Page 1

Quick Start

Ultra1500 Digital Drives

(Catalog Numbers 2092-DA1, 2092-DA2, 2092-DA3, 2092-DA4, and 2092-DA5)

This Quick Start guide provides the basic information for installing and verifying the

operational status of an Ultra1500™ with a compatible motor. This Quick Start is intended

for qualified drive service personnel only.

For detailed and application related information about Ultra1500 drives, refer to the on-line

help provided with v1.60 or higher of Ultraware™ software (catalog number 2098-UWCPG)

and the Ultra1500 Digital Drive User Manual (publication 2092-UM001x-EN-E).

Set up your drive as easy as:

• Wire the drive.

• Configure using the Setup Wizard in Ultraware.

• Spin the motor.

Important User Information

Because of the variety of uses for the products described in this publication, those responsible

for the application and use of this control equipment must satisfy themselves that all

necessary steps have been taken to assure that each application and use meets all performance

and safety requirements, including any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in this guide are

intended solely for purposes of example. Since there are many variables and requirements

associated with any particular installation, Allen-Bradley® does not assume responsibility or

liability (to include intellectual property liability) for actual use based upon the examples

shown in this publication.

Allen-Bradley publication SGI-IN001A-EN-P, Safety Guidelines for the Application, Installation

and Maintenance of Solid-State Control (available from your local Allen-Bradley office), describes

some important differences between solid-state equipment and electromechanical devices

that should be taken into consideration when applying products such as those described in

this publication.

Unpacking Your Ultra1500 Digital Drive

The box contains the following:

• One Ultra1500 drive (catalog numbers are listed above),

• Three removable plugs mounted on the power connectors of the drive,

• One connector tool for opening wire clamps on power connectors, and

• This Quick Start

document.

Publication 2092-QS001D-EN-P — July 2005

Page 2

2 Ultra1500 Digital Drives Quick Start

Installation Checklist

Always adhere to the following installation guidelines:

Mechanical Checklist

❒ The ambient temperature of the drive must be in the range of 0°C to 50°C (32°F to 122°F).

❒ The air should be free of oil, corrosives, or electrically conductive contaminates.

❒ The humidity of the drive environment must not exceed 95%, and water must never condense

on the drive.

❒ Ensure that adequate clearances are present above, below, and at the sides of the drive for

ventilation (see Figure 1). Allow adequate clearance in front for proper cable bend radius.

❒ Size the drive enclosure adequately to properly manage the ambient temperature, after taking the

drive power dissipation into consideration.

❒ Implementation of safety circuits and risk assessment is the responsibility of the machine

builder.

Electrical Checklist

❒ Follow all applicable local codes and regulations to safely ground your system.

❒ Separate AC input power wiring and motor power cables from other control and motor

feedback cables.

❒ When using transformer isolation of the input power, the secondary must be grounded.

Transformers must be sized at double the sum of the output power of each axis.

❒ The electronic equipment, enclosure, machine frame, and motor housing should all be

electrically bonded at high frequencies. Heavy braid wire should be used when mechanical

bonding is not possible.

❒ In applications that repeatedly apply and remove main AC power to the drive, ensure that the

cycling rate of the drive is not exceeded.

❒ AC line filters are recommended and should be located as close to the drive as possible.

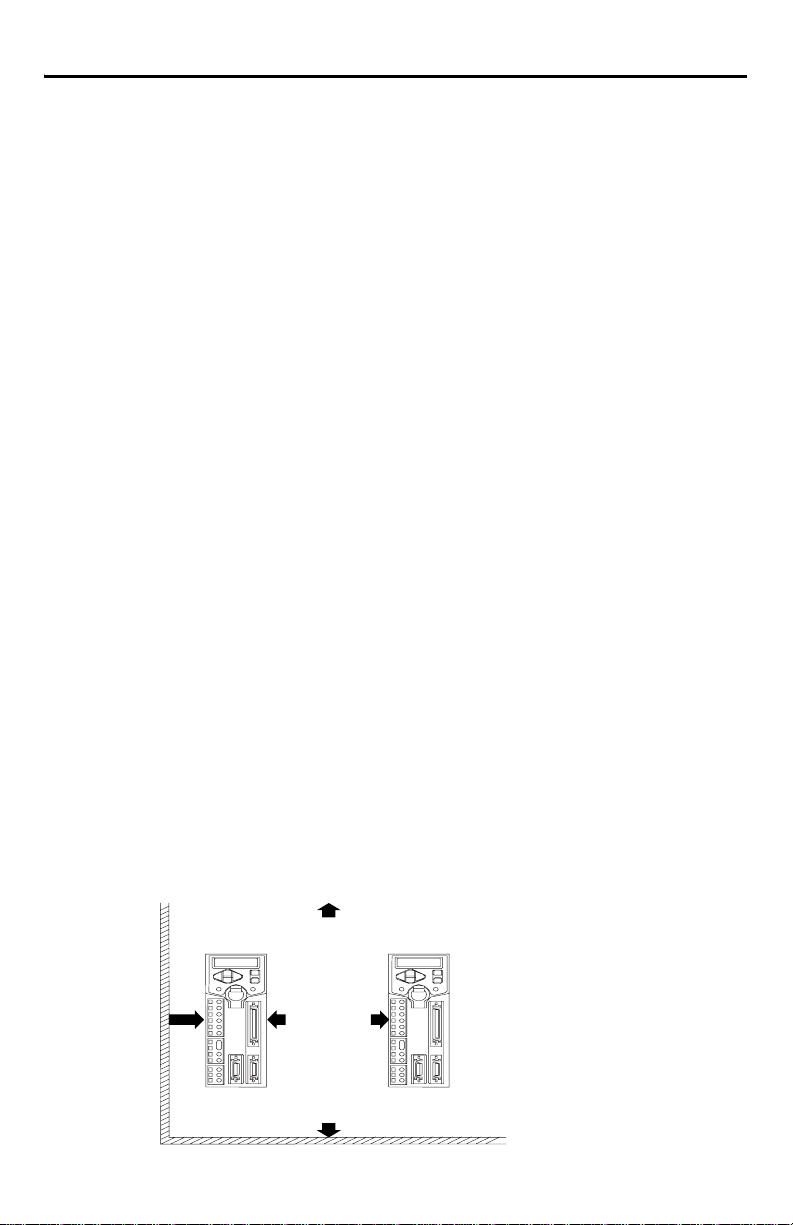

Figure 1 Clearance Requirements for 2092 Drives

50.0 mm (1.97 in.)

above drives

30.0 mm

(1.18 in.)

from adjacent

wall

Publication 2092-QS001D-EN-P — July 2005

10.0 mm

(0.39 in.)

between

drives

below drives

50.0 mm (1.97 in.)

