Page 1

Installation Instructions

Compact

Block

Distributed I/O on

PROFIBUS DP Series D

(Cat. No. 1791P-16B0, -0B16P, -8B8P, -4B4P, -8V8P)

1791P CompactBlock™ I/O modules are stand-alone 24V dc Block

I/O products that communicate via a PROFIBUS DP link. Each PROFIBUS

DP node consists of either one base module or one base module and one

expansion module. Any expansion module can be coupled with any base

module. CompactBlock 1791P consists of only base modules. The expansion

modules are part of the CompactBlock 1791D family of products.

CompactBlock PROFIBUS DP modules must be installed in a secondary

enclosure. Base modules are equipped with 8 to 16 points.

CompactBlock PROFIBUS DP provides sinking and sourcing inputs and

outputs. Sinking inputs are 24V dc IEC Type 3 compatible. Self-protected

24V dc outputs can provide up to 0.5 amp each.

Important User Information

Because of the variety of uses for the products described in this publication,

those responsible for the application and use of these products must satisfy

themselves that all necessary steps have been taken to assure that each

application and use meets all performance and safety requirements, including

any applicable laws, regulations, codes and standards. In no event will

Rockwell Automation be responsible or liable for indirect or consequential

damage resulting from the use or application of these products.

Publication 1791P-IN002B-EN-P - October 2003

Page 2

2 CompactBlock Distributed I/O on PROFIBUS DP Series D

Any illustrations, charts, sample programs, and layout examples shown in this

publication are intended solely for purposes of example. Since there are many

variables and requirements associated with any particular installation,

Rockwell Automation does not assume responsibility or liability (to include

intellectual property liability) for actual use based upon the examples shown in

this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application,

Installation and Maintenance of Solid-State Control (available from your local

Rockwell Automation office), describes some important differences between

solid-state equipment and electromechanical devices that should be taken into

consideration when applying products such as those described in this

publication.

Reproduction of the contents of this copyrighted publication, in whole or

part, without written permission of Rockwell Automation, is prohibited.

Throughout this publication, notes may be used to make you aware of safety

considerations. The following annotations and their accompanying statements

help you to identify a potential hazard, avoid a potential hazard, and recognize

the consequences of a potential hazard:

WARNING

ATTENTION

IMPORTANT

Publication

Identifies information about practices or circumstances

that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property

damage, or economic loss.

Identifies information about practices or circumstances

that can lead to personal injury or death, property

damage or economic loss.

Identifies information that is critical for successful

application and understanding of the product.

1791P-IN002B-EN-P - October 2003

Page 3

ATTENTION

CompactBlock Distributed I/O on PROFIBUS DP Series D 3

Environment and Enclosure

This equipment is intended for use in a Pollution Degree

2 industrial environment, in overvoltage Category II

applications (as defined in IEC publication 60664-1), at

altitudes up to 2000 meters without derating.

This equipment is considered Group 1, Class A industrial

equipment according to IEC/CISPR Publication 11.

Without appropriate precautions, there may be potential

difficulties ensuring electromagnetic compatibility in

other environments due to conducted as well as radiated

disturbance.

This equipment is supplied as "enclosed" equipment. It

should not require additional system enclosure when

used in locations consistent with the enclosure type

ratings stated in the Specifications section of this

publication. Subsequent sections of this publication may

contain additional information regarding specific

enclosure type ratings, beyond what this product

provides, that are required to comply with certain

product safety certifications.

See NEMA Standards publication 250 and IEC

publication 60529, as applicable, for explanations of the

degrees of protection provided by different types of

enclosure. Also, see the appropriate sections in this

publication, as well as the Allen-Bradley publication

1770-4.1 ("Industrial Automation Wiring and Grounding

Guidelines"), for additional installation requirements

pertaining to this equipment.

Publication

1791P-IN002B-EN-P - October 2003

Page 4

4 CompactBlock Distributed I/O on PROFIBUS DP Series D

Installing CompactBlock I/O

Follow these steps, to install the 1791P I/O module:

1. Set the Station Address on the Base Module.

2. Mount the Block(s).

3. Connect the Input/Output Wires to the Block.

4. Connect the PROFIBUS DP connector.

5. Select termination for the module.

6. Connect power to the module.

7. Remove the terminal block.

8. Insert the terminal block.

9. Communicate with the 1791P Module.

These steps are explained in detail in the following procedures.

