Page 1

1791 Analog Block I/O Input/Output Modules

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this control

equipment must satisfy themselves that all necessary steps have been taken

to assure that each application and use meets all performance and safety

requirements, including any applicable laws, regulations, codes and

standards.

The illustrations, charts, sample programs and layout examples shown in

this guide are intended solely for example. Since there are many variables

and requirements associated with any particular installation, Allen-Bradley

does not assume responsibility or liability (to include intellectual property

liability) for actual use based upon the examples shown in this publication.

Allen-Bradley publication SGI–1.1, “Safety Guidelines For The

Application, Installation and Maintenance of Solid State Control”

(available from your local Allen-Bradley office) describes some important

differences between solid-state equipment and electromechanical devices

which should be taken into consideration when applying products such as

those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or

in part, without written permission of Allen–Bradley Company, Inc. is

prohibited.

Throughout this manual we make notes to alert you to possible injury to

people or damage to equipment under specific circumstances.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

damage or economic loss.

Attention helps you:

- Identify a hazard

- Avoid the hazard

- recognize the consequences

Important: Identifies information that is critical for successful application

and understanding of the product.

Important: We recommend you frequently backup your application

programs on appropriate storage medium to avoid possible data loss.

Page 3

Summary of Changes

Summary of Changes

Summary of Changes

This release of the publication contains new and updated information from

the last release.

New Information

This release includes information on new block I/O modules now

available. This information was not included in the previous release of

this publication. The modules are:

1791-NDV – 24V dc Analog Block I/O (voltage outputs)

1791-NDC – 24V dc Analog Block I/O (current outputs)

Updated Information

Generally, change bars (as shown to the right of this paragraph) are used to

show new or significantly revised copy. Certain additions, such as adding

octal numbering or corrected typographical errors, are not shown by

change bars.

S-1

Page 4

Table of Contents

Summary of Changes S1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using This Manual P1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purpose

Audience P1

Vocabulary P1

Manual Organization P1

Block I/O Products Covered by this Publication P2

of Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

P1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introducing Block I/O 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

General Description 11

How

Inputs 14

Scaling 16

Outputs 18

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block I/O Fits in a PLC System

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13. . . . . . . . . . . . . . . . . . . . . . .

Installing Block I/O 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Preinstallation Considerations 21

Installing

Connecting Wiring 24

Termination Resistor 213

Remote

Extended

Compatibility of 1771 I/O Products with Extended Node Numbers 215

Selecting

Objectives

the Block I/O

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O Link

Node Capability

Remote I/O Link Speed

21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

213. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

214. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. .

215. . . . . . . . . . . . . . . . . . . . . . . .

Configuring Your Block I/O for PLC Family

Programmable Controllers 31. . . . . . . . . . . . . . . . . . . . .

Chapter

Setting

Module Scan Time 37

Objectives

the Configuration Switches

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31. . . . . . . . . . . . . . . . . . . . . . . .

Analog Block Applications Using Block Transfers 41. . . . . . .

Chapter

Reading Data and Status from the Module 41

Block Transfer Read Data Format 41

Configuring

Objectives

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

the Module and Setting Outputs with Block T

Instructions 43

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ransfer Write

41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Table of Contentsii

Analog Block Applications Using Discrete Transfers 51. . . . .

Chapter

Discrete Data Transfer 51

Input Data Format 51

Output Data Format 52

Objectives

51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Your Analog Block I/O Module 61. . . . . . . . . . .

Chapter

Block Transfer Programming 61

PLC3 Program Example 62

PLC5 and PLC-5/250 Program Example 63

Sample Programs for Analog Block 64

PLC3 Family Processors 64

PLC5 Family Processors 65

Objectives

61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Calibration 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Tools and Equipment 71

Calibrating your Module 71

Objective

71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Module Indicators 81

Objectives

81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 6

Using This Manual

Preface

Purpose

of Manual

Audience

Vocabulary

Manual Organization

This manual shows you how to use your block I/O with an Allen-Bradley

programmable controller. It helps you:

install your module

program your module

troubleshoot your module

You must be able to program and operate an Allen-Bradley programmable

controller (PLC) to make efficient use of block I/O modules.

We assume that you know how to do this in this manual. If you do not,

refer to the appropriate PLC programming and operations manual before

you attempt to program this module.

In this manual, we refer to:

the block I/O module as the “block” or the “module”

the programmable controller as the “controller” or “processor”

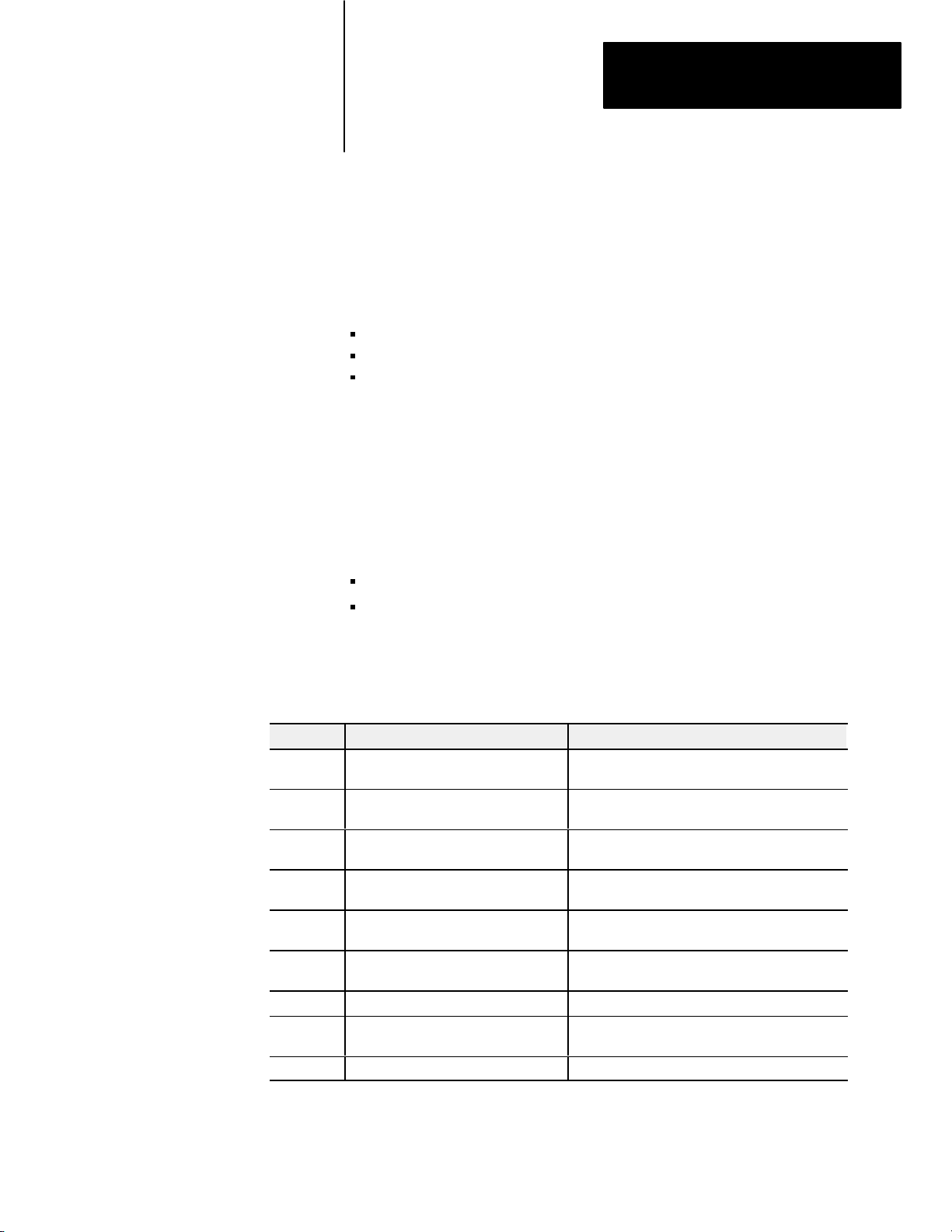

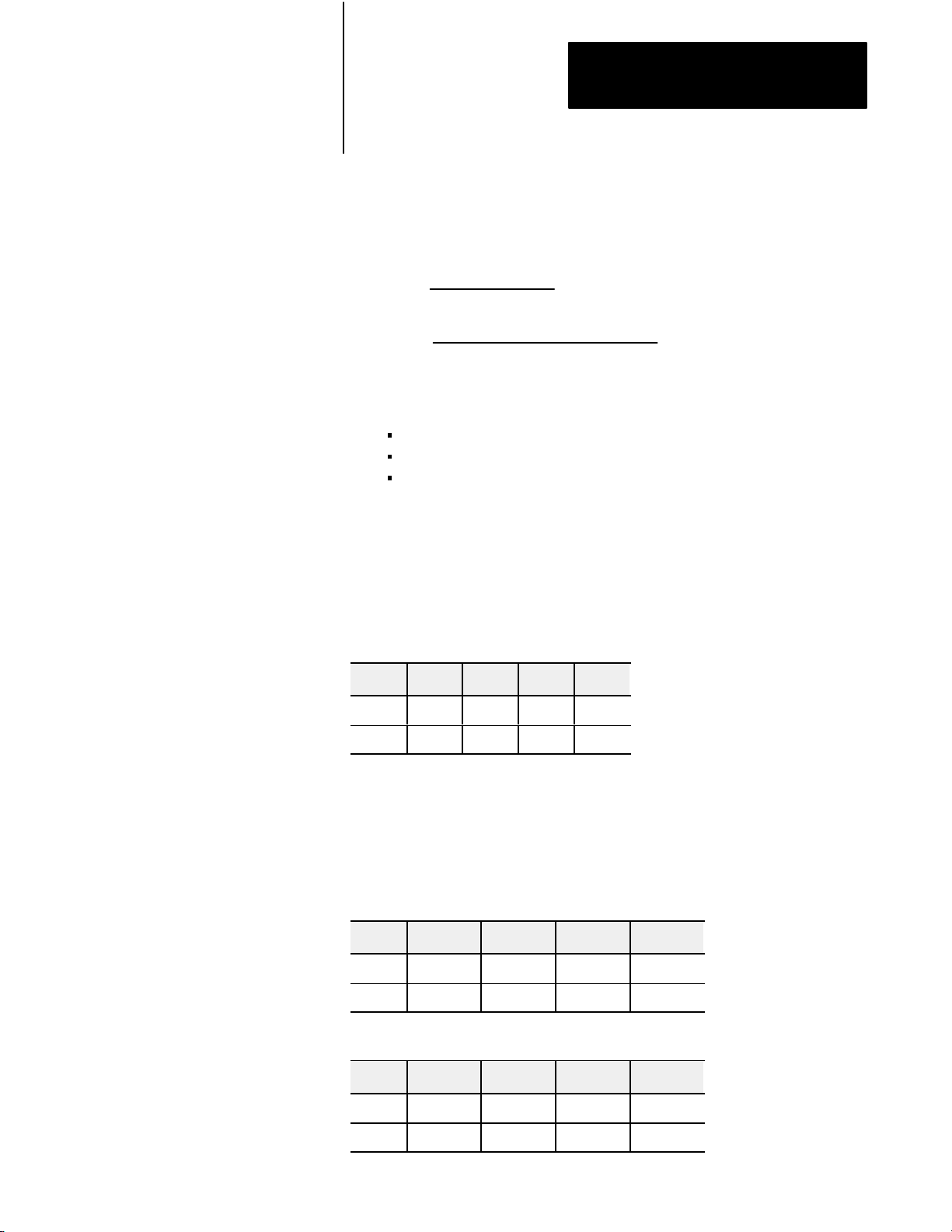

This manual is divided into eight chapters. The following chart shows each

chapter with its corresponding title and brief overview of the topics

covered in that chapter.

