Page 1

Installation Instructions

FLEX I/O ac Digital Input Modules

Cat. Nos. 1794-IA8, -IA8K, IA8I, -IA16

(Modules with a K in the last position of the catalog number are conformally

coated to meet noxious gas requireme nts of ISA / AN SI-71.040 1985 Class

G3 Environment.)

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application, Installation and

Maintenance of Solid State Controls (Publication SGI-1.1 available from your local Rockwell

Automation sales office or online at http://www.ab.com/manuals/gi) describes some

important differences between solid state equipment and hard-wired electromechanical

devices. Because of this difference, and also because of the wide variety of uses for solid

state equipment, all persons responsible for applying this equipment must satisfy themselves

that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or

consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes.

Because of the many variables and requirements associated with any particular installation,

Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the

examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information,

circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of

Rockwell Automation, Inc. is prohibited.

Throughout this manual we use notes to make you aware of safety considerations.

WARNING

IMPORTANT

ATTENTION

ATTENTION

Identifies information about practices or circumstances that can cause

an explosion in a hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

Identifies information that is critical for successful application and

understanding of the product.

Identifies information about practices or circumstances that can lead

to personal injury or death, property damage, or economic loss.

Attentions help you:

• identify a hazard

• avoid a hazard

• recognize the consequence

Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2

industrial environment, in overvoltage Category II applications

(as defined in IEC publication 60664-1), at altitudes up to 2000

meters without derating.

This equipment is considered Group 1, Class A industrial

equipment according to IEC/CISPR Publication 11. Without

appropriate precautions, there may be potential difficulties

ensuring electromagnetic compatibility in other environments

due to conducted as well as radiated disturbance.

This equipment is supplied as "open type" equipment. It must be

mounted within an enclosure that is suitably designed for those

specific environmental conditions that will be present and

appropriately designed to prevent personal injury resulting from

accessibility to live parts. The interior of the enclosure must be

accessible only by the use of a tool. Subsequent sections of this

publication may contain additional information regarding specific

enclosure type ratings that are required to comply with certain

product safety certifications.

See NEMA Standards publication 250 and IEC publication

60529, as applicable, for explanations of the degrees of

protection provided by different types of enclosure. Also, see the

appropriate sections in this publication, as well as the

Allen-Bradley publication 1770-4.1 ("Industrial Automation

Wiring and Grounding Guidelines"), for additional installation

requirements pertaining to this equipment.

WARNING

WARNING

ATTENTION

ATTENTION

When you insert or remove the module while backplane power is on,

an electrical arc can occur. This could cause an explosion in

hazardous location installations. Be sure that power is removed or the

area is nonhazardous before proceeding.

If you connect or disconnect wiring while the field side power is on,

an electrical arc can occur. This could cause an explosion in

hazardous location installations. Be sure that power is removed or the

area is nonhazardous before proceeding..

FLEX I/O is grounded through the DIN rail to chassis ground. Use

zinc plated yellow-chromate steel DIN rail to assure proper grounding.

The use of other DIN rail materials (e.g. aluminum, plastic, etc.) that

can corrode, oxidize, or are poor conductors, can result in improper or

intermittent grounding.

Preventing Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which can cause

internal damage and affect normal operation. Follow these guidelines

when you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• If available, use a static-safe workstation.

North American Hazardous Location Approval

The following input modules are North American Hazardous Location

approved: 1794-IA8, -IA8K, -IA8I and 1794-IA16.

.

The following information applies when operating this

equipment in hazardous locations:

Products marked “CL I, DIV 2, GP A, B, C, D” are suitable for use

in Class I Division 2 Groups A, B, C, D, Hazardous Lo cations and

nonhazardous loc ations only. Each product is supplied with

markings on the rating nameplate indicating the hazardous

location temperature code. When combining products within a

system, the mos t adverse temperatur e code (lowest “T”

number) may be used to help determine the overall temperature

code of the sys tem. Combinations of e quipment in your system

are subject to i nvestigation by the loca l Authority Having

Jurisdiction at the t ime of installation.

