pin 9

11 violet

13 blue

14 white

15 orange

16 red

K3, 11-pin Female

-->>

-->>

-->>

-->>

-->>

-->>

-->>

-->>

-->>

-->>

-->>

-->>

-->>

-->>

-->>

-->>

-->>

Connector

to S19 in

Ter mi na l

RJ-45 Jack

Ethernet to S4 in

Ter mi na l

Signal

Description

6 - 24V DC

7 - GND_IN

8 - E-stop, circuit 1, positive

9 - E-stop, circuit 1, negative

10 - E-stop, circuit 2, positive

11 - E-stop, circuit 2, negative

1 - enabling switch, circuit 1, positive

2 - enabling switch, circuit 1, negative

3 - enabling switch, circuit 2, positive

4 - enabling switch, circuit 2, negative

- - not used

- - not used

5 - not used

- 1 TD+ (transmit)

- 2 TD- (transmit)

- 3 RD+ (receive)

- 6 RD- (receive)

K2, 8-pin

K3, 11-pin

female connector

to S19 at MobileView terminal

K2, 8-pin

RJ-45 jack to S4

at MobileView

terminal

K1, 17-pin circular connector

view from connector side

9

8

5, 10, 15, or 20 meter (6.4, 32.8, 49.2, or 65.6 ft)

Publication 2727-UM002D-EN-P

11

10

1

2

12

16

7

13

17

15

6

3

14

4

5

Page 36

3-8 Terminal Connections

MobileView Junction Box Cable

The MobileView Junction Box Cable (2727-MREX1) connects the

Junction Box to the circular jack in the wall of the enclosure. The

cable length is 2 meters (6.5 ft.). When the MobileView terminal is not

connected to the Junction Box, the dust cover provides protection for

the 17-pin connector.

K1, 17-pin

Circular Jack

Pin #

MobileView

Junction Box Cable

Wire Color

K2, 8-pin

RJ-45 Jack

to S1 at

Junction Box

K3, 12-pin

Terminal Block

to X1 at

Junction Box

1pink--> - 1 24V DC

2black

3 green-brown

4 white-green

5 grey-pink

6 red-blue

7brown

8yellow

12 green

17 grey

9-

10 -

11 violet

13 blue

14 white

15 orange

16 red

--> - 2 GND_IN

--> - 3 E-stop, circuit 1, positive

--> - 4 E-stop, circuit 1, negative

--> - 5 E-stop, circuit 2, positive

--> - 6 E-stop, circuit 2, negative

--> - 7 enabling switch, circuit 1, positive

--> - 8 enabling switch, circuit 1, negative

--> - 9 enabling switch, circuit 2, positive

--> - 10 enabling switch, circuit 2, negative

--> - not used

--> - 12 not used

--> - 11 not used

--> 1 - TD+ (transmit)

--> 2 - TD- (transmit)

--> 3 - RD+ (receive)

--> 6 - RD- (receive)

Signal

Description

K3, 12-pin connector

for terminal block X1

at Junction Box

K2, 8-pin RJ-45 jack

Ethernet for S1

at Junction Box

Publication 2727-UM002D-EN-P

2 meter (6.5 ft)

K1, 17-pin circular jack

view from connector side

1

11

2

12

10

16

13

3

14

4

5

9

17

15

8

7

6

K1, 17-pin circular jack

mounts to enclosure

Dust Cover

Page 37

Terminal Connections 3-9

Accessing/Wiring the MobileView Connection Compartment

Removing the Back Cover

This section shows how to remove the back cover of the MobileView

terminal. Once the back cover is removed, you have access to the

area which contains all of the connectors.

ATTENTION

Turn off the power supply before removing the back

cover of the MobileView terminal.

When the back cover is removed, the MobileView

terminal is sensitive to electrostatic discharge (ESD).

!

1. Place the terminal on a stable, flat surface.

2. Remove the 6 screws that secure the back cover to the

MobileView terminal.

3. Carefully lift off the back cover and place it on a secure surface.

Back Cover

Publication 2727-UM002D-EN-P

Page 38

3-10 Terminal Connections

RS-232 Serial Port

for downloading software.

Main connector (S19)

for power supply and

control lines

Connection Compartment Details

The following illustration shows what the connection compartment of

the MobileView terminal looks like with the back cover removed.

Reset Button

for rebooting Windows CE.

All data not flushed to Registry or

saved to Flash Storage is lost.