Publication

1791P-IN002B-EN-P - October 2003

Page 5

CompactBlock Distributed I/O on PROFIBUS DP Series D 5

Preventing Electrostatic Discharge

This equipment is sensitive to electrostatic discharge,

which can cause internal damage and affect normal

operation. Follow these guidelines when you handle

this equipment:

• Touch a grounded object to discharge potential

ATTENTION

static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component

boards.

• Do not touch circuit components inside the

equipment.

• If available, use a static-safe workstation.

• When not in use, store the equipment in

appropriate static-safe packaging.

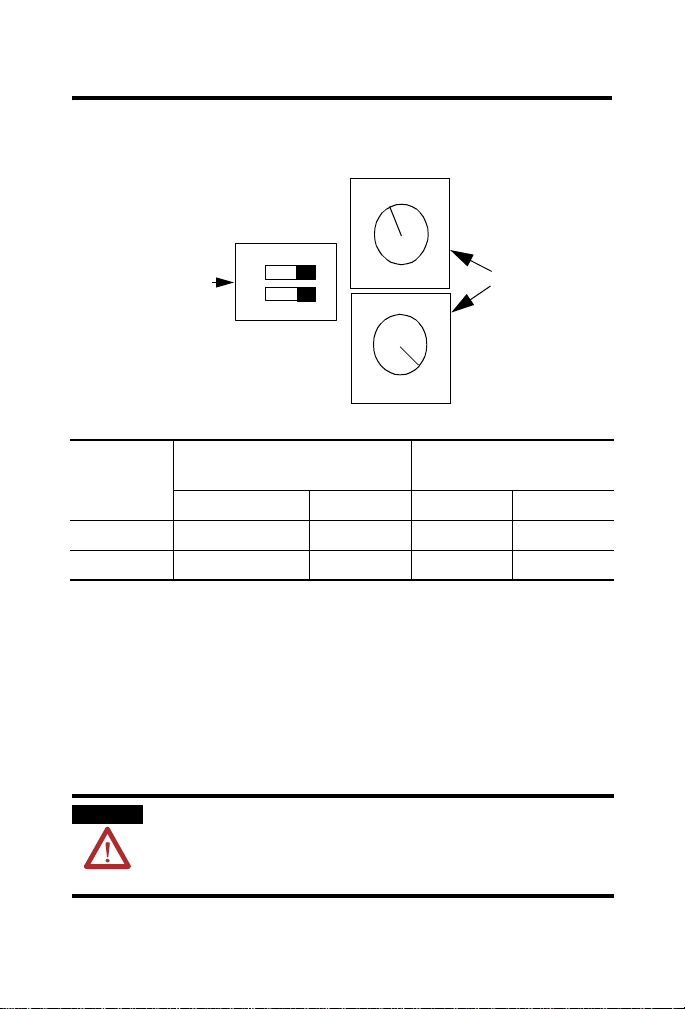

Set the Station Address on the Base Module

To set the station address, lift the door containing the status LEDs on the top

left side of the module. Adjust the switches located behind the door.

The rotary switches can be set between 00 and 99. Use the adjusting tool

provided in the package, or a small bladed screwdriver to rotate the switches.

The DIP switches are used for addresses between 100 and 125.

Publication

1791P-IN002B-EN-P - October 2003

Page 6

6 CompactBlock Distributed I/O on PROFIBUS DP Series D

The switches are read at module power up only.

View when looking into module.

3

2

10’s

1

4

100’s

DIP Switches

(100-125)

ON

0

9

1 2

1

0

9

1’s

5

6

8

7

3

2

4

5

6

8

7

Rotary Switches

Example: Node

Address is set at 26

(00-99)

43112

DIP Switches

Address

Position 1 Position 2 10’s 1’s

0-99 0 0 0-9 0-9

100-125 1 0 0-2 0-5

100’s

Rotary Switches

Mount the Block(s)

The base and expansion modules mount to a panel or DIN rail, which must

be grounded before installing the module(s).

