Page 1

User Manual

DeviceNet™ Configuration Terminal

Catalog Numbers 193-DNCT

Page 2

™ Configuration Terminal

Page 3

Important User Information

IMPORTANT

Because of the variety of uses for the products described in this publication, those responsible for the application and use of

this control equipment must satisfy themselves that all necessary steps have been taken to assure that each application and

use meets all performance and safety requirements, including any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in this guide are intended solely for purposes of

example. Since there are many variables and requirements associated with any particular installation, Rockwell Automation

does not assume responsibility or liability (to include intellectual property liability) for actual use based upon the examples

shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application, Installation and Maintenance of Solid-State

Control (available from your local Allen-Bradley distributor), describes some important differences between solid-state

equipment and electromechanical devices that should be taken into consideration when applying products such as those

described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or part, without written permission of Rockwell

Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety considerations:

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage or economic loss

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

Identifies information that is critical for successful application and understanding of the product.

European Communities (EC) Directive Compliance

If this product has the CE mark, it is approved for installation within the European Union and EEA regions. It has been

designed and tested to meet the following directives.

• EMC Directive

• This product is tested per EN61

Allen-Bradley is a trademark of Rockwell Automation. DeviceNet™ is a trademark of the Open DeviceNet™ Vendors

Association (ODVA). All other trademarks and/or registered trademarks are the property of their respective owners.

000-6-4:2001 and EN61000-6-2:2005.

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 iii

Page 4

Manual Objectives

IMPORTANT

IMPORTANT

The purpose of this manual is to provide you with the information necessary to apply the DeviceNet™ Configuration

Terminal. Described in this manual are methods for installing, configuring, and troubleshooting the DeviceNet™

Configuration Terminal.

Read this manual in its entirety before installing, operating, servicing, or initializing the DeviceNet™

Configuration Terminal.

Who Should Use This Manual

This manual is intended for qualified personnel responsible for setting up and servicing DeviceNet™ devices. You must have

previous experience with and a basic understanding of communications terminology, configuration procedures, required

equipment, and safety precautions.

You should understand DeviceNet™ network operations, including how devices operate on the network.

Vocabulary

In this manual we refer to the:

Bulletin 193 DeviceNet™ Configuration Terminal as 193-DNCT, DNCT, terminal, Configuration Terminal, or HIM

(Human Interface Module)

Programmable Logic Controller as a Programmable Controller, PLC controller, SLC controller, ControlLogix Controller,

or PLC

DeviceNet™ as DNet or DNET

Reference Manuals

DeviceNet™ Media Design and Installation Guide

• Publication DNET-UM072_-EN-P

Read the DeviceNet™ Media Design and Installation Guide (Publication DNET-UM072_-EN-P)

in its entirety before planning and installing a DeviceNet™ system. If the network is not installed

according to this document, unexpected operation and intermittent failures may occur.

Copies of this and all other reference publications are available at http://www.rockwellautomation.com/literature/.

iv Rockwell Automation Publication 193-UM009B-EN-P - February 2013

Page 5

Product Overview

Installation and Wiring

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

European Communities (EC) Directive Compliance. . . . . . . . . . . . . . . . . iii

Manual Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Vocabulary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Reference Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Chapter 1

Product Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Bill of Material. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 2

Installation and Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

193-CB1 Physical Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

193-CM1 Physical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

193-DNCT-BZ1 Physical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Powering the 193-DNCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 3

Physical Features

Quick Start

Device Choices Menu

Physical Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Communication Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Key Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Shifted Key Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 4

Powerup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Terminal Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Network Who Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Device Choices Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Parameter Monitoring and Editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

DeviceNet™ Configuration Terminal Setup Menus. . . . . . . . . . . . . . . . . . 15

Port Object And Routing Sub Nets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Who Menu Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 5

Device Choices Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Version Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Standard Device Status Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Fault/Warning Choice Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Fault Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Warning Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 1

Page 6

Table of Contents

Chapter 6

Parameter Choices Menu

Copy Cat Menu

Parameter Choices Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Groups Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Num List Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Parameter Edit Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Numeric Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Accessing a Different Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Changing a Parameter Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Enumerated Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Floating Point Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Search for Changed Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Parameter Display-Value Enumerated. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Chapter 7

Copy Cat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Copy Cat Uploading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Copy Cat Downloading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Copy Cat Downloading and Product Revisions . . . . . . . . . . . . . . . . . . . . . 33

Copy Cat Downloading and Product Current Ratings. . . . . . . . . . . . . . . 34

Deleting Copy Cat Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Copy Cat Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

DeviceLogix™ Library 5 Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Tools Menu

Advanced Functions Menu

I/O Message Monitoring

Chapter 8

Tools Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Node Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Class Instance Attribute Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Graph Setup Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Graph View Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Assembly Consumed/Produced Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Chapter 9

Advanced Functions Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Chapter 10

HeartBeat Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Chapter 11

I/O Message Monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

2 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

Page 7

Chapter 12

Table of Contents

DeviceLogix™ Functionality

Discrete I/O Status

Zone Interlock Protocol (ZIP)

DeviceLogix™ Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

DeviceLogix™ Choices Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

DeviceLogix™ Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Boolean Gates: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Bistable Latches: RS Latch and SR Latch . . . . . . . . . . . . . . . . . . . . . . . 50

Counters: Up Counter and Up/Down Counter . . . . . . . . . . . . . . . . 50

Timers: On Delay, Off Delay and Pulse Timer . . . . . . . . . . . . . . . . . . 51

Discrete Output Points (DOPs): . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Produced Network Bits (PNBs):. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

DeviceLogix™ Editor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Creating a New Function Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Function Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Assigning Source Bits to Function Block Inputs . . . . . . . . . . . . . . . . . . . . 53

Chapter 13

Discrete I/O Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Chapter 14

Zone Interlock Protocol (ZIP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

ZIP Consumed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Mapping Consumed ZIP Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

ZIP Produced Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

ZIP Data Table Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

DeviceNet™ Scanner Menu

Terminal Choices Menu

Chapter 15

DeviceNet™ Scanner Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Scanner Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

AutoScan Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

ScanList Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Node Activation Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Chapter 16

Terminal Choices Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Version Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Offline Connection Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Offline Change Address Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

DeviceNet™ Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Network Statistics Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 3

Page 8

Table of Contents

Chapter 17

Terminal Setup Menu

Copy and Paste Feature

Menu Help Feature

Terminal Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Communication Setup Screen (HIM Comm) . . . . . . . . . . . . . . . . . . . . . . 69

Password Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Password Setup (Primary) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Password Setup (Secondary) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Entering a Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Resetting Forgotten Passwords. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Auto Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

AutoDisplay Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

AutoDisplay Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Programmable User Function Key Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Function Key Setup Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

LCD Contrast. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Chapter 18

Copy and Paste Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Chapter 19

Menu Help Feature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Specifications

DeviceNet™ Objects

Chapter 20

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Appendix A

Identity Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Message Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

DeviceNet™ Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Connection Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

4 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

Page 9

Product Overview

Chapter 1

Product Overview

Bill of Material

Accessories

The 193-DNCT product is a handheld device that can be used to commission,

configure, program, and monitor other devices on a DeviceNet™ network. In

addition, the 193-DNCT can be used to upload, store, and later download

complete device configurations for DeviceNet™ devices via the network. The

193-DNCT also has the capability to present DeviceNet™ physical layer

diagnostics and network bandwidth statistics to the user.