Pin 1

Serial

Serial

port

port

S19

Reset

Reset

B5

B5

B4

B4

00:60 :B5:06:00:01

00:60 :B5:06:00:01

AABBCCDDEEFF

AABBCCDDEEFF

2250-00001

2250-00001

B2 B6 B3

B2 B6 B3

Ethernet label

Ethernet (MAC) address

S6,

COM -Modul

S6,

COM -Modul

Cable Tag

allows the terminal to be

uniquely identified.

Important: Install plug on the

unused MobileView

Connection Cable outlet.

Ethernet

Ethernet

Position of switches does

not affect terminal

operation (for future use)

Ethernet connector (S4)

for data exchange

S4

Connector

not used

Strain Relief

for connecting MobileView Connection Cable

(on left or right side)

Publication 2727-UM002D-EN-P

Page 39

Terminal Connections 3-11

Attaching the MobileView Connection Cable

You can attach the Connection Cable on either side of the terminal for

right or left-hand operation. To relocate the cable, simply grasp the

strain relief and/or the plug and slide off of mount with a rocking

motion.

IMPORTANT

Make sure the K3, 11-pin female connector clicks

completely into S19, Main Connector when plugged

in. Ensure proper seating of K2, 8-pin RJ-45 jack into

S4, Ethernet Connector.

To avoid pinching the cable with the back cover,

avoid laying the cable on top of the T-supports.

After routing the cable, secure the back cover to the

terminal. To maintain IP54 degree protection, tighten

the 6 screws to a torque of 4.42 in-lb.

Attaching Connection Cable on Right Side

Avoid routing cable

over T-support.

S19

Main Connector

S4, Ethernet Connector

S6,

COM -Modul

Attaching Connection Cable on Left Side

S4, Ethernet Connector

S19, Main Connector

Avoid routing cable

over T-support.

S6,

COM-Modul

Publication 2727-UM002D-EN-P

Page 40

3-12 Terminal Connections

Connecting a Computer using the RS-232 Serial Port

Use the RS-232 Serial Port in the MobileView terminal to download

software or to modify/transmit data between the MobileView terminal

and computer using Active Sync software.

The RS-232 Serial Port uses these fixed communication parameters:

• 115200 baud

• 8 data bits

• 1 stop bit

• No parity

• No handshake

The MobileView Download Cable (Catalog Number 2727-MRC1)

connects the MobileView terminal to the serial port of your computer.

PC

9-pin DSUB

(female connector)

1

6

2

3

4

5

PC 9-pin

(male connector)

To

(male connector)

To

MobileView

10-pin Latch

1*

2*

3

5

7*

9

ActiveSync

ActiveSync

Tx

Rx

ActiveSync

Gnd

MobileView

Serial Port S2 Connector

(female)

1

2

10

9

* Pins 1, 2 and 7 are connected together on the CPU board in the MobileView terminal. They are

used for the ActiveSync signal. If you make your own cable, do not eliminate these 3 wires.

Pin 1

Ader 1

4 meters (13.12 feet)

Serial

port

Reset

B5

B4

2250-00001

00:60:B5:06:00:01

AABBCCDDEEFF

S6,

COM -Modul

B2 B6 B3

Ethernet

9

1

1

Serial

Port

Publication 2727-UM002D-EN-P

Page 41

Terminal Connections 3-13

Making an Ethernet Connection

Using the PC Card Slot

The MobileView terminal is equipped with a 10Base-T interface which

supports TCP/IP protocol at 10MBaud for half-duplex

communications.

