Page 1

Installation Instructions

FLEX XT I/O Isolated Input Analog Module

Cat. No. 1794-IF4ICFXT

Important User Information

Solid state equipment has operational characterist ics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (Publication

SGI-1.1 available from your local Rockwell Automation sales office or online at

http://literature.rockwellautomation.com) describes some important differences between solid state

equipment and hard-wired electromechanical d evices. Because of this difference, and also because of the

wide variety of uses for solid state equip ment, all persons responsible for applying thi s equipment must

satisfy themselves that each intended application of t his equipment is acceptable.

In no event will Rockwell Automation , Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of t his equipment.

The examples and diagrams in this manual are i ncluded solely for illustrative purposes. Because of the many

variables and requirements associated wit h any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of informa tion, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc., is prohibited.

Throughout this manual we use notes to make you aware of safety considerations.

WARNING

ATTENTION

IMPORTANT

Identifies information about practi ces or circumstances that can cause an explosion

in a hazardous environment, which may lead to personal injury or death, property

damage, or economic loss.

Identifies information about prac tices or circumstances that can lead to personal

injury or death, property damage, or econom ic loss. Attentions help you:

• identify a hazard

• avoid a hazard

• recognize the consequence

Identifies information that is critical fo r successful application and understanding of

the product.

WARNING

ATTENTION

ATTENTION

ATTENTION

ATTENTION

If you connect or disconnect wiring while the field side power is on, an

electrical arc can occur. This could cause an explosion in hazardous location

installations. Be sure that power is removed or the area is nonhazardous

before proceeding.

FLEX I/O is grounded through the DIN rail to chassis ground. Use zinc plated

yellow-chromate steel DIN rail to assure proper grounding. The use of other

DIN rail materials (for example, aluminum or plastic) that can corrode, oxidize,

or are poor conductors, can result in improper or intermittent grounding.

Secure DIN rail to mounting surface approximately every 200 mm (7.8 in.) and

use end-anchors appropriately.

Prevent Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which can cause

internal damage and affect normal operation. Follow these guidelines when

you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation, if available.

• Store the equipment in appropriate static-safe packaging when not in

use.

Do not substitute a 1794-IF4I or 1794-IF4IXT with the 1794-IF4ICFXT, as this

will force a remapping of IO and configuration data.

Personnel responsible for the application of safety-related programmable

electronic systems (PES) shall be aware of the safety requirements in the

application of the system and shall be trained in using the system.

ATTENTION

WARNING

Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2 industrial

environment, in overvoltage Category II applications (as defined in IEC

60664-1), at altitudes up to 2000 m (6562 ft) without derating.

This equipment is considered Group 1, Class A industrial equipment according

to IEC/CISPR 11. Without appropriate precautions, there may be difficulties

with electromagnetic compatibility in residential and other environments due

to conducted and radiated disturbances.

This equipment is supplied as open-type equipment. It must be mounted within

an enclosure that is suitably designed for those specific environmental

conditions that will be present and appropriately designed to prevent personal

injury resulting from accessibility to live parts. The enclosure must have

suitable flame-retardant properties to prevent or minimize the spread of flame,

complying with a flame spread rating of 5VA, V2, V1, V0 (or equivalent) if

non-metallic. The interior of the enclosure must be accessible only by the use

of a tool. Subsequent sections of this publication may contain additional

information regarding specific enclosure type ratings that are required to

comply with certain product safety certifications.

In addition to this publication, see:

• Industrial Automation Wiring and Grounding Guidelines, Rockwell

Automation publication 1770-4.1,

requirements.

• NEMA Standard 250 and IEC 60529, as applicable, for explanations of

the degrees of protection provided by different types of enclosure.

If you insert or remove the module while backplane power is on, an electrical

arc can occur. This could cause an explosion in hazardous location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

for additional installation

ATTENTION

To comply with the CE Low Voltage Directive (LVD), all connections to this

equipment must be powered from a source compliant with the following:

Safety Extra Low Voltage (SELV) or Protected Extra Low Voltage (PELV).

ATTENTION

ATTENTION

Do not remove or replace a Terminal Base unit while power is applied.

