Page 1

Quick Start

MobileView Guard G750

(Catalog Number 2727-G7P20D1P4, -G7P20D1P5, -G7P20D1Q6, -G7P20D3Q7)

Inside . . .

English..................................................................................................................................3

Français..............................................................................................................................35

Deutsch..............................................................................................................................69

Español.............................................................................................................................103

Italiano.............................................................................................................................137

Português.........................................................................................................................169

Publication 2727-QS002E-MU-P

Page 2

Publication 2727-QS002E-MU-P

Page 3

Quick Start

MobileView Guard G750

Catalog Numbers (2727-G7P20D1P4, 2727-G7P20D1P5, 2727-G7P20D1Q6, 2727-G7P20D3Q7)

English

For more detailed information on the MobileView Guard G750, refer to publication

2727-UM002.

Download a free electronic version of publication 2727-UM002 from:

• installation CD

• www.support.rockwellautomation.com

www.theautomationbookstore.com

Inside . . .

Important User Information ............................................................................................... 4

MobileView Guard G750 Description ................................................................................ 5

Safety Precautions and Elements ...................................................................................... 6

MobileView Junction Box Mounting and Wiring ............................................................ 12

Removing the Back Cover ................................................................................................ 19

Ethernet Connection ........................................................................................................ 21

Using the PC Card Slot ..................................................................................................... 21

Startup/Power On ............................................................................................................ 24

Hardware Configuration .................................................................................................. 25

Ethernet Network Configuration ...................................................................................... 25

Saving Registry Settings .................................................................................................. 27

Starting Terminal Services ............................................................................................... 27

Shutdown/Power Off ....................................................................................................... 28

Mounting Bracket Installation ......................................................................................... 29

European Communities (EC) Directive Compliance ......................................................... 30

Standards and Agency Certifications .............................................................................. 31

MobileView Guard G750 Configurations ......................................................................... 32

Accessories ...................................................................................................................... 32

Specifications .................................................................................................................. 33

Publication 2727-QS002E-MU-P

Page 4

4 MobileView Guard G750

Important User Information

Because of the variety of uses for the products described in this publication, those

responsible for the application and use of this control equipment must satisfy

themselves that all necessary steps have been taken to assure that each application

and use meets all performance and safety requirements, including any applicable

laws, regulations, codes and standards.

The illustrations, charts, and layout examples shown in this guide are intended

solely for purposes of example. Since there are many variables and requirements

associated with any particular installation, Allen-Bradley does not assume

responsibility or liability (to include intellectual property liability) for actual use

based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application, Installation

and Maintenance of Solid-State Control (available from your local Allen-Bradley

office), describes some important differences between solid-state equipment and

electromechanical devices that should be taken into consideration when applying

products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or part,

without written permission of Rockwell Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety considerations:

ATTENTION

Identifies information about practices or circumstances that can

lead to personal injury or death, property damage, or

economic loss.

!

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

IMPORTANT

Allen-Bradley is a trademark of Rockwell Automation

Publication 2727-QS002E-MU-P

Identifies information that is critical for successful application

and understanding of the product.

Page 5

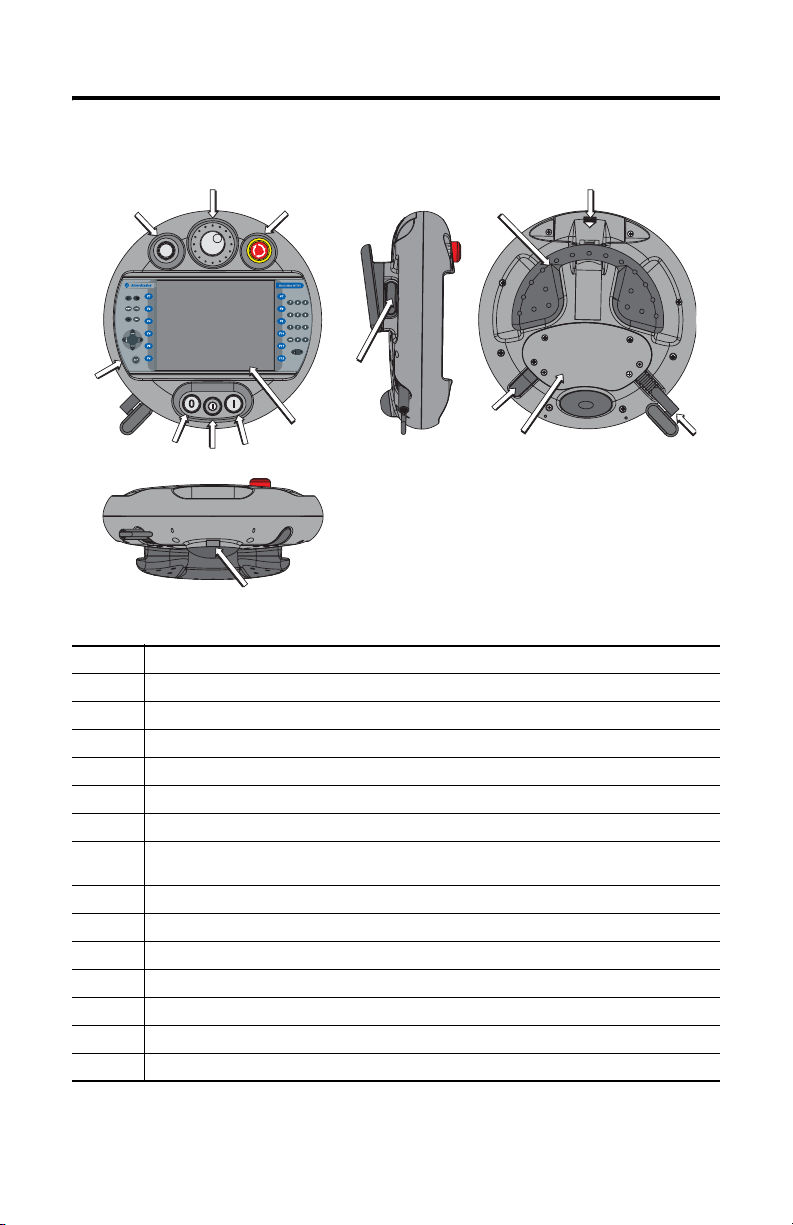

MobileView Guard G750 Description

2

1

3

MobileView Guard G750 5

12

11

4

8

5

1 Potentiometer with 0-127 linear resolution (option)

2 Electronic handwheel, 50 pulses/rev -32768 to +32768 (option)

3 Emergency stop switch, twin-circuit, N/C contacts, 24V dc, 500 mA maximum (option)

4 Membrane keypad with tactile feedback - standard Windows keyboard operation

5 Illuminated momentary push button, normally open, OFF marking, yellow LED (option)

6 3-position key switch (option)

7 Illuminated momentary push button, normally open, ON marking, yellow LED (option)

8 7.7 inch VGA (640 x 480 pixels) passive matrix color LCD display with analog resistive touch

9 3-position, twin circuit, enabling switch (one each side of handle) for safety system interface

10 IrDA keyboard/printer interface, 9600 or 115.2K baud

11 Handle for left or right-hand operation

12 Single slot PC card interface for Type I, II and III cards (option)

13 Strain relief for connection cable (shipped with cable)

14 Back cover to connection compartment

15 Plug for cable outlet when not used (meets degree protection IP54)

screen

7

6

10

9

15

14

13

Publication 2727-QS002E-MU-P

Page 6

6 MobileView Guard G750

Safety Precautions and Elements

This section covers general safety precautions in addition to important information

on the power supply, emergency stop switch, and enabling switches used with the

MobileView Guard G750.

General Safety

It is important to follow the instructions in this document in all circumstances.

Failure to do so could result in potential sources of danger or the defeating of safety

features integrated in the terminal.

In addition to the safety instructions in this document, you must also use safety

precautions and accident prevention measures appropriate to the situation.

ATTENTION

!

• Make sure interrupted processes can be properly restarted

after power failures or power dips. No dangerous

operating conditions must be allowed to occur, even

temporarily.

• In situations where faults occurring within the automation

system could cause personal injury or significant damage

to machinery and equipment, take additional external

safety measures to ensure the system remains in a safe

operating condition.

• Make sure unauthorized persons are not allowed to adjust

settings or make memory modifications that could lead to

dangerous situations.

• Test the functionality of safety-related parts (E-stop and

enabling switches) on a regular basis.

• If the MobileView terminal and controller do not

communicate using a point-to-point connection, keypad

data, for example, may transmit with a delay. Use of an

Ethernet switch between the MobileView terminal and

controller is recommended for a higher speed connection.

• Test safety-relevant parts after strong shocks to the

terminal (for example, if terminal is dropped on ground).

• When the MobileView terminal is used to operate the

machine/plant, ensure that the MobileView is the single

point of operation (C.F. ANSI/RIA 15.06).

• If you use a PC card with the MobileView, always make

sure the PC card is properly loaded. After a strong impact,

the PC card cover remains closed. Verify that card is

properly loaded to maintain a good electrical contact.

• When the MobileView terminal is used in manual mode

(for example, teaching of robot), insure robot moves at a

slower speed (C.F. ANSI/RIA 15.06).

Publication 2727-QS002E-MU-P

Page 7

MobileView Guard G750 7

Handling of MobileView Guard Terminal

Refer to MobileView Guard G750 User Manual for additional handling instructions

to avoid terminal malfunctions or damage.

Power Supply

ATTENTION

!

• The device meets safety class III in accordance with EN

61131-2 and EN 50178. The 24V power supply for the

equipment must provide appropriate isolation between

safety-extra-low-voltage circuits and dangerous-contact

voltage circuits (for example, by safety transformers or

similar facilities).

• Protect the power supply circuit with a 3.15 A fuse.

• The nominal supply voltage of the MobileView terminal

(without Mobile View Connection Cable) is +24V dc

(supply voltage range: 18 to 32V dc).

Typical current consumption is:

- 300 mA at 24V dc

-400 mA at 18V dc

When planning the power supply, consider the voltage

drop on the MobileView Connection Cable.

Specifications of power supply lines in this cable are:

Cross section: AWG24 (0.24 mm

Material: zinc-coated copper strand

Line resistance:

<90 Ohm/km (<145 Ohm/mile)

2

)

Enabling Switches

The electronic enabling switch realizes the enabling equipment as a safety function

for machines in special operating modes. The enabling switch is part of the

MobileView terminal.

Each machine features a normal operating mode and a special operating mode.

• In normal operating mode, guards and/or operative protection devices are

used to prevent access and guarantee safety. Special operating modes are

used to maintain the normal operating mode.

Publication 2727-QS002E-MU-P

Page 8

8 MobileView Guard G750

• In special operating mode, safety must be guaranteed in other ways since the

operator must enter dangerous areas of the machine, and targeted

movements must be possible. In this case, a reduced speed of the machine

must be defined by means of the risk assessment. A movement will only be

possible if an enabling device is actuated. The user must be trained and

must know the details of the intended use. The safety related parts of the

control for reducing speed and for the enabling device must be constructed

so that they meet the safety category according to EN 954-1, defined by the

risk assessment.

To meet safety category 3 in accordance with EN 954-1, the enabling switch must

be implemented with 2 circuits.

EN 60204-1 describes the functioning of the enabling device. Due to the latest

findings of analysis of accidents and since technical solutions are available, the

3-position enabling switch became state of the art. The positions 1 and 3 of the

enabling switch are OFF functions. Only the central position is used for enabling.

The EN 60204-1 is identical with IEC 60204-1. So the 3-position enabling switch is

of international relevance.

The enabling switch consists of a 3-position operating element and separated

evaluation electronics. Essential features are the continuous two-channel circuits

between the actuating elements and the connecting terminals. For the evaluation

circuits, different technologies and circuits are used. Because of the electronic

switching contacts, their lifetime does not depend on the load as long as the

nominal values of the load (ohmic, inductive and capacitive) are not exceeded.

ATTENTION

!

Publication 2727-QS002E-MU-P

• Enabling switches may only be used if the operator

activating the switch recognizes the dangerous situation in

time to take immediate action if necessary.

• The enabling switch is only used to enable commands for

performing dangerous movements. The commands must

be activated by a separate operating element (key on

terminal). Only persons allowed to activate the enabling

switch are allowed to work in the dangerous area.

• On the MobileView Guard terminal, the enabling switches

always feature 2 circuits.

