Page 1

User Manual

Bulletin 193 EtherNet/IP Communications Auxiliary

Catalog Number

193-DNENCAT, 193-DNENCATR

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

available from

) describes some

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the

consequence

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Chapter 1

Installation & Wiring

Configure the EtherNet/IP

Communications Auxiliary

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Network Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Determining Network Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Setting the IP Network Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

EtherNet/IP Node Address Selection Switches. . . . . . . . . . . . . . . . . . 16

Assign Network Parameters via the BOOTP/DHCP Utility. . . . . . . . . 17

Assign Network Parameters Via a Web Browser & MAC Scanner

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Other Factors to Consider When Assigning Network Parameters. 22

Duplicate IP Address Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Behavior of Modules With Duplicate IP Addresses . . . . . . . . . . . . . . 23

DNS Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Electronic Data Sheet (EDS) File Installation . . . . . . . . . . . . . . . . . . . . . . . 23

Download the EDS File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Register the EDS File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Configure the DeviceNet

Network

Add Devices to the DeviceNet

Network

Chapter 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Chapter 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

DeviceNet Node Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Node Address Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Set the Node Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Using the Hardware Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Using the DeviceNet Node Commissioning Tool . . . . . . . . . . . . . . . 37

Add DeviceNet Modules to the Scan List. . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Simple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

User-Defined. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3 Rockwell Automation Publication 193-UM014B-EN-P - December 2011

Page 4

Chapter 5

View & Configure Parameters

Automatic Device Recovery or

Replace

Automation Controller

Communications

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

View & Edit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Chapter 6

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Setting ADR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Chapter 7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Ethernet Messaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

I/O Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

ControlLogix Configuration with Add-On Profiles . . . . . . . . . . . . . 51

EtherNet/IP Network Configuration with Add-On Profiles . . . . . 53

Accessing Module Data with Add-On Profiles . . . . . . . . . . . . . . . . . . 56

ControlLogix Generic Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 57

EtherNet/IP Generic Module Configuration . . . . . . . . . . . . . . . . . . . 58

Accessing Generic Module Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Logic Explicit Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

E-mail/Text

Device Parameters

Chapter 8

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

E-mail Notifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

E-mail Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

E-mail Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Configure Device Identity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Text Notifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Chapter 9

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Parameter Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Parameter Listing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4 Rockwell Automation Publication 193-UM014B-EN-P - July 2011

Page 5

Chapter 10

Troubleshooting

Specifications

EtherNet/IP & DeviceNet

Information

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

EtherNet/IP Modules of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Power-Up Reset Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Recoverable Error Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Unrecoverable Error Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Troubleshooting Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Appendix A

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Appendix B

Electronic Data Sheet (EDS) Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Common Industrial Protocol (CIP) Objects. . . . . . . . . . . . . . . . . . . . . . . . 89

Identity Object — CLASS CODE 0x01. . . . . . . . . . . . . . . . . . . . . . . . 89

Message Router Object — CLASS CODE 0x02. . . . . . . . . . . . . . . . . 90

DeviceNet Object — CLASS CODE 0x03 . . . . . . . . . . . . . . . . . . . . . 91

Assembly Object — CLASS CODE 0x04 . . . . . . . . . . . . . . . . . . . . . . 91

Connection Manager Object — CLASS CODE 0x06 . . . . . . . . . . . 95

Parameter Object — CLASS CODE 0x0F. . . . . . . . . . . . . . . . . . . . . . 96

Device Level Ring (DLR) Object — CLASS CODE 0x47 . . . . . . . 97

QoS Object — CLASS CODE 0x48 . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Non-Volatile Storage Object — CLASS CODE 0xA1 . . . . . . . . . . . 98

Port Object — CLASS CODE 0x0F4 . . . . . . . . . . . . . . . . . . . . . . . . . . 99

TCP/IP Interface Object — CLASS CODE 0xF5 . . . . . . . . . . . . . 100

Ethernet Link Object — CLASS CODE 0xF6 . . . . . . . . . . . . . . . . . 101

Rockwell Automation Publication 193-UM014B-EN-P - July 2011 5

Page 6

6 Rockwell Automation Publication 193-UM014B-EN-P - July 2011

Page 7

Installation & Wiring

Chapter

1

Introduction

Overview

The purpose of this chapter is to provide the necessary instructions to successfully

install the Bulletin 193 Ethernet™/IP Communications Auxiliary and properly

connect it to an EtherNet/IP and DeviceNet™ network.

The Bulletin 193 EtherNet/IP Communications Auxiliary is an EtherNet/IP to

DeviceNet linking device. It provides a means for devices that primarily

communicate on a DeviceNet network (e.g., a Bulletin 193 or 592 E3 Plus

Overload Relay or a Bulletin 825-P Electronic Overload Relay) to communicate

to EtherNet/IP-based scanners. The EtherNet/IP Communications Auxiliary

allows up to six (6) DeviceNet-based devices to be scanned via Implicit Messaging

and can bridge explicit messaging for all nodes on a DeviceNet network. The

EtherNet/IP Communications Auxiliary uses an internal web server to configure

the module, the DeviceNet network, and DeviceNet-based devices that fully

support the Parameter Object.

SHOCK HAZARD: To prevent electrical shock, disconnect the EtherNet/

IP Communications Auxiliary from its power source before installing or

servicing. Install in suitable enclosure. Keep free from contaminants.

ATTENTION: The EtherNet/IP Communications Auxiliary contains ESD

(electrostatic discharge) sensitive parts and assemblies. Static control

precautions are required when installing, testing, servicing, or repairing

the EtherNet/IP Commuications Auxiliary. Component damage may result

if ESD control procedures are not followed. If you are not familiar with

static control procedures, refer to Rockwell Automation publication 8000-

4.5.2, “Guarding Against Electrostatic Damage”, or any other applicable

ESD protection handbook.

ATTENTION: The purpose of this document is to serve as a guide for

proper installation. The National Electrical Code (NEC) and any other

governing regional or local code will take precedence. Rockwell

Automation cannot assume responsibility for the compliance or proper

installation of the EtherNet/IP Communications Auxiliary or associated

equipment. A hazard of personal injury and/or equipment damage exists if

codes are ignored during installation.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 7

Page 8

Chapter 1

ATT ENTI ON: An incorrectly applied or installed EtherNet/IP

Communications Auxiliary can result in damage to the components or

reduction in product life. Wiring or application errors (e.g., supplying

incorrect or inadequate supply voltage or operating/storing in excessive

ambient temperatures) may result in malfunction of the product.

ATT ENTI ON: Only personnel familiar with the EtherNet/IP

Communications Auxiliary and associated machinery should plan to

install, set up, and maintain the system. Failure to comply may result in

personal injury and/or equipment damage.

ATT ENTI ON: This is a Class A product. In a domestic environment, this

product may cause radio interference in which case the user may be

required to take adequate measures.

ATT ENTI ON: To remain compliant with UL/CSA Certifications, the

DeviceNet power supply must meet NEC Class 2 Requirements.

8 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 9

Chapter 1

Features

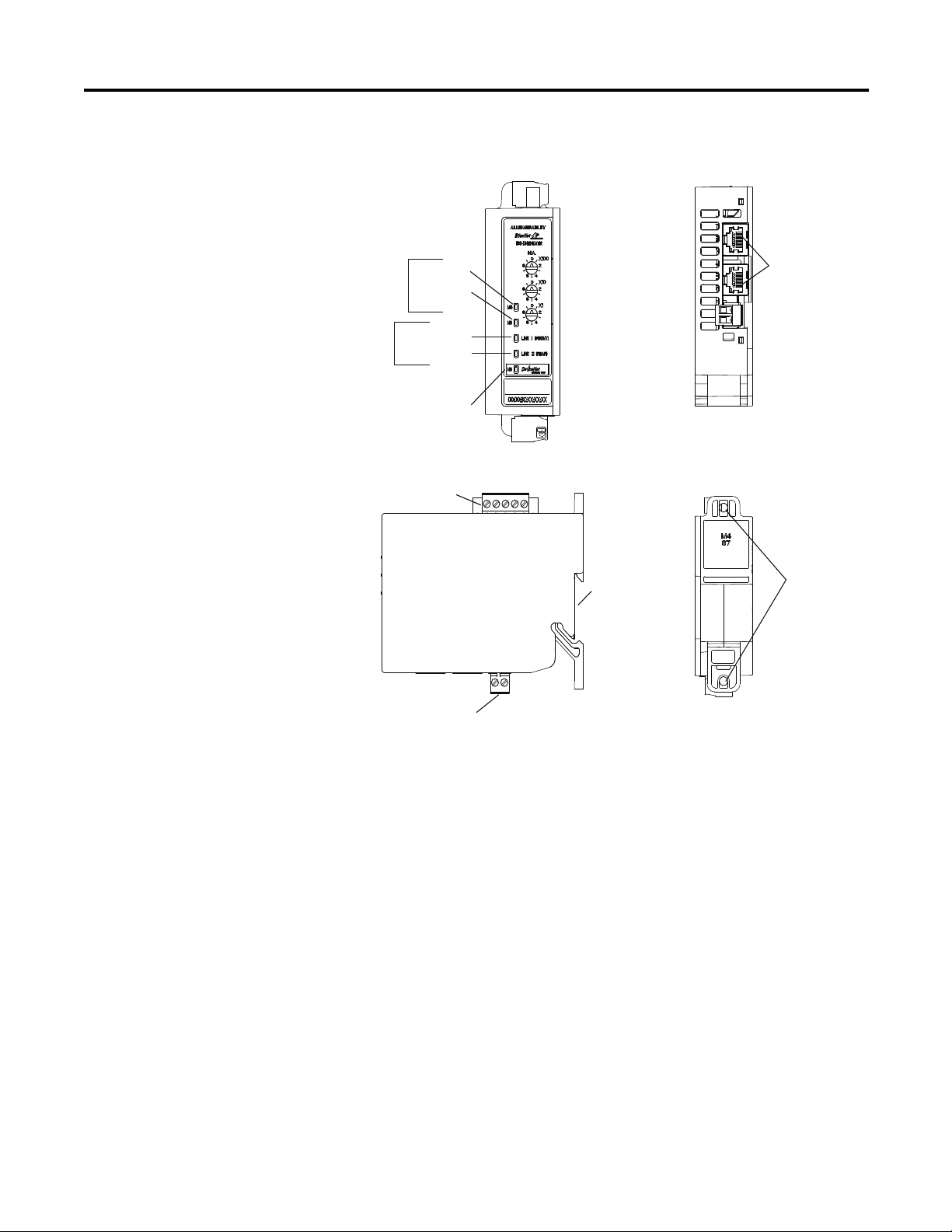

Figure 1 - Features

Front View

Status

LEDs

Activity

LEDs

DeviceNet Network

DeviceNet Connector

Module

Ethernet/IP

Network

Front Port Link

Rear Port Link

Status LED

Side View

DIN

Rail Mounting

Top View

Ethernet Connectors

RJ-45

Rear View

Panel Mounting

Installation

Earth Ground Connector

The EtherNet/IP Communications Auxiliary may be DIN Rail or panel

mounted. To avoid overheating, the unit must be mounted vertically and

requires 37.4 mm (1-1/2 in.) of clearance at the top and bottom to allow proper

air flow. The temperature ratings for the unit will be derated if not mounted in

this manner.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 9

Page 10

Chapter 1

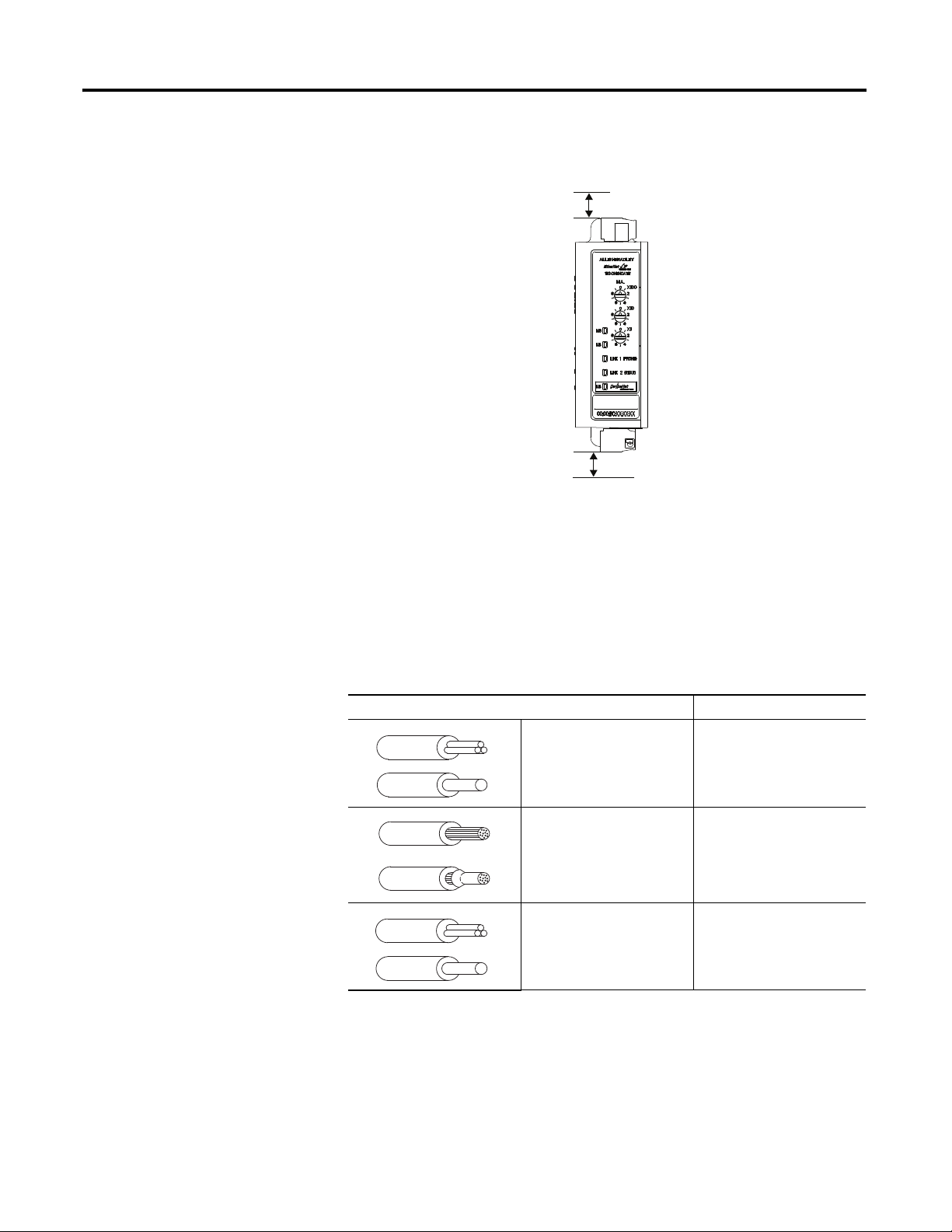

Front View

37.44 mm

(1-1/2 in.)

