Page 1

DeviceNet To

SCANport

Communication

Module with

Digital Inputs

Catalog Number 2100-GK61

Firmware 2.xxx

User Manual

Page 2

Important User Information Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes, and standards.

The illustrations, charts, sample programs, and layout examples

shown in this guide are intended solely for purposes of example.

Since there are many variables and requirements associated with any

particular installation, Rockwell Automation does not assume

responsibility or liability (to include intellectual property liability) for

actual use based upon the examples shown in this publication.

Rockwell Automation publication SGI-1.1, Safety Guidelines for the

Application, Installation, and Maintenance of Solid-State Control

(available from your local Rockwell Automation office), describes

some important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in

whole or in part, without written permission of Rockwell

Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies information about practices

or circumstances that can lead to personal injury or

!

Attention statements help you to:

• Identify a hazard.

• Avoid the hazard.

• Recognize the consequences.

IMPORTANT: Identifies information that is critical for successful

application and understanding of the product.

death, property damage, or economic loss.

Publication 2100-UM001B-EN-P – January 2001

Page 3

Preface

Using this Manual

Objectives Read this preface to become familiar with the organization of the

manual. In this preface, you will read about the following:

• Who should use this manual.

• An overview of the DeviceNet to SCANport Communication

Module with Digital Inputs.

• The purpose of this manual.

• Terms and abbreviations.

• Conventions used in this manual.

• Rockwell Automation support.

Who Should Use this Manual? Use this manual if you are responsible for installing, wiring,

programming, or troubleshooting control systems that use th e

DeviceNet to SCANport Communication Module with Digital Inputs.

This manual is intended for qualified service personnel responsible

for setting up and servicing the DeviceNet to SCANport

Communication Module with Digital Inputs. You must have previous

experience with and a basic understanding of electrical terminology,

programming procedures, networking, required equipment and

software, and safety precautions.

Purpose of this Manual This manual is a learning and reference guide for the DeviceNet to

SCANport Communication Module with Digital Inputs. It describes

the procedures needed to install, configure, and troubleshoot th e

adapter.

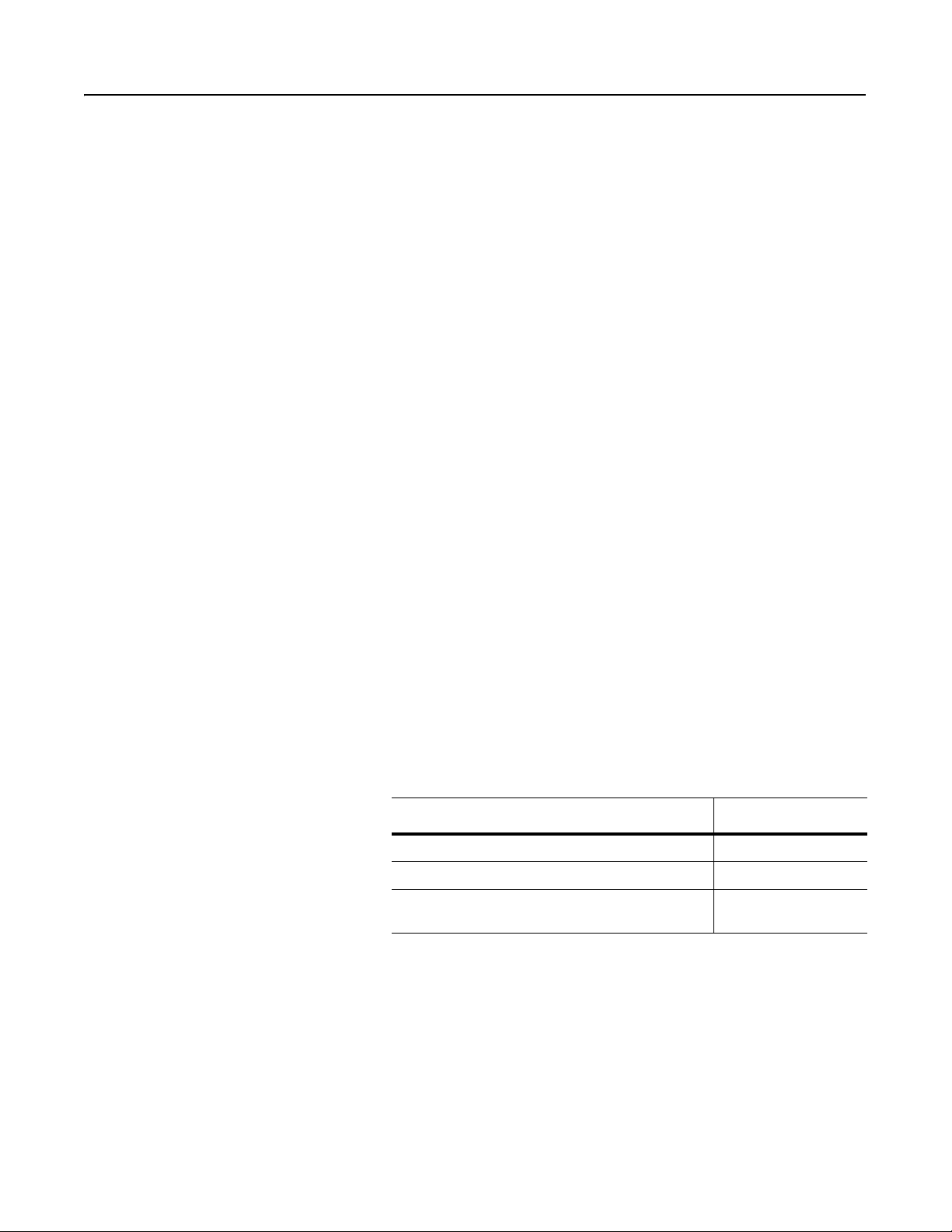

Related Publications

Title Publication Number

1771-SDN Scanner Configuration Manual 1771-6.5.118

DeviceNet Scanner Configuration Manual 1747-6.5.2

DeviceNet Cable System Planning and Installation

Manual

DN-6.7.2

Publication 2100-UM001B-EN-P – January 2001

Page 4

P-2 Using this Manual

Safety Precautions Please read the following safety precautions carefully.

ATTENTION: Only personnel familiar with

SCANport products and associated machinery should

!

plan or implement the installation, start-up,

configuration, and subsequent maintenance of the

DeviceNet to SCANport Communication Module with

Digital Inputs. Failure to comply may result in personal

injury and/or equipment damage.

Terms and Abbreviations The following terms and abbreviations are specific to this product.

For a complete listing of Allen-Bradley terminology, refer to the

Allen-Bradley Industrial Automation Glossary, Publication AG-7.1.

Terms Definition

DeviceNet An open network that provides probabilistic I/O control

through a managed bit-wise non-destructive multiplexing

scheme.

SCANport A standard peripheral communications interface for various

Allen-Bradley drives and power products.

SCANport

Peripheral

SCANport

Product

Digital Input ON-OFF input voltages of 230Vac, 115Vac, or

RSNetWorx,

RSLinx,

RSLogix,

RSLogix500

A device that provides an interface between SCANport and

a network. It is often referred to as an adapter. For example,

the DeviceNet to SCANport Communication Module with

Digital Inputs is a SCANport peripheral.

A device that uses the SCANport communications interface

to communicate with one or more peripheral devices. For

example, a motor drive such as a 1336 PLUS is a SCANport

product.

24Vdc.

Rockwell Software products which provide communication to

a wide range of applications. Refer to

http://www.software.rockwell.com for more information.

Publication 2100-UM001B-EN-P – January 2001

Page 5

Using this Manual P-3

Conventions Used in this

The following conventions are used throughout this manual:

Manual

• Bulleted lists provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical

information.

• Italic type is used for chapter names and for parameter names.

• Bold type is used for names of menus, menu options, screens, and

dialog boxes.

Important: This type of paragraph contains tips or notes that have

been added to call attention to useful information.

Rockwell Automation Support Rockwell Automation offers support services worldwide, with more

than 75 sales/support offices, more than 500 authorized distributors,

and more than 250 authorized systems integrators located throughout

the United States alone. In addition, Rockwell Automation

representatives are in every major country in the world.

Local Product Support

Contact your local Rockwell Automation representative for:

• Sales and order support.

• Product technical training.

• Warranty support.

• Support service agreements.

Technical Product Support

If you need to contact Rockwell Automation for technical assistance,

please call your local Rockwell Automation representative.

Publication 2100-UM001B-EN-P – January 2001

Page 6

P-4 Using this Manual

Publication 2100-UM001B-EN-P – January 2001

Page 7

Table of Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Using this Manual Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P-1

Who Should Use this Manual? . . . . . . . . . . . . . . . . . . . . . .P-1

Purpose of this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . .P-1

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P-2

Terms and Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . .P-2

Conventions Used in this Manual. . . . . . . . . . . . . . . . . . . . P-3

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . P-3

Local Product Support. . . . . . . . . . . . . . . . . . . . . . . . . . . .P-3

Technical Product Support . . . . . . . . . . . . . . . . . . . . . . . .P-3

Chapter 1

Overview Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Overview of the Communication Adapter. . . . . . . . . . . . . . 1-1

Features of the Communication Adapter . . . . . . . . . . . . . . 1-3

SCANport Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Hardware and Parts Description . . . . . . . . . . . . . . . . . . . . . 1-6

2100-GK61 Module Hardware . . . . . . . . . . . . . . . . . . . . . 1-6

Overview of Setting Up the Adapter. . . . . . . . . . . . . . . . . . 1-7

Required Tools and Equipment . . . . . . . . . . . . . . . . . . . . . . 1-7

Chapter 2

Installation Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Installing a 2100-GK61 Module . . . . . . . . . . . . . . . . . . . . . .2-1

Required Tools and Equipment. . . . . . . . . . . . . . . . . . . . 2-1

Selecting Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Installing the DeviceNet to SCANport Communication

Module with Digital Inputs (2100-GK61). . . . . . . . . . . 2-3

Removing the DeviceNet to SCANport Communication

Module with Digital Inputs (2100-GK61). . . . . . . . . . 2-10

Chapter 3

Configuring the DeviceNet to

SCANport Communication Module

with Digital Inputs

Configuring a Scanner to Communicate with the Adapter

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Factory Default Settings for the 2100-GK61. . . . . . . . . . . . . 3-1

What is RSNetWorx for DeviceNet? . . . . . . . . . . . . . . . . . . 3-2

Required Equipment and Software. . . . . . . . . . . . . . . . . . . . 3-2

Using RSNetWorx to Edit Your Adapter’s Parameters. . . . 3-3

Chapter 4

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

What is RSNetWorx for DeviceNet?. . . . . . . . . . . . . . . . . . 4-1

Required Equipment and Software. . . . . . . . . . . . . . . . . . . . 4-1

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Using Online Mode in RSNetWorx for DeviceNet . . . . . . . . 4-2

Downloading an EDS File for Your SCANport Product . . . . 4-4

Configuring a Scanner . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Configuring a PLC Scanner (1771-SDN) to Communicate

with the Adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Configuring an SLC Scanner (1747-SDN) to Communicate

with the Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Configuring an SLC Scanner . . . . . . . . . . . . . . . . . . . . 4-23

Configuring a ControlLogix Scanner (1756-DNB) to

Communicate with the Adapter. . . . . . . . . . . . . . . . . . . . 4-30

Page 8

Chapter 5

Ladder Logic Programming Including Reading Inputs

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Required Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

What is RSLogix?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

What are Ladder Logic Programs?. . . . . . . . . . . . . . . . . . . 5-3

Example Ladder Logic Programs . . . . . . . . . . . . . . . . . . . . 5-4

PLC Ladder Logic Example . . . . . . . . . . . . . . . . . . . . . . . 5-7

SLC Ladder Logic Program Example . . . . . . . . . . . . . . 5-11

ControlLogix Programming Example . . . . . . . . . . . . . . . . 5-15

Chapter 6

Using DeviceNet Explicit

Messaging

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Explicit Message Program Control for PLC-5 . . . . . . . . . . . 6-1