Chapter Title Topics Covered

1 Introducing Block I/O

2 Installing Block I/O

3

4

5

6

7 Module Calibration How to calibrate analog block I/O

8 Troubleshooting

Appendix A Specifications Specifications for the block I/O modules

Configuring Your Block I/O for PLC

Family Programmable Controllers

Analog Block Applications using Block

Transfers

Analog Block Applications using Discrete

Transfers

Programming Your Analog Block I/O

Module

Description of the modules, including general and

hardware features

Module power requirements, location, and wiring

information

How to set the configuration switches and address

the block I/O

How to use block transfer programming with your

block I/O

How to use discrete transfer with your block I/O

Programming examples for analog block I/O and

PLC family controllers

How to use the indicators to troubleshoot your block

I/O module

P-1

Page 7

Preface

Using This Manual

Block

I/O Products Covered

by this Publication

Related Publications

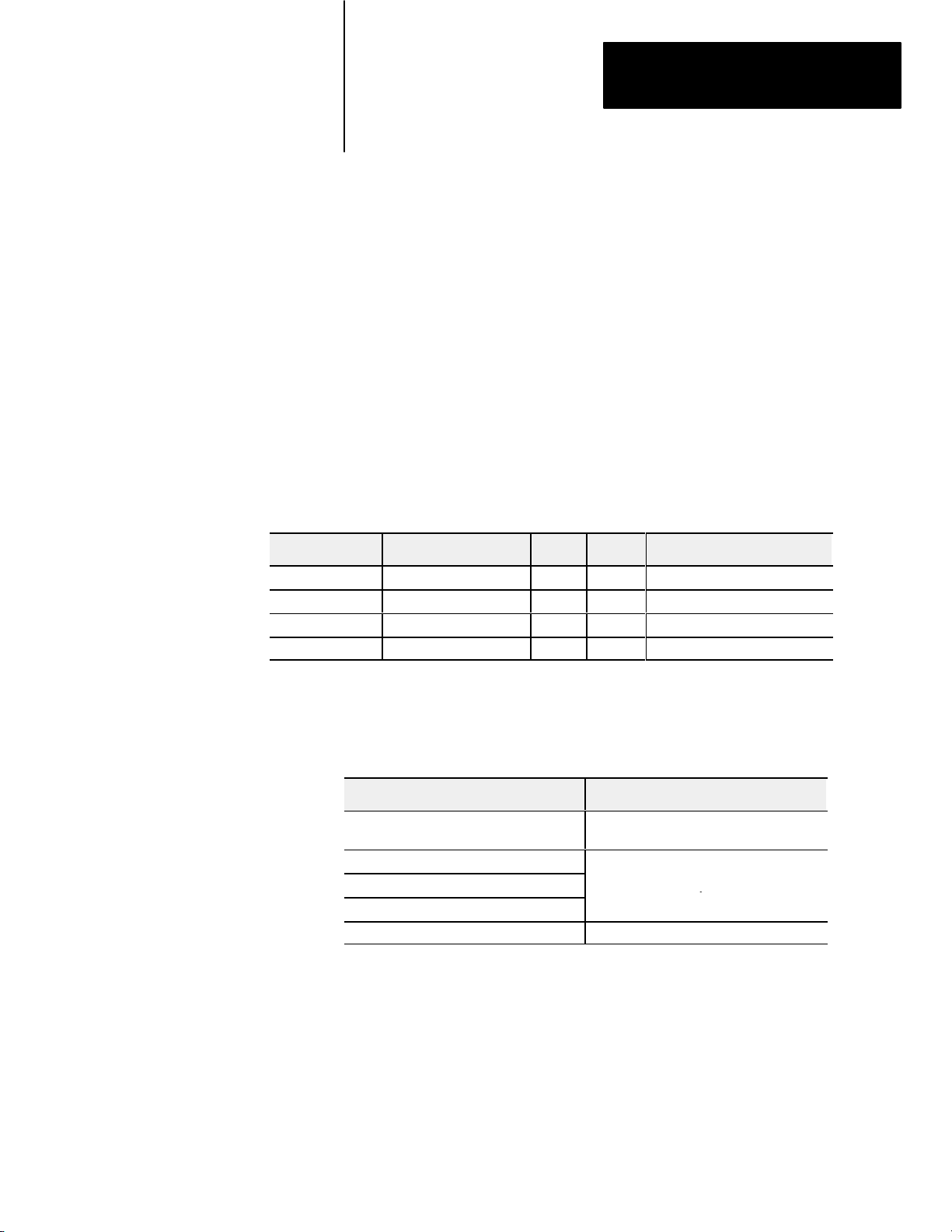

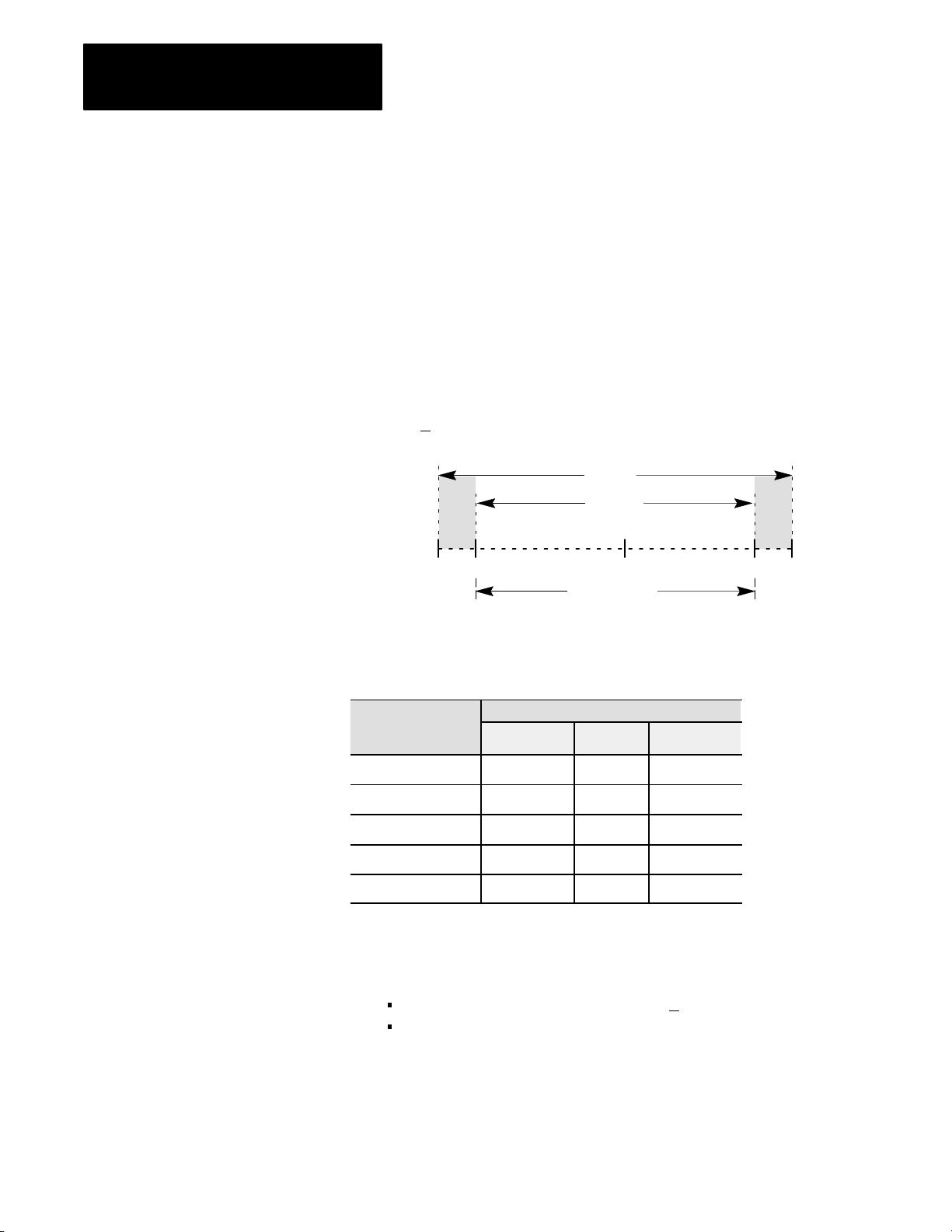

This publication covers the following analog block I/O products:

Catalog Number Power Supply Voltage Inputs Outputs Description

1791N4V2 120V ac 4 2 analog - 4 input, 2 voltage output

1791N4C2 120V ac 4 2 analog - 4 input, 2 current output

1791NDV 24V dc 4 2 analog - 4 input, 2 voltage output

1791NDC 24V dc 4 2 analog - 4 input, 2 current output

For a list of publications with information on Allen-Bradley products,

consult our publication index (SD499).

P-2

Page 8

Introducing Block I/O

y

Chapter

1

Chapter

Objectives

General Description

In this chapter, you will learn what analog block I/O is, its features, and

how it functions.

Block I/O consists of small, self-contained remote I/O devices complete

with power supply, programmable controller interface, input/output

connections and signal conditioning circuitry. Table 1.A is a list of block

I/O modules covered in this publication.

Table 1.A

of Block I/O

Types

Catalog Number Power Supply Voltage Inputs Outputs Description

1791N4V2 120V ac 4 2 analog - 4 input, 2 voltage output

1791N4C2 120V ac 4 2 analog - 4 input, 2 current output

1791NDV 24V dc 4 2 analog - 4 input, 2 voltage output

1791NDC 24V dc 4 2 analog - 4 input, 2 current output

The analog blocks are compatible with PLC-2, PLC-3, PLC-5/250 and

PLC-5

modular controllers. Refer to the table below for information on using

block I/O with various Allen-Bradley programmable controllers.

family programmable controllers, and the SLC 5/02 (or greater)

If You are Using: You must use:

PLC2 family programmable controller

PLC3 family programmable controller

PLC5 family programmable controller

PLC5/250 programmable controller

SLC 500 programmable controller 1747SN remote I/O scanner

The analog blocks communicate via block transfer or discrete transfer with

any Allen-Bradley programmable controller that connects to the remote

I/O network. The analog blocks communicate with SLC family controllers

using discrete transfer.

Each analog block has four independent inputs, which can be configured as

either all voltage inputs or all current inputs. The block contains a 24V dc

current limited voltage source for accommodating loop-powered current

transducer inputs.

1771SN subI/O scanner or

1772SD and SD2 remote I/O scanners

Block attaches directly to controller

1-1

Page 9

Chapter 1

Introducing Block I/O

Analog block outputs are configured at the factory for either a current

output or a voltage output. Outputs are not user-configurable.

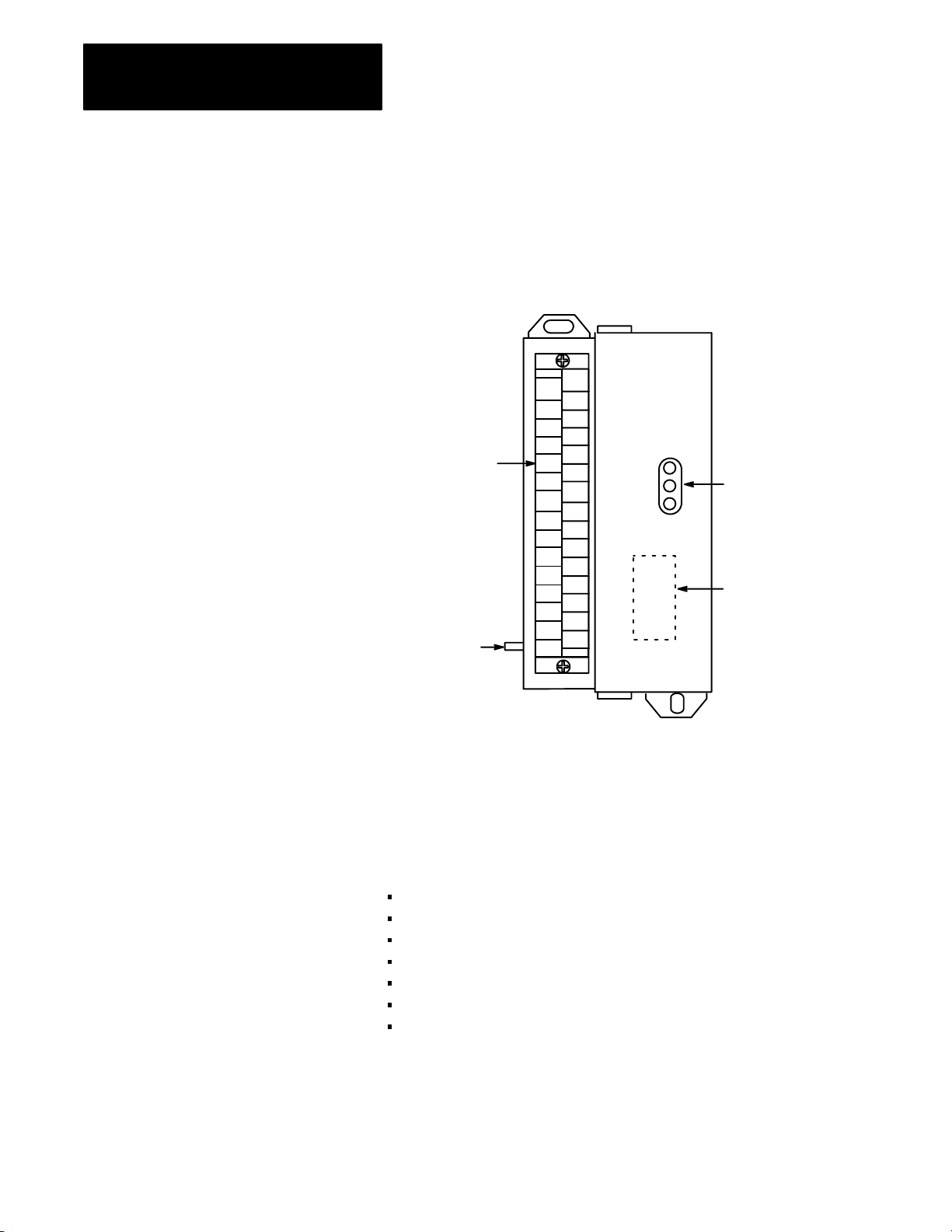

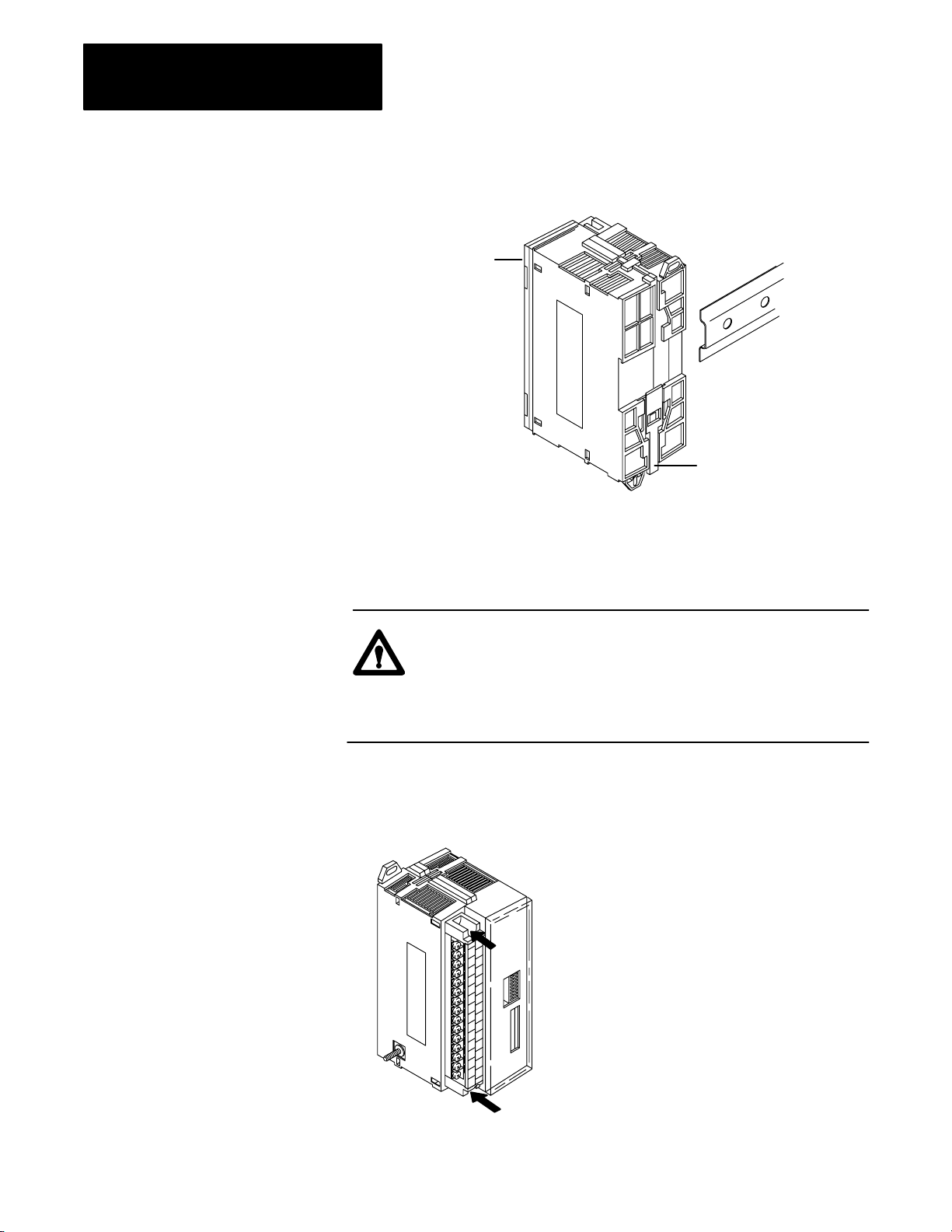

Figure 1.1 shows the physical features of the block I/O.

Figure 1.1

Features of the Analog Block I/O Modules (1791N4V2 shown)

Major

1791N4V2

ANALOG

POWER

COMM

FAULT

BLOCK

Indicators

1

Removable

Terminal Strip for

Input, Output, Remote

I/O and Power

Connections

Switch

Assemblies

Equipment

Grounding

Stud

30

2 mounting holes

for 1/4inch screws

12631I

Terminal Strip - Remote I/O link, power and input/output connections are

made to the removable terminal strip for easy connection of wiring.

Switch Assembly - The modules contain two switch assemblies. Use these

assemblies to make the following settings:

I/O rack number

starting I/O group

communication rate

last I/O group

last state

transfer type

processor restart/lockout

1-2

Status Indicators - Indicators display the status of module power,

communication and fault. Use these indicators to help in troubleshooting.

Page 10

Chapter 1

Introducing Block I/O

How

Block I/O Fits in a

PLC System

Programmable

Controller

or Scanner

Block I/O is a complete I/O interface that includes the functionality of the

I/O rack, adapter, power supply, and I/O module in a single unit. Connect

sensors and actuators to the module and use the remote I/O cable to

connect the block I/O to your programmable controller.

Connect the block I/O to your remote I/O link as you would any other

device. Input and output data is scanned asynchronously and transferred

back and forth between the block and the programmable controller using

either block transfer or discrete transfer. When using block transfer

(Figure 1.2), the block looks like a 1/4 I/O rack to the processor (two

words of input image table memory and two words of output image table

memory). Block transfer provides the most efficient use of your data table

image memory, and allows access to all implemented user functions of

the block.

