Page 1

User Manual

EC4 Current Monitoring Relay

Catalog Number

193-EC4

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

available from

) describes some

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the

consequence

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Preface

IMPORTANT

Manual Objectives

Who Should Use This

Manual

The purpose of this manual is to provide you with the necessary information to

apply the EC4 Current Monitoring Relay with DeviceNet communications.

Described in this manual are methods for installing, configuring, and

troubleshooting.

Read this manual in its entirety before installing, operating, servicing,

or initializing the EC4 Current Monitoring Relay.

This manual is intended for qualified personnel responsible for setting up and

servicing these devices. You must have previous experience with and a basic

understanding of communications technology, configuration procedures,

required equipment, and safety precautions.

To make efficient use of the EC4 Current Monitoring Relay, you must be able to

program and operate devices with communications and have a basic

understanding of the EC4 Current Monitoring Relay’s parameter settings and

functions. You should also understand DeviceNet network operations, including

how slave devices operate on the network and communicate with a DeviceNet

master.

Conventions

Reference Manuals

Parameter names are shown in italic typeface.

For SLC 500 and 1747-SDN information:

• DeviceNet Scanner Module Installation Instructions Publication

1747-IN058E-EN-P

• DeviceNet Scanner Module User Manual Publication

1747-UM655B-EN-P

For PLC5 and 1771-SDN information:

• DeviceNet Scanner Module Installation Instructions Publication 1771-5.14

• DeviceNet Scanner Module Configuration Manual Publication

1771-6.5.118

For MicroLogix/CompactLogic and 1769-ADN information:

• DeviceNet Module Installation Instructions Publication

1769-IN001B-EN-P

• DeviceNet Module User Manual Publication 1769-UM001B-EN-P

For ControlLogic and 1756-DNB information:

• DeviceNet Module Installation Instructions Publication

1756-IN566C-EN-P

• DeviceNet Module User Manual Publication DNET-UM004A-EN-P

Rockwell Automation Publication 193-UM011A-EN-P - September 2010 3

Page 4

1

IMPORTANT

To install and implement a DeviceNet network:

• DeviceNet Media Design and Installation Guide Publication

DNET-UM072_-EN-P

Read the DeviceNet Media Design and Installation Guide, Publication

DNET-UM072_-EN-P, in its entirety before planning and installing a

DeviceNet system. If the network is not installed according to this

document, unexpected operation and intermittent failures can occur.

If this manual is not available, please contact either the local Rockwell

Automation Distributor or Sales Office and request a copy. Electronic

copies may also be obtained via the Internet or from the Allen-Bradley

Home Page at “www.ab.com.”.

4 Rockwell Automation Publication 193-UM011A-EN-P - September 2010

Page 5

Preface

Manual Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Reference Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Table of Contents Chapter 1

Table of Contents

Product Overview

Installation and Wiring

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Single-/Three-Phase Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Protection and Warning Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Current Monitoring Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Diagnostic Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Trip Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Status Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Test/Reset Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Node Address Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

DeviceNet Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Flash Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Unpacking/Inspecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Storing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Starter Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Starter Assembly Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Starter Approximate Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Separate Mount Adapter Approximate Dimensions . . . . . . . . . . . . . 21

Power Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Control and DeviceNet Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Terminal Designations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Control Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

DeviceNet Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Short-Circuit Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Fuse Coordination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Typical Motor Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Three-Phase Direct-on-Line (D.O.L). . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Rockwell Automation Publication 193-UM011A-EN-P - September 2010 5

Page 6

Table of Contents

Single-Phase Full-Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

External Line Current Transformer Application . . . . . . . . . . . . . . . . . . . . 28

Current Transformer Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Installation Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

External Ground Fault Sensor Application . . . . . . . . . . . . . . . . . . . . . . . . . 30

Power Cable Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Typical Control Circuit Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . 33

Full-Voltage Non-Reversing (with Network Control) . . . . . . . . . . . 34

External/Remote Reset (FRN 3.001 and later) . . . . . . . . . . . . . . . . . . 35

Chapter 3

Protective Trip and Warning

Functions

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Trip Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Warning Enable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Overcurrent Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Overcurrent Warning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Overcurrent Trip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Ground Fault Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Ground Fault Setting Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Ground Fault Trip. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Ground Fault Trip Inhibit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Ground Fault Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Undercurrent Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Undercurrent Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Undercurrent Trip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Communication Fault Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Comm Fault Trip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Comm Fault Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Communication Idle Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Comm Idle Trip. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Comm Idle Warning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Remote Trip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Preventive Maintenance Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Preventive Maintenance Flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Queue Clearing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Chapter 4

DeviceNet Node

Commissioning

6 Rockwell Automation Publication 193-UM011A-EN-P - September 2010

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Setting the Hardware Switches (Series B and later) . . . . . . . . . . . . . . 48

Using RSNetWorx for DeviceNet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Building and Registering an EDS File. . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Page 7

Table of Contents

Using the Node Commissioning Tool of RSNetWorx

for DeviceNet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Produced and Consumed Assembly Configuration . . . . . . . . . . . . . . 54

Mapping to the Scanner’s Scan List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Chapter 5

Programmable Parameters

Current Monitoring Parameters

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Parameter Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Program Lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Resetting to the Factory Default Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Parameter Group Listing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Advanced Setup Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Reset/Lock Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

DeviceNet Setup Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Output Setup Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

DeviceLogix Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Chapter 6

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Phase Current Reporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Current Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Reporting Accuracy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Ground Fault Current Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Current Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Frequency Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Monitor Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Diagnostic Parameters

Trip History and Snapshot

Rockwell Automation Publication 193-UM011A-EN-P - September 2010 7

Chapter 7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Monitor Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Chapter 8

Trip and Warning History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

TripWarn History Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Trip History Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Warning History Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Trip Snapshot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Trip Snapshot Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Page 8

Table of Contents

Chapter 9

Logic Controller Application

Example with Explicit

Messaging

Using DeviceLogix™

Troubleshooting

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

I/O Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Explicit Messaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Reading Device Status using the Parameter Object Class (0x0F) . . 99

Reading Device Status using the Control Supervisor Object Class

(0x29) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Reading a Group of Parameters using the Status

Object Class (0x0375) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Chapter 10

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

DeviceLogix Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

DeviceLogix Programming Example. . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Chapter 11

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Advisory LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Trip/Warn LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Network Status LED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

OUT A & OUT B LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

IN 1,2,3 & 4 LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Power-Up Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

DeviceNet Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Power-Up Reset Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Recoverable Error Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Unrecoverable Error Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Resetting a Trip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Trip/Warn LED Troubleshooting Procedures. . . . . . . . . . . . . . . . . . . . . 115

DeviceNet Troubleshooting Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Loss of Node Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Input and Output Troubleshooting Procedures. . . . . . . . . . . . . . . . . . . . 116

Appendix A

Specifications

8 Rockwell Automation Publication 193-UM011A-EN-P - September 2010

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Electromagnetic Compatibility Specifications. . . . . . . . . . . . . . . . . . . . . . 121

Functionality Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Page 9

Table of Contents

Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Appendix B

DeviceNet Information

Electronic Data Sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Product Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

DeviceNet Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Identity Object – Class Code 0x01. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Message Router – Class Code 0x02 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

DeviceNet Object – Class Code 0x03 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Assembly Object – Class Code 0x04 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Output Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Input Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Connection Object – Class Code 0x05. . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Discrete Input Point Object – Class Code 0x08. . . . . . . . . . . . . . . . . . . . 133

Discrete Output Point Object – Class Code 0x09. . . . . . . . . . . . . . . . . . 133

Parameter Object – Class Code 0x0F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Parameter Group Object – Class Code 0x10. . . . . . . . . . . . . . . . . . . . . . . 136

Control Supervisor Object – Class Code 0x29 . . . . . . . . . . . . . . . . . . . . . 140

Acknowledge Handler Object – 0x2B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

DeviceNet Interface Object – Class Code 0xB4 . . . . . . . . . . . . . . . . . . . . 144

ODVA Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Logic Supervisor Object - CLASS CODE 0x030E . . . . . . . . . . . . . . . . . 146

Status Object - CLASS CODE 0x0375. . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

CE Compliance

Two-Speed Applications

Accessories

Index

Appendix C

European Communities (EC) Directive Compliance . . . . . . . . . . . . . . . 149

EMC Directive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Low Voltage Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Appendix D

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

External Control Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Output Control Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Appendix E

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Rockwell Automation Publication 193-UM011A-EN-P - September 2010 9

Page 10

Product Overview

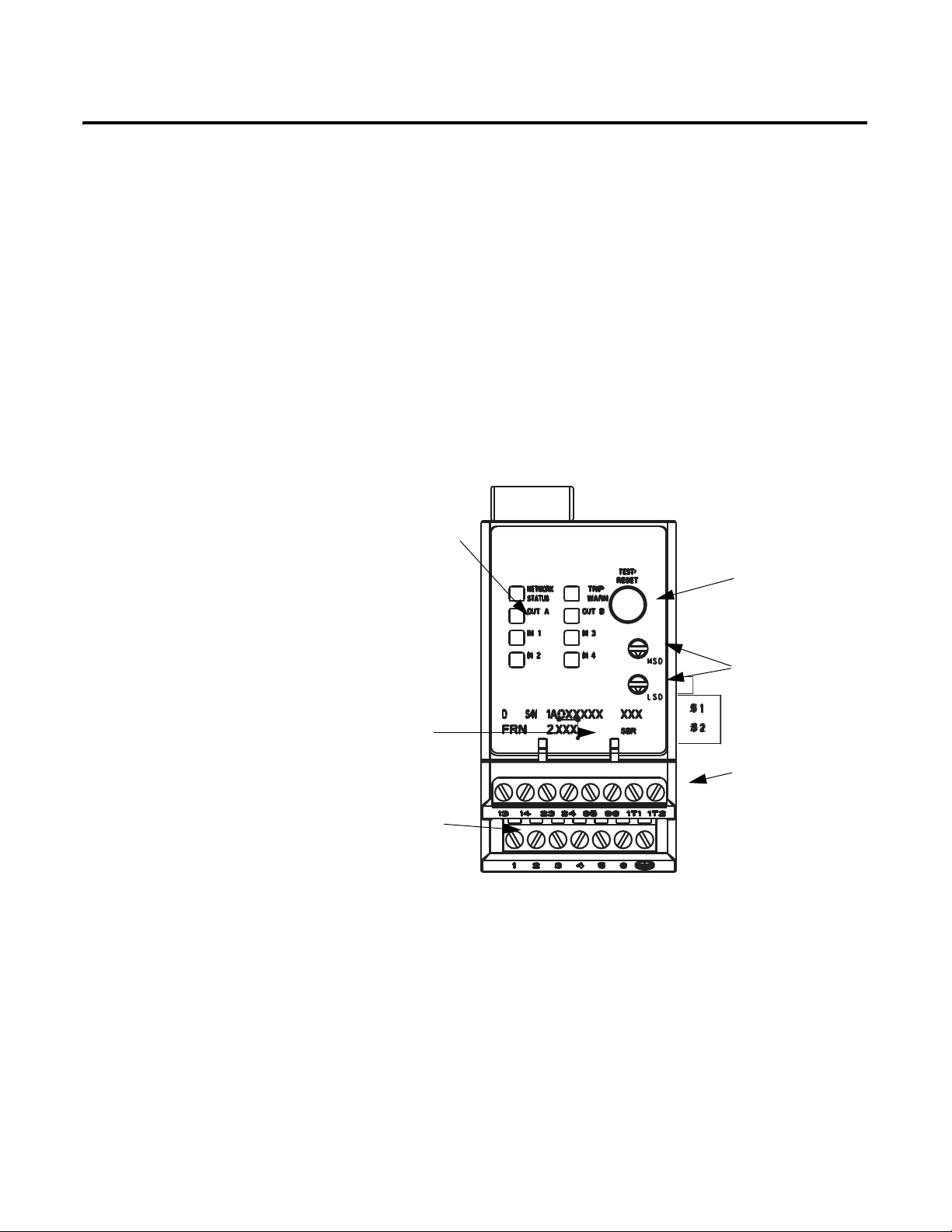

C

LED Status

Indicators

DeviceNet Port

Input Terminals

Test/Reset Button

Node Address

Switches (Series B

and later)

Output and PTC

Te rm in al s

Chapter

1

Introduction

Description

This chapter provides a brief overview of the features and functionality of the

EC4 Current Monitoring Relay.

The EC4 Current Monitoring Relay is a multi-function solid-state

microprocessor-based electronic current monitoring relay for loads rated from

0.4…5000 A.

Figure 1 - EC4 Feature Overview

Rockwell Automation Publication 193-UM011A-EN-P - September 2010 11

Page 11

Chapter 1 Product Overview

193 - EC4 B B

Bulletin

Number

Typ e

EC4 EC4

Current Rating

(Amps)

P 0.4…2.0

A1…5

B3…15

C5…25

D9…45

E 18…90

Z 9…5000

Bulletin 100

Contactor Size

B C09…C23

D C30…C43

E C60…C85

Z Panel Mount, CT fed

Catalog Number

Explanation

Single-/Three-Phase

Operation

Figure 2 - Catalog Number Explanation

The EC4 Current Monitoring Relay is factory-programmed to monitor

three-phase current. The installer can easily change to single-phase operation by

accessing and changing the setting of Parameter 27, Single/Three Ph. Refer to

Chapter 2 — Installation and Wiring – for typical motor connections.

