Page 1

Installation Instructions

PowerFlex 700H, 700S, and 700AFE Drive Fan Systems

Frames 9...14 Drives

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, PowerFlex, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

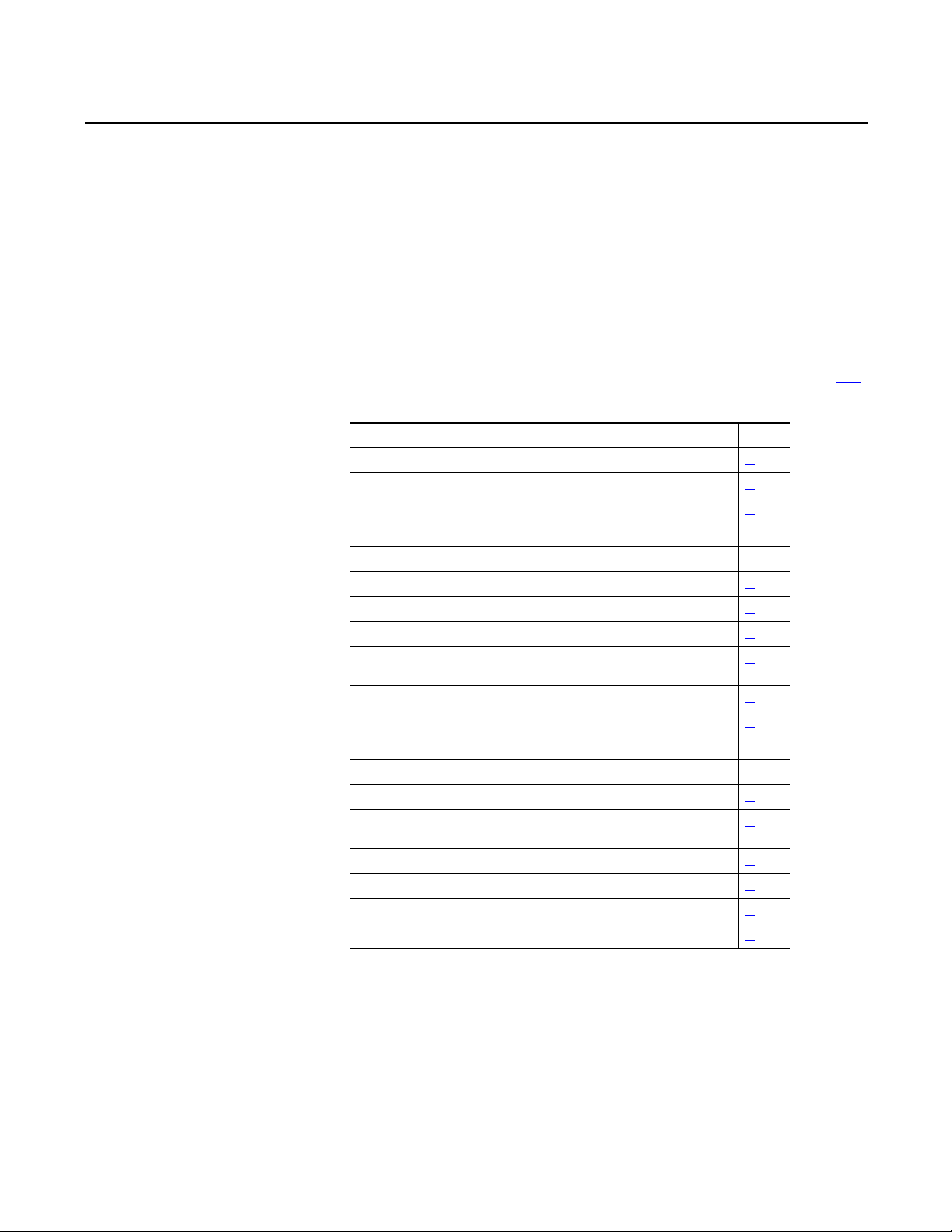

This manual contains new and updated information.

Summary of Changes

New and Updated Information

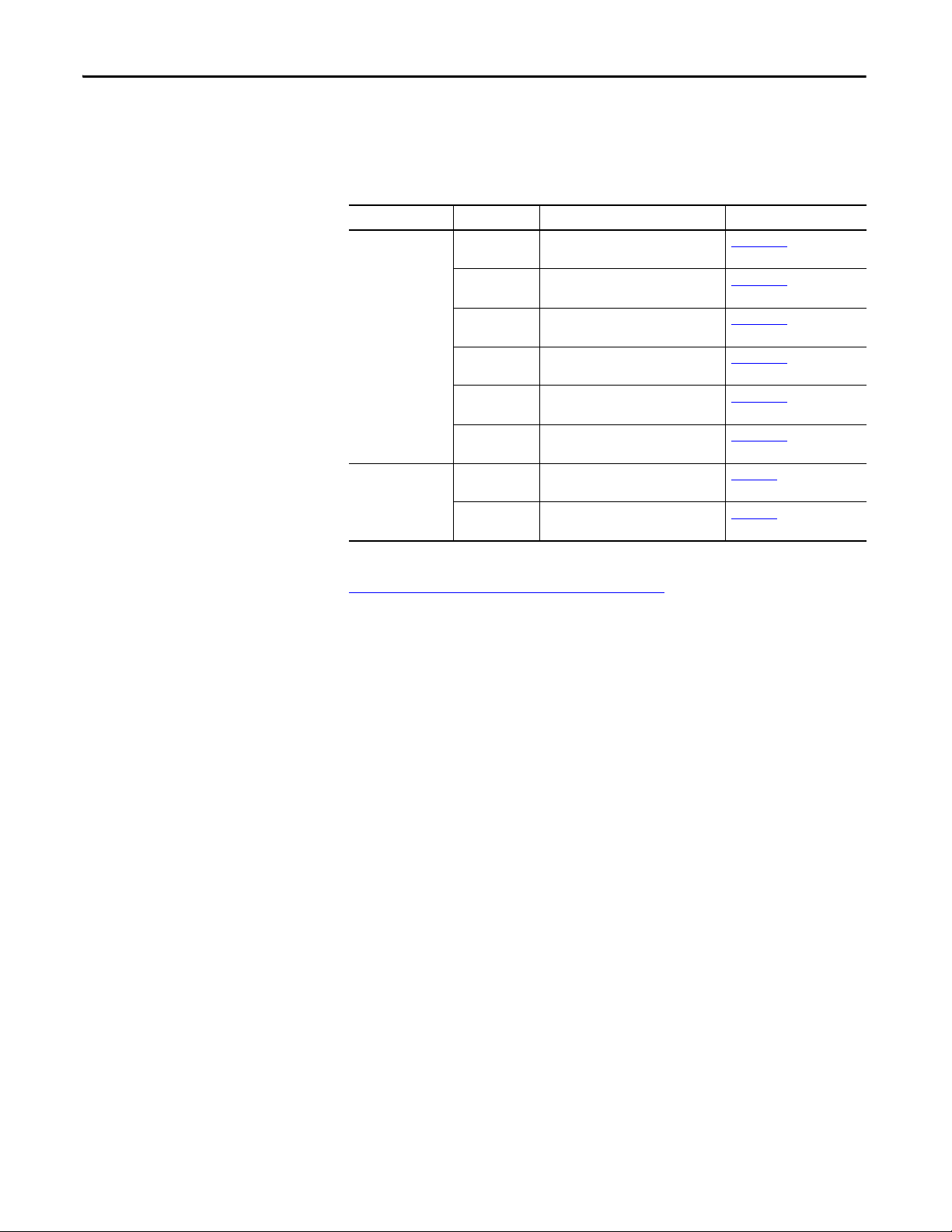

This table contains the changes made to this revision.

Top ic Pag e

Added information on parts availability to Phase 3 - Starts January 1, 2015 in the Energy-related

Products Fan Efficiency Directive section.

Add spare part information for the frame 9 drive fan bracket. 20

Updated the Frame 10 AFE Drive Configurations section to include a drawing and information on the

IP20 NEMA / UL Type 1 (MCC) Cabinet.

Updated the DC Fan Systems spare parts table to include the new LCL filter fan DC power supply kit. 188

Updated the Frame 10 AFE (LCL Filter Section) DC Fan System Wiring Schematic Diagram to reflect the

new LCL filter fan DC power supply kit.

Updated the LCL Filter Section table to include the new LCL filter fan DC power supply kit. 214

Added the LCL Filter DC Fan Power Supply Kit (SK-Y1-DCPS2-F10) Removal and Installation procedures

for the new kit.

Added the LCL Filter DC Fan Power Supply Circuit Board (SK-H1-DCFANBD1) Removal and Installation

procedures for the new kit.

Updated the LCL Filter Main DC Fan (SK-Y1-DCFAN1) Assembly Removal and Installation to include new

steps.

Updated the DC Fan Systems spare parts table to include the new LCL filter fan DC power supply kit. 239

Updated the LCL Filter Fan DC Power Supply (SK-Y1-DCPS2-F13) Wiring Diagram - Newer Version to

reflect the new LCL filter fan DC power supply kit.

Updated the LCL Filter Section table to include the new LCL filter fan DC power supply kit. 243

Added the LCL Filter Fan DC Power Supply (SK-Y1-DCPS2-F13) Removal and Installation procedures for

the new kit.

Updated the Spare Part Kit Contents to include the new LCL filter fan DC power supply kits. 277

13

186

191

219

225

230

247

247

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 3

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

Page 5

Table of Contents

Preface

PowerFlex 700H and 700S Drives Frame 9 Procedures

Who Should Use this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Verify Your Drive Frame Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

What is Not in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Energy-related Products Fan Efficiency Directive . . . . . . . . . . . . . . . . . . . 12

Phase 1 - Starts January 1, 2013 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Phase 2 - Starts January 1, 2013, and Ending December 31, 2014 . 13

Phase 3 - Starts January 1, 2015 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Fan System Replacement FAQs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Fan System Replacement Recommendations. . . . . . . . . . . . . . . . . . . . 14

How to Use this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Fastener/Tool/Torque Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Qualified Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Personal Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Product Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Class 1 LED Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 1

Frame 9 Fan System Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

AC Fan Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

DC Fan Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Tools Needed for Frame 9 Fan System Repairs. . . . . . . . . . . . . . . . . . . . . . 20

Frame 9 Schematic Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Frame 9 Fan System Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . 22

Remove Power from the Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Remove the Lower Protective Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Remove the Upper Protective Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Removing the Main Fan Inverter Capacitor Bracket. . . . . . . . . . . . . 25

Main Fan Fuses (20-PP20202) and Fuse Holder (20-PP20300)

Removal and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Main Fan Inverter Cooling Fan (20-PP01049) Removal and

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Main AC Fan Inverter Capacitor (SK-H1-FANCAP-F9) Removal

and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Main AC Fan Inverter Circuit Board Assembly (20-VB00299)

Removal and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Main DC Fan Power Supply Circuit Board (SK-H1-DCFANBD1)

Removal and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

AC to DC Fan System Retrofit Kit (SK-H1-DCFANRETROFIT-

F9) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Main AC Fan (20-PP01080) and Main DC Fan (SK-Y1-DCFAN1)

Assembly Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Main AC Fan Inverter Output Transformer (20-PP09055) Removal

and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Chassis Stirring Fan (20-PP01068) Removal and Installation . . . . 50

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 5

Page 6

Table of Contents

Cross-plate Stirring Fan (20-PP01068) Removal and Installation . 51

Internal Stirring Fan (20-PP01068) Removal and Installation . . . . 52

Chapter 2

PowerFlex 700H and 700S Drives Frame 10 Procedures

Frame 10 Fan System Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

AC Fan Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

DC Fan Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Tools Needed for Frame 10 Fan System Repairs. . . . . . . . . . . . . . . . . . . . . 56

Frame 10 Schematic Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Frame 10 Fan System Replacement Procedures. . . . . . . . . . . . . . . . . . . . . . 59

Remove Power from the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Move the Control Frame and Remove the Air Flow Plate and

Protective Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Remove the Main AC or DC Fan Power Supply Assemblies . . . . . . 63

Main AC Fan Inverter Circuit Board (20-VB00299) and AC Fan

Output Transformer Assembly [20-FR10844 (Left) or 20-FR10845

(Right)] Removal and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Main DC Fan Power Supply System (SK-H1-DCFANBD1) Removal

and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

AC to DC Fan System Retrofit Kit (SK-H1-DCFANRETROFIT-

F10) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Main AC Fan Inverter Capacitor (SK-H1-FANCAP-F1012)

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Main AC Fan (20-PP01080) and Main DC Fan (SK-Y1-DCFAN1)

Assembly Removal and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

ASIC Circuit Board Assembly Cooling Fan (20-PP01096) Removal

and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

AC or DC Fan System Fuses (20-PP20202) and Fuse Holder (20-

PP20300) Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Chapter 3

PowerFlex 700H and 700S Drives Frame 11 Procedures

6 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

Frame 11 Fan System Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

AC Fan Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

DC Fan Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Tools Needed for Frame 11 Fan System Repairs. . . . . . . . . . . . . . . . . . . . . 88

Frame 11 Schematic Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Frame 11 Fan System Replacement Procedures. . . . . . . . . . . . . . . . . . . . . . 91

Remove Power from the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Move the Control Frame and Remove the Air Flow Plate and

Protective Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Removing the Main AC or DC Fan Power Supply Assemblies . . . . 95

Main AC Fan Inverter Circuit Board (20-VB00299) and AC Output

Transformer Assembly (20-FR10845) Removal and Installation. . 99

Main DC Fan Power Supply Circuit Board (SK-H1-DCFANBD1)

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Page 7

PowerFlex 700H and 700S Drives Frame 12 Procedures

Table of Contents

AC to DC Fan System Retrofit Kit (SK-H1-DCFANRETROFIT-

F11). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Main AC Fan Inverter Capacitor (SK-H1-FANCAP-F11) Removal

and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Main AC Fan (20-PP01080) and Main DC Fan (SK-Y1-DCFAN1)

Assembly Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

ASIC Circuit Board Assembly Cooling Fan (20-PP01096) Removal

and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

AC or DC Fan System Fuses (20-PP20202) and Fuse Holder (20-

PP20300) Removal and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Chapter 4

Frame 12 Fan System Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

AC Fan System Spare Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

DC Fan System Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Frame 12 Schematic Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Chapter 5

PowerFlex 700H and 700S Drives Frame 13 Procedures

Frame 13 Drive Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Frame 13 Fan System Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

AC Fan Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

DC Fan Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Tools Needed for Frame 13 Fan System Repairs . . . . . . . . . . . . . . . . . . . 125

Frame 13 AFE Schematic Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Frame 13 Fan System Replacement Procedures . . . . . . . . . . . . . . . . . . . . 134

Remove Power from the Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Move the Control Frame, and Remove the Screens, Airflow Plates, and

Protective Covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Remove the Voltage Feedback Circuit Board Assembly (Inverter

Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

ASIC Circuit Board Assembly Cooling Fan (20-PP01096) Removal

and Installation (Inverter Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

AC or DC Fan System Fuses (20-PP20202) and Fuse Holder (20-

PP20300) Removal and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Remove the Main Fan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Removing the Main AC or DC Fan Power Supply Assemblies

(Inverter Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Main AC Fan Inverter Circuit Board (20-VB00299) and DC Fan

Power Supply Circuit Board (SK-H1-DCFANBD1) Removal and

Installation (Converter Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Main AC Fan Inverter Circuit Board (20-VB00299) Removal and

Installation (Inverter Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Main DC Fan Power Supply Circuit Board (SK-H1-DCFANBD1)

Removal and Installation (Inverter Only). . . . . . . . . . . . . . . . . . . . . . 153

AC to DC Main Fan System (SK-x1-DCFANRETROFIT-F13x and

-14x) Retrofit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 7

Page 8

Table of Contents

PowerFlex 700H and 700S Drives Frame 14 Procedures

Main AC Fan Inverter Capacitor (SK-H1-FANCAP-F1314)

Removal and Installation (Converter Only). . . . . . . . . . . . . . . . . . . . 169

Main AC Fan Inverter Capacitor (SK-H1-FANCAP-F1314)

Removal and Installation (Inverter Only). . . . . . . . . . . . . . . . . . . . . . 170