Interruption of the backplane can result in unintentional operation or machine

motion.

Personnel responsible for the application of safety-related programmable

electronic systems (PES) shall be aware of the safety requirements in the

application of the system and shall be trained in using the system.

European Hazardous Location Approval

European Zone 2 Certification (The following applies when the product bears the Ex

or EEx Marking)

This equipment is intended for use in potentially explosive atmospheres as defined by European

Union Directive 94/9/EC and has been found to comply with the Essential Health and Safety

Requirements relating to the design and construction of Category 3 equipment intended for use

in potentially explosive atmospheres, given in Annex II to this Directive.

Compliance with the Essential Health and Safety Requirements has been assured by compliance

with EN 60079-15 and EN 60079-0.

Publication 1794-IN130A-EN-P - December 2009

Page 2

2

WARNING

Observe the following additional Zone 2 certification requirements.

• This equipment is not resistant to sunlight or other sources of UV

radiation.

• This equipment must be installed in an enclosure providing at least IP54

protection when applied in Zone 2 environments.

• This equipment shall be used within its specified ratings defined by

Allen-Bradley.

• Provision shall be made to prevent the rated voltage from being

exceeded by transient disturbances of more than 40% when applied in

Zone 2 environments.

• Secure any external connections that mate to this equipment by using

screws, sliding latches, threaded connectors, or other means provided

with this product.

• Do not disconnect equipment unless power has been removed or the

area is known to be nonhazardous.

North American Hazardous Location Approval

The following adapters are North American Hazardous Location approved:

1794-IF4ICFXT

The following information applies when operating this

equipment in hazardou s locations:

Products marked “CL I, DIV 2, GP A, B, C, D” are suitable for

use in Class I Division 2 Groups A, B, C, D, Hazardous

Locations and nonhazardous locations only. Each product is

supplied with markings on the rating nameplate indicating

the hazardous location temperature code. When combining

products within a system, the most adverse temperature code

(lowest “T” number) may be used to help determine the

overall temperature code of the system. Combinations of

equipment in your system are subject to investigation by the

local Authority Having Jurisdiction at the time of installation.

WARNING

EXPLOSION HAZARD

• Do not disconnect equipment

unless power has been removed or

the area is known to be

nonhazardous.

• Do not disconnect connections to

this equipment unless power has

been removed or the area is known

to be nonhazardous. Secure any

external connections that mate to

this equipment by using screws,

sliding latches, threaded

connectors, or other means

provided with this product.

• Substitution of components may

impair suitability for Class I,

Division 2.

• If this product contains batteries,

they must only be changed in an

area known to be nonhazardous.

Informations sur l’utilisation de cet équipement en

environnements dangere ux :

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne conviennent

qu’à une utilisation en environnements de Classe I Division 2

Groupes A, B, C, D dangereux et non dangereux. Chaque produit

est livré avec des marquages sur sa plaque d’identification qui

indiquent le code de température pour les environnements

dangereux. Lorsque plusieurs produits sont combinés dans un

système, le code de température le plus défavorable (code de

température le plus faible) peut être utilisé pour déterminer le

code de température global du système. Les combinaisons

d’équipements dans le système sont sujettes à inspection par

les autorités locales qualifiées au moment de l’installation.

AVERTISSEMENT

RISQUE D’EXPLOSION

• Couper le courant ou s’assurer que

l’environnement est classé non

dangereux avant de débrancher

l'équipement.

• Couper le courant ou s'assurer que

l’environnement est classé non

dangereux avant de débrancher les

connecteurs. Fixer tous les

connecteurs externes reliés à cet

équipement à l'aide de vis, loquets

coulissants, connecteurs filetés ou

autres moyens fournis avec ce

produit.

• La substitution de composants peut

rendre cet équipement inadapté à

une utilisation en environnement de

Classe I, Division 2.

• S’assurer que l’environnement est

classé non dangereux avant de

changer les piles.

About the module

In addition to the features supported by the 1794-IF4I and 1794-IF4IXT

modules, the 1794-IF4ICFXT features three additional parameters that allow

additional control over the way the analog signals are processed by the

module. The settings are at the module level.