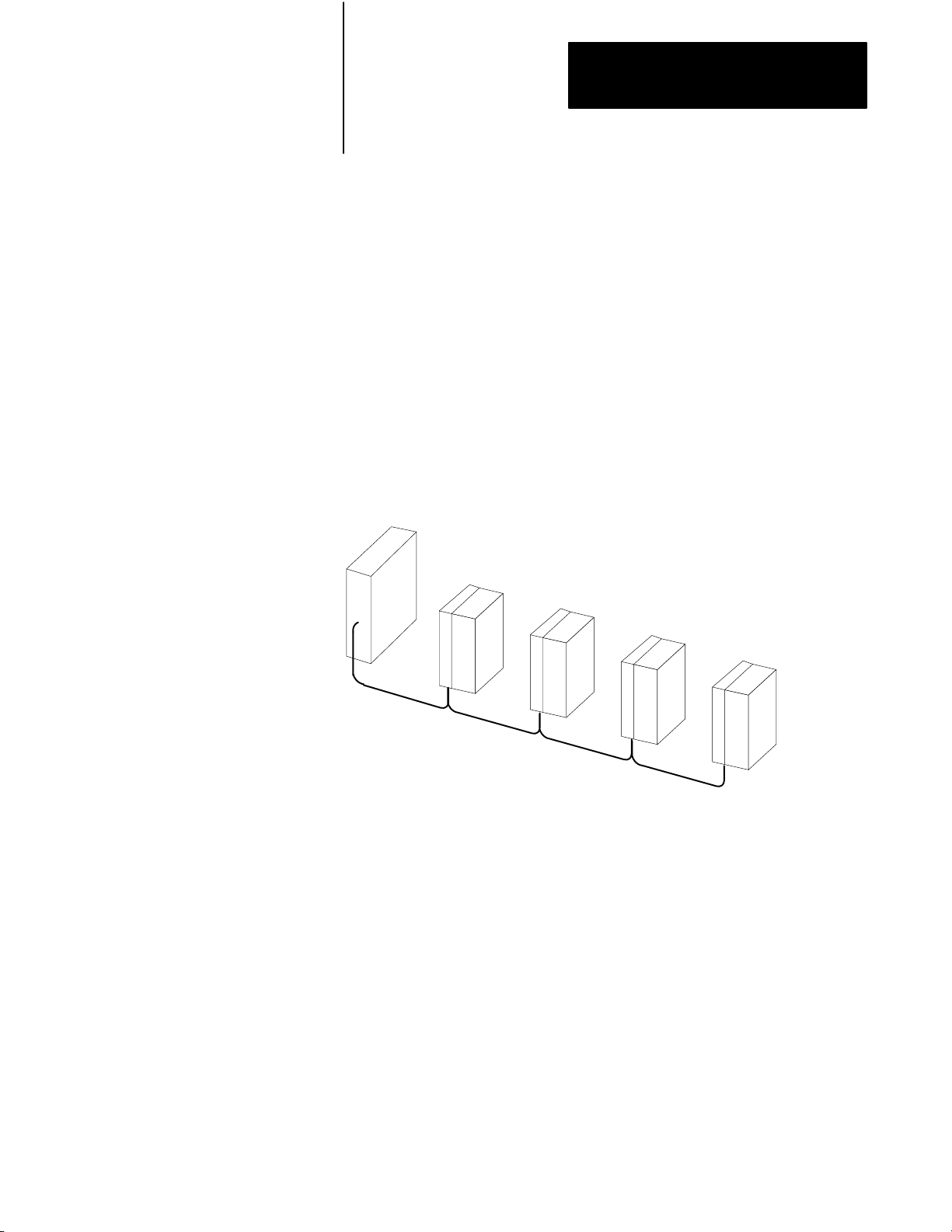

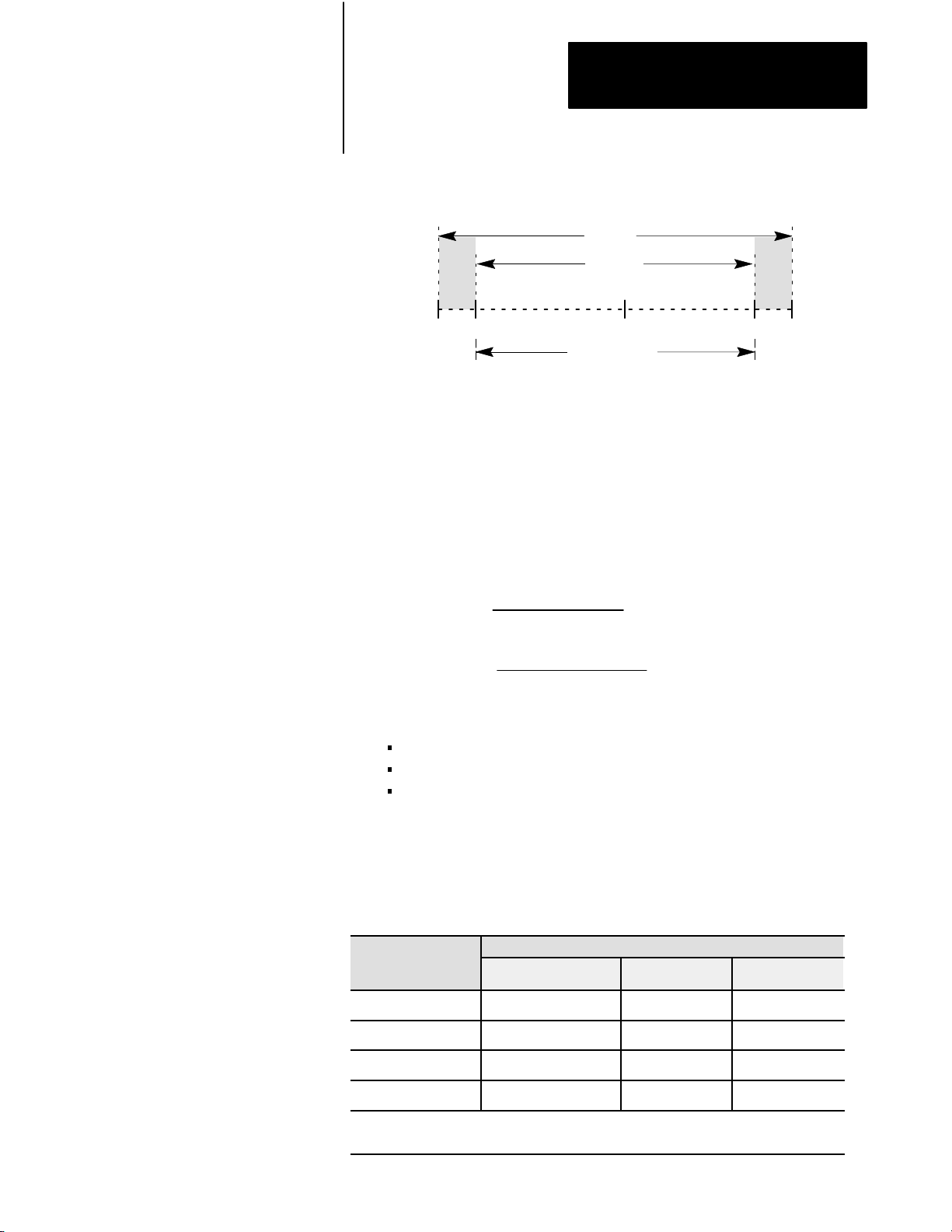

Figure 1.2

I/O Connection in a PLC System using block transfer

Block

Block I/O each block

1/4

is 1/4 I/O rack

1/4

1/4

+

Blocks are daisychained to

a programmable controller or

a scanner

1/4

+

+

= 1 I/O Rack

10828I

1-3

Page 11

Chapter 1

Introducing Block I/O

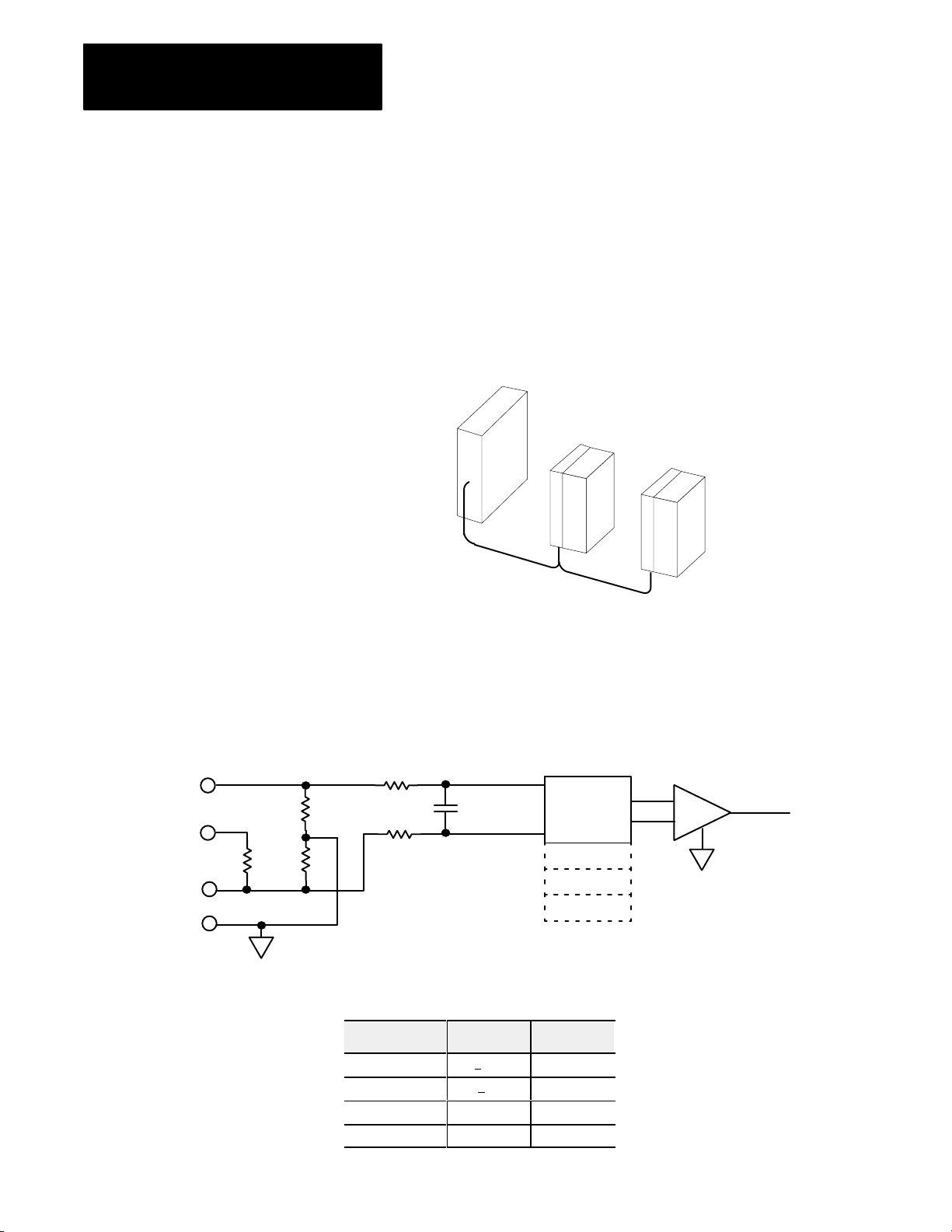

Discrete transfer (Figure 1.3) is intended to be used with controllers which

do not have block transfer capability. However, discrete transfer can be

used with any PLC family controller. When using discrete transfer, the

block looks like a 1/2 I/O rack to the controller (four words of input image

table memory and four words of output image table memory). Note that

certain alarms and user scaling features are not available when using

discrete transfer.

Figure 1.3

I/O Connection in an SLC System using discrete transfer

Block

Block I/O each block

1747SN Remote I/O

Scanner Module

1/2

is 1/2 I/O rack

1/2

Inputs

Simplified Schematic

Channel 0 Input

inV0

inI0

249Ω

RET in0

GND in0

20MΩ

20MΩ

Analog Input

1

Common

+

= 1 I/O Rack

Blocks are daisychained to

a scanner

A simplified schematic of the input circuit of one input channel is

shown below.

Analog Multiplexer

ATTENTION: The 249 ohm

input current shunt is rated at

0.25 Watts. Do not exceed this

power rating or apply more

than 6V across the resistor

Channel 0

Channel 1

Channel 2

Channel 3

Instrumentation

Amplifier

+

-

Analog Input

1

Common

10828I

A/D

12501-I

1-4

Inputs have selectable input ranges as shown below.

Application Input Range Resolution

voltage +10V 14 Bits

voltage or current +5V 14 Bits

voltage 0 to 10V 14 Bits

voltage or current 0 to 5V 14 Bits

Page 12

Chapter 1

Introducing Block I/O

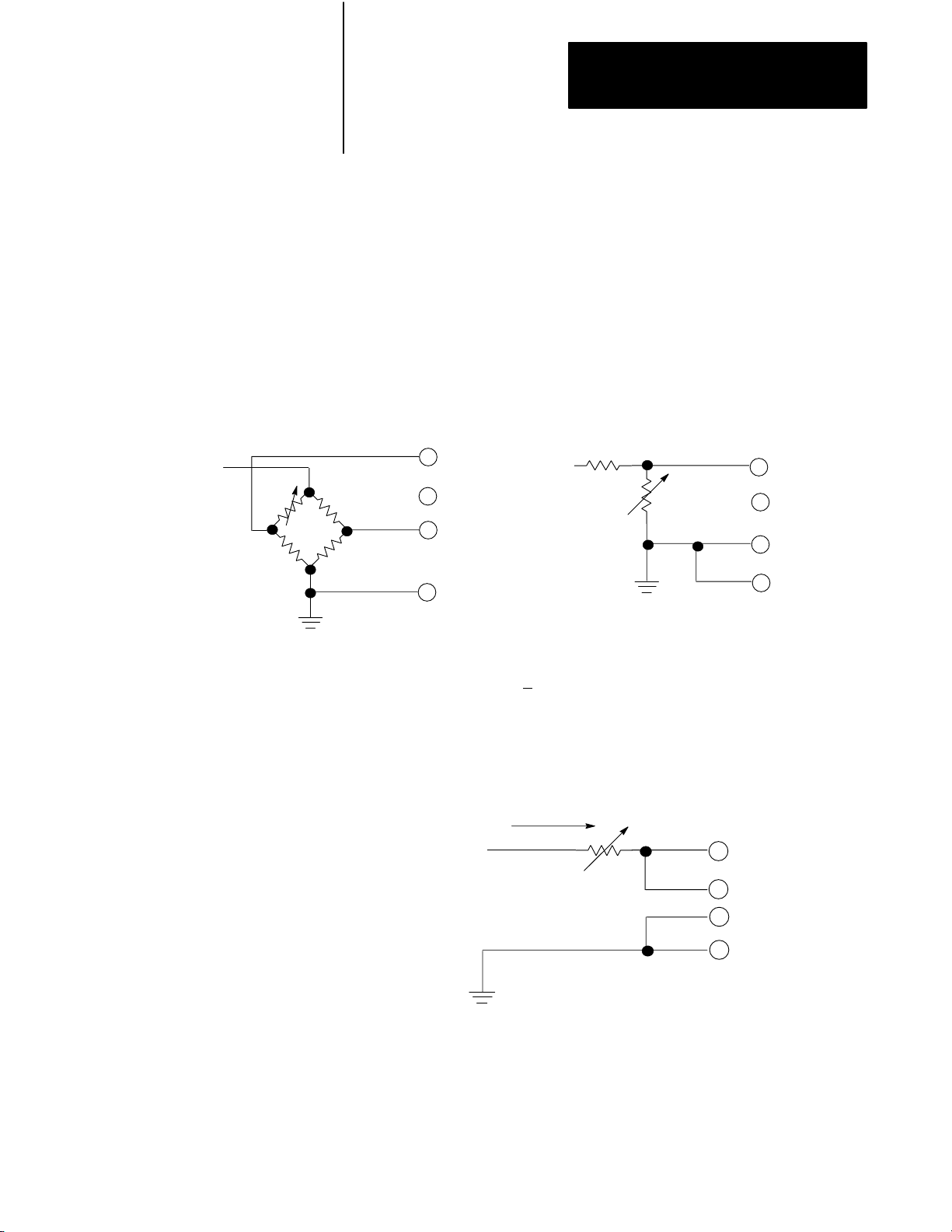

Voltage Input

Voltage inputs can be either single-ended or differential. In the voltage

mode, a signal applied between inV0 and the combination of RET in0

shorted to GND in0 provides a single-ended input mode. A signal applied

between inV0 and RET in0 provides a differential input mode. The four

terminals for ground are internally connected together to form the analog

input common. In either input mode (single-ended or differential) the

common mode voltage between any input terminal and analog input

common cannot exceed 11V or unreliable operation will occur. The figures

below show examples of differential input mode and single-ended input

mode.

10V

Differential Input Mode Singleended Input Mode

inV0

inI0

(no connection)

RET in0

GND in0

10V inV0

Current Input

When using the 0–5V or +5V range, an internal precision 249Ω shunt is

provided on each input. Input current is measured when the I

terminals are connected together. To get the proper input voltages, you

must indicate that the current shunt is connected when you configure the

module at powerup. A +24V power supply is provided for two-wire

current transducers.

I

5V

Current Input

inV0

inI0

RETin0

inI0

(no connection)

RETin0

GNDin0

and V

IN

IN

GNDin0

Each range setting has a margin of 2.5% to allow for compensation of

system or calibration inaccuracies.