Main AC Fan (20-FI13300) and Main DC Fan (SK-Y1-DCFAN1)

Assembly Removal and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Chapter 6

Frame 14 Drive Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Frame 14 Fan System Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

AC Fan Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

DC Fan Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Frame 14 System Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Chapter 7

PowerFlex 700AFE Drive - Frame 10

Procedures

PowerFlex 700AFE Drive - Frame 13

Procedures

Frame 10 AFE Drive Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Frame 10 AFE Fan System Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

AC Fan Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

DC Fan Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Tools Needed for Frame 10 AFE Fan System Repairs. . . . . . . . . . . . . . . 188

Frame 10 AFE Fan System Schematic Diagrams. . . . . . . . . . . . . . . . . . . . 189

Frame 10 AFE Fan System Replacement Procedures. . . . . . . . . . . . . . . . 192

Power Structure Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

LCL Filter Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Chapter 8

Frame 13 AFE Drive Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Frame 13 AFE Fan System Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

AC Fan Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

DC Fan Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Tools Needed for Frame 13 AFE Fan System Repairs. . . . . . . . . . . . . . . 239

Frame 13 AFE Schematic Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Frame 13 AFE Fan System Replacement Procedures. . . . . . . . . . . . . . . . 243

Power Structure Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

LCL Filter Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Appendix A

PowerFlex 700H and 700S Diagnostic

Procedures

8 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

Qualified Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Personal Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Product Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Class 1 LED Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Fan Inverter System Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

AC Fan Inverter System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

DC Fan System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

PowerFlex 700H and PowerFlex 700S Drives . . . . . . . . . . . . . . . . . . 257

Page 9

Table of Contents

PowerFlex 700AFE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Checking the Fan Inverter Fuses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Checking Fuse Integrity with no Power Applied . . . . . . . . . . . . . . . 263

Checking Fuse Integrity with Power Applied . . . . . . . . . . . . . . . . . . 263

Checking the Main Fan Supply Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Checking the AC Fan Inverter Capacitor . . . . . . . . . . . . . . . . . . . . . . . . . 265

Isolating a Faulty Fan Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Frame 9 PowerFlex 700H and 700S Drives . . . . . . . . . . . . . . . . . . . . 265

Frames 10 and 12 PowerFlex 700H and 700S Drives . . . . . . . . . . . 265

Frame 11 PowerFlex 700H and 700S Drives . . . . . . . . . . . . . . . . . . . 267

Frames 13 and 14 PowerFlex 700H and 700S Drives . . . . . . . . . . . 268

Frames 10 and 13 PowerFlex 700AFE. . . . . . . . . . . . . . . . . . . . . . . . . 268

Checking the Main AC Fan Inverter Circuit Board Diagnostic LEDs 268

AC Fan System LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

DC Fan System LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Fan System Wiring and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Testing the Main Fan Inverter Circuit Board Diagnostic LEDs . . . . . 274

AC Fan System Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

DC Fan System Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Available Fan System Kits

Appendix B

Spare Part Kit Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 9

Page 10

Table of Contents

10 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

Page 11

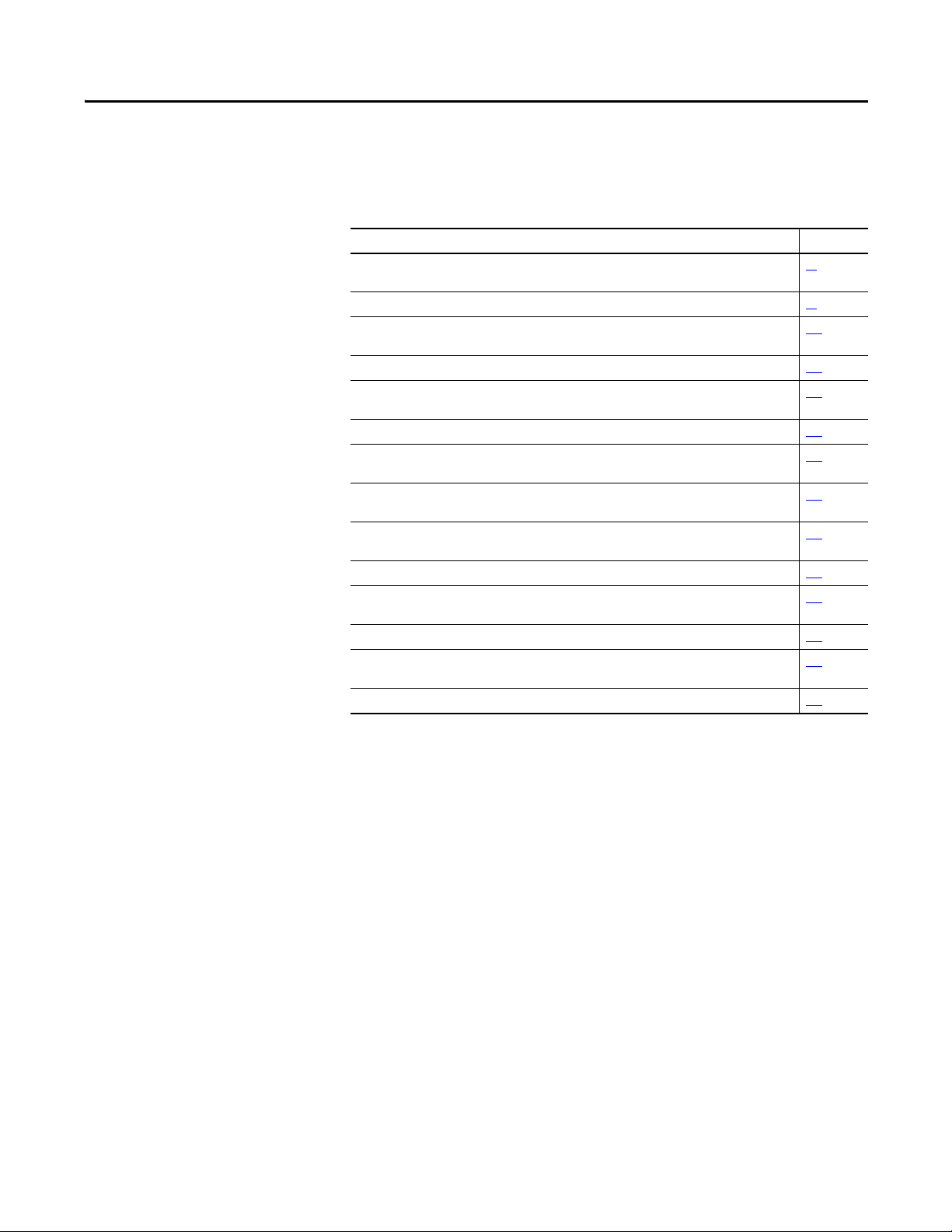

Preface

PowerFlex 700S Frame 10 drive shown

Top ic Pag e

Who Should Use this Manual 11

Verify Your Drive Frame Size 11

What is Not in this Manual 12

How to Use this Manual 15

Fastener/Tool/Torque Information 16

General Precautions 17

This manual contains fan system service information for frame 9…14 PowerFlex

700H and PowerFlex 700S AC drives, and the frame 10 and 13 PowerFlex

700AFE.

Who Should Use this Manual

Verify Your Drive Frame Size

This manual is intended for qualified service personnel responsible for

troubleshooting and repairing frame 9…14 PowerFlex 700H and 700S and frame

10 and 13 PowerFlex 700AFE drives. You must have previous experience with,

and a basic understanding of, electrical terminology, procedures, required

troubleshooting equipment, equipment protection procedures and methods, and

safety precautions to make repairs on these drives and use this manual.

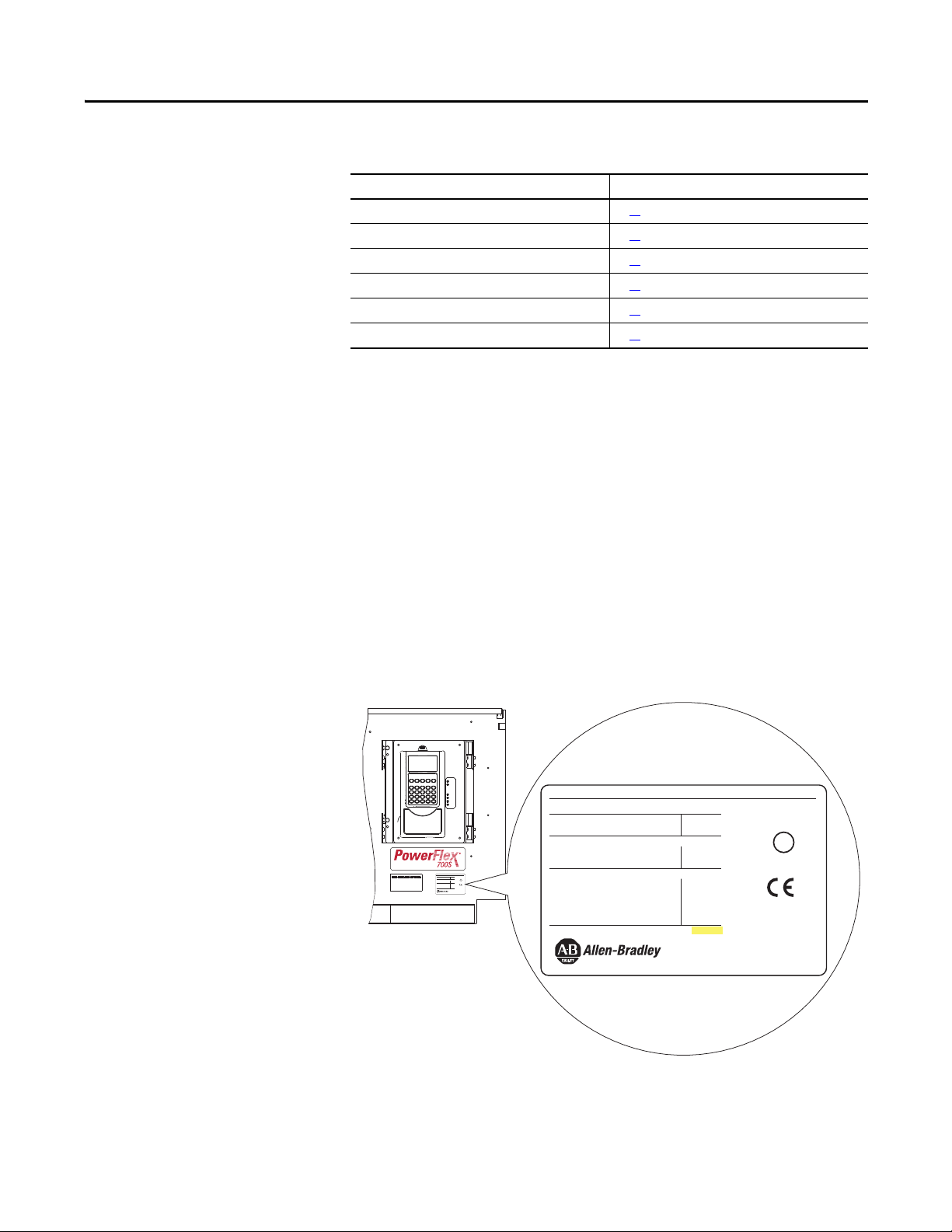

You can verify your drive frame size by checking the data nameplate. This

information is printed just above the serial number.

20DJ500 N 0 NNNBNNNN

Cat No.

UL Open Type/IP00

Frame #: 10

Normal Duty Power

Heavy Duty Power

Input: DC,

DC Voltage Range

20DJ300 N 0 NNNBNNNN

Cat No.

UL Open Type/IP00

Series: A

540V 650V

Standard I/O: NONE

Original Firmware No. 2.04

160 kW

250 kW

Normal Duty Power

132 kW

200 kW

Heavy Duty Power

U

Input: DC,

USC

L

Æ

462 - 594

583 - 713

DC Voltage Range

LISTED

Amps

350

350

IND CONT EQ

Output: 3 Phase, 0 - 320Hz

AC Voltage Range

0 - 400

0 - 460

Base Hz (default)

50 Hz

60 Hz

Continuous Amps

300/245

300/245

330/368

330/368

1 Min Overload Amps

450/490 450/490

2 Sec Overload Amps

MFD. in 1989 on Nov 9

Serial Number: 2622381652

2622381652

MADE IN THE USA (FAC 1B)

Amps

Output: 3 Phase, 0 - 320Hz

AC Voltage Range

Base Hz (default)

Continuous Amps

1 Min Overload Amps

2 Sec Overload Amps

MFD. in 1989 on Nov 9 Frame #: 10

MADE IN THE USA (FAC 1B)

540V 650V

250 kW

450 kW

200 kW

500 kW

462 - 594

583 - 713

350

350

0 - 400

0 - 460

50 Hz

60 Hz

420/500

420/500

630/550

630/550

840/630 840/630

Serial Number: 2622381652

2622381652

Series: A

Standard I/O: NONE

Original Firmware No. 2.04

U

L

Æ

LISTED

IND CONT EQ

9D42

USC

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 11

Page 12

Preface

What is Not in this Manual

This manual does not contain information about parts and functions of the drive

that are not related to fan system service within the drive. For more information

and service procedures for your particular drive, see the applicable publication in

this table.

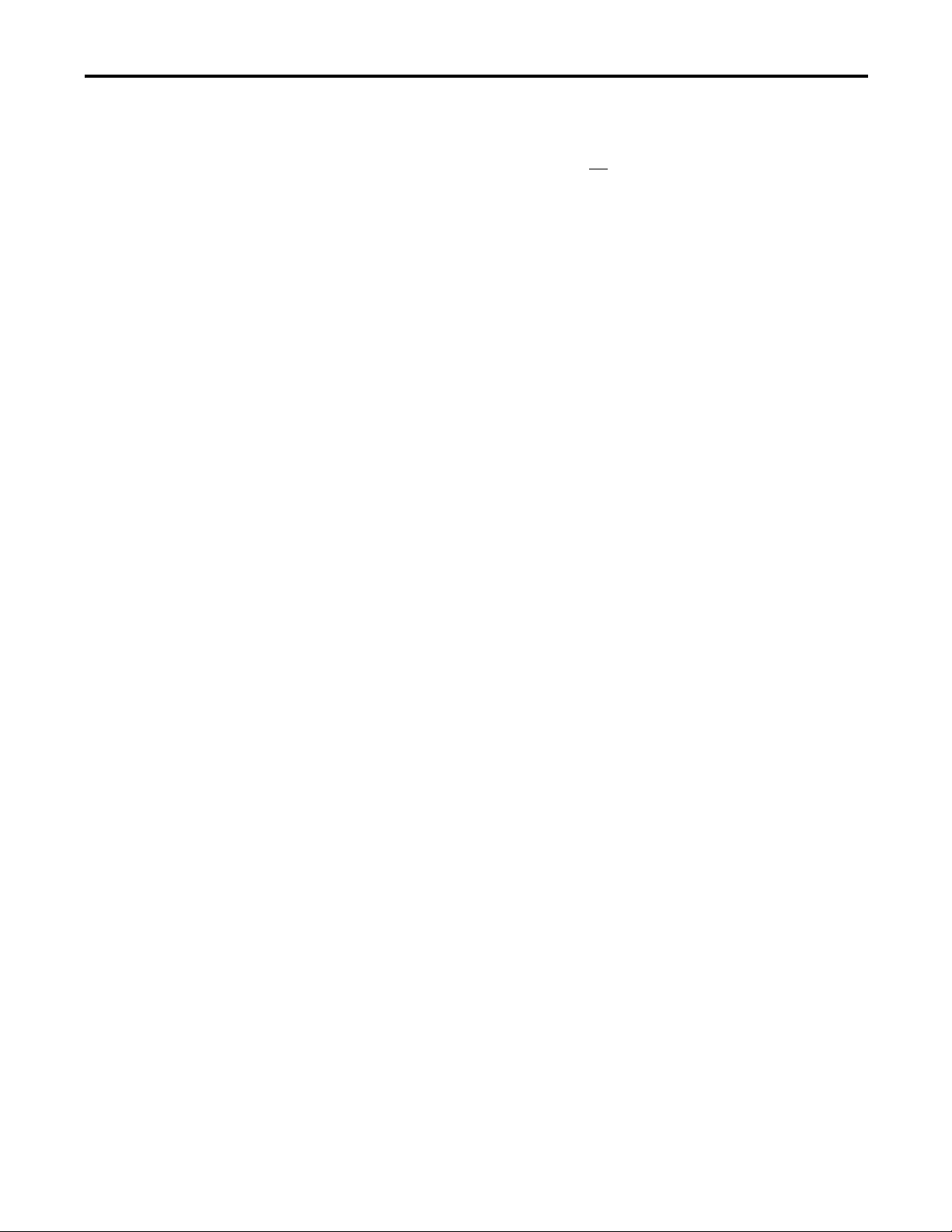

Drive Type Frame Size Publication Title Publication Number

PowerFlex 700H and

700S

PowerFlex 700AFE 10 PowerFlex 700AFE Frame 10 Hardware

9 PowerFlex 700H/S Drives, Frame 9

Hardware Service Ma nual

10 PowerFlex 700H/S Drives, Frame 10

Hardware Service Ma nual

11 PowerFlex 700H/S Drives, Frame 11

Hardware Service Ma nual

12 PowerFlex 700H/S Drives, Frame 12

Hardware Service Ma nual

13 PowerFlex 700H/S Drives, Frame 13

Hardware Service Ma nual

14 PowerFlex 700H/S Drives, Frame 14

Hardware Service Ma nual

Service Manual

13 PowerFlex 700AFE Frame 13 Hardware

Service Manual

PFLEX-TG001

PFLEX-TG002

PFLEX-TG003

PFLEX-TG004

PFLEX-TG005

PFLEX-TG006

20Y-TG001

20Y-TG002

You can view or download publications at

http://www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Energy-related Products Fan Efficiency Directive

The Energy-related Products (ErP) Directive (2012/27/EU on Energy

Efficiency, 25, October 2012) is the European Commission Directive required

for products sold and exported to the European Union (EU). This directive aims

to protect the environment by increasing energ y efficiency in the EU. This

directive, among other things, defines the minimum efficiency for fans in the

range of 0.125…500 kW.