WARNING

EXPLOSION HAZARD

• Do not discon nect equipment unless

power has been removed or the area is

known to be n onhazardous.

• Do not disconnect connections to this

equipment un less power has been

removed or the area is known to be

nonhazardous. Secure any external

connections that mate to this

equipment by using scr ews, sliding

latches, thre aded connectors, or other

means provided with this product.

• Substituti on of components ma y

impair suitability f or Class I,

Division 2.

• If this product contains batteries, they

must only be changed in an area known

to be nonhazar dous.

Informations sur l’utilisation de cet équipement en

environnements dangereux :

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne

conviennent qu’à une utilisation en environnements de Classe I

Division 2 Grou pes A, B, C, D dangere ux et non dangereux.

Chaque produit est livré avec des mar quages sur sa plaque

d’identificati on qui indiquent le code de température pour les

environnemen ts dangereux. Lorsq ue plusieurs produits s ont

combinés dans un syst ème, le code de température le plus

défavorable (c ode de température le p lus faible) peut être

utilisé pour dé terminer le code de tem pérature global du

système. Les c ombinaisons d’équipeme nts dans le système

sont sujettes à inspe ction par les autorités local es qualifiées

au moment de l’ installation.

AVERTISSEMENT

RISQUE D’EXPLOSION

• Couper le cou rant ou s’assurer que

l’environnement est classé non

dangereux avant de débrancher

l'équipement .

• Couper le cou rant ou s'assurer que

l’environnement est classé non

dangereux avant de débrancher les

connecteurs. Fixer tou s les connecteurs

externes reli és à cet équipement à

l'aide de vis , loquets coulissants,

connecteurs filetés ou autres moyens

fournis avec c e produit.

• La substitut ion de composants peut

rendre cet é quipement inadapté à une

utilisation en en vironnement de Classe

I, Division 2.

• S’assurer que l’environnement est

classé non da ngereux avant de change r

les piles.

FLEX I/O is a trademark of Rockwell Automation

DeviceNet is a trademark of ODVA, Inc. Publication 1794-IN102B-EN-P - June 2004

Page 2

2

European Hazardous Location Approval

The following module is European Zone 2 approved: 1794-IA8K.

European Zone 2 Certification (The following applies when the product bears

the EEx Marking)

This equipment is intended for use in potentially explosive atmospheres as defined by

European Union Directive 94/9/EC.

The LCIE (Laboratoire Central des Industries Electriques) certifies that this

equipment has been found to comply with the Essential Health and Safety

Requirements relating to the design and construction of Categor y 3 equipment

intended for use in potentially explosive atmospheres, given in Annex II to this

Directive. The examination and test results are recorded in confidential report No. 28

682 010.

Compliance with the Essential Health and Safety Requirements has been assured by

compliance with EN 50021.

IMPORTANT

Observe the following additional Zone 2 certification requirements.

• This equipment is not resistant to sunlight or other sources of UV

radiation.

• The secondary of a current transformer shall not be open-circuited

when applied in Class I, Zone 2 environments.

• Equipment of lesser Enclosure Type Rating must be installed in an

enclosure providing at least IP54 protection when applied in Class I,

Zone 2 environments.

• This equipment shall be used within its specified ratings defined by

Allen-Bradley.