37.44 mm

(1-1/2 in.)

Figure 2 - Installation

Wiring

The EtherNet/IP Communications Auxiliary can accept all forms of DeviceNet

cable. However, DeviceNet shielded cable is recommended. The EtherNet/IP

Communications Auxiliary complies with the Open Device Vendors Association

(ODVA) DeviceNet compliance testing when the distance between end nodes is

100 m or less with 60 or fewer network drops.

Table 1 - Wire & Torque Specifications

Wire Torque

1X

2X

1X

2X

1X

2X

24…12 AWG

24…16 AWG

5 lb.•in.

0.2…2.5 mm

0.25…1 mm

0.56 N•m

0.2…2.5 mm

0.2…1 mm

0.56 N•m

2

2

2

2

10 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 11

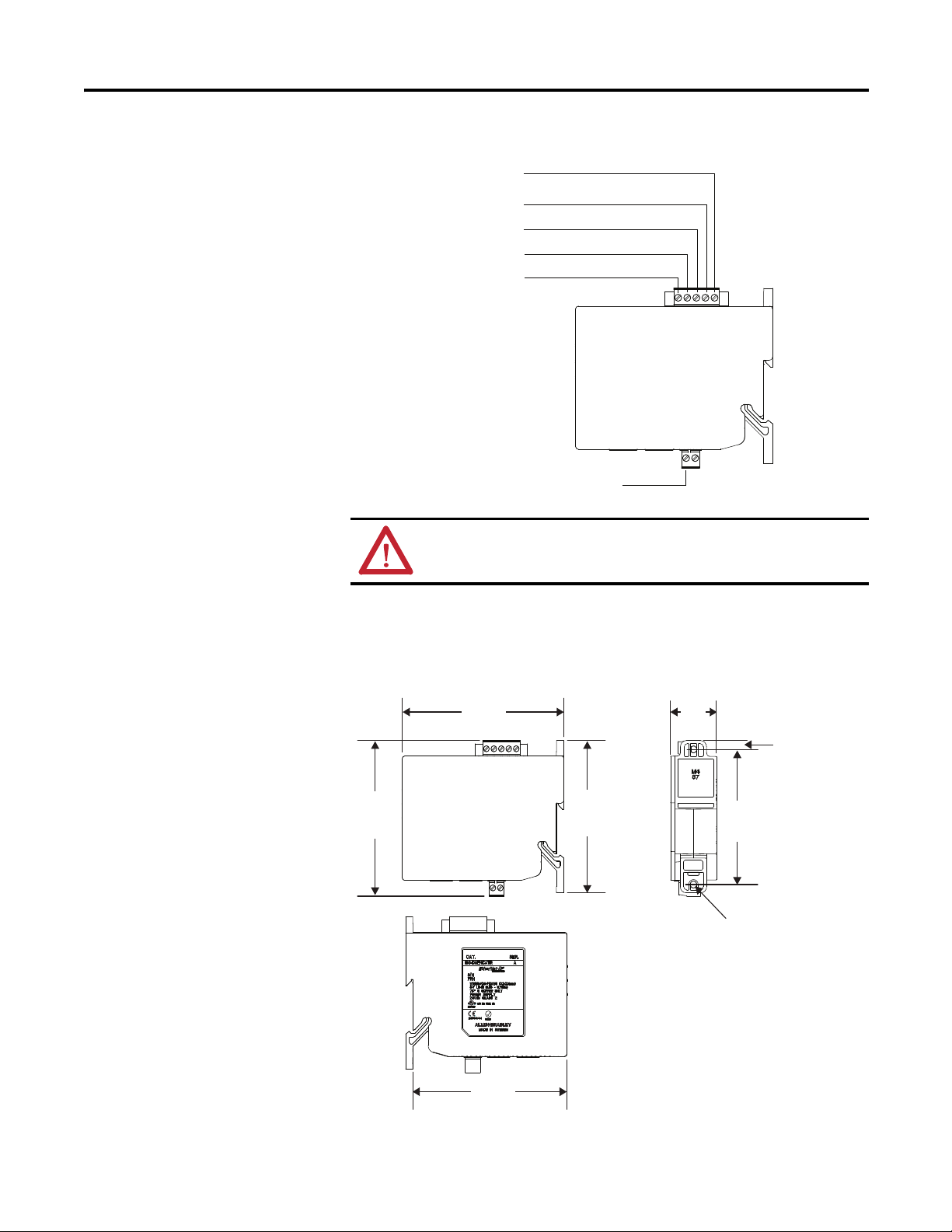

Figure 3 - Wiring Diagram

5.85

(0.23)

105.0

(4.13)

100.5

(3.95)

98.0

(3.86)

110.0

(4.33)

Ø 4.50

(0.16)

87.0

(3.43)

31.3

(1.23)

Dimensions are shown in millimeters (inches).

DNET (Black)

24V -

CAN L (Blue)

Shield

CAN H (White)

DNET (Red)

24V +

Chapter 1

Earth Ground

Dimensions

ATTENTION: Use a shielded DeviceNet cable to comply with CISPR 22

and CISPR 24.

Figure 4 - Dimension Diagram

Rockwell Automation Publication 193-UM014B-EN-P December 2011 11

Page 12

Chapter 1

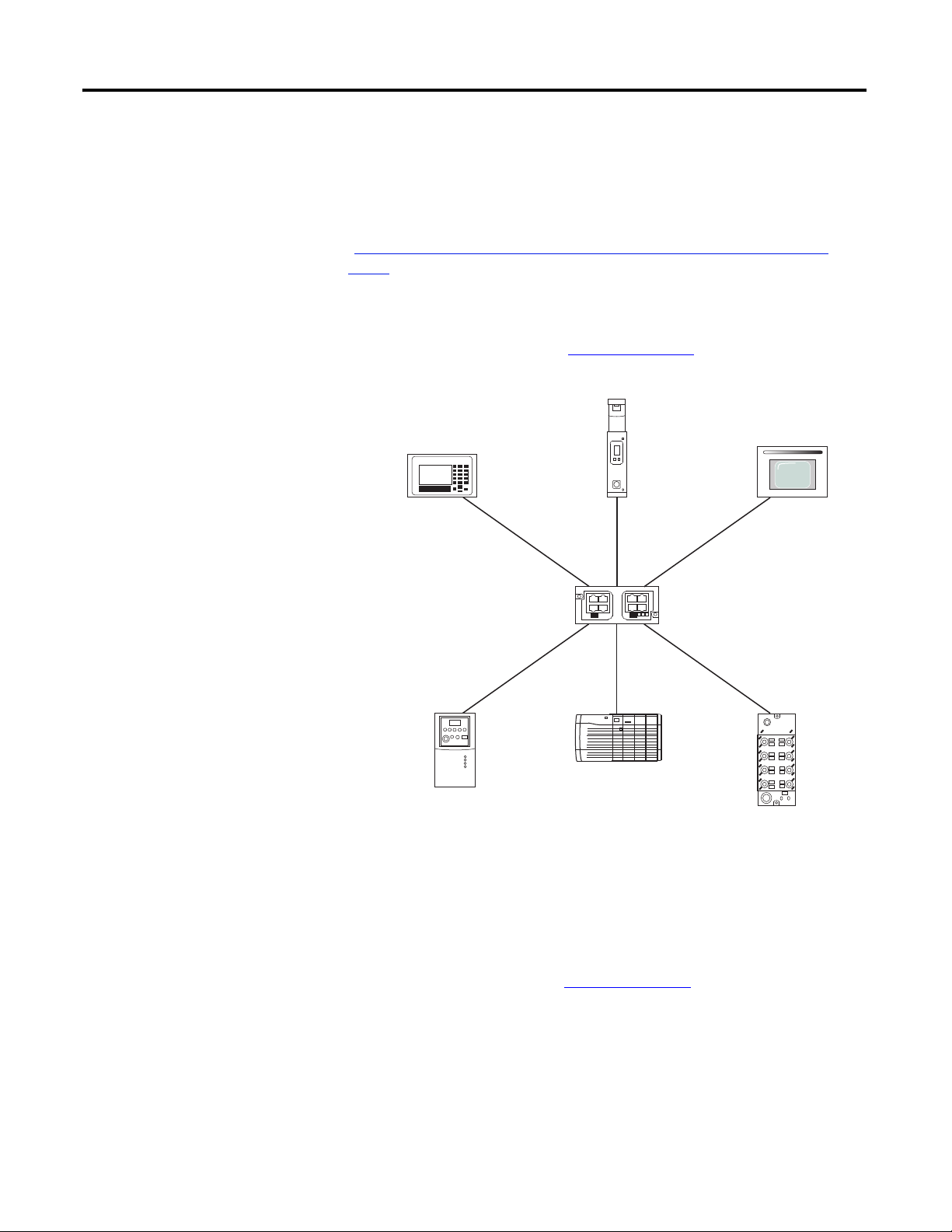

Network Design

The EtherNet/IP Communications Auxiliary is available as a single Ethernet port

(Cat. No. 193-DNENCAT) and dual Ethernet port (Cat. No.

193-DNENCATR) module that has RJ-45 ports to connect to Ethernet cable

CAT5 type or better . Rockwell Automation offers a wide variety of

Allen-Bradley Ethernet patch cables with its Bulletin 1585 line of Ethernet cables

(http://ab.rockwellautomation.com/Connection-Devices/RJ45-Network-

Media).

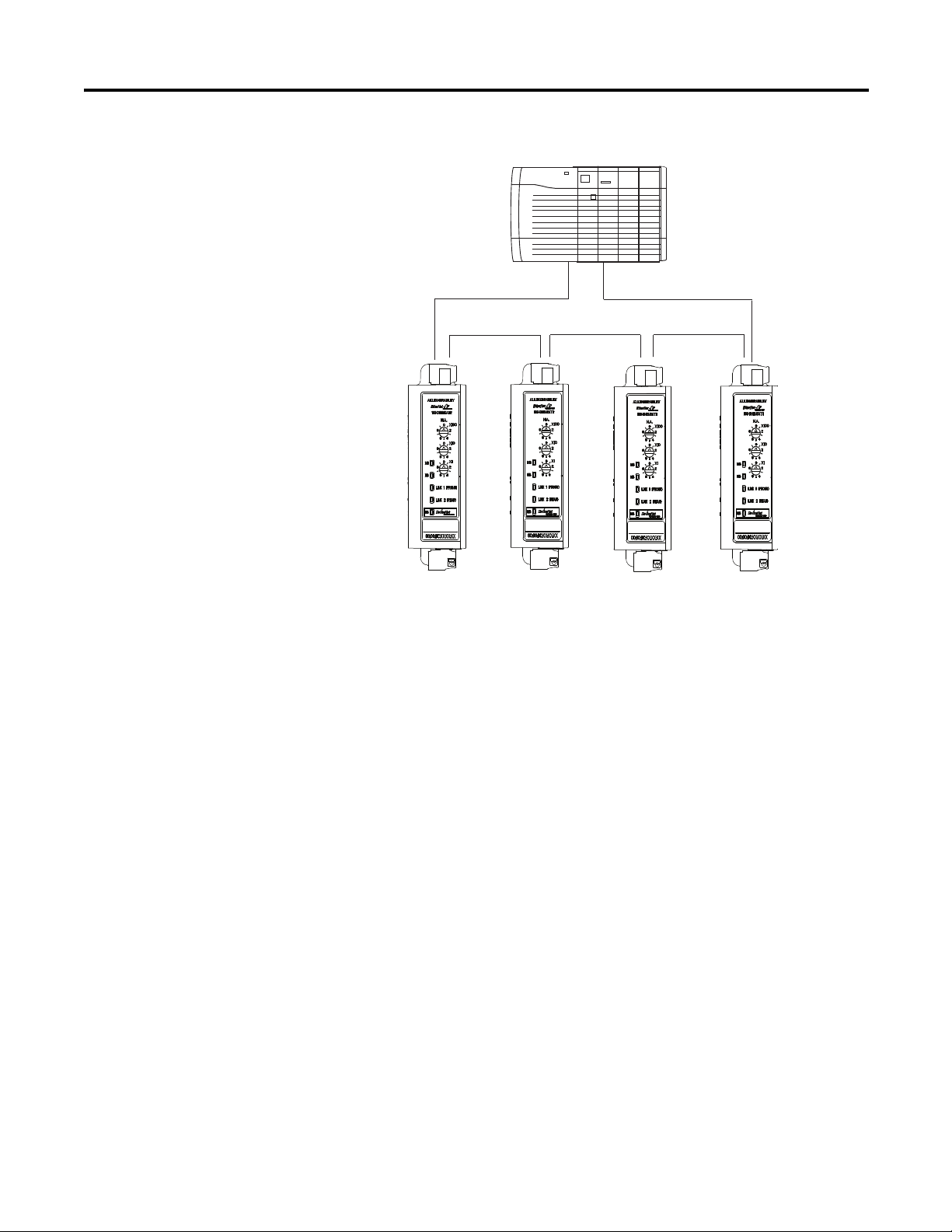

Both the 193-DNENCAT and 193-DNENCATR devices support a Star

Ethernet topology in which all Ethernet nodes wire back to a central Ethernet

switch, hub, or router as shown in Figure 5 on page 12

Figure 5 - Star Ethernet Topology

.

Rockwell Automation also offers a line of managed and unmanaged

Allen-Bradley Ethernet Switches with its Stratix™ family of Ethernet switches.

Refer to

Ethernet-IP-Infrastructure

http://ab.rockwellautomation.com/Networks-and-Communications/

for more information.

The Cat. No. 193-DNENCATR Module also supports a Ring Ethernet topology

in which all Ethernet nodes are wired in series with one another until a complete

network ring is made as shown in Figure 6 on page 13

12 Rockwell Automation Publication 193-UM014B-EN-P December 2011

.

