Page 1

User Manual

PhaseManager User Manual

Catalog Numbers

with DriveLogix

1756 ControlLogix, 1769 CompactLogix, 1789 SoftLogix, 1794 FlexLogix, 20D PowerFlex 700S

Page 2

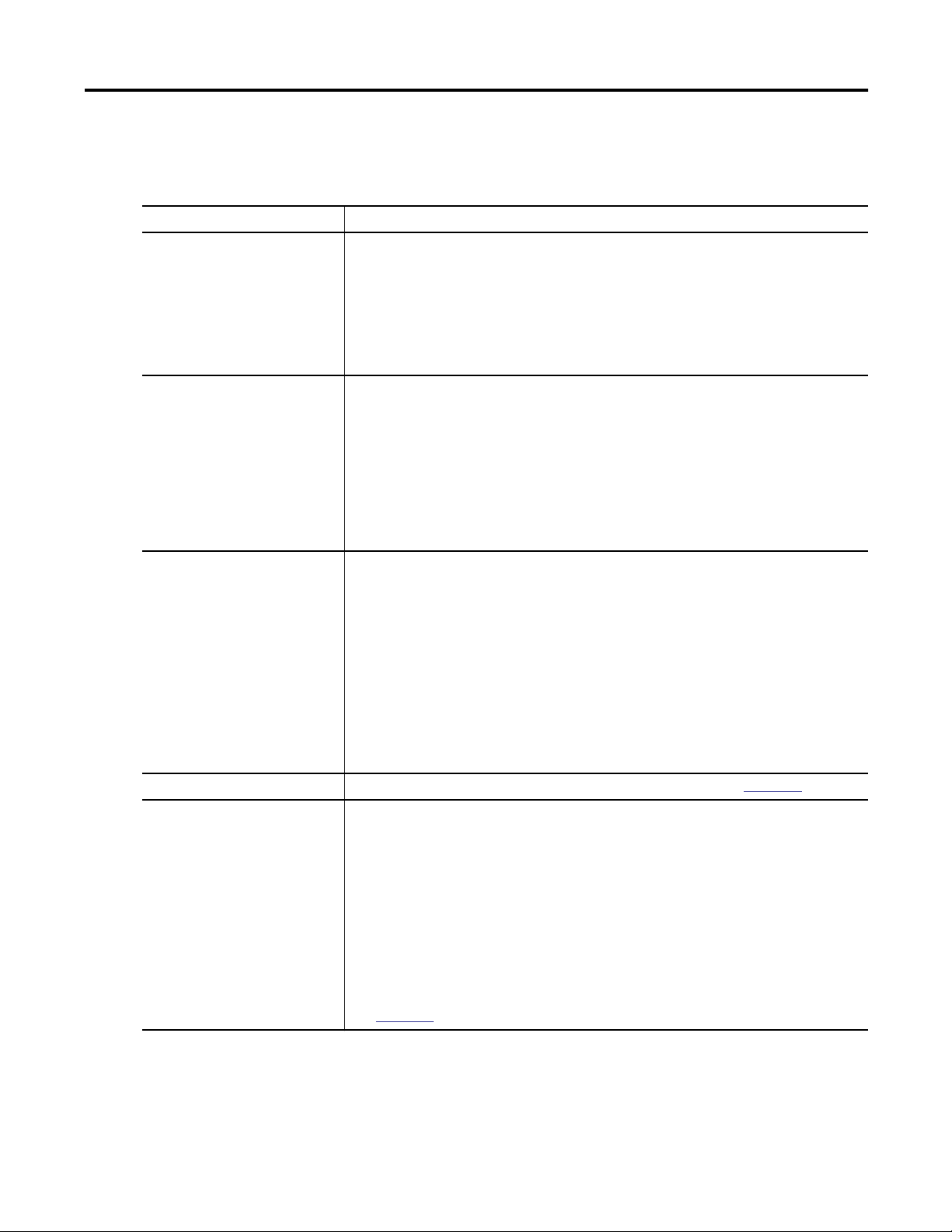

Important User Information

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication

your local Rockwell Automation sales office or online at

http://www.rockwellautomation.com/literature/) describes some

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

SGI-1.1 available from

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the

consequence

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

IMPORTANT

Allen-Bradley, Rockwell Software, Rockwell Automation, SoftLogix, FlexLogix, CompactLog ix, ControlLogix, DriveLogix, PhaseManager, Powerflex 700S, Logix5000, Logix5550, PLC -5, SLC 500, SoftLogix5800,

FactoryTalk Batch, RSLogix 5000, RSBizWare Batch, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Identifies information that is critical for successful application and understanding of the product.

Page 3

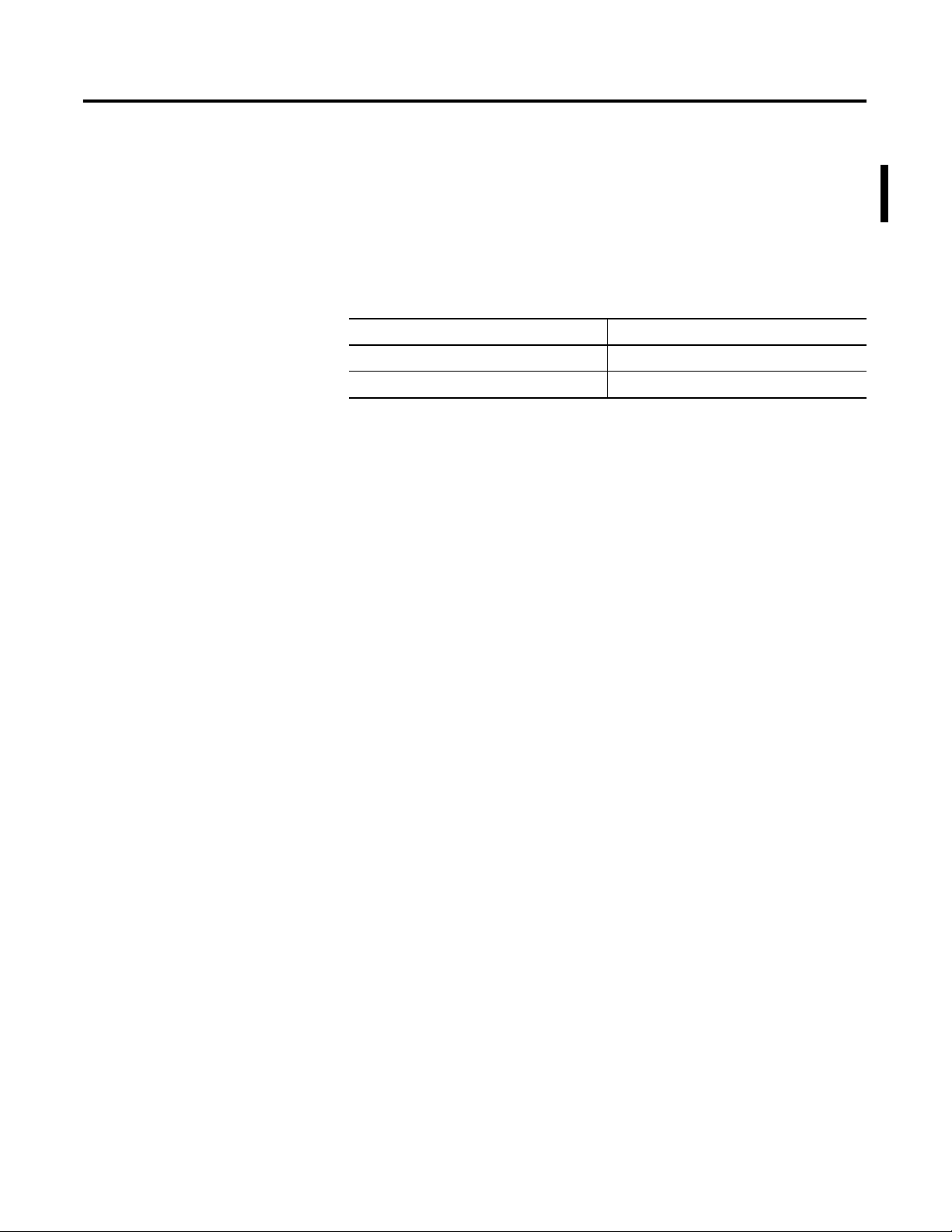

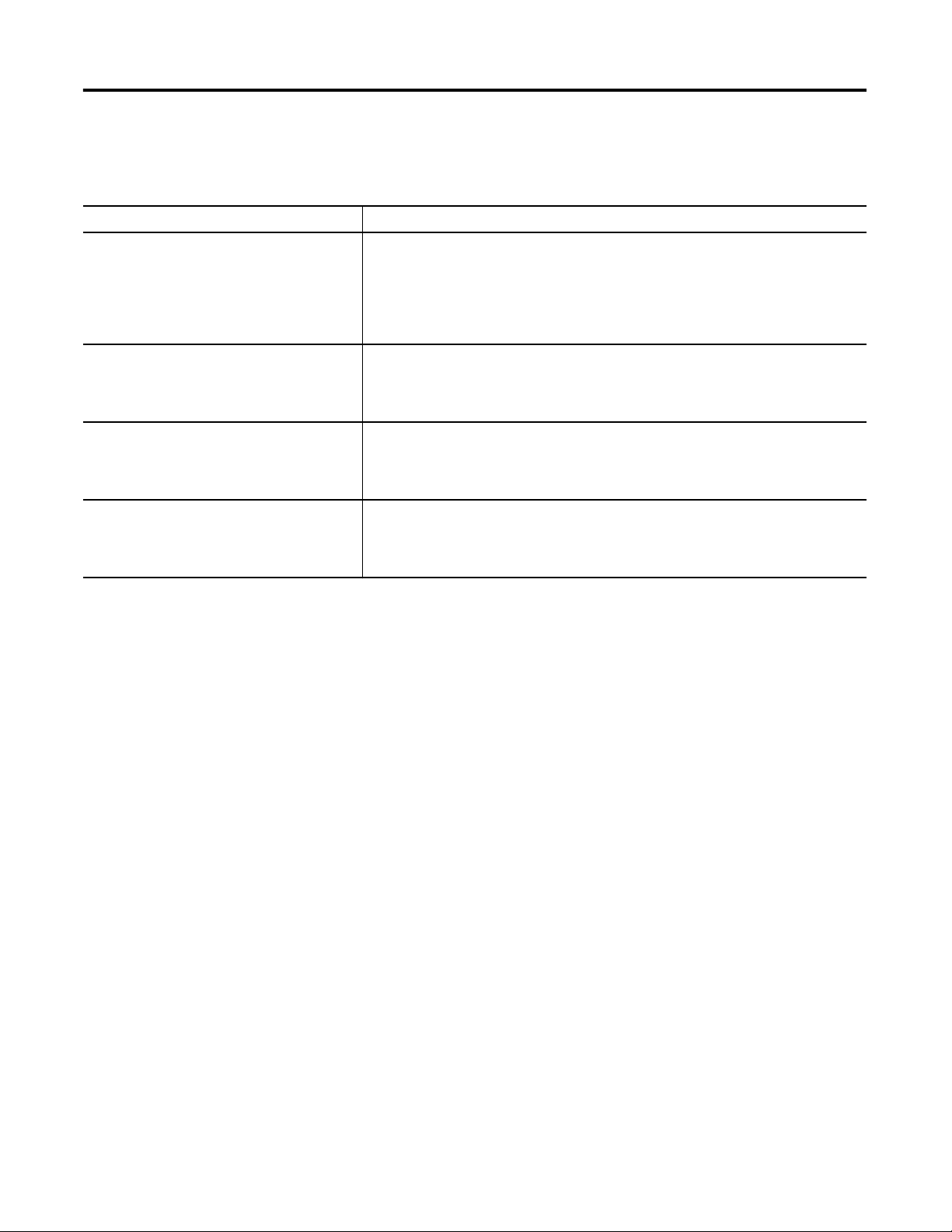

Summary of Changes

Introduction

Updated Information

The release of this document contains new and updated information. To find

new and updated information, look for change bars, as shown next to this

paragraph.

This document contains the these changes.

Topic Page

Execution Guidelines 34

PXRQ Error Codes 86

3Publication LOGIX-UM001B-EN-P - April 2010 3

Page 4

Summary of Changes

Notes:

4 Publication LOGIX-UM001B-EN-P - April 2010

Page 5

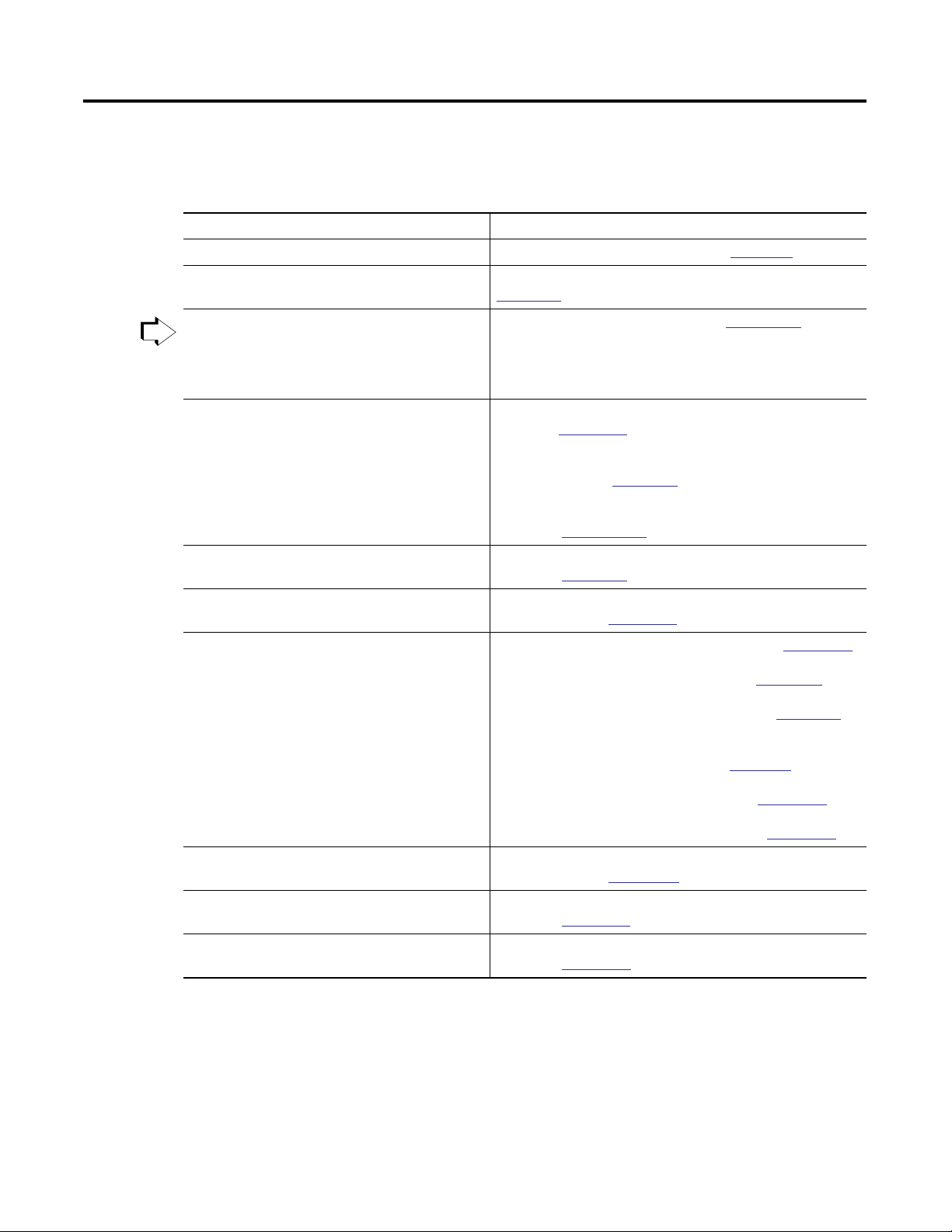

Table of Contents

Preface

Introduction

PhaseManager Quick Start

When To Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Purpose of This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Who Should Use This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

How To Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 1

PhaseManager Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

State Model Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Equipment States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

State Transitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Manually Change State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Ownership . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Comparison of Other State Models . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 2

