Page 1

Installation Instructions

PowerFlex® 700L Frame 3A and 3B Input Filter

Precharge Resistor Kit (20L-RESPRE-A1)

ATTENTION: To avoid an electric shock hazard, ensure that all

power to the complete drive cabinet has been removed before

!

performing any steps of these instructions.

ATTENTION: To avoid an electric shock hazard, verify that the

voltage on the bus capacitors has completely discharged before

!

performing any work on the complete drive cabinet. After

removing power, wait 5 minutes for the power module bus

capacitors to discharge. Remove the lower front cover of the

power module. Measure the DC bus voltage at the DC+

TESTPOINT and DC- TESTPOINT sockets on the front of the

power module. The voltage must be zero.

ATTENTION: HOT surfaces can cause severe burns. Do not

touch the heatsink surface during operation of the power module.

!

After disconnecting power allow time for cooling.

Where This Kit Is Used

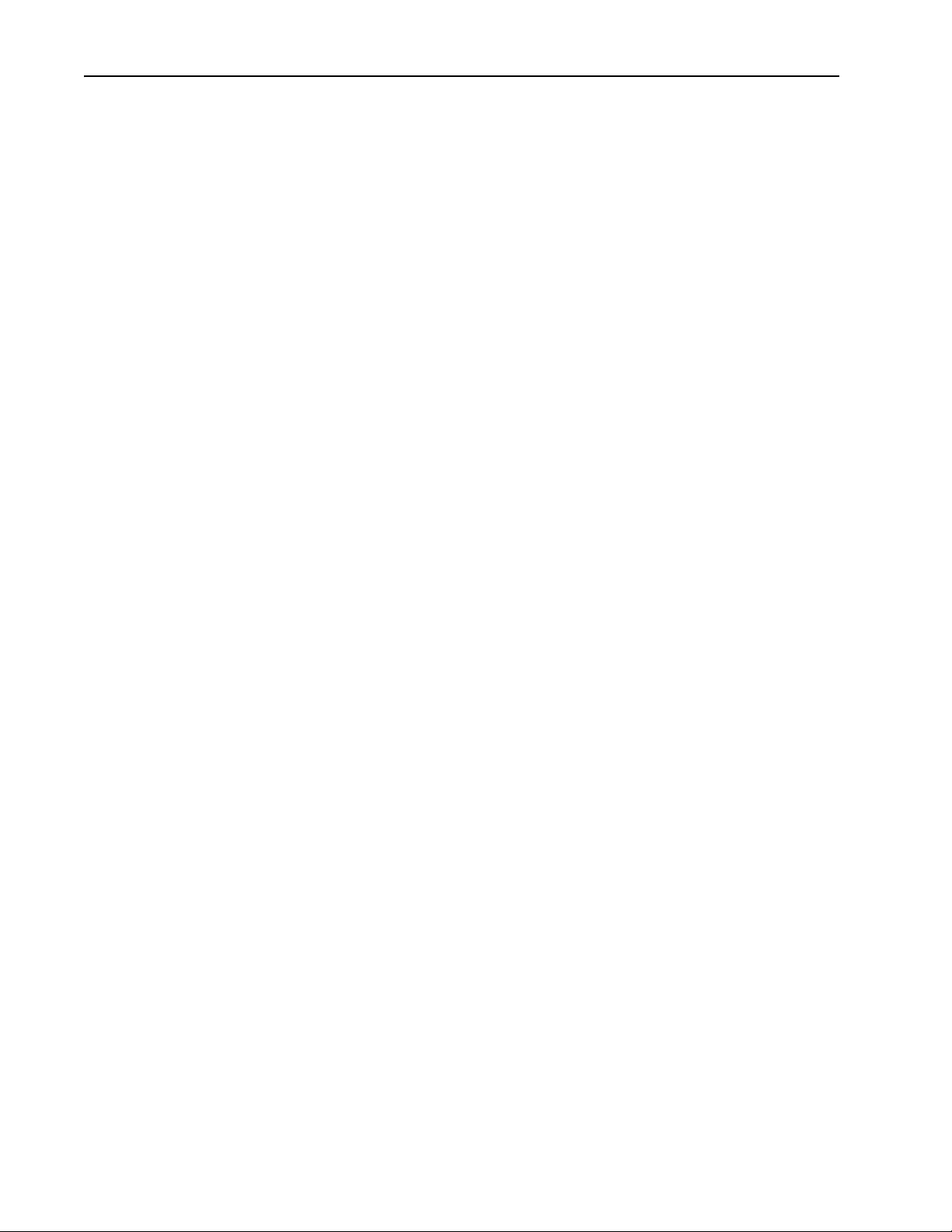

Table A Maximum DC Bus Capacitance with Existing Precharge

Input Voltage 400V AC 480V AC 600V AC 690V AC

Frame Size 3A 3B 3A 3B 3A 3B 3A 3B

Drive’s Internal DC Bus Capacitance (µF) 16,200 32,400 16,200 32,400 10,800 21,600 10,800 21,600

Maximum External DC Bus Capacitance (µF) 19,150 38,301 8,349 16,698 4,911 9,823 1,080 2,160

Maximum Total DC Bus Capacitance (µF) 35,350 70,701 24,549 49,098 15,711 31,423 11,880 23,760

Table B Maximum DC Bus Capacitance with Precharge Kit Plus Existing Precharge

Input Voltage 400V AC 480V AC 600V AC 690V AC

Frame Size 3A 3B 3A 3B 3A 3B 3A 3B

Drive’s Internal DC Bus Capacitance (µF) 16,200 32,400 16,200 32,400 10,800 21,600 10,800 21,600

Maximum External DC Bus Capacitance (µF) 89,851 109,002 57,447 65,796 36,334 41,245 24,840 25,920

Maximum Total DC Bus Capacitance (µF) 106,051 141,402 73,647 98,196 47,134 62,845 35,640 47,520

ATTENTION: The complete drive cabinet contains ESD

(Electrostatic Discharge) sensitive parts and assemblies. Static

!

control precautions are required when installing, testing,

servicing or repairing the complete drive. Component damage

may result if ESD control procedures are not followed. If you are

not familiar with static control procedures, refer to Allen-Bradley

publication 8000-4.5.2, “Guarding Against Electrostatic

Damage” or any other applicable ESD protection handbook.

This kit can only be used with PowerFlex 700L Frame 3A and 3B complete

drives. It is used to increase the precharge power capacity of the drive. This

kit may be required when powering another drive from the DC bus of a

Frame 3A or 3B complete drive. Only one kit per drive is permitted. See the

tables below for comparisons of maximum DC bus capacitance.

Page 2

2 PowerFlex® 700L Frame 3A and 3B Input Filter Precharge Resistor Kit (20L-RESPRE-A1)

Parameter 162 - [Capacitance] of the PowerFlex 700L Active Converter

must be set to the total DC bus capacitance of the PowerFlex 700L complete

drive plus the other drives connected to the DC bus.

What This Kit Includes

Tools That You Need

What You Need to Do

• Precharge Resistor Plate Assembly

• Four (4) M6 x 16 mm (0.63 in.) long hex head Taptite

Taptite is a registered trademark of REMINC (Research Engineering & Manufacturing Inc.)

Note: The customer must provide wire, lugs, and hardware.

• 10 mm socket

• Phillips

• Phillips

• Torque wrench

• Wire stripper

Phillips is a registered trademark of Phillips Screw Company.

To install the PowerFlex® 700L Frame 3A and 3B Precharge Resistor Kit:

❐ Step 1: Remove power from the complete drive.

❐ Step 2: Drill installation holes (only required for input filter panel

❐ Step 3: Mount the kit.

®

#1 screwdriver

®

#2 screwdriver

without holes).

®

screws

❐ Step 4: Wire the kit.

Page 3

PowerFlex® 700L Frame 3A and 3B Input Filter Precharge Resistor Kit (20L-RESPRE-A1) 3

Step 1: Removing Power from the Complete Drive

ATTENTION: To avoid an electric shock hazard, verify that the

voltage on the bus capacitors has completely discharged before

!

performing any work on the complete drive cabinet. After

removing power, wait 5 minutes for the power module bus

capacitors to discharge. Remove the lower front cover of the

power module. Measure the DC bus voltage at the DC+

TESTPOINT and DC- TESTPOINT sockets on the front of the

power module. The voltage must be zero.

Remove power before making or breaking cable connections.

When you remove or insert a cable connector with power

applied, an electrical arc may occur, which can cause personal

injury or property damage by:

• sending an erroneous signal to your system’s field devices,

causing unintended machine motion

• causing an explosion in a hazardous environment

Electrical arcing causes excessive wear to contacts on both the

module and its mating connector. Worn contacts may create

electrical resistance.

1. Turn off and lock out complete drive input power. Wait 5 minutes.

L1 L2 L3

2. Verify that there is no voltage at the complete drive’s input power

terminals.

3. Remove the lower front cover of the power module. Loosen the two (2)

captive screws and pull the cover off the power module. Set the cover

aside to be reinstalled later.

4. Measure the DC bus voltage at the DC+ TESTPOINT and DC-

TESTPOINT sockets on the front of the power module chassis. The

voltage must be zero.

I

O

Page 4

4 PowerFlex® 700L Frame 3A and 3B Input Filter Precharge Resistor Kit (20L-RESPRE-A1)

Step 2: Drilling Installation Holes (only required for input filter panel without pre-drilled holes)

ATTENTION: To avoid damaging critical electrical

components behind the input filter divider panel when drilling

!

holes, set the drill bit length to a maximum of 25.4 mm (1.0 in.).