Page 13

Figure 6 - Ring Ethernet Topology

Chapter 1

The Cat. No. 193-DNENCATR Module supports Rockwell Automation’s

Device Level Ring (DLR) topology as a slave device in which the EtherNet/IP

network will still continue to communicate in the event that one of the network

chains is disrupted.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 13

Page 14

Chapter 1

14 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 15

Chapter

2

Configure the EtherNet/IP Communications Auxiliary

Introduction

Determining Network Parameters

This chapter describes how to configure an EtherNet/IP Communications

Auxiliary to operate on an EtherNet/IP network.

When you first install an EtherNet/IP Communications Auxiliary, the module is

Dynamic Host Configuration Protocol (DHCP) enabled.

To operate an EtherNet/IP network, you must define these parameters.

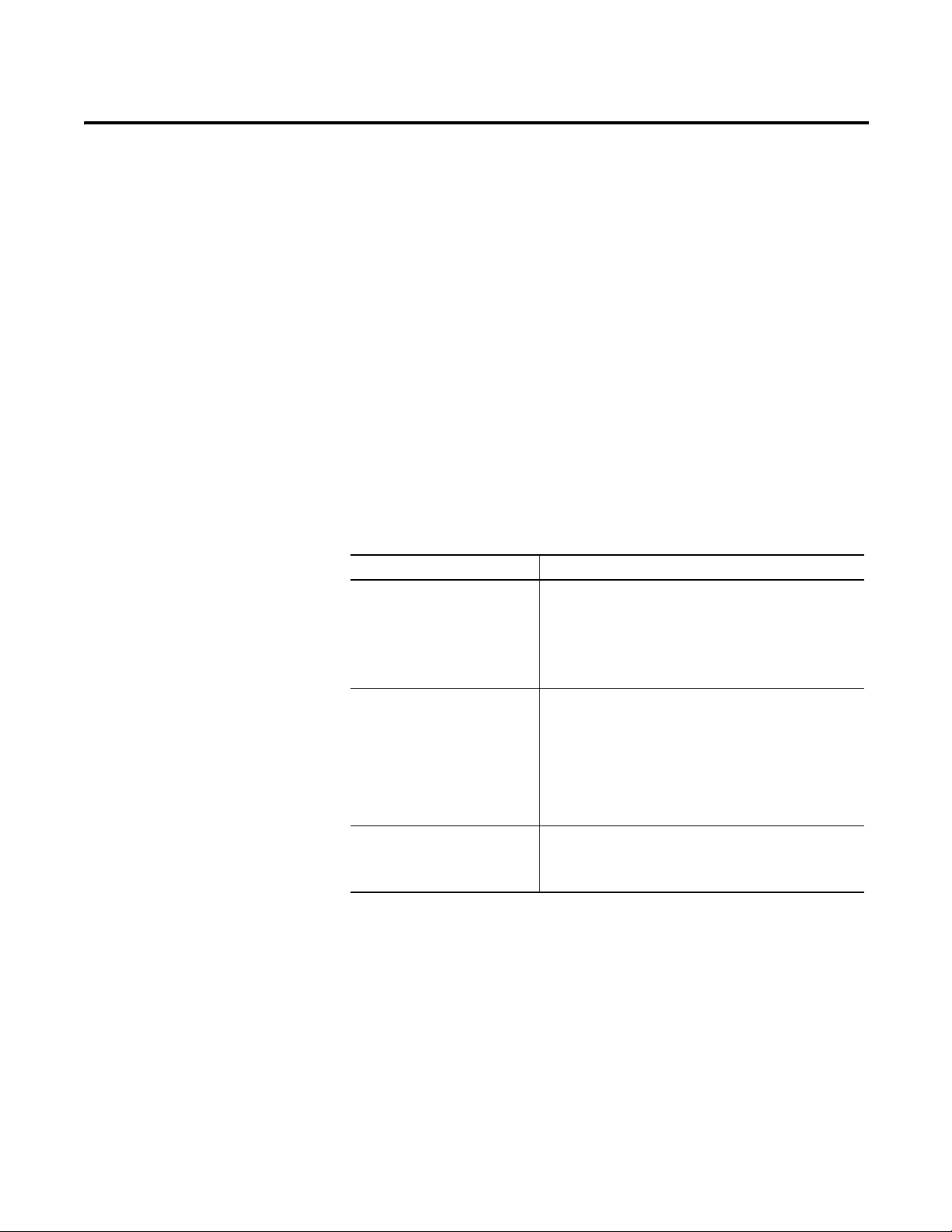

Table 2 - EtherNet/IP Network Parameters

Network Parameter Description

IP Address The IP address uniquely identifies the module. The IP address

is in the form xxx.xxx.xxx.xxx where each xxx is a number from

0...255. Do not use the following IP addresses, as these are

reserved values:

• 0.0.0.1...0.255.255.255

• 127.0.0.0...127.255.255.255

• 224.255.255.255...255.255.255.255

Subnet Mask Subnet addressing is an extension of the IP address scheme

that allows a site to use a single network ID for multiple

physical networks. Routing outside of the site continues by

dividing the IP address into a net ID and a host ID via the

class. Inside a site, the subnet mask is used to redivide the IP

address into a custom network ID portion and host ID portion.

NOTE: If you change the subnet mask of an alreadyconfigured module, you must cycle power to the module for

the change to take effect.

Gateway A gateway connects individual physical networks into a

system of networks. When a node needs to communicate

with a node on another network, a gateway transfers the data

between the two networks.

If DNS addressing is used or if the module is referenced via a host name in an

MSG instruction, the following parameters must be defined.

NOTE: Consult with your Ethernet network administrator to determine if these

parameters need to be specified.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 15

Page 16

Chapter 2

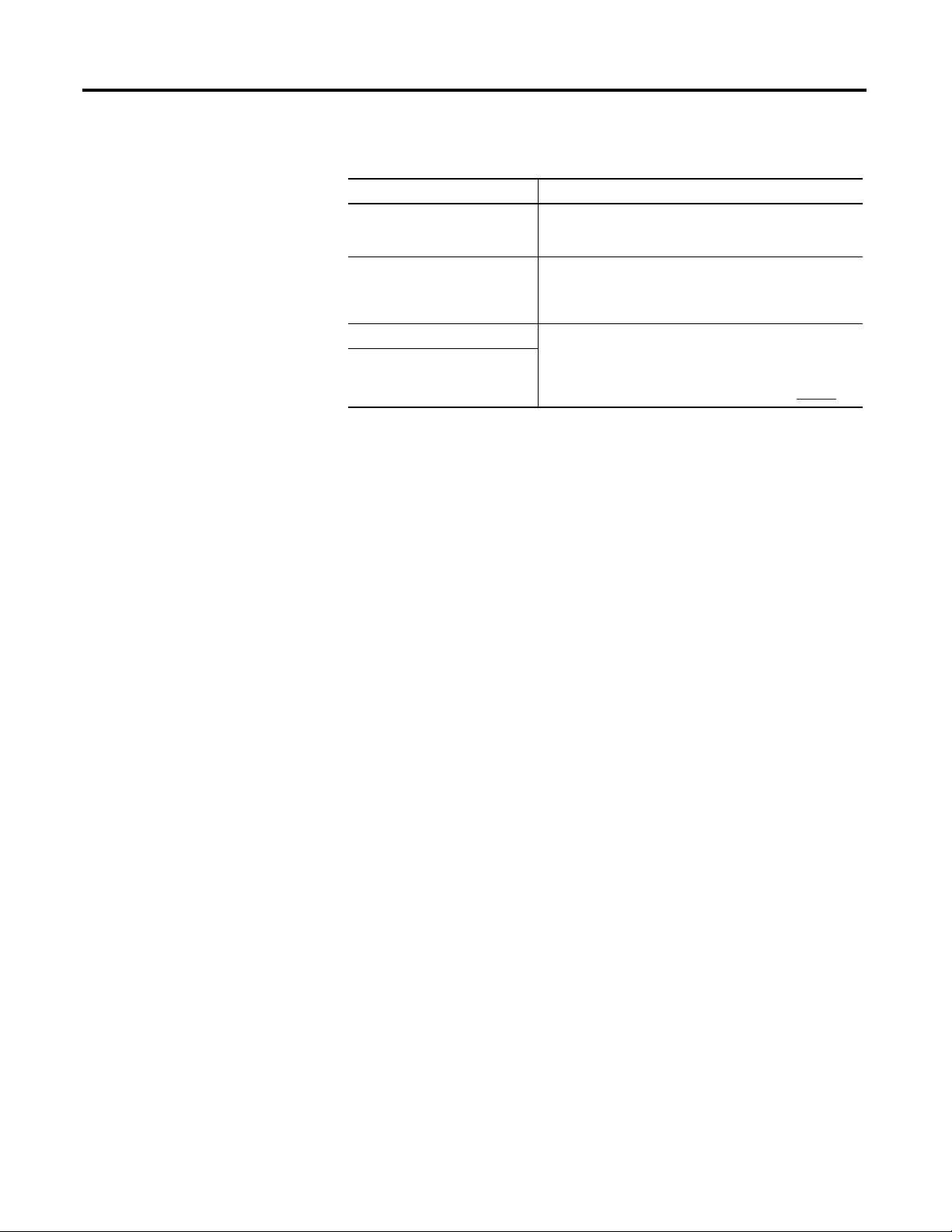

Table 3 - EtherNet/IP Network Parameters for DNS Addressing

Network Parameter Description

Host Name A host name is part of a text address that identifies the

Domain Name A domain name is part of a text address that identifies the

Primary DNS Server Address This identifies any DNS servers used in the network. You must

Secondary DNS Server Address

module. The full text address of a module is:

host_name.domain_name.

domain in which the module resides. The full text address of a

module is: host_name.domain_name. The domain name has a

48-character limit.

have a DNS server configured if you specify an SMTP server

with a name. The DNS server converts the domain name or

host name to an IP address that can be used by the network.

For more information on DNS addressing, refer to page 23.

Setting the IP Network Address

An EtherNet/IP Communications Auxiliary ships with DHCP enabled. You can

set the network Internet Protocol (IP) address by using:

• the EtherNet/IP node address selection switches,

• a Bootstrap Protocol (BOOTP)/Dynamic Host Configuration Protocol

(DHCP) server (e.g., the Rockwell Automation BOOTP-DHCP Server

Utility, which is included with Rockwell Software’s RSLinx™ Classic

software), OR

• a web browser and MAC scanner software.

EtherNet/IP Node Address Selection Switches

The EtherNet/IP Communications Auxiliary comes with three node address

selection switches that allow the user to select the last octet for the IP address

192.168.1.xxx.

16 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 17

Figure 7 - Last Octet Selection

EXAMPLE

IMPORTANT

When the top dial is set to 1, the middle dial is set to 2, and the bottom

dial is set to 3, the resulting IP address is: 192.168.1.123.

Chapter 2

x 100 Digit

x 10 Digit

x 1 Digit

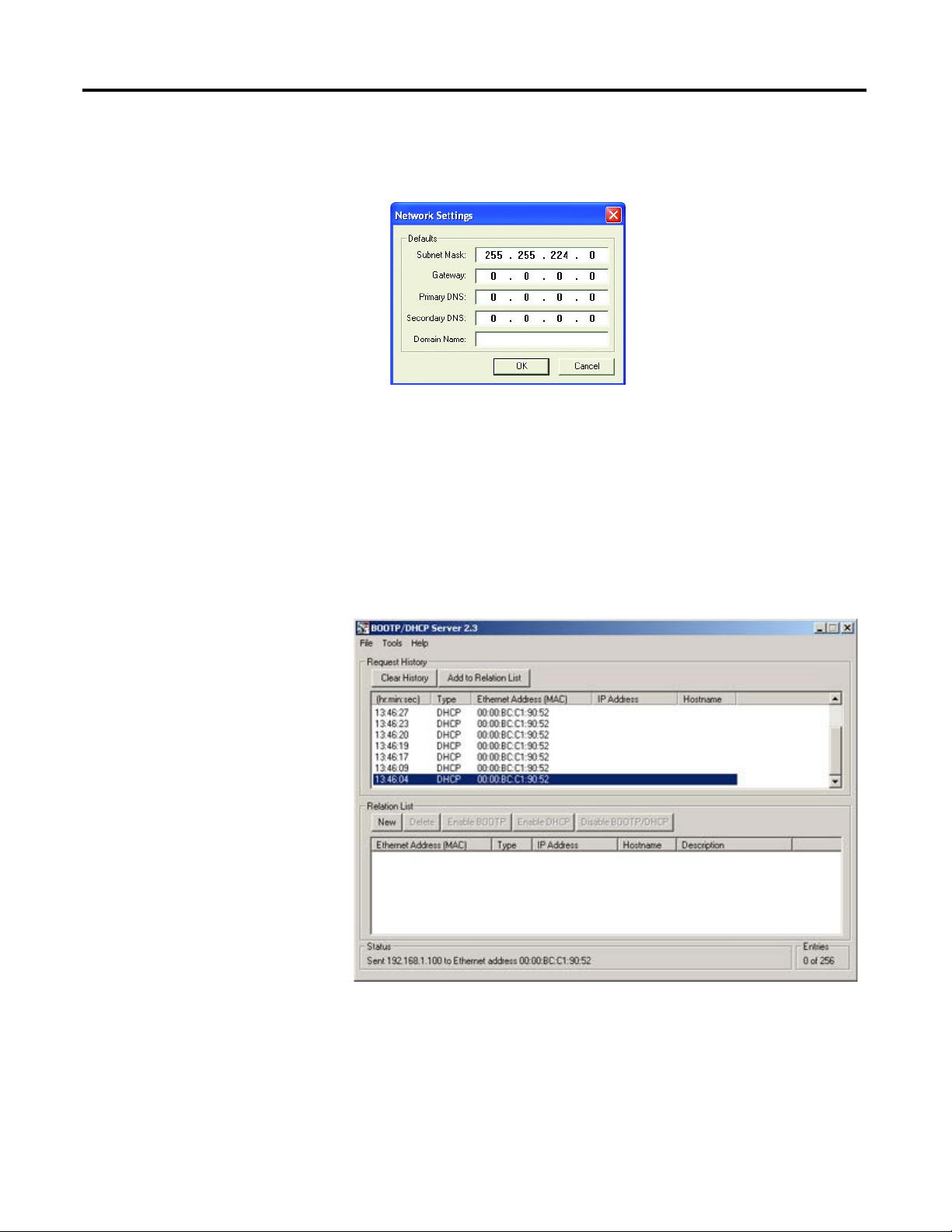

Assign Network Parameters via the BOOTP/ DHCP Utility

When the node address selection switches are set to a value greater than 255, the

IP address is set to DHCP Enabled or programmed for a static IP address.