Purpose of This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Create an Equipment Phase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Create a State Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Manually Step Through the States. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Configure the Initial State for an Equipment Phase. . . . . . . . . . . . . . . 22

Guidelines

Chapter 3

Purpose of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Equipment Model Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Example 1: Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Example 2: Smart Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

State Model Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

State Model Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Example 1: Add Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Example 2: Space Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Equipment Code Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Example 1: Add Water to a Tank . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Example 2: Smart Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Execution Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Example 1: Add Water to a Tank . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Example 2: Smart Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Transition Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Example 1: Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Example 2: Smart Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Example 3: Jam Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

State Completion Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Example 1: Add Water to a Tank . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Example 2: Smart Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Equipment Interface Tag Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5Publication LOGIX-UM001B-EN-P - April 2010 5

Page 6

Table of Contents

Equipment Phase Instructions

(PSC, PCMD, POVR, PFL, PCLF, PX

RQ, PRNP, PPD, PATT, PDET)

Example 1: Add Water to a Tank . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Example 2: Smart Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Example 2: Smart belt, Continued . . . . . . . . . . . . . . . . . . . . . . . . . 52

Alias Tag Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Appendix A

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Set and Clear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Relay Ladder Rung Condition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Prescan of Routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Choose an Equipment Phase Instruction . . . . . . . . . . . . . . . . . . . . . . . 58

Phase State Complete (PSC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Equipment Phase Command (PCMD) . . . . . . . . . . . . . . . . . . . . . . . . . 62

Equipment Phase Override Command (POVR) . . . . . . . . . . . . . . . . . 67

Equipment Phase Failure (PFL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Equipment Phase Clear Failure (PCLF) . . . . . . . . . . . . . . . . . . . . . . . . 75

Equipment Phase External Request (PXRQ) . . . . . . . . . . . . . . . . . . . . 77

Equipment Phase New Parameters (PRNP). . . . . . . . . . . . . . . . . . . . . 88

Equipment Phase Paused (PPD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Attach to Equipment Phase (PATT). . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Detach from Equipment Phase (PDET) . . . . . . . . . . . . . . . . . . . . . . 101

PHASE Data Type

Configure an Equipment Phase

Glossary

Index

Appendix B

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Set and Clear Equipment Phase Tag Values . . . . . . . . . . . . . . . . . . . . 103

PHASE Data Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Appendix C

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Open the Configuration for an Equipment Phase . . . . . . . . . . . . . . . 109

Equipment Phase Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

6 Publication LOGIX-UM001B-EN-P - April 2010

Page 7

Preface

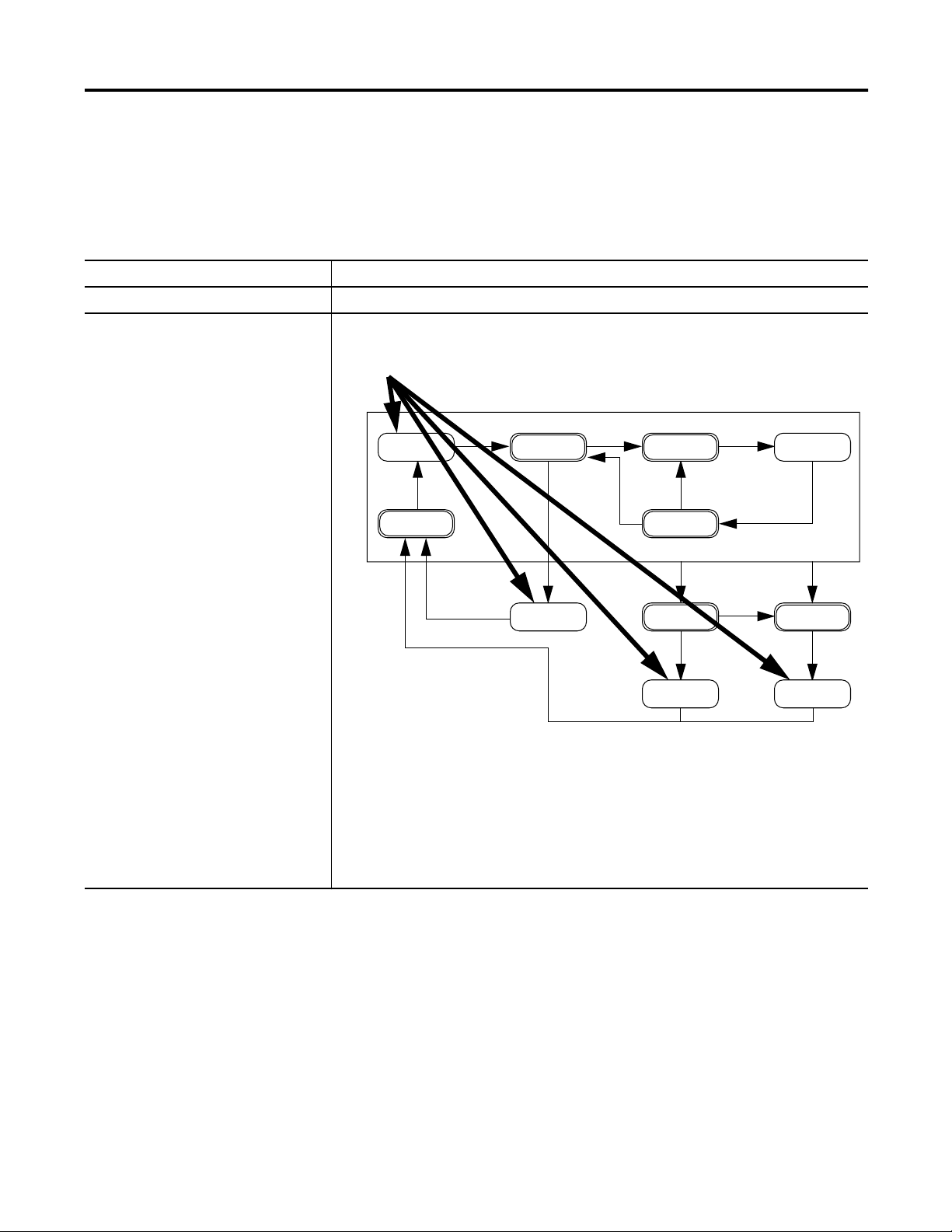

When To Use This Manual

To See

get started with a Logix5000 controller

program a Logix5000 controller—detailed and

comprehensive information

You are

here

• use equipment phases

• set up a state model for your equipment

• program in a way that is similar to S88 and

PackML models

program a specific Logix5000 programming

instruction

import or export a Logix5000 project or tags from or

to a text file

convert a PLC-5 or SLC 500 application to a

Logix5000 project

use a specific Logix5000 controller CompactLogix Controllers User manual, publication

The manual is one of various Logix5000 manuals.

Logix5000 Controllers Quick Start, publication 1756-QS001

Logix5000 Controllers Common Procedures, publication

1756-PM001

PhaseManager User Manual, publication

Logix5000 Controllers General Instructions Reference Manual,

publication

Logix5000 Controllers Process and Drives Instructions Reference

Manual, publication

Logix5000 Controllers Motion Instructions Refernce Manual,

publication

Logix5000 Controllers Import/Export Reference Manual,

publication

Converting PLC-5 or SLC 500 Logix to Logix5550 Logic Refernce

Manual, publication

1756-RM003

1756-RM006

MOTION-RM002

1756-RM084

1756-RM085

LOGIX-UM001

1769-UM007

ControlLogix System User Manual, publicaton

DriveLogix System 5720 User Manual, publication

DriveLogix5730 Controller for PowerFlex 700S Drives with

PhaseII Control User Manual, publication

FlexLogix Controllers User Manual, publication

SoftLogix5800 System User Manual, publication

control devices over an EtherNet/IP network EtherNet/IP Modules in Logix5000 Control Systems User

Manual, publication

control devices over an ControlNet network ControlNet Modules in Logix5000 Control Systems User Manual,

publication

control devices over an DeviceNet network DeviceNet Modules in Logix5000 Control Systems User Manual,

publication

CNET-UM001

DNET-UM004

ENET-UM001

1756-UM001

20D-UM002

20D-UM003

1794-UM001

1789-UM002

7Publication LOGIX-UM001B-EN-P - April 2010 7

Page 8

Preface Preface

Purpose of This Manual

Who Should Use This Manual

This manual shows you how to set up and program a Logix5000 controller to

use equipment phases. It gives you guidance and examples to:

• lay-out your code in sections that include equipment phases.

• set up a state model for your equipment.

• program your equipment to run by the state model.

• use equipment phase instructions to transition to a different state,

handle faults, set up break points, and so forth.

A Logix5000 controller is any of the following:

• 1756 ControlLogix controllers

• 1769 CompactLogix controllers

• 1789 SoftLogix5800 controllers

• 1794 FlexLogix controllers

• 20D PowerFlex 700S with DriveLogix controllers

This manual is for those who program or maintain industrial automation

systems.

How To Use This Manual

To use this manual, you must already have experience with:

• programmable controllers.

• industrial automation systems.

• personal computers.

As you use this manual, text that is courier identifies information that you

must supply based on your application (a variable). For example, ‘Right-click

name_of_program ...’ means that you must identify the specific program in

your application. Typically, it is a name or variable that you have defined.

8 Publication LOGIX-UM001B-EN-P - April 2010

Page 9

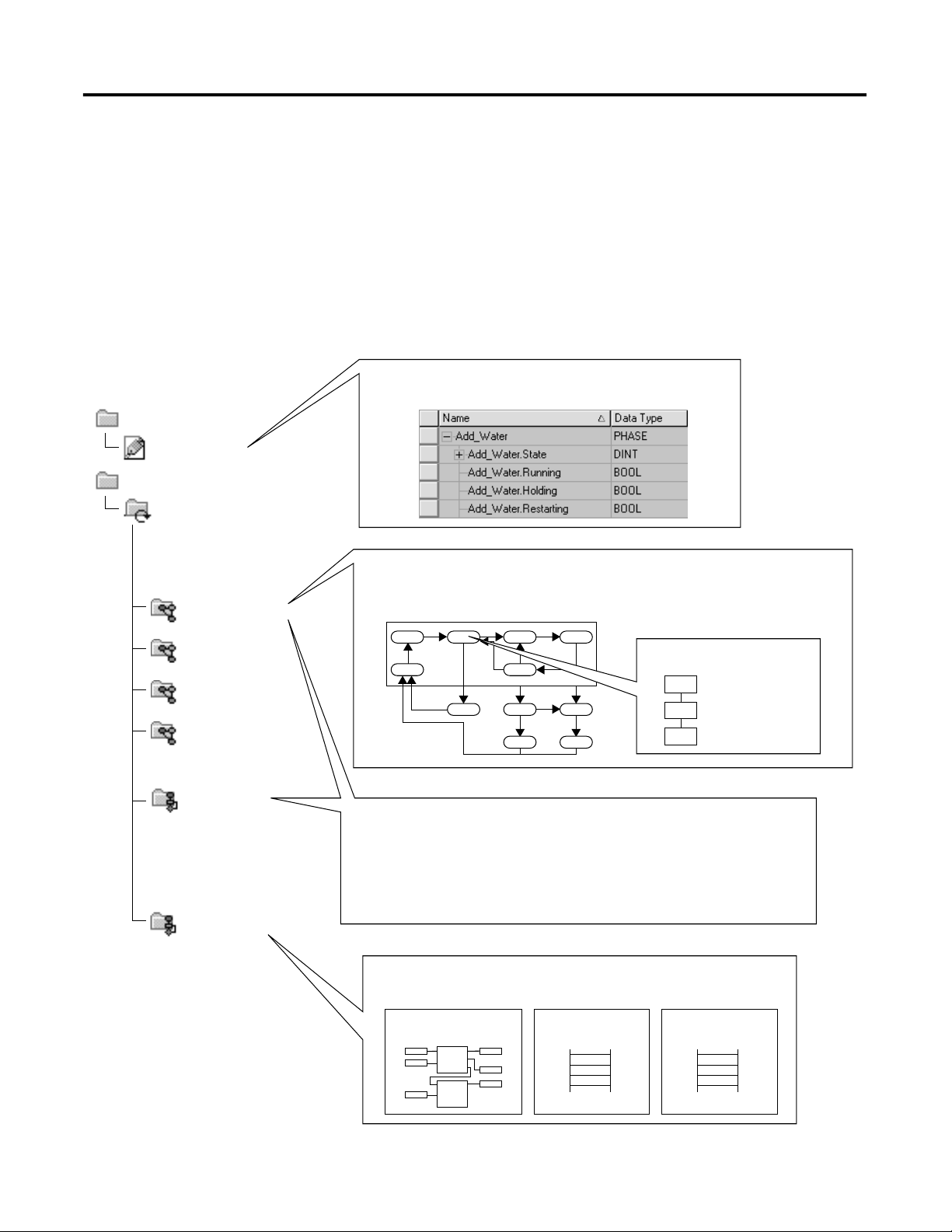

Introduction

Chapter 1

PhaseManager Overview

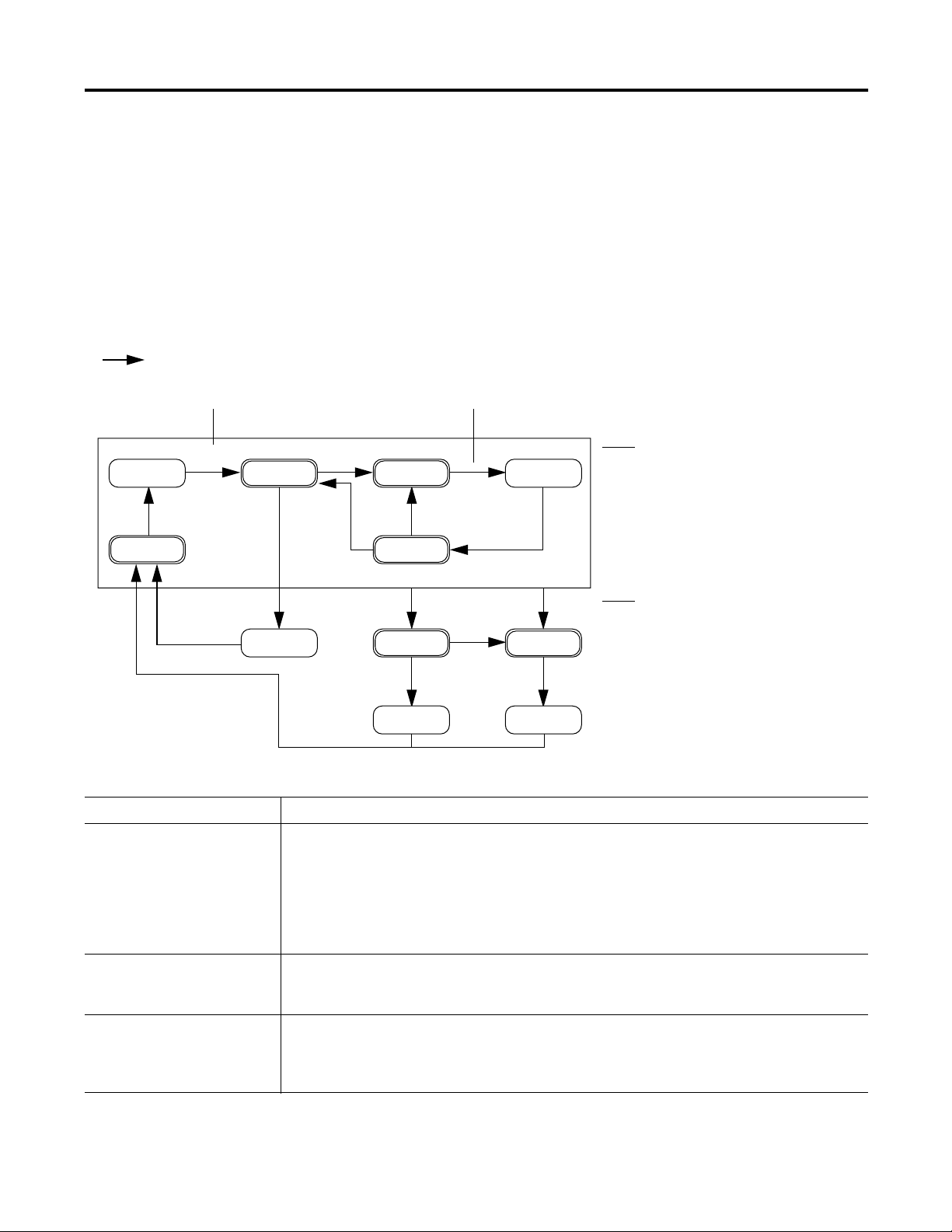

Controller

Controller Tags

Tasks

MainTask

Add_Water_Phase

Mix_Phase

Drain_Phase

Space_Parts_Phase

PhaseManager software lets you add equipment phases to your controller. An

equipment phase makes it easier to write, use, and manage the code for your

machine or equipment.

