Page 1

Installation Instructions

PowerFlex® DC Drive Resolver Feedback Option Module

ATTENTION: Only qualified personnel familiar with DC drives and

associated machinery should plan or implement the installation, start-up

and subsequent maintenance of the system. Failure to comply may result in

personal injury and/or equipment damage.

ATTENTION: To avoid an electric shock hazard, ensure that all power to

the drive has been removed before performing the following.

ATTENTION: This drive contains ESD (Electrostatic Discharge) sensitive

parts and assemblies. Static control precautions are required when

installing, testing, servicing or repairing this assembly. Component damage

may result if ESD control procedures are not followed. If you are not

familiar with static control procedures, reference A-B publication 8000-

4.5.2, “Guarding Against Electrostatic Damage” or any other applicable

ESD protection handbook.

What This Kit Includes

Tools That You Need

IMPORTANT

• Resolver Feedback circuit board

• Resolver Interface circuit board

• Two stacker connectors

• Four 28 mm stand-offs and washers

• Three 14 mm stand-offs and washers

• Seven screws with captive lock washers

• Static strap

• Phillips® screwdriver (PH2)

• Hexalobular screwdriver

• Nut driver or wrench

• Flathead screwdriver

Phillips® is a registered trademark of Phillips Screw Company.

The Resolver Feedback option module can only be used with

PowerFlex DC drives with firmware version 5.002 or higher.

20P-IN071B-EN-P

Page 2

PowerFlex® DC Drive Resolver Feedback Option Module

What You Need to Do

Step 1: Remove Power

from the Drive

To install the resolver feedback option module:

❐ Step 1: Remove power from the drive

❐ Step 2: Open the drive

❐ Step 3: Install the resolver interface board

❐ Step 4: Install the resolver feedback board

❐ Step 5: Wire the resolver interface and feedback boards

❐ Step 6: Replace the protective covers and configure the resolver feedback

option module

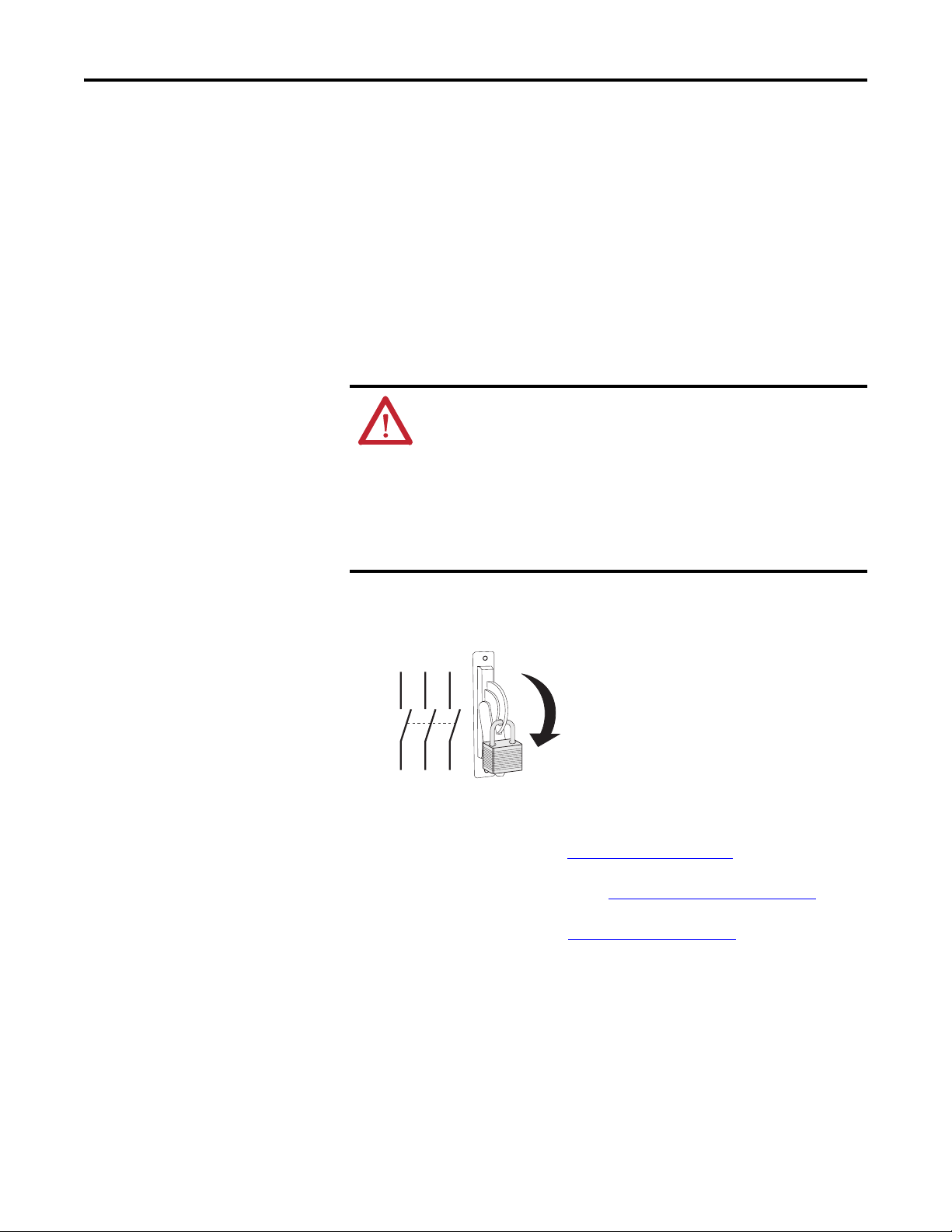

ATTENTION: Remove power before making or breaking cable

connections. When you remove or insert a cable connector with power

applied, an electrical arc may occur. An electrical arc can cause personal

injury or property damage by:

• sending an erroneous signal to your system’s field devices, causing

unintended machine motion

• causing an explosion in a hazardous environment

Electrical arcing causes excessive wear to contacts on both the module

and its mating connector. Worn contacts may create electrical resistance.

• Remove and lock-out all incoming power to the drive.

L1 L2 L3

I

O

Step 2: Open the Drive • To open frame A drives see Frame A Drives on page 3.

• To open frame B and C drives see Frame B and C Drives

• To open frame D drives see Frame D Drives

on page 4.

on page 4.

2 Rockwell Automation Publication 20P-IN071B-EN-P - June 2011

Page 3

PowerFlex® DC Drive Resolver Feedback Option Module

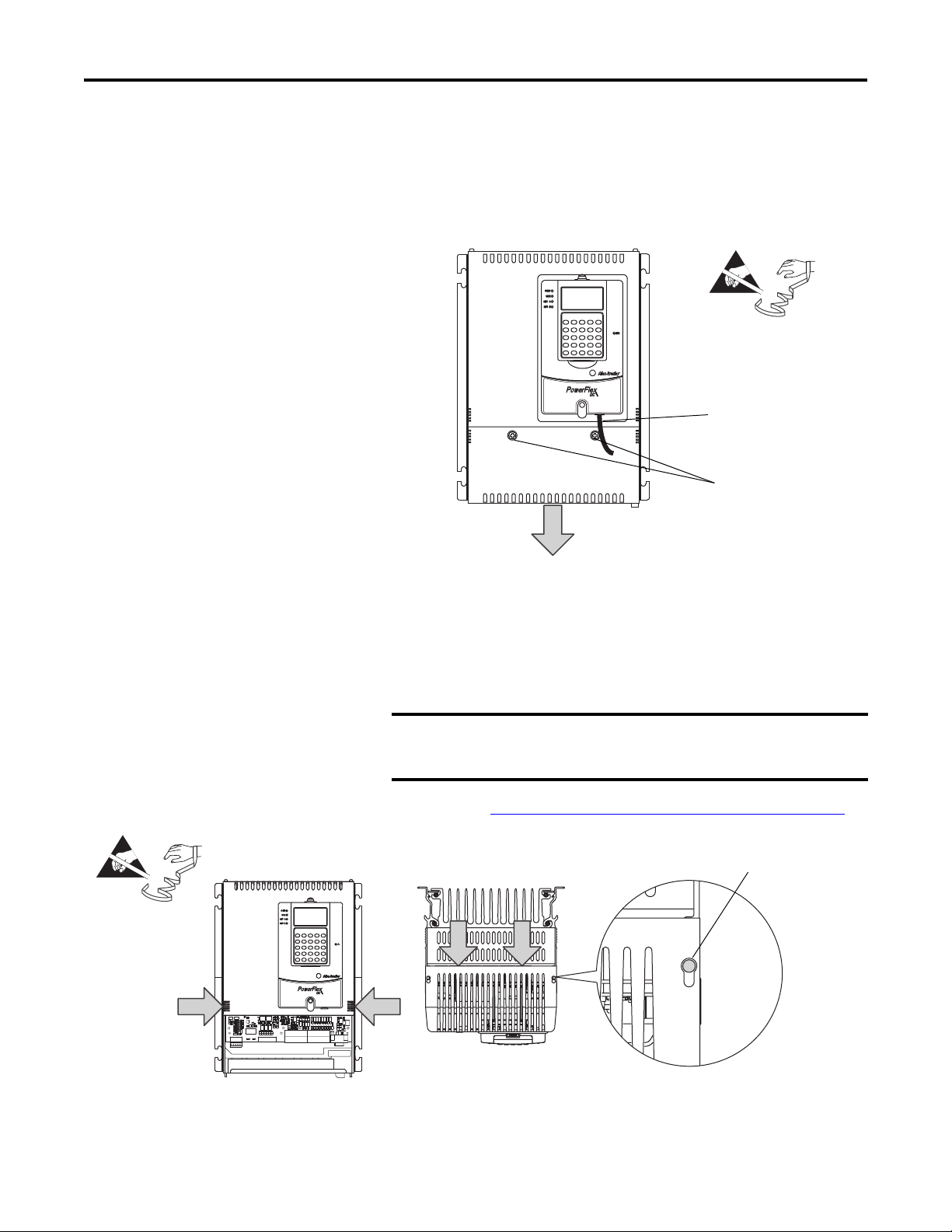

Frame A Drives

1. Disconnect the DPI cable from the HIM (if installed).

2. Loosen the captive screws that secure the bottom front cover to the drive,

then slide the cover down and off the drive chassis.