By default, the EtherNet/IP Communications Auxiliary is DHCP Enabled. The

BOOTP/DHCP utility is a standalone program that is located in the BOOTPDHCP Server folder accessed from the Start menu.

Before starting the BOOTP/DHCP utility: Make sure you have the

hardware MAC ID of the module, which is printed on the front of the

EtherNet/IP Communications Auxiliary. The MAC ID has a format

similar to: 00-0b-db-14-55-35.

This utility recognizes DHCP-enabled devices and provides an interface to

configure a static IP address for each device.

To assign network parameters via the BOOTP/DHCP utility, perform this

procedure:

1. Execute the BOOTP/DHCP software.

2. Choose Tool >Network Settings.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 17

Page 18

Chapter 2

3. If appropriate for the network, type the subnet mask, gateway address,

primary/secondary server addresses, and domain name in their respective

fields.

4. Click OK.

The Request History panel displays the hardware addresses of modules

issuing BOOTP or DHCP requests.

5. Double-click the MAC address of the module to be configured.

NOTE: The MAC address is printed on the front of the EtherNet/IP Communications

Auxiliary. The format of the hardware address resembles:

00-0b-db-14-55-35

18 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 19

The New Entry window appears with the module’s Ethernet Address

(MAC).

6. Type the IP address, host name, and a module description.

7. Click OK.

Chapter 2

Assign Network Parameters Via a Web Browser & MAC Scanner Software

8. Cycle power to the module by removing and reapplying the DeviceNet

connector.

9. To permanently assign this configuration to the module: Select the module

in the Relation List panel and click Disable BOOTP/DHCP.

When module power is cycled, it uses the assigned configuration and does

not issue a DHCP request.

If you do not click Disable BOOTP/DHCP, on a power cycle, the module

clears the current IP configuration and will again begin sending DHCP

requests.

In the event that a user does not have access to a DHCP software utility, a user

can assign network parameters via a web browser (e.g., Microsoft® Internet

Explorer) and Media Access Control (MAC) scanner software (e.g., MAC

Scanner from Colasoft® - http://www.colasoft.com/

configure the module using this method.

1. Locate and identify the MAC ID printed on the label of the EtherNet/IP

Communications Auxiliary. This address has a format that is similar to:

00-0b-db-14-55-35

). Follow these steps to

2. Connect the EtherNet/IP Communications Auxiliary to the same wide

area network (WAN) as your personal computer.

3. Initiate the MAC scanner software.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 19

Page 20

Chapter 2

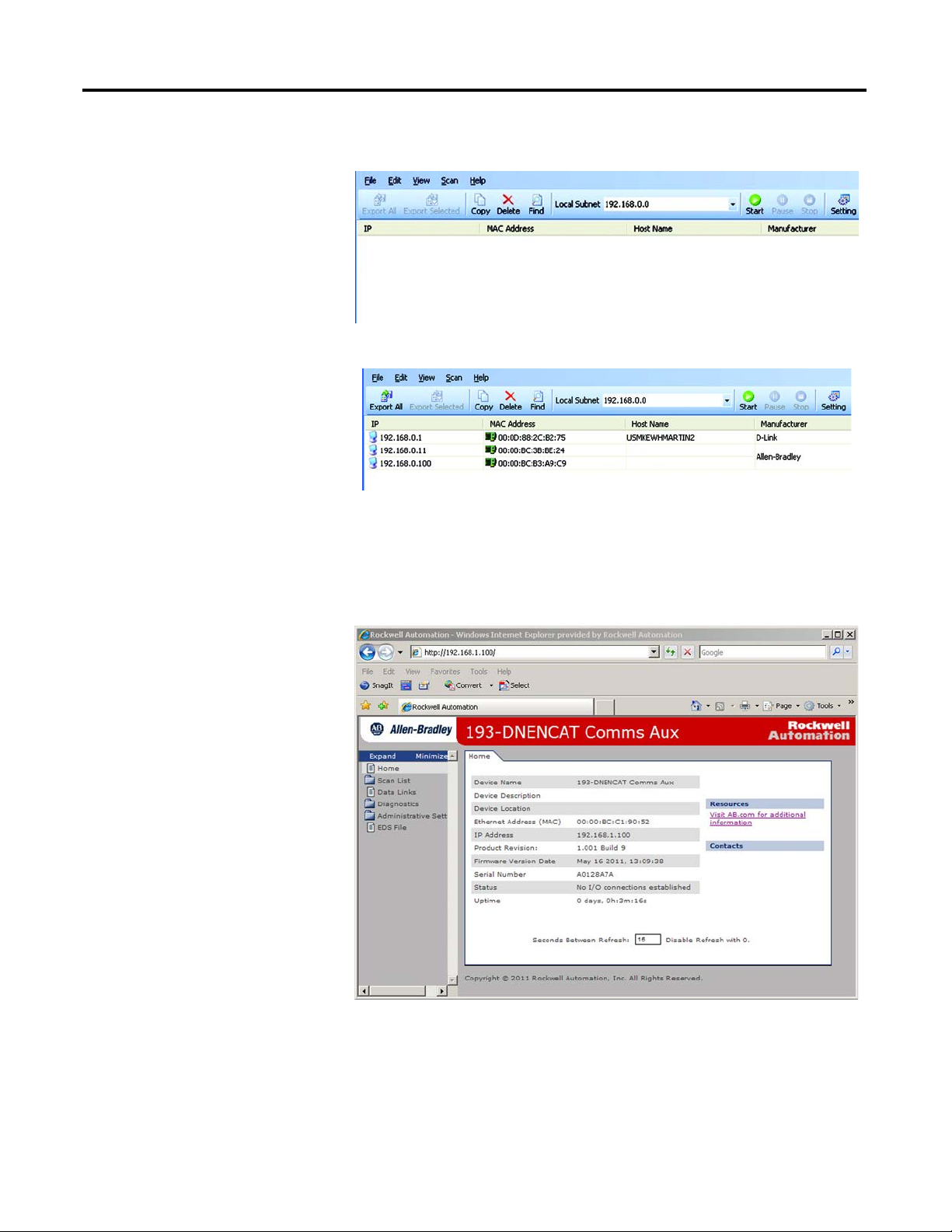

4. Select the appropriate subnet to scan for available MAC addresses.

5. Scan the Subnet for all available MAC addresses.

6. Identify the IP address assigned to the MAC ID of the EtherNet/IP

Communications Auxiliary. The IP address will have a format that is

similar to 192.168.0.100.

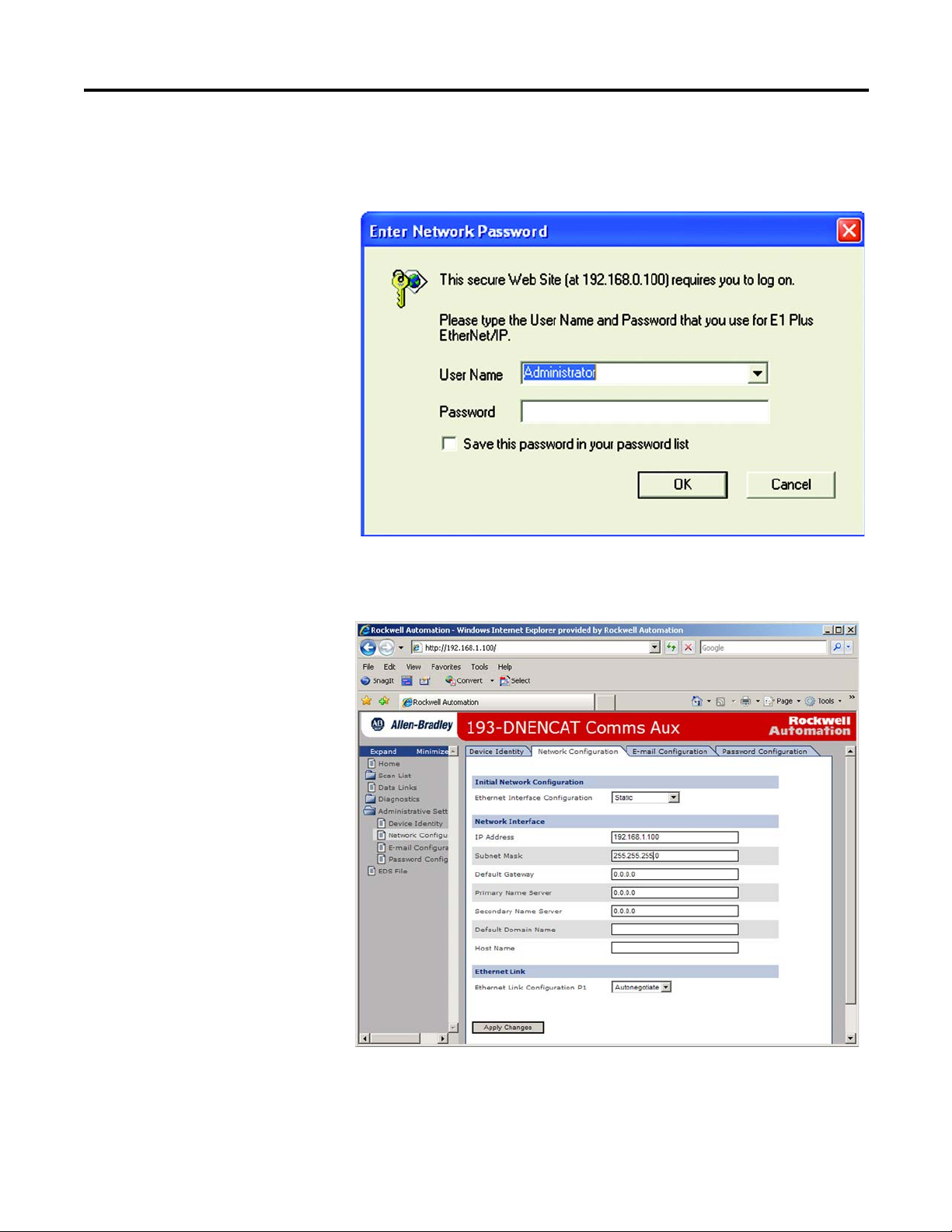

7. Open a web browser and type the IP address on the address line to view the

internal web server of the EtherNet/IP Communications Auxiliary.

8. Select Administration Settings>Network Configuration to change the IP

address of the EtherNet/IP Communications Auxiliary to a static IP

address.

20 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 21

Chapter 2

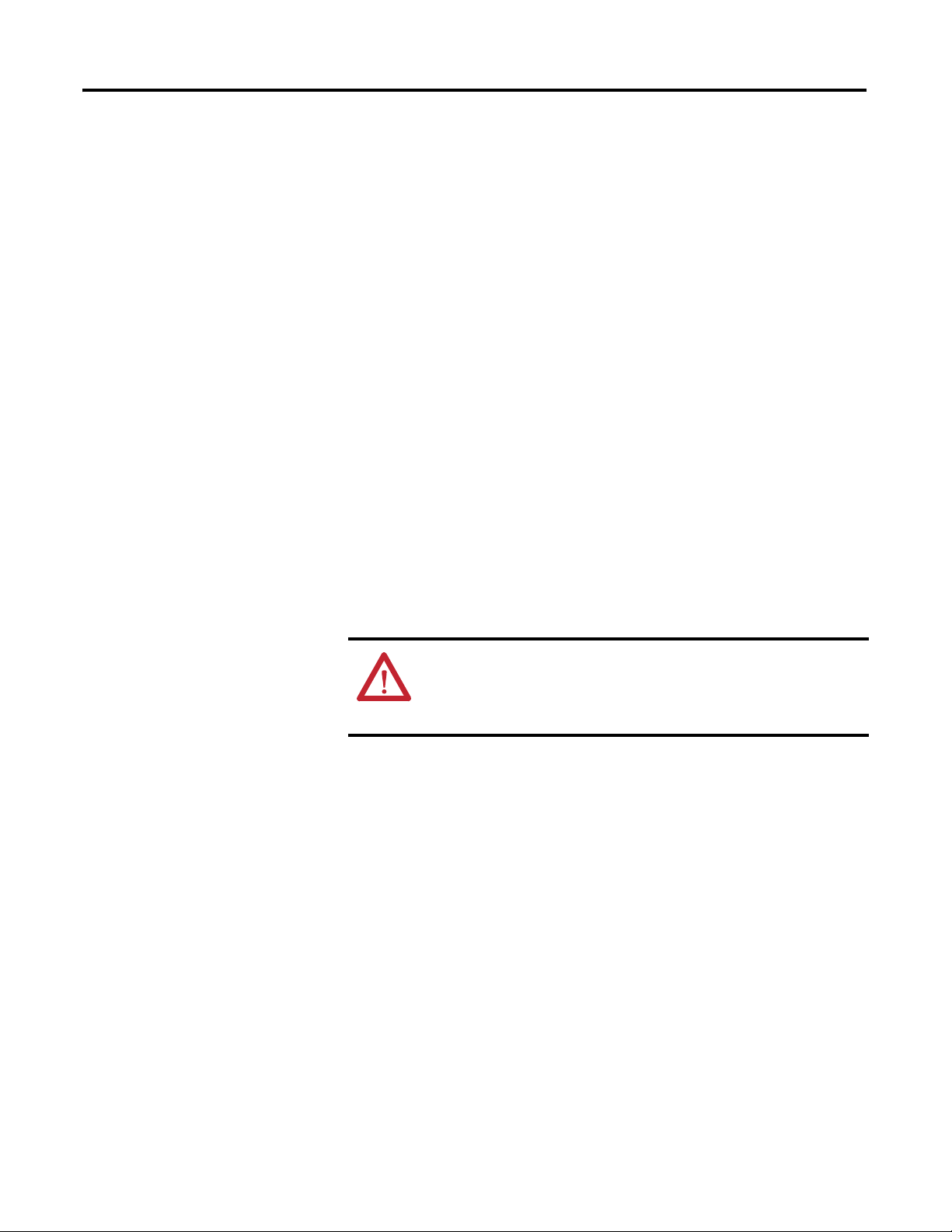

9. The module will prompt the user for a User Name and Password. Type

“Administrator” as the user name, leave the password field blank, then click

OK.

