Page 1

FLEX I/O Diagnostic Modules

Catalog Numbers 1794-IB16D, 1794-OB16D

User Manual

Page 2

Important User Information

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Solid state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (publication SGI-1.1

http://literature.rockwellautomation.com

) describes some important differences between solid state equipment and hard-wired electromechanical

devices. Because of this difference, and also because of the wide variety of uses for solid state equipment, all persons responsible for applying this

equipment must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or application of this

equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements associated

with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the examples and

diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software described in this

manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from your local Rockwell Automation sales office or online at

Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may

lead to personal injury or death, property damage, or economic loss.

Identifies information that is critical for successful application and understanding of the product.

Identifies information about practices or circumstances that can lead to: personal injury or death, property damage, or

economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Labels may be on or inside the equipment, such as a drive or motor, to alert people that dangerous voltage may be present.

Labels may be on or inside the equipment, such as a drive or motor, to alert people that surfaces may reach dangerous

temperatures.

Allen-Bradley, Rockwell Automation, FLEX I/O, RSLogix, RSLinx, RSLogix 5000 and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

1794 FLEX I/O Diagnostic Digital

Modules Overview

About the FLEX I/O Diagnostic

Input Module

Table of Contents

Preface

Purpose of This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Important Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

North American Hazardous Location Approval . . . . . . . . . . . . . . . 7

Related Products and Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

General Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Network Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1794-IB16D Diagnostic Input Module Compatibility . . . . . . . . . . 14

1794-OB16D Diagnostic Output Module Compatibility . . . . . . . 15

Install Your Digital Input or Output Module. . . . . . . . . . . . . . . . . . . . 16

Chapter 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

About the 1794-IB16D Diagnostic Input Module . . . . . . . . . . . . . . . . 19

Diagnostic Fault Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

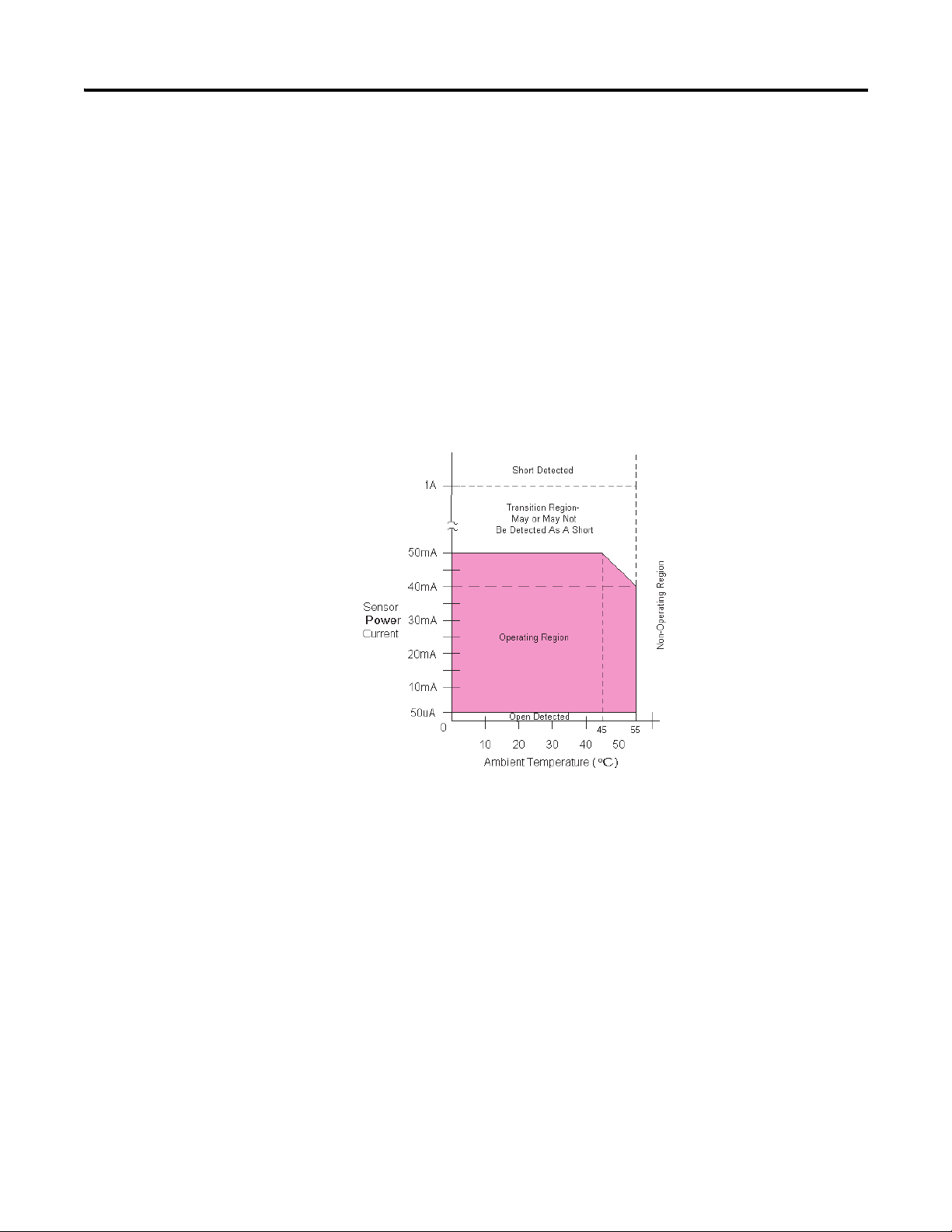

Sensor Power Open and Short Circuit Detection . . . . . . . . . . . . . 22

User Power Supply Reverse Voltage Detection . . . . . . . . . . . . . . . 23

User Power Supply Loss Detection . . . . . . . . . . . . . . . . . . . . . . . . 23

Indicator Status Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Module Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Input Voltage Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Sensor-Power Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Unused Sensor Power Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Open Contact Mechanical Switches and Relays. . . . . . . . . . . . . . . 25

Sensor Power Internal Voltage Drop . . . . . . . . . . . . . . . . . . . . . . . 25

Configure Your Diagnostic Input Module . . . . . . . . . . . . . . . . . . . . . . 26

Input Filter Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Chapter 3

About the FLEX I/O Diagnostic

Output Module

iii Publication 1794-UM065B-EN-E - July 2006

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

About the 1794-OB16D Diagnostic Output Module . . . . . . . . . . . . . 27

Wiring Output Loads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Diagnostic Fault Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Module Protection Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Output Fault & Idle States With Network Communication Failure .

31

Indicator Status Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Module Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Unused Output Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Configure Your Output Diagnostic Module. . . . . . . . . . . . . . . . . . . . . 32

Page 4

Table of Contents iv

Configuring Modules for

Communication on a Remote I/O

Network

Configure FLEX I/O Digital

Modules on a DeviceNet Network

Chapter 4

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Add a 1756-DHRIO Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Add a 1794 Remote Adapter Module . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Configure Digital Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Create a Block Transfer (Read or Write) Message Instruction . . . . . . 42

Ladder Logic Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Chapter 5

How to Use This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Add the Scanner to the I/O Configuration of the Controller Using

RSLogix 5000 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

If You Need to Conserve EtherNet/IP or ControlNet Network

Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Add the Scanner to the I/O Configuration Folder . . . . . . . . . . . . 50

Define the Properties of the Scanner . . . . . . . . . . . . . . . . . . . . . . . 51

Determine the Address of DeviceNet Data . . . . . . . . . . . . . . . . . . . . . 52

Tally Memory Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

If You Configure the Adapter Offline . . . . . . . . . . . . . . . . . . . . . . . . . 55

Set the Address of the Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Configure Your Adapter and

Digital Modules on a ControlNet

Network

Configure your Digital Module on

an EtherNet/IP Network

Chapter 6

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Set Up the Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Setting a Requested Packet Interval (RPI) . . . . . . . . . . . . . . . . . . . . . . 58

Select a Communication Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Direct or rack-optimized connection . . . . . . . . . . . . . . . . . . . . . . . 61

Ownership . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Add Local and Remote ControlNet Modules. . . . . . . . . . . . . . . . . . . . 65

Add Distributed I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Download the Program to the Controller. . . . . . . . . . . . . . . . . . . . . . . 68

Configure the 1794-ACN15 Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Schedule I/O Module Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Access Module Data via the 1794-ACN15 Adapter. . . . . . . . . . . . . . . 75

Slot Status Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Change Configuration Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Chapter 7

How to Use This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Set Up the Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Select a Requested Packet Interval (RPI) . . . . . . . . . . . . . . . . . . . . . . . 82

Select a Communication Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Choose Direct or Rack-optimized Connection . . . . . . . . . . . . . . . 84

Ownership . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Select a Remote Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Page 5

Interpret the Indicators

Table of Contents v

Add Distributed I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Add a Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Download the Program to the Controller. . . . . . . . . . . . . . . . . . . . . . . 89

Access Distributed I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

General Information About IP Addresses . . . . . . . . . . . . . . . . . . . . . . 93

Determining Required Network Parameters . . . . . . . . . . . . . . . . . 93

Assigning Network Parameters via the BOOTP/DHCP Utility. . . . . 94

Using RSLinx software to set the IP address . . . . . . . . . . . . . . . . . 98

Using RSLogix 5000 software to set the IP address . . . . . . . . . . . 99

Using DHCP software to set the IP address . . . . . . . . . . . . . . . . 100

Duplicate IP Address Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Duplicate detection scenarios . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

IP Address Swapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Appendix A

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

About the Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

1794-IB16D Diagnostic Functional Details . . . . . . . . . . . . . . . . . . . . 104

Diagnostic Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Diagnostic Functions for the 1794-IB16D. . . . . . . . . . . . . . . . . . 105

1794-OB16D Diagnostic Functional Details . . . . . . . . . . . . . . . . . . . 107

Diagnostic Functions for the 1794-OB16D. . . . . . . . . . . . . . . . . 108

Simplified Schematics of FLEX I/O

Digital Modules

Appendix B

Find Your Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

1794-IA8 120V AC 8 Input Module. . . . . . . . . . . . . . . . . . . . . . . 110

1794-IA8I 120V AC 8 Input Module . . . . . . . . . . . . . . . . . . . . . . 110

1794-IA16 120V AC 16 Input Module. . . . . . . . . . . . . . . . . . . . . 111

1794-OA8 120V AC 8 Output Module . . . . . . . . . . . . . . . . . . . . 111

1794-OA8I 120V AC 8 Output Module . . . . . . . . . . . . . . . . . . . 112

1794-OA16 120V AC 16 Output Module. . . . . . . . . . . . . . . . . . 112

1794-IM 8 220V AC 8 Input Module . . . . . . . . . . . . . . . . . . . . . . 113

1794-OM8 220V AC 8 Output Module . . . . . . . . . . . . . . . . . . . . 113

1794-IB8 24V DC 8 Input Module. . . . . . . . . . . . . . . . . . . . . . . . 114

1794-IB16 24V DC 16 Input Module. . . . . . . . . . . . . . . . . . . . . . 114

1794-IB16D 24V DC 16 Diagnostic Input Module. . . . . . . . . . . 115

1794-IB32 24V DC 32 Input Module. . . . . . . . . . . . . . . . . . . . . . 116

1794-IB10XOB6 24V DC 8 10 Input/6 2A Output Module . . . 117

1794-IB16XOB16P 24V DC 16 Input/16 Output Module . . . . 118

1794-IV16 24V DC 16 Source Input Module . . . . . . . . . . . . . . . 119

1794-OB8 24V DC 8 Output Module . . . . . . . . . . . . . . . . . . . . . 119

1794-OB8EP 24V DC Electronically Protected 8 Output Module .

120

1794-OB16 24V DC 16 Output Module . . . . . . . . . . . . . . . . . . . 120

1794-OB16D 24V DC 16 Diagnostic Output Module . . . . . . . . 121

Publication 1794-UM065B-EN-E - July 2006

Page 6

Table of Contents vi

Index

1794-OB16P 24V DC 16 Output Module . . . . . . . . . . . . . . . . . . 121

1794-OB32P 24V DC 32 Output Module . . . . . . . . . . . . . . . . . . 122

1794-OV16 24V DC 16 Sink Output Module . . . . . . . . . . . . . . . 123

1794-OV16P 24V DC 16 Sink Output Module. . . . . . . . . . . . . . 123

1794-IC 48V DC 16 Input Module. . . . . . . . . . . . . . . . . . . . . . . . 124

1794-OC 48V DC 16 Output Module . . . . . . . . . . . . . . . . . . . . . 124

1794-OW8 Relay Output Module. . . . . . . . . . . . . . . . . . . . . . . . . 124

Publication 1794-UM065B-EN-E - July 2006

Page 7

Preface

ATTENTION

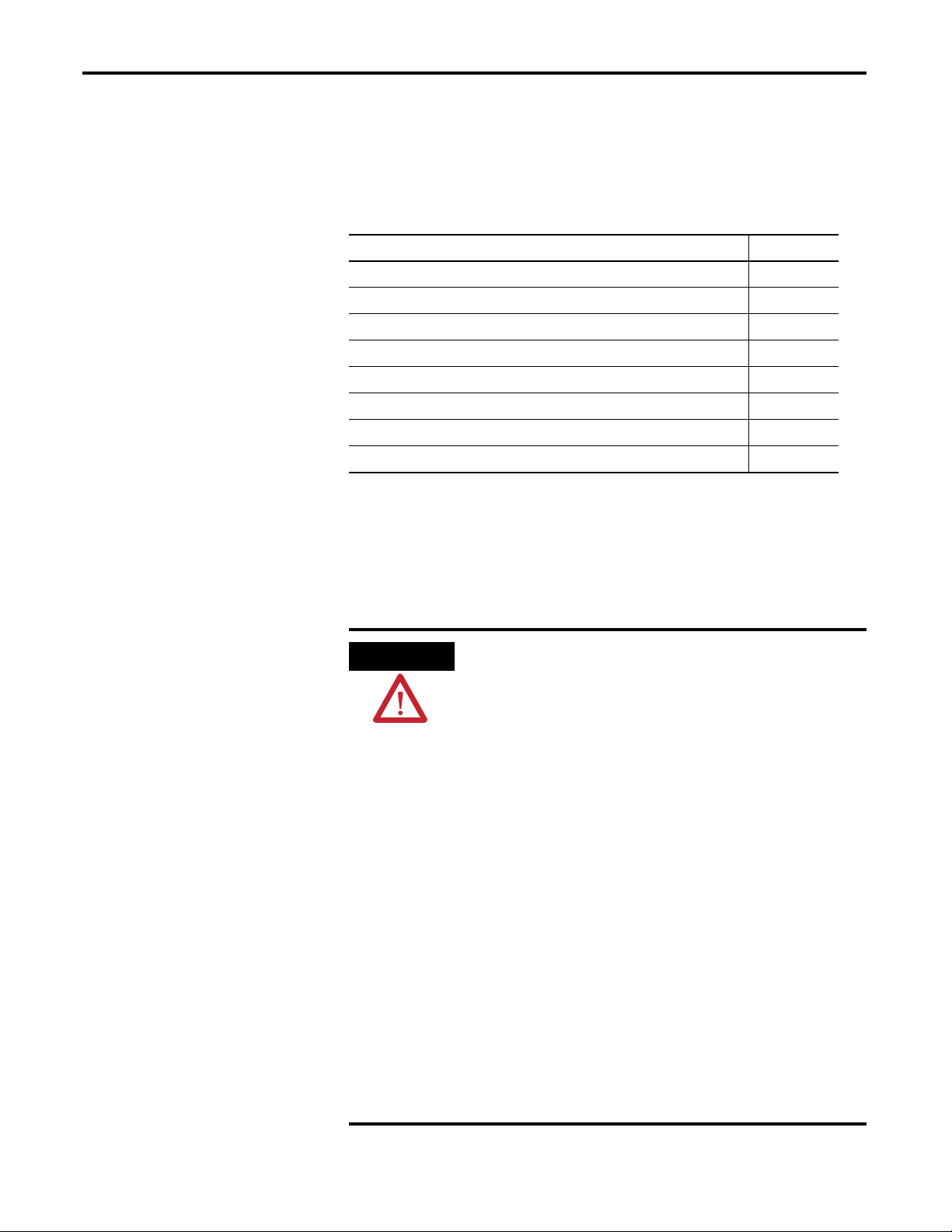

Purpose of This Manual

Important Warnings and Cautions

This manual provides information on installation, setting, and reading your

diagnostics on the 1794-IB16D and the 1794-OB16D Diagnostic modules.

For information on See Chapter

1794 Diagnostic Modules 1

Specific Diagnostic Module 2 or 3

Using Diagnostic Modules in a Remote I/O System 4

Using Diagnostic Modules in a DeviceNet System 5

Using Diagnostic Modules in a ControlNet System 6

Using Diagnostic Modules in an EtherNet /IP System 7

Using the Indicators for Troubleshooting Appendix A

Simplified Schematics for all 1794 Digital Modules Appendix B

Obey the following warnings and cautions when installing or using these

modules.

Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2 industrial

environment, in overvoltage Category II applications (as defined in IEC

publication 60664-1), at altitudes up to 2000 meters without derating.

This equipment is considered Group 1, Class A industrial equipment

according to IEC/CISPR Publication 11. Without appropriate

precautions, there may be potential difficulties ensuring

electromagnetic compatibility in other environments due to conducted

as well as radiated disturbance.