=

Disconnect DPI cable

Loosen screws

Tightening torque:

1.5 N•m (13.3 lb•in)

3. Press in on the sides at the bottom edge of the cover and at the same time

pull the cover toward you to pull it partially off the drive chassis. Next, at

the top of the drive, pull the cover forward, away from the drive, until the

pins fit in the keyhole in the top of the cover, then carefully lift the cover

off of the drive chassis.

IMPORTANT

Continue with Disconnect the HIM Communication Cable

=

The HIM assembly is connected via a cable to the control

board and therefore will not pull free from the drive until

disconnected.

on page 5.

When metal pin fits in keyhole, lift

cover off drive chassis.

Rockwell Automation Publication 20P-IN071B-EN-P - June 2011 3

Page 4

PowerFlex® DC Drive Resolver Feedback Option Module

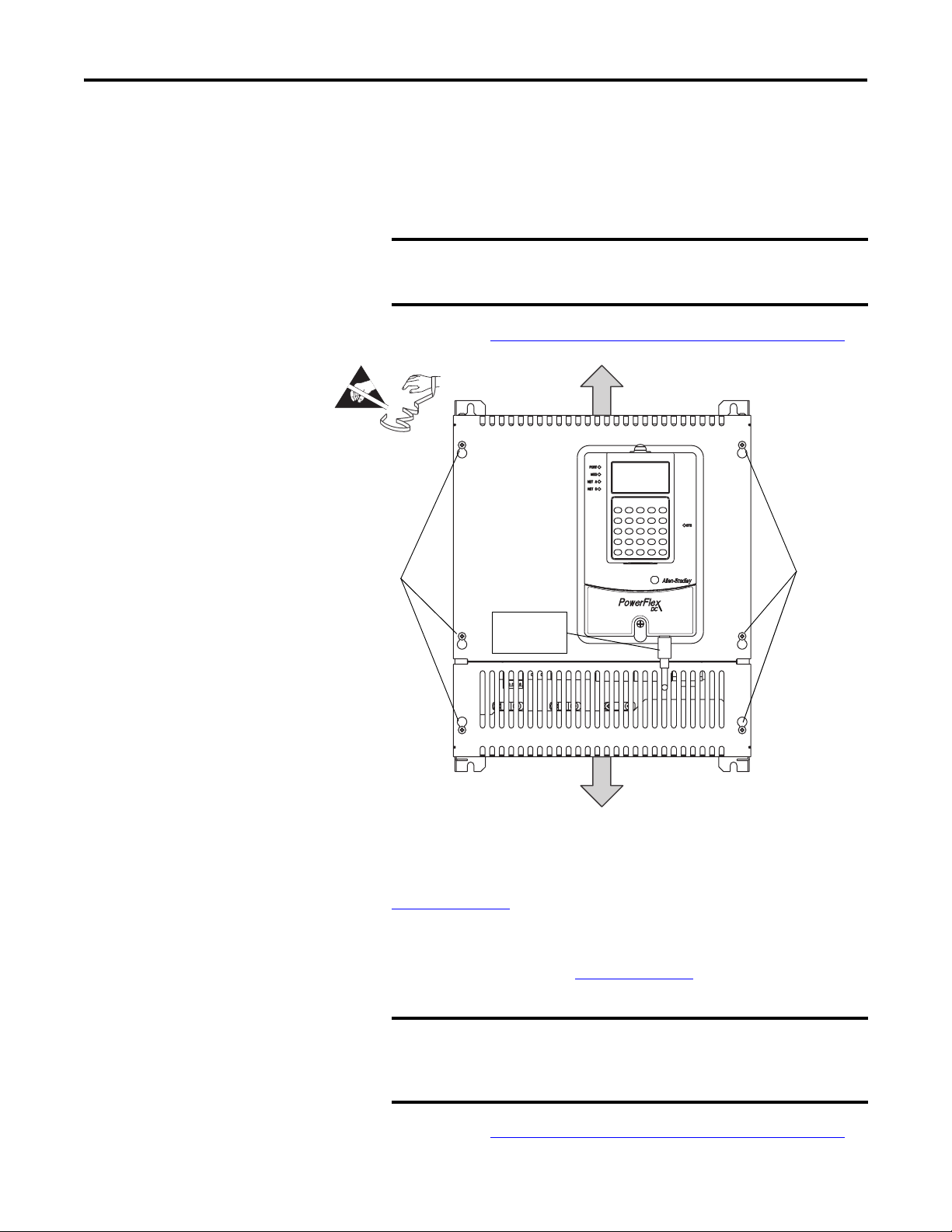

Frame B and C Drives

1. Disconnect the DPI cable from the HIM (if installed).

2. Loosen, but do not remove, the screws that secure the top and bottom

front cover to the drive, then slide the covers off the drive chassis.