A PHASE tag gives you the status of an equipment phase.

An equipment phase directs 1 activity of your equipment.

A state model divides the activity into a set of states that have specific transitions.

Running State Routine

How to add

water

MainProgram

My_Equipment_Program

9Publication LOGIX-UM001B-EN-P - April 2010 9

Equipment phase instructions control the transitions between

states, handle faults, and so forth.

PSC POVR PCLF PRNP PATT

PCMD PFL PXRQ PPD PDET

Other code does the specific actions of your equipment

Water Feed

Conveyor Enable Axes

Page 10

Chapter 1 Introduction

PhaseManager Terms

Term Description

equipment phase An equipment phase is similar to a program:

state model A state model divides the operating cycle of your equipment into a set of states. Each state

state machine The controller has an embedded state machine for the equipment phase. This makes it a lot

• you run the equipment phase in a task.

• you give the equipment phase a set of routines and tags.

An equipment phase is different from a program in these ways:

• The equipment phase uses a state model.

• Use an equipment phase to do 1 activity of your equipment.

is an instant in the operation of the equipment. It's the actions or conditions of the

equipment at a given time.

The state model of an equipment phase is similar to these state models:

• U.S. standard ISA S88.01-1995 and its IEC equivalent IEC 61512-1-1998, commonly

referred to as S88

• PackML, which was previously under the supervision of OMAC but is now a working

group within ISA

easier to use the state model. The state machine:

• calls the main routine (state routine) for an acting state.

• manages the transitions between states with minimal coding.

You code the transition conditions. When the conditions are true, the state machine

transitions the equipment to the next required state.

• makes sure that the equipment goes from state to state along an allowable path.

For example, if the equipment is in the Complete or Stopped state, the equipment phase

makes sure that it goes only to the Resetting state. This simplifies the amount of

interlocking that you have to do.

equipment phase instructions Specific instructions that you use to control an equipment phase. See

PHASE tag When you add an equipment phase, RSLogix 5000 programming software makes a tag for

the equipment phase. The tag uses the PHASE data type. Use the tag to:

• see which state the equipment phase is in.

• hold a failure code for the equipment phase.

• hold an index for your steps.

• hold the unit ID.

• see the status of an external request to FactoryTalk Batch software.

• see if FactoryTalk Batch software has new parameters for the equipment phase.

• set up producing and standby states.

See

Appendix B

for more information about the PHASE data type.

Appendix A

.

PhaseManager software helps you write the code for your equipment in a

structured way. This results in the same behavior for all the equipment across a

plant.

10 Publication LOGIX-UM001B-EN-P - April 2010

Page 11

Introduction Chapter 1

PhaseManager Questions and Answers

Question Answer

How can I get the highest performance possible

from my equipment?

You have to measure equipment performance to improve it. The state model gives you a

way to measure the status of your equipment. With that data, you'll be able to calculate

the efficiency and performance measures that you want.

If you use PhaseManager software across your plant, you have consistent data from

equipment to equipment.

How can I cut the cost of integrating my

equipment into the plant?

Clear structure and consistent tags make it a lot easier to plug the equipment into your

plant and set up communication right away. Equipment up and down that line share

data using the same tag names. And all equipment communicates with higher-level

systems in the same way.

How can I make it easier to maintain the code? A state model helps you lay out the general functions of your equipment. We found that

the best programmers use a state model as the heart of their code. A state model serves

as a map for the code. With a clear structure, you'll know just where to look for the

piece of code that you want.

How can I give my operators a clean, intuitive

HMI?

A state model lets you make all your equipment behave the same. Your HMIs can then

show consistent equipment conditions across the plant. When an HMI says that the

equipment is idle, running, or holding, your operators will know exactly what that

means.

Publication LOGIX-UM001B-EN-P - April 2010 11

Page 12

Chapter 1 Introduction

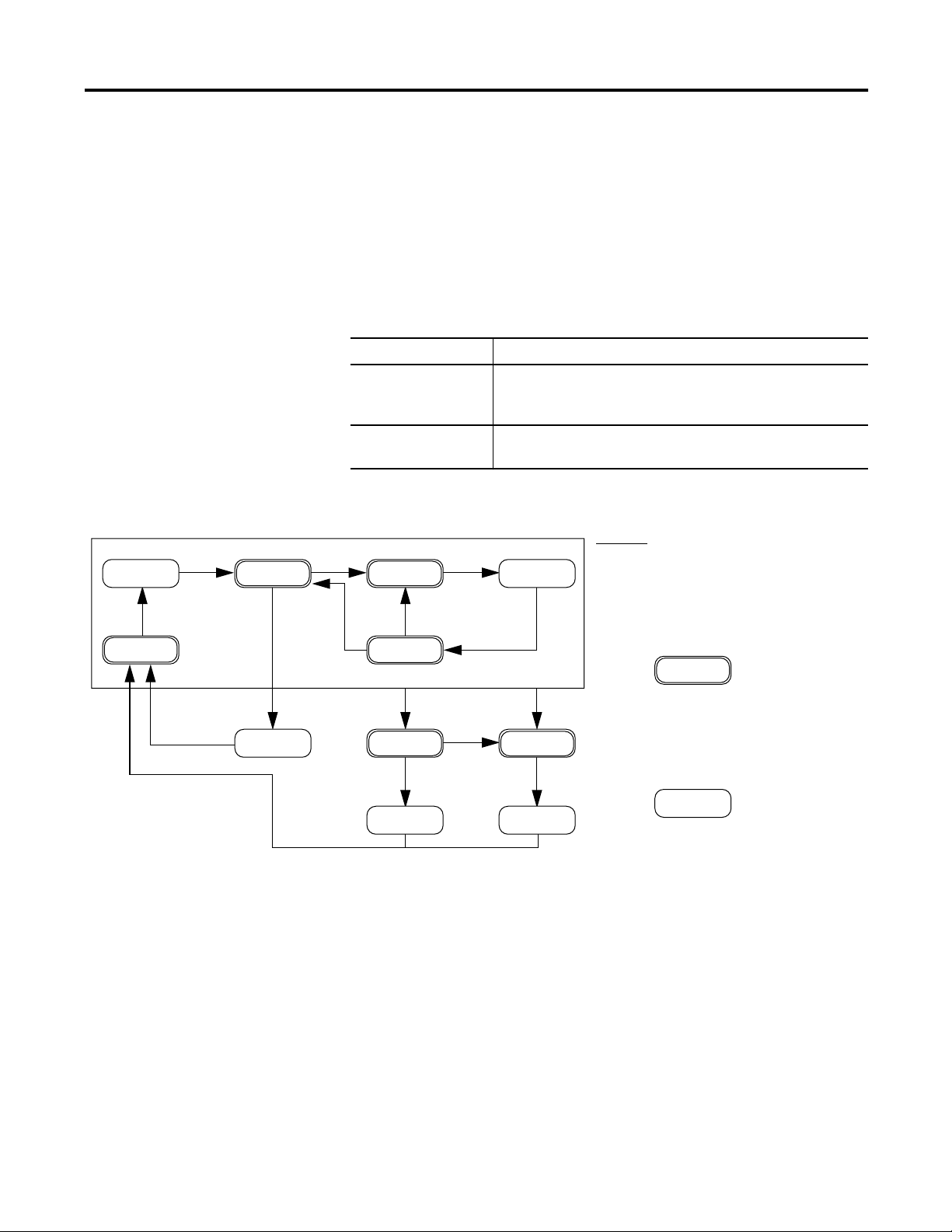

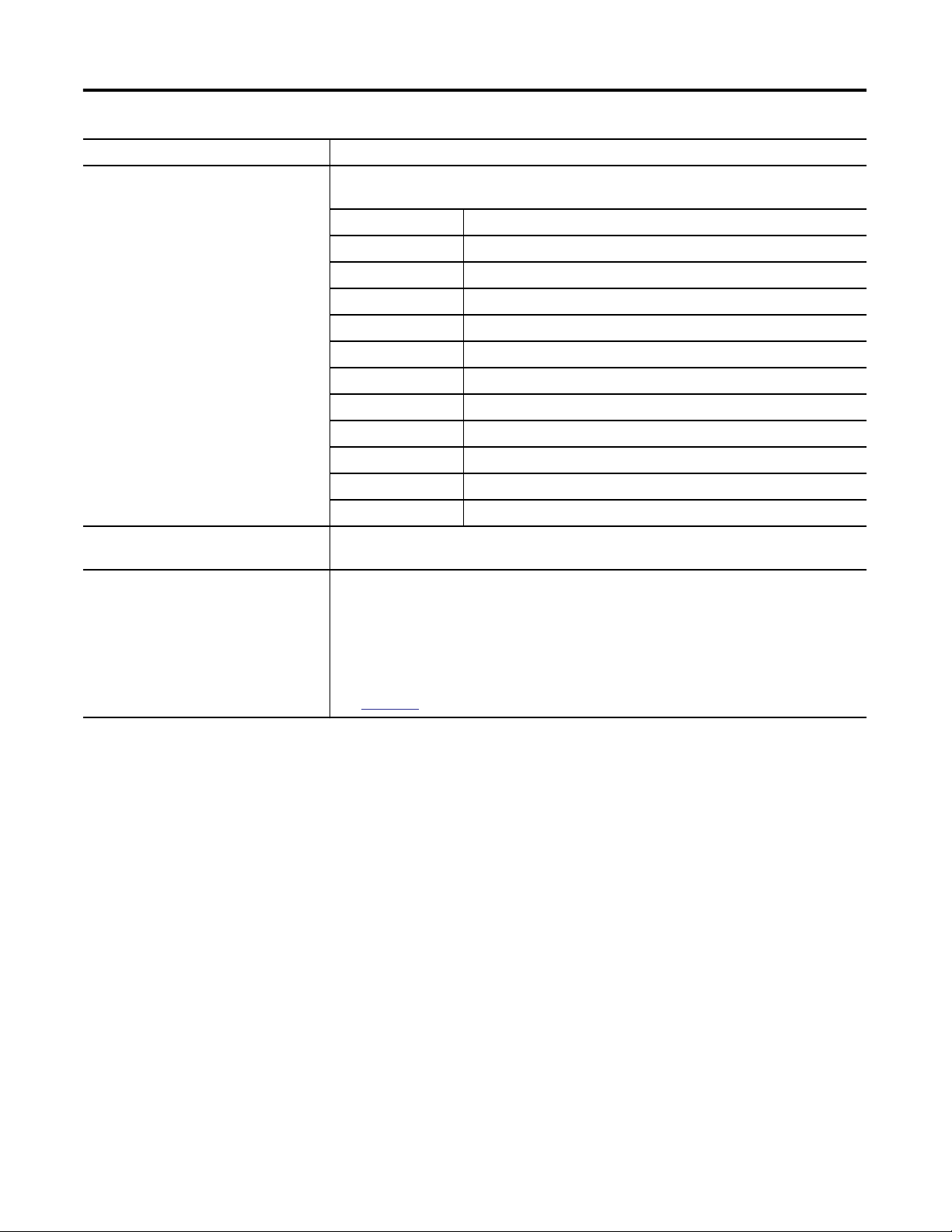

State Model Overview

Start

Idle

Running

A state model divides the operating cycle of your equipment into a series of

states. Each state is an instant in the operation of the equipment. It's the

actions or conditions of the equipment at a given time.

In a state model, you define what your equipment does under different

conditions, such as run, hold, stop, and so forth. You don’t need to use all the

states for your equipment. Use only the states that you want.

There are two types of states.

Type of State Description

Acting Does something or several things for a certain time or until

certain conditions are met. An acting state runs one time or

repeatedly.

Waiting Shows that certain conditions are met and the equipment is

waiting for the signal to go to the next state.

PhaseManager software uses the following states.

Hold

Holding

Held

Your equipment can go from any

state in the box to the stopping or

aborting state.

Resetting

Reset

Complete

Reset

Hold

Restart

Restarting

Stop

Abort

Stopping

Stopped Aborted

Aborting

Abort

Acting

Acting states represent the

things your equipment does at

a given time.

Waiting

Waiting states represent the

condition of your equipment

when it is in-between acting

states.

12 Publication LOGIX-UM001B-EN-P - April 2010

Page 13

Introduction Chapter 1

One common objection to a state model is that it doesn't fit all equipment.

You may hear or think: ‘My equipment is very complex. There's a lot of

synchronization and many things happen in parallel.’

Keep in mind that a state model looks at your equipment at a very general

level. Different equipment does different things and needs specific code for

everything it does. A state model simply gives you a higher-level framework for

your code.

• The state model defines the general behavior, commands, and status of

the equipment.

• You program the details of the equipment within that framework.

Equipment States

The use of a state model may sound like a big change for programmers. But it's

simply a different way to look at the same control problem.

With a state model, you define the behavior of your equipment and put it into

a brief functional specification. In this way you show what happens and when

it happens.

For this State Ask

Stopped What happens when you turn on power?

Resetting How does the equipment get ready to run?

Idle How do you tell that the equipment is ready to run?

Running What does the equipment do to make product?

Holding How does the equipment temporarily stop making product without

making scrap?

Held How do you tell if the equipment is safely holding?

Restarting How does the equipment resume production after holding?

Complete How do you tell when the equipment is done with what it had to do?

Stopping What happens during an normal shutdown?

Aborting How does the equipment shutdown if a fault or failure happens?

Aborted How do you tell if the equipment is safely shutdown?

Publication LOGIX-UM001B-EN-P - April 2010 13

Page 14

Chapter 1 Introduction

State Transitions

= transition

Command Done — No command. Use PSC instruction instead.

Start

Idle

Resetting

Running

The arrows in the state model show to which states your equipment can go

from the state it is in now.

• Each arrow is called a transition.

• A state model lets the equipment make only certain transitions. This

gives the equipment the same behavior as any other equipment that uses

the same model.

PhaseManager software uses the following transitions.

Hold

Holding

Hold

Restarting

Held

Restart

Your equipment can go from any

state in the box to the stopping or

aborting state.

Stop

Reset

Complete

Reset

Type of Transition Description

Command A command tells the equipment to start doing something or do something different. For example the

operator pushes the start button to start production and the stop button to shutdown.

PhaseManager software uses these commands:

reset stop restart

start hold abort

Done Equipment goes to a waiting state when it's done with what it's doing. You don’t give the equipment a

command. Instead, you set up your code to signal when the equipment is done. The waiting state

shows that the equipment is done.

Fault A fault tells you that something out of the ordinary has happened. You set up your code to look for

faults and take action if it finds any. Suppose you want your equipment to shut down as fast as

possible if a certain fault happens. In that case, set up your code look for that fault and give the abort

command if it finds it.