This equipment is supplied as open-type equipment. It must be

mounted within an enclosure that is suitably designed for those

specific environmental conditions that will be present and

appropriately designed to prevent personal injury resulting from

accessibility to live parts. The interior of the enclosure must be

accessible only by the use of a tool. Subsequent sections of this

publication may contain additional information regarding specific

enclosure type ratings that are required to comply with certain

product safety certifications.

See NEMA Standards publication 250 and IEC publication 60529, as

applicable, for explanations of the degrees of protection provided by

different types of enclosure. Also, see the appropriate sections in this

publication, as well as Industrial Automation Wiring and Grounding

Guidelines, Allen-Bradley publication 1770-4.1, for additional

installation requirements pertaining to this equipment.

5 Publication 1794-UM065B-EN-E - July 2006

Page 8

6 Preface

WARNING

ATTENTION

ATTENTION

ATTENTION

When you insert or remove the module while backplane power is on,

an electrical arc can occur. This could cause an explosion in

hazardous location installations. Be sure that power is removed or the

area is nonhazardous before proceeding.

FLEX I/O is grounded through the DIN rail to chassis ground. Use zinc

plated yellow-chromate steel DIN rail to assure proper grounding. The

use of other DIN rail materials (such as aluminum or plastic) that can

corrode, oxidize, or are poor conductors, can result in improper or

intermittent grounding.

Prevent Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which can

cause internal damage and affect normal operation. Follow these

guidelines when you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• If available, use a static-safe workstation.

During mounting of all devices, be sure that all debris (such as metal

chips or wire strands) is kept from falling into the module. Debris that

falls into the module could cause damage on power up.

Publication 1794-UM065B-EN-E - July 2006

Page 9

Preface 7

WARNING

AVERTISSEMENT

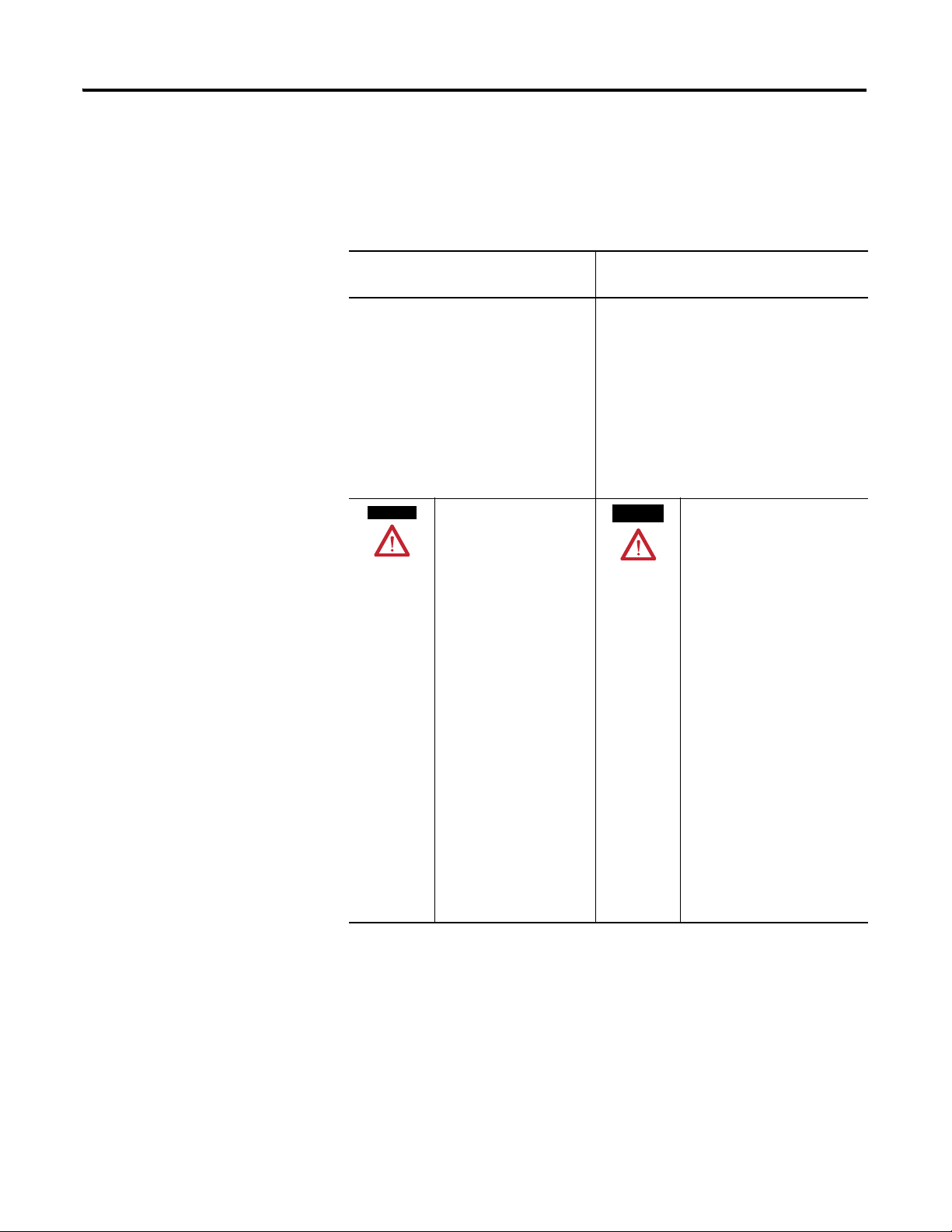

North American Hazardous Location Approval

The 1794-IB16D and 1794-OB16D diagnostic modules are North American

Hazardous Location approved.

The following information applies when

operating this equipment in hazardous

locations:

Products marked “CL I, DIV 2, GP A, B, C, D”

are suitable for use in Class I Division 2

Groups A, B, C, D, Hazardous Locations and

nonhazardous locations only. Each product is

supplied with markings on the rating

nameplate indicating the hazardous location

temperature code. When combining products

within a system, the most adverse

temperature code (lowest “T” number) may be

used to help determine the overall

temperature code of the system. Combinations

of equipment in your system are subject to

investigation by the local Authority Having

Jurisdiction at the time of installation.

EXPLOSION HAZARD

•Do not disconnect

equipment unless power

has been removed or the

area is known to be

nonhazardous.

•Do not disconnect

connections to this

equipment unless power

has been removed or the

area is known to be

nonhazardous. Secure any

external connections that

mate to this equipment by

using screws, sliding

latches, threaded

connectors, or other means

provided with this product.

•Substitution of

components may impair

suitability for Class I,

Division 2.

•If this product contains

batteries, they must only be

changed in an area known

to be nonhazardous.

Informations sur l’utilisation de cet

équipement en environnements dangereux :

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne

conviennent qu’à une utilisation en environnements

de Classe I Division 2 Groupes A, B, C, D dangereux

et non dangereux. Chaque produit est livré avec des

marquages sur sa plaque d’identification qui

indiquent le code de température pour les

environnements dangereux. Lorsque plusieurs

produits sont combinés dans un système, le code

de température le plus défavorable (code de

température le plus faible) peut être utilisé pour

déterminer le code de température global du

système. Les combinaisons d’équipements dans le

système sont sujettes à inspection par les autorités

locales qualifiées au moment de l’installation.

RISQUE D’EXPLOSION

•Couper le courant ou s’assurer

que l’environnement est classé

non dangereux avant de

débrancher l'équipement.

•Couper le courant ou s'assurer

que l’environnement est classé

non dangereux avant de

débrancher les connecteurs. Fixer

tous les connecteurs externes

reliés à cet équipement à l'aide

de vis, loquets coulissants,

connecteurs filetés ou autres

moyens fournis avec ce produit.

•La substitution de composants

peut rendre cet équipement

inadapté à une utilisation en

environnement de Classe I,

Division 2.

•S’assurer que l’environnement

est classé non dangereux avant

de changer les piles.

Publication 1794-UM065B-EN-E - July 2006

Page 10

8 Preface

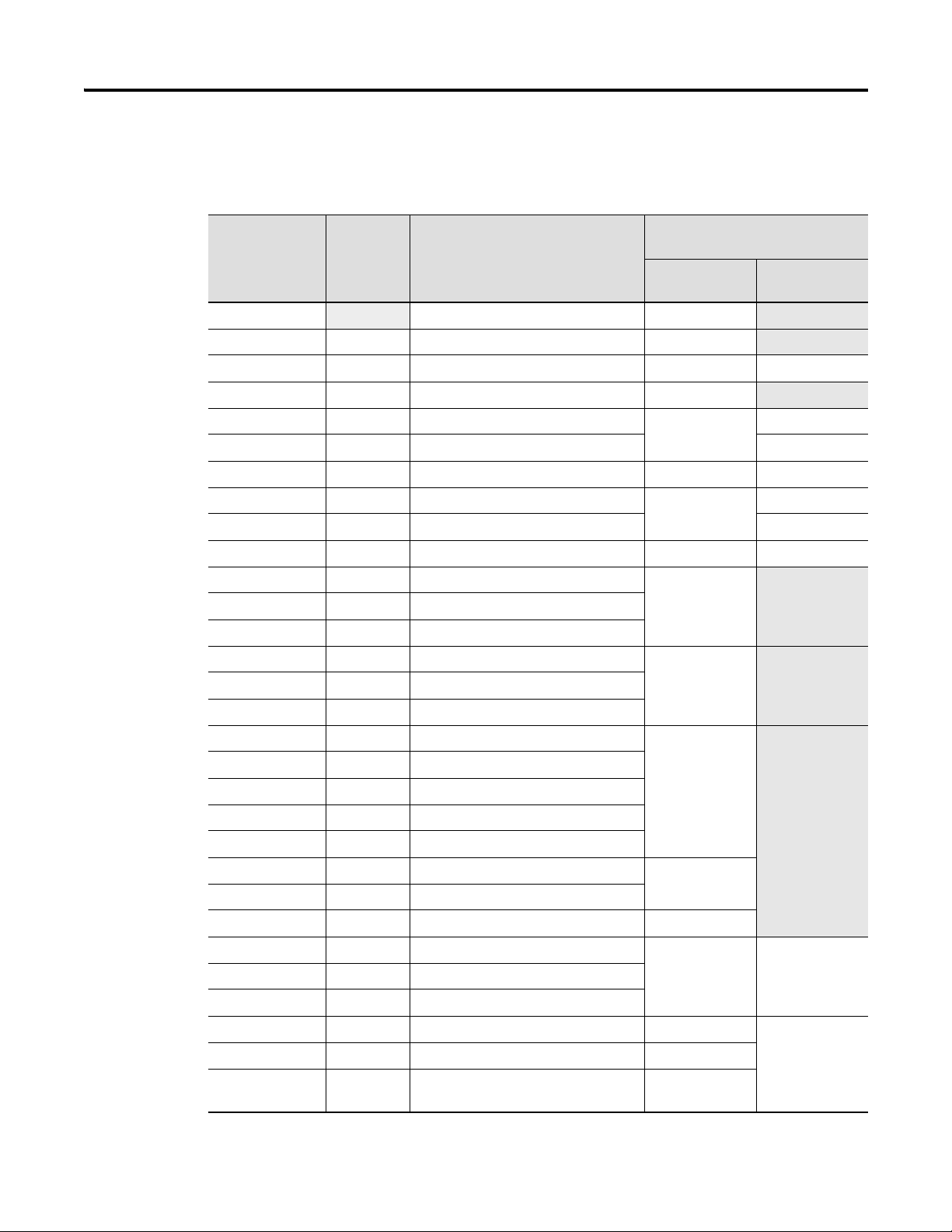

Related Products and Documentation

Catalog

Number

1794

1794–ACN 24V dc ControlNet Adapter 1794–IN101

1794-AENT EtherNet/IP Adapter 1794-IN082 ENET-UM001

1794–ACNR 24V dc Redundant Media ControlNet Adapter 1794–IN101

1794–ACN15 24V dc ControlNet Adapter 1794-IN101 CNET-UM001

1794–ACNR15 24V dc Redundant Media ControlNet Adapter CNET-UM001

1794–ADN 24V dc DeviceNet Adapter 1794-IN099 1794–6.5.5

1794–ASB/E 24V dc Remote I/O Adapter 1794–IN098 1794–UM009

1794–ASB2/D 24V dc 2–Slot Remote I/O Adapter 1794–UM059

1794–APB 24V dc Profibus Adapter 1794-IN087 1794–UM057

1794–IB8 24V dc 8 Sink Input Module 1794-IN093

1794–IB16 24V dc 16 Sink Input Module

1794–IB32 24V dc 32 Sink Input Module

For additional information on FLEX I/O systems and modules, refer to the

following documents:

Voltage Description Publications

Installation

Instructions

1794 FLEX I/O Selection Guide 1794–SG002

User Manual

1794–IV16 24V dc 16 Source Input Module 1794-IN095

1794–OV16 24V dc 16 Sink Output Module

1794–OV16P 24V dc 16 Protected Sink Output Module

1794–OB8 24V dc 8 Source Output Module 1794-IN094

1794–OB8EP 24V dc 8 Electronically Fused Output Module

1794–OB16 24V dc 16 Source Output Module

1794–OB16P 24V dc 16 Protected Source Output Module

1794–OB32P 24V dc 32 Protected Source Output Module

1794–IB10XOB6 24V dc 10 Input/6 Output Module 1794-IN083

1794–IB16XOB16P 24V dc 16 Input/16 Output Module

1794–OW8 24V dc 8 Relay Output Module 1794-IN019

1794–IE8 24V dc Analog 8 Input Module 1794-IN100 1794–6.5.2

1794–OE4 24V dc Analog 4 Output Module

1794–IE4XOE2 24V dc 4 Input/2 Output Analog Module

1794–OF4I 24V dc 4 Output Isolated Analog Module 1794-IN037 1794–6.5.8

1794–IF4I 24V dc 4 Input Isolated Analog Module 1794-IN038

1794–IF2XOF2I 24V dc 2 Input/2 Output Isolated Analog

Module

1794-IN039

Publication 1794-UM065B-EN-E - July 2006

Page 11

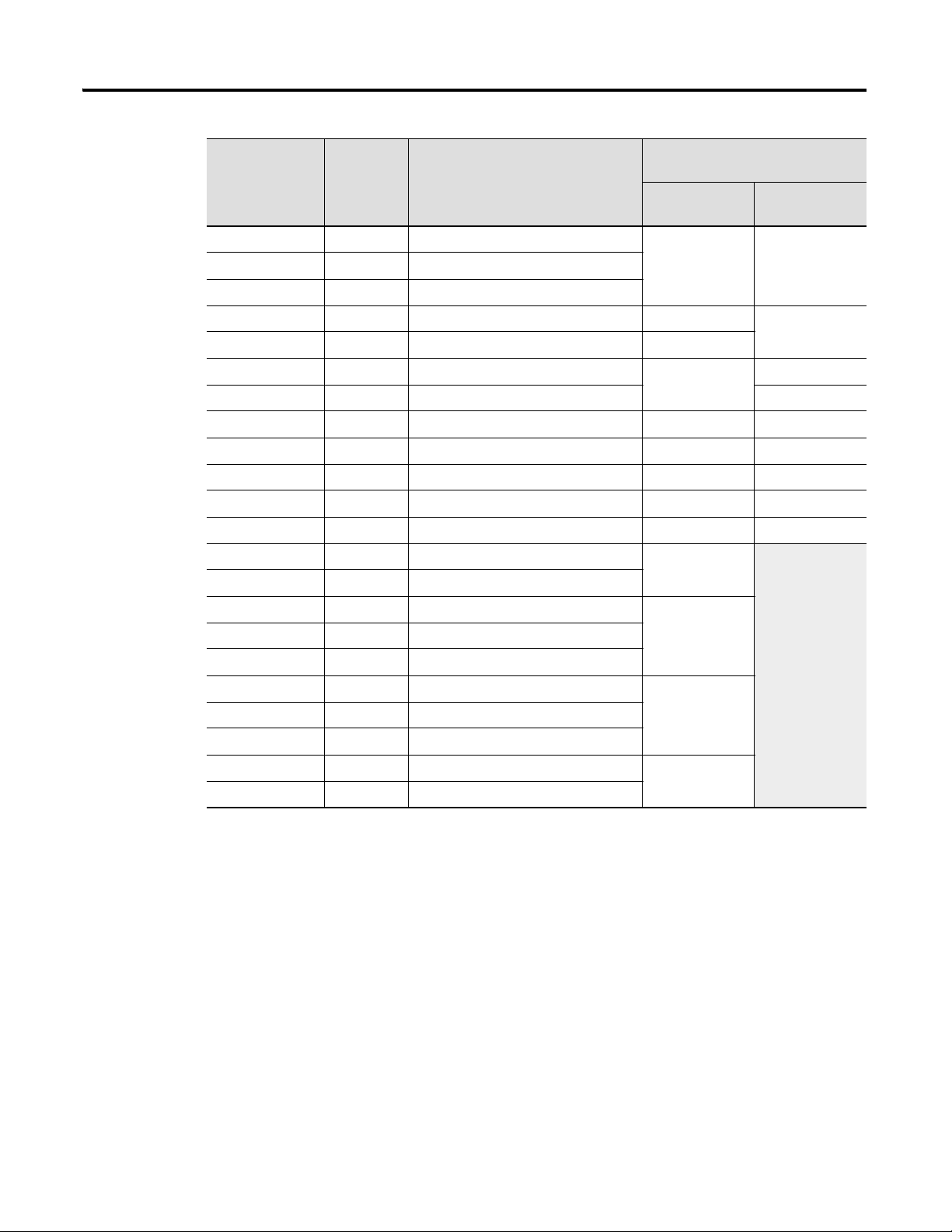

Preface 9

Catalog

Voltage Description Publications

Number

Installation

User Manual

Instructions

1794-IE12 24V dc 12 Input Analog Module 1794-IN106

1794-OE12 24V dc 12 Output Analog Module

1794-IE8XOE4 24V dc 8 Input/4 Output Analog Module

1794-IE8H 24V dc 8 HART Input Module 1794-IN108 1794-UM063

1794-OE8H 24V dc 8 HART Output Module 1794-IN109

1794–IR8 24V dc 8 RTD Input Analog Module 1794-IN021 1794–6.5.4

1794–IT8 24V dc 8 Thermocouple Input Module 1794–6.5.7

1794–IRT8 24V dc 8 Thermocouple/RTD Input Module 1794-IN050 1794–6.5.12

1794–IJ2 24V dc 2 Channel Frequency Input Module 1794-IN049 1794–6.5.11

1794–ID2 24V dc 2 Channel Frequency Input Module 1794-IN063 1794–6.5.15

1794–IP4 24V dc 2 Channel Pulse Counter Module 1794-IN064 1794–6.5.16

1794–VHSC 24V dc Very High Speed Counter Module 1794IN067 1794–6.5.10

1794–IC16 48V dc 16 Sink Input Module 1794-IN105

1794–OC16 48V dc 16 Source Output Module

1794–IA8 120V ac 8 Input Module 1794-IN102

1794–IA8I 120V ac Isolated 8 Input Module

1794–IA16 120V ac 16 Input Module

1794–OA8 120V ac 8 Output Module 1794-IN103

1794–OA8I 120V ac Isolated 8 Output Module

1794–OA16 120V ac 16 Output Module

1794–IM8 220V ac 8 Input Module 1794-IN104

1794–OM8 220V ac 8 Output Module

Publication 1794-UM065B-EN-E - July 2006

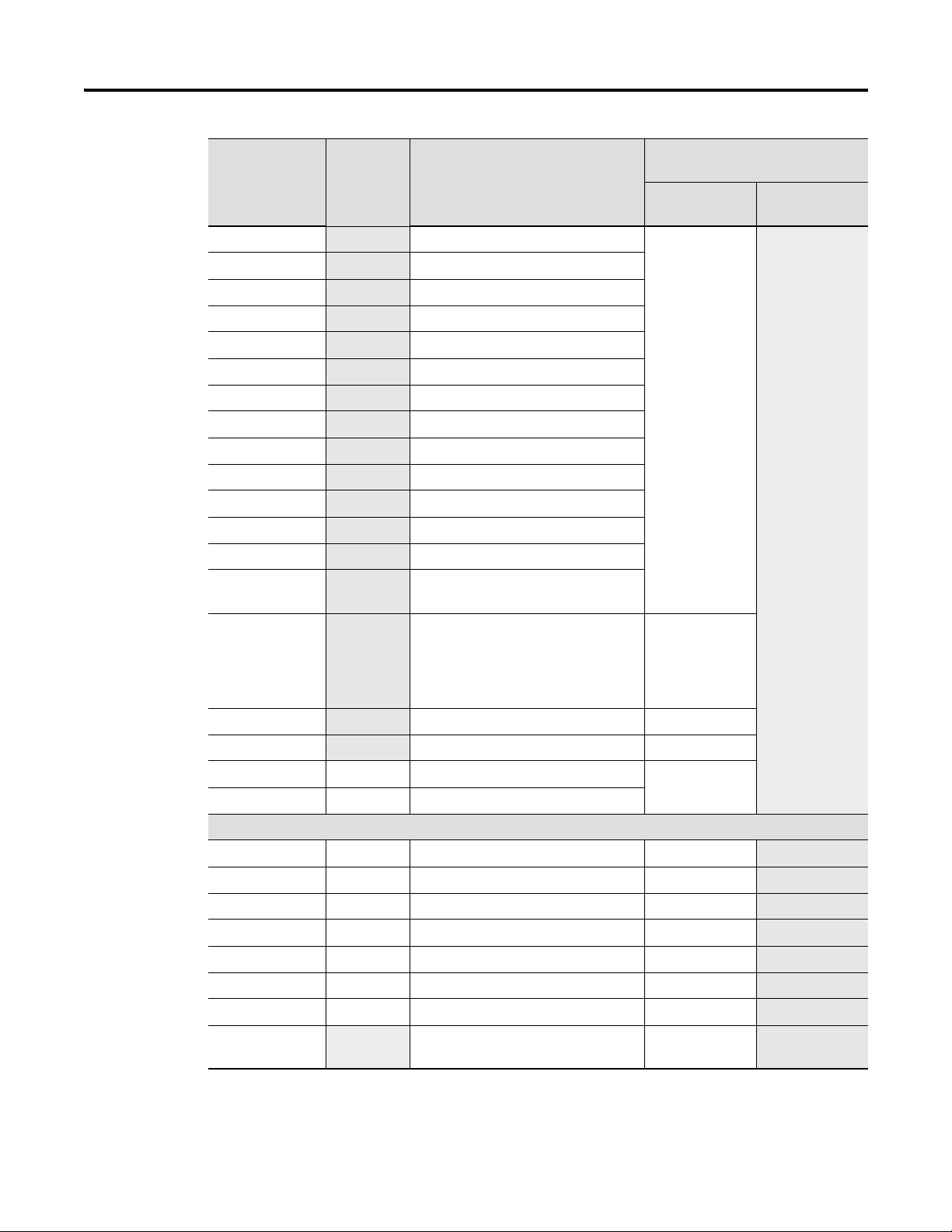

Page 12

10 Preface

Catalog

Voltage Description Publications

Number

Installation

Instructions

1794–TB2 Cage Clamp Terminal Base 1794-IN092

1794–TB3 Cage Clamp Terminal Base

1794–TB3S

1794–TB3T

1794–TB3TS

1794–TB3G

1794–TB3GS

1794–TB32

1794–TB32S

1794–TBN

1794–TBNF,

, 1794-TB3GK

1794-TB3K

1794-TBNFK

Spring Clamp Terminal Base Unit

Temperature Terminal Base Unit

Spring Clamp Temperature Base Unit

Terminal Base Unit

Spring Clamp Terminal Base Unit

Cage Clamp Terminal Base Unit

Spring Clamp Terminal Base Unit

Terminal Base Unit

Fused Terminal Base Unit

Conformally Coated Terminal Base Unit

Conformally Coated Terminal Base Unit

Conformally Coated Fused Terminal

Base Unit

User Manual

1794-TB37DS,

-TB62DS,

D-Shell Terminal Base Units and

Distribution Boards

1794-IN107

TB37EXD4VM8,

-TB37EXD4CM8,

-TB62EXD4X15

1794–CE1, –CE3

1794–NM1

Extender Cables 1794–5.12

Mounting Kit 1794–5.13

1794–PS13 24V dc Power Supply 1794-IN069

1794–PS3 24V dc Power Supply

FLEX Ex

1797–IBN16 See note 16 NAMUR Digital Input Module 1797-5.7

1797–OB4D See note 4 NI, Ex Source Digital Output Module 1797-5.6

1797–IE8, -IE8H See note 8 Input Module 1797-5.5

1797–IE8NF See note 8 Selectable Filter Analog Input Module 1797-5.31

1797–OE8, -OE8H See note Analog 8 Output Module 1797-5.3

1797–IRT8 See note 8 Thermocouple/RTD Input Module 1797-5.4

1797–IJ2 See note 2 Channel Frequency Input Module 1797-5.9

1797–TB3

1797–TB3S

Cage Clamp Terminal Base

Spring Clamp Terminal Base

1797-5.1

1797-5.2

Publication 1794-UM065B-EN-E - July 2006

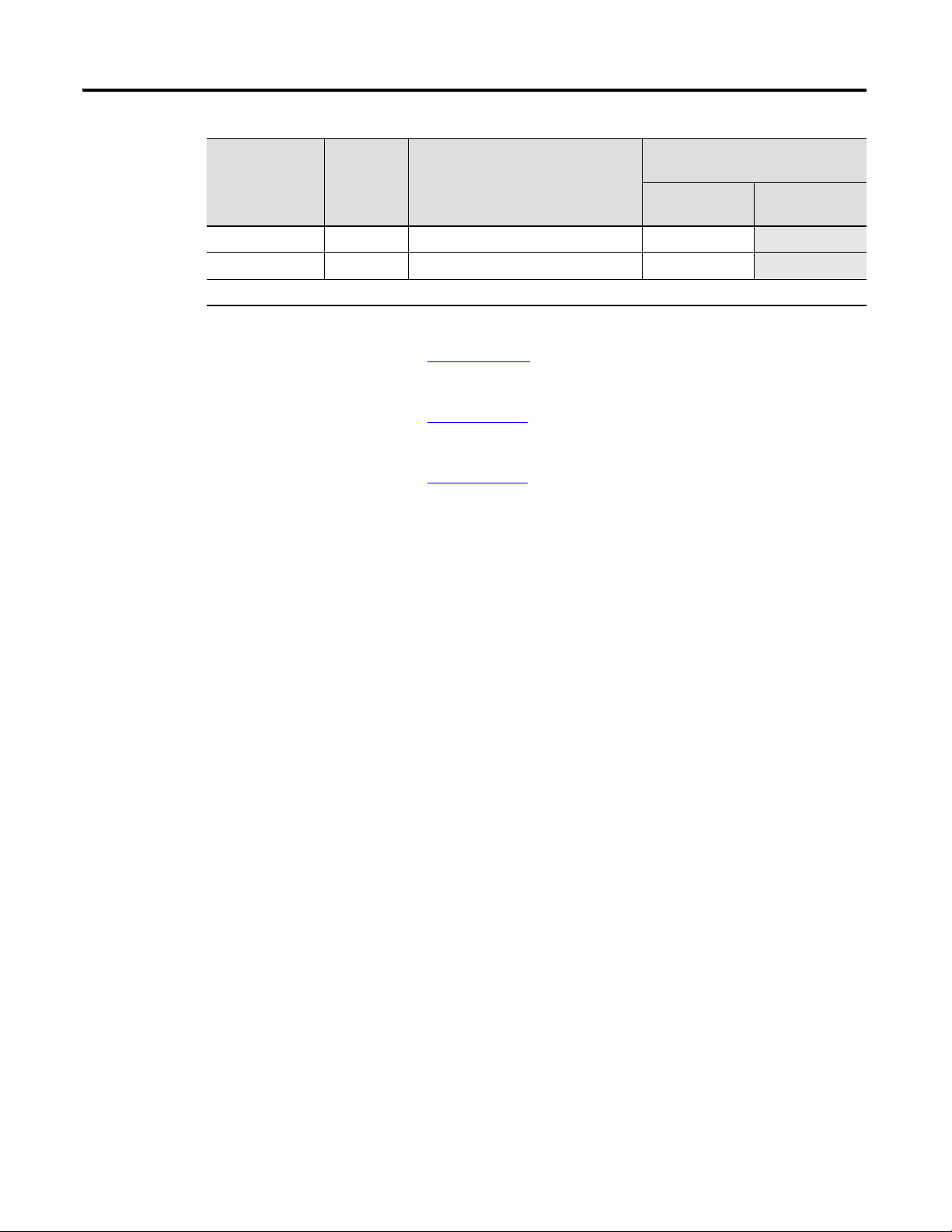

Page 13

Preface 11

Catalog

Number

1797–BIC See note I.S. Bus Isolator 1797-5.13

1797–CEC See note FLEX Ex Bus Connector 1797-5.13

Note: Intrinsically Safe Voltage

Voltage Description Publications

Installation

Instructions

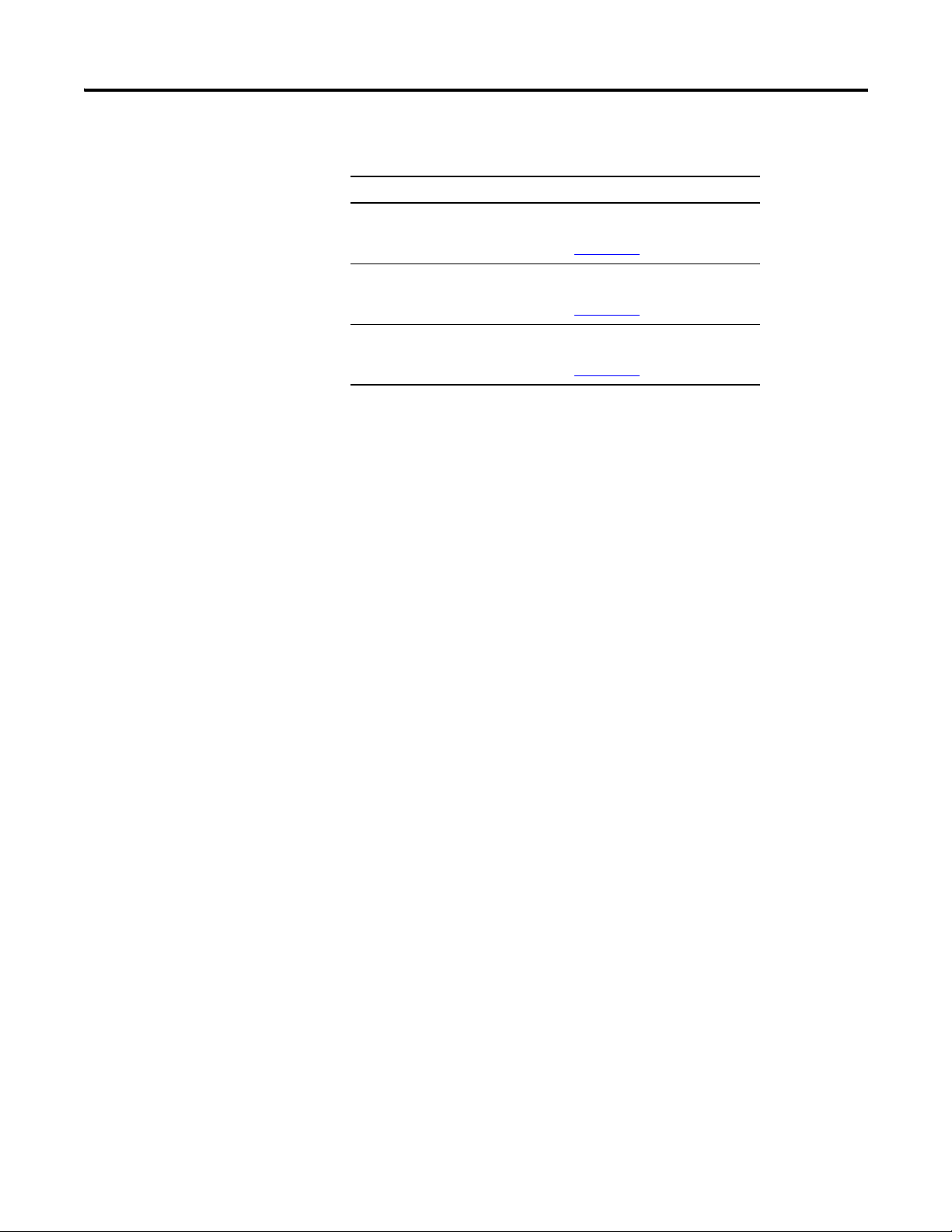

For more information on DeviceNet modules in Logix5000 systems, see

publication DNET-UM004

, DeviceNet Modules in Logix5000 Systems.

For more information on ControlNet modules in Logix5000 systems, see

publication CNET-UM001

, ControlNet Modules in Logix5000 Systems.

For more information on EtherNet/IP modules in Logix5000 systems, see

publication ENET-UM001

, EtherNet/IP Modules in Logix5000 Systems.

User Manual

Publication 1794-UM065B-EN-E - July 2006

Page 14

12 Preface

Notes:

Publication 1794-UM065B-EN-E - July 2006

Page 15

Chapter

1

1794 FLEX I/O Diagnostic Digital Modules

Overview

Introduction

General Description

In this chapter, you will learn about the diagnostic input module, cat. no.

1794-IB16D, and the diagnostic output module, cat. no. 1794-OB16D.