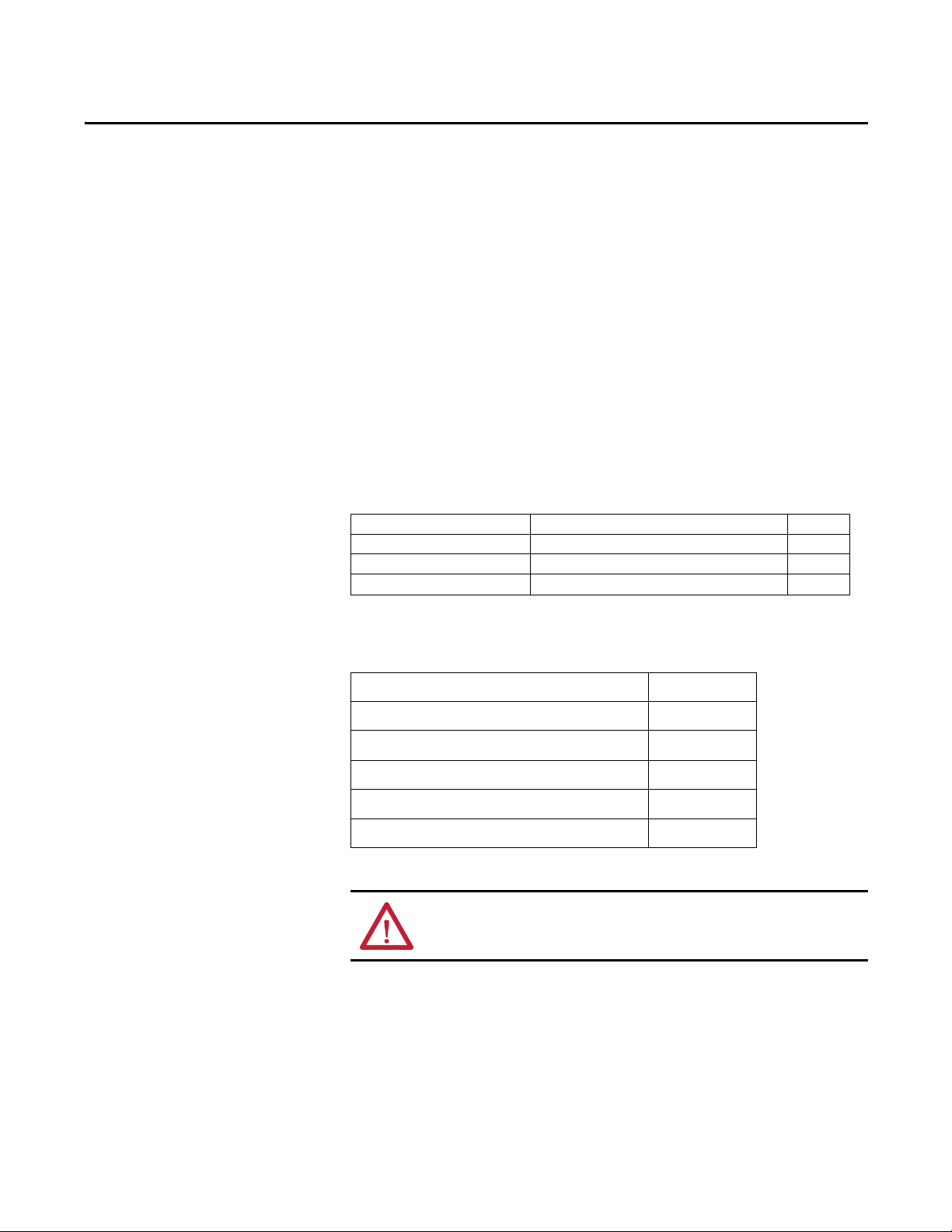

The 193-DNCT product package includes the following items:

Item Description Quantity

193-DNCT DeviceNet™ Configuration Terminal 1

193-CB1 1 m DNCT Cable with color-coded bare leads 1

193-QR002_-EN-P DeviceNet™ Configuration Terminal Quick Reference 1

Description Catalog No.

1 m DNCT Cable with color-coded bare lead 193-CB1

1 m DNCT Cable with microconnector (male) 193-CM1

Door mount bezel kit 193-DNCT-BZ1

Mini-Mini-Micro Tee for connection to ArmorStart 1485P-P1R5-MN5R1

5-pin connector 1787-PLUG10R

ATTENTION: The Bulletin 193 DeviceNet™ Configuration Terminal

should only be used on a DeviceNet™ network.

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 5

Page 10

Chapter 1 Product Overview

Notes:

6 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

Page 11

Installation and Wiring

Drain

Can_L

Can_H

V+

V-

Chapter 2

Installation and Wiring

The DNCT ships complete with a 1 m cable (193-CB1) for connection to a

DeviceNet™ network. This cable has a plug connection to the terminal on one

end, and color coded bare leads on the other end. Alternately, a 1 m cable (193CM1) can be ordered that has a plug connection to the terminal on one end, and

a DeviceNet™ male micro style connector on the other end. A bezel mounting kit

(193-DNCT-BZ1) is available for mounting the terminal to a panel door.

193-CB1 Physical Connections

The 193-CB1 cable that ships with the Configuration Terminal has a plug

connection to the terminal on one end, and color coded bare leads on the other

end. The cable’s bare leads are wired to a DeviceNet™ connector according to the

following table:

Signal Function Color

V- Common Black

Can_L Signal Low Blue

Drain Shield Non-insulated

Can_H Signal High White

V+ Power Supply Red

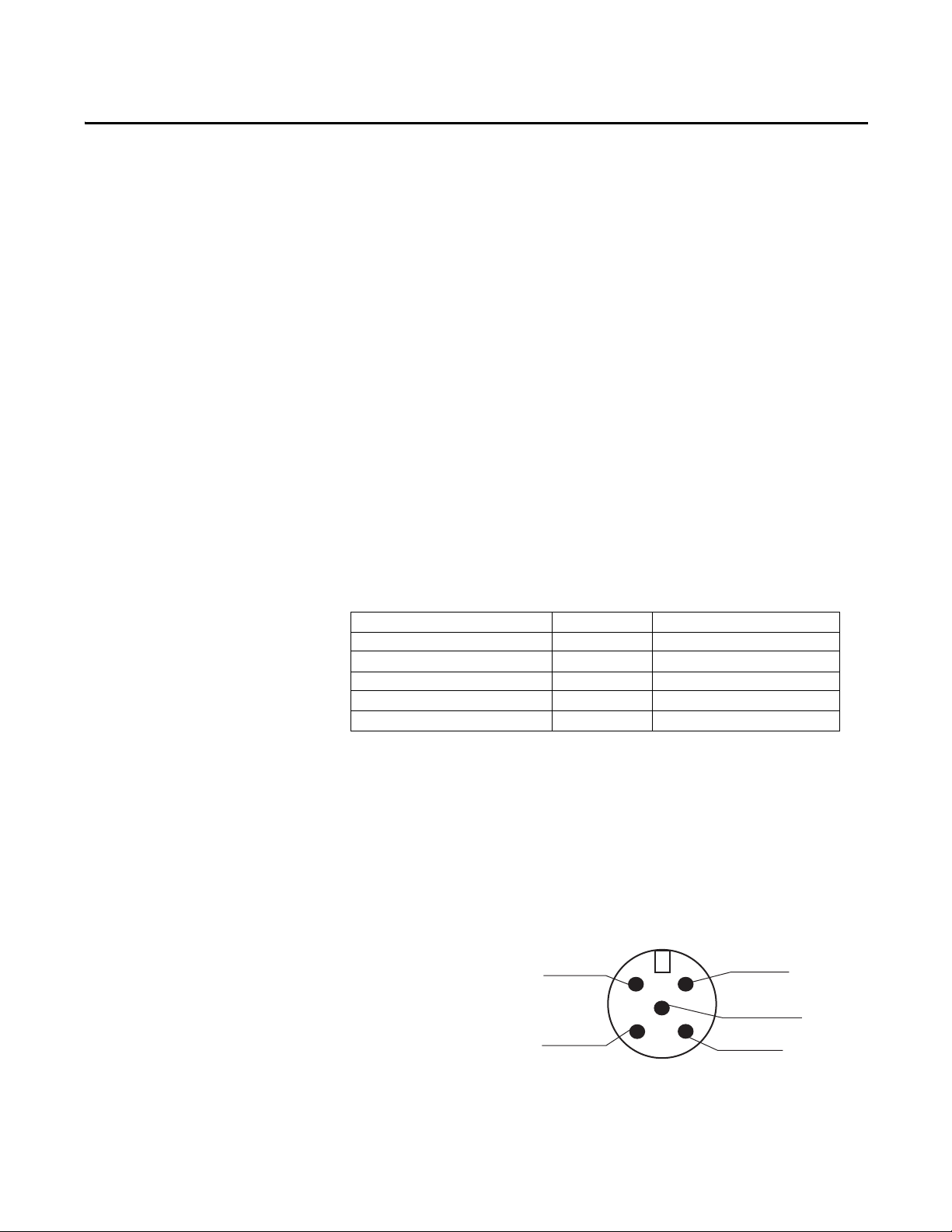

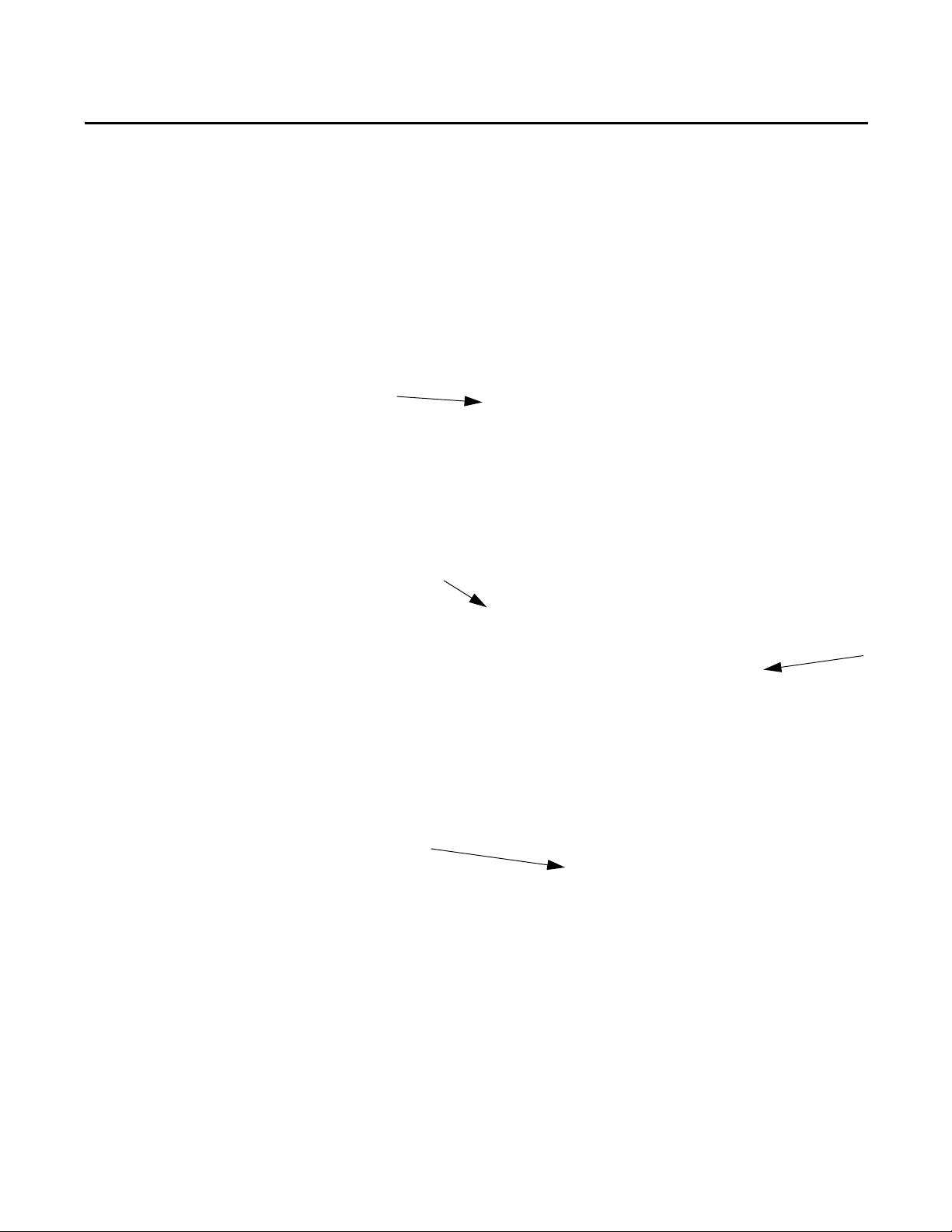

193-CM1 Physical Connections

The optional Cat. No.193-CM1 has a plug connection to the terminal on one

end and a DeviceNet™ male micro-style connector on the other end. The cable’s

micro connector pin-out is shown in Figure 1 -

Figure 1 - Cat. No. 193-CM1 Pinout

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 7

Page 12

Chapter 2 Installation and Wiring

193-DNCT-BZ1 Physical Connections

ATTENTION: When mounting in a door or panel-mounted bezel kit,

only the Cat. No. 193-DNCT-BZ1 DeviceNet™ Bezel Kit should be used

with the Bulletin 193-DNCT DeviceNet™ Configuration Terminal.

The optional Cat. No. 193-DNCT-BZ1 connects to the DeviceNet™ network via

an attached cable that has color coded bare leads. The cable’s bare leads are wired

to a DeviceNet™ connector according to the following table:

Signal Fun ction Color

V- Common Black

Can_L Signal Low Blue

Drain Shield Non-insulated

Can_H Signal High White

V+ Power Supply Red

Powering the 193-DNCT

The DNCT must be powered from an external 24V DC source through the

communication cable. The 24V DC connections should be made to the V+ and

V- pins/wires in the above cable pinout/wire definitions.

ATTENTION: Before physically connecting the DNCT to a target device,

verify that the external power sup ply has adequate capacity to p ower all

devices on the network.

8 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

Page 13

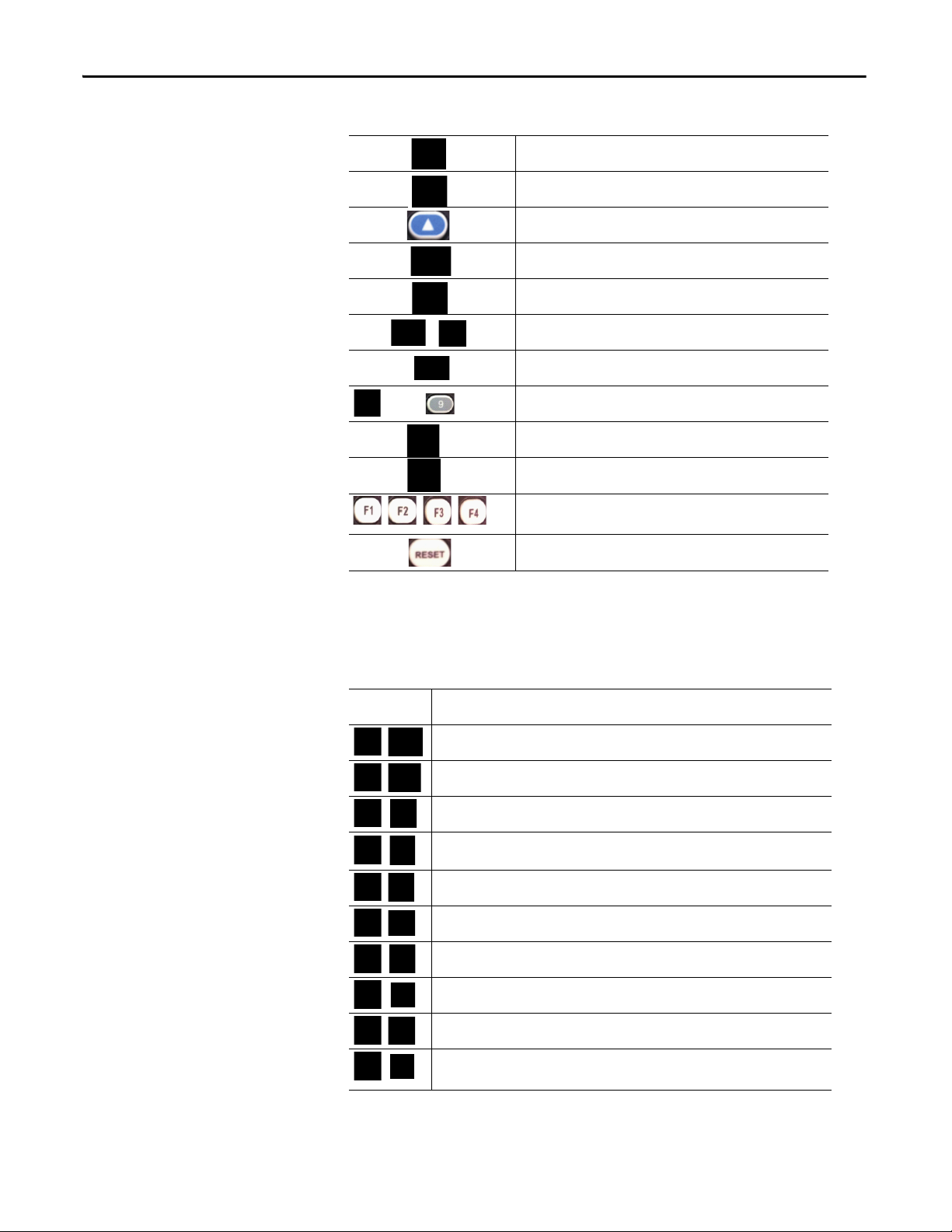

Physical Features

8-Line, 21-Character,

Backlit LCD Display

Function Keys

Numeric Entry Keys

Navigation Keys

Communication Port

Reset Key

Chapter 3

Physical Features

Figure 1 - Cat. No. 193-DNCT Physical Features

Communication Port

The communication port is used to connect the DNCT to a DeviceNet™

network through use of a communication cable or bezel mount kit (Cat. No. 193DNCT-BZ1). Additionally, 24V DC power is provided to the DNCT at the

communication port.

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 9

Page 14

Chapter 3 Physical Features

…

Key Descriptions

Escape Key. Exit a menu or cancel a change.

Select key. Select a value, digit, or screen choice.

Increment key. Scroll through options, increase a value, or toggle a bit.

Decrement key. Scroll through options, decrease a value, or toggle a bit.

Enter key. Enter a menu, enter a mode, or enter a value.

Shifted Key Descriptions

Scroll left or right keys. Scroll left or right through a value.

Shift key. Small values (yellow text) on top of keys are entered when

pressed after the shift key.

Used to enter numbers.

Used to enter a decimal place for a number.

