Page 1

Installation Instructions

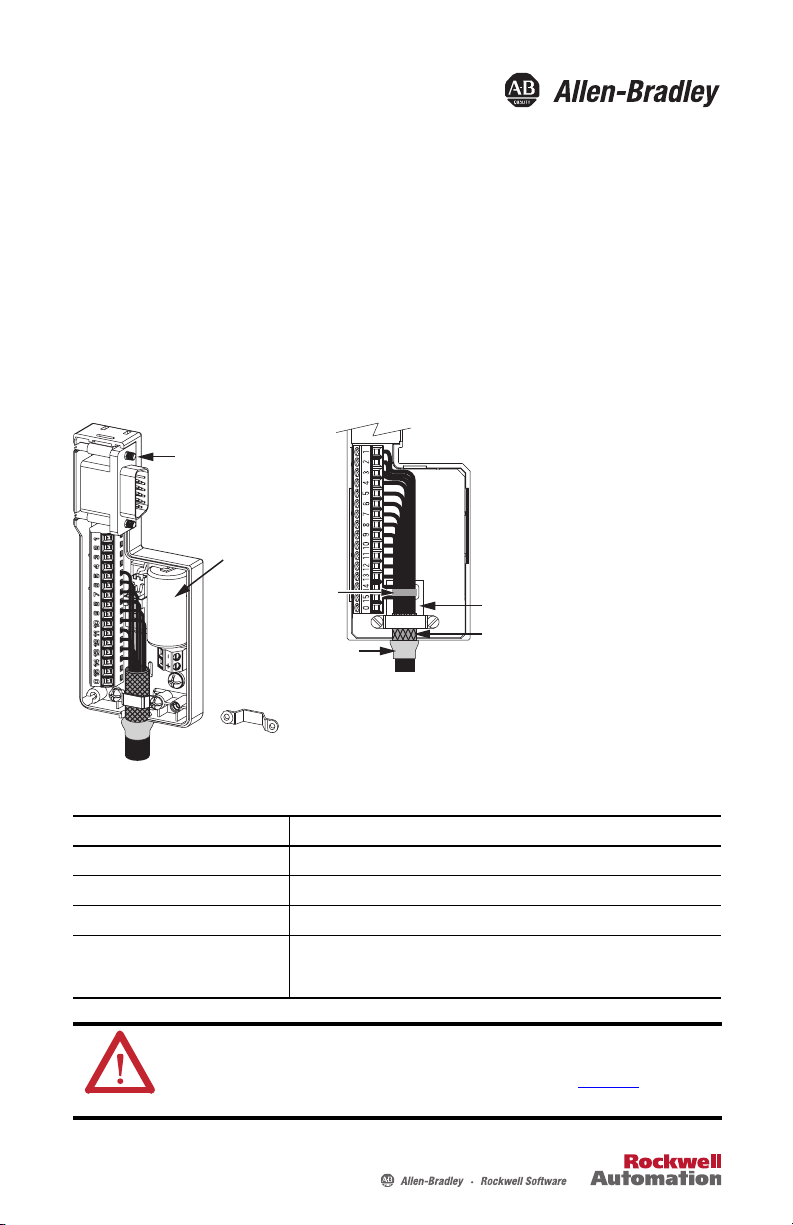

If necessary, turn clamp over to hold small wires secure.

Mounting

Screw (2)

Tie wrap secures

wire bundles.

Shrink-wrapped

Insulation

Follow these steps to form a compact

connection.

1. Push the insulation down-and-over itself.

2. Move the insulation so it butts against the

outside wall of the cover.

3. Tape or shrink-wrap the end of the

insulation to the cable.

Battery (optional)

Cable Shield Termination Pad

Cable Shi eld

Low-profile Connector Kit for

Motor Feedback Signals

Catalog Numbers 2090-K2CK-D15M, 2090-DA-BAT2

Install the Low-profile Connector Kit

2090-K2CK-D15M Connector Kit Specifications

Attribute Value

Cable diameter 4…10 mm (0.16…0.39 in.)

2

Screw te rminal wire si ze 0.06…1 .31 mm

Recommended wire strip length 5 mm (0.2 in.) single conductor

Recommended torque

Mounting screw

Ter mi nal scr ew

ATTENTION: This connector kit contains electrostatic discharge (ESD) sensitive parts that can be

damaged if you do not follow ESD control procedures. If you are unfamiliar with ESD control

procedures, refer to Guarding Against Electrostatic Damage, publication 8000-4.5.2

applicable ESD protection handbook.