Protection and Warning

Functions

Current Monitoring

Parameters

The EC4 Current Monitoring Relay provides the following protection and

warning functions:

• L(1-3) Undercurrent

• L(1-3) Overcurrent

• L(1-3) Loss

• Communication Fault/Idle

• Number of Starts (warning only)

• Number of Hours (warning only)

Refer to Chapter 3 — Protective Trip and Warning Functions and Chapter 5

— Programmable Parameters for further explanation of these functions.

The EC4 Current Monitoring Relay allows the user to monitor the following

operational data over the DeviceNet network:

• Individual phase currents (in amperes)

• Ground fault current (in amperes)

Refer to Chapter 6 — Current Monitoring Parameters for further information.

12 Rockwell Automation Publication 193-UM011A-EN-P - September 2010

Page 12

Product Overview Chapter 1

Diagnostic Parameters

Trip Relay

Inputs and Outputs

The EC4 Current Monitoring Relay allows the user to monitor the following

diagnostic information over the DeviceNet network:

• Device status

• Tri p s tat us

• Wa rn in g s ta tu s

• Elapsed Time

• Operating Hours

• History of past 5 trips and warnings

Refer to Chapter 7 — Diagnostic Parameters for detailed information of these

parameters.

When the EC4 Current Monitoring Relay is in the unpowered state, the trip relay

contact is open. The trip relay contact closes approximately 2.35 seconds after

power is applied if no trip condition exists.

In addition to the trip relay, the EC4 Current Monitoring Relay provides 4 inputs

and 2 outputs. the inputs are rated 24V DC only. For 120V AC inputs, add the

AC input interface module, Cat. No. 193-EIMD

The status of each can be monitored over the DeviceNet network through

parameter 21, Device Status, or one of the input assemblies. Additionally, the

outputs can be controlled over the network by using one of the output assemblies.

Refer to Appendix B — DeviceNet Information for listings of the available input

and output assemblies.

The EC4 Current Monitoring Relay offers added flexibility by providing the

capability to perform control functions with the inputs and outputs through

DeviceLogix.

The EC4 Current Monitoring Relay inputs are independently configurable for

Trip Reset, Remote Trip, L1 Loss Arm, L2 Loss Arm, L3 Loss Arm, L1L2 Loss

Arm, L2L3 Loss Arm, L1L3 Loss Arm, L1L2L3 Loss Arm, and normal

operation.

ATTENTION: If the outputs are being commanded via an

explicit message, ensure that there is no established I/O

connection that is actively controlling them, and that the explicit

message connection has a non-zero expected packet rate (EPR)

setting.

Rockwell Automation Publication 193-UM011A-EN-P - September 2010 13

Page 13

Chapter 1 Product Overview

NETWORK

STATUS

TRIP / WARN

OUT A OUT B

IN 1 IN 3

IN 2 IN 4

ATTENTION: The state of the outputs during a Protection Fault,

DeviceNet Comm Fault, or a DeviceNet Comm Idle may be

dependent on the OUTA or OUTB Pr FltState, Pr FltValue, Dn

FltState, Dn FltValue, Dn IdlState, and Dn IdlValue

programmable parameters. For details refer to the Output Setup

Group section of Chapter 5 – Programmable Parameters.

ATTENTION: The EC4 Current Monitoring Relay’s output control

firmware latches “OUT A” and “OUT B” closed upon receipt of a

network “close” command. The outputs will maintain the

commanded closed state until receipt of a network “open”

command. Parameters “OutX Pr FltState” and “OutX Pr

FltValue”, found in the EC4 Current Monitoring Relay’s Output

Setup group, allow flexibility concerning the operation of the

outputs in the event of a trip. Factory default settings cause

the outputs to open upon occurrence of a trip. EC4 outputs

that were closed prior to a trip will re-close upon trip

reset, provided that a network “open” command is not

received first.

Status Indication

The EC4 Current Monitoring Relay provides the following LED indicators:

NETWORK STATUS: This green/red LED indicates the status of the network

connection. See Chapter 11 — Troubleshooting for the possible LED

indications and the associated definitions.

TRIP / WARN: This red/amber LED flashes an amber code under a warning

condition and a red code when tripped. The warning or trip code is indicated by

the number of flashes in sequence. Refer to the side label on the product for

trip/warning codes or Chapter 11 — Troubleshooting.

OUT A and B: These amber LEDs illuminate when the output contacts are

commanded closed.

IN 1…4: These amber LEDs illuminate when the user-connected device contact

is closed.

Test/Reset Button

14 Rockwell Automation Publication 193-UM011A-EN-P - September 2010

The Test/Reset button located on the front of the EC4 Current Monitoring

Relay allows the user to perform the following:

Page 14

Product Overview Chapter 1

Te s t : If Tes t E na bl e is enabled, the trip relay contact will open if the EC4

Current Monitoring Relay is in an un-tripped condition and the

Test/Reset button is pressed. The Test/Reset button must be pressed for a

minimum of 2 seconds to activate the test function.

Reset: The trip relay contact will close if the EC4 Current Monitoring

Relay is in a tripped condition, the cause of the trip is no longer present,

and the Test/Reset button is pressed.

ATTENTION: The “Test” function associated with the Test/Reset

button is enabled by default. Activating it while a motor is

operating will cause the starting contactor to drop out and stop

motor operation.

Node Address Switches

DeviceNet Compatibility

Flash Memory

The node address switches located on the front of the EC4 Current Monitoring

Relay provides physical means for setting the device node address value. Switch

settings greater than 63 allow the node address to be software configured.

The EC4 Current Monitoring Relay supports the following DeviceNet

functionality:

• Polled I/O messaging

• Change-of-state / cyclic messaging

• Explicit messaging

• Group 4 off-line node recovery messaging

• Full parameter object support

• Auto-baud rate identification

• Configuration consistency value

• UCMM (Unconnected Message Manager)

• DeviceLogix component technology

The EC4 Current Monitoring Relay incorporates flash memory. This facilitates

updating of the product firmware as new revisions are released.

Rockwell Automation Publication 193-UM011A-EN-P - September 2010 15

Page 15

Installation and Wiring

Chapter

2

Introduction

Receiving

Unpacking/Inspecting

Storing

This chapter provides instructions for receiving, unpacking, inspecting, and

storing the EC4 Current Monitoring Relay. Installation and wiring instructions

for common applications are also included.

It is the responsibility of the user to thoroughly inspect the equipment before

accepting the shipment from the freight company. Check the item(s) received

against the purchase order. If any items are damaged, it is the responsibility of the

user not to accept delivery until the freight agent has noted the damage on the

freight bill. Should any concealed damage be found during unpacking, it is again

the responsibility of the user to notify the freight agent. The shipping container

must be left intact and the freight agent should be requested to make a visual

inspection of the equipment.

Remove all packing material from around the EC4 Current Monitoring Relay.

After unpacking, check the item’s nameplate catalog number against the purchase

order.

The EC4 Current Monitoring Relay should remain in its shipping container

prior to installation. If the equipment is not to be used for a period of time, it

must be stored according to the following instructions in order to maintain

warranty coverage:

• Store in a clean, dry location.

• Store within an ambient temperature range of -40°C…+85°C

(-40°…+185°F).

• Store within a relative humidity range of 0…95%, non-condensing.

• Do not store where the device could be exposed to a corrosive atmosphere.

• Do not store in a construction area.

General Precautions

In addition to the specific precautions listed throughout this manual, the

following general statements must be observed.

Rockwell Automation Publication 193-UM011A-EN-P - September 2010 16

Page 16

Installation and Wiring Chapter 2

ATTENTION: The EC4 Current Monitoring Relay contains ESD

(electrostatic discharge) -sensitive parts and assemblies. Static

control precautions are required when installing, testing,

servicing, or repairing this assembly. Component damage may

result if ESD control procedures are not followed. If you are not

familiar with static control procedures, refer to Allen-Bradley

publication 8200-4.5.2, “Guarding Against Electrostatic

Damage”, or any other applicable ESD protection handbook.

ATTENTION: An incorrectly applied or installed EC4 Current

Monitoring Relay can result in damage to the components or

reduction in product life. Wiring or application errors, such as

supplying incorrect or inadequate DeviceNet supply voltage,

connecting an external supply voltage to the input, or

operating/storing in excessive ambient temperatures may result

in malfunction of the EC4 Current Monitoring Relay.

ATTENTION: Only personnel familiar with the EC4 Current

Monitoring Relay and associated machinery should plan to

install, start up, and maintain the system. Failure to comply may

result in personal injury and/or equipment damage.

Starter Installation

ATTENTION: The purpose of this user manual is to serve as a

guide for proper installation. The National Electrical Code and

any other governing regional or local code will overrule this

information. Rockwell Automation cannot assume responsibility

for the compliance or proper installation of the EC4 Current

Monitoring Relay or associated equipment. A hazard of personal

injury and/or equipment damage exists if codes are ignored

during installation.

ATTENTION: The Earth Ground terminal of the EC4 Current

Monitoring Relay shall be connected to a solid earth ground via

a low-impedance connection.

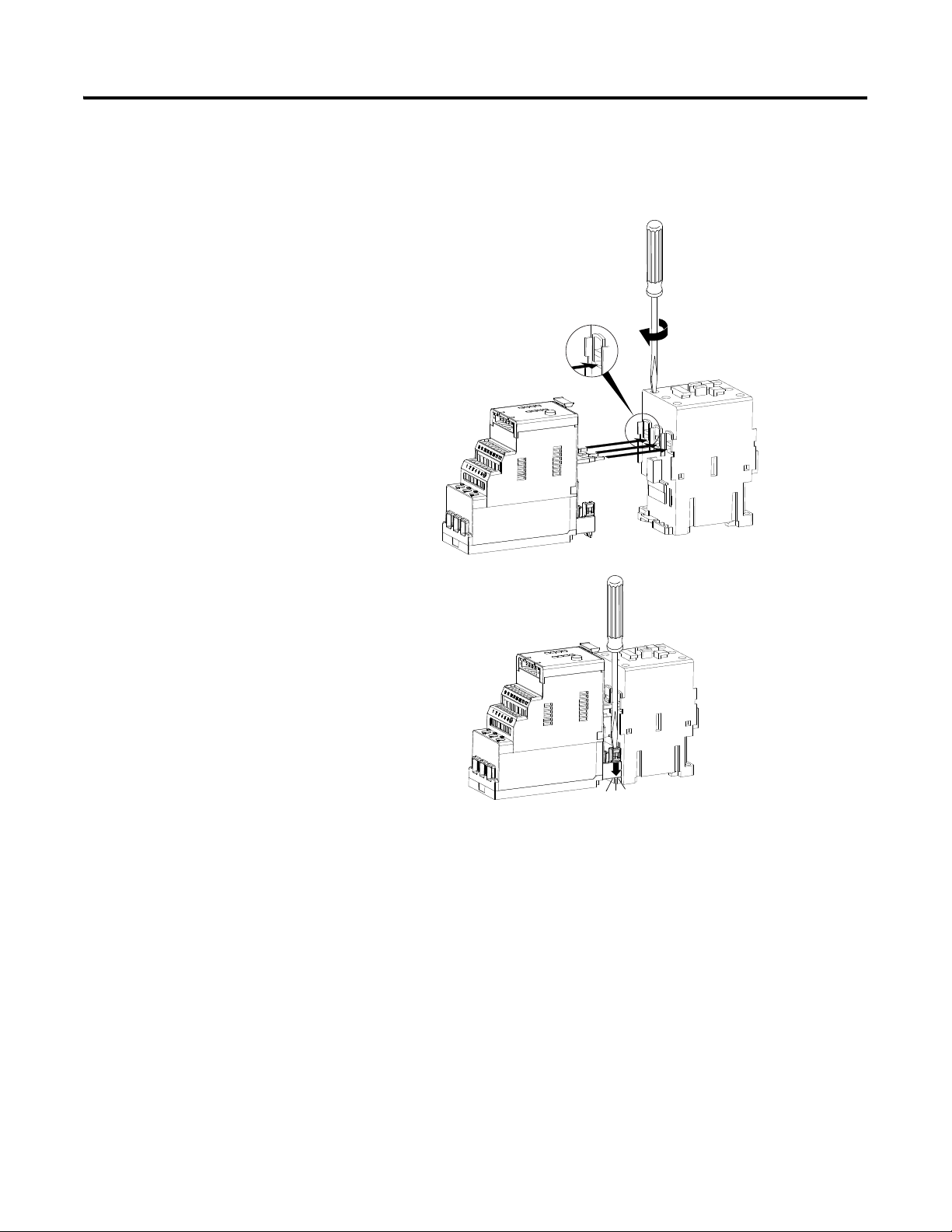

The following figures and tables illustrate the starter assembly instructions and

approximate dimensions.