Settings to these parameters affect all inputs set to 150 Hz, 300 Hz, or

Hz. The parameters do not affect channels set at 1200 Hz.

600

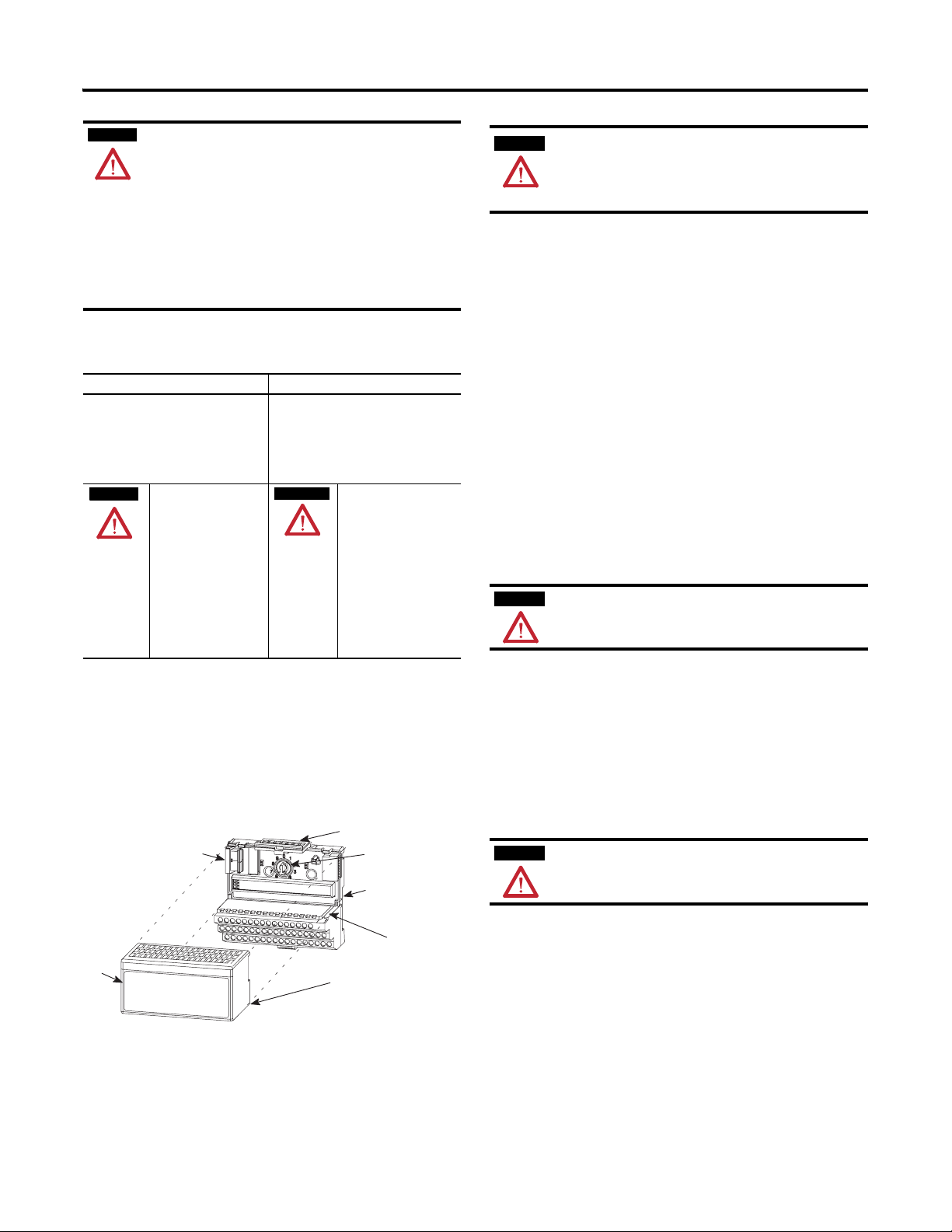

Install Your Analog Input Module

7

3

1

ATTENTION

During mounting of all devices, be sure that all debris (such as metal chips, or

wire strands) is kept from falling into the module. Debris that falls into the

module could cause damage on

power up.