For PowerFlex 700H and 700S drive fan systems, this directive will be

implemented in multiple phases.

Phase 1 - Starts January 1, 2013

New products delivered within the EU (with a power structure manufacture date

of January 1, 2013 and later) will have a DC fan system installed. Phase I includes

PowerFlex 700H and 700S frame 9 and larger drives and PowerFlex 700AFE

systems.

DC fan system kits have been developed to support the repair of damaged units

and to provide retrofit solutions. However, the ErP Directive does not require

drives with existing AC fan systems to be retrofitted.

12 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

Page 13

Preface

Phase 2 - Starts January 1, 2013, and Ending December 31, 2014

According to the ErP Directive, delivering the existing AC fan systems as spare

parts for PowerFlex 700H and 700S, frame 9 and larger, drives and PowerFlex

700AFE systems is allowed until the December 31, 2014 deadline within the EU.

DC fan systems are available as spare parts.

Phase 3 - Starts January 1, 2015

Use DC fan systems as spare part kits for PowerFlex 700H and 700S, frame 9 and

larger, drives, and PowerFlex 700AFE systems. DC fan system retrofit kits are

available for drives that were originally manufactured with AC fan systems.

AC fan system kits that were manufactured before January 1, 2015 can still be

used as a replacement spare part kit.

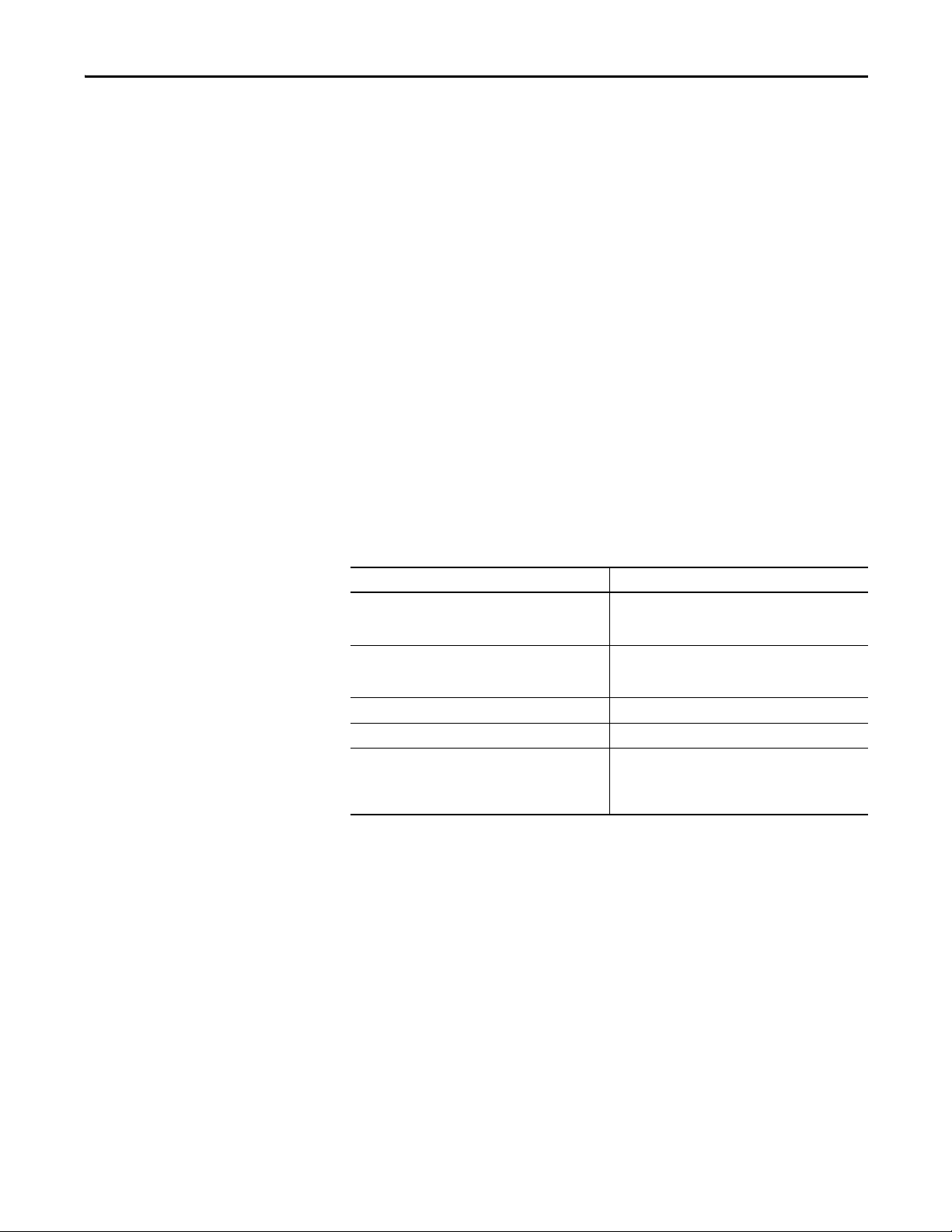

Fan System Replacement FAQs

Typical questions and solutions to fan system replacements can include:

Question Solution

Do all AC fans in a drive need to be replaced with a new DC

fan if only one has failed?

If only one AC fan inverter circuit board fails, can I replace

only the damaged board with a new one?

What does a DC fan kit include? This kit includes the DC fan assembly.

What does a DC fan circuit board kit include? This kit includes the DC fan power supply circuit board.

Are retrofit kits available? Kits are available to retrofit an AC to DC fan power

It is recommended that a power structure always

contains the same type of fan system, either all AC or

all DC.

Yes, if the other components of the AC fan unit are

functioning properly, you can replace the circuit board

only.

supply. These kits include the DC fan assembly, DC fan

power supply, fan inverter circuit board, all wire

harnesses, and required hardware.

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 13

Page 14

Preface

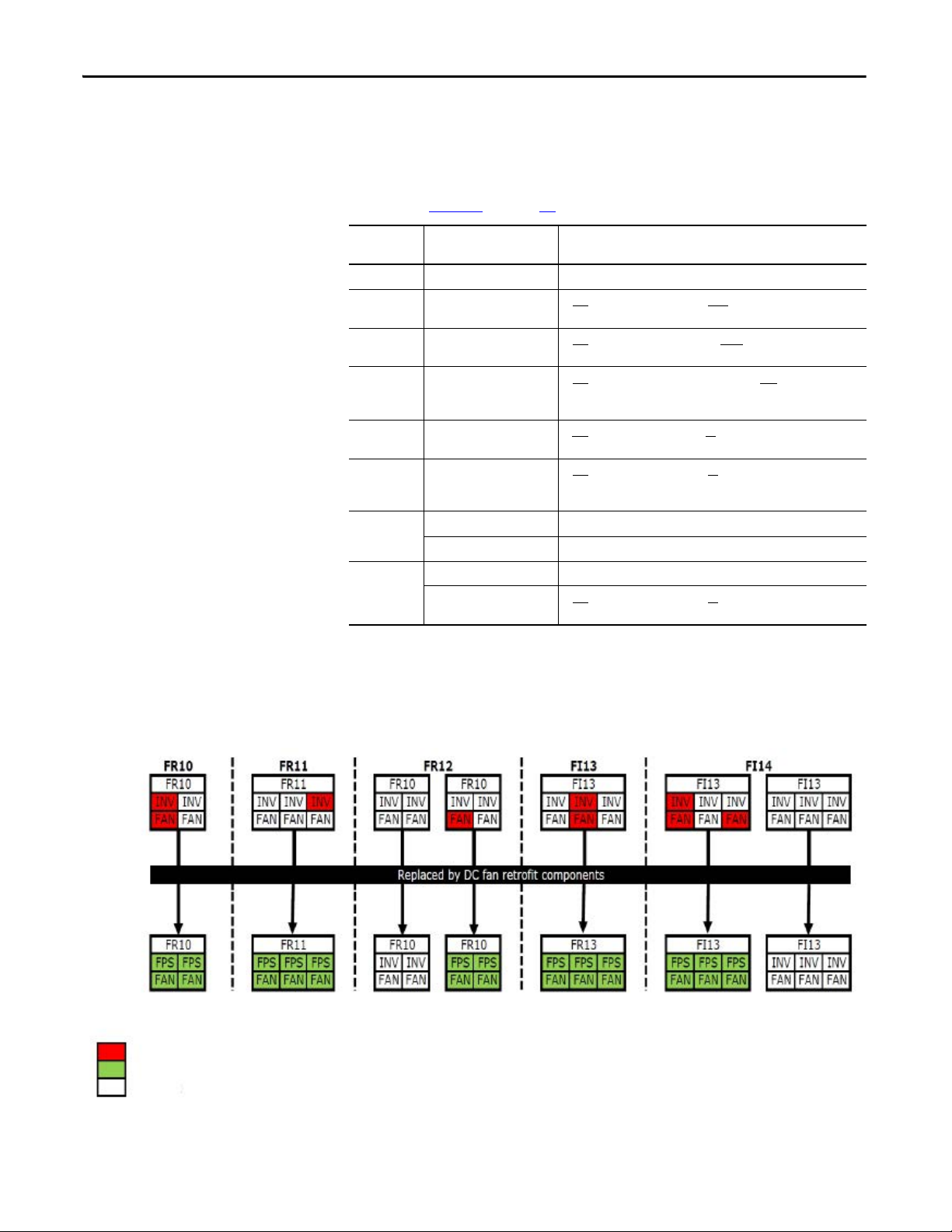

FAN = Mai n Fan

INV = Fan Inverter (AC)

FPS = Fan Power Supply (DC)

= Defective AC Fan Component

= Replacement DC Fan Kit Components

= No Change

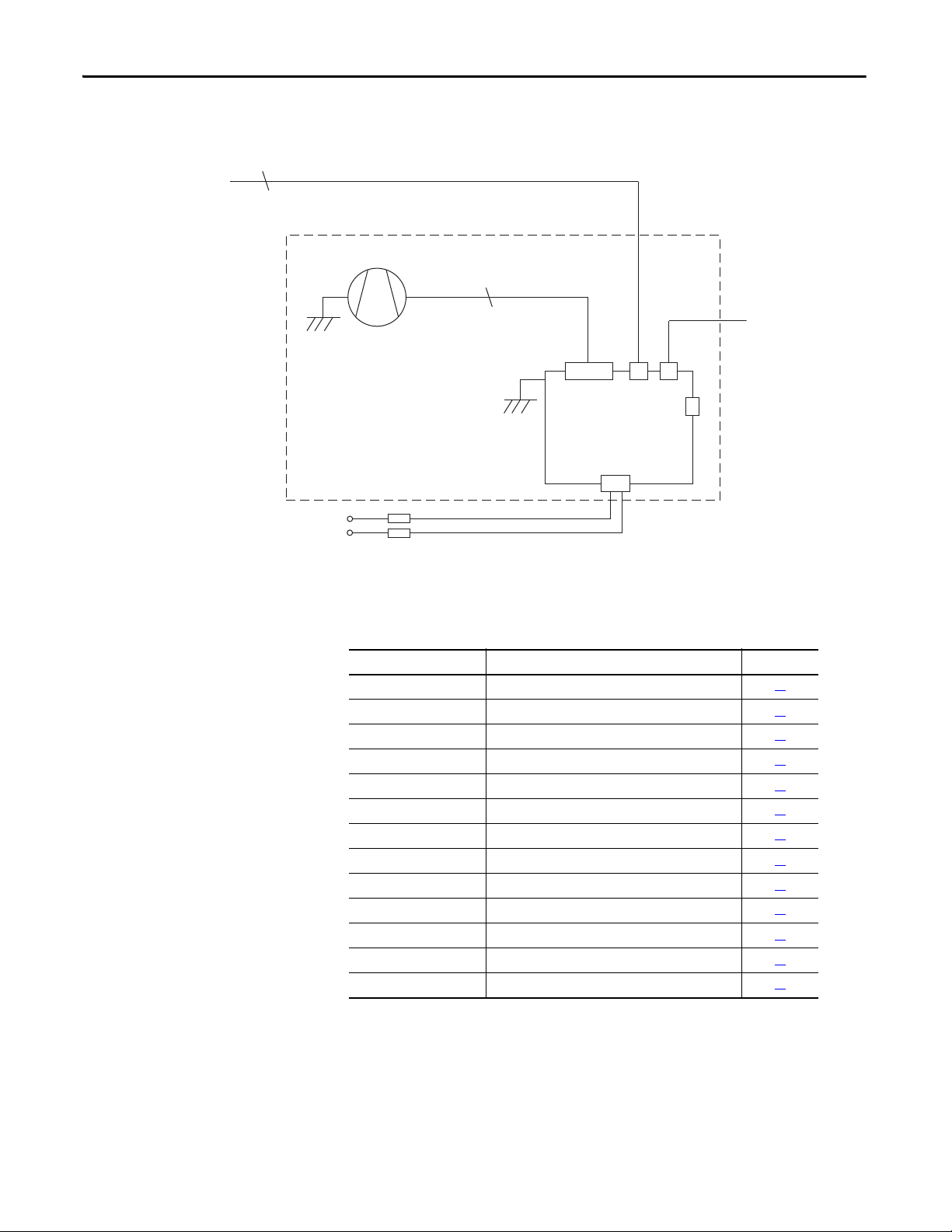

Fan System Replacement Recommendations

This table provides recommendations for replacing a failed fan system on

PowerFlex 700H and 700S frame 9 and larger drives and PowerFlex 700AFE

systems. See Figure 1

on page 14 for more information.

Frame Size Number of Fan Systems

in the Drive

9 1 Always replace the failed AC fan system with a new DC fan system.

10 2 If one AC fan system fails, replace both existing AC fan systems with

11 3 If one

12 4 If one AC fan system fails, replace the existing two AC fan systems

13 5 or 6 If one AC fan system fails, replace all existing AC fan systems with new

14 9…12 If one

10 AFE 1 (LCL) Replace the existing DC fan systems, as necessary.

2 (Drive) Always replace the failed AC fan system with a new DC fan system.

