Page 1

User Manual

Kinetix 6200 and Kinetix 6500 Modular

Multi-axis Servo Drives

Catalog Numbers

2094-BCxx-Mxx-M, 2094-BMxx-M

2094-SE02F-M00-Sx, 2094-EN02D-M01-Sx,

2094-BSP2, 2094-PRF, 2094-SEPM-B24-S

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation® sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

) describes some

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, CompactLogix, ControlFLASH, ControlLogix, Guardmaster, HPK-Series, Integrated Architecture, Kinetix, LDC-Series, LDL-Series, MP-Series, PanelView, POINT I/O, PowerFlex, RSLinx, RSLogix,

SoftLogix, RDD -Series, Rockwell Automation, Rockwell Software, Stratix, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

This manual contains new and updated information.

Summary of Changes

New and Updated Information

Much information regarding the Kinetix® 6000M integrated drive-motor (IDM)

system has been added to this manual, however, the focus in this manual is on

how the IDM system affects the overall operation of the Kinetix 6200 drive

system.

For mounting, wiring, configuring, and troubleshooting information specific to

the Kinetix 6000M integrated drive-motor systems, refer to the Kinetix 6000M

Integrated Drive-Motor System User Manual, publication 2094-UM003

.

This revision also includes the following new and updated information:

• Bulletin 2090-K6CK-D44S0 connector kit and 2090-CS0DSDS-AAxx

cable for cascading safe torque-off signals

• Motor connector and cable changes for the Bulletin MPL-A/B15xxx and

MPL-A/B2xxx low-inertia motors and MPAR-A/B1xxx and

MPAR-A/B2xxx electric cylinders with SpeedTec DIN (M7) connectors

• MPAI-A/B2xxxx (frame 64 and 144) heavy-duty electric cylinders

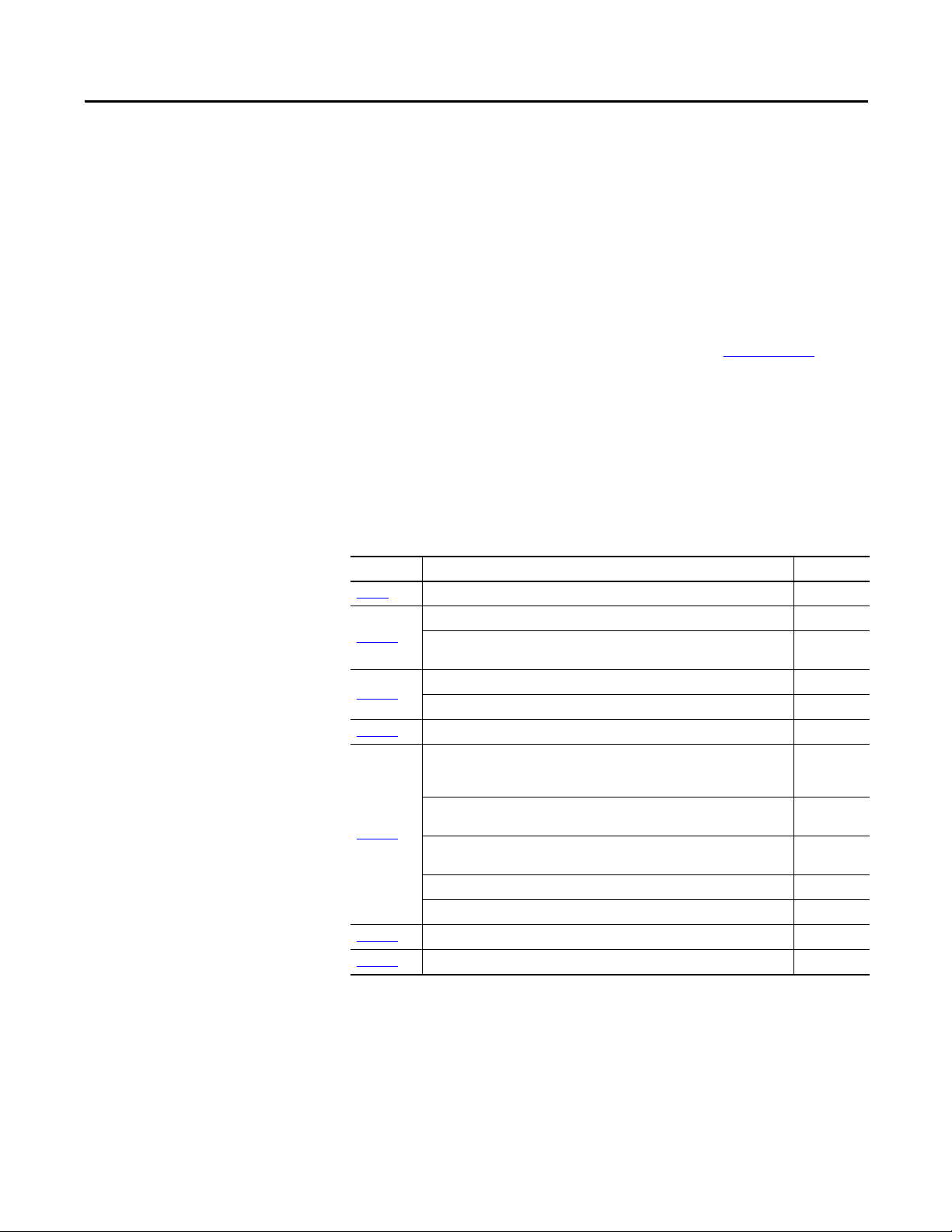

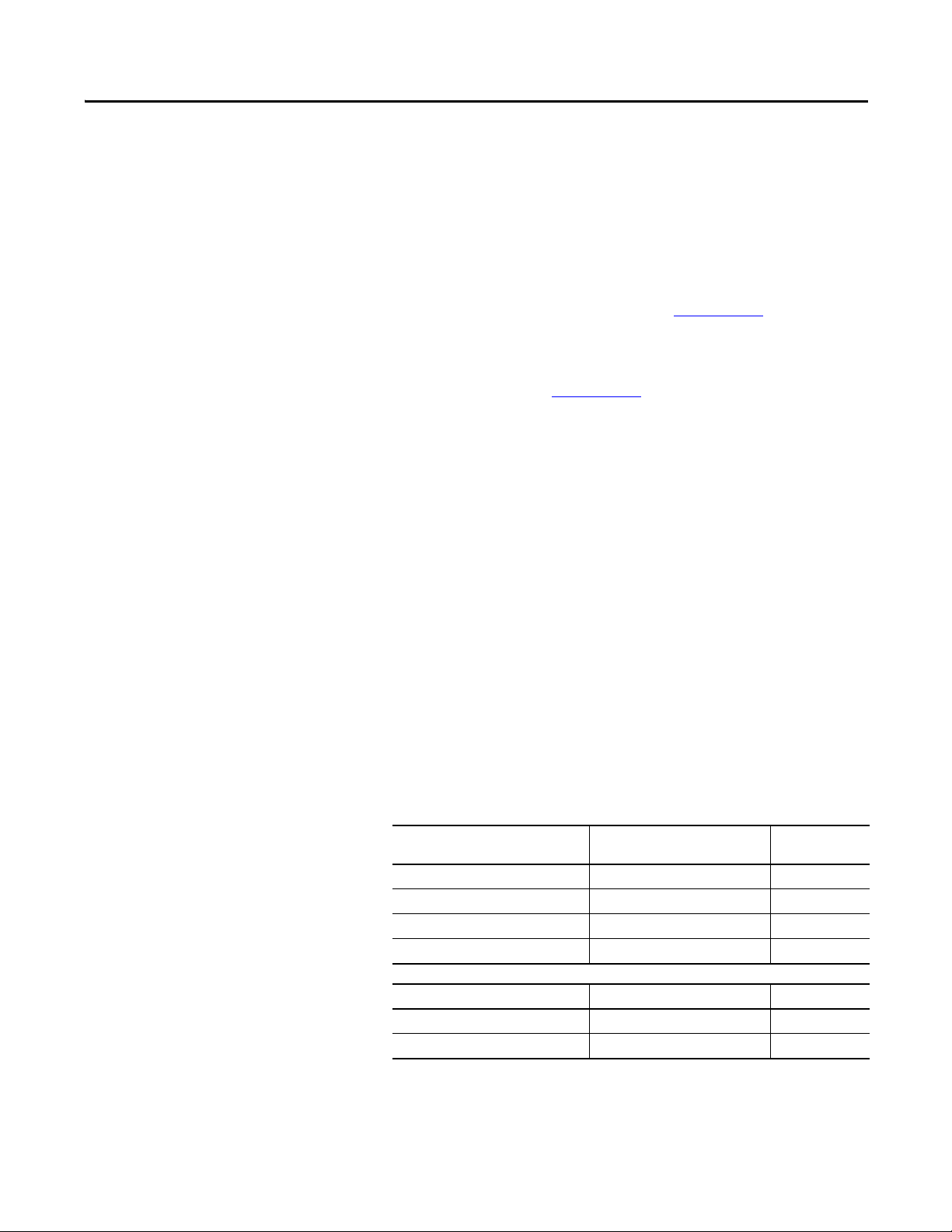

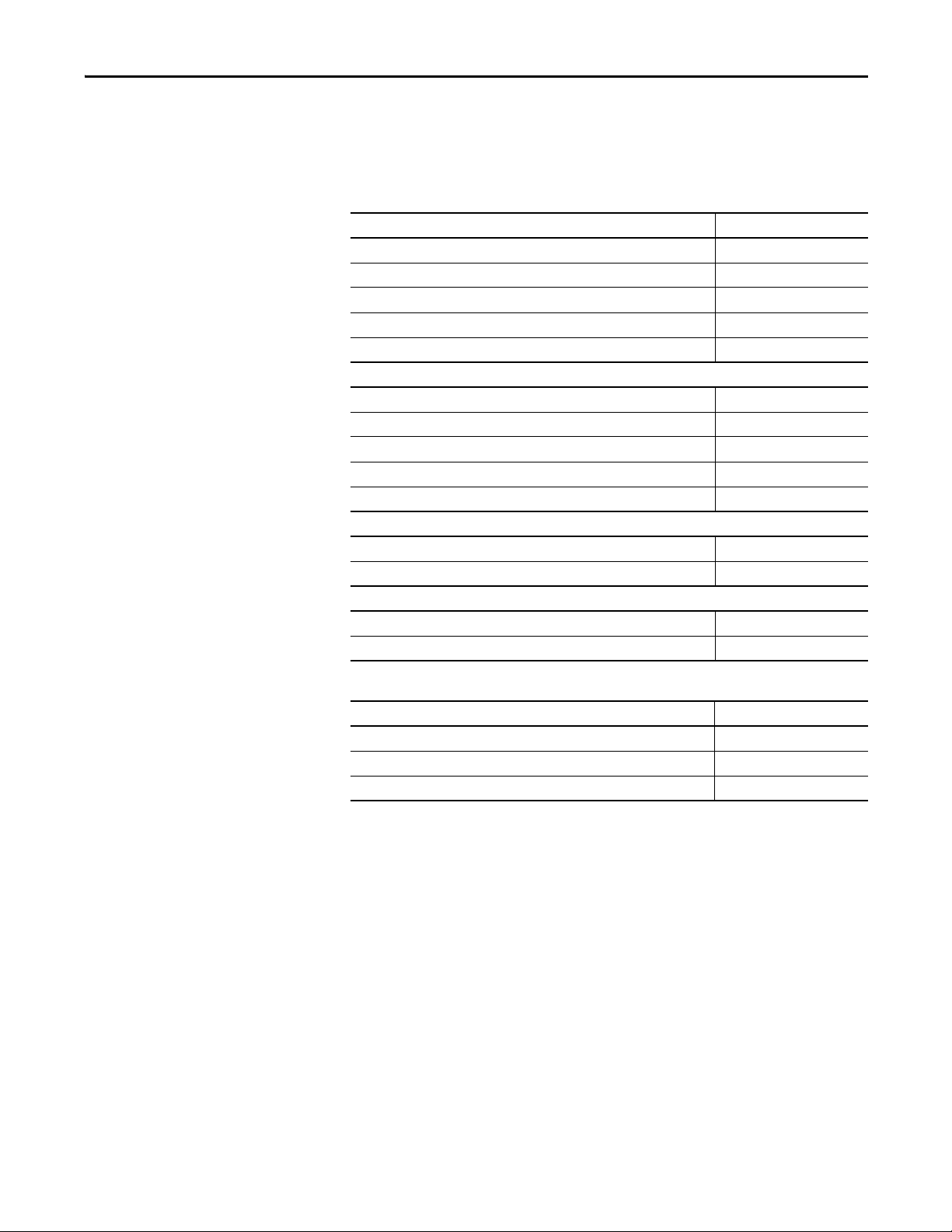

Section Topic Page

Preface Added acronyms for the Kinetix 6000M integrated drive-motor (IDM) system. 11

Added the IPIM module to About the Kinetix 6200 and Kinetix 6500 Drive Systems. 14

Chapter 1

Chapter 2

Chapter 3

Chapter 5

Chapter 6

Chapter 8

Added the Kinetix 6000M integrated drive-motor (ID M) to typical system installatio n

diagrams and catalog number explanation.

Added the IPIM module to Minimum Clearance Requirements. 35

Added the IPIM module to Es tablishing Noise Zones. 45

Added the IPIM module to Determine Mounting Order. 56

Revised motor power, brake, and feedback cable compatibility tables to include the

MPL-A/B15xxx-xx7xAA and MPL-A/B2xxx-xx7xAA low-inertia motors and

MPAR-A/B1xxx and MPAR-A/B2xxx electric cylinders with SpeedTec (M7) connectors.

Added 2090-K6CK-D44S0 with 2090-CS0DSDS-AAxx cable for cascading safe torqueoff signals from drive-to-drive.

Added IPIM Module Connections with summary of installation connections and links

to other diagrams and publications with additional information.