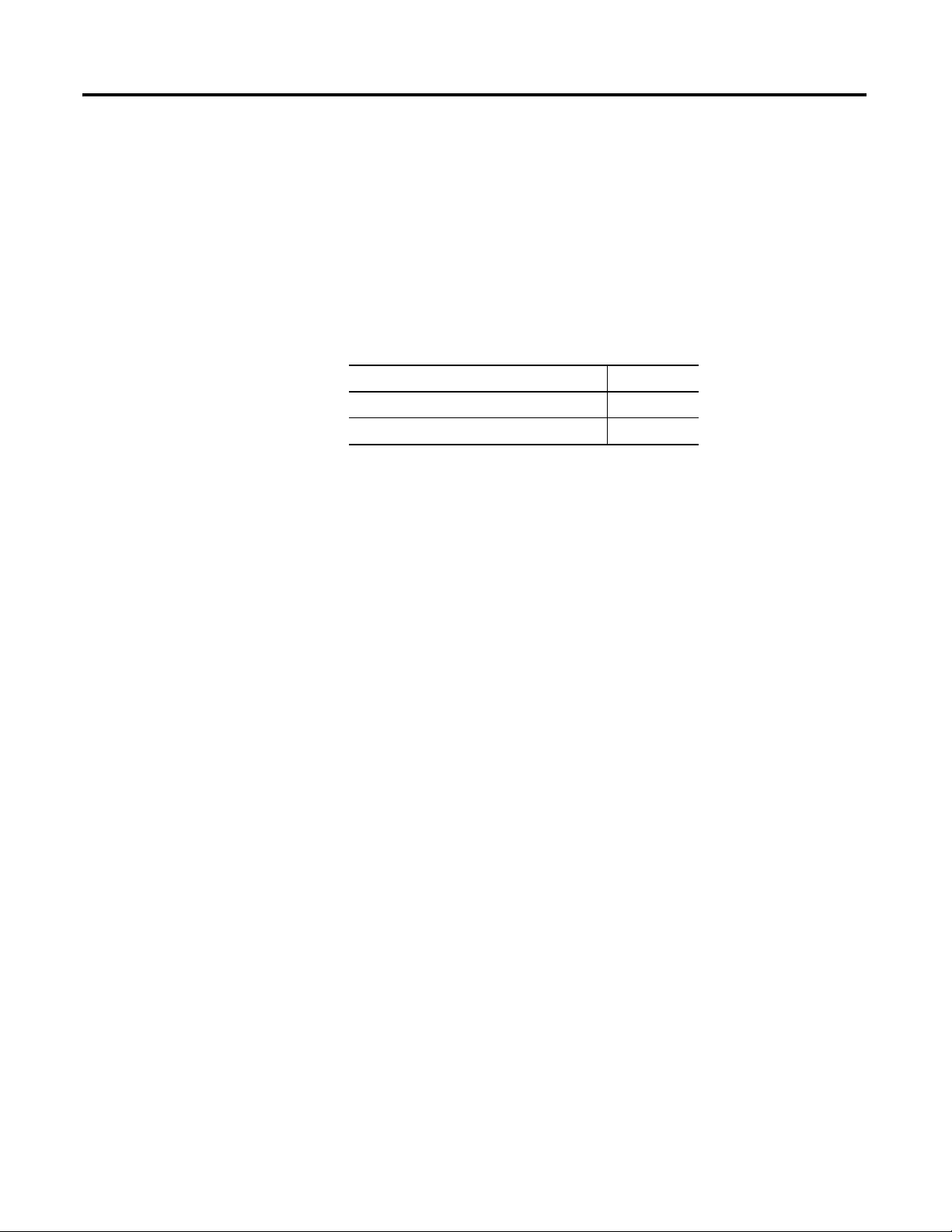

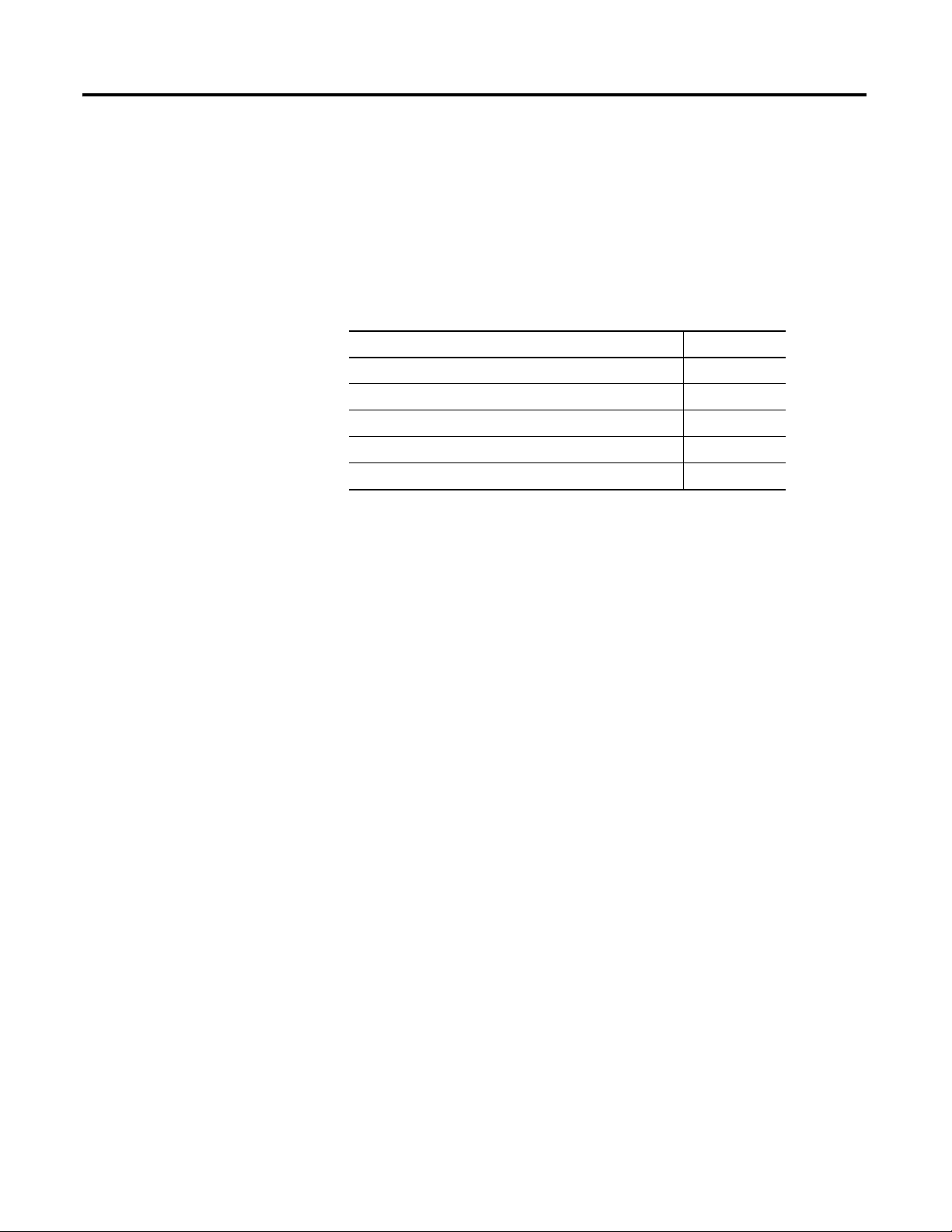

Topic See Page

General Description 13

Install Your Digital Input or Output Module 16

This chapter contains an overview of the FLEX I/O diagnostic digital

modules, the 1794-IB16D input module and 1794-OB16D output module.

You can use the FLEX I/O diagnostic modules to help diagnose problems

with input and output field devices, I/O wiring and the user power supply.

Additionally, these modules can reduce installation start-up time and help

minimize time to find and fix failures.

This chapter explains how to use the FLEX I/O diagnostic modules to help

detect the following types of faults:

• Open input or output field devices

• Open input or output wiring

• Shorted output field devices

• Shorted input or output wiring

• Reversed polarity of user supply wiring

• Open user supply wiring or failed user supply (using one diagnostic

input channel)

13 Publication 1794-UM061A-EN-P - July 2006

Page 16

14 1794 FLEX I/O Diagnostic Digital Modules Overview

Network Compatibility

You can use the diagnostic modules with ControlNet, DeviceNet,

EtherNet/IP, or remote I/O networks.

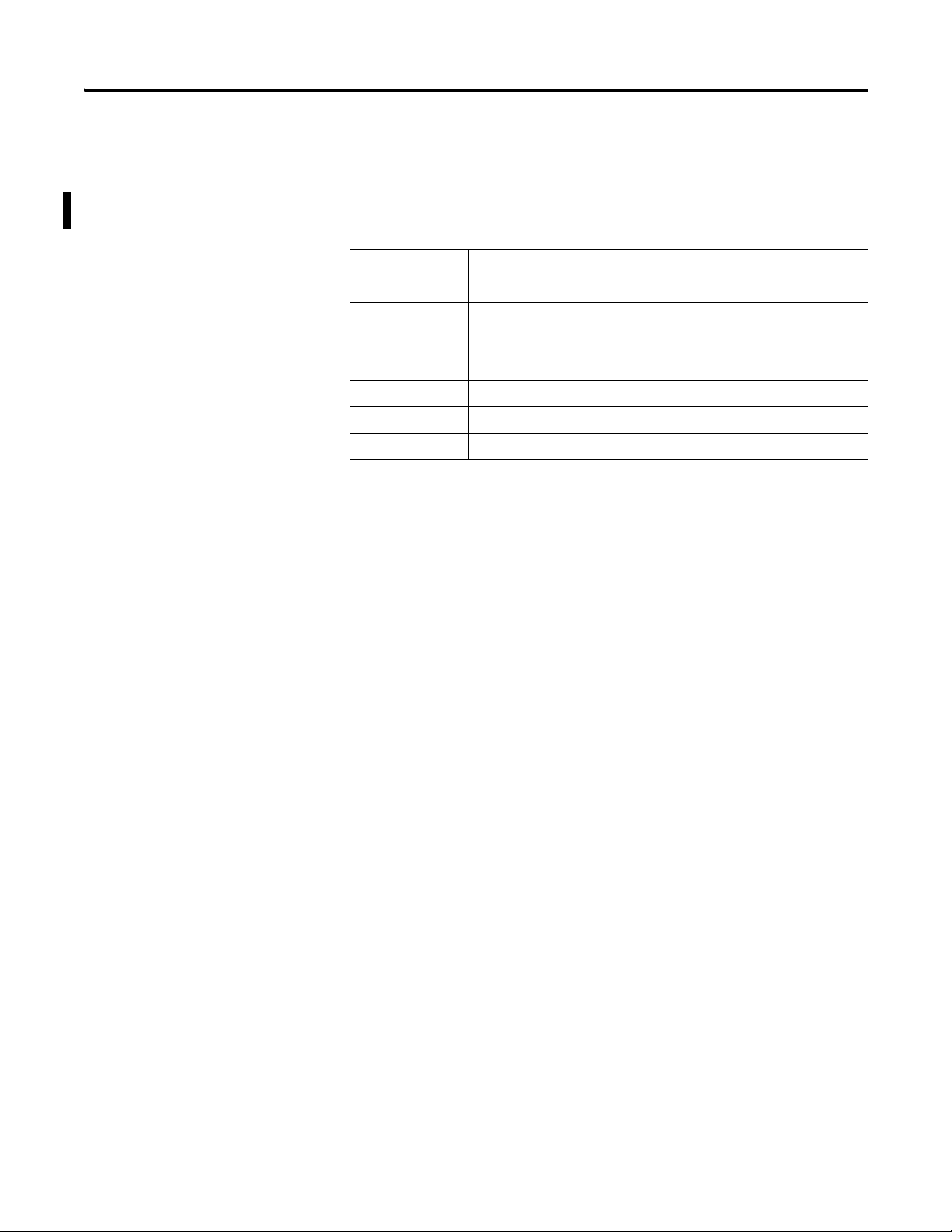

Network 1794-IB16D 1794-OB16D

Remote I/O Compatible with 1794-ASB

DeviceNet No limitations or constraints.

ControlNet Direct connection only. Direct or rack connections.

EtherNet/IP Direct connection only. Direct or rack connections.

Usage Limitations

series E (or higher) and

1794-ASB2 series D (or higher)

remote I/O adapters.

Compatible with 1794-ASB

series D (or higher) and

1794-ASB2 series C (or higher)

remote I/O adapters.

1794-IB16D Diagnostic Input Module Compatibility

The 1794-IB16D diagnostic input module interfaces to sensing devices and

detects whether they are on or off. The diagnostic input module converts dc

signals from user devices to the appropriate logic level for use in the

FLEX I/O system. Typical input devices include these types of switches.

• Proximity switches

• Limit switches

• Photoelectric switches

• Selector switches

•Float switches

• Pushbutton switches

When designing a system using a FLEX I/O diagnostic input module, you

must consider:

• the voltage necessary for your application.

• current leakage through the input devices.

• the amount of current consumed by the input devices.

• whether the application requires sinking or sourcing devices.

Publication 1794-UM061A-EN-P - July 2006

Page 17

1794 FLEX I/O Diagnostic Digital Modules Overview 15

Capabilities of the 1794-IB16D include:

• 61131-2 Type 3 compatible sinking inputs.

• interface with PNP sourcing sensors.

• 10-31.2V dc operating range.

• provides up to 50 mA to power an attached sensor.

• detects for an open wire condition down to 50 μA.

You need a dummy resistor to mask the channel diagnostic function for each

unused sensor port. Used sensor ports must have a 50 μA minimum current

draw with the input field device in both the on- and off-state.

1794-OB16D Diagnostic Output Module Compatibility

You can use FLEX I/O diagnostic output modules to drive a variety of output

devices. Typical output devices include the following.

•Relays

• Solenoids

• Contactors

• Indicators

• Small motor starters

When you design a system using FLEX I/O diagnostic output modules, you

must consider:

• The output must supply the necessary surge and continuous current for

the output device being used.

• When sizing output loads, check the documentation supplied with the

output device for the surge and continuous current needed to operate

the device.

Capabilities of the 1794-OB16D diagnostic output module include:

• sourcing style outputs for loads connected to common.

• 10-31.2V dc operating range.

• provides continuous current of 0.5 A maximum (8 A per module),

2.0 mA minimum per output.

• capable of 2 A surge for 50 ms, repeatable every 2 s.

• protection from short circuit and overload.

You need a dummy resistor to mask the channel diagnostic function for each

unused output channel.

Publication 1794-UM061A-EN-P - July 2006

Page 18

16 1794 FLEX I/O Diagnostic Digital Modules Overview

Install Your Digital Input or Output Module

To install a digital diagnostic module, follow these steps:

✓ Installation Step

❑ 1. Mount the terminal base unit

See installation instructions 1794-IN096

❑ 2. Install the module in the terminal base unit

See installation instructions 1794-IN096

❑ 3. Connect the wiring to the terminal base unit

See installation instructions 1794-IN096

.

.

.