Message Translations . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Messaging for the 1771-SDN Scanner. . . . . . . . . . . . . . . . . 6-3

Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

PLC-5 Ladder Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

PLC Messaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

Explicit Messaging Programming Example . . . . . . . . . . . . 6-10

Example Ladder Program Explanation . . . . . . . . . . . . . . . 6-10

Explicit Message Program Control for SLC . . . . . . . . . . . .6-15

Message Translations. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Messaging for the 1747-SDN Scanner . . . . . . . . . . . . . . . 6-16

SLC Ladder Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-19

SLC Messaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-19

Using Messages to Control SCANport Products . . . . . . . .6-21

Writing to Register Objects. . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Reading Values from DeviceNet Using Explicit Messaging

and ControlLogix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-23

Configure the I/0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-23

Chapter 7

Troubleshooting Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

LEDs on the 2100-GK61 Module . . . . . . . . . . . . . . . . . . . . .7-1

DeviceNet Network Status LED States . . . . . . . . . . . . . . . .7-2

Module Status LED States . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

SCANport Status LED States . . . . . . . . . . . . . . . . . . . . . . .7-3

Input Status LED States . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Product Specifications Appendix Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

2100-GK61 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

DeviceNet to SCANport Communication Module with Digital Inputs

Parameters

Appendix Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Setting the Node Address. . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Setting the Data Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

Using Datalinks and Command I/O . . . . . . . . . . . . . . . . . . .B-3

Using Master-Slave Communications. . . . . . . . . . . . . . . . . .B-5

Polled Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-5

COS (Change of State) Allocation. . . . . . . . . . . . . . . . . . B-7

Cyclic Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-8

Polled and COS Allocation . . . . . . . . . . . . . . . . . . . . . . B-10

Polled and Cyclic Allocation . . . . . . . . . . . . . . . . . . . . . .B-11

Using Peer-to-Peer Communications . . . . . . . . . . . . . . . .B-12

Enabling the Adapter to Receive Peer I/O . . . . . . . . . . .B-13

Enabling the Adapter to Transmit Peer I/O . . . . . . . . . .B-15

Using Fault Configurable Inputs . . . . . . . . . . . . . . . . . . . .B-16

Page 9

DeviceNet to SCANport Communication Module

with Digital Inputs Parameters . . . . . . . . . . . . . . . . . . . .B-17

M-S Input Parameter Configurations . . . . . . . . . . . . . . .B-24

M-S Output Parameter Configurations . . . . . . . . . . . . . .B-26

DeviceNet Objects Appendix Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

Object Classes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

Class Code 0x01 — Identity Object . . . . . . . . . . . . . . . . . . .C-2

Class Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Instances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Instance Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-3

Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-3

Get_Attribute_All Response . . . . . . . . . . . . . . . . . . . . . . .C-3

Class Code 0x02 — Message Router Object. . . . . . . . . . . .C-4

Class Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Instances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4

Instance Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4

Common Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4

Class Code 0x03 — DeviceNet Object . . . . . . . . . . . . . . . .C-5

Class Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Instances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-5

Instance Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Common Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Class Code 0x05 — Connection . . . . . . . . . . . . . . . . . . . . C-6

Class Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Instances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6

Instance Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7

Common Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7

Class Code 0x07 — Register Object . . . . . . . . . . . . . . . . . .C-8

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-8

Instances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8

Instance Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-9

Common Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-9

Class Code 0x0F — Parameter Object . . . . . . . . . . . . . . .C-10

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-10

Instances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-10

Instance Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-11

Bit Definitions for Instance Attribute 4 . . . . . . . . . . . . . .C-12

Data Types for Instance Attribute 5. . . . . . . . . . . . . . . . C-13

Common Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-14

Get_Attribute_All Response . . . . . . . . . . . . . . . . . . . . . .C-14

Object Specific Services . . . . . . . . . . . . . . . . . . . . . . . . C-15

Class Code 0x10 — Parameter Group Object . . . . . . . . . C-16

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-16

Instances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-16

Instance Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-16

Common Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-17

Get_Attribute_All Response . . . . . . . . . . . . . . . . . . . . . .C-17

Class Code 0x93 — SCANport Pass-Through . . . . . . . . .C-18

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-18

Instance Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-18

Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-18

Object-Specific Services. . . . . . . . . . . . . . . . . . . . . . . . .C-18

Class Code 0x97 — SCANport Pass-Through

Fault Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-19

Class Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-19

Instance Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-19

Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-20

Page 10

Class Code 0x98 — SCANport Pass-Through Warning. . C-21

Class Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-21

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-21

Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-22

Class Code 0x99 — SCANport Pass-Through Link Object C-23

Class Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-23

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-23

Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-23

Object-Specific Services. . . . . . . . . . . . . . . . . . . . . . . . C-23

Class Code 0x67 — PCCC Object. . . . . . . . . . . . . . . . . . .C-25

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-25

Instance Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-25

Common Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-25

Object Specific Services . . . . . . . . . . . . . . . . . . . . . . . . .C-25

Message Structure for Execute_PCCC. . . . . . . . . . . . . C-25

Message Structure for Execute_Local_PCCC . . . . . . . .C-26

N-File Addresses Appendix Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

N-File Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Supported Emulated Block Transfer Commands

Appendix Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-1

What is Emulated Block Transfer? . . . . . . . . . . . . . . . . . . .E-1

Supported Emulated Block Transfer Commands . . . . . . . . .E-1

Emulated Block Transfer Status Word . . . . . . . . . . . . . . . . .E-2

Parameter Value Read . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-3

PLC Block Transfer Emulation Instruction Data . . . . . . . .E-3

Message Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-3

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3

Parameter Value Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-4

PLC Block Transfer Emulation Instruction Data . . . . . . . .E-4

Message Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-4

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-4

Parameter Read Full . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-5

PLC Block Transfer Emulation Instruction Data . . . . . . . E-5

Message Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-6

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-6

Product ID Number Read . . . . . . . . . . . . . . . . . . . . . . . . . .E-8

PLC Block Transfer Emulation Instruction Data . . . . . . . .E-8

Message Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-9

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-9

Scattered Parameter Value Read . . . . . . . . . . . . . . . . . . .E-10

PLC Block Transfer Emulation Instruction Data . . . . . . .E-10

Message Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-11

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-11

Scattered Parameter Value Write . . . . . . . . . . . . . . . . . . .E-12

PLC Block Transfer Emulation Instruction Data . . . . . . E-12

Message Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . E-13

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-13

NVS Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-14

PLC Block Transfer Emulation Instruction Data . . . . . . E-14

Message Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-14

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-14

Fault Command Write . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-15

PLC Block Transfer Emulation Instruction Data . . . . . . E-15

Message Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-15

Fault Queue Entry Read Full . . . . . . . . . . . . . . . . . . . . . . E-16

PLC Block Transfer Emulation Instruction Data . . . . . . .E-16

Message Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-17

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E -17

Fault Queue Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-18

PLC Block Transfer Emulation Instruction Data . . . . . . E-18

Message Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-18

Page 11

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-18

Trip Fault Queue Number . . . . . . . . . . . . . . . . . . . . . . . . .E-19

PLC Block Transfer Emulation Instruction Data . . . . . . .E-19

Message Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-19

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-19

Digital Input Parameter Read. . . . . . . . . . . . . . . . . . . . . . E-20

PLC Block Transfer Emulation Instructions Data . . . . . E-20

Message Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . E-21

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-21

Page 12

Page 13

Chapter 1

Overview

Chapter Objectives Chapter 1 provides an overview of your DeviceNet to SCANport

Communication module with Digital Inputs. In this chapter, you will

read about the following:

• Function of the 2100-GK61 module.

• Features of the 2100-GK61 module.

• SCANport products.

• Parts and hardware of the 2100-GK61 module.

• Steps for setting up the adapter.

• Required tools and equipment.

Overview of the

Communication Adapter

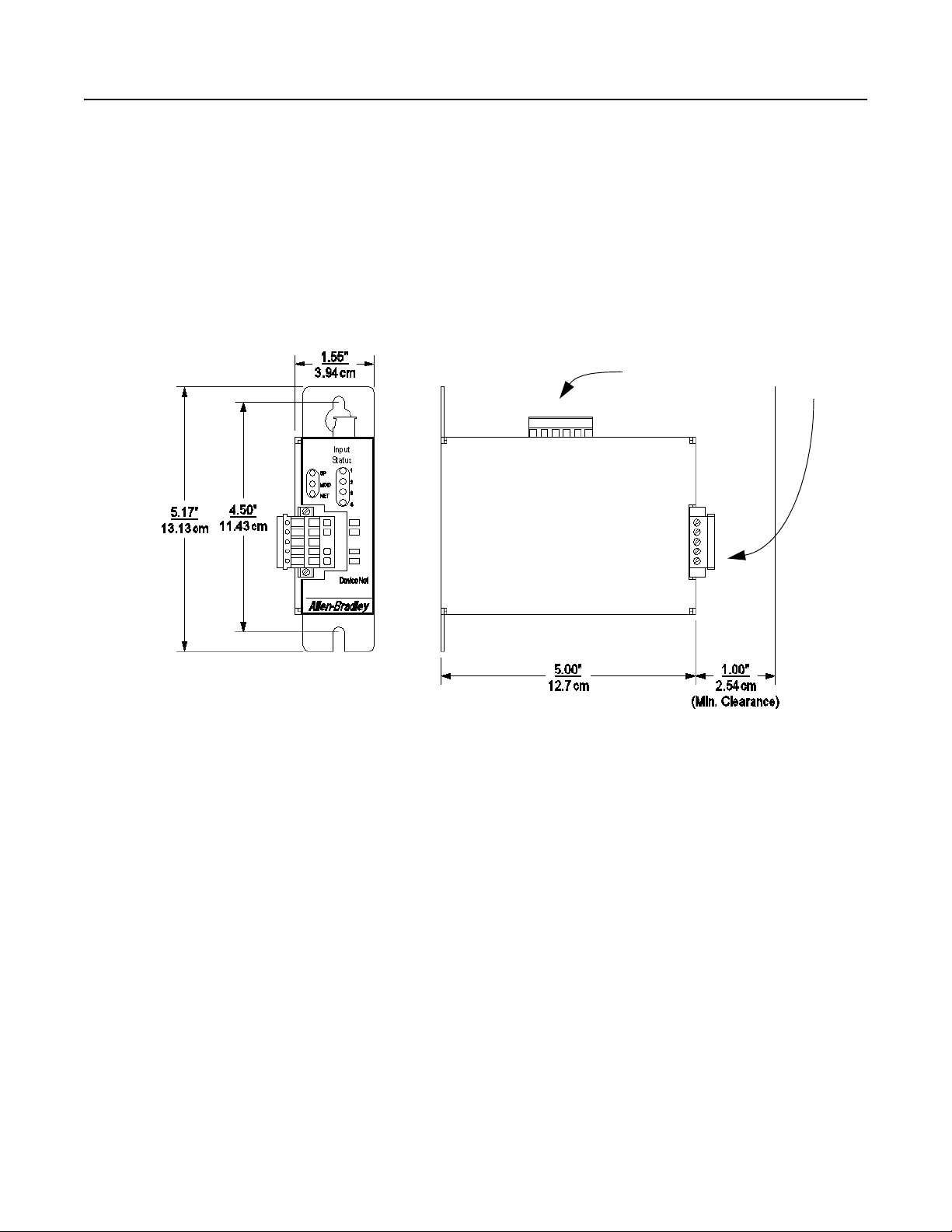

Figure 1.1

2100-GK61 Module

2100-GK61 Module

2100-GK61 Module - Front View

The 2100-GK61 module mounts on a panel and connects to the

SCANport product via a SCANport cable. Digital inputs of 230Vac,

115Vac, or 24Vdc are connected to the adapter via discrete wires. The

voltage level used for the digital inputs is set via a dip switch SW1.