0.40 N•m (3.5 lb•in)

0.25 N•m (2.2 lb•in)

(30…16 AWG)

, or any other

Page 2

2 Low-profile Connector Kit for Motor Feedback Signals

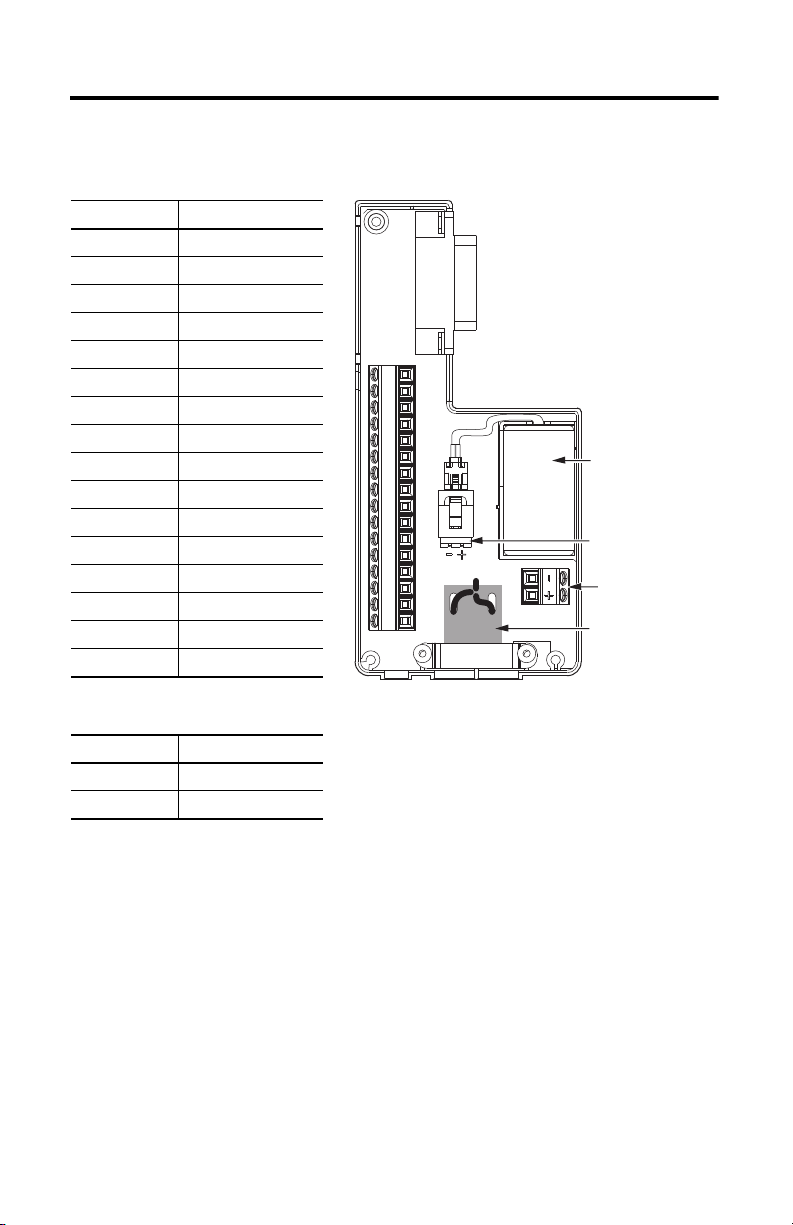

Optional Battery (BAT)