13 AFE 1 (LCL) Replace the existing DC fan systems, as necessary.

3 (Drive) If one

Recommendation for Replacement

new DC fan systems.

AC fan system fails, replace all three existing AC fan systems

with new DC fan systems.

contained in the power structure that contains the failed AC fan

system with new DC fan systems.

DC fan systems.

AC fan system fails, replace all existing AC fan systems

contained in the power structure that contains the failed AC fan

system with new DC fan systems.

AC fan system fails, replace all three existing AC fan systems

with new DC fan systems.

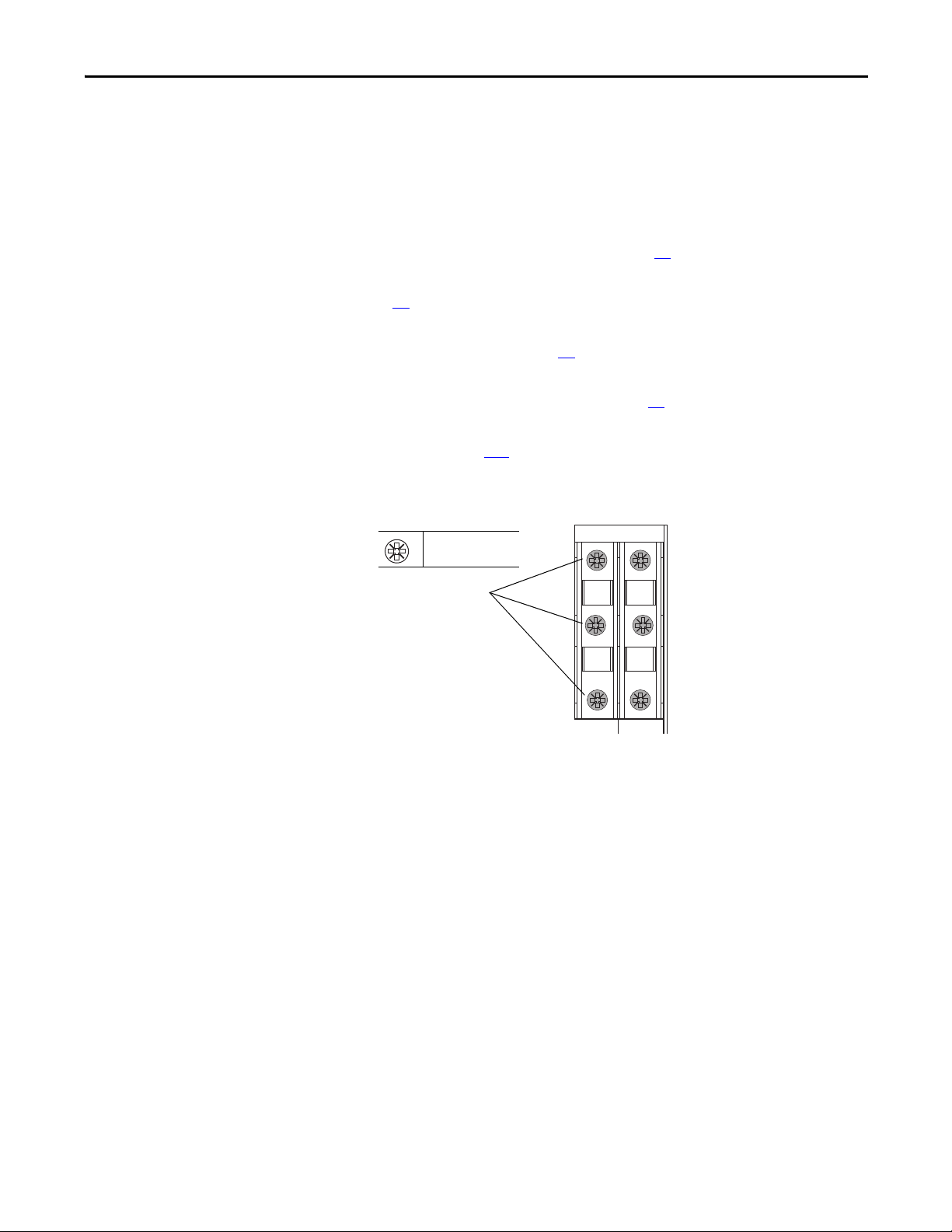

Figure 1 - DC Fan System Replacement Examples

14 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

Page 15

Preface

How to Use this Manual

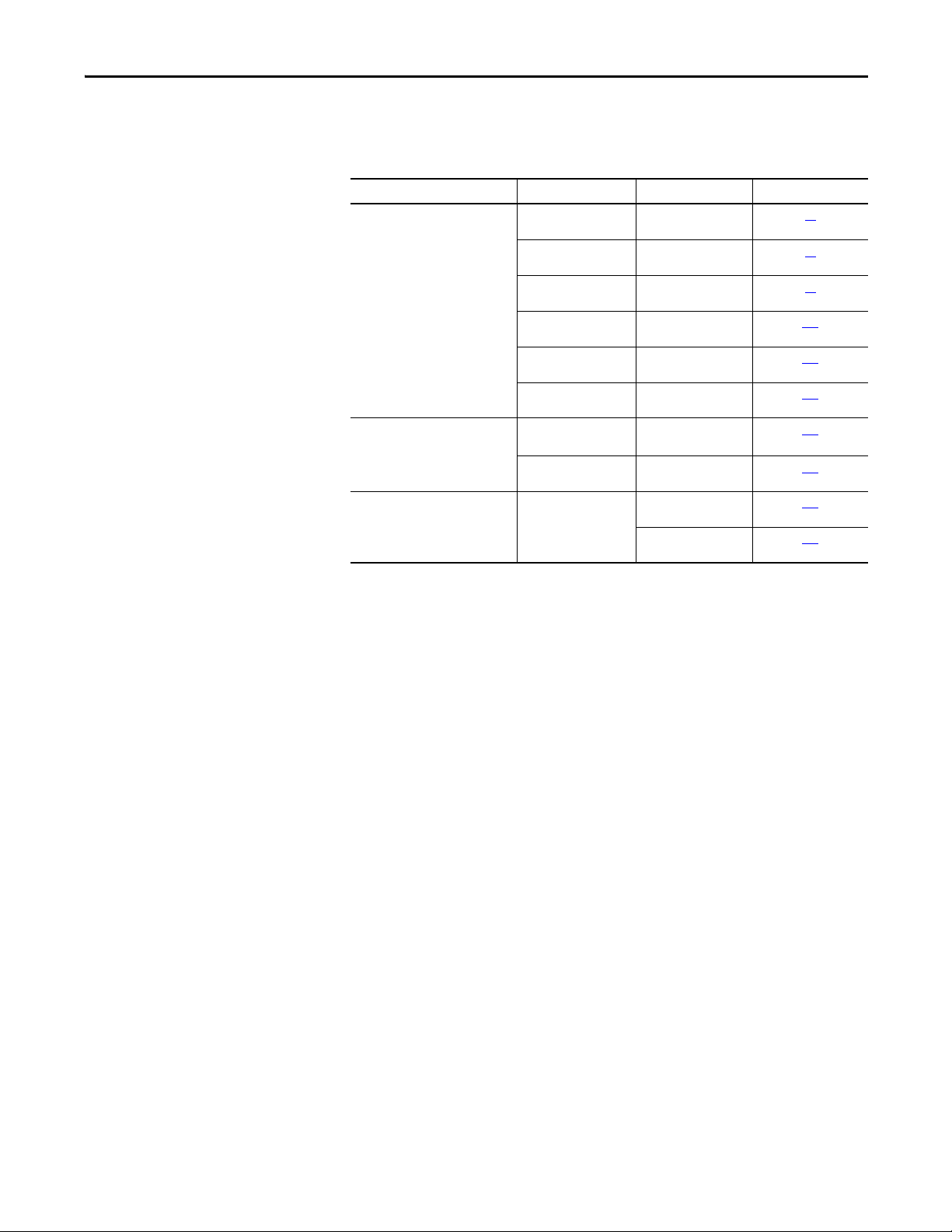

This manual contains a chapter for each drive type and frame size. Use this table

to locate a list of available spare parts and the procedures for replacing fan system

components for a specific drive and frame size.

Drive Type Frame Size Chapter / Appendix Page Number

PowerFlex 700H and 700S 9 1 19

10 2 55

11 3 87

12 4 117

13 5 121

14 6 179

PowerFlex 700AFE 10 7 185

13 8 235

PowerFlex 700H, 700S, and 700AFE 9…14 A 255

B 277

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 15

Page 16

Preface

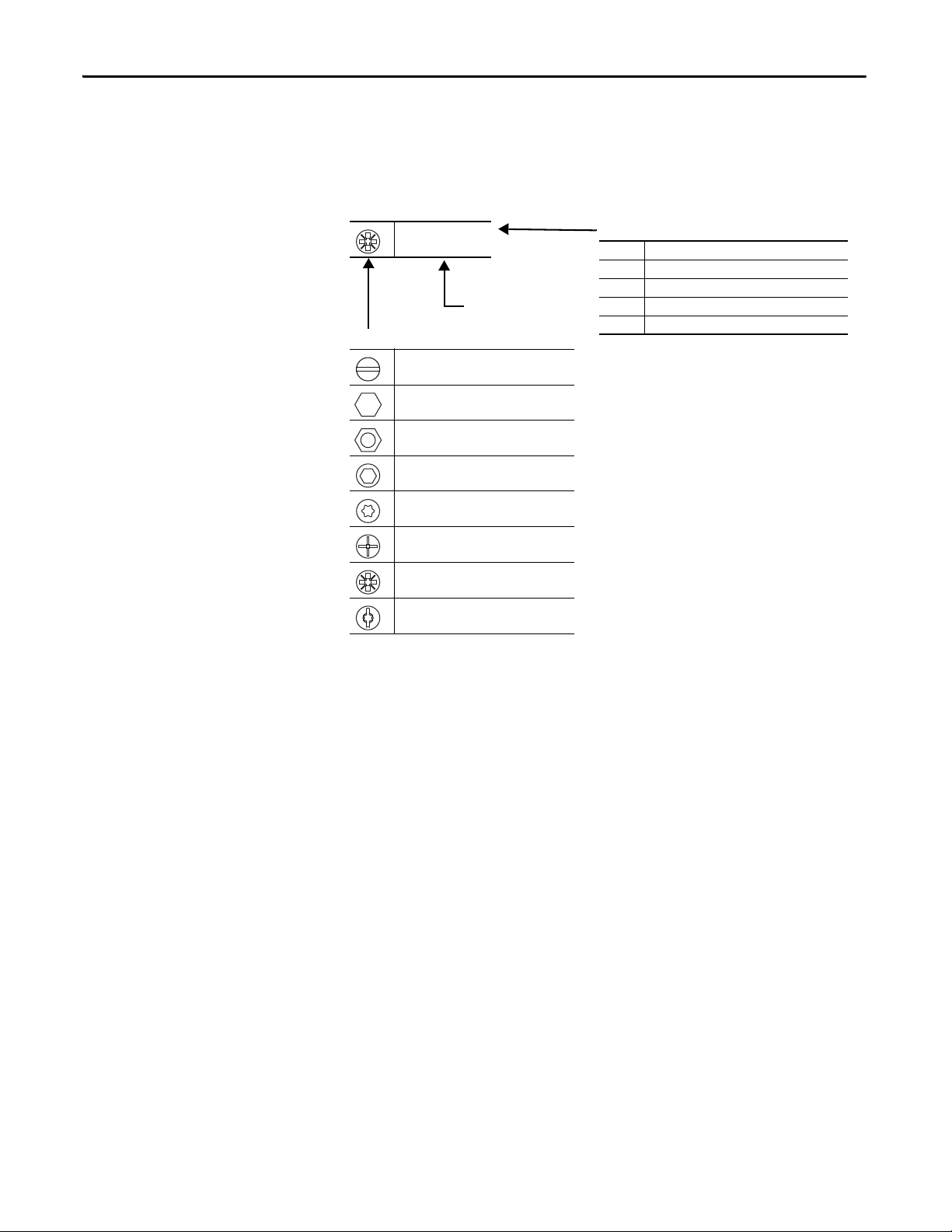

Tool Type and Size:

FFlat nose screw driver

Px Phillips screw driver/bit and size

PZx POZIDRIV screw driver/bit and size

Txx Hexalobular screw driver/bit and size

xx mm Hexagonal socket wrench

Tightening Torque

Fastener Type:

Flat head screw

Hexagonal bolt

Hexagonal nut or standoff

Hexagonal screw

Hexalobular head screw

Phillips head screw

(1)

POZIDRIV head screw

(1)

Slotted Hexalobular head screw

Fastener/Tool/Torque Information:

PZ2

3.0 N

•m (27 lb•in)

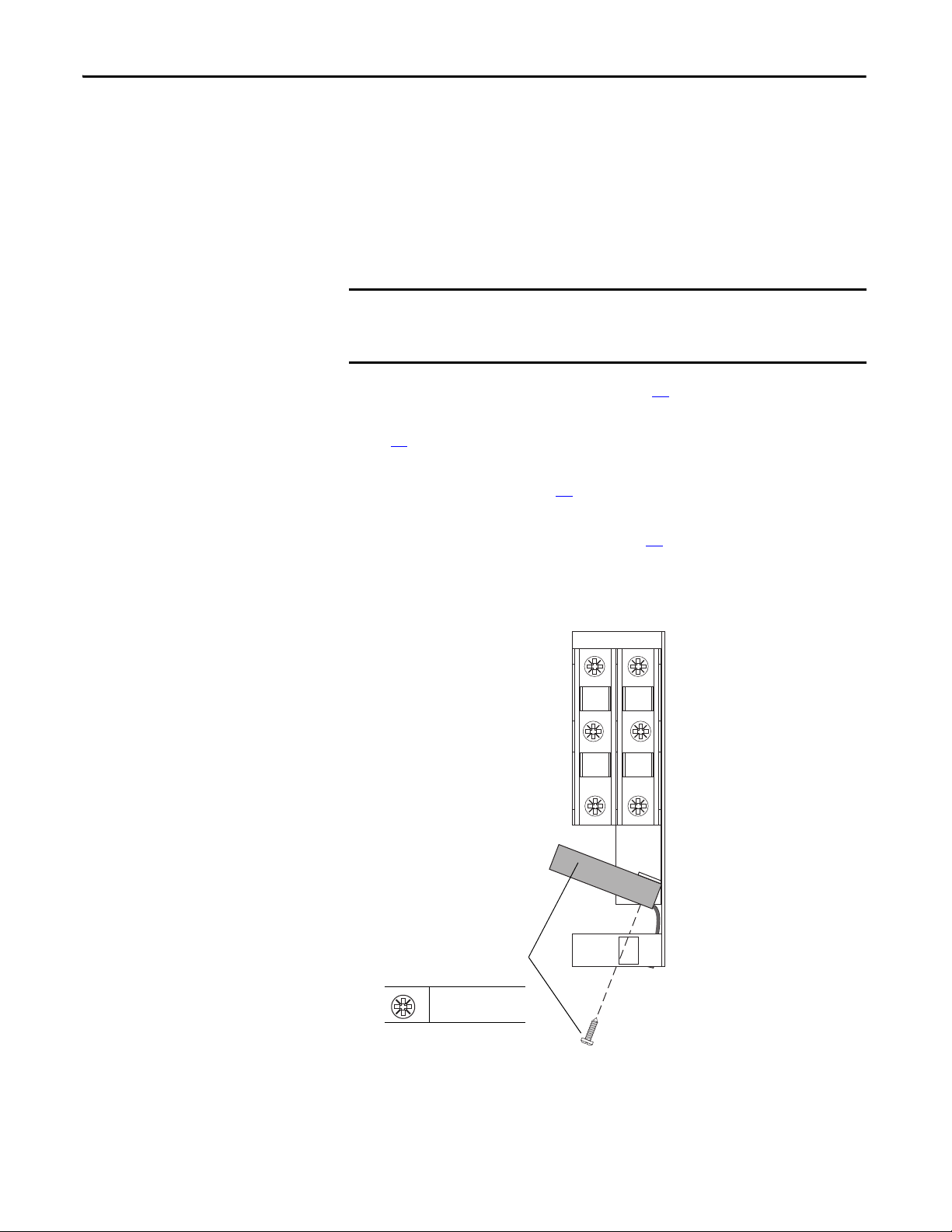

Fastener/Tool/Torque Information

The disassembly illustrations contained in this manual identify the type of

fastener, tool, and tightening torque used for disassembly/assembly of

components in the drive.