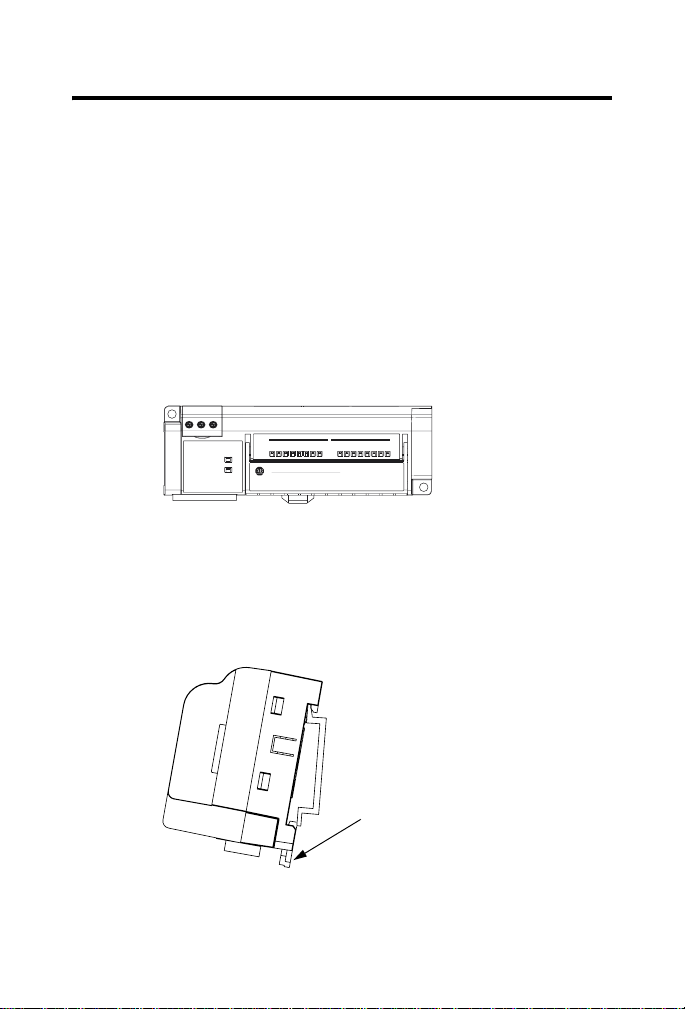

Base Module Mounting

You c a n install t h e Compact Block base module on a panel or DIN rail.

WARNING

Publication

1791P-IN002B-EN-P - October 2003

When used in a Class I, Division 2, hazardous

location, this equipment must be mounted in a suitable

enclosure with proper wiring method that complies

with the governing electrical codes.

Page 7

CompactBlock Distributed I/O on PROFIBUS DP Series D 7

Panel Mounting

1. Place the module against the panel where you want to mount it.

2. Drill holes in the panel that are aligned with mounting holes on the

module.

3. Place screws through each of the 2 mounting holes and tighten until

the module is firmly in place.

Base Module

141 mm

5.55 in

Module

Status

Network

Status

Profibus DP

01234567

Allen-Bradley

01234567

CompactBlock I/O

8 INPUTS / 8 OUTPUTS - DC POWER

1791P-8V8P

41 mm

1.6 in

43115

DIN Rail Mounting

1. Hook top of slot over the DIN Rail.

2. Pull down on the locking lever while pressing the block against the

rail.

Locking Lever

90358

3. Push up on the locking lever to secure the block to the rail when block

is flush against the rail.