Page 3

Ultra1500 Digital Drives Quick Start 3

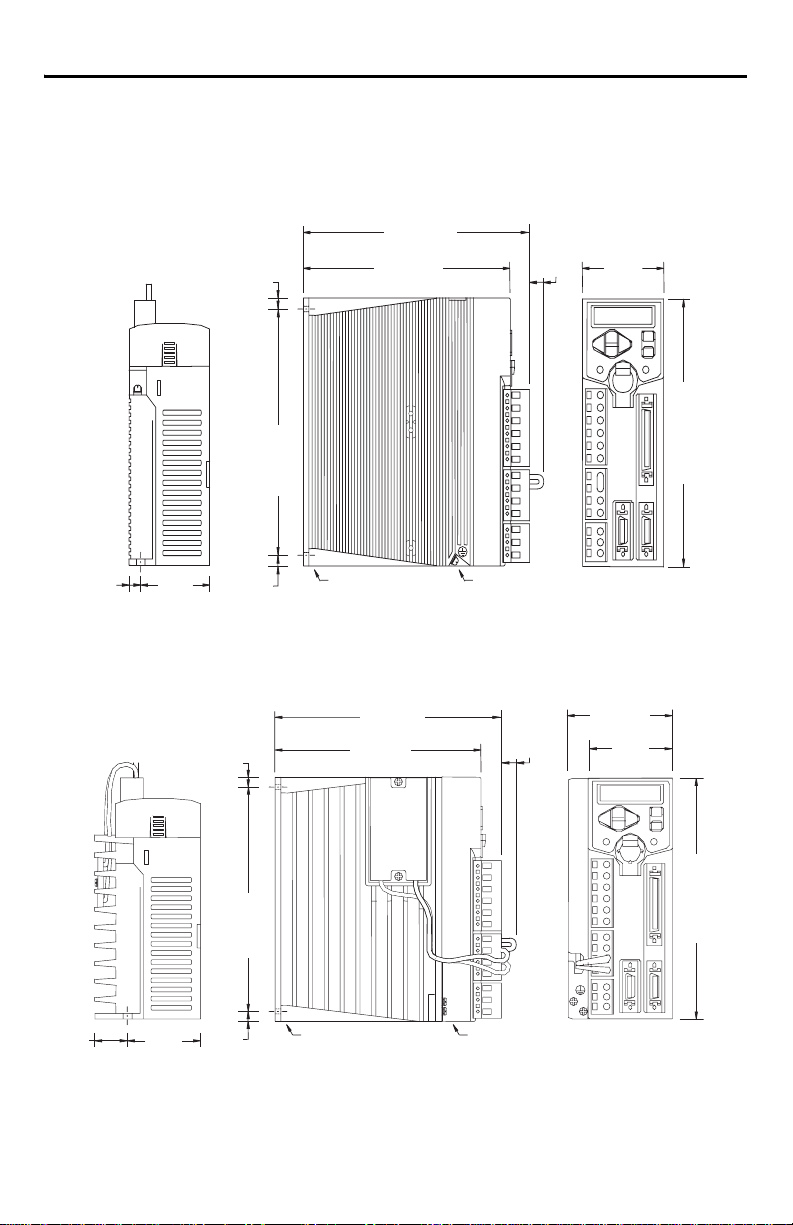

Drive Dimensions and Mounting Locations

Drive dimensions are shown in the following diagrams. Clearance requirements are shown on page 2.

Figure 2 Dimensional Outline Drawing for 2092-DA1 and 2092-DA2

153.0

5.0

(0.20)

(6.02)

140.0

(5.51)

145.0

(5.70)

12.0

(0.47)

55.0

(2.17)

155.0

(6.10)

5.0

(0.20)

Dimensions are in millimeters (inches). Drives are designed to metric dimensions; inches are mathematical conversion.

50.0

(1.97)

5.0

(0.20)

Mounting hole (top)

and slot (bottom)

require M4 x 10 bolts

Chassis ground

terminal

Figure 3 Dimensional Outline Drawing for 2092-DA3

153.0

(6.02)

5.0

(0.20)

145.0

(5.70)

20.0

(0.79)

Dimensions are in millimeters (inches). Drives are designed to metric dimensions; inches are a mathematical conversion.

50.0

(1.97)

5.0

(0.20)

Mounting hole (top) and

slot (bottom) require

M4 x 10 bolts

140.0

(5.52)

12.0

(0.47)

Chassis ground terminals (2)

70.0

(2.76)

55.0

(2.17)

155.0

(6.10)