Publication 1794-UM061A-EN-P - July 2006

Page 19

1794 FLEX I/O Diagnostic Digital Modules Overview 17

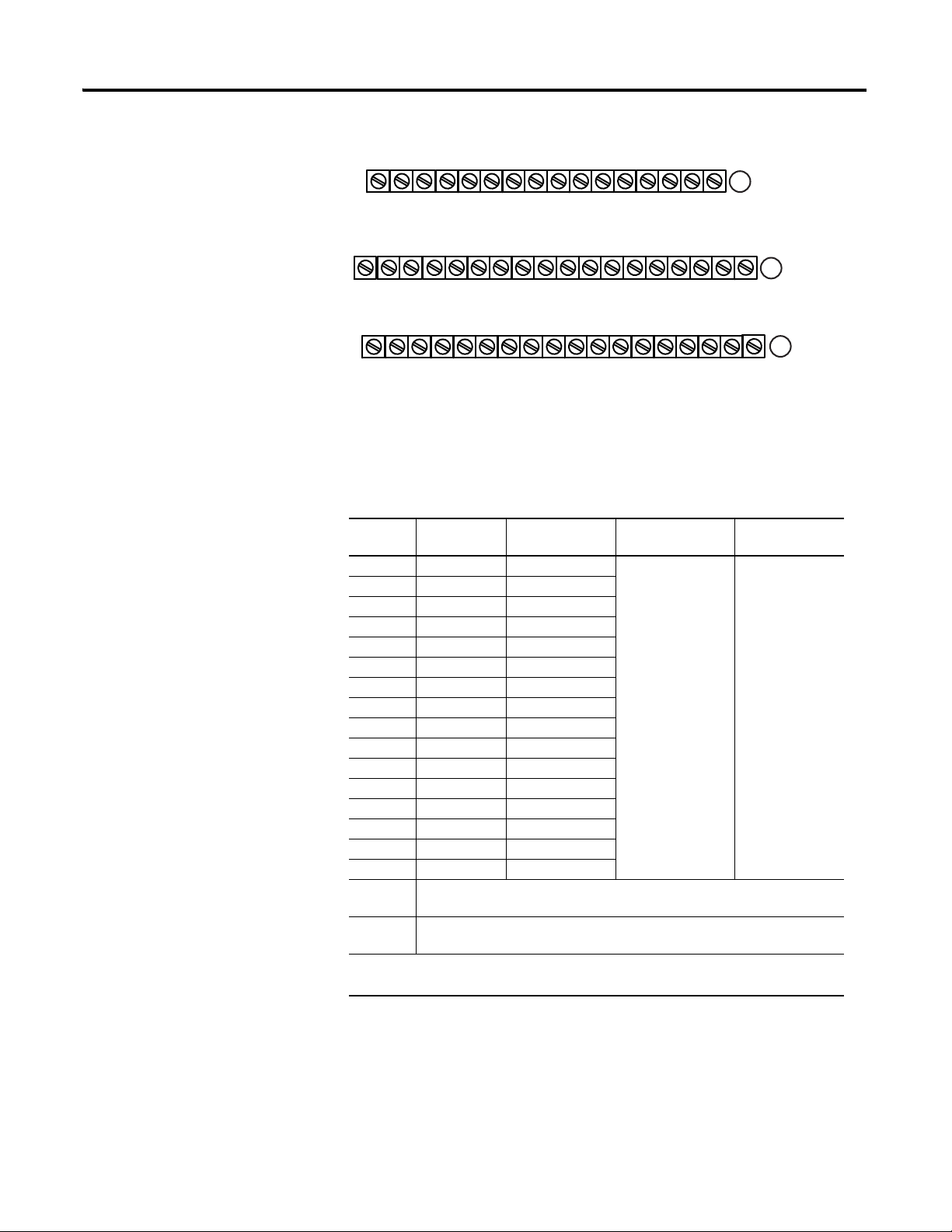

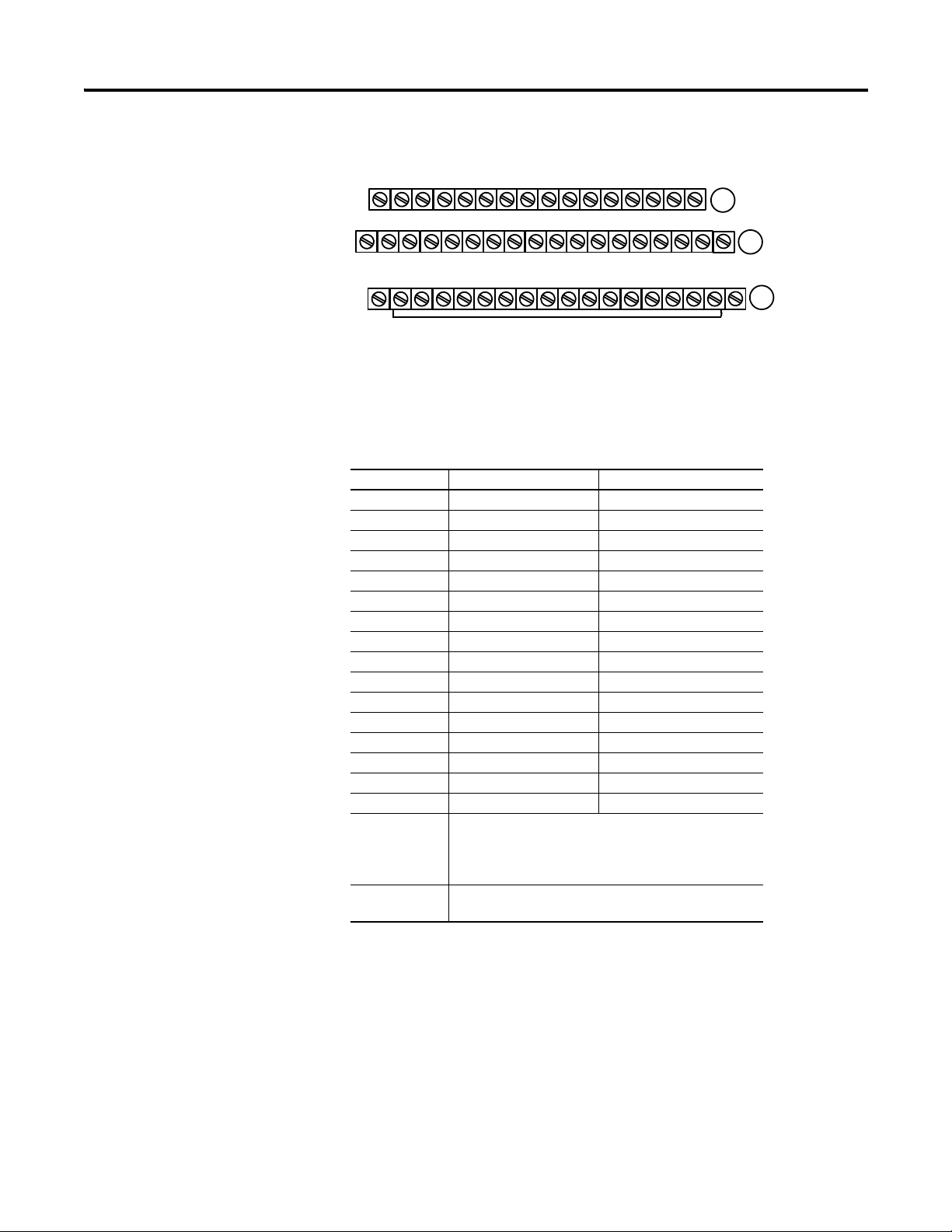

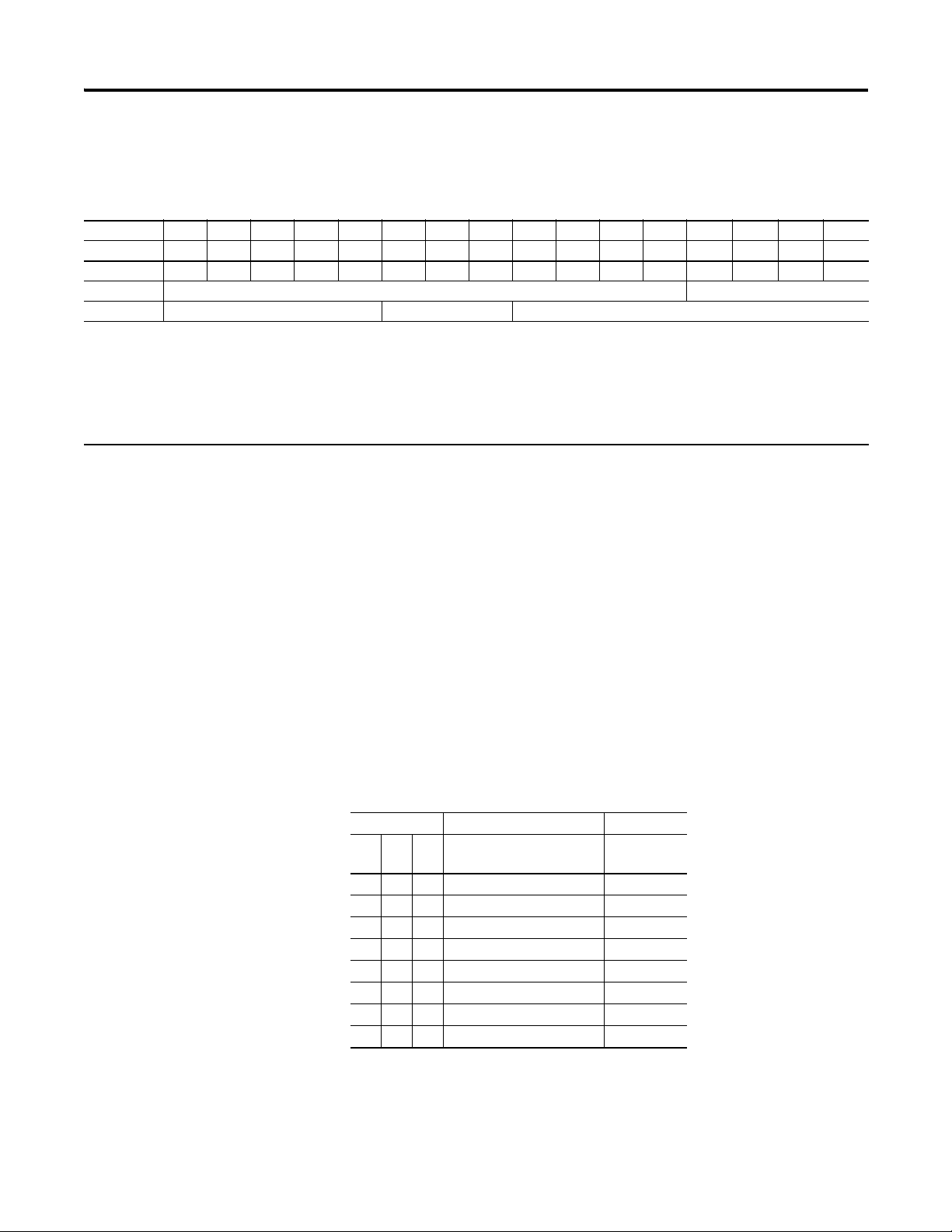

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

16

35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

34

NC

Inputs Channels 0-15

Sensor Power Terminals for Channels 0-15

+V1 COM1 +V1 COM1 +V1 COM1 +V1 COM1 +V2 COM2 +V2 COM2 +V2 COM2 +V2 COM2 NC

NC NC

A

B

C

Sensor Common and User Power Common:

Terminals C-36, C-38, C-40, C-42, C-44, C-46, C-48 and C-50.

User power (+) Voltage: Terminals C-43, C-45, C-47 and C-49.

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

COM1 and COM2 are connected together in the module.

+V1 Terminals C-35, C-37, C-39, and C-41 are not used

1794-TB32 and 1794-TB32S Terminal Base Wiring for the 1794-IB16D

Wiring for 1794-IB16D (use with 1794-TB32 or 1794-TB32S Terminal Base Units)

Input Input

Term ina l

Sensor Power

Term in al

Common

IN 00 A-0 B-17 -V common

IN 01 A-1 B-18

IN 02 A-2 B-19

IN 03 A-3 B-20

connected to

terminals 36, 38,

40, 42, 44, 46, 48,

and 50

IN 04 A-4 B-21

1

Supply

+V2 connected

to terminals 43,

45, 47, and 49

(+V1 terminals

35, 37, 39, and

41 are not used).

IN 05 A-5 B-22

IN 06 A-6 B-23

IN 07 A-7 B-24

IN 08 A-8 B-25

IN 09 A-9 B-26

IN 10 A-10 B-27

IN 11 A-11 B-28

IN 12 A-12 B-29

IN 13 A-13 B-30

IN 14 A-14 B-31

IN 15 A-15 B-32

+V2 dc

power

COM dc

Return

(1)

3-wire devices only. 2-wire devices use input and sensor power terminals; 3-wire

Power terminals 43, 45, 47, and 49 (power terminals are internally

connected together in the module)

Common terminals 36, 38, 40, 42, 44, 46, 48, and 50 (common terminals

COM 1 and COM 2 are internally connected together in the module)

devices use input, sensor power and common terminals.

Publication 1794-UM061A-EN-P - July 2006

Page 20

18 1794 FLEX I/O Diagnostic Digital Modules Overview

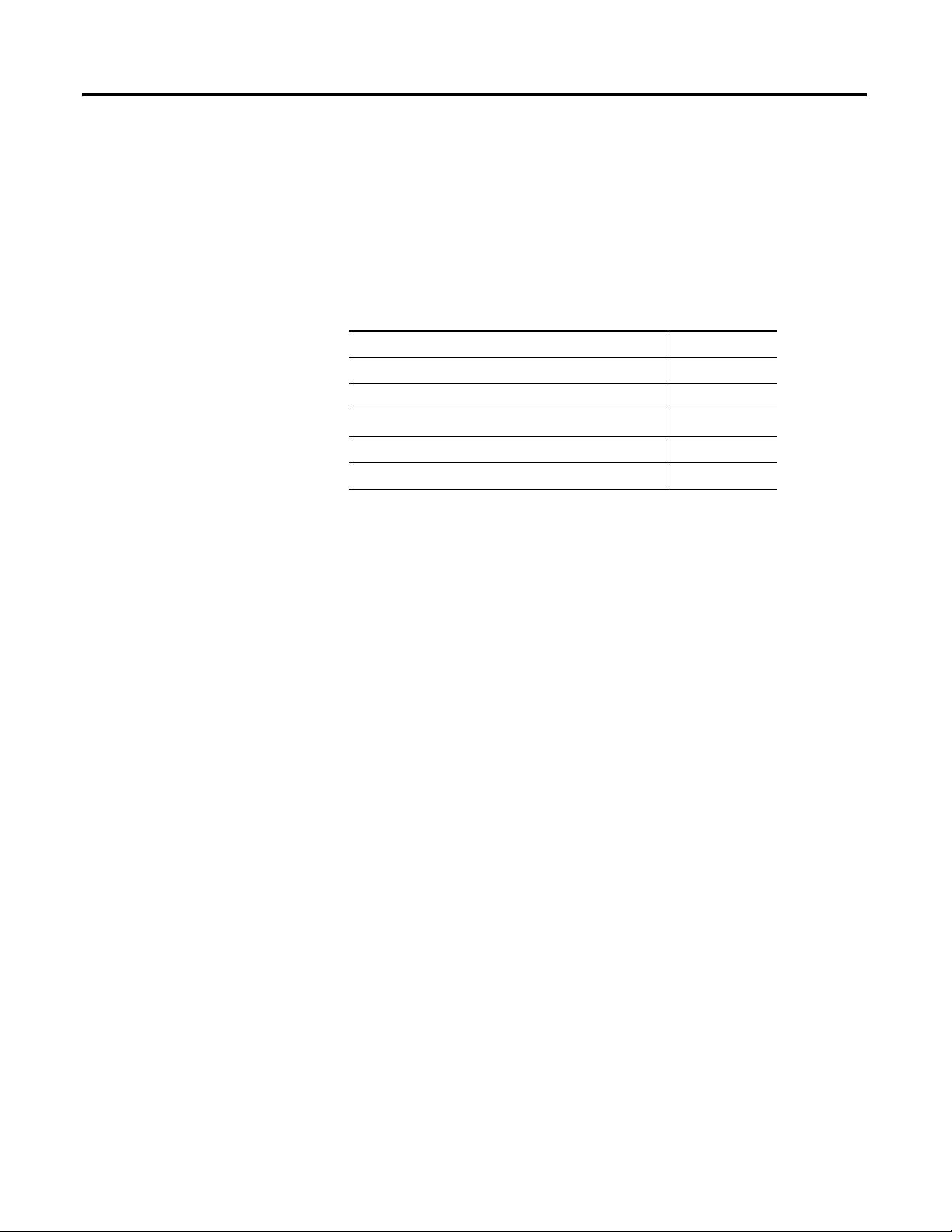

1794-TB2, -TB3, and -TB3S Terminal Base Wiring for the 1794-OB16D

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Outputs

A

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

16

B

-V

Common

Commons

35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

34

-V

Common

C

Voltage

In +V

Terminals 35 through 50 not available on 1794-TB2

Voltage

Out +V

Voltage

-V (Supply Common) = Terminals B-16 through B-33.

+V (Supply +Voltage In) = Terminals C-34 through C-51.

(Use B-33 and C-51 for daisy-chaining to next terminal base unit.)

(1794-TB3 shown)

Wiring Connections for the 1794-OB16D (use with 1794-TB2, 1794-TB3 or 1794-TB3S Terminal

Base Units)

.

Outputs Output Terminal Common Terminal

Output 00 A-0 B-17

Output 01 A-1 B-18

Output 02 A-2 B-19

Output 03 A-3 B-20

Output 04 A-4 B-21

Output 05 A-5 B-22

Output 06 A-6 B-23

Output 07 A-7 B-24

Output 08 A-8 B-25

Output 09 A-9 B-26

Output 10 A-10 B-27

Output 11 A-11 B-28

Output 12 A-12 B-29

Output 13 A-13 B-30

Output 14 A-14 B-31

Output 15 A-15 B-32

+V dc C-34 and C-51 (1794-TB2) (Power Terminals are

internally connected in the terminal base unit.

C-34…C-51 (1794-TB3, 1794-TB3S) (Power terminals

are internally connected in the terminal base unit.

Common B-16…B-33 (Common terminals are internally

connected in the terminal base unit.

Page 21

2

About the FLEX I/O Diagnostic Input Module

Introduction

About the 1794-IB16D Diagnostic Input Module

In this chapter, you will learn about the diagnostic input module, cat. no.

1794-IB16D.

For Information About See Page

About the 1794-IB16D Diagnostic Input Module 19

Diagnostic Fault Detection 21

Indicator Status Information 2

Module Limitations 24

Configure Your Diagnostic Input Module 26

The 1794-IB16D diagnostic input module provides 16 points of 24V dc

sinking inputs with open-wire, short-circuit, and user supply reverse polarity

diagnostic features. Each input signal has an associated sensor power

connection. The module monitors current and voltage at each input channel

sensor power terminal.

The module detects:

• an open fault if the sensor-power current drops.

• a short fault if the sensor-power voltage goes low.

• a reverse-polarity fault if reverse voltage is applied to the user terminals.

19 Publication 1794-UM061A-EN-P - July 2006

Page 22

20 About the FLEX I/O Diagnostic Input Module

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

16

35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

34

COM1NC

Sensor Common and User Power Common:

Input Channels 0-15

NC

Sensor Power Terminals for Channels 0-15

+V1 COM1 +V1 COM1 +V1 COM1

+V1

+V2 COM2 +V2 COM2+V2 COM2 +V2 COM2 NC

Terminals C-36, C-38, C-40, C-42, C-44, C-46, C-48 and C-50.

User power (+) Voltage: Terminals C-43, C-45, C-47 and C-49

+V1 Terminals C-35, C-37, C-39 and C-41 are not used

NC

COM1 and COM2 are connected together in the module.