1-5

Page 13

Chapter 1

Introducing Block I/O

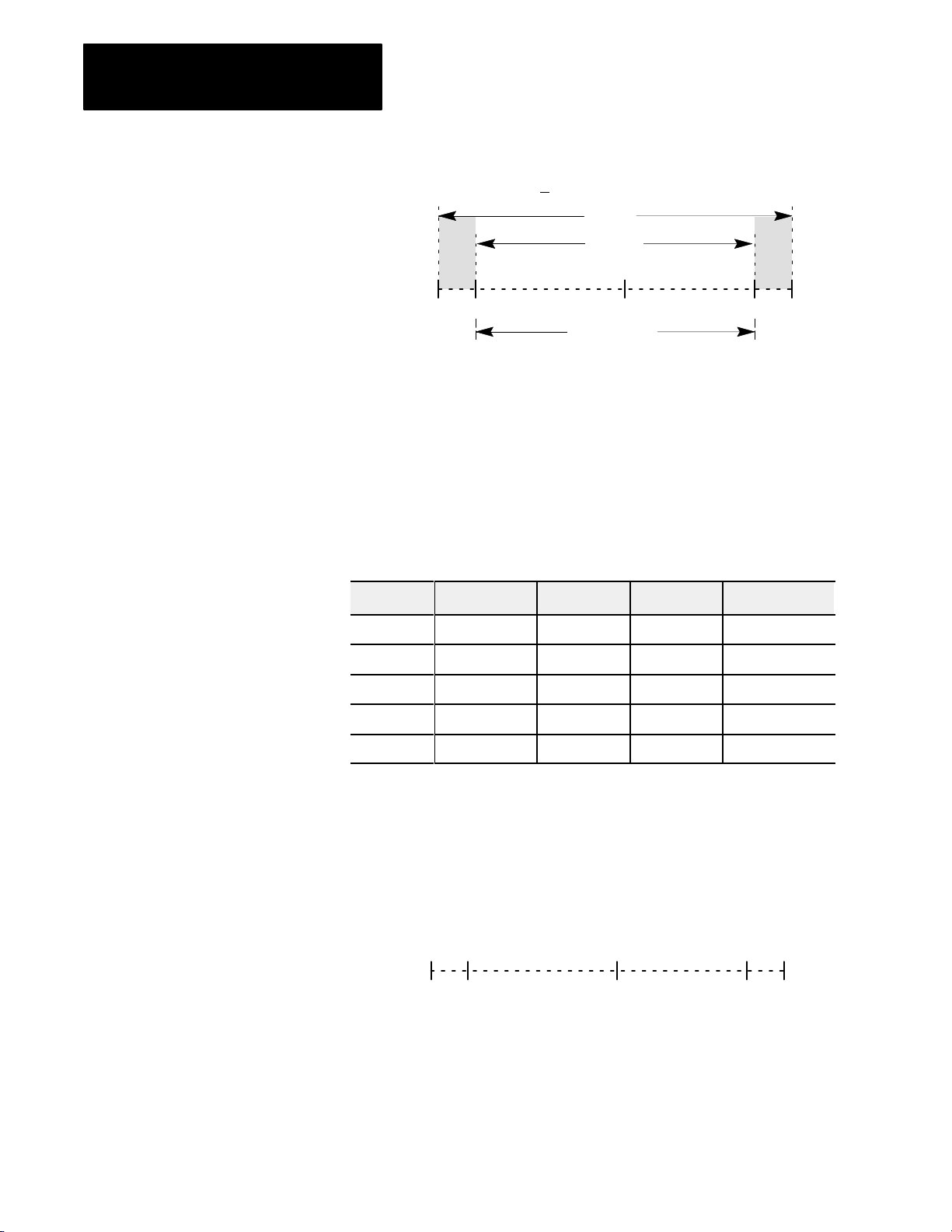

This is illustrated using the +10V scale below:

14 Bits

Resolution

Margin

13.96 Bits

Margin

Input Signal

I1 I2 I3 I4 I5

Nominal Range

In the above scale, input signals 1 thru 5 produce corresponding internal

analog to digital converter (ADC) binary counts. A full scale (FS) voltage

input produces an internal count of 16383 (input signal 1), while a bottom

scale (BS) voltage input produces an internal count of 0000 (input 5).

During calibration, the module’s representation of the counts are adjusted

so a voltage of nominal full scale (NFS) will produce a count shown as

input signal 2 while the nominal bottom scale voltage (NBS) produces a

count shown as input signal 4. For each range scale, the input voltage

which produces the ADC count of input signals 1 thru 5 in the above scale

are shown below:

Input Signal +/-10V 0-10V +/-5V 0-5V

I1 10.25V (FS) 10.25V (FS) 5.125V (FS) 5.125V (FS)

I2 +10.000V (NFS) 10.00V (NFS) 5.000V (NFS) 5.000V (NFS)

I3 0.000V 5.00V 0.000V 2.500V

I4 -10.000V (NBS) 0.00V (NBS) -5.000V (NBS) 0.000V (NBS)

I5 -10.25V (BS) -0.25V (BS) -5.125V (BS) -0.125V (BS)

Scaling

1-6

The input data represented at the module is always the internal ADC binary

counts scaled by values set in the maximum (S

) and minimum (S

max

min

)

scaler value using a two point scaling method. The input voltage which

produces input signal 2 (V

signal 4 (V

Scaling

Input Signal

Voltage

) is equal to S

nbs

Smax

I1 I2 I3 I4 I5

Vnfs

) is always equal to S

nfs

as shown below:

min

, and voltage of input

max

Smin

Vnbs

Page 14

Chapter 1

Introducing Block I/O

The following equation shows how the module interprets the input data:

Module

where:

data = M x Vin + B

– S

(S

M =

B =

(V

(S

max

nfs

min

– V

x V

(V

min

nbs

nfs

nfs

)

) – (S

)

– V

nbs

max

)

x V

nbs

)

You can choose one of three scaling methods:

binary counts (module sets scalers)

default scaling (module sets scalers)

user scaling (you set scalers)

User scaling is not available when you select discrete transfer mode.

Binary Counts Scaling

Binary counts scaling mode activates when the module powers up. This

mode guarantees the maximum resolution. The module sets the scalers as

shown in the following table:

Scaler +/-10V 0-10V +/-5V 0-5V

S

max

S

min

8191 16383 8191 16383

-8192 0 -8192 0

Default Scaling

Default scaling mode scales inputs to the input stimulus in either millivolts

or microamps. The module sets the scalers as shown in the following

tables:

With Voltage Input Selected

Scaler +/-10V 0-10V +/-5V 0-5V

S

S

With Current Input Selected

Scaler +/-10V 0-10V +/-5V 0-5V

S

S

10,000mV 10,000mV 5000mV 5000mV

max

-10,000mV 0mV -5000mV 0mV

min

max

min

N/A N/A 20000uA 20000uA

N/A N/A -20000uA 0uA

1-7

Page 15

Chapter 1

Introducing Block I/O

User Scaling

User scaling is available only when using the block transfer mode. This

mode allows you to define S

max

and S

in engineering units in the block

min

transfer write data table. The integer range is 32,767 to –32,768.

Important: If the range of user scaling values is set less than the range of

binary counts scaling values, input resolution is sacrificed.

Scaling Example

Using the +10V range scale, the following illustration shows five possible

input signals.

14 Bits

Resolution

Margin

13.96 Bits

Margin

Outputs

Input Signal

10.25 10 0 -10 -10.25

Nominal Range

The following table shows how the five signals will be scaled using each

of the three scaling methods. In the user scaling column, the S

to represent 5000 and the S

Input Value

Approx. +10.25V 8395 10250 5062

+10.000V 8191 10000 5000 (Smax)

0.000V 0000 00000 2500

-10.000V -8192 -10000 0000 (Smin)

Approx. -10.25V -8396 -10250 -0062

Binary Counts Default User

was set to represent 0.

min

Scaling Method

max

was set

The type of output your block I/O module has depends on its catalog

number:

1791-N4V2 and 1791-NDV have two +10V voltage outputs

1791-N4C2 and 1791-NDC have two 0-20mA current outputs

1-8

For any of the above modules, if your program tries to write a value which

is outside the output range, the output will be clamped at either the

maximum or minimum value. This condition will be indicated in the block

transfer read status word.

Page 16

V

OUTS

Digital

Output

Opto

Isolation

Isolated Analog

Output Common

Chapter 1

Introducing Block I/O

V

oltage Outputs - 1791N4V2 and 1791NDV

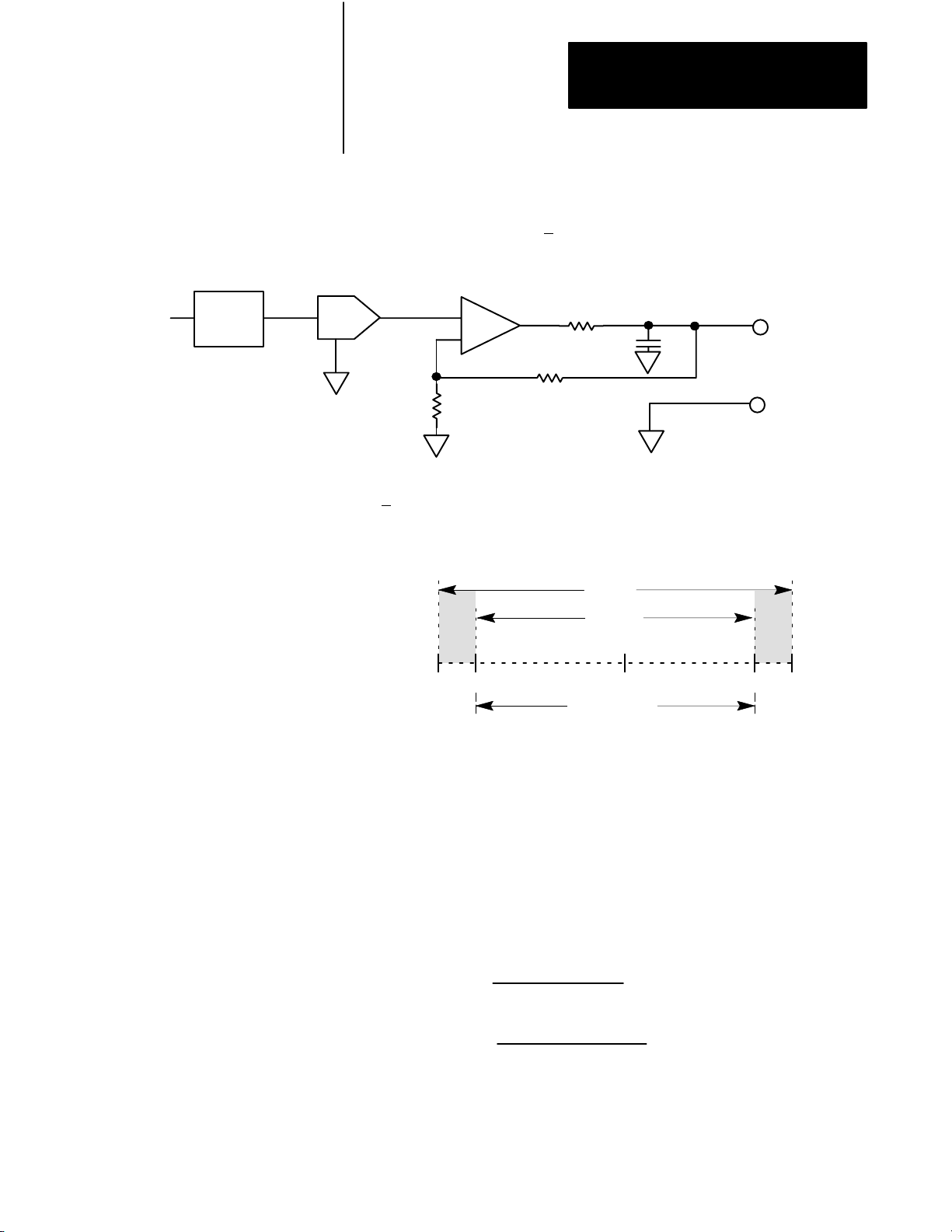

A simplified schematic of a +10V output channel is shown below.

Precision

Operational

Amplifier

DAC

2

+

-

2

V

OUT

V

RET

Note: Schematic does not show overvoltage protection circuits.

The +10V output provides 14 bits of resolution and is capable of driving

loads as small as 1k ohm. The output sacrifices a small amount of the

resolution to provide a margin of 2.5% to allow for system or calibration

inaccuracies as shown below.

Resolution

Output Signal

Scaling

The digital data sent to the output is always scaled by the values set in the

maximum (S

scaling method. When digital data sent equals S

+10.000V and the digital data sent equals S

–10.000V. The following equations shows this relationship:

Isolated Analog

2

Output Common

14 Bits

13.96 Bits

Margin

10.25 10 0 -10 -10.25

Nominal Range

) and minimum (S

max

) scaler values using a two point

min

Isolated Analog

2

Output Common

, the output produces

max

, the output produces

min

12501-I

Margin

Vout

= M x Module Data + B

where:

M =

B =

(Smax – Smin)

10 x (Smax + Smin)

(Smax – Smin)

20V

1-9

Page 17

Chapter 1

Introducing Block I/O

You can choose one of three scaling methods:

binary counts

default scaling

user scaling

User scaling is not available when you select discrete transfer mode.

The following table shows the output signals produced by various module

data values entered in each of the three scaling methods. In the user scaling

column, S

Output Signal

Approx. +10.25V 8395 10250 5062

was set to 5000 and S

max

Binary Counts

Scaling

was set to 0000.

min

Module Data

Default

Scaling

User

Scaling

+10V 8191 10000 5000 (Smax)

0.000V 0000 00000 2500

-10.00V -8192 -10000 0000 (Smin)

Approx. -10.25V -8396 -10250 -0062

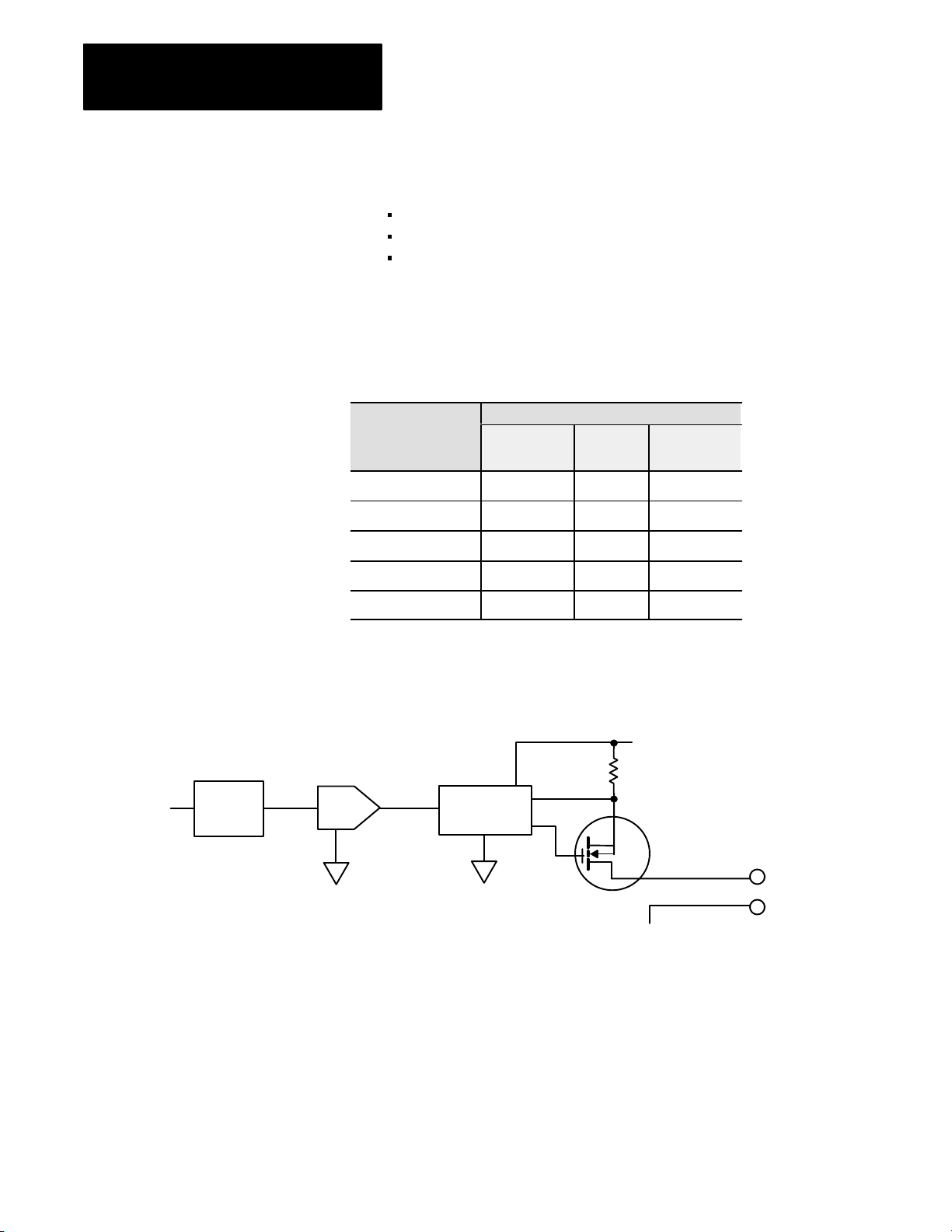

Current Outputs - 1791N4C2 and 1791NDC

A simplified schematic of a 0 to 20mA output channel is shown below.