IMPORTANT

Continue with Disconnect the HIM Communication Cable

=

Frame B shown

Loosen

screws

The HIM assembly is connected via a cable to the control

board and therefore will not pull free from the drive until

disconnected.

on page 5.

Tightening torque:

1.5 N•m (13.3 lb•in)

Loosen

screws

Disconnect DPI

cable

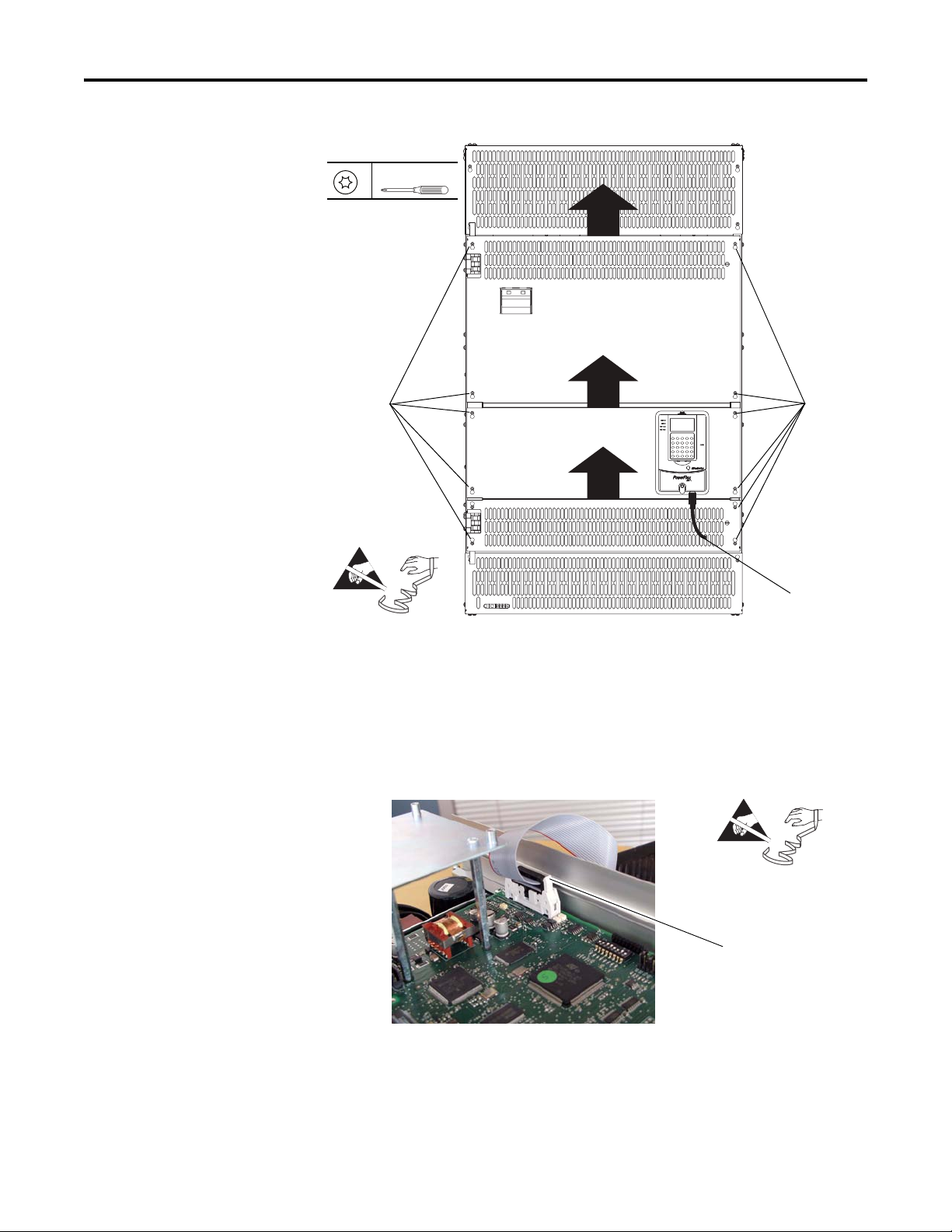

Frame D Drives

1. Disconnect the DPI cable from the HIM assembly (if installed) (see

Figure 1 on page 5

2. Loosen, but do not remove, the four hexalobular screws that secure each of

the three covers to the control pan on the drive, then slide the covers up

and off the drive chassis (see Figure 1 on page 5

noted in the illustration for reassembly.

