Page 1

Installation Instructions

ArmorBlock MaXum Robot I/O Cable Base

and Kempf Box Plate

(Cat. No. 1792D-CB23 and -KPLT)

CB23

43333

The 23mm ArmorBlock MaXum Robot Ι/Ο Cable Base mates with 4

or 8 point modules, depending on your installation requirements, and

optionally the Kempf box plate. No modification is required. Modules

are interchangeable whether flat or round media cable bases are

used. This interchangeability provides plug and play block upgrade

capability and easy field replacement. The completely assembled

ArmorBlock module and base requires no enclosure.

Publication 1792D-IN054B-EN-P - April 2003

KPLT

43338

Page 2

2 ArmorBlock MaXum Robot I/O Cable Base and Kempf Box Plate

These instructions describe the installation of the cable base. The

catalog numbers for the cable base and Kempf box are:

• 1792D-CB23 (for 23mm trunk or drop cable installation)

• 1792D-KPLT (to mount the cable base on a Kempf box)

IMPORTANT

ArmorBlock MaXum modules and media cables

are ordered and shipped separately.

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of these

products must satisfy themselves that all necessary steps have been

taken to assure that each application and use meets all performance

and safety requirements, including any applicable laws, regulations,

codes and standards. In no event will Rockwell Automation be

responsible or liable for indirect or consequential damage resulting

from the use or application of these products.

Any illustrations, charts, sample programs, and layout examples

shown in this publication are intended solely for purposes of

example. Since there are many variables and requirements associated

with any particular installation, Rockwell Automation does not

assume responsibility or liability (to include intellectual property

liability) for actual use based upon the examples shown in this

publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation and Maintenance of Solid-State Control

(available from your local Rockwell Automation office), describes

some important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in

whole or part, without written permission of Rockwell Automation, is

prohibited.

Publication

1792D-IN054B-EN-P - April 2003

Page 3

ArmorBlock MaXum Robot I/O Cable Base and Kempf Box Plate 3

!

WARNING

ATTENTION

!

IMPORTANT

Throughout this publication, notes may be used to make you aware

of safety considerations. The following annotations and their

accompanying statements help you to identify a potential hazard,

avoid a potential hazard, and recognize the consequences of a

potential hazard:

Identifies information about practices or

circumstances that can cause an explosion in a

hazardous environment, which may lead to

personal injury or death, property damage, or

economic loss.

Identifies information about practices or

circumstances that can lead to personal injury or

death, property damage, or economic loss.

Identifies information that is critical for

successful application and understanding of the

product.

Publication

1792D-IN054B-EN-P - April 2003

Page 4

4 ArmorBlock MaXum Robot I/O Cable Base and Kempf Box Plate

Environment and Enclosure

This equipment is intended for use in a Pollution

Degree 2 industrial environment, in overvoltage

Category II applications (as defined in IEC

publication 60664-1), at altitudes up to 2000 meters

without derating.

This equipment is considered Group 1, Class A

industrial equipment according to IEC/CISPR

Publication 11. Without appropriate precautions,

there may be potential difficulties ensuring

electromagnetic compatibility in other

environments due to conducted as well as radiated

disturbance.

ATTENTION

!

This equipment is supplied as "enclosed"

equipment. It should not require additional system

enclosure when used in locations consistent with

the enclosure type ratings stated in the

Specifications section of this publication.

Subsequent sections of this publication may

contain additional information regarding specific

enclosure type ratings, beyond what this product

provides, that are required to comply with certain

product safety certifications.

See NEMA Standards publication 250 and IEC

publication 60529, as applicable, for explanations

of the degrees of protection provided by different

types of enclosure. Also, see the appropriate

sections in this publication, as well as the

Allen-Bradley publication 1770-4.1 ("Industrial

Automation Wiring and Grounding Guidelines"),

for additional installation requirements pertaining

to this equipment.