I

OUTS

Digital

Output

Note: Schematic does not show overvoltage protection circuits.

Opto

Isolation

Isolated Analog

Output Common

DAC

2

Isolated Analog

Output Common

High Side

Current

Monitor

2

+15V

-15V

I

OUT

I

RET

12505-I

1-10

The 0 to 20mA output provides 13 bits of resolution and is capable of

driving loads as large as 1k ohm.

Page 18

Chapter 1

Introducing Block I/O

The output sacrifices a small amount of the resolution to provide a margin

of 2.5% to allow for system or calibration inaccuracies as shown below.

13 Bits

Resolution

Margin

12.9 Bits

Margin

Input Signal

20.5 20 10 0.0 –0.5

Nominal Range

Scaling

The digital data sent to the output is always scaled by the values set in the

maximum (S

scaling method. When digital data sent equals S

20.000mA and the digital data sent equals S

0.000mA. The following equations shows this relationship:

Iout

where:

You can choose one of three scaling methods:

binary counts

default scaling

user scaling

) and minimum (S

max

= M x Module Data + B

M =

B =

(Smax – Smin)

20mA x (Smax + Smin)

(Smax – Smin)

min

20mA

) scaler values using a two point

, the output produces

max

, the output produces

min

User scaling is not available when you select discrete transfer mode.

The following table shows the output signals produced by various module

data values entered in each of the three scaling methods. In the user scaling

column, S

Output Signal

Nominally +20.5mA 8395 10250 5062

20.000mA 8191 10000 5000 (Smax)

0.000mA 0000 00000 2500 (Smin)

Nominally -0.5mA

1

The actual output can never go negative. However

compensation.

was set to 5000 and S

max

Binary Counts Scaling Default Scaling User Scaling

1

-0396 -00050 -2437

was set to 0000.

min

Module Data

, some of the output range is used to allow for zero of

fset

1-11

Page 19

Installing Block I/O

1771SN

14 blocks with 150 ohm terminator

PLC2 famil

1772SD, 1772SD2

16 blocks/channel, 28 blocks/scanner

A

PLC3

with 150 ohm terminator. 128 blocks

32 blocks/channel, 64 blocks/scanner

with 2 scanners, 82 ohm terminator

PLC

Chapter

2

Chapter

Objectives

Preinstallation

Considerations

When using and Maximum Capacity

y

In this chapter, you will learn how to mount the block, connect the remote

I/O link, connect the input and output wiring to the block, and terminate

the remote I/O link.

Before installation, you must determine the:

scanner/processor to use

number of blocks on your network

throughput requirements

total distance of the installation

transmission rate desired

external fuses required (if any)

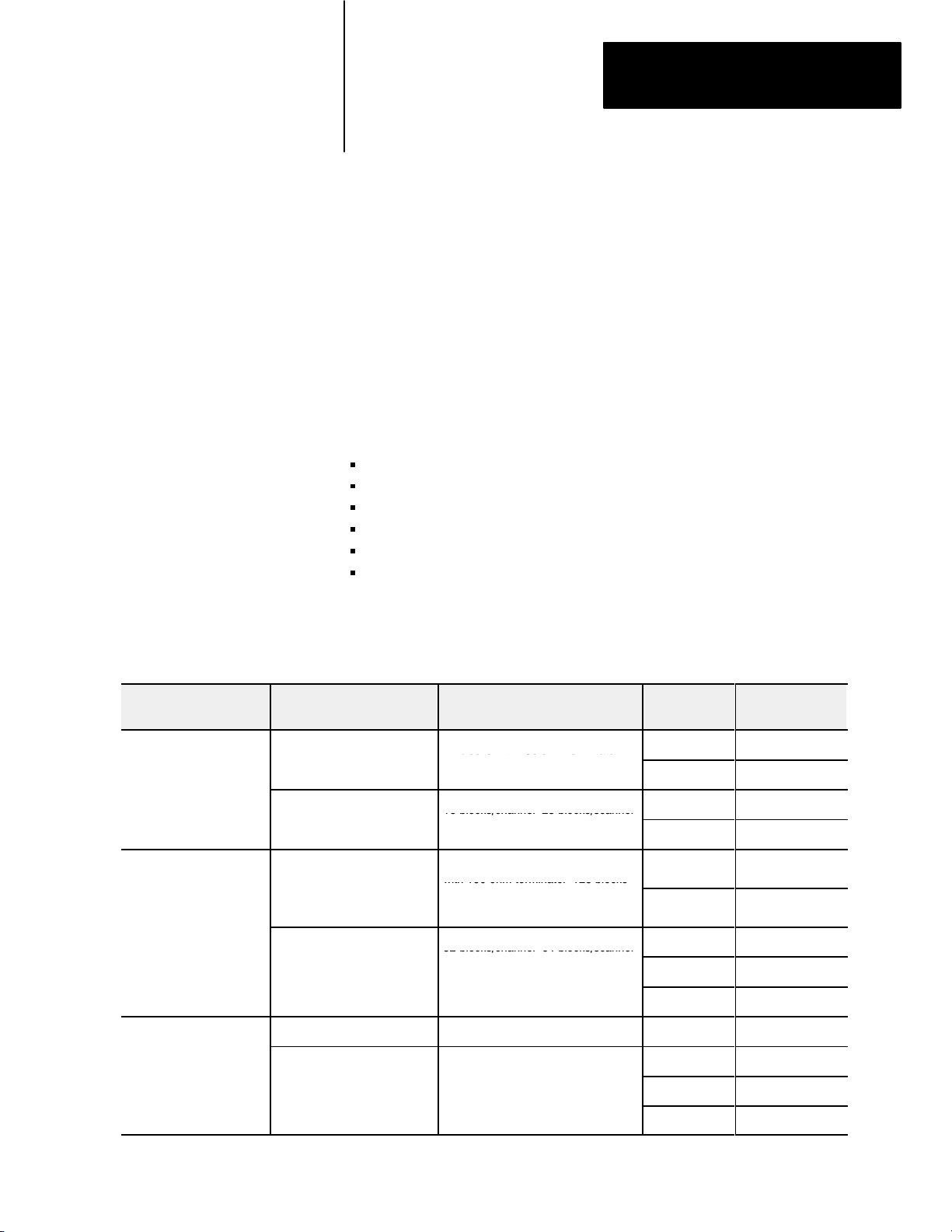

Acceptable combinations are shown in Table 2.A.

Table 2.A

Acceptable

Combinations of Processor and Block I/O

Baud Rate

14 blocks with 150 ohm terminator

and discrete transfer

16 blocks/channel, 28 blocks/scanner

with 150 ohm terminator

57.6K 10,000 cablefeet

115.2K 5,000 cablefeet

57.6K 10,000 cablefeet

115.2K 5,000 cablefeet

Used

Maximum

Network Distance

PLC3 family

5 family

ny

1775S5, or SR5 module

PLC5VME (6008LTV)

PLC5/11

scanner module

16 blocks/channel, 64 blocks/scanner

with 150 ohm terminator. 128 blocks

with 2 scanners and 150 ohm

terminator.

32 blocks/channel, 64 blocks/scanner

with 82 ohm terminator. 128 blocks

with 2 scanners, 82 ohm terminator

and extended node addressing.

4 blocks with 150 ohm terminator

4 blocks with 150 ohm terminator

57.6K 10,000 cablefeet

115.2K 5,000 cablefeet

57.6K 10,000 cablefeet

115.2K 5,000 cablefeet

230.4K 2,000 cablefeet

57.6K 10,000 cablefeet

57.6K 10,000 cablefeet

115.2K 5,000 cablefeet

230.4K 2,500 cablefeet

2-1

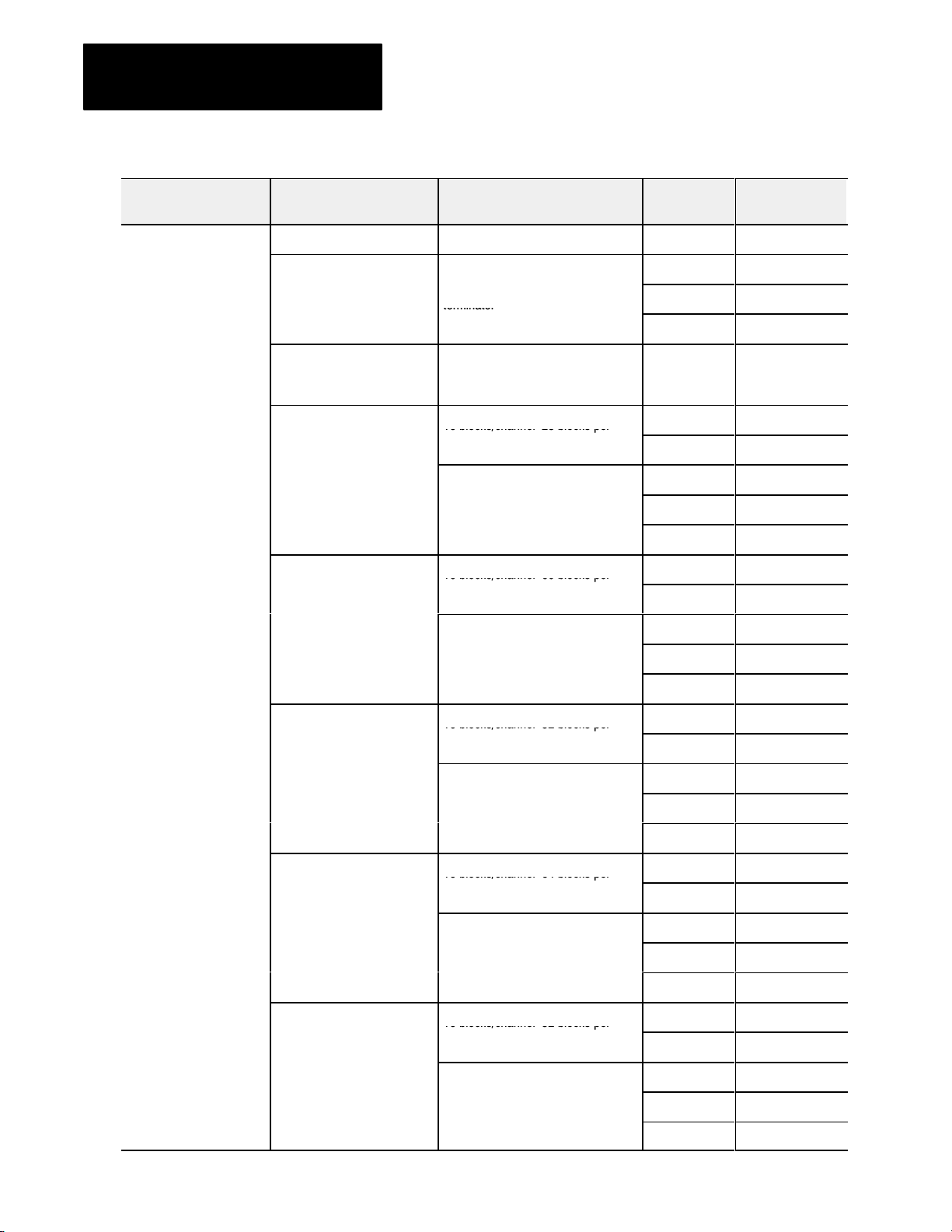

Page 20

Chapter 2

terminator

16 blocks/channel, 28 blocks per

28 blocks/ch

16 blocks/channel, 60 blocks per

32 blocks/ch

16 blocks/channel, 32 blocks per

32 blocks/ch

16 blocks/channel, 64 blocks per

32 blocks/ch

16 blocks/channel, 32 blocks per

32 blocks/ch

Installing Block I/O

PLC5 family (continued)

PLC5/15

PLC5/20

PLC5/25

PLC5/30

PLC5/40

Maximum CapacityandWhen using

1

12 blocks with 150 ohm terminator 57.6K 10,000 cablefeet

Baud Rate

Used

Maximum

Network Distance

57.6K 10,000 cablefeet

12 blocks with 82 ohm or 150 ohm

terminator

115.2K 5,000 cablefeet

230.4K 2,500 cablefeet

2

16 blocks with 150 ohm terminator,

28 blocks with 82 ohm terminator and

57.6K 10,000 cablefeet

extended node addressing

16 blocks/channel, 28 blocks per

processor with 150 ohm terminator

57.6K 10,000 cablefeet

115.2K 5,000 cablefeet

57.6K 10,000 cablefeet

annel, 28 blocks per

processor with 82 ohm terminator

115.2K 5,000 cablefeet

and extended node addressing

230.4K 2,500 cablefeet

16 blocks/channel, 60 blocks per

processor with 150 ohm terminator

57.6K 10,000 cablefeet

115.2K 5,000 cablefeet

57.6K 10,000 cablefeet

annel, 60 blocks per

processor with 82 ohm terminator

115.2K 5,000 cablefeet

and extended node addressing

230.4K 2,500 cablefeet

PLC5/40L

PLC5/60

PLC5/60L

16 blocks/channel, 32 blocks per

processor with 150 ohm terminator

annel, 60 blocks per

processor with 82 ohm terminator

and extended node addressing

16 blocks/channel, 64 blocks per

processor with 150 ohm terminator

annel, 92 blocks per

processor with 82 ohm terminator

and extended node addressing

16 blocks/channel, 32 blocks per

processor with 150 ohm terminator

annel, 64 blocks per

processor with 82 ohm terminator

and extended node addressing

57.6K 10,000 cablefeet

115.2K 5,000 cablefeet

57.6K 10,000 cablefeet

115.2K 5,000 cablefeet

230.4K 2,500 cablefeet

57.6K 10,000 cablefeet

115.2K 5,000 cablefeet

57.6K 10,000 cablefeet

115.2K 5,000 cablefeet

230.4K 2,500 cablefeet

57.6K 10,000 cablefeet

115.2K 5,000 cablefeet

57.6K 10,000 cablefeet

115.2K 5,000 cablefeet

230.4K 2,500 cablefeet

2-2

Page 21

Chapter 2

a 5 50 S e o e sca e

32 blocks/channel, 32

scanners) with 82 ohm terminator

8 block

3

Controller

Module (discrete mode only)

Installing Block I/O

Maximum CapacityandWhen using

16 blocks/channel, 32

Baud Rate

Used

57.6K 10,000 cablefeet

blocks/scanner, (128 blocks with 4

scanners) with 150 ohm terminator

PLC5 family (continued)

PLC5/250 requires

a 5150RS remote scanner

32 blocks/channel, 32

blocks/scanner, (128 blocks with 4

scanners) with 82 ohm terminator

and extended node addressing

SLC5/02 (and greater)

Controller

1747SN Remote I/O Scanner

Module (discrete mode only)

s with 150 ohm terminator

8 blocks with 82 ohm terminator

1

PLC5/15 series A and PLC5/15 series B prior to revision H (B/H) can only address 3 blocks.

2

PLC5/25 revisions prior to A/D can only address 7 blocks.

3

Analog block is 1/2 rack in discrete transfer mode. If you combine analog block and discrete transfer on the same RIO link, the capacity ranges between 8 and 15 blocks.