2100-GK61 Module - Top View

Publication 2100-UM001B-EN-P – January 2001

Page 14

1-2 Overview

The communications adapter provides an electronic communications

interface between a DeviceNet network and any single SCANport

product.

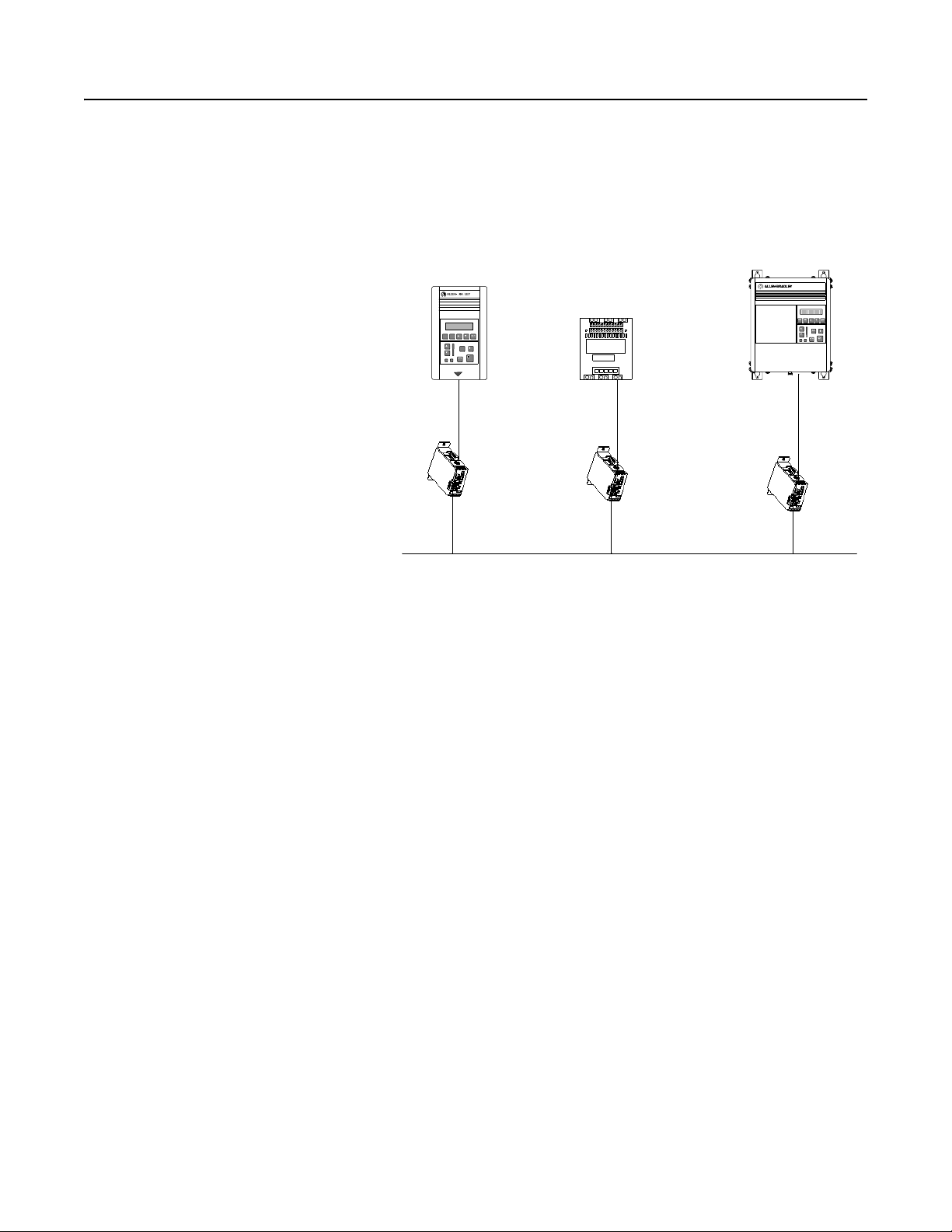

Figure 1.2

Example of 2100-GK61 Modules Connecting SCANport Produ ct s

to DeviceNet

1336 PLUS

1305

SMC Dialog Plus

DeviceNet

In Figure 1.2, a SCANport cable connects a 2100-GK61 module to a

SCANport product through a port on the SCANport product. A

DeviceNet cable co nn ec ts the module to the DeviceNet network. The

module then translates the DeviceNet messages into SCANport

messages that can be understood by the connected product.

The adapter is also capable of connecting to four (4) common switch

inputs. These inputs can monitor status of disconnect switches, starter

and contactor auxiliary contact, relays, push buttons, or any ON-OFF

device capable of switching 230Vac, 115Vac, or 24Vdc.

Publication 2100-UM001B-EN-P – January 2001

Page 15

Overview 1-3

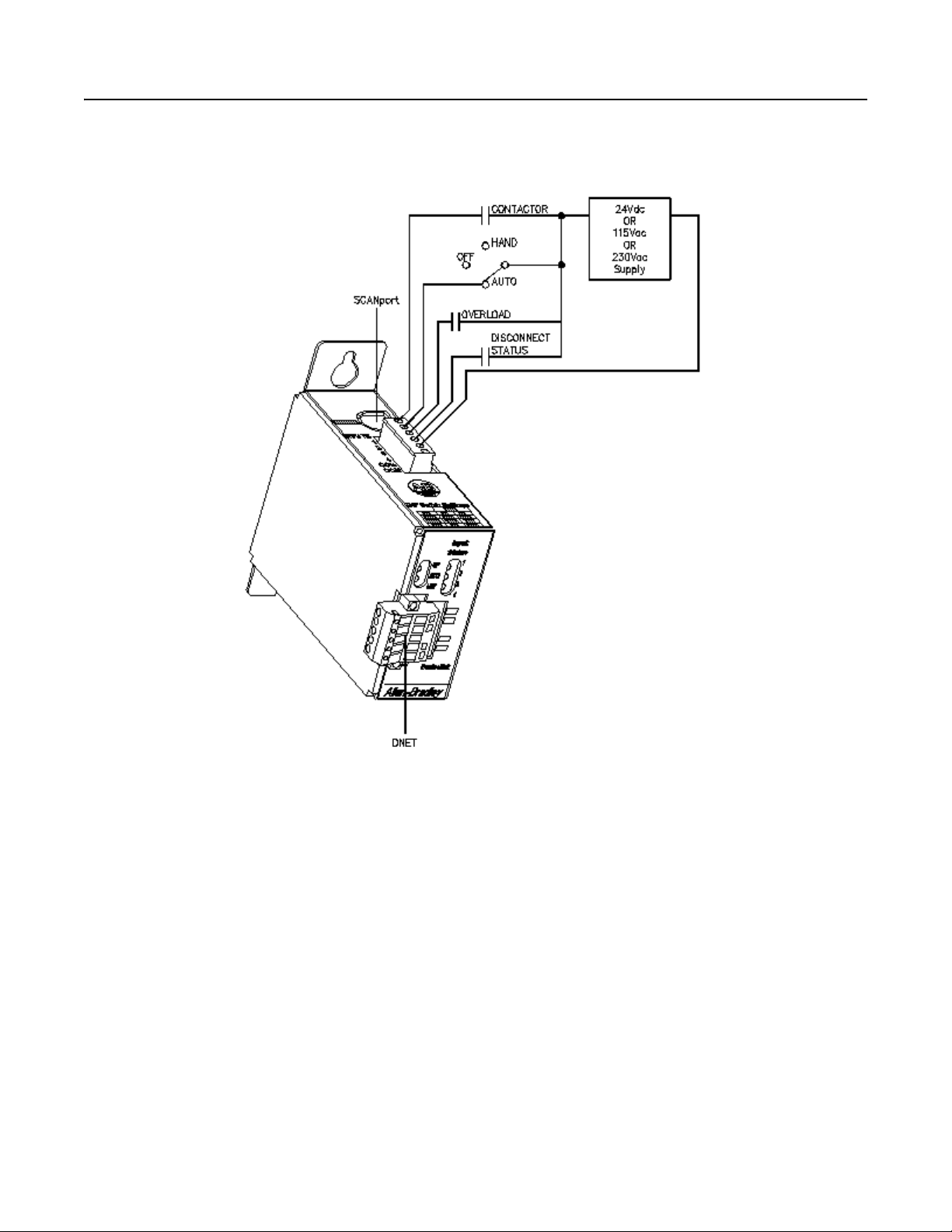

Figure 1.3

Example of 2100-GK61 Module Connecting Digital Inputs

Features of the Communication

Adapter

In Figure 1.3, discrete wiring connects up to four (4) digital inputs to

the 2100-GK61 module. A DeviceNet cable connects the module to

the DeviceNet network and a SCANport cable connects a SCANport

product to the module. The contact status is then translated into a

DeviceNet message that can be used to control SCANport devices

attached to the module or other devices on the DeviceNet network.

The DeviceNet network is an open, global industry-standard

communication network designed to provide an interface through a

single cable from a programmable controller directly to “smart”

devices such as sensors, push buttons, motor starters, simple operator

interfaces, and drives.

The 2100-GK61 module lets you connect your SCANport products to

a DeviceNet network. This adapter features the following:

• Flash upgradeability allows for field updates in the event of

changes to the adapter’s firmware.

Publication 2100-UM001B-EN-P – January 2001

Page 16

1-4 Overview

• COS (Change of State) capability lets you customize this device’ s

activity on the network by configuring the adapter to report only

new data.

• Cyclic operation lets you customize the devices’s activity on the

network by configuring the adapter to report its data at specific

intervals.

• Polled operation allows you to customize the device’s activity on

the network to respond only after the scanner sends control data.

• Peer I/O capabilities let the drive’s I/O (logic command,

reference, logic status, feedback and datalinks) be broadcast to or

received from other drives connected via 1203-GU6, 1336-GM6

or 2100-GK61 adapters.

• Software configuration lets you configure the adapter using

RSNetWorx for DeviceNet.

• Faulted Node Recovery lets you change an item, such as a node

address of a device, even when it is faulted on the network.

• User-configurable fault response pro vides the ability to customize

the adapter’s actions to communication errors.

• A Module Status LED helps to diagnose network, module, and

SCANport product health.

• Monitor and report status of four (4) individual digital inputs.

