Page 1

Installation Instructions

Feeder Circuit Breaker Units Secure Support Pan and Change Door Latch

Catalog Numbers

2193F and 2100M

About This Publication

Top ic Pa ge

About This Publication 1

Required Tools 1

Important User Information 2

Before You Begin 4

Secure the Support Pan and Change the Door Latch 4

Remove the Feeder Unit from the Section 4

Remove the Unit Below the Feeder Unit 6

Secure the Support Pans 6

Install Latch Angle Bracket 8

Install Units 9

Install New Door Latch Screw and Label 10

Additional Resources 12

This document provides instructions on how to replace one of the

¼-turn door latches found in the upper right corner of the unit door with a new

screw-type door latch. This document also covers the addition of fasteners to the

support pans for these plug-in units.

Required Tools

Refer to Figure 1

control center section (MCC).

This document is intended for 1.5 space factor, and larger, plug-in units with a

225/250 A frame circuit breaker, including the following units:

• Bulletin 2193F plug-in units (Feeder unit), circuit breaker

• Bulletin 2100M plug-in units, circuit breaker with catalog code ‘43CT’

through ‘45CT’ and ‘43CM’ through ‘45CM’

You need the following tools:

• Small flat-bladed screwdriver

• 5/16 in. and a 3/8 in. socket wrench

• Optional, battery operated screwdriver

for a description of the parts of a CENTERLINE 2100 motor

Page 2

Feeder Circuit Breaker Units Secure Support Pan and Change Door Latch

IMPORTANT

Important User Information

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc.,

is prohibited.