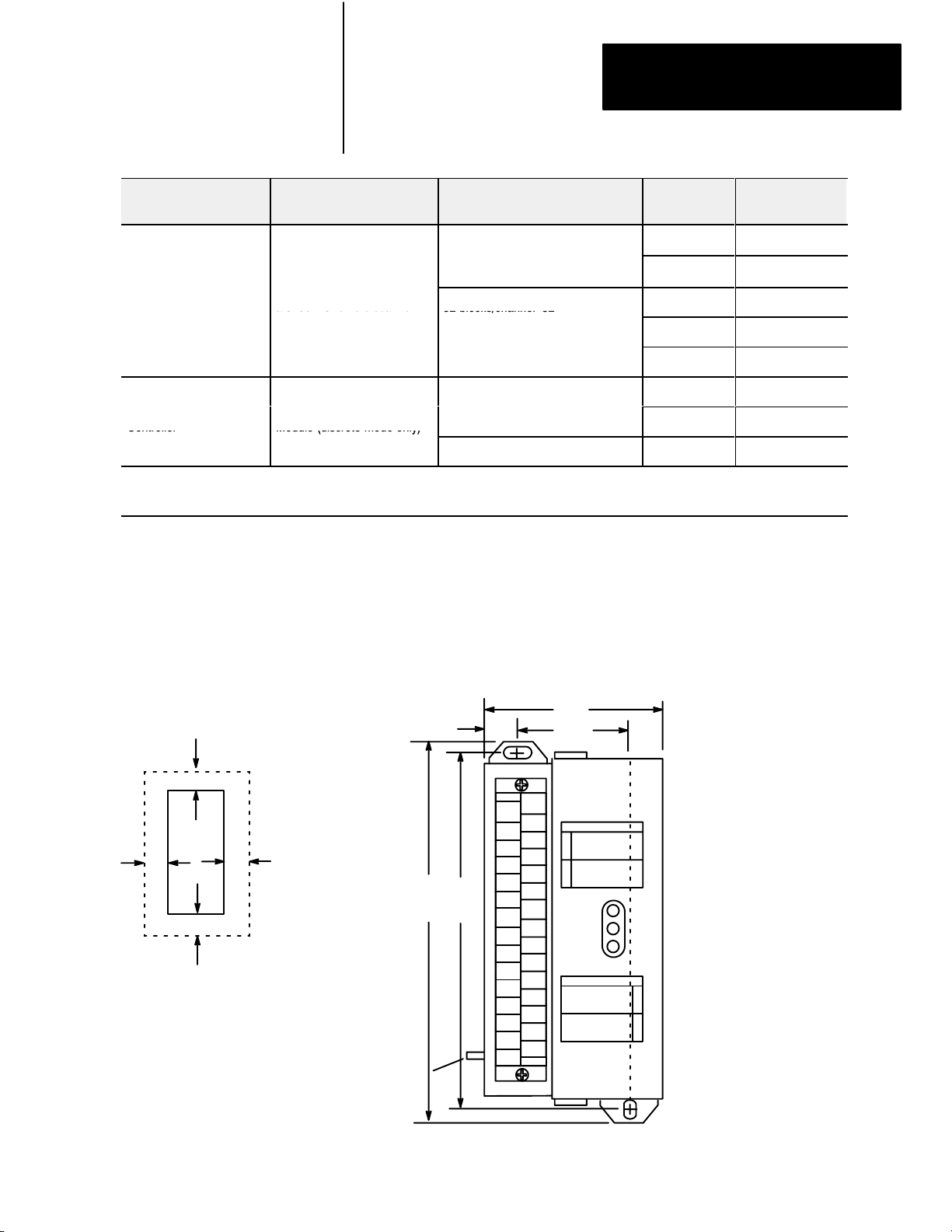

Installing the Block I/O

Figure 2.1 shows the mounting dimensions for the block I/O module.

115.2K 5,000 cablefeet

57.6K 10,000 cablefeet

115.2K 5,000 cablefeet

230.4K 2,500 cablefeet

57.6K 10,000 cablefeet

3

115.2K 5,000 cablefeet

3

230.4K 2,500 cablefeet

Mount the blocks vertically with a minimum of 2” between blocks. This air

gap is necessary to maintain proper cooling air flow through the block.

Maximum

Network Distance

Block

2.0 (50.8) air gap

on all 4 sides.

Operating temperature in

gap

below module must

air

not

exceed 60oC (140oF).

Figure 2.1

Mounting

Equipment

Grounding

Stud

CAUTION:

Dimensions for the Block I/O Modules (1791N4V2 shown)

2.710

1

(68.8)

1.71

(43.4)

ANALOG BLOCK

0

1

POWER

COMM

FAULT

1791N4V2

OUTPUT

INPUT

Inches

(Millimeters)

6.95H x 2.710W x 3.85D

(176.5H x 68.8W x 98D)

0

1

2

3

2 mounting holes

for 1/4inch screws

0.5

(12.7)

6.95

6.60

(176.5)

(167.6)

30

When tightening grounding stud nut, do not exceed 15 inlbs.

2-3

Page 22

Chapter 2

Installing Block I/O

Connecting Wiring

Figure 2.2

Mounting

1. Hook top of slot over DIN rail.

2. While pressing block against rail,

pull down on locking lever.

3. When block is flush against rail,

push up on locking lever to

secure block to rail.

on a DIN Rail

Block

DIN Rail

AB pt. no. 199DR1

DIN 462773

EN 50022

(3.4 x 7.5mm)

Locking Lever

12382I

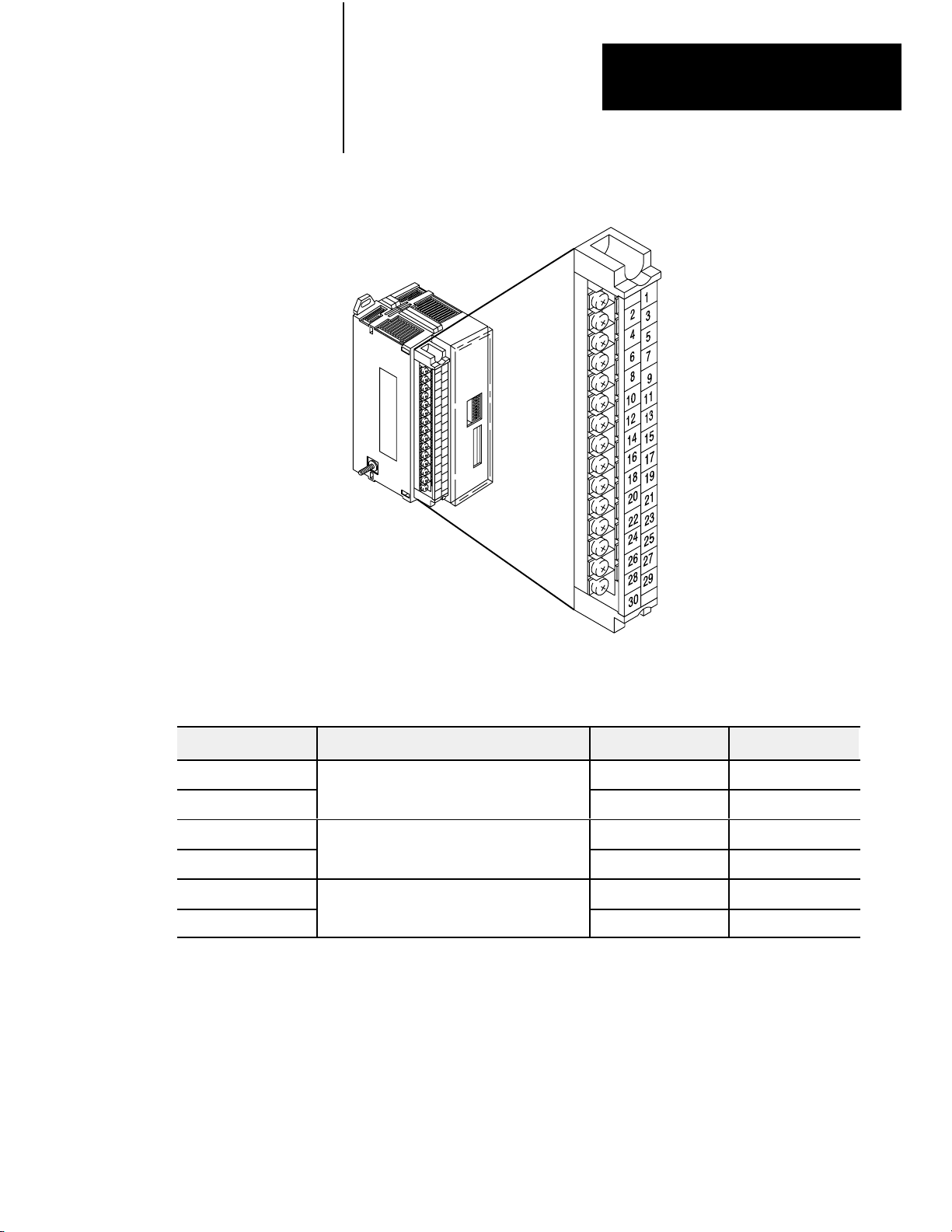

Make wiring connections to the removable terminal block which plugs into

the front of the block.

Figure 2.3

Removing

ATTENTION: The terminal block is not keyed to prevent

incorrect insertion. If you remove the terminal block, make

certain that it is inserted with the lower row of screws on the

outside of the block with number 1 at the top of the

terminal strip.

the T

erminal Block

To remove the terminal strip,

unscrew the two captive screws

and pull the terminal strip out.

2-4

12383I

Page 23

Chapter 2

Installing Block I/O

Figure 2.4

Terminal

Block Pin Numbering

Refer to the following table for wiring schematics and connecting wiring

lists for the analog block modules.

Power Supply Voltage Input For Schematic refer to: For wiring refer to:

120V ac

24V dc

120V ac

24V dc

120V ac

24V dc

Wiring Connections for the Analog Block with

Wiring Connections for the Analog Block with

Voltage Inputs

Wiring Connections for the Analog Block with

Wiring Connections for the Analog Block with

Current Input and CustomerSupplied Loop Power

Wiring Connections for the Analog Block with

Wiring Connections for the Analog Block with

Current Input and BlockSupplied Loop Power

Figure 2.5, page 26 Table 2.B, page 29

Figure 2.6, page 26 Table 2.C, page 210

Figure 2.7, page 27 Table 2.D, page 211

Figure 2.8, page 27 Table 2.E, page 212

Figure 2.9, page 28 Table 2.D, page 211

Figure 2.10, page 28 Table 2.E, page 212

2-5

Page 24

Chapter 2

Installing Block I/O

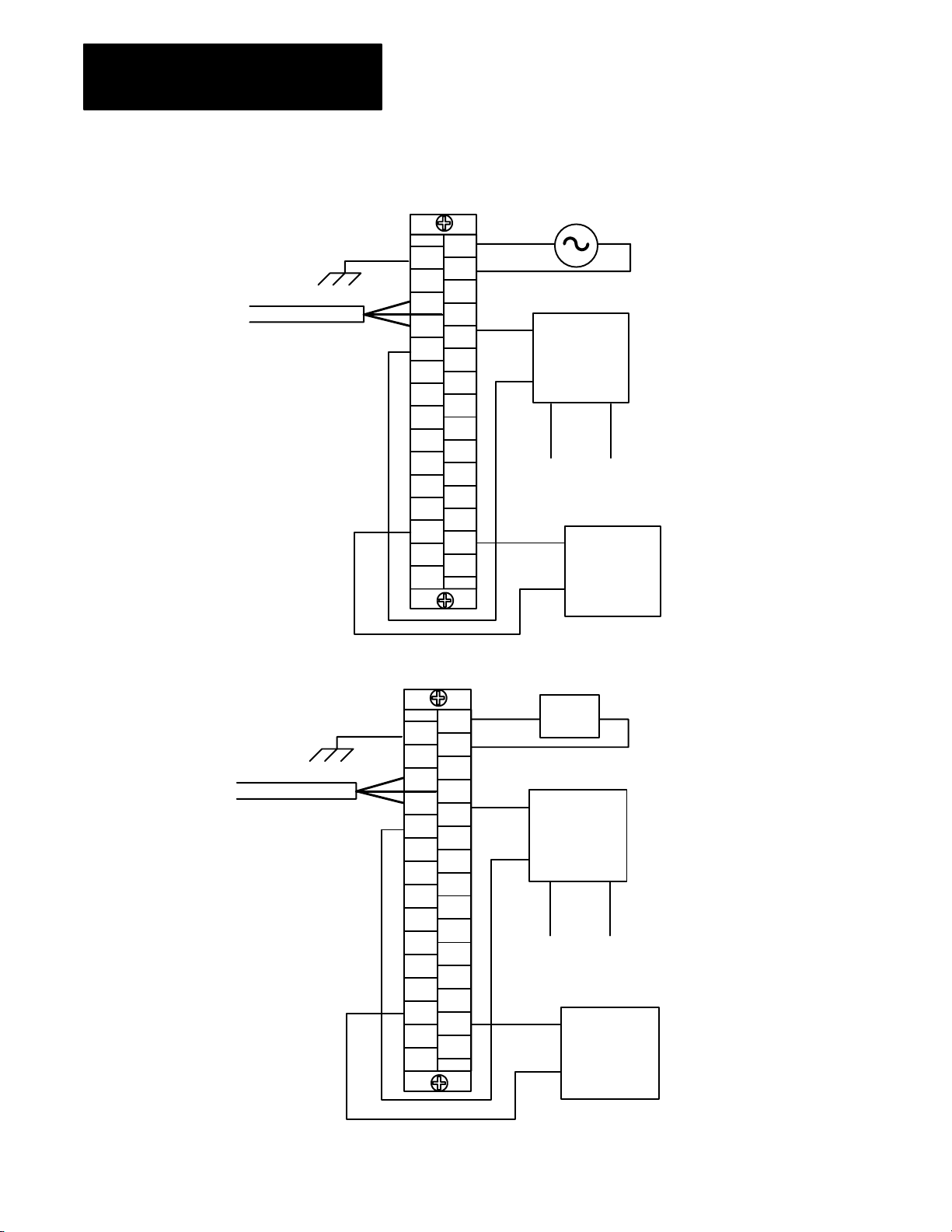

RIO

Figure 2.5

Connections for the 120V ac Analog Block with V

Wiring

GND

NOT

USED

BLU

CLR

RET

in0

GND

in0

RET

in1

GND

in1

RET

in2

GND

in2

RET

in3

GND

in3

RET

out0

RET

out1

NOT

USED

30

NOT

USED

SHD

in

in I0

in V1

in I1

in V2

in I2

in V3

in I3

+24

Vdc

out0

out1

1

L1

N

V0

L1

Voltage Input

+

User Analog

Input Device

-

User +24V User GND

Output

+

User Analog

Output Device

-

oltage Inputs

L2/N

Analog signals must be within the 10V

common mode voltage range which is

referenced to the analog input common

(GND). Typically, this is accomplished by

connecting to user ground. If an input

channel floats outside of this range,

invalid input readings will result.

RIO

Figure 2.6

Connections for the 24V dc Analog Block with V

Wiring

GND

NOT

USED

BLU

CLR

RET

in0

GND

in0

RET

in1

GND

in1

RET

in2

GND

in2

RET

in3

GND

in3

RET

out0

RET

out1

NOT

USED

30

RET

+24

NOT

USED

SHD

in

in I0

in V1

in I1

in V2

in I2

in V3

in I3

+24

Vdc

out0

out1

1

+24

V0

+

+24V dc

Supply

Voltage Input

+

User Analog

Input Device

-

User +24V User GND

Output

+

User Analog

Output Device

-

oltage Input

-

Analog signals must be within the 10V

common mode voltage range which is

referenced to the analog input common

(GND). Typically, this is accomplished by

connecting to user ground. If an input

channel floats outside of this range,

invalid input readings will result.

2-6

Page 25

RIO

Output

User Analog

Output Device

Figure 2.7

Connections for the 120V ac Analog Block with Current Input and

Wiring

CustomerSupplied Loop Power

GND

NOT

USED

BLU

CLR

RET

in0

GND

in0

RET

in1

GND

in1

RET

in2

GND

in2

RET

in3

GND

in3

-

+

RET

out0

RET

out1

NOT

USED

30

NOT

USED

SHD

in

in I0

in V1

in I1

in V2

in I2

in V3

in I3

+24

Vdc

out0

out1

Chapter 2

Installing Block I/O

1

L1

N

L1

+

V0

-

User +24V User GND

ATTENTION: The 249 ohm

input current shunt is rated

at 0.25 Watts. Do not

exceed this rating.