Rockwell Automation Publication 193-UM011A-EN-P - September 2010 17

Page 17

Chapter 2 Installation and Wiring

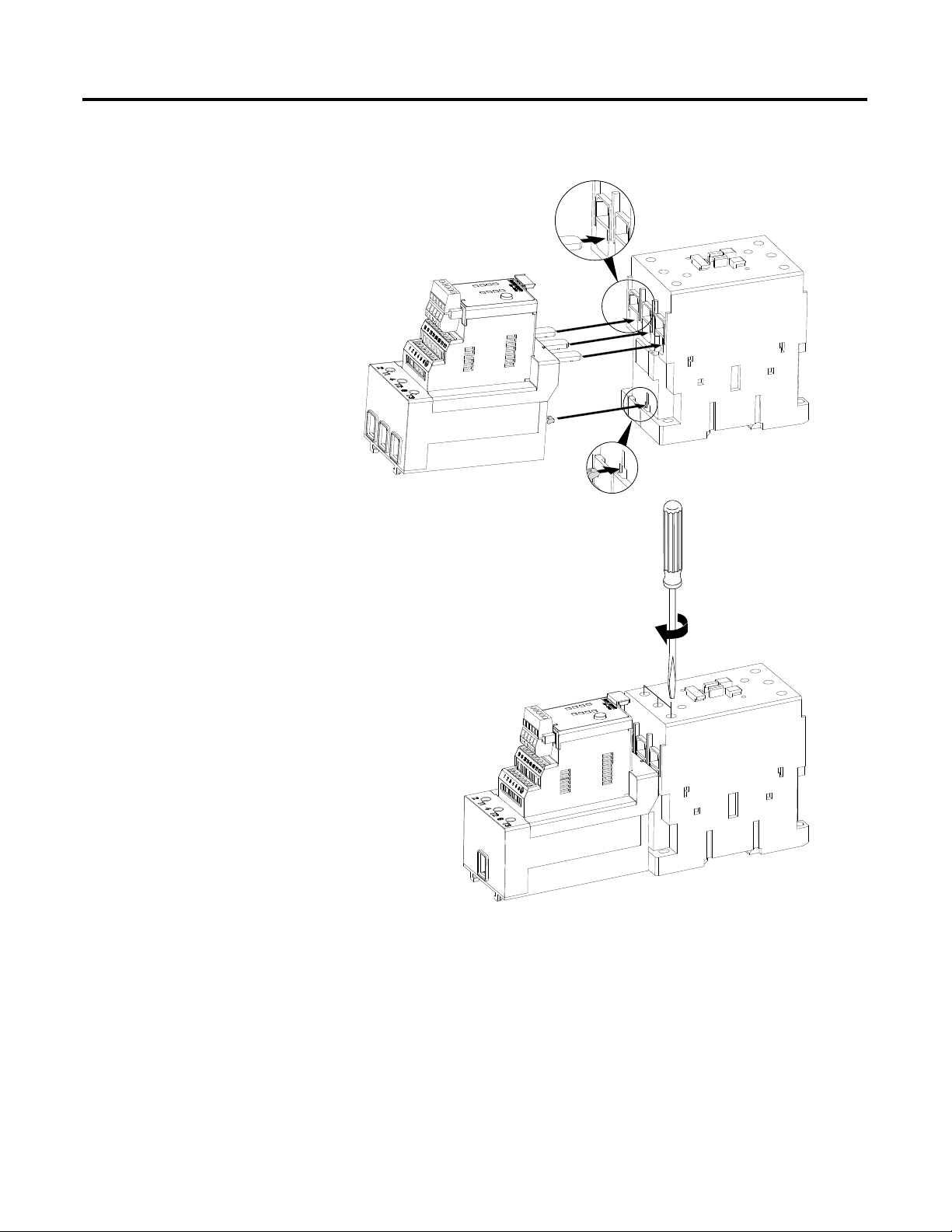

CLICK

➊

➋

➌

2.5 N•m

22 lb•in

Starter Assembly Instructions

Figure 3 - 100-C09…C43 Starter Assembly Instructions (for use with Cat. Nos.

193-EC_ _B and -EC_ _D)

18 Rockwell Automation Publication 193-UM011A-EN-P - September 2010

Page 18

Installation and Wiring Chapter 2

➊

➋

4 N•m

35 lb•in

Figure 4 - 100-C60…C85 Starter Assembly Instructions (for use with Cat. No.

193-EC_ _E)

Rockwell Automation Publication 193-UM011A-EN-P - September 2010 19

Page 19

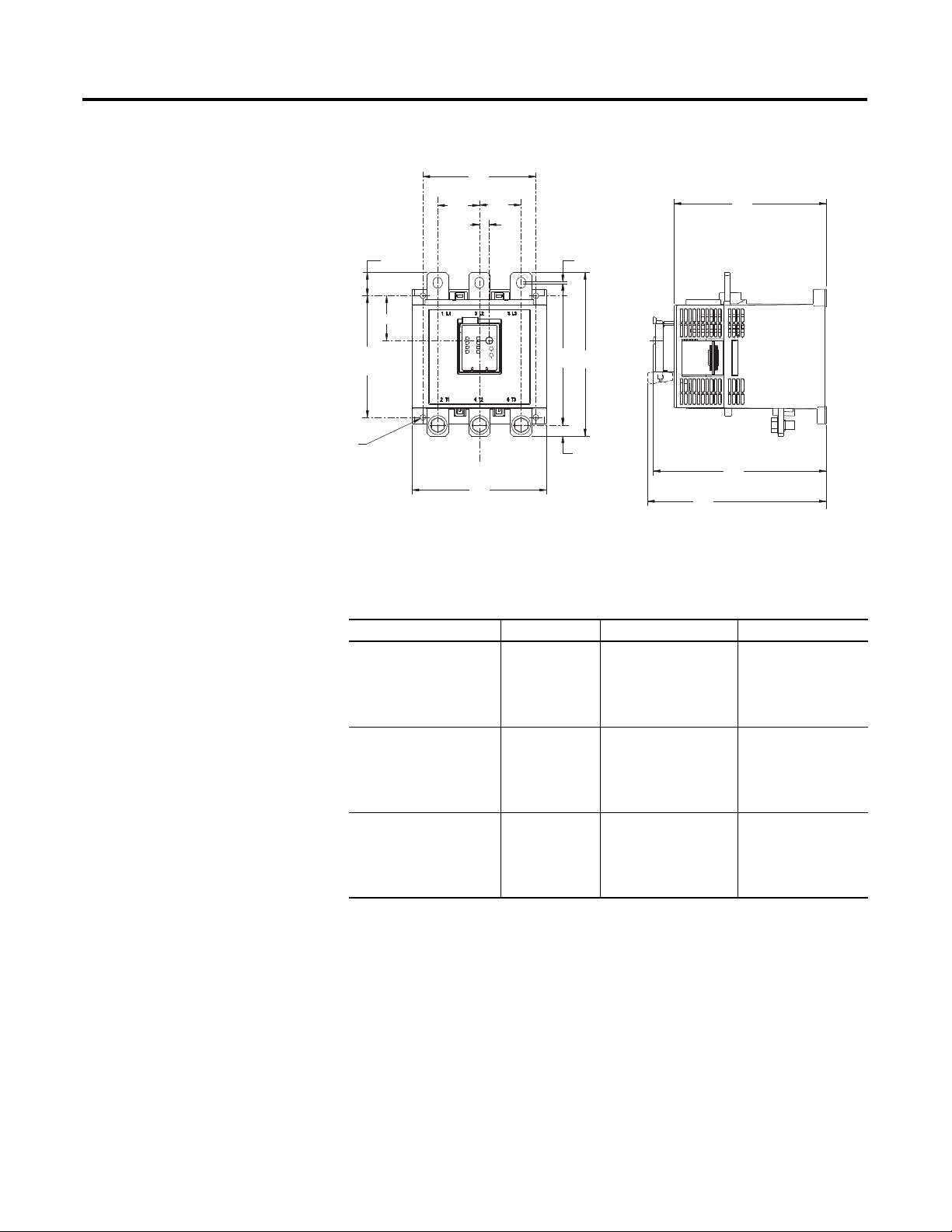

Chapter 2 Installation and Wiring

AA

D2D2

D1D1

F1F1

E2E2

B1B1

B

1E

Ø

D

H

C

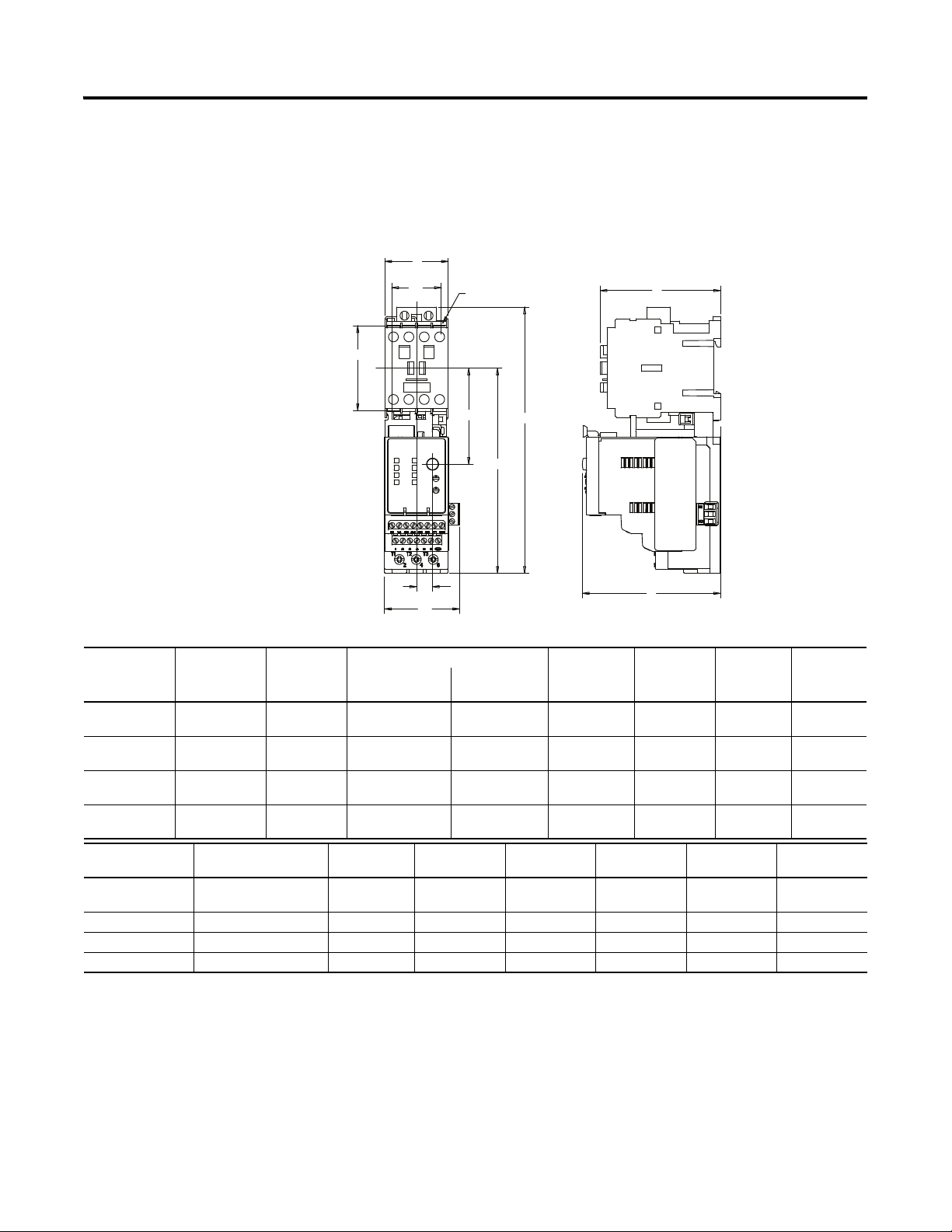

Starter Approximate Dimensions

Approximate dimensions are shown in millimeters (inches). Dimensions are not

intended to be used for manufacturing purposes.

Figure 5 - Bulletin 109 Approximate Starter Dimensions

Table 1 - Bulletin 109 Approximate Starter Dimensions

Overload Cat.

No.

193-EC_ _B 100-C09, -C12

193-EC_ _D 100-C30, -C37 45 (1-25/32) 188.3 (7-13/32) 207.7 (8-11/64) 145.1

193-EC_ _D 100-C43 54 (2-1/8) 188.3 (7-13/32) 207.7 (8-11/64) 145.1

193-EC_ _E 100-C60, -C72,

Overload Cat.

No.

193-EC_ _B 100-C09, -C12 -C16,

193-EC_ _D 100-C30, -C37 53.2 (2-3/32) 60 (2-23/64) 35 (1-3/8) 104 (4-3/32) 2 (5/64) Ø4.2 (11/64Ø)

193-EC_ _D 100-C43 62.2 (2-7/16) 60 (2-23/64) 45 (1-25/32) 107 (4-7/32) 2 (5/64) Ø4.2 (11/64Ø)

193-EC_ _E 100-C60, -C72, -C85 80.2 (3-9/64) 100 (3-15/16) 55 (2-11/64) 125.5 (4-15/16) 2 (5/64) Ø5.5 (7/32Ø)

Contactor

Cat. No.