The Ethernet connector at S3 on the Junction Box provides a

connection to an Ethernet network. The connector uses an 8-pin

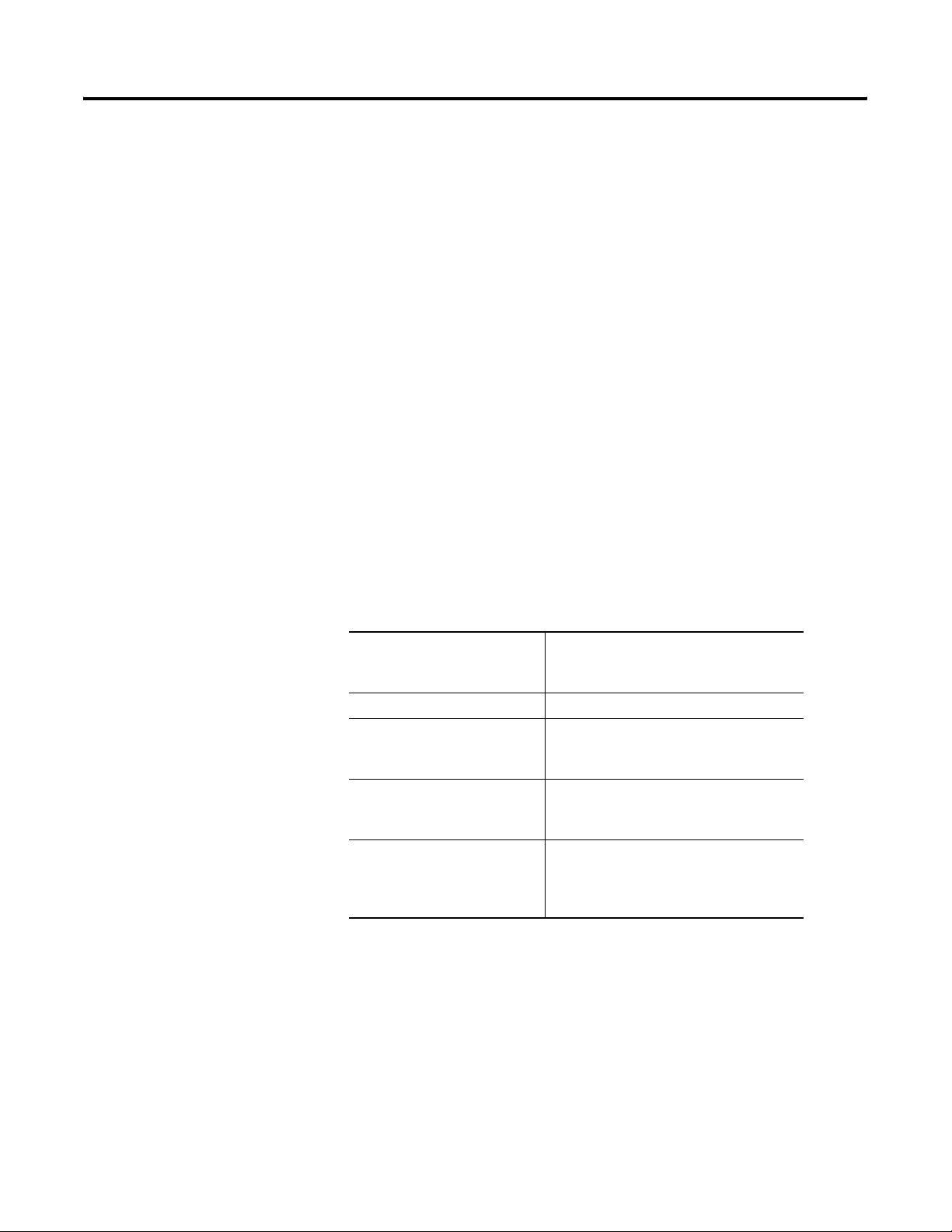

modular jack connector. Pinouts are as follows:

Pin # Ethernet Signal

1TD+

2TD-

3RD+

4 Not Used

5 Not Used

6RD-

7 Not Used

8 Not Used

The PC card slot is a factory installed option and supports Type I, II,

and III PC cards. The following PC cards are available from

Allen-Bradley. The terminal does not support SRAM cards, CardBus

cards, or cards that use 12 volts for programming.

Catalog No. Description

2711-NM28 8M flash ATA card for storing applications.

2711-NM216 16M flash ATA card for storing applications.

2711-NM232 32M flash ATA card for storing applications.

Publication 2727-UM002D-EN-P

Page 42

3-14 Terminal Connections

Inserting the PC Card

Lay the MobileView with the display facing down onto a flat, clean

table, preferably on Electrostatic Discharge (ESD) pad. Take care

not to damage the terminal and its elements.

1

2

1. Open the cover.

2. Insert the PC card as shown.

Ejection button

Attention:

Verify that this corner

is inserted into the slot

on the side of the

ejection button.

1

Unlock the PC card cover as shown (until

the locking lever is released)

3

Attention:

Check the condition

and position of the

cover seal before

closing the PC card

cover.

Insert the PC card until it locks in and the ejection

button pops out.

5

2

4

6

1

1. Close the cover.

2. and 3. Lock the cover as shown.