BAT Connections

BAT Terminals

Cable Shi eld

Termination Pad

Connector Data

Motor Feedback (MF) Connections

Terminal Signal

1AM+

2AM–

3BM+

4BM–

5DATA+/IM+

6ECOMM

7EPWR_9V

8S3

9E_OT+

10 DATA–/IM–

11 TS

12 S1

13 S2

14 EPWR_5V

15 E_OT–

0 SHIELD

14 13 12 11 10 9 708654312

15

Optional Battery Connections

Terminal Signal

+BAT+

–BAT–

Rockwell Automation Publication 2093-IN005C-EN-P - May 2013

Page 3

Low-profile Connector Kit for Motor Feedback Signals 3

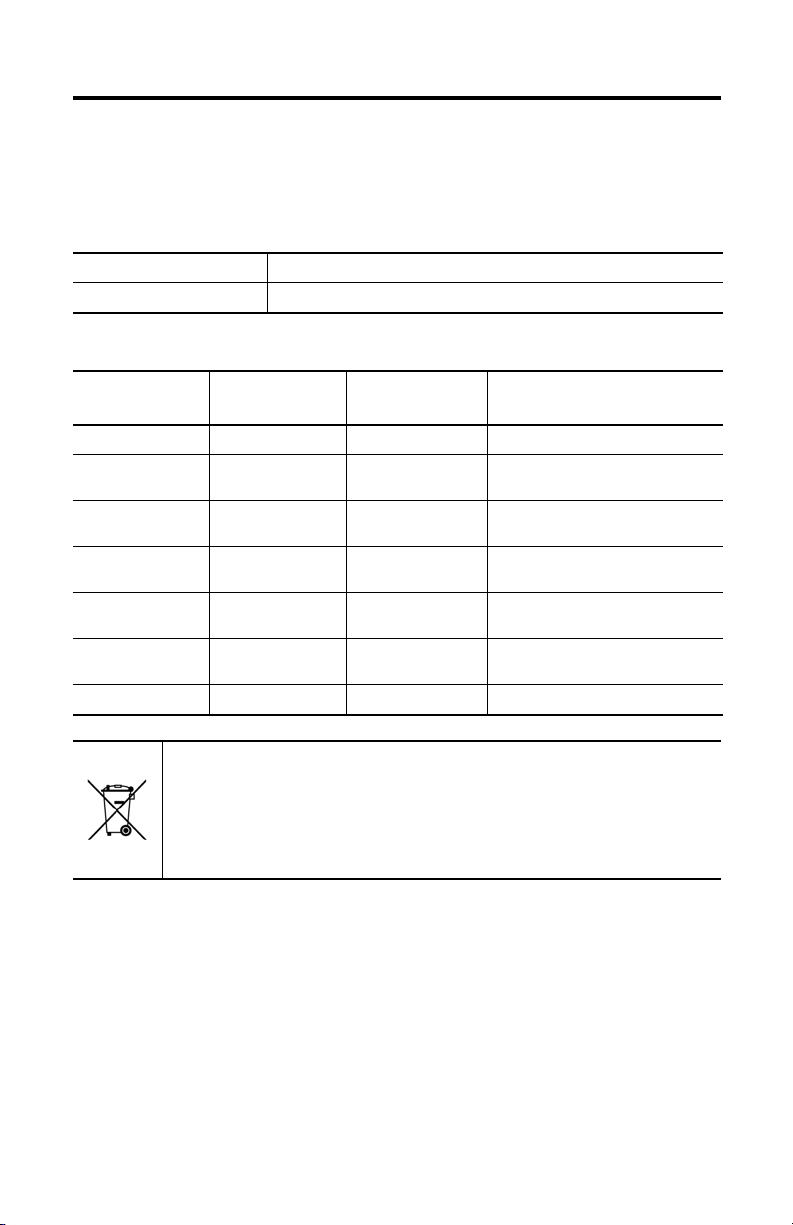

Battery Specifications

The 2090-DA-BAT2 battery is required for absolute position backup of TL-Series encoders, but

is not included with the connector kit.

Battery Catalog Number

Cat. No. Description

2090-DA-BAT2 3.6V, half-height, non-rechargeable lithium battery with 2-pole mini connector

Battery Life

Drive Power On Time

Hours/week

0 168 1.0 Drive power is never ON

40 128 3.5 Drive power is ON for one 8-hour shift,

56 112 4.0 Drive power is ON for one 8-hour shift,

80 88 5.5 Drive power is ON for two 8-hour shifts,

112 56 7.5 Drive power is ON for two 8-hour shifts,

120 48 8.0 Drive power is ON for three 8-hour shifts,

168 0 10.5 Drive power is never OFF

Drive Power Off Time

Hours/week

This product contains a sealed lithium battery which may need to be replaced during the life of the product.

At the end of its life, the battery contained in this product should be collected separately from any unsorted

municipal waste.

The collection and recycling of batteries helps protect the environment and contributes to the conservation of

natural resources as valuable materials are recovered.

Expected Battery Life

Yea r s

Operating Conditions

5 days/week

7 days/week

5 days/week

7 days/week

5 days/week

Rockwell Automation Publication 2093-IN005C-EN-P - May 2013

Page 4

Rockwell Automation Support

Rockwell Automation provides tec hnical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

links to software service packs, and a MySupport feature that you can customize to make the best use of these tools. You can also visit

our Knowledgebase at http://www.rockwellautomation.com/knowledgebase

forums, software updates, and to sign up for product notification updates.

For an additional level of technical phone support for installation, configuration and troubleshooting, we offer TechConnect

support programs. For more information, contact your local distributor or Rockwell Automation representative, or visit

http://www.rockwellautomation.com/support/

Installation Assistance

If you experience a problem within the first 24 hours of installation, please review the information that's contained in this manual.

You can also contact a special Customer Support number for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or

Canada

Use the Wor ldwi de Loc ator

http://www.rockwellautomation.com/rockwe llautomation/support/overview.page

local Rockwell Automation representative.

New Product Satisfaction Return

Rockwell Automation tests all of its products to help ensure that they are fully operational when shipped from the manufacturing

facility. However, if your product is not functioning and needs to be returned, follow these procedures.

, you can find technical manuals, technical and application notes, sample code and

for FAQs, technical information, support chat and

SM

.

at

, or contact your

United States

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

Contact your distributor. You must provide a Customer Support case number (call the phone number

above to obtain one) to your distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document,

complete this form, publication RA-DU002

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belong ing to Rockwell Automation are property of their respective companies.

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Publication 2093-IN005C-EN-P - May 2013 PN-204918

Supersedes Publication 2093-IN005B-EN-P - August 2010 Copyright © 2013 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

, available at http://www.rockwellautomation.com/literature/.

Loading...

Loading...