Used to negate a numeric value. Used to add a sign character when

editing a value.

Programmable function keys. See Chapter 16, Function Key Setup

Screen.

Programmable Reset key. See Chapter 16, Function Key Setup Screen.

The following table describes the alternate functionality of each key when it is

pressed after the shift key.

Key

Combination

The letter A. Used to enter values in hexadecimal.

The letter B. Used to enter values in hexadecimal.

The letter C. Used to enter values in hexadecimal.

The letter D. Used to enter values in hexadecimal.

The letter E. Used to enter values in hexadecimal.

The letter F. Used to enter values in hexadecimal.

Copy function. Used to copy Class, Instance, and/or Attribute data to the clipboard. Available

on screens displaying a small “C” in the upper right corner.

Exponential function. Used to enter values in exponential notation.

Paste function. Used to paste Class, Instance, and/or Attribute data from the clipboard.

Available on screens displaying a small “P” in the upper right corner.

Help function. Invoke help information for the current screen.

10 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

Page 15

Quick Start

IMPORTANT

Baud = Fixed

baud rate

Auto =

AutoBauding

Actual baud

rate

Adrs = Fixed H IM

MacID

Auto = Auto

Addressing

Actual

terminal

address

Chapter 4

Powerup

The DeviceNet™ Configuration Terminal is shipped so that when it is placed on

the network for the first time, it will automatically set its baud rate to that of the

traffic on the network, and then assign itself an unused network address. On

power up, the following screen is displayed:

Note that there is a 10-second powerup delay programmed at the factory. The

above screen will appear for at least 10 seconds on initial powerup. The powerup

delay can be modified in the Terminal Setup screen described in the following

section. Once the baud rate is determined and a network address has been set, the

terminal will display the Network Who screen, which displays a list of all devices

on the network.

If the terminal fails to enter the Network Who screen

after approximately 20 seconds, it is because it could

not determine the network baud rate due to lack of

traffic on the network. Pressing the ESC key will allow

the user to enter the Terminal Setup screen so that a

fixed baud rate and network address can be set for the

terminal.

Note: To go directly to the Terminal Setup screen, press and hold the ESC key

during powerup.

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 11

Page 16

Chapter 4 Quick Start

Powerup delay

in seconds

Fixed Address

setting OR the

starting address for

auto address

Enable = AutoBaud enabled

Disable = Use fixed Baud Rate

Fixed Baud

Rate setting

Enable = Auto addressing on power up

Disable = Use fixed network address

Searching at this address

Curren tly

selected device

Device address

“-“=Device is not faulted

“~” = Device is faulted

Currently selected operation

Terminal Setup

To scroll through the items on the screen, press the SEL key. To change the value

of a selected item, press the Increment or Decrement key. To commit the new

value for use, press the Enter (return arrow) key. To exit this screen, press the

ESC key.

Network Who Screen

Device Choices Menu

The terminal searches for all devices on the network and reports the devices it has

found on the Network Who screen. Use the Increment or Decrement key to

scroll through devices. Press Enter (return arrow) to invoke the Device Choices

menu.

This menu allows the user to choose what operation is to be performed for the

selected device. The terminal only displays choices that are appropriate for the

selected device. The Increment and Decrement keys allow the operator to scroll

through the selections. The Enter key will advance to the selected operation.

12 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

Page 17

Quick Start Chapter 4

Press Shift Copy to copy parameter Clas s,

Instance, Attribute info to the clipboard

Param eter

number

Parameter name

Param ete

r value

Parameter units

A parameter help string, minimum value, maximum

value and default value are scrolled across the screen

Ve r s i o n : Displays Version information for the selected device.

Params: Provides access to configuration and status parameters for the selected

device. Allows the operator to search for parameters that are not at factory

defaults.

Copy Cat: Upload and store complete device configurations, including

DeviceLogix™ programs to the programming terminal’s memory. Download

stored device configurations from the programming terminal memory to the

selected device.

To o l s : Provides access to Node Commissioning functions, the Class Instance

Attribute editor, and the real time graphing function.

Advanced: Provides access to the DeviceLogix™ editor, DeviceNet™ IO message

timing information, ZIP configuration, and local input and output status display.

Scanner: If the selected device is a DeviceNet™ scanner, provides access to simple

scanner configuration values and access to the scan list.

Parameter Monitoring and Editing

Parameters can be accessed as either groups or as a numbered list of all

parameters. The Parameter Screen displays all information for a single parameter.

From the Parameter Screen, parameter values can be monitored or edited.

Scrolling through a parameter list is accomplished by pressing the Increment or

Decrement keys from the Parameter Screen. Parameters can also be accessed by

entering a parameter number with the numeric keys while in the Parameter

Screen. The parameter screen has the following format:

Parameter values are continuously updated.

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 13

Page 18

Chapter 4 Quick Start

1) Press the SEL key to

select the value

2) The Increment and Decrement keys increment or decrement the value

when it is selected. An edit box will appear when a key is pressed.

OR

Enter a numbe r from t he nume ric key pad. An e dit box will ap pear wh en a

key is pressed.

1) Press the SEL key to select a bit to

change.The selected bit name is

displayed here

Press < (scroll left) or > (scroll right) to select the next

bit

2) Press the Increment (or 0) or Decrement (or 1) key or to toggle the bit value

Change a parameter value by first pressing the SEL key and then modifying the

selected value.

Pressing the Enter key will write the new value to the selected device. When a

parameter value is selected, pressing the ESC key will deselect the parameter

value and allow movement within the parameter list or group.

Bit-enumerated parameters are displayed and modified as follows:

Pressing the Enter key will write the new value to the selected device. When a

parameter value is selected, pressing the ESC key will deselect the parameter

value and allow movement within the parameter list or group. Pressing the ESC

key will delete changes and revert to the previous settings for that parameter.

14 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

Page 19

Quick Start Chapter 4

Displays version information

Allows the user to perform Faulted

Node Recovery for nodes that fail

the Dup Mac ID test

Displays and latches Network Diagnostic information such as Baud Rate,

Bus Voltages, Bus Loading characteristics and CAN errors

Displays the HIM Setup Menu

(shown below)

Displays a

DeviceNet™

communicatio

n error log

Invokes the Terminal Setup screen described

above

Sets up the 5 security

passwords:

1 primary and 4

secondary passwords.