10. Assign the appropriate network settings per the recommendation of the

network administrator for the network that this module will be

communicating on and click Apply.

11. Remove and reapply the DeviceNet connector to allow the

communications changes to take affect.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 21

Page 22

Chapter 2

Other Factors to Consider When Assigning Network Parameters

There are other factors to consider when assigning networks parameters, which

include the:

• network isolation from or integration into the plant/enterprise network.

• network size.

For large networks, even isolated networks, it might be more convenient

and safer to use a BOOTP/DHCP server rather than RSLinx software.

The BOOTP/DHCP server also limits the possibility of assigning

duplicate IP addresses.

• company policies and procedures associated with plant floor network

installation and maintenance.

• level of involvement by information technology personnel in plant floor

network installation and maintenance.

• type of training offered to control engineers and maintenance personnel.

If the Rockwell Automation BOOTP or DHCP server is used in an uplinked

subnet where an enterprise DHCP server exists, a module may get an address

from the enterprise server before the Rockwell Automation utility even sees the

module. In this case, disconnect the uplink to set the address and configure the

module to retain its static address before reconnecting to the uplink. This is not a

problem if you have node names configured in the module and leave DHCP

enabled.

ATT ENTI ON: The EtherNet/IP Communications Auxiliary must be

assigned a fixed network address. The IP address of this module must not

be dynamically provided. Failure to observe this precaution may result in

unintended machine motion or loss of process control.

Duplicate IP Address Detection

When you change the IP address or connect the module to an EtherNet/IP

network, the module checks to make sure that the IP address assigned to this

module does not match the address of any other network device. If the module

determines that another device on the network with a matching IP address, the

EtherNet/IP port of the module goes into conflict mode where the Network

Status LED indicator is solid red.

To resolve this conflict, use the instructions below to change the IP address of the

module. Then, cycle power to the module or reset the modules by disconnecting

and then reconnecting the Ethernet cable.

Two modules could possibly detect a conflict simultaneously. If this occurs,

perform this procedure.

1. Remove the module with the incorrect IP address and correct its conflict.

2. Cycle power or disconnect the Ethernet cable from the second module and

reconnect it.

22 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 23

Chapter 2

Behavior of Modules With Duplicate IP Addresses

Devices in conflict over an IP address behave differently depending on whether

connections have been established to either of the modules and whether both

modules support duplicate IP address detection.

Table 4 - Device Conflict over Duplicate IP Addresses

If then

both modules support duplicate IP

address detection,

both modules support duplicate IP

address detection and are started at

roughly the same time,

one module supports duplicate IP address

detection and a second module does not,

the first started module uses and retains its IP address.

The other module will detect a conflict, give up the IP

address and enter conflict mode.

one of the modules surrenders the IP address and enters

conflict mode.

the second module generally keeps its IP address,

regardless of which module first obtains the IP address.

The module that supports duplicate IP address detection

will detect the conflict and give up the IP address.

DNS Addressing

To further qualify a module’s address, use DNS addressing to specify a host name

for a module, which also includes specifying a domain name and DNS servers.

DNS addressing makes it possible to set up similar network structures and IP

address sequences under different domains.

DNS addressing is only necessary if you refer to the module by host name, such as

in path descriptions in MSG instructions.

To use DNS addressing, perform this procedure.

Electronic Data Sheet (EDS) File Installation

Before the EtherNet/IP Communications Auxiliary is configured to

communicate on an EtherNet/IP network, it must be registered to the software

that configures the network (e.g., Rockwell Automation RSLinx Classic and

RSNetWorx for EtherNet/IP software). A user registers the module by installing

an EDS file. The EDS file for the EtherNet/IP Communications Auxiliary can

be obtained from one of two locations:

1. Assign a host name to the module.

NOTE: Contact the network administrator ro have a host name assigned. Valid host

names should be IEC-1131-3 compliant.

2. Configure the module's parameters.

3. In addition to the IP address, subnet mask, and gateway address, configure

a host name for the module, domain name, and primary/secondary DNS

server addresses.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 23

Page 24

Chapter 2

• embedded in the module OR

• the Allen-Bradley EDS file download website.

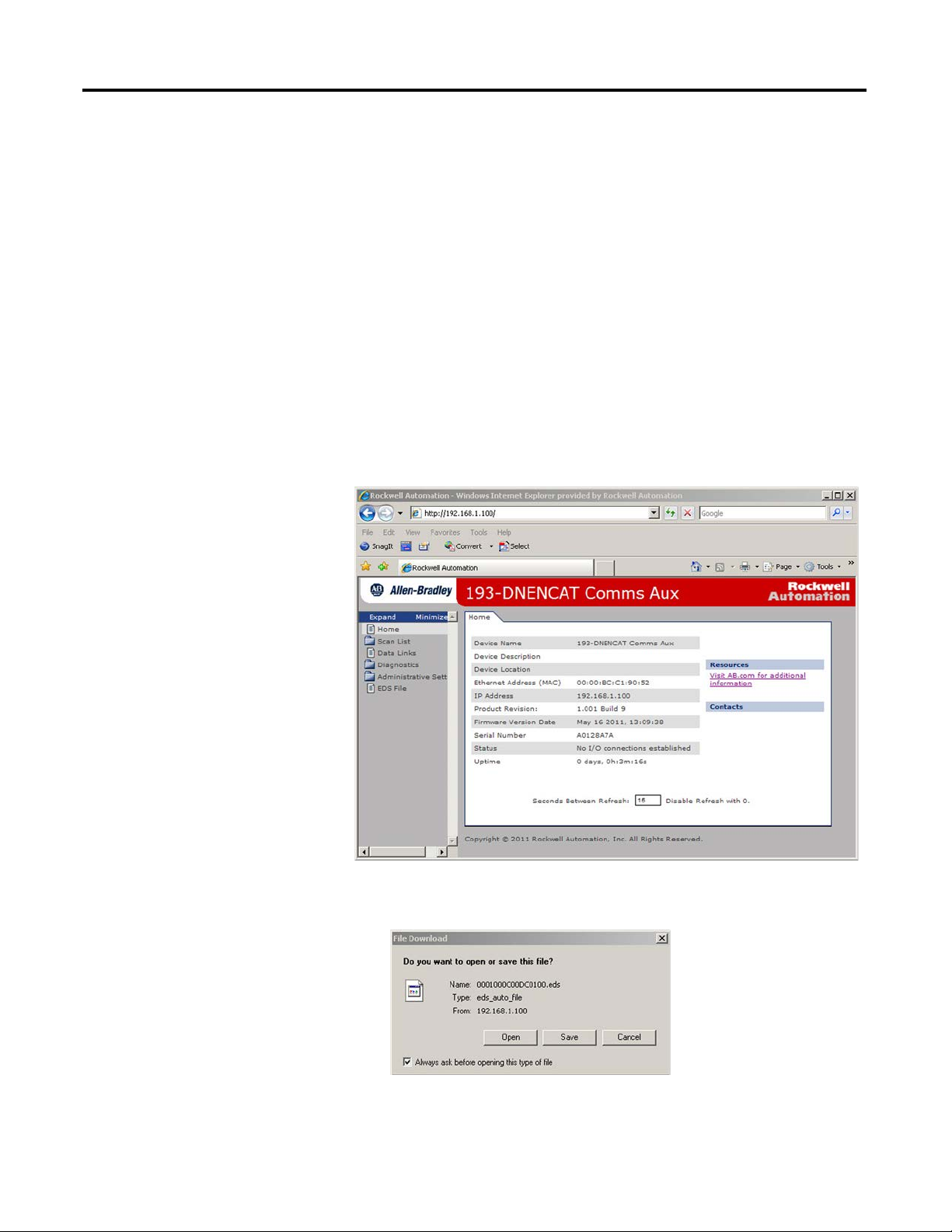

Download the EDS File

Embedded in the Module

The EDS file for the EtherNet/IP Communications Auxiliary is embedded

within the module. After the IP address for the module has been configured,

connect the module to same Ethernet network as a personal computer. Using a

web browser on the personal computer, a user can download the EDS file using a

web browser by following these steps:

1. Type the IP address of the EtherNet/IP Communications Auxiliary on the

address line of the web browser.

2. Select EDS File link

3. Click Save to save the EDS file to the personal computer.

24 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 25

Chapter 2

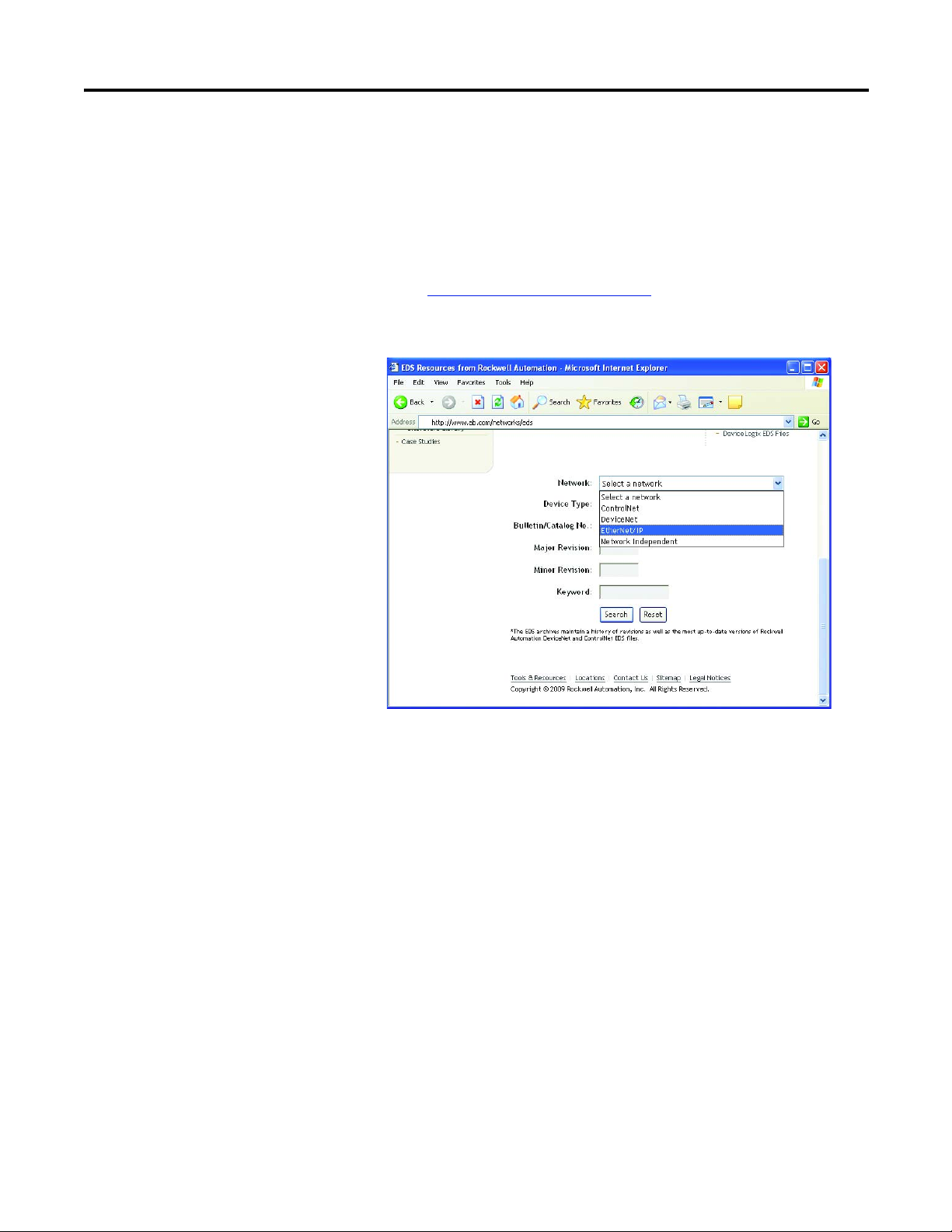

From the EDS File Download Site

The EDS file for the EtherNet/IP Communications Auxiliary can also be

downloaded from the Allen-Bradley EDS File download site. Using a web

browser on the personal computer that is connected to the internet, a user can

download the EDS file by following these steps:

1. Ty p e http://www.ab.com/networks/eds

browser.