Page 9

MobileView Guard G750 9

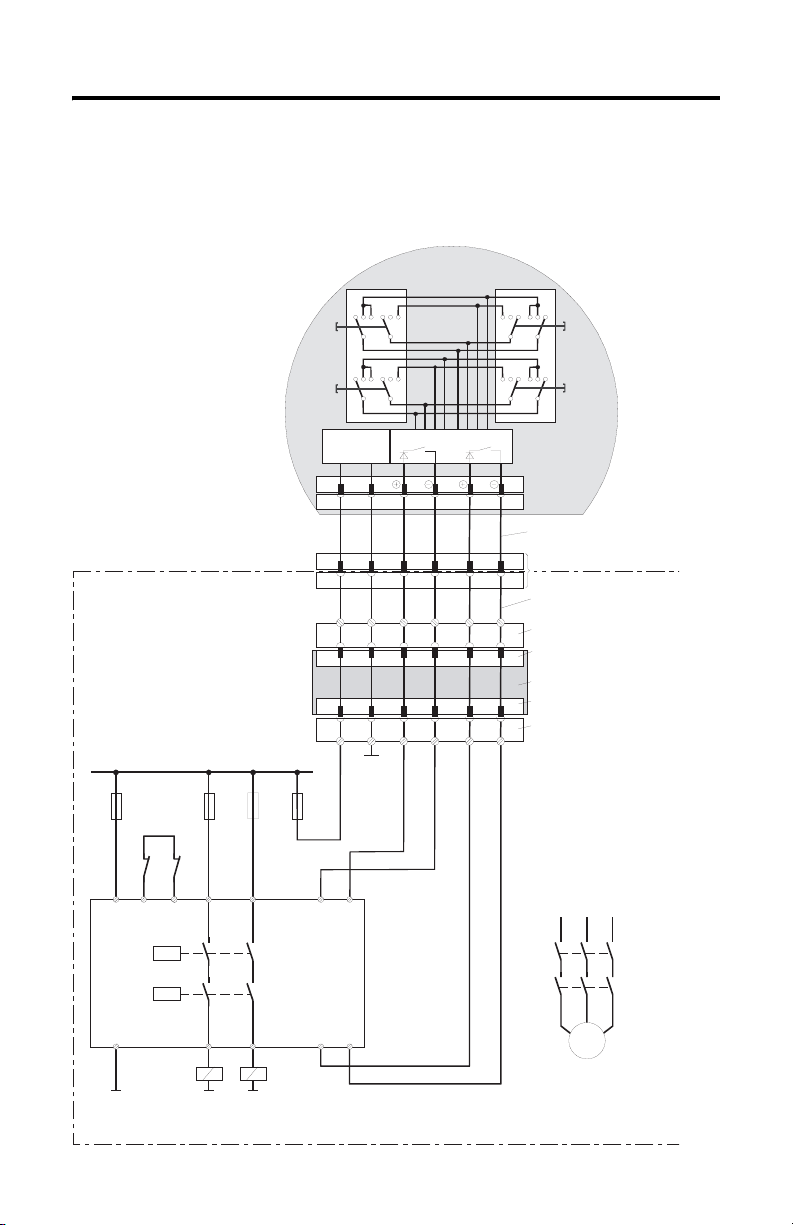

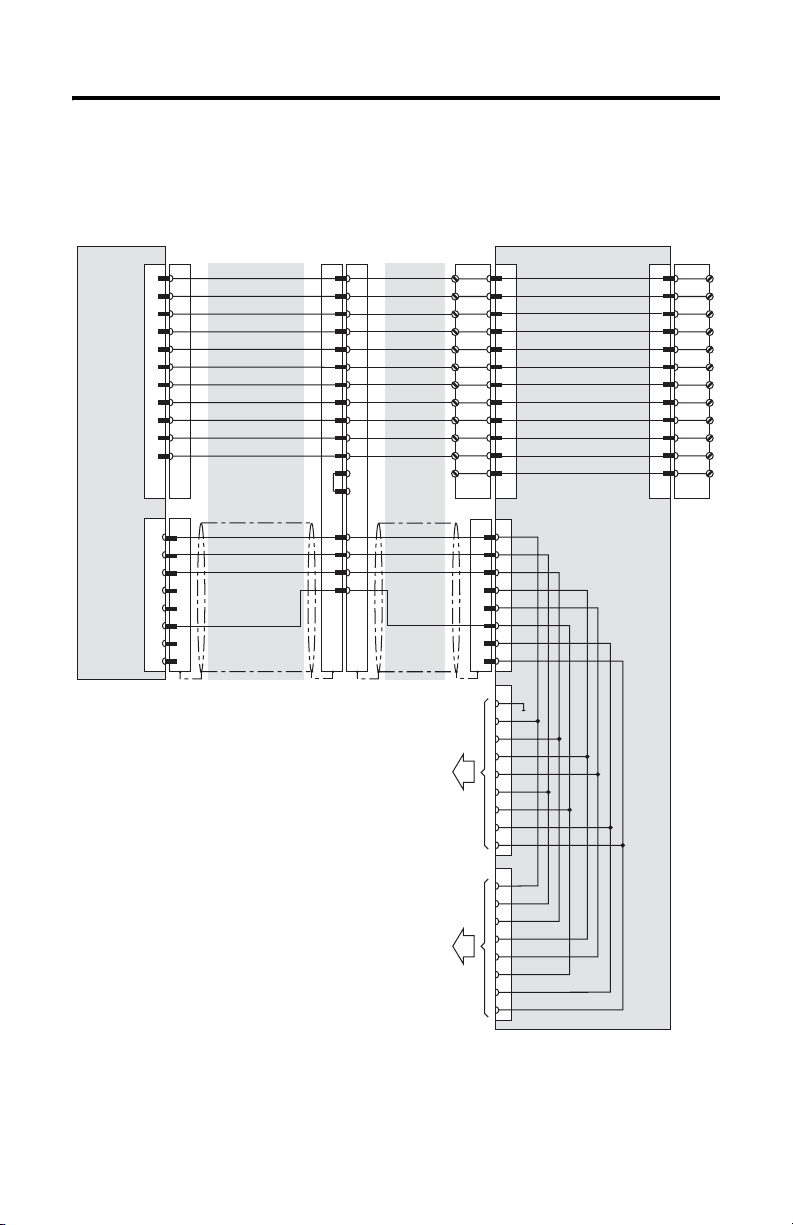

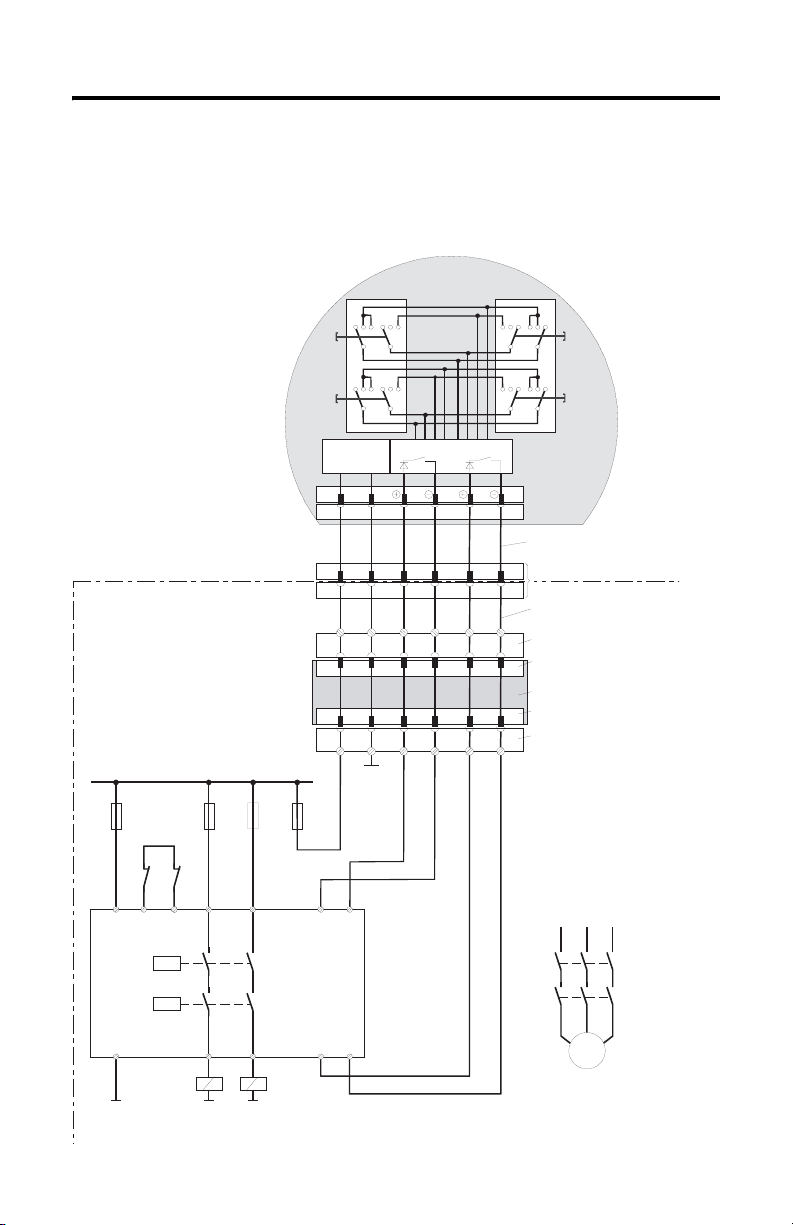

Connection Example with a Safety Control Relay

The diagram below shows suggested wiring for enabling switches using an

PILZ PST safety control relay to meet safety category 3. Refer to PILZ PST

documentation for additional information.

123123 321321

ZT1

L

123123 321321

ZT2

L

MobileView

(2 enabling switches with 3

positions and 2 circuits each)

ZT1

R

ZT2

R

Control cabinet

+24 VDC

F2

F3

4A(t)

F1

1A

Feedback

control lo op

KA KB

X1 X2

A1(+) 23 S11

K1

PILZ

PST1

K2

6A(f)

4A(t)

or

or

6A(f)

13

3,15A

S19:

K3:

K1:

DC/DC

converter

67

67

Evaluation electronics

Circu it 1 Circu it 2

12 34

12 34

7 8 12 17K1: 1 2

7 8 12 1712

ZTxy ....... enabling switch x

Connection cable

MobileView

17-pin coinvers jack

Intermediate cable

y

MobileView

+24V GND ED1+ ED1- ED2+ ED2-

K3:

X1

X2

+24V GND ED1+ ED1- ED2+ ED2-K4:

GND

F4

S12

Terminal block socket K3

on connection box

Male connector X1 on

connection box

Connection box

Male connector X2 on

connection box

Terminal block socket K4 on

connection box

L1 L2 L3

KA

KB

Enabling of

dangerous

movement

A2(-)

14 24 S23 S24

KA KB

GND

GND GND

M

Note: All contacts of KA and KB must be force-guided!

Publication 2727-QS002E-MU-P

Page 10

10 MobileView Guard G750

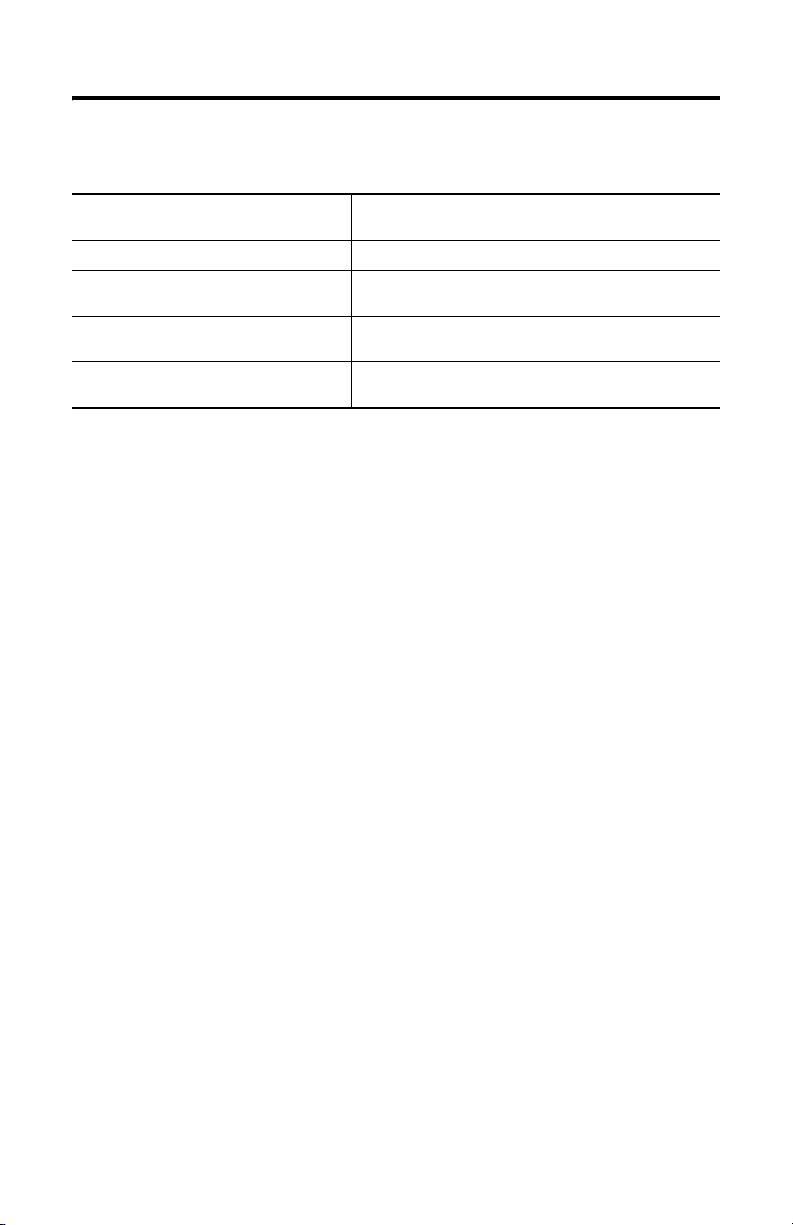

Switching Element Data

Nominal voltage 24V dc (typical)

Nominal current 500 mA (typical)

Short-circuit current circuit 1; maximum 1.9 A

Max. inductive load (at 500 mA) circuit 1: >1H

Max. capacitive load circuit 1: no limit since the transistor is protected thermally

32V dc (maximum)

circuit 2: maximum 600 mA

circuit 2: maximum 320 mH

circuit 2: maximum 500 µ F

The switching elements of the enabling switches are protected against reversed

polarity. The outputs of both circuits are protected against short circuits and excess

load.

• Circuit 1: thermal protective circuit

• Circuit 2: fold back protective circuit

Foreseeable Misuse of Enabling Switch

Foreseeable misuse means not allowing the enabling switch to be fixed in the

enabling position. The foreseeable misuse of the enabling switch must be restricted.

The following measures are recommended, which cause the machine to stop in

manual mode.

• Inquiry of the enabling switch when turning on the machine/plant and

inquiry of the enabling switch when changing the operating mode from

automatic to manual. (The enabling switch must not be in the enabling

position.)

• The enabling switch must be released within a defined period of time and

pushed into the enabling position again. The length of time must be defined

according to the activity.

Publication 2727-QS002E-MU-P

Page 11

MobileView Guard G750 11

Emergency Stop Switch

The emergency stop switch of the MobileView terminal meets the requirements of

EN 418. It must be designed as an emergency stop of category 0 or category 1 (see

EN 60204-1, chapter 9.2.5.4.2) on the basis of the risk assessment for the machine.

The connection of the positive-break contacts to an appropriate monitoring system

must meet the safety category which is defined by means of the risk assessment (in

accordance with EN954-1) of the machine.

The emergency stop has 2, potential-free, normally closed contacts for connecting

external peripherals, a nominal operating voltage of 24V (Safety Extra Low Voltage

in accordance with EN 61131-2 and EN 50178), and a maximum operating current

of 500 mA.

ATTENTION

!

• When the emergency stop switch is not wired into the

emergency stop circuit, the MobileView terminal must be

stored where it is not available to operators.

Consider that the operator might instinctively activate the

nearest emergency stop in case of danger. This could have

fatal consequences if the emergency stop does not

function.

• Emergency stop functions must remain operational in all

operating modes. Resetting an activated emergency stop

must not result in uncontrolled startup of machines or

installations.

• The emergency stop switch does not replace other safety

devices.

Risk Assessment of Machinery

For the risk assessment, the following standards must be applied:

• EN 292-1 “General principles for design of machinery”

• EN 1050 “Principles for risk assessment of machinery”

• EN 954-1 “Safety-related parts of control systems”

• ANSI/RIA 15.06-1999 “American National Standard for Industrial Robots and

Robot Systems - Safety Requirements (Section 9)”

• ANSI B11.TR3-2000 “Risk Assessment and Risk Reduction - A guide to estimate,

evaluate and reduce risks associated with machine tools”

The safety categories (B, 1, 2, 3, 4) define the structure of safety-related parts of a

machine and are derived from this risk assessment.

Page 9 shows how the enabling function of the MobileView terminal meets safety category 3

using a PILZ PST 1 safety control relay. Please keep in mind, that the entire concept of the

machine must be layed out accordingly.

Publication 2727-QS002E-MU-P

Page 12

12 MobileView Guard G750

MobileView Junction Box Mounting and Wiring

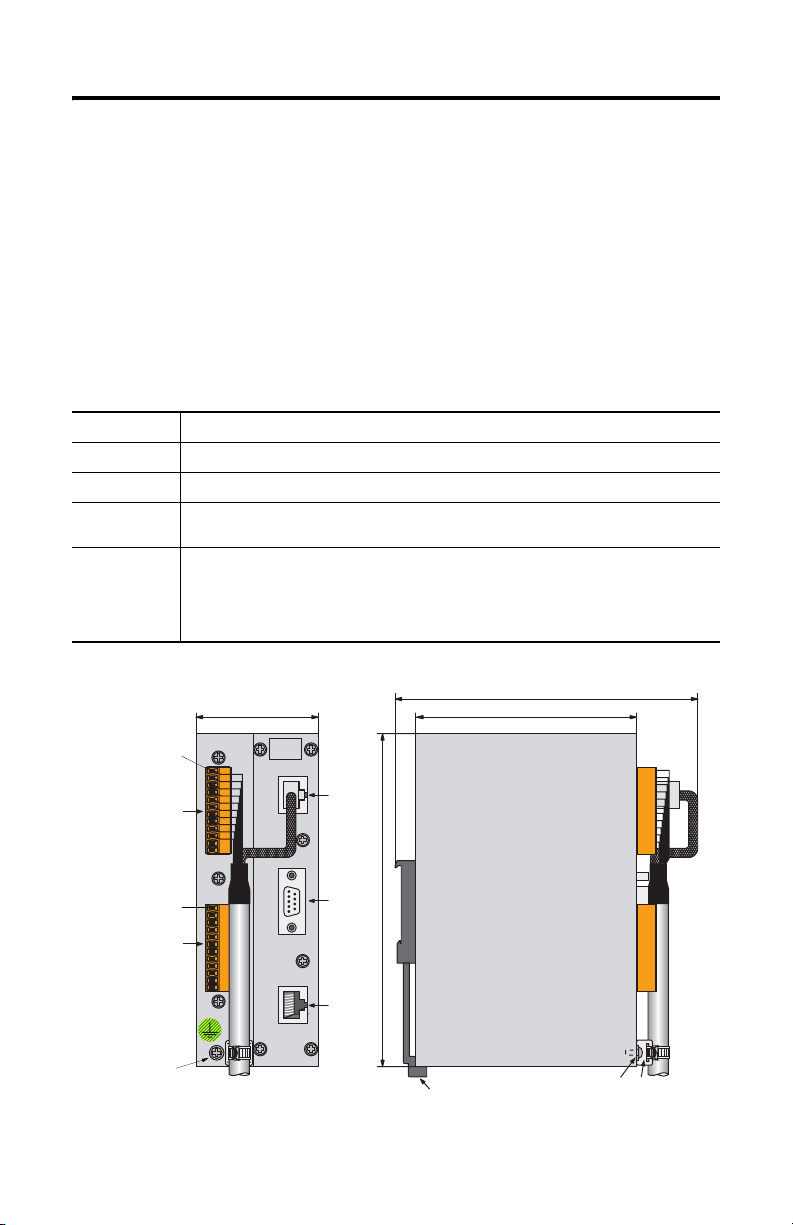

The MobileView Junction Box (2727-MRJB1) integrates the MobileView terminal

into the control system and is mounted on a DIN rail.

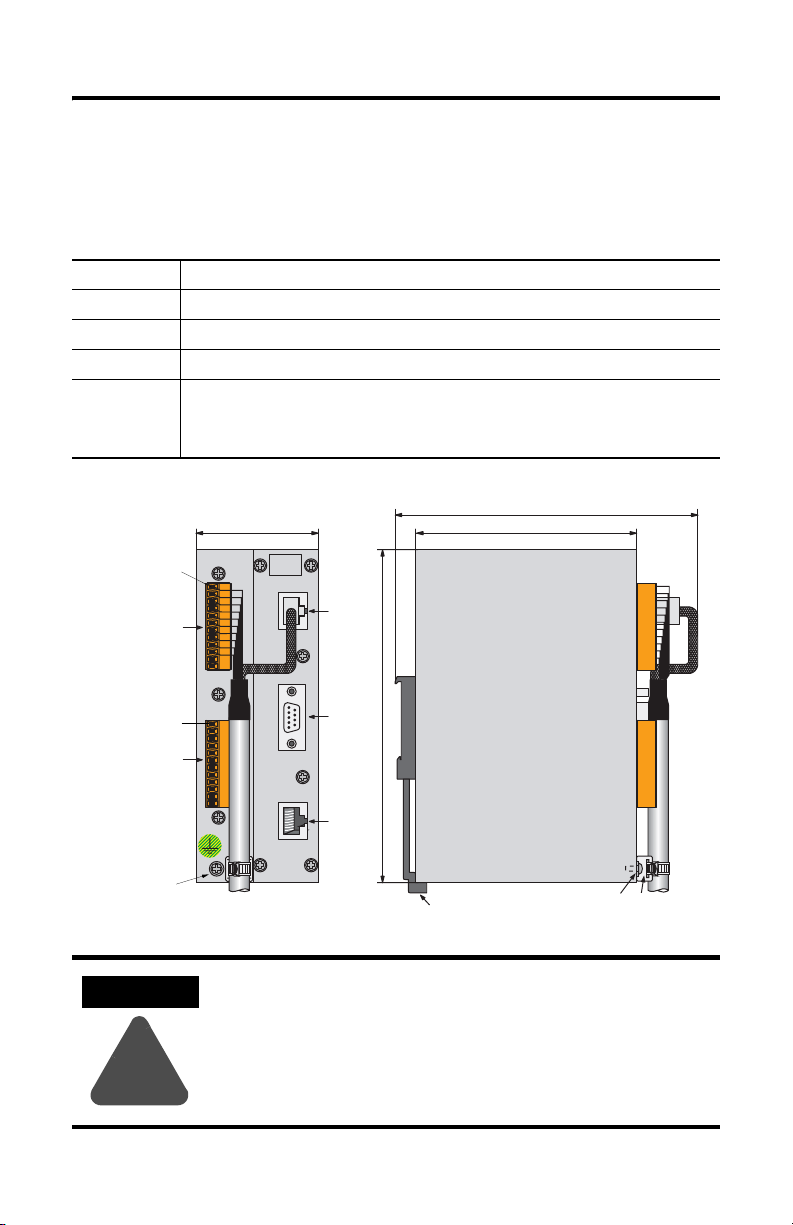

S1 RJ-45 jack for connecting the MobileView data lines.