• Provision shall be made to prevent the rated voltage from being

exceeded by transient disturbances of more than 40% when

applied in Class I, Zone 2 environments

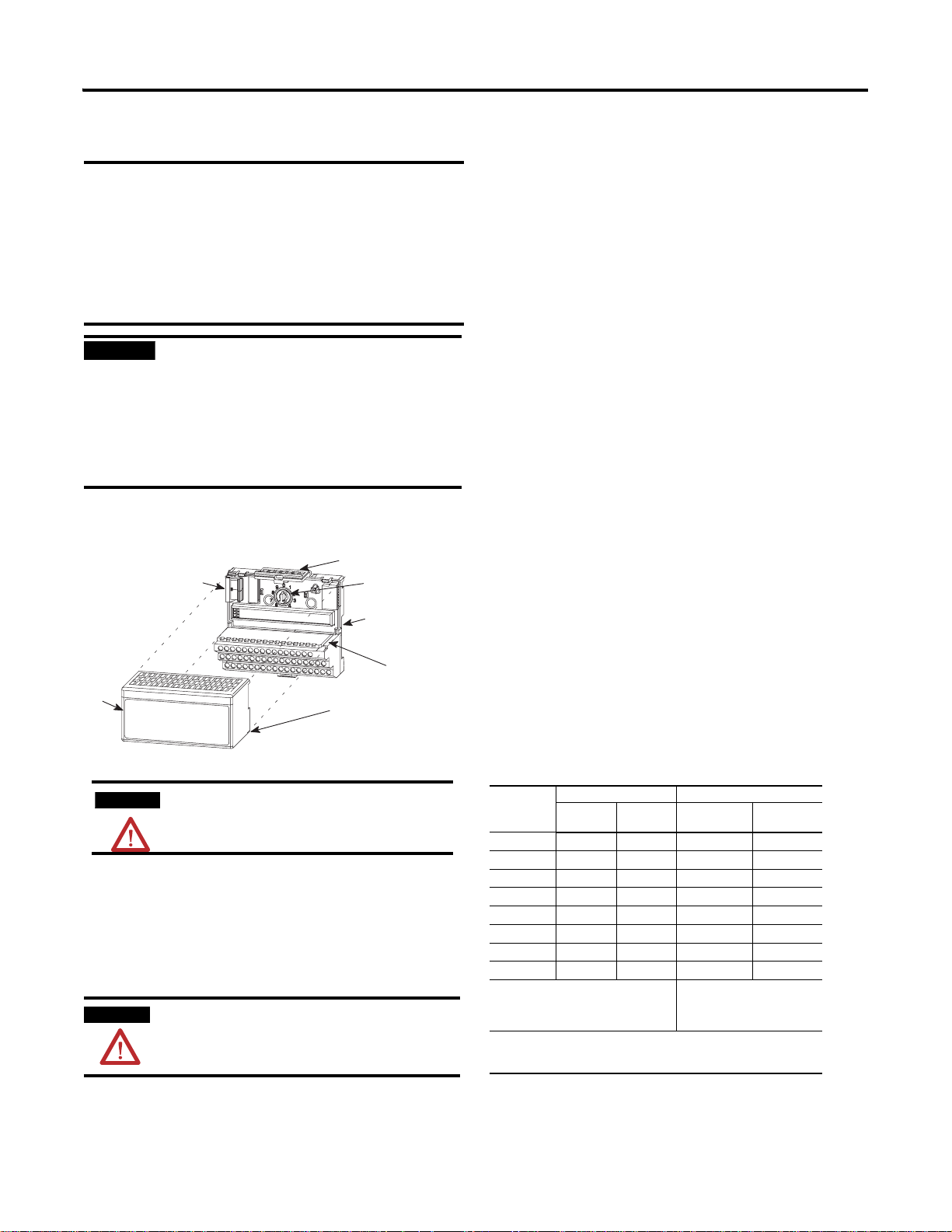

Installing Your ac Digital Input Module

7

3

4

1

2

6

5

5. Press firmly and evenly to seat the module in the terminal base unit.

The module is seated when the latching mechanism (7) is locked into

the module.

Connecting Wiring for the 1794-IA8 and -IA8K

1. For 1794-TB2, -TB3, or -TB3S - Connect individual input wiring to

even numbered terminals on the 0-15 row (A) as indicated in the table

below .

For 1794-TBN - Connect individual input wiring to numbered

terminals on the 16-33 row (B) as indicated in the table below.

2. For 1794-TB2 - Connect the associated 120V ac power lead (L1) of

the input device to the corresponding odd numbered terminals on the

0-15 row A for each input as indicated in the table below. (The odd

numbered terminals on row A are internally connected to 120V ac

L1.)

For 1794-TB3, or -TB3S - Connect the associated 120V ac power

lead (L1) of the input device to the corresponding odd numbered

terminals on the 34-51 row (C) or to the corresponding terminal on

row (C) for each input as indicated in the table below. (The odd

numbered terminals on row (A) and the terminals of row (C) are

internally connected to 120V ac power L1.)

For 1794-TBN - Connect the associated 120V ac power lead (L1) of

the input device to the corresponding odd numbered terminal on the

34-51 row (C) for each input as indicated in the table below. (The

120V ac power terminals of row (C) are internally connected

together.)

3. Connect 120V ac power (L1) to terminal 34 on the 34-51 row (C).

4. Connect 120V ac common (L2) to terminal 16 on the 16-33 row (B).

5. If daisychaining power to the next terminal base, connect a jumper

from terminal 51 (+120V ac L1) on this base unit to terminal 34 on

the next base unit

6. .If continuing ac common to the next base unit, connect a jumper

from terminal 33 (120V common L2) on this base unit to terminal 16

on the next base unit.

The module mounts on a 1794 terminal base.

ATTENTION

During mounting of all devices, be sure that all debris

(metal chips, wire strands, etc.) is kept from falling

into the module. Debris that falls into the module

could cause damage on power up.

1. Rotate the keyswitch (1) on the terminal base (2) clockwise to position

8 as required for this type of module.

2. Make certain the flexbus connector (3) is pushed all the way to the left

to connect with the neighboring terminal base/adapter. You cannot

install the module unless the connector is fully extended.

3. Make sure the pins on the bottom of the module are straight so they

will align properly with the connector in the terminal base.

WARNING

If you remove or insert the module while the backplane

power is on, an electrical arc can occur. This could cause an

explosion in hazardous location installations. Be sure that

power is removed or the area is nonhazardous before

proceeding..

4. Position the module (4) with its alignment bar (5) aligned with the

groove (6) on the terminal base.

Publication 1794-IN102B-EN-P - June 2004

Wiring Connections for the 1794-IA8 and -IA8K

Input

Input 0 A-0

Input 1 A-2

Input 2 A-4

Input 3 A-6

Input 4 A-8

Input 5 A-10

Input 6 A-12

Input 7 A-14

A = Input terminals (Even numbe red terminals

0 thru 14)

B = Common terminals

C = Power terminals (C-34 and C-51 on - TB2; C-34

thru C-51 on -TB3 and -TB3S)

1 A-1, 3, 5, 7, 9, 11, 13 and 15 on the 1794-TB2, -TB3 and - TB3S are internally connected in the

module to 120V ac L1.

2 C-1, 3, 5, 7, 9, 11, 13 and 15 on the 1794-TBN are internally connected in the module to

120V ac L1.

1794-TB2,-TB3, -TB3S 1794-TBN

Input

Ter mi nal

120V ac

Supply

A-11/C-35

A-31/C-36

A-51/C-37

A-71/C-38

A-91/C-39

A-111/C-40

A-131/C-41

A-151/C-42

Input

Te rm in al

B-0

B-2

B-4

B-6

B-8

B-10

B-12

B-14

B = Even numbered Input terminals

0-14, ac common terminals 16 and 33

C = Power terminals C-34 and C-51, and

odd numbered input terminals 1 thru 1 5

120V ac

Supply

2

C-1

2

C-3

2

C-5

2

C-7

2

C-9

2

C-11

2

C-13

2

C-15

Page 3

3

Inputs

)

Even Numbered I/O Terminals 0 thru 14

n)

L

L

U

1794-TB2, -TB3 and -TB3S Terminal Base Wiring for 1794-IA8,

IA8K and -IA16

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

16

L2

35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

34

L1

Connect 120V ac L1 power to terminal C-34

Connect 120V ac common L2 to terminal B-16

Use B-33 and C-51 for daisychaining to the next terminal base unit

(Terminals C-35 thru C-50 not available on the 1794-TB2.)

Commons

Voltage

A

B

L2

C

L1

(1794-TB3 shown

1794-TBN Terminal Base Wiring for 1794-IA8, IA8K

and -IA16

L2

16

34

L1

1 = 120V ac - Connect to terminal C-34

2 = 120V ac common - Connect to terminal B-16

se B-33 and C-51 for daisychaining to the next terminal base unit

4

2

0

1

6789101112

3

5

Odd Numbered I/O Terminals 1 thru 15

L2

14

33

15

B

51

C

L1

(1794-TBN show

13

Connecting Wiring for the 1794-IA16

1. For 1794-TB3, or -TB3S - Connect individual input wiring to

numbered terminals on the 0-15 row (A) as indicated in the table

below .

For 1794-TBN - Connect individual input wiring to even numbered

terminals on the 16-33 row (B), and to the odd numbered terminals

on the 34-51 row (C) as indicated in the table below.

2. For 1794-TB3, or -TB3S - Connect the associated 120V ac power

lead (L1) of the input device to the corresponding terminals on the

34-51 row (C) for each input as indicated in the table below. (The

120V power terminals of row (C) are internally connected together.)

For 1794-TBN - An external terminal strip is needed to distribute

120V ac power (L1) to each device.

Terminal Base Wiring for 1794-IA16

Input

Channel

Input 0 A-0 B-0 C-35

Input 1 A-1 C-1 C-36

Input 2 A-2 B-2 C-37

Input 3 A-3 C-3 C-38

Input 4 A-4 B-4 C-39

Input 5 A-5 C-5 C-40

Input 6 A-6 B-6 C-41

Input 7 A-7 C-7 C-42

Input 8 A-8 B-8 C-43

Input 9 A-9 C-9 C-44

Input 10 A-10 B-10 C-45

Input 11 A-11 C-11 C-46

Input 12 A-12 B-12 C-47

Input 13 A-13 C-13 C-48

Input 14 A-14 B-14 C-49

Input 15 A-15 C-15 C-50

120V ac L1 Power terminals C-34 thru C-51 (C-34 and C-51 on -TBN) are

120V ac L2 Common terminals B-16 thru B-33 (B-16 and B-33 for -TBN) are

1

When using the 1794-TBN, an external terminal strip is needed to connect the 120V ac power

connections.

Input Terminal

1794-TB3, -TB3S

Input Terminal

1794-TBN

internally connected together. Connect 120V ac L1 to C-34

internally connected together. Connect 120V ac common L2 to

terminal B-16

Connecting Wiring for the 1794-IA8I

1. For 1794-TB2, -TB3, or -TB3S - Connect individual input wiring to

even numbered terminals on the 0-15 row (A) as indicated in the table

below .

For 1794-TBN - Connect individual input wiring to even numbered

terminals 0-14 on the 16-33 row (B) as indicated in the table below.

2. For 1794-TB2, -TB3, or -TB3S - Connect the associated 120V ac

common (L2) of the isolated supply to the corresponding odd

numbered terminals on the 0-15 row A for each input as indicated in

the table below.

For 1794-TBN - Connect the associated 120V ac common lead (L2)

of the isolated supply to the corresponding odd numbered terminal

1-15 on the 34-51 row (C) as indicated in the table below.

120V ac

Supply (L1)

1

3. Connect 120V ac power (L1)to terminal 34 on the 34-51 row (C).

4. Connect 120V ac common (L2) to terminal 16 on the 16-33 row (B).

IMPORTANT

Individual isolated 120V ac L1 power leads must

be run externally to each of the input devices.

5. If daisychaining power to the next terminal base, connect a jumper

from terminal 51 (+120V ac L1) on this base unit to terminal 34 on

the next base unit.

6. If continuing ac common to the next base unit, connect a jumper

from terminal 33 (120V common L2) on this base unit to terminal 16

on the next base unit.

Publication 1794-IN102B-EN-P - June 2004

Page 4

4

n)

C

C

Even Numbered I/O Terminals 0 thru 14

n)

C

L

)

Wiring Connections for the 1794-IA8I

1794-TB2, -TB3, -TB3S 1794-TBN

Input

Input

Terminal

Input 0 A-0 A-1 B-0 C-1

Input 1 A-2 A-3 B-2 C-3

Input 2 A-4 A-5 B-4 C-5

Input 3 A-6 A-7 B-6 C-7

Input 4 A-8 A-9 B-8 C-9

Input 5 A-10 A-11 B-10 C-11

Input 6 A-12 A-13 B-12 C-13

Input 7 A-14 A-15 B-14 C-15

A = Even numbered terminals 0 thru 14 for cus tomer

connections; corresponding odd numbered 120V ac

common L2 terminals 1 thru 15 f or customer

connections from isolat ed power supply.

120V ac L2

Common

Input

Ter m in al

B = Even numbered term inals 0 thru 14

for customer connections; C = Odd

numbered120V ac common L2

terminals 1 thru 15 for customer

connections from isolat ed power

supply.

120V ac L2

Common

1794-TB2, -TB3, or -TB3S Terminal Base Wiring for the

1794-IA8I

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

16

35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

34

onnect Inputs to even numbered terminals on row (A)

onnect 120V ac common L2 to odd numbered terminals on row (A)

A

B

C

(1794-TB3 show

1794-TBN Terminal Base Wiring for 1794-IA8I

16

0

34

4

2

1

6789101112

3

5

Odd Numbered I/O Terminals 1 thru 15

onnect Inputs to even numbered terminals on row (B)

2 = 120V ac common - Connect to odd numbered terminals on row (C

14

33

13

15

B

51

C

(1794-TBN show

Configuring Your ac Input Module

Image Table Memory Map for the 1794-IA8, -IA8K

and -IA8I

.

Dec. 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Oct. 17 16 15 14 13 12 11 10 7 6 5 4 3 2 1 0

Read I7 I6 I5 I4 I3 I2 I1 I0

Write Not used - set to 0 Filter Time FT

Where I = Input

FT = Input filter time.

0-7

Setting the Input Filter Time

You can increase the input filter time (FT) for channels 00-07 (1794-IA8,

-IA8K, -IA8I) and channels 00-15 (1794-IA16) by setting the corresponding

bits in the output image table (complementary word) for the module.

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

O:010

FT = 12-15 FT = 0-11

1794-IA8, -IA8I

1794-IA16

Dec.

For example, to increase the off-to-on filter time to 12ms for all inputs at

address rack 1, module group 0, set bits and program as shown below.

Write filter time on system startup.

I:000

00

765432 1 0

1794-IA8

1794-IA8I

76543

1794-IA16

FLL

Fill File

Source

Destination

Length

0

1

21 0

1

010100

00

Write FT to complement

of input module.

#O:010

1

= 4 Octal or 4 Decimal

0

= 44 Octal or 36 Decimal

To increase the filter time, set the bits according to the table below.

Input Filter Time

Maximum

Bits Description

02 01 00 Filter Time -

05 04 03 Filter Time -

0 0 0 Filter Time 0

inputs 00-11

inputs 12-15

(Default)

Selected

Filter

Tim e

256µs 8.4 26.4 8.4 26.4 7.5 26.5

Filter Time

1794-IA8, -IA8K

(ms)

Off to OnOn to

0 0 1 Filte r Tim e 1 51 2µs 8.6 26.6 8.6 26.6 8 27

0 1 0 Filte r Tim e 2 1m s 9 27 9 27 9 28

0 1 1 Filte r Tim e 3 2m s 10 28 10 28 10 29

1 0 0 Filte r Tim e 4 4m s 12 30 12 30 12 31

1 0 1 Filte r Tim e 5 8m s 16 34 16 34 16 35

1 1 0 Filte r Tim e 6 16 ms 24 42 24 42 24.5 44

1 1 1 Filte r Tim e 7 32 ms 40 58 40 58 42 60.5

Maximum

Filter Time

1794-IA8I

Off

to

Off

On

(ms)

Maximum

Filter Time

1794-IA16

(ms)

On

Off

to

Off

On

to

to

On

Off

Image Table Memory Map for the 1794-IA16

Dec. 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Oct. 17 16 15 14 13 12 11 10 7 6 5 4 3 2 1 0

Read 1 I15I14I13I12I11I10I9 I8 I7 I6 I5 I4 I3 I2 I1 I0

Write 3 Not used - set to 0 Input Filter FT

Where I = Input

FT = Input filter time

12-15

Input Filter FT

0-11

Publication 1794-IN102B-EN-P - June 2004

Page 5

Specifications

Specifications 1794-IA8, 1794-IA8K 1794-IA8I

Number of Inputs 8, (1 group of 8), nonisolated 8 isolated

Module Location Cat. No. 1794-TB2, -TB3, -TB3S and -TBN Terminal Base Units

On-state Voltage 65V ac minimum

On-state Current

Off-state Voltage 43V ac maximum

Off-state Current 2.9mA minimum

Input Impedance 10.6K ohms nominal

Nominal Input Current 12mA @ 120V ac, 6 0Hz

Isolation Voltage Tested at 2150V dc for 1s between

Input Filter Time Refer to Input F ilter Time ta ble

Flexbus Current 30mA @5V dc

Power Dissipation 4.5W maximum @ 132V ac

Thermal Dissipation Maximum 15.3 BTU/hr @ 132V ac

Specifications - Cat. No. 1794-IA16

Number of Inputs 16 (1 group of 16), nonisolated

Module Location Cat. No. 1794-TB3, -TB3S and -TBN Terminal Base Units

On-state Voltage 74V ac minimum

On-state Current1

Off-state Voltage 20V ac maximum

Off-state Current 2.9 mA minimum

Nominal Input Impedance 10K ohms

Nominal Input Current 12mA @ 120V ac, 60Hz

Isolation Voltage Tested at 2150V dc for 1s between u ser and system

Flexbus Current 20mA

Power Dissipation 6.4W maximum @ 132V ac

Thermal Dissipation Max imum 21.8 BTU/hr @ 132V ac

120V ac nominal

132V ac maximum

1

7.1mA minimum

user and system

No isolation between individual

channels

120V ac nominal

132V ac maximum

minimum

nominal

maximum

5.49mA @ 74V ac, 47Hz

12.06mA @ 120V ac, 60Hz

14.81mA @ 132V ac, 63Hz

No isolation between individual chann els

Tested at 2150V dc for 1s between

user and system and between

individual channels

5

General Specifications

Input Filter Time

Terminal Base Screw

Torque

Dimensions (with module

installed)

Indicators (field side

indication, custome r

device driven)

External ac power

Supply voltage

Voltage range

Keyswitch Position 8

Environmental Conditions

Enclosure Type Rating None (open-style)

Conductors Wire Size

Certifications (when

product is marked)

1 Ac inputs compatible with proximity switches wit h leakage ratings of I

2 Input off-to-on filte r time is the time from a v alid input signal to recogn ition by the module. Input o n-to-off filter

3 You use this category information for planning conductor routing as described in Allen-Bradley

4 For the latest up-to- date information, see the Product Certificat ion link at www.ab.com for Declarations of

2

Off to On

On to Off

Operating

Temperature

Storage Temperature IEC 60068-2-1 (Test Ab, Un-packaged Non-oper ating Cold),

Relative Humidity IEC 60068-2-30 (Test Db, Un-packaged Non-operating

Vibration IEC60068-2-6 (Test Fc, Operating):

Shock IEC60068-2-27 (Test Ea, Unpackaged shock):

Emissions CISPR 11:

ESD Immunity IEC 61000-4-2:

Radiated RF Immunity IEC 61000-4-3:

EFT/B Immunity IEC 61000-4-4:

Surge Transient

Immunity

Conducted RF

Immunity

Category

time is time from the input signal droppin g below the valid level to recognition by the module.

publication 177 0-4.1, Industrial Automat ion Wiring and Groundin g Guidelines.

Conformity, Certificates and other certification details. For notification of any additional release notes, refer to

www.ab.com/manuals/.

Refer to Input Filter Time chart for values.

7 pound-inches (0.8Nm)

9 pound-inches (1.0Nm) for 1794- TBN

3.7H x 3.7W x 2.7D inches

94H x 94W x 69D mm

1794-IA8, -IA8K - 8 yellow status indicators

1794-IA8I - 8 yellow status in dicators

1794-IA16 - 16 yellow status indicat ors

120V ac nominal

1794-IA8, -IA8K, -IA8I - 85 to 132V ac, 47-63 Hz

1794-IA16 - 74 to 132V ac, 47-63Hz

IEC 60068-2-1 (Test Ad, Operating Cold),

IEC 60068-2-2 (Test Bd, Operating Dry Heat),

IEC 60068-2-14 (Test Nb, Operating Thermal Shock):

0 to 55°C (32 to 131°F)

IEC 60068-2-2 (Test Bb, Un-packaged Non-operating Dry Heat),

IEC 60068-2-14 (Test Na, Un-packaged Non-operating Thermal

Shock):

–40 to 85°C (–40 to 185°F)

Damp Heat):

5 to 95% non-condensing

5g @ 10-500Hz

Operating 30g

Non-operating 50g

Group 1, Class A (with appropriate e nclosure)

4kV contact discharges

8kV air discharges

10V/m with 1kHz sine-wave 80%AM f rom 30MHz to 1000MHz

10V/m with 200Hz 50% Pulse 100% A M at 900Hz

±2kV at 5kHz on signal ports

±2kV at 5kHz on power ports

IEC 61000-4-5:

±1kV line-line(DM) and ±2kV line-earth(CM ) on signal ports

±1kV line-line(DM) and ±2kV line-earth(CM) on power ports

IEC 61000-4-6:

10Vrms with 1kHz sine-wave 80%AM from 150kHz to 80MHz

12-22AWG (2.5mm2-0.34mm2) stranded copper wire r ated at 75°C

or higher

3/64 inch (1.2mm) insulation maximu m

3

2

UL UL Listed Industrial Control Equipm ent

4

CSA CSA certified for Class I, Division 2, Groups A, B, C and D

Hazardous locations

EEx5European Union 94/9/EEC ATEX Directive, compliant with:

EN 50021; Potentially Explosiv e Atmospheres,

Protection “n” (European Zone 2) - (1794-IA8K only)

CE4 European Union 89/336/EEC EMC D irective, compliant with:

EN 61000-6-4; Industrial Emis sions

EN 50082-2; Industrial Immun ity

EN 61326; Meas./Control/Lab., Industria l Requirements

EN 61000-6-2; Industrial Immu nity

European Union 73/23/EEC LVD Directive, comp liant with:

EN 61131-2; Programmable Control lers

C-Tick4 - Australian Radiocommunications Act compliant with

AS/NZS CISPR 11, Industrial Emissions

< 2.5mA and Ion minimum = 5mA.

leak

Publication 1794-IN102B-EN-P - June 2004

Page 6

Publication 1794-IN102B-EN-P - June 2004 6 PN 957867-39

Supersedes Publication 1794-IN102A -EN-P - March 2004 Copyright © 2004 Rockwell Automatio n, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...