(1) Phillips® and POZIDRIV® are registered trademarks of the Phillips Screw Company.

16 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

Page 17

Preface

General Precautions

Read the following precautions before you begin testing components, performing

maintenance, or repairing the drive.

Qualified Personnel

ATT EN TI ON : Only qualified personnel familiar with adjustable frequency AC

drives and associated machinery should plan or implement the installation,

start-up and subsequent maintenance of the system. Failure to comply may

result in personal injury and/or equipment damage.

Personal Safety

ATT EN TI ON : To avoid an electric shock hazard, verify that the voltage on the

bus capacitors has discharged before servicing the drive. Check the DC bus

voltage at the Power Terminal Block by measuring between the +DC & -DC

terminals, between the +DC terminal and the chassis, and between the -DC

terminal and the chassis. The voltage must be zero for all three measurements.

ATT EN TI ON : Potentially fatal voltages may result from improper usage of an

oscilloscope and other test equipment. The oscilloscope chassis may be at a

potentially fatal voltage if not properly grounded. If an oscilloscope is used to

measure high voltage waveforms, use appropriately rated differential voltage

probes. Be sure that they are set to the highest voltage scaling in order to

achieve safe measurement resolution. Verify that the oscilloscope chassis is

correctly grounded to an earth ground.

ATT EN TI ON : The sheet metal cover and mounting screws on the ASIC board

located on the inverters of the power structure are energized at (-) DC bus

potential high voltage. Risk of electrical shock, injury, or death exists if someone

comes into contact with the assembly.

Product Safety

ATT EN TI ON : This drive contains ESD (Electrostatic Discharge) sensitive parts

and assemblies. Static control precautions are required when installing, testing,

servicing or repairing this assembly. Component damage may result if ESD

control procedures are not followed. If you are not familiar with static control

procedures, reference Guarding Against Electrostatic Damage, publication

8000-4.5.2

Class 1 LED Product

ATT EN TI ON : Hazard of permanent eye damage exists when using optical

transmission equipment. This product emits intense light and invisible

radiation. Do not look into module ports or fiber-optic cable connectors.

or any other applicable ESD protection handbook.

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 17

Page 18

Preface

Notes:

18 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

Page 19

Chapter 1

PowerFlex 700H and 700S Drives - Frame 9

Procedures

This chapter contains spare part information and procedures for testing and

replacing fan system components for frame 9 PowerFlex 700H and 700S drives.

See Appendix A PowerFlex 700H and 700S Diagnostic Procedures on page 255

for additional component test procedures.

Top ic Pag e

Frame 9 Fan System Spare Parts 20

Tools Needed for Frame 9 Fan System Repairs 20

Frame 9 Schematic Diagrams 21

Frame 9 Fan System Replacement Procedures 22

Remove Power from the Drive 23

Remove t he Lower Protect ive Cover 24

Remove the Uppe r Protective Cover 24

Removing the Main Fan Inverter Capacitor Bracket 25

Main Fan Fuses (20-PP20202) and Fuse Holder (20-PP20300) Removal and

Installation

Main Fan Inverter Cooling Fan (20-PP01049) Removal and Installation 30

Main AC Fan Inverter Capacitor (SK-H1-FANCAP-F9) Removal and Installation 31

Main AC Fan Inverter Circuit Board Assembly (20-VB00299) Removal and Installation 33

Main DC Fan Power Supply Circuit Board (SK-H1-DCFANBD1) Removal and Installation 36

AC to DC Fan System Retrofit Kit (SK-H1-DCFANRETROFIT-F9) 39

Main AC Fan (20-PP01080) and Main DC Fan (SK-Y1-DCFAN1) Assembly Removal and

Installation

Main AC Fan Inverter Output Transformer (20-PP09055) Removal and Installation 49

Chassis Stirring Fan (20-PP01068) Removal and Installation 50

Cross-plate Stirring Fan (20-PP01068) Removal and Installation 51

Internal Stirring Fan (20-PP01068) Removal and Installation 52

29

43

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 19

Page 20

Chapter 1 PowerFlex 700H and 700S Drives - Frame 9 Procedures

Frame 9 Fan System Spare Parts

AC Fan Systems

See Available Fan System Kits starting on page 277 for an illustration of the spare

part kit contents.

Cat. No. Part Description Quantity

20-PP01049 50 mm cooling fan for fan inverter 1 Sinwan

20-PP01068 80 mm x 80 mm x 32 mm internal stirring fan

20-PP01080 230 W Main AC fan assembly 1 –

20-PP09055 Output transformer for main fan inverter 1 –

20-PP20202 Fuse for fan system 2 Ferraz Shawmut

20-PP20300 Fuse holder for main fan system fuses 1 Ferraz Shamut 30322

20-VB00299 Main fan inverter circuit board

SK-H1-FANCAP-F9 Capacitor (7 μF) for main fan inverter 1 –

SK-H1-FR9BRKT AC fan bracket 1 –

(1) The same part and catalog number is used for both 400/480V AC and 600/690V AC input drives.

(2) 2 for PowerFlex 700H drives and 3 for PowerFlex 700S drives.

(3) This part may not contain wires, connectors, or mounting hardware when bought directly from the vendor.

(4) The factory default fuses are Ferraz Shawmut ATQ8, 8 A fuses. Older drives may contain Bussman 6 A fuses.

assembly

(1)

per Drive

2 or 3

Original Vendor and

Model Number

SD5012PT-24H

(2)

Japan Servo Co., LTD

PUDC24H4C-049

(4)

ATQ 8

1–

(3)

Tools Needed for Frame 9 Fan System Repairs

DC Fan Systems

See Available Fan System Kits starting on page 277 for an illustration of the spare

part kit contents.

Cat. No. Part Description Quantity

SK-Y1-DCFAN1 Main DC fan assembly 1 –

SK-H1-DCFANBD1 Main DC fan power supply circuit board

SK-H1-DCFANRETROFIT-F9 AC to DC fan system retrofit kit 1 –

(1) Circuit Board only, no sheet metal bracket.

per Drive

(1)

• #2 Phillips head screwdriver

• #2 POZIDRIV screwdriver

• Flat blade screwdriver

• 13 mm socket wrench

• 19 mm socket wrench

• T20 hexalobular screwdriver with a shaft length of at least 9 cm (3.54 in.)

• Cable ties

• Electrical tape

• Fuse puller

• Multi-meter

• Needle-nose pliers

Original Vendor and

Model Number

1–

20 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

Page 21

PowerFlex 700H and 700S Drives - Frame 9 Procedures Chapter 1

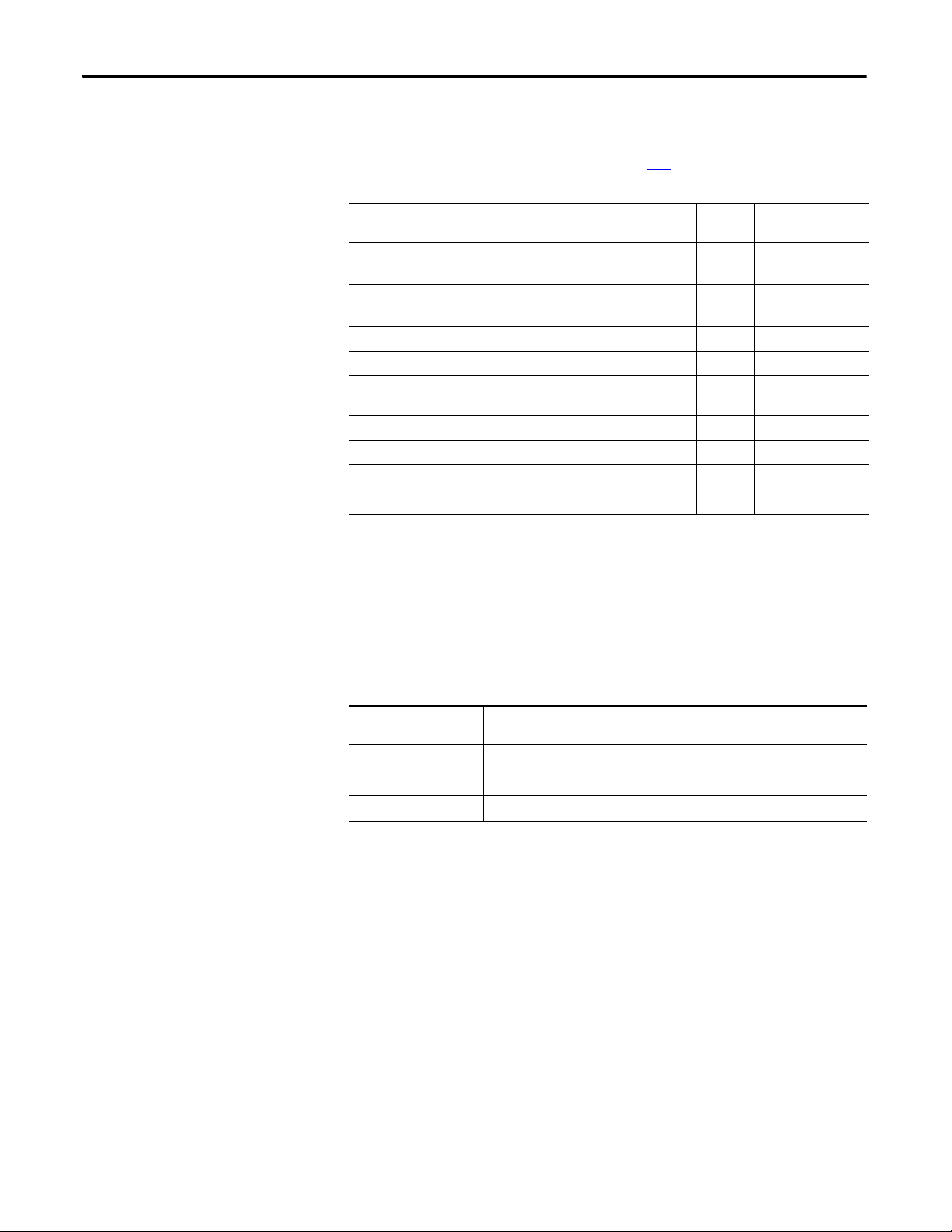

X8

F2

X2

4

Fan Frequency

Converter

+-

O

S1-1

O

S1-2

On

S1-3

O

S1-4

S1 - Setup Switch

F1

From Power

Board X10

From Power

Board X7

M1

Brown

Black

Blue

Main Fan

M

Black 6

Black 5

Black 4

Black 3

Black 2

Black 1

X4

X5

2.2 µf 10 MΩ

2.2 µf 10 MΩ

Yellow/Green

7 µf

X3

Install Jumper on

400/480V AC input drives only

(Not present on fan inverter

circuit boards, cat. no. VB00399)

Switch Setting To indicate the following:

S1 Off 50 Hz fan motor frequency

S2 Off 220 V AC motor voltage

S3 On 230 V AC motor voltage

S4 Off Frame size 9…14

Frame 9 Schematic Diagrams

Figure 2 - Frame 9 AC Fan System Wiring Schematic Diagram

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 21

Page 22

Chapter 1 PowerFlex 700H and 700S Drives - Frame 9 Procedures

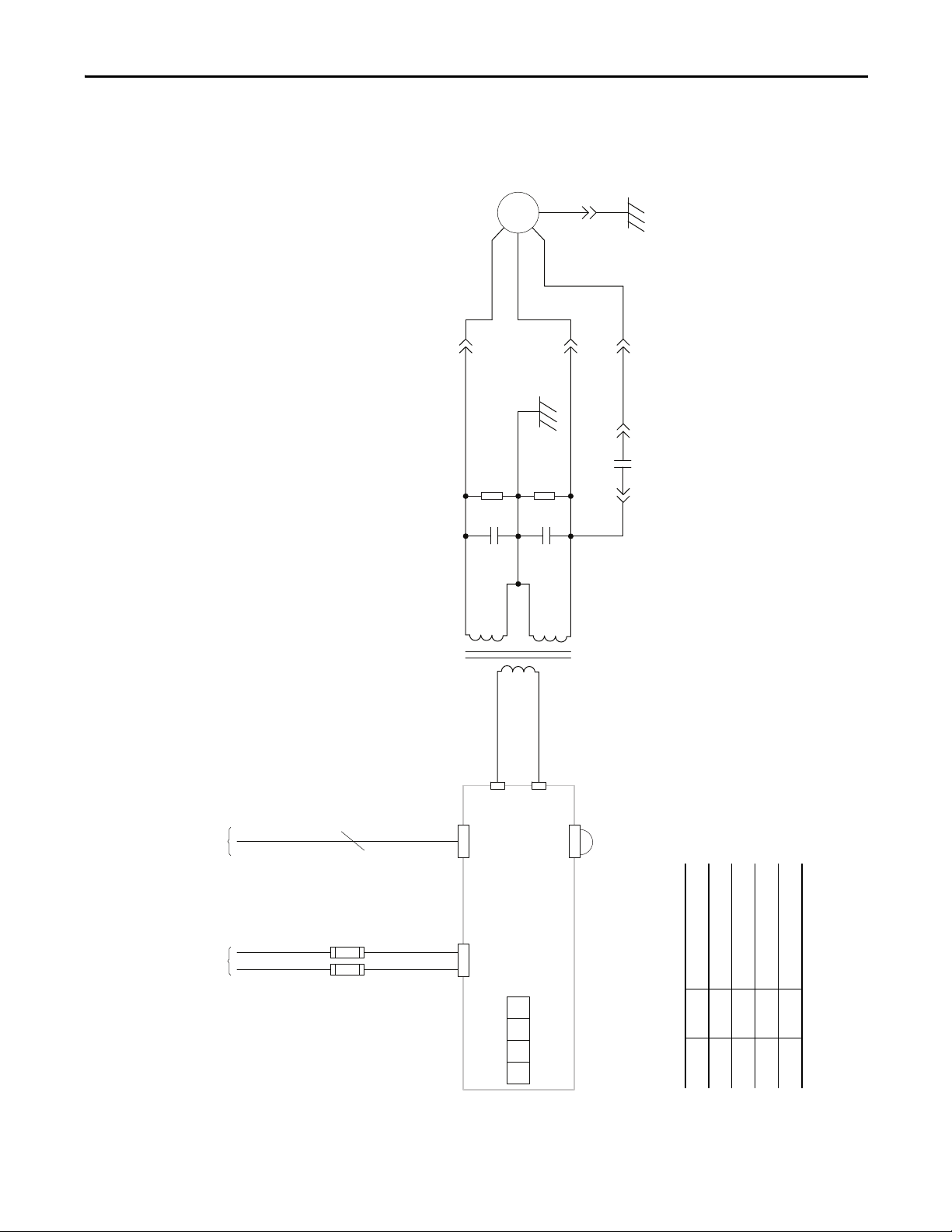

To P owe r Ci rcu it Bo ard X7

(Fan Control)

3

4

Main DC Fan

Fan Module

DC +

DC -

Isolated 48V DC Power

Supply Circuit Board

X81 X8 X3

X82

X2

Figure 3 - Frame 9 DC Fan System Wiring Schematic Diagram

Frame 9 Fan System Replacement Procedures

Replacement procedures for these frame 9 fan system parts are included in this

chapter.