2. Select EtherNet/IP as the network type, then click Search.

3. Locate the EDS file for the EtherNet/IP Communications Auxiliary and

download it to the personal computer.

on the address line of the web

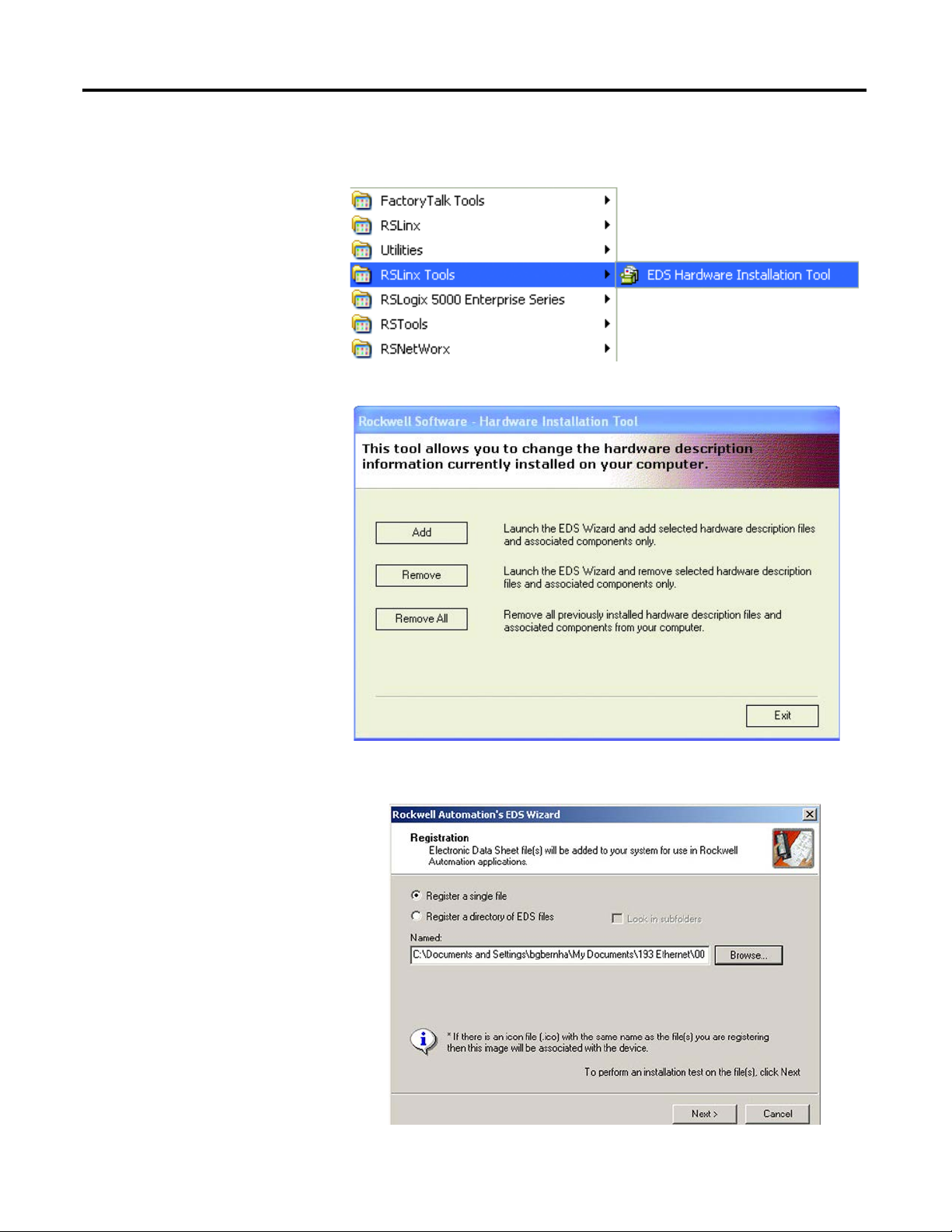

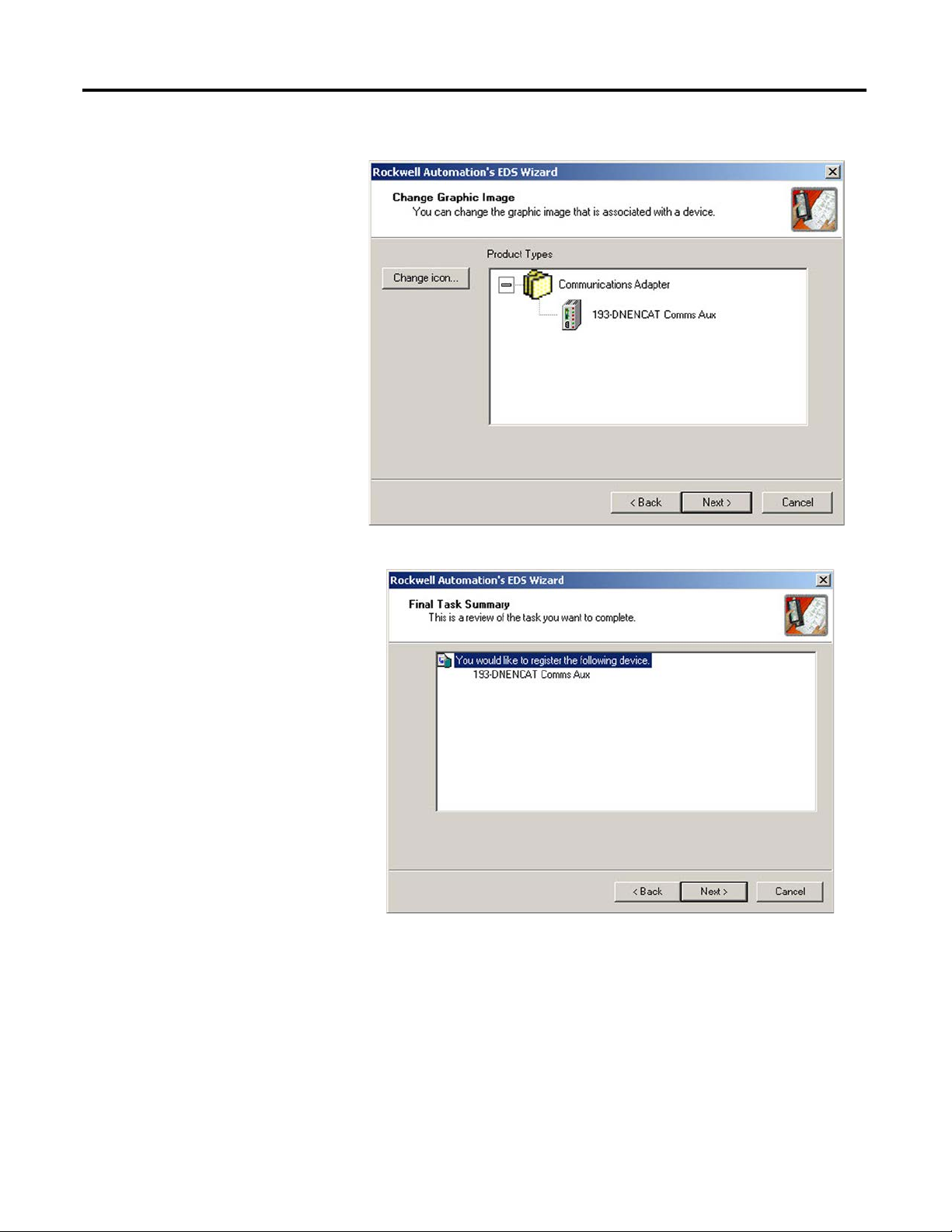

Register the EDS File

After the EDS file has been downloaded, a user will need to register the EDS file

with the software that configures the EtherNet/IP network. The following

example lists the steps needed to register an EDS file with Rockwell Automation’s

RSLinx Classic software.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 25

Page 26

Chapter 2

1. Start the EDS Hardware Installation Tool located at Start>Programs>

Rockwell Software>RSLinx Tools.

2. Click Add to register a new device.

3. Click the “Register a single file” radio button, then browse to the location

where the EDS file is located. Click Next.

26 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 27

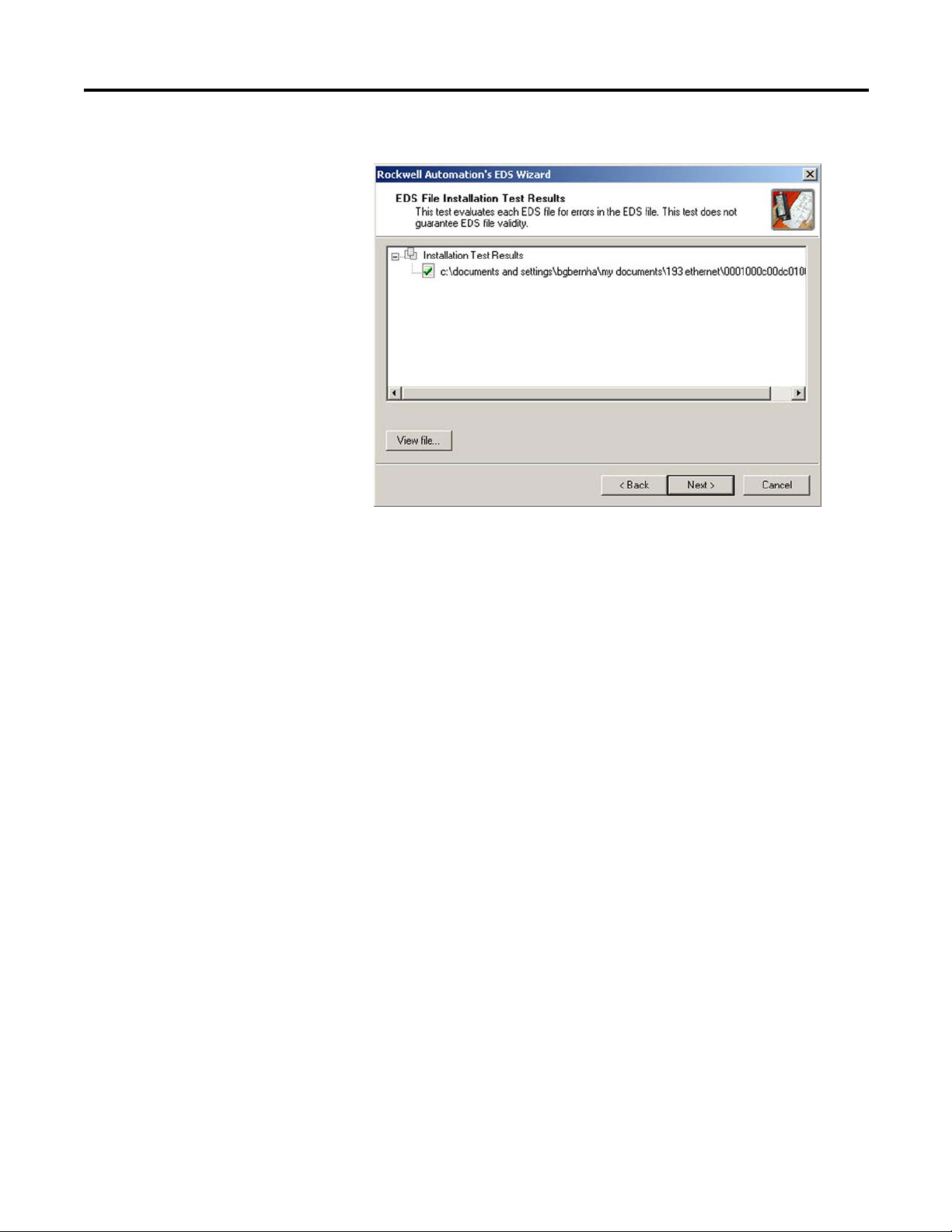

4. Click Next to accept the installation test results.

Chapter 2

Rockwell Automation Publication 193-UM014B-EN-P December 2011 27

Page 28

Chapter 2

5. Click Next to accept the graphic image.

6. Click Next to register the device.

28 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 29

7. Click Finish to successfully register the module.

Chapter 2

Rockwell Automation Publication 193-UM014B-EN-P December 2011 29

Page 30

Chapter 2

30 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 31

Configure the DeviceNet Network

Chapter

3

Introduction

Configuration

The purpose of this chapter is to assist in configuring the DeviceNet Network

with the EtherNet/IP Communications Auxiliary. A DeviceNet network can be

configured using the internal web interface from the EtherNet/IP

Communications Auxiliary.

1. From the web page, navigate to Scan List>Configuration>Advanced.

2. If desired, change the baud rate using the DeviceNet Baud Rate pull-down

menu. The default value of 125K for the DeviceNet network.

NOTE: Autobaud is not supported with this product.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 31

Page 32

Chapter 3

3. Type the size of the Scan List I/O Entry in the field.

The entry size determines the number of input and output bytes that the

EtherNet/IP Communications Auxiliary will scan from each of the

scanned devices. The maximum Scan List I/O Entry Size supported is 50

bytes with the default value being 8 bytes.

NOTE: Auto Device Replacement (ADR) is discussed in Chapter 6, Automatic Device

Recovery or Replace.

4. If necessary, adjust DNet IO Request Packet Interval (RPI) and DNet IO

Inhibit.

DNet IO RPI determines the time it takes for data to be requested; DNet

IO Inhibit is the time used on DeviceNet Change of State (COS) I/O.

Both of these parameters are measured in milliseconds.

NOTE: Electronic keying is implemented on all scan list entries. Electronic keys are

captured when a scan list is configured form the EtherNet/IP Communications

Auxiliary webpage. The proper setting of the electronic keying becomes more

important with ADR functions and replacing units in the network.

5. Navigate to Scan List>Configuration>Scan List to change the DeviceNet

node address of the EtherNet/IP Communcations Auxiliary.

32 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 33

Chapter 3

6. Change the DeviceNet network address to the appropriate node address,

then click Save.

NOTE: Typically, DeviceNet scanners have the node address of 0.

7. Click OK to finish changing the scanner DeviceNet network address.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 33

Page 34

Chapter 3

34 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 35

Chapter

Add Devices to the DeviceNet Network

4

Introduction

DeviceNet Node Addressing

In this chapter, you will be able to assign an address to each DeviceNet module

and configure the DeviceNet scanner to scan up to six modules.

Each module being added to the DeviceNet network must have a unique network

mode address. A unique network node address can be created by using hardware

devices (e.g., DIP and Selector Switches) or by the Node Commissioning tool

from the internal web interface of the EtherNet/IP Communications Auxiliary.

The following chart shows the recommended node addresses.

Table 5 - Recommended Node Addresses

Assign this

Device:

Scanner 0 • For multiple scanners, assign the lowest addresses in

Any Device on the

Network

(except the scanner)

Computer Interface

to the Network

New DeviceNet

Module

This

Node Address: Notes:

sequence (0, 1...).

1...61 • Give the lower addresses to devices with 15 bytes or

more of input or output data.

• Gaps between addresses are acceptable and have no

effect on system performance. If the final layout of the

system is not certain at this time, leave gaps between

addresses to allow flexibility as the system is

developed.

62 • If a computer is connected directly to the DeviceNet

network, use address 62 for the computer. The reason

for this is that many computer interface devices use 63

as the default address.

• The 1784-U2DN device can connect a computer directly

to a DeviceNet network.

63 • To avoid conflict, always leave address 63 open. This is

due to the following:

– most DeviceNet devices have a factory preset

address of 63.

– leaving address 63 open allows for configuration of a

new device.

– the auto-address recovery feature requires address

63 to be open.

• Some devices do not have switches or push buttons to

set the address. Therefore, the device must first be

connected to the network then software (e.g.,

RSNetworx for DeviceNet) must be used to change the

address.

• If another device is already using address 63, an address

conflict will occur and communication will not occur

with the newly connected device.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 35

Page 36

Chapter 4

IMPORTANT

IMPORTANT

Node Address Basics

• Verify the node address assigned to the new device.

• Prevent duplicate node address assignments.