A

B

C

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

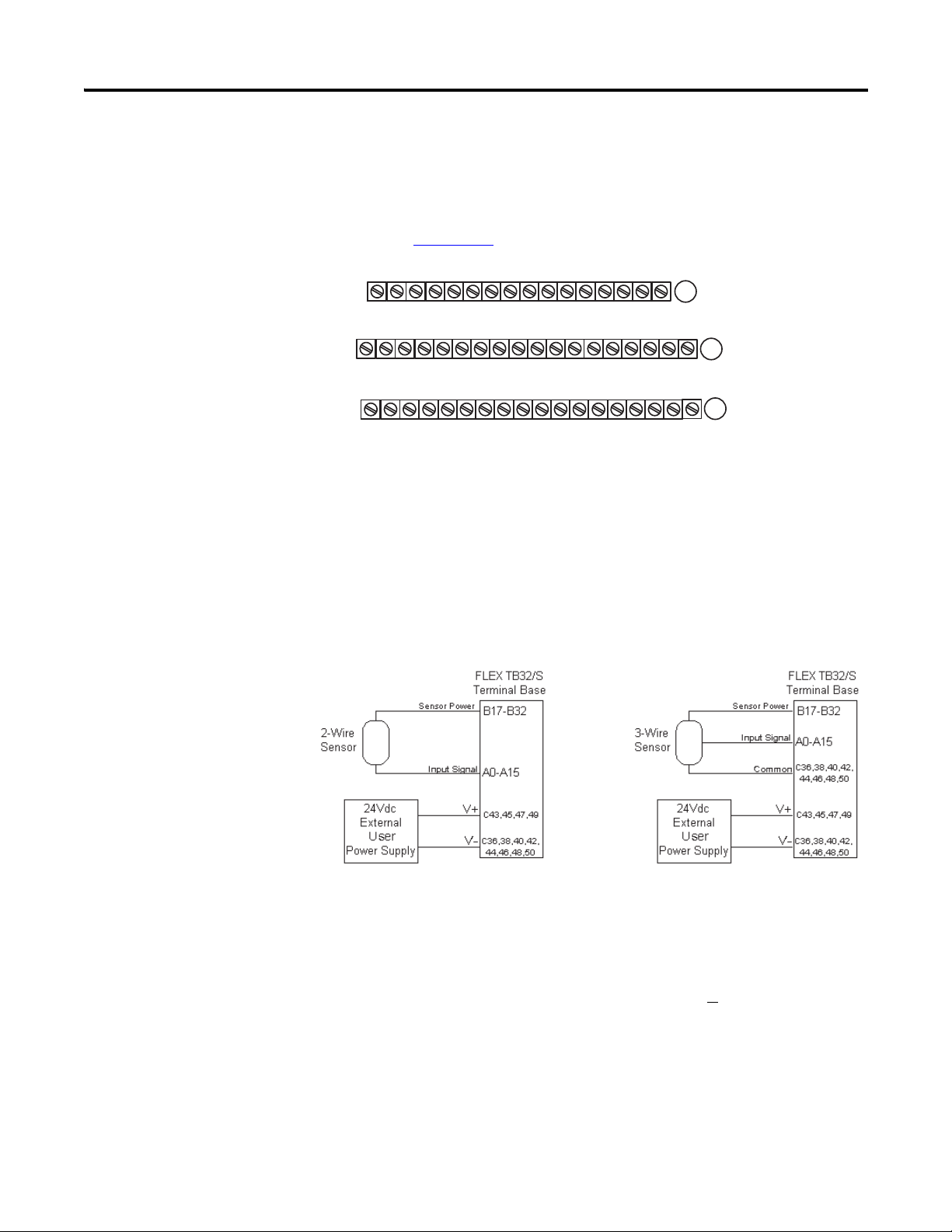

Wiring Input Sensors

You must use a 1794-TB32 or 1794-TB32S terminal base unit with the

1794-IB16D diagnostic input module. See installation instructions

ldkg df;l 1794-IN096

for complete information.

Publication 1794-UM061A-EN-P - July 2006

Two-wire input devices connect to the input and sensor power terminals;

3-wire devices use input, sensor power and common terminals. You can wire

2-wire and 3-wire sensors to the FLEX I/O 1794-TB32 or 1794-TB32S

terminal base units.

Unused sensor-power ports or open-contact input devices must use a dummy

resistor to mask the diagnostic function. If these external resistors are not

used, the module’s fault indicator will light, along with the module’s error bits,

thus rendering fault detection of the remaining channels useless. The

recommended value of this dummy resistor is 20 kΩ (+

larger). Connect the resistor between sensor power and input signal or

10%), 1/8 Watt (or

between sensor power and common.

Page 23

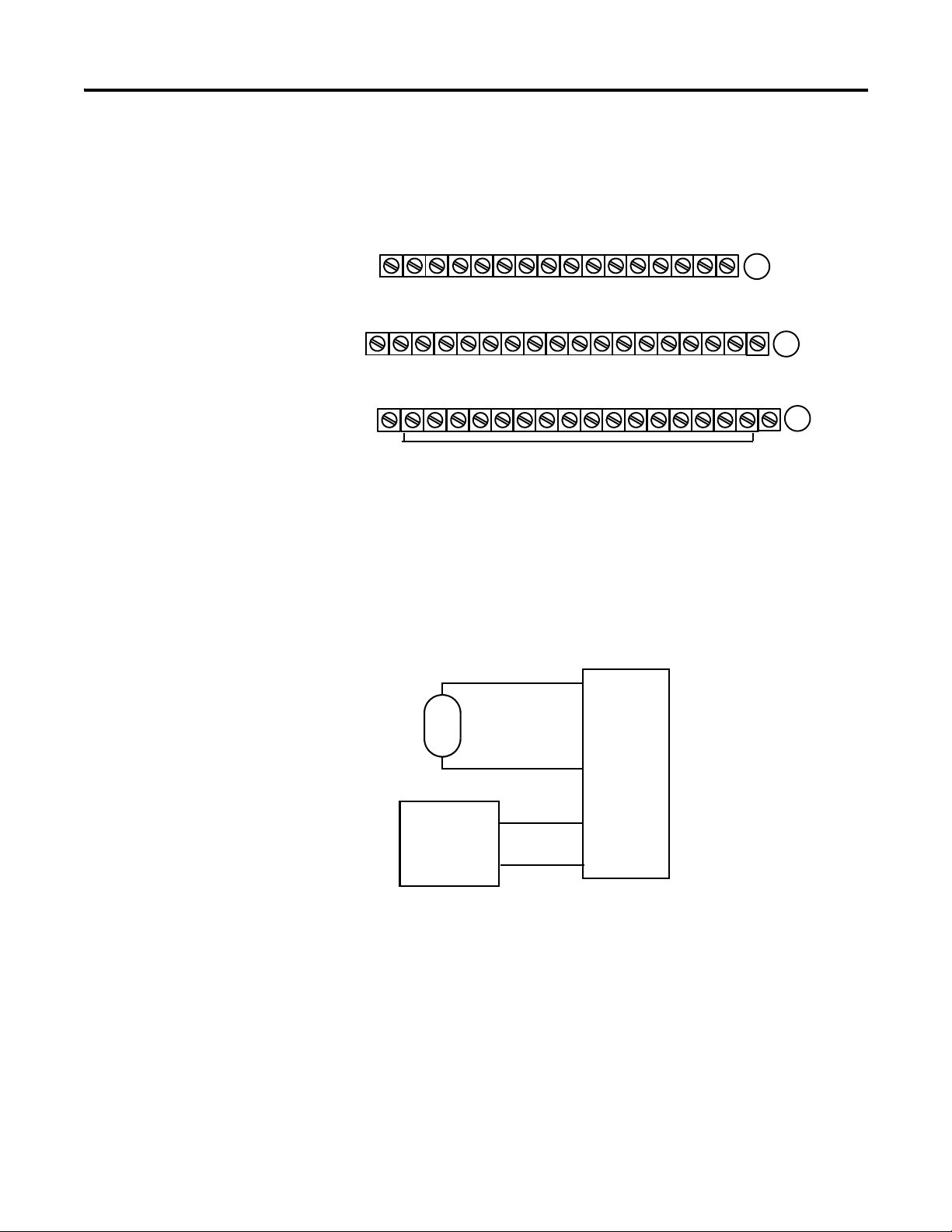

About the FLEX I/O Diagnostic Input Module 21

.

.

User Power

Reverse

Voltage

Monitor

PTC

Shorted

Input

Monitor

Open Wire

Monitor

Input Circuit Indicator

+

-

Input

Sensor Power

Reverse

Short

Open

Input

Flexbus Interface

V+

Fault Indicator

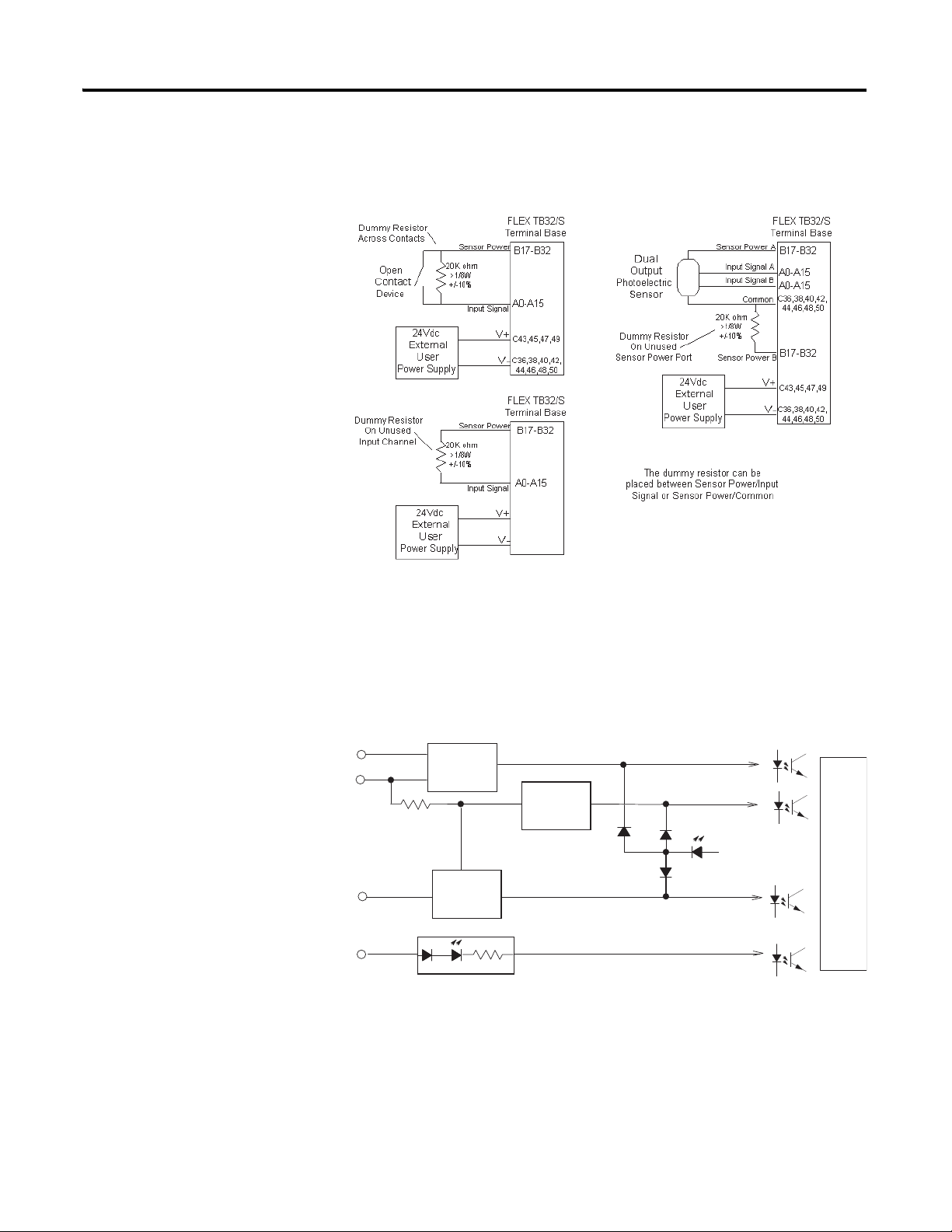

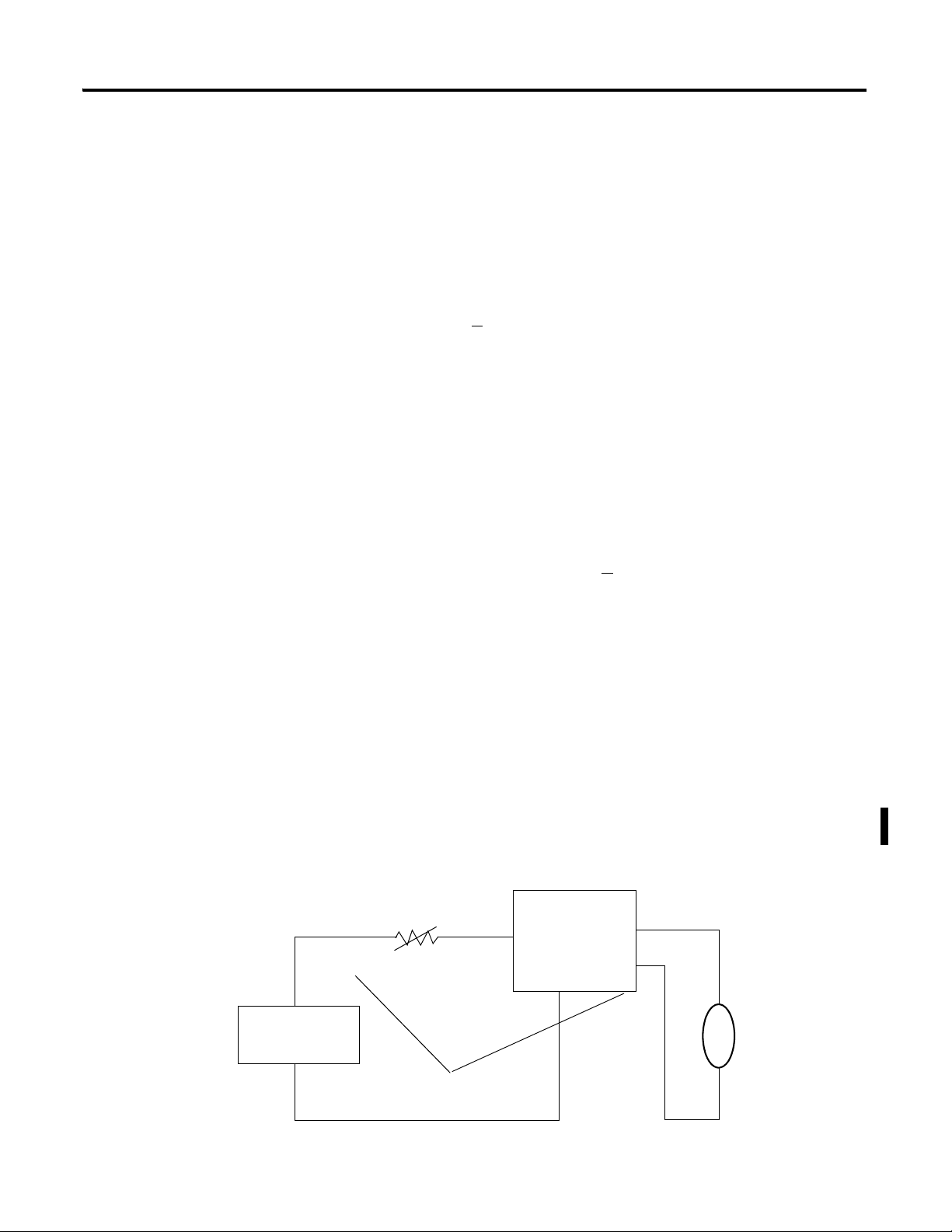

Diagnostic Fault Detection

The module monitors current and voltage at each input channel sensor power

terminal, and monitors the user supply for reverse user supply voltage. The

figure below shows the location of these fault monitors in the 1794-IB16D

diagnostic input module.

Publication 1794-UM061A-EN-P - July 2006

Page 24

22 About the FLEX I/O Diagnostic Input Module

Sensor Power Open and Short Circuit Detection

The sensor-power open-wire current monitor detects a fault condition if the

sensor-power current drops below 50 μA. Sensor-power shorts are protected

by the positive temperature coefficient (PTC) resistor in series with each

sensor power output (16 total). For overcurrents or shorts, the PTC resistor

heats up, the resistance increases and the sensor power output opens, similar to

a fuse opening. This shorted condition is monitored by the sensor power

voltage monitor. It detects a short if the sensor power voltage disappears.

When the short is removed, the PTC resistor cools down and the previously

shorted sensor-power port, sensor power is automatically restored and normal

operation continues.

The module’s embedded monitors detect open and short conditions.

Publication 1794-UM061A-EN-P - July 2006

When a fault is detected:

• the corresponding channel’s red indicator lights.

• the module’s red fault indicator lights.

• the module’s open, short or reverse error bit is set.

• the module error bit is set.

The input circuit is a conventional sinking style with an input voltage dropping

resistor. The yellow input indicator is in series with the input signal (field-side

indication). FLEX I/O system-side logic voltages are isolated from the user

power supply and input channels by optocouplers. This provides protection

against field side voltages and transients.

Page 25

About the FLEX I/O Diagnostic Input Module 23

(1794-IB16D shown)

User Power Supply Reverse Voltage Detection

If the external user power supply is miswired (incorrect polarity), the module is

protected and reports a reverse user voltage fault. The reverse voltage

condition must be at least -10V to detect a fault. The module’s Fault indicator

turns red and the reverse fault bit is set. The module error bit is also set. When

the correct user power supply polarity is applied, the module Fault indicator is

off and the reverse fault bit is not set.