Cat. No. Part Description Page

20-PP20202 Fuse for fan system 29

20-PP20300 Fuse holder for main fan system fuses 29

20-PP01049 50 mm cooling fan for fan inverter 30

SK-H1-FANCAP-F9 Main AC fan capacitor (7 μF) 31

20-VB00299 Main AC fan inverter circuit board 33

SK-H1-DCFANBD1 Main DC fan power supply circuit board 36

SK-H1-DCFANRETROFIT-F9 AC to DC fan system retrofit kit 39

SK-Y1-DCFAN1 Main DC fan assembly 43

20-PP01080 230 W main AC fan assembly 43

20-PP09055 Main AC fan inverter output transformer 49

20-PP01068 80 mm x 80 mm x 32 mm internal stirring fan assembly 50

20-PP01068 Cross-plate stirring fan (80 mm x 80 mm x 32 mm) 51

20-PP01068 Internal stirring fan (80 mm x 80 mm x 32 mm) 52

22 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

Page 23

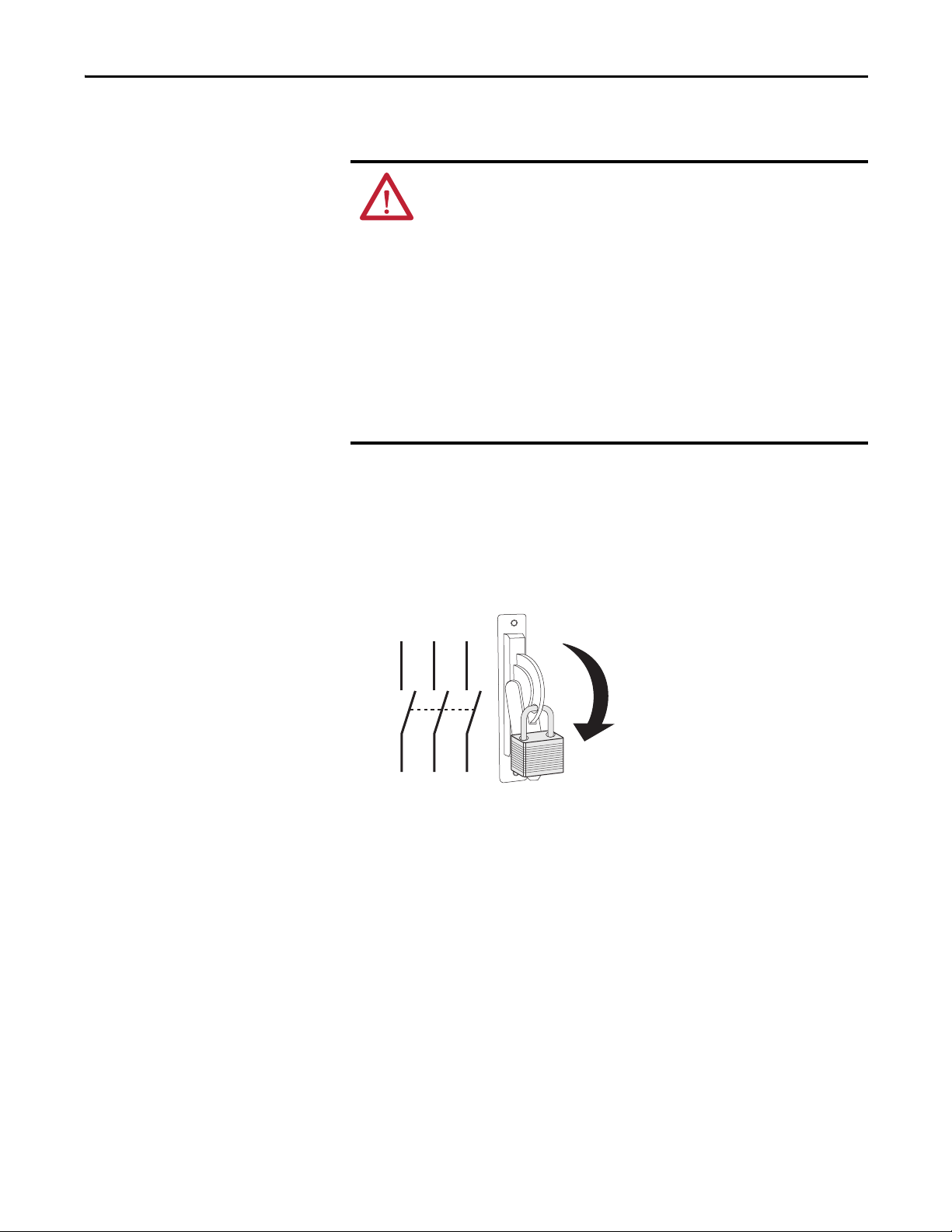

Remove Power from the Drive

L1 L2 L3

O

I

ATTENTION: To avoid an electric shock hazard, verify that the voltage on the bus

capacitors has discharged completely before servicing. Check the DC bus voltage

at the Power Terminal Block by measuring between the +DC and -DC terminals,

between the +DC terminal and the chassis, and between the -DC terminal and

the chassis. The voltage must be zero for all three measurements.

Remove power before making or breaking cable connections. When you remove or

insert a cable connector with power applied, an electrical arc may occur. An

electrical arc can cause personal injury or property damage by:

• sending an erroneous signal to your system’s field devices, causing unintended

machine motion

• causing an explosion in a hazardous environment

Electrical arcing causes excessive wear to contacts on both the module and its

mating connector. Worn contacts may create electrical resistance.

1. Turn off and lock out input power.

2. Wa it fi ve m in ut es .

PowerFlex 700H and 700S Drives - Frame 9 Procedures Chapter 1

3. Check the DC bus voltage at the Power Terminal Block by measuring

between the +DC and -DC terminals, between the +DC terminal and the

chassis, and between the -DC terminal and the chassis. The voltage must

be zero for all three measurements.

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 23

Page 24

Chapter 1 PowerFlex 700H and 700S Drives - Frame 9 Procedures

(8 Screws)

L1 L2 L3 L1 L2 L3 U/T1 V/T2 W/T3 U/T1 V/T2 W/T3

PZ2

3.0 N

•m (27 lb•in)

L1 L2 L3 L1 L2 L3 U/T1 V/T2 W/T3 U/T1 V/T2 W/T3

(8 Screws)

PZ2

3.0 N

•m (27 lb•in)

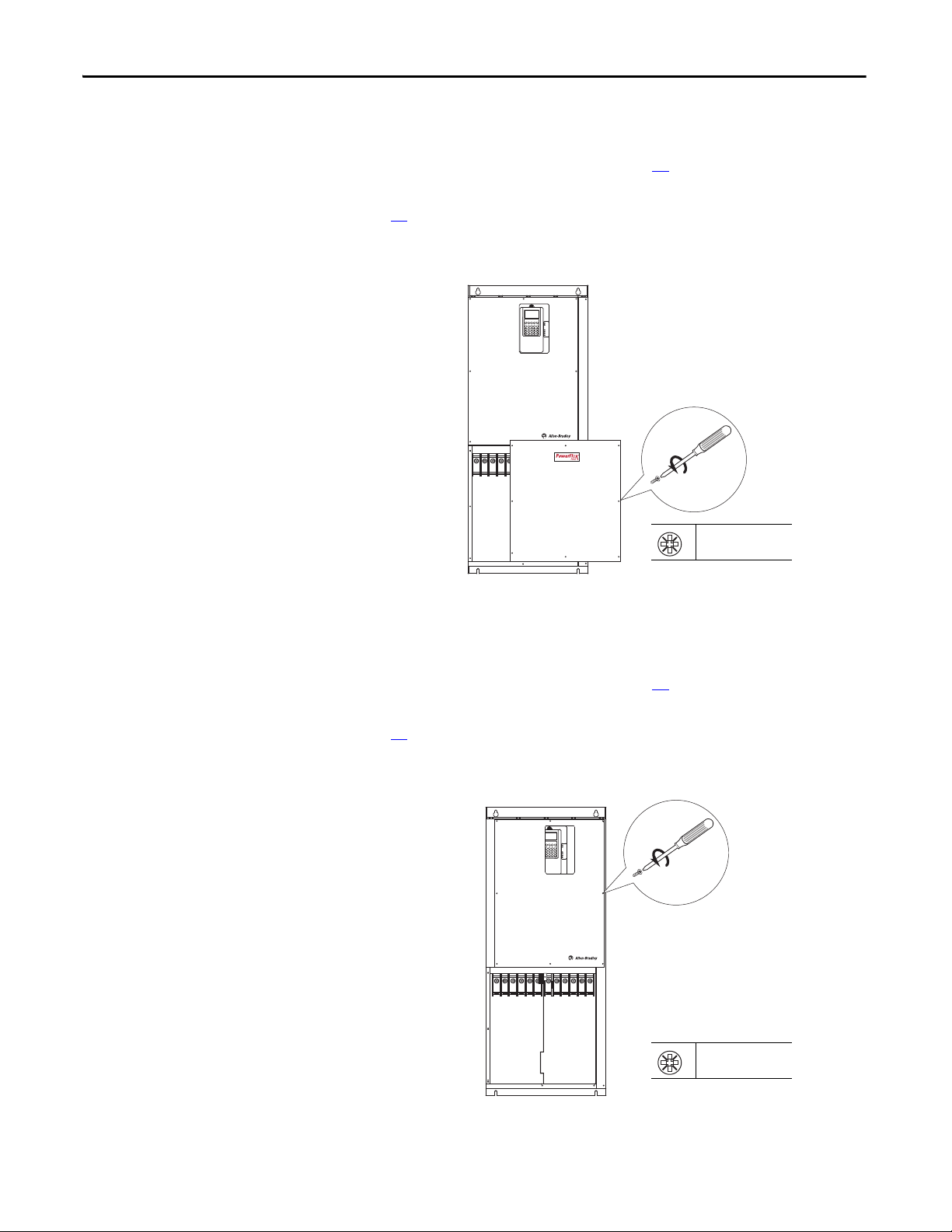

Remove the Lower Protective Cover

1. Review the General Precautions on page 17.

2. Remove power from the drive. See Remove Power from the Drive on page

3. Remove the eight M4 x 8 mm POZIDRIV screws that secure the lower

23

.

protective cover to the drive and remove the cover.

Remove the Upper Protective Cover

1. Review the General Precautions on page 17.

2. Remove power from the drive. See Remove Power from the Drive on page

23

.

3. Remove the eight M4 x 8 mm POZIDRIV screws that secure the upper

protective cover to the drive and remove the cover.

24 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

Page 25

PowerFlex 700H and 700S Drives - Frame 9 Procedures Chapter 1

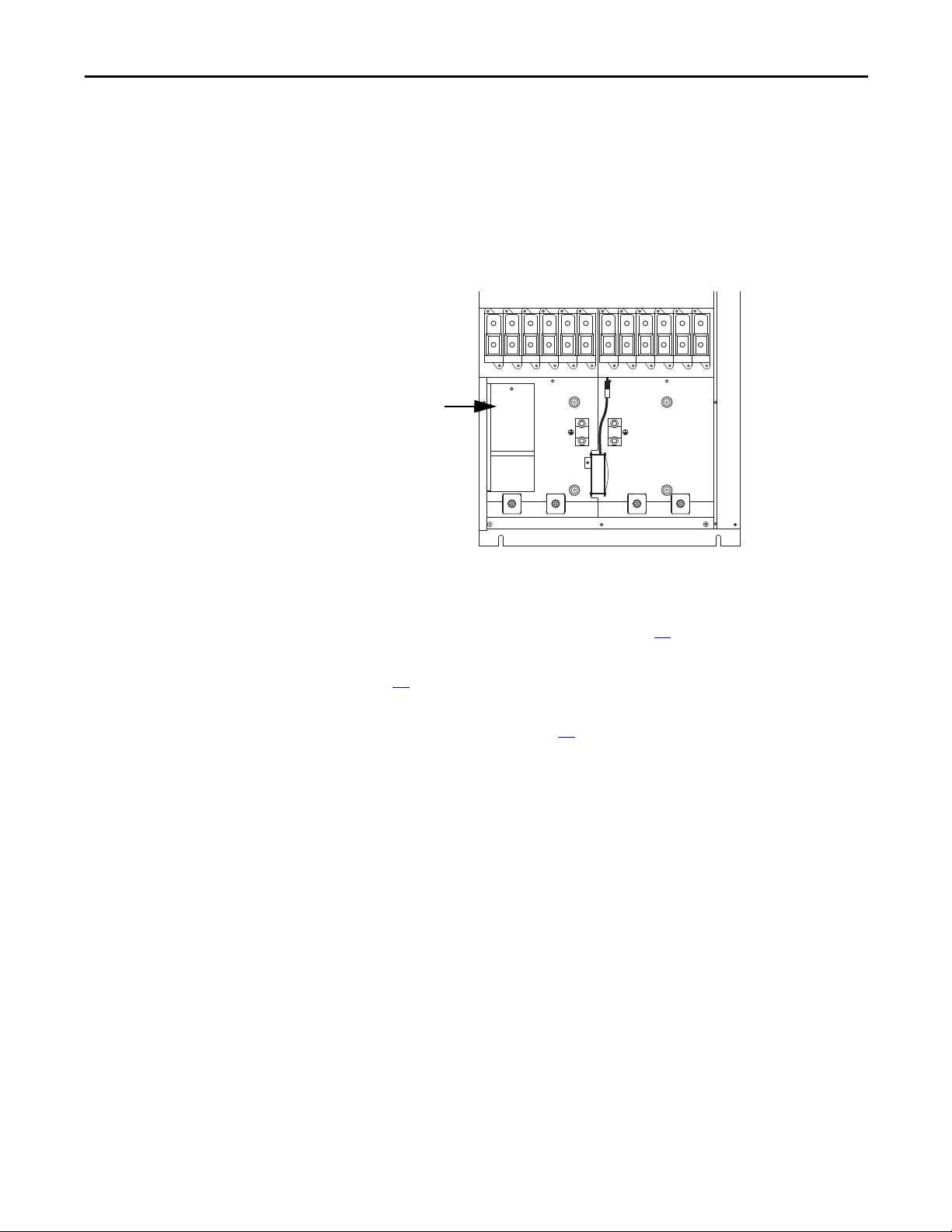

Removing the Main Fan Inverter Capacitor Bracket

In order to test and/or replace other fan system components in the drive, you

must first remove the main fan inverter cooling fan capacitor bracket from the

drive.

The main fan inverter compartment is located in the bottom, left-hand corner of

the drive, under the connection plate.

Follow these steps to remove the main fan inverter capacitor bracket.

1. Review the General Precautions on page 17

.

2. Remove power from the drive. See Remove Power from the Drive on page

23

.

3. Remove the lower protective cover from the drive. See Remove the Lower

Protective Cover on page 24

.

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 25

Page 26

Chapter 1 PowerFlex 700H and 700S Drives - Frame 9 Procedures

1 2 3 4

ON

X6

X1

X4

X5

X7

S1

X2 X8

=

PZ2

1.3 N•m (11.5 lb•in)

Series A Cover Shown

Series B Cover S eries A Cover

4. Remove the M4 x 8 mm POZIDRIV screw that secures the fan inverter

cover to the drive frame and remove the cover.

26 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

Page 27

PowerFlex 700H and 700S Drives - Frame 9 Procedures Chapter 1

IMPORTANT

IMPORTANT

6

6

5

7

Red Black

Red Black

Mark all connections and wires before removing to avoid incorrect wiring

during reassembly.

5. Remove the fuses from the fuse holder.

6. Disconnect the four fuse power wires (black and red pairs) from the top

and bottom of the fuse holder.

Note that the red wires connect to the left side terminal on the fuse

holder and the black wires connect to the right side terminal on the

fuse holder.

7. Disconnect the stirring fan power wires.

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 27

Page 28

Chapter 1 PowerFlex 700H and 700S Drives - Frame 9 Procedures

1

2

3

4

ON

X6

X1

X4

X5

X7

S1

X2 X8

9

8

P2

4.0 N

•m (35 lb•in)

Series A Assembly Shown

Series A Assembly Series B Assembly (Note the Larger Capacitor)

8. Remove the two M5 x 10 mm Phillips head screws that secure the fan

9. Disconnect the fan capacitor wires from the connectors labeled ‘Blue’ and

capacitor, fuse holder, and cooling fan bracket to the drive frame and lift

the bracket out of the drive.

Note that the fan capacitor is still connected to the drive circuitry.

‘Brown’.