Keep a minimum of 25 mm (1 in.) of space on the top and bottom of the

module, for adequate ventilation between equipment.

The module mounts on a 1794 terminal base.

1. Rotate the keyswitch (1) on the terminal base (2) clockwise to

position 3 as required for 1794-IF4ICFXT.

2. Make certain the flexbus connector (3) is pushed all the way to the

left to connect with the neighboring terminal base/adapter.

You cannot install the module unless the connector is fully

extended.

3. Make sure the pins on the bottom of the module are straight so

they will align properly with the connector in the terminal base.

4. Position the module (4) with its alignment bar (5) aligned with the

groove (6) on the terminal base.

5. Press firmly and evenly to seat the module in the terminal base

unit. The module is seated when the latching mechanism (7) is

locked into the module.

Connect Wiring for Analog Inputs and Outputs

1. 1794-TB2, 1794-TB3, 1794-TB3S, 1794-TB3T, 1794-TB3TS -

Connect individual input/output wiring to numbered terminals on

the 0-15 row (A) as indicated in the Wire Connections table.

Use Belden 8761 cable for signal wiring.

1794-TBN - Connect individual input/output wiring to even

numbered terminals on the 16-33 row (B) as indicated in the

following table.

Use Belden 8761 cable for signal wiring.

ATTENTION

2. 1794-TB2, -TB3, -TB3S, -TB3T, -TB3TS - Connect each channel

3. Connect any signal wiring shields to functional ground as near as

4. Connect the +V DC power to terminal 34 on the 34-51 row (C) and

ATTENTION

Connect only one current or one voltage signal per channel. Do not connect

both current and voltage on one channel.

signal return to numbered terminals on 0-15 row (A) as indicated

in the following table. Use Belden 8761 cable for signal wiring.

1794-TBN - Connect each channel signal return to odd numbered

terminals on row (C) as indicated in the following table.

possible to the module.

1794-TB3T or -TB3TS only: Connect cable shield to terminate

C-39 through C-46 (earth ground).

-V common/return to terminal 16 on the B row.

To reduce susceptibility to noise, power analog modules and digital modules

from separate power supplies.

4

Publication 1794-IN130A-EN-P - December 2009

2

5. If daisychaining +V power to the next terminal base, connect a

6

5

jumper from terminal 51 (+V DC) on this base unit to terminal 34

on the next base unit.

6. If continuing DC common (-V) to the next base unit, connect a

jumper from terminal 33 (common) on this base unit to terminal 16

on the next base unit.

Page 3

3

Wire Connections for 1794-IF4ICFXT Modules

Channel Signal Type Label

Markings

Input 0 Current I0 A-0 C-39 B-0

Current I0 Ret A-1 C-1

Volt age V0 A-2 C-40 B-2

Volt age V0 Ret A-3 C-3

Input 1 Current I1 A-4 C-41 B-4

Current I1 Ret A-5 C-5

Volt age V1 A-6 C-42 B-6

Volt age V1 Ret A-7 C-7

Output 0 Current I2 A-8 C-43 B-8

Current I2 Ret A-9 C-9

Volt age V2 A-10 C-44 B-10

Volt age V2 Ret A-11 C-11

Output 1 Current I3 A-12 C-45 B-12

Current I3 Ret A-13 C-13

Volt age V3 A-14 C-46 B-14

Volt age V3 Ret A-15 C-15

-V DC

Common

+V DC

Power

Chassis

Ground

(Shield)

1794-TB2, -TB3, -TB3S - Terminals B-16 through B-33 are internall y connected in the terminal

base unit.

1794-TBN - Terminals B-16 and B-33 are internally connected in the termi nal base unit.

1794-TB3T, -TB3TS - Terminals 16, 17, 19, 21, 23, 25, 27, 29, 31 and 33 are inte rnally

connected in the terminal base unit.

1794-TB3, -TB3S - Terminals 34 through 51 are internally connected in the terminal base unit.

1794-TB3T, -TB3TS - Terminals 34, 35, 50 and 51 are internally connected in the ter minal base

unit.

1794-TBN, -TB2 - Terminals 34 and 51 are internally connected in t he terminal base unit.