Added Kinetix 6000M Integrated Drive-Motor Sercos Connections 134

Added Ethernet Cable Connections 135

Updated the introduction with an overview of IDM system configuration. 139

Updated the introduction with an overview of the IDM system troubleshooting 196

14…18

111, power

116, brake

119, feedback

119…127

129

Rockwell Automation Publication 2094-UM002E-EN-P - May 2012 3

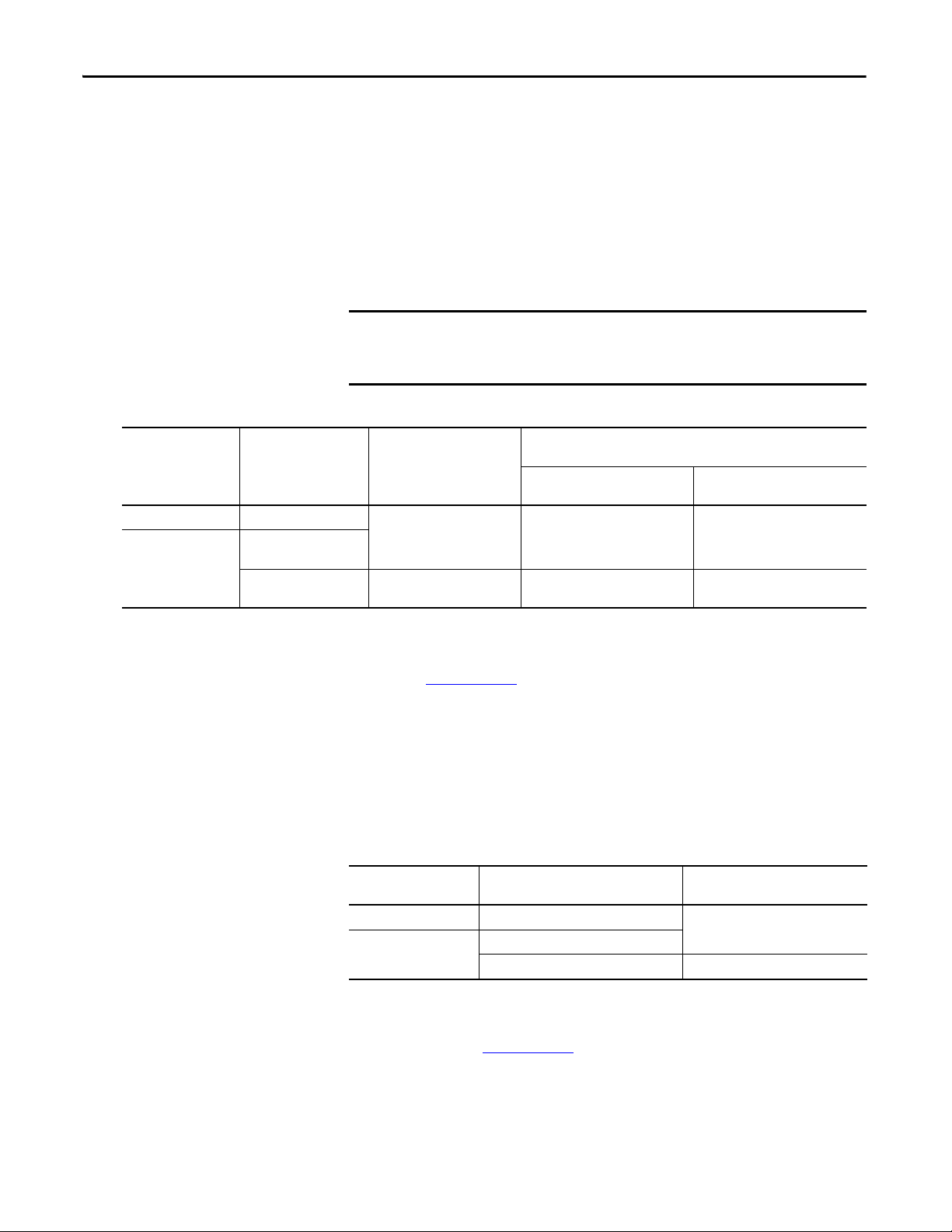

Page 4

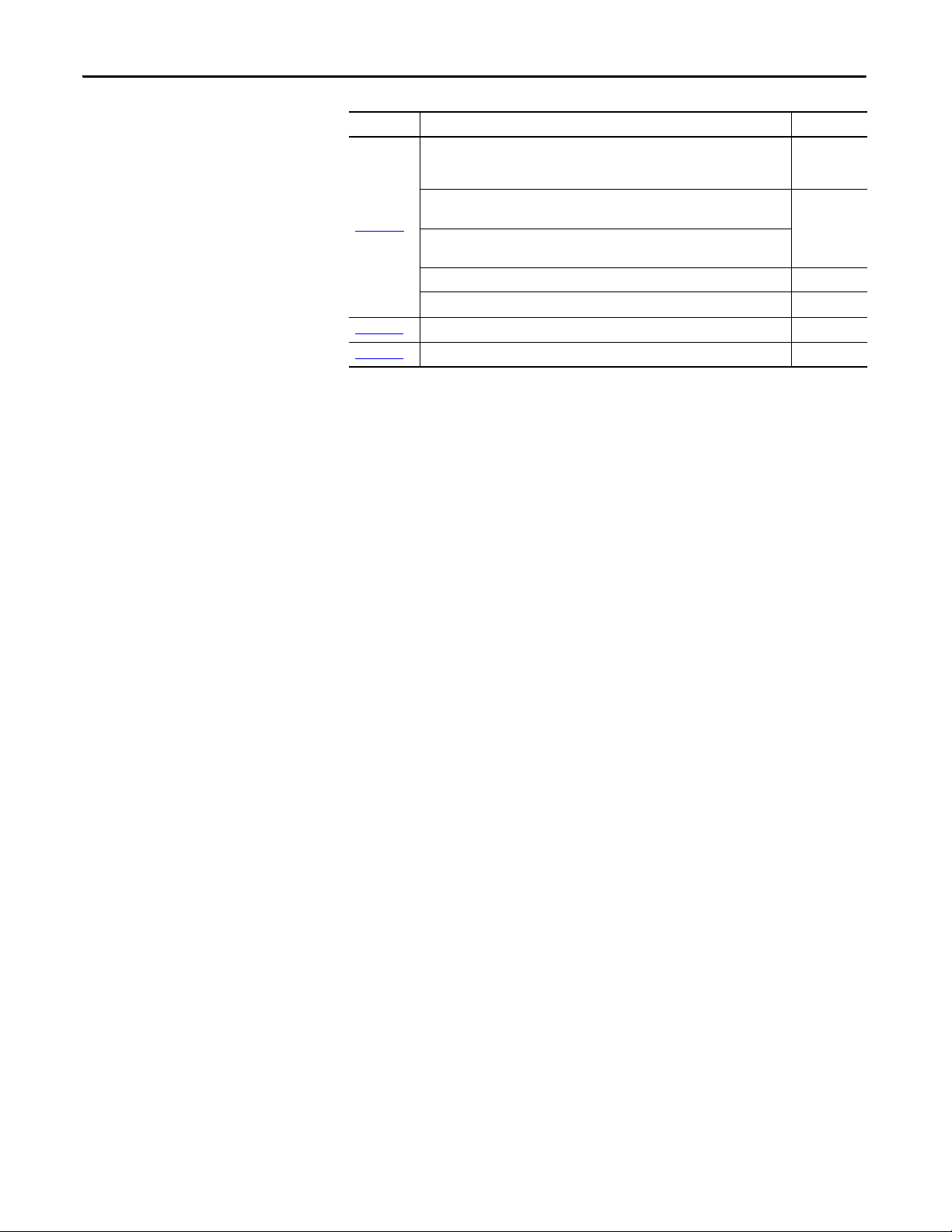

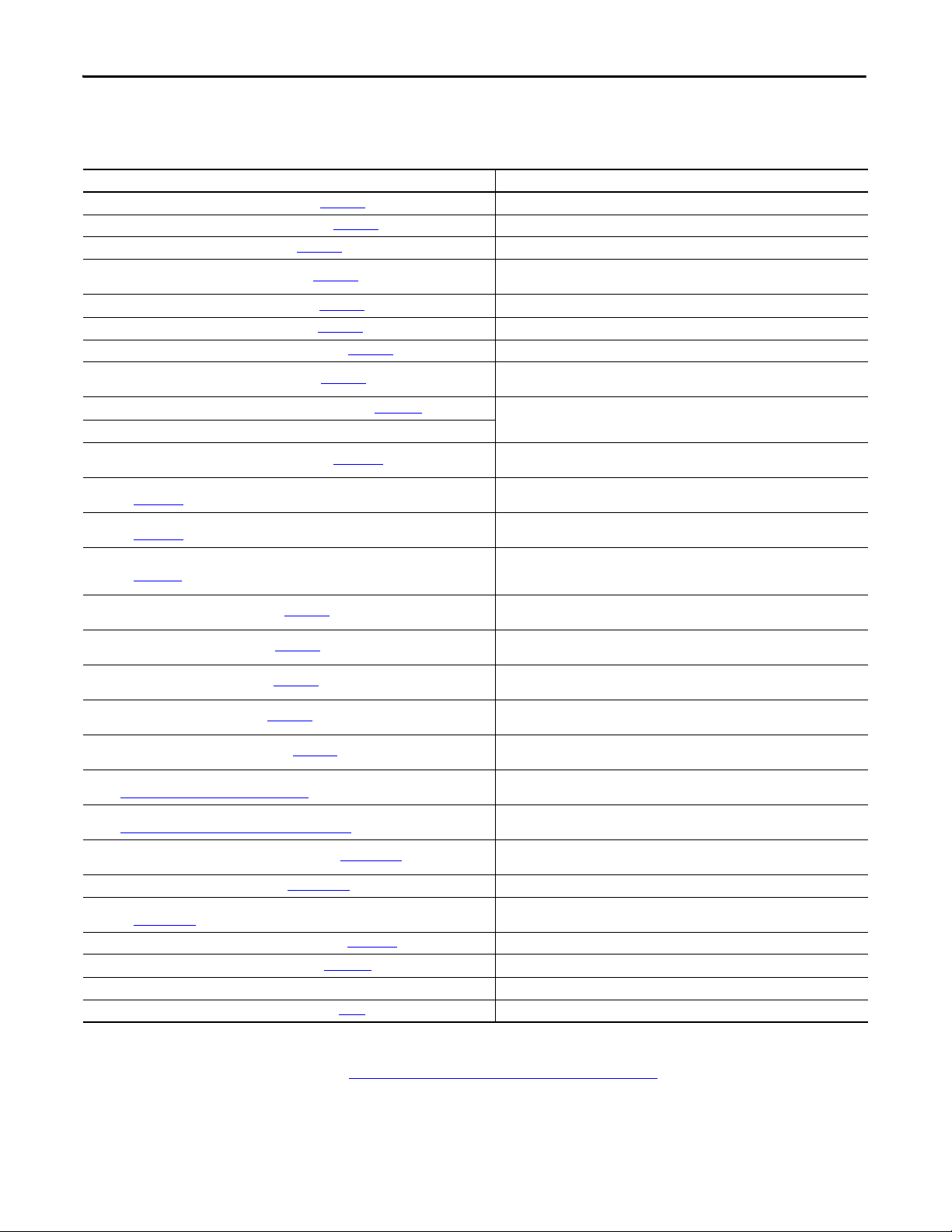

Summary of Changes

Section Topic Page

Updated existing circular DIN (SpeedTec) interconnect diagram with Bulletin

Appendix A

Appendix B

Appendix C

MPL-A/B15xxx-xx7xAA and MPL-A/B2xxx-xx7xAA low-inertia motors with SpeedTec

(M7) connectors.

Updated the MP-Series™ (Bulletin MPAI) electric cylinders interconnect diagram

with frame 64 and 144 cable catalog numbers.

Updated the MP-Series (Bulletin MPAR) electric cylinders interconnect diagram with

cable catalog number changes for SpeedTec (M7) connector

Added Kinetix 6000M Integrated Drive-Motor Wiring Example. 251

Added Bulletin MDF catalog numbers to Controlling a Brake Example 252

Added an overview for IDM system firmware upgrades. 257

Updated the procedure and tables with IPIM module values. 267

244

248

4 Rockwell Automation Publication 2094-UM002E-EN-P - May 2012

Page 5

Start

Table of Contents

Preface

About This Publication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Conventions Used in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 1

About the Kinetix 6200 and Kinetix 6500 Drive Systems. . . . . . . . . . . . 14

Typical Hardware Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Typical Communication Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Kinetix Drive Component Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Kinetix 6000M Integrated Drive-Motor System Compatibility . . . . . . 24

Agency Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

CE Requirements (system without LIM module) . . . . . . . . . . . . . . . 25

CE Requirements (system with LIM module). . . . . . . . . . . . . . . . . . . 25

Planning the Kinetix 6200 and

Kinetix 6500 Drive System

Installation

Mounting the Kinetix 6200 and

Kinetix 6500 Drive System

Chapter 2

System Design Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

System Mounting Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Transformer Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Circuit Breaker/Fuse Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Enclosure Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Minimum Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Electrical Noise Reduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Bonding Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Bonding Multiple Subpanels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Establishing Noise Zones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Cable Categories for Kinetix 6200 and Kinetix 6500 Systems . . . . 47

Noise Reduction Guidelines for Drive Accessories. . . . . . . . . . . . . . . 50

Chapter 3

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Using the 2094 Mounting Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Installing the 2094 Power Rail. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Determine Mounting Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Mount Modules on the Power Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Mount the Control Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Kinetix 6200 and Kinetix 6500

Connector Data

Chapter 4

2094 Power Module and Control Module Features . . . . . . . . . . . . . . . . . 64

I/O, Safety, and Auxiliary Feedback Connector Pinout . . . . . . . . . . 67

Motor Feedback Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Ethernet Communication Connector Pinout . . . . . . . . . . . . . . . . . . . 69

Rockwell Automation Publication 2094-UM002E-EN-P - May 2012 5

Page 6

Table of Contents

IAM Input Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

IAM and AM Motor Power and Brake Connector Pinout. . . . . . . . 70

Control Signal Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Ethernet Communication Specifications . . . . . . . . . . . . . . . . . . . . . . . 73

Sercos Communication Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Contactor Enable Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Power and Relay Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Motor/Resistive Brake Relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Input Power Cycle Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Peak Current Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Control Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Feedback Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Absolute Position Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Motor Feedback Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Auxiliary Position Feedback Specifications. . . . . . . . . . . . . . . . . . . . . . 88

Safe Speed Monitoring Safety Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Safe Torque-off Safety Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Connecting the Kinetix 6200 and

Kinetix 6500 Drive System

Chapter 5

Basic Wiring Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Building Your Own Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Routing the Power and Signal Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Determine the Input Power Configuration . . . . . . . . . . . . . . . . . . . . . . . . . 93

Grounded Power Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Ungrounded Power Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

DC Common Bus Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Common Bus Fusing Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Setting the Ground Jumper in Ungrounded Power Configurations . . . 97

Set the Ground Jumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Grounding the Modular Drive System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Ground the Power Rail to the System Subpanel . . . . . . . . . . . . . . . . 100

Ground Multiple Subpanels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Power Wiring Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Power Wiring Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Wiring the IAM/AM Module Connectors . . . . . . . . . . . . . . . . . . . . . . . . 105

Wire the Control Power (CPD) Connector . . . . . . . . . . . . . . . . . . . 105

Wire the Input Power (IPD) Connector. . . . . . . . . . . . . . . . . . . . . . . 106

Wire the Contactor Enable (CED) Connector. . . . . . . . . . . . . . . . . 108

Wire the Motor Power (MP) Connector . . . . . . . . . . . . . . . . . . . . . . 109

Wire the Motor/Resistive Brake (BC) Connector . . . . . . . . . . . . . . 115

Apply the Motor Cable Shield Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Feedback and I/O Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Flying-lead Feedback Cable Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Wiring the Feedback and I/O Connectors. . . . . . . . . . . . . . . . . . . . . . . . . 123

Connect Premolded Motor Feedback Cables. . . . . . . . . . . . . . . . . . . 123

Connect Panel-mounted Breakout Board Kits . . . . . . . . . . . . . . . . . 124

6 Rockwell Automation Publication 2094-UM002E-EN-P - May 2012

Page 7

Configure and Start the

Kinetix 6200 Drive System

Table of Contents

Wire Low-profile Connector Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

External Shunt Module Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

IPIM Module Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

RBM Module Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Sercos Fiber-optic Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Kinetix 6000M Integrated Drive-Motor Sercos Connections . . . . . . . 134