Primary passwords

enable/disable all

editing functions

Secondary passwords

enable/disable editing

of the features

presented by the

terminal

Auto Display setup

enables the display of up

to 4 parameter values

from one or more devices

at powerup

Configures the

operation of the User

Adjust the

screen contrast

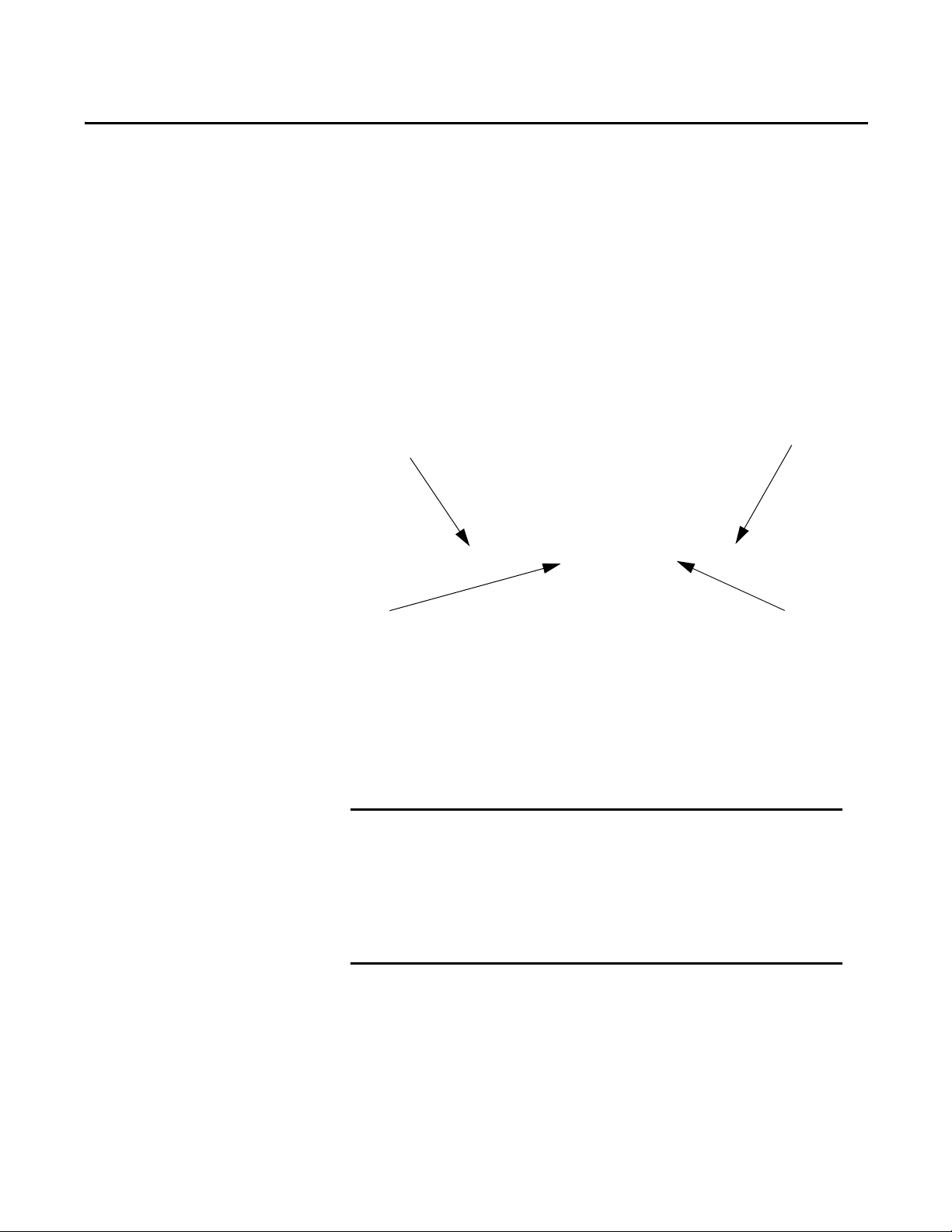

DeviceNet™ Configuration Terminal Setup Menus

The 193 DeviceNet™ Configuration Terminal often refers to itself as a HIM

(Human Interface Module). When This DNet HIM is chosen from the Network

Who screen, the following HIM Choices Menu appears:

The HIM Setup menu allows the user to configure many of the programming

terminal features.

Port Object And Routing Sub Nets

The 193-DNCT has the capability to route down one DeviceNet™ sub net for

devices that support the Port Object. This allows the user to easily view devices

on the network display menu.

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 15

Page 20

Chapter 4 Quick Start

Who Menu Display

The Who Menu displays the device information for devices that support a

DeviceNet™ sub net.

When the +DeviceNet Subnet choice is selected and the Enter key is pressed,

the Subnet Who Menu will be displayed.

Selecting a device at the Subnet Who menu and pressing the Enter key will

display all of the menus available at the standard Who menu.

16 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

Page 21

Device Choices Menu

Currently selected operation

If the currently selected device is the DeviceNet™ HIM, this menu will be slightly dif ferent.

See Chapter 15, DeviceNet™ Terminal Choices, for description. Not all choices will be

available for all devices.

Displays vendor ID,

device type and

product code

Optional build

number

Identity Object

instance name

Chapter 5

Device Choices Menu

Version Menu

The Device Choices menu is entered from the Network Who screen when a

device is selected and the Enter key is pressed. This menu allows the operator to

choose what operation is to be performed on the selected device. The choices on

this menu are only displayed for features that the selected device supports. The

Inc and Dec keys allow the operator to move up and down through the

selections. The Enter key will advance to the selected menu.

The Version Screen appears when Ve r s i o n is selected from the Device Choices

Menu. It displays the major revision, minor revision, and if supported the build

number of the selected device. If multiple instances of the Identity Object are

supported in the selected device, the revision number for each instance is

displayed. Use the Inc/Dec keys to select the different instances of the Identity

Objects. The Esc key will return the user to the Device Choices menu.

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 17

Page 22

Chapter 5 Device Choices Menu

Status of the Fault

0= Fault is not active

1= Fault is active

Status of the

four fault

states in the

device

Note: Help String is

displayed only if

the fault is active

Standard Device Status Menu

Fault/Warning Choice Menu

The 193-DNCT displays the following menu for devices that do not support the

Fault or Warning Object.The Identity Object Status Attribute (5) is monitored

continuously when viewing this menu. The display is updated to reflect the status

of the device.

The following menu appears after the Fault button is pressed on the Device

Choices menu if the current device supports both the Fault Object and the

Wa rn in g O bje ct.

Fault Menu

18 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

The fault menu displays a buffer of fault information. From the Fault Object, the

193-DNCT is able to read the size of the fault buffer, the trip fault, the fault

codes and the fault name strings. Other optional information may also be

available such as a fault timestamp and a help string explaining the fault. The

menu has a Clear Buffer command that will clear all of the entries in the buffer,

however, it will not clear any active faults. The reset button on the 193-DNCT

keypad can be used to attempt to clear the current active fault and it will sent a

clear fault command to the device's Fault Object.

NOTE: The 193-DNCT has a limited buffer size of 25 faults

Page 23

Device Choices Menu Chapter 5

Use the INC/

DEC keys to

move thru

the Fault

Buffer.

Faul t cod e

number and

name

The Devi ce is

currently faulted

and the buffer

entry is reported

as trip fault.

The TimeStamp Attribute is an

Optional Attribute, and if the

Device supports it, the

timestamp will display in

the following format

Elapsed Timer:

days:hours:minutes:secon

ds

Real Time Clock:

yyyy:mm:dd:hh:ss:xxx

yyyy = year

mm = month

dd = day

hh = hour

ss = second

xxx = mSecond

Figure 1 - Fault Buffer with all optional attributes supported with a fault present.

Figure 2 - Fault Buffer with all optional attributes supported

Warning Menu

The Warning Menu is designed to display a buffer of warning information. Based

on the Warning Object, the 193-DNCT can read the size of the warning buffer,

the warning codes and the warning name strings. Other optional information,

such as a timestamp and a help string about the warning, are also available. The

menu has a Clear Buffer command which will clear all of the entries in the buffer,

but it will not clear any current warnings. The Reset button on the 193-DNCT

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 19

Page 24

Chapter 5 Device Choices Menu

War nin g

code

number and

name

War nin g

code

number

and name

Use the SEL key to move

back and forth from

the Buffer number to

the Clear Buffer

Command. With the

Clear Buffer choice

highlighted, press the

Enter key to clear the

buffer.

keypad can be used to attempt to clear the current warning by sending a clear

warning command to the devices Warning Object.

Figure 3 - Warning Buffer without optional attributes supported

20 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

Page 25

Parameter Choices Menu

Currently selected function

Currently selected parameter

group

Parameter group names

Chapter 6

Parameter Choices Menu

Groups Screen

The Parameter Choices Menu is only available if the selected device has built-in

parameter support (DeviceNet™ Parameter Object). This menu allows the

operator to go to screens that monitor and change parameters, view/select

parameter groups, and search for parameters that are not at their default settings.

The Inc and Dec keys allow the operator to move up and down through the

selections. The Enter key advances the user to the selected item. The Esc key

returns the user to the Device Choices Menu.

This screen allows the operator to select a group of parameters to be monitored/

edited. The Inc and Dec keys allow the operator to move up and down through

the selections. The Enter key advances the operator to a Parameter Edit Screen.

The Esc key will return the user to the Parameter Choices Menu. The choices in

this menu are only displayed for groups that the selected device supports.

Num List Selection

A numerical list (Num List) of Parameter Edit Screens are presented when Num

List is selected and the Enter key is pressed.

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 21

Page 26

Chapter 6 Parameter Choices Menu

OR

Parameter number

Indicates that this

parameter is Read Only

and its value cannot be

edited.

Param eter

units

Param ete

r name

Param eter

value

This c indicates that the Class,

Instance, and Attribute data for this

parameter can be copied to the

clipboard by pressing Shift key

then the Copy Key.

If the Parameter has a Help

string, the string will be

scrolled across the bottom

line. After the Help String is

displayed, the Min value will

be display for 3 seconds,

followed by the Max value,

and then the Default value.

After the D efault is displayed

the string will repeat.

Numeric

Param eter

values have this

format

Note: If the parameter is a monitor parameter, the HIM stores the HI and LO values for the parameter

during monitoring. The HI:/LO: values are displayed on the same line as the Min, Max, Def and Help

string.

Parameter Edit Screens

Numeric Parameters

The Parameter Edit Screens allow the device’s parameters to be monitored and

edited. The parameter screens have slightly different formats for each parameter

data type (numeric, value enumerated, bit enumerated Boolean, etc.)

Numeric parameter values are displayed as follows:

Accessing a Different Parameter

Accessing a different parameter from a Parameter Edit Screen is done by entering

or changing a new parameter number. Changing the parameter number can be

done using the Inc or Dec key to increment through the currently active group of

22 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

Page 27

Parameter Choices Menu Chapter 6

Current parameter number

Pressing a numeric key will displayed

an edit box to enter a new parameter

number in.

parameters. Entering a new parameter number directly can be done by entering a

number with the numeric keypad (only if accessed through the Num List).

Changing a Parameter Value

Changing a parameter value is done by pressing the Sel key to highlight the

parameter value then using the Inc/Dec keys or numeric keys to enter the value.