IMPORTANT

Continue with Disconnect the HIM Communication Cable

4 Rockwell Automation Publication 20P-IN071B-EN-P - June 2011

).

A communication cable connects the HIM assembly to the

control board mounted on the control pan. Therefore, the

middle control pan cover and HIM assembly cannot be fully

removed from the drive until the cable is disconnected.

). Tightening torque is

on page 5.

Page 5

Figure 1 - Frame D Cover Removal

T15

Tightening torque:

1.5 N•m (13 lb•in)

PowerFlex® DC Drive Resolver Feedback Option Module

Loosen

screws

=

Disconnect the HIM Communication Cable

• Disconnect the HIM communication cable from the connector on the

upper right corner of the Control board and remove the bottom cover.

=

Loosen

screws

Disconnect

DPI cable

All Frames

(Frame A shown)

Pull tabs out to

disconnect cable.

Rockwell Automation Publication 20P-IN071B-EN-P - June 2011 5

Page 6

PowerFlex® DC Drive Resolver Feedback Option Module

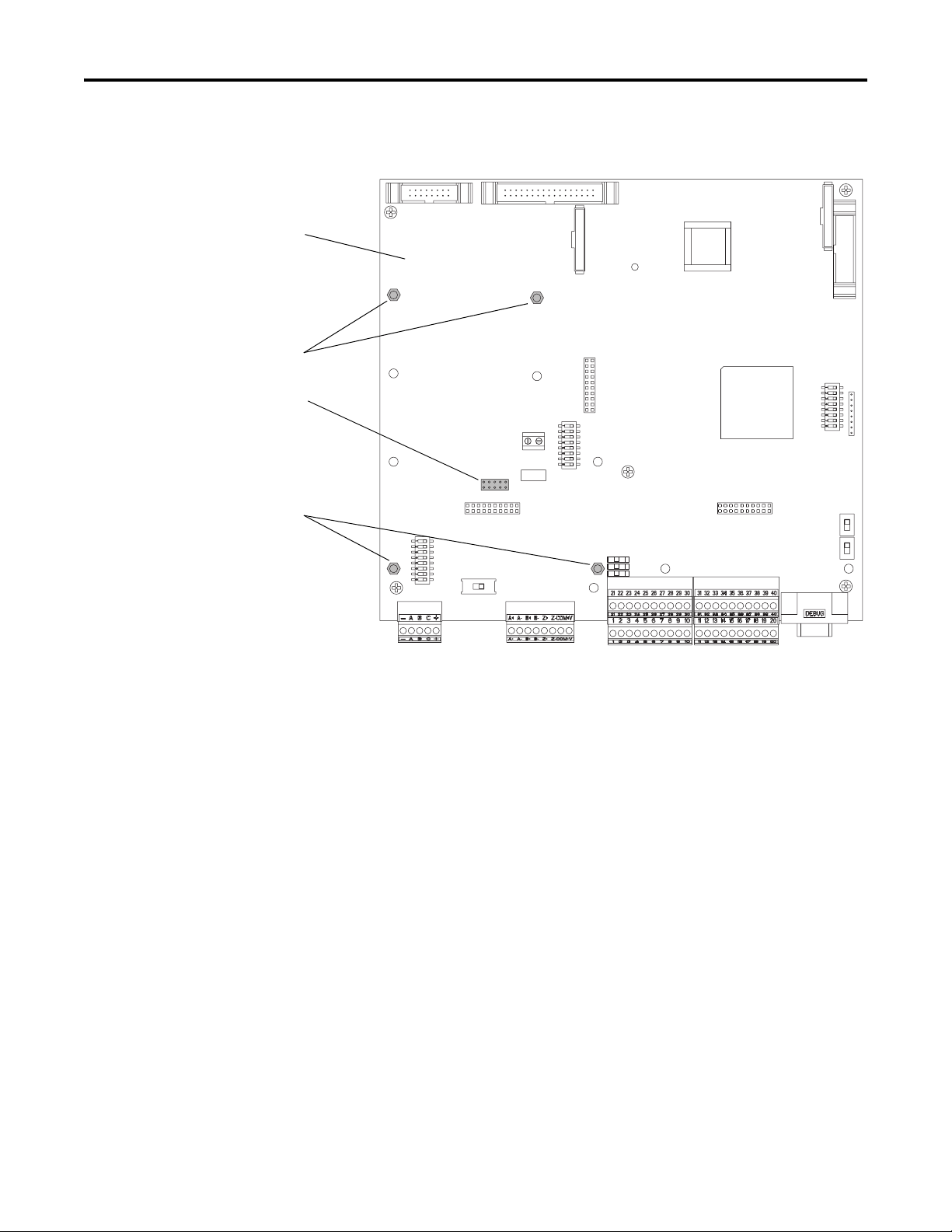

Step 3: Install the

Resolver Interface Board

Control board

Install stand-offs

and washers

Connector XRE

Install stand-offs

and washers

1. Secure the four 28 mm (1.1 in.) (longer) stand-offs and washers to the

control board. Tightening torque is 0.7 N•m (6.2 lb•in).