Ethernet Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Chapter 6

Configure the Kinetix 6000M Integrated Drive-Motor System . . . . . 139

Configure the Drive Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Configure the Logix Sercos interface Module . . . . . . . . . . . . . . . . . . . . . . 146

Configure the Logix Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Configure the Logix Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Configure the Kinetix 6200 Drive Modules. . . . . . . . . . . . . . . . . . . . 150

Configure the Motion Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Configure Axis Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Download the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Apply Power to the Kinetix 6200 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Test and Tune the Axes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Test the Axes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Tune the Axes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Configure and Start the

Kinetix 6500 Drive System

Troubleshooting the Kinetix 6200

and Kinetix 6500 Drive System

Chapter 7

Configure the Drive Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Configure the Logix EtherNet/IP Module . . . . . . . . . . . . . . . . . . . . . . . . 171

Configure the Logix Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Configure the Logix Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Configure the Kinetix 6500 Drive Modules. . . . . . . . . . . . . . . . . . . . 175

Configure the Motion Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Configure Axis Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Download the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Apply Power to the Kinetix 6500 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Test and Tune the Axes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Test the Axes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Tune the Axes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Chapter 8

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Interpret Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Kinetix 6000M IDM System Error Codes . . . . . . . . . . . . . . . . . . . . . 196

Four-character Display Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Control Module Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Shunt Module Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

General System Anomalies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Rockwell Automation Publication 2094-UM002E-EN-P - May 2012 7

Page 8

Table of Contents

Removing and Replacing the

Kinetix 6200 and Kinetix 6500 Drive

Modules

Interconnect Diagrams

Logix Controller and Drive Behavior. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Kinetix 6500 Drive Exception Behavior . . . . . . . . . . . . . . . . . . . . . . . 214

Kinetix 6200 Drive Fault Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Drive Exception/Fault Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Chapter 9

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Remove Kinetix 6200 and Kinetix 6500 Drive Modules . . . . . . . . . . . . 224

Remove the Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Remove the Drive Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Replace Kinetix 6200 and Kinetix 6500 Drive Modules. . . . . . . . . . . . . 227

Replace the Drive Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Replace the Control Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Remove the Power Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Replace the Power Rail. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Appendix A

Interconnect Diagram Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Power Wiring Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

DC Common Bus Wiring Examples . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Shunt Module Wiring Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Axis Module/Rotary Motor Wiring Examples. . . . . . . . . . . . . . . . . . 242

Axis Module/Linear Motor/Actuator Wiring Examples . . . . . . . . 247

Kinetix 6000M Integrated Drive-Motor Wiring Example . . . . . . . 251

Controlling a Brake Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

System Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Appendix B

Upgrading the Drive Firmware

Upgrade Kinetix 6000M System Firmware . . . . . . . . . . . . . . . . . . . . . . . . 257

Upgrade Drive Firmware with ControlFLASH Software . . . . . . . . . . . 258

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Configure Logix Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Upgrade Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Verify the Firmware Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Appendix C

DC Common Bus Applications

8 Rockwell Automation Publication 2094-UM002E-EN-P - May 2012

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Calculate Total Bus Capacitance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Calculate Additional Bus Capacitance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Bulletin 2094 Drive Capacitance Values. . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Common Bus Capacitance Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Page 9

Appendix D

Table of Contents

Changing the Default IDN Parameter

Values

RBM Module Interconnect Diagrams

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Change IDN Parameter Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Read the Present IDN Parameter Value . . . . . . . . . . . . . . . . . . . . . . . 272

Calculate/Select the New IDN Value . . . . . . . . . . . . . . . . . . . . . . . . . 274

Write the New IDN Parameter Value . . . . . . . . . . . . . . . . . . . . . . . . . 275

Appendix E

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

RBM Module Wiring Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Index

Rockwell Automation Publication 2094-UM002E-EN-P - May 2012 9

Page 10

Table of Contents

Notes:

10 Rockwell Automation Publication 2094-UM002E-EN-P - May 2012

Page 11

Preface

About This Publication

Who Should Use This Manual

This manual provides detailed installation instructions for mounting, wiring, and

troubleshooting Kinetix 6200 and Kinetix 6500 (Bulletin 2094) drives; and

system integration for your drive and motor/actuator combination with a Logix

controller.

For information on wiring, configuring, and troubleshooting the safe-speed

monitoring functions, refer to the Kinetix 6200 and Kinetix 6500 Safe Speed

Monitoring Safety Reference Manual, publication 2094-RM001

For information on wiring, configuring, and troubleshooting the safe torque-off

functions, refer to the Kinetix 6200 and Kinetix 6500 Safe Torque-off Safety

Reference Manual, publication 2094-RM002

This manual is intended for engineers or technicians directly involved in the

installation and wiring of the Kinetix 6200 and Kinetix 6500 drives; and

programmers directly involved in the operation, field maintenance, and

integration of these drives with a sercos interface or EtherNet/IP communication

module.

If you do not have a basic understanding of the Kinetix 6200 and Kinetix 6500

drives, contact your local Rockwell Automation sales representative for

information on available training courses.

.

.

Conventions Used in This Manual

The conventions starting below are used throughout this manual.

• Bulleted lists such as this one provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical information.

• Acronyms for the Kinetix 6200 and Kinetix 6500 drive modules are shown

in the table below and are used throughout this manual.

Kinetix 6200 and Kinetix 6500 Drive

Modules

Integrated Axis Module 2094-BCxx-Mxx-MIAM

Axis Module 2094-BMxx-M AM

Line Interface Module 2094-BLxx and 2094-BLxxS-xx LIM

Resistive Brake Module 2090-XBxx-xx RBM

Kinetix 6000M Drive Modules Cat. No. Acronym

Integrated Drive-Motor MDF-SBxxxxx IDM

IDM Power Interface Module 2094-SEPM-B24-S IPIM

Cat. No. Acronym

Rockwell Automation Publication 2094-UM002E-EN-P - May 2012 11

Page 12

Preface

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

Kinetix 6000 Power Rail Installation Instructions, publication 2094-IN003

Kinetix 6000 Shunt Module Installation Instructions, publication 2094-IN004

Slot-filler Module Installation Instructions, publication 2094-IN006

Line Interface Module Installation Instructions, publication 2094-IN005

2094 Mounting Bracket Installation Instructions, publication 2094-IN008

Resistive Brake Module Installation Instructions, publication 2090-IN009

Fiber-optic Cable Installation and Handling Instructions, publication 2090-IN010

External Shunt Modules Installation Instructions, publication 209 0-IN004

System Design for Control of Electrical Noise Reference Manual, publication GMC-RM001

EMC Noise Management DVD, publication GMC-SP004

Kinetix 6000M Integrated Drive-Motor User Manual, publication 2094-UM003

Kinetix 6200 and Kinetix 6500 Safe Speed Monitoring Ser vo Drives Safety Reference Manual,

publication 2094-RM001

Kinetix 6200 and Kinetix 6500 Safe Torque-off Servo Drives Safet y Reference Manual,

publication 2094-RM002

Kinetix 6000 and Kinetix 6200/6500 Drive Systems,

publication GMC-RM003

Kinetix Motion Control Selection Guide, publication GMC-SG001

Kinetix Rotary Motion Specifications, publication GMC-TD001

Kinetix Linear Motion Specifications, publication GMC-TD002

Kinetix Servo Drives Specifications, publication GMC-TD003

Kinetix Motion Accessories Specifications, publication GMC-TD004

Rockwell Automation Configuration and Selection Tools

website http://ww w.rockwellautomation.com/en/e-tools

Rockwell Automation Product Certification,

website http://ww w.rockwellautomation.com/products/certification

Sercos and Analog Motion Configuration User Manual, publication MOTION-UM001

Motion Coordinate System User Manual, publication MOTION-UM002

Integrated Motion on the EtherNet/IP Network Configuration and Startup User Manual,

publication MOTION-UM003

SoftLogix Motion Card Setup and Configuration Manual, publication 1784-UM003

ControlFL ASH Firmware Upg rade Kit User Ma nual, public ation 1756-QS105

National Electrical Code, published by the National Fire Protection Association of Boston, MA An article on wire sizes and types for grounding electrical equipment.

Rockwell Automation Industrial Automation Glossary, publication AG-7.1

Information on the installation of your Bulletin 2094 power rail.

Information on the installation of your Bulletin 2094 shunt module.

Information on the installation of Bulletin 2094 slot-filler module.

Information on the installation and troubleshooting of Bulletin 2094 line interface modules

(LIM).

Information on the installation of Bulletin 2094 mounting brackets.

Information on the installation and wiring of Bulletin 2090 Resistive Brake Modules.

Information on proper handling, installing, testing, and troubleshooting fiber-optic cables.

Information on mounting and wiring the Bulletin 1394 shunt modules with Bulletin 2 094 servo

drive systems.

Information, examples, and techniques designed to minimize system failures caused by

electrical noise.

Information on installing, configuring, startup, troubleshooting, and applications for your

Kinetix 6000M integrated drive-motor (IDM) system.

Information on wiring, configuring, and troubleshooting the safe-speed features of your

Kinetix 6200 and Kinetix 6500 drives.

Information on wiring, configuring, and troubleshooting the safe torque-off features of your

Kinetix 6200 and Kinetix 6500 drives.

System design guide to select the required (drive specific) drive module, power accessory,

connector kit, motor cable, and interface cable catalog numbers for your drive and motor/

actuator motion control system.

Overview of Kinetix servo drives, motors, actuators, and motion accessories designed to help

make initial decisions for the motion control products best suited for your system requirements.

Product specifications for MP-Series (Bulletin MPL, MPM, MPF, MPS), Kinetix 6000M

(Bulletin MDF), TL-Series™, RDD-Serie s™, and HPK-Series™ rotary motors.

Product specifications for Bulletin MPAS and MPMA linear stages, Bulletin MPAR, MPAI, and

TLAR electric cylinders, and LDC-Series™ and LDL-Series™ linear motors.

Product specifications for Kinetix Integrated Motion over the EtherNet/IP network, Integrated

Motion over sercos interface, EtherNet/IP networking, and component servo drive families.

Product specifications for Bulletin 2090 motor and inter face cables, low-profile connector kits,

drive power components, and other servo drive accessory items.

Motion Analyzer application analysis software for drive/motor sizing and online product

selection and system configuration tools, including AutoCAD (DXF) files.

For declarations of conformity (DoC) currently available from Rockwell Automation.

Information on configuring and troubleshooting your ControlLogix®, CompactLogix™, and

SoftLogix™ sercos interface modules.

Information to create a mot ion coordinate system with sercos or analog motion modules.

Information on configuring and troubleshooting your ControlLogix and CompactLogix

EtherNet/IP network modules.

Information on configuring and troubleshooting SoftLogix PCI cards.

For ControlFLASH™ information not specific to any drive family.

A glossary of industrial automation terms and abbreviations.

You can view or download publications at

http://www.rockwellautomation.com/literature

technical documentation, contact your local Allen-Bradley® distributor or

Rockwell Automation sales representative.

12 Rockwell Automation Publication 2094-UM002E-EN-P - May 2012

. To order paper copies of

Page 13

Chapter 1

Start

Use this chapter to become familiar with the design and installation requirements

for Kinetix 6200 and Kinetix 6500 drive systems.

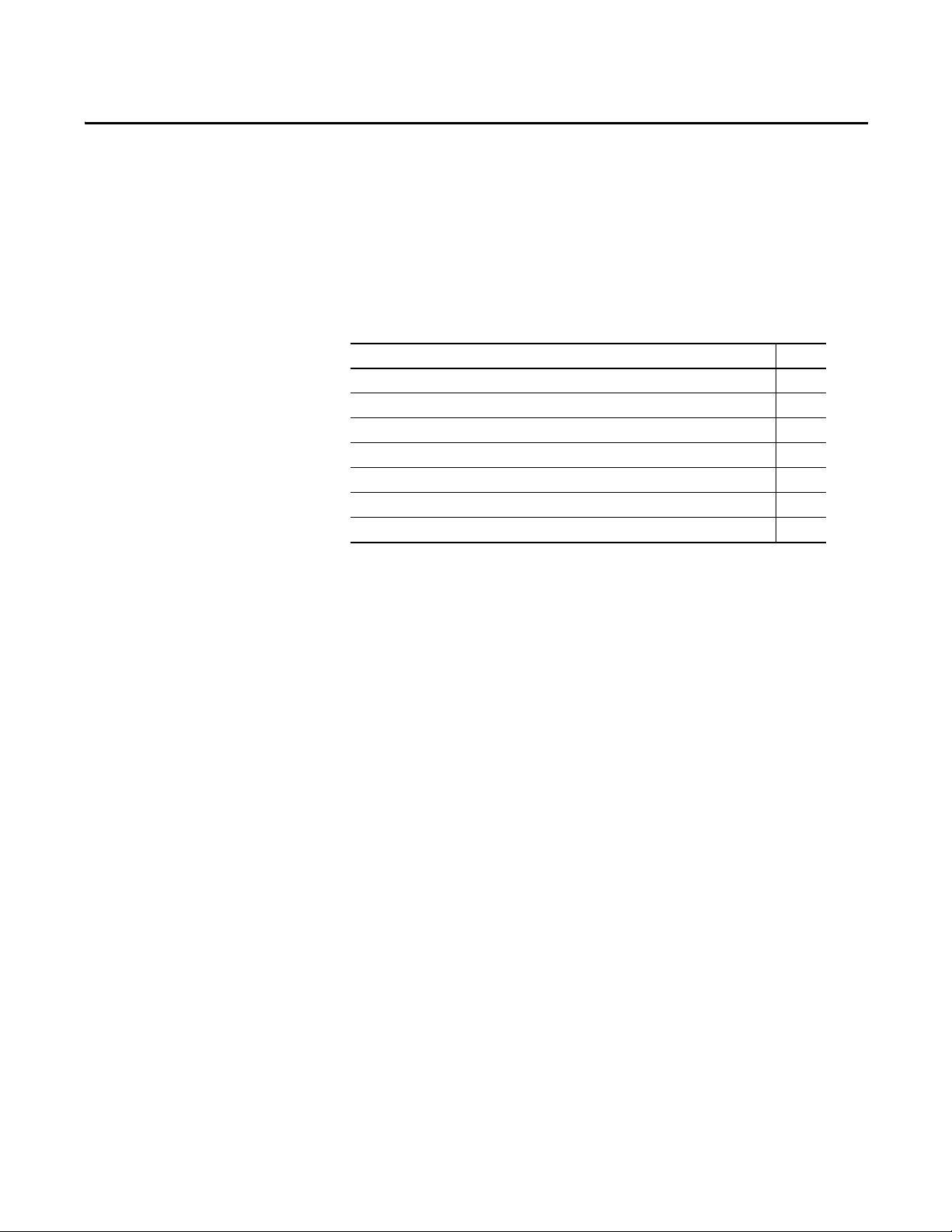

Top ic Pa ge

About the Kinetix 6200 and Kinetix 6500 Drive Systems 14

Typical Ha rdware Configurations 15

Typical Communication Configurations 19

Catalog Number Explanation 23

Kinetix Drive Component Compatibility 24

Kinetix 6000M Integrated Drive-Motor System Compatibility 24

Agenc y Compliance 25

Rockwell Automation Publication 2094-UM002E-EN-P - May 2012 13

Page 14

Chapter 1 Start

About the Kinetix 6200 and Kinetix 6500 Drive Systems

The Kinetix 6200 and Kinetix 6500 modular multi-axis servo drives are designed

to provide a Kinetix Integrated Motion solution for your drive/motor/actuator

applications.