3

2

Press down the cover until it snaps in completely to

meet the protection degree IP54.

Must snap

completely.

Publication 2727-UM002D-EN-P

Page 43

Removing the PC Card

Terminal Connections 3-15

Unlock the PC card cover as shown

(until the locking lever is released).

1

1. Close the cover.

2. and 3. Lock the cover as shown.

1

1

3

2

1. Open the PC card cover.

2. Press the ejection button of the PC card slot.

3. Remove the PC Card

3

3

2

Press down the cover until it snaps in completely to meet

the protection degree IP54.

Must

snap

completely.

2

4

Connecting a Keyboard / Printer Using the IrDA Interface

The IrDA keyboard/printer interface is built into the lower rim of the

MobileView terminal (see page

1-3) and supports communication

with:

• keyboards

• printers

The port is located for convenient operation with an IrDA keyboard.

To use a standard PC keyboard with the IrDA port, you must use a

converter (PS2 keypad to IrDA).

To print using the IrDA port, you must orient the MobileView towards

the IrDA port of the printer. The printer must be PCL compatible.

The IrDA port is assigned to the COM 3 or COM 4 interface port.

Protocol: Only the HP-SIR (Low Speed) coding is used (LPM Mode

enabled). The maximum baud rate is 115.2K baud.

Publication 2727-UM002D-EN-P

Page 44

3-16 Terminal Connections

Installing the Mounting Bracket

Height Adjustment Plate

Carrier

MobileView

Connection

Cable

Holder

The MobileView Mounting Bracket (2727-MRMB1) is used for

stationary operation or storage of the MobileView terminal. The

following illustration shows the mounting bracket with and without

the terminal mounted.

Dimensions and Mounting Holes

120 mm (4.72 in)

6

m

m

d

1

i

a

2

.

(

0

.

m

2

4

i

m

d

i

526 mm (20.71 in)

550 mm (21.65 in)

n

a

.

)

(

0

.

4

7

i

n

)

28 mm

150 mm (5.91 in)

22 mm (0.87 in)

12 mm (0.47 in)

(1.1 in)

20 mm

(0.79 in)

The carrier is adjustable in 8 positions over a height of 320 mm (12.60

in). It is important to attach the carrier at all 4 points on the height

adjustment plate. Mount the cable holder on the carrier using the

screws shipped with the bracket.

Use suitable screws (not shipped with product) to mount the height

adjustment plate.

Publication 2727-UM002D-EN-P

Page 45

Chapter

Configuring the MobileView Terminal

4

Chapter Objectives

Using the MobileView Configuration Tool

This chapter shows how to:

• configure settings of the MobileView hardware using the MV

Configuration Tool

• verify operating and control elements

• transfer data with a Personal Computer

• install programs

• save registry settings

IMPORTANT

Use the MobileView Configuration Tool to:

• calibrate and test operating elements

• adjust display

• calibrate the touch screen

• set start-up functions

Settings not made with the MV Configuration Tool,

must be saved using the Registry Backup utility

found in Start>Programs>MobileView folder. See

page 4-15.

To activate the tool from the Start menu, select:

Start>Programs>MobileView>MV Configuration Tool

The MobileView Config Tool dialog opens with the default

Potentiometer tab selected.

1 Publication 2727-UM002D-EN-P

Page 46

4-2 Configuring the MobileView Terminal

After making configuration changes and exiting the MobileView

Config Tool dialog, you will be prompted to write the registry changes

to Flash memory. You must do this to retain changes through power

cycles.

The following dialog appears.

Tap the Yes button to save the configuration to Flash memory.

Calibrating the Potentiometer

The Potentiometer tab allows calibration of the potentiometer.

To start calibration, tap the Calibrate button. The radio button

indicator prompts you to move the potentiometer to the:

• Min (Minimum) position, full travel in the counter clockwise

direction and then to

• Max (Maximum) position, full travel in the clockwise direction.

After moving the potentiometer to the Min and then the Max position,

tap the Calibrate button again to complete the calibration. The value

to the right of the Potentiometer slide bar should read 127 and the

slide bar pointer should be centered on the rightmost tick line.

Publication 2727-UM002D-EN-P

To verify calibration, move the potentiometer knob to the Min and

Max positions. The slide bar value should read as a linear value from

0 to 127.

Page 47

Configuring the MobileView Terminal 4-3

Adjusting Display and Touch Screen Settings

The Display/Touch tab lets you control the brightness and contrast

of the display, and calibrate the touch screen.