Publication

1792D-IN054B-EN-P - April 2003

Page 5

ArmorBlock MaXum Robot I/O Cable Base and Kempf Box Plate 5

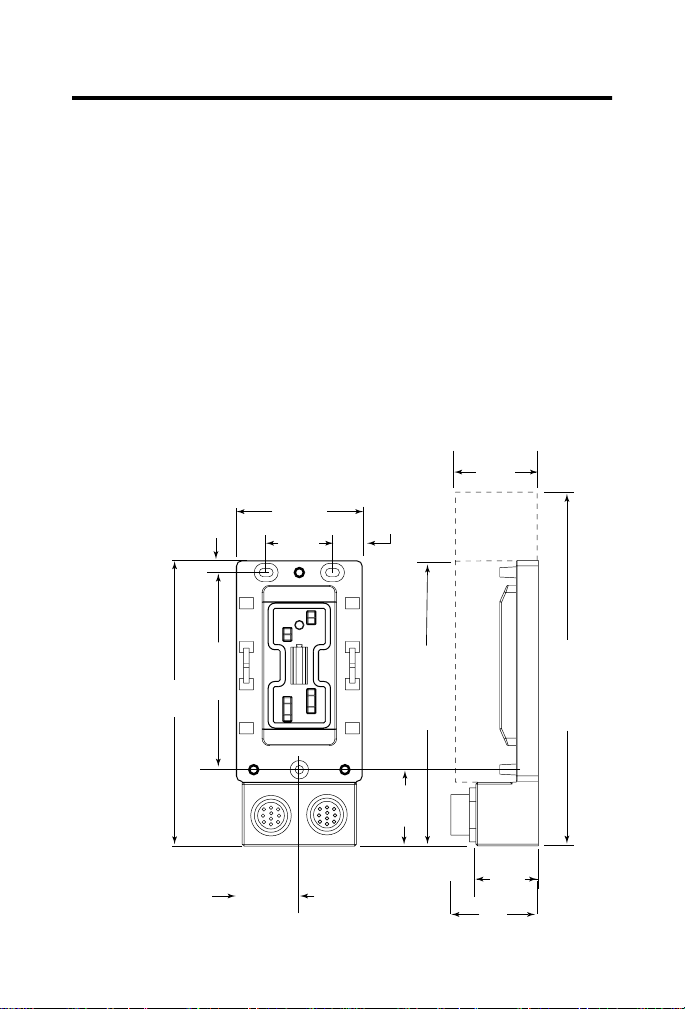

Install Your ArmorBlock Cable Base

To install the cable base:

• Mount the cable base

• Attach the module to the base

• Attach the cables

These procedures are explained in detail in the following sections.

Mount the Cable Base

The cable base can be mounted either vertically or horizontally, using

3 screws. Cable bases accommodate 4 or 8 point ArmorBlock MaXum

modules. You must allow additional space for installation of 8 point

ArmorBlock MaXum module, which are longer than 4 point modules.

1792D-CB23

When

installing a

cable base

with an 8

connector

module,

allow for

the

additional

length.

6.10in

155mm

0.26in

6.5mm

4.21in

107mm

1.35in

34.25mm

2.70in

68.5mm

1.42in

36mm

0.64in

16.25mm

6.10in

155mm

4 connector

module

1.63in

41.5mm

Publication

1.90in

48.18mm

8.23in

209mm

8 connector

module

1.34in

34mm

2.27in

57.6mm

1792D-IN054B-EN-P - April 2003

43332

Page 6

6 ArmorBlock MaXum Robot I/O Cable Base and Kempf Box Plate

1. Mount the MaXum Kempf plate to the Kempf box.

MaXum Kempf plate

MaXum Kempf box

43339

2. Mount the CB23 cable base to the gasket and the Kempf box.

The mounting instructions are illustrated below.

MaXum CB23

gasket

Publication

MaXum Kempf plate

MaXum

Kempf box

31467-m

1792D-IN054B-EN-P - April 2003

Page 7

ArmorBlock MaXum Robot I/O Cable Base and Kempf Box Plate 7

!

WARNING

Attach the Module to the Base

IMPORTANT

1. Position the module over the mounted cable base. Align the

three captive screws in the module with the accepting

receptacles in the base.

2. Tighten the screws with a torque of 8 inch-pounds to secure

the module to the base.

Make sure you properly align the screws to

complete the connections between the module

contacts and the cable contacts.