– When connecting new DeviceNet modules with the Node

Commissioning tool from the EtherNet/IP Communications Auxiliary

web interface, place one new DeviceNet module on the network at a

time. Refer to “New DeviceNet Module” in Tab le 5 on pag e 35

– If DIP or selector switches on hardware will be used, set the network

node address for the device before connecting it to the network.

• Leave node address 63 open.

For more information about setting the node address for DeviceNet devices, refer

to the Rockwell Automation Literature Library at:

www.rockwellautomation.com/literature

.

Set the Node Address

Using the Hardware Mechanism

Many DeviceNet devices feature a hardware mechanism to set the network node

address (e.g., a rotary switch or a push wheel switch). Use the following procedure

to set the node address.

Ensure each device’s node address set by the hardware mechanism

matches the node address used in the DeviceNet network. Note that if

the network node address is set higher than 63, the Ethernet /IP

Communications Auxiliary Node Commissioning tool can be used instead

of the hardware mechanism.

In order for the node address change to take effect, cycle the module’s

power.

1. Usi ng Tab le 5 o n pa ge 3 5

new device.

as a guide, select a node address to apply to the

36 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 37

Chapter 4

2. Change the node address using the appropriate mechanism for the new

device.

Mechanism Procedure

Rotary Switch Turn the rotary switch dials to the desired node address value.

2

0

PGM

MSD

Push Wheel Switch

2

4

0

8

6

LSD

Usually, a small, flathead screwdriver is needed to turn the dials.

4

Once the device is powered up, the rotary switch settings are

recognized. If the set node address value needs to be changed,

6

power down the device, turn the dials to the desired setting, then

power up the device again.

Turn the push wheel to the desired node address value.

Using the DeviceNet Node Commissioning Tool

A device’s network node address can be set using the Node Commissioning Tool

on the EtherNet/IP Communications Auxiliary web page. This tool uses the

Network Who to view the DeviceNet modules on the network.

Refer to the following guidelines when using the Network Commissioning tool.

• Only use this tool with an online DeviceNet network.

• Only use this tool when adding new devices to the network if :

– the new device does not feature a hardware mechanism to set the node

address or

– the new device’s node address is set higher than 63.

NOTE: If the new device features a hardware mechanism and the node address

is set at 63 or lower, the Network Commissioning tool does not change

the device’s node address.

• Each time a new device is added to the DeviceNet network, the procedures

beginning on page 38

• To avoid conflict with duplicate node addresses, due largely in part to

modules having a factory node setting of 63, configure a module to the

online DeviceNet network one a time.

• Record the node address for each device that is set by the Node

Commissioning Tool.

must be performed.

Complete the following steps to set a device’s node address using the Node

Commissioning Tool on the EtherNet/IP Communications Auxiliary web page.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 37

Page 38

Chapter 4

1. From the EtherNet/IP Communications Auxiliary web page, navigate to

Scan List>Configuration>Node Commissioning.

2. Select the device where node address needs to be assigned. Once selected,

the Current Settings aand New Settings areas are populated.

3. Double-click the “Node address” field’s value. The value will be

highlighted in blue.

38 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 39

Chapter 4

4. Using the keypad on the PC keyboard, change the network node address

to the desired value. Ensure the desired value is not duplicating any other

device’s node address, then click the Apply button.

5. The following window will appear confirming a successful node address

value change. Click OK.

6. Verify the node address was changed to the desired value in the “New

settings” section of the page. Note that the “Current settings” area will still

display the old node address unitl the device is selected again from the

Network Who list.

7. Repeat steps 1 through 6 until all new or additional devices are added to

the DeviceNetwork.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 39

Page 40

Chapter 4

Add DeviceNet Modules to the Scan List

After each DeviceNet device has been assigned a unique node address, up to six

DeviceNet devices can be added to the EtherNnet/IP Communications Auxiliary

DeviceNet scan list. The EtherNet/IP Communications Auxiliary provide two

methods to configure the scan list, Simple and User-Defined.

Simple

1. From the EtherNet/IP Communications Auxiliary web page, navigate to

Scan List>Configuration>Scan List. The EtherNet/IP Communications

Auxiliary will read the available DeviceNet modules on the DeviceNet

network.

2. Click Config. The lowest six DeviceNet node addresses will populate into

the Scan List field on the right.

40 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 41

Chapter 4

3. Click OK to complete the configuration.

The DeviceNet scanner on the EtherNet/IP Communications Auxiliary

will begin scanning the DeviceNet devices.

User-Defined

If there are more than six DeviceNet devices on the network, the user can select

up to six DeviceNet devices to scan. Follow the steps below to select specific

DeviceNet devices for the scan list.

1. From the EtherNet/IP Communications Auxiliary web page, navigate to

Scan List>Configuration>Scan List. The EtherNet/IP Communications

Auxiliary will read the available DeviceNet modules on the DeviceNet

network.

2. Select the DeviceNet device in the Network Who screen to be added to

the Scan List. The >> button becomes highlighted.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 41

Page 42

Chapter 4

3. Click >> to move the selected device into the Scan List.

4. Repeat steps 2 and 3 to add five additional DeviceNet devices.

5. Click Save at the bottom right of the screen.

6. Click OK to complete the scan list configuration.

42 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 43

View & Configure Parameters

Chapter

5

Introduction

View & Edit

In this chapter, you will be able to view and configure parameters for a DeviceNet

device that supports the full implementation of the Parameter Object.

The EtherNet/IP Commuications Auxiliary is able to view and configure

parameters for a DeviceNet device that supports the full implementation of the

Parameter Object. Users can use the web interface to view and edit parameters for

a DeviceNet Module in the scan list.

Follow the steps below to view and edit parameters using the web interface of the

EtherNet/IP Commuications Auxiliary.

1. Navigate to Scan List>Configuration, then select the DeviceNet device

folder to view or edit its parameters. The selected DeviceNet device folder

will expand.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 43

Page 44

Chapter 5

2. Click on the Identity folder. The Identity tab will appear, providing

information about the selected device.

3. Click on the Parameter folder. Subfields for this folder will appear.

44 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 45

Chapter 5

TIP

4. Select a parameter group. A list of up to 15 parameters will be displayed. If

more than 15 parameters are available, select the page number or use the

navigation arrows to view the additional parameter screens.

To increase the update rate of the data being displayed on the

screen, lower the value in the “Seconds before refresh:” field.

5. Select a parameter group that contains programmable parameters, then

click the Edit button. The value options will appear.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 45

Page 46

Chapter 5

6. Click the down arrow on the pull-down boxes to adjust fixed values and/or

enter numerical values in the fields without an arrow to adjust the values.

7. Click Apply once all parameter edits have been completed. The EtherNet/

IP Communications Auxiliary will download the new parameter values to

the device. A confirmation window will appear.

8. Click OK.

9. Continue editing the remaining parameters, if desired.

NOTE:

46 Rockwell Automation Publication 193-UM014B-EN-P December 2011

If a DeviceNet module does not support the parameter object, the following

window will appear:

Page 47

Chapter

IMPORTANT

Automatic Device Recovery or Replace

6

Introduction

Setting ADR

In this chapter, using the Automatic Device Recovery or Replace (ADR) will be

explained. The use of this feature reduces downtime if a device needs to be

replaced.

With ADR, there is no need for software tools to get a replacement device

configured and online. The EtherNet/IP Communications Auxiliary

automatically configures the replacement device if the device was listed in the

scan list and the appropriate electronic keying was selected.

Not all DeviceNet devices support ADR.

1. Navigate to Scan List>Configuration>Advanced.

2. Select the appropriate electronic keying for your DeviceNet network

application.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 47

Page 48

Chapter 6

By default, the Device Type, Vendor, and Product Code will be enabled.

Electronic keying will define how closely a replacement device must match

a failed device before the EtherNet/IP Auxiliary reconfigures a module. If

the new module does not match the criteria of one of the checked boxes,

the ADR will not function and an ADR error will appear.

3. Once the scan list and DeviceNet module programmable parameters have

been configured, click Upload ADR Data.

The EtherNet/IP Communications Auxiliary will upload and store the

configuration data from the modules in the scan list and a confirmation

message will appear,

4. Select Enable from the Auto Device Replace pull-down menu. This will

enable the ADR.

48 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 49

Chapter 6

5. Click Save, then cycle power on the EtherNet/IP Communications

Auxiliary.

An ADR download is performed immediately before an I/O connection is

allocated by the DeviceNet master.

If the download is unsuccessful, an “ADR Error” for the appropriate node

will be reported in the corresponding “Scan List Entry Status Word”. If the

electronic keys for the device at a given node address do not match the

saved electronic keys, no ADR download will take place, an I/O

connection will not be allocated, and a “Keying Mismatch” will be

reported in the corresponding “Scan List Entry Status Word”.

A warning list will appear after enabling the ADR and a change has been

made to the scan list.

AAR (Auto Address Recovery) is also supported by the EtherNet/IP

Communications Auxiliary. When the EtherNet/IP Communications Auxiliary

detects a node is missing from the scan list and a module matching the electonic

Rockwell Automation Publication 193-UM014B-EN-P December 2011 49

Page 50

Chapter 6

key is detected on node 63, the EtherNet/IP Communications Auxiliary will

attempt to change the module’s network node address to that of the missing scan

list node number. When successful, the EtherNet/IP Communications Auxiliary

will download the ADR information to the module.

50 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 51

Chapter

Automation Controller Communications

7

Introduction

Ethernet Messaging

I/O Messaging

This chapter describes and gives examples of how each type of EtherNet/IP

messaging, I/O messaging and Explicit messaging, is used.

The EtherNet/IP Communications Auxiliary supports two types of EtherNet/IP

messaging.

• I/O Messaging — Used for deterministic EtherNet/IP communications

with ControlLogix™, CompactLogix™, SoftLogix™, and EtherNet/IP

scanners. Its primary use is to read and write I/O data for control purposes.

• Logic Explicit Messaging — Used for non-deterministic communications

in which the data is not critical for control. Logic explicit messages have a

lower priority compared to I/O messages and are used to read and write

non-critical data.

RS Logix 5000™ software is used to configure I/O messaging between an

automation controller and an EtherNet/IP Communications Auxiliary on an

EtherNet/IP network.

The following example provides the steps necessary to configure a Logix

controller for I/O messaging.

ControlLogix Configuration with Add-On Profiles

An Add-On Profile is available for the EtherNet/IP Communications Auxiliary

and can be used with RSLogix 5000 version 17 and higher. The profile can be

downloaded from:

http://support.rockwellautomation.com/controlflash/LogixProfiler.asp

An existing project can be used or a new project can be created to configure

EtherNet/IP I/O Messaging. To create a new project, perform the following

steps.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 51

Page 52

Chapter 7

1. Select File>New from the RSLogix 5000.

2. Select the controller type, chassis type, slot number, and project path.

Then, enter a name for the controller and click OK.

3. Right-click the I/O Configuration folder, then select New Module. The

Select Module Type window will appear.

52 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 53

4. Select the desired EtherNet/IP scanner module, then click OK.

Chapter 7

5. Enter the desired communication settings, then click Finish.

EtherNet/IP Network Configuration with Add-On Profiles

After the controller configuration, the EtherNet/IP Communications Auxiliary

has to be added to the I/O configuration.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 53

Page 54

Chapter 7

1. Place the program in offline mode.

2. Right-click on the EtherNet/IP scanner within the I/O Configuration

folder, then select New Module to open the Select Module Type window.

3. Select the appropriate device (either 193-DNENCAT or 193DNENECATR, then click OK.

54 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 55

Chapter 7

4. Enter a name for the EtherNet/IP Communications Auxiliary. The name

will create tags in RSLogix 5000 that can be used to read and write data

from DeviceNet modules being scanned by the EtherNet/IP

Communications Auxiliary.

5. Enter the IP address of the EtherNet/IP Communications Auxiliary.

6. Select Change to select a motor protection device with predefined tag

names for Data Mapping. For non-motor protection devices, select

Generic.

NOTE: Predefined tag names exist for the E3 Plus EC1, EC2, EC3, EC4, and EC-5

models and the 825-P Overload Relay.

7. Select the appropriate data format, then click OK.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 55

Page 56

Chapter 7

8. Click OK at the next window to have RSLogix 5000 create the predefined

tags. The EtherNet/IP Communications Auxiliary will now show as a

module in the I/O Configuration folder.

Accessing Module Data with Add-On Profiles

With both the Logix controller and EtherNet/IP network configured, the Logix

controller can exchange data with the EtherNet/IP Communication Auxiliary.

1. Open the Controller Tags window.

2. Select the Monitor Tags tab.

In the above example, the predefined input and output tags were generated for

each of the six scanned devices. To control the output relays for the scanned

device, use the output tags. For diagnostic informaton from the device, use the

input tags.

56 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 57

Chapter 7

ControlLogix Generic Configuration

An existing project can be used or a new project can be created to configure

EtherNet/IP I/O Messaging. To create a new project, perform the following

steps.

1. Select File>New from the RSLogix 5000.

2. Select the controller type, chassis type, slot number, and project path.

Then, enter a name for the controller and click OK.

3. Right-click the I/O Configuration folder, then select New Module. The

Select Module Type window will appear.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 57

Page 58

Chapter 7

4. Select the desired EtherNet/IP scanner module, then click OK.

5. Enter the desired communication settings, then click Finish.

EtherNet/IP Generic Module Configuration

Once the Logix controller has been configured, the EtherNet/IP

Communications Auxiliary must be added to the I/O configuration.

58 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 59

Chapter 7

1. Place the program in offline mode.

2. Right-click on the EtherNet/IP scanner within the I/O Configuration

folder, then select New Module to open the Select Module Type window.

3. Select Generic Ethernet Module, then click OK.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 59

Page 60

Chapter 7

4. Enter a name for the EtherNet/IP Communications Auxiliary. The name

will create a tag in RSLogix 5000 that can be used to read and write data

from the devices being scanned by the EtherNet/IP Communication

Auxiliary.

5. Select Data-INT for the Comm Format. The Data-INT format wil l

represent the data from the EtherNet/IP Communications Auxiliary as a

field of 16-bit values.

6. Set the Connection Parameters. I/O data is accessed using Input Instance

101 and Output Instance 100. The size of the input connection and the

output connection shall correspond to the size of the chosen instance. The

configuration assembly instance is 102.

NOTE: In this example, configuration data is not used. Thus, the data size is set to 0

60 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 61

Chapter 7

7. Type the IP address of the EtherNet/IP Communications Auxiliary.

8. Type the value for the time between each scan of the module. The

recommended RPI time is 250 ms. Ensure that the Inhibit Module is not

checked.