Publication 2100-UM001B-EN-P – January 2001

Page 17

Overview 1-5

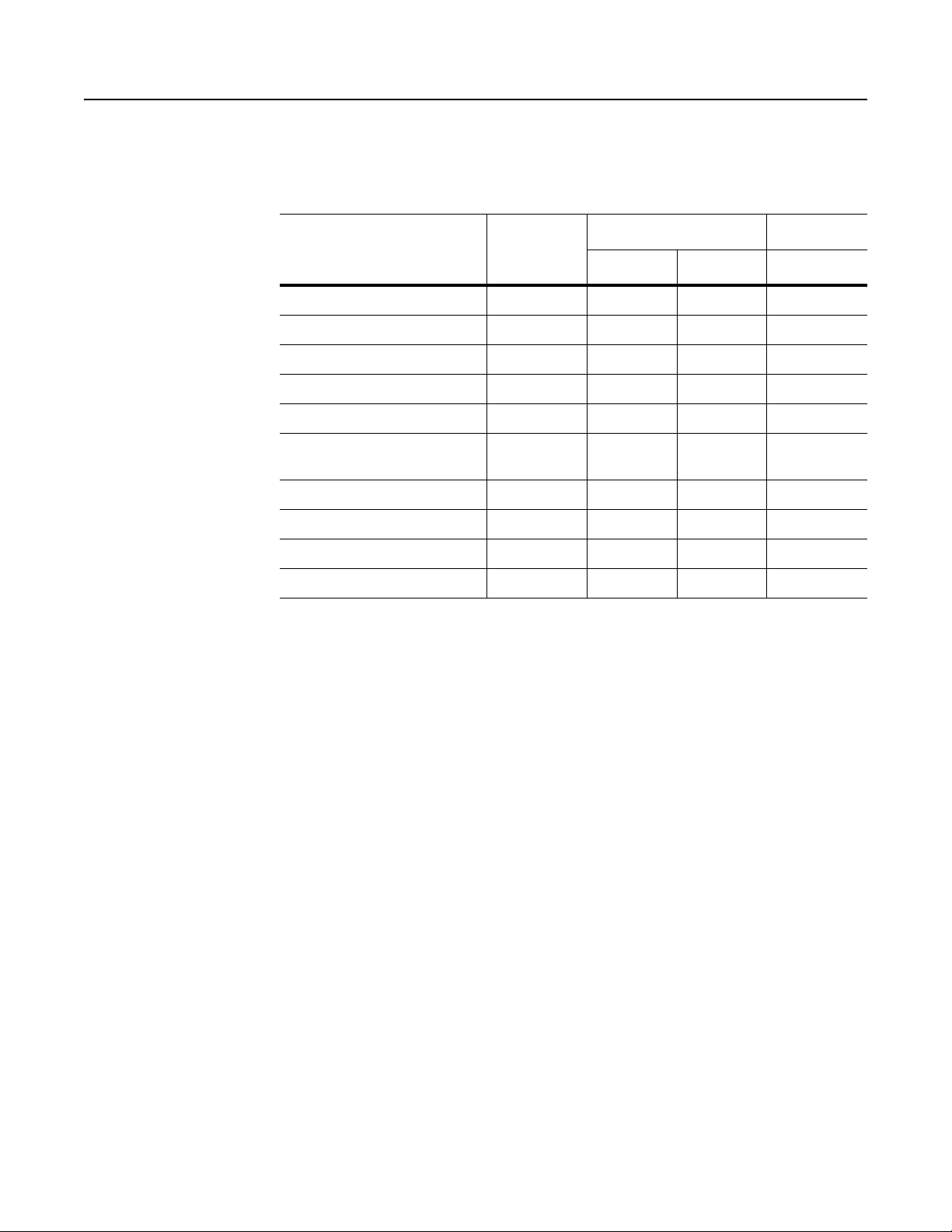

SCANport Products Some SCANport products support one peripheral; others support up

to six peripherals. The table below lists SCANport products, the

number of peripherals each supports, the minimum and maximum I/O

words, and the type of adapter that can be used.

Number of

Product

1305 AC MICRO Drive 5 0 10 Yes

1336 IMPACT™ Drive 6

1336 PLUS AC Drive 6

1336 PLUS II Drive 6

1336 FORCE™ Drive 6

1394 AC Mult-Axis Motion

Control System

SMC Dialog Plus 1 0 2 Yes

SMP-3 Smart Motor Protector 2 0 2 Yes

1397 Digital DC Drive 5 0 10 Yes

1557 Medium Voltage Drive 5 0 10 Yes

➀ Lower horsepower products may not support a sixth peripheral. Refer to your user manual to verify that your

product supports a sixth peripheral.

Peripherals

Supported

➀ 010Yes

➀ 010Yes

➀ 010Yes

➀ 010Yes

5010Yes

I/O Words Adapter Use

Minimum Maximum 2100-GK61

Important: To connect multiple peripherals to a SCANport product,

a port expander may be required. Refer to your product’s

documentation for more information.

Important: If you intend to use datalinks to communicate with and

control your SCANport product, verify that your SCANport product

supports datalinks before enabling them in the adapter.

Publication 2100-UM001B-EN-P – January 2001

Page 18

1-6 Overview

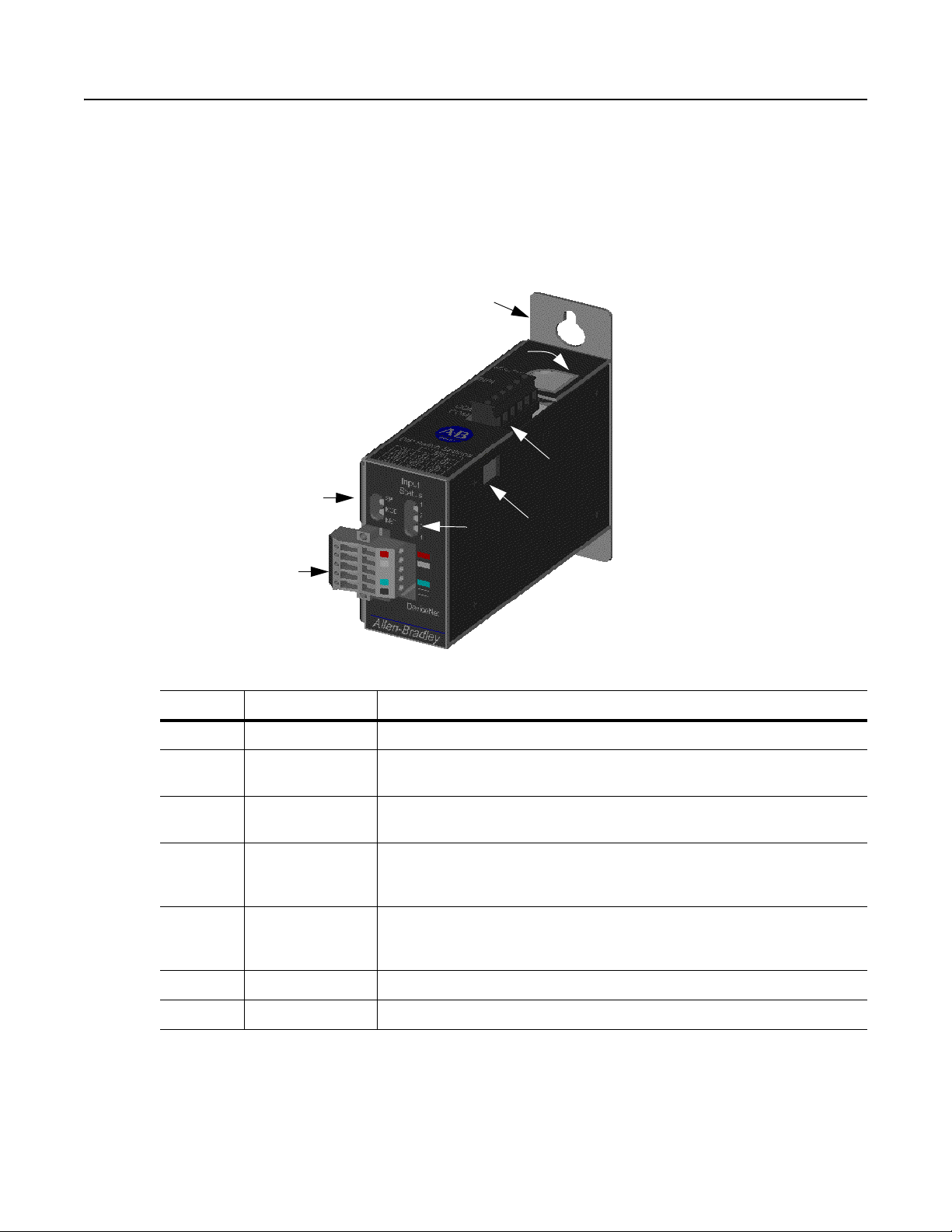

Hardware and Parts

Description

2100-GK61 Module Hardware

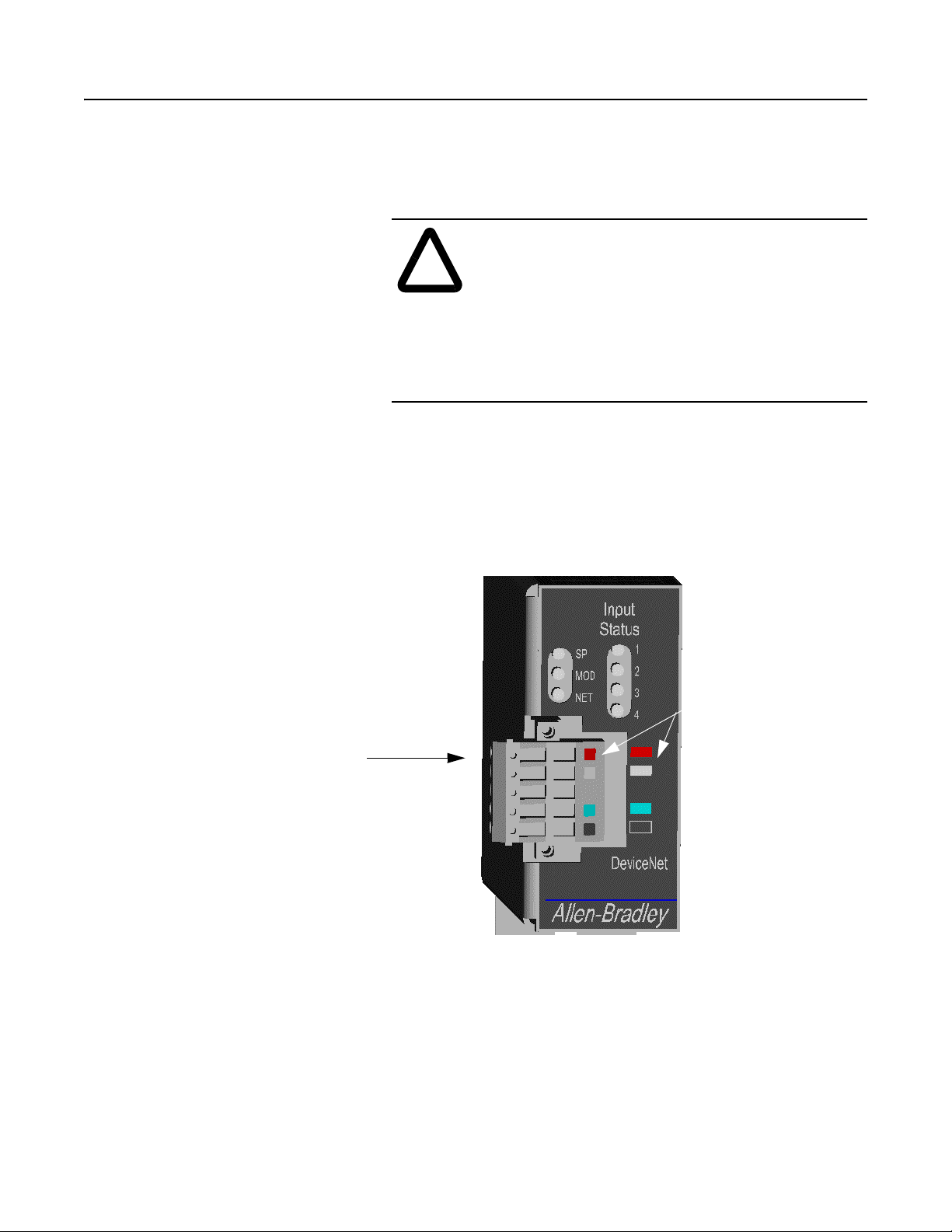

Figure 1.4 illustrates and the following table lists the main parts of the

2100-GK61 DeviceNet to SCANport communication module with

Digital Inputs:

Figure 1.4

Parts of the 2100-GK61 Module

1

2

3

4

6

7

5

Number Part Description

1 Panel mount Attach module to sub-panel through mounting holes.

2 SCANport

Connection

3 Digital Input

Connector

4 Bi-Color LEDs Indicate the status of the DeviceNet media channel, of the SCANport con-

5 DeviceNet Con-

nection

6 Input Status LEDs Indicate the ON-OFF status of the digital inputs.

7 SW1 Set to match the digital input voltage applied of 230Vac, 115Vac, or 24Vdc.

Provides a standard SCANport 8-pin circular mini-DIN connector for the

SCANport cable.