1794-TB3T, -TB3TS - Terminals 39 through 46 are internally connected to chassis ground.

1794-TB2, -TB3, -TB3S, -TB3T,

-TB3TS

Terminal Shield (1794-TB3T,

-TB3TS

1794-TBN

Terminal

7. 1794-TB2, -TB3, and -TB3S - Connect wiring shields to functional

earth ground as near as possible to the module.

1794-TB2, 1794-TB3, 1794-TB3S, 1794-TB3T and 1794-TB3TS Terminal Base

Wiring

I RVRIRV R IRVRIRVR

1 2 3 4 5 6 7 8 9 10 11 12 13 14 150

0 123 45678

16

17 18 19 20 21 22 23 24 25 26 27 28 29 30 333231

34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

I

+

Current

Output

Device

+

AC or DC

4-Wire Output

Device

I I

_

+

Current

Output

Device

_

+

DC only

3-Wire Output

Device

_

9101112

I

+

Current

Output

Device

_

Current only

2-Wire Output

Device

13 1514

+

Voltage

Output

Device

+

DC only

3-Wire Output

Device

A

0-15

16-33

B

34-51

C

_

1794-TBN Terminal Base Wiring

Even Numbered Terminals 0 thru 14

16

16 0 2 4 6 8 10 12 14 33

34 1 3 5 7 9 11 13 15 51

34

I

+-

Current

Input

+-

AC or DC

4-Wire Current

Transmitter

Transmitter

+

I

Current

Input

+

DC only

3-Wire

I

+

Current

Input

+

Current only

2-Wire Current

Transmitter

+

I

Voltage

Input

+

DC only

3-Wire

Transmitter

33

16, 0, 2, 4, 6,

8, 10, 12, 14, 33

34, 1, 3, 5, 7,

9, 11, 13, 15, 51

51

1794-TBN shown

+

Row B

Row C

Input Map

Dec. 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Oct. 17 16 15 14 13 12 11 10 7 6 5 4 3 2 1 0

Word 0 Analog Value Channel 0

Word 1 Analog Value Channel 1

Word 2 Analog Value Channel 2

Word 3 Analog Value Channel 3

Word 4 Real Time Sample

Dec. 1514131211109876543210

Oct. 17 16 15 14 13 12 11 10 7 6 5 4 3 2 1 0

Word 5 PU FP CF 0 Reserved 0 0 0 0 0 BD DN 0

Word 6 0 0 0 0 0 0 0 0 V3 V2 V1 V0 U3 U2 U1 U0

Where :

PU = Power up inconfigured

FP = Field power off

CF = In configuration mode

BD = Bad calibration

DN = Calibration accepted

U = Underrange for specified channel

V = Overrange for specified channel

Output Map

Dec. 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Oct. 17 16 15 14 13 12 11 10 7 6 5 4 3 2 1 0

Word 0 EN 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Word 1 Channel 3 Filter Channel 2 Filter Channel 1 Filter Channel 0 Filter

Word 2 Ch 3 Configuration Ch 2 Configuration Ch 1 Configuration Ch 0 Configuration

Word 3 0 Real Time Sample Interval

Word 4 IC 1 TR IT 0 CH SK FS RV QK CK GO Channel Number

Word 5 Reserved

Where :

EN = Enable bit (not used on input module)

IC = Initiate Configuration bit

TR = Transparent bit

IT = Interrupt toggle bit

CH - Chop Mode Disable — use to disable the chop mode. Chop mode used by the module to reduce offset and drift errors. The

default is chop mode enabled (0).

SK = FIR Filter Disable — use to disable the FIR filter. The Finite Impulse Response filter is used by the module to improve signal

stability. The default is FIR filter enabled (0).

FS = Fast Step Response — use to enable a fast step response algorithm. The fast step response algorithm, upon sensing a step

input, uses an averaging method rather than the FIR filter. The FIR goes back into operation once the input has settled. The default is

fast step response disabled (0).