Stopping

Stopped Aborted

Abort

Abort

Aborting

Fault (specific use of the abort

command)

14 Publication LOGIX-UM001B-EN-P - April 2010

Page 15

Introduction Chapter 1

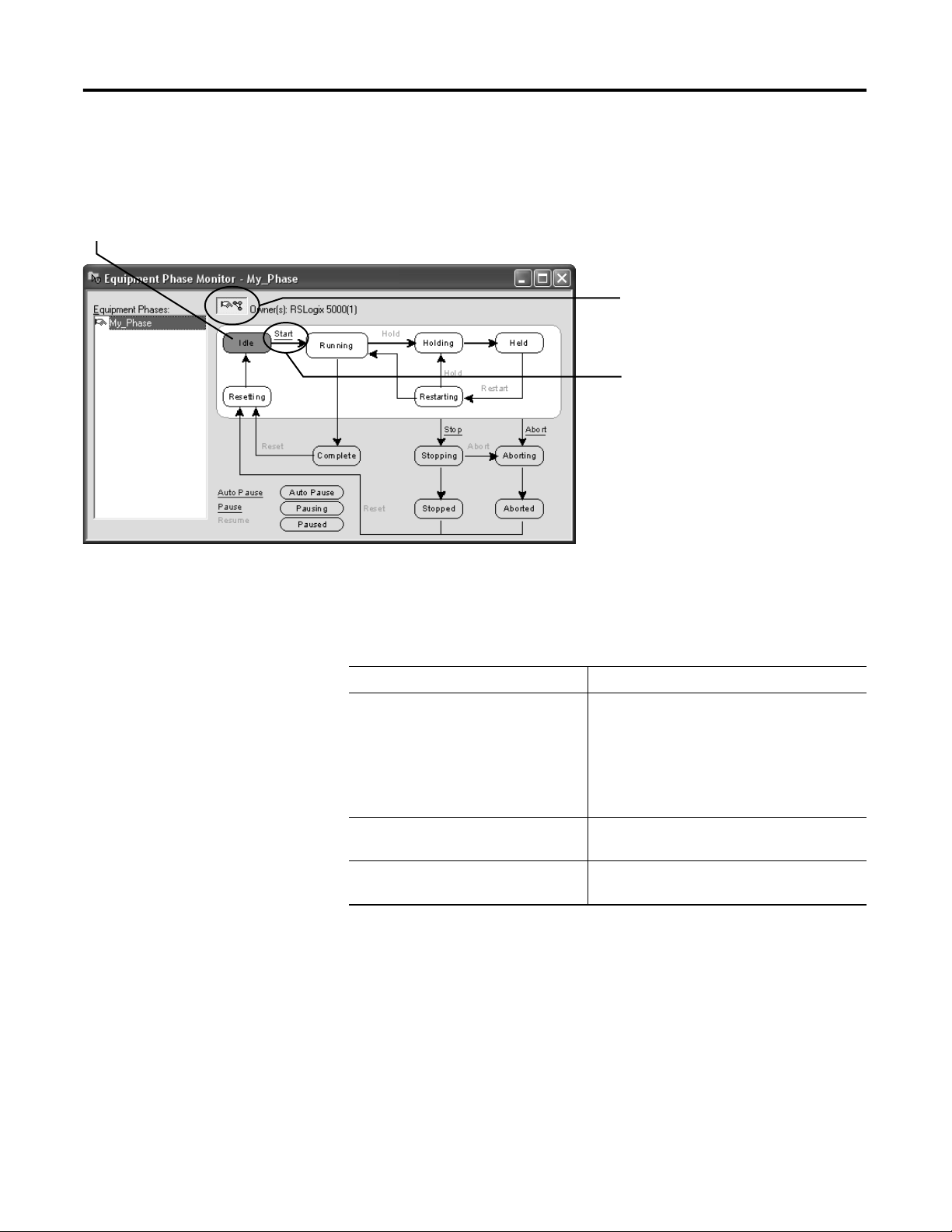

Manually Change State

State that the equipment phase is in right now

RSLogix 5000 programming software has a window that lets you monitor and

command an equipment phase.

To manually change states.

1. Take ownership of the equipment phase.

2. Give a command.

Ownership

Ownership locks out programs or FactoryTalk Batch software from giving

commands to an equipment phase.

If this owns the equipment phase Then

RSLogix 5000 programming software Sequencers can’t give commands to the

equipment phase. This includes:

• Internal sequencer — program in the

controller.

• External sequencer — FactoryTalk Batch

software.

Internal sequencer — program in the

controller

External sequencer — FactoryTalk Batch

software

Other sequencers can’t give commands to the

equipment phase.

Other sequencers can’t give commands to the

equipment phase.

Exception: Use an Equipment Phase Override Command (POVR)

instruction to give a hold, stop, or abort command regardless of ownership.

Publication LOGIX-UM001B-EN-P - April 2010 15

Page 16

Chapter 1 Introduction

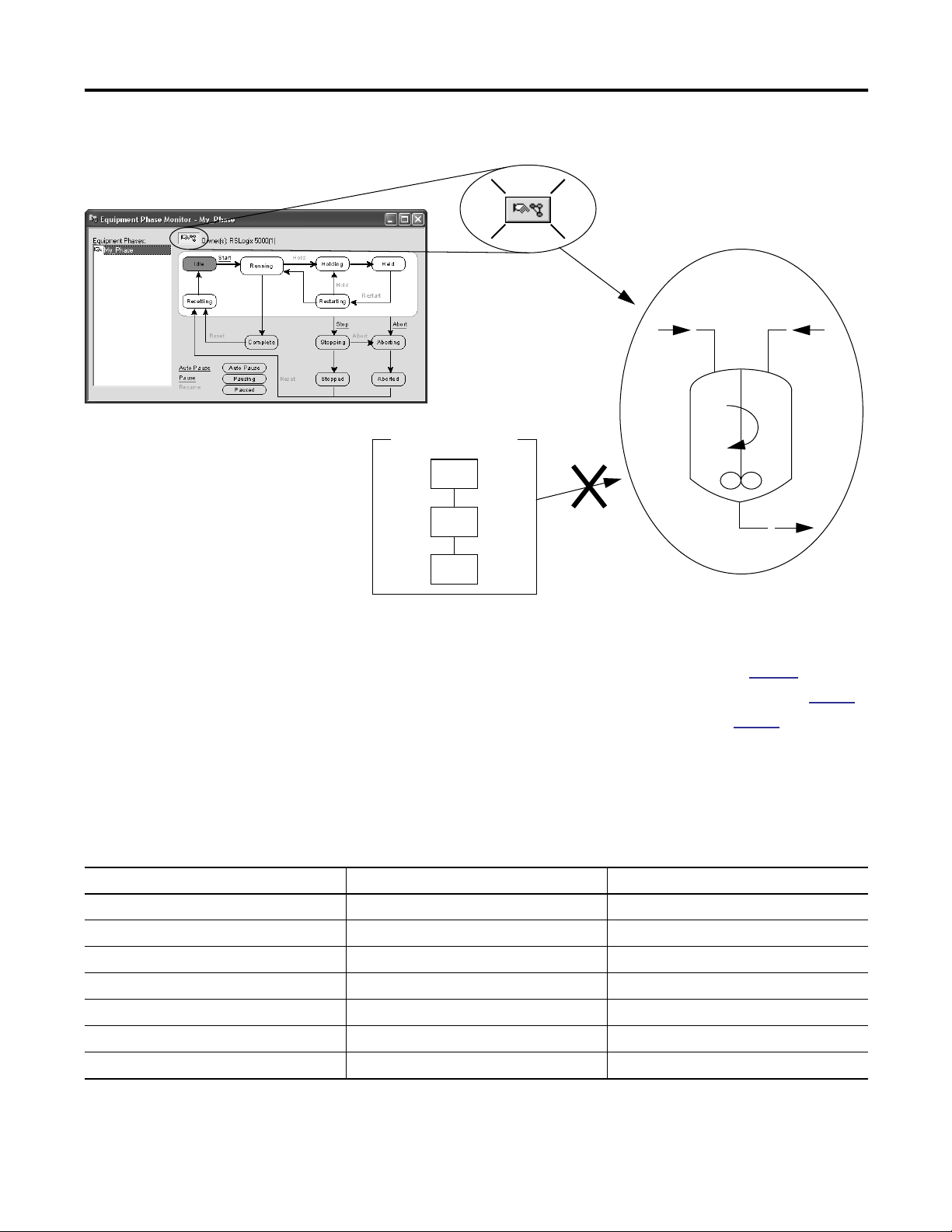

Takes ownership

My Code

Can’t command

See the following for additional information.

• Equipment Phase Command (PCMD) instruction on

page 62.

• Equipment Phase Override Command (POVR) instruction on

• Attach to Equipment Phase (PATT) instruction on

Comparison of Other State Models

S88 PackML PhaseManager Software

Idle Starting Ready Resetting Idle

Running Complete Producing Running Complete

Pausing Paused Standby subroutines, breakpoints, or both.

Holding Held Holding Held Holding Held

Restarting none Restarting

Stopping Stopped Stopping Stopped Stopping Stopped

Aborting Aborted Aborting Aborted Aborting Aborted

The following table compares PhaseManager software’s state model to other

common state models.

page 97

.

page 68

.

16 Publication LOGIX-UM001B-EN-P - April 2010

Page 17

PhaseManager Quick Start

Chapter 2

Purpose of This Chapter

Use this quick start to:

• get an introduction to how an equipment phase runs.

• monitor an equipment phase.

• manually tell an equipment phase to go to a different state.

Use this quick start when you want to:

• try out PhaseManager software for the first time.

• test an equipment phase by manually stepping through its states.

Topic Page

Create an Equipment Phase 18

Create a State Routine 18

Manually Step Through the States 19

Configure the Initial State for an Equipment Phase 22

Equipment

17Publication LOGIX-UM001B-EN-P - April 2010 17

To use this quick start, you need:

• a Logix5000 controller. See the preface if you aren’t sure which

controllers are Logix5000 controllers.

• firmware, revision 18.0 or later, for the controller

• a power supply for the controller

• a communication path to the controller:

– Communication card or built-in port

– Corresponding communication cable

• RSLogix 5000 programming software, version 18.0 or later

Page 18

Chapter 2 PhaseManager Quick Start

2

3

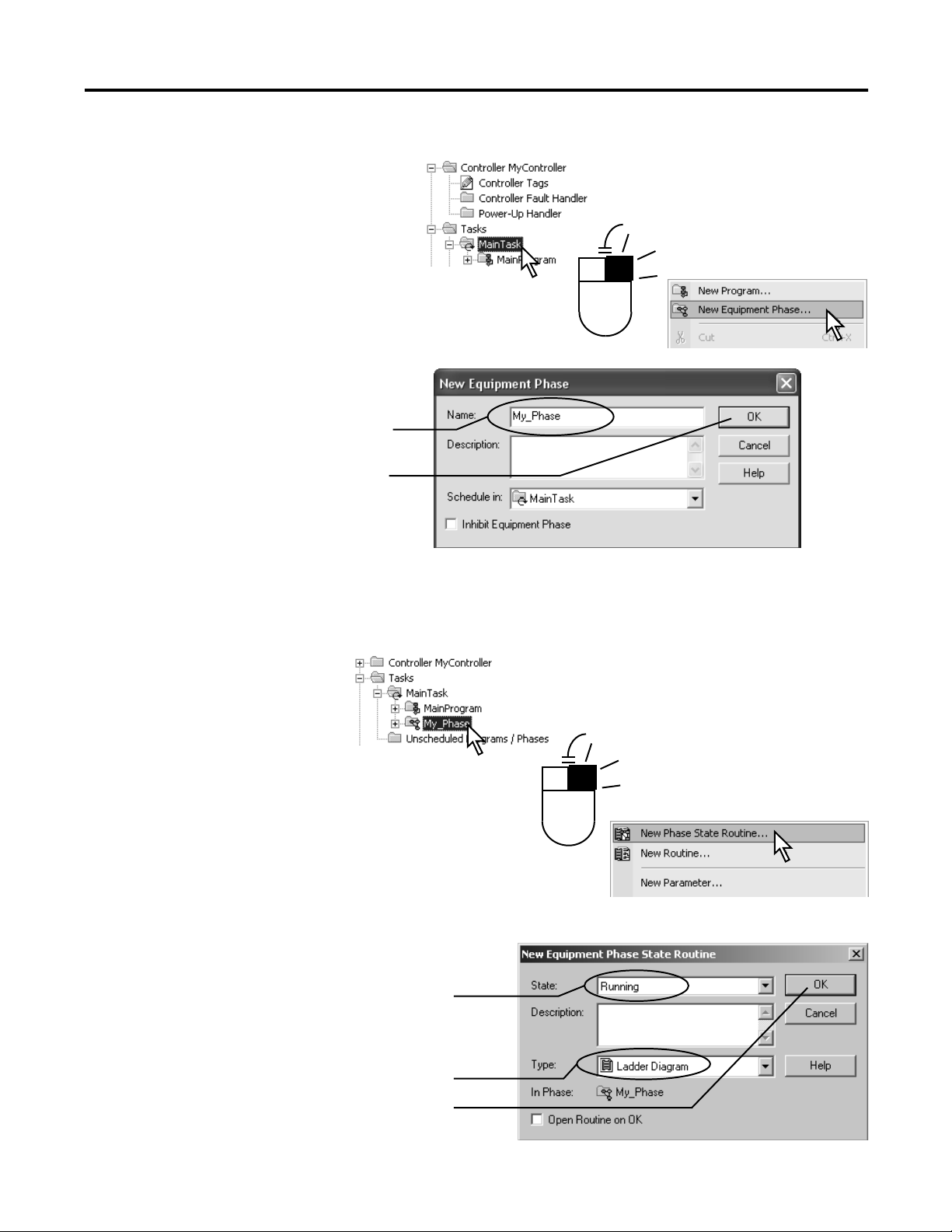

Create an Equipment Phase

1.

.

.

Create a State Routine

1.

2.

3.

18 Publication LOGIX-UM001B-EN-P - April 2010

4.

Page 19

PhaseManager Quick Start Chapter 2

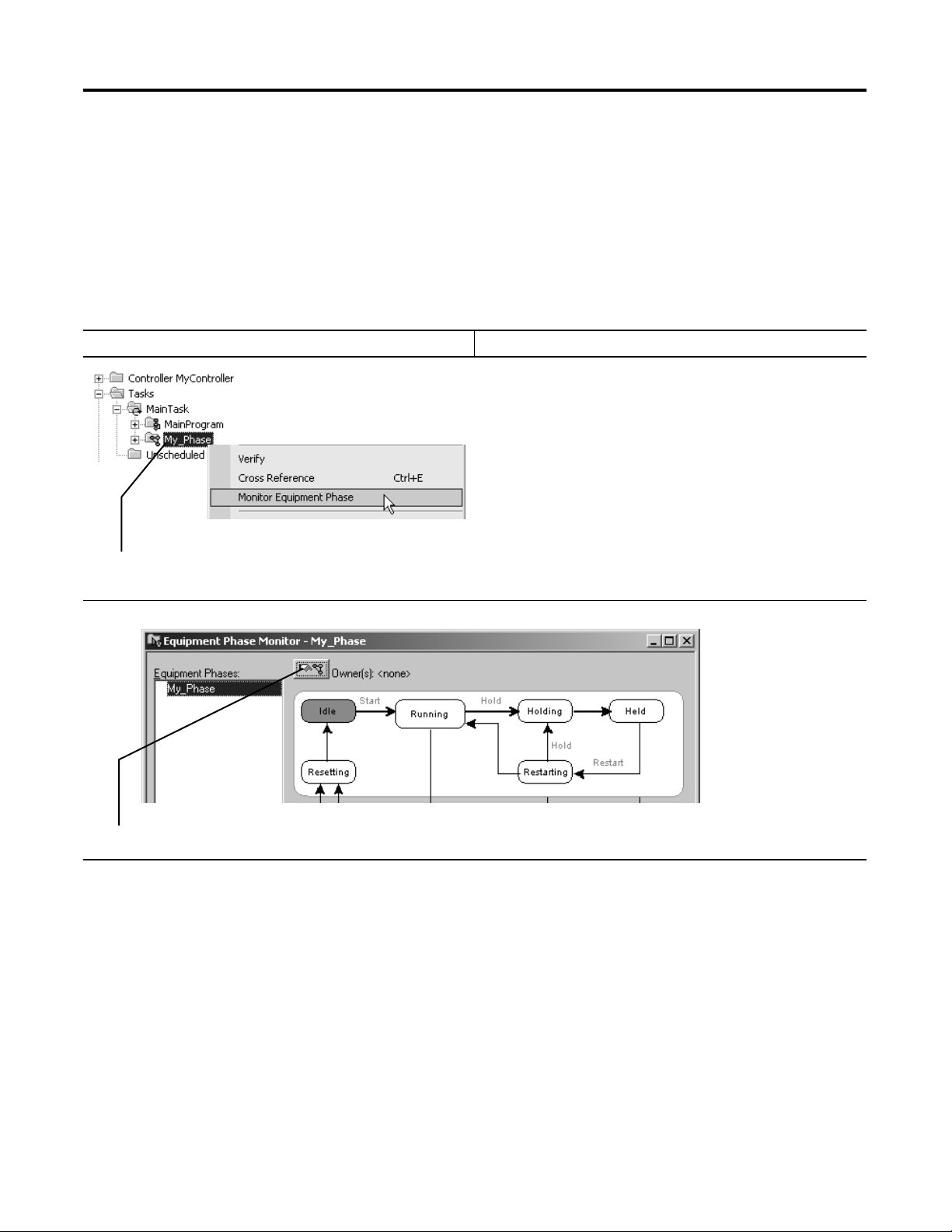

Manually Step Through the States

Step Notes

1. Right-click the equipment phase and choose Monitor Equipment

Phase.