Allows connection of switched 230Vac, 115Vac, or 24Vdc inputs to module.

The 6-pin plug-in connector (PIN 192 929) is supplied with the module.

nection, and of the module. For more information, refer to Chapter 7, Trou-

bleshooting.

Provides a 10-pin Phoenix connector to attach the module to the DeviceNet

network. The 10-pin plug-in connector (PIN 94220605) is supplied with the

module.

Publication 2100-UM001B-EN-P – January 2001

Page 19

Overview 1-7

Overview of Setting Up the

Adapter

To set up the DeviceNet to SCANport Communication Module with

Digital Inputs, you must perform the following tasks:

1. Install the module. Refer to Chapter 2, Installation.

2. Set the adapter’s node address and configure the adapter’s

parameters. Refer to Chapter 3, Configuring the DeviceNet to

SCANport Communication Module with Digital Inputs.

3. Configure a scanner (either PLC or SLC) to communicate with

the Adapter. Refer to Chapter 4 , Configuring a Scanner to

Communicate with the Adapter.

4. If necessary, create a ladder logic program to control the

SCANport product. Refer to Chapter 5, Ladder Logic

Programming—Including Reading Inputs.

Required Tools and Equipment To install and configure a 2100-GK61 module, you need the

following:

• DeviceNet to SCANport Communication Module with Digital

Inputs (2100-GK61).

• 10-pin plug-in DeviceNet connector (supplied with module).

• Appropriate cables for SCANport and DeviceNet connections.

Refer to the Selecting Cables section in Chapter 2, Installation.

• 6-pin plug-in Input connector (supplied with module).

• #10 hardware for attaching module to a panel.

• A PC that is:

– Running RSNetWorx.

– Connected to and communicating with the DeviceNet

network using a 1784-PCD card or a 1770-KFD adapter.

– Running RS Linx.

– Running RSLogix5 (if using PLC) or RSLogix500 (if using

SLC).

Important: Refer to http://www.software.rockwell.com for more

information on these software products.

Publication 2100-UM001B-EN-P – January 2001

Page 20

1-8 Overview

Publication 2100-UM001B-EN-P – January 2001

Page 21

Chapter 2

Installation

Chapter Objectives Chapter 2 provides the information that you need to install the

2100-GK61 module. In this chapter, you will read about the

following:

• Required tools and equipment.

• Selecting cables.

• Installing the adapter.

• Removing the adapter.

Installing a 2100-GK61 Module Follow these procedures to install a 2100-GK61 module.

Required Tools and Equipment

To install your 2100-GK61 module, you will need the following tools

and equipment:

• DeviceNet to SCANport Communication Module with Digital

Inputs(2100-GK61).

• A 6-pin and 10-pin plug-in connector (supplied with module).

• Screwdriver or nutdriver and mounting screws (#10).

• Appropriate cables for SCANport and DeviceNet connections.

Refer to the “Selecting Cables” section below.

Selecting Cables

To connect the 2100-GK61 to the SCANport product and the

DeviceNet network, you must select an appropriate DeviceNet cable

and Allen-Bradley SCANport cable. Use the following information to

select appropriate cables for each connection.

Publication 2100-UM001B-EN-P – January 2001

Page 22

2-2 Installation

SCANport Cables

When selecting the SCANport cable to connect the 2100-GK61

module to the SCANport product, you need to:

• Use an Allen-Bradley SCANport cable. Refer to the table below.

Male to Male Connection Male to Female Connection

Length Catalog Number Length Catalog Number

1/3 m 1202-C03 1/3 m 1202-H03

1 m 1202-C10 1 m 1 202-H10

3 m 1202-C30 3 m 1 202-H30

9 m 1202-C90 9 m 1 202-H90

• Use less than 10 meters (33 feet) of cable between the SCANport

product and adapter.

• Keep SCANport cables away from high power cables to guard

against introducing noise into your system.

DeviceNet Cables

The 2100-GK61 module comes with a 10-pin (dual row 5-pin)

connector. This connector is used to wire the module for both single

drops, when only one side of each terminal is used, or to daisy chain

devices together when both sides of the terminals are used. A drop

line connects a node such as a 2100-GK61 module in the DeviceNet

cable system to the DeviceNet trunk.

Before connecting modules to the network, you must determine if

your network is within limits of the cable system. Class 1 cables are

rated 600 volts, 8 amps. Class 2 cables are rated 300 volts, 4 amps.

The cables in the chart below can be used for Trunk or Drop

applications. When used for Trunk, length limits must be observed.

Cable Type Part Number Dat a Rates

125 Kbps 250 Kbps 500 Kbps

Class 1 Flat 1485C-P1-E75 420m (1378 ft.) 200m (656 ft.) 75m (246 ft.)

Class 2 Thick Round 1485C-P1-A50 500m (1640 ft.) 250m (820 ft.) 100m (328 ft.)

Class 2 Thin Round 1485C-P1-C50 100m (328 ft.) 100m (328 ft.) 100m (328 ft.)

Publication 2100-UM001B-EN-P – January 2001

Class 1 round drop cable is recommended for connections between

devices and Class 1 Trunk. Maximum drop length is 6m (20 ft.)

Cumulative Drop Budget is based on Data Rate.

125 Kbps 250 Kbps 500 Kbps

156m (512 ft.) 78m (256 ft.) 39m (128 ft.)

Page 23

Installation 2-3

Class 1 Drop Cable is available in three spool sizes:

Cable Part Number Spool Size

1485C-P1-B50 50m (164 ft.)

1485C-P1-B150 150m (492 ft.)

1485C-P1-B300 300m (984 ft.)

For more information on DeviceNet cables and cable systems, refer to

the DeviceNet Cable System Planning and Installation Manual,

Publication DN-6.7.2.

Input Wires

Choose a suitable wire to handle 230Vac, 115Vac, or 24Vdc voltage,

depending on installation. The input connector is capable of installing

12-24AWG wire.

Installing the DeviceNet to SCANport Communication

Module with Digital Inputs (2100-GK61)

The following instructions explain how to physically install your

DeviceNet to SCANport Communication Module with Digital Inputs.

ATTENTION: Severe injury or death can result from

electrical shock, burn, or unintended actuation of controlled

!

equipment. Hazardous volta ges may exist in the cabinet even

with the circuit breaker in the off position. Recommended

practice is to disconnect and lock out control equipment from

power sources and discharge stored ener g y in capacitors, if

present. If it is necessary to work in the vicinity of energized

equipment, the safety related work practices of NFPA 70E,

Electrical Safety Requirements for Employee Workplaces,

must be followed.

ATTENTION: DO NOT work alone on energized

equipment!