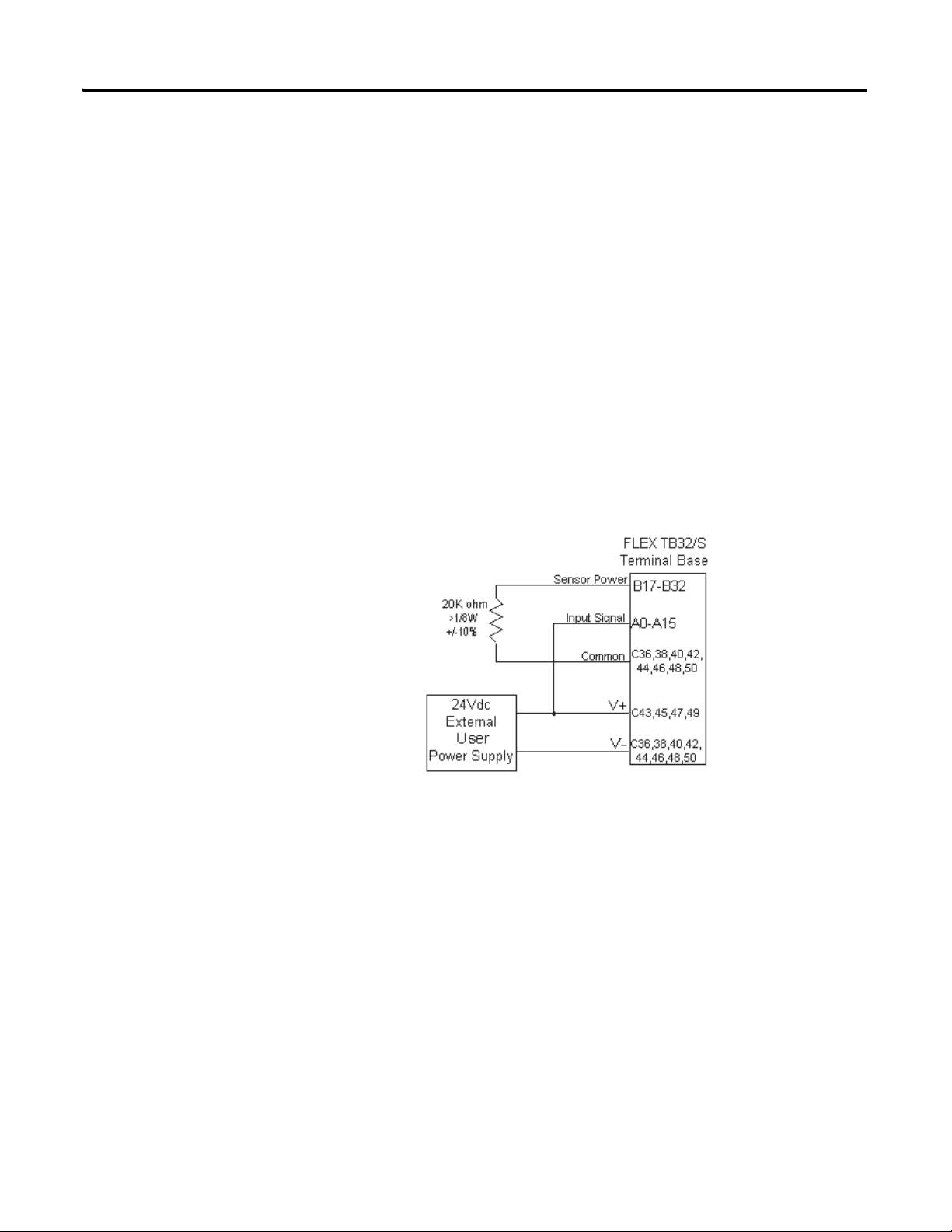

User Power Supply Loss Detection

The module does not check for presence of the external user power supply.

Detection can be accomplished by wiring an input channel to the user supply.

Any 24V dc input can be used. You can wire a 1794-IB16D diagnostic input

module or 1794-IB16 input module to monitor the user supply as shown

below:

Indicator Status Information

The 1794-IB16D diagnostic input module has indicators that let you check the

module health and operational status. The following status can be checked

with the indicators.

• Channel I/O Status - This indicator displays the ON/OFF state of the

input channel, as well as channel wiring fault conditions:

– Off indicates the input channel is off with no faults.

– Yellow indicates the input channel is on with no faults.

– Red indicates either a channel sensor power open or short condition.

• Module Fault Status- This indictor turns red for any individual input

channel open, short or module reverse power conditions.

With no fault, the module fault status indicator turns off.

Publication 1794-UM061A-EN-P - July 2006

Page 26

24 About the FLEX I/O Diagnostic Input Module

10

Ambient Temperature

(0°C)

Input

Voltage

(V)

Sensor

Power

Current

(mA)

Ambient Temperature (° C)

Module Limitations

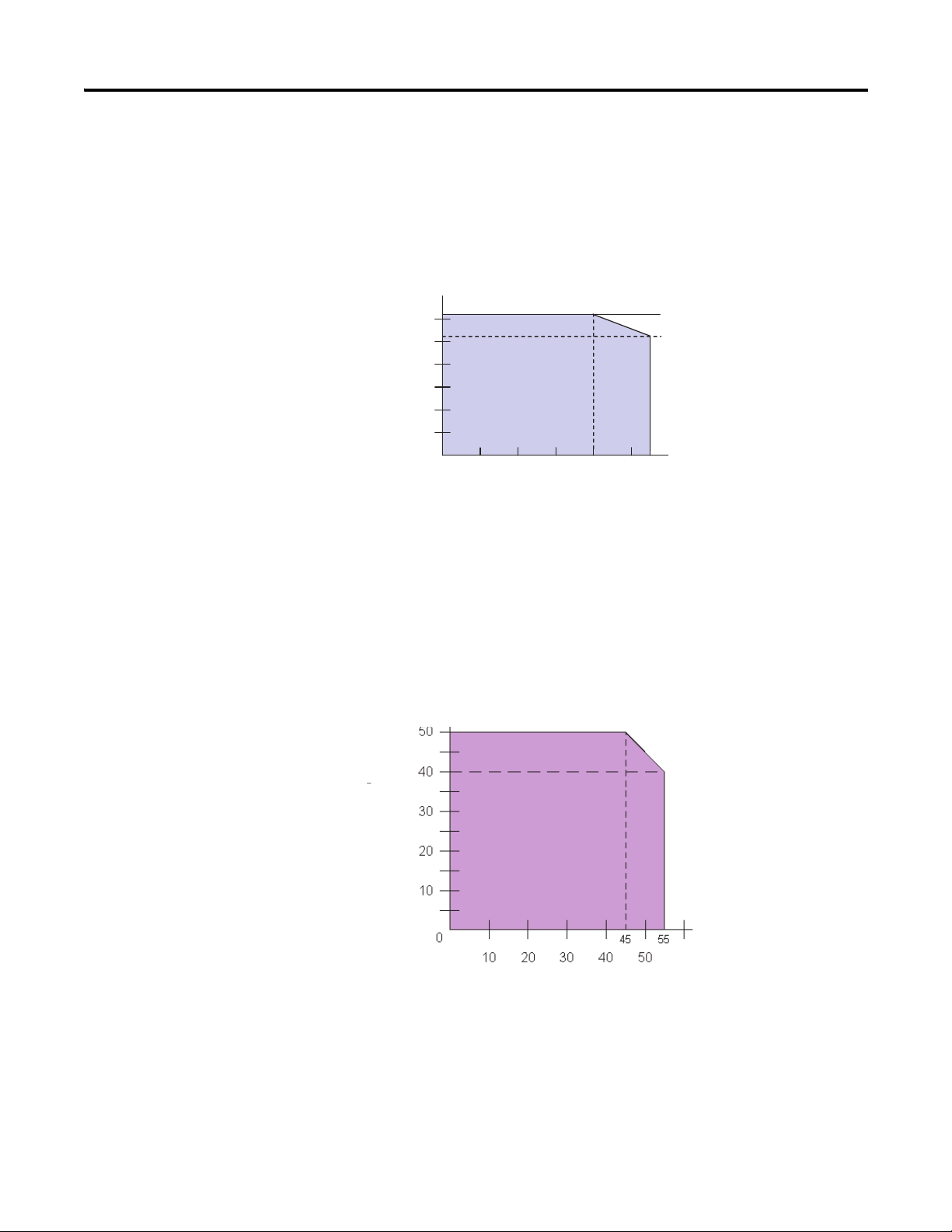

Input Voltage Derating

You must derate the input voltage applied to each input channel, based on

operating ambient temperature, to keep module power dissipation within an

acceptable level.

31.2

30

26.4

25

20

15

10

5

0

20 30 40 50 55

Sensor-Power Derating

You must derate the allowable current from each channel sensor-power port

based on operating ambient temperature to keep module power dissipation to

an acceptable level.

Publication 1794-UM061A-EN-P - July 2006

Page 27

About the FLEX I/O Diagnostic Input Module 25

User Power +

PTC Resistor

Off-Wire

Current Monitor

Fault if:

1 < 50 μA

Sensor Power

Sensor

Input

Vsensor = (Ext Pwr) - 2.2V

Overcurrent causes PTC to open

Voltage Drop = 2.2V maximum

24V dc External

User Power Supply

User Power

-

Unused Sensor Power Ports

You must connect dummy resistors to unused Sensor Power ports to mask the

diagnostic function. If external resistors are not used, the module's sensing

circuitry will not detect the intended voltage or current and not report that a

fault exists. The module’s fault and open-channel indicators light, and the

module’s open and module error bits are set, thus rendering fault detection of

the remaining channels useless. The recommended value of this dummy

resistor is 20 KΩ (+

10%), 1/8 W (or larger).

Open Contact Mechanical Switches and Relays

The module's sensing circuitry must detect a minimum current level to

conclude that an open circuit does not exist. Electronic input field devices

typically have sufficient leakage current to satisfy the minimum requirement.

However, hard contacts have no leakage current, so you must add dummy

resistors in parallel to the hard contacts to supply the minimum current needed

for the module to sense that an open circuit does not exist. The

recommended resistor value is 20 kΩ (+

the dummy resistor at the field device also allows for monitoring of field

wiring conditions. Connect the resistor between sensor power and input signal,

or between sensor power and common.

10%), 1/8 W (or larger). Placement of

Sensor Power Internal Voltage Drop

The modules sensor power circuit exhibits an internal voltage drop. This

voltage drop can be as large as 2.2V for all operating conditions. You must

subtract 2.2V from the value of your external user power supply to determine

the voltage applied to power attached sensors. Make sure this voltage meets

sensor requirements. Consult the data sheet for your sensor to determine what

voltage is necessary.

Publication 1794-UM061A-EN-P - July 2006

Page 28

26 About the FLEX I/O Diagnostic Input Module

Configure Your Diagnostic Input Module

Dec. 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Oct. 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Read 1 I 15 I 14 I 13 I 12 I 11 I 10 I 9 I 8 I 7 I 6 I 5 I 4 I 3 I 2 I 1 I 0

Read 2 Not used Read Diagnostics Status

Write 1 Not used Input Filter FT 0-15 Not used

Where: I = Input

FT = Input filter time

Diagnostic status;

Bit 00 = module error;

Bit 01 = external power reverse polarity error;

Bit 02 = sensor power short error;

Bit 03 = sensor power open wire error

The configuration and input filter selection table are shown below.

Data Table & Input Filter Time Selection

The inputs are read in Word 1. Bit 00 is the first input and decimal bit 15 is the

last input.

Diagnostic status is read from Word 2:

Bit 00: Module Error Bit

Bit 01: External Power Reverse Polarity Error Bit

Bit 02: Sensor Power Short Error Bit

Bit 03: Sensor Power Open Wire Error Bit

Input Filter Times

Input filter times are configurable on a module basis. Both off-to-on and

on-to-off times are set by write Word 3. The default filter time is 0.25 ms.

Bits Description Filter Time

10 09 08 Filter time for inputs 0

thru 15

0 0 0 Filter time 0 (default) 0.25 ms

0 0 1 Filter time 1 0.5 ms

0 1 0 Filter time 2 1 ms

0 1 1 Filter time 3 2 ms

1 0 0 Filter time 4 4 ms

1 0 1 Filter time 5 8 ms

1 1 0 Filter time 6 16 ms

1 1 1 Filter time 7 32 ms

Off-to-On/

On-to-Off

Publication 1794-UM061A-EN-P - July 2006

Page 29

Chapter

3

About the FLEX I/O Diagnostic Output Module

Introduction

About the 1794-OB16D Diagnostic Output Module

In this chapter, you will learn about the diagnostic output module, cat. no.

1794-OB16D.

For Information About See Page

About the 1794-OB16D Diagnostic Output Module 27

Diagnostic Fault Detection 29

Module Protection Functions 30

Module Limitations 32

Configure Your Output Diagnostic Module 32

The 1794-OB16D diagnostic output module provides sixteen 24V dc sourcing

outputs with open-wire, short-circuit, and user supply reverse polarity

diagnostic features. The module monitors current and voltage at each output

channel.

The module detects:

• an open fault if no current is present at the output terminal.

• a short fault if no voltage is present at the output terminal.

• a reverse-polarity fault if reverse voltage is applied.

When an open or short fault is detected:

• the corresponding channels red indicator is illuminated.

• the module’s red fault indicator is illuminated.

• the module’s open or short error bit is set.

• the module error bit is set.

When a user supply reverse-polarity fault is detected:

• the modules red fault indicator is turned on,

• and the reverse error bit is set.

• the module error bit is set.

27 Publication 1794-UM061A-EN-P - July 2006

Page 30

28 About the FLEX I/O Diagnostic Output Module

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

16

35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

34

Output Channel 0-15

Common

(1794-TB3 shown)

-V

Voltage

In +V

Voltage

Out +V

Voltage (24V dc)

Terminals 35 thru 50 not available on 1794-TB2

A

B

C

Common

-V

Common

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

FLEX TB2/3/3S

Terminal Base

A0-A15

B17-B32

C34

B16

Output

Common

V+

V-

Output

Device

24V dc

External User

Power Supply

Wiring Output Loads

You can use the 1794-OB16D diagnostic module with the 1794-TB2,

1794-TB3, or 1794-TB3S terminal base units.

User power can be wired to the (+) voltage and common terminals directly, or

power can be daisychained from the FLEX I/O terminal base units on the

DIN rail. Output channels are not isolated from one another. All 16 channels

share a common return (group isolation from FLEX I/O system-side logic

voltages).

Publication 1794-UM061A-EN-P - July 2006

Page 31

About the FLEX I/O Diagnostic Output Module 29

User Power

Open Wire

Detect

Current

Shorted

Output

Monitor

Fault Indicator

-

Reverse

Short

Open

Output

V+

Open Wire

Monitor

Reverse

Voltage

Monitor

Output Indicator

Output

Flexbus Interface

+

40117C

Current Limiting

Thermal Prot.

Output FET

You must connect dummy resistors to unused sensor power ports to mask the

diagnostic function. If these external resistors are not used, the module’s

sensing circuitry will not detect the intended voltage or current and signal a

module fault. The channel fault indicator and the module’s fault indicator will

light, and the module’s open and error bits are set, thus rendering fault

detection of the remaining channels useless. The recommended value of this

dummy resistor is 10 KΩ (+

10%), 1/8 W (or larger). The resistor is wired

between unused output channels and common. The figure depicts wiring of a

dummy resistor.

Diagnostic Fault Detection

The module monitors current and voltage at each output channel terminal,

and monitors the user supply for reverse supply voltage. The figure below

shows the location of these fault monitors within the 1794-OB16D diagnostic

output module.

Publication 1794-UM061A-EN-P - July 2006

Page 32

30 About the FLEX I/O Diagnostic Output Module

ATTENTION

The output open-wire current monitor detects a fault condition if the output

OFF-state current drops below 0.1 mA. Output channel shorts are protected

by a current limit and over-temperature thermal sensor built into the output

device. For overcurrents, the output device’s internal current limit is tripped

and the output voltage begins to collapse.

For a sustained overcurrent or direct output short the output device’s thermal

limit is tripped and the output is automatically turned off. This shorted

condition is monitored by the on-state output channel short monitor. It

detects a short if the output voltage drops below 2V. If the on-state output

channel short is removed, the output will automatically recover and voltage

will appear at the output, thus driving the attached load on.

A shorted output channel turns off and deenergizes a connected

load. Following removal of the short the output channel

becomes active and will reenergize a connected load. Be

careful for unexpected machine operation following removal of

an active output channel short.

Module Protection Functions

Optocouplers isolate FLEX I/O system-side logic voltages from the user

power supply and output channels. This provides protection against field-side

voltages and transients.

The module protection functions consist of output device short protection,

external power supply reverse voltage protection, and power supply loss

detection

Output Device Short Protection

Diagnostic digital outputs have internal electronics to prevent too much

current from flowing through the module. This feature protects the module,

attached wiring, and load from damage. Current limit and over-temperature

thermal sensor built into the output device protect against output shorts. For

an overcurrent, the output device’s internal current limit trips and output

voltage collapses. The output device’s thermal limit is tripped and the output is

automatically turned off if an output short circuit is detected. This shorted

condition is monitored by the on-state output channel short monitor. It will

detect a short if the output voltage drops below 2V. Under shorted conditions,

the shorted channels indicator turns red, the module fault indicator turns red

and the short fault bit and module error bit are set. If the on-state output

channel short is removed, the output automatically recovers and voltage

appears at the output, thus driving the attached load on.