9. Click OK to add the EtherNet/IP Communications Auxiliary to the I/O

Configuration in RSLogix 5000.

Accessing Generic Module Data

With both the ControlLogix controller and the EtherNet/IP network

configured, the ControlLogix controller can exchange data with the EtherNet/IP

Communications Auxiliary.

1. Go online, then switch the controller to Remote Run mode.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 61

Page 62

Chapter 7

2. Open the Controller Tags window.

3. Select the Monitor Tags tab.

An array of input and output tags were generated for each of the six scanned

devices. To control the output relays for the scanned device, use the output tags;

to obtain diagnostic information from the scanned device, use the input tags.

The format of output data is shown in the table to follow.

Table 6 - Output Assembly — Instance 100

Byte Size Contents

Scan List I/O Size Data to be delivered to the first scan list entry.

Scan List I/O Size Data to be delivered to the second scan list entry.

Scan List I/O Size Data to be delivered to the third scan list entry.

Scan List I/O Size Data to be delivered to the fourth scan list entry.

Scan List I/O Size Data to be delivered to the fifthscan list entry.

Scan List I/O Size Data to be delivered to the sixth scan list entry.

The format of the input data is shown in the table to follow.

Table 7 - Input Assembly — Instance 101

Byte Size Contents

4 bytes Logix Status Word

2 bytes DeviceNet Scanner Status (Parameter 1) See Table 9 on page 73

2 bytes Scan List Entry 1 Status Word (Parameter 2) See Table 10 on page 74

2 bytes Scan List Entry 2 Status Word (Parameter 3) See Table 11 on page 74

2 bytes Scan List Entry 3 Status Word (Parameter 4) See Table 12 on page 74

2 bytes Scan List Entry 4 Status Word (Parameter 5) See Table 13 on page 75

2 bytes Scan List Entry 5 Status Word (Parameter 6) See Table 14 on page 75

2 bytes Scan List Entry 6 Status Word (Parameter 7) See Table 15 on page 75

Scan List I/O Size Produced I/O data from the first scan list entry.

Scan List I/O Size Produced I/O data from the second scan list entry.

Scan List I/O Size Produced I/O data from the third scan list entry.

62 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 63

Byte Size Contents

Scan List I/O Size Produced I/O data from the fourth scan list entry.

Scan List I/O Size Produced I/O data from the fifth scan list entry.

Scan List I/O Size Produced I/O data from the sixth scan list entry.

2 bytes Data Link 1 Data

2 bytes Data Link 2 Data

2 bytes

: :

2 bytes Data Link 48 Data

Data Link 3 Data

: :

Chapter 7

Logic Explicit Messaging

CompactLogix, ControlLogix, and SoftLogix controllers can read and write

specific information to and from DeviceNet modules on the same DeviceNet

network through the EtherNet/IP Communications Auxiliary using Explicit

Messaging.

The following steps configure a ControlLogix explicit message using the MSG

instruction to read diagnostic parameters from an E3 Plus Model and EC5

Overload Relay.

1. In an interger array named MSG_Read_Request, define the number of

attributes to read and list the specific attribute numbers.

The MSG instruction will return in an integer array with the first integer

representing the following information:

• number of attributes

• first attribute number being returned

• first attribute number data status

• first attribute data…

• last attribute number being returned

• last attribute number data status

• last attribute data

Rockwell Automation Publication 193-UM014B-EN-P December 2011 63

Page 64

Chapter 7

In the screen capture below, the user-defined structure listing the integers is

being returned in this example.

64 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 65

Chapter 7

2. Set up the MSG instruction in the Configuration tab to read the list of

attributes (Parameters Group) by configuring the following fields:

• Message Type: CIP Generic

• Service Type: Custom

• Service Code: 0x03 (hex)

• Class: 0x375 (hex)

• Instance: 1 (dec)

• Attribute: 0x00 (hex)

• Source Element: MSG_Read_Request [0]

• Source Length: 14 (bytes)

• Destination: MSG_Read_Data

3. Set up the communications path in the Communications tab to read the

data from the E3 Plus Overload Relay located at Node 6 by configuring the

communication path as “MotorStarter, 3, 6”.

NOTE: Motor Starter — the name of the EtherNet/IP Communications Auxiliary

3 — the port number of the DeviceNet Scanner of the EtherNet/IP

Communications Auxiliary.

6 — the node address of the E3 Plus Overload Relay.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 65

Page 66

Chapter 7

4. Click OK. When finished, the MSG instruction will read the 25

parameters from the E3 Overload Relay and place the results into

MSG_Read_Data as shown below.

66 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 67

E-mail/Text

Chapter

8

Introduction

E-mail Notifications

This chapter describes e-mail notifications and how to configure an EtherNet/IP

Communications Auxiliary to send e-mail messages and text notifications for

different communication events.

Events

Several communication events can trigger e-mail notifications. These events are

fault conditions for the DeviceNet scan list and EtherNet/IP Communications

Auxiliary.

Fault Conditions for the DeviceNet Scan List

Minor Recoverable Major Unrecoverable Wrong Data Size Slave Init Error

Minor Unrecoverable Connection Timeout No Such Device I/O Data Overflow

Major Recoverable Keying Mismatch Frag/Idle Error Automatic Device

Replacement Error

Acknowledge Timeout

Fault Conditions for the EtherNet/IP Communications Auxiliary

On Line Global ADR Error In Idle Mode Duplicate Mac Error

Illegal Scan List Data No Scanner Messages Hardware Error Data Link Error

No Network Messages Transmit Failure Bus Off Error Non Volatile Storage Error

E-mail Contents

The subject and body contents in the e-mail message wil be created from the:

• type of trip or warning that is detected,

• device name,

• device description,

• device location, and

• contact information.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 67

Page 68

Chapter 8

EXAMPLE

E-mail Subject:

193-DNENCATR Comms Aux has detected a fault

E-mail Body:

Fault Status:

Device Name: 193-DNENCATR Comms Aux

Device Description: Motor Starters

Device Location: Bay 6-U29

Contact Info: Contact Person contactperson@thecontact.com

The first word in the e-mail subject is the device name. If a device name is not

configured, then the product name attribute from the identity object will be used.

E-mail Configuration

To be able to send an e-mail, the IP address ot the hostname of a Simple Mail

Transfer Protocol (SMTP) server must be configured and notifications must be

selected. Follow these steps to configure an e-mail notification.

1. In the web browser, type the IP address of the EtherNet/IP

Communications Auxiliary in the address bar, then press the enter key on

the keyboard.

2. Select Administrative Settings E-Mail Configuration. A login window will

appear.

68 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 69

Chapter 8

3. Log in with the username “Adminstrator”, leave the password field blank,

and click OK.

NOTE: If desired, a password can be set within the Administrative Settings tab.

4. Type the information into the e-mail notification fields as stated below.

E-mail Recipient The e-mail address of the person who will receive the notifications.

E-Mail Sender The e-mail address from which the notification will be sent.

SMTP Server Consult with the network administrator for the SMTP server address.

SMTP Username Consult with the network administrator for the SMTP username.

SMTP Password Consult with the network administrator for the SMTP password.

SMTP Port Consult with the network administrator which SMTP port number to

use. Port 25 is the most common SMTP port.

5. Check the desired notification time, fault conditions, and local conditions

to be included in notification e-mails to the recipient. These can be

changed after the initial configurations.

6. ClickApply Changes to save the configuration.

Configure Device Identity

The properties of the Device Identity populate the notification e-mail subject

and e-mail body. To configure the Device Identity, perform the following steps.

1. Select Administrative Settings>Device Identity.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 69

Page 70

Chapter 8

2. Type the Device Identity information into the fields as described below.

Device Name The name of the EtherNet/IP Communications Auxiliary.

Device Description The description of the EtherNet/IP Communications Auxiliary.

Device Location The location of the EtherNet/IP Communications Auxiliary.

Contact Information The contact information for the EtherNet/IP Communications

Auxiliary.

Device X Name The name of the DeviceNet device being scanned.

Device X Description The description of the DeviceNet device being scanned.

3. Click Apply Changes to save the configuration.

Text Notifications

The EtherNet/IP Communications Auxiliary can send a text message to a

wireless phone be e-mailing the wireless phone’s service provider. The format for

the text message is provided by the service provider and looks similar to the

example formats below.

AT& T™ 10-digit wireless phone number@txt.att.net

Sprint® 10-digit wireless phone number@messaging.sprint.pcs.com

70 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 71

Chapter 8

EXAMPLE

Multiple e-mail addresses can be entered into the E-mail Recipient field,

separating each e-mail address with a semicolon (;). The E-mail Recipient field is

limited to 255 characters.

An EtherNet/IP Communications Auxiliary sending an e-mail and text

message when a Communications Timeout event occurs:

Limitations

Based on the functionality of the EtherNet/IP Communications Auxiliary, there

are some limitations on when the e-mails can be triggered.

• If two events occur at the same time, an e-mail will only be sent for the

most significant error.

• If the device has been configured to send an e-mail for a lower prioritized

event and this event occurs at the same time as a higher prioritized event

for which the device has not been programmed to send an e-mail, an e-mail

will not be sent for either event.

• The Clear e-mail will only be sent when all events have been cleared and an

event e-mail has previously been sent.

Rockwell Automation Publication 193-UM014B-EN-P December 2011 71

Page 72

Chapter 8

72 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 73

Device Parameters

IMPORTANT

Chapter

9

Introduction

Parameter Programming

The EtherNet/IP Communications Auxiliary provides parameters to allow the

user to view the status and configure the DeviceNet scanner with RSNetWorx for

DeviceNet if the user does not want to use the internal web server of the

EtherNet/IP Communications Auxiliary. The 14 available parameters are listed

below.

Table 8 - Parameter List

1 Scanner Status 8 SL Entry Size

2 SL Entry 1 Status 9 Device Keys

3 SL Entry 2 Status 10 Scanlist Config

4 SL Entry 3 Status 11 ADR Record

5 SL Entry 4 Status 12 ADR Enable

6 SL Entry 5 Status 13 DNet IO RPI

7 SL Entry 6 Status 14 DNet IO Inhibit

Parameter setting changes to the EtherNet/IP Communications Auxiliary

take effect immediately even during a “running” status.

Parameter Listing

The details for each of the 14 available parameters are listed below.

Table 9 - Parameter 1 — Scanner Status

Value

Description Access Rule Data Type Units

Provides the status of the

Devicenet scanner.

0 On Line 3 No Scanner Messages 6 Initializing

1 Illegal Scan List 4 Transmit Failure 7 Duplicate MAC Failure

2 No Network Messages 5 In Idle Mode 8 Bus Off

Rockwell Automation Publication 193-UM014B-EN-P December 2011 73

Get WORD — 0 16383 0

Bit

Min. Max. Default

Page 74

Chapter 9

Table 10 - Parameter 2 — SL Entry 1 Status

Value

Description Access Rule Data Type Units

Provides the status of the

first scan list entry in the

DeviceNet scanner.

0 On Line 4 No Such Device 8 Device Went Idle

1 Connection Timeout 5 Fragment Error

2 Keying Mismatch 6 Slave Initialization Error

3 Wrong Data Size 7 I/O Data Overflow 10 Acknoledgement Timeout

Get WORD — 0 2047 0

Bit

Min. Max. Default

Automatic Device

9

Replacement Error

Table 11 - Parameter 3 — SL Entry 2 Status

Value

Description Access Rule Data Type Units

Provides the status of the

second scan list entry in the

DeviceNet scanner.

0 On Line 4 No Such Device 8 Device Went Idle

1 Connection Timeout 5 Fragment Error

2 Keying Mismatch 6 Slave Initialization Error

3 Wrong Data Size 7 I/O Data Overflow 10 Acknoledgement Timeout

Get WORD — 0 2047 0

Bit

Min. Max. Default

Automatic Device

9

Replacement Error

Table 12 - Parameter 4 — SL Entry 3 Status

Value

Description Access Rule Data Type Units

Provides the status of the

third scan list entry in the

DeviceNet scanner.

0 On Line 4 No Such Device 8 Device Went Idle

1 Connection Timeout 5 Fragment Error

2 Keying Mismatch 6 Slave Initialization Error

3 Wrong Data Size 7 I/O Data Overflow 10 Acknoledgement Timeout

Get WORD — 0 2047 0

Bit

Min. Max. Default

Automatic Device

9

Replacement Error

74 Rockwell Automation Publication 193-UM014B-EN-P December 2011

Page 75

Chapter 9

Table 13 - Parameter 5 — SL Entry 4 Status

Value

Description Access Rule Data Type Units

Provides the status of the

fourth scan list entry in the

DeviceNet scanner.

0 On Line 4 No Such Device 8 Device Went Idle

1 Connection Timeout 5 Fragment Error

2 Keying Mismatch 6 Slave Initialization Error

3 Wrong Data Size 7 I/O Data Overflow 10 Acknoledgement Timeout

Get WORD — 0 2047 0

Bit

Min. Max. Default

Automatic Device

9

Replacement Error

Table 14 - Parameter 6 — SL Entry 5 Status

Value

Description Access Rule Data Type Units

Provides the status of the

fifth scan list entry in the

DeviceNet scanner.

0 On Line 4 No Such Device 8 Device Went Idle

1 Connection Timeout 5 Fragment Error

2 Keying Mismatch 6 Slave Initialization Error

3 Wrong Data Size 7 I/O Data Overflow 10 Acknoledgement Timeout

Get WORD — 0 2047 0

Bit

Min. Max. Default

Automatic Device

9

Replacement Error

Table 15 - Parameter 7 — SL Entry 6 Status

Value

Description Access Rule Data Type Units

Provides the status of the

sixth scan list entry in the

DeviceNet scanner.

0 On Line 4 No Such Device 8 Device Went Idle

1 Connection Timeout 5 Fragment Error

2 Keying Mismatch 6 Slave Initialization Error

3 Wrong Data Size 7 I/O Data Overflow 10 Acknoledgement Timeout

Get WORD — 0 2047 0

Bit

Min. Max. Default

Automatic Device

9

Replacement Error

Rockwell Automation Publication 193-UM014B-EN-P December 2011 75

Page 76

Chapter 9

Table 16 - Parameter 8 — SL Entry Size