RV = Revert to default bit

QK = Quick calibration

CK = Calibration clock

GO = Gain Offset select

Configure Your Input Channels

Input Channel Configuration

03 02 01 00 Set these bits for channel 0

07 06 05 04 Set these bits for channel 1

11 10 09 08 Set these bits for channel 2

15 14 13 12 Set these bits for channel 3

Bit Settings Input Values Data Format % Underrange

0 0 0 0 Channel not configured

0 0 0 1 4…20 mA signed 2’s

0 0 1 0 ±10V 2% under; 2% over <831F-7CE1>

0 0 1 1 ±5V 4% under; 4% over <8618-79E8>

0 1 0 0 0…20 mA signed 2’s

0 1 0 1 4…20 mA 4% under; 4% over <0…10000>

0 1 1 0 0…10V 0% under; 2% over <0…10000>

0 1 1 1 ±10V 2% under; 2% over <-10000…10000>

1 0 0 0 0…20 mA binary 0% under; 4% over <0000…F3CF>

1 0 0 1 4…20 mA 4% under; 4% over <0000…F0F1>

1 0 1 0 0…10V 0% under; 2% over <0000…F9C2>

1 0 1 1 0…5V 0% under; 4% over <0000…F3CF>

1 1 0 0 ±20 mA offset binary,

1 1 0 1 4…20 mA offset binary,

1 1 1 0 ±10V offset binary,

1 1 1 1 ±5V 4% under; 4% over <0618…F9E8>

complement

complement %

8000H = 0 mA

8000H = 4 mA

8000H = 0 mA

% Overrange

4% under; 4% over <0000-7878>

0% under; 4% over <0…10000>

4% under; 4% over <0618…F9E8>

4% under; 4% over <8000…F878>

2% under; 2% over <031F…FCE1>

Input Range

Input Update Rate for Real Time Sample Interval = 0

Configuration Bits

MSD LSD

0 0 0 1 4…20 mA 7.5 ms 5.0 ms

0 0 1 0 ±10V 2.5 ms 2.5 ms

0 0 1 1 ±5V 2.5 ms 2.5 ms

0 1 0 0 0…20 mA 7.5 ms 5.0 ms

0 1 0 1 4…20 mA 7.5 ms 5.0 ms

0 1 1 0 0…10V 5.0 ms 5.0 ms

0 1 1 1 ±10V 5.0 ms 5.0 ms

1 0 0 0 0…20 mA 2.5 ms 2.5 ms

1 0 0 1 4…20 mA 7.5 ms 5.0 ms

1 0 1 0 0…10V 2.5 ms 2.5 ms

1 0 1 1 0…5V 2. 5 ms 2.5 ms

1 1 0 0 ±20 mA 2.5 ms 2.5 ms

Input

Nominal

Ranges

Channel Update Rate

RTSI = 0 and No low

pass filter

(1)

Channel Update Rate

RTSI and Filter = 0

IT bit = 1

(1)

Publication 1794-IN130A-EN-P - December 2009

Page 4

4

1 1 0 1 4…20 mA 7.5 ms 5.0 ms

1 1 1 0 ±10V 2.5 ms 2.5 ms

1 1 1 1 ±5V 2.5 ms 2.5 ms

(1)

When IT = 1, the channel update rate for all channels is determined by the slowest channel.

Set the Input Filters

Input Channel Configuration

03 02 01 00 Set these bits for channel 0

07 06 05 04 Set these bits for channel 1

11 10 09 08 Set these bits for channel 2

15 14 13 12 Set these bits for channel 3

Bit Settings A/D Conversion Rate Low Pass Filter

0 0 0 0 1200 Hz No low pass

0 0 0 1 1200 Hz 100 ms low pass

0 0 1 0 1200 Hz 500 ms low pass

0 0 1 1 1200 Hz 1000 ms low pass

0 1 0 0 600 Hz No low pass

0 1 0 1 600 Hz 100 ms low pass

0 1 1 0 600 Hz 500 ms low pass

0 1 1 1 600 Hz 1000 ms low pass

1 0 0 0 300 Hz No low pass

1 0 0 1 300 Hz 100 ms low pass

1 0 1 0 300 Hz 500 ms low pass

1 0 1 1 300 Hz 1000 ms low pass

1 1 0 0 150 Hz No low pass

1 1 0 1 150 Hz 100 ms low pass

1 1 1 0 150 Hz 500 ms low pass

1 1 1 1 150 Hz 1000 ms low pass

Power/status Indicator

The OK status indicator is bicolor red and green. The indicator flashes

green for any of the following 3 reasons:

1. The module configuration word is zero (for example, powerup

reset condition).

2. The 24V DC user power is off.

3. The module is in configuration mode.

The indicator displays red to indicate the module did not pass the initial

hardware test. Recycle power.

After powerup, if the status indicator is not flashing green or solid green,

recycle module power to verify a proper reset of the bus interface.

Specifications

General

Attribute Value

Module location Cat. No. 1794-TB2, 1794-TB3, 1794-TB3S, 1794-T B3T, 1794-TB3TS, a nd 1794-TBN

Number of inputs 4 isolated

Resolution

Voltage

Current

Update rate 2.5/5.0/7.5 ms all channels (see input up date rate table)

Input current terminal 4…20 mA (user configurable)

Input voltage terminal ±10V (user configurable)

Input Resistance

Voltage terminal

Current terminal

Data format 2’s compl ement

Conversion type Si gma Delta

Update rate 2.5/5.0/7.5 ms all channels (see input up date rate table)

Normal mode rejection

ratio - voltage or current

Ter mi na l

16 bits - unipolar; 15 bits plus si gn - bipolar

0.156 mV/cnt unipolar; 0313 mV/cnt bipola r

0.320 μA/cnt unipolar; 0.640 μA/cnt bipolar

0…20 mA (user configurable)

±20 mA (user configurable)

0…10V (user configurable)

±5V (user configurable)

0…5V (user configurable)

>10 MΩ

(3)

<100 Ω

2’s complement %

binary

offset binary

-3 dB @ 12 Hz (300 Hz conversion rate)

-80 dB @ 50 Hz (300 Hz conversion rate)

-3 dB @ 6 Hz (150 Hz conversion rate)

-80 dB @ 60 Hz (150 Hz conversion rate)

General

Attribute Value

Common mode rejection

ratio

Step response to 63% voltage or current

terminal

Absolute accuracy

voltage terminal

current terminal

Accuracy drift with

temperature

Voltage terminal

Current terminal

Calibration required Factory calibrated. Can be calibrated in field when necessary

Maximum overload 30V continuous o r 32 mA continuous, one channel at a time.

Indicators 1 red/green power/status indicator

Isolation voltage 120V (continuous), Basic Insu lation Type, when used with 1794-TB2, 1794-TB3,

Flexbus current 50 mA

Power dissipation 2.0 W maximum @ 31.2V DC

Thermal dissipation Maximu m 6.8 BTU/hr @ 31.2V DC

Keyswitch position 3

External DC Power

Supply voltage

Voltage range

Supply current

Dimensions 46 mm x 94 mm x 75 mm (1.8 in. x 3.7 in. x 2.95 in.) with module installed in base

Wire size Determined by installed terminal base

Wiring category

Wire type Shielded on signal ports

Enclosure type rating None (open-style)

Terminal screw torque Determine d by installed terminal base

North American temp

code

IEC temp code T4

(1)

Includes offset, gain, nonlin earity and repeatability error terms.

(2)

Use this Conductor Category information for planning conductor routing. Refer to Industrial Automation Wiring and

Grounding Guidelines, publication

(3)

If 24V DC is removed fr om the module, input resistance = 10 kΩ

-120 dB @ 50/60 Hz

1200 Hz conversion rate = 0.6 ms

600 Hz conversion rate = 06.7 ms

300 Hz conversion rate = 13.4 ms

150 Hz conversion rate = 26.7 ms

(1)

0.1% Full Scale @ 25 °C

0.1% Full Scale @ 25 °C

0.0028% Full Scale/°C

0.0038% Full Scale/°C

1794-TB3S, 1794-TB3T, or 1794-TB3TS

250V (continuous), Basic Insulation Type, when used with 1794-TBN

Type tested at 1500V AC for 60 s and Routine tested at 2550V DC for 1 s, between

channel to power, channel to system, and power to system, and chan nel to channel

24V DC nominal

SUPPLY: 19.2-31.2V DC, 80 mA

FLEXBUS: 5V DC, 50 mA

Input: 0…20 mA, ±10V DC

(2)

2 - on signal ports

2 - on power ports

T4

1770-4.1.