Table 1 - Kinetix 6200 and Kinetix 6500 Drive System Overview

System

Component

Integrated Axis

Module

Axis Module 2094-BMxx-M

Control Module

Shunt Module 2094-BSP2 The Bulletin 2094 shunt module mounts to the power rail and provides additional shunting in regenerative applications.

Kinetix 6000M

IDM System

Power Rai l

Power Rai l

Slot-filler Module

Logix Controller

Platform

RSLogix™ 5000

Software

Rotary Servo

Motors

Linear Motors LDC-Series Compatible motors include LDC-Series iron core (400V-class) linear motors.

Linear Actuators MP-Series

Cables

AC Line Filters 2090-XXLF-xxxx

Line Interface

Modules

External Shunt

Modules

Resistive Brake

Module

Cat. No. Description

2094-BCxx-Mxx-M

2094-SE02F-M00-Sx Interchangeable modular components for wiring I/O, safety, and feedback options using sercos interface.

2094-EN02D-M01-Sx Interchangeable modular components for wiring I/O, safety, and feedback options using EtherNet/IP networking.

2094-SEPM-B24-S

Bulletin MDF

2094-PRSx

2094-PRx

2094-PRF

1756-MxxSE modules

1768-M04SE module

1784-PM16SE PCI card

1756-ENxTx modules

CompactLogix 5370 controllers

9324-RLD300ENE RSLogix 5000 software provides support for programming, commissioning, and maintaining the Logix family of controllers.

MP-Series, RDD-Series

1326AB

2090-Series motor/actuator

cables

Kinetix 6000M integrated

drive-motor cables

Communication

2094-xLxx

2094-xLxxS

2094-XL75S-Cx

1394-SRxxxx

2090-XBxx-xx

Integrated Axis (power) Modules (IAM) with safe speed monitoring are available with 400V-class AC input power and contains

an inverter and converter section. The IAM power module requires one control module.

Axis (power) Modules (AM) are a shared DC-bus inverter rated for 400V-class input power. The AM power modules each require

one control module and must be used with an IAM power module.

The Kinetix 6000M integrated drive-motor (IDM) system consists of the IDM power interface module (IPIM) and up to 16

(Bulletin MDF) IDM units. The IPIM module mounts on the Bulletin 2094 power rail and provides power and communication to

the IDM units. The IPIM module also monitors power output and provides overload protection.

The Bulletin 2094 power rail consists of copper bus bars and a circuit board with connectors for each module. The power rail

provides power and control signals from the converter section to adjacent inverters. The IAM and AM power modules, shunt

module, slot-filler modules mount to the power rail.

The Bulletin 2094 slot-filler module is used when one or more slots on the power rail are empty after all the other power rail

modules are installed. One slot-filler module is required for each empty slot.

The sercos interface module/PCI card serves as a link between the ControlLogix/CompactLogix/SoftLogix platform and the

Kinetix 6200 drive system. The communication link uses the IEC 61491 SErial Real-time COmmunication System (sercos)

protocol over a fiber-optic cable.

The EtherNet/IP network module serves as a link between the ControlLogix platform and Kinetix 6500 drive system. Linear,

device-level ring (DLR), and star topology is supported. The Kinetix 6000M IPIM module connects to the EtherNet/IP network

for monitoring, diagnostics, and firmware upgrades.

Compatible rotary motors include the MP-Series (Bulletin MPL, MPM, MPF, and MPS), RDD-Series (Bulletin RDB), and 1326AB

(M2L/S2L) 400V-class motors.

Compatible actuators include MP-Series (400V-class) Bulletin MPAS single-axis and Bul letin MPMA multi-axis integrated linear

stages, and MP-Series (400V-class) Bulletin MPAR and MPAI electric cylinders.

Bulletin 2090 motor/actuator cables are available with bayonet, threaded, and SpeedTec connectors. Power/brake cables have

flying leads on the drive end and straight connectors that connect to s

to low-profile connector kits on the drive end and straight connectors on the motor end.

Bulletin 2090 integrated drive-motor (IDM) hybrid and network cables connect between the 2094 IPIM module and the

Kinetix 6000M IDM units. Bulletin 889D and 879D cables connect between digital input connectors and sensors.

Bulletin 2090 sercos fiber-optic cables are available as enclosure only, PVC, nylon, and glass with connectors at both ends.

Ethernet cables are available in standard lengths for Kinetix 6500, Kinetix 6200, and Kinetix 6000M IPIM modules. Shielded

cable is recommended.

Bulletin 2090-XXLF-xxxx three-phase AC line filters are required to meet CE and available for use in all Kinetix 6200 and

Kinetix 6500 (400V-class) drive systems.

Line interface modules (LIM) include the circuit breakers, AC line filter (catalog number 2094-BL02 only), power supplies, and

safety contactor required for Kinetix 6200 and Kinetix 6500 operation. The LIM module does not mount to the power rail. You

can purchase individual components separately in place of the LIM module.

You can use Bulletin 1394 external passive shunt modules when the IAM/AM power module internal shunt and power rail

mounted 2094-BSP2 shunt module capability is exceeded.

Resistive Brake Modules (RBM) include a safety contactor for use in a control circuit. Contactors and resistors reside in this

module such that the motor leads can be disconnected from the drive with the permanent magnet motor brought to an

immediate stop. This module does not mount to the power rail.

ervo motors. Feedback cables have flying leads that wire

14 Rockwell Automation Publication 2094-UM002E-EN-P - May 2012

Page 15

Start Chapter 1

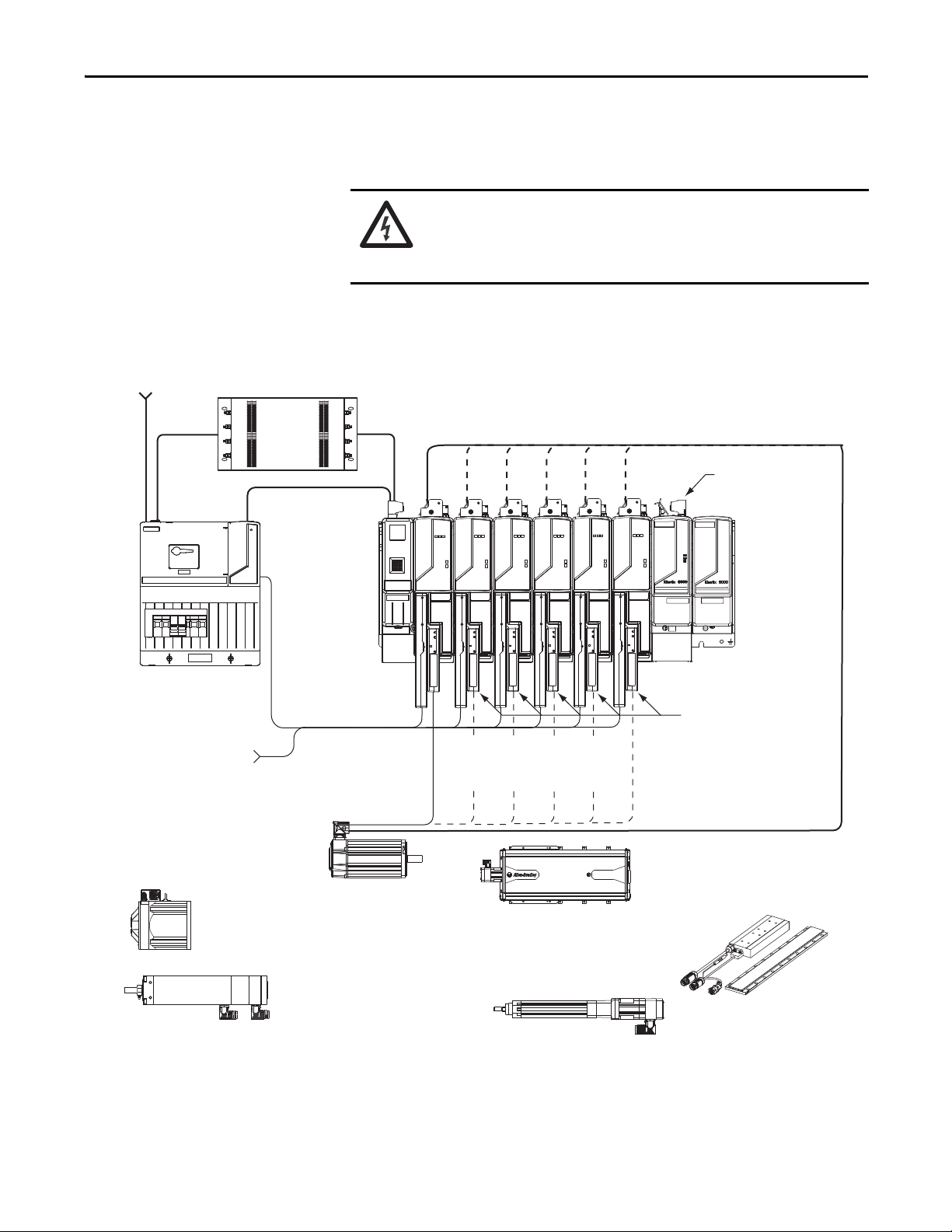

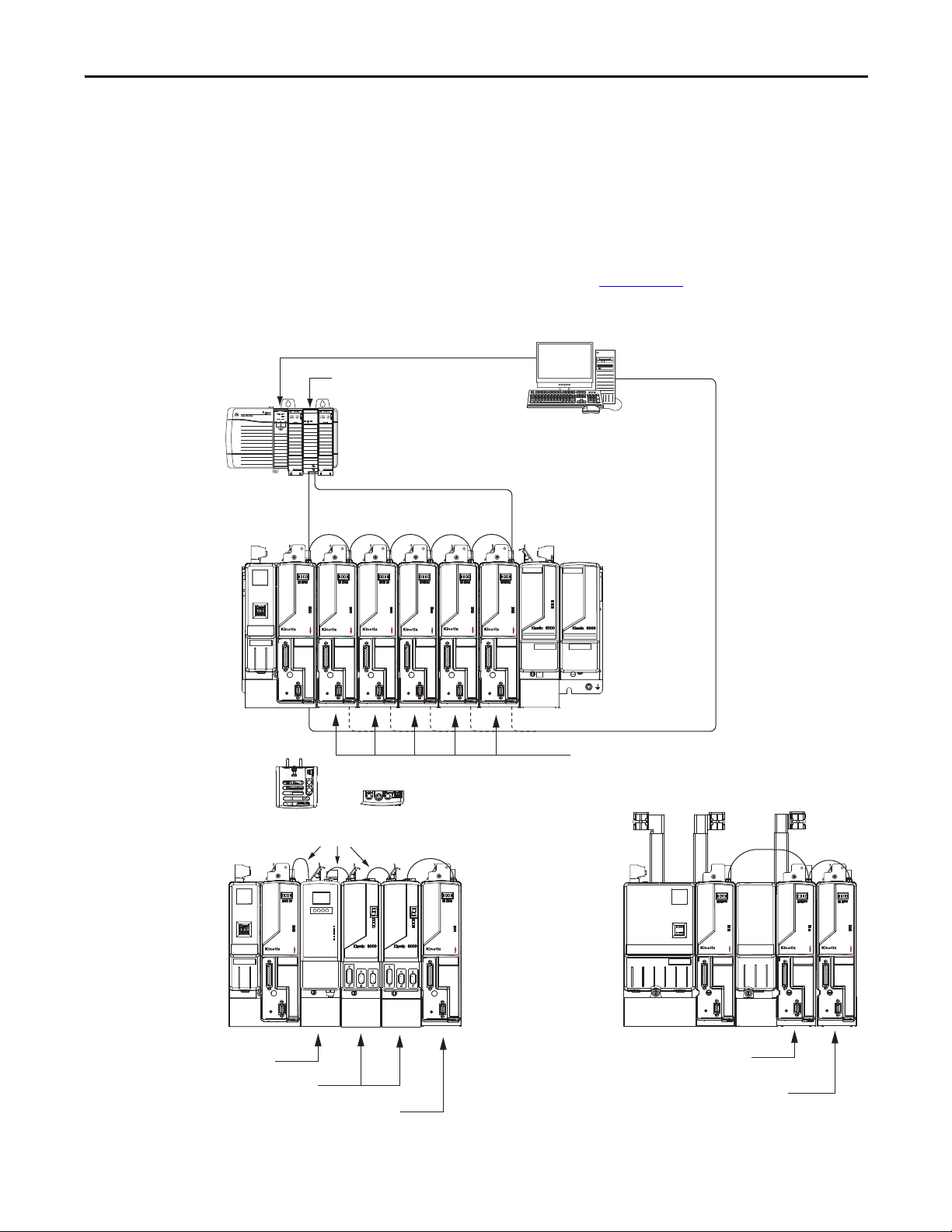

Kinetix 6200 or Kinetix 6500 Multi-axis Servo Drive System

2094-BLxxS

Line Interface Module

(optional component)

2094-BMxx-M

AM Power Modules (5) with

Bulletin 2094

Control Modules (5)

Three-phase

Input Power

2094-BCxx-Mxx-M

IAM Power Module

with

Bulletin 2094

Control Module

2094-BSP2

Shunt Module

(optional component)

2090-XXLF-xxxx

AC Line Fi lter

(required for CE)

2094-PRSx

Power Rail

2094-PRF

Slot Filler Module

(required to fill any

unused slots)

I/O Connections

To Input Sensors

and Control String

115/230V Control Power

2090-K6CK-Dxxxx

Low Profile Connector Kits for I/O, Safety,

Motor Feedback, and Aux Feedback

MP-Series Integrated Linear Stages

(MPAS-B9xxx ballscrew shown)

MP-Series Rotary Motors

(MPL-Bxxxx motors shown)

Bulletin 2090

Motor Feedback Cables

Bulletin 2090

Motor Power Cables

MP-Series Electric Cylinders

(MPAR-Bxxxx electric cylinder shown)

LDC-Series Linear Motors

(LDC-Cxxxxxxx linear motor shown)

RDD-Series Direct Drive Motors

(RDB-Bxxxx motor shown)

MP-Series Heavy Duty Electric Cylinders

(MPAI-Bxxxx electric cylinders shown)

Typical Hardware Configurations

MAIN VAC

Typical Kinetix 6200 and Kinetix 6500 system installations include three-phase

AC configurations, with and without the line interface module (LIM), and DC

common-bus configurations.

SHOCK HAZARD: To avoid personal injury due to electrical shock, place a

2094-PRF slot-filler module in all empty slots on the power rail.

Any power rail connector without a module installed will disable the threephase power; however, control power is still present.

Figure 1 - Typical Kinetix 6200 or Kinetix 6500 System Installation (with LIM)

m

b.co

.a

w

w

w

E IN USA

D

A

M

00

55

C-M07

. LD

XXXX X XXXX

. NO

NO.

CAT

SERIAL

S A

SERIE

Rockwell Automation Publication 2094-UM002E-EN-P - May 2012 15

Page 16

CAT. NO. LDC-M075500

SERIAL NO. XXXX X XXXX

SERIES A

www.ab.com

MADE IN USA

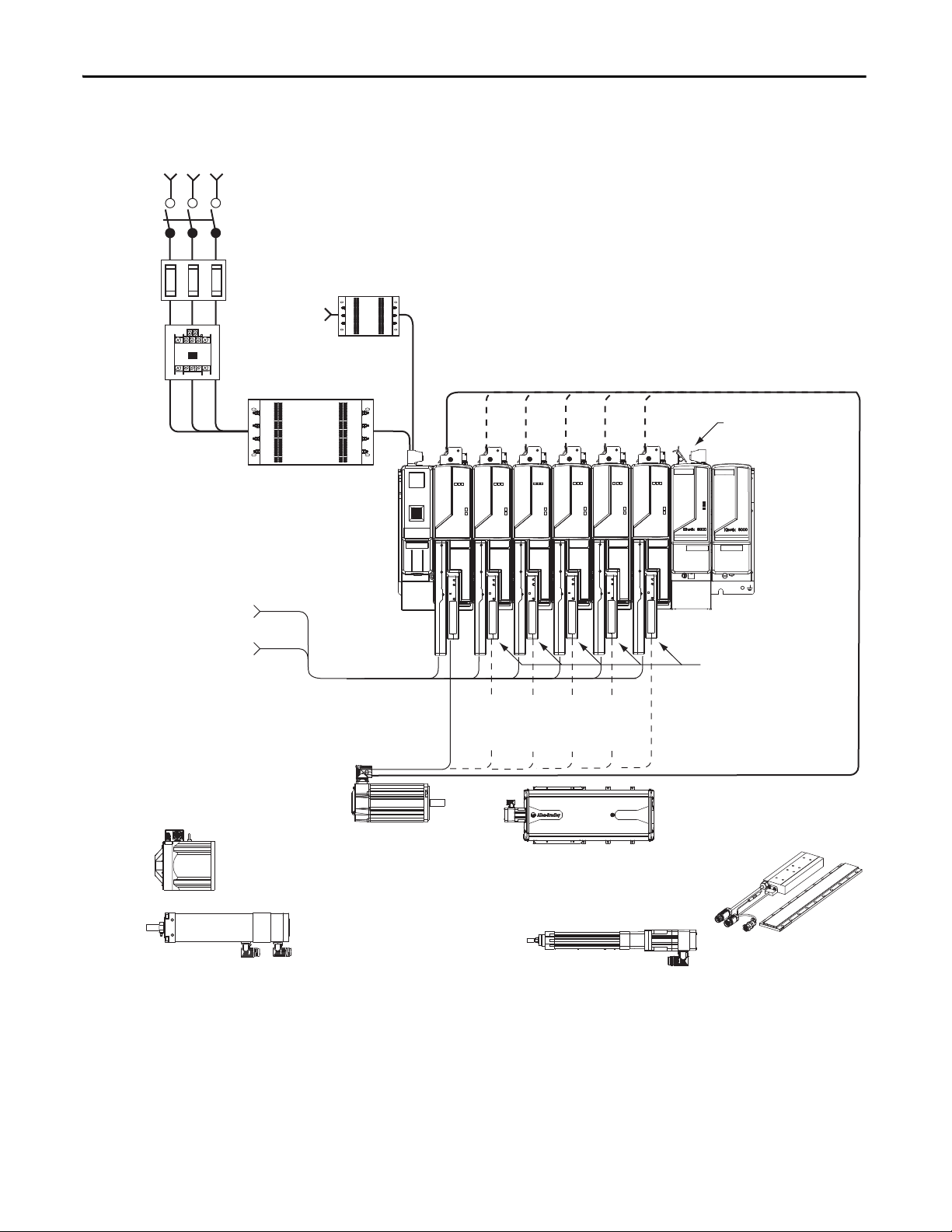

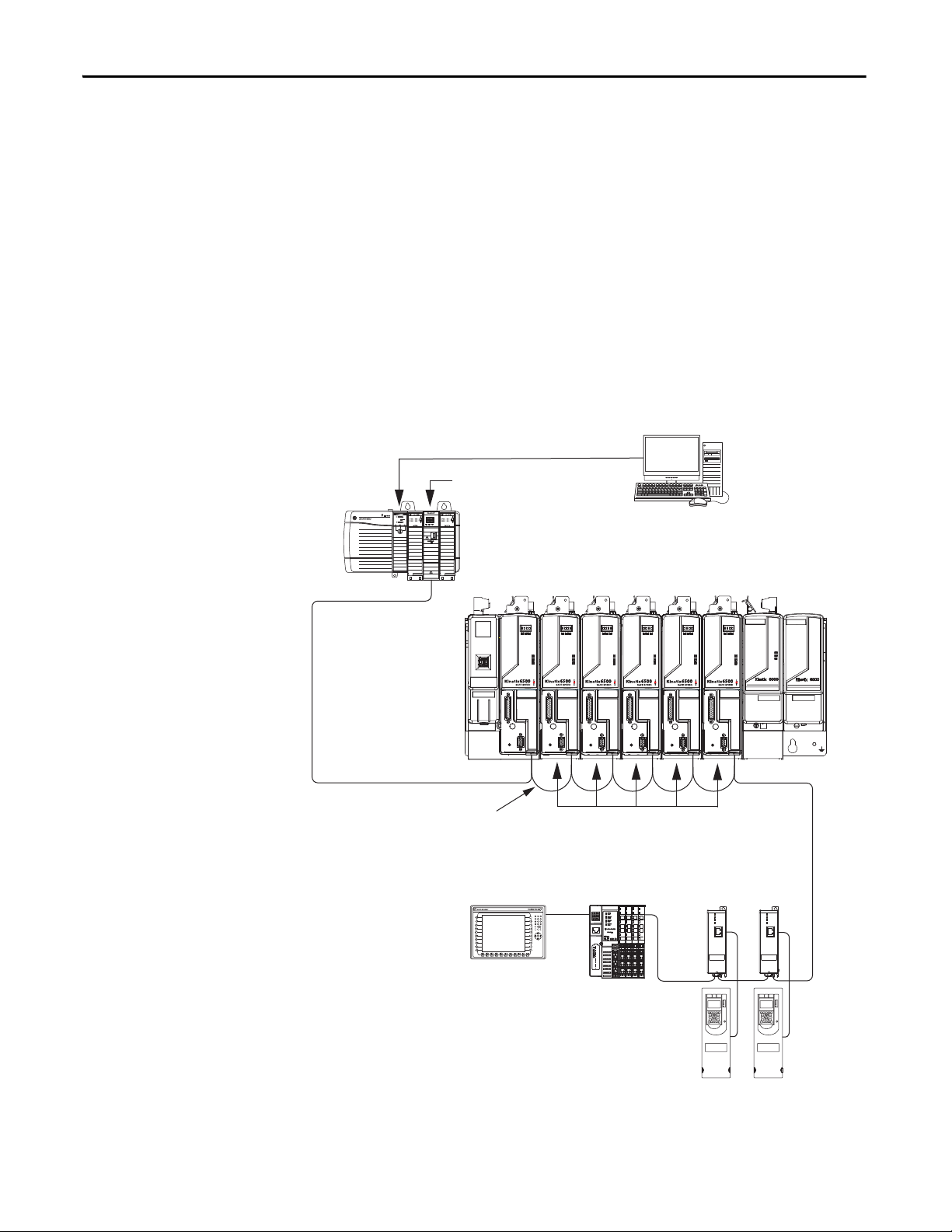

Kinetix 6200 or Kinetix 6500 Multi-axis Servo Drive System

Three-p hase

Input Power

Single-phase

Control Power

I/O Connections

To Input Sensors

and Control String

2090-K6CK-Dxxxx

Low Profile Connector Kits for I/O, Safety,

Motor Feedback, and Aux Feedback

MP-Series Rotary Motors

(MPL-Bxxxx motors shown)

Bulletin 2090

Motor Feedback Cables

Bulletin 2090

Motor Power Cables

Line

Disconnect

Device

Magnetic

Contac tor

Input

Fusing

2094-BMxx-M

AM Power Modules (5) with

Bulletin 2094

Control Modules (5)

2094-BCxx-Mxx-M

IAM Power Module

with

Bulletin 2094

Control Module

2094-BSP2

Shunt Module

(optional component)

2090-XXLF-xxxx

AC Line Filter

(required for CE)

2094-PRSx

Power Rail

2094-PRF

Slot Filler Module

(required to fill any

unused slots)

MP-Series Integrated Linear Stages

(MPAS-B9xxx ballscrew shown)

LDC-Series Linear Motors

(LDC-Cxxxxxxx linear motor shown)

RDD-Series Direct Drive Motor

(RDB-Bxxxx motor shown)

MP-Series Electric Cylinders

(MPAR-Bxxxx electric cylinder shown)

MP-Series Heavy Duty Electric Cylinders

(MPAI-Bxxxx electric cylinders shown)

2090-XXLF-xxxx

AC Line Filter

(required for CE)

Chapter 1 Start

Figure 2 - Typical Kinetix 6200 or Kinetix 6500 System Installation (without LIM)

16 Rockwell Automation Publication 2094-UM002E-EN-P - May 2012

Page 17

Start Chapter 1

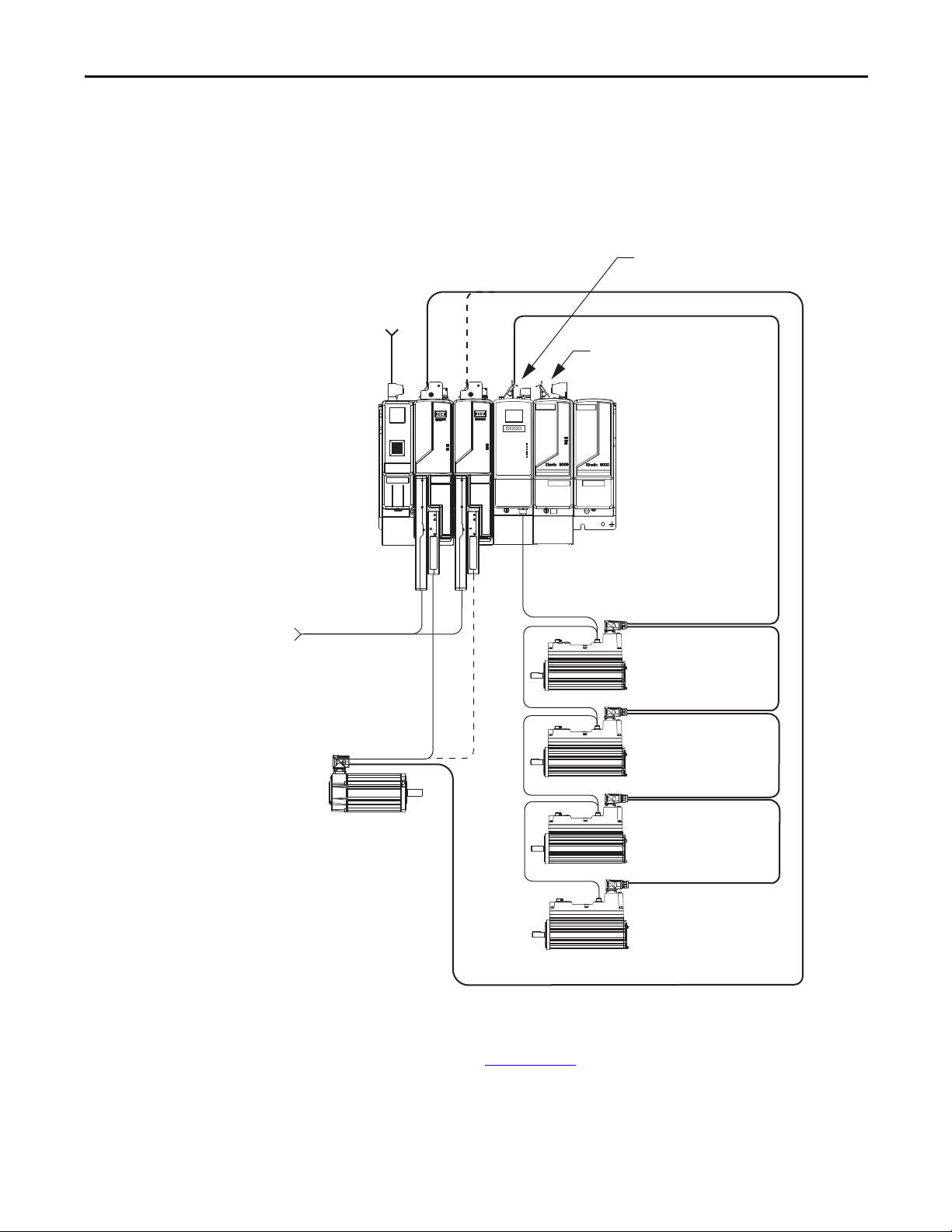

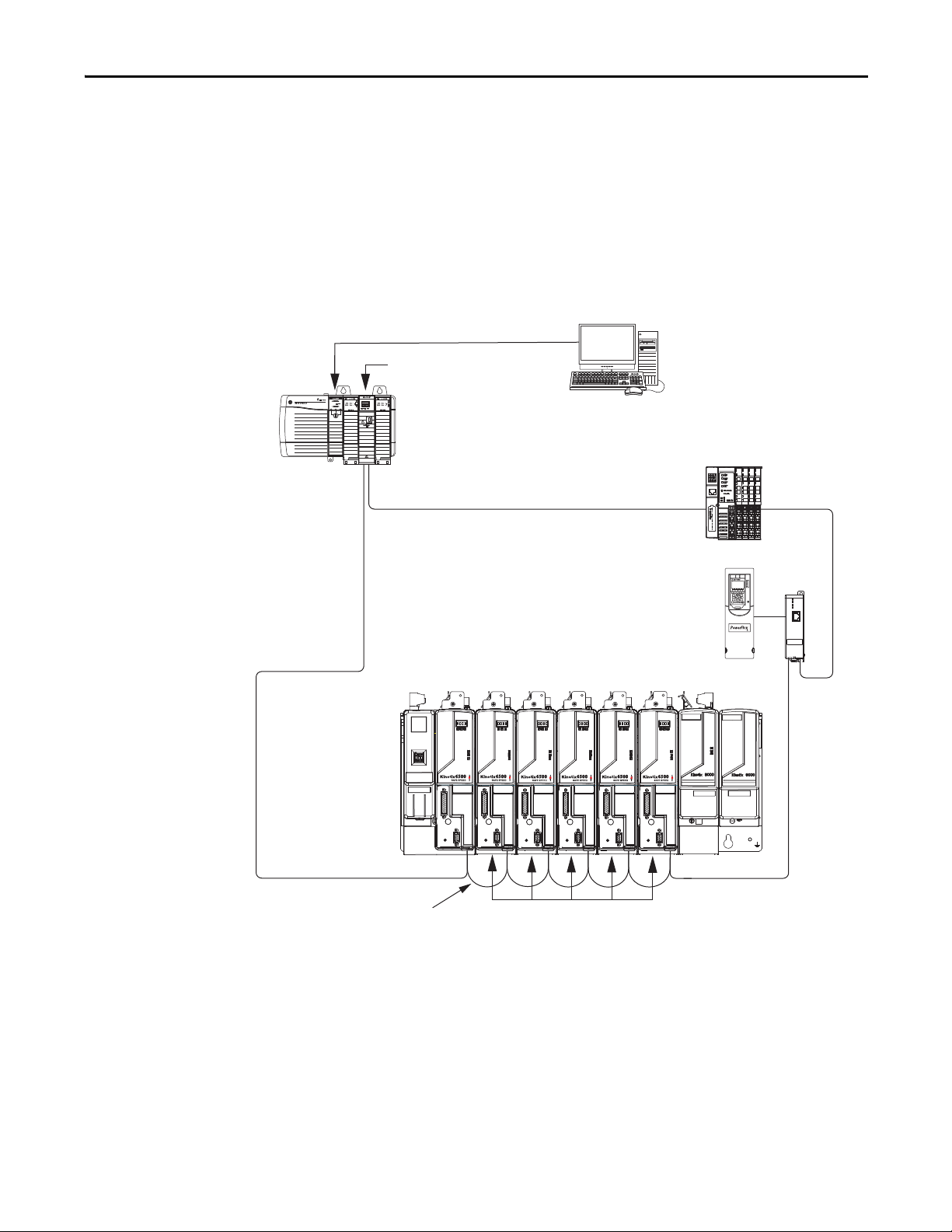

Three-phase

Input Power

Kinetix 6200 Modular

Servo Drive System

2094-BSP2

Shunt Module

(optional component)