28 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

Page 29

PowerFlex 700H and 700S Drives - Frame 9 Procedures Chapter 1

PZ2

3.0 N

•m (27 lb•in)

6

Main Fan Fuses (20-PP20202) and Fuse Holder (20-PP20300) Removal and Installation

The main fan fuses and fuse holder are located on the fan inverter capacitor

bracket below the fan inverter cover.

1. Review the General Precautions on page 17

.

2. Remove power from the drive. See Remove Power from the Drive on page

23

.

3. Remove the lower protective cover from the drive. See Remove the Lower

Protective Cover on page 24

.

4. Remove the main fan inverter capacitor bracket. See Removing the Main

Fan Inverter Capacitor Bracket on page 25

.

5. Remove and replace the fuses, if necessary. See Checking the Fan Inverter

Fuses on page 263

.

6. If, necessary, remove the two M4 x 8 mm POZIDRIV screws that secure

the fuse block to the sheet metal.

7. Install the fuses and fuse block in the reverse order of removal.

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 29

Page 30

Chapter 1 PowerFlex 700H and 700S Drives - Frame 9 Procedures

IMPORTANT

5. Note Direction of Air

Flow Arrow on Fan.

PZ2

3.0 N•m (27 lb•in)

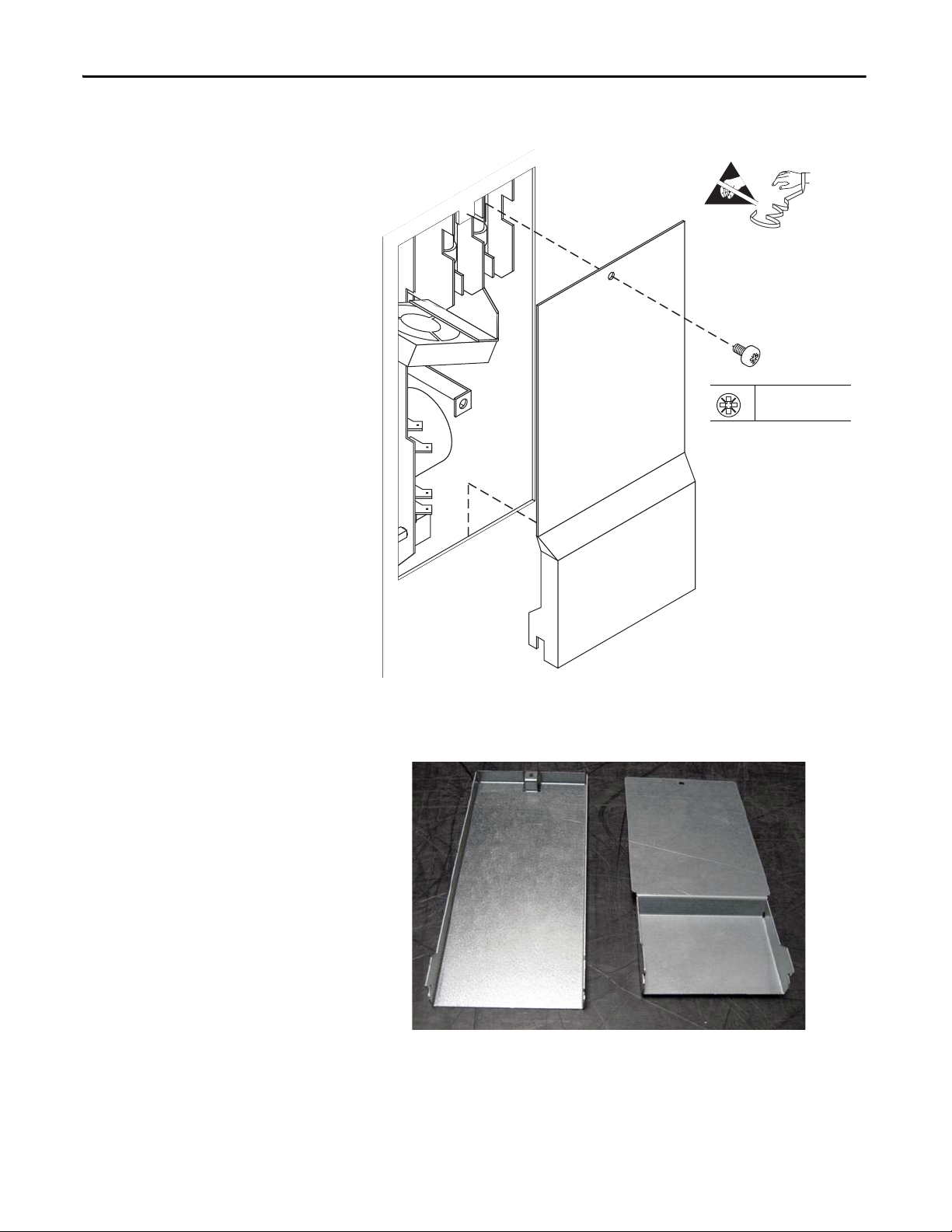

Main Fan Inverter Cooling Fan (20-PP01049) Removal and Installation

Note: This spare part kit includes a fan mounted on a piece of sheet metal.

Remove the fan from the sheet metal and discard the sheet metal.

Follow these steps to remove and replace the main fan inverter cooling fan.

Note the orientation of the air flow direction arrow on the cooling fan housing

before removal. The fan must be installed facing the same direction when reinstalled.

1. Review the General Precautions on page 17

.

2. Remove power from the drive. See Remove Power from the Drive on page

.

23

3. Remove the lower protective cover from the drive. See Remove the Lower

Protective Cover on page 24

.

4. Remove the main fan inverter capacitor bracket. See Removing the Main

Fan Inverter Capacitor Bracket on page 25

.

5. Remove the two M4 x 16 mm POZIDRIV screws that secure the cooling

fan to the bracket and remove and discard the fan.

6. Install the new cooling fan in the reverse order of removal.

30 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

Page 31

PowerFlex 700H and 700S Drives - Frame 9 Procedures Chapter 1

Main AC Fan Inverter Capacitor (SK-H1-FANCAP-F9) Removal and Installation

Note: The AC fan inverter capacitor replacement kit (SK-H1-FANCAP-F9)

contains a new sheet metal bracket, hardware and fasteners, and a series B

capacitor (identified in the table and shown below). The series B capacitor

(50 mm dia. x 62 mm tall) is larger than the series A capacitor (35 mm dia. x

57 mm tall). If a series A capacitor is currently installed, always

new series B capacitor.

Photo ID# Part Description Quantity

1 Fan capacitor 1

2 Fan capacitor, fuse holder and fan bracket 1

3 Fan inverter compartment cover 1

4 Fan capacitor nut (M12) 1

5 Fan capacitor lock washer (M12) 1

6 Stirring fan screws (M4 x 16 mm) 2

7 Fuse holder and fan inverter cover screws (M4 x 8 mm) 3

8 Fan capacitor, fuse holder and fan bracket screws (M5 x 10 mm) 2

9 Connector screw (M3 x 8 mm - for SAF option only) 1

replace it with the

Follow these steps to remove, test, and replace the main AC fan inverter

capacitor.

1. Review the General Precautions on page 17

.

2. Remove power from the drive. See Remove Power from the Drive on page

23

.

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 31

Page 32

Chapter 1 PowerFlex 700H and 700S Drives - Frame 9 Procedures

8

19 mm

12.0 N•m (106 lb•in)

3. Remove the lower protective cover from the drive. See Remove the Lower

4. Remove the main AC fan inverter capacitor bracket. See Remove the

5. Remove the main AC fan inverter cooling fan from the bracket. Save the

6. Remove the two M4 x 8 mm POZIRDRIV screws that secure the fuse

7. If a series A capacitor is installed, continue with the next step. If a series B

8. Remove the M12 nut and lock washer that secures the capacitor to the

Protective Cover on page 24

Removing the Main Fan Inverter Capacitor Bracket on page 25

.

.

fan for reuse. See Main Fan Inverter Cooling Fan (20-PP01049) Removal

and Installation on page 30

.

holder to the bracket and remove the fuse holder. Save the fuse holder for

reuse.

capacitor is installed, measure the value of the capacitor. If the value of the

capacitor is less than 7 μF, continue with the next step.

bracket and remove the capacitor.

9. Install the new capacitor. If replacing a smaller series A capacitor with a

larger series B capacitor, discard the existing fan capacitor bracket.

10. Install the existing AC cooling fan on the new capacitor bracket.

11. Install the existing fuse holder on the new capacitor bracket.

12. Install the new capacitor and new bracket in the reverse order of removal.

Note: Take care to protect the fan power wires from damage during

installation.

13. Install the new fan inverter compartment (series B) cover.

32 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

Page 33

PowerFlex 700H and 700S Drives - Frame 9 Procedures Chapter 1

IMPORTANT

Main AC Fan Inverter Circuit Board Assembly (20-VB00299) Removal and Installation

See Checking the Main AC Fan Inverter Circuit Board Diagnostic LEDs on page

for test procedures used to determine if the circuit board requires

268

replacement.

Follow these steps to replace the main AC fan inverter circuit board.

1. Review the General Precautions on page 17

2. Remove power from the drive. See Remove Power from the Drive on page

23

.

3. Remove the lower protective cover from the drive. See Remove the Lower

Protective Cover on page 24

4. Remove the main AC fan inverter capacitor bracket. See Removing the

Main Fan Inverter Capacitor Bracket on page 25

Mark the existing isolation transformer wires so that you can identify

them later in this procedure.

5. Reach into the fan inverter compartment and disconnect the isolation

transformer wires from X4 and X5 on the fan inverter board.

6. Disconnect the wires from connector X8 on the fan inverter board.

7. Disconnect the wires from connector X2 on the fan inverter board. Retain

these wires for reuse.

.

.

.

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 33

Page 34

Chapter 1 PowerFlex 700H and 700S Drives - Frame 9 Procedures

1

2

3

4

ON

X6

X1

X4

X5

X7

S1

X2 X8

Fan I nver ter C ircu it Bo ard

PZ2

3.0 N

•m (27 lb•in)

8

8. Remove the three M4 x 8 mm POZIDRIV screws that hold the fan

inverter assembly to the drive and remove the fan inverter assembly.

34 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

Page 35

PowerFlex 700H and 700S Drives - Frame 9 Procedures Chapter 1

IMPORTANT

Connect Jumper to Connector X3

X8

X2

IMPORTANT

X6

X1

X4

X5

X7

S1

X2 X8

1

ON

2

3 4

S1

1

ON

2

34

S1-1 S1-2 S1-3 S1-4

Off Off On Off

Switch Setting To Indicate the Following:

S1 Off 50 Hz Fan Motor Frequency

S2 Off 220 V AC Motor Voltage

S3 On 230 V AC Motor Voltage

S4 Off Frame Size 9…14

9. Install the new fan inverter assembly in the reverse order of removal.

If you are servicing a 400V/480V Frame 9 drive, insert the jumper on connector

X3 as shown here.

Verify that dip switch S1 on the new fan iverter board is properly configured, as

shown below.

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 35

Page 36

Chapter 1 PowerFlex 700H and 700S Drives - Frame 9 Procedures

1 2 3

4

ON

X6

X1

X4

X5

X7

S1

X2 X8

=

PZ2

1.3 N•m (11.5 lb•in)

Series A Cover Shown

Series B Cover Series A Cover

Main DC Fan Power Supply Circuit Board (SK-H1-DCFANBD1) Removal and Installation

Note: You can retrofit an existing AC fan system or replace a DC fan system with

a new DC fan system. See Energy-related Products Fan Efficiency Directive on

page 12

system.

Follow these steps to remove and replace a DC fan system.

for guidelines on replacing an existing fan system with a new DC fan

1. Review the General Precautions on page 17

.

2. Remove power from the drive. See Remove Power from the Drive on page

.

23

3. Remove the lower protective cover from the drive. See Remove the Lower

Protective Cover on page 24

.

4. Remove the M4 x 8 mm POZIDRIV screw that secures the fan power

supply cover to the drive frame and remove the cover.

36 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

Page 37

PowerFlex 700H and 700S Drives - Frame 9 Procedures Chapter 1

5

6

7

9

8

10

P2

4.0 N

•m (35 lb•in)

5. Disconnect the stirring fan power wires.

6. Disconnect the DC supply wire from fan inverter connector X2.

7. Disconnect the fan supply wire from fan inverter connector X8.

8. Disconnect the DC fan power supply wire from connector X81

9. Disconnect the four fuse power wires (black and red pairs) from the top

and bottom of the fuse holder.

10. Remove the two M5 x 10 mm Phillips head screws that secure the fuse

holder / cooling fan bracket to the frame and left the bracket out of the

drive.

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 37

Page 38

Chapter 1 PowerFlex 700H and 700S Drives - Frame 9 Procedures

IMPORTANT

PZ2

2.3 N

•m (20.4 lb•in)

11. Remove the two M4 x 8 mm fan inverter mounting screws and, while

turning the fan inverter slightly sideways, remove the DC fan power supply

assembly.

12. Install the main DC fan power supply system in the reverse order of

removal.

If you are servicing a 400V/480V Frame 9 drive, insert the jumper on connector

X3.

38 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

Page 39

PowerFlex 700H and 700S Drives - Frame 9 Procedures Chapter 1

IMPORTANT

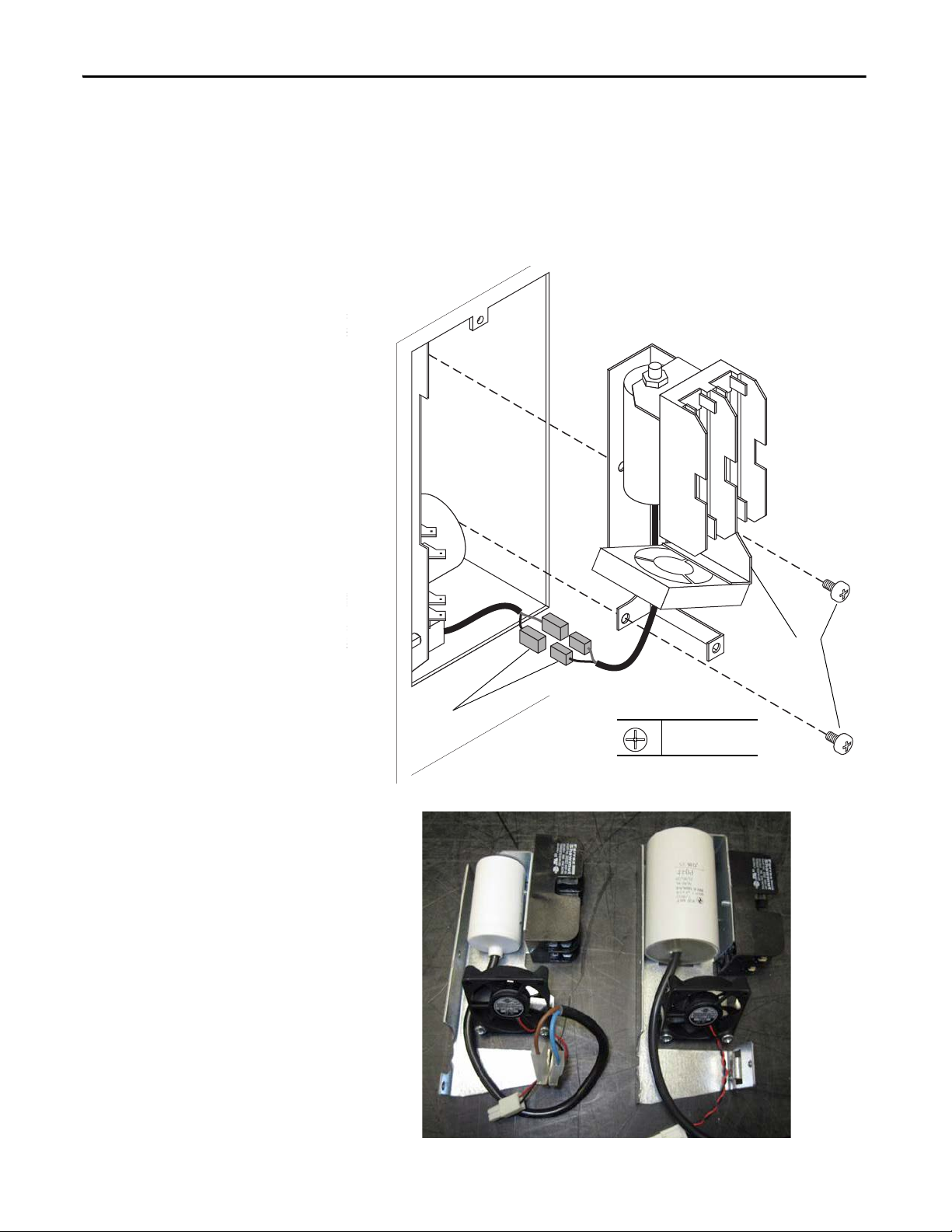

AC to DC Fan System Retrofit Kit (SK-H1-DCFANRETROFIT-F9)

The frame 9 AC to DC main fan system retrofit kit contains the following parts:

Item

Number

Description Quantity

1 DC fan assembly 1

2 DC fan supply assembly 1

3 M4 x 8 mm POZIDRIV screw 2

4 M5 x 10 mm POZIDRIV screw 4

Follow these steps to remove the main AC fan inverter system and replace it with

a main DC fan inverter system.

1. Review the General Precautions on page 17

.

2. Remove power from the drive. See Remove Power from the Drive on page

.

23

3. Remove the lower protective cover from the drive. See Remove the Lower

Protective Cover on page 24

.

Verify that the upper mounting bolts are secure and properly torqued

so that they will hold the drive to the wall of the system enclosure.

4. Remove the main AC fan inverter capacitor bracket. See Removing the

Main Fan Inverter Capacitor Bracket on page 25

.

5. Remove the AC fan inverter capacitor from the bracket and discard the

capacitor. See Main AC Fan Inverter Capacitor (SK-H1-FANCAP-F9)

Removal and Installation on page 31

.

6. Remove the main AC fan inverter circuit board assembly and discard the

assembly. See Main AC Fan Inverter Circuit Board Assembly (20VB00299) Removal and Installation on page 33

.

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 39

Page 40

Chapter 1 PowerFlex 700H and 700S Drives - Frame 9 Procedures

PZ2

3.2 N

•m (28.3 lb•in)

9

10 1211

7. Remove the main AC fan from the drive and discard the old AC fan and

8. Remove the main AC fan inverter output transformer assembly from the

9. Partially insert the new retrofit DC fan assembly into the bottom of the

10. Insert the DC fan supply cable into the hole (inside the drive chassis) that

11. Secure the retrofit DC fan assembly to the drive chassis using the four

12. Position the grommet into the hole and ensure the ware harness doesn't

bracket assembly. See Main AC Fan (20-PP01080) and Main DC Fan

(SK-Y1-DCFAN1) Assembly Removal and Installation on page 43

. Note:

You do not need to complete the steps to measure the resistance of the fan

supply wires or removing the main fan from the fan bracket.

drive and discard the assembly. See Main AC Fan Inverter Output

Transformer (20-PP09055) Removal and Installation on page 49

.

drive.

leads to the fan circuit board assembly location.

M5 x 10 mm POZIDRIV screws.

contact any sheetmetal surface.

40 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

Page 41

PowerFlex 700H and 700S Drives - Frame 9 Procedures Chapter 1

13

T20

3.0 N

•m (27 lb•in)

14

13. Using a 9 cm long T20 hexalobular screwdriver, tighten (approximately 12

full screw rotations) the four screws (accessible through the holes in the

drive chassis) to secure the fan plenum sheet metal bracket against the fan

assembly inside the drive.

14. Install the four rubber bushings in the four holes in the drive chassis.

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 41

Page 42

Chapter 1 PowerFlex 700H and 700S Drives - Frame 9 Procedures

PZ2

2.3 N

•m (20.4 lb•in)

16

17

18

20

19

15. Insert the DC fan inverter assembly into the fan inverter compartment and

secure the assembly to the drive using the two M4 x 8 mm POZIDRIV

screws.

16. Connect the stirring fan power wires.

17. Connect the DC supply wire from fan inverter connector X2.

18. Connect the fan supply wire from fan inverter connector X8.

19. Connect the DC fan power supply wire from connector X81

20. Connect the four fuse power wires (black and red pairs) from the top and

bottom of the fuse holder.

42 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

Page 43

PowerFlex 700H and 700S Drives - Frame 9 Procedures Chapter 1

1 2 3 4

ON

X6

X1

X4

X5

X7

S1

X2 X8

PZ2

1.3 N

•m (11.5 lb•in)

Series A Cover Shown

21. Secure the fan inverter cover to the drive using the M4 x 8 mm

POZIDRIV screw.

22. Install the lower protective cover in the reverse order of removal. See

Remove the Lower Protective Cover on page 24

.

23. Remove the backing from the drive modification label and attach the label,

in a clearly visible location, to the front of the drive.

24. Write “DC fan retrofit” and the installation date on the label.

Main AC Fan (20-PP01080) and Main DC Fan (SK-Y1-DCFAN1) Assembly Removal and Installation

Follow these steps to measure the resistance between the main fan supply wires

and remove and replace the main fan, if necessary.

Notes:

• To identify which fan is installed in your drive, see Fan Inverter System

Block Diagrams on page 257

• For AC fan systems, the sheet metal bracket is available as a spare part (SKH1-FR9BRKT). See page 288

metal bracket is only available as part of the retrofit kit (SK-H1DCFANRETROFIT-F9). See page 289

• The main fan replacement kit only contains the fan motor and impeller

assembly. Therefore, if the sheet metal mounting bracket is not available as

a spare part for your fan system, it must be reused.

.

for details. For DC fan systems, the sheet

for details.

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 43

Page 44

Chapter 1 PowerFlex 700H and 700S Drives - Frame 9 Procedures

IMPORTANT

5

4

1. Review the General Precautions on page 17.

2. Remove power from the drive. See Remove Power from the Drive on page

3. Remove the lower protective cover from the drive. See Remove the Lower

4. Remove the lower mounting bolts from the bottom of the frame.

5. Remove the four rubber bushings that cover the mounting screws for the

23

.

Protective Cover on page 24

.

Verify that the upper mounting bolts are secure and properly torqued

so that they will hold the drive to the wall of the system enclosure.

main fan assembly. Retain these bushings for reuse.

6. Remove the rubber bushing from the hole that covers the main fan motor

power connector at the bottom of the drive.

44 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

Page 45

PowerFlex 700H and 700S Drives - Frame 9 Procedures Chapter 1

7

Note: DC fan

system shown

7. Disconnect the main fan motor power connector from the output

transformer.

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 45

Page 46

Chapter 1 PowerFlex 700H and 700S Drives - Frame 9 Procedures

Blue (Motor) Pin 4

Green/Yellow (Ground) Pin 1

Brown (Motor) Pin 3

Black (Motor) Pin 2

AC Fan Pinouts

White (Tach Output) Pin 3

Red (+) Pin 1

Blue (-) Pin 4

Yellow (Control Output) Pin 2

DC Fan Pinouts

8. Using the appropriate table below, measure the resistance between the fan

supply wires.

AC Fan: If the measurements are not similar to those in this table, replace

the AC fan.

Connection wires Resistance ±5%

Black-Brown 62 Ω

Brown-Blue 36 Ω

Blue-Black 27 Ω

Green-chassis 0 Ω

DC Fan: If the measurements are not similar to those in this table, replace

the DC fan.

Connection wires Resistance ±5%

Red-Blue ∞ Ω

Red-White ∞ Ω

White-Yellow ∞ Ω

Blue-White ∞ Ω

46 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

Page 47

PowerFlex 700H and 700S Drives - Frame 9 Procedures Chapter 1

9

T20

3.0 N•m (27 lb•in)

IMPORTANT

IMPORTANT

9. Using the 9 cm long T20 hexalobular screwdriver, loosen (approximately

12 full screw rotations), but do not

remove the four screws (accessible

through the holes vacated by the rubber bushings) so that the fan assembly

can be removed from the drive. Note: These screws secure a sheet metal

plate against the fan assembly inside the drive chassis, effectively sealing the

fan plenum chamber.

The next step assumes that the drive is mounted in a vertical position.

Once the screws that secure the main fan assembly to the drive are

loosened, the fan will be free to slide out of the bottom of the drive

chassis. Support the fan assembly when the screws are loosened.

10. Remove the four M5 x 10 mm POZIDRIV screws that secure the fan

assembly to the bottom of the drive chassis and slide the fan assembly

down and out of the drive.

If the fan assembly does not easily come out of the dive chassis, loosen the

front screws (as instructed in step 9) another turn and attempt to remove

the fan assembly again. Continue loosening the screws until the fan

assembly slides easily from the drive.

Do not attempt to force the fan plate from the drive. This may bend the

fan and surrounding sheet metal. The sheet metal bracket must be

reused.

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 47

Page 48

Chapter 1 PowerFlex 700H and 700S Drives - Frame 9 Procedures

IMPORTANT

10

PZ2

4.0 N

•m (35 lb•in)

11

F - 6.4 mm (0.25 in.)

4.0 N

•m (35 lb•in)

11. Remove the four screws that secure the main fan to the fan bracket and

discard the fan. The sheet metal bracket must be reused.

Note: The Main AC and DC fans have different mounting hardware and

hole dimensions. The AC fan uses four M4 x 8 mm screws that are spaced

40 mm apart on the bracket. The DC fan uses four M5 x 10 mm screws

that are spaced 65 mm apart on the bracket. Based on the manufacturing

date, the sheet metal mounting bracket was fabricated for either an AC

fan, a DC fan, or both.

48 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

12. Install the main fan in the reverse order of removal.

Verify that the fan turns easily on the bracket before installing it in the

drive.

Page 49

PowerFlex 700H and 700S Drives - Frame 9 Procedures Chapter 1

7

T8

4.0 N

•m (35 lb•in)

Main AC Fan Inverter Output Transformer (20-PP09055) Removal and Installation

Follow these steps to remove and replace the main AC fan inverter output

transformer.

1. Review the General Precautions on page 17

.

2. Remove power from the drive. See Remove Power from the Drive on page

23

.

3. Remove the lower protective cover from the drive. See Remove the Lower

Protective Cover on page 24

.

4. Remove the main AC fan inverter cooling fan, fuses, and capacitor bracket.

See Removing the Main Fan Inverter Capacitor Bracket on page 25

.

5. Remove the main AC fan inverter circuit board assembly. See Main AC

Fan Inverter Circuit Board Assembly (20-VB00299) Removal and

Installation on page 33

.

6. Remove the main AC fan from the drive. See Main AC Fan (20-PP01080)

and Main DC Fan (SK-Y1-DCFAN1) Assembly Removal and Installation

on page 43

.

7. Remove the hexalobular screw, located at the back, left-hand corner of the

fan inverter compartment, that secures the output transformer assembly to

the drive frame.

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 49

Page 50

Chapter 1 PowerFlex 700H and 700S Drives - Frame 9 Procedures

8

PZ2

4.0 N•m (35 lb•in)

8. Remove the two M5 x 10 POZIDRIV screws that secure the output

9. While pushing the output transformer wires and rubber bushing through

transformer to the drive frame.

the hole in the back of the fan inverter compartment, remove the output

transformer from the bottom of the drive.

10. Install the new output transformer assembly in the reverse order of

removal.

Chassis Stirring Fan (20-PP01068) Removal and Installation

Note: The chassis stirring fan is only installed on PowerFlex 700S Phase II drives.

Follow these steps to remove and replace the chassis stirring fan.

1. Review the General Precautions on page 17

2. Remove power from the drive. See Remove Power from the Drive on page

23

.

3. Remove the upper protective cover from the drive. See Remove the Upper

Protective Cover on page 24

.

4. Disconnect the fan power cable from connector J18 on the power interface

circuit board.

.

50 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

Page 51

PowerFlex 700H and 700S Drives - Frame 9 Procedures Chapter 1

5

PZ2

3.0 N

•m (27 lb•in)

5. Remove the two M5 x 45 mm POZIDRIV screws that secure the

protective metal grate and stirring fan to the control frame and remove the

fan.

6. Install the chassis stirring fan in the reverse order of removal.

Cross-plate Stirring Fan (20-PP01068) Removal and Installation

Follow these steps to remove and replace the stirring fan located on the cross plate

in the lower part of the drive.

1. Review the General Precautions on page 17

2. Remove power from the drive. See Remove Power from the Drive on page

23

.

3. Remove the lower protective cover from the drive. See Remove the Lower

Protective Cover on page 24

.

4. Disconnect the stirring fan power wire connector.

.

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 51

Page 52

Chapter 1 PowerFlex 700H and 700S Drives - Frame 9 Procedures

4

5

PZ2

3.0 N

•m (27 lb•in)

5. Remove the two M4 x 40 mm POZIDRIV screws that secure the fan to

the cross-plate and remove the fan. Retain the fan grill plate for reuse.

6. Install the fan in the reverse order of removal.

Internal Stirring Fan (20-PP01068) Removal and Installation

Follow these steps to remove and replace the internal stirring fan located on the

drive frame in the lower part of the drive.

1. Review the General Precautions on page 17

2. Remove power from the drive. See Remove Power from the Drive on page

23

.

3. Remove the lower protective cover from the drive. See Remove the Lower

Protective Cover on page 24

4. Remove the covers or protective isolation barriers from the U/T1, V/T2,

and W/T3 power terminals.

5. Remove the M8 nut and washer that secure the U/T1, V/T2, and

W/T3 power wires to the terminals, to loosen the wires only. You do not

52 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

need to remove the external wires from the terminals.

.

.

Page 53

PowerFlex 700H and 700S Drives - Frame 9 Procedures Chapter 1

7

8

PZ2

3.0 N•m (27 lb•in)

Lug

Hex Nut

Was her

Bus Bar

Power Wire

U1 U2

V1

V2

W1 W2

13 mm

20.0 N

•m (177 lb•in)

6. Push the power wires on terminals U/T1, V/T2, and W/T3 to the side in

order to gain access to the stirring fan.

7. Disconnect the stirring fan power wire connector.

8. Remove the two M4 x 8 mm POZIDRIV screws that secure the fan to the

drive frame and remove the fan.

9. Install the fan in the reverse order of removal. Refer to the motor terminal

wire placement diagrams below during reassembly.

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 53

Page 54

Chapter 1 PowerFlex 700H and 700S Drives - Frame 9 Procedures

Notes:

54 Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

Page 55

Chapter 2

PowerFlex 700H and 700S Drives - Frame 10

Procedures

This chapter contains spare part information and procedures for testing and

replacing fan system components for frame 10 PowerFlex 700H and PowerFlex

700S drives. See Appendix A PowerFlex 700H and 700S Diagnostic Procedures

on page 255

Top ic Pag e

Frame 10 Fan System Spare Parts 56

Tools Needed for Frame 10 Fan System Repairs 56

Frame 10 Schematic Diagrams 57

Frame 10 Fan System Replacement Procedures 59

Remove Power from the Drive 59

Move the Control Frame and Remove the Air Flow Plate and Protective Covers 60

Remove the Main AC or DC Fan Power Supply Assemblies 63

Main AC Fan Inverter Circuit Board (20-VB00299) and AC Fan Output Transformer

Assembly [20-FR10844 (Left) or 20-FR10845 (Right)] Removal and Installation

Main DC Fan Power Supply System (SK-H1-DCFANBD1) Removal and Installation 69

AC to DC Fan System Retrofit Kit (SK-H1-DCFANRETROFIT-F10) 70

Main AC Fan Inverter Capacitor (SK-H1-FANCAP-F1012) Removal and Installation 74

Main AC Fan (20-PP01080) and Main DC Fan (SK-Y1-DCFAN1) Assembly Removal and

Installation

ASIC Circuit Board Assembly Cooling Fan (20-PP01096) Removal and Installation 82

AC or DC Fan System Fuses (20-PP20202) and Fuse Holder (20-PP20300) Removal and

Installation

for additional component test procedures.

67

78

85

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014 55

Page 56

Chapter 2 PowerFlex 700H and 700S Drives - Frame 10 Procedures

Frame 10 Fan System Spare Parts

AC Fan Systems