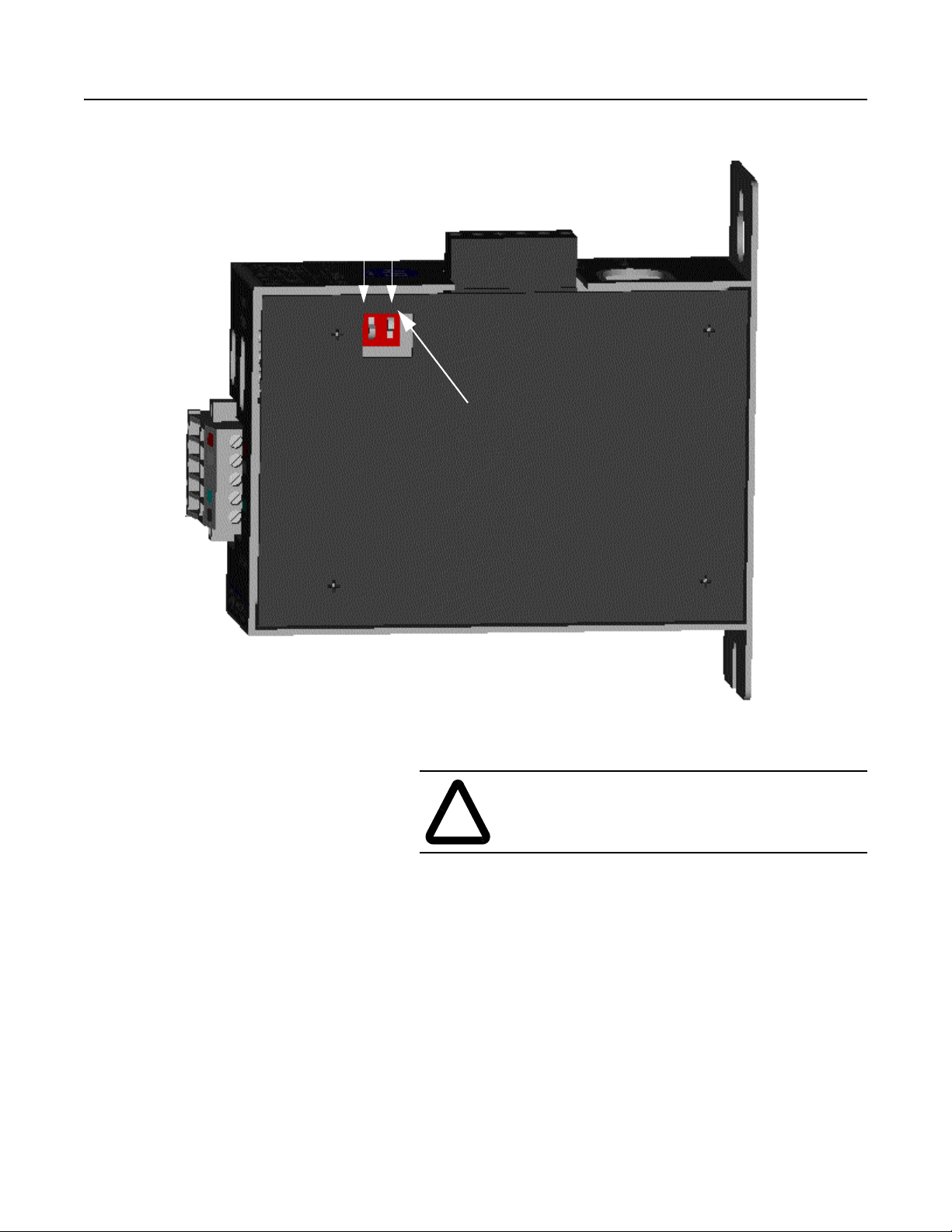

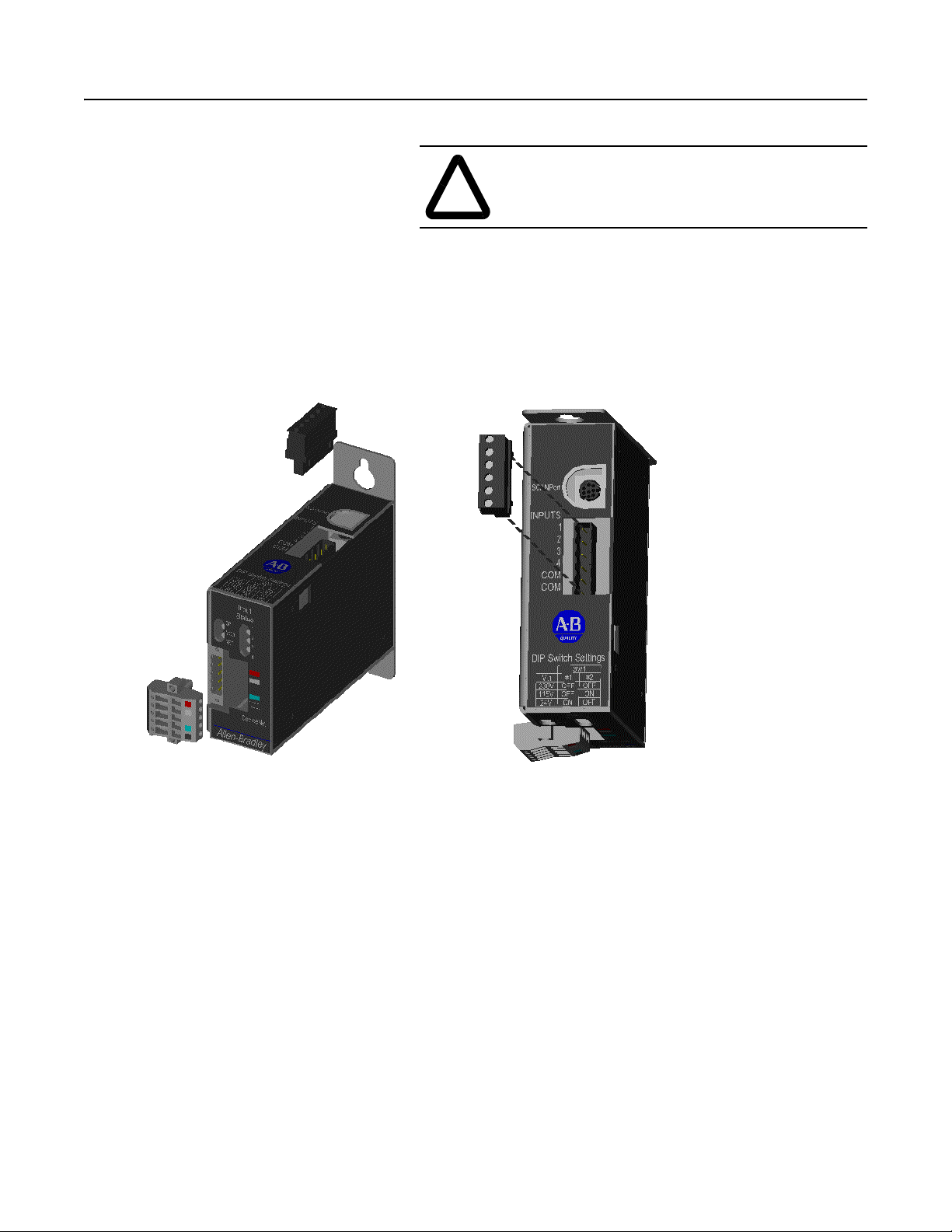

1. Before installing the module, set the Digital Input selection

switch SW1 to the proper input voltage per the table below.

VIN

#1 #2

230Vac OFF OFF

SW1

115Vac OFF ON

24Vdc ON OFF

Publication 2100-UM001B-EN-P – January 2001

Page 24

2-4 Installation

SW1 is accessed through the plastic cover on the 2100-GK61

module as show in Figure 2.1

ATTENTION: To guard against possible

component damage, assure that Dip Switch

!

SW1 is set for the correct input voltage used

in the system before power is applied to the

module.

Publication 2100-UM001B-EN-P – January 2001

Page 25

Installation 2-5

Figure 2.1

Dip Switch Access - Side View of 2100-GK61 Module

1

2

Dip Switch Location

2. Determine a suitable mounting location within a desired location

close to its interconnecting devices and /or components.

A TTENTION: The 2100-GK61 module is an open

panel device and must be mounted inside a suitabl e

!

When choosing a suitable mounting location, allo w 1.0” (2.54cm)

clearance from the front of the module to the door of the enclosure or other devices. This clearance is needed for DeviceNet wiring harness/bend radius.

enclosure.

Publication 2100-UM001B-EN-P – January 2001

Page 26

2-6 Installation

Mount the module to the panel with #10 hardware as detailed in

Figure 2.2.

Figure 2.2

Mounting Dimensions

Digital Input

Connector

DeviceNet

Connector

Publication 2100-UM001B-EN-P – January 2001

Page 27

Installation 2-7

3. Remove power from the network.

4. Insert the DeviceNet cable wires into the 10-pin connector . Mak e

sure you follow the color key next to the connector receptacle on

the module.

ATTENTION: If you wire the 10-pin header after

you’ve connected it to the module, static control

!

precautions are required. Device malfunction may occur

if you do not follow ESD control procedures. If yo u are

not familiar with static control procedures, refer to

Allen-Bradley Publication 8000-4.5.2, Guarding

Against Electrostatic Damag e, or other applicable ESD

protection handbook.

Figure 2.3

DeviceNet Connections

10-pin Dual Row

DeviceNet Connection

Color Key

1 - Red - V+

2 - White-CAN_H

3 - Shield

4 - Blue-CAN_L

5 - Black- V-

Front View of 2100-GK61 Module

Publication 2100-UM001B-EN-P – January 2001

Page 28

2-8 Installation

5. Plug the connector into the module.

A TTENTION: Danger of electrical shock exists if

power is not disconnected to Digital Input Devices.

!

Verify power is removed before proceeding.

6. Connect the Digital Inputs to the Digital Input six (6) pin connec-

tors. Below is the connection pinout detail.

Figure 2.4

Digital Input Connections

Pin 1 = Input #1

Pin 2 = Input #2

Pin 3 = Input #3

Pin 4 = Input #4

Pin 5 = Input Common

Pin 6 = Input Common

Publication 2100-UM001B-EN-P – January 2001

7. Plug the Input connector into the module.

8. Connect the SCANport cable to the communications adapter and

then to the SCANport product.

Page 29

Figure 2.5

SCANport Connection

Installation 2-9

SCANport Cable

9. Reapply power to the DeviceNet network.

10. If necessary, apply power to the connected SCANpo rt product

and to the Digital Inputs.

Publication 2100-UM001B-EN-P – January 2001

Page 30

2-10 Installation

Your 2100-GK61 module is now installed. The SCANport LED is

green. The network and module LEDs are blinking green. If your

module’s LEDs are different, refer to Chapter 7, Troubleshooting, for

more information.

You must now edit the adapter’s node address, and you may want to

edit some of its other parameters. Refer to Chapter 3 for more

information.

Removing the DeviceNet to SCANport

Communication Module with Digital Inputs

(2100-GK61)

T o remo ve the De viceNet to SCANport Communication Module with

Digital Inputs, you need to:

1. Disconnect Input Power from Digital Inputs.

ATTENTION: Electrical shock hazard exists if

power is not disconnected to Digital Input Devices.

!

Verify power is removed before proceeding.

2. Remove the SCANport cable from the SCANport product and

then from the module.

3. Unplug the 10-pin DeviceNet connector from the module.

4. Unplug the 6-pin Digital Input connector from the module.

5. Remove the module from the panel.

Publication 2100-UM001B-EN-P – January 2001

Page 31

Chapter 3

Configuring the DeviceNet to

SCANport Communication Module

with Digital Inputs

Using RSNetWorx for DeviceNet

Chapter Objectives Chapter 3 provides information that you need to configure the

2100-GK61 module over the DeviceNet network. In this chapter, you

will read about the following:

• Factory-default settings for the module.

• RSNetWorx software.

• Equipment necessary to use RSNetWorx software.

• Editing the 2100-GK61 adapter’s parameters using RSNetWorx

software.

Factory Default Settings for the

2100-GK61

This section assumes you have experience using RSNetWorx

software to configure a DeviceNet network.

The factory-default settings of the DeviceNet to SCANport

Communication Module with Digital Inputs include the following:

• 16-bit Logic Command/Status enabled for polling.

• 16-bit Reference/Feedback enabled for polling.

• If the scanner is put into program mode or the network faults, the

SCANport product will be faulted by the module. (Firmware

must be version 2.080 or above. Earlier firmware versions are

flash upgradeable. Consult the factory.)

• A node address of 63.

• DeviceNet autobaud detection enabled.

Publication 2100-UM001B-EN-P – January 2001

Page 32

3-2 Configuring the DeviceNet to SCANport Communication Module with Digital Inputs

You should change the node address by editing the DN Node Address

(2) parameter. Note: The number in ( ) following the parameter name

corresponds to the parameter number as found in Appendix B,

DeviceNet to SCANport Communication Module with Digital Inputs

Parameters. You must change the autobaud detection if no other

devices on your DeviceNet network have a fixed data rate by editing

DN Data Rate (3) parameter in the module.

Important: Refer to Appendix B, DeviceNet to SCANport

Communication Module with Digital Inputs Parameters, for

information on changing the node address or data rate.

If you wish to change other functions (e. g., Fault Con figurable in puts)

or add more functions (e.g., datalinks), you must edit the adapter’s

parameters. To do so, refer to:

• Appendix B, DeviceNet to SCANport Communication Module

with Digital Inputs P arameter s, for detailed information about the

adapter’s parameters.

• Instructions in this chapter on using RSNetW orx for De viceNet to

edit parameters.

What is RSNetWorx for

DeviceNet?

Required Equipment and

Software

RSNetWorx for DeviceNet is a Windows application that lets you

configure DeviceNet networks. Using a graphical representation of

your network, you can configure network-wide parameters and the

network-wide schedule.

After installing or mounting the adapter, you can use RSNetWorx for

DeviceNet to configure or edit the adapter’s parameters.

Before configuring or editing your adapter’s parameters, your PC

must be:

• Running RSNetWorx for DeviceNet. Refer to

http://www.software.rockwell.com for more information on this

product.

• Connected to and communicating with the DeviceNet netw o rk

using a 1784-PCD card, a 1784-PCID card, a 1784-PCID5 card,

or a 1770-KFD adapter running with RSLinx. Refer to

http://www.software.rockwell.com for more information on the

RSLinx product. Refer to http://www.ab.com/products.html for

more information on “DeviceNet Network, ” under “Networks and

Communication Products.”

Publication 2100-UM001B-EN-P – January 2001

Page 33

Configuring the DeviceNet to SCANport Communication Module with Digital Inputs 3-3

Using RSNetWorx to Edit Your

Adapter’s Parameters

The following instructions describe how to use RSNetWorx for

DeviceNet in online mode to edit your adapter’s parameters.

1. Use RSLinx to configure the DeviceNet drivers for your system

using the Configure Drivers option in the Communications

menu.

2. Start RSNetWorx for DeviceNet. The RSNetWorx for DeviceNet

screen appears as seen in Figure 3.1.

Figure 3.1

RSNetWorx for DeviceNet Screen

3. In the Network menu, select Online, or click on the Online icon

as indicated in Figure 3.2.

4. The Browse Network screen appears asking to select which

network you wish to go online with. Select the DeviceNet

network desired and click on OK.

Publication 2100-UM001B-EN-P – January 2001

Page 34

3-4 Configuring the DeviceNet to SCANport Communication Module with Digital Inputs

Figure 3.2

Online Screen

Step #3

Step #4

5. The network will be scanned and the screen will build the online

configuration as shown in Figure 3.3.

Figure 3.3

RSNetWorx Graphical View

Publication 2100-UM001B-EN-P – January 2001

In Figure 3.3, Node 00 is scanner, Node 62 is the PC, and Node 63 is

the module we are configuring.

Your module appears as Node 63 by default. If you have changed its

node address parameter and reset the module, its new node address

will appear on the screen.

Page 35

Configuring the DeviceNet to SCANport Communication Module with Digital Inputs 3-5

Important: If the module does not appear:

– Verify there is an EDS file for the device. Refer to “Creating

an EDS file for your SCANport Product” in Chapter 4,

Configuring a Scanner to Communicate with the

Adapter.