S2 9-pin DSUB female connector (for future use).

S3 RJ-45 jack to Ethernet network.

X1 12-pin male connector for connecting Junction Box Cable.

X2 12-pin male connector (shipped with female terminal block connector) for connecting the:

Pin 1, 24V dc

X1

(with Female

Terminal Block

Connector K3)

• 24V dc power supply

• emergency stop switch

• enabling switches

60 mm (2.36 in)

24V DC

ON LY

+24V

TERM INAL IN

GND

ES1+

ES1-

ES2+

ES2-

ED1+

ED1-

ED2+

ED2-

RS422 OUT

150 mm (5.91 in)

108 mm (4.25 in

S1

Pin 1, 24V dc

(with Female

Terminal Block

Connector K4)

+24V

GND

ES1+

ES1-

ES2+

X2

ES2-

ED1+

ED1-

ED2+

ED2-

ETHERNET OUT

Grounding

Screw

ATTENTION

The Junction Box and the MobileView terminal meet the safety

class III in accordance with EN 61131-2 and EN 50178.

When connecting the terminal, make sure all voltages

connected to the MobileView terminal are safety extra low

!

voltages by using a safety transformer or a similar facility.

Publication 2727-QS002E-MU-P

S2

162 mm (6.4 in)

S3

DIN Rail Latch

Grounding

Screw

Strain Relief

Page 13

MobileView Guard G750 13

Mounting Junction Box on a DIN Rail

Mount the MobileView Junction Box within an enclosure using a DIN rail.

To install the Junction Box on a DIN rail:

1. Mount the DIN rail.

2. Hook the top slot over the DIN rail.

3. While pressing the Junction Box against the rail, snap the Junction Box into

position.

To remove your Junction Box from the DIN rail:

1. Place a screwdriver in the DIN rail latch at the bottom of the Junction Box.

2. Holding the Junction Box, pry downward on the latch until the Junction Box is

released from the DIN rail.

Publication 2727-QS002E-MU-P

Page 14

14 MobileView Guard G750

Connecting the MobileView to the Junction Box

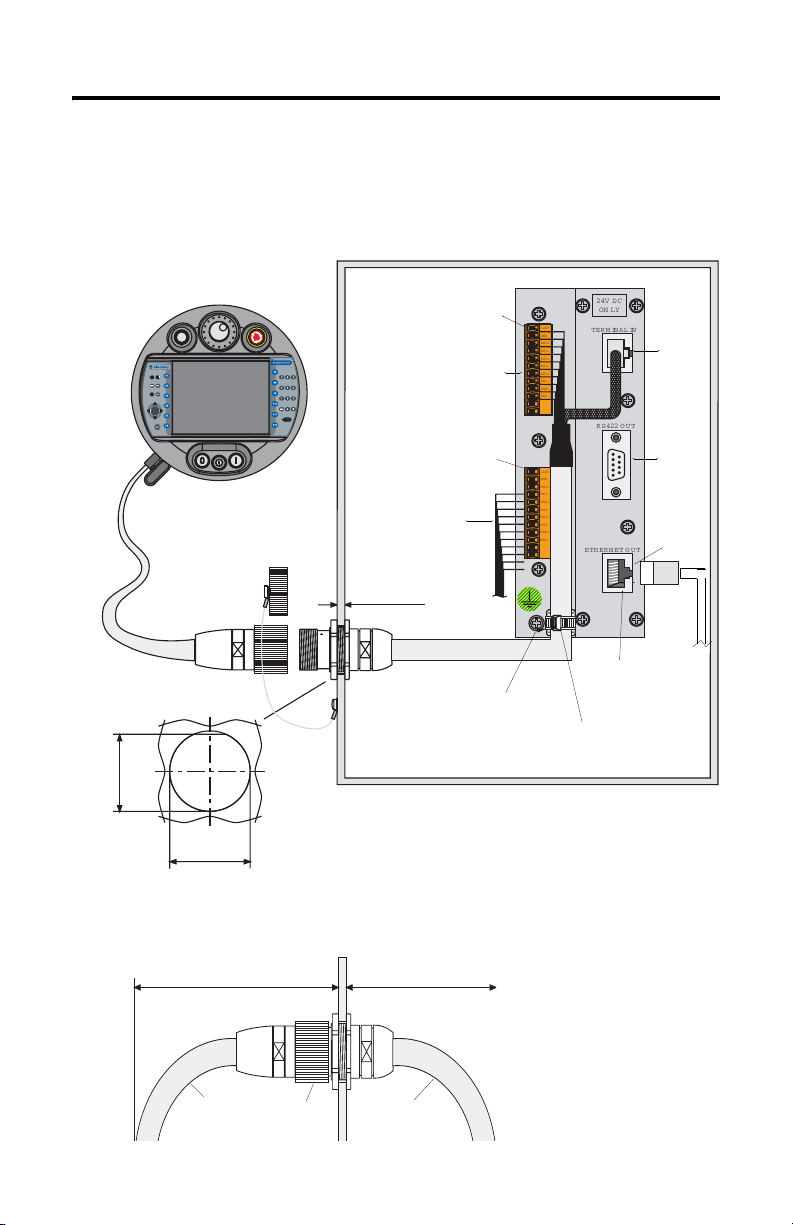

The following illustration shows how the MobileView terminal connects to the

Junction Box.

MobileView Terminal

ESC

7 8 9

5 6

4

3

1 2

.

-

0

MobileView

Connection Cable

Connector Cutout

24 mm

(0.94 in)

(1.0 ± 0.0039 in)

25 ± 0.1 mm

n

u

R

KETOP

Dust Cover

Typical Control Cabinet

Pin 1, 24V dc

r

o

r

Er

Terminal Connections

X1/K3

MobileView

Pin 1, 24V dc

X2/K4

Safety Equipment

Connections

maximum wall

thickness 5 mm (0.2 in)

Junction Box

+24V

TERM INAL IN

GND

ES1+

ES1-

ES2+

ES2-

ED1+

ED1-

ED2+

ED2-

+24V

GND

ES1+

ES1-

ES2+

ES2-

ED1+

ED1-

ED2+

ED2-

ETHERNET OUT

24V DC

ON LY

RS 422 OUT

S1

S2

S3

Junction Box Cable

K1

2 m (6.5 ft)

Use Grounding

Screw to Connect

Earth Ground to the

Junction Box

10 Base-T

Connection to

Ethernet Network

Junction Box Cable

Wire Tie

Cable Clearance on Both Sides of Enclosure Wall

130 mm (5.12 in)

Connection

Cable

Publication 2727-QS002E-MU-P

K1

Connection

108 mm (3.94 in)

Junction Box

Cable

Page 15

Junction Box Pinout and Wiring

MobileView Guard G750 15

MobileView

S19

S4

Connection Cable

K3

6

7

8

9

10

11

1

2

3

4

5

K2

1

2

3

6

MobileView

pink

black

green-brown

white-green

grey-pink

red-blue

brown

yellow

green

grey

violet

blue

white

orange

red

MobileView

Junction Box Cable

K1

1

2

3

4

5

6

7

8

12

17

11

9

10

13

14

15

16

pink

black

green-brown

white-green

grey-pink

red-blue

brown

yellow

green

grey

violet

blue

white

orange

red

Future Use

To Ethernet Network

K3

X1

1

2

GND_IN

E-Stop, circuit 1, pos.

3

4

E-Stop, circuit 1, neg.

5

E-Stop, circuit 2, pos.

6

E-Stop, circuit 2, neg.

7

Enable sw. circ. 1, pos

8

Enable sw. circ. 1, neg

9

Enable sw. circ. 2, pos

10

Enable sw. circ. 2, neg

11

Not used

12

Not used

K2

S1

1

2

3

4

5

6

7

8

S2

1

2

3

4

5

6

7

8

9

S3

1

TD+

2

TD-

3

RD+

4

5

6

RD-

7

8

Junction Box

24V DC

X2 K4

1

2

3

4

5

6

7

8

9

10

11

12

+24V

GND

ES1+

ES1-

ES2+

ES2ED1+

ED1ED2+

ED2-

Publication 2727-QS002E-MU-P

Page 16

16 MobileView Guard G750

Power Supply Requirements

Electrical Specifications

24V dc Power Supply Use a 24V dc Safety Extra Low Voltage power supply.

Grounding Connect Earth Ground to the Junction Box using the Earth

Supply Voltage Range: 18V dc to 32V dc

Current Consumption: 300mA at 24V dc

Peak Inrush Current: 5.6 A maximum

Ground Screw (shown on page 14).

ATTENTION

!

• The device meets the safety class III in accordance with EN

61131-2 and EN 50178. The 24V power supply for the

equipment must provide appropriate isolation between the

safety-extra-low-voltage circuits and dangerous-contact

voltage circuits (for example, by safety transformers or

similar facilities).

• The power supply circuit must be protected with a 3.15 A

fuse.

• The nominal supply voltage directly of the MobileView

terminal (without the MobileView Connection Cable) is

+24V dc (supply voltage range: 18 to 32V dc).

Typical current consumption is:

- 300 mA at 24V dc

-400 mA at 18V dc

When planning the power supply, take into account the

voltage drop on the Connection Cable.

Specification of power supply lines in this cable:

Cross section: AWG24 (0.24 mm

Material: zinc-coated copper strand

Line resistance: <90 Ohm/km (<145 Ohm/mile)

2

)

Publication 2727-QS002E-MU-P

Page 17

MobileView Guard G750 17

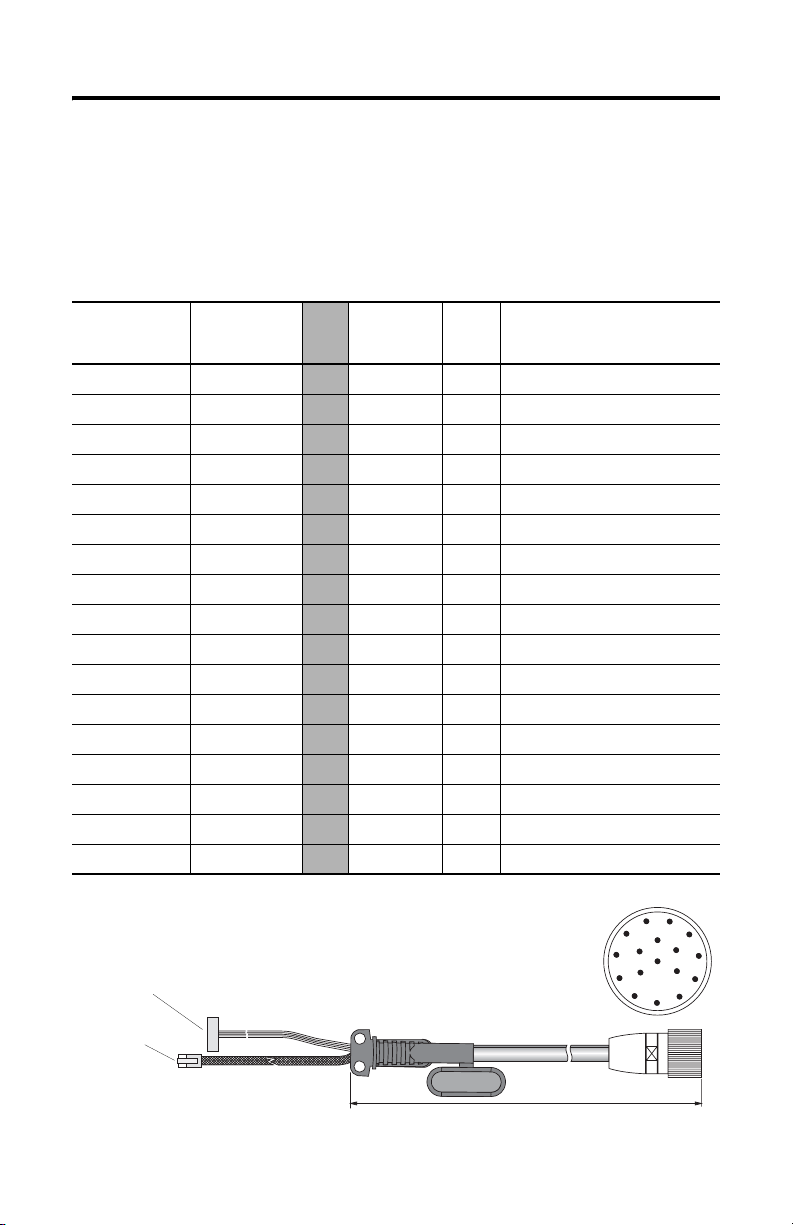

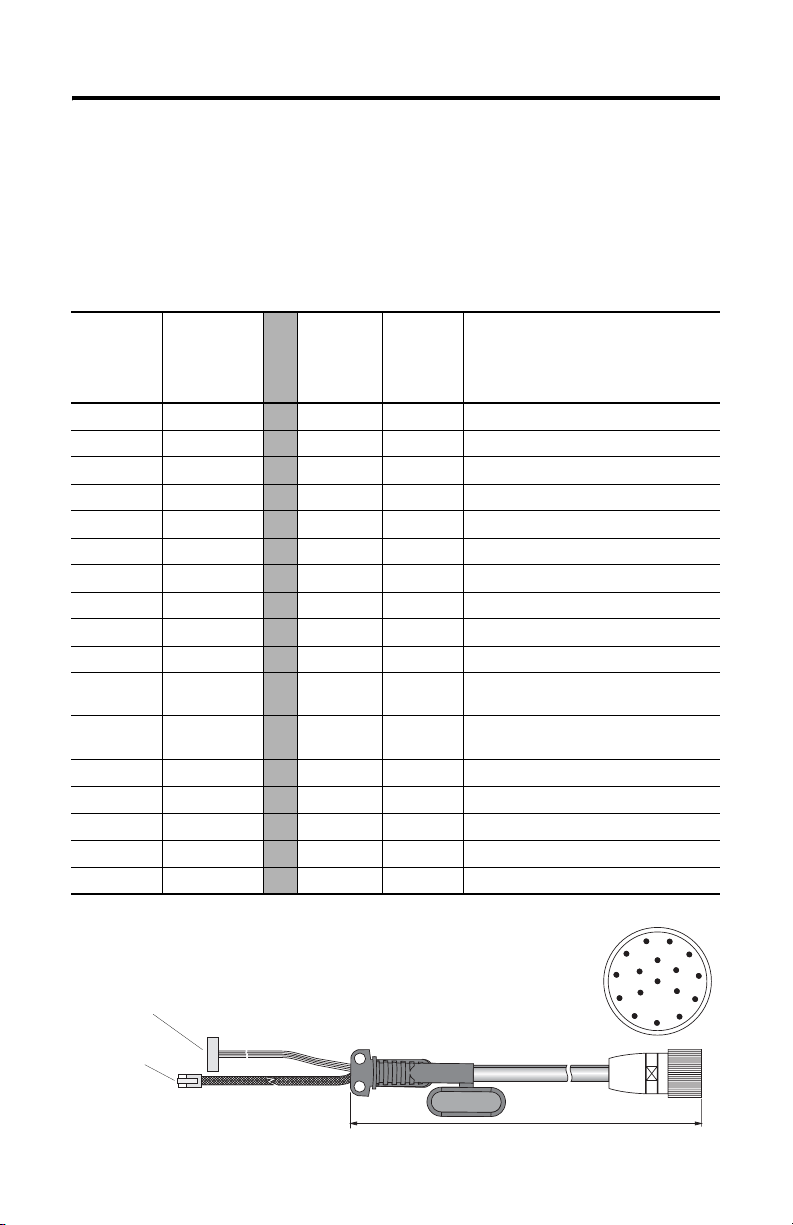

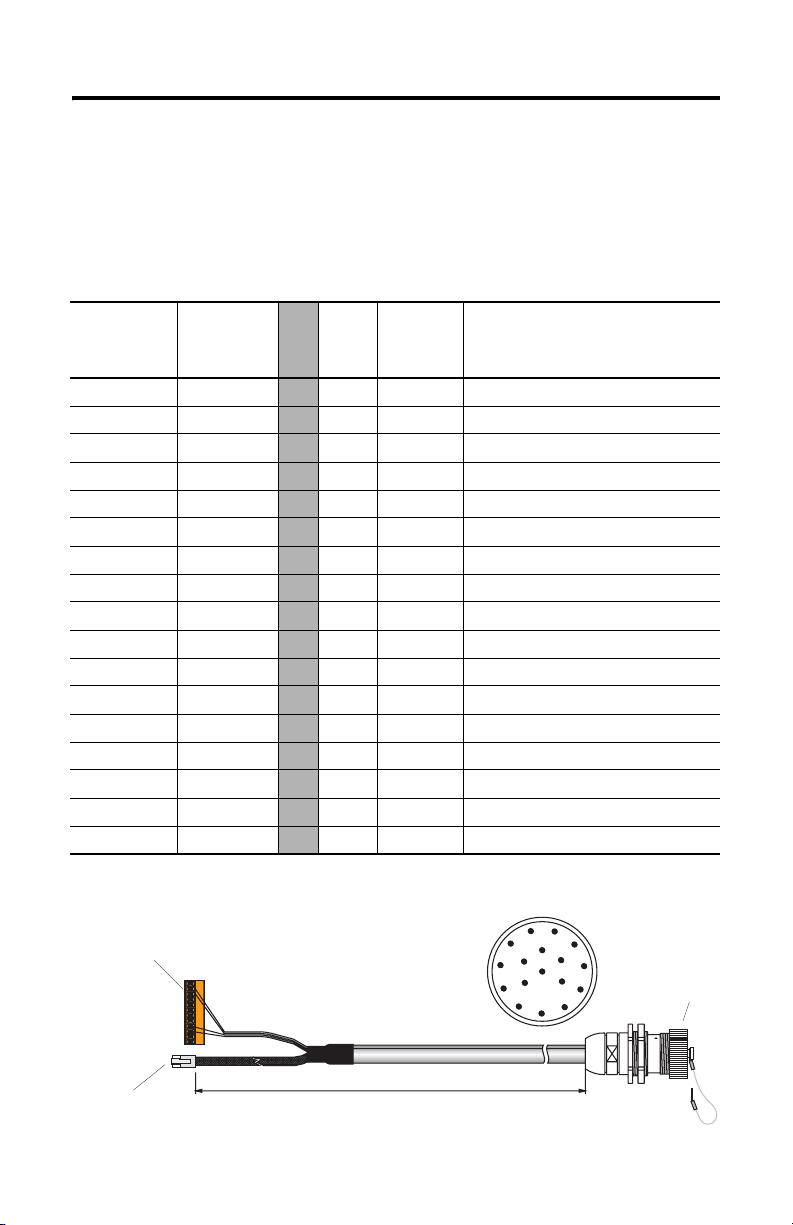

MobileView Connection Cable

The MobileView Connection Cable (2727-MRTxx) connects the MobileView

terminal to the Junction Box Cable. The Connection Cable is 5, 10, 15, or 20 meters

(16.4, 32.8, 49.2, or 65.6 feet). This cable withstands water, cleaning agents, motor

oil, drilling oils, grease, lubricants and condensates containing hydrochloric acid.

K1

17-pin Circular

Connector Pin #

Connection

Cable

Wire Color

1pink

2black

3 green-brown

4 white-green

5grey-pink

6 red-blue

7brown

8yellow

12 green

17 grey

9 bridge to pin 10

10 bridge to pin 9

11 violet

13 blue

14 white

15 orange

16 red

K3, 11-pin

Female

Connector

-->> 6 - 24V DC

-->> 7 - GND_IN

-->> 8 - E-stop, circuit 1, positive

-->> 9 - E-stop, circuit 1, negative

-->> 10 - E-stop, circuit 2, positive

-->> 11 - E-stop, circuit 2, negative

-->> 1 - Enabling switch, circuit 1, positive

-->> 2 - Enabling switch, circuit 1, negative

-->> 3 - Enabling switch, circuit 2, positive

-->> 4 - Enabling switch, circuit 2, negative

-->> - - Not Used

-->> - - Not Used

-->> 5 - Not Used

-->> - 1 TD+ (transmit)

-->> - 2 TD- (transmit)

-->> - 3 RD+ (receive)

-->> - 6 RD- (receive)

K2,

8-pin

RJ-45

Signal

Description

K3, 11-pin

female connector to S19

at MobileView terminal

K2, 8-pin RJ-45

jack to S4 at

MobileView

terminal

K1, 17-pin circular connector

view from connector side

5, 10, 15, or 20 meters (6.4, 32.8, 49.2, or 65.6 feet)

Publication 2727-QS002E-MU-P

11

1

10

9

8

2

12

16

13

17

3

14

15

4

5

7

6

Page 18

18 MobileView Guard G750

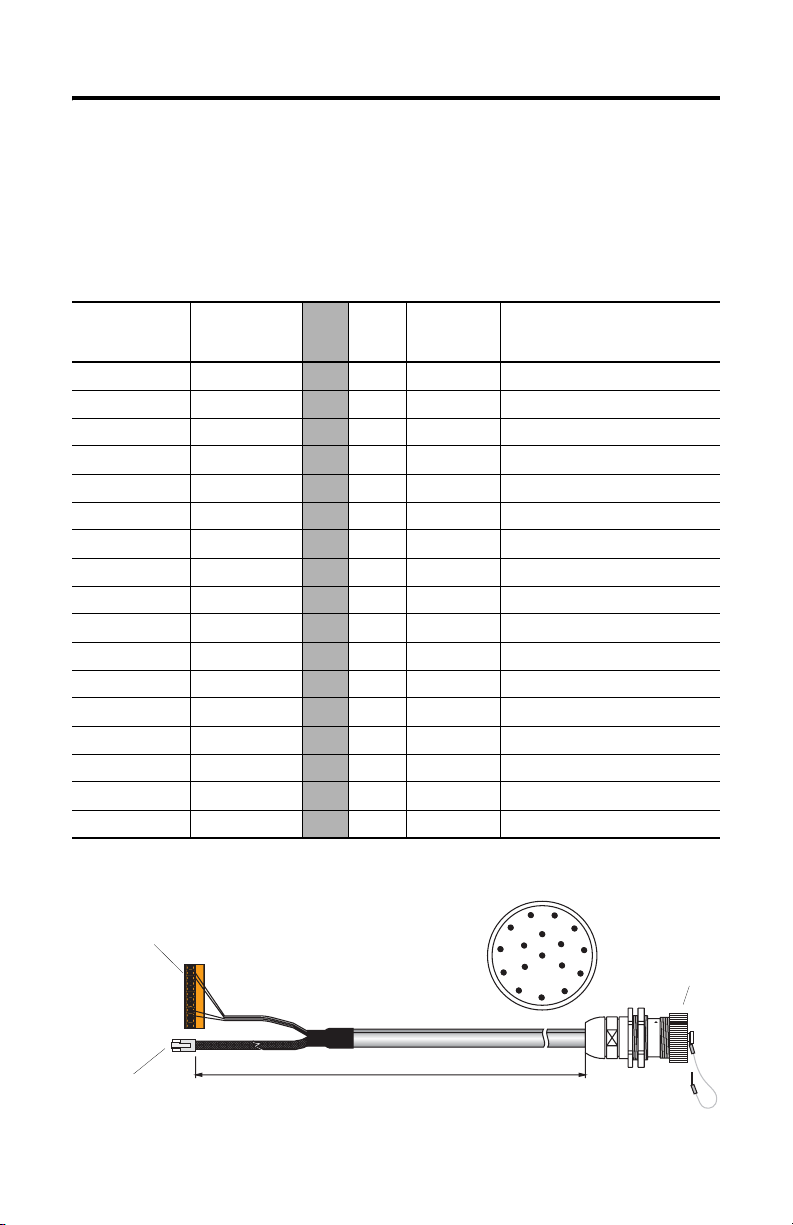

MobileView Junction Box Cable

The MobileView Junction Box Cable (2727-MREX1) connects the Junction Box to

the circular jack in the wall of the enclosure. The cable length is 2 meters (6.5 feet).

When the MobileView terminal is not connected to the Junction box, the dust cover

provides protection for the 17-pin connector.

K1, 17-pin

Circular Jack

Pin #

MobileView

Junction Box

Wire Color

1pink

2black

3 green-brown

4 white-green

5grey-pink

6 red-blue

7brown

8yellow

12 green

17 grey

910 11 violet

13 blue

14 white

15 orange

16 red

K3, 12-pin

connector for

terminal block X1

at Junction Box

K2,

8-Pin

RJ-45

K3, 12-Pin

Ter mi nal

Block

Signal

Description

-->> - 1 24V DC

-->> - 2 GND_IN

-->> - 3 E-stop, circuit 1, positive

-->> - 4 E-stop, circuit 1, negative

-->> - 5 E-stop, circuit 2, positive

-->> - 6 E-stop, circuit 2, negative

-->> - 7 Enabling switch, circuit 1, positive

-->> - 8 Enabling switch, circuit 1, negative

-->> - 9 Enabling switch, circuit 2, positive

-->> - 10 Enabling switch, circuit 2, negative

-->> - - Not Used

-->> - 12 Not Used

-->> - 11 Not Used

-->> 1 - TD+ (transmit)

-->> 2 - TD- (transmit)

-->> 3 - RD+ (receive)

-->> 6 - RD- (receive)

K1, 17-pin circular jack

view from connector side

1

11

2

12

10

16

13

3

14

4

5

9

17

15

8

7

6

Dust Cover

K2, 8-pin RJ-45

jack (Ethernet) for

S1 at Junction Box

Publication 2727-QS002E-MU-P

2 meter (6.5 ft)

K1, 17-pin circular jack

mounts to enclosure

Page 19

MobileView Guard G750 19

MobileView Terminal

This section provides details on:

• How to remove the back cover of the MobileView terminal

• Ethernet connection

• Using the PC Card slot

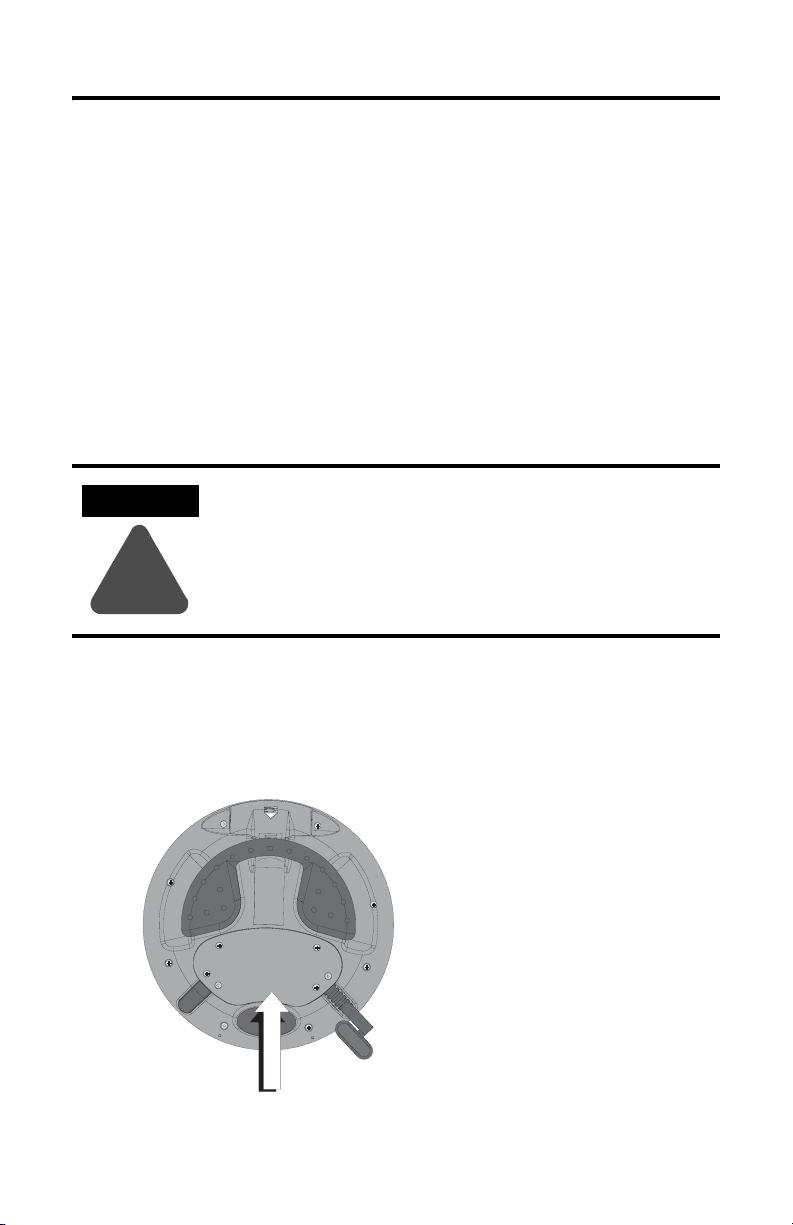

Removing the Back Cover

This section shows how to remove the back cover of the MobileView terminal.

Once the back cover is removed you have access to the area which contains all of

the connectors.

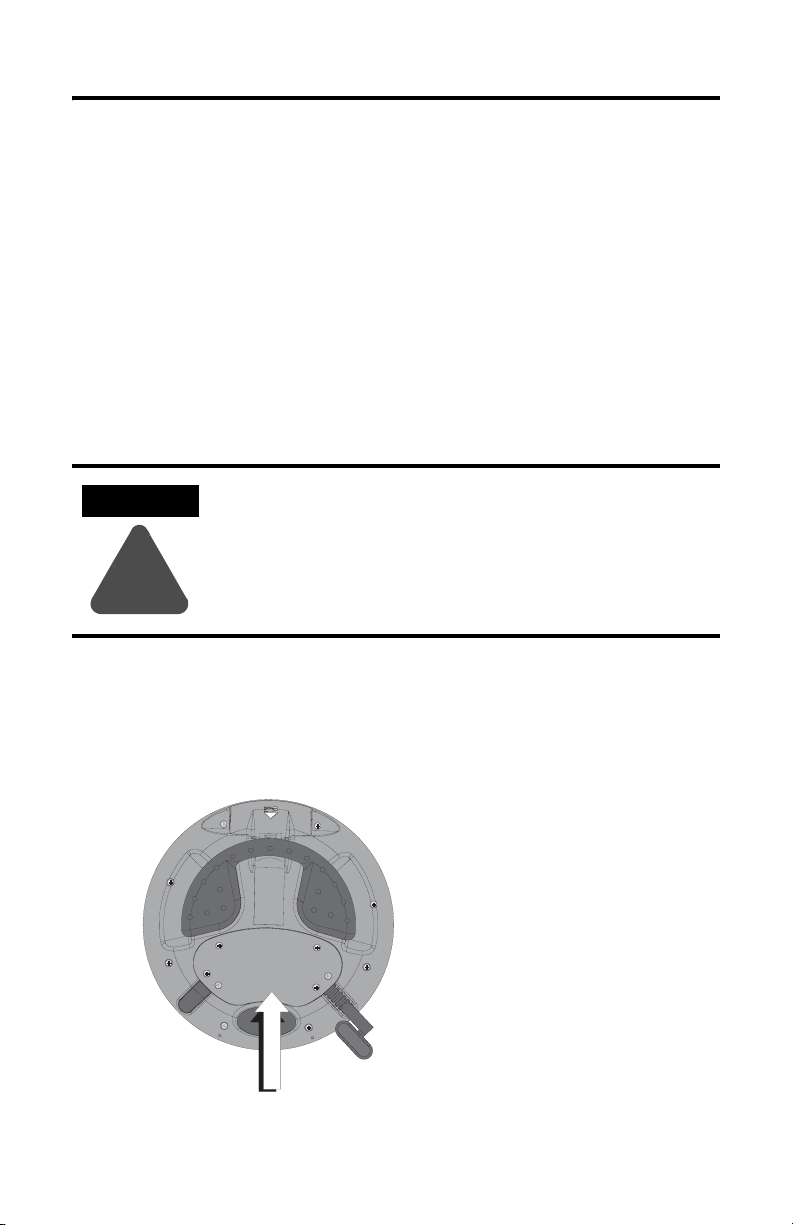

ATTENTION

Turn off the power supply before removing the back cover of

the MobileView terminal.

When the back cover is removed, the MobileView terminal is

sensitive to electrostatic discharge.

!

1. Place the terminal on a stable, flat surface.

2. Remove the 6 screws that secure the back cover to the terminal.

3. Carefully lift off the back cover and set aside.

Back Cover

Publication 2727-QS002E-MU-P

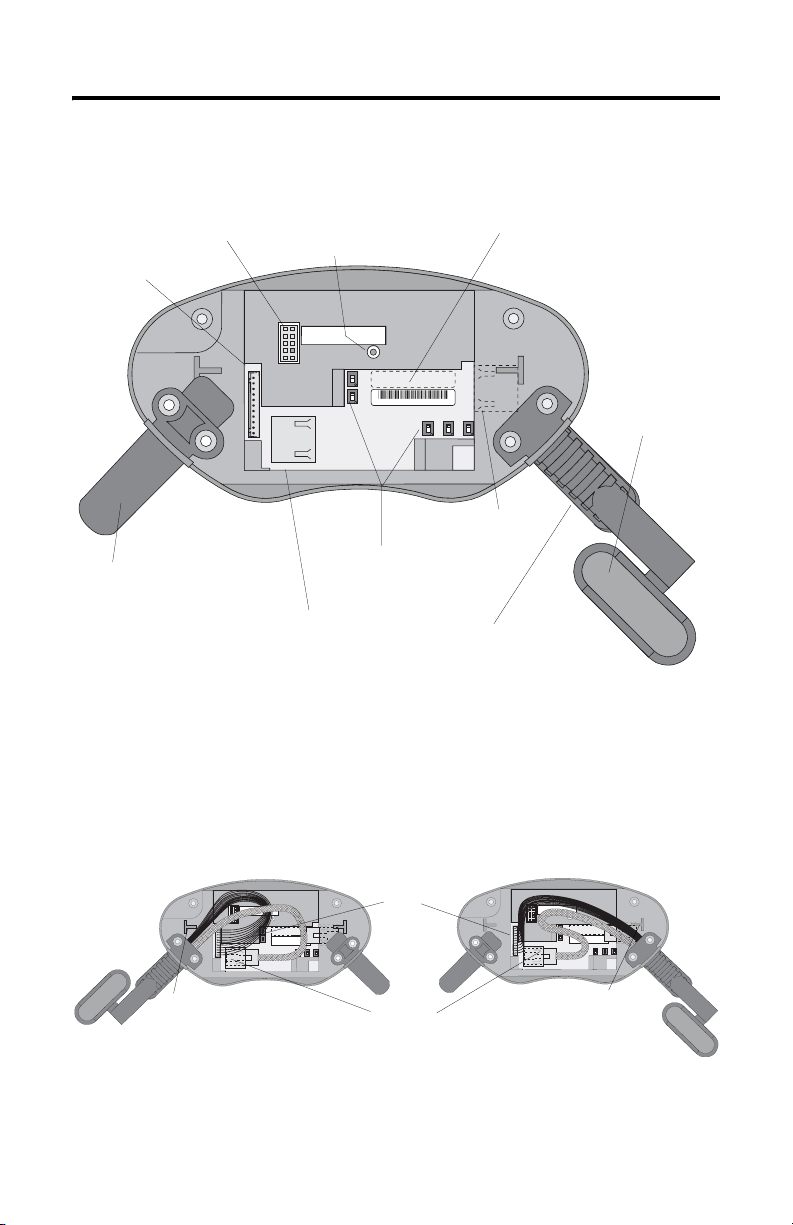

Page 20

20 MobileView Guard G750

The following illustration shows what the connection area of the MobileView

terminal looks like with the back cover removed.

RS-232 Port

for downloading software.

Main connector (S19)

for power supply and

control lines

Important: Install plug on

unused MobileView

Connection Cable outlet.

Reset Button

for rebooting Windows CE.

All data not flushed to Registry or

saved to Flash Storage is lost.

pin 1

Serial

port

S19

Reset

B5

B4

00:60:B5:06:00:01

S4

Ethernet

Position of switches does not

affect terminal operation (for

future use)

Ethernet connector (S4)

for data exchange

Ethernet Label

Ethernet (Mac) Address

2250-00001

AABBCCDDEEFF

B2 B6 B3

S6,

COM -Modul

Connector (not used)

Strain Relief

for connecting MobileView

Connection Cable (on left or right side)

Cable Tag

Allows the terminal to

be uniquely identified.

Relocating MobileView Connection Cable

The MobileView Connection Cable can be attached on the right or left side of the

terminal for right or left-hand operation. To relocate the cable, simply grasp the

strain relief and/or the plug and slide off of mount with a rocking motion.

Attaching Cable on Right

S19

Main

S6,

Connector

COM -Modul

Avoid routing cable

over T-support.

S4, Ethernet Connector

Important: Make sure the K3, 11-pin female connector clicks completely into S19, Main Connector when

plugged in. Ensure proper seating of K2, 8-pin RJ-45 jack into S4, Ethernet Connector. Avoid routing the

cable over the T-supports. After routing the cable, secure the back cover to the terminal with the 6 screws.

Tighten screws to a torque of 4.42 In-lbs to maintain IP54 degree protection.

Publication 2727-QS002E-MU-P

Attaching Cable on Left

Avoid routing cable

over T-support.

S6,

COM-Modul

Page 21

MobileView Guard G750 21

Ethernet Connection

The MobileView terminal is equipped with a 10Base-T interface which supports

TCP/IP protocol at 10MBaud for half-duplex communications.

The Ethernet connector at S3 on the Junction Box provides a connection to an

Ethernet network. The connector uses an 8-pin modular jack connector. Pinouts are

as follows:

Pin # Ethernet Signal

1TD+

2TD-

3RD+

4 Not Used

5 Not Used

6RD-

7 Not Used

8 Not Used

Using the PC Card Slot

The PC card slot is a factory installed option and supports Type I, II, and III PC

cards. The following PC cards are available from Allen-Bradley. The terminal does

not support SRAM cards, Cardbus cards, or cards that use 12 volts for programming.

Catalog No. Description

2711-NM28 8M flash ATA card for storing applications.

2711-NM216 16M flash ATA card for storing applications.

2711-NM232 32M flash ATA card for storing applications.

PC Card

Compartment

Publication 2727-QS002E-MU-P

Page 22

22 MobileView Guard G750

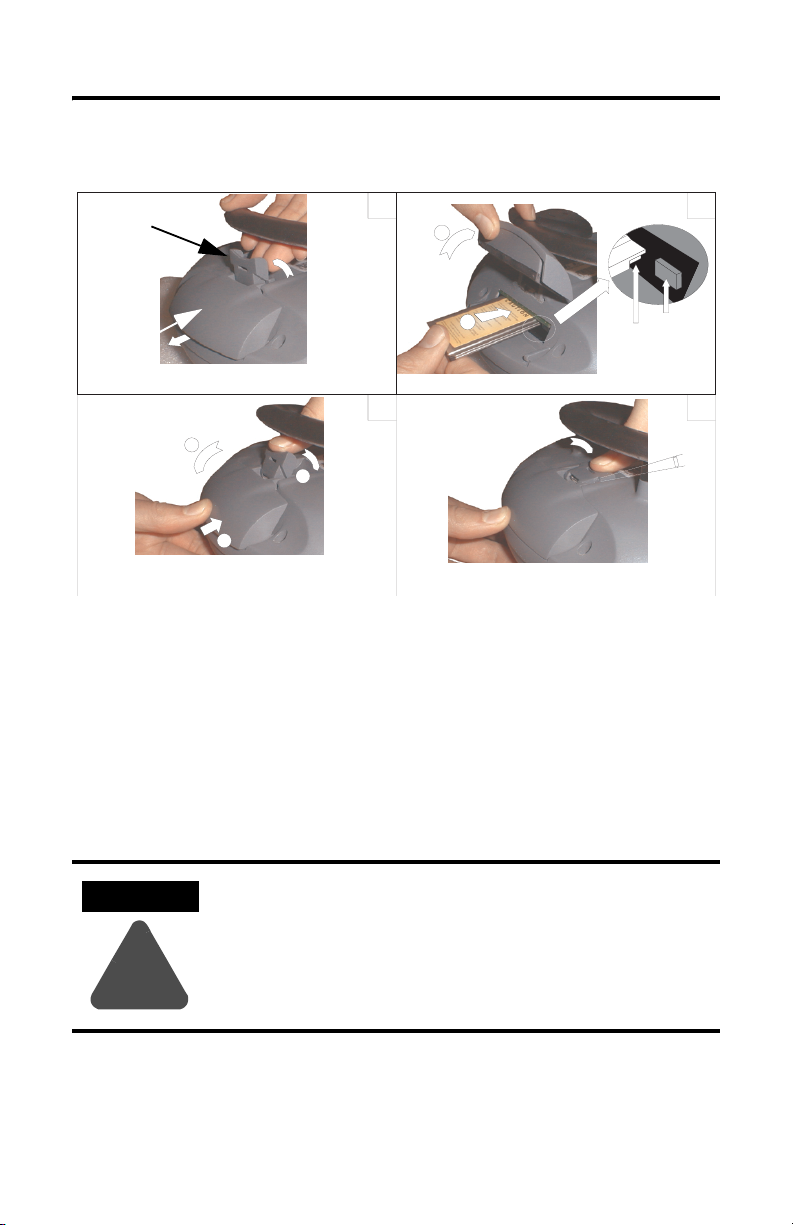

Inserting the PC Card

Locking Lever

PC Card Cover

a

c

b

1

a

b

3

1. Unlocking PC card cover (see illustration 1).

a. Lay the MobileView with the display facing down onto a flat, clean table

(preferably on ESP pad). Take care not to damage the terminal and its

elements.

b. Lift up on locking lever until PC Card Cover is released.

2. Inserting PC card (see illustration 2).

a. Lift the cover up.

b. Insert the PC card until it locks in and the ejection button pops out.

2

Ejection button

4

Must snap

completely.

ATTENTION

Verify that the corner of the PC card (with the notch) is

inserted into the slot on the side of the ejection button.

Check the condition and position of the cover seal before

closing the PC card cover.

!

3. Close and lock the cover (see illustration 3).

4. Press the cover down until it snaps in completely (see illustration 4).

Publication 2727-QS002E-MU-P

Page 23

MobileView Guard G750 23

Removing the PC Card

1

1

3

2

1. Open the PC card cover. Refer to Inserting the PC Card on page 22 for procedures.

2. Press the ejection button on the PC card slot.

3. Remove the PC Card.

4. Close and lock the cover.

5. Press the cover down until it snaps in completely.

Publication 2727-QS002E-MU-P

Page 24

24 MobileView Guard G750

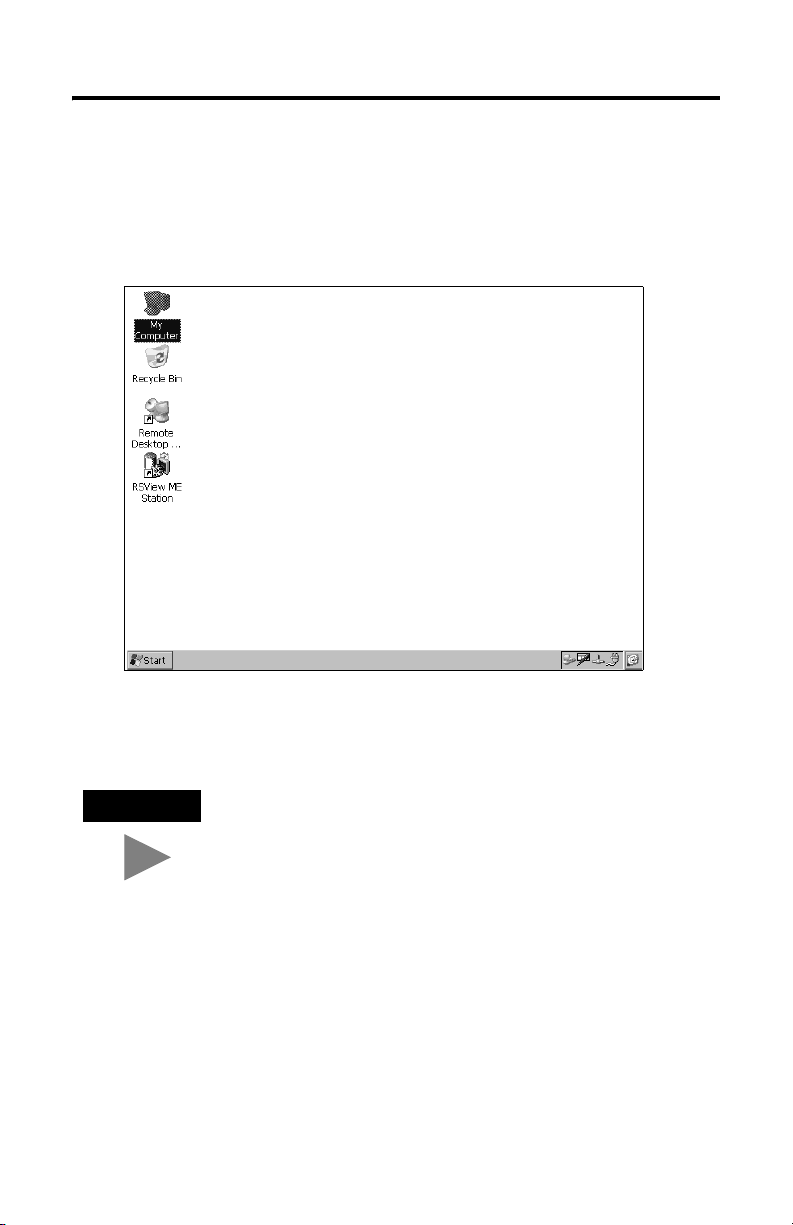

Startup/Power On

1. Attach the MobileView Connection Cable to the Junction Box Cable as

shown on page 14. Tighten threaded coupling until it is finger tight.

2. Check the MobileView terminal for a start-up screen.

If the start-up screen does not appear, check the 24V dc power source and

cable connections at the Junction Box and MobileView terminal.

TIP

Publication 2727-QS002E-MU-P

An icon for RSView ME software appears on the MobileView

2727-G7P20D1Q6 and 2727-G7P20D3Q7 start-up screens only.

Page 25

MobileView Guard G750 25

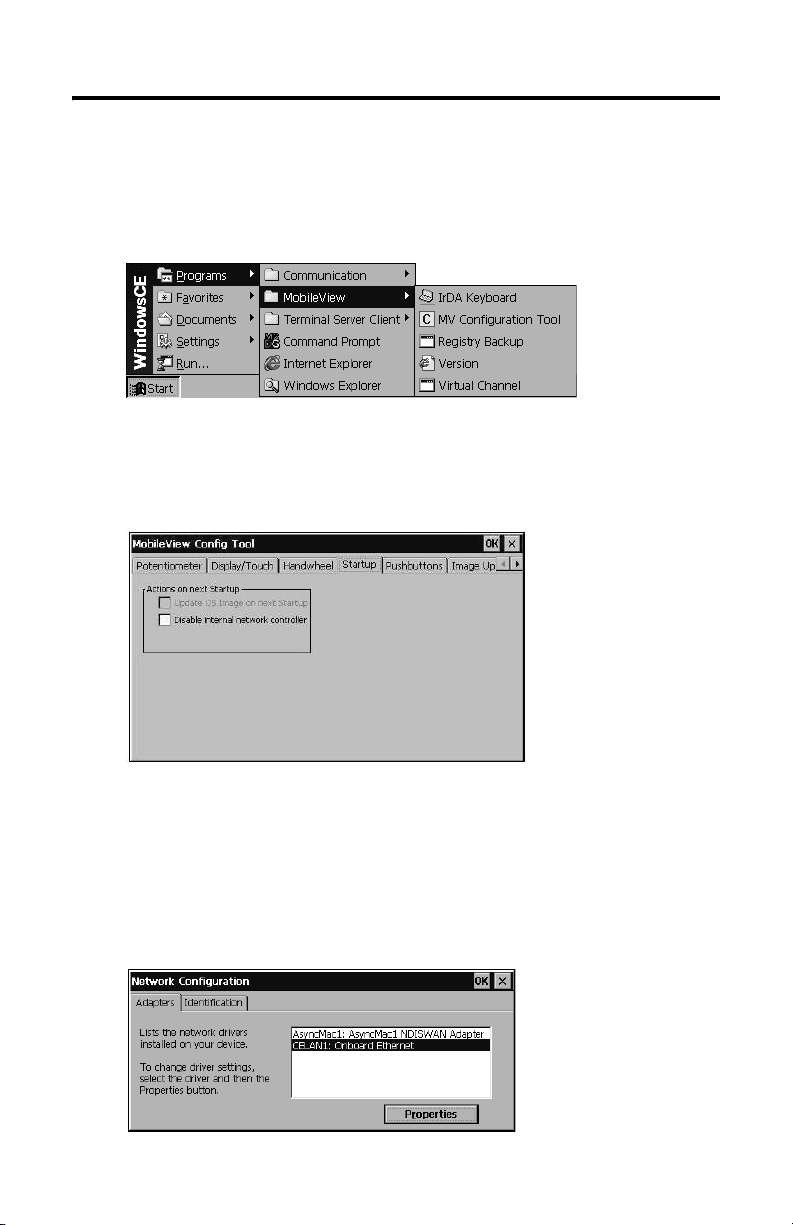

Hardware Configuration

1. From the task bar, select Start>Programs>MobileView>MV

Configuration Tool.

The Config Tool dialog opens with the default tab selected. Adjust display

touch screen and device settings, as desired. Refer to publication

2727-UM002, MobileView Guard G750 User Manual for details.

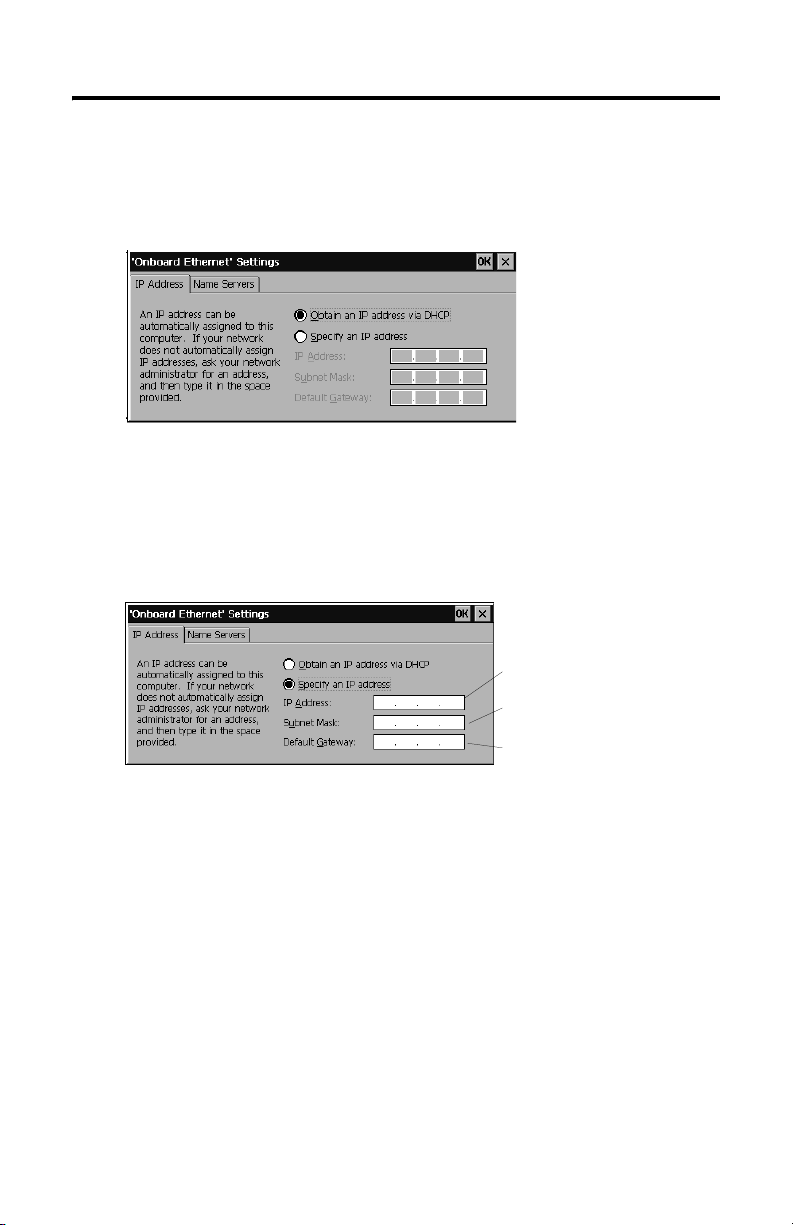

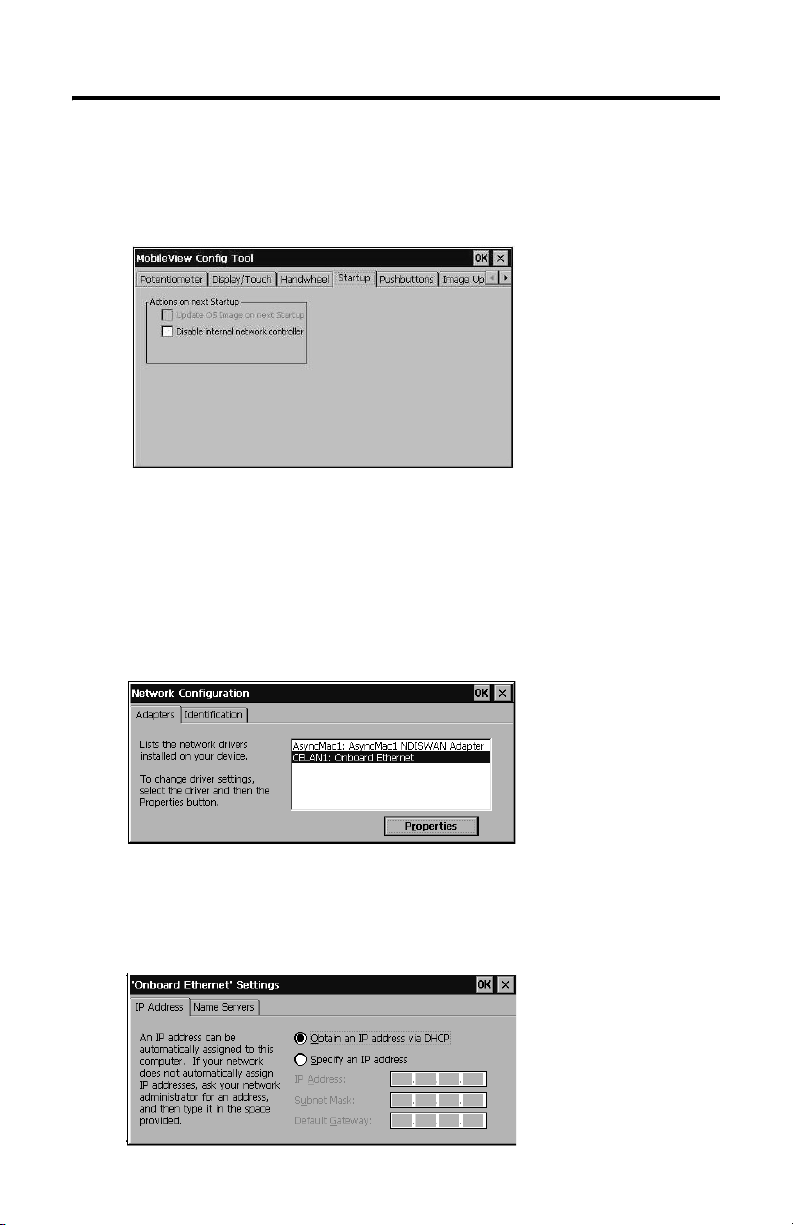

Ethernet Network Configuration

To configure the onboard Ethernet communications hardware of your

MobileView terminal:

1. Tap the Start button and select Settings>Control Panel.

2. Double-tap the Network icon.

Publication 2727-QS002E-MU-P

Page 26

26 MobileView Guard G750

3. Tap the Adapters tab in the Network Configuration dialog.

4. Select the CELAN1:Onboard Ethernet from the list of drivers, then tap the

Properties button.

5. Tap the IP Address tab and select either Obtain an IP Address via DHCP

or Specify an IP Address, depending on your network configuration. If you

select Specify an IP Address, complete the 3 text boxes with information

from your network administrator or ISP. Use the on-screen input panel to

enter the text. You can access the input panel by tapping the Stylus icon on

the task bar.

IP Address must be a unique

address on the LAN.

Subnet Mask must be identical

to the server subnet mask.

Default Gateway is optional.

6. Tap OK in the settings dialog. A notification window appears prompting you

to either remove and reinstall your card or restart the device for the new

settings to take effect. Tap the OK button in notification window.

7. Tap OK on the Network Configuration dialog and close the Control Panel.

Publication 2727-QS002E-MU-P

Page 27

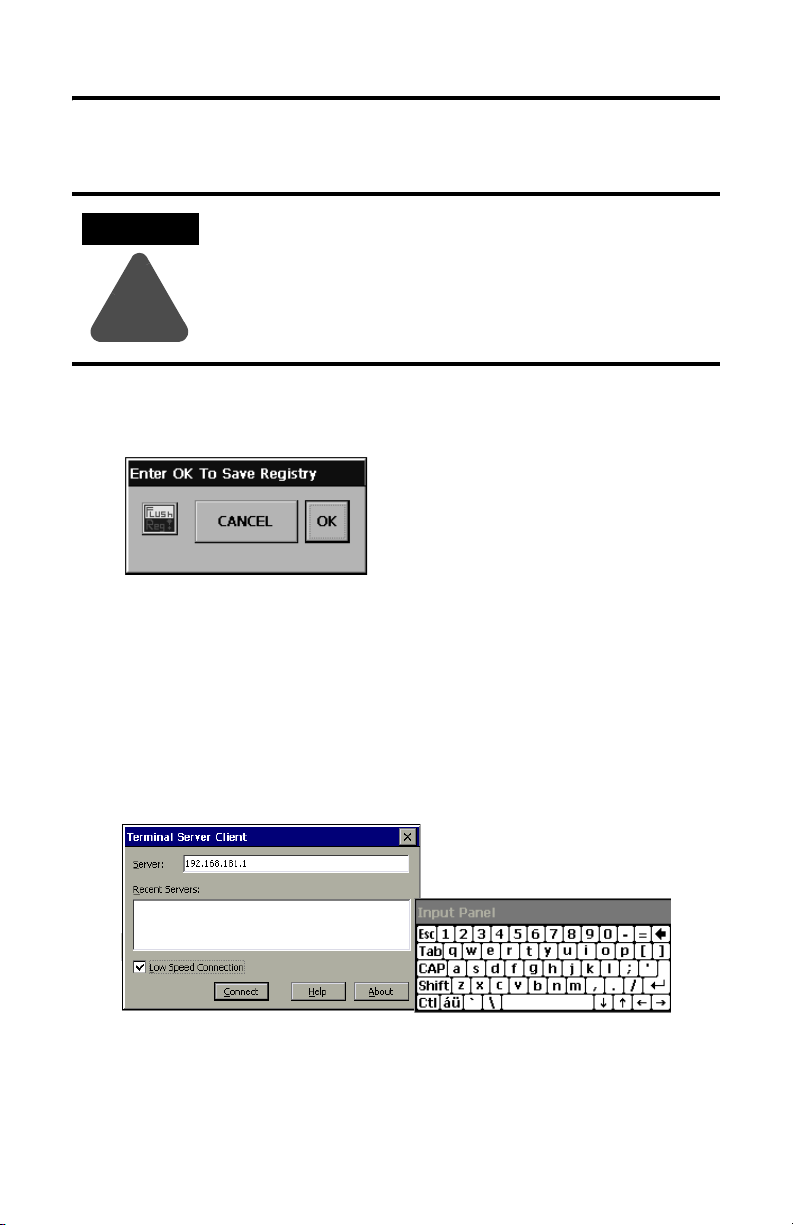

Saving Registry Settings

MobileView Guard G750 27

ATTENTION

Any hardware configuration or Ethernet network configuration

changes must be saved to the registry or they will be lost during a

MobileView terminal power cycle.

!

To save the current registry settings:

1. Tap the Start button and select Programs>MobileView>Registry Backup.

2. To save the registry, tap the OK button. Saving the registry may take up to

15 seconds. The registry backup will automatically close.

Starting Terminal Services

To connect to a terminal server as a CE client:

1. Double-tap the Terminal Server Client shortcut on the desktop of the

MobileView terminal or select the Terminal Server Client application from

the Programs>Terminal Server Client folder on the Start menu.

2. Enter the Terminal Server’s Name or a valid TCP/IP address in the Server

box using the on-screen input panel or select a server name or address from

the Recent Servers box.

3. Tap the Connect button. A server log on window similar to the one below

appears.

Publication 2727-QS002E-MU-P

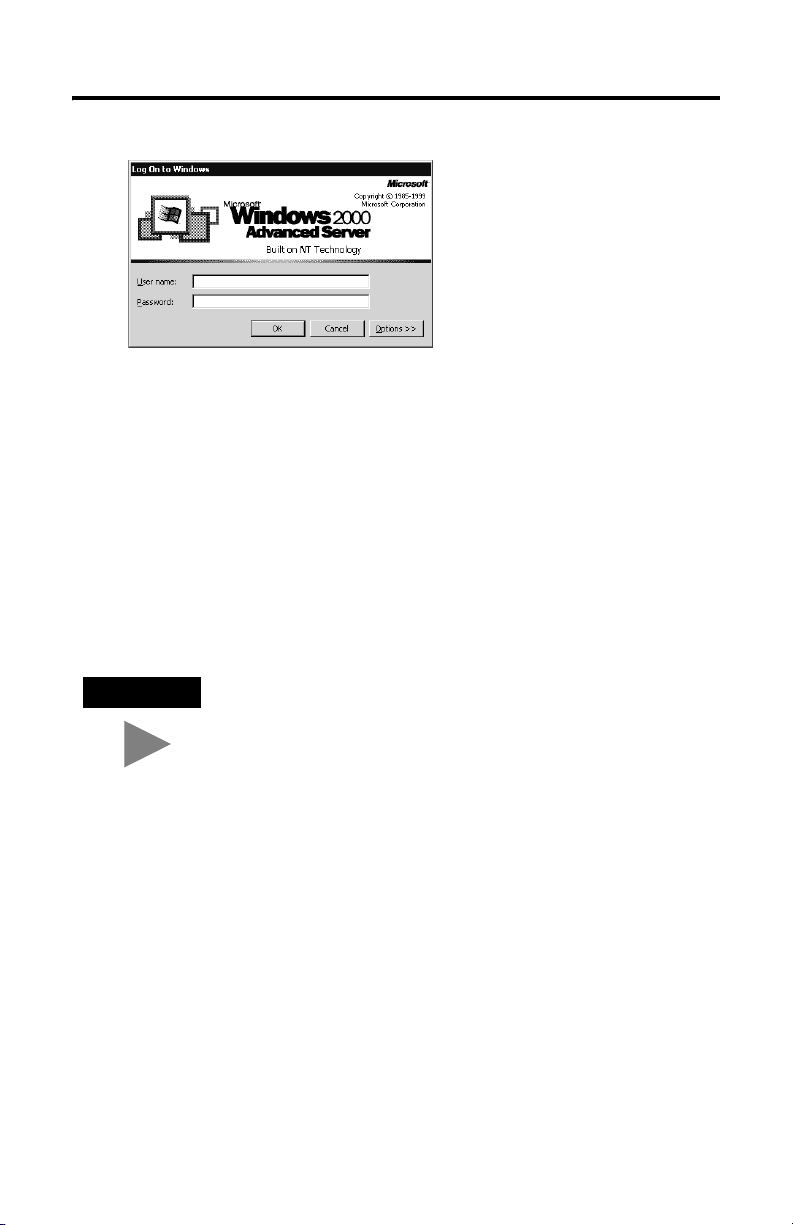

Page 28

28 MobileView Guard G750

4. Enter your user name and password to operate as an active CE client.

Shutdown/Power Off

1. Close down all applications that are running on CE client.

2. Tap the Start button on the CE client task bar. Select Shutdown and then

Log Off to disconnect from the terminal server.

3. Remove 24V dc power from the MobileView junction box or disconnect the

MobileView connection cable from the junction box cable.

TIP

Publication 2727-QS002E-MU-P

Time/Date/Regional Setting information is not saved during a

reboot.

Page 29

MobileView Guard G750 29

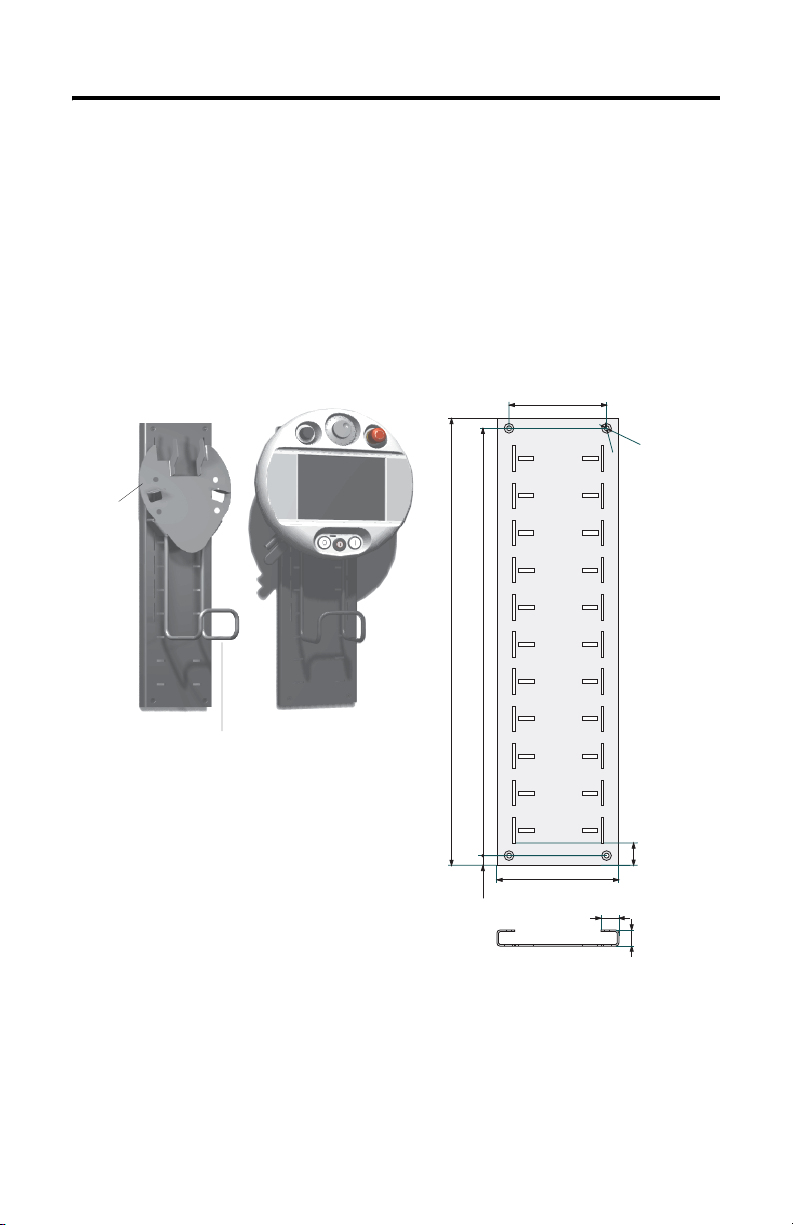

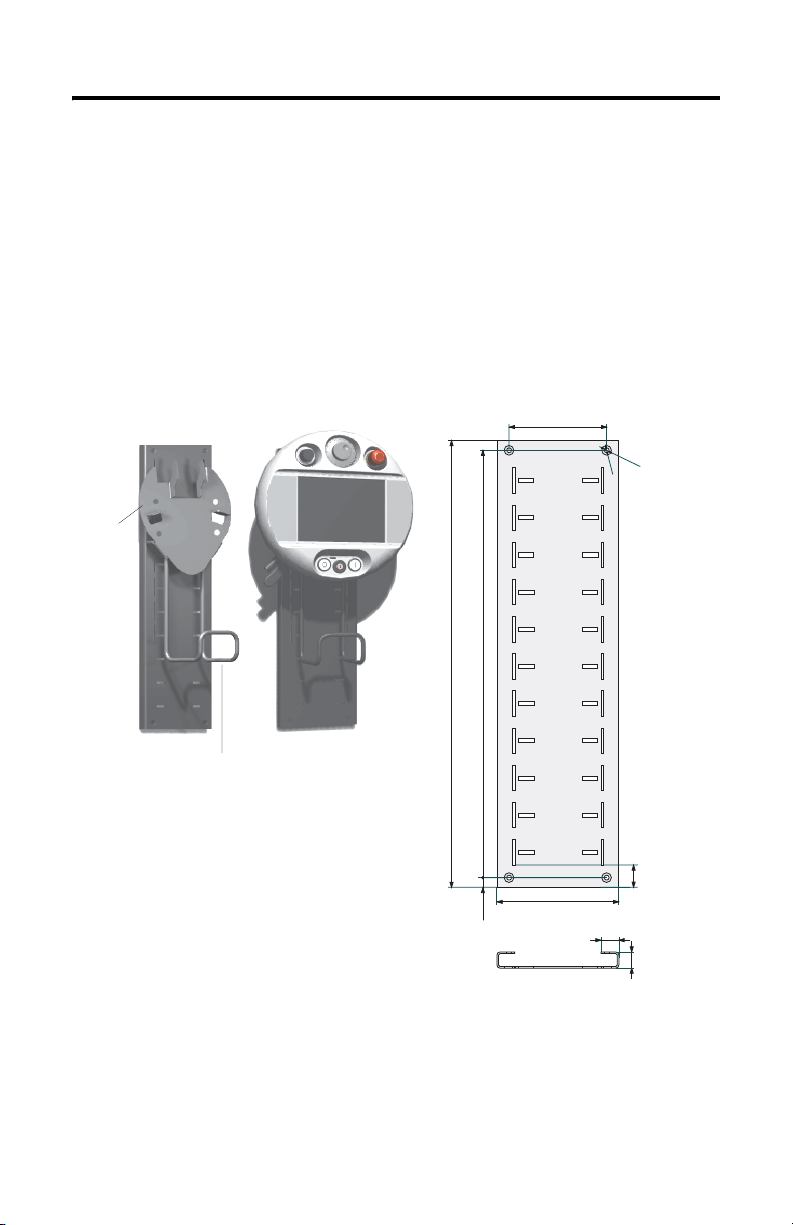

Mounting Bracket Installation

The MobileView Mounting Bracket (catalog number 2727-MRMB1) is used for

stationary operation or storage of the terminal. The following illustration shows the

mounting bracket with and without the terminal mounted.

The carrier is adjustable in 8 positions over a height of 320 mm (12.6 in). It is

important to attach the carrier at all 4 points on the height adjustment plate. Mount

the cable holder on the carrier using the screws delivered with the bracket.

Height Adjustment Plate

Carrier

Connection Cable Holder

Plate Dimensions and Mounting Holes

550 mm (21.65 in)

MobileView

120 mm (4.72 in)

526 mm (20.71 in)

150 mm (5.91 in)

22 mm (0.87 in)

12 mm (0.47 mm)

Use suitable screws (not shipped with product) to mount the plate.

6

m

m

1

d

2

i

a

.

(

0

m

.

2

4

.

(

0

.

4

7

i

n

28 mm

)

20 mm

(1.1 in)

(0.79 in)

i

n

)

m

d

i

a

Publication 2727-QS002E-MU-P

Page 30

30 MobileView Guard G750

European Communities (EC) Directive Compliance

The product has a CE mark and is approved for installation within the European

Union and EEA regions. It has been designed and tested to meet the following

directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC Electromagnetic

Compatibility (EMC) by applying the following standards, in whole or in part,

documented in a technical construction file:

• EN 61000-6-4:2001 EMC - Generic Standard - Emission Standard for Industrial

Environments

• EN 61000-6-2:2001 EMC - Generic Standard - Immunity for Indutrial

Environments

• EN 61131-2:1994 - Programmable Controllers Part 2 - Equipment

Requirement and Tests

This product is intended for use in an industrial environment.

Machinery Directive

The MobileView Guard G750 is tested to meet the Council Directive 98/37/EC,

Safety of Machinery, by applying the following standards:

• EN 954-1:1996 Safety-related parts of control systems

• EN 292-1:1991 - Basic concepts, general principles for design

• EN 292-2:1991 + A1:1995 - Technical principles and specifications

• EN 418:1992 - Emergency stop equipment, function aspects, principles of design

• EN 60204-1:1997 - Electrical equipment of machines, general requirements

A Declaration of Conformity is available upon request.

Publication 2727-QS002E-MU-P

Page 31

MobileView Guard G750 31

Standards and Agency Certifications

General

UL 508 Industrial Control Equipment

CSA C22.2 No. 14 Industrial Control Equipment

C-Tick Marked for all applicable acts

Electromagnetic Compatibility (EMC)

EN 61000-6-4:2001 EMC - generic emission standard for industrial environment

EN 61000-6-2:2001 EMC - generic immunity standard for industrial environment

IEC 61131-2 final draft chapt 7+8 Programmable Controllers - Equipment requirements and test

Operating Safety

IEC 61131-2, EN 61131-2:1994 +

A11:1996 + A12:2000

IEC 60204-1, EN 60204-1:1997 Safety of machinery - electrical equipment of machines, general

EN 50178:1997 Electronic equipment for use in power installations

Machinery Standards

EN 614-1:1995 Ergonomic design principles

EN 894-1:1997, -2, -3 Ergonomic requirements for the design of displays and control actuators

ISO 13849-1:1999, EN 954-1:1996 Safety-related parts of control systems

ISO DIS 12100-1, EN 292-1:1991 Basic concepts, general principles of design

ISO DIS 12100-2,

EN 292-2:1991 + A1:1995

ISO 13850:1996, EN 418:1992 Emergency stop equipment, functional aspects, principles for design

EN 60204-1: 1997 Safety of machinery - electrical equipment of machines, general

Programmable Controllers - Equipment requirements and test

requirements

Technical principles and specifications

requirements

Standards for MobileView used in Robot Systems

EN 775:1992 Industrial robots

ANSI/RIA R15.06 - 1999 American National Standard for Industrial Robots and Robot Systems -

ANSI/RIA R15.02/1 American National Standard for Industrial Robots and Robot Systems -

UL 1740 Robots and Robot Equipment

Standards for MobileView used in Machining Centers

ISO 11161 Industrial Automation Systems - Safety of Integrated Manufacturing

EN 12417:2001 Machine tools - Safety - Machining Centers

safety requirements

Hand-Held robot Control Pendants - Human Engineering Design Criteria

Systems

Publication 2727-QS002E-MU-P

Page 32

32 MobileView Guard G750

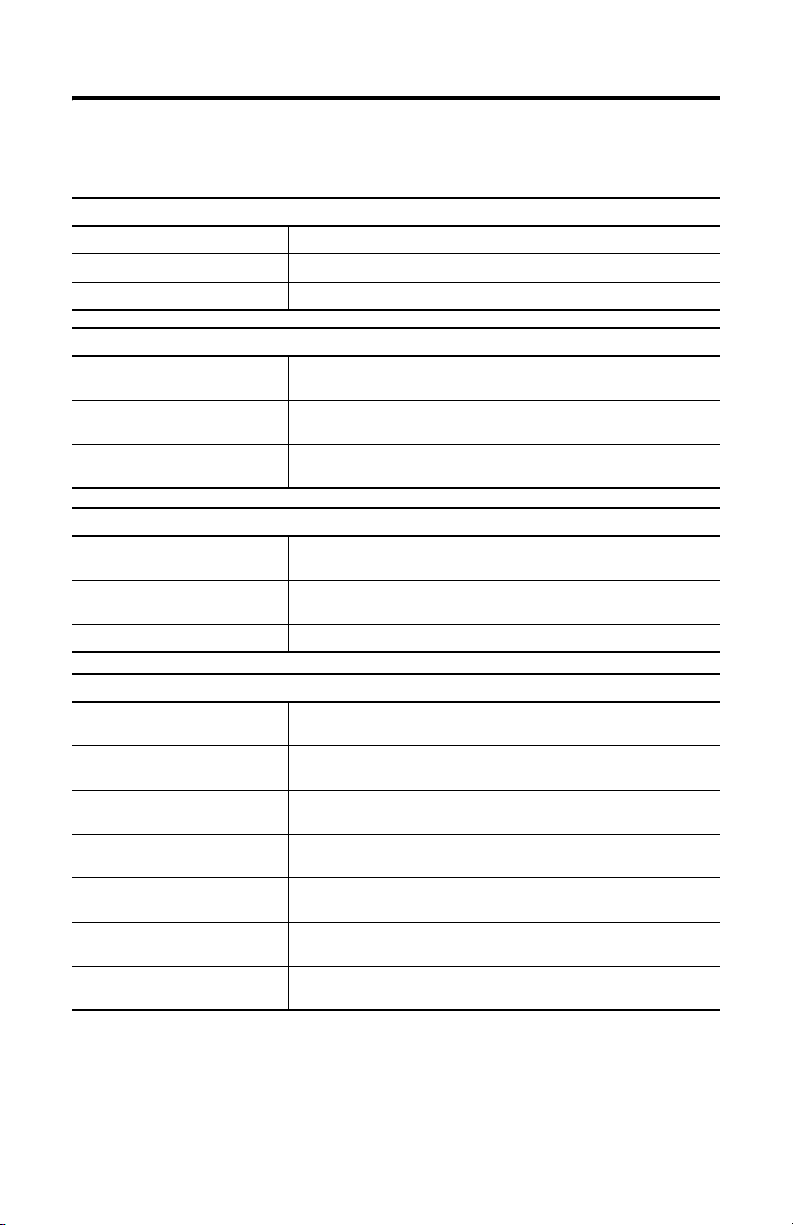

MobileView Guard G750 Configurations

Features 2727-G7P20D1P4 2727-G7P20D1P5 2727-G7P20D1Q6 2727-G7P20D3Q7

7.7 Inch VGA Display Yes

IrDA Interface Yes

3-Position Enable Switch Yes

2-Circuit E-Stop- Position 3 No Yes

Memory 16MB DRAM/32MB Flash 64MB DRAM/64MB Flash

PC Card Slot No Yes

Communications 10Base-T Ethernet

Push Button with

OFF Marking Position 5

Key Switch Position 6

Operating Elements No No

Windows CE OS Yes

RSView Machine Edition No Yes

Thin Client Application Yes

Push Button with

ON marking Position 7

Potentiometer Position 1

Electronic

Handwheel

-Position 2

No

Accessories

Catalog Number Description

2727-MRT5 MobileView Guard Connection Cable (5 meter /16.4 ft) - connects Guard terminal to the

2727-MRT10 MobileView Guard Connection Cable (10 meter /32.8 ft) - connects Guard terminal to the

2727-MRT15 MobileView Guard Connection Cable (15 meter /49.2 ft) - connects Guard terminal to the

2727-MRT20 MobileView Guard Connection Cable (20 meter/65.6 ft) - connects Guard terminal to the

2727-MRJB1 MobileView Guard Junction Box - provides controller, Ethernet, power supply, emergency

2727-MREX1 MobileView Guard Junction Box Cable (2 meter / 6.5 ft) - connects the MobileView Guard

2727-MRC1 MobileView Guard Download Cable (4 meter /13.1 ft) - connects between the MobileView

2727-MRMB1 MobileView Guard Mounting Bracket for stationary operation or storing the MobileView

2727-MRSDK1 MobileView Guard SDK file set for Windows CE development

Publication 2727-QS002E-MU-P

Junction Box cable.

Junction Box cable.

Junction Box cable.

Junction Box cable.

stop switch, and enabling switch connections.

Connection Cable to the Junction Box.

Guard terminal to a PC.

Guard terminal.

Page 33

MobileView Guard G750 33

Specifications

General

Processor Intel StrongARM SA-1110/206 MHz

Operating System

2727-G7P20D1P4, -G7P20D1P5

2727-G7P20D1Q6, -G7P20D3Q7

Memory 2 sizes: 16M DRAM/32M Flash or

Display Passive LCD 7.0-inch VGA with 256 colors

Touch Screen 7.7-inch analog resistive

Keypad Stainless steel dome membrane switches with tactile

Housing Twin shell

Dimensions

Diameter

Depth without handle

Depth with handle

Weight 1550 grams (3.42 lbs) - without options

Microsoft Windows CE 3.0

Microsoft Windows CE 4.1

64M DRAM/64M Flash

feedback

Resistive to grease, oil, lubricants, alcohol

Silicone-free

Flammability class: UL 94-V0

290 mm (11.42 inches)

80 mm (3.15 inches)

130 mm (5.12 inches)

Electrical

Nominal Supply Voltage 24V dc safety-extra-low-voltage

Supply Voltage Range 18V dc to 32V dc

Input Current 300mA maximum

Peak Inrush Current 5.6A maximum

Power Supply 10 ms minimum holdup time (EN 61131-2:1994 and

Environmental

Operating Temperature

Storage Temperature

Relative Humidity (non-condensing)

Protection Degree IP54

Vibration (operating) 10 Hz <

Shock (operating) 25 G / 11 ms IEC 60068-2-27

EN 50178:1997)

° to 50°C (32° to 122°F)

0

-25

° to +70°C (-13° to +158°F)

5 to 95% at 0 to 50

f < 57 Hz with 0.15 mm (0.0059 in)

f < 150 Hz with 2 g (0.0044 lb)

57 Hz <

°C (32° to 122°F)

Publication 2727-QS002E-MU-P

Page 34

34 MobileView Guard G750

Publication 2727-QS002E-MU-P

Page 35

Guide de mise en route

MobileView Guard G750

(Références 2727-G7P20D1P4, 2727-G7P20D1P5, 2727-G7P20D1Q6, 2727-G7P20D3Q7)

Français

Pour des informations plus détaillées sur le MobileView Guard G750, consultez la

publication 2727-UM002.

Vous pouvez télécharger une version électronique gratuite de la

publication 2727-UM002 à partir :

• du CD d’installation ;

• www.support.rockwellautomation.com

www.theautomationbookstore.com

Sommaire . . .

Informations importantes destinées à l’utilisateur ......................................................... 36

Description du MobileView Guard G750 ......................................................................... 37

Consignes de sécurité ...................................................................................................... 38

Montage et câblage du boîtier de raccordement MobileView ....................................... 45

Démontage du capot arrière ............................................................................................ 53

Connexion Ethernet .......................................................................................................... 55

Utilisation du logement pour carte PC ............................................................................. 55

Démarrage/Mise sous tension ........................................................................................ 58

Configuration matérielle .................................................................................................. 58

Configuration du réseau Ethernet .................................................................................... 59

Enregistrement des paramètres de la base de registres ................................................ 60

Démarrage des services Terminal Server ........................................................................ 61

Arrêt/Mise hors tension .................................................................................................. 62

Installation du support de fixation ................................................................................... 63

Conformité aux directives européennes (CE) ................................................................... 64

Normes et certifications .................................................................................................. 65

Configurations du MobileViewGuard G750 .................................................................... 67

Accessoires ...................................................................................................................... 67

Spécifications .................................................................................................................. 68

Publication 2727-QS002E-MU-P

Page 36

36 MobileView Guard G750

Informations importantes destinées à l’utilisateur

En raison de la diversité des utilisations des produits décrits dans la présente

publication, les personnes qui en sont responsables doivent s’assurer que toutes les

mesures nécessaires ont été prises pour que l’application et l’utilisation des produits

soient conformes aux exigences de performance et de sécurité, ainsi qu’aux lois,

règlements, codes et normes en vigueur.

Les illustrations, schémas et exemples de programmes contenus dans ce manuel

sont présentés à titre indicatif uniquement. En raison du nombre important de

variables et d’impératifs associés à chaque installation, la société Allen-Bradley ne

saurait être tenue pour responsable ni être redevable (y compris en matière de

propriété intellectuelle) des suites d’utilisation réelle basée sur les exemples et

schémas présentés dans cette publication.

La publication Allen-Bradley SGI-1.1, « Safety Guidelines for the Application,

Installation and Maintenance of Solid-State Control » (disponible auprès de votre

agence commerciale Allen-Bradley), décrit certaines différences importantes entre

les équipements électroniques et les équipements électromécaniques, qui devront

être prises en compte lors de l’application de ces produits, comme indiqué dans la

présente publication.

Toute reproduction totale ou partielle de la présente publication sans autorisation

écrite de la société Rockwell Automation est interdite.

Des remarques sont utilisées tout au long de ce manuel pour attirer votre attention

sur les mesures de sécurité à prendre en compte :

ATTENTION

Actions ou situations risquant d’entraîner des blessures

pouvant être mortelles, des dégâts matériels ou des pertes

financières.

!

Les mises en garde « Attention » vous aident à :

• identifier un danger ;

• éviter ce danger ;

• en discerner les conséquences.

IMPORTANT

Allen-Bradley est une marque commerciale de Rockwell Automation.

Publication 2727-QS002E-MU-P

Informations particulièrement importantes dans le cadre de

l’utilisation du produit.

Page 37

Description du MobileView Guard G750

2

1

3

MobileView Guard G750 37

12

11

4

8

5

1 Potentiomètre avec résolution linéaire de 0 à 127 (option)

2 Volant de manœuvre électronique, 50 impulsions/tour de -32768 à +32768 (option)

3 Interrupteur d’arrêt d’urgence, circuit jumelé, contacts N.F., 24 V c.c., 500 mA maximum (option)

4 Clavier tactile - Fonctionnalités Windows standard

5 Bouton-poussoir lumineux à impulsion, normalement ouvert, marquage désactivé, voyant jaune

6 Commutateur à clé à 3 positions (option)

7 Bouton-poussoir lumineux à impulsion, normalement ouvert, marquage activé, voyant jaune

8 Ecran LCD couleur à matrice passive VGA 7,7 pouces (640 x 480 pixels) avec dalle tactile

9 Commutateurs d’activation, circuit jumelé, à 3 positions (un de chaque côté de la poignée) pour

10 Interface IrDA imprimante/clavier, 9600 ou 115,2 Kbauds

11 Poignée pour gaucher ou pour droitier

12 Interface de carte PC à un logement pour cartes de type I, II et III (option)

13 Languette de réduction de tension pour câble de raccordement (livrée avec le câble)

14 Capot arrière du compartiment de raccordement

15 Obturateur pour la prise de câble non utilisée (degré de protection IP54)

(option)

(option)

analogique résistive

l’interface système de sécurité

7

6

10

9

15

14

13

Publication 2727-QS002E-MU-P

Page 38

38 MobileView Guard G750

Consignes de sécurité

Cette section présente les consignes générales de sécurité, ainsi que des

informations importantes sur l’alimentation, le bouton-poussoir d’arrêt d’urgence et

les commutateurs d’activation utilisés avec le MobileView Guard G750.

Sécurité générale

Il est important de se conformer aux instructions de ce document en toutes

circonstances. Le non-respect de ces instructions peut entraîner des dangers ou

rendre les fonctions de sécurité intégrées au terminal inopérantes.

Outre les instructions de sécurité indiquées dans ce document, vous devez

également suivre les précautions de sécurité et les mesures de prévention

d’accidents qui conviennent à la situation.

Publication 2727-QS002E-MU-P

Page 39

MobileView Guard G750 39

ATTENTION

!

• Veillez à ce que les procédures interrompues puissent être

redémarrées après des coupures d’alimentation ou des

microcoupures. N’utilisez jamais le matériel dans des

conditions dangereuses, même brièvement.

• Dans les cas où des pannes survenues au sein du système

d’automatisation pourraient provoquer des blessures

corporelles ou des dégâts importants aux machines et à

l’équipement, prenez des mesures de sécurité

supplémentaires pour préserver un fonctionnement sans

risque du système.

• Veillez à ce que les personnes non autorisées ne puissent

pas régler les paramètres ni effectuer des modifications de

mémoire qui pourraient entraîner des situations

dangereuses.

• Testez régulièrement les fonctionnalités des composants de

sécurité (bouton-poussoir d’arrêt d’urgence et

commutateurs d’activation).

• Si le terminal MobileView et l’automate ne communiquent

pas par une connexion point-à-point, il est possible que

les données du pavé numérique, par exemple, soient

transmises avec du retard. Il est recommandé d’utiliser un

commutateur Ethernet entre le terminal MobileView et

l’automate pour augmenter la vitesse de connexion.

• Testez les composants de sécurité si le terminal a subi des

chocs importants (s’il est tombé à terre par exemple).

• Lorsque le terminal MobileView est utilisé pour faire

fonctionner une machine ou une unité de production,

veillez à ce qu’il soit le seul et unique point de

fonctionnement (cf. ANSI/RIA 15.06).

• Si vous utilisez une carte PC avec le MobileView, veillez

toujours à ce que cette carte soit correctement insérée.

Après un choc violent, vérifiez que le volet du logement

pour carte PC est bien fermé et que la carte est

correctement insérée afin de maintenir un bon contact

électrique.

• Lorsque le terminal MobileView est utilisé en mode

manuel (pour des instructions sur un robot par exemple),

définissez une vitesse plus lente pour les mouvements du

robot (cf. ANSI/RIA 15.06).

Publication 2727-QS002E-MU-P

Page 40

40 MobileView Guard G750

Manipulation d’un terminal MobileView Guard

Pour de plus amples informations sur la manipulation d’un

MobileView Guard G750, consultez son manuel utilisateur afin d’éviter tout

dommage ou dysfonctionnement du terminal.

Alimentation

ATTENTION

!

• Cet appareil est conforme à la classe de sécurité III, selon

les normes EN 61131-2 et EN 50178. L’alimentation 24 V

destinée à l’équipement doit fournir une isolation

appropriée entre les circuits haute sécurité et les circuits à

tensions dangereuses (les transformateurs de sécurité par

exemple).

• Protégez le circuit d’alimentation par un fusible de 3,15 A.

• La tension d’alimentation nominale du terminal

MobileView (sans le câble de raccordement) est de

+24 V c.c. (plage de tensions de l’alimentation : de 18 à

32 V c.c.).

La consommation est généralement la suivante :

-300 mA à 24 V c.c.

-400 mA à 18 V c.c.

Lors de la planification de l’alimentation, tenez compte de

la chute de tension du câble de raccordement MobileView.

Caractéristiques des fils d’alimentation de ce câble :

Diamètre : 0,24 mm

Matériau : fil de cuivre galvanisé

Résistance de ligne :

2

(calibre 24)

< 90 ohms/km

Commutateurs d’activation

Le commutateur d’activation électronique considère le dispositif d’activation comme

une fonction de sécurité pour les machines ayant des modes de fonctionnement

particuliers. Le commutateur d’activation est intégré au terminal MobileView.

Chaque machine comprend un mode de fonctionnement normal et un mode de

fonctionnement spécial.

• En mode de fonctionnement normal, les protections et/ou les dispositifs de

protection des opérations servent à empêcher l’accès et à garantir la sécurité.

Les modes de fonctionnement spéciaux sont utilisés pour maintenir le mode

de fonctionnement normal.

Publication 2727-QS002E-MU-P

Page 41

MobileView Guard G750 41

• En mode de fonctionnement spécial, la sécurité doit être assurée

différemment, l’opérateur devant accéder à des zones dangereuses : des

mouvements ciblés doivent donc être possibles. Dans ce cas, la vitesse de la

machine doit être réduite en fonction des risques évalués et tout mouvement

commandé uniquement par un dispositif d’activation. L’utilisateur doit être

formé et connaître en détails l’utilisation recherchée. Les éléments de

commande de réduction de la vitesse d’une machine et de déclenchement

du dispositif d’activation, relatifs à la sécurité, doivent être construits en

conformité avec la catégorie de sécurité définie dans la norme EN 954-1,

suivant les risques évalués.

Pour se conformer à la catégorie de sécurité 3 selon la norme EN 954-1, le

commutateur d’activation doit comporter deux circuits.

La norme EN 60204-1 décrit le fonctionnement du dispositif d’activation. Grâce aux

derniers résultats d’analyse des accidents et depuis que des solutions techniques

existent, le commutateur d’activation à trois positions est à la pointe de la

technologie. Les positions 1 et 3 du commutateur sont des fonctions désactivées.

Seule la position centrale est utilisée pour l’activation. La norme EN 60204-1 est

identique à la norme CEI 60204-1. Les avantages du commutateur d’activation à

trois positions sont donc internationalement reconnus.

Le commutateur d’activation est constitué d’un élément de fonctionnement à trois

positions et de circuits électroniques d’évaluation séparés. Les circuits continus à

deux voies entre les éléments de commande et les bornes de connexion

représentent des fonctions essentielles. Pour les circuits d’évaluation, diverses

technologies et circuits sont utilisés. En raison des contacts de commutation

électroniques, leur autonomie ne dépend pas de la charge tant que les valeurs

nominales de la charge (ohmique, inductive et capacitive) ne sont pas dépassées.

ATTENTION

!

• Les commutateurs d’activation peuvent être utilisés

uniquement si l’opérateur les activant identifie le danger à

temps pour intervenir.

• Les commutateurs d’activation servent uniquement à

activer les commandes d’exécution de mouvements

dangereux. Ces commandes doivent être activées par un

élément de fonctionnement séparé (clé sur le terminal).

Seules les personnes autorisées à manipuler le

commutateur d’activation sont autorisées à travailler dans

la zone dangereuse.

• Sur le terminal MobileView Guard, les commutateurs

d’activation actionnent toujours deux circuits.

Publication 2727-QS002E-MU-P

Page 42

42 MobileView Guard G750

Exemple de connexion avec un relais de sécurité

Le schéma ci-dessous présente un exemple de câblage pour les commutateurs

d’activation avec un relais de sécurité PILZ PST, conforme à la catégorie de

sécurité 3. Pour de plus amples informations, consultez la documentation sur les

PILZ PST.

123123 321321

ZT1

L

123123 321321

ZT2

L

MobileView

(2 commutateurs d’activation à

3 positions et 2 circuits chacun)

ZT1

R

ZT2

R

Control cabinet

+24 VDC

F2

F3

4A(t)

F1

1A

Feedback

control lo op

KA KB

X1 X2

A1(+) 23 S11

K1

PILZ

PST1

K2

A2(-)

GND

4A(t)

or

or

6A(f)

6A(f)

13

14 24 S23 S24

KA KB

GND GND

3,15A

DC/DC

converter

67

S19:

K3:

67

K1:

K3:

+24V GND ED1+ ED1- ED2+ ED2-

X1

X2

+24V GND ED1+ ED1- ED2+ ED2-K4:

GND

F4

S12

Evaluation electronics

Circu it 1 Circu it 2

12 34

12 34

7 8 12 17K1: 1 2

7 8 12 1712

ZTxy ....... enabling switch x

Câble de raccordement

MobileView

y

Connecteur 17 broches

Câble intermédiaire

MobileView

Prise du bornier K3 du

boîtier de raccordement

Connecteur mâle X1 du

boîtier de raccordement

Boîtier de raccordement

Connecteur mâle X2 du

boîtier de raccordement

Prise du bornier K4 du boîtier

de raccordement

L1 L2 L3

KA

KB

Contacts

d’activation

d’un

mouvement

dangereux

M

Remarque : tous les contacts de KA et KB doivent être à

guidage forcé !

Publication 2727-QS002E-MU-P

Page 43

Données techniques des contacts

MobileView Guard G750 43

Tension nominale 24 V c.c. (type)

Courant nominal 500 mA (type)

Courant de court-circuit circuit 1: 1,9 A maximum

Charge inductive maximale (à 500 mA) circuit 1 : > 1 H

Charge capacitive maximale circuit 1 : aucune limite le transistor étant protégé contre les

32 V c.c. (maximum)

circuit 2 : 600 mA maximum

circuit 2 : 320 mH maximum

surchauffes

circuit 2 : 500 µF maximum

Les contacts des commutateurs d’activation sont protégés contre la polarité

inversée. Les sorties des deux circuits sont protégées contres les courts-circuits et

les surcharges.

• Circuit 1 : circuit de protection thermique

• Circuit 2 : circuit de protection par repli

Mauvaise utilisation prévisible du commutateur d’activation

Par mauvaise utilisation prévisible, on entend le fait d’interdire la position

d’activation du commutateur. La mauvaise utilisation prévisible du commutateur

d’activation doit être limitée. Les mesures suivantes, recommandées, provoquent

l’arrêt de la machine en mode manuel.

• Demande du commutateur d’activation lors de la mise sous tension de la

machine/de l’équipement et demande du commutateur d’activation lorsque

le mode de fonctionnement passe d’automatique à manuel (le commutateur

d’activation ne doit pas se trouver en position d’activation).

• Le commutateur doit être relâché dans un laps de temps défini, puis

réenclenché en position d’activation. Le laps de temps doit être défini en

fonction de l’activité.

Publication 2727-QS002E-MU-P

Page 44

44 MobileView Guard G750

Bouton-poussoir d’arrêt d’urgence

Le bouton-poussoir d’arrêt d’urgence du terminal MobileView est conforme aux

directives de la norme EN 418. Il doit être conçu comme un arrêt d’urgence de

catégorie 0 ou 1 (voir la norme EN 60204-1, chapitre 9.2.5.4.2) sur la base d’une

évaluation de risque pour la machine. La connexion des contacts de sécurité

positive à un système de surveillance adapté doit être conforme à la classe de

sécurité qui est définie en fonction des risques évalués (selon la norme EN 954-1)

de la machine.

L’arrêt d’urgence comporte deux contacts, libres de potentiel, normalement fermés,

pour la connexion de périphériques externes, présente une tension de

fonctionnement nominale de 24 V (très basse tension de sécurité selon les normes

EN 61131-2 et EN 50178) et un courant de fonctionnement de 500 mA maximum.

ATTENTION

!

• Lorsque le bouton-poussoir d’arrêt d’urgence n’est pas

branché sur le circuit d’arrêt d’urgence, le terminal

MobileView doit être stocké dans un endroit inaccessible

aux opérateurs.

N’oubliez pas que l’opérateur peut instinctivement activer

l’arrêt d’urgence le plus proche en cas de danger, ce qui

pourrait avoir des conséquences fatales si l’arrêt d’urgence

ne fonctionnait pas.

• Les fonctions d’arrêt d’urgence doivent rester

opérationnelles quel que soit le mode de fonctionnement.

La réinitialisation après activation d’un arrêt d’urgence ne

doit pas se traduire par un démarrage incontrôlé des

machines ou des installations.

• Le bouton-poussoir d’arrêt d’urgence ne remplace pas les

autres dispositifs de sécurité.

Evaluation des risques machines

Pour évaluer les risques, les normes suivantes doivent être respectées :

• EN 292-1 : « Sécurité des machines - Notions fondamentales et de

conception » ;

• EN 1050 : « Principes pour l’appréciation du risque » ;

• EN 954-1 : « Sécurité des machines - Parties des systèmes de commande

relatives à la sécurité » ;

• ANSI/RIA 15.06-1999 : « Norme américaine pour les robots et systèmes

robotisés industriels - Exigences de sécurité (Section 9) » ;

• ANSI B11.TR3-2000 « Evaluation et réduction des risques - Guide pour

l’estimation, l’évaluation et la réduction des risques associés aux

machines-outils ».

Publication 2727-QS002E-MU-P

Page 45

MobileView Guard G750 45

Les catégories de sécurité (B, 1, 2, 3, 4) définissent la structure des composants de

sécurité d’une machine et sont dérivées de cette évaluation des risques.

Le schéma de la page 42 montre comment la fonction d’activation du terminal

MobileView est conforme à la catégorie de sécurité 3 grâce à l’utilisation d’un relais

de sécurité PILZ PST 1. L’ensemble du système de commande de la machine doit

être conçu en conformité avec ces principes de sécurité.

Montage et câblage du boîtier de raccordement MobileView

Le boîtier de raccordement MobileView (2727-MRJB1) intègre le terminal

MobileView au système de commande ; il est monté sur un rail DIN.

S1 Connecteur RJ-45 pour la connexion des lignes de données de MobileView.

S2 Connecteur femelle sub-D à 9 broches (pour utilisation ultérieure).

S3 Connecteur RJ-45 pour la connexion au réseau Ethernet.

X1 Connecteur mâle 12 broches pour le branchement du câble de connexion du boîtier de

X2 Connecteur mâle 12 broches (fourni avec un connecteur bornier femelle) pour le

raccordement.

branchement de :

• l’alimentation 24 V c.c. ;

• le bouton-poussoir d’arrêt d’urgence ;

• les commutateurs d’activation.

Broche 1,

24 V c.c

(avec

connecteur

bornier

femelle K3)

Broche 1,

24 V c.c

(avec

connecteur

bornier

femelle K4)

Vis de mise

à la terre

60 mm

24V DC

ON LY

+24V

TERM INAL IN

GND

ES1+

ES1-

ES2+

ES2-

X1

ED1+

ED1-

ED2+

ED2-

+24V

GND

ES1+

ES1-

ES2+

X2

ES2-

ED1+

ED1-

ED2+

ED2-

ETHERNET OUT

S1

RS422 OUT

S2

162 mm

108 mm

S3

150 mm

Vis de mise

Verrou du rail DIN

à la terre Languette de

réduction de

tension pour câble

Publication 2727-QS002E-MU-P

Page 46

46 MobileView Guard G750

ATTENTION

!

Le boîtier de raccordement et le terminal MobileView sont

conformes à la sécurité de classe III selon les normes EN 61131

et EN 50178.

Lors du branchement du terminal MobileView, vérifiez que

toutes les tensions connectées au terminal sont des basses

tensions de sécurité et qu’elles sont isolées de l’alimentation

basse tension par un transformateur de sécurité ou par un

système de sécurité similaire.

Publication 2727-QS002E-MU-P

Page 47

MobileView Guard G750 47

Montage du boîtier de raccordement sur un rail DIN

Montez le boîtier de raccordement MobileView sur un rail DIN à l’intérieur d’une

armoire.

Pour installer le boîtier de raccordement sur un rail DIN :

1. Montez le rail DIN.

2. Accrochez l’encoche supérieure sur le rail DIN.

3. Exercez une pression sur le boîtier jusqu’à ce qu’il s’enclenche sur le rail.

Pour retirer le boîtier de raccordement du rail DIN :

1. Placez l’extrémité d’un tournevis dans le verrou du rail DIN, sous le boîtier de

raccordement.

2. Tout en tenant le boîtier, faites levier sur le verrou à l’aide du tournevis afin

d’extraire le boîtier du rail DIN.

Publication 2727-QS002E-MU-P

Page 48

48 MobileView Guard G750

Connexion du terminal MobileView au boîtier de raccordement

La figure suivante indique comment connecter le terminal MobileView au boîtier de

raccordement.

Terminal MobileView

ESC

7 8 9

5 6

4

3

1 2

.

-

0

Câble de raccordement

MobileView

Découpe pour le

connecteur

24 mm

25 ± 0,1 mm

r

o

n

r

u

Er

R

KETOP

Capuchon

anti-poussière

K1

Armoire de commande type

Broche 1, 24 V c.c

X1/K3

Connexions du

terminal MobileView

Broche 1, 24 Vc.c

X2/K4

Connexions de

l’équipement de

sécurité

Epaisseur maximale de

la paroi : 5 mm

Câble de connexion du boîtier

de raccordement 2m

Utilisez la vis

de mise à la terre

pour relier le boîtier

de raccordement à

la terre

Boîtier de raccordement

24V DC

ON LY

+24V

TERM INAL IN

GND

ES1+

ES1-

ES2+

ES2-

ED1+

ED1-

ED2+

ED2-

RS 422 OUT

+24V

GND

ES1+

ES1-

ES2+

ES2-

ED1+

ED1-

ED2+

ED2-

ETHERNET OUT

Connexion 10

Base-T au réseau

Ethernet

Attache du câble

de connexion du boîtier

de raccordement

S1

S2

S3

Dégagements nécessaires pour les câbles de chaque côté de la paroi de l’armoire

130 mm

Câble

de raccordement

Connexion

K1

108 mm

Câble de connexion

du boîtier de

raccordement

Publication 2727-QS002E-MU-P

Page 49

Brochage et câblage du boîtier de raccordement

MobileView Guard G750 49

MobileView

S19

S4

Câble de raccordement

du MobileView

K3

6

7

8

9

10

11

1

2

3

4

5

rose

noir

vert-brun

blanc-vert

gris-rose

rouge-bleu

brun

jaune

vert

gris

violet

K2

1

2

3

6

bleu

blanc

orange

rouge

Câble de connexion du

boîtier de raccordement

MobileView

K1

1

2

3

4

5

6

7

8

12

17

11

9

10

13

14

15

16

rose

noir

vert-brun

blanc-vert

gris-rose

rouge-bleu

brun

jaune

vert

gris

violet

bleu

blanc

orange

rouge

Pour une utilisation ultérieure

Vers un réseau Ethernet

K3

X1

24 V c.c.

1

Mise à la terre

2

Arrêt d’urg., circ. 1, pos.

3

4

Arrêt d’urg., circ. 1, nég.

5

Arrêt d’urg., circ. 2, pos.

6

Arrêt d’urg., circ. 2, nég.

7

Com. d’activ., circ. 1, pos.

8

Com. d’activ., circ. 1, nég.

9

Com. d’activ., circ. 2, pos.

10

Com. d’activ., circ. 2, nég.

11

Non utilisé

12

Non utilisé

K2

S1

1

2

3

4

5

6

7

8

S2

1

2

3

4

5

6

7

8

9

S3

1

TD+

2

TD-

3

RD+

4

5

6

RD-

7

8

Boîtier de raccordement

10

11

X2 K4

+24 V

1

2

3

4

5

6

7

8

9

12

GND

ES1+

ES1-

ES2+

ES2ED1+

ED1ED2+

ED2-

Publication 2727-QS002E-MU-P

Page 50

50 MobileView Guard G750

Alimentation requise

Spécifications électriques

Alimentation 24 V c.c. Utilisez une alimentation de type haute sécurité de 24 V c.c.

Mise à la terre Reliez le boîtier de raccordement à la terre avec la vis de

Plage de tensions de l’alimentation : 18 à 32 V c.c.

Consommation : 300 mA à 24 V c.c.

Courant d’appel crête : 5,6 A maximum

mise à la terre (illustrée à la page 48).

ATTENTION

!

• Cet appareil est conforme à la classe de sécurité III, selon

les normes EN 61131-2 et EN 50178. L’alimentation 24 V

destinée à l’équipement doit fournir une isolation

appropriée entre les circuits haute sécurité et les circuits à

tensions dangereuses (les transformateurs de sécurité par

exemple).