XR

XA

S15

XRE

XFCD

S4

S21

XP3

6 Rockwell Automation Publication 20P-IN071B-EN-P - June 2011

Page 7

PowerFlex® DC Drive Resolver Feedback Option Module

2. Carefully insert the stacker connector on the back of the resolver interface

board into connector XRE on the control board (identified in the previous

illustration).

IMPORTANT

Resolver

interface

board

Side view

The two pins of the stacker connector that are capped should

be to the right of connector XRE when installed on the control

board.

Control board

Resolver interface board

XRE connector

Stacker connector

XRE connector

Bottom view

Capped pins to

right

Control board

Rockwell Automation Publication 20P-IN071B-EN-P - June 2011 7

Page 8

PowerFlex® DC Drive Resolver Feedback Option Module

Resolver interface board

Install screws

Install screws

3. Secure the resolver interface board to the stand-offs using four screws with

captive washers. Tightening torque is 0.7 N•m (6.2 lb•in).

XR

XA

XP3

P2 P3

S15

XRE

S1

S2

TB1 TB2

8 Rockwell Automation Publication 20P-IN071B-EN-P - June 2011

Page 9

PowerFlex® DC Drive Resolver Feedback Option Module

Step 4: Install the

Resolver Feedback

Board

Connectors P2 and P3

Install stand-offs and

washers

1. Secure the three 14 mm (0.6 in.) (shorter) stand-offs and washers to the

resolver interface board. Tightening torque is 0.7 N•m (6.2 lb•in).

XR

XA

XP3

P2 P3

S15

XRE

XFCD

S1

S2

TB1 TB2

Rockwell Automation Publication 20P-IN071B-EN-P - June 2011 9

Page 10

PowerFlex® DC Drive Resolver Feedback Option Module

2. Carefully insert the long pins of the stacker connectors into connectors P2

and P3 on the back of the resolver feedback option board.

IMPORTANT

The end of the stacker connectors with the long

pins must

connect to the mating connectors (P2 and P3) on the resolver

feedback option board. The end of the stacker connectors with

the short

pins must connect to the mating connectors (P2 and

P3) on the resolver interface board.

3. Carefully insert the stacker connectors on the back of the resolver feedback

option board into connectors P2 and P3 (identified in the previous

illustration) on the resolver interface board.

Long

pins of stacker connector mate

with resolver feedback option board

P2 and P3

connectors

Resolver feedback

option board

pins of stacker connector mate

Short

with resolver interface board connectors

P2 and P3

connectors

Resolver interface board

Side view

10 Rockwell Automation Publication 20P-IN071B-EN-P - June 2011

Page 11

PowerFlex® DC Drive Resolver Feedback Option Module

4. Secure the resolver feedback board to the stand-offs using three screws

with captive washers. Tightening torque is 0.7 N•m (6.2 lb•in).

XR

XA

Resolver feedback board

Install screws

Step 5: Wire the

Resolver Interface and

Feedback Boards

P2 P3

P4

S2

P2 P3

XRE

TB1 TB2

P1

S1

S1

Wiring the Resolver Interface Board

Table 1 - Resolver Interface Board TB1 Wire Size and Tightening Torque

Wire Size and Type

2

) Multi-core (mm2)AWG

0.140…1.500 0.140…1.500 26…16 0.4 (3.5)

Tightening Torque N

XP3

S15

•m (lb•in)Flexible (mm

Terminal block TB1 on the resolver interface (bottom) board provides

connection points for an external 24V DC power supply input, resolver feedback

board voltage status output and resolver feedback board reset input. Tab le 2 on

page 12 details the connections.

The resolver feedback module can be powered via an internal or external

(customer-supplied) 24V supply. The voltage source is selected by switch S2 on

the resolver interface board. See Figure 3 on page 13

for the location of switch S2.

The customer-supplied, external 24V power supply is only needed when using

the resolver interface board with a PowerFlex DC frame A drive or Stand-Alone

Regulator under the following conditions.

• A resolver is wired to the resolver feedback board (terminal block P1)

• A digital encoder is wired to the control board

• The frame A drive has a fan(s)

Rockwell Automation Publication 20P-IN071B-EN-P - June 2011 11

Page 12

PowerFlex® DC Drive Resolver Feedback Option Module

Switch S2 on the resolver interface board must be set to the “Ext” position when

using an external 24V DC power supply for the resolver feedback option module.

Table 2 - Resolver Interface Board TB1 Terminal Descriptions

Figure 2 - Resolver Feedback Board Voltage Status Wiring Example

Terminal Signal Description

1 0V External power supply input common

1

2

3

4

5

6

2 +24V External +24V DC power supply input

3 OK- Resolver feedback board voltage status output common

4 OK+ +5…24V Resolver feedback board voltage status output

Vcc OK = voltage present and within +5…24V range

when connected to a digital input.