Pressing the Enter key will write the new value to the parameter. When the

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 23

Page 28

Chapter 6 Parameter Choices Menu

Press Sel key to select t he Parameter

Valu e

Pressing a numeric key will display an

edit box to enter a n ew parameter

value

parameter value is selected, pressing the Esc key will deselect the parameter value

and allow the parameter number to be changed.

24 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

Page 29

Parameter Choices Menu Chapter 6

Enumerated Parameter value

To change a value, press the Sel key to

select the Enumerated Parameter

value, then use the Inc/Dec key to

change the value

Enumerated Parameters

Parameters that display Value Enumerated data values appear as follows:

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 25

Page 30

Chapter 6 Parameter Choices Menu

Bit enumerated parameter

value

Bit selected

Tex t s tri ng

associated with the

selected bit

Press the left/right

arrow key to select the

next bit

Parameters with Bit Enumerated data values are displayed as follows:

Floating Point Parameters

26 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

Parameters with Floating Point values will be displayed as follows:

Page 31

Parameter Choices Menu Chapter 6

Use the Shift key then the Exp key to

add the E into the value when editing

a floating point value

Number of

parameters to

search through

Number of

non-default

parameters

found

Current parameter

being checked for

default value

Selected parameter

Param eter

number of nondefault

parameters

Names of nondefault

parameters

Entering floating point numbers is performed much the same as regular numeric

parameters described earlier. The exponential (displayed as an “E”) is entered as

follows:

Search for Changed Parameters

This function is invoked by selecting the Search option from the Parameter

Choices Menu. The function searches through the selected device’s parameters

and finds the parameters that are not at their default setting. The following

screen is displayed when searching the parameter list for the selected device:

When all the parameters have been checked, a list of parameters that are not at

their default value will be displayed. The Inc and Dec keys allow the operator to

move up and down through the non-default parameters. Pressing the Enter key

allows the parameter value to be viewed/edited.

When accessing parameters found by the Search function, the format of the

parameter screen will be similar to a Parameter Edit Screen with a few changes.

The title line will say “Non-Default Parameter”, and when Inc or Dec is pressed,

only the parameter found in the search will be displayed

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 27

Page 32

Chapter 6 Parameter Choices Menu

Parameter Display-Value Enumerated

Certain parameters have enumerated values that are not bit enumerated values,

the following screen is displayed and shows the “Raw Value” of the enumerated

value.

28 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

Page 33

Copy Cat Menu

These choices will only be display if

one or more Copy Cat files have been

stored in the Configuration Terminal

Chapter 7

Copy Cat

The copy cat menu allows the operator to upload and download complete device

configurations to and from the Configuration Terminal. For DeviceNet™ slave

devices, these complete device configurations consist of all configuration

parameter values and any DeviceLogix™ program that is programmed in the

device. For Allen-Bradley DeviceNet™ Scanners, device configurations consist of

the scan list. This feature is only available for devices that support the Parameter

Object or devices that support the Scanner Object.

The Copy Cat menu uses the acronym HIM in many of its menu selections and

screens. HIM stands for Human Interface Module and is used to refer to the

Configuration Terminal itself. The HIM acronym is used in this product for

historical reasons, as this acronym was used on older hand-held configuration

tools and many users are familiar with its use with regard to the Copy Cat

function.

The Copy Cat Menu is shown below:

Copy Cat Uploading

To upload the parameters and the DeviceLogix™ program (or scan list) from a

device, select Dev->HIM at the Copy Cat Menu and press the Enter key. The

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 29

Page 34

Chapter 7 Copy Cat Menu

Selected file

New

unnamed

“em pt y” f ile

Existing Copy

Cat file

names

File name the

Copy Cat data will

be saved to

Selected

Character; use

the Sel key to

move the cursor

to the right to

select the next

character

Use the Inc/Dec key to move the cursor to change the character. The numeric

keypad can be used to enter a number into the file name

Upload progress bar

Currently uploading parameters. Note:

Will display ScanList for Copy Cat of an

Allen-Bradley DeviceNet™ Scanner

first screen will allow the operator to select where the data will be stored, either to

an existing file or a new file:

After selecting a file, you will be able to name/rename it:

30 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

When done editing the file name, press the Enter key to start uploading:

Page 35

Copy Cat Menu Chapter 7

Currently uploading the Logix program

Selected file to download

Once the parameters are uploaded, the DeviceLogix™ program will be uploaded

(if applicable):

When the upload is complete, the screen will appear as follows:

Copy Cat Downloading

To download complete device configuration files that have been stored in the

Configuration Terminal, select HIM->Dev at the Copy Cat Menu. The first

screen that appears will allow the operator to select which stored file to

download:

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 31

Page 36

Chapter 7 Copy Cat Menu

Mismatch type. This could be:

Ven dor

ProdType

ProdCode

Revision

IMPORTANT

Currently downloading

parameters. Note: Will

display “ScanList” for

copy cat of a scanner

Progress b ar

Currently

downloading the

DeviceLogix™

program

After selecting the file to download, press the Enter key to start the download. If

the device being downloaded to does not match the device the file was uploaded

from, an error is displayed before the download continues:

Pressing the Enter key will cause the Configuration Terminal to ignore the

electronic keying errors and continue the download.

The following screen will appear when the downloading starts:

After parameters are downloaded, the DeviceLogix™ program is downloaded.

When the download is complete, the screen will appear as follows:

32 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

Page 37

Copy Cat Menu Chapter 7

Errors may occur in either or both

parameters and/or the DeviceLogix™

program downloading

If there are errors during the download process, the screen will look like this:

If parameter errors occur, pressing the Enter key will bring up the following

screen, which will allow the operator to choose to view the parameters that had

errors during the download. Note: Only the first 32 parameters with errors are

stored.

Copy Cat Downloading and Product Revisions

If the operator chooses to view the parameters that had errors during the

download, a Parameter Edit Screen will be displayed with minor changes. The

title line will say “CopyCat Error Params,” and when Inc or Dec is pressed, the

user will only view the next parameter that had an error during the download.

.

From time to time, new firmware revisions are released in the DeviceNet™

product portfolio. Great care is taken in these product upgrades to ensure

backward compatibility with previous revisions when it comes to being able to

accept Copy Cat data files. Great care is also taken to ensure that the new revision

of the product will behave the same as the older revision after a Copy Cat data file

has been downloaded.

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 33

Page 38

Chapter 7 Copy Cat Menu

Pressing the

Enter key will

cause the

Confi guration

Terminal to ignore

the revision

difference and

continue the

download

Pressing ESC

will cause the

download to

be aborted

When a Copy Cat data file is downloaded to a different firmware revision of the

same product, the user is made aware of the revision difference as follows:

In some products, new firmware revisions were released in order to add

DeviceLogix™ capability to the product. When downloading a Copy Cat data file

that was uploaded from a revision of a product without DeviceLogix™ to a

revision of the product that contains DeviceLogix™, the status bar on the

Download Status screen will not reach 100%. The “Download Complete” line

above the status bar will be the indication that the download was indeed

completed.

Copy Cat Downloading and Product Current Ratings

Often times it is useful to download Copy Cat data files to devices within a

product family that have different current ranges. This is particularly useful if the

user wishes to download a DeviceLogix™ program to multiple members of a

product family. When a Copy Cat data file is downloaded to a product whose

34 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

Page 39

Copy Cat Menu Chapter 7

Pressing the Enter

key will cause the

Confi guration

Terminal to ignore

the product code

(current range)

Pressing ESC

will cause the

download to

be aborted

When Inc or Dec are

pressed from the Parameter

Edit Screen, the next or

previous parameter that

had an error during the

download will be displayed

current range is different from that of the product that the data file was uploaded

from, the following screen appears:

When downloading to devices in the same product family with different current

ranges, the download results will often include Parameter Errors. These errors are

the result of downloading parameters such as FLA current settings whose min/

max range is outside the FLA current setting that was downloaded. When this

occurs, the following screen appears:

Pressing the Enter key will bring the operator to the Parameter Edit Screens for

the out-of-range parameters. The title line will say “CopyCat Error Params”.

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 35

Page 40

Chapter 7 Copy Cat Menu

File to be deleted

Deleting Copy Cat Files

Copy Cat Memory

Deleting a Copy Cat file from the memory of the Configuration Terminal is done

by selecting the Delete option at the Copy Cat Choice menu. Select the file name

to delete, and press the Enter key to delete the file. If all the files have been

deleted, the screen will again display the Copy Cat Choice menu, but the Delete

and HIM -> Dev options will not be displayed.

The Copy Cat memory screen displays how many files are stored in the

DeviceNet™ HIM and how many blocks of memory are left for copying. The

maximum number of files that can be stored in the Configuration Terminal is 31.