2094-SEPM-B24-S

IPIM Module

2094-PRSx

Power Rail

2094-PRF

Slot Filler Module

(required to fill any

unused slots)

To Input Sensors

and Control String

2090-K6CK-Dxxxx

Low Profile Connector Kits for I/O, Safety,

Motor Feedback, and Aux Feedback

Compatible Rotary Motors,

Linear Motors, and Linear Actuators

(MPL-Bxxxx motor shown)

Bulletin 2090

Motor Feedback Cables

Bulletin 2090

Motor Power Cables

Bulletin 2090 Hybrid Cables

Bulletin 2090

Network Cables

MDF-SBxxxxx-Qx8xA-S

Drive-Motor Unit

MDF-SBxxxxx-Qx8xA-S

Drive-Motor Unit

MDF-SBxxxxx-Qx8xA-S

Drive-Motor Unit

MDF-SBxxxxx-Qx8xA-S

Drive-Motor Unit

This configuration illustrates the Kinetix 6000M integrated drive-motor (IDM)

system with IDM power interface module (IPIM) installed on the Bulletin 2094

power rail. The IPIM module is included in the drive-to-drive fiber-optic cable

installation along with the axis modules.

Figure 3 - Typical Kinetix 6000M Integrated Drive-Motor System Installation

For more information on Kinetix 6000M integrated drive-motor system

installation, refer to the Kinetix 6000M Integrated Drive-Motor System User

Manual, publication 2094-UM003

.

Rockwell Automation Publication 2094-UM002E-EN-P - May 2012 17

Page 18

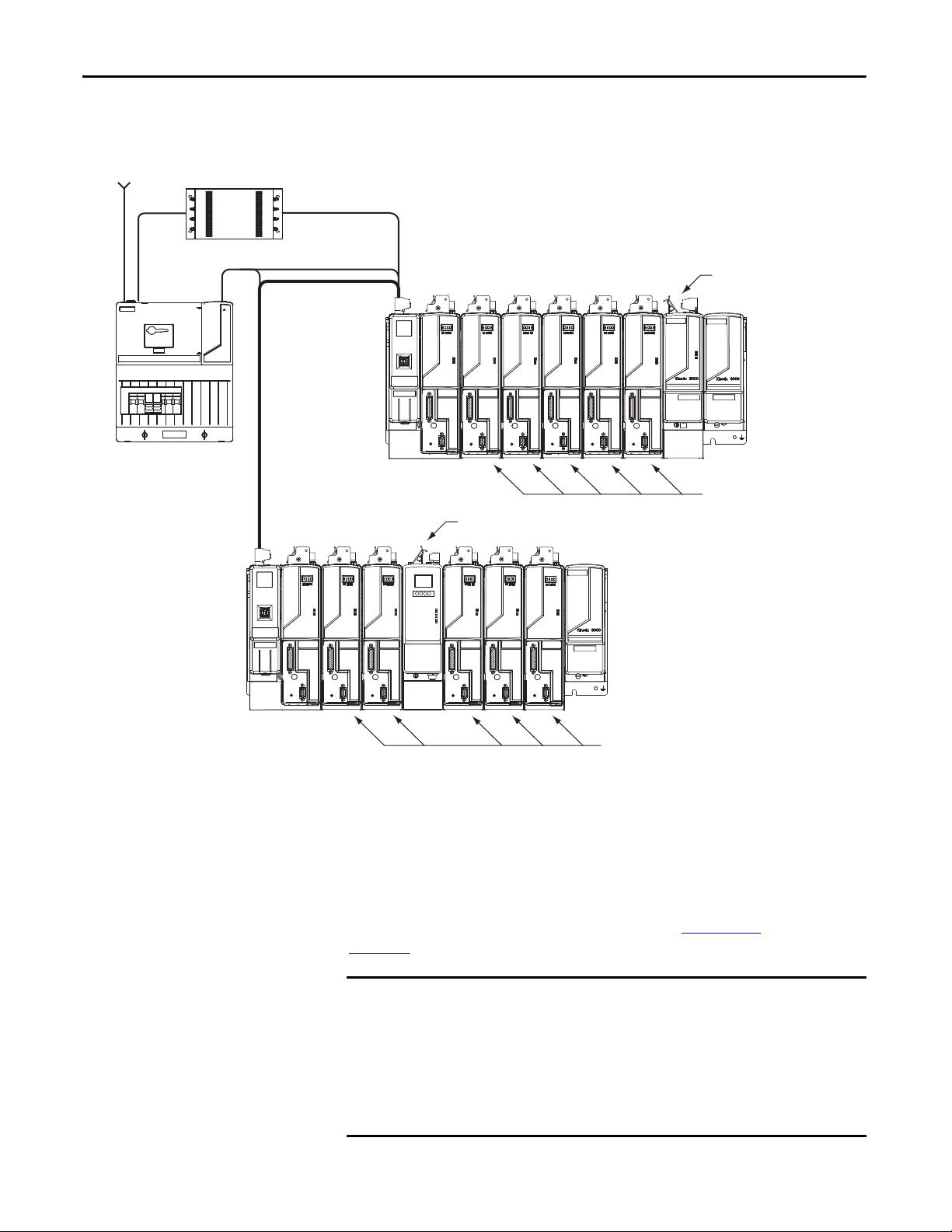

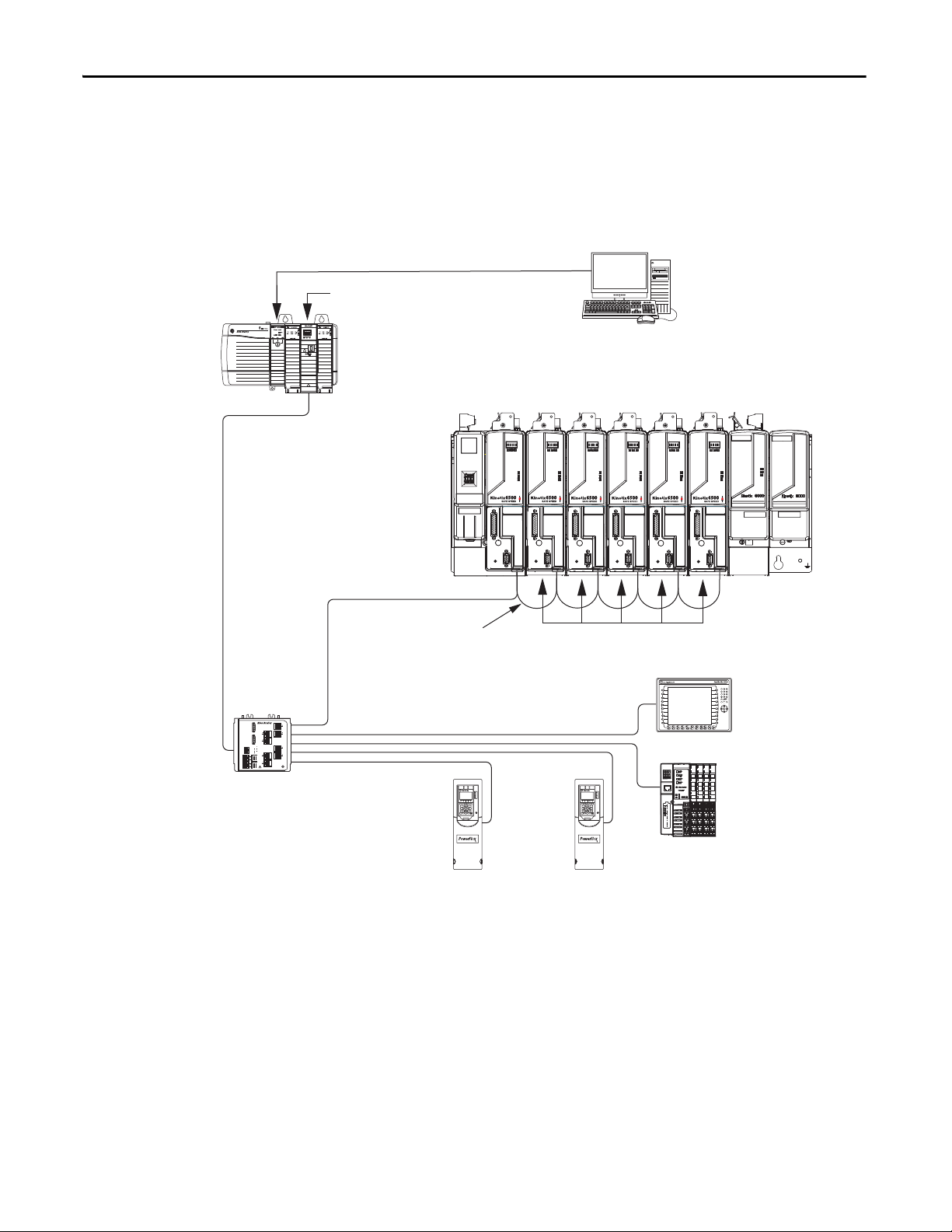

Chapter 1 Start

Three-phase

Input Power

115/230V Control Power

DC Common Bus

Kinetix 6200 or Kinetix 6500 Multi-axis Servo Drive System

2094-BLxxS

Line Interface Module

(optional component)

2094-BMxx-M

AM Power Modules (5) with

Bulletin 2094 Control Modules (5)

2094-BCxx-Mxx-M

IAM Power Module

with

Bulletin 2094

Control Module

2094-BSP2

Shunt Module

(optional component)

2090-XXLF-xxxx

AC Line Filter

(required for CE)

2094-PRSx

Power Rail

2094-PRF

Slot Filler Module

(required to fill any

unused slots)

2094-BMxx-M

AM Power Modules (5) with

Bulletin 2094 Control Modules (5)

2094-BCxx-Mxx-M

IAM Power Module

with

Bulletin 2094

Control Module

2094-PRSx

Power Rail

2094-PRF

Slot Filler Module

(required to fill any

unused slots)

2094-SEPM-B24-S

IPIM Module

IMPORTANT

Figure 4 - Typical DC Common Bus System Installation

In the example above, the leader IAM module is connected to the follower IAM

module via the DC common-bus. The follower system also includes the

Kinetix 6000M integrated drive-motor (IDM) power interface module (IPIM)

that supports up to 16 IDM units.

When planning your panel layout, you must calculate the total bus capacitance of

your DC common-bus system to be sure that the leader IAM module is sized

sufficiently to pre-charge the entire system. Refer to Appendix

page 267,

for more information.

If total bus capacitance of your system exceeds the leader IAM power module

pre-charge rating, the IAM module four-character display scrolls a power cycle

C, beginning on

user limit condition. If input power is applied, the display scrolls a power cycle

fault limit condition.

To correct this condition, you must replace the leader IAM power module with a

larger module or decrease the total bus capacitance by removing the IPIM

module or AM power modules.

18 Rockwell Automation Publication 2094-UM002E-EN-P - May 2012

Page 19

Start Chapter 1

SERCOS interface

Tx (rear)

Rx (front)

OK

CP

62006200

SAFE SPEED

62006200

SAFE SPEED

0.2 m

(7.1 in.)

0.1 m

(5.1 in.)

62006200

SAFE SPEED

62006200

SAFE SPEED

62006200

SAFE SPEED

62006200

SAFE SPEED

62006200

SAFE SPEED

62006200

SAFE SPEED

0.3 m

(12.0 in.)

0.2 m

(7.1 in.)

TX

RX

TX

RX

62006200

SAFE SPEED

62006200

SAFE SPEED

62006200

SAFE SPEED

Logix Sercos interface Module

Logix Platform

(Control Logix is shown)

RSLogix 5000

Software

2090-SCxxx-x

Sercos Fiber-optic Cable

Logix Controller Programming Network

2094-BMxx-M

AM Power Modules (5)

with 2094-SE02F-M00-Sx

Control Modules (5)

2094-BCxx-Mxx-M

IAM Power Module

with

2094-SE02F-M00-Sx

Control Module

Ethernet (RJ45) connections are

required only for programming

the 2094-SE02F-M00-S1

safety configuration.

1585J-M8TBJM-x

Ethernet Cable

0.2 m (7.1 in.)

Kinetix 6200 Drive-to-Drive Sercos Cables

Kinetix 6200 Single-wide

2094-BCxx-Mxx-M

IAM Power Module

with

2094-SE02F-M00-Sx

Control Module

Kinetix 6200 Double-wide

2094-BCxx-Mxx-M

IAM Power Module

2094-SE02F-M00-Sx

Control Module

2094-BMxx-M Single-wide AM Power Module with

2094-SE02F-M00-Sx Control Module

2094-BMxx-M Double-wide AM Power Module with

2094-SE02F-M00-Sx Control Module

Kinetix 6200 (top view)

Sercos Connectors

2094-PRSx

Power Rail

2094-BMxx-M Single-wide AM Power Module

with 2094-SE02F-M00-Sx Control Module

2094-SEPM-B24-S IPIM Module

2094-BMxx-S Single-wide AM Modules

Kinetix 6000 and Kinetix 6000M

(top view) Sercos Connectors

Typical Communication Configurations

In this example, drive-to-drive sercos cables and catalog numbers are shown when

Kinetix 6000, Kinetix 6000M, and Kinetix 6200 drive modules exist on the same

power rail.

The Kinetix 6200 control modules use sercos interface for configuring the Logix

module and the EtherNet/IP network for diagnostics and configuring safety

functions. An Ethernet cable is connected to each control module during safety

configuration. For more information on Ethernet cables, refer to the Industrial

Ethernet Media Brochure, publication 1585-BR001

Figure 5 - Typical Kinetix 6000 and Kinetix 6200 Communication (sercos)

.