Vcc not OK = voltage not present or below +5V when

connected to a digital input. See Figure 2

wiring example.

5 R- Resolver feedback board reset input common

6 R+ +24V Resolver feedback board reset input

In this example digital input 2, on drive I/O TB2, is configured as an Enable input. When the signal

from terminals 3 and 4 on TB1 of the Resolver Interface board = “VCC not OK,” the drive is disabled.

Resolver Interface

Board TB1

1

2

3

4

5

6

Drive Control Board

I/O TB2

11

12

Digital Input 2

13

14

15

Digital Input Common

16

17

24V Supply Common

18

+24V DC Supply

19

20

below for

Terminal block TB2 on the resolver interface board is used to send the signals

from the primary digital encoder installed and wired to the encoder terminal

block on the control board to a second “follower” drive/regulator. When the

outputs on TB2 are used, switch S1 on the resolver interface board must be set to

match the encoder power supply voltage set for the primary encoder on the

follower drive’s control board (set via switch S21). See the PowerFlex Digital DC

Drive User Manual, publication 20P-UM001

digital encoder and using switch S21 on the control board.

The S1 switch settings correspond to each of the three LEDs on the left side of

the resolver interface board and indicate the selected supply voltage as follows:

• Green LED indicates a 5V supply when lit (on)

• Yellow LED indicates a 12V supply when lit (on)

• Blue LED indicates a 24V supply when lit (on)

See Figure 3 on page 13

for the location of switch S1 and corresponding LEDs on

the resolver interface board.

See “Cable and Wiring Recommendations” in the PowerFlex Digital DC Drive

User Manual, publication 20P-UM001

12 Rockwell Automation Publication 20P-IN071B-EN-P - June 2011

, for encoder wiring recommendations.

, for details on installing a primary

Page 13

PowerFlex® DC Drive Resolver Feedback Option Module

Table 3 - Resolver Interface Board TB2 Terminal Descriptions

Terminal Signal Description

1 A+ Encoder A

1

2

3

4

5

6

7

2 A- Encoder A (NOT)

3 B+ Encoder B

4 B- Encoder B (NOT)

5 Z+ Encoder Z

6 Z- Encoder Z (NOT)

7 Shield Connection point for encoder cable shield

Table 4 - TB2 Encoder Output Specifications

Max. Output Current 20 mA

Max. Output Low Voltage 0.5V @ 20 mA

Min. Output High Voltage Vcc - 2.6V @ 20 mA (where Vcc = 5V or 30V)

Figure 3 - Resolver Interface Board Switch and LED Locations

P2 P3

Encoder output voltage LEDs

(set with S1)

Green LED - 5V

Yellow LED - 12V

Blue LED - 24V

Internal (Int) supply position

External (Ext) supply position

Switch S2 shown in

the “Ext” position

S2

XRE

TB1 TB2

Switch S1 shown in

the +24V selection

position

+5V position

+12V position

+24V position

S1

Rockwell Automation Publication 20P-IN071B-EN-P - June 2011 13

Page 14

PowerFlex® DC Drive Resolver Feedback Option Module

Wiring the Resolver Feedback Board

Terminal block P1 on the resolver feedback option (top) board provides the

connection points for a single resolver. Ta b l e 5

Table 5 - Resolver Feedback Board P1 Terminal Descriptions

details the connections.

Terminal Signal Description

8 REF HIGH Positive Reference signal

7 SHIELD Connection point for resolver cable shield

6 REF LOW Negative Reference signal

5 SIN HIGH Positive Sine signal

4 SHIELD Connection point for resolver cable shield

3 SIN LOW Negative Sine signal

12345 6 78

2 COS HIGH Positive Cosine signal

1 COS LOW Negative Cosine signal

• P1 terminal block part number: 1639300000

• P1 terminal block material number: BL 3.50/08/90F SN BK BX

Recommended Resolver Cable

For the best results, Belden® 9730 (or equivalent) cable is recommended. For

retro-fit applications where Reliance Electric™ resolvers (800123-xxx), wiring

(417900-207CG) or Automax™ systems were used, existing wiring may be used

(assuming it is in good working condition).

Belden 9730 (or Equivalent) Cable Attributes

• 3 twisted pairs, 24 AWG, shielded, -20 to +80 °C, 300V

• Inductance = 0.23 μH/ft

• Capacitance = 12.5 pF/ft

• Resistance = 24 Ω/1000 ft

• See Ta b l e 6

Reliance Electric 417900-207CG Cable Attributes

• 3 Twisted Pairs, 18 AWG, unshielded, 80°C, 300V

• Chrome FPR Jacket, Plenum Rated

• Twists Per Inch: 2-3 twists per inch of wire lay per pair

• Inductance per 1000 Feet: 0.13 μH ±10% as read on a GEN_RAD Model

1658 RLC Digibridge or equivalent

• Capacitance Per Pair: not to exceed 30 pF/ft ±0.3 pF as read on a

GEN_RAD Model 1658 RLC Digibridge or equivalent

• Capacitance Difference Pair to Pair: not to exceed 0.6 pF/foot as read on a

GEN_RAD Model 1658 RLC Digibridge or equivalent

• Resistance per 1000 Feet: 17.15Ω ±10%

• Insulation Thickness: 0.008 in.

• Conductor Stranding 16/30

• Jacket Thickness: 0.018 in.

• See Ta b l e 6

for maximum cable lengths

for maximum cable lengths

14 Rockwell Automation Publication 20P-IN071B-EN-P - June 2011

Page 15

PowerFlex® DC Drive Resolver Feedback Option Module

Table 6 - Maximum Resolver Cable Length

Maximum Cable Length

Cable

Belden 9730 305 m (1000 ft) 183 m (600 ft)

417900-207CG 240 m (800 ft) 150 m (500 ft)

x1 and x2 Resolver Speed Ratio x5 Resolver Speed Ratio

Resolver Feedback Option Board Specifications

Consideration Description

Excitation Frequency 2381…9300 Hz

Excitation Voltage 8…26 Vrms

Resolver Feedback Voltage 2 Vrms +/- 300 mV

Compatible Resolvers

The table below specifies which resolvers are compatible with the PowerFlex DC

resolver feedback option module.

Manufacturer Manufacturer Model/Catalog Number

Advanced Micro Controls Inc. R11X-C10/7

Reliance Electric 800123-R

800123-1R

800123-2R

800123-S

800123-1S

800123-2S

800123-T

800123-1T

800123-2T (flange mounted)

Tamagawa TS-2014N181E32

TS-2014N182E32

TS-2014N185E32

TS-2087N1E9

TS-2087N2E9

TS-2087N5E9

TS-2087N11E9

TS-2087N12E9

Rockwell Automation Publication 20P-IN071B-EN-P - June 2011 15

Page 16

PowerFlex® DC Drive Resolver Feedback Option Module

Resolver Wiring Diagrams

REF HIGH 8

SHIELD 7

REF LOW 6

SIN HIGH 5

SHIELD 4

SIN LOW 3

COS HIGH 2

COS LOW 1

IMPORTANT

The shield connections must only be made at the drive end of the

cable (resolver end of cable shield is unattached) as shown in the

diagrams below. Grounding both ends of the shielded cable can result

in ground loops that could damage the resolver and/or drive.

Also, the resolver connections are considered signal level wiring and

MUST be run separate from control and power wiring (and at least 12

inches apart).

Figure 4 - Resolver Interface Connection Example for Clockwise Rotation - Count

Up

Terminal Block P1 Resolver

+

-

+

-

+

-

+

-

+

-

+

-

+

REF

SIN COS

-

+-

-

+

Reverse Polarity of Sine

or Cosine Signals

Terminal Block P1 Resolver

REF HIGH 8

SHIELD 7

REF LOW 6

SIN HIGH 5

SHIELD 4

SIN LOW 3

COS HIGH 2

COS LOW 1

REF HIGH 8

SHIELD 7

REF LOW 6

SIN HIGH 5

SHIELD 4

SIN LOW 3

COS HIGH 2

COS LOW 1

Figure 5 - Resolver Interface Connection Examples for Clockwise Rotation - Count

Down

+

-

-

+

+

-

+

-

+

-

-

+

+

-

+

-

+

-

+

-

+

-

+

-

+

+

SIN COS

-

SIN COS

-

REF

REF

+-

-

+

+-

-

+

16 Rockwell Automation Publication 20P-IN071B-EN-P - June 2011

Page 17

PowerFlex® DC Drive Resolver Feedback Option Module

Step 6: Replace the

Protective Covers and

Configure the Resolver

Feedback Option Module

1. Close the drive covers in the reverse order as described in Step 2: Open the

Drive on page 2.

2. Configure the resolver feedback option module. See the PowerFlex Digital

DC Drive User Manual, publication 20P-UM001

.

Rockwell Automation Publication 20P-IN071B-EN-P - June 2011 17

Page 18

U.S. Allen-Bradley Drives Technical Support - Tel: (1) 262.512.8176, Fax: (1) 262.512.2222, E-mail: support@drives.ra.rockwell.com, Online: www.ab.com/support/abdrives

www.rockwellautomation.com

Power, Control and Information Solutions Headquarters

Americas: Rockwell Automation, 1201 South Second Street,

/

Middle East/Africa: Rockwell Automati

Europe

Asia Pacific: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

on,

Milwaukee, WI 53204-2496 USA,

Pegasus Park, De Kleetlaan 12a,

Tel:

(1) 414.382.2000, Fax: (1) 414.382.4444

1831 Diegem, Belgium,

Tel: (32) 2 663 0600, Fax: (32) 2 663 0640

1S7A72

Publication 20P-IN071B-EN-P – June 2011

Copyright © 2011 Rockwell Automation, Inc. All rights reserved. Printed in USA.

Loading...

Loading...