Before you do this procedure, do the following:

• Download the project to the controller.

• Put the controller in run or remote run mode.

2. Click the ownership button and then Yes—take ownership. This lets you use this window to step through the states.

Publication LOGIX-UM001B-EN-P - April 2010 19

Page 20

Chapter 2 PhaseManager Quick Start

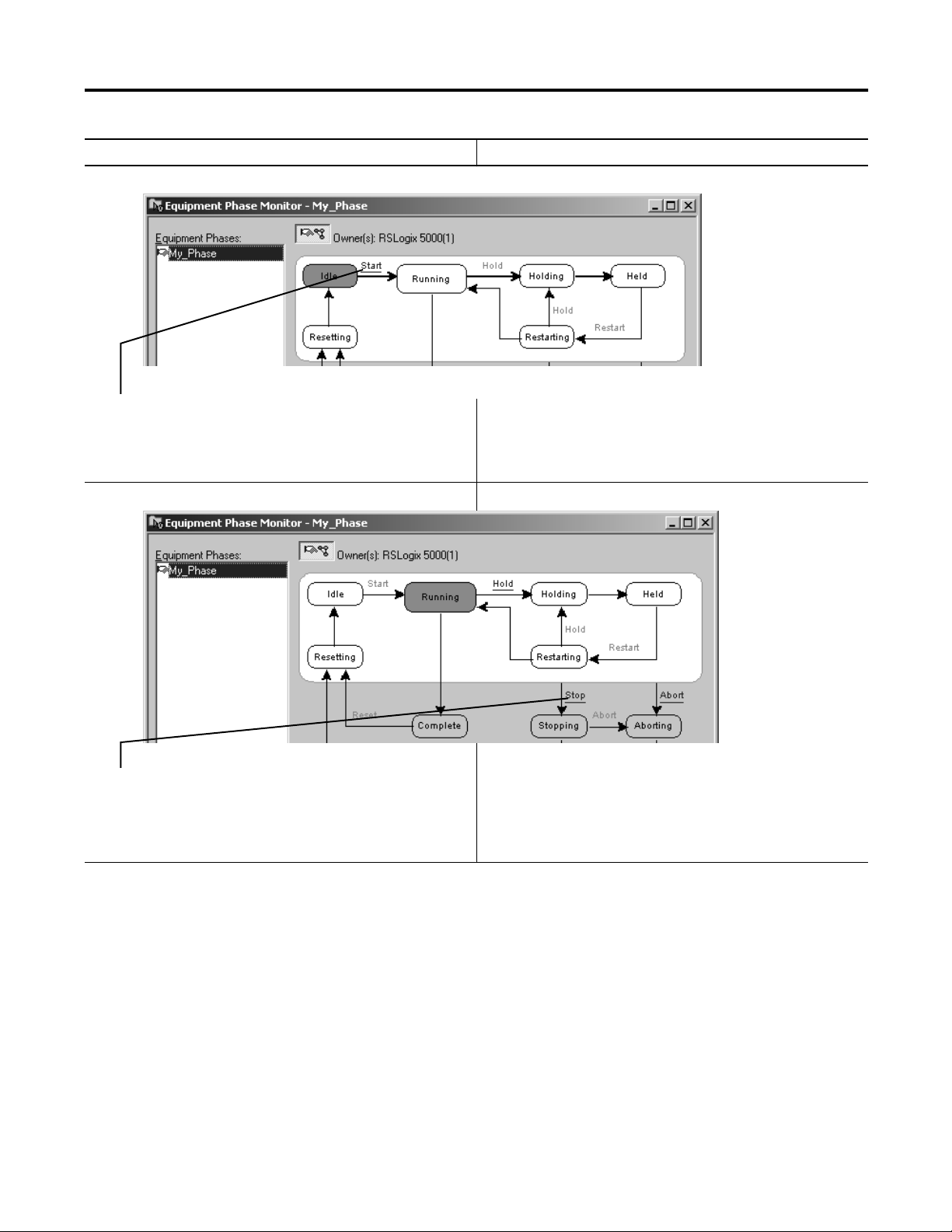

Step Notes

3. Click Start. • The equipment phase goes to the Running state.

• Any code in the Running state routine starts running. This is

where you put the code for the normal production sequence of

your equipment.

4. Click Stop. • The equipment phase goes to the Stopped state.

• The Running state routine stops running.

• The Stopping state routine is optional. Without it, the

equipment phase goes directly to the Stopped state.

20 Publication LOGIX-UM001B-EN-P - April 2010

Page 21

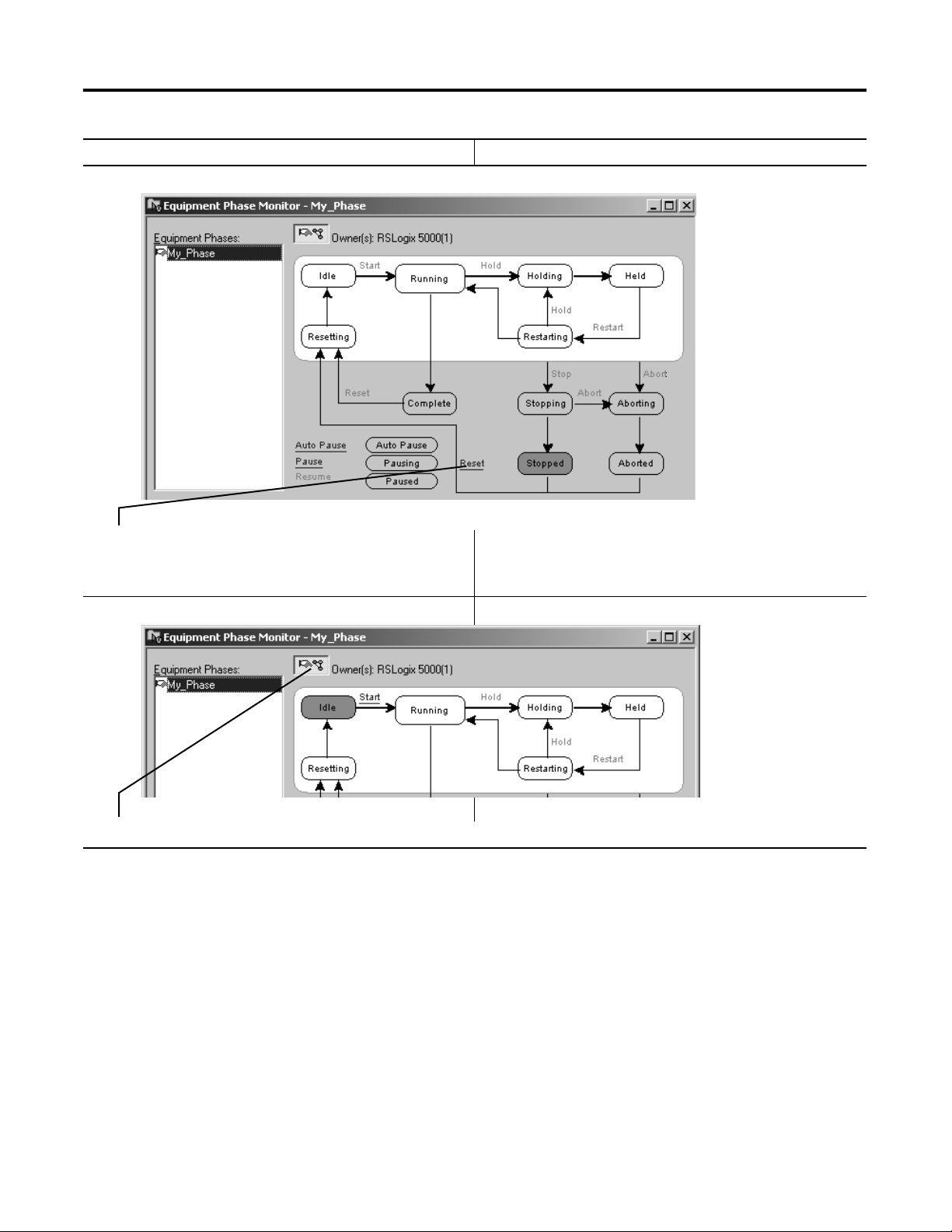

Step Notes

PhaseManager Quick Start Chapter 2

5. Click Reset. • The equipment phase goes to the Idle state.

• The Resetting state routine is optional. Without it, the

equipment phase goes directly to the Idle state.

6. Click the ownership button. This releases the equipment phase from control by this window.

Publication LOGIX-UM001B-EN-P - April 2010 21

Page 22

Chapter 2 PhaseManager Quick Start

3

4

2

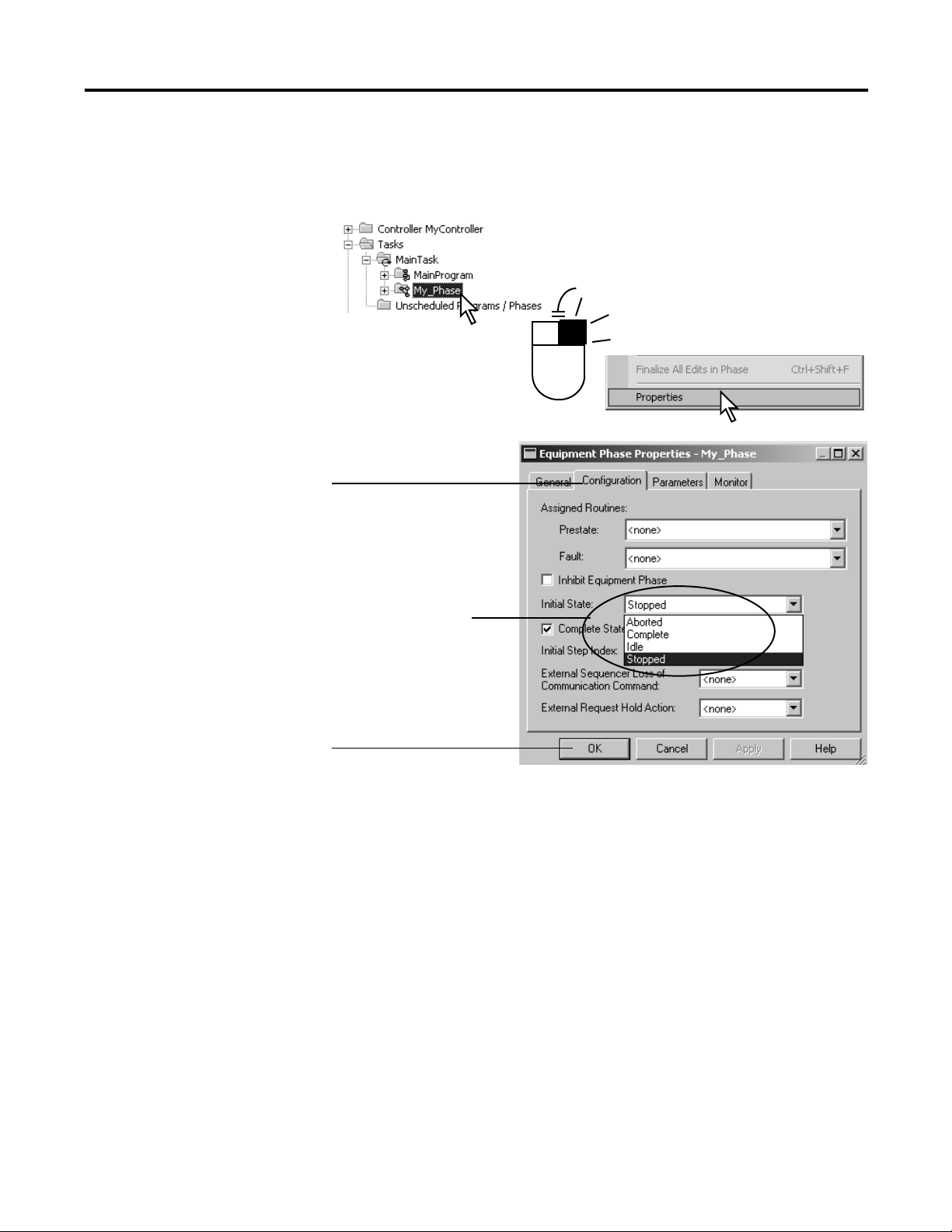

Configure the Initial State for an Equipment Phase

1.

.

The initial state is the first state to which the equipment phase goes after

power up.

. Choose your initial state.

.

22 Publication LOGIX-UM001B-EN-P - April 2010

Page 23

Guidelines

Chapter 3

Purpose of this chapter

To guide your development and programming of a Logix5000 project that

uses equipment phases

Use this chapter:

• before you lay-out the equipment phases for your Logix5000 project.

• as a reference while you program the project.

Review the following guidelines before you lay-out your project and refer back

to them as needed:

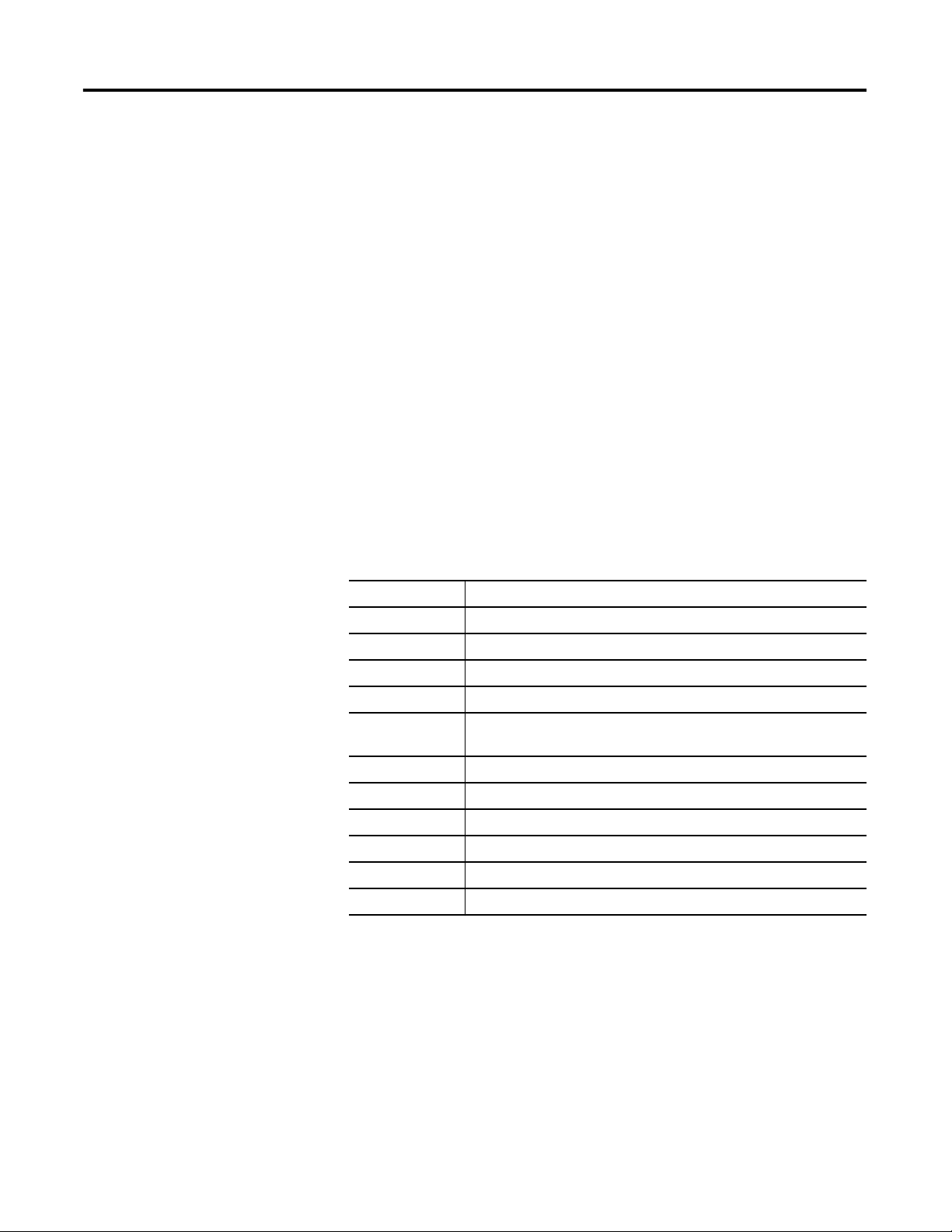

Topic Page

Equipment Model Guidelines 24

State Model Guidelines 26

Equipment Code Guidelines 31

Execution Guidelines 34

State Completion Guidelines 46

Transition Guidelines 40

Equipment Interface Tag Guidelines 48

Alias Tag Guidelines 53

23Publication LOGIX-UM001B-EN-P - April 2010 23

Page 24

Chapter 3 Guidelines

Equipment Model

Each equipment phase is a specific activity that your equipment does. An

equipment phase tells the equipment what to do and when to do it.