Rockwell Automation Publication 2094-UM002E-EN-P - May 2012 19

Page 20

Chapter 1 Start

TIP

Logix Platform

(Contro lLogix is shown)

RSLogix 5000

Software

Kinetix 6500 Modular Multi-axis Servo Drive System

1585J-M8CBJM-x

Ethernet (shielded) Cable

1756-ENxT EtherNet/IP Module

1734-AENT POINT I/O™

EtherNet/IP Adapter

ControlLogix Controller Programming Network

Panel View™ Pl us

Display Terminal

1783-ETAP

Modules

PowerFlex® 755

Drive Modules

2094-BMxx-M Axis Modules (5) with

2094-EN02D-M01-Sx Control Modules (5)

2094-BCxx-Mxx-M

Integrated

Axis Module

with

2094-EN02D-M01-Sx

Control Module

1585J-M8CBJM-OM3

0.3 m (1.0 ft) Ethernet cable

for drive-to-drive connections.

The Kinetix 6500 control modules can use any Ethernet topology including star,

linear, and device-level ring (DLR). DLR is an ODVA standard and provides

fault tolerant connectivity.

1756-EN2F modules are available for applications that require fiber-optic cable

for noise immunity.

In this example, all devices are connected in linear topology. The Kinetix 6500

control module includes dual-port connectivity. Devices without dual ports

should include the 1783-ETAP module or be connected at the end of the line.

• Up to 64 devices in linear configurations.

• No redundancy. If any device becomes disconnected, all the devices

downstream loose communication.

Figure 6 - Kinetix 6500 Linear Communication Installation (EtherNet/IP network)

20 Rockwell Automation Publication 2094-UM002E-EN-P - May 2012

Page 21

Start Chapter 1

ControlLogix Platform

RSLogix 5000

Software

Kinetix 6500 Modular Multi-axis Servo Drive System

1585J-M8CBJM-x

Ethernet (shielded) Cable

1756-ENxTR EtherNet/IP Module

1734-AENT POINT I/O

EtherNet/IP Adapter

ControlLogix Controller Programming Network

1783-ETAP

Module

PowerFlex 755

Drive Module

2094-BMxx-M Axis Modules (5) with

2094-EN02D-M01-Sx Control Modules (5)

2094-BCxx-Mxx-M

Integrated

Axis Module

with

2094-EN02D-M01-Sx

Control Module

1585J-M8CBJM-OM3

0.3 m (1.0 ft) Ethernet cable

for drive-to-drive connections.

In this example, the devices are connected by using device-level ring (DLR)

topology. DLR topology is fault redundant. For example, if a device in the ring is

disconnected, the rest of the devices in the ring continue to maintain

communication.

• Up to 64 devices in the DLR configurations.

• All Devices in a DLR ring should have dual-port connectivity or be

connected in the ring by using a 1783-ETAP module.

Figure 7 - Kinetix 6500 Ring Communication Installation (EtherNet/IP network)

755

Rockwell Automation Publication 2094-UM002E-EN-P - May 2012 21

Page 22

Chapter 1 Start

ControlLogix Platform

RSLogix 5000

Software

Kinetix 6500 Modular Multi-axis Servo Drive System

2094-BMxx-M Axis Modules (5) with

2094-EN02D-M01-Sx Control Modules (5)

2094-BCxx-Mxx-M

Integrated

Axis Module

with

2094-EN02D-M01-Sx

Control Module

1585J-M8CBJM-x

Ethernet (shielded) Cable

1756-ENxT EtherNet/IP Module

1734-AENT POINT I/O

EtherNet/IP Adapter

ControlLogix Controller Programming Network

Panel View Plus

Display Terminal

PowerFlex 755

Drive Module

1783-EMS

Stratix™ Switch

PowerFlex 755

Drive Module

1585J-M8CBJM-OM3

0.3 m (1.0 ft) Ethernet cable

for drive-to-drive connections.

In this example, the devices are connected by using star topology. Each device is

connected directly to the switch, making this topology fault tolerant. The 2094

power rail modules and other devices operate independently. The loss of one

device does not impact the operation of the other devices.

Figure 8 - Kinetix 6500 Star Communication Installation (EtherNet/IP network)

755755

22 Rockwell Automation Publication 2094-UM002E-EN-P - May 2012

Page 23

Start Chapter 1

Catalog Number Explanation

Kinetix 6200 and Kinetix 6500 (Bulletin 2094) modular drive catalog numbers

and descriptions are listed in the tables below. All power modules are compatible

with the Kinetix 6200 and Kinetix 6500 control modules.

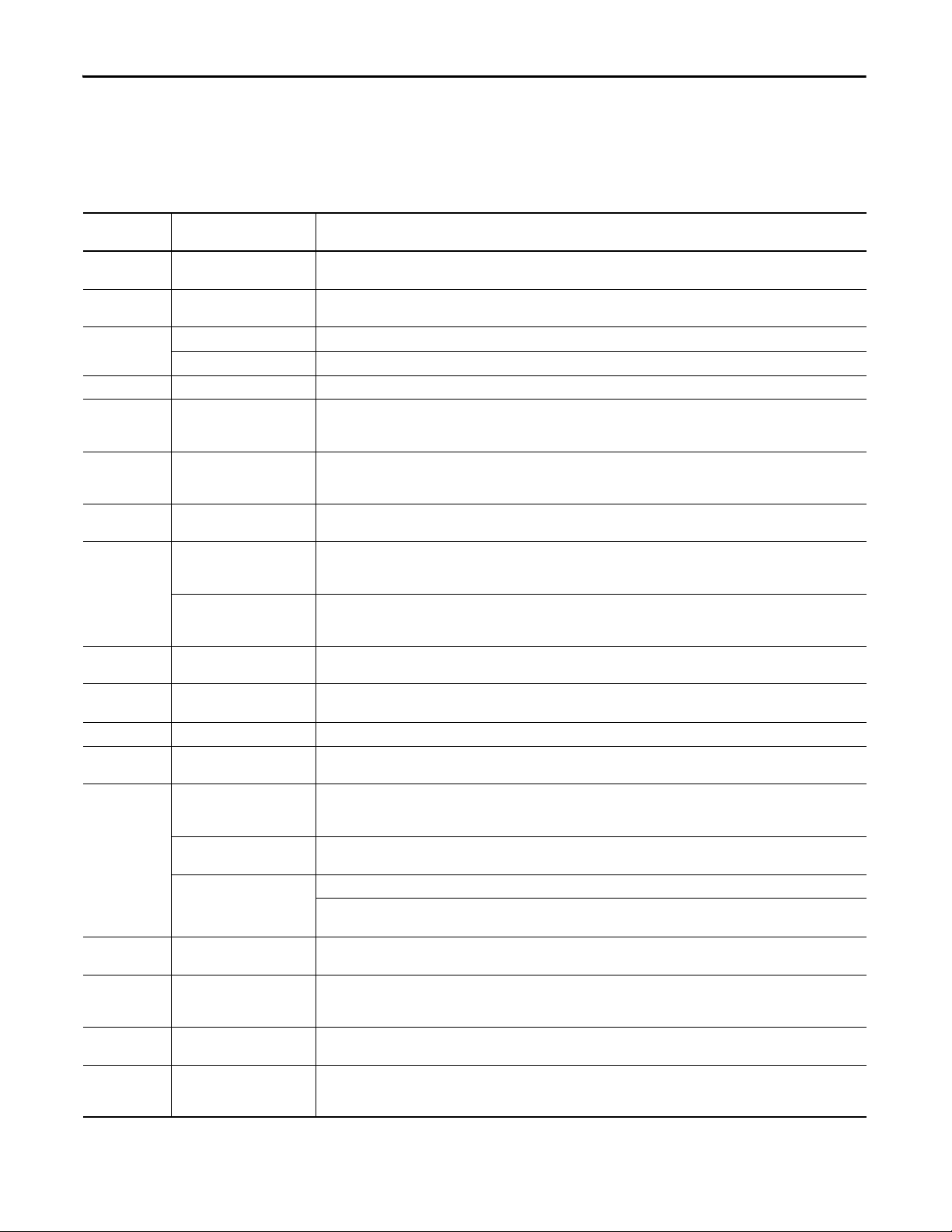

Table 2 - Kinetix 6200 and Kinetix 6500 Drive Catalog Numbers

Integrated Axis Modules (460V) Cat. No.

IAM power module, 400V-class, 6 kW converter, 4 A (0-pk) inverter 2094-BC01-MP5-M

IAM power module, 400V-class, 6 kW converter, 9 A (0-pk) inverter 2094-BC01-M01-M

IAM power module, 400V-class, 15 kW converter, 15 A (0-pk) inverter 2094-BC02-M02-M

IAM power module, 400V-class, 28 kW converter, 30 A (0-pk) inverter 2094-BC04-M03-M

IAM power module, 400V-class, 45 kW converter, 49 A (0-pk) inverter 2094-BC07-M05-M

Axis Modules (460V)

AM power module, 400V-class, 4 A (0-pk) 2094-BMP5-M

AM power module, 400V-class, 9 A (0-pk) 2094-BM01-M

AM power module, 400V-class, 15 A (0-pk) 2094-BM02-M

AM power module, 400V-class, 30 A (0-pk) 2094-BM03-M

AM power module, 400V-class, 49 A (0-pk) 2094-BM05-M

Kinetix 6200 Control Modules

Control module, sercos interface, safe torque-off 2094-SE02F-M00-S0

Control module, sercos interface, safe speed monitoring 2094-SE02F-M00-S1

Kinetix 6500 Control Modules

Control module, EtherNet/IP network, safe torque-off 2094-EN02D-M01-S0

Control module, EtherNet/IP network, safe speed monitoring 2094-EN02D-M01-S1

Table 3 - Kinetix 6000 Drive Component Catalog Numbers

Drive Components Cat. No.

Integrated power interface (IPIM) module, 400V-class, 15 kW, 24 A (rms) 2094-SEPM-B24-S

Kinetix 6000 shunt module, 200/400V-class, 200 W 2094-BSP2

Kinetix 6000 slot-filler module, 200/400V-class 2094-PRF

Rockwell Automation Publication 2094-UM002E-EN-P - May 2012 23

Page 24

Chapter 1 Start

IMPORTANT

Kinetix Drive Component Compatibility

IAM Module Control Module

2094-xCxx-Mxx-S N/A

2094-SE02F-M00-Sx

2094-BCxx-Mxx-M

(IAM power module)

sercos interface

2094-EN02D-M01-Sx

EtherNet/IP network

The 2094-BCxx-Mxx-M and 2094-BMxx-M power modules contain the same

power structure as the 2094-BCxx-Mxx-S and 2094-BMxx-S drive modules.

Because of this, the 2094-BSP2 shunt module, 2094-PRF slot-filler module, and

2094-PRSx power rails are supported by both drive families.

In addition, 2094-BMxx-M AM power modules with sercos interface are

supported on power rails with a 2094-BCxx-Mxx-S IAM drive module.

Conversely, 2094-BMxx-S AM drive modules are supported on power rails with

a 2094-BCxx-Mxx-M IAM power module with sercos interface.

Kinetix 6500 EtherNet/IP control modules (catalog numbers

2094-EN02D-M01-Sx) are not compatible with IAM/AM modules on the same

Bulletin 2094 power rail with Kinetix 6000 or Kinetix 6200 sercos drives.

Table 4 - IAM and AM Module/Network Compatibility

2094-BMxx-M

2094-xMxx-S

Kinetix 6000 AM Module

Fully compatible Fully compatible Not compatible

Not compatible Not compatible Fully compatible

2094-SE02F-M00-Sx

Kinetix 6200 Control Module

AM Power Modules

2094-EN02D-M01-Sx

Kinetix 6500 Control Module

Kinetix 6000M Integrated Drive-Motor System Compatibility

For additional information on the 2094-BCxx-Mxx-S IAM and 2094-BMxx-S

AM modules, refer to the Kinetix 6000 Multi-axis Servo Drives User Manual,

publication 2094-UM001

.

Bulletin 2094 power rails with Kinetix 6000 (series B) or Kinetix 6200 drives are

compatible with Kinetix 6000M integrated drive-motor (IDM) systems. The

IDM power interface module (IPIM) mounts to the power rail and connects to

as many as 16 IDM units.

Table 5 - IPIM Module Compatibility

IAM Module Control Module

2094-BCxx-Mxx-S (series B) N/A

2094-BCxx-Mxx-M

(IAM power module)

2094-SE02F-M00-Sx sercos interface

2094-EN02D-M01-Sx EtherNet/IP network Not compatible

2094-SEPM-B24-S

IDM Power Interface Module (IPIM)

Fully c ompatible

For more information on Kinetix 6000M integrated drive-motor system

installation, refer to the Kinetix 6000M Integrated Drive-Motor System User

Manual, publication 2094-UM003

.

24 Rockwell Automation Publication 2094-UM002E-EN-P - May 2012

Page 25

Start Chapter 1

Agency Compliance

If this product is installed within the European Union and has the CE mark, the

following regulations apply.

ATT EN TI ON : Meeting CE requires a grounded system, and the method of

grounding the AC line filter and drive must match. Failure to do this renders the

filter ineffective and may cause damage to the filter.

For grounding examples, refer to Grounded Power Configurations on page 93

For more information on electrical noise reduction, refer to the System Design

for Control of Electrical Noise Reference Manual, publication GMC-RM001

.

.

CE Requirements (system without LIM module)

To meet CE requirements when your Kinetix 6200 and Kinetix 6500 system

does not include the LIM module, these requirements apply.

• Install 2090-XXLF-xxxx AC line filters for three-phase input power and

single-phase control power as close to the IAM module as possible.

• Use 2090 series motor power cables or use connector kits and terminate

the cable shields to the chassis clamp provided.

• Combined motor power cable lengths for all Kinetix 6200 and

Kinetix 6500 axes and hybrid cable lengths for all IDM units on the same

DC bus must not exceed 240 m (787 ft) with 400V-class systems. Driveto-motor power cables must not exceed 90 m (295.5 ft).

• Use 2090 series motor feedback cables or use connector kits and properly

terminate the feedback cable shield. Drive-to-motor feedback cables must

not exceed 90 m (295.5 ft).

• Install the Kinetix 6200 and Kinetix 6500 system inside an enclosure. Run

input power wiring in conduit (grounded to the enclosure) outside of the

enclosure. Separate signal and power cables.

Refer to Appendix A on page 231

power wiring and drive/motor interconnect diagrams.

for interconnect diagrams, including input

CE Requirements (system with LIM module)

To meet CE requirements when your Kinetix 6200 and Kinetix 6500 system

includes the LIM module, follow all the requirements as stated in CE

Requirements (system without LIM module) and these additional requirements

as they apply to the AC line filter.

• Install the LIM module (catalog numbers 2094-BL02) as close to the IAM

module as possible.

• Install the LIM module (catalog numbers 2094-BLxxS or 2094-XL75S-

Cx) with line filter (catalog number 2090-XXLF-xxxx) as close to the

IAM module as possible.

When the LIM module (catalog numbers 2094-BLxxS or 2094-XL75SCx) supports two IAM modules, each IAM module requires an AC line

filter installed as close to the IAM module as possible.

Rockwell Automation Publication 2094-UM002E-EN-P - May 2012 25

Page 26

Chapter 1 Start

Notes:

26 Rockwell Automation Publication 2094-UM002E-EN-P - May 2012

Page 27

Chapter 2

Planning the Kinetix 6200 and Kinetix 6500

Drive System Installation

This chapter describes system installation guidelines used in preparation for

mounting your Kinetix 6200 and Kinetix 6500 drive components.

Top ic Pa ge

System Design Guidelines 28

Electrical Noise Reduction 36

ATT EN TI ON : Plan the installation of your system so that you can perform all

cutting, drilling, tapping, and welding with the system removed from the

enclosure. Because the system is of the open type construction, be careful to

keep any metal debris from falling into it. Metal debris or other foreign matter

can become lodged in the circuitry, which can result in damage to components.

Rockwell Automation Publication 2094-UM002E-EN-P - May 2012 27

Page 28

Chapter 2 Planning the Kinetix 6200 and Kinetix 6500 Drive System Installation

IMPORTANT

System Design Guidelines

Use the information in this section when designing your enclosure and planning

to mount your system components on the panel.

For on-line product selection and system configuration tools, including

AutoCAD (DXF) drawings of the product, refer to

http://www.rockwellautomation.com/en/e-tools

.

System Mounting Requirements

• To comply with UL and CE requirements, the Kinetix 6200 and Kinetix

6500 drive systems must be enclosed in a grounded conductive enclosure

offering protection as defined in standard EN 60529 (IEC 529) to IP2X

such that they are not accessible to an operator or unskilled person. A

NEMA 4X enclosure exceeds these requirements providing protection to

IP66.

• The panel you install inside the enclosure for mounting your system

components must be on a flat, rigid, vertical surface that won’t be subjected

to shock, vibration, moisture, oil mist, dust, or corrosive vapors.

• Size the drive enclosure so as not to exceed the maximum ambient

temperature rating. Consider heat dissipation specifications for all drive

components.

• Combined motor power cable lengths for all axes and hybrid cable lengths

for all IDM units on the same DC bus must not exceed 240 m (787 ft)

with 400V-class systems. Drive-to-motor power cables must not exceed 90

m (295.5 ft).

System performance was tested at these cable length specifications.

These limitations also apply when meeting CE requirements.

• Combined length of Ethernet cables on Kinetix 6500 systems connecting

drive-to-drive, drive-to-controller, or drive-to-switch must not exceed 100

m (328 ft).

• Segregate input power wiring and motor power cables from control wiring

and motor feedback cables. Use shielded cable for power wiring and

provide a grounded 360° clamp termination.

• Use high-frequency (HF) bonding techniques to connect the modules,

enclosure, machine frame, and motor housing, and to provide a lowimpedance return path for high-frequency (HF) energy and reduce

electrical noise.

Refer to the System Design for Control of Electrical Noise Reference Manual,

publication GMC-RM001

reduction.

, to better understand the concept of electrical noise

28 Rockwell Automation Publication 2094-UM002E-EN-P - May 2012

Page 29

Planning the Kinetix 6200 and Kinetix 6500 Drive System Installation Chapter 2

IMPORTANT

IMPORTANT

Transformer Selection

The IAM power module does not require an isolation transformer for threephase input power. However, a transformer may be required to match the voltage

requirements of the controller to the available service.

To size a transformer for the main AC power inputs, refer to the Kinetix 6200/

6500 power specifications in the Kinetix Servo Drives Technical Data,

publication GMC-TD003

If using an autotransformer, make sure that the phase to neutral/ground

voltages do not exceed the input voltage ratings of the drive.

Use a form factor of 1.5 for three-phase power (where form factor is used to

compensate for transformer, drive module, and motor losses, and to account

for utilization in the intermittent operating area of the torque speed curve).

For example, to size a transformer to the voltage requirements of a

2094-BC01-M01-M integrated axis module:

2094-BC01-M01-M = 6 kW continuous x 1.5 = 9.0 KVA transformer

.

Rockwell Automation Publication 2094-UM002E-EN-P - May 2012 29

Page 30

Chapter 2 Planning the Kinetix 6200 and Kinetix 6500 Drive System Installation

Circuit Breaker/Fuse Options

The 2094-BCxx-Mxx-M and 2094-BMxx-M drive modules and the

Kinetix 6000M integrated drive-motor system (2094-SEPM-B24-S IPIM

module and MDF-SBxxxxx IDM units) use internal solid-state motor shortcircuit protection and, when protected by suitable branch circuit protection, are

rated for use on a circuit capable of delivering up to 200,000 A. Fuses or circuit

breakers, with adequate withstand and interrupt ratings, as defined in NEC or

applicable local codes, are permitted.

The 2094-BL02 LIM module contains supplementary protection devices and,

when protected by suitable branch circuit protection, is rated for use on a circuit

capable of delivering up to 5000 A. When this module is used, protection on the

line side of the LIM module is required. Fuses must be class J or CC only.

The 2094-BLxxS, and 2094-XL75S-Cx LIM modules contain branch circuit

rated devices suitable for use on a circuit capable of delivering up to 65,000 A

(400V-class).

Refer to the Line Interface Module Installation Instructions, publication

2094-IN005

module.

, for power specifications and more information on using the LIM

The Bulletin 140M and 140U products are another acceptable means of

protection. As with fuses and circuit breakers, you must make sure that the

selected components are properly coordinated and meet applicable codes

including any requirements for branch circuit protection. When applying the

140M/140U product, evaluation of the short circuit available current is critical

and must be kept below the short circuit current rating of the 140M/140U

product.

In most cases, class CC, J, L, and R fuses selected to match the drive input current

rating will meet the NEC requirements or applicable local codes, and provide the

full drive capabilities. Dual element, time delay (slow-acting) fuses should be

used to avoid nuisance trips during the inrush current of power initialization.

30 Rockwell Automation Publication 2094-UM002E-EN-P - May 2012

Page 31

Planning the Kinetix 6200 and Kinetix 6500 Drive System Installation Chapter 2

IMPORTANT

Circuit Breaker and Fuse Specifications

While circuit breakers offer some convenience, there are limitations for their use.

Circuit breakers do not handle high current inrush as well as fuses.

Make sure the selected components are properly coordinated and meet

acceptable codes including any requirements for branch circuit protection.

Evaluation of the short-circuit available current is critical and must be kept below

the short-circuit current rating of the circuit breaker.

The following fuse examples and Allen-Bradley circuit breakers are

recommended for use with 2094-BCxx-Mxx-M IAM power modules when the

Line Interface Module (LIM) is not used.

LIM Module (catalog number 2094-BLxxS) provides branch circuit protection to the IAM power module. Follow all applicable

NEC and local codes.

V AC Input Power Control Input Power DC Common Bus Fuse

IAM Module

Cat. No.

2094-BC01-MP5-M

2094-BC01-M01-M

2094-BC02-M02-M KTK-R-30 (30 A) 1492-SP3D400 140M-F8E-C45 FWJ-40A A70QS40-4

2094-BC04-M03-M LPJ-45SP (45 A)

2094-BC07-M05-M LPJ-80SP (80 A) 140U-H6C3-C90 FWJ-125A A70QS125-4

Bussmann

Fuse

KTK-R-20 (20 A) 1492-SP3D300 140M-F8E-C32

Allen-Bradley Circuit Breaker

Disconnect

N/A

Magnetic

Contactor

140U-H6C3-C50 FWJ-70A A70QS70-4

Bussmann Fuse

FNQ-R-10 (10 A) or

FNQ-R-7.5 (7.5 A)

Allen-Bradley

(1)

Circuit Breaker

1492-SP2D060 or

1492-SP1D150

(2)

Bussmann

Fuse

FWJ-20A14F DCT20-2

Ferraz Shawmut

Fuse

(1) Use FNQ-R-7.5 fuse for higher single-cycle inrush current capability. This is recommended when the continuous control power current exceeds 3.0 A.

(2) Use 1492-SP1D150 circuit breaker for higher single-cycle inrush current capability. This is recommended when the continuous control power current exceeds 3.0 A.

Refer to the Kinetix Servo Drives Technical Data, publication GMC-TD003

additional power specifications for your IAM power module.

, for

Rockwell Automation Publication 2094-UM002E-EN-P - May 2012 31

Page 32

Chapter 2 Planning the Kinetix 6200 and Kinetix 6500 Drive System Installation

Enclosure Selection

This example is provided to assist you in sizing an enclosure for your Bulletin

2094 drive system. The example system consists of these components:

• 6-axis Bulletin 2094 servo drive system

• Line Interface Module (LIM)

• ControlLogix chassis and modules (controller)

Size the Bulletin 2094 servo drive and LIM module and use the results to predict

the amount of heat dissipated into the enclosure. You will also need heat

dissipation data from other equipment inside the enclosure (such as the

ControlLogix controller). Once the total amount of heat dissipation (in watts) is

known, you can calculate the minimum enclosure size.

Table 6 - Bulletin 2094 System Heat Dissipation Example

Enclosure Component Description Loading

2094-BC02-M02-M

2094-BM02-M Axis module (AM), 400/460V, 15 A 60% 93

2094-BM02-M Axis module (AM), 400/460V, 15 A 60% 93

2094-BM01-M Axis module (AM), 400/460V, 9 A 40% 73

2094-BM01-M Axis module (AM), 400/460V, 9 A 40% 73

2094-BM01-M Axis module (AM), 400/460V, 9 A 20% 57

2094-BL25S Line interface module (LIM), 400/460V, 25 A; 24V DC 20 A 100% 43

2094-PRS6 Power rail, 460V, 6 axis N/A 0

2090-XB33-32 Resistive brake module (RBM), 33 A, 32 Ω N/A 30

Total Kinetix 6200 and Kinetix 6500 system wattage 578

Integrated axis module (IAM),

400/460V

(1)

15 kW (converter section) 20% 44

15 A (inverter section) 40% 72

Heat Dissipation

watts

(1)

(1) To determine heat dissipation specifications for your drive system components, refer to Tabl e 8 on page 34.

32 Rockwell Automation Publication 2094-UM002E-EN-P - May 2012

Page 33

Planning the Kinetix 6200 and Kinetix 6500 Drive System Installation Chapter 2

75

60

45

30

15

0

0 2 0 4 0 6 0 8 0 100

Backplane

Power Load

(watts)

Real Power (watts)

1756-P B72

1756-P B75

DC

A =

4.08Q

T - 1.1

A =

0.38 (612)

1.8 (20) - 1.1

= 6.66 m

2

Table 7 - ControlLogix System Heat Dissipation Example

Enclosure Component Description

Backplane Power Load

watts

1756-M08SE 8-axis sercos interface module 3.2 0

1756-L5563 L63 ControlLogix processor 4.5 0

1756-IB16D 16 -point input module 0.84 5.8

1756-OB16D 16 -point output module 4.64 3.3

1756-ENxTx EtherNet/IP communication module 4.0 0

Backplane total 17.18

(2)

1756-PB72 24V DC ControlLogix power supply N/A 25

1756-A7 7-slot mounting chassis N/A N/A

Total ControlLogix system wattage 34.1

(1) For ControlLogix module specifications, refer to the ControlLogix Selection Guide, publication 1756-SG001.

(2) Real power heat dissipation is determined by applying the backplane power load (17.18W) to the graph below.

(1)

Figure 9 - ControlLogix Real Power

Heat Dissipation

watts

N/A

(2)

(1)

For backplane power loading requirements of other ControlLogix power

supplies, refer to the ControlLogix Selection Guide, publication 1756-SG001

.

In this example, the amount of power dissipated inside the cabinet is the sum of

the Bulletin 2094 system value (578 W) and the ControlLogix system value

(34 W) for a total of 612 W.

With no active method of heat dissipation (such as fans or air conditioning)

either of these approximate equations can be used.

Metric Standard English

0.38Q

A =

1.8T - 1.1

Where T is temperature difference between inside air and

outside ambient (°C), Q is heat generated in enclosure

(Watts), and A is enclosure surface area (m

2

). The exterior

surface of all six sides of an enclosure is calculated as

Where T is temperature difference between inside air and

outside ambient (°F), Q is heat generated in enclosure

(Watts), and A is enclosure surface area (ft²). The exterior

surface of all six sides of an enclosure is calculated as

A = 2dw + 2dh + 2wh A = (2dw + 2dh + 2wh) / 144

Where d (depth), w (width), and h (height) are in meters. Where d (depth), w (width), and h (height) are in inches.

Total system watts dissipated (Q) was calculated at 612 W. The maximum

ambient rating of the Bulletin 2094 system is 50 °C (122 °F) and if the maximum

environmental temperature is 30 °C (86 °F), then T=20 in the equation below.

Rockwell Automation Publication 2094-UM002E-EN-P - May 2012 33

Page 34

Chapter 2 Planning the Kinetix 6200 and Kinetix 6500 Drive System Installation

In this example, the enclosure must have an exterior surface of 6.66 m2. If any

portion of the enclosure is not able to transfer heat, it should not be included in

the calculation.

Because the minimum cabinet depth to house the 460V drive (selected for this

example) is 302 mm (11.9 in.), then the cabinet needs to be approximately 2500

mm (high) x 950 mm (wide) x 302 mm (deep).

2 x (0.3 x 0.95) + 2 x (0.3 x 2.5) + 2 x (0.95 x 2.5) = 6.82 m

2

Because this cabinet size is considerably larger than what is necessary to house the

system components, it may be more efficient to provide a means of cooling in a

smaller cabinet. Contact your cabinet manufacturer for options available to cool

your cabinet.

Table 8 - Power Dissipation Specifications

Usage as % of Rated Power Output

Bulletin 2094 Drive Modules

IAM (converter) power module

2094-BC01-MP5-M

2094-BC01-M01-M 33

2094-BC02-M02-M 3644546475

2094-BC04-M03-M 50 67 87 110 135

2094-BC07-M05-SM 71 101 137 179 226

IAM (inverter) module or AM power module

2094-BC01-MP5-S or 2094-BMP5-M 46 54 61 69 77

2094-BC01-M01-S or 2094-BM01-M 57 73 90 108 126

2094-BC02-M02-S or 2094-BM02-M 53 72 93 116 142

2094-BC04-M03-S or 2094-BM03-M 94 130 169 211 255

2094-BC07-M05-S or 2094-BM05-M 121 183 252 326 407

Shunt module - 2094-BSP2 68 121 174 227 280

IPIM module - 2094-SEPM-B24-S

(1)

20% 40% 60% 80% 100%

(2)

18 21 25 29

(2)

To calculate power dissipation for IPIM modules on your 2094 power rail, refer to the Kinetix 6000M Integrated Drive-Motor User

Manual, publication 2094-UM003

.

(watts)

34

(1) Power dissipation for the Bulletin 2094 control modules, catalog numbers 2094-SE02F-M00-Sx and 2094-EN02D-M01-Sx, is included in the IAM and AM power module specific ations.

(2) Internal shunt power is not included in the calculations and must be added based on utilization.

34 Rockwell Automation Publication 2094-UM002E-EN-P - May 2012

Page 35

Planning the Kinetix 6200 and Kinetix 6500 Drive System Installation Chapter 2

IMPORTANT

F

Clearance right of the

module is not required.

(1)

Clearance above

for airflow and installation.

Clearance left of the

module is not required.

(1)

Kinetix 6200 or

Kinetix 6500 Drive System

Mounted on 2094 Power Rail