If the input filter panel has no pre-drilled holes, drill four (4) mounting

holes at the dimensions shown in the drawings below in the right side panel

of the input filter. Use a #16 (4.5 mm/0.177 inch diameter) twist drill bit to

make the required diameter holes for the M6 x 16 mm (0.63 in.) long Taptite

hex head screws provided in the kit. Take care to prevent metal chips from

entering the enclosure.

Dimensions are in millimeters (inches).

Frame 3A

Right Side View

431.8 (17.00)

Frame 3B

Right Side View

142.9 (5.63)

247.6 (9.75)

166.2

(6.54)

40.0 (1.57)

142.9 (5.63)

232.3

(9.15)

431.8

(17.00)

Page 5

PowerFlex® 700L Frame 3A and 3B Input Filter Precharge Resistor Kit (20L-RESPRE-A1) 5

Step 3: Mounting the Kit

1. Orient the kit vertically (Frame 3A) or horizontally (Frame 3B) on the

right side panel of the input filter as shown in the drawings below.

Right Side View

Grommet for Routing Kit Wiring

Frame 3A Precharge Resistor Kit (shown installed)

Right Side View

Grommet for Routing Kit Wiring

Frame 3B Precharge Resistor Kit (shown installed)

Page 6

6 PowerFlex® 700L Frame 3A and 3B Input Filter Precharge Resistor Kit (20L-RESPRE-A1)

2. Mount the kit using the four (4) new M6 x 16 mm (0.63 in.) long

Screw, Phillips Slot Head

M5, 3 Places

Screw, Phillips Slot Head

#6, 3 Places

Taptite

shown in the drawing below.

®

Phillips #2

3.9 N-m

(35 lb.-in.)

Phillips #1

1.0 N-m

(9 lb.-in.)

hex head screws from the kit. Tighten the screws to the torque

Frame 3A

Screw, Taptite Hex Head

M6 x 16 mm Long

4 Places

10 mm

5.4 N-m

(48 lb.-in.)

Frame 3B

Screw, Phillips Slot Head

M5, 3 Places

Phillips #2

3.9 N-m

(35 lb.-in.)

Screw, Taptite Hex Head

M6 x 16 mm Long

4 Places

10 mm

5.4 N-m

(48 lb.-in.)

Screw, Phillips Slot Head

#6, 3 Places

Phillips #1

1.0 N-m

(9 lb.-in.)

Page 7

PowerFlex® 700L Frame 3A and 3B Input Filter Precharge Resistor Kit (20L-RESPRE-A1) 7

Step 4: Wiring the Kit

Connect the kit’s resistors in parallel with the existing precharge resistors in

the input filter. Wire the kit as follows:

From Kit To Input Filter

TB5-1 K1A-L2

TB5-2 K1B-L2

TB5-4 K1C-L2

FU13 K1A-T2

FU14 K1B-T2

FU15 K1C-T2

On the kit side, tighten the screws to the torque shown in the drawings of

Step 3. Use tie-wraps to bundle the wiring. Route the wiring through the

grommet hole shown in the drawing on page 5. On the input filter side, use

the existing M8 hex head screws on the contactors as shown in the drawings

below and ring lugs (not provided) for wiring connections. Tighten the

screws on the contactors to 14.9 N-m (132 lb.-in.).

L1 L2 L3

To Kit TB5-1 To Kit TB5-2

L1 L2 L3

L1 L2 L3

To Kit TB5-4

Frame 3A

Frame 3B

K1A K1B K1C

T1 T2

T3

To Kit FU13

L1 L2 L3

K1A

T1 T2

T1 T2 T3

To Kit FU14

To Kit TB5-1 To Kit TB5-2 To Kit TB5-4

L1 L2 L3

K1B

T3

T1 T2

T3

L1 L2 L3

T1 T2

T1 T2 T3

To Kit FU15

K1C

T3

To Kit FU13 To Kit FU14 To Kit FU15

Page 8

A

A

U.S. Allen-Bradley Drives Technical Support - Tel: (1) 262.512.8176, Fax: (1) 262.512.2222, Email: support@drives.ra.rockwell.com, Online: www.ab.com/support/abdrives

www.rockwellautomation.com

Power, Control and Information Solutions Headquarters

mericas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414.382.2000, Fax: (1) 414.382.4444

Europe/Middle East/Africa: Rockwell Automation, Vorstlaan/Boulevard du Souverain 36, 1170 Brussels, Belgium, Tel: (32) 2 663 0600, Fax: (32) 2 663 0640

sia Pacific: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

Publication 20L-IN010A-EN-P – September, 2007 P/N 367549-P01

Copyright © 2007 Rockwell Automation, Inc. All rights reserved. Printed in USA.

Loading...

Loading...