– Verify that the device has a unique node address. Check the

network LED on the module. If it is red, it is not an unique

address. You must configure the module in a point-to-point

connection.

6. Double-click the icon for the 2100-GK61 module. (In our

example, it is node 63 in Figure 3.3.)

The DeviceNet Configuration screen appears for the selected device.

The screen has three tabs to choose from: General, Device

Parameters, and EDS I/O Default.

The General tab allows you to give the device a name and add a

description for the device. These names and descriptions will be used

to represent and describe the product throughout RSNetWorx for

DeviceNet.

Step #7

The DeviceNet Parameters and EDS I/O Default tabs allow you to

see the parameters and configuration of the device selected.

7. Click on the Device Parameters tab . A dialog box req uesting to

upload or download the de vice’s parameters appears. Click on the

Upload button to upload the parameters from the module. The

screen listing all the device’s parameters appears. In this example

the 2100-GK61 is configured with an SMP3 device.

Figure 3.4

Device Parameters, all

Publication 2100-UM001B-EN-P – January 2001

Page 36

3-6 Configuring the DeviceNet to SCANport Communication Module with Digital Inputs

8. Click on the Groups pull-down arrow and select DeviceNet

Module. The display changes, listing only the parameters

associated with the 2100-GK61.

Figure 3.5

Device Parameters, Module Only

Step #8

Step #9

Step #11

Step #10

9. Double click on the parameter(s) you wish to edit. Change the

data to the desired value (refer to Appendix B for acceptable

values for each parameter). A lock icon indicates that the

parameter is read-only and cannot be changed.

10. Click on the Download to Device button to save the changes

made to the module.

Important: It may be necessary to reset the adapter for the changes

to take effect. Refer to Appendix B to see if the parameter you

changed required the module to be reset in order to take effect.

11. Click on the OK button to return to the graph screen.

Publication 2100-UM001B-EN-P – January 2001

Page 37

Chapter 4

Configuring a Scanner to

Communicate with the Adapter

Chapter Objectives Chapter 4 provides instructions for configuring your scanner to

communicate with the 2100-GK61 module. This allows the product

connected to the adapter to be an active node on the DeviceNet

network. In this chapter, you will read about the following:

• RSNetWorx for DeviceNet software.

• Equipment and software needed for the configuration.

• Configuring a PLC, SLC, or ControlLogix scann er to

communicate with the adapter.

This chapter assumes you have experience using RSNetWorx for

DeviceNet to configure a DeviceNet network.

What is RSNetWorx for

DeviceNet?

Required Equipment and

Software

RSNetWorx for DeviceNet is a Windows application that lets you

configure DeviceNet networks. Using a graphical representation of

your network, you can configure network-wide parameters and the

network-wide schedule.

After installing and configuring the DeviceNet to SCANport

Communication Module with Digital Inputs, you can use RSNetW orx

for DeviceNet to configure the scanner to recognize and communicate

with it.

For more information on RSNetWorx for DeviceNet, refer to the

RSNetWorx for DeviceNet online help.

Before configuring the scanner, your PC must be:

• Running RSNetWorx for DeviceNet. Refer to

http://www.software.rockwell.com for more information on this

product.

• Connected to and communicating with the DeviceNet network

using a 1784-PCD card, a 1784-PCID card, a 1784-PCID5 card,

or a 1770-KFD adapter running with RSLinx. Refer to

http://www.software.rockwell.com for more information on the

RSLinx product. Refer to http://www.ab.com/products.html for

more information on “DeviceNet Network” under “Networks an d

Communication Products.”

Publication 2100-UM001B-EN-P – January 2001

Page 38

4-2 Configuring a Scanner to Communicate with the Adapter

Getting Started For the scanner on the DeviceNet network to transmit control I/O

and/or messages to the adapter, you must first configure it to

recognize and communicate with the adapter.

The following instructions describe how to use RSNetWorx for

DeviceNet to configure a new DeviceNet network in online mode.

The main steps in the configuration are:

• Using online mode in RSNetWorx for DeviceNet.

• Downloading an EDS file for your SCANport product (if

necessary).

• Configuring the PLC scanner or SLC scanner.

Using Online Mode in

RSNetWorx for DeviceNet

Although you can configure the DeviceNet network offline, it is

easier to configure the network online because you can see a

graphical representation of your network in RSNetWorx for

DeviceNet. The following directions explain how to use online mode.

1. Start RSLinx to configure the DeviceNet Drivers for your

system, using the Configure Drivers option in the

Communications menu.

2. Start RSNetWorx for DeviceNet. The RSNetW orx for DeviceNet

screen appears.

Figure 4.1

RSNetWorx for DeviceNet Screen

Publication 2100-UM001B-EN-P – January 2001

Page 39

Configuring a Scanner to Communicate with the Adapter 4-3

3. In the Network menu, select Online, or click on the Online icon

as indicated in Figure 4.2.

4. The Browse Netw ork screen appears, requesting specif ication of

which network you wish to go online with. Select the DeviceNet

network desired and click on OK.

Figure 4.2

Online Screen

Step # 3

Step # 4

5. The network will be scanned and the screen will build the online

configuration as shown in Figure 4.3.

Figure 4.3

Online Graphical View

Important: In our example, our module is Node 3. It has a

Unrecognized Device icon, and the error code lists it as an

unregistered device, so we will need to download an EDS file for it.

Publication 2100-UM001B-EN-P – January 2001

Page 40

4-4 Configuring a Scanner to Communicate with the Adapter

You are now in online mode. You must check to see if you need an

EDS file for the device you are adding. Refer to the “Download an

EDS file for Your SCANport product” selection in this chapter.

Downloading an EDS File for

Your SCANport Product

Each DeviceNet product has a unique EDS file based on electrical

ratings, I/O, and DeviceNet-to-SCANPort communication interface

(if used). For IntelliCENTER software or RSNetWorx to function

properly, a matching EDS file must be registered on the PC or laptop

connected to DeviceNet network.

• An Electronic Data Sheet (EDS) is a simple file format that

includes the device’s configurable parameters.

• There is a unique EDS file for each size of E3, each type of DSA,

and every combination of GK61 and connected ScanPort Product

(Drive, SMC, SMP-3).

• EDS files can be used by network tools (such as RSNetworx for

DeviceNet) to read or set device parameters.

• Each vendor is required to supply the configuration information.

The vendor must also supply an EDS file to successfully pass

conformance testing.

1. To get information about an unregistered Device in RSNetworx

for DeviceNet, double-click the icon.

Figure 4.4

Unrecognized Device in RSNetWorx

Publication 2100-UM001B-EN-P – January 2001

Step #1

Page 41

Configuring a Scanner to Communicate with the Adapter 4-5

2. An Unrecognized Device screen appears. The device identity can

be obtained from this screen. Included in the example shown in

Figure 4.4 are Vendor Code (1), Device Code (122), Product

Code (20), and Major Revision Code (1).

RSNetWorx Information Screen for Unrecognized Device

Step #2

3. EDS files are available for download at the Allen-Bradley web

site http://www.ab.com/networks/eds. There is a unique EDS

(Electronic Data Sheet) file for each size of E3, each type of

DSA, and every combination of 2100-GK61 and connected

SCANPort Product (Drive, SMC, or SMP-3).

Publication 2100-UM001B-EN-P – January 2001

Page 42

4-6 Configuring a Scanner to Communicate with the Adapter

4. In the example below, a search is being performed for an EDS file

for a 1336 drive with 2100-GK61. The procedure involves (1)

selecting Smart MCC for the device type 2100-GK61, (2)

entering at least a portion of the catalog numbers, and (3) clicking

on Search.

Figure 4.5

EDS Search for 1336 Drive with 2100-GK61

Step #4

5. The next example displays an EDS search for an SMP-3 SolidState Overload Relay with 2100-GK61. The procedure involves

(1) selecting Smart MCC for the device type 2100-GK61, (2)

entering SMP-3 for the product name, and (3) clicking on

Search.

Figure 4.6

EDS Search for SMP-3 with 2100-GK61

Step #5

Publication 2100-UM001B-EN-P – January 2001

Page 43

Configuring a Scanner to Communicate with the Adapter 4-7

6. The search results display nine different EDS files available for a

combination of an SMP-3 with a 2100-GK61. The correct one

can be selected based on SMP-3 current range.

Figure 4.7

EDS Search Results for SMP-3 with 2100-GK61

7. By clicking on Rockwell Automation/Allen-Bradley next to the

chosen product description in Figure 4.8, an EDS File Details

screen appears (Figure 4.9). The example for a “1336 Drive”

provides file detail and a file download button. After clicking on

the Download File button, do wnload the EDS f ile to a temporary

directory on your PC’s hard drive.

Figure 4.8

EDS File Details and Download Button

Publication 2100-UM001B-EN-P – January 2001

Page 44

4-8 Configuring a Scanner to Communicate with the Adapter

8. To register the EDS file, start EDS Wizard from the toolbar in

RSNetWorx for DeviceNet.

Figure 4.9.

EDS Wizard in RSNetWorx for DeviceNet

Step #8

9. Select Register an EDS file(s).

Figure 4.10

Registering an EDS File

Step #9

Publication 2100-UM001B-EN-P – January 2001

Page 45

Configuring a Scanner to Communicate with the Adapter 4-9

10. A single EDS file or a directory of EDS f iles may be registered as

illustrated here. After selecting file or directory, click Next to

continue.

Figure 4.11

Registering an EDS File

Step #10

11. EDS files are evaluated for errors. Click Next to continue.

Figure 4.12

EDS File Validity Test

Step #11

Publication 2100-UM001B-EN-P – January 2001

Page 46

4-10 Configuring a Scanner to Communicate with the Adapter

12. The Change Icon screen now appears. Here you will be able to

select an icon that best represents the connected devices for the

graph presentation of the network.

13. Select the device description yo u wish to change. In this e xample,

we click on the test “SMP-3 via 2100-GK61.” Click the Change

icon button.

Figure 4.13

Change Icon Screen

Step #13

Publication 2100-UM001B-EN-P – January 2001

Page 47

Configuring a Scanner to Communicate with the Adapter 4-11

14. Pictures of various icons appear. Select the icon by clicking on

the one which best represents your device.

Figure 4.14

Icon Options

15. Click Next to complete EDS file registration.

Figure 4.15

Final Task Summary Screen

Step #15

Publication 2100-UM001B-EN-P – January 2001

Page 48

4-12 Configuring a Scanner to Communicate with the Adapter

16. Click Finish.

Figure 4.16

EDS Installation Complete Screen

Step #16

17. The program updates the EDS directory registry for the computer

and redraws the graphical representation of the device with the

new icon as shown.

Figure 4.17

Updated Online Screen

Step #17

Publication 2100-UM001B-EN-P – January 2001

Page 49

Configuring a Scanner to Communicate with the Adapter 4-13

18. Registered EDS files are stored on a PC’s hard drive under

c:\Program Files\Rockwell Software\RS Common\Eds. A typical

location is shown here.

Figure 4.18

PC Hard Drive Directory Example

tep 18

Additional EDS detail can be viewed by opening the file with a text

editor such as WordPad. EDS identifiers are in decimal within the

body of the EDS document. RSNetWorx for DeviceNet also uses

decimal IDs (1 122 1026 4). (Refer to the example in Figure 4.20.)

The equivalent EDS file name is in hexadecimal

(0001007A04020400.eds).

Figure 4.19

EDS File Detail

Publication 2100-UM001B-EN-P – January 2001

Page 50

4-14 Configuring a Scanner to Communicate with the Adapter

A scientific calculator, such as the one in Windows, can be used to

convert decimal to hexadecimal and v.s. In the example, 122 is

entered in the calculator with Dec button selected. When the Hex

button is chosen, the display changes to 7A.

1 122 1026 4 ID code in decimal = 0001 007A 0402 0400 in

hexadecimal.

Figure 4.20

Windows Scientific Calculator Used for Conversion

Figure 4.21

Device Configuration Screen

Step #19

Important: This screen allows you to edit any of the parameters in

the SMP or adapter itself. Refer to Chapter 3, Configuring the

DeviceNet to SCANport Communication Module with Digital Inputs,

for information on editing parameters.

Publication 2100-UM001B-EN-P – January 2001

19. Click on the Cancel button. The online screen appears.

Once all your devices have registered EDS files for RSNetWorx to

Page 51

Configuring a Scanner to Communicate with the Adapter 4-15

use, do one of the following.

Configuring a Scanner

To configure the scanner, you verify its properties, add d e vi ces on the

network to its scan list, and determine how the scanner will

communicate (e.g., polling) with each device. Follow these

directions:

If Using: Refer To:

PLC Scanner (1771-SDN) Configuring a PLC Scanner (1771-SDN) to

Communicate with the Adapter on page 4-15

SLC Scanner (1747-SDN) Configuring an SLC Scanner (1747-SDN) to

Communicate with the Adapter on page 4-23

ControlLogix Scanner (1756DNB)

RSNetworx for DeviceNet to

edit parameters.

Configuring a PLC Scanner

(1771-SDN) to Communicate

with the Adapter

Configuring a ControlLogix Scanner (1756-DNB) to

Communicate with the Adapter on page 4-30

Chapter 3, Configuring the DeviceNet to SCANport

Communication Module with Digital Inputs

The following instructions describe how to configure a PLC scanner

on a DeviceNet network.

For the PLC to recognize your device, you must do the following:

• Configure the PLC scanner.

• Map your adapter to the PLC scanner (1771-SDN).

1. In the Online screen, double-click on the scanner icon. The

1771-SDN Scanner Module properties and configuration screen

appears.

Publication 2100-UM001B-EN-P – January 2001

Page 52

4-16 Configuring a Scanner to Communicate with the Adapter

Figure 4.22

1771-SDN Configuration Dialog Box

Publication 2100-UM001B-EN-P – January 2001

Page 53

Configuring a Scanner to Communicate with the Adapter 4-17

The dialog box contains 6 data tabs which are used to configure

various portions of the scanner. The General tab allows the user to

edit the name and descriptions of the scanner . The Module tab allo ws

the user to configure the scanner setup properties. The Scanlist tab

allows the user to choose which components the scanner will scan for

data. The Input and Output tab is where the user sets up where the

data from the scanned devices is kept to be used by the PLC

processor. Finally, the Summary tab allows the user to view a concise

summary of how the scanner has been configured.

2. On the General page, place the cursor in the name field and type

the name you want to assign the scanner. If you want to add a

description to the scanner, place the cursor in the description f ield

and enter a description. Click on the Apply button to save the

information.

3. Click on the Module tab. A dialog box will appear requesting to

upload or download information from the scanner. Click on

Upload. All the scanlist information currently stored in the

scanner will be uploaded. Once the upload is complete, the

Module screen will appear.

Figure 4.23

1771 SDN Module Screen

Step #4

Verify the default values listed on this page. Edit them as necessary.

Refer to RSNetworx for DeviceNet online help for more information.

4. Click Apply to save.

Publication 2100-UM001B-EN-P – January 2001

Page 54

4-18 Configuring a Scanner to Communicate with the Adapter

5. Click on the Scanlist tab so that the Scanlist page appears.

Figure 4.24

Scanlist Screen

6. Select the available devices you wish to add to the scan list.

Verify that the Automap on Add box is checked. This will map

the devices into the scanner’ s memory automatically when added.

Refer to the RSNetWorx for DeviceNet help menu for additional

information on automapping. Once a device is selected, click on

the Add (>) or Add All (>>) button.

Step #6

Figure 4.25

Scanlist Configuration Screen

Step #6

Step #7

Publication 2100-UM001B-EN-P – January 2001

Page 55

Configuring a Scanner to Communicate with the Adapter 4-19

7. Modify each device’s I/O parameters if needed. Select the device

and click on the Edit I/O Parameters button. The I/O Parameters

dialog screen appears.

Figure 4.26

I/O Configuration Edit Screen

Publication 2100-UM001B-EN-P – January 2001

Page 56

4-20 Configuring a Scanner to Communicate with the Adapter

8. Make the changes as necessary. You must configure your PLC

based on how your adapter’s parameters are configured and how

you want your module to send and receiv e data from the netw ork.

Refer to the following table:

If Using: Refer To:

Polled Polled Allocation on page B-5.

COS (Change of State) COS (Change of State) Allocation on page B-7.

Cyclic Cyclic Allocation on page B-8.

Polled and COS Polled and COS Allocation on page B-10.

Polled and Cyclic Polled and Cyclic Allocation on page B-11.

9. Click OK to return to the Scanlist screen.

10. Click on the Apply button. A dialog box appears asking if you

wish to download the changes to the device. Click on Yes.

Important: If the processor is not in Program mode, a dialog box

will appear stating which mode the processor is in. Clicking on the

OK button returns the Scanlist screen without

information to the processor. You must now place the processor in

program mode and repeat the apply function.

downloading any

11. Click on the Input tab to view the input table map. From this

screen you can customize the arrangement of the scanner’s data

table. Refer to the RSNetWorx online help for additional

information.

Figure 4.27

Input Data Table Map Screen

Publication 2100-UM001B-EN-P – January 2001

Page 57

Configuring a Scanner to Communicate with the Adapter 4-21

12. Click on the Output tab to view the output table map. From this

screen you can customize the arrangement of the scanner’s data

table. Refer to the RSNetWorx online help for additional

information.

Figure 4.28

Output Data Table Map Screen

Publication 2100-UM001B-EN-P – January 2001

Page 58

4-22 Configuring a Scanner to Communicate with the Adapter

13. Click on the Summary tab. This screen provides the user with a

concise summary of how the scanner has been configured. Note:

all of the information that appears on this page is read-only . If you

want to change any of the parameters, you have to edit them on

the appropriate property page.

Figure 4.29

Summary Screen

14. Click on the OK button. You are returned to the online screen.

15. To save the information just entered to your computer, select

Save As under the File menu.

16. Select a path to store the information.

17. Enter a file name and click on Save.

Figure 4.30

“Save As” Dialog Screen

Step #17

Publication 2100-UM001B-EN-P – January 2001

Page 59

Configuring a Scanner to Communicate with the Adapter 4-23

Your device is now configured on the DeviceNet network. The

network LED on the module is solid green. If it is not, refer to

Chapter 7, Troubleshooting, for more information.

Refer to Chapter 5, Ladder Logic Programming—Including Reading

Inputs, for information on creating a PLC Ladder Logic Program.

Configuring an SLC Scanner

(1747-SDN) to Communicate

with the Adapter

The following instructions describe how to conf igure an SLC scanner

on a DeviceNet network.

For the SLC to recognize your device, you must do the following:

• Configure the SLC Scanner.

• Map your adapter to the SLC (1747-SDN).

Configuring an SLC Scanner

To configure the scanner, you verify its properties, add d e vi ces on the

network to its scan list, and determine how the scanner will

communicate (e.g., polling) with each device. Follow these

directions:

1. In the Online screen, double-click on the scanner icon. The

1747-SDN Scanner Module properties and configuration screen

appears.

Figure 4.31

1747-SDN Configuration Dialog Box

The dialog box contains six data tabs which are used to configure

various portions of the scanner. The General tab allows the user to

edit the name and descriptions of the scanner . The Module tab allo ws

the user to configure the scanner setup properties. The Scanlist tab

Publication 2100-UM001B-EN-P – January 2001

Page 60

4-24 Configuring a Scanner to Communicate with the Adapter

allows the user to choose which components the scanner will scan for

data. The Input and Output tabs are for setting up where the data

from the scanned devices is kept for use by the SLC processor.

Finally , the Summary tab allows the user to view a concise summary

of how the scanner has been configured.

2. On the General page, place the cursor in the name field and type

the name you want to assign the scanner. If you want to add a

description to the scanner, place the cursor in the d escription field

and enter a description. Click on the Apply button to save the

information.

3. Click on the Module tab. A dialog box will appear requesting to

upload or download information from the scanner. Click on

Upload. The scanlist information currently stored in the scanner

will be uploaded. Once the upload is complete, the Module

screen will appear.

Figure 4.32

1747-SDN Module Configuration Screen

Step #4

Verify the default values listed on this page. Edit them as necessary.

Refer to RSNetWorx for DeviceNet online help for more information.

4. Click Apply to save.

5. Click on the Scanlist tab so that the Scanlist page appears.

Publication 2100-UM001B-EN-P – January 2001

Page 61

Configuring a Scanner to Communicate with the Adapter 4-25

Figure 4.33

1747-SDN Scanlist Configuration Screen

Step #6

6. Select the available de vices you wish to add to the Scanlist. Verify

that the Automap on Add box is checked. This will map the

devices into the scanner’s memory automatically when added.

Refer to the RSNetWorx for DeviceNet help menu for additional

information on automapping. Once a device is selected, click on

the Add (>) or Add All (>>) button.

Figure 4.34

Scanlist Configuration Screen

Step #7

Publication 2100-UM001B-EN-P – January 2001

Page 62

4-26 Configuring a Scanner to Communicate with the Adapter

7. Modify each device’s I/O parameters if needed. Select the device

and click on the Edit I/O Parameters button. The I/O Parameters

dialog screen appears.

Figure 4.35

I/O Configuration Edit Screen

8. Make the changes as necessary. You must configure your PLC

based on how your adapter’s parameters are configured and how

you want your module to send and receiv e data from the netw ork.

Refer to the following table.

If Using: Refer To:

Polled Polled Allocation on page B-5.

COS (Change of State) COS (Change of State) Allocation on page B-7.

Cyclic Cyclic Allocation on page B-8.

Polled and COS Polled and COS Allocation on page B-10.

Polled and Cyclic Polled and Cyclic Allocation on page B-11.

9. Click OK to return to the Scanlist screen.

10. Click on the Apply button. A dialog box appears asking if you

wish to download the changes to the device. Click on Yes.

Important: If the processor is not in Program mode, a dialog box

will appear stating which mode the processor is in. Clicking on the

OK button returns you to the Scanlist screen without

downloading

any information to the processor. You must now place the process in

program mode and repeat the apply function.

Publication 2100-UM001B-EN-P – January 2001

Page 63

Configuring a Scanner to Communicate with the Adapter 4-27

11. Click on the Input tab to view the input table map. From this

screen you can customize the arrangement of the scanner’s data

table. Refer to the RSNetWorx online help for additional

information.

Figure 4.36

Input Data Table Mapping Screen

Publication 2100-UM001B-EN-P – January 2001

Page 64

4-28 Configuring a Scanner to Communicate with the Adapter

12. Clicking on the Advanced button moves to the advance memory

mapping screen. From this screen you can specify where to map

the data to.

13. Selecting the Memory Arrow under the Map To: allows you to

select Discrete or M File Memory. This example leaves the

mapping in discrete memory.

Figure 4.37

Advanced Mapping Screen

Step #13

14. Click on the Output tab to view the output table map. From this

screen you can customize the arrangement of the scanner’s data

table. Refer to the RSNetWorx online help for additional

information.

Figure 4.38

Output Data Table Mapping Screen

Publication 2100-UM001B-EN-P – January 2001

Page 65

Configuring a Scanner to Communicate with the Adapter 4-29

15. Click on the Summary tab. This sc reen provides the user with a

concise summary of how the scanner has been configured. Note:

all of the information that appears on this page is read only . If you

want to change any of the parameters, you have to edit them on

the appropriate property page.

Figure 4.39