available from

) describes some

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

AT TE NT IO N: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

2 Rockwell Automation Publication 2100-IN091A-EN-P - April 2013

Page 3

Feeder Circuit Breaker Units Secure Support Pan and Change Door Latch

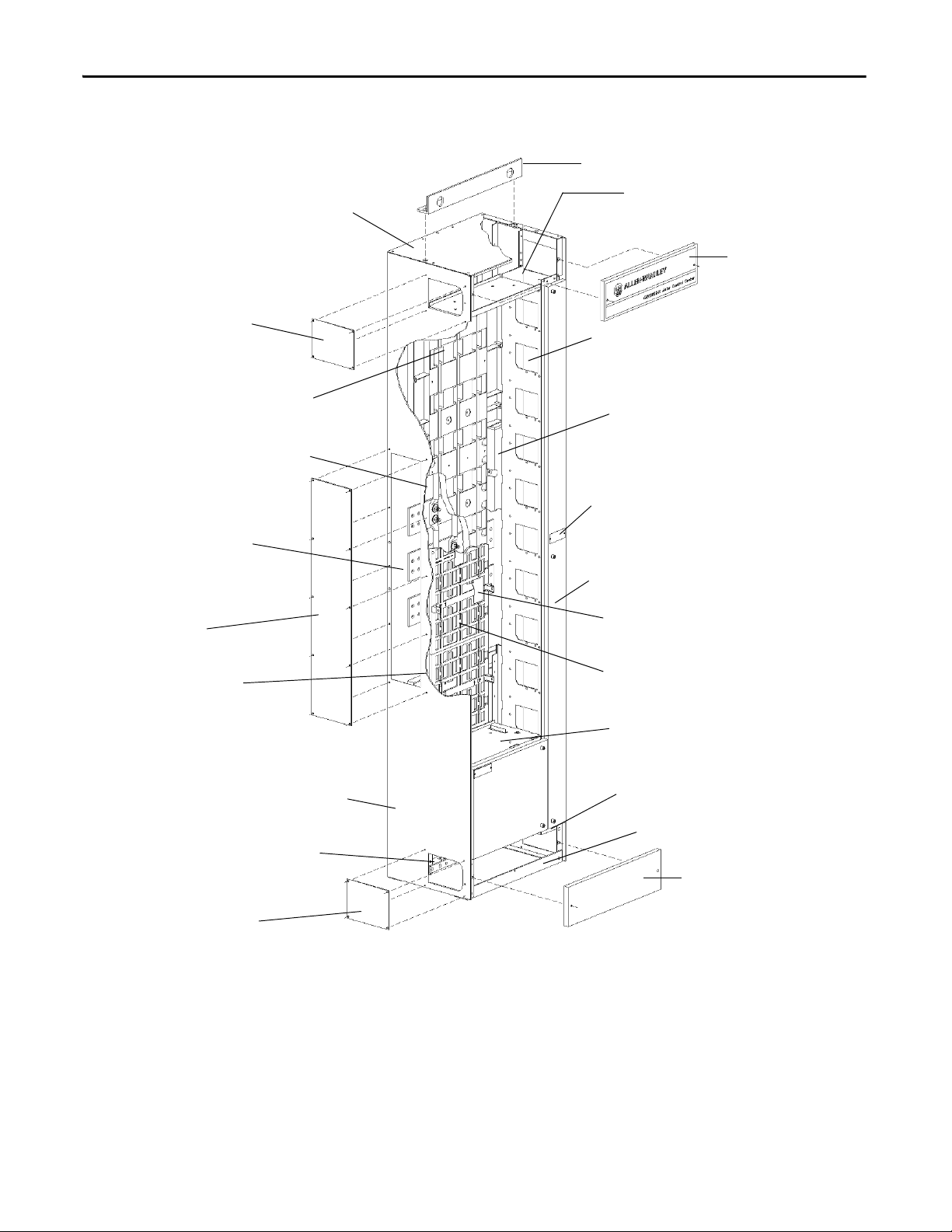

Lifting Angle

Top Horizontal

Wireway Baffle

Top Horizontal

Wireway Cover

Right Hand Unit Support

Vertical Wireway Assembly

Bus Splice Access Cover

Section Nameplate

Vertical Wireway Door

Vertical to Horizontal Bus

Connection Access Cover

Vertical Bus Support Cover

Unit Support Pan

Sealing Strap

Top and Bottom

Bottom Support Angle

Bottom Horizontal

Wireway Cover

Left Hand

Bottom End Closing Plate

Horizontal Ground Bus

Top or Bottom

Left Hand Side Plate Assembly

Vertical Plug-in

Ground Bus

Left Hand

Center End Plate

Horizontal Power Bus

Vertical Power Bus

Horizontal and Vertical

Bus Support

Left Hand

Top End Closing Plate

Removable Top Plate

Figure 1 - Structure Diagram

3 Rockwell Automation Publication 2100-IN091A-EN-P - April 2013

Page 4

Feeder Circuit Breaker Units Secure Support Pan and Change Door Latch

Before You Begin

ATTENTION: De-energize all power sources to the Motor Control Center before

opening any section or unit doors. Verify that all power is OFF, as per NFPA 70E,

Standards for Electrical Safety Requirements. Failure to de-energize all power

sources can result in severe injury or death.

ATT EN TI ON : To prevent personal injury or damage to equipment, make sure

that the unit operator handle is in the OFF/O position before removing plug-in

units.

ATT EN TI ON : De-energize all units before installing or removing.

When installing or removing MCC units, when possible, de-energize, lockout, and

tag-out all sources of power to the MCC. If the MCC units are installed or removed

with power applied to the main power bus, follow established electrical safety

work practices. Refer to the NFPA 70E Standard for Electrical Safety in the

Workplace publication.

Review your company safety lockout and tag-out procedure.

If power sources are connected to the motor control center, use extreme caution

when inserting units. All buses and the line sides of the inserted units are

energized, and contact with these parts can cause injury or death.

All covers and doors must be in place before applying power to the MCC. If units are

removed, they must be replaced with the appropriate items, such as units, doors,

and unit support pans.

Secure the Support Pan and Change the Door Latch

Remove the Feeder Unit from the Section

To secure the support pan and change the door latch, complete these steps.