Depending on the number of parameters in each file, there may not be enough

memory to store all 31. Note : Each block of memory is equal to 128 bytes in the

memory, and there are 128 blocks of memory reserved for file storage.

DeviceLogix™ Library 5 Support

36 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

The 193-DNCT Series B or higher supports the upload/download of a

DeviceLogix file. This feature is only available when the device supports the

parameter object and DeviceLogix.

Page 41

Tools Menu

Currently

selected item

This only appears if one

of the fields has been

changed. Pressing Enter

here will reset the

DeviceNet™ HIM after

writing any changes to

the device

Chapter 8

Tools Menu

Node Commissioning

The Tools Menu gives the user access to the Node Commissioning screen, a Class

Instance Attribute editor, Graphical parameter chart recorder screen, Assembly

menu, and Heartbeat menu. The Tools Menu is shown below:

Pressing Enter while the NodeComm item is selected in the Tools Menu invokes

the Node Commissioning screen. Node commissioning allows the operator to

change the Mac ID and/or the baud rate for the currently selected device.

Class Instance Attribute Editor

The Class Instance Attribute (CIA) Editor allows the operator to perform

DeviceNet™ explicit messaging. Get, Set, and Reset services can be sent to any

Class, Instance, and Attribute.

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 37

Page 42

Chapter 8 Tools Menu

CIA Copy and Paste

is available for

this menu

Highlight and

press the

Enter key to

Selected

service

Display size of read

data. Choices: Byte,

Word, Dword, or

Data that is read

when a message

is requested

Highlight and

press the Enter

key to perform the

Display size of data

to write. Choices:

Byte, Word, Dword,

Data to write

Highlight and press the Enter key t o

perform the Reset service

The Get service is outlined in the following screen description:

The Set service is outlined in the following screen description:

:

Graph Setup Screens

38 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

The Reset service is outlined in the following screen description:

The Graph function allows the Configuration Terminal to become a simple

graphing device. From the Graph Setup Screens, the user sets up to four Class,

Instance, or Attributes to be monitored and displayed as a scrolling graph (similar

Page 43

Too ls Men u Chapter 8

CIA Copy and Paste is

available for this menu

Class, Instance,

Attribu te to

graph, Note:

Traces with the

class set to zero

will not be

graphed.

Trace number 1-4

Max is the CIA’s value that

will be represented as the

top of the screen. Min is

the CIA’s value that will be

represented as the bottom

of the screen. (In this

example, a CIA value of 50

would be in the middle of

the screen; any CIA value at

or above 100 would be

displayed on the top pixel

of the screen). Note there

are only 64 vertical pixels

Offset is the

number of pixels

from the bottom of

the screen the min

value for this trace

will be displayed

at. The range for

this field is 0…64,

with 32 being the

middle of the

Rate the CIA will be polled, in 10 mSec

increments

The value is the trigger

point; this is the raw value

obtained by reading the

CIA for the selected trace.

This could be trace

1…4

Positive Slope: the

raw value (obtained

by reading the CIA

for the trace) moving

from below the

Programmed Value

to equal or above the

Programmed Value.

Negative Slope =

Position value is 0 …128 (128 pixels

across the screen) 64 = 50%

Position is the location

on the screen at which

the trigger point will be

displayed when the

trigger condition is

found.

to an oscilloscope or chart recorder). The first screen allows the operator to

configure the four Class, Instance, or Attributes to be monitored.

Press the Enter key after the CIA data is configured to display the Graph Trigger

Screen. This screen allows the operator to program a trigger point to stop the

graph display from updating. The operator can set which trace will be used as the

trigger as well as the slope, value, and position of trigger. The trigger point can be

disabled if the operator does not need this feature.

Press the Enter key after the trigger data is configured to display the Graph View

Screen.

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 39

Page 44

Chapter 8 Tools Menu

This screen show only one trace

configured

The raw data value

corresponding to a

point on the graph

where the cursor

intersects. Note: T1:

reflexes the trace

number that the

value corresponds to.

To change the trace

number, use the Sel

key.

The Cursor ;

pressing the Inc/

Dec key will

HI:/LO: reflect the high and low data

values contained in this trace

Graph View Screen

This menu displays the CIA data in graphical form.

Pressing the Enter key while the Graph View Screen is displayed stops the trace

and displays a cursor that can be used to view the raw value that was read for that

point on the graph.

Assembly Consumed/ Produced Menu

40 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

The Assembly choice can be selected from the Tools Menu. This menu allows the

user to choose between the consumed (input) and produced (output) assemblies

available in the unit.

Page 45

Too ls Men u Chapter 8

Pressing the Enter Key at the “Assembly Consumed / Produced” menu will

advance the 193-DNCT to the next menu. This menu lists all of the available

assemblies to view. The format for the “Assembly List” menu is as follows:

The Assemblies Tag Menu is similar to the IO Tags Menu, however, the data for

consumed assemblies can be modified if there is no active IO connections present

between the device and the PLC.

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 41

Page 46

Chapter 8 Tools Menu

Notes:

42 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

Page 47

Advanced Functions Menu

Only available if Zone

Interlock Protocol

Object is supported in

the currently selected

device

Only available if DIP,

DOP or PNB Objects

are supported in the

currently selected

device

Only available if

DeviceLogix™ is supported

in the currently selected

Chapter 9

Advanced Functions Menu

The Advanced Functions Menu provides access to a DeviceLogix™ editor, Zone

Interlocking Protocol (ZIP) configuration and monitoring screens, an I/O

message timing screen that monitors I/O messaging timing between the selected

device and a DeviceNet™ scanner, and Discrete I/O statistics. The Advanced

Functions Menu is shown below:

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 43

Page 48

Chapter 9 Advanced Functions Menu

Notes:

44 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

Page 49

Chapter 10

HeartBeat Menus

The HeartBeat feature can be found in the Tools Menu

The user can enable or disable the Heartbeat feature and modify the scanning

interval from the Setup Menu.

The Heartbeat Monitor menu displays the contents of the last received

Heartbeat message. The menu is displayed when the Monitor button is pressed

on the Heartbeat Choices Menu.

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 45

Page 50

Chapter 10

Notes:

46 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

Page 51

I/O Message Monitoring

Press the INC/DEC

key to switch

between consumed

and produced data

Type of IO

connection. Polled

or COS

I/O Message

Count

Size of the I/O data in bytes

Most recent produced or

consumed I/O data for the

currently selected device

Message

recepti on rate

Min, Max and

Averag e

Chapter 11

I/O Message Monitoring

This screen displays I/O message timing information and I/O message data for

the currently selected device. It is accessed by selecting I/O Msg and pressing the

Enter key at the Advanced Functions Menu.

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 47

Page 52

Chapter 11 I/O Message Monitoring

Notes:

48 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

Page 53

DeviceLogix™ Functionality

Only available if the

DeviceLogix™

DataTable Object is

supported in the

currently selected

device

Currently

selected

function

Chapter 12

DeviceLogix™ Functionality

DeviceLogix™ Choices Menu

The Configuration Terminal allows the operator to monitor, edit or delete

DeviceLogix™ programs for devices that support DeviceLogix™. DeviceLogix™

can also be enabled or disabled for a device. The DeviceLogix™ functions can be

accessed through the DeviceLogix™ Choices Menu, which is accessed by pressing

Enter from the Advanced Functions Menu while the DevLogix menu item is

selected.

The DeviceLogix™ Choices Menu is shown below:

DeviceLogix™ Monitor

This function allows the operator to view a DeviceLogix™ program, including all

programmed function blocks, Discrete Output Points (DOP) and Produced

Network Bits (PNB). Text string for inputs, outputs, PNBs, and fault bits are

displayed for devices that support the DeviceLogix™ Data Table Object. The

counter and timer preset and accumulator value’s can be modified when selected.

To view each function block, use the INC/DEC keys to move to the next

function block. When the last programmed function block is reached, pressing

the INC key will advance the screen to the Programmed DOP screen. Pressing

the INC key again will then display the Programmed PNB screen and if the INC

key is pressed a third time, the first function block will be displayed again. When

viewing Function Blocks, the screen will have the following formats:

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 49

Page 54

Chapter 12 DeviceLogix™ Functionality

IN3 and

IN4 may or

may not

be present

Value of input

or output

Function block

number and

type

Negated

(Active Low)

inputs

Press the SEL key to

highlight the function

block’s inputs and

outputs text strings.