Publication

1791P-IN002B-EN-P - October 2003

Page 8

8 CompactBlock Distributed I/O on PROFIBUS DP Series D

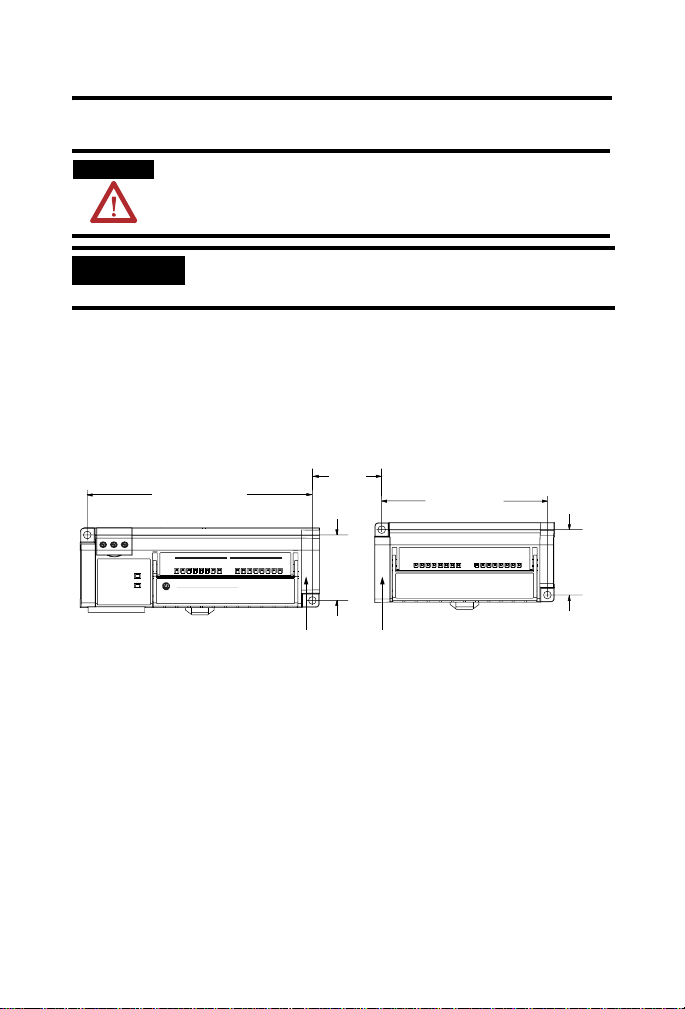

Connecting an Expansion Module to a Base Module

ATTENTION

Expansion blocks should not be installed when power

is applied to the base.

IMPORTANT

Carefully read the section “Word/Bit Definitions” on

page 18 to change produce and consume data sizes.

1. Remove the expansion covers from both the base and expansion

modules.

2. Position the expansion block with the proper spacing. See the

illustration below.

Module

Status

Network

Status

Profibus DP

Base Module Expansion Module

141 mm

5.55 in

01234567

01234567

Allen-Bradley

CompactBlock I/O

8 INPUTS / 8 OUTPUTS - DC POWER

25 mm

1 in

41 mm

1.6 in

1791P-8V8P

Expansion covers

104 mm

4.09 in

3. Mount expansion module using panel or DIN rail mounting, as

described in the previous section.