1. Remove the Feeder Unit from the Section

2. Remove the Unit Below the Feeder Unit

3. Secure the Support Pans

4. Install Latch Angle Bracket

5. Install Units

6. Install New Door Latch Screw and Label

Follow these steps to remove the Feeder unit.

1. Make sure the operator handle is in the OFF/O position.

2. Verify that all control power and other power sources are off in the Motor

Control Center lineup.

3. Open the Feeder unit door completely.

4. Mark the phase on each load wire in the Feeder unit to assist with later

wire connection.

.

.

.

.

.

.

4 Rockwell Automation Publication 2100-IN091A-EN-P - April 2013

Page 5

Feeder Circuit Breaker Units Secure Support Pan and Change Door Latch

IMPORTANT

Top Captive Latch Bottom Captive Latch

5. Disconnect the Feeder unit load wires and pull the load wires away from

the unit so the unit can be removed from the section.

6. Mark and disconnect control circuit wires if they interfere with the

removal of the Feeder unit.

7. Remove other cables or devices that prevent the unit from being

withdrawn.

8. Disengage the captive latches at the front of the unit, one at the top and

one at the bottom of the unit.

Units that are 2.0 space factor and larger have two latches at the top.

Units that are 0.5 space factor do not have captive latches. After you open the

unit door, push the latch mechanism to the left with your right hand and then

remove the unit from the section.

9. Pull the unit forward (outward), approximately 3 in. (7.5 cm) out of the

MCC, by using the handle provided at the lower left of the unit and the

tab in the upper right of the unit as finger holds.

Reposition your hands as necessary to properly support the unit while you

are removing the unit from the MCC.

ATTENTION: Plug-in MCC units can be heavy or awkward to handle.

Use an assistant or a platform lift device if necessary to help you handle

the unit.

10. Remove the unit from the MCC.

11. Carefully install protective caps or close manual shutters after the unit is

removed.

Automatic shutters close as units are removed.

Rockwell Automation Publication 2100-IN091A-EN-P - April 2013 5

Page 6

Feeder Circuit Breaker Units Secure Support Pan and Change Door Latch

IMPORTANT

TIP

Unit Support Pan

10-32 self-tapping

screw

32 lb•in (3.6 N•m)

Unit Support Pan

Right-hand Unit

Support

Pry Bar

Gently apply pry

bar to align holes.

12. If one of the following units is directly above or below the Feeder/Main

unit, verify that the incoming power source is off and that the operator

handle is in the OFF/O position before you open that unit door:

• Main Lug Compartment unit (Bulletin 2191)

• Main Disconnect Switch unit (Bulletin 2192M)

• Main Circuit Breaker unit (Bulletin 2193M)

• Frame mounted unit

• Bottom horizontal wireway

Remove the Unit Below the Feeder Unit

Secure the Support Pans

If the unit below the Feeder unit is a plug-in unit, remove that plug-in unit from

the section. Follow step 1

…11 of Remove the Feeder Unit from the Section to

remove any additional units from the MCC section.

Follow these steps to secure the support pans.

1. Secure the left-rear corner of the unit support pan with a 10-32

self-tapping screw and tighten to 32 lb•in (3.6 N•m) by using a 5/16 in.

socket wrench.

Add the screw to the Feeder unit support pan and the unit support pan above

the Feeder unit, if one is installed.

You can use an industrial, battery-powered screwdriver with a strong magnetic

bit. Use a driver bit extension. We recommend placing a cloth near the work

area to catch the screw if it falls from the driver bit. You can use a small pry bar

between the right-hand edge of the unit support pan and the right-hand unit

support to better align the holes on the left-hand edge of the unit support

pan. Inserting these screws can take more than one attempt.

6 Rockwell Automation Publication 2100-IN091A-EN-P - April 2013

Page 7

Feeder Circuit Breaker Units Secure Support Pan and Change Door Latch

Remove

Retaining Clip

Tighten to 55 lb•in

(6 N•m)

Top Horizontal

Wireway Pan

Tighten to 55 lb•in

(6 N•m)

2. Remove the plastic retaining clip from the unit support pan and secure the

unit support pan to the right-hand unit support with a 1/4-20 bolt, lock

washer, and nut.

3. Tighten to 55 lb•in (6 N•m) with a 3/8 in. socket wrench.

4. If the unit at the top of the section, directly above the Feeder unit, is a

Main Lug Compartment (Bulletin 2191) unit, a Main Disconnect Switch

(Bulletin 2192M) unit, or a Main Circuit Breaker (Bulletin 2193M) unit,

complete these steps:

a. Remove the plastic retaining clip.

b. Secure the top horizontal wireway pan to the right-hand unit support

with a 1/4-20 bolt, lock washer, and nut.

c. Tighten to 55 lb•in (6 N•m) with a 3/8 in. socket wrench.

5. If the unit at the bottom of the section, directly below the Feeder unit, is a

Main Lug Compartment (Bulletin 2191) unit, a Main Disconnect Switch

(Bulletin 2192M) unit, or a Main Circuit Breaker (Bulletin 2193M) unit,

complete these steps:

a. secure the bottom horizontal wireway pan to the right-hand unit

support with a 1/4-20 bolt, lock washer, and nut:

b. Tighten to 55 lb•in (6 N•m) with a 3/8 in. socket wrench.

Rockwell Automation Publication 2100-IN091A-EN-P - April 2013 7

Page 8

Feeder Circuit Breaker Units Secure Support Pan and Change Door Latch

TIP

Latch Angle

Bracket

¼-20 Screw and

Lock Washer

55 lb•in (6 N•m)

Latch Angle

Bracket

Mounting Holes

Install Latch Angle Bracket

The latch angle bracket installs in the top-right corner of the Feeder unit

compartment. Follow these steps to install the latch angle bracket.

1. Remove the plastic retaining clip from the right-hand unit support pan.

2. Secure the latch angle bracket to the right-hand unit support with a ¼-20

screw and lock washer and tighten to 55 lb•in (6 N•m) with a 3/8 in.

socket wrench.

The latch angle bracket has two tapped holes, but only one hole is used for

mounting. The tapped hole used depends on where the Feeder unit was

mounted in the section:

• If the Feeder unit was mounted directly below the top horizontal wireway

pan, then the bottom tapped hole of the latch angle bracket is used to

mount the bracket to the right-hand unit support.

• Otherwise, use the top tapped hole of the latch angle bracket.

8 Rockwell Automation Publication 2100-IN091A-EN-P - April 2013

Page 9

Feeder Circuit Breaker Units Secure Support Pan and Change Door Latch

TIP

TIP

Install Units

Follow these steps to install the units.

ATT EN TI ON : De-energize all units before installing or removing.

When installing or removing MCC units, when possible, de-energize, lockout, and

tag-out all sources of power to the MCC. If the MCC units are installed or removed

with power applied to the main power bus, follow established electrical safety

work practices. Refer to the NFPA 70E Standard for Electrical Safety in the

Workplace publication.

Review your company safety lockout and tag-out procedure.

If power sources are connected to the motor control center, use extreme caution

when inserting units. All buses and the line sides of the inserted units are

energized, and contact with these parts can cause injury or death.

All covers and doors must be in place before applying power to the MCC. If units are

removed, they must be replaced with the appropriate items, such as units, doors,

and unit support pans.

ATT EN TI ON : Plug-in MCC units can be heavy or awkward to handle. Use an

assistant or a platform lift device if necessary to help you handle the unit.

1. Remove the protective caps from the stab openings or open the manual

shutters if present (automatic shutters open as the units are inserted).

2. Place the unit on the unit support pan and slide it into the section until it

is flush with the front of the structure and the power stabs are connected to

the vertical bus.

ATT EN TI ON : For 0.5 space factor units, a style 3 unit-support pan with bushing

must be used below the unit for proper operation of the latch/interlock

mechanism. If the unit support pan with bushing is not used, the unit could be

removed under load, resulting in injury or death.

Reposition your hands as necessary to properly support the unit while you are

installing the unit into the MCC.

For Feeder units, you need to tilt the top of the unit slightly to the rear to avoid

interference with the top angle latch bracket. If you do not have enough

clearance, you need to loosen the angle latch bracket screw (approximately

two turns) to install the unit.

Rockwell Automation Publication 2100-IN091A-EN-P - April 2013 9

Page 10

Feeder Circuit Breaker Units Secure Support Pan and Change Door Latch

IMPORTANT

Unit support pan above the unit not

shown for clarity.

3. For all units 1.0 space factor and larger, secure the unit by tightening the

top and bottom captive latches to 22 lb•in (2.5 N•m).

Units that are 2.0 space factors or larger have two captive latches on the top

of the unit and one on the bottom of the unit.

Top captive latch must be rotated to vertical and engage behind the front

flange of the unit support pan above the unit.

The bottom captive latch must be rotated to vertical and engaged into the slot

of the unit support pan as shown.

Install New Door Latch Screw and Label

4. Connect the marked unit load wires.

5. Connect the marked control wires.

6. Verify that all power and control wires have been connected properly and

to the proper phases.

Follow these steps to install the new door latch.

1. On the Feeder unit door, remove the ¼ turn door latch in the upper righthand corner of the door.

2. Insert the ¼-20 pan-head screw, with the screw head on the outside of the

door, thru the open hole in the upper right-hand corner of the door.

10 Rockwell Automation Publication 2100-IN091A-EN-P - April 2013

Page 11

Feeder Circuit Breaker Units Secure Support Pan and Change Door Latch

¼-20 Pan-head Screw

Screw Retainer

3. Install the screw retainer over the threaded end of the screw.

Leave a slight gap between the screw retainer and the inside of the door so

the screw retainer is not tight against the door. This provides easier

alignment of the Door Screw with the latch angle bracket.

4. Clean the front door surface, just below the pan-head screw, by using

window glass cleaner and a clean cloth.

5. Align the door-screw torque label with the door edges.

6. Gently work out air bubbles from under the label if they are present.

7. Ensure that all tools, hardware, and other debris have been removed from

the units and section.

8. Close and secure all open unit doors.

ATT EN TI ON : All covers and doors must be in place before applying power to the

MCC. If units are removed, they must be replaced with the appropriate items,

such as units, doors, and unit support pans.

9. Power up the equipment in accordance with CENTERLINE 2100 Low

Voltage Motor Control Centers Installation Instructions, publication

2100-IN012

and as per NFPA 70E, Standards for Electrical Safety

Requirements.

Rockwell Automation Publication 2100-IN091A-EN-P - April 2013 11

Page 12

Feeder Circuit Breaker Units Secure Support Pan and Change Door Latch

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

CENTERLINE 2100 Low Voltage Motor Control Centers

Installation Instructions, publication 2100-IN012

CENTERLINE 2100 Motor Control Center (MCC) Units with

Vertical Operating Handles, publication 2100-IN014

CENTERLINE 2100 Motor Control Center (MCC) Units with

Horizontal Operating Handles, publication 2100-IN060

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Product Certifications website, http://www.ab.com

Provides additional information on the CENTERLINE

2100 MCC.

Provides information on installing units with vertical

operator handles.

Provides information on installing units with horizontal

operator handles.

Provides general guidelines for installing a Rockwell

Automation industrial system.

Provides declarations of conformity, certificates, and

other certification details.

You can view or download publications at

http:/www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Allen-Bradley, Rockwell Software, Rockwell Automation, CENTERLINE, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respec tive companies.

Publication 2100-IN091A-EN-P - April 2013 PN-200223

Copyright © 2013 Rockwell Auto mation, Inc. All rights reserved. Pr inted in the U.S.A.

Loading...

Loading...