Width A Height B B1 Depth C E1 E2

without

with 193-EIMD

193-EIMD

-C16, -C23

45 (1-25/32) 188.3 (7-13/32) 207.7 (8-11/64) 145.1

(5-23/32)

107 (4-7/32) 11.4 (29/64) 67.9

107 (4-7/32) 11.4 (29/64) 67.9

(5-23/32)

107 (4-7/32) 11.4 (29/64) 67.9

(5-23/32)

-C85

72 (2-53/64) 236.1 (9-19/64) 255.5 (10-1/16) 173.2

(6-13/16)

124.6

(4-29/32)

11.4 (29/64) 89.8

Contactor Cat. No. F1 D1 D2 H J ØD

53.2 (2-3/32) 60 (2-23/64) 35 (1-3/8) 85.1 (3-23/64) 2 (5/64) Ø4.2 (11/64Ø)

-C23

(2-43/64)

(2-43/64)

(2-43/64)

(3-17/32)

20 Rockwell Automation Publication 193-UM011A-EN-P - September 2010

Page 20

Installation and Wiring Chapter 2

45

(1-25/32)

159.3

(6-17/64)

7.3

(9/32)

135

(5-5/16)

6.1

(1/4)

100.5

(3-31/32)

ø 4.4

(11/64 ø)

11.4

(29/64)

30

(1-3/16)

115

(4-17/32)

115

(4-17/32)

11.4

(29/64)

30

(1-3/16)

45

(1-25/32)

7.3

(9-32)

135

(5-5/16)

154.2

(6-5/64)

ø 4.4

(11/64 ø)

100.5

(3-31/32)

6.1

(1/4)

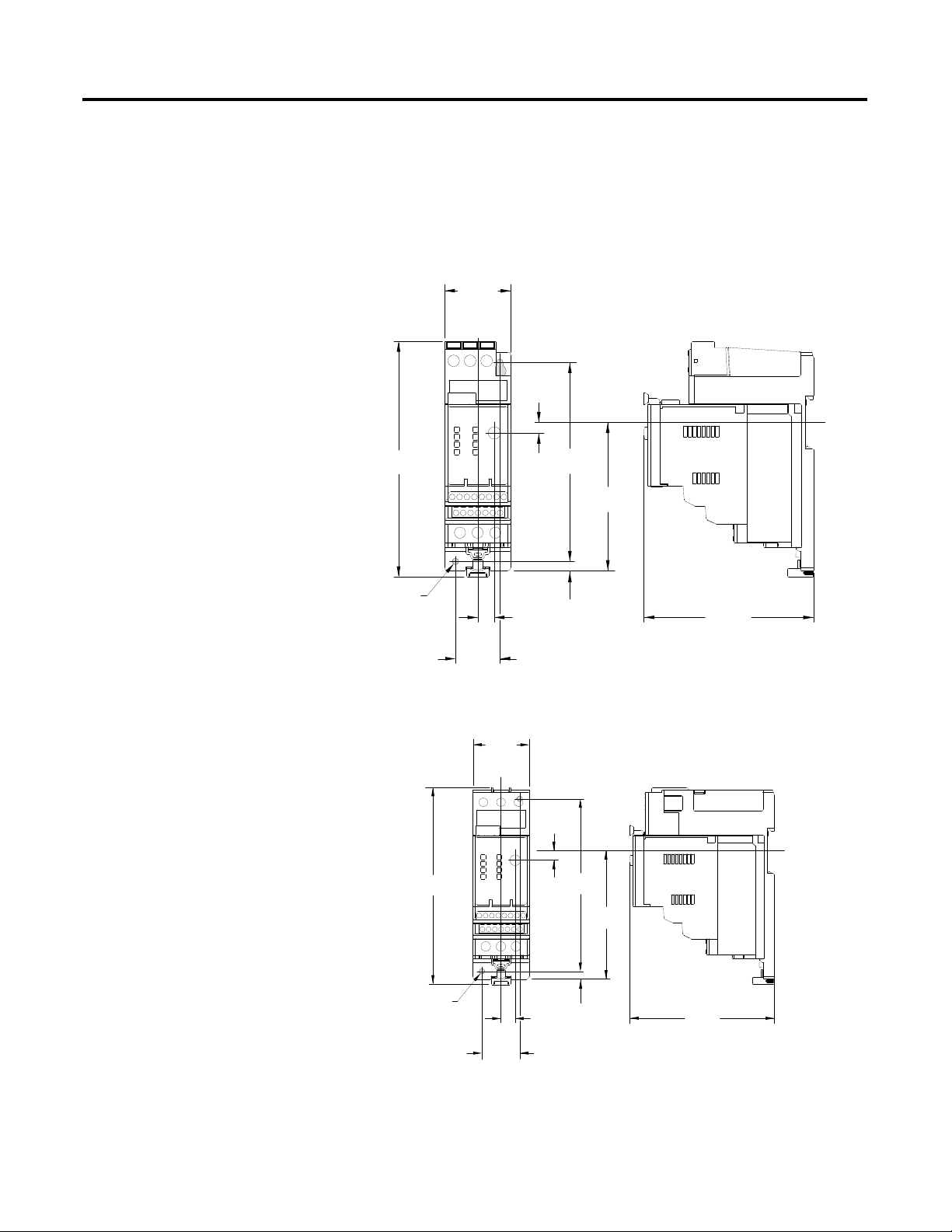

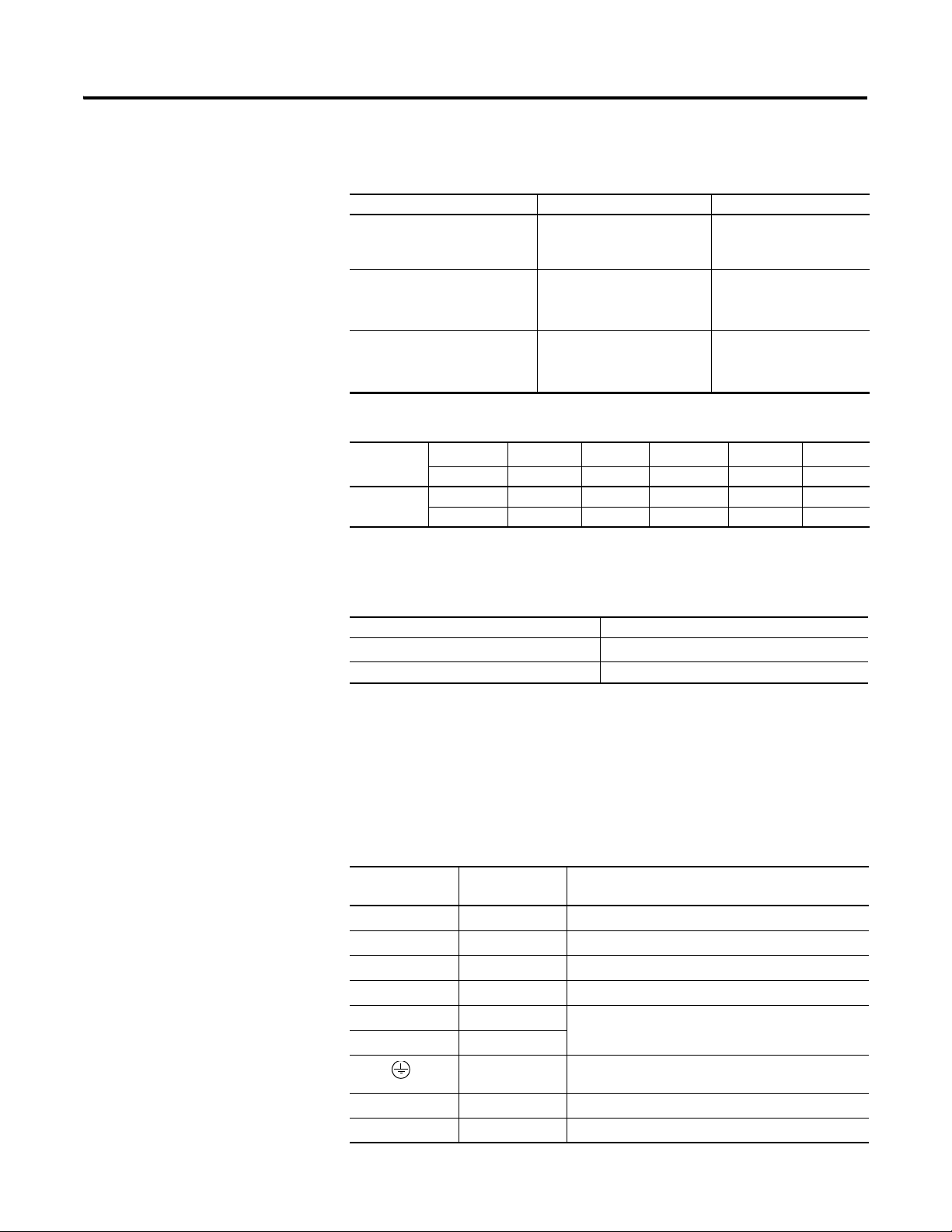

Separate Mount Adapter Approximate Dimensions

Approximate dimensions are shown in millimeters (inches). Dimensions are not

intended to be used for manufacturing purposes.

Figure 6 - 193-ECPM1 Panel Mount Adapter Approximate Dimensions (for use with

Cat. No. 193-EC_ _B)

Figure 7 - 193-ECPM2 Panel Mount Adapter Approximate Dimensions (for use with

Cat. No. 193-EC_ _D and 193-EC_ _Z)

Rockwell Automation Publication 193-UM011A-EN-P - September 2010 21

Page 21

Chapter 2 Installation and Wiring

71.7

(2-53/64)

131.2

(5-11/64)

15

(19/32)

77

(3 - 1/32)

ø 5.5

(7/32 ø)

5

(13/64)

60

(2-23/64)

11.4

(29/64)

150.5

(5-15/16)

130

(5-1/8)

77

(3-1/32)

155.1

(6-7/64) w/

193-EIMD

Figure 8 - 193-ECPM3 Panel Mount Adapter Approximate Dimensions (for use with

Cat. No. 193-EC_ _E)