If you insert or remove the module while

backplane power is on, an electrical arc can

occur. This could cause an explosion in

hazardous location installations.

Be sure that power is removed or the area is

nonhazardous before proceeding.

Screws must be

aligned properly to

complete contact

connections.

Publication

Contact

connections

1792D-IN054B-EN-P - April 2003

43335

Page 8

8 ArmorBlock MaXum Robot I/O Cable Base and Kempf Box Plate

ArmorBlock MaXum I/O modules are described in the following

publications:

• 1792D series of ArmorBlock MaXum Installation Instructions

• 1792-TD001 ArmorBlock Technical Data

The DeviceNet Network uses advanced network technology,

producer/consumer communication, to increase network

functionality and throughput. Visit our web site at

http://www.ab.com/networks

information and updates.

for producer/consumer technology

Attach the Cables

1. Attach your network cable and power cable (if used) to the

connectors.

2. Cover the power connector with a cap if it is not used.

Publication

1792D-IN054B-EN-P - April 2003

Page 9

ArmorBlock MaXum Robot I/O Cable Base and Kempf Box Plate 9

!

WARNING

3. Attach your I/O connector cables.

Female

Male

Network

In

If you connect or disconnect the DeviceNet cable

with power applied to this module or any device

on the network, an electrical arc can occur. This

could cause an explosion in hazardous location

installations.

Be sure that power is removed or the area is

nonhazardous before proceeding.

Publication

Network

Out

31463-m

1792D-IN054B-EN-P - April 2003

Page 10

10 ArmorBlock MaXum Robot I/O Cable Base and Kempf Box Plate

!

WARNING

!

WARNING

Use supply wires suitable for 30°C above

surrounding ambient.

If you connect or disconnect wiring while the

field-side power is on, an electrical arc can occur.

This can cause an explosion in hazardous location

installations. Be sure that power is removed or the

area is nonhazardous before proceeding.

Publication

1792D-IN054B-EN-P - April 2003

Page 11

ArmorBlock MaXum Robot I/O Cable Base and Kempf Box Plate 11

Use the graphics below to connect DeviceNet cable to your module.

4

2

14

5

1

17

6

12

16

Outgoing

installation

remote bus

(Male connector)

7

Assembly side

8

43478

DI

DO

~DI

~DO

COM

reserved

10

11

Red

10

11

SCM2 (~DI)

COM (Profi A)

+24V (US1)

64132

Red

Black

Green

6

4

+24V (US1)

reserved (Profi B)

Outgoing

Hybrid Cable

789

Pink

Gray

Green

Yellow

789

DO

~DO

Incoming

SCM1 (DI)

Hybrid Cable

RET (US1)

+24V (US2)

Brown

132

RET (US1)

+24V (US2)

RET (US2)

Blue

RET (US2)

CCR1

121713

Red

Blue

121713

CCR1

CCR2

CCR2

White

DeviceNet High

DeviceNet High

DeviceNet Low

14515

Blue

Green/Yellow

14515

DeviceNet Low

PE

UL

RBST

Flange

16

CCR = Constant current regulation

SCM = Secondary circuit monitoring

16

PE

Flange

reserved

reserved

8

7

6

16

17

5

12

4

14

Incoming

installation

remote bus

1

2

Assembly side

(Female connector)

Publication

1792D-IN054B-EN-P - April 2003

Page 12

12 ArmorBlock MaXum Robot I/O Cable Base and Kempf Box Plate

Specifications

Robot I/O Cable Bases - Cat. No. 1792D-CB23 & -KPLT

General Specific at ions

For general specifications, see the ArmorBlock MaXum module’s documentation

or the Technical Data, publicatio n number 1792-TD001. The specific a ti ons li sted

in these publicat ions are for the assembled module and cable base.

Publication

1792D-IN054B-EN-P - April 2003

Page 13

ArmorBlock MaXum Robot I/O Cable Base and Kempf Box Plate 13

Hazardous Location Approval

The following information applies when operating

this equipment in hazardous locations:

Products marked “CL I, DIV 2, GP A, B, C, D” are suita ble

for use in Class I Division 2 Groups A, B, C, D, Hazardo us

Locations and nonhazardou s locations only. Each product

is supplied with markings on the rating nameplate

indicating the hazardous location temperature code.