Publication 1794-UM061A-EN-P - July 2006

Page 33

About the FLEX I/O Diagnostic Output Module 31

(1794-IB16D shown)

External Power Supply Reverse Voltage

If the external user power supply polarity is incorrect, the module is protected

and reports a reverse user voltage fault. The reverse voltage condition must be

at least -10V to detect a fault. The modules fault indicator turns red and the

reverse fault bit is set. The module error bit is also set. When the correct user

power supply polarity is applied, the module Fault indicator is off and the

reverse fault bit is not set.

User Power Supply Loss Detection

The module does not check for presence of the external user power supply.

You can detect user power loss by wiring any spare 24V dc input on a

1794-IB16D input module or 1794-IB16 input module to the power leads of

the power supply for the 1794-OB16D.

Output Fault & Idle States With Network Communication Failure

Configure module outputs for fault states, (either all on, all off or Hold Last

State), in the event of a network communication failure (fault state) or

switchover to Program mode (idle state). For example, if your module is

configured so that the state of the outputs turn off during Program (idle)

mode, any on-state outputs will turn off when in idle mode (processor

keyswitch placed in Program mode). Refer to documentation for your FLEX

I/O adapter and associated processor or controller for further information.

Indicator Status Information

The 1794-OB16D diagnostic output module has status indicators that allow

you to check the module health and operational status.

Publication 1794-UM061A-EN-P - July 2006

Page 34

32 About the FLEX I/O Diagnostic Output Module

• Channel I/O Status- This indicator displays the on/off state of each

output channel, as well as channel wiring fault conditions:

– Off indicates the output channel is off with no faults.

– Yellow indicates the output channel is on with no faults.

– Red indicates either an output channel open or short condition.

• Module Fault Status- This indictor turns red for individual output

channel opens, shorts or module reverse power conditions.

With no fault, the module fault indicator turns off.

Module Limitations

Unused Output Channels

You must connect dummy resistors to unused output channels to mask the

diagnostic function. If these external resistors are not used, the module’s

sensing circuitry will not detect the intended voltage or current and signal a

module fault. The channel fault indicator and the module’s fault indicator will

light. The module’s open and error bits are set, thus rendering fault detection

of the remaining channels useless. The recommended value of this dummy

resistor is 10 Kohms (+

10%), 1/8 W (or larger). The resistor is wired between

unused output channels and common.

Configure Your Output Diagnostic Module

Dec. 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Oct. 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Read 1 Not used

Write 2 O15 O14 O13 O12 O11

Where O = Output

Diagnostic status;

Bit 00 = module error;

Bit 01 = external power reverse polarity error;

Bit 02 = output short error;

Bit 03 = output open wire error

The configuration data table is shown below.

1794-OB16D Configuration Data Table

Read Diagnostics Status

O10O9O8O7O6O5O4O3 02 O1 O0

Publication 1794-UM061A-EN-P - July 2006

The outputs are written in Word 2. Decimal bit 00 is the first output and

decimal bit 15 is the last output.

Diagnostic status is read from Word 1:

Bit 00: Module Error Bit

Bit 01: External Power Reverse Polarity Error Bit

Bit 02: Output Short Error Bit

Bit 03: Output Open Wire Error Bit

Page 35

Chapter

ControlLogix Chassis with

1756-DHRIO module

Remote I/O Network

1771-ASB Adapter

1794-ASB Adapter

1747-ASB Adapter

PLC-5 Controller in Adapter Mode

4

Configuring Modules for Communication on a

Remote I/O Network

Chapter Objectives

This chapter provides you with the RSLogix 5000 software steps you need to

configure a 1756-DHRIO module, remote adapter module and block transfer

and digital modules for use with a ControlLogix controller on a Remote I/O

(RIO) network.

For this Information: See page:

Add a DHRIO module to the project 34

Add a 1794-ASB adapter module to the

project

Configuring Block Transfer Modules 40

Create a Block Transfer (Read or Write)

Message Instruction

37

42

33 Publication 1794-UM061A-EN-P - July 2006

Page 36

34 Configuring Modules for Communication on a Remote I/O Network

A. Right-click on I/O Configuration folder

in the controller organizer and select

New Module

from the pull-down menu.

B. Click on the + to the nonisolated left of

the Communications group to display

the communication modules available.

C. Select the series of 1756-DHRIO

module you are using in your

configuration.

D. Click OK.

Add a 1756-DHRIO Module

The 1756-DHRIO module provides two configurable channels that can either

send and receive messages over DH+ or scan remote I/O devices. When a

channel is configured for remote I/O, the 1756-DHRIO module is designed to

function as a remote I/O scanner for a ControlLogix controller. I/O data is

exchanged between the 1756-DHRIO module and:

• remote adapters on the remote I/O link

• the ControlLogix controller

• remote block transfer modules

Use the following steps to add a 1756-DHRIO module to your RSLogix5000

project.

1. Start the RSLogix 5000 software.

2. Begin a new project or open an existing project offline.

3. Add the 1756-DHRIO Module to the project.

Publication 1794-UM061A-EN-P - July 2006

Page 37

1756-DHRIO Module Properties Dialog Box

A. Define the following parameters:

•Name

•Slot

•Type

• Baud Rate

• Revision

• Electronic Keying

• Open Module Properties

Refer to the 1756-DHRIO Module

Properties Dialog Box table for

information on how to fill-in the dialog

box.

Click OK.

If: Then Select:

all of the following must match:

•type

• catalog number

• vendor

• major and minor revision

number

Exact Match

all information except the minor

revision number must match

Compatible Module

no information must match Disable Keying

Configuring Modules for Communication on a Remote I/O Network 35

4. Configure the 1756-DHRIO module parameters.

In This Field: Do the Following:

Name Type a name for the module (i.e.,DHRIO_module_in_slot_1).

Slot Type or select the slot number where the module is installed.

Type

Channel A

Channel B

Baud Rate Specify a baud rate for the Remote I/O channel. This value defines the communication rate at which the

Revision Select the major and minor revision level for your module.

Electronic Keying Specify a keying option.

Select RIO for the Channel that is connected to the remote I/O network. If only one channel is configured as

a remote I/O scanner, we recommend that you use Channel B. If you configure Channel A as a remote I/O

scanner, you cannot use the programming terminal din connector on the front of the 1756-DHRIO module.

1756-DHRIO module scans the remote I/O modules.

When you configure a module, you specify the slot number for the module. However, it is possible to place a

different module in that slot, either on purpose or accidently. Electronic keying lets you protect your system

against accidental placement of the wrong module in a slot. The keying option you choose determines how

closely a module in a slot must match the configuration for that slot.

Open Module Properties Ensure that this box is checked to access all of the available configuration screens for the module. If this box

is not checked, clicking OK assigns the default parameters for the remaining configuration fields.

Publication 1794-UM061A-EN-P - July 2006

Page 38

36 Configuring Modules for Communication on a Remote I/O Network

A. Define the following parameters:

• Requested Packet Interval

• Inhibit Module

• Major Fault on Controller if Connection Fails While

in Run Mode

Refer to the Connection Tab Screen table for

information on how to fill-in the dialog box.

B. Click OK.

The 1756-DHRIO module is now listed in the controller

organizer

ATTENTION

5. Specify parameters on 1756-DHRIO Connection tab screen.

.

Connection Tab Screen

In This Field: Do the Following:

Requested Packet

Interval (RPI)

Inhibit Module Check/clear this box if you want to disable/enable connection to the DHRIO module when the controller

Define the requested rate of packet arrival. This value defines the rate for status information about the

DHRIO module to be sent to the controller. We recommend that this value be equal to the overall scan

time of your program. The parenthetical values to the right of this field display the module-dependant

minimum and maximum values.

goes online. If this box is checked, and you go online, the controller organizer displays an inhibit icon next

to the module. Although the 1756-DHRIO module connection is inhibited, the DHRIO scanner (Channel A

or B) changes to program mode and continues to scan the remote I/O adapters on the remote I/O network.

When inhibited, the 1756-DHRIO module accepts configuration from any ControlLogix controller in the

control system.

Inhibiting the DHRIO module causes the connection to the module to be disabled

and can result in the loss of data.

Major Fault on

Controller if

Connection Fails

While in Run Mode

Determine what action you want the controller to take if communication is lost to the DHRIO module.

Place a checkmark in this box if you want a major fault to occur on the controller if the connection

between the controller and the DHRIO module is lost. Leaving this box unchecked means that failure to

connect to the DHRIO module will not cause a major controller fault.

Publication 1794-UM061A-EN-P - July 2006

Page 39

Configuring Modules for Communication on a Remote I/O Network 37

A. From controller organizer, select the

channel you are using for your

configuration then, right-click to display

the pull-down menu.

In this example, only channel B is connected to

remote I/O. You can connect both channels to

remote I/O simultaneously if necessary. If only

one channel is connected to remote I/O, we

recommend that you use channel B. If you

connect channel A to remote I/O, you cannot

use the programming terminal din connector

on the front of the 1756-DHRIO module.

B. Choose New Module.

C. Click on the Communications group to

expand the tree and then, choose the

1794-ASB Adapter module from the list.

D. Click OK.

A. Define the following parameters:

•Name

•Rack #

•Starting Group

•Size

• Open Module Properties

Refer to the 1794-ASB Adapter Module

Properties Dialog Box table for

additional information.

B. Click OK.

Add a 1794 Remote Adapter

The following steps show you how to add a 1794-ASB module to your project

and set the configuration parameters.

Module

1. Add the 1794-ASB adapter module to the controller organizer.:

2. Define configuration parameters for the 1794-ASB module.

Publication 1794-UM061A-EN-P - July 2006

Page 40

38 Configuring Modules for Communication on a Remote I/O Network

A. Define the following parameters:

• Requested Packet Interval

• Inhibit Module

• Major Fault on Controller if Connection Fails

While in Run Mode

Refer to the 1794-ASB Connection Tab

Configuration Parameters table for additional

information.

B. Click OK.

1794-ASB Adapter Module Properties Dialog Box

In This Field: Do the Following:

Name Type a name for the adapter module. We recommend that you use a name that identifies the I/O type

for the adapter module you are configuring.

Rack # (Octal) Select the Remote I/O network rack ID for the rack.

Starting Group Select the starting group of this rack based on the switch setting of the 1794-ASB adapter module.

Size Select the rack size for the adapter based on the switch setting of the 1794-ASB adapter module.

Open Module Properties Ensure that this box is checked to access all of the available configuration screens for the adapter

module. If this box is not checked, clicking OK assigns the default parameters for the remaining

configuration fields.

3. Specify parameters on 1794-ASB adapter module Connection tab

screen.

Publication 1794-UM061A-EN-P - July 2006

Page 41

Configuring Modules for Communication on a Remote I/O Network 39

ATTENTION

ATTENTION

If the baud rate of the scanner is configured for: The scan rate per adapter equals:

57.6 Kbaud 8ms

115.2 Kbaud 5ms

230.4 Kbaud 3ms

1794-ASB Connection Tab Configuration Parameters

In This Field: Do the Following:

Requested Packet Interval (RPI) Select the rate at which the DHRIO module sends discrete data from the I/O rack to the controller. The

rate of data exchange is directly related to the configured baud rate for the 1756-DHRIO module.

All adapter modules under the same DHRIO channel should be set to the same RPI time. We recommend

that the value be equal to 0.5ms x the number of adapters under a given channel x 3,5 8ms depending on

the baud rate. For example, if you are using 4 adapters on Channel A of the 1756 DHRIO module

configured for a baud rate of 57.6 Kbaud, the recommended RPI for all adapters would be:

(0.5ms x 4 adapters x 8ms per adapter = 16ms)

Inhibit Module Check/clear this box if you want to disable/enable connection to the adapter module when the controller

goes online. If this box is checked, and you go online, the controller organizer displays an inhibit icon

next to this module.

Inhibiting the adapter module causes the connection to the module to be disabled

and can result in the loss of data.

Major Fault On Controller If

Connection Fails While in Run

Mode

Determine what action you want the controller to take if communication is lost to the adapter module.

Place a checkmark in this box if you want a major fault to occur on the controller if communication with

the adapter module is lost. Leaving this box unchecked means that failure to connect to the adapter

module will not cause a major controller fault.

If communication with a module fails, the controller operates on old data from the

module. To avoid potential injury or damage, either monitor communications with

modules or configure modules to produce a major fault if communications fail.

Publication 1794-UM061A-EN-P - July 2006

Page 42

40 Configuring Modules for Communication on a Remote I/O Network

You can browse to a

module in the I/O tree.

A. In the controller organizer, right-click

on the adapter module and then, select

New Module from the pull-down

menu.

B. Depending on the type of Block I/O

module you are using, expand the

Analog or Digital list by clicking on

the + sign to the left of the group.

C. Right-click on RIO-MODULE to

highlight.

D. Click OK.

Configure Digital Modules

Although not required, when the module is in the I/O configuration, you gain

these advantages:

• It is easier to complete the communication path to the module.

• The I/O configuration provides documentation about the module.

For example, once you add an I/O module to the controller organizer window

you can use the Browse button on the Communication Tab to select the path

for the block transfer message.

1. Add a block transfer module to your project configuration...

Publication 1794-UM061A-EN-P - July 2006

Page 43

Configuring Modules for Communication on a Remote I/O Network 41

A. Define the following parameters:

•Name

•Group

•Slot

• Open Module Properties

Refer to the 1756-DHRIO Block Module

Transfer Parameters table for additional

information.

B. Click OK.

C. Repeat steps A and B for the Diagnostic

output module.

The I/O modules are added to the controller

organizer tree.

2. Configure parameters for the RIO Block Transfer module.

1756-DHRIO Block Module Transfer Parameters

In This Field: Do the following:

Name Type a name for the I/O module on the RIO network. You must name this module to be able to choose a

path from the pull-down menu for the message instruction.

Group Determine what group on the module provides the first word of I/O data. This selection is affected by

the parent module’s configuration. For example, if the parent module’s size is equal to 1/2 rack (4 I/O

groups), this module’s configuration offers the option of starting with group 0, 1, 2 or 3.

Slot Enter the location of the remote I/O module.

Open Module Properties Uncheck this box. There are no additional module properties to configure for the module.

Publication 1794-UM061A-EN-P - July 2006

Page 44

42 Configuring Modules for Communication on a Remote I/O Network

A. Right-click on Main Routine.

B. Click Open in the pull-down menu.

Create a Block Transfer (Read or Write) Message Instruction

Analog and specialty I/O modules are block transfer I/O modules. The size of

the data that is transferred from the modules to the controller is larger than the

space that RSLogix 5000 software has allocated in the controller memory. As a

result, you must create message instructions in the Ladder Logic program of

the ControlLogix controller to initiate the block transfer request and generate

tags (for example, space in the controller’s memory) for the data transferred.

This section explains how to configure a block transfer application.

To monitor or control an I/O device, assign the tag name of the device to an

instruction in your ladder logic:

• For step-by-step instructions on how to enter logic and tag names, refer

to the Logix5000 Controllers Common Procedures, publication number

1756-PM001.

• Data for I/O modules is stored at the controller scope. Controller scope

data tags can be used by all programs. In other words, the data in a

controller tag is available to every task or program within the controller

application. Controller tags can be viewed as global variables. When you

assign addresses, be sure the scope selection is at the Controller to view

the I/O tags.

1. Access the project’s Main Routine of ladder logic in the controller

organizer.

Publication 1794-UM061A-EN-P - July 2006

Page 45

Configuring Modules for Communication on a Remote I/O Network 43

A. Click on the Input/Output

instruction set tab.

B. Click on MSG to insert the

message instruction.

A. Right-click on the ? in the

MSG instruction.

B. Click on New Tag in the

pull-down menu.

A. Enter information for the following fields:

•Name

•Type

• Data Type

•Scope

• Open Message Configuration

Refer to the Defining Tag Parameters table for additional

information.

B. Click OK.

2. Add a Message instruction (MSG).

3. Add a new tag to the MSG instruction.

Defining Tag Parameters

In this Field: Do the following:

Name Enter a name for the tag. We recommend that you name the tag to indicate what module service is sent

Type Choose Base type.

Data Type Choose Message type.

Scope Message Tags can only be created within the Controller Scope.

Open Message Configuration Ensure this box contains a check mark to access all of the available configuration screens.

by the message instruction as well as the module type and location.

4. Name and define the parameters for the MSG tag.

Publication 1794-UM061A-EN-P - July 2006

Page 46

44 Configuring Modules for Communication on a Remote I/O Network

A. Define the following message configuration

fields:

•Message Type

•Number of Elements

• Destination Element or New Tag (Block

Transfer Read only)

• Source Element

(Block Transfer Write only)

Refer to the Message Configuration

Parameters - Block Transfer Read or Write

table below for additional information.

B. Click on the Communication tab.

5. Define the Block Transfer Configuration Tab parameters

Message Configuration Parameters - Block Transfer Read or Write

In This Field: Do the following:

Message Type Select Block Transfer Read or Block Transfer Write from the pull-down menu. The fields for the screens

change based on the type of message you choose.

Number of Elements Define the number of 16-bit integers to transfer. The value entered in this field is determined by the type

of module you are using. The value range is 0 to 64.