Publication 2092-QS001D-EN-P — July 2005

Page 4

4 Ultra1500 Digital Drives Quick Start

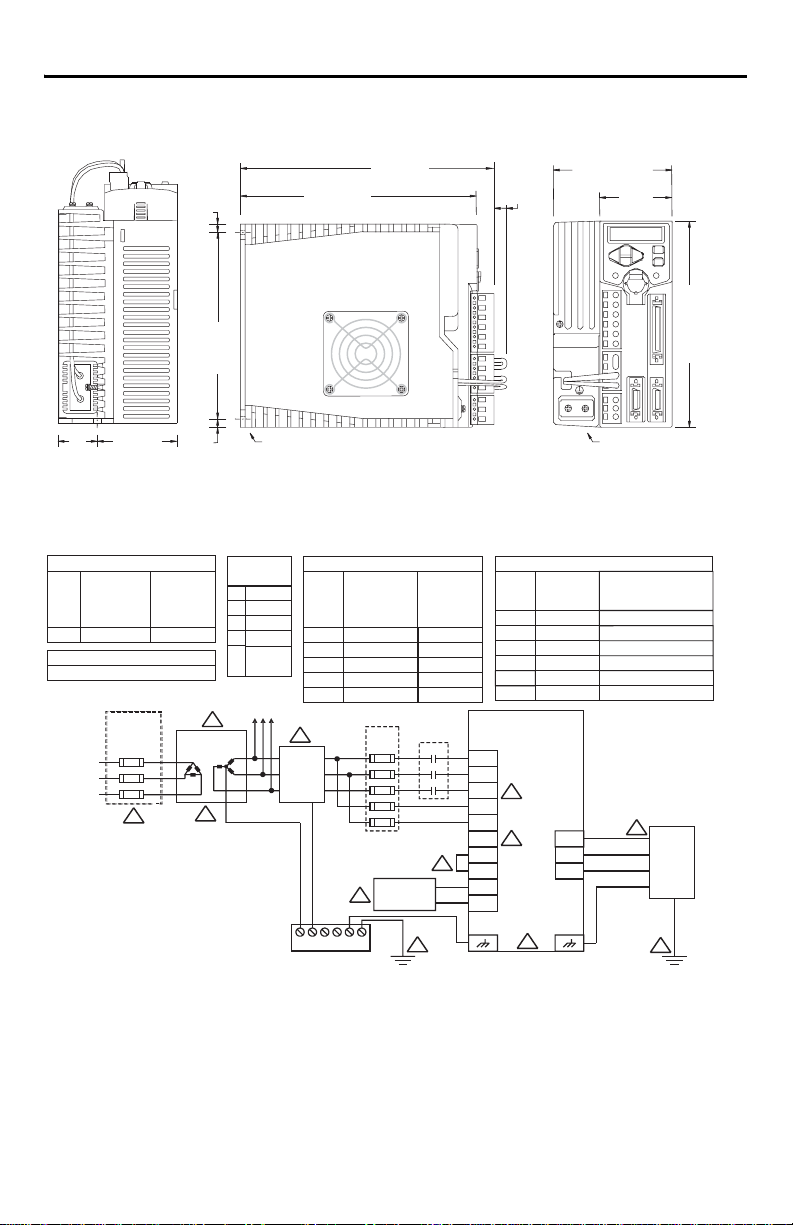

Figure 4 Dimensional Outline Drawing for 2092-DA4 and 2092-DA5

90.0

(3.54)

55.0

(2.17)

Chassis ground

terminals (2)

155.0

(6.10)

5.0

(0.20)

185.0

(7.28)

198.0

(7.80)

12.0

(0.47)

145.0

(5.70)

63.0

27.0

(1.06)

(2.48)

5.0

(0.20)

Mounting hole (top) and slot

(bottom) require M5 x 10 bolts

Dimensions are in millimeters (inches). Drives are designed to metric dimensions; inches are a mathematical conversion.

Power Wiring Diagram

MOTOR POWER WIRES U, V, W, AND GND

MOTOR

MOTOR POWER

MATING CONNECTOR

CONTACT SIZE

2.5 mm (14 AWG)

TL-SERIES

TERMINAL STRIP ACCEPTABLE WIRE RANGES

0.8 - 2.5 mm (28 - 12 AWG)

230V

3-PHASE

AC LINE

50/60 HZ

2

2

FUSED

DISCONNECT

OR CIRCUIT

BREAKER

1

MINIMUM

RECOMMENDED

POWER WIRE SIZE

O

(75 C COPPER)

2.5 mm (14 AWG)

2

2

1:1 ISOLATION

TRANSFORMER

3

MOTOR POWER

CONNECTOR

PIN

SIGNAL

A

B

W

C

D

MOTOR CASE

(GROUND)

DRIVES

U

V

4

AC

LINE

FILTER

DRIVE

2092-DA1

2092-DA2

2092-DA3

2092-DA4

2092-DA5

INPUT POWER WIRES

TERMINALS

L1, L2, L1C, L2C, GND

L1, L2, L1C, L2C, GND

L1, L2, L1C, L2C, GND

L1, L2, L3, L1C, L2C, GND

L1, L2, L3, L1C, L2C, GND

FUSE

BLOCK

SHUNT

5

RESISTOR

MINIMUM

RECOMMENDED

POWER WIRE SIZE

O

(75 C COPPER)

2

2.5 mm (14 AWG)

2

2.5 mm (14 AWG)

2

2.5 mm (14 AWG)

2

2.5 mm (14 AWG)

2

2.5 mm (14 AWG)

M1

L1C

L2C

7

DIGITAL DRIVE MODULE INPUT CURRENT REQUIREMENTS

DRIVES

TERMINALS

2092-DA1

L1, L2, GROUND

L1, L2, GROUND

2092-DA2

L1, L2, GROUND

2092-DA3

L1, L2, L3, GROUND

2092-DA4

L1, L2, L3, GROUND

2092-DA5

L1C, L2C

ALL

ULTRA1500

2092-DA1

2092-DA2

2092-DA3

L1

2092-DA4

L2

2092-DA5

L3

8

N

9

P1

P2

B1

B2

MAXIMUM

CURRENT REQUIREMENT,

(AMPS, AC RMS)

3.3 AMPS AC at 200-240 VOLTS AC

5.5 AMPS AC at 200-240 VOLTS AC

8.0 AMPS AC at 200-240 VOLTS AC

11.0 AMPS AC at 200-240 VOLTS AC

15.0 AMPS AC at 200-240 VOLTS AC

2.0 AMPS AC at 200-240 VOLTS AC

U

V

W

11

MOTOR

Notes:

1. A supply disconnecting device is required for maintenance and safety. Local regulations should be observed.

2. If using an isolation transformer, ensure the phase to neutral/ground voltage does not exceed the input ratings of the drive.

3. Isolation transformer is optional. If used, the secondary of the transformer must be grounded.

4. AC line filter and shielded motor cable are to be used for improving the drive module's electromagnetic compatiblity (EMC), and are required to meet European EMC directive.

CAUTION: AC line filters have large leakage currents and require discharge time upon power removal.

Wiring between the drive module and filter should be kept as short as possible. The common ground bus bar should be as close to the drive as possible.

5. Internal shunt resistor is present only on 2092-DA3, 2092-DA4, and 2092-DA5 drives. B1 and B2 should be left disconnected on 2092-DA1 and 2092-DA2 drives.

6. High-frequency grounding, using heavy braided wires, should connect together the electronic equipment, electrical enclosure, machine frame, and motor housing.

7. If the power factor or harmonic distortion needs improvement, the jumper from P1 to P2 can be replaced with an inductor.

8. 2092-DA1, 2092-DA2, and 2092-DA3 drives are single-phase AC input drives; input power is not connected to L3 on these drives. .

9. DC Bus Voltage connection - not an AC power input.

10. 2092-DA1 and 2092-DA2 drives have one grounding screw on the heatsink. 2092-DA3, 2092-DA4, and 2092-DA5 drives have two grounding screws on the heatsink.

Tighten the ground terminal screw(s) to 1.25 Nm (11 lbs-in.)

11. Refer to manual included with motor for power, feedback, and brake interconnect information (pinouts and/or wire colors).

12. Wire sizes are minimum recommended values. Local regulations should be observed.

GROUND BAR

6

10

6

Publication 2092-QS001D-EN-P — July 2005

Page 5

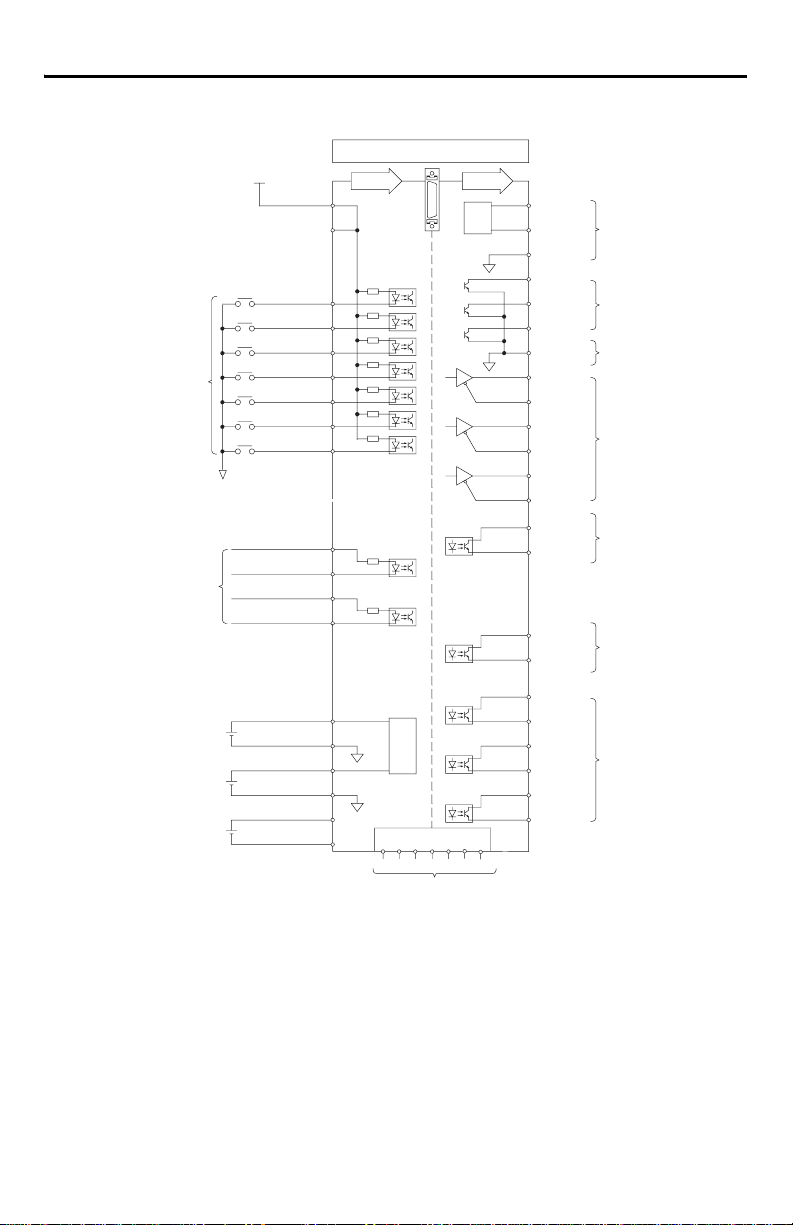

I/O Interface Diagram

24V

Active Low

Pro grammab le

Digital Inputs

24V Ground

Position

Comma nd

Speed Command

-10V to +10V

Current Command

-10V to +10V

3.6V Backup Battery

for Absolute Encoder

24V Power

+24VIN

INPUT1

INPUT2

INPUT3

INPUT4

INPUT5

INPUT6

INPUT7

AX+

AX-

BX+

BX-

VCMD+

VCMD-

ICMD+

ICMD- 22

BAT+

BAT-

CN1

Input Output

1

2

3

4

5

6

7

8

9

11

12

13

14

19

20

A/D

21

49

25

15 26 35

16 24

Ultra1500 Digital Drives Quick Start 5

28

D/A

36 50

AOUT1

23

AOUT2

27

ACOM

37

FAULT1

38

FAULT2

39

FAULT3

40

FCOM

29

AM+

30

AM-

31

BM+

32

BM-

33

IM+

34

IM-

17

Z-PULSE+

18

Z-PULSE-

45

FAULT+

46

FAULT-

41

OUTPUT1+

42

OUTPUT1-

43

OUTPUT2+

44

OUTPUT2-

47

OUTPUT3+

48

OUTPUT3-

Analog Output

-10V to +10V

Binary

Fault

Code

Output

Binary Fault

Code Ground

Buffer ed

Encoder

Output

Encoder

Marker

Pulse

Fault

Output

24V

Pro grammab le

Digital

Outputs

Reserved

Drive Setup

The Setup Wizard found in the Commands menu of Ultraware software (v1.60 or higher) is a quick

way to configure your Ultra1500 servo system. A step-by-step procedure assists in the selection of

controls and motor to be configured with the Ultra1500 drive, and then tunes the assembled system.

For detailed hardware, interconnect, and application related information about Ultra1500 drives, refer

to the following:

• The on-line help provided with Ultraware software, v1.60 or higher (catalog no. 2098-UWCPG).

• The Ultra1500 Digital Drive User Manual (publication 2092-UM001x-EN-E).

Publication 2092-QS001D-EN-P — July 2005

Page 6

6 Ultra1500 Digital Drives Quick Start

Figure 5 Ultra1500 Front Panel Display and Connections

7-Segment LED

Display

Left/Right and

Up/Down Keys

Main Power Indicator

Input Power

L1 - Main AC Power

L2 - Main AC Power

L3 - Main AC Power

L1C - Control Power

L2C - Control Power

N - DC Bus Negative

DC Bus and Shunt Power

P1 - Diode Bridge Output

P2 - DC Bus Positive

B1 - Shunt Resistor +

B2 - Shunt Resistor -

Motor Power

U - Mtr Power U-Phase

V - Mtr Power V-Phase

W - Mtr Power W-Phase

CN3 - Serial Interface

1 - GND

2 - Reserved

3 - GND

4 - Reserved

5 - GND

6 - Reserved

7 - Reserved

8 - VCC

9 - VCC

10 - VCC

11 - XMT

12 - RCV

13 - Reserved

14 - Reserved

15 - Reserved

16 - Reserved

17 - Reserved

18 - Reserved

19 - Reserved

20 - Reserved

CN2 - Motor Feedback

1 - ECOM

2 - TS

3 - A+

4 - A5 - B+

6 - B7 - I+

8 - I9 - Reserved

10 - S1/SD+

BATT

L3

L1C

P1P2B1B2 L1L2L2CN

CN3

UVW

CN1

CN2

11 - Reserved

12 - Reserved

13 - SD14 - S2

15 - Reserved

16 - S3

17 - Reserved

18 - BAT+

19 - BAT20 - EPWR

Mode/Set Key

Enter Key

Control Power Indicator

Battery Holder (connector inside)

1 - Positive 2 - Negative

CN1 - Input/Output

1 - +24V IN

2 - +24V IN

3 - INPUT1

4 - INPUT2

5 - INPUT3

6 - INPUT4

7 - INPUT5

8 - INPUT6

9 - INPUT7

10 - Reserved

11 - AX+

12 - AX13 - BX+

14 - BX15 - Reserved

16 - Reserved

17 - Z-PULSE+

18 - Z-PULSE19 - VCMD+

20 - VCMD21 - ICMD+

22 - ICMD23 - AOUT2

24 - Reserved

25 - BAT-

26 - Reserved

27 - ACOM

28 - AOUT1

29 - AM+

30 - AM31 - BM+

32 - BM33 - IM+

34 - IM35 - Reserved

36 - Reserved

37 - FAULT1

38 - FAULT2

39 - FAULT3

40 - FCOM

41 - OUTPUT1+

42 - OUTPUT143 - OUTPUT2+

44 - OUTPUT245 - FAULT+

46 - FAULT47 - OUTPUT3+

48 - OUTPUT349 - BAT+

50 - Reserved

Publication 2092-QS001D-EN-P — July 2005

Page 7

Ultra1500 Digital Drives Quick Start 7

Mating Connectors

Connector Type Wire Size A-B Connector Kit or

Input Power Single-row, spring

DC Bus and Shunt Power Wago 231-204/026-000

Output (Motor) Power Wago 231-203/026-000

CN1 - Input/Output 50-pin mini-D 0.2 mm

CN2 - Motor Feedback 20-pin mini-D 9101-1477

clamp connectors

with 7.5 mm spacing

2

2.5 - 0.8 mm

(12 - 28 AWG)

8 mm (0.3 in.) of wire

exposed

2

(24 - 30 AWG)

Manufacturer P/N

Wago 231-206/026-000

9101-1476

1

1

1

CN3 - Serial Interface 20-pin mini-D

1 Tool (Wago 231-131) for opening individual cage clamps on abo ve power connectors is supplied.

Drive Displays

The 7-segment display provides operational information when the drive is functioning, or warning/

error messages when abnormalities are encountered.

Normal operational information consists of six characters that display data in three categories. The

categories consist of a Control Mode (characters 0 and 1), a Row Display (2), and Status (3 to 5).

Figure 6 depicts these categories and defines the information provided. Overtravel displays (see the

table following Figure 6) occur if the drive detects an overtravel condition.

Figure 6 Operational Drive Displays

Character: 0 1 2 3 4 5

Control Mode: Characters 0 and 1

C = Analog Current

d = Dual Current Command

F = Follower

S = Analog Speed

P = Preset Velocity

Row Display: Character 2

Top Row = Inactive for any Current mode

Active if Velocity Mode. and Velocity Error is within the velocity window

Active if Follower Mode. and Position Error is within following error setting

Middle Row = Active if velocity exceeds Up To Speed parameter

Bottom Row = Active for hall startup motors once the commutation angle is set

Active for TL motor once the first index pulse occurs

Status: Characters 3 through 5

rdy = Drive is disabled, but ready to be enabled

run = Drive is enabled and motor is under control

Overtravel Display Possible Cause Action/Solution

A Positive Overtravel condition is

detected.

Apply motion in a negative direction to back

off limit.

Positive Overtravel

A Negative Overtravel condition is

detected.

Apply motion in a positive direction to back

off limit.

Negative Overtravel

Publication 2092-QS001D-EN-P — July 2005

Page 8

8 Ultra1500 Digital Drives Quick Start

Warning and Error Displays

Warnings or errors are displayed by the drive as shown and explained in the following tables.

• Warnings are drive abnormalities that allow motor control to continue. The Warning display

uses only the last three digits of the six-digit display.

• Errors are serious abnormalities that do not allow motor control. The Error display alternates

between a three-digit error code and a six-digit text message.

Warning Display Possible Cause Action/Solution

3.2V or less output from encoder battery

Absolute Encoder Battery

or external power supply.

Control power is applied to the drive

Power Up Overspeed

while the motor is in motion.

Improper setting of analog current scale Verify scaling parameter corresponds to

Over Current Command

System cannot meet motion profile • Verify velocity loop tuning.

Incorrect current limit settings Verify current limits do not restrict current to

Improper setting of analog velocity scale Verify scaling parameter corresponds to

Over Speed Command

System cannot meet motion profile • Verify position loop tuning.

Inappropriate assignment of digital

Digital I/O Assignment

1 Battery replacement causes los s of absolute position. Homing m ay be necessary.

Error

Code

Tex t

Message

inputs or outputs

Possible Cause Action/Solution

Motor thermal switch trips due to:

Motor Overtemperature

• High motor ambient temperature,

and/or

• Excessive current

Motor wiring error Check motor wiring.

Incorrect motor selection Verify the proper motor has been selected.

Replace battery or verify external power

1

supply.

After verifying motor has stopped, recycle

control power.

analog signal range.

• Verify system sizing.

less than system capabilities.

analog signal range.

• Verify system sizing.

• If operated in preset mode, verify presets

are assigned.

• If operated in a normal/override mode,

verify the override function is assigned.

• Operate within (not above) the continuous

torque rating for the ambient temperature.

• Lower ambient temperature, or increase

motor cooling.

Publication 2092-QS001D-EN-P — July 2005

Page 9

Ultra1500 Digital Drives Quick Start 9

Error

Code

Tex t

Message

IPM Error

Bus Undervoltage

Bus Overvoltage

Motor Overspeed

Excess Position Error

Motor Continuous Current

Overload

Possible Cause Action/Solution

Motor cables shorted Verify continuity of motor power cable and

connector.

Motor winding shorted internally Disconnect motor power cables from the

motor. If the motor is difficult to turn by hand,

it may need to be replaced.

Drive temperature too high • Check for clogged vents or defective fan.

• Ensure cooling is not restricted by

insufficient space around the drive.

Operation above continuous power

rating

• Verify ambient temperature is not too

high.

• Operate within the continuous power

rating.

• Reduce acceleration rates.

Drive has a bad IPM output, short circuit,

or overcurrent

Remove all power and motors connections,

then perform a continuity check from the DC

bus to the U, V, and W motor terminals. If

continuity exists, check for wire fibers

between terminals, or send drive in for repair.

Low AC line/AC power input • Verify voltage level of the incoming AC

power.

• Check AC power sources for glitches or

line drop.

• Install uninterruptible power supply (UPS)

on the AC input.

Attempted to enable drive without main

Apply main power before enabling drive.

power active.

Excessive regeneration of power (i.e.,

When the motor is driven by an external

mechanical force, it may regenerate too

much peak energy through the drive’s

power supply and the drive faults to save

itself from an overload.)

• Verify shunt circuit.

• Adjust motion profile to stay within the

range of the regenerative resistor.

• Replace regenerative transistor.

• Replace drive.

Excessive AC input voltage Verify input is within specification.

Motor speed exceeds maximum • Confirm encoder wiring.

• Retune drive system.

• Verify input gain of external speed or

torque command.

Position error exceeds permitted value • Increase following error limit.

• Check position loop tuning.

The internal filter protecting the motor

from overheating has tripped

• Reduce acceleration rates.

• Reduce duty cycle (ON/OFF) of

commanded motion.

• Increase time permitted for motion.

• Use larger drive and motor.

• Checking tuning.

Publication 2092-QS001D-EN-P — July 2005

Page 10

10 Ultra1500 Digital Drives Quick Start

Error

Code

Tex t

Message

Drive Overload

Encoder Data Range Error

Encoder Cable Open

Encoder Data Parameter

Error

Drive Overtemperature

AC Line Loss

User Parameter

Initialization Error

Current Feedback Offset

User Parameter Checksum

Error

Watchdog Timeout

PWM Hardware Error

Possible Cause Action/Solution

The motion application requires average

drive current in excess of rated capability

• Reduce acceleration rates.

• Reduce duty cycle (ON/OFF) of

commanded motion.

• Increase time permitted for motion.

• Use larger drive and motor.

• Check tuning.

Encoder not programmed correctly Replace motor.

Encoder memory corrupted

Communication not established with an

intelligent encoder.

Hall error

• Verify motor selection.

• Verify the motor supports automatic

identification.

• Verify encoder wiring.

Encoder not programmed correctly Replace motor.

Encoder memory corrupted

Excessive heat exists in the drive • Verify cooling fan operation (2092-DA4

and 2092-DA5 only).

• Check tuning.

• Reduce acceleration rate.

• Reduce duty cycle (ON/OFF) of

commanded motion.

• Increase time permitted for motion.

• Use larger drive and motor.

Poor quality power Increase Ride Through time.

Attempted to enable drive without main

Apply main power before enabling drive.

power active

Phase connection missing Remove power and verify all physical

connections.

Fault Delay parameter is set too short Increase the Fault Delay parameter setting.

Error in parameter memory storage • Reinitialize parameter.

• Reset drive to factory defaults.

Defective hardware Replace drive.

Checksum error • Confirm and reset parameter.

• Reset drive to factory defaults.

Excessive system noise Verify wiring and installation methods.

Defective hardware Replace drive.

Defective hardware Contact A-B.

Publication 2092-QS001D-EN-P — July 2005

Page 11

Ultra1500 Digital Drives Quick Start 11

Error

Code

Tex t

Message

User Parameter Range

Error

Drive Initialization Error

Shunt Overload Protection

Shunt Overcurrent

Protection

Absolute Encoder Battery

Error

Absolute Encoder

Overspeed

Absolute Encoder

Multi-turn Count Error

Encoder Single-Turn Count

Error

Drive Set Up

Motor Power Cable Open

Motor Instantaneous

Current Overload

Motor Mismatch

Possible Cause Action/Solution

Range of parameter is invalid • Enter parameter with value(s) within

range.

• Reset drive to factory defaults.

Hardware error Replace drive.

Power at regenerative resistor exceeds

the permitted value

Shunt resistor is disconnected or

damaged

Shunt current exceeded allowable

instantaneous value

Adjust motion profile to stay within the range

of the regenerative resistor.

• Verify resistor connection.

• Verify resistance of shunt resistor.

• Verify shunt is not shorted or damaged.

• Verify load energy is not excessive during

deceleration.

Encoder Backup Battery parameter is set

to installed, but a battery is not installed.

Battery voltage is sensed below 2.7V dc. • Confirm battery voltage and connection.

Battery powered encoder is

mechanically rotated at high speed

while drive is powered down

Set Encoder Backup Battery parameter to Not

Installed.

• Replace battery.

• Mechanically disengage motor from

system.

• Cycle power to drive and reset alarm.

Noise in the encoder Cycle power to drive and reset alarm.

Defective encoder Replace motor.

Noise in the encoder Cycle power to drive and reset alarm.

Defective encoder Replace motor.

The drive operating mode and motor

selection are incompatible.

Change the operating mode and/or the motor

selection, and reset the drive.

Motor cable open Verify power connection between motor and

drive.

Motion profile requires a peak current

for an excessive time interval

• Verify motor wiring.

• Adjust accel/decel time.

• Confirm motor selection.

Defective current feedback sensing Verify phase currents.

Dynamic braking current of the selected

motor exceeds twice the drive peak

current rating

Install a different motor.

Publication 2092-QS001D-EN-P — July 2005

Page 12

12 Ultra1500 Digital Drives Quick Start

Error

Code

Tex t

Message

Continuous Power

Overload

Encoder Type Mismatch

Encoder Communication

Error

Special Communication

Error

Position Command

Frequency Error

Possible Cause Action/Solution

Motion application requires average

drive power in excess of rated capability

• Reduce acceleration rates.

• Reduce duty cycle (ON/OFF) of

commanded motion.

• Increase time permitted for motion.

• Use larger drive and motor.

• Check tuning.

Motor encoder signals do not match

drive configuration

Verify motor selection.

Defective encoder Replace motor.

Wiring between drive and encoder is

faulty or disconnected, or EMI (noise)

• Verify encoder wiring.

• Contact A-B.

disrupts encoder signals.

Communications error between host and

drive (noise)

Input frequency limit exceeded • Verify hardware type selected in the drive

• Verify serial cable.

• Check for noise on serial interface.

matches the physical hardware.

• Change from open collector to line drive.

• Reduce the speed command.

• Apply gearing.

Publication 2092-QS001D-EN-P — July 2005

Page 13

Ultra1500 Digital Drives Quick Start 13

Drive Specifications

Drive 2092-DA1 2092-DA2 2092-DA3 2092-DA4 2092-DA5

Weight 0.9 kg (1.98 lbs)

Temperature 0° C to 50° C (32° F to 122° F)

Operating Shock,

and Vibration

Short Circuit Current Rating with

No Fuse Restrictions

Short Circuit Current Rating with

Fuse Restrictions

15 G, Half Sine, 11 ms

5 – 500 Hz @ 2.5 G, 0.381 mm (0.015 in.) maximum displacement

Suitable for use on a circuit capable of delivering not more than 5000 rms

symmetrical amperes, 240 Volts maximum.

Suitable for use on a circuit capable of delivering not more than 200,000 rms

symmetrical amperes, 240 Volts maximum, when protected by high interrupt

capacity, current limiting fuses UL198C (Class CC, G, J, L, R, T).

Motor Overload Protection Utilizes solid state motor overload protection which operates:

• within 8 minutes at 200% overload.

• within 20 seconds at 600% overload

Symbols Used on Drive Protective ground conductor terminal

Certification and Compliance

1

UL® listed to U.S. and Canadian safety standards (UL 508C File E145959)

CE and C-Tick marked for all applicable directives

Main Input Power

Nominal Input Voltage (V

Input Current (A

) 3.3A 5.5A 8.0A 11.0A 15.0A

rms

2,3

200-240V, 1 phase, 50 or 60 Hz 200- 240V, 3 phase, 50 or 60 Hz

rms)

Maximum Inrush Current (0-peak) 200A

Maximum Power Cycles/Minute 1 power cycle/2 minute interval

DC Bus Discharge Time 3 minutes after removal of main AC power

Control Input Power

Input Voltage (V

Input Current (A

2,3

)

200-240V, 1 phase, 50/60 Hz

rms

)2.0A

rms

Maximum Inrush Current (0-peak) 75A

Motor Output

Continuous Output Current (0-peak)

Intermittent Output Current (0-peak)

Continuous Output Power @ 240Vac

1.4A 2.4A 4.7A 10.7A 16.4A

3.4A 7.2A 11.3A 24.8A 43.4A

400W 650W 1000W 3000W 4000W

Power Dissipation

Maximum Power Dissipation

1 Refer to www.ab.com/certification/ce/doc for more information.

2 Nominal values are listed. Abso lute range is 180 to 264 V

3 The AC input voltage between any two in put power pins (L1, L2, L3, L1C, L2C, and CHASSIS) must not exceed this r ating. This note also applies to the

CHASSIS ground connection, which im plies that transformer secondaries must be grounded.

4 Maximum Power Dissipation in cludes dissipative power of drive plus the Continuous Shunt Power rating of the drive’s internal shunt.

50W 50W 50W +30W

.

rms

1.2 kg (2.65 lbs)

2.1 kg (4.63 lbs)

4

100W+50W 4 150W+70W 4

Publication 2092-QS001D-EN-P — July 2005

Page 14

14 Ultra1500 Digital Drives Quick Start

Drive 2092-DA1 2092-DA2 2092-DA3 2092-DA4 2092-DA5

Internal Shunt Power

Continuous Shunt Power

Instantaneous Shunt Power

– – 30W 50W 70W

– – 3000W 3000W 5000W

Digital Input/Output Specifications

Type Active Low, current sinking

External Power Supply

Requirements

Voltage: 21.6V to 26.4V

Maximum Current Draw: 64 mA

Note: Digital I/O is not powered by an internal supply, customer must connect an

external power supply.

Analog Input/Output Specifications

Inputs Voltage range is -10V to +10V

Impedance of10 k Ω.

A/D conversion with 16-bit resolution

Outputs Voltage range -10V to +10V

Current output of up to 10 mA into a resistive load

D/A conversion with 12-bit resolution

Motor Control Specifications

Feedback Device Power 5V supplied by drive for incremental and serial encoder devices.

Incremental Encoder

Requirements

Differential drivers for A, B, Z, and single-ended Hall signals S1, S2, and S3

Maximum line frequency: 4,000,000 lines/second (16,000,000 counts second)

Fuse and Contactor Recommendations

Main Power Fuses

Recommended Fuse Group 1

Recommended Fuse Group 2 3

Control Power Fuses 1

Recommended Fuse Group 1 4 FRS-R-2-1/2

Recommended Fuse Group 2

Recommended Fuse Group 3

Contactor

1 Fuses specified are Bussmann® fuses.

2 FNQ-R fuses are described as Time-Delay Fus es, Class CC.

3 LPJ fuses are described as Dual-Elem ent Time-Delay Fuses, Class J.

4 FRS-R fuses are described as Dual-E lement Time-Delay Fuses, Class RK5.

5 For contactors: x represents coil voltage, and y represents number of contacts.

Publication 2092-QS001D-EN-P — July 2005

1

2092-DA1 2092-DA2 2092-DA3 2092-DA4 2092-DA5

2

FNQ-R-7 FNQ -R-10 FNQ-R-15 FNQ-R-20

NA LPJ-15 LPJ-20

2

FNQ-R-7-1/2

3

LPJ-6

5

100-M05Nxy 100-M09Nxy 100-M12Nxy 100-C16xy 100-C23xy

Page 15

Ultra1500 Digital Drives Quick Start 15

Accessories

Catalog Number or Item Description and/or Specifications

2090-DA-BAT 3.6V Battery with connector (for multi-turn encoder)

AC Line Filters 2092-DA1 2092-DA2 2092-DA3 2092-DA4 2092-DA5

2090-UXLF-106

Connector Kits

9101-1476 50 pin Mini-D Connector Kit (solder cup type) for CN1

9101-1477 20 pin Mini-D Connector Kit (solder cup type) for CN2 and CN3

Cables

2090-DANFCT-Sxx

2090-DANBT-18Sxx

2090-DANPT-16Sxx

2090-DAIO-D50xx

2090-DAPC-D09xx

1 Cable length (xx) is specified in meters: xx = 01, 03, 09, etc. Consult Motion Control Selection Guide (GMC-SG001x-EN-P) for available lengths.

1

Feedback Cable for TL-Series Motors, connectors both ends

1

Brake Cable for TL-Series Motors, ring lugs to drive

1

Power Cable for TL-Series Motors, ferruled leads to drive

1

CN1 Control Cable, connector to drive, flying leads to controller

1

PC Cable, connectors both ends

2090-UXLF-110

2090-UXLF-HV323

Publication 2092-QS001D-EN-P — July 2005

Page 16

Related Documentation

These publications provide additional information; specifically about Rockwell Automation drives. To

obtain a copy, contact your local Rockwell Automation office or distributor, or access the documents

on-line at www.rockwellautomation.com/literature.

For information about: Read this document: Publication Number

Ultra1500 drive configuration and operation Ultra1500 Digital Drive User Manual 2092-UM001x-EN-E

Programming motion using Ultra1500 drives Help files for v1.6 or higher of

Ultraware

A glossary of industrial automation terms and

abbreviations

How to minimize and control system-level noise. System Design for Control of

An overview of Allen-Bradley motion controls

Allen-Bradley Industrial Automation

Glossary

Electrical Noise Reference Manual

Motion Control Selection Guide GMC-SG001x-EN-P

and systems, including this and other products

General guidelines for personal safety in the

application, installation, and maintenance of

solid state controls

An article on wire sizes and types for grounding

Safety Guidelines for the Application,

Installation and Maintenance of

Solid-State Control

National Electrical Code Published by the

electrical equipment

Ultraware CD

(Ctlg. No. 2098-UWCPG)

AG-7.1

GMC-RM001x-EN-P

SGI-IN001A-EN-P

National Fire Protection

Association of Boston,

MA

For more information refer to our web site:

For Rockwell Automation Technical Support information refer to:

Allen-Bradley is a registered trademarks of Rockwell Automation, Inc.

Bussman is a registered trademark of Cooper Industries, Inc.

UL is a registered trademark of Underwriters Laboratories, Inc.

Ultra1500 and Ultraware are trademarks of Rockwell Automation, Inc.

www.ab.com/motion

www.ab.com/support

or Tel: (1) 440.646.5800

Publication 2092-QS001D-EN-P — July 2005 PN 0013-2066-004

Supersedes publication 2092-QA001C-EN-P — July 2004 Copyright © 2005 Rockwell Automation, Inc. All rights reserved. Printed in the USA.

Loading...

Loading...