22 Rockwell Automation Publication 193-UM011A-EN-P - September 2010

Page 22

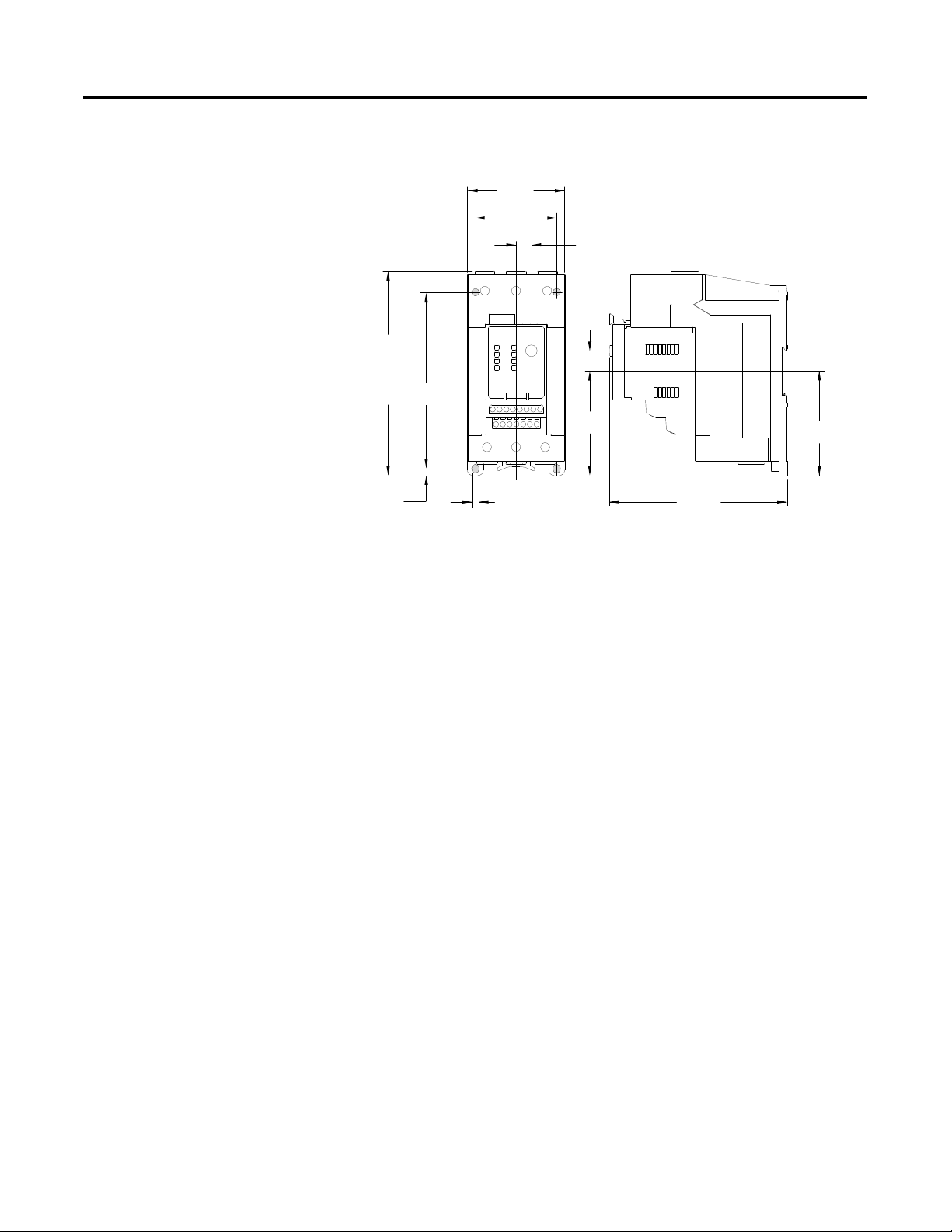

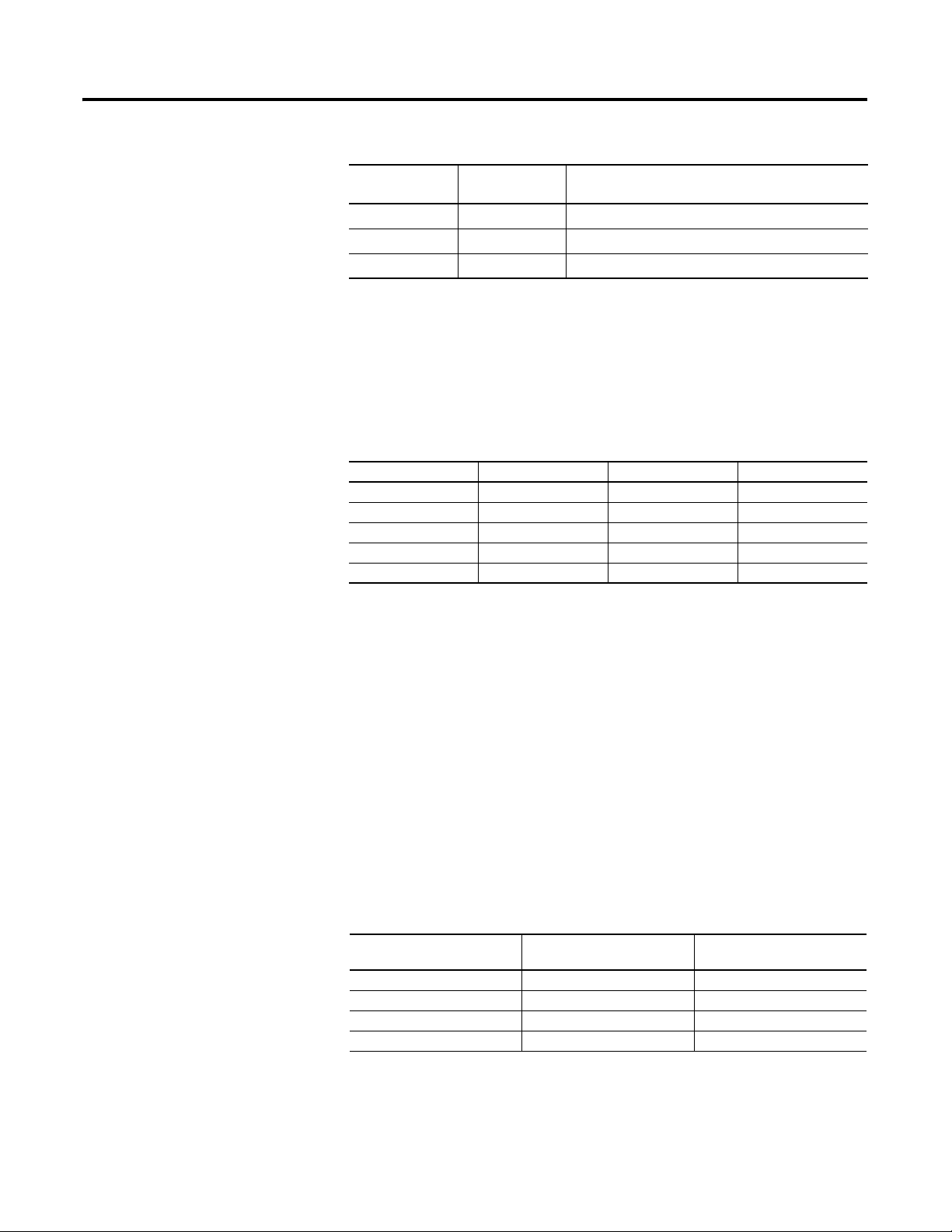

Figure 9 - Wire Size and Torque Specifications

A

B

M

N

P

C

L

K

D

E

E

F

I

G

H

J

0

2

4

6

8

0

2

4

6

8

Installation and Wiring Chapter 2

Power Terminals

Table 2 - Power Terminal Wire Size and Torque Specification

Cat. No.

Stranded/Solid

AWG

Single Conductor

Tor qu e

Multiple

Conductor

Tor qu e

Flexible-Stranded with

Ferrule

Metric

Single Conductor

Tor qu e

Multiple

Conductor

Tor qu e

Coarse-Stranded/Solid

Metric

Single Conductor

Tor qu e

Multiple

Conductor

Tor qu e

193-EC

_ _B, -EC_ _D 193-EC_ _E

#14...6 AWG

22 lb-in

#10...6 AWG

30 lb-in

2.5...16 mm

2

2.5 N•m

6...10 mm

2

3.4 N•m

2.5...25 mm

2

2.5 N•m

6...16 mm

2

3.4 N•m

#12...1 AWG

35 lb-in

#6...2 AWG

35 lb-in

4...35 mm

2

4 N•m

4...25 mm

2

4 N•m

4...50 mm

2

4 N•m

4...35 mm

2

4 N•m

Rockwell Automation Publication 193-UM011A-EN-P - September 2010 23

Page 23

Chapter 2 Installation and Wiring

Control and DeviceNet Terminals

Table 3 - Control and DeviceNet Terminal Wire Size and Torque Specification

Cat. No. All Types

Stranded/Solid

AWG

Flexible-Stranded with Ferrule

Metric

Coarse-Stranded/Solid

Metric

Table 4 - Maximum Wire Lengths (Input)

Single Conductor

Multiple Conductor

To rq ue

Single Conductor

Multiple Conductor

To rq ue

Single Conductor

Multiple Conductor

To rq ue

24...12 AWG

24...16 AWG

5 lb-in

0.25...2.5 mm

0.5...0.75 mm

0.55 Nm

0.2...4.0 mm

0.2...1.5 mm

0.55 Nm

2

2

2

2

Terminal Designations

Min. Cross

Section

Max.

Length ➊

2

mm

AWG 20 18 16 14 12

m 160 250 400 600 1000

ft 525 825 1300 1950 3200

0.5 0.75 1.5 2.5 4.0

For reliable input signal processing, input wiring should be routed in raceways

separate from power cabling.

Table 5 - Ground Fault Sensor Terminals (S1 and S2)

Wire type Shielded, twisted pair

Cross section

To rq ue

0.2…4.0 mm

0.55 N•m (5 lb-in.)

2

(#24…12 AWG)

Control Terminals

The following table defines the EC4 Current Monitoring Relay control terminal

designations.

Table 6 - Control Terminal Designation

Terminal

Designation

1 IN 1 General-purpose sinking input number 1

2 IN 2 General-purpose sinking input number 2

3 IN 3 General-purpose sinking input number 3

4 IN 4 General-purpose sinking input number 4

5 V+ +24V DC supply for inputs

6V+

Reference Description

End Earth Ground

➊

13/14 OUT A Output A

23/24 OUT B Output B

24 Rockwell Automation Publication 193-UM011A-EN-P - September 2010

Page 24

Table 6 - Control Terminal Designation

Installation and Wiring Chapter 2

Terminal

Designation

95/96 Trip Relay Trip Relay

IT1/IT2 — —

S1/S2 — External ground fault sensor input

➊ An earth ground connection to this terminal will assist in obtaining compliance with Electromagnetic

Compatibility requirements.

Reference Description

DeviceNet Terminals

The following table defines the DeviceNet connector terminal designations.

Table 7 - DeviceNet Terminal Designation

Terminal Signal Function Color

1V-CommonBlack

2 CAN_L Signal Low Blue

3 Drain Shield Non-insulated

4 CAN_H Signal High White

5 V+ Power Supply Red

Grounding

Short-Circuit Ratings

The following grounding recommendations are provided to ensure

Electromagnetic Compatibility compliance during installation:

• The earth ground terminal of the EC4 Current Monitoring Relay shall be

connected to a solid earth ground via a low-impedance connection

• Installations employing an external ground fault sensor shall ground the

cable shield at the sensor with no connection made at the EC4 Current

Monitoring Relay

The EC4 Current Monitoring Relay is suitable for use on circuits capable of

delivering not more than the RMS symmetrical amperes listed in the following

tables.

Table 8 - UL Short-Circuit Ratings

Cat. No. Maximum Available Fault

_ _B

193-EC

193-EC

_ _D

_ _E

193-EC

_ _Z

193-EC

Current [A]

5,000 600

5,000 600

10,000 600

5,000 600

Maximum Voltage

[V]

Rockwell Automation Publication 193-UM011A-EN-P - September 2010 25

Page 25

Chapter 2 Installation and Wiring

Table 9 - IEC Short-Circuit Ratings

Fuse Coordination

Cat. No. Prospective Current

193-EC_ _B

_ _D

193-EC

193-EC_ _E

Ir [A]

1,000 100,000 690

3,000 100,000 690

5,000 100,000 690

Conditional Short

Circuit Current I

[A]

Maximum Voltage

[V]

q

The following table illustrates the Type I and Type II fuse coordination when

used in conjunction with Bulletin 100-C contactors.

Table 10 - Type I and Type II Fuse Coordination with 100-C and 100-D Contactors

Overload

Cat. No.

193-EC_ _B

_ _D

193-EC

_ _E

193-EC

Contactor

Cat. No.

100-C09 1,000 100,000 20 20

100-C12 1,000 100,000 25 25

100-C16 1,000 100,000 35 35

100-C23 3,000 100,000 40 40

100-C30 3,000 100,000 60 60

100-C37 3,000 100,000 80 80

100-C43 3,000 100,000 90 90

100-C60 3,000 100,000 125 125

100-C72 5,000 100,000 150 150

100-C85 5,000 100,000 175 175

Prospective

Current

[A]

I

r

Conditional

Short Circuit

Current

Iq [A]

Type I

Class J or CC

[A]

Type II

Class J or CC

[A]

Typical Motor Connections

ATTENTION: Select the motor branch circuit protection that

complies with the National Electrical Code and any other

governing regional or local codes.

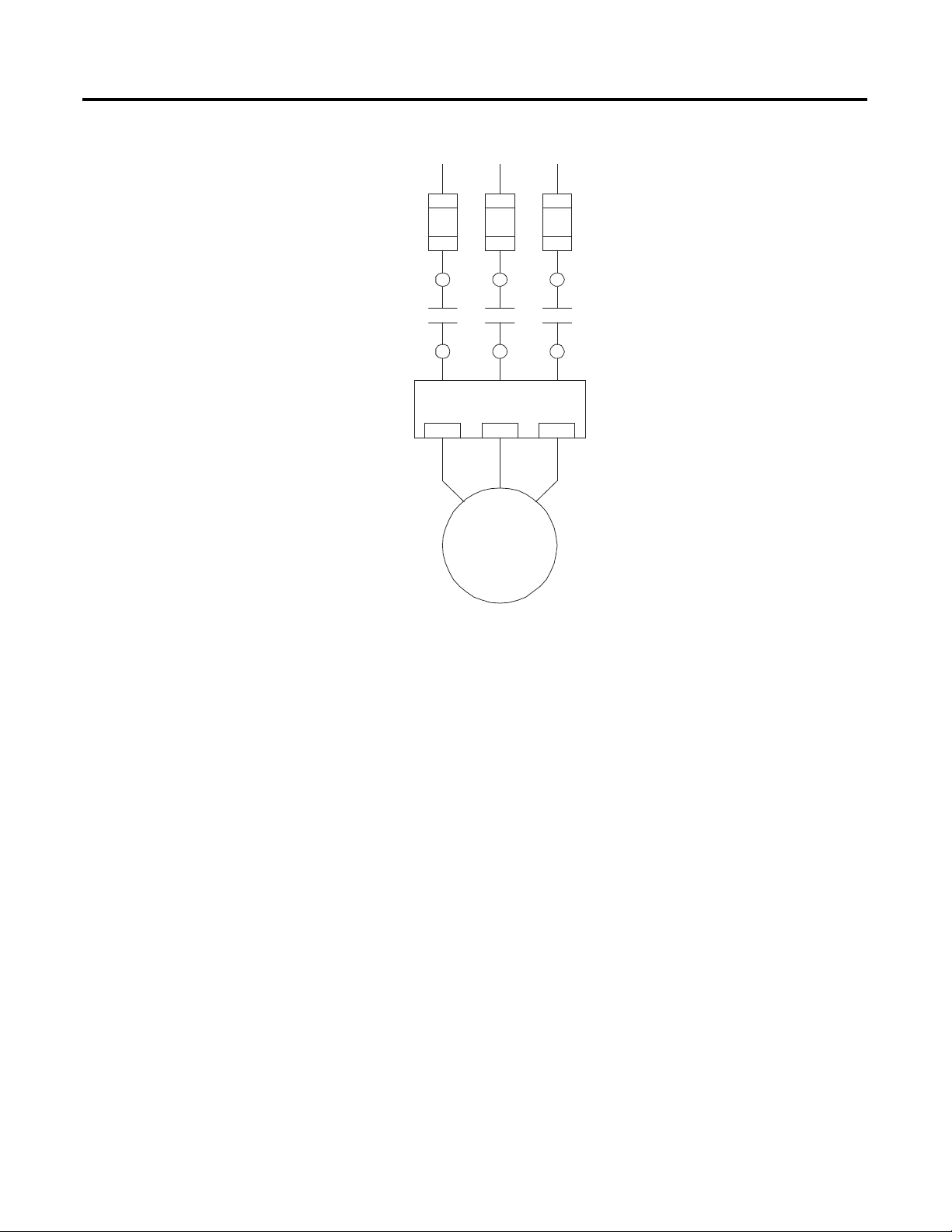

Three-Phase Direct-on-Line (D.O.L)

The following figure illustrates the EC4 Current Monitoring Relay typical motor

connections in a three-phase D.O.L application.