Display Configuration

To adjust the brightness and contrast, simply move the associated

scroll bars and/or tap buttons.

Screen Saver

To set the screen saver, select Start>Settings>Control Panel and run

Display Settings. The screen saver will extend the life of the backlight.

The screen saver will be enabled if there is no keypad, touch screen,

or operator activity for a time period exceeding the Idle Time setting

in the Backlight tab of the Display Settings. The screen saver

backlight brightness can also be set. To turn off the backlight while

on external power, enter a turn-off time of 30 seconds to 30 minutes.

Once in screen saver mode, the first keypad key or touch screen

activation will deactivate the screen saver but not activate the buttons

or functions assigned to the keypad key or touch screen touch cells.

The handwheel, keyswitch, pushbutton, and potentiometer operators

will deactivate the screen saver but remain fully functional while

screen saver mode is active. The emergency stop button and enable

switches are also fully functional in screen saver mode but will not

deactivate the screen saver.

Publication 2727-UM002D-EN-P

Page 48

4-4 Configuring the MobileView Terminal

Touch Screen Calibration

To calibrate the touch screen, tap the Calibrate Touch button. An

image with a white background, a cross hair target in the center of the

screen, and instructions at the top, will appear. Simply follow the

instructions to complete the calibration. For best results use a stylus.

ATTENTION

Do not use a sharp object, such as a screw driver

when operating the touch screen. Using sharp

objects may damage the touch screen.

!

Setting the Handwheel to Zero

The Handwheel tab calibrates the electronic handwheel of the

MobileView terminal.

Publication 2727-UM002D-EN-P

The handwheel registers a 16-bit value (-32768 to +32768) which can

be processed in the target application as needed and is calibrated for

50 pulses per revolution. Every single increment of the handwheel is

equal to a value of 1.

To calibrate the handwheel:

1. Move the handwheel to the desired start position.

2. Tap the Reset button on the Handwheel tab of the MobileView

Config dialog.

The handwheel slide bar will move to the leftmost tick mark and

the actual value will be reset to a start value of 0.

Page 49

Configuring the MobileView Terminal 4-5

Configure Keypad Settings

You can adjust the keypad auto-repeat rate through the Keyboard

Properties dialog in the Control Panel.

To set the auto-repeat rates:

1. Select Start>Settings>Control Panel.

2. Double-tap Keyboard.

3. Tap the Enable character repeat check box.

4. Select the desired Repeat delay and Repeat rate settings and

then tap OK to save the changes and exit the dialog.

TIP

The Keypad auto-repeat rate settings are for the

physical left and right membrane keypads only. You

cannot configure the on-screen, alphanumeric input

panel.

Configuring Startup Settings

The Startup tab determines what occurs after a restart or power cycle

of the MobileView terminal.

Publication 2727-UM002D-EN-P

Page 50

4-6 Configuring the MobileView Terminal

You can select the following startup actions for the MobileView

terminal:

• Update OS Image on Next Startup - Loads the OS (Operating

System) image from the BOOTP Server via the network the next

time the MobileView is started.

IMPORTANT

The Ethernet connection must have been

established, the BOOTP Server must be correctly

configured, and an OS image file must be available.

See the MobileView G750/MT750 Flash Update

documentation for more information.

• Disable internal network controller: - Deactivates the internal

Ethernet interface CELAN1:Onboard Ethernet at the next startup.

To enable the network controller after disabling:

a. Deselect “Disable Internal Network Controller”.

b. Perform a registry backup by selecting

Start>Programs>MobileView>Registry Backup.

c. Cycle power to the MobileView terminal.

Activating/Testing Pushbutton LEDs

The Pushbuttons tab allows activation of the push button LEDs, that

are present, on the MobileView terminal.

Publication 2727-UM002D-EN-P

Tap one of the 3 pushbutton targets to switch the corresponding LED

to Flashing, On, or Off. The first tap switches the LED to Flashing, the

second tap switches the LED to On, and the third tap switches the

LED to Off.

IMPORTANT

This activation test utility activates the push button

LEDs only. The push button and keyswitch position

states are not affected.

Page 51

Configuring the MobileView Terminal 4-7

Loading a New Image File

The Image Update tab allows selection, validation, and loading of a

new WinCE Flash image file to the MobileView terminal.