Guidelines

Follow these guidelines to decide how many equipment phases to use.

Guideline Details

Make sure each equipment phase does

an independent activity.

Keep the number of equipment phases

and programs within the following limits.

List the equipment that goes along with

each equipment phase.

Make sure each equipment phase does an activity that is independent (relatively

independent) from other equipment. The equipment phase commands all the equipment that

works together to do the specific activity.

Example

This is probably an equipment

phase

• Fill bottles with product.

• Put bottles in carton.

• Add water to a tank.

• Mix ingredients in tank

If you have this controller You can have up to

ControlLogix 100 programs and equipment phases per task

SoftLogix 100 programs and equipment phases per task

FlexLogix 32 programs and equipment phases per task

CompactLogix 32 programs and equipment phases per task

Example

This equipment phase Relates this equipment

Add_Water water pump

Smart_Belt Coarse belt axis

This in probably NOT an equipment phase

• Accelerate filler axis (too small)

• Run bottling line (too big)

• Open water valve (too small)

• Brew ingredients (too big)

water valve

limit switch

Fine belt axis

Exit belt axis

24 Publication LOGIX-UM001B-EN-P - April 2010

Page 25

tank completes these steps.

1. Adds water.

2. Heats the water.

3. Adds other ingredients.

4. Mixes all the ingredients.

5. Dispenses the finished

product.

Guidelines Chapter 3

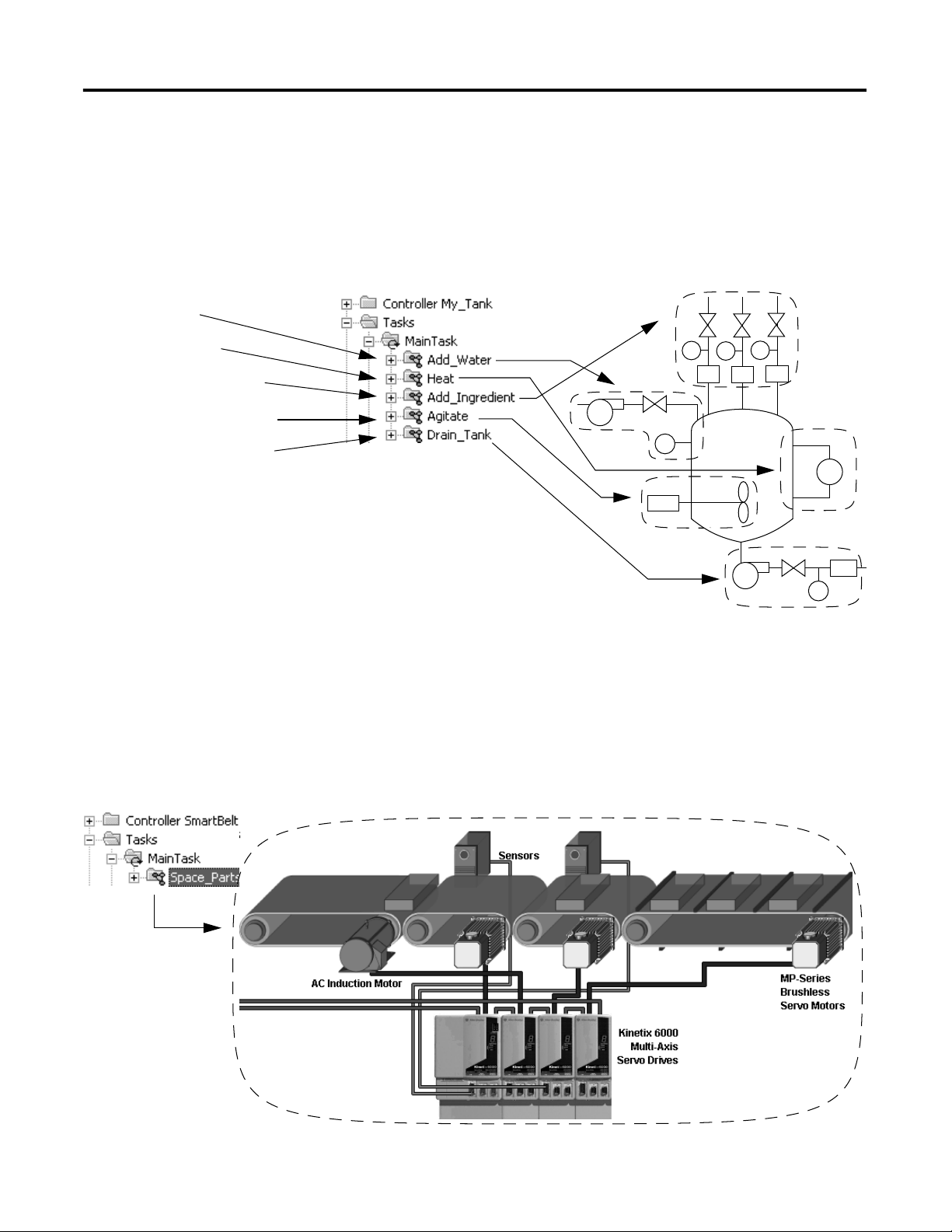

Example 1: Tank

The following example shows the equipment phases for a tank that cooks

ingredients.

Which become these phases Which commands this equipmentTo cook the ingredients, the

Example 2: Smart Belt

The following example shows a smart belt. The smart belt does only one

activity. It spaces product evenly on an exit belt. Because it does only one

activity, it needs only 1 equipment phase.

Publication LOGIX-UM001B-EN-P - April 2010 25

Page 26

Chapter 3 Guidelines

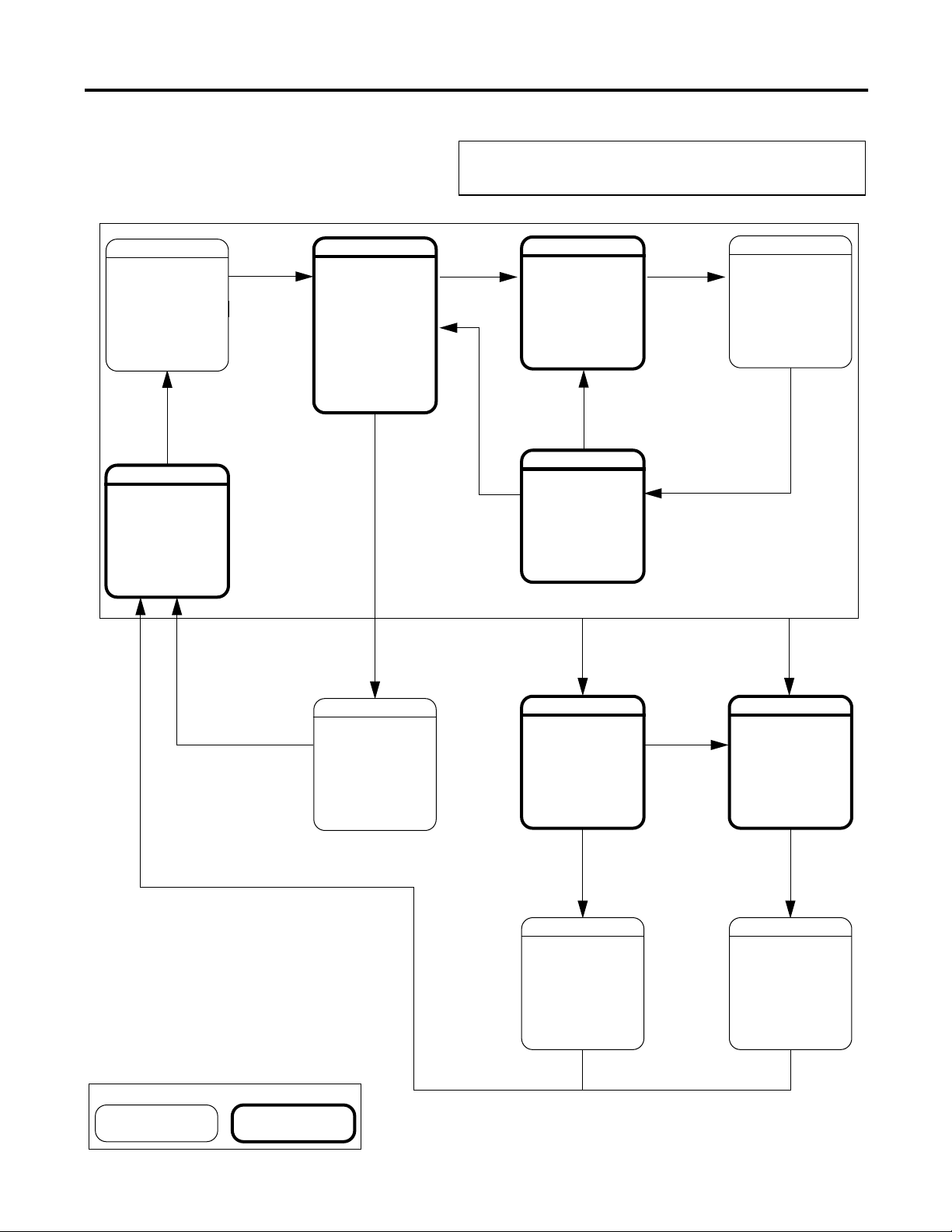

State Model Guidelines

A state model divides the operating cycle of your equipment into a series of

states. Each state is an instant in the operation of the equipment. It's the

actions or conditions of the equipment at a given time.

Follow these guidelines as you fill out the state model for an equipment phase.

Guideline Details

Fill out 1 state model for each phase. Each phase runs its own set of states. Fill out 1 state model worksheet for each phase.

Decide which state you want as your

initial state after power-up.

Which state do you want the equipment phase to go to when you turn on power?

ON

?

Idle

Resetting

Start

Running

Reset

Complete

Hold

Holding

Hold

Restarting

Stop

Stopping

Restart

Abort

Aborting

Held

Abort

Reset

An equipment phase goes to its initial state when you turn on power. We recommend that you

use one of these states as the initial state:

• Idle (default)

• Complete

• Stopped

Choose the initial state that best shows what your equipment is waiting to do after power-up

(reset, run, and so forth).

Stopped Aborted

26 Publication LOGIX-UM001B-EN-P - April 2010

Page 27

Guidelines Chapter 3

Guideline Details

Start with the initial state and work

through the model.

Start with the initial state. Then work forward from that point. Use the following questions to

help you.

For this State Ask

Stopped What happens when you turn on power?

Resetting How does the equipment get ready to run?

Idle How do you tell that the equipment is ready to run?

Running What does the equipment do to make product?

Holding How does the equipment pause without making scrap?

Held How do you tell if the equipment is safely paused?

Restarting How does the equipment resume production after a pause?

Complete How do you tell when the equipment is done with what it had to do?

Stopping What happens during an normal shutdown?

Aborting How does the equipment shutdown if a fault or failure happens?

Aborted How do you tell if the equipment is safely shutdown?

Use only the states that you want. Define only the states that are appropriate for your equipment. You don’t need to use all the

states. The equipment phase just skips any states that you don’t add.

For the producing and standby states, use

subroutines.

If you want to define producing and standby states for your equipment, use subroutines.

A. Create a routines for the producing state and another routine for the standby state.

B. In the running state, check for the produce verses standby conditions. Set either the

Producing bit or the Standby bit of the equipment phase tag.

C. Use the Producing and Standby bits as conditions to call the corresponding routine.

See

Appendix B

.

Publication LOGIX-UM001B-EN-P - April 2010 27

Page 28

Chapter 3 Guidelines

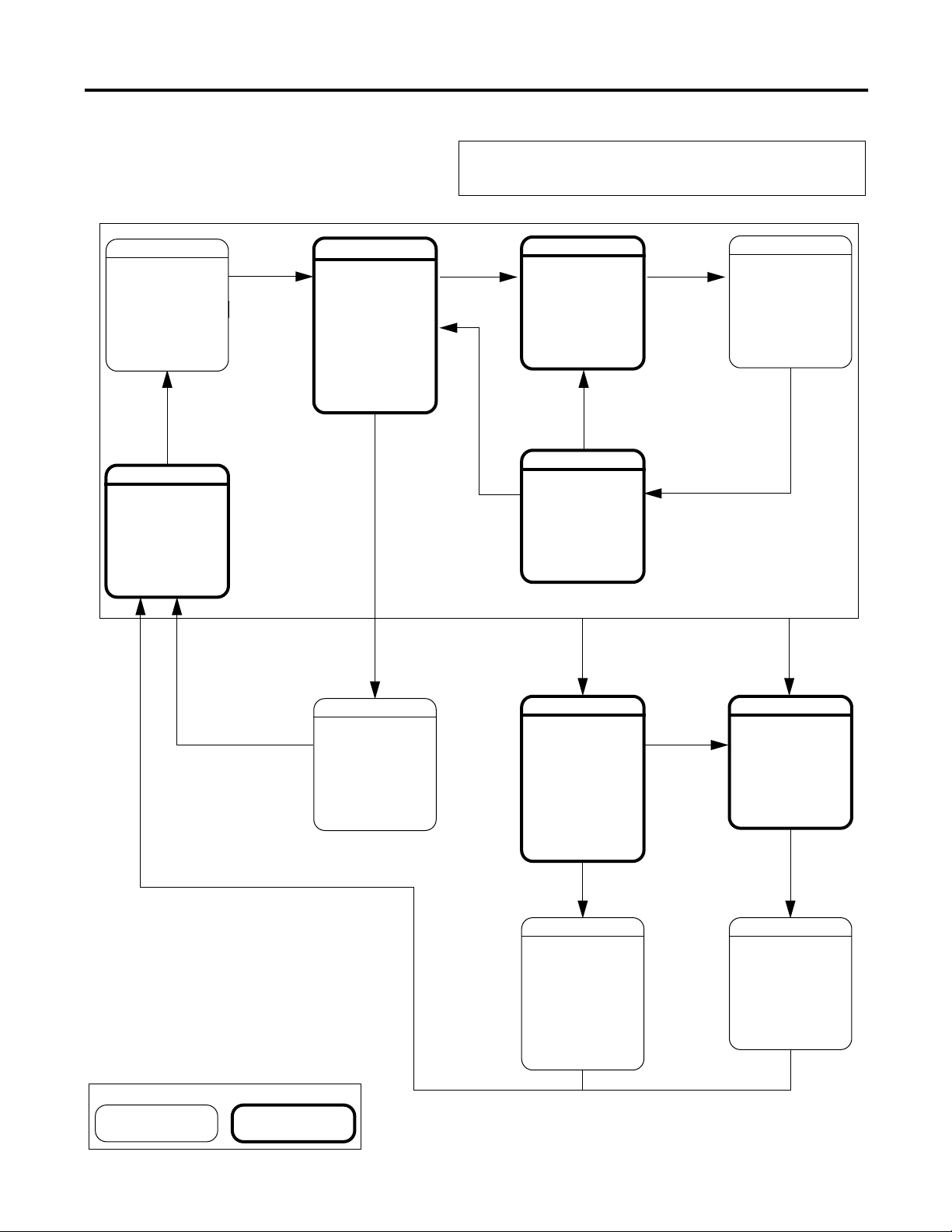

State Model Worksheet

IDLE

To

Done

RESETTING

Start

Command

RUNNING

Done

Equipment Phase:

Hold

Command

Done

HOLDING

RESTARTING

Done

HELD

Hold

Command

Restart

Command

Reset

Command

COMPLETE

Reset

Command

Command

STOPPING

Done

STOPPED

Stop

Abort

Command

Abort

Command

ABORTING

Done

ABORTED

Key

Waiting State Acting State

28 Publication LOGIX-UM001B-EN-P - April 2010

Page 29

Guidelines Chapter 3

Example 1: Add Water

IDLE

· No water flow

· Tank Not full

· Operator can

control equipment

To

Done

RESETTING

Command

Start

RUNNING

· Lock equipment in

program control

· Add water

· Unlock equipment

from program

control

Done

Equipment Phase: Add Water

Hold

Command

Done

HOLDING

· Stop water

· Unlock equipment

from program

control

Hold

Command

RESTARTING

· Lock equipment in

program control

Done

HELD

· No water flow

· Operator can

control equipment

Restart

Command

Reset

Command

COMPLETE

· No water flow

· Water at high limit

· Operator can

control equipment

Reset

Command

Stop

Command

STOPPING

· Stop water

· Unlock equipment

from program

control

Done

STOPPED

· No water flow

· Operator can

control equipment

Abort

Command

Abort

Command

ABORTING

· Stop water

· Unlock equipment

from program

control

Done

ABORTED

· No water flow

· Operator can

control equipment

Key

Waiting State Acting State

Publication LOGIX-UM001B-EN-P - April 2010 29

Page 30

Chapter 3 Guidelines

Example 2: Space Parts

IDLE

· No axes faults

· All axes = on

· Exit belt = homed

· Registration =

armed

· Clear axes faults

· Turn on all axes

· Home exit belt

· Arm registration

To

Done

RESETTING

Start

Command

RUNNING

· Jog exit belt

· Gear other belts

· Put 1 box on fine

belt

· Put 1 box on each

flight

Done

Equipment Phase: Space Parts

Hold

Command

Done

HOLDING

· Set speed of exit

belt = 0

Hold

Command

RESTARTING

· Jog exit belt

Done

HELD

· Speed of exit belt

=0

Restart

Command

Reset

Command

COMPLETE

Not used

Reset

Command

Stop

Command

STOPPING

· Run out boxes on

coarse belt

· Stop coarse and

fine belts

· Empty exit belt

· Stop exit belt

Done

STOPPED

· All axes = off

· SERCOS = phased

up

· All network

connections are

made

Abort

Command

Abort

Command

ABORTING

· Turn off all axes

Done

ABORTED

· All axes = off

· Boxes may still be

on belts

Key

Waiting State Acting State

30 Publication LOGIX-UM001B-EN-P - April 2010

Page 31

Guidelines Chapter 3

Equipment Code Guidelines

Step 1

Step 2

Step 3

Step 4

To start the equipment, the equipment

phase gives the equipment program a start

command, a set point, and so forth.

The equipment program sends back

information such as current state, total, and

so forth.

One advantage of an equipment phase is that it lets you separate the

procedures (recipes) for how to make the product from the control of the

equipment that makes the product. This makes it much easier to execute

different procedures for different products using the same equipment.

Equipment Phase

Directs the actions of the

equipment (what to do and

when)

• produce product

• stop producing product

• add water to a tank

• wait for the operator to do

Equipment Program

Does the actions for a specific

group of devices (does it)

• jog axis

• run pump

• open valve

• calculate control variable

Step 5

Step 6

The equipment program controls the

equipment.

Publication LOGIX-UM001B-EN-P - April 2010 31

Page 32

Chapter 3 Guidelines

Example 1: Add Water to a Tank

The equipment phase tells the equipment program to go to

program mode and add water.

The equipment program follows the commands of the equipment

phase and sends back its mode and state.

32 Publication LOGIX-UM001B-EN-P - April 2010

Page 33

Example 2: Smart Belt

The equipment phase tells the equipment program to reset faults. The

equipment phase then waits for the equipment program to turn on a done

bit. When the done bit turns on, the equipment phase clears the command

to reset faults. The equipment phase then goes to the next step in the

sequence.

Guidelines Chapter 3

The equipment program resets faults when it gets the fault reset command

from the equipment phase. It turns on a done bit after it clears the faults.

Publication LOGIX-UM001B-EN-P - April 2010 33

Page 34

Chapter 3 Guidelines

Execution Guidelines

Use the resetting, running, and stopping states

for the normal execution of the equipment.

A state model makes it much easier to separate the normal execution of your

equipment from any exceptions (faults, failures, off-normal conditions).

Use the holding, restarting, and aborting states to

handle exceptions (faults, failures, off-normal

conditions).

HoldingIdle Running Held

Resetting

Complete

Restarting

Stopping Aborting

Stopped Aborted

Guideline Details

Use the prestate routine to watch for

faults

Use the prestate routine for conditions that you want to watch all the time such as fault bits.

The prestate routine:

• runs all the time.

• runs before each scan of a state.

• runs even in the waiting states (idle, held, complete, stopped, or aborted).

prestate routine

current state

routine

34 Publication LOGIX-UM001B-EN-P - April 2010

Page 35

Guideline Details

Create a prestate routine just like the

routine for a program. It’s not a phase

state routine.

1.

2.

Guidelines Chapter 3

3. Choose any language.

4.

Publication LOGIX-UM001B-EN-P - April 2010 35

Page 36

Chapter 3 Guidelines

3

4

2

Guideline Details

Assign a prestate routine.

1.

.

.

.

Use a state bit to limit code to a specific

state

RSLogix 5000 software automatically makes a tag for each equipment phase. The tag has bits

that tell you the state of the equipment phase.

• The tag is at the controller scope.

• The tag uses the PHASE data type.

• Use bits of the tag for code that you want to limit to certain states.

Example

Suppose the name of your equipment phase is My_Phase. And you have some code that you

want to run only when the equipment phase is in the running state. In that case, check the

My_Phase.Running bit for on (1):

If My_Phase.Running then…

See

Appendix B

for more information.

36 Publication LOGIX-UM001B-EN-P - April 2010

Page 37

Guidelines Chapter 3

Guideline Details

Use the empty phase state routine to

complete phase execution

Unlike normal program routines, phase state routines are called by the batch manager (not

other program routines(, so they always have the potential of being called.

In the configuration for a phase state routine, if the Complete State Immediately if not

Implemented option is checked in RSLogix 5000 programming software, version 18 or later, an

implemented, but empty (no logic), phase state routine behaves the same as an implemented

phase state routine. The state immediately completes and execution of the phase continues.

The phase then enters the next state in the state machine.

In RSLogix 5000 programming software, version 16 and earlier, if a phase enters a state for

which a state routine exists, but contains no logic, execution of the phase stops. The routine

does complete, but there is no logic to execute.

Choose from the following if you import a new state routine and in the Online Options dialog

box.

• Import Logic Edits as Pending, an empty routine is created in the controller and the

pending edits exist in the offline project.

• Accepts Program Edits, an empty routine is created in the controller and the logic is placed

in a test edits container in the routine. If you are not actively testing edits, then the routine

appears as empty when running.

• Finalize All Edits in Program, the routine is created with the new logic and does not appear

empty.

In the first two cases, if the Complete State Immediately if not Implemented option is

checked, the empty routine will complete immediately and allow phase execution to continue.

Use the PFL instruction to signal a fault The Equipment Phase Failure (PFL) instruction sets a failure code for an equipment phase. Use

the code to signal a specific failure such as the fault of a specific device.

• The PFL instruction writes a code to the failure member for the equipment phase.

• To see the failure code of an equipment phase, look at the phase_name.Failure tag.

• The failure code stays until any of the following happens:

• A PFL instruction sets the failure code to a larger number.

• The equipment phase transitions from the resetting state idle state.

• A PCLF instruction clears the failure code.

• FactoryTalk Batch software clears the failure code.

See

page 72

for more information.

Use a PCLF instruction to clear a failure

code

The Equipment Phase Clear Failure (PCLF) instruction clears the failure code for an equipment

phase.

• A CLR instruction, MOV instruction, or assignment (:=) d doesn’t change the failure code of

an equipment phase.

• If you are testing a PCLF instruction, make sure RSLogix 5000 software doesn’t own the

equipment phase. The PCLF instruction doesn’t work if RSLogix 5000 software owns the

equipment phase.

See

page 76

for more information.

Publication LOGIX-UM001B-EN-P - April 2010 37

Page 38

Chapter 3 Guidelines

Example 1: Add Water to a Tank

The prestate routine watches for equipment faults while the equipment phase is in

the running state (Add_Water.Running = 1). If Water_Feed.Health = 1, then a fault

happened. If a fault happens, the equipment phase sets a failure code of 202.

If Add_Water.Running And Water_Feed.Health Then

PFL(202);

End_If;

The equipment program watches the fault bits of the valve, pump, and their feedback devices.

If any of that equipment faults, the equipment program turns on the Water_Feed.Health bit.

38 Publication LOGIX-UM001B-EN-P - April 2010

Page 39

Example 2: Smart Belt

Guidelines Chapter 3

The preset value of this step = 20000 ms. The step

turns on its DN bit if it doesn’t clear the faults

within 20000 ms.

If Step_000.DN = on, a timeout happened. When a timeout happens, the OSR instruction

turns on the Clear_Faults_Timeout bit for one scan.

If MyPhase is in the resetting state and Clear_Faults_Timeout is on, then the PFL instruction

signals a failure. The PFL instruction sets the failure code = 501.

Publication LOGIX-UM001B-EN-P - April 2010 39

Page 40

Chapter 3 Guidelines

Transition Guidelines

To start an acting state, you usually have to give the equipment phase a

command. The command tells the equipment phase and its equipment to start

doing something or do something different. Use the Equipment Phase

Command (PCMD) instruction to give a command to an equipment phase.

Optional: You can also use FactoryTalk Batch software in place of a PCMD

instruction to trigger transitions

Use the state model to see which transitions need a PCMD instruction.

Idle

Resetting

PCMD instruction

Start

Reset

Running

done donedone

Complete

Hold

Restarting

Stopping

Holding

PSC instruction

done

Hold

Restart

Stop

Abort

Held

Abort

Aborting

Reset

Type of Transition Description Instruction

Command A command tells the equipment to start doing something or do something

different. For example the operator pushes the start button to start production

and the stop button to shutdown.

PhaseManager software Software Software uses these commands:

reset stop restart

start hold abort

Done Equipment goes to a waiting state when it's done with what it's doing. You

set up your code to signal when the equipment is done. The waiting state

shows that the equipment is done.

Exception: The restarting state goes to the running state when it’s done.

Stopped Aborted

PCMD

Use an Equipment Phase

Command (PCMD) instruction

to give a command. Or use

RSLogix 5000 software.

See

page 62

information.

PSC

Use the Phase State Complete

(PSC) instruction to signal

when a state is done. See

page 59

for more information.

donedone

for more

40 Publication LOGIX-UM001B-EN-P - April 2010

Page 41

Guideline Details

A PCMD instruction causes a transition

right away.

A PCMD instruction makes an equipment phase go to the commanded state. The equipment

phase changes states as soon as it finishes its current scan. This happens even if the current

state isn’t done.

See if you need to reset the state that

you’ve left.

Are you leaving an acting state (for example, running, holding)?

• YES — Consider resetting the code of the state that you’ve left.

• NO — You probably don’t need to reset anything.

The equipment phase stops running the code of the current state when it goes to a different

state. This leaves outputs at their last values unless the new state takes control of them. It

also leaves an SFC at the step it was at when the equipment phase changed states.

Example 1: You don’t need to reset

Suppose your equipment phase is in the idle state. In that case, it isn’t running any state code.

So you probably don’t need to reset any state when you go to a different state like running,

stopping, and so forth.

Example 2: You don’t need to reset

Suppose your equipment phase is in the running state and you go to the holding state. When

you go back to the running state, you probably want to pick up where you left off. In that case,

you probably don’t need to reset the code in the running state.

Guidelines Chapter 3

Use an SFR instruction to reset the SFC of

a state routine.

Use the PCMD instruction to go to an

allowed next state.

Example 3: You must reset

Suppose your equipment phase is half way through the resetting state and you give the stop

command. And suppose you want to run the entire resetting sequence when you go back to it.

In that case, you probably need to reset the code of the resetting state. If the resetting state

uses an SFC, then use the SFR instruction to reset it to the first step.

An SFC Reset (SFR) instruction is one way to reset an SFC. In some cases, reset an SFC from

several other state routines.

To reset the SFC of this

Place an SFR instruction in this state routine

state

Running Resetting

Holding Holding—Let the SFC reset itself at the last step.

Restarting Reset the restarting routine in both these routines:

• Holding—In case you go back to holding before you finish

restarting.

• Restarting—Let the SFC reset itself at the last step.

PhaseManager software makes sure that an equipment phase follows the state model. So the

equipment phase goes only to certain states from the state that it is in right now.

Example 1: A transition is allowed

Suppose your equipment phase is in the running state and you give it the hold command. In

that case, the equipment phase goes to holding because that transition is allowed.

Example 2: A transition isn’t allowed

Suppose your equipment phase is in the running state and you give it the reset command. In

that case, the equipment phase stays in the running state. To go to the resetting state, you

first have to stop or abort the equipment phase.

Publication LOGIX-UM001B-EN-P - April 2010 41

Page 42

Chapter 3 Guidelines

Guideline Details

See if you must use a POVR instruction

instead of a PCMD instruction.

Takes ownership

My Code

Can’t command

A. Are you giving the hold, stop, or abort command?

· NO — Use the PCMD instruction.

· YES — Go to step B.

B. Must the command work even if you have manual control of the equipment phase via

RSLogix 5000 software?

· YES — Use the POVR instruction instead. See

page 68

.

· NO — Go to step C.

C. Must the command work even if FactoryTalk Batch software or another program owns the

equipment phase?

· YES — Use the POVR instruction instead. See

page 68

.

· NO — Use the PCMD instruction.

42 Publication LOGIX-UM001B-EN-P - April 2010

Page 43

Guidelines Chapter 3

Example 1: Tank

The controller uses an SFC to command the phases that run the tank (add water,

heat, add ingredients, and so forth).

Give the start command to the Add_Water equipment

phase. The P1 qualifier limits this to the first scan of

the step.

Wait until the Add_Water equipment phase

is done (complete). When the equipment

phase is done, give the reset command. The

P0 qualifier limits this to the last scan of the

step.

Start the next equipment phase.

Publication LOGIX-UM001B-EN-P - April 2010 43

Page 44

Chapter 3 Guidelines

Example 2: Smart Belt

If the operator presses the start button on the machine or HMI, then

My_Inputs.AnyStartPressed = on for 1 scan.

The ONS instruction makes sure that My_Inputs.AnyStartPressed turns on only

when a start button goes from off on.

If the equipment phase is in the idle state and My_Inputs.AnyStartPressed = on, then

The PCMD instruction gives MyPhase the start command.

44 Publication LOGIX-UM001B-EN-P - April 2010

Page 45

Guidelines Chapter 3

Example 3: Jam Detection

The equipment program watches for the following faults:

• Faulted axis

• Jammed material

If there is a fault, then

Local_Interface.Equipment_Faults_Cleared = 0. This tag is an alias for the

controller-scoped tag Shear_1.

The prestate routine of the equipment phase watches for the equipment program to signal a

fault.

• If Interface_To_Equipment.Equipment_Faults_Cleared = 0 then there is a fault.

• Both Interface_To_Equipment and Local_Interface are aliases for Shear_1, so they have

the same values.

If there is a fault Then

Give the Shear_One_Phase equipment phase the abort command. The POVR instruction

makes sure the command works even if someone has manual control of the equipment

phase through RSLogix 5000 software.

The PFL instruction sets the failure code for Shear_One_Phase = 333.

The Fault_Strobe keeps these actions to a single scan.

Publication LOGIX-UM001B-EN-P - April 2010 45

Page 46

Chapter 3 Guidelines

State Completion Guidelines

IMPORTANT

To leave an acting state, you usually signal that the state is done doing what it

had to do. Use the Phase State Complete (PSC) instruction to signal when a

state is done.

The PSC instruction doesn’t stop the current scan of a routine.

When the PSC instruction executes, the controller scans the rest of the routine and

then transitions the equipment phase to the next state. The PSC instruction does not

terminate the execution of the routine.

Use the state model to see which transitions need a PSC instruction.

Idle

Resetting

PCMD instruction

Start

Hold

Running

done donedone

Restarting

Holding

PSC instruction

done

Held

Hold

Restart

Stop

Reset

Complete

Reset

Type of transition Description Instruction

Command A command tells the equipment to start doing something or do something

different. For example the operator pushes the start button to start production

and the stop button to shutdown.

PhaseManager software Software uses these commands:

reset stop restart

start hold abort

Done Equipment goes to a waiting state when it's done with what it's doing. You

set up your code to signal when the equipment is done. The waiting state

shows that the equipment is done.

Exception: The restarting state goes to the running state when it’s done.

Stopping

Stopped Aborted

Abort

PCMD

Use an Equipment Phase

Command (PCMD) instruction

to give a command. Or use

RSLogix 5000 software.

PSC

Use the Phase State Complete

(PSC) instruction to signal

when a state is done. See

page 59

for more information.

Abort

Aborting

donedone

46 Publication LOGIX-UM001B-EN-P - April 2010

Page 47

Example 1: Add Water to a Tank

The holding state does three things.

1. Rung 0 — stop the water.

2. Rung 1 — unlock the devices from program control.

3. Rung 2 — signal that the state is done.

Guidelines Chapter 3

Example 2: Smart Belt

At the last step of the resetting state:

• the SFR instruction resets the SFC

so it is ready for the next time you

need it.

• the PSC instruction signals that the

state is done.

Note: The P1 qualifier runs the actions

only one time.

Publication LOGIX-UM001B-EN-P - April 2010 47

Page 48

Chapter 3 Guidelines

Equipment Interface Tag Guidelines

Equipment Phase

Directs the actions of the

equipment (what to do and

when)

• produce product

• stop producing product

• add water to a tank

• wait for the operator to do

An equipment interface tag links an equipment phase to an equipment

program.

• The equipment phase uses the tag to configure and command the

equipment program.

• The equipment program uses the tag to report its status or condition.

You are here.

Interface Tags

Links equipment phase to

equipment program

• jog at this speed

• go to the 1 state (run

pump)

• axis is jogging

• valve is faulted

Equipment Program

Does the actions for a specific

group of devices (does it)

• jog axis

• run pump

• open valve

• calculate control variable

Guideline Details

List the values that your equipment phase

must give to the equipment program or get

back from it.

Create a user-defined data type A user-defined data type lets you make a template for your data. It lets you group related

Think of these values as a faceplate to the equipment program. It is the values that your

equipment phase uses to control and monitor the equipment program. Do not include I/O

data.

Inputs to the equipment program Outputs from the equipment program

• mode requests

• set points

• commands such as on, off, start,

stop, reset

• permissives

• overrides

data into a single data type. You then use the data type to make tags with the same data

lay-out.

If you have more than one equipment phase, lay out the data type so that it’s easy to use

with more than one equipment phase. Consider the following:

• Include a range of data that makes the data type more versatile.

• Use names that are as general as possible.

Example: The name State_Cmnd lets you use it for any equipment that runs in 2

states like on/off, running/not running, pumping/not pumping. It is easier to re-use

than names such as Open or Close. Those names apply to valves but not pumps or

motors.

• mode status

• control values

• done or completion

• alarms

• faults

• health indication

• totals or accumulated values

48 Publication LOGIX-UM001B-EN-P - April 2010

Page 49

Guideline Details

Create a tag for each equipment phase Create tag for the interface data of each equipment phase.

• Make a tag for each equipment phase.

• Use the data type from guideline .

• Make the tag at the controller scope. Both the equipment phase and the equipment

program must get to the tag.

• Consider using alias tags. See Alias Tag Guidelines on

Additional Resources

For this information See this publication

Guidelines and considerations regarding:

• user-defined data types

• alias tags

Step-by-step procedures on how to:

• create user-defined data types

• assign alias tags

Logix5000 Controllers Design

Considerations, publication

Logix5000 Controllers Common Procedures

Programming Manual, publication

1756-PM001

page 53

Guidelines Chapter 3

.

1756-RM094

Publication LOGIX-UM001B-EN-P - April 2010 49

Page 50

Chapter 3 Guidelines

1. The equipment phase and equipment program

share this data.

Go to program mode

Go to this state

In program mode

No faults

Hardware OK

In this state

2. A user-defined data type creates a template

for the data.

Example 1: Add Water to a Tank

Water_Feed

LS

3. A tag stores the data that is shared by the

equipment phase and equipment program. The

tag uses the user-defined data type from step

2.

50 Publication LOGIX-UM001B-EN-P - April 2010

Page 51

Example 2: Smart Belt

Guidelines Chapter 3

The equipment phase and equipment

program share this data.

A separate user-defined data type holds

data for each axis.

Equipment program interface

Commands Conditions or status

Enable Abort FaultScroll EnableCyclingDone

Disable FaultReset Faulted DisableCyclingDone

Home Stop EnableDone AbortingDone

ActivateRun ArmRegistration DisableDone FaultResetDone

EnableProduct HomeDone StoppingDone

DisableProduct ActivateRunDone Selected

EnableCycling EnableProductDone RegistrationArmed

DisableCycling DisableProductDone

Axis interface

Commands Conditions or status

Enable Abort State NoMotion MoveActive

Disable Stop On Homed HomeDone

Home ActivateRun Ok AxisSelected RunDone

AutoRun Auto GearActive

ResetFaults Jogging CamActive

There is an interface tag for each axis and

one for the entire machine.

Interface tag for each axis

Interface tag for entire machine

One tag stores the data that is shared by the equipment phase and equipment program.

Other tags store the data for each individual axis.

Publication LOGIX-UM001B-EN-P - April 2010 51

Page 52

Chapter 3 Guidelines

Example 2: Smart belt, Continued

The equipment program gets the command

from the equipment phase and passes it to

each axis.

Routine of the equipment program

This tag Is the interface between

My_Equipment equipment phase and equipment program

Coarse_Belt_Vars equipment program and an axis

The equipment program collects the fault

status of each axis and passes it back to

the equipment phase.

Routine of the equipment program

The equipment program checks the fault code of each axis. If an axis isn’t faulted, the OK bit

for the axis turns on.

The equipment program collects the OK status of each axis. If the OK bit of each axis = on,

then My_Equipment.Faulted = off (no faults).

52 Publication LOGIX-UM001B-EN-P - April 2010

Page 53

Guidelines Chapter 3

Alias Tag Guidelines

Program-scoped tags and phase-scoped tags make your code easier to reuse.

Make the tags aliases for tags at the controller scope. If you reuse the

equipment phase (for example, copy/paste), simply point the phase-scoped

tags to new tags at the controller scope. This reduces address fixes within the

code.

Example

The controller automatically makes a tag for an equipment phase. The tag is at

the controller scope (controller tag). Suppose you plan to reuse an equipment

phase for a different part of your tank.

1. Make an alias tag for the first equipment phase. Make the tag at the

phase scope and point it to the controller tag for that equipment phase.

2. Use the alias tag throughout the code of the equipment phase (This

Phase).

3. Make a copy of the equipment phase.

4. Point the alias tag of the copy to its controller tag.

Publication LOGIX-UM001B-EN-P - April 2010 53

Page 54

Chapter 3 Guidelines

Additional Resources

For this information See this publication

Guidelines and considerations for alias tags Logix5000 Controllers Design

Considerations, publication

Steps to assign alias tags Logix5000 Controllers Common Procedures

Programming Manual, publication

1756-PM001

1756-RM094

54 Publication LOGIX-UM001B-EN-P - April 2010

Page 55

Appendix A

Equipment Phase Instructions

(PSC, PCMD, POVR, PFL, PCLF, PXRQ, PRNP, PPD, PATT, PDET)

Introduction

This section Provides this type of information

Instruction name identifies the instruction

Operands lists all the operands of the instruction

Instruction structure lists control status bits and values, if any, of the instruction

Description describes the instruction’s use

Arithmetic status flags defines whether or not the instruction affects arithmetic status flags

Fault conditions defines whether or not the instruction generates minor or major faults

Execution defines the specifics of how the instruction operates

Example provides at least one programming example in each available programming language

This appendix provides a description of each equipment phase instruction in

this format.

defines any differences when the instruction is enabled and disabled, if appropriate

if so, defines the fault type and code

includes a description explaining each example

Set and Clear

This manual uses set and clear to define the status of bits (booleans) and

values (non-booleans).

This term Means

set the bit is set to 1 (ON)

a value is set to any non-zero number

clear the bit is cleared to 0 (OFF)

all the bits in a value are cleared to 0

If an operand or parameter support more than one data type, the bold data

types indicate optimal data types. An instruction executes faster and requires

less memory if all the operands of the instruction use the same optimal data

type, typically DINT or REAL.

Publication LOGIX-UM001B-EN-P - April 2010 55

Page 56

Appendix A Equipment Phase Instructions (PSC, PCMD, POVR, PFL, PCLF, PXRQ, PRNP, PPD, PATT, PDET)

Relay Ladder Rung Condition

The controller evaluates ladder instructions based on the rung condition

preceding the instruction (rung-condition-in). Based on the rung-condition-in

and the instruction, the controller sets the rung condition following the

instruction (rung-condition-out), which in turn, affects any subsequent

instruction.

input instruction

rung-in

condition

rung-out

condition

output instruction

If the rung-in condition to an input instruction is true, the controller evaluates

the instruction and sets the rung-out condition based on the results of the

instruction. If the instruction evaluates to true, the rung-out condition is true;

if the instruction evaluates to false, the rung-out condition is false.

56 Publication LOGIX-UM001B-EN-P - April 2010

Page 57

Equipment Phase Instructions (PSC, PCMD, POVR, PFL, PCLF, PXRQ, PRNP, PPD, PATT, PDET) Appendix A

Prescan of Routines

The controller also prescans routines. Prescan is a special scan of all routines in

the controller. During prescan, the controller:

• scans all main routines.

• scans all state routines of equipment phases.

• scans all prestate routines of equipment phases.

• scans all subroutines of programs and equipment phases one time.

Once the controller prescans a subroutine, it does not prescan the

subroutine again during that prescan.

• scans all routines called by FOR instructions of a ladder diagram

routine.

• ignores jumps that could skip the execution of instructions.

• executes all instructions in prescan mode.

For details on how a specific instruction operates during prescan, see the

Execution section for the instruction.

• resets to 0 all non-retentive assignments.

• does not update input values.

• does not write output values.

The following conditions generate prescan:

• Toggle from Program to Run mode

• Automatically enter Run mode from a power-up condition

Prescan does not occur for a program or equipment phase when:

• the program or equipment phase becomes scheduled while the

controller is running.

• the program or equipment phase is unscheduled when the controller

enters Run mode.

Publication LOGIX-UM001B-EN-P - April 2010 57

Page 58

Appendix A Equipment Phase Instructions (PSC, PCMD, POVR, PFL, PCLF, PXRQ, PRNP, PPD, PATT, PDET)

Choose an Equipment Phase Instruction

If You Want To Use This Instruction Available In These Languages See Page

signal an equipment phase that the state

routine is complete so go to the next state

change the state or substate of an equipment

phase

give a hold, stop, or abort command to an

equipment phase regardless of ownership

signal a failure for an equipment phase Equipment Phase Failure (PFL) relay ladder

clear the failure code of an equipment phase Equipment Phase Clear Failure (PCLF) relay ladder

Phase State Complete (PSC) relay ladder

structured text

Equipment Phase Command (PCMD) relay ladder

structured text

Equipment Phase Override Command

(POVR)

relay ladder

structured text

structured text

59

62

68

72

76

structured text

initiate communication with FactoryTalk Batch

software

clear the NewInputParameters bit of an

equipment phase

set up breakpoints within the logic of an

equipment phase

take ownership of an equipment phase to

either:

• prevent another program or FactoryTalk

Batch software from commanding an

equipment phase

• make sure another program or FactoryTalk

Batch software does not already own an

equipment phase

relinquish ownership of an equipment phase Detach from Equipment Phase (PDET) relay ladder

Equipment Phase External Request

(PXRQ)

Equipment Phase New Parameters

(PRNP)

Equipment Phase Paused (PPD) relay ladder

Attach to Equipment Phase (PATT) relay ladder

relay ladder

structured text

relay ladder

structured text

structured text

structured text

structured text

78

89

92

97

102

58 Publication LOGIX-UM001B-EN-P - April 2010

Page 59

Equipment Phase Instructions (PSC, PCMD, POVR, PFL, PCLF, PXRQ, PRNP, PPD, PATT, PDET) Appendix A

Phase State Complete (PSC)

Operands:

Description: The PSC instruction signals the completion of a phase state routine.

Use the PSC instruction to signal an equipment phase that the state routine is

complete so go to the next state.

Relay Ladder

none

Structured Text

none

You must enter the parentheses ( ) after the instruction mnemonic, even

though there are no operands.

In the running state routine, use the PSC instruction to

transition the equipment phase to the complete state.

Publication LOGIX-UM001B-EN-P - April 2010 59

Page 60

Appendix A Equipment Phase Instructions (PSC, PCMD, POVR, PFL, PCLF, PXRQ, PRNP, PPD, PATT, PDET)

Guidelines for Using the PSC Instruction

Guideline Details

Use the PSC instruction in each

phase state routine that you add to

an equipment phase.

Without a PSC instruction, the equipment phase remains in the state and does not go to the

next state.

• Place the PSC instruction as the last step in your phase state routine.

• When the state is done (complete), execute the PSC instruction.

In the holding state routine, use

the PSC instruction to let the

equipment phase go to the Held

state.

Remember that the PSC instruction

does not stop the current scan of a

routine.

Do not use a PSC instruction in a

prestate routine.

When the PSC instruction executes, the controller scans the rest of the routine and then

transitions the equipment phase to the next state. The PSC instruction does not termiN/Ate

the execution of the routine.

Use the PSC instruction only to signal the transition from one state to another.

Arithmetic Status Flags: not affected

Fault Conditions: none

Execution:

Condition Relay Ladder Action Structured Text Action

prescan The rung-condition-out is set to false. No action taken.

rung-condition-in is false The rung-condition-out is set to false. N/A

rung-condition-in is true The instruction executes.

The rung-condition-out is set to true.

scan of structured text N/A In structured text, instructions execute each time

instruction execution The instruction signals that the state is complete. The instruction signals that the state is complete.

postscan The rung-condition-out is set to false. No action taken.

N/A

they are scanned. To limit the scan of an instruction,

use a qualifier of an SFC action and/or a structured

text construct.

60 Publication LOGIX-UM001B-EN-P - April 2010

Page 61

Equipment Phase Instructions (PSC, PCMD, POVR, PFL, PCLF, PXRQ, PRNP, PPD, PATT, PDET) Appendix A

Example:

Relay Ladder

If ThisPhase.StepIndex = 30 (The routine is at step 30.)

Then the PSC instruction signals that the state is done (complete).

After the controller scans the rest of the routine (rung 5, rung 6, and so forth.), the equipment phase goes to the next

Structured Text

When the SFC reaches Step_002, the PSC instruction signals that

the state is done (complete).

Publication LOGIX-UM001B-EN-P - April 2010 61

Page 62

Appendix A Equipment Phase Instructions (PSC, PCMD, POVR, PFL, PCLF, PXRQ, PRNP, PPD, PATT, PDET)

Equipment Phase Command (PCMD)

Operands:

Use the PCMD instruction to change the state or substate of an equipment

phase.

Relay Ladder

Operand Type Format Description

Phase Name phase name of the

equipment

phase

Command command name of the

command

Result DINT immediate

tag