When combining products wi thin a system, the most

adverse temperature code (lo west “T” number) may be

used to help determine the over all temperature code of

the system. Combinations of equipment in your system

are subject to investigation by the local Authority Having

Jurisdiction at the time of installation.

WARNING

!

EXPLOSION HAZARD

• Do not disconnect equipment

unless power has been

removed or the area is known

to be nonhazardous.

• Do not disconnect

connections to this equipment

unless power has been

removed or the area is known

to be nonhazardous. Secure

any external connectio ns that

mate to this equipment by

using screws, sliding latches,

threaded connectors, or other

means provided with this

product.

• Substitution of components

may impair suitability for

Class I, Division 2.

• If this product contains

batteries, they must onl y be

changed in an area known to

be nonhazardous.

Informations sur l’utilisation de cet équipement en

environnements dangereux :

Les produits marqués "CL I , DIV 2, GP A, B, C, D" ne

conviennent qu’à une utilisatio n en environnements de

Classe I Division 2 Groupes A, B, C, D da ngereux et non

dangereux. Chaque produit est liv ré avec des marquages sur

sa plaque d’identification qui ind iquent le code de

température pour les environn ements dangereux. Lorsque

plusieurs produits sont combinés dans un système, le code

de température le plus défavorable (c ode de température le

plus faible) peut être utilisé pour déterm iner le code de

température global du système. Les combinaisons

d’équipements dans le système sont sujettes à inspection

par les autorités locales qualifiées au moment de

l’installation.

AVERTISSEMENT

!

RISQUE D’EXPLOSION

• Couper le courant ou

s’assurer que l’environnemen t

est classé non dangereux

avant de débrancher

l'équipement.

• Couper le courant ou

s'assurer que l’environnement

est classé non dangereux

avant de débrancher les

connecteurs. Fixer tous les

connecteurs externes rel iés à

cet équipement à l'aide de

vis, loquets coulissants ,

connecteurs filetés ou autre s

moyens fournis avec ce

produit.

• La substitution de

composants peut rendre c et

équipement inadapté à une

utilisation en environnement

de Classe I, Division 2.

• S’assurer que

l’environnement est classé

non dangereux avant de

changer les piles.

Publication

1792D-IN054B-EN-P - April 2003

Page 14

14 ArmorBlock MaXum Robot I/O Cable Base and Kempf Box Plate

This product has been tested at an Open DeviceNet Vendor

Association, Inc. (ODVA) authorized independent test laboratory and

found to comply with ODVA Conformance Test. Please contact the

ODVA website (http://www.odva.org) for listing of products tested by

ODVA independent test labs for further details.

Publication

1792D-IN054B-EN-P - April 2003

Page 15

Notes:

ArmorBlock MaXum Robot I/O Cable Base and Kempf Box Plate 15

Publication

1792D-IN054B-EN-P - April 2003

Page 16

Rockwell Automation Support

Rockwell Automation tests all of our products to ensure that they are

fully operational when shipped from the manufacturing facility.

If you are experiencing installation or startup problems, please

review the troubleshooting information contained in this publication

first. If you need technical assistance to get your module up and

running, please contact Customer Support (see the table below); our

trained technical specialists are available to help.

If the product is not functioning and needs to be returned, contact

your distributor. You must provide a Customer Support case number

to your distributor in order to complete the return process.

Phone United States/Canada 1.440.646.5800

Outside United

States/Canada

You can access the phone number for your country

via the Internet:

1. Go to http://support.rockwellautomation.com/

Contacting Customer Support

2. Under

Countries, click on

Internet Worldwide Go to http://support.rockwellautomation.com/

ArmorBlock and ArmorBlock MaXum are trademarks of Rockwell Automation.

DeviceNet is a trademark of Open DeviceNet Vendor Association (ODVA).

Click here

and Other

Publication 1792D-IN054B-EN-P - April 2003 PN 957782-47

Supersedes Pub lication 1792D-IN054A-E N-P - August 2002 Copyright © 2003 Rockw ell Automation, Inc. All r ights reserved. Print ed in the U.S.A.

Loading...

Loading...