You can update the image directly from a PC card or using an

Ethernet or Serial connection download the update file to the

MobileView Terminal. Do not remove the PC card until the image

update procedure is complete.

Interruptions may occur when downloading large files over Ethernet

connections using two or more switches.

1. Tap the Image Update tab.

2. Tap the Image File button. Browse and select the .bin file, then

tap the Start Update button.

IMPORTANT

If the IPSM is still formatting the flash area, you will

see the message, “PSM is active. Do you want to

deactivate PSM and reset the device?”. Follow the

bulleted procedure. If this message does not appear,

proceed with step 3.

• Tap the OK button to stop the IPSM. The message “PSM

deactivate” appears.

• Tap the OK button to quit and reset the terminal. If the terminal

did not reset, the file SoftReset.exe will not copy to the

terminal’s root directory.

• Select Start>Programs>MobileView>MV Configuration Tool

• Repeat step 1.

Publication 2727-UM002D-EN-P

Page 52

4-8 Configuring the MobileView Terminal

3. Tap Yes to continue past two warnings.

4. The image update starts.

The Updating Image dialog shows the progress of the update.

Tool Version

ATTENTION

!

After starting an update, do not cycle power or

remove the PC card until the update is

complete. If the update is interrupted, the

terminal will become inactive and can only be

initialized and updated using the BootP server.

Contact Technical Support for more

information.

Publication 2727-UM002D-EN-P

Page 53

Configuring the MobileView Terminal 4-9

When the update is complete, the following dialog appears.

5. Tap the OK button to reset the terminal.

A dialog displays the message “erasing PSM, please wait...”.

When this operation is complete, the terminal resets.

6. The update is complete. You can calibrate the touch screen and

safely remove the PC card from the terminal.

Clearing the Registry

IMPORTANT

All modifications made to the registry since product

delivery will be deleted.

To clear the registry and restore factory default settings:

1. Tap the Clear Registry button on the Image Update tab.

A warning dialog appears letting you know that the current

settings will be replaced with the factory default settings and

that the terminal will reset.

2. Tap Yes to continue. The terminal resets.

Publication 2727-UM002D-EN-P

Page 54

4-10 Configuring the MobileView Terminal

Checking the Operating and Control Elements

You can verify the operating and control elements of the MobileView

terminal using the System Check software. You can check the

following operating and control elements:

• Override potentiometer (option)

• Electronic handwheel (option)

• Membrane Keypad

• Touch screen

• Display

ATTENTION

Any changes to the contrast or brightness

setting in the display backlight system check

will be applied to the MobileView terminal and

the configuration tool.

!

• Illuminated push button (option)

• Key switch (option)

• IPSM Flash file system

The following safety elements cannot

be checked with this utility:

• Emergency stop switch

• Enabling switches

The System Check software also lets you check the MobileView

terminal data, such as the CPU memory, interface module, or

operating elements.

To run this software, select:

Start>Programs>MobileView>System Check

Publication 2727-UM002D-EN-P

Page 55

Configuring the MobileView Terminal 4-11

Transferring Data with a Personal Computer

This section shows how to transmit data between the MobileView

terminal and a PC using the MicroSoft ActiveSync software. It shows

how to:

• verify serial port availability

• install the Microsoft ActiveSync software

• connect the MobileView terminal to a PC

• disconnect communications

Verifying Serial Port Availability

To verify that your PC serial port is available:

1. For Windows 95, Windows 98 and Windows NT systems:

On your PC, select Start>Settings>Control Panel.

For Windows 2000 systems:

On your PC, right-click My Computer, select Manage and then

Device Manager.

2. For Windows 95 and Windows 98 systems:

Double-click the System icon and select Device Manager tab.

For Windows NT systems:

Double-click the Ports icon.

For Windows 2000 systems:

Double-click Ports from the menu.

3. View the devices by type or number. Double-click the desired port.

4. Click the Port Settings tab or the Settings button and set the

Bits Per Second or Baud Rate to match MobileView settings.

Bits per second setting

5. Click OK to apply any changes and close the windows.

Publication 2727-UM002D-EN-P

Page 56

4-12 Configuring the MobileView Terminal

Installing Microsoft ActiveSync Software

Microsoft ActiveSync enables you to connect the IDA to your PC.

ActiveSync version 3.1 or greater is required. Download ActiveSync

from the Internet at

www.microsoft.com/pocketpc/downloads/activesync.asp