Environmental

Attribute Va lue

Operating

temperature

Non-operating

temperature

Relative humidity IEC 60068-2-30 (Test Db, Unpackaged Damp Heat):

Vibrati on IEC 60068-2-6 (Test Fc, Operating):

IEC 60068-2-1 (Test Ad, Operating Cold),

IEC 60068-2-2 (Test Bd, Operating Dry Heat),

IEC 60068-2-14 (Test Nb, Operating Thermal Shock):

-20…70 °C (-4…158 °F)

IEC 60068-2-1 (Test Ab, Unpackaged Non-operating Cold),

IEC 60068-2-2 (Test Bb, Unpackaged Non-operating Dry Heat),

IEC 60068-2-14 (Test Na, Unpackaged Non-operating Thermal Shock):

-40…85 °C (-40…185 °F)

5…95% noncondensing

5 g @ 10…500 Hz

Publication 1794-IN130A-EN-P - December 2009

Page 5

Environmental

Operating shock IEC 60068-2-27 (Test Ea, Unpackaged Shock):

Non-operating shock IEC 60068-2-27 (Test Ea, Unpackaged Shock):

Emissions CISPR 11:

ESD immunity IEC 61000-4-2:

Radiated RF

immunity

EFT/B immunity IEC 61000-4-4:

Surge transient

immunity

Conducted RF

immunity

30 g

50 g

Group 1, Class A (with appropriate enclosu re)

6 kV contact discharges

8 kV air discharges

IEC 61000-4-3:

10V/m with 1 kHz sine-wave 80% AM fro m 80…2000 MHz

10V/m with 200 Hz 50% Pulse 100% A M at 900 MHz

10V/m with 200 Hz 50% Pulse 100% AM at 1890 MHz

3V/m with 1 kHz sine-wave 80% AM from 2000…270 0 MHz

±2 kV at 5 kHz on power ports

±2 kV at 5 kHz on signal ports

IEC 61000-4-5:

±1 kV line-line(DM) and ±2 kV line-earth(CM) on po wer ports

±2 kV line-earth(CM) on shielded signal por ts

IEC 61000-4-6:

10V rms with 1 kHz sine-wave 80% AM from 150 kHz…80 MHz

5

Certifications (when product is marked)

(1)

Attribute Value

c-UL-us UL Listed Industrial Control Equipment, certified for US and Canada. See UL File

CE European Union 2004/108/EC EMC Directive, com pliant with:

C-Tick Australian Radiocommunications Act, comp liant with:

Ex Eur opean Union 94/9/EC ATEX Directive, compliant with:

TÜV TÜV Certified for Functional Safety:

(1)

See the Product Certification link at http://www.ab.com for Declaration of Confo rmity, Certificates, and other

certification details.

E65584.

UL Listed for Class I, Division 2 Group A,B,C,D Hazardous Locations, certified for U.S.

and Canada. See UL File E194810.

EN 61326-1; Meas./Control/Lab., Industrial Requ irements

EN 61000-6-2; Industrial Immunity

EN 61000-6-4; Industrial Emissions

EN 61131-2; Programmable Controllers (Clause 8, Zone A & B)

European Union 2006/95/EC LVD, compliant with:

EN 61131-2; Programmable Controllers (Cla use 11)

AS/NZS CISPR 11; Industrial Emissions

EN 60079-15; Potentially Explosive Atmospheres, Protection "n"

EN 60079-0; General Requirements

II 3 G Ex nA IIC T4 X

Capable of SIL 2

Publication 1794-IN130A-EN-P - December 2009

Page 6

Notes:

Publication 1794-IN130A-EN-P - December 2009 6 PN-65201

Supersedes Publication 1794-IN129B-EN-P - A pril 2009 Copyright © 2009 Rockwell Automation, Inc. All rights reserved.

Loading...

Loading...