26 Rockwell Automation Publication 193-UM011A-EN-P - September 2010

Page 26

Figure 10 - Three-Phase D.O.L Wiring Diagram

S.C.P.D.

E3 / E3 Plus

L1 L2 L3

2/T1 4/T2 6/T3

M

T1

T2

T3

Installation and Wiring Chapter 2

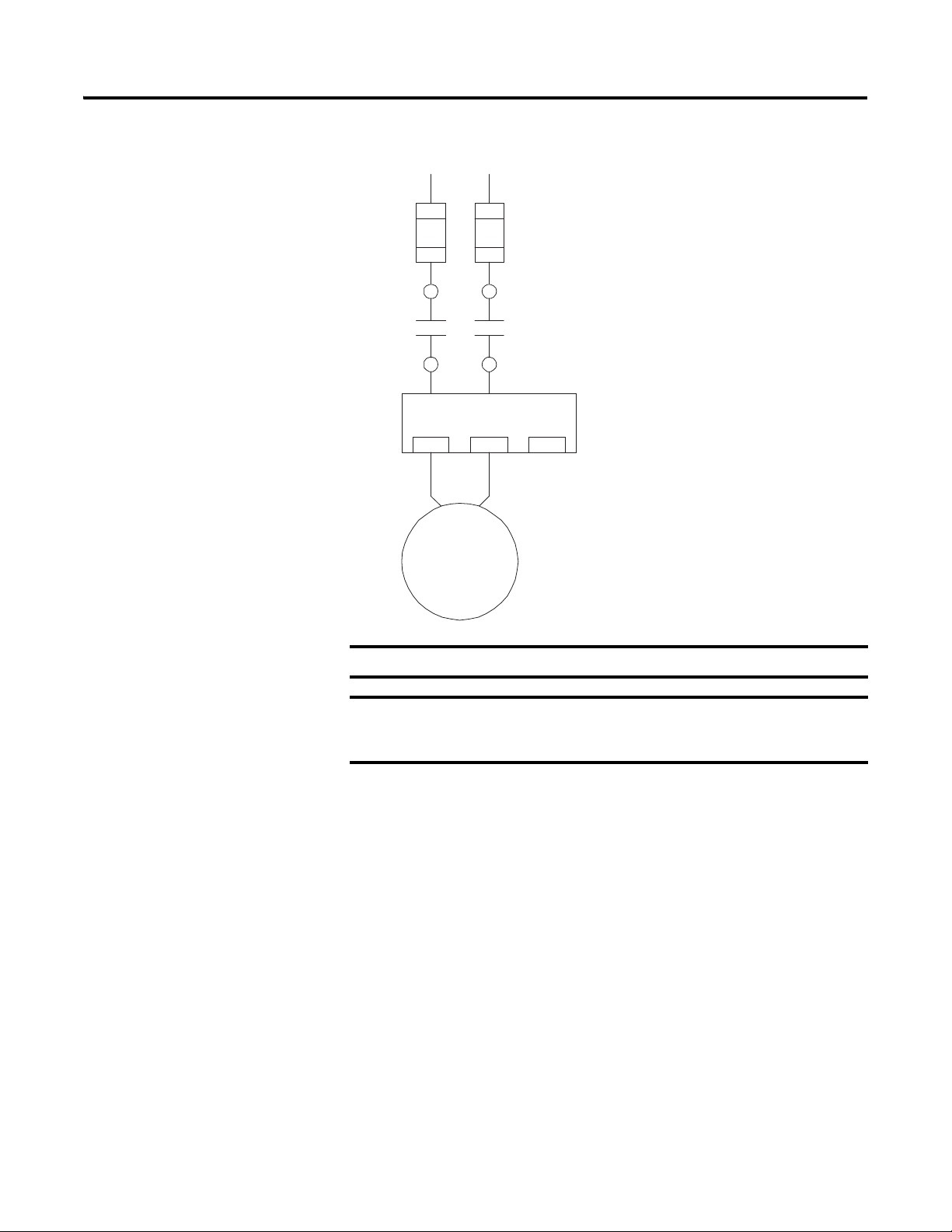

Single-Phase Full-Voltage

The following figure illustrates the EC4 Current Monitoring Relay Typical

motor connections in a single-phase full voltage application.

Rockwell Automation Publication 193-UM011A-EN-P - September 2010 27

Page 27

Chapter 2 Installation and Wiring

IMPORTANT

IMPORTANT

S.C.P.D.

E3 / E3 Plus

L1 L2

2/T1 4/T2 6/T3

M

T1 T2

Figure 11 - Single-Phase Full-Voltage Wiring Diagram

External Line Current

Transformer Application

Parameter 27, Single/Three Ph, should be set to single-phase.

Traditional single-phase wiring (connecting T2 to L3) will result in a

vector imbalance of current flowing through the EC4 Current Monitoring

Relay. This will result in inaccurate ground fault reporting and protection.

EC4 Current Monitoring Relays are designed for use with separately mounted,

customer-supplied line current transformers (CTs) as required in higher-current

applications. The FLA setting range is 9…5000 A for these units, with a legal

setting range per current transformer. Parameter 78, CT Ratio, is provided for

setting the current transformer ratio to be installed.

Current Transformer Specifications

The 193-EC_ZZ current monitoring relays are intended for use with CTs with a

secondary current rating of 5 A. The installer shall provide one CT for each

motor phase and shall connect the CT’s secondary leads to the appropriate EC4

Current Monitoring Relay power terminals as shown in . The CTs shall have an

appropriate ratio rating as detailed in Table 3.1. Additionally, the CT shall be

selected to be capable of providing the required VA to the secondary load, which

includes the EC4 Current Monitoring Relay burden of 0.1 VA at the rated

28 Rockwell Automation Publication 193-UM011A-EN-P - September 2010

Page 28

Installation and Wiring Chapter 2

6x

6x

OR

y

C

t

s

d

y

secondary current and the wiring burden. Finally, the CT shall be rated for

protective relaying to accommodate the high inrush currents associated with

motor startup and shall have an accuracy of

≤±2% over its normal operating

range. Typical CT ratings include:

ANSI (USA) Class C5 B0.1

CSA (Canada) Class 10L5

IEC (Europe) 5 VA Class 5P10

ATTENTION: The improper selection of a current transformer can

result in the EC4 Current Monitoring Relay reporting inaccurate

motor operational data, and possible motor damage. The selected

current transformer must be rated for protective relaying

applications.

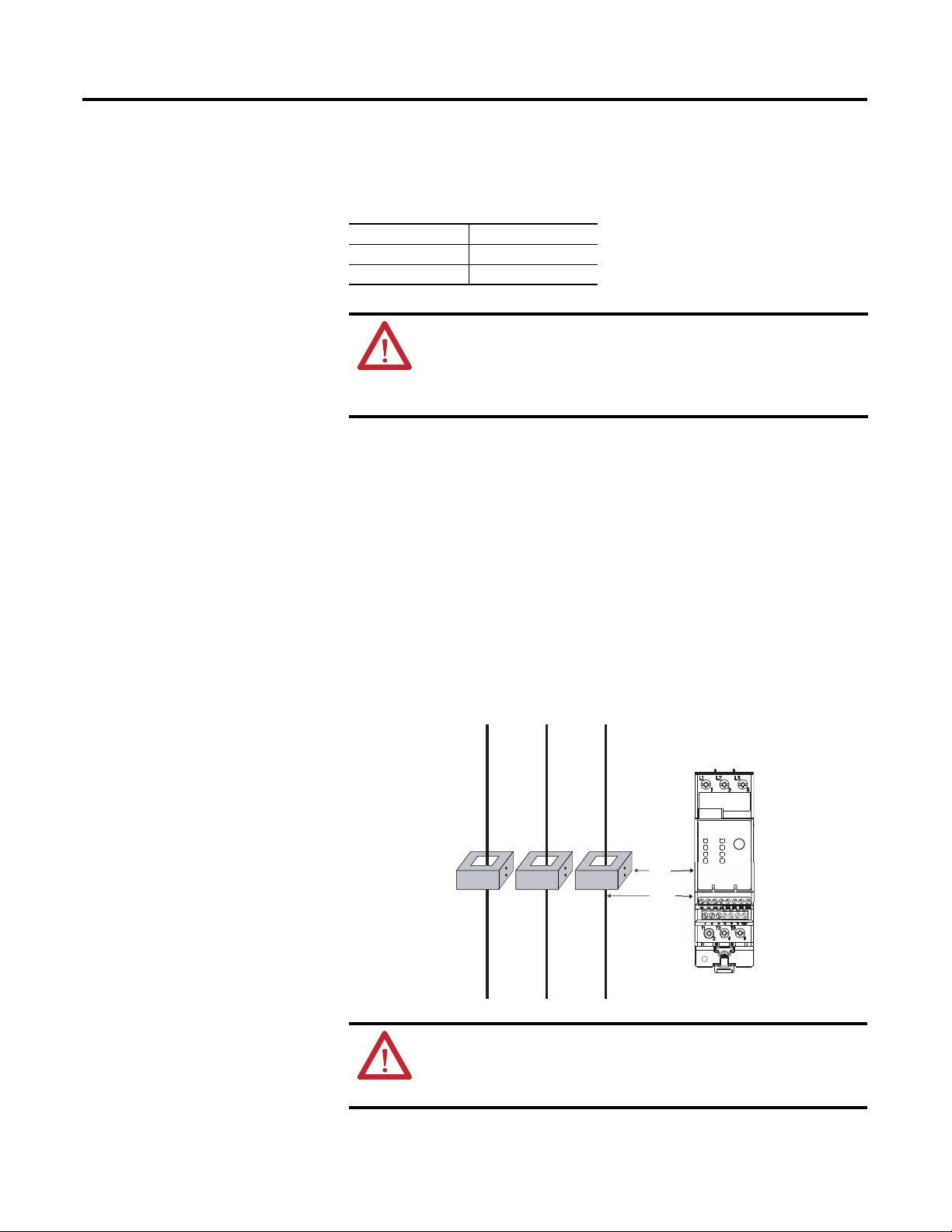

Installation Instructions

Cat. No. 193-EC_ZZ current monitoring relays are designed to be installed in

cat. no. 193-ECPM2 panel mount adapters and connected to separately mounted

current transformers. For panel mount adapter assembly, refer to the instructions

included with the panel mount adapter.The EC4 Current Monitoring Relay must

be mounted a distance equal to or greater than six times the cable diameter

(including insulation) from the nearest current-carrying conductor or current

transformer. For applications employing multiple conductors per phase, the

diameter of each cable should be added and multiplied by six to determine the

proper placement distance for the EC4 Current Monitoring Relay.

Figure 12 - Cat. No. 193-EC_ZZ Current Monitoring Relay Mounting Placement

Primar

urren

Transformer

E3 Overloa

Rela

ATTENTION: Placement of the EC4 Current Monitoring Relay

closer than the recommended distance of six times the cable

diameter may compromise its current reporting and protection

capabilities.

Rockwell Automation Publication 193-UM011A-EN-P - September 2010 29

Page 29

Chapter 2 Installation and Wiring

C

3

3

3E3

/2

3

/4

T

/1L2/3

L

3/6

/1L2/3L3/5

y

C

t

s

y

C

t

s

Figure 13 - External CT Connection Diagrams

IE

L

L

External Ground Fault

Sensor Application

Primar

urren

Transformer

L1

E

T1

T2

Primar

urren

Transformer

T

L1

T1/2T2/4T

EC4 Current Monitoring Relays are intended to provide ground fault protection

when used with the Cat. No. 193-CBCT_ external ground fault (core balance)

sensor. The ground fault sensor mounts separately from the EC4 current

monotoring relay and must be placed within three meters of it. The

customer-supplied cable for wiring the ground fault sensor to the EC4 should

meet the specifications outlined in Table 5.

Power Cable Installation Instructions

1. All power cables (including the neutral when used) must pass through the

sensor window. The equipment ground conductor (the conductor used to

carry the non-current-carrying metal parts of equipment, as defined by

Article 100 of the NEC) must not pass through the sensor window.

2. The power cables through the sensor window should be straight, tightly

bundled, centered in the window, and perpendicular to the sensor for a

length equal to or greater than six times the cable diameter (including

insulation) from the sensor.

3. All other conductors with available fault currents in excess of 1 000 A

should be placed a distance equal to or greater than six times the cable

diameter (including insulation) from the sensor.

4. The power cables of the branch circuit to be protected by the EC4 Current

Monitoring Relay must not be grounded on the load side of the ground

fault sensor.

5. If the power cables are enclosed in a conducting jacket, the jacket must be

grounded on the line side of the sensor. The jacket must not pass through

the sensor window, but must be cut at the window and joined with a

conductor that passes outside the sensor window.

30 Rockwell Automation Publication 193-UM011A-EN-P - September 2010

Page 30

Installation and Wiring Chapter 2

IMPORTANT

L1

L2 L2

L3

L3 L1

1

1

The spacer is a short (approximately 10 times

the cable diameter in length) piece of cable

with no connections to any terminal.

6. The power system may be solidly grounded or grounded through an

impedance at its source as long as the impedance allows a magnitude of

current to flow that is within the 20 mA…5 A operational range of the

EC4 Current Monitoring Relay.

Figure 14 - Ground Fault Sensor Mounting Placement

GF Sensor

90˚

Power

Cables

6x

6x

Figure 15 - Power Cable Configuration — Two Cables per Phase

Rockwell Automation Publication 193-UM011A-EN-P - September 2010 31

Figure 16 - Ground Fault Sensor Wiring to the EC4 Current Monitoring Relay

L2 L3L1

S1

S2

E3 Plus Overload Relay

Motor

Cat. No. 193-CBCT_

Ground Fault Sensor

The shield of the twisted pair cable must be connected to earth ground

at the sensor, with no connection made at the EC4 Current Monitoring

Relay.

Maximum length of the shielded cable is 100 ft. All control terminals are for

copper wire only in sizes #12…24 AWG. Ring lug termination is required for the

ground sensor terminals of Cat. Nos. 193-CBCT2 and larger. Sensor fastener

torque: 26…30 lb-in. Cat. No. 193-CBCT1 wires should be twisted before

termination by applying one twist per inch.

Page 31

Chapter 2 Installation and Wiring

Catalog Number

Maximum

Current

Frequency

Turns

Ratio

Sensor Window I.D. Sensor Type

Maximum Recommended

Cable Size

Ref: IEC Contactor

Catalog Number

Ref: NEMA

Contactor Size

193-CBCT2

193-CBCT3

#2 AWG (35 mm

2

) @ 600V

100-C09…100-C37

100-C09…100-C85

00…2

00…3

100-C09…100-D180 00…4

193-CBCT1 45 A 50/60 Hz 1000:1

1000:150/60 Hz

90 A

#8 AWG (10 mm2) @ 600V

For a three-phase system with one cable per phase.

39.6 mm (1.56 in.)

19.1 mm (.75 in.)

For a three-phase system with two cables per phase.

#250MCM (120 mm2) @ 600V

100-C09…100-D420 00…5

#350MCM (185 mm

2

) @ 600V

1000:150/60 Hz

180 A

63.5 mm (2.50 in.)

193-CBCT4

1000:150/60 Hz420 A 82.3 mm (3.25 in.)

45.3

(1.78)

23.1

(.91)

Ø 19.1

(Ø .75)

Ø 44.5

(Ø 1.75)

63.5

(2.50)

50.8

(2.00)

3.2

(.12)

4

(.16)

12.7

(.50)

Cat. No. 193-CBCT1

Figure 17 - Control Wire Installation

Figure 18 - Cat. No. 193-CBCT1 Approximate Dimensions [mm (in.)]

32 Rockwell Automation Publication 193-UM011A-EN-P - September 2010

Page 32

Installation and Wiring Chapter 2

11.8

(.47)

3.2

(.13)

Ø D

5.3

(.21)

E

FB

A

C

96

(3.78)

Cat. No.

193-CBCT2

A

89.6

(3.53)

B

48.3

(1.90)

C

Dimensions

39.6

(1.56)

ø D

54.6

(2.15)

E

69.9

(2.75)

122.4

(4.82)

193-CBCT3

115.9

(4.56)

59.7

(2.35)

63.5

(2.50)

54.1

(2.13)96(3.78)

F

44.5

(1.75)

56.2

(2.21)

74.4

(2.93)

123.2

(4.85)

96.7

(3.81)

Cat. No. 193-CBCT4

11.8

(.47)

146.8

(5.78)

143.5

(5.65)

5.5

(.22)

74.9

(2.95)

3.2

(.13)

82.6

(3.25)

Figure 19 - Cat. No. 193-CBCT2, -CBCT3 Approximate Dimensions [mm (in.)]

Figure 20 - Cat. No. 193-CBCT4 Approximate Dimensions [mm (in.)]

Typical Control Circuit

Wiring Diagrams

Rockwell Automation Publication 193-UM011A-EN-P - September 2010 33

ATTENTION: The ratings of the EC4 Current Monitoring Relay’s

output and trip relay must not be exceeded. If the coil current or

voltage of the contactor exceeds the relay’s ratings, an

interposing relay must be used.

ATTENTION: When the power is applied to the EC4 Current

Monitoring Relay (DeviceNet terminals V+ and V-), the N.O. trip

relay contact across terminals 95 and 96 will close after

approximately 2.35 seconds if no trip condition exists.

Page 33

Chapter 2 Installation and Wiring

S.C.P.D.

E3 / E3 Plus

L1 L2

2/T1 4/T2 6/T3

M

T1 T2

S.C.P.D.

E3 / E3 Plus

L1 L2 L3

2/T1 4/T2 6/T3

M

T1T2T3

M

95 96A1 A21413

Out A Trip Relay ➊

E3 E3

➊ Contact shown with supply voltage applied.

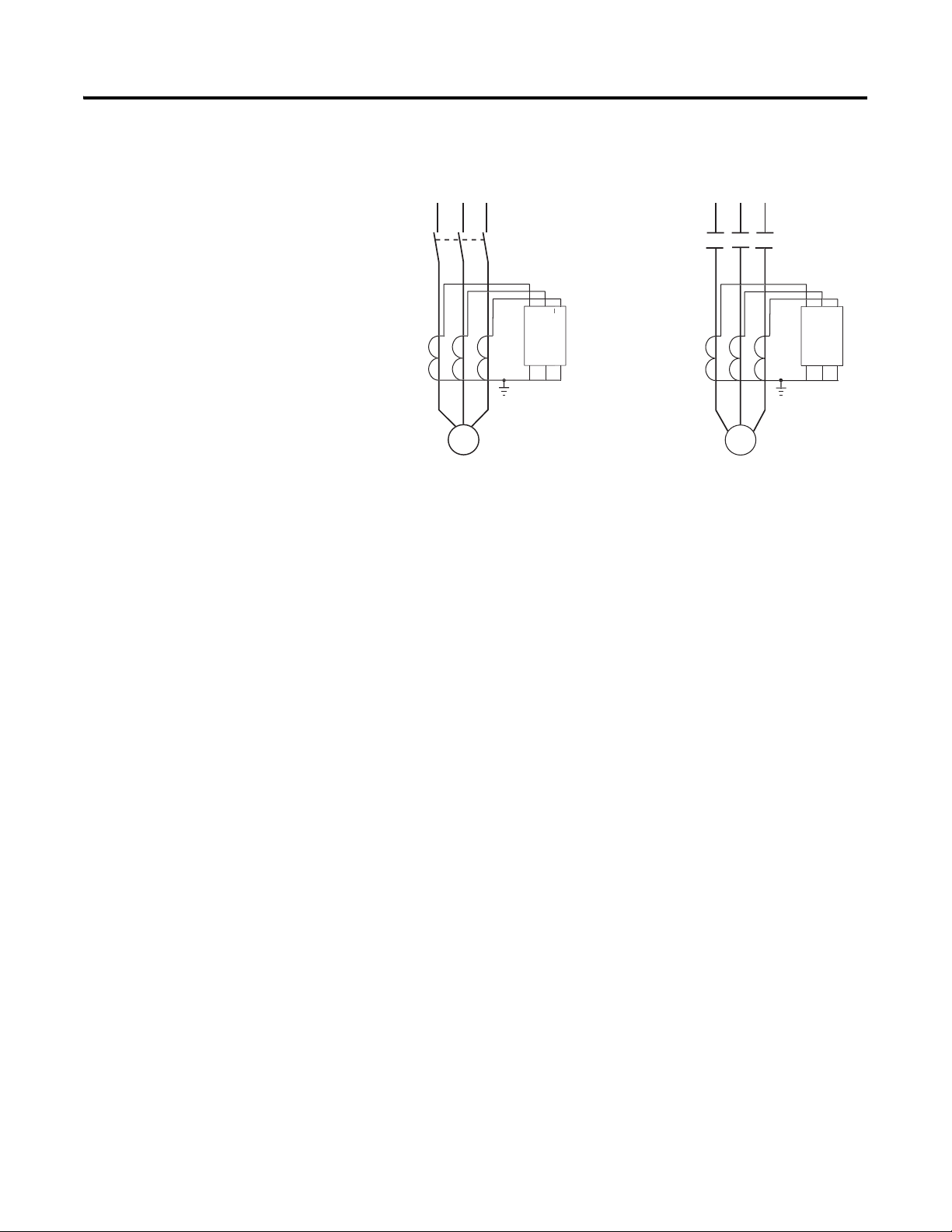

Single-Phase

Three-Phase

95

96

A1

A2

14

13

Out A

Trip Relay ➋

E3

E3

➋

Contact shown with supply voltage applied.

K

L1

N

ATTENTION: Additional control circuit protection may be

required. Refer to the applicable electrical codes.

ATTENTION: Do not apply external voltage to 1T1, 1T2, or the

input terminals IN 1…4. This may cause equipment damage.

Full-Voltage Non-Reversing (with Network Control)

Figure 21 - Full-Voltage Non-Reversing Starter Wiring Diagram (NEMA

Nomenclature)

Figure 22 - Full-Voltage Non-Reversing Starter Wiring Diagram (CENELEC

Nomenclature)

34 Rockwell Automation Publication 193-UM011A-EN-P - September 2010

Page 34

Installation and Wiring Chapter 2

IMPORTANT

Reset

1- 5

External/Remote Reset (FRN 3.001 and later)

To reset a trip from an external/remote location, configure one of the EC4

Current Monitoring Relay’s inputs for trip reset operation using one of

parameters 83…86. Wire the input as shown in Figure 23 .

Figure 23 - External/Remote Reset Wiring

Reset operation is edge sensitive and trip free; that is, holding the

push button down (maintaining the reset contact in a closed position)

will not prevent the EC4 Current Monitoring Relay from tripping.

Rockwell Automation Publication 193-UM011A-EN-P - September 2010 35

Page 35

Chapter

IMPORTANT

Protective Trip and Warning Functions

3

Introduction

Trip Enable

The purpose of this chapter is to provide detailed information regarding the

protective trip and warning functions of the EC4 Current Monitoring Relay. In

this chapter, you will find considerable mention given to programming

parameters as they relate to these functions. For complete descriptions of the

programming parameters, refer to Chapter 5 — Programmable Parameters.

Parameter 24, Tri p E nable, allows the installer to enable or disable the desired

protective functions separately. The overcurrent, undercurrent, and

communication fault trip functions are enabled from the factory.

The EC4 Current Monitoring Relay requires undercurrent

(UC)/overcurrent (OC) to be enabled at all times. The EC4 Current

Monitoring Relay requires either UC/OC to be enabled at all times.

ATTENTION: The Trip Enable settings should not be altered during

machine operation, as unexpected behavior of the outputs could

occur. This may result in an unintended actuation of controlled

industrial equipment, with the potential for machine damage or

serious injury to personnel.

Warning Enable

Overcurrent Protection

Rockwell Automation Publication 193-UM011A-EN-P - September 2010 36

Parameter 25, Wa r ni n g E n a bl e , allows the installer to enable or disable the desired

warning functions separately. All warning functions are disabled from the factory.

The EC4 Current Monitoring Relay provides UC/OC protection through true

RMS current measurement of the individual phase currents of the connected

loads. For Undercurrent & Overcurrent Trip and Warning Level parameters, a

warning or trip will occur when the programmed conditions are satisfied.

Page 36

Protective Trip and Warning Functions Chapter 3

Table 11 - Overcurrent Setting Ranges

Current Range [A] Min. [A] Max. [A] Default [A]

0.4…2 0.4 2.5 0.4

1…5 1 6.25 1

3…15 3 18.75 3

5…25 5 31.25 5

9…45 9 56.25 9

18…90 18 112.5 18

9…5000 9 6250 9

Overcurrent Warning

The EC4 Current Monitoring Relay will issue a warning with an overcurrent

condition if:

• The current in any of the phases exceeds the current specified for the

corresponding OC Warn Level parameter (Parameter 120 for L1,

parameter 123 for L2, & parameter 126 for L3)

• No warning condition already exists

If an overcurrent warning parameter is satisfied, the following will occur:

• The TRIP/WARN LED will flash a yellow blinking pattern depending on

which phase encountered the overcurrent warning condition

– 5 blinks for L1 overcurrent

– 6 blinks for L2 overcurrent

– 7 blinks for L3 overcurrent

• Parameter 15, Warning Status, will change

– Bit 4 will go to "1" for L1 overcurrent

– Bit 5 will go to "1" for L2 overcurrent

– Bit 6 will go to "1" for L3 overcurrent

• Bit _ in Parameter 21, Device Status, will go to "1"

Overcurrent Trip

The EC4 Current Monitoring Relay will trip with an overcurrent indication if:

• The current in any of the phases exceeds the current specified for the

corresponding OC Trip Level parameter (Parameter 118 for L1, parameter

121 for L2, & parameter 124 for L3)

• No trip currently exists

If the EC4 Current Monitoring Relay trips on an overcurrent condition, the

following will occur:

Rockwell Automation Publication 193-UM011A-EN-P - September 2010 37

Page 37

Chapter 3 Protective Trip and Warning Functions

• The TRIP/WARN LED will flash a red blinking pattern depending on

which phase encountered the overcurrent

– 5 red blinks for L1 overcurrent

– 6 red blinks for L2 overcurrent

– 7 red blinks for L3 overcurrent

• Parameter 14, Trip Status, will change

– Bit 4 will go to "1" for L1 overcurrent

– Bit 5 will go to "1" for L2 overcurrent

– Bit 6 will go to "1" for L3 overcurrent

• Bit 0 in Parameter 21, Device Status, will go to "1"

• The outputs will be placed in their Protection Fault state (if so

programmed)

Ground Fault Protection

In isolated or high impedance-grounded systems, core-balanced current sensors

are typically used to detect low level ground faults caused by insulation

breakdowns or entry of foreign objects. Detection of such ground faults can be

used to interrupt the system to prevent further damage, or to alert the

appropriate personnel to perform timely maintenance.

The EC4 Current Monitoring Relay provides core-balanced ground fault

detection capability, with the option of enabling Ground Fault Trip, Ground

Fault Warning, or both. The ground fault detection method and range depends

upon the catalog number of the relay ordered. The EC4 can measure from

20 mA…5 A of ground fault current

➊ Must use one of the followign ground fault sensors:

Cat. No. 193-CBCT1 — 20 mm diameer window

Cat. No. 193-CBCT2 — 40 mm diameer window

Cat. No. 193-CBCT3 — 65 mm diameer window

Cat. No. 193-CBCT4 — 85 mm diameer window

➋ 20…100 mA for resistive loads only. For motor load information, please consult your local Allen-Bradley

distributor.

ATTENTION: The EC4 Current Monitoring Relay is not a ground

fault circuit interruptor for personnel protection as defined in

Article 100 of the NEC.

➊➋.

ATTENTION: The EC4 Current Monitoring Relay is not intended to

signal a disconnecting means to open the faulted current. A

disconnecting device must be capable of interrupting the maximum

available fault current of the system on which it is used.

38 Rockwell Automation Publication 193-UM011A-EN-P - September 2010

Page 38

Protective Trip and Warning Functions Chapter 3

IMPORTANT

Ground Fault Setting Range

EC4 Current Monitoring Relays using the external ground fault sensor (Cat. no.

193-CBCT_) have four sensing ranges, which are selectable via the GF Sensing

Range parameter.

Parameter 106, GF Sensing Range (Series C and later)

• 20…100 mA (For resistive loads only. For motor load information, please

consult your local Rockwell Automation sales office or Allen-Bradley

distributor.)

• 100…500 mA

• 200 mA …1.0 A

• 1.0…5.0 A

Ground Fault Trip

The EC4 Current Monitoring Relay will trip with a ground fault indication if:

• No trip currently exists

• Ground fault protection is enabled

• GF Inhibit Time has expired

• GF Current is equal to or greater than the GF Trip Level for a time period

greater than the GF Trip Delay

If the EC4 Current Monitoring Relay trips on a ground fault, the following will

occur:

• The TRIP/WARN LED will flash a red 4-blink pattern

• Bit 3 in Parameter 14, Trip Stat us , will go to “1”

• Bit 0 of Parameter 21, Device Status, will go to “1”

• The Trip Relay contact will open

• The outputs will be placed in their Protection Fault state (if so

programmed)

The Protection Fault State of OUT A and OUT B is defined by Parameter

65 (OUTA Pr FltState), Parameter 66 (OUTA Pr FltValue), Parameter 71

(OUTB Pr FltState), and Parameter 72 (OUTB Pr FltValue).

Parameter 35, GF Inhibit Time, allows the installer to inhibit a ground fault trip

from occurring during the motor starting sequence and is adjustable from 0…250

seconds.

Parameter 36, GF Trip Delay, allows the installer to define the time period a

ground fault condition must be present before a trip occurs. It is adjustable from

0.0…25.0 seconds.

Rockwell Automation Publication 193-UM011A-EN-P - September 2010 39

Page 39

Chapter 3 Protective Trip and Warning Functions

IMPORTANT

Parameter 37, GF Trip Level, allows the installer to define the ground fault

current at which the EC4 Current Monitoring Relay will trip. It is adjustable

from 20.0 mA…5.0 A

The ground fault inhibit timer starts after the maximum phase of load

current transitions from 0 A to 30% of the device’s minimum FLA Setting

or the GF Current is greater than or equal to 50% of the device’s

minimum GF Current setting. The EC4 Current Monitoring Relay does not

begin monitoring for a ground fault condition until the GF Inhibit Time

expires.

Ground Fault Trip Inhibit

Ground faults can quickly rise from low-level arcing levels to short circuit

magnitudes. A motor starting contactor may not have the necessary rating to

interrupt a high magnitude ground fault. In these circumstances it is desirable for

an upstream circuit breaker with the proper rating to interrupt the ground fault.

When enabled, Parameter 89, GF Trip Inhibit, inhibits a ground fault trip from

occurring when the ground fault current exceeds the maximum range of the core

balance sensor (approximately 10 A). Note: This feature is only available in series

B and later devices.

Ground Fault Warning

The EC4 Current Monitoring Relay will indicate a Ground Fault warning if:

• No warning currently exists

• Ground fault warning is enabled

• GF Inhibit Time has expired

• GF Current is equal to or greater than the GF Warn Level (Series C and

later devices; for a time period greater than the GF Warn Delay)

When the Ground Fault warning conditions are satisfied, the following will

occur:

• The TRIP/WARN LED will flash an amber 4-blink pattern

• Bit 3 in Parameter 15, War n in g S ta t us , will go to “1”

• Bit 1 of Parameter 21, Device Status, will go to “1”

Parameter 38, GF Warn Level, allows the installer to define the ground fault

current at which the EC4 Current Monitoring Relay will indicate a warning and

is adjustable from 20 mA…5.0 A.

Parameter 105, GF Warn Delay (Series C and later), allows the installer to define

the time period (adjustable from 0.0…25.0 s) for which a ground fault condition

must be present before a warning occurs.

40 Rockwell Automation Publication 193-UM011A-EN-P - September 2010

Page 40

Protective Trip and Warning Functions Chapter 3

IMPORTANT

In EC4 Current monitoring relays, the Ground Fault warning function

does not include a time delay feature. Once the GF Inhibit Time has

expired, the Ground Fault warning indication is instantaneous.

Undercurrent Protection

Motor current less than a specific level may indicate a mechanical malfunction in

the installation, such as a torn conveyor belt, damaged fan blade, broken shaft, or

worn tool. Such conditions may not harm the motor, but they can lead to loss of

production. Rapid undercurrent fault detection helps to minimize damage and

loss of production.

Table 12 - Undercurrent Setting Ranges

Current Range [A] Min. [A] Max. [A] Default [A]

0.4…2 0.2 2 2

1…5 0.5 5 5

3…15 1.5 15 15

5…25 2.5 25 25

9…45 4.5 45 45

18…90 9 90 90

9…5000 5 5000 45

Undercurrent Warning

The EC4 Current Monitoring Relay will issue a warning with an undercurrent

condition if:

• The current in an of the phases is lower than the current specified for the

corresponding UC Trip Level parameter (Parameter 110 for L1, parameter

113 for L2, & parameter 116 for L3)

• No warning condition already exists

If an undercurrent warning parameter is satisfied, the following will occur:

• The TRIP/WARN LED will flash a yellow blinking pattern depending on

which phase encountered the undercurrent warning condition

– 2 blinks for L1 undercurrent

– 3 blinks for L2 undercurrent

– 4 blinks for L3 undercurrent

• Parameter 15, War n in g St a tu s , will change

– Bit 1 will go to "1" for L1 undercurrent

– Bit 2 will go to "1" for L2 undercurrent

– Bit 3 will go to "1" for L3 undercurrent

• Bit 1 in Parameter 21, Device Status, will go to "1"

Rockwell Automation Publication 193-UM011A-EN-P - September 2010 41

Page 41

Chapter 3 Protective Trip and Warning Functions

IMPORTANT

IMPORTANT

IMPORTANT

Parameter 48, UL Warn Level, allows the installer to define the current at which

the EC4 Current Monitoring Relay will indicate a warning.

The Underload Warning function does not include a time delay feature.

Once the UL Inhibit Time has expired, the Underload warning indication

is instantaneous.

For any given application, the practical limit of UL Warn Level (Parameter

48) will be dependent upon the FLA setting and the lower limit of the EC4

Current Monitoring Relay’s current measurement capability. See Table 20

- on page 83

Undercurrent Trip

The EC4 Current Monitoring Relay will trip with an undercurrent indication if:

• The current in any of the phases is lower than the current specified for the

corresponding UC Trip Level parameter (Parameter 108 for L1, parameter

111 for L2, & parameter 114 for L3)

• No trip currently exists

If the EC4 Current Monitoring Relay trips on an undercurrent condition, the

following will occur:

• The TRIP/WARN LED will flash a red blinking pattern depending on

which phase encountered the undercurrent condition

– 2 blinks for L1 undercurrent

– 3 blinks for L2 undercurrent

– 4 blinks for L3 undercurrent

• Parameter 14, Tri p S tat us , will change

– Bit 1 will go to "1" for L1 undercurrent

– Bit 2 will go to "1" for L2 undercurrent

– Bit 3 will go to "1" for L3 undercurrent

• Bit 0 in Parameter 21, Device Status, will go to "1"

• The outputs will be placed in their Protection Fault state (if so

programmed)

The Protection Fault State of OUT A and OUT B is defined by Parameter

65 (OUTA Pr FltState), Parameter 66 (OUTA Pr FltValue), Parameter 71

(OUTB Pr FltState), and Parameter 72 (OUTB Pr Flt Value).

Parameter 45, UL Inhibit Time, allows the installer to inhibit an underload trip

from occurring during the motor starting sequence and is adjustable from 0…250

seconds.

42 Rockwell Automation Publication 193-UM011A-EN-P - September 2010

Page 42

Protective Trip and Warning Functions Chapter 3

IMPORTANT

IMPORTANT

IMPORTANT

Parameter 46, UL Trip Delay, allows the installer to define the time period that an

underload condition must be present before a trip occurs. It is adjustable from

0.1…25.0 seconds.

Parameter 47, UL Trip Level, allows the installer to define the current at which

the EC4 Current Monitoring Relay will trip on an Underload.

The underload inhibit timer starts after the maximum phase of load

current transitions from 0 A to 30% of the device’s minimum FLA Setting.

The EC4 Current Monitoring Relay does not begin monitoring for an

underload condition until the UL Inhibit Time expires.

For any given application, the practical limit of ULTrip Level (Parameter

47) will be dependent on the FLA setting and the lower limit of the EC4

Current Monitoring Relay’s current measurement capability. See Table 20

- on page 83.

Communication Fault

Protection

A disruption of the communication link between the EC4 Current Monitoring

Relay and a DeviceNet network can result in the loss of application control

and/or critical process diagnostic data. Rapid communication fault detection

helps minimize potential damage due to uncontrolled or unmonitored

applications.

Comm Fault Trip

The EC4 Current Monitoring Relay will trip with a Comm Fault indication if:

• No trip currently exists

• Comm Fault protection is enabled

• The EC4 Current Monitoring Relay experiences a loss of communication

If the relay trips on a Comm Fault, the following will occur:

• The Network Status LED will blink red or become solid red

• The TRIP/WARN LED will flash a red 10-blink pattern

• Bit 9 in Parameter 14, Trip Stat us , will go to “1”

• Bit 0 in Parameter 21, Device Status, will go to “1”

• The Trip Relay contacts will open

• The outputs will be placed in their Protection Fault State (if so

programmed)