L2/N

Current Input

User Analog

Input Device

Analog signals must be within the

10V common mode voltage range

which is referenced to the analog

input common (GND). Typically, this

is accomplished by connecting to

user ground. If an input channel

floats outside of this range, invalid

input readings will result.

RIO

Output

User Analog

Output Device

Figure 2.8

Connections for the 24V dc Analog Block with Current Input and

Wiring

CustomerSupplied Loop Power

GND

NOT

USED

BLU

CLR

RET

in0

GND

in0

RET

in1

GND

in1

RET

in2

GND

in2

RET

in3

GND

in3

-

+

RET

out0

RET

out1

NOT

USED

30

RET

+24

NOT

USED

SHD

in

in I0

in V1

in I1

in V2

in I2

in V3

in I3

+24

Vdc

out0

out1

1

+24

V0

+

+24V dc

Supply

Current Input

+

User Analog

Input Device

-

User +24V User GND

ATTENTION: The 249 ohm

input current shunt is rated

at 0.25 Watts. Do not

exceed this rating.

-

Analog signals must be within the

10V common mode voltage range

which is referenced to the analog

input common (GND). Typically,

this is accomplished by connecting

to user ground. If an input channel

floats outside of this range, invalid

input readings will result.

2-7

Page 26

Chapter 2

Installing Block I/O

Figure 2.9

Connections for the 120V ac Analog Block with Current Input and

Wiring

BlockSupplied Loop Power

RIO

Output

User Analog

Output Device

RIO

Output

User Analog

Output Device

1

L1

GND

N

NOT

USED

NOT

USED

BLU

SHD

CLR

in

V0

RET

in0

in I0

GND

in0

in V1

RET

in1

in I1

GND

in1

in V2

RET

in2

in I2

GND

in2

in V3

RET

in3

in I3

GND

in3

+24

RET

-

+

out0

RET

out1

NOT

USED

30

Vdc

out0

out1

L1

i

i

+24V dc loop power supplied

at terminal 25 on block

ATTENTION: The 249 ohm

input current shunt is rated

at 0.25 Watts. Do not

exceed this rating.

L2/N

Loop Powered

Current Input

User Analog

Input Device

Analog signals must be within the

10V common mode voltage range

which is referenced to the analog

input common (GND). Typically, this

is accomplished by connecting to

user ground. If an input channel

floats outside of this range, invalid

input readings will result.

Figure 2.10

Connections for the 24V dc Analog Block Module with Current

Wiring

Input and BlockSupplied Loop Power

1

+24

GND

RET

+24

NOT

USED

NOT

USED

BLU

SHD

CLR

in

V0

RET

in0

in I0

GND

in0

in V1

RET

in1

in I1

GND

in1

in V2

RET

in2

in I2

GND

in2

in V3

RET

in3

in I3

GND

in3

+24

RET

-

+

out0

RET

out1

NOT

USED

30

Vdc

out0

out1

+

+24V dc

-

Supply

Loop Powered

Current Input

i

User Analog

i

Input Device

+24V dc loop power supplied

at terminal 25 on block

ATTENTION: The 249 ohm

input current shunt is rated

at 0.25 Watts. Do not

exceed this rating.

Analog signals must be within the

10V common mode voltage range

which is referenced to the analog

input common (GND). Typically, this

is accomplished by connecting to

user ground. If an input channel

floats outside of this range, invalid

input readings will result.

2-8

Page 27

Table 2.B

Power

Remote I/O

Block Designations for Cat. No. 1791N4V2

Wiring

Connections

Designation Description Terminal No.

Chapter 2

Installing Block I/O

1791-N4V2

Power

Connections

L1 ac hot 1

N

ac neutral 3

GND Chassis ground 2

Transducer

2

Power

Remote I/O

Connections

+24V For current input only 25

BLU Blue wire - RIO 6

CLR

Clear wire - RIO 8

SHD Shield - RIO 7

I/O Connections

inV0 thru inV3 Voltage Input 0 through 3 9, 13, 17, 21

Voltage Input

RET in0 thru

RET in3

Input Return 0 through 3 10, 14, 18, 22

inI0 thru inI3 Current Input 0 through 3 11, 15, 19, 23

Current Input

RET in0 thru

RET in3

Input Return 0 through 3 10, 14, 18, 22

Input Ground GNDin0GNDin3 Channels 03 ground 12, 16, 20, 24

out 0 - RET out 0

Output

out 1 - RET out 1

Not used

1

Connect

chassis ground to equipment grounding stud. These are not internally connected.

2

2028V dc (nominal 24V, 100mA)) voltage source for accommodating looppowered current transducer inputs.

3

Terminals

4

12, 16, 20, and 24 are internally connected.

T

erminals 26 and 28 internally connected together

.

Output 0 (+)

Return output 0 (-)

Output 1 (+)

Return output 1 (-)

For internal test only; not

for customer use.

4, 5, 30

26

28

27

29

1

3

4

4

2-9

Page 28

Chapter 2

Power

Remote I/O

Installing Block I/O

Table 2.C

Block Designations for Cat. No. 1791NDV

Wiring

Connections

Power

Connections

Transducer

2

Power

Remote I/O

Connections

Designation Description Terminal No.

+24 +24V dc Power 1

RET +24

GND Chassis ground 2

dc Return 3

1

+24V For current input only 25

BLU Blue wire - RIO 6

CLR

Clear wire - RIO 8

SHD Shield - RIO 7

I/O Connections

inV0 thru inV3 Voltage Input 0 through 3 9, 13, 17, 21

1791-NDV

Voltage Input

RET in0 thru

RET in3

Input Return 0 through 3 10, 14, 18, 22

inI0 thru inI3 Current Input 0 through 3 11, 15, 19, 23

Current Input

RET in0 thru

RET in3

Input Return 0 through 3 10, 14, 18, 22

Input Ground GNDin0-GNDin3 Channels 0-3 ground 12, 16, 20, 24

out 0 - RET out 0

Output

out 1 - RET out 1

Not used

1

Connect

chassis ground to equipment grounding stud. These are not internally connected.

2

2028V dc (nominal 24V, 100mA) voltage source for accommodating looppowered current transducer inputs.

3

T

erminals 12, 16, 20, and 24 are internally connected.

4

T

erminals 26 and 28 internally connected together

Output 0 (+)

Return output 0 (-)

Output 1 (+)

Return output 1 (-)

For internal test only; not

for customer use.

.

27

4

26

29

4

28

4, 5, 30

3

2-10

Page 29

Table 2.D

Power

Remote I/O

Block Designations for Cat. No. 1791N4C2

Wiring

Connections

Designation Description Terminal No.

Chapter 2

Installing Block I/O

1791-N4C2

Power

Connections

Transducer

2

Power

Remote I/O

Connections

L1 ac hot 1

N

ac neutral 3

GND Chassis ground 2

+24V For current input only 25

BLU Blue wire - RIO 6

CLR

Clear wire - RIO 8

1

SHD Shield - RIO 7

I/O Connections

inV0 thru inV3 Voltage Input 0 through 3 9, 13, 17, 21

Voltage Input

RET in0 thru

RET in3

Input Return 0 through 3 10, 14, 18, 22

inI0 thru inI3 Current Input 0 through 3 11, 15, 19, 23

Current Input

RET in0 thru

RET in3

Input Return 0 through 3 10, 14, 18, 22

Input Ground GNDin0GNDin3 Channels 03 ground 12, 16, 20, 24

out 0 - RET out 0

Output

out 1 - RET out 1

Not used

1

Connect

chassis ground to equipment grounding stud. These are not internally connected.

2

2028V dc (nominal 24V, 100mA) voltage source for accommodating looppowered current transducer inputs.

3

T

erminals 12, 16, 20, and 24 are internally connected.

4

T

erminals 26 and 28 internally connected together

.

Output 0 (+)

Return output 0 (-)

Output 1 (+)

Return output 1 (-)

For internal test only; not

for customer use.

27

4

26

29

4

28

4, 5, 30

3

2-11

Page 30

Chapter 2

Remote I/O

Installing Block I/O

Table 2.E

Block Designationsfor Cat. No. 1791NDC

Wiring

Connections

Designation Description Terminal No.

+24 +24V dc Power 1

1791-NDC

Power Connections

RET +24

dc Return 3

GND Chassis ground 2

Transducer Power

Remote I/O

Connections

2

+24V For current input only 25

BLU Blue wire - RIO 6

CLR

Clear wire - RIO 8

SHD Shield - RIO 7

I/O Connections

inV0 thru inV3 Voltage Input 0 through 3 9, 13, 17, 21

Voltage Input

RET in0 thru

RET in3

Input Return 0 through 3 10, 14, 18, 22

inI0 thru inI3 Current Input 0 through 3 11, 15, 19, 23

Current Input

RET in0 thru

RET in3

Input Return 0 through 3 10, 14, 18, 22

Input Ground GNDin0-GNDin3 Channels 0-3 ground 12, 16, 20, 24

out 0 - RET out

0

Output

out 1 - RET out

1

Not used

1

Connect

chassis ground to equipment grounding stud. These are not internally connected.

2

2028V dc (nominal 24V, 100mA) voltage source for accommodating looppowered current transducer inputs.

3

T

erminals 12, 16, 20, and 24 are internally connected.

4

T

erminals 26 and 28 internally connected together

.

Output 0 (+)

Return output 0 (-)

Output 1 (+)

Return output 1 (-)

For internal test only; not

for customer use.

1

27

4

26

29

4

28

4, 5, 30

3

2-12

Table 2.F

W

Acceptable

Remote I/O link Belden 9463

Input and output wiring Up to 14AWG (2mm2) stranded with 3/64 inch insulation

iring Cables for Block I/O Connection

Use Cable Type

Page 31

Chapter 2

Installing Block I/O

Termination Resistor

Remote I/O Link

A termination resistor must be installed on the last block in a series.

Connect the resistor as shown in Figure 2.11.

Figure 2.11

Installing

Connect termination resistor across

terminals 6 (BLU) and 8 (CLR).

Refer to Table 2.A for proper

terminator for your application.

the T

ermination Resistor

Termination

Resistor

BLU

CLR

SHD

10835I

Blocks must be wired in series as shown in Figure 2.12 or Figure 2.13. Do

not attempt to wire any block in parallel.

The number of blocks used depends not only on the user requirements but

also on the system used. Refer to Table 2.A (page 2-1) for maximum

block usage for individual systems.

Figure 2.12

Connection for Block I/O Using PLC2, PLC3 or PLC5 Family

Series

Programmable Controllers

To Programmable

Controller or I/O

Scanner Module

Install terminating resistor on last block.

1 I/O Rack

1 I/O Rack

1 I/O Rack

1 I/O Rack

10833I

2-13

Page 32

Chapter 2

Installing Block I/O

To 1747SN

Scanner Module

Figure 2.13

Configurations for Block I/O Using the SLC Programmable

Series

Controller

1

2

7

8

Up to 8 blocks with

SLC5/02

Extended Node Capability

Install terminating resistor

on last block.

10834I

If this is the last remote I/O adapter on the remote I/O link in a PLC

system, you must use a terminating resistor to terminate both ends of the

remote I/O link (scanner end and last block end). The size of the terminator

is determined by the system configuration.

Older system configurations must use a 150 ohm resistor at both ends.

With newer devices that can support it, you can use an 82 ohm termination

resistor at both ends. The 82 ohm terminators provide “extended node”

capability which allows you to have up to 32 physical devices on the

remote I/O link. (The number of logical racks capable of being addressed

by the scanner is not affected.)

ATTENTION: Devices that are operating at 230.4K baud must

have 82 ohm terminators in place for proper operation.

2-14

Page 33

Chapter 2

Installing Block I/O

Compatibility

of 1771 I/O

Products with Extended

Node Numbers

Certain products are not compatible with extended node capabilities

obtained with the use of 82 ohm terminators. Table 2.G lists those products

that are not compatible.

Table 2.G

Noncompatible

Scanners

Adapters 1771AS All

Miscellaneous 1771AF All

Products

Device Series

1771SN All

1772SD All

1772SD2 All

1775SR All

1775S4A All

1775S4B All

1771ASB Series A

1771DCM All

1771AF1 All

Selecting Remote I/O Link Speed

The remote I/O link can operate at three speeds: 57.6K, 115.2K or 230.4K

bits/s. The selection of link speed is dependent on the scanner/processor

used, throughput requirements, distance required and the type of remote

I/O devices being used.

Throughput Requirements

Block throughput using analog block is dependent on the controllers data

transfer rate. Analog block outputs are updated within 10ms of receiving

output data from the controller. The analog block inputs are sampled in a

“round robin” fashion with an input channel sampled every 27ms. This

means that a given input channel is sampled every 108ms (four input

channels times 27ms). At the end of every sample period of 27ms, the most

recent input data is made available for data transfer to the controller.

Consult your programmable controller user manual for Remote I/O

Communications to determine your system throughput.

2-15

Page 34

Chapter

3

Configuring Your Block I/O for PLC Family

Programmable Controllers

Chapter

Setting the Configuration Switches

Objectives

In this chapter, you will learn how to configure your block I/O when used

with PLC family programmable controllers. This includes the following:

setting the configuration switches

addressing the block I/O

Each block I/O module has two 8-position switches for setting:

starting I/O group

I/O rack number

communication rate

last chassis

last state

block transfer/discrete transfer

processor restart/lockout

These switches are accessible by opening the clear plastic door on the front

of the module (Figure 3.1).

ATTENTION: Recycle power to the block I/O module after

setting the switches.

3-1

Page 35

Chapter 3

Configuring Your Block I/O for PLC

Family Programmable Controllers

1

Figure 3.1

Settings for the Analog Block I/O Modules

Switch

1791N4V2

ANALOG

BLOCK

SW2-8

Not used

87654321

SW2-7

Not Used

30

Open clear front

cover to access

switches

POWER

COMM

FAULT

SW2

01

SW1

01

Position = 1Position = 0

End View of Switch

87654321

SW2-6 Last I/O Group

0 Not last rack

1 Last rack

SW2-5

Processor

Restart/Lockout (PRL)

0 Processor Restart

1 Processor Lockout

SW2-4 Hold Last State

0 Reset Outputs

1 Hold Last State

SW2-3 Transfer Type

0 Block Transfer

1 Discrete Transfer

Communication Rate

SW2-2 SW2-1 Bits/s

3-2

ATTENTION: Recycle power to the block I/O module

after setting the switches.

0 0 57.6 K

0 1 115.2 K

1 0 230.4 K

1 1 230.4 K

Starting Quarter

SW1-2 SW1-1

0 0 0 (1st)

0 1 2 (2nd)

1 0 4 (3rd)

1 1 6 (4th)

Module

Group

Page 36

Chapter 3

Configuring Your Block I/O for PLC

Family Programmable Controllers

1747SN

Rack

Number

Rack

Rack 1 Rack 2 Rack 2 Rack 1 Rack 1 Rack 1

Rack 2 Rack 3 Rack 3 Rack 2 Rack 2 Rack 2

Rack 3 Rack 4 Rack 4 Rack 3 Rack 3 Rack 3

1771SN

Rack

Number

0

Rack 1 Rack 1

Rack 5 Rack 5 Rack 4 Rack 4 Rack 4

Rack 6 Rack 6 Rack 5 Rack 5 Rack 5

Rack 7 Rack 7 Rack 6 Rack 6 Rack 6

PLC2

Rack

Number

PLC5

Rack

Number

Not V

Rack 7 Rack 7 Rack 7

Rack 10 Rack 10 Rack 10

Rack 1

Rack 12 Rack 12 Rack 12

Rack 13 Rack 13 Rack 13

Rack 14 Rack 14 Rack 14

Rack 15 Rack 15 Rack 15

Rack 16 Rack 16 Rack 16

Rack 17 Rack 17 Rack 17

Rack 20 Rack 20 Rack 20

Rack 21 Rack 21 Rack 21

Rack 22 Rack 22 Rack 22

Rack 23 Rack 23 Rack 23

Rack 24 Rack 24 Rack 24

Rack 25 Rack 25 Rack 25

Rack 26 Rack 26 Rack 26

Rack 27 Rack 27 Rack 27

PLC5/250

Number

alid

1

Rack 1

Rack 30 Rack 30

Rack 31 Rack 31

Rack 32 Rack 32

Rack 33 Rack 33

Rack 34 Rack 34

Rack 35 Rack 35

Rack 36 Rack 36

Rack 37 Rack 37

Rack

Rack 0 Rack 0

PLC3

Rack

Number

1

Rack 1

Rack 40

Rack 41

Rack 42

Rack 43

Rack 44

Rack 45

Rack 46

Rack 47

Rack 50

SW1 Switch Position

8 7 6 5 4 3

0 0 0 0 0 0

0 0 0 0 0 1

0 0 0 0 1 0

0 0 0 0 1 1

0 0 0 1 0 0

0 0 0 1 0 1

0 0 0 1 1 0

0 0 0 1 1 1

0 0 1 0 0 0

1 0 0 1 0 0 1

0 0 1 0 1 0

0 0 1 0 1 1

0 0 1 1 0 0

0 0 1 1 0 1

0 0 1 1 1 0

0 0 1 1 1 1

0 1 0 0 0 0

0 1 0 0 0 1

0 1 0 0 1 0

0 1 0 0 1 1

0 1 0 1 0 0

0 1 0 1 0 1

0 1 0 1 1 0

0 1 0 1 1 1

0 1 1 0 0 0

0 1 1 0 0 1

0 1 1 0 1 0

0 1 1 0 1 1

0 1 1 1 0 0

0 1 1 1 0 1

0 1 1 1 1 0

0 1 1 1 1 1

1 0 0 0 0 0

1 0 0 0 0 1

1 0 0 0 1 0

1 0 0 0 1 1

1 0 0 1 0 0

1 0 0 1 0 1

1 0 0 1 1 0

1 0 0 1 1 1

1 0 1 0 0 0

3-3

Page 37

Chapter 3

Configuring Your Block I/O for PLC

Family Programmable Controllers

1747SN

1747SN

Rack

Rack

Number

Number

Rack

address 77 is an illegal configuration.