(Only available if the

device supports the

DeviceLogix™ Data

Tab le O bjec t)

Down input may or

may not be present

Press the Sel key to

highlight the preset

or count value. To

accept new value

press the Enter key

Boolean Gates: AND, OR, XOR, NAND, NOR, NXOR and NOT

Bistable Latches: RS Latch and SR Latch

Counters: Up Counter and Up/Down Counter

50 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

Page 55

Timers: On Delay, Off Delay and Pulse Timer

Time base: 1

mSec or 10

mSec

Press the Sel key to highlight the

preset or count value. To accept a

new value press the Enter key

Discrete Output Point

(DOP). The name text

for this comes from the

product, so names may

vary product to product

The name of what is

driving the Discrete

Output Point in the

Device Logix program

Produced Network

Bit (PNB). The name

text for this comes

from the product, so

names may vary

product to product.

The name of what is

driving the Produced

Network Bit in the

DeviceLogix™ program

Discrete Output Points (DOPs):

DeviceLogix™ Functionality Chapter 12

DeviceLogix™ Editor

Note : The Programmed DOP screen is only available for devices that support the

DeviceLogix™ Data Table Object.

Produced Network Bits (PNBs):

Note : The “Programmed PNB” screen is only available for devices that support

the DeviceLogix™ Data Table Object.

This DeviceLogix™ Editor allows the operator to create or edit a DeviceLogix™

program. Function blocks are displayed in the same format as in the

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 51

Page 56

Chapter 12 DeviceLogix™ Functionality

The Edit a nd Delete choices are o nly

present if there are function blocks

already programmed

DeviceLogix™ Monitor. To create, edit or delete a program element, use the INC/

DEC keys to navigate to the item to create/edit and then press the Enter key. To

edit one of the inputs of a function block, use the SEL key to highlight the input

and then press the Enter key. To invoke the DeviceLogix™ Editor, select the Edit

item in the DeviceLogix™ Choices Menu and press the Enter key.

Creating a New Function Block

Consider the following example of creating a new AND gate function block.

First, invoke the Device Logix editor. One of two displays will appear, either a

display of a function block or a screen displaying “No FB’s programmed”. At this

point press the Enter key and the following screen appears:

Press the Enter key to create a new function block. Now that a new function

block has been created, the type of function block must be selected. The

following screen will appear:

52 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

Use the INC/DEC keys to select the new function block type. Press the Enter

key when the desired function block type is selected. The following screen will

appear (the Boolean type screen is shown below. Other similar screens appear for

other function bock types.)

Page 57

DeviceLogix™ Functionality Chapter 12

Function Blocks

The 193-DNCT has function blocks available in the DeviceLogix Library. The

DeviceLogix Library version 3 and 5 are available with firmware v2.001 and

v3.001, respectively. Devices that use the DeviceLogix Library version 3 or later

may enable support for an enable line on each function block. An upgrade to the

existing Boolean function block displays the enable line, if the device supports

this feature.

The 193-DNCT Series A v2.001 and later are able to display analog function

blocks. Each analog function block contains a PAR A M selection on it, which is

used to display and edit additional data that is specific to the type of function

block.

The available analog function blocks are:

• Arithmetic

• Alarm

• Compare

• Masked Compare

• Timing Diagnostic

• Limit

• Filter

• Select

• Ave ra ge

Assigning Source Bits to Function Block Inputs

Use the INC/DEC keys to assign a type to the new function block. Press the

Enter key when the desired type is selected. The screen should now display a new

function block of the selected type:

Note : At this time a new function block has been created and assigned a type, but

the inputs and outputs are not assigned at this time.

To assign or edit input source bits for a function block, first choose the function

block input by pressing the Sel key to scroll through the function block inputs.

With each successive Sel key press, a different input will be selected on the screen.

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 53

Page 58

Chapter 12 DeviceLogix™ Functionality

The Assignment text

will disappear after

three seconds

Negating an input

makes the input an

active low instead of

an active high input

Not all inputs of all

function block types

can be left

unassigned, so this

option will not be

available for all inputs

of all function block

Not all inputs sources may be

supported by all products

Notice that the current source bit assignment for a selected input will be

displayed on the screen for three seconds as shown below:

To edit an input source bit assignment, press the Enter key while the desired

input is selected. The following screen appears:

54 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

Press the Enter key when Edit is selected and the following screen appears:

Page 59

Discrete I/O Status

The type of bits that

are selected and are

being displayed. Press

the Sel key to sele ct a

different bit type

Unused bits

Value of each

bit, 1 or 0

Range of bits

displayed on this line

Chapter 13

Discrete I/O Status

The Discrete I/O Status screen is displayed by selecting I/O Stat and pressing the

Enter key at the Advanced Functions Menu. This screen displays the status of any

Discrete Input Points (DIP’s), Discrete Output Points (DOPs) and Produced

Network Bits (PNBs) that are implemented in the currently selected device. This

screen will be available if any one of the DIPs, DOPs or PNBs are supported in

the currently selected device.

Note : In this example the device supports 4 instances of the Discrete Input Point

Object.

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 55

Page 60

Chapter 13 Discrete I/O Status

Notes:

56 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

Page 61

Zone Interlock Protocol (ZIP)

Zone number (1…4) that is associated with data currently

highlighted. Note: x = no zone is associated at this time

The Node Number of

the device whose I/O

data is mapped in

this zone

This is the internal zip data

table. B:00-07 indicates that

we are viewing data table

bytes 0…7 (B:08-15 would

be displayed on the next line

if the data table was 16 bytes

long). Each XX represents one

byte in the data table. The XX

will display the Devices Node

Number whose I/O data is

mapped to that byte in the

ZIP data table.

Number of Zones

left in this device

that are not

Chapter 14

Zone Interlock Protocol (ZIP)

ZIP Consumed

The Zone Interlock Protocol (ZIP) menu is available for devices that support the

DeviceNet™ Zone Interlock Protocol Object. The Zone Interlock Protocol

provides a way for devices to share I/O message data directly, and the data that is

consumed from other devices can then be used in a DeviceLogix™ program. The

ZIP Choices Menu is displayed by selecting ZIP and pressing the Enter key at the

Advanced Functions Menu. The following menu choices are available to edit and

monitor the ZIP configuration:

This screen allows the operator to configure the ZIP data that the device is going

to consume. Configuring ZIP Consumed data consists of mapping I/O data from

other nodes or zones on the network to the device’s internal ZIP Data Table (the

ZIP Data Table is where a DeviceLogix™ program accesses ZIP data). Devices

that support ZIP can define the number of zones from which they can consume

at one time. In this manual it is assumed that the device can consume data from

up to four zones at one time. The size of the internal ZIP data table is device

specific. In this manual it is also assumed that the internal ZIP data table is eight

bytes long.

The following screen shows a device with no ZIP I/O data configured or

mapped:

Rockwell Automation Publication 193-UM009B-EN-P - February 2013 57

Page 62

Chapter 14 Zone Interlock Protocol (ZIP)

Thi s is By te 7 o f the

ZIP internal data

table

The selected byte in the ZIP

data table is highlighted. In

this case Byte 0 is selected.

Use the Right/Left arrow

keys to select the byte

Node 5 is

mapped to

byte 0 of the

ZIP data table

These are the

current ZIP

configuration

parameters for

Zone 1

Zone 1 is now

configured to

Node 5

The node: Field allows the node

number associated with this Zone to

be changed

Mapping Consumed ZIP Data

This section explains mapping I/O data for a Zone. Assume that the DeviceNet™

Configuration Terminal is currently configuring Node 11 on the Network. Also

assume Node 5 is on the network, and is producing I/O data. Node 11 will be

configured to consume the I/O data that Node 5 is producing, which will be

done by mapping Node 5 I/O data to Zone 1 in the ZIP data table of Node 11.

First, use the Left/Right arrow keys to select the byte in the ZIP data table where

Node 5 I/O data will be mapped to.

Once the desired byte in the internal ZIP data table is selected, enter a Node

number using the numeric keys on the keypad of the node whose I/O is to be

mapped (this example maps Node 5 data to byte 0 of the ZIP data table). Press

the Enter key after the Node Number has been entered and the following display

should appear:

58 Rockwell Automation Publication 193-UM009B-EN-P - February 2013

Use the Sel key to highlight the various ZIP configuration parameters for this

zone. The following screen shows the Node field highlighted:

Page 63

Zone Interlock Protocol (ZIP) Chapter 14

EPR (Expected Packet Rate) allows

the expected packet rate of the I/O

data from node (Node 5) to be

changed. This value is in

milliseconds.

The “IO Msg:” field allows the choice

of which bytes of the I/O data from

node 5 are going to be mapped to

the ZIP data table. Each bit in the IO

Msg field maps or un-maps a byte of

the I/O data from node 5. The value

1 means map this byte of I/O data. In

this example, o nly byte 0 of the I/O

data from node 5 is being mapped.

This 1 maps” byte 2

of the IO data from

node 5

Two byt es o f I/ O da ta

from node 5 are now

mapped to the

internal ZIP data

table

This 1 maps

byte 0 of the

IO data from

node 5

The following screen shows the EPR (Expected Packet Rate) field highlighted: