Page 1

Installation Instructions

FLEX Integra

2 Input/2 Protected Output Module

(Cat. No. 1793-IB2XOB2P and -IB2XOB2PS)

41355

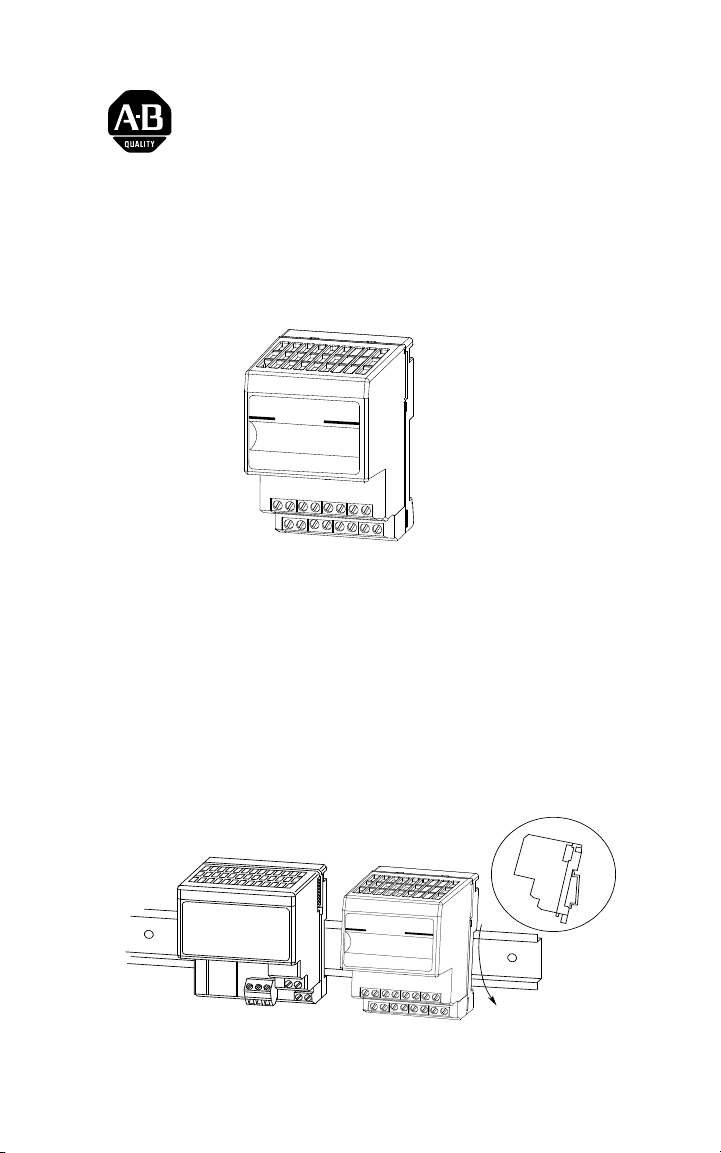

Module Installation

This module mounts on a DIN rail. It connects to an adapter or another

FLEX I/O or Integra module. Note: If using this module with FLEX I/O

modules, do not mount between FLEX I/O modules. Mount Integra

modules to the right of the FLEX I/O modules. To mount this module:

1. Remove the cover plug (if used) in the male connector of the unit to

which you are connecting this module.

2. Position the module on the 35 x 7.5mm DIN rail A (A-B pt. no.

199-DR1).

3. Rotate the module onto the DIN rail with the top of the rail hooked

under the lip on the rear of the module.

A

A

30720-M

FLEX Integra and FLEX I/O are

trademarks of Rockwell Automation Publication 1793-5.3 - September 1999

Page 2

2 FLEX Integra 2 Input/2 Protected Output Module

41377

A

41370

41371

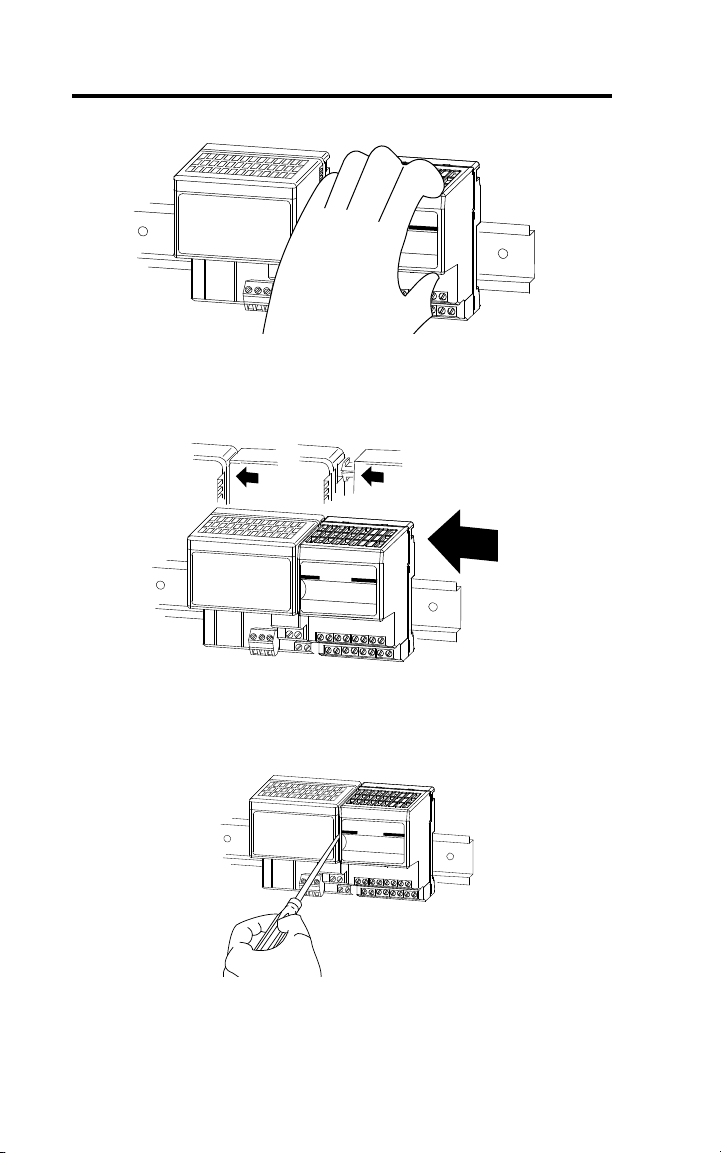

4. Press down to lock the module on the DIN rail.

If the module does not lock in place, use a screwdriver of similar

device to move the locking tab down, press the module flush with the

DIN rail and release the locking tab to lock the module in place.

5. Firmly push the module into the adjacent module/terminal base until

the units lock together.

6. Repeat the above steps to install the next module.

7. To remove an Integra module, you must work from the right side and

remove one module at a time. To disengage a module from its

neighbor, place a common flat-bladed screwdriver between the 2

modules and turn 1/4 turn to separate the modules.

41373

8. Then slide the module away from its left neighbor, and release the

locking lever to remove the module from the DIN rail.

Publication 1793-5.3 - September 1999

Page 3

FLEX Integra 2 Input/2 Protected Output Module 3

ATTENTION: Do not remove this module under

power. Removing this module under power will break the

!

electrical backplane (flexbus) connections. This can cause

personal injury or property damage by:

• sending an erroneous signal to your system's field

devices causing unintended machine motion

• causing an explosion in a hazardous environment

• breaking communication to modules beyond this

module

European Union Directive Compliance

If this product has the CE mark it is approved for installation within the

European Union and EEA regions. It has been designed and tested to meet

the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards, in

whole or in part, documented in a technical construction file:

• EN 50081-2 EMC - Generic Emission Standard, Part 2 - Industrial

Environment

• EN 50082-2 EMC - Generic Immunity Standard, Part 2 - Industrial

Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage,

by applying the safety requirements of EN 61131-2 Programmable

Controllers, Part 2 - Equipment Requirements and Tests.

For specific information required by EN 61131-2, see the appropriate

sections in this publication, as well as the following Allen-Bradley

publications:

• Industrial Automation Wiring and Grounding Guidelines For Noise

Immunity, publication 1770-4.1

• Automation Systems Catalog, publication B111

This equipment is classified as open equipment and must be mounted in an

enclosure during operation to provide safety protection.

Publication 1793-5.3 - September 1999

Page 4

4 FLEX Integra 2 Input/2 Protected Output Module

0 123456 7

8 9 10 11 12 13 14 15

A

B

41469

CV CV

CCVVCCVV

OOII

Ch 0

Ch 1

Ch 0

Ch 1

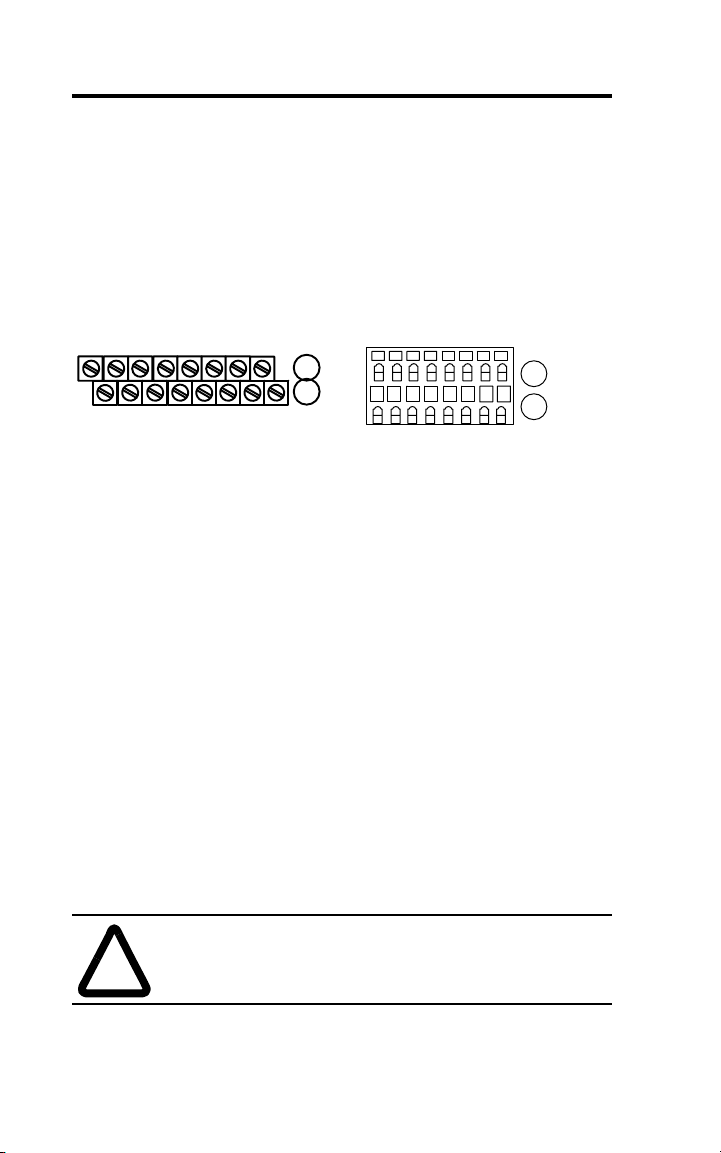

Wiring

This module is available with 2 styles of terminations; 1794-IB2XOB2P screw-cage and 1793-IB2XOB2PS - spring-clamp. Refer to the wiring

figure below.

1793-IB2XOB2P 1793-IB2XOB2PS

Ch 1

Ch 1

Ch 0

Ch 0

CV CV

01234567

8 9 10 11

Where: C - common, V = + voltage, I = input, O = output

1. Connect individual sensor input leads to terminals 2 (channel 0) and 3

(channel 1) on row A.

2. Connect sensor supply lead to +24V dc (terminals 1, 6, 9, or 14).

(Terminals 1, 6, 8, 9, 14 and 15 are connected internally to +24V dc.)

3. Connect associated input common (3-wire sensors only) to terminals

10 and 11 on row B.

4. Connect individual output wiring to terminals 4 (channel 0) and 5

(channel 1) on row A.

5. Connect associated output common to terminals 12 and 13 on row B.

6. Connect +24Vdc voltage to terminal 8 on row B

7. Connect 24V dc common to terminal 0 on row A.

8. If daisy-chaining +24V dc from this module to the next FLEX Integra

module, connect a jumper from terminal 15 to terminal 8 on the next

FLEX Integra module.

9. If daisy-chaining 24V dc common from this module to the next FLEX

Integra module, connect a jumper from terminal 7 on this module to

terminal 0 on the next Integra module.

.

OOII

A

B

CCVVCCVV

13 14 1512

41468

!

Publication 1793-5.3 - September 1999

ATTENTION: Total current draw through the module’s

(+) voltage terminals is limited to 10A. Separate power

connections to the module may be required.

Page 5

FLEX Integra 2 Input/2 Protected Output Module 5

Wiring

Channel

Sink Input

1

Input Terminal Supply Terminal

021

136

Source Output Output Terminal Common

0412

1513

+24V dc Terminals 1, 6, 8, 9, 14, 15 are internally

connected together in the module.

24V dc common Terminals 0, 7, 10 thru 13 are internally

connected together in the module

1 Two-wire devices use signal input and power terminals, 3-wire devices use

signal input, supply and common terminal s.

Example of 2-wire and 3-wire Sensors

123456

0

8

9 10 11121314

7

15

3-Wire Sensor

2-Wire Sensor

41338

Indicators

24V DC 2x2 DIGITAL COMBO

iNPUT OUTPUT

0

A

A = Status indicators - shows status of individual outputs

B = Insertable label for writing individual output designations

1793-IB2XOB2PS

1

1

0

41339

B

Publication 1793-5.3 - September 1999

Page 6

6 FLEX Integra 2 Input/2 Protected Output Module

Memory Mapping

Bit/

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Word

Read Reserved I1 I0

Write Reserved O1 O0

Write Reserved FT time

Where: I = Input

O = Output

FT = Filter time

Setting the Input Delay Time

You can select the input delay time (DT) for input channels 00 and 01.

Select the input delay time by setting the corresponding bits in the

configuration word (word 3) for the module.

For example, to set a delay time of 4ms for an input module at address rack

1, module group 0, set bits 02, 01 and 00 as shown below.

Input Delay Times

02 01 00 Filter Time for Inputs 00-01

000Filter Time 0 (default) 512

001Filter Time 1 1ms

010Filter Time 2 2ms

011Filter Time 3 4ms

100Filter Time 4 8ms

101Filter Time 5 16ms

110Filter Time 6 32ms

111Filter Time 7 64ms

Publication 1793-5.3 - September 1999

Selected

Filter Time

μ

s

Page 7

FLEX Integra 2 Input/2 Protected Output Module 7

CUL Hazardous Location Approval

CUL certifies products for general use as well as

for use in hazardous locations. Actual CUL

certification is indicated by the product label

as shown below, and not by statements in any

user documentation.

Example of the

CUL

certification

product label

To comply with CUL certification for use in

hazardous locations, the following information

becomes a part of the product literature for this

CUL-certified industrial constrol product.

•

This equipment is suitable for use in Class

I, Division 2, Groups A, B, C, D, or

non-hazardous locations only.

•

The products having the appropriate CUL

markings (that is, Class I, Division 2, Groups

A, B, C, D) are certified for use in other

equipment where the suitability of

combination (that is, application or use) is

determined by the CUL or the local

inspection office having jurisdiction

Important: Due to the modular nature of a

CUS

programmable control system, the

product with the highest temperature

rating determines the overall

temperature code rating of a

programmable control system in a Class

I, Division 2, location. The temperature

code rating is marked on the product

label as shown.

CL I, DIV 2

GP A,B,C,D

TEMP

Approbation d’utilisation dans des

environnements dangereux par la CUL

La CUL certifie des produits pour une utilisation

générale aussi bien que pour une utilisation en

environnements dangereux. La certification CUL

en vigueur est indiquée par l'étiquette produit et

non par des indications dans la documentation

utilisateur.

Exemple

d'étiquette de

certification

d'un produit

par la CUL

EPour satisfaire à la certification CUL en

environnements dangereux, les informations

suivantes font partie intégrante de la

documentation des produits de commande

industrielle certifiés.

•

•

Importa nt: De par la nature modulaire des systèmes

CUS

Cet équipement ne convient qu’à une

utilisation dans

des environnements de Classe I, Division 2,

Groupes A, B, C, D ou non dangereux.

Les produits portant le marquage CUL

approprié (c'est-à-dire Classe I, Division 2,

Groupes A, B, C, D) sont certifiés pour une

utilisation avec d'autres équipements, les

combinaisons d’applications et d’utilisation

étant déterminées par la CUL ou le bureau

local d'inspection.

de commande programmables, le prod uit

ayant le code de température le plus élevé

détermine le code de température global

du système dans un environnement de

Classe I, Division 2. Le code de

température est indiqué sur l'étiquette

produit.

7HPSHUDWXUHFRGHUDWLQJ &RGHGHWHPSpUDWXUH

CL I, DIV 2

CUS

GP A,B,C,D

TEMP

CUS

CL I, DIV 2

Look for temperature

code rating here.

GP

A,B,C,D

/

e code de température

est indiqué ici.

CL I, DIV 2

GP A,B,C,D

TEMP

The following warnings apply to products having

CUL certification for use in hazardous locations.

Les avertissements suivants s'appliquent aux

produits ayant la certification CUL pour une

utilisation dans des environnements dangereux.

Publication 1793-5.3 - September 1999

Page 8

8 FLEX Integra 2 Input/2 Protected Output Module

CUL Hazardous Location Approval

$77(17,21 ([SORVLRQ+D]DUG

Substitution of components may impair

•

suitability for Class I, Division 2.

•

Do not replace components unless power

has been switched off or the area is known

to be non-hazardous.

•

Do not disconnect equipment unless power

has been switched off or the area is known

to be non-hazardous.

•

Do not disconnect connectors unless

power has been switched off or the area is

known to be non-hazardous. Secure any

user-supplied connectors that mate to

external circuits on this equipment by using

screws, sliding latches, threaded

connectors, or other means such that any

connection can withstand a 15 Newton (3.4

lb.) separating force applied for a minimum

of one minute.

•

Batteries must only be changed in an area

known to be non-hazardous.

CUL logo is a registered trademark of the

Underwriters Laboratories.

Approbation d’utilisation dans des

environnements dangereux par la CUL

$9(57,66(0(175LVTXHGH[SORVLRQ

La substitution de composants peut rendre

•

ce matériel inadapté à une utilisation en

environnement de

Classe I, Division 2.

•

Couper le courant ou s'assurer que

l’environnement est classé non dangereux

avant de remplacer des composants.

•

Couper le courant ou s’assurer que

l’environnement est classé non dangereux

avant de débrancher l'équipement.

•

Couper le courant ou s'assurer que

l’environnement est classé non dangereux

avant de débrancher les connecteurs. Fixer

tous les connecteurs fournis par l'utilisateur

pour se brancher aux circuits externes de cet

appareil à l 'aide de vis, loquets coulissants,

connecteurs filetés ou autres, de sorte que

les connexions résistent à une force de

séparation de 15 Newtons (1,5 kg - 3,4 lb.)

appliquée pendant au moins une minute.

•

S'assurer que l'environnement est classé

non dangereux avant de changer les piles.

Le sigle CUL est une marque déposée de la

Underwriters Laboratories.

Publication 1793-5.3 - September 1999

Page 9

FLEX Integra 2 Input/2 Protected Output Module 9

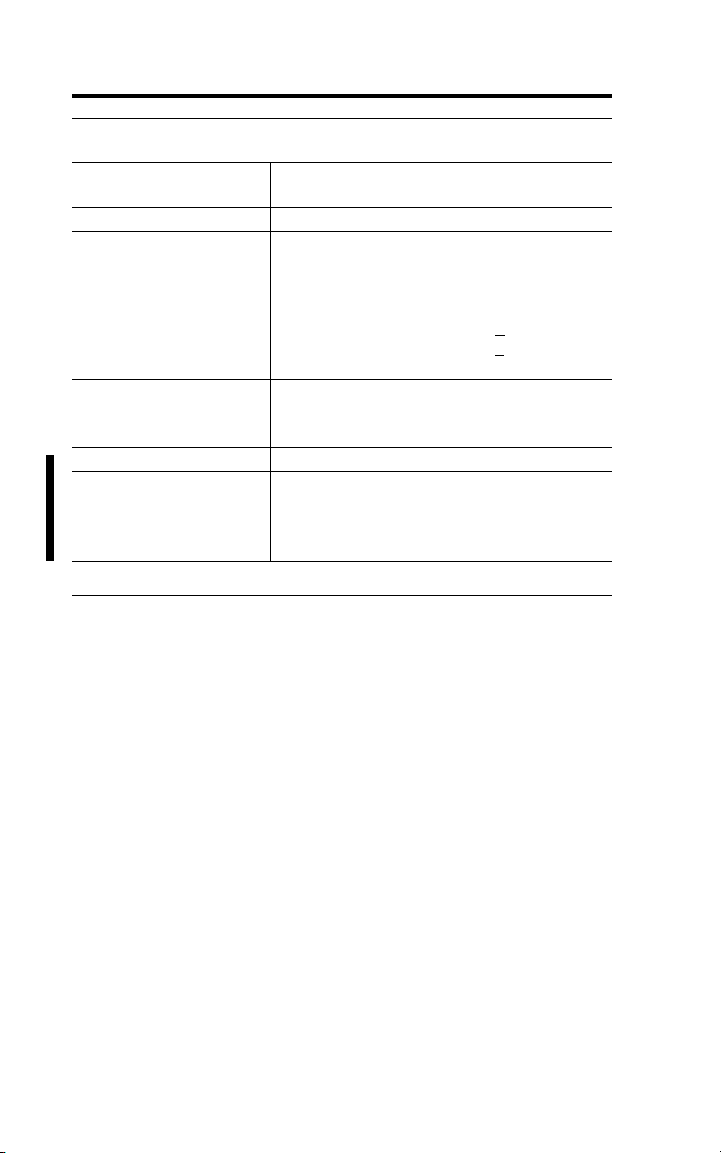

Specifications - 2 Input/2 Protected Output Module Cat. No. 1793-IB2XOB2P

and -IB2XOB2PS

Module Type 2 input/2 output digital combination w/electronic fusing

1793-IB2XOB2P - screw-clamp terminations

1793-IB2XOB2PS - spring-clamp terminations

Module Location DIN rail mounting

Number of Channels 2 digital input - sinking/2 digital output - sourcing,

protected

Input

On-state Voltage 10-31.2V dc; 24V dc nominal

On-state Current 2-12 mA; 8mA @ 24V dc

Off-state Voltage 5V dc maximum

Off-state Current 1.5mA minimum

Channel Impedance 4.6K

Ω

Isolation Voltage Channel to system - 850V dc for 1s

Channel to channel - None

Input Delay - selectable

Off to On

On to Off

512μs, 1, 2, 8, 16, 32 or 64ms

512μs, 1, 2, 8, 16, 32 or 64ms

Default = 512μs

Output

On-state Voltage 10-31.2V dc; 24V dc nominal

On-state Current 1-500mA per channel

Off-state Voltage 31.2V dc maximum

Off-state Current 0.5mA maximum leakage

Channel Impedance 1.0Ω (0.5V dc maximum drop)

Surge Current 1.5A for 50ms, repeatable every 2s

Isolation Voltage Channel to system - 850V dc for 1s

Channel to channel - None

Delay Time Off to On

On to Off

0.5ms maximum

1.0ms maximum

General

Flexbus Current 20mA maximum

Power Dissipation 1.4W @ 31.2V dc

Thermal Dissipation 4.8 BTU/hr @ 31.2V dc

Indicators 4 yellow channel status indicators

External dc Power Voltage

Current

19.2-31.2V dc (5% ac ripple)

40mA maximum

Publication 1793-5.3 - September 1999

Page 10

10 FLEX Integra 2 Input/2 Protected Output Module

Specifications - 2 Input/2 Protected Output Module Cat. No. 1793-IB2XOB2P

and -IB2XOB2PS

Dimensions in

2.72H x 3.15D x 2.17W

(mm)

(69H x 80D x 55W)

Fusing Outputs electronically fused

Environmental Conditions

Operational Temperature

Storage Temperature

Relative Humidity

Shock Operating

Nonoperating

Vibration

Conductors Wire Size

Category

o

C (32 to +131oF)

0 to +55

-40 to +85

o

C (-40 to +185oF)

5 to 95% noncondensing

Tested to 30g peak acceleration, 11(+

Tested to 50g peak acceleration, 11(+

Tested 5g @ 10-500Hz per IEC68-2-6

2

12 gauge (4mm

) stranded wire

3/64 in (1.2mm) maximum insulation

2

1)ms pulse width

1)ms pulse width

Screw Terminal Torque 7-9 lb-in

Agency Certification

(when product is marked)

• CUL Listed

• CUL Class I, Division 2 Groups A, B, C and D certified

• UL listed

• CE marked for all applicable directives

1 Use this categor y information for planning conductor routing as described in publication 1770-4.1, “Wiring and

Grounding Guidelines for Noise Immunity.”

Publication 1793-5.3 - September 1999

Page 11

FLEX Integra 2 Input/2 Protected Output Module 11

Publication 1793-5.3 - September 1999

Page 12

Publication 1793-5.3 - September 1999 PN 955132-32A

Supersedes Publication 1793-5.3 - September 1998 © (1999) Rockwell International Corporation.Printed in USA

Loading...

Loading...