PLC5/1

PLC5/15 and PLC5/20 processors can scan racks 0103.

PLC5/25 and PLC5/30 processors can scan racks 0107.

PLC5/40 and PLC5/40L processors can scan racks 0117.

PLC5/60 and PLC5/60L processors can scan racks 0127.

PLC5/250 processors can scan racks 037.

PLC3 processors can scan racks 076.

1771SN

1771SN

Rack

Rack

Number

Number

1 processors can scan rack 03.

PLC2

PLC2

Rack

Rack

Number

Number

PLC5

PLC5

Rack

Rack

Number

Number

PLC5/250

PLC5/250

Rack

Rack

Number

Number

PLC3

PLC3

Rack

Rack

Number

Number

Rack

51

Rack 52

Rack 53

Rack 54

Rack 55

Rack 56

Rack 57

Rack 60

Rack 61

Rack 62

Rack 63

Rack 64

Rack 65

Rack 66

Rack 67

Rack 70

Rack 71

Rack 72

Rack 73

Rack 74

Rack 75

Rack 76

Not V

alid 1 1 1 1 1 1

SW1 Switch Position

1 0 1 0 0 1

1 0 1 0 1 0

1 0 1 0 1 1

1 0 1 1 0 0

1 0 1 1 0 1

1 0 1 1 1 0

1 0 1 1 1 1

1 1 0 0 0 0

1 1 0 0 0 1

1 1 0 0 1 0

1 1 0 0 1 1

1 1 0 1 0 0

1 1 0 1 0 1

1 1 0 1 1 0

1 1 0 1 1 1

1 1 1 0 0 0

1 1 1 0 0 1

1 1 1 0 1 0

1 1 1 0 1 1

1 1 1 1 0 0

1 1 1 1 0 1

1 1 1 1 1 0

345678

3-4

The SLC 500 controllers communicate with the block I/O using an I/O

Scanner module (cat. no. 1747-SN series A). Refer to the user manual for

the 1747-SN/A Scanner module for more information.

Note: These block I/O modules are not compatible with the 1747-DSN

Distributed I/O Scanner module.

Page 38

Block transfer requires 1/4 rack.

Chapter 3

Configuring Your Block I/O for PLC

Family Programmable Controllers

When using block transfer, each analog block I/O module uses 2 words of

output image table memory and 2 words of input image table memory.

Each block occupies 1/4 rack of data table, with 4 blocks comprising 1

logical rack. Image table usage for one assigned rack number is shown in

Figure 3.3.

Figure 3.2

Image T

I/O

1791N4C2

MSB = Module Status Byte

MCB = Module Control Byte

able for One Assigned Rack Number using Block T

Input Image

0

1

2

3

4

5

6

7

1791N4C2

0

1

2

3

4

5

6

7

MSB

Reserved

MSB

Reserved

Output Image

710

MCB

Reserved

MCB

Reserved

ransfer

PLC

017 710

1/4 Rack

1/4 Rack

PLC

017

1/4 Rack

1/4 Rack

3-5

Page 39

Chapter 3

Configuring Your Block I/O for PLC

Family Programmable Controllers

Discrete transfer requires 1/2 rack.

1791N4C2

When using discrete transfer, each analog block I/O module uses 4 words

of output image table memory and 4 words of input image table memory.

Each block occupies 1/2 rack of data table, with 2 blocks comprising 1

logical rack. Image table usage for one assigned rack number is shown in

Figure 3.3.

Figure 3.3

Image Table for One Assigned Rack Number using Discrete T

I/O

Input Image

0

1

2

3

4

5

6

7

1791N4C2

0

1

2

3

4

5

6

7

Input 0

Input 1

Input 2

Input 3

Input 0

Input 1

Input 2

Input 3

Output Image

710

Configuration

Output 0

Output 1

Reserved

Configuration

Output 0

Output 1

Reserved

ransfer

017 710

1/2 Rack

017

SLC 50007815

PLC

1/2 Rack

SLC 50007815

PLC

1/2 Rack

1/2 Rack

3-6

Page 40

Chapter 3

Configuring Your Block I/O for PLC

Family Programmable Controllers

Module

Scan T

ime

Scan time depends on the block transfer rate over the remote I/O network,

which is asynchronous to the module input sample rate and output update

rate. The block transfer rate is dependent on the controller, program length,

the amount of communication traffic to other modules on the remote I/O

network and the speed (baud rate) of the remote I/O network.

Figure 3.4

Scan Time Relationships

Module

Block Transfer

Read

Input Sample

Rate

Block Transfer

Write

Output Update

1

Time depends on the remote I/O network configuration.

BTR1

108ms

Ch 0 Ch 1 Ch 2 Ch 3 Ch 0 Ch 1 Ch 2 Ch 3 Ch 0 Ch 1

BTW1

10ms 10ms

Ch 0 & Ch 1

updated

100ms to 2s

100ms to 2s

1

BTR2

1

BTW2

Ch 0 & Ch 1

updated

3-7

Page 41

Chapter

4

Analog Block Applications Using

Block Transfers

Chapter

Objectives

Reading Data and Status from the Module

Block Transfer Read Data Format

In this chapter, you will read about:

reading data and status from the module

block transfer read data format

configuring the module and setting outputs with block transfer

write instructions

Block transfer instructions are used when the analog block is used with

PLC programmable controllers with block transfer capability. Block

transfer read (BTR) programming moves status and data from the module

to the processor’s data table in one I/O scan. The processor user program

initiates the request to transfer data from the module to the processor.

The transferred words contain module status, channel status and input data

from the module. The maximum BTR data file length required is five

words (0 thru 4).

The block transfer read data format consists of input data and module

status. Word 0 contains the power up bit (PU), the bad configuration bit

(BC), out of range bit (OR), status code, high alarm and low alarm bits.

Words 1 through 4 contain input channel data.

Complete configuration data and bit/word descriptions are shown in

Figure 4.1 and Table 4.A.

Figure 4.1

T

ransfer Read for Analog Blocks using PLC Controllers

Block

Decimal 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Octal 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

0 PU BC OR Status Code High Alarm Low Alarm

1 Input Channel 0 Data

2 Input Channel 1 Data

3 Input Channel 2 Data

4 Input Channel 3 Data

4-1

Page 42

Chapter 4

Analog Block Applications Using

Block Transfers

Word

Word 0

Table 4.A

Bit/Word

Decimal

(Octal Bit)

Bits 15 (17)

Bit 14 (16)

Bit 13 (15)

Bits 0812

(1014)

Descriptions for Block Transfer Read Instruction

Bit

Power up (PU) status bit. This bit is set (1) if the module has not been

configured since the last power up. It is reset (0) when at least one valid BTW

has occurred since power up. Outputs are not enabled until the PU bit is reset.

Bad configuration (BC) bit. This bit is set (1) if an invalid configuration data has

been received, and the previous configuration remains in effect.

Out of range (OR) bit. When set, indicates one or both of the outputs has

received a value which exceeds the output range. Outputs are clamped at their

maximum or minimum values depending on the direction of the out of range

value.

Status Codes. When the Bad Configuration (BC) bit 14 (16), is set (1), the

status code indicates the following:

1 output channel 0 scaling error

2 output channel 1 scaling error

3 input channel 0 scaling error

4 input channel 1 scaling error

5 input channel 2 scaling error

6 input channel 3 scaling error

7 channel 0 alarm error

8 channel 1 alarm error

9 channel 2 alarm error

A channel 3 alarm error

When the output out of range (OR) bit 13 (15) is set (1), the status code bits

indicate the following:

Bit 08 (10) output 0 has been clamped at its minimum

Bit 09 (11) output 1 has been clamped at its minimum

Bit 10 (12) output 0 has been clamped at its maximum

Bit 11 (13) output 1 has been clamped at its maximum

Description

4-2

Word 1

Word 2

Word 3

Word 4

Bits 0407

Bits 0003

Bits 0015

(0017)

Bits 0015

(0017)

Bits 0015

(0017)

Bits 0015

(0017)

High alarm bits. Set (1) if the input channel value is greater than the

corresponding high alarm value.

Bit 04 high alarm bit for channel 0

Bit 05 high alarm bit for channel 1

Bit 06 high alarm bit for channel 2

Bit 07 high alarm bit for channel 3

Low alarm bits. Set (1) if the input channel value is less than the corresponding

low alarm value.

Bit 00 low alarm bit for channel 0

Bit 01 low alarm bit for channel 1

Bit 02 low alarm bit for channel 2

Bit 03 low alarm bit for channel 3

Input data for channel 0.

Input data for channel 1.

Input data for channel 2.

Input data for channel 3.

Page 43

Chapter 4

Analog Block Applications Using

Block Transfers

Configuring the Module and

Setting Outputs with Block

ransfer W

T

rite Instructions

You must configure your block module by performing a block transfer

write (BTW) instruction from the programmable controller to the module.

Each input can be independently configured in one BTW.

Maximum length of the BTW is 27 words (0 thru 26). When configuring

the module, first send the complete BTW. You can shorten the BTW to 3

words for subsequent write operations if parameters for each channel

remain the same.

Block transfer write data is shown in Figure 4.2.

Figure 4.2

T

ransfer W

Block

Decimal 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Octal 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

0 Module Mode Scaling Range Alarm Enable Filter

1 Output Channel 0 Data

2 Output Channel 1 Data

3 Output Channel 0 Minimum Scaling

4 Output Channel 0 Maximum Scaling

5 Output Channel 1 Minimum Scaling

6 Output Channel 1 Maximum Scaling

7 Input Channel 0 Minimum Scaling

8 Input Channel 0 Maximum Scaling

9 Input Channel 1 Minimum Scaling

10 Input Channel 1 Maximum Scaling

11 Input Channel 2 Minimum Scaling

12 Input Channel 2 Maximum Scaling

13 Input Channel 3 Minimum Scaling

14 Input Channel 3 Maximum Scaling

15 Input Channel 0 Low Alarm Level

16 Input Channel 0 High Alarm Level

17 Input Channel 0 Alarm Deadband

18 Input Channel 1 Low Alarm Level

19 Input Channel 1 High Alarm Level

20 Input Channel 1 Alarm Deadband

21 Input Channel 2 Low Alarm Level

22 Input Channel 2 High Alarm Level

23 Input Channel 2 Alarm Deadband

24 Input Channel 3 Low Alarm Level

25 Input Channel 3 High Alarm Level

26 Input Channel 3 Alarm Deadband

rite for Analog Block I/O

4-3

Page 44

Chapter 4

Analog Block Applications Using

Block Transfers

The bit/word descriptions are shown in Table 4.B.

Word

Word0

Word 0

Decimal

Bit

(Octal Bit)

Bits 1215 (1417)

Bits 1215 (1417)

Bits 1011 (1213)

Table 4.B

Bit/Word

Descriptions for the Block T

Module Mode. Bits 1215 (1417) determine the operation of the block module.

Bit 15 (17) 14 (16) 13 (15) 12 (14)

0 0 0 0 Normal operation with voltage inputs

0 0 0 1 Normal operation with current inputs

1 1 0 0

Scaler Mode

Bit 11 (13) 10 (12) Mode Binary Counts binary data sent to the

0 X binary

1 0 default

1 1 user

Default Scaling Values are shown below:

Bit 09

(11)

Range

Bit 08

(10)

Module

Module

Mode

Bit 12 (14)

0 0 0 10000 +10000 14 Bits

0 0 1 5000 +5000 13 Bits

1 0 1 20000 +20000 14 Bits

0 1 0 0000 +10000 13 Bits

0 1 1 0000 +5000 12 Bits

1 1 1 0000 +20000 14 Bits

Default scaling for the output is determined by the catalog number as follows:

ransfer W

Minimum

rite Instruction

Description

Calibration operation (refer to

Chapter 7)

outputs and returned from the inputs is

outputsandreturnedfromtheinputsis

calibrated, but not scaled, providing maximum

possibleresolution

possible resolution.

User Scaling the input and output data are

scaled by the values in words 3 thru 6 for

scaledbythevaluesinwords3thru6for

outputs, and words 7 thru 14 for inputs.

Default Default Approximate

Default

Default

Maximum

Approximate

Default Resolution

4-4

Catalog Number

1791N4V2, NDV 10000 +10000 14 Bits

1791N4C2, NDC 00000 +20000 13 Bits

Range selection bits. Bit 08 selects voltage and bit 09 selects unipolar or bipolar.

Bit

Bits 0809 (1011) 09 (11) 08 (10)

()

0 0 +10V

0 1 +5V

1 0 010

1 1 05

Alarm Enable bits. Enables input alarm when set (1). Bit 04 corresponds to channel 0, bit 05

Bits 0407

Bits 0003 Digital Filter selection. Default of 0000 selects No Filter. Refer to Table 4.C.

corresponds to channel 1, bit 06 corresponds to channel 2 and bit 07 corresponds to

channel 3.

Range

Range

Default

Minimum

Default

Maximum

Approximate

Default Resolution

Page 45

Chapter 4

Analog Block Applications Using

Block Transfers

Word

Word 1 Bits 0015 (0017) Output data for channel 0.

Word 2 Bits 0015 (0017) Output data for channel 1.

Word 3 Bits 0015 (0017) Minimum engineering scale factors for output channel 0 data.

Word 4 Bits 0015 (0017) Maximum engineering scale factors for output channel 0 data.

Word 5 Bits 0015 (0017) Minimum engineering scale factors for output channel 1 data.

Word 6 Bits 0015 (0017) Maximum engineering scale factors for output channel 1 data.

Word 7 Bits 0015 (0017) Minimum engineering scale factors for input channel 0 data.

Word 8 Bits 0015 (0017) Maximum engineering scale factors for input channel 0 data.

Word 9 Bits 0015 (0017) Minimum engineering scale factors for input channel 1 data.

Word 10 Bits 0015 (0017) Maximum engineering scale factors for input channel 1 data.

Word 11 Bits 0015 (0017) Minimum engineering scale factors for input channel 2 data.

Word 12 Bits 0015 (0017) Maximum engineering scale factors for input channel 2 data.

Word 13 Bits 0015 (0017) Minimum engineering scale factors for input channel 3 data.

Word 14 Bits 0015 (0017) Maximum engineering scale factors for input channel 3 data.

Word 15 Bits 0015 (0017)

Word 16 Bits 0015 (0017)

Word 17 Bits 0015 (0017)

Decimal Bit

(Octal Bit)

Low alarm level for input channel 0. When the input value for this channel is less than the low

value, the corresponding low alarm bit is set in the BTR.

High alarm level for input channel 0. When the input value for this channel is greater than the

high value, the corresponding high alarm bit is set in the BTR.

Alarm deadband for input channel 0. This field creates a hysteresis effect on the low and high