41 mm

1.6 in

43116

Publication

1791P-IN002B-EN-P - October 2003

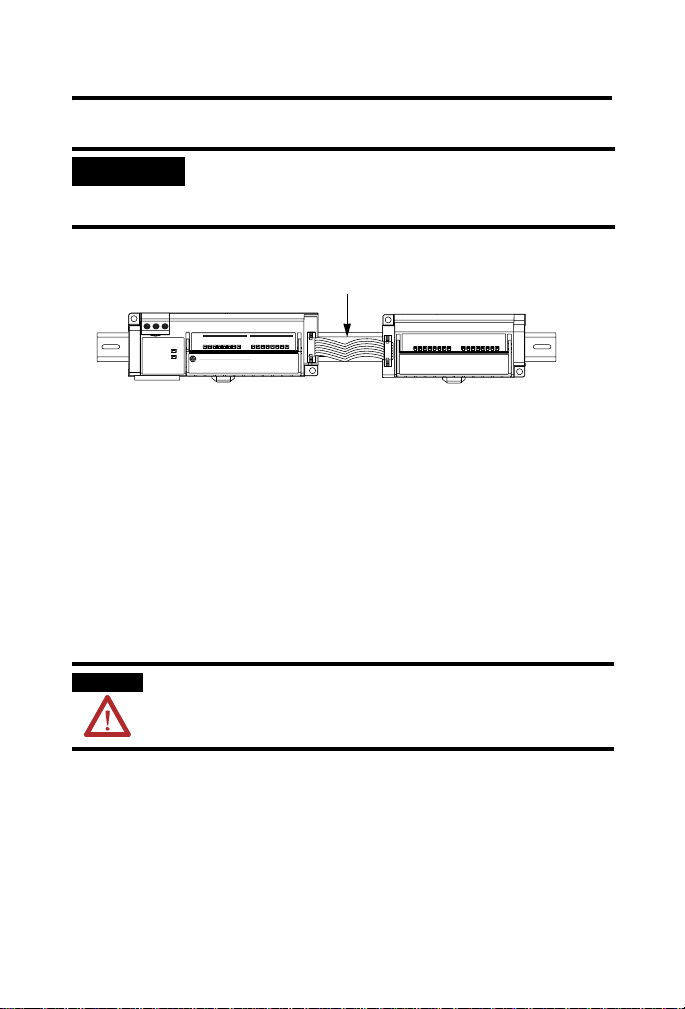

Page 9

CompactBlock Distributed I/O on PROFIBUS DP Series D 9

4. Plug the expansion cable into both the base and expansion modules.

IMPORTANT

The expansion cable can only be connected to the

modules such that the red stripe on the cable is on top as

shown below.

Red strip must be on top of ribbon cable.

01

67

01

Module

Status

Network

Status

Profibus DP

2345

Allen-Bradley

2345

CompactBlock I/O

1791P-8V8P

8 INPUTS / 8 OUTPUTS - DC POWER

67

43117

5. Replace the expansion covers on both modules.

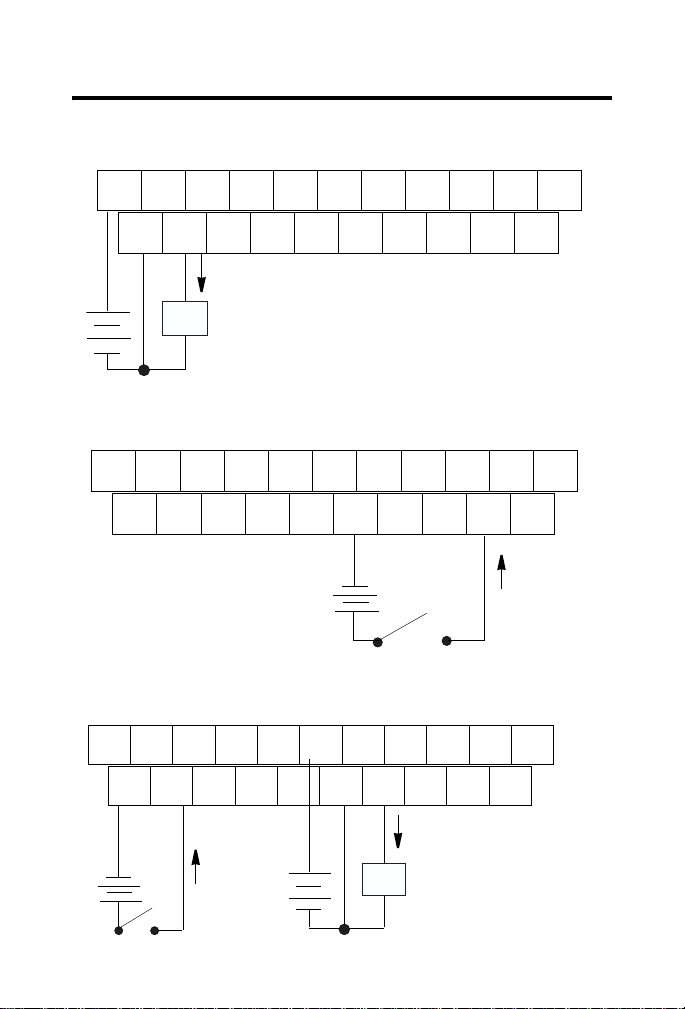

Connect the Input/Output Wires to the Block

Two sets of VDC+ and GND power pins are located on each terminal (one

for each bank of 8 points) except on the 1791P-4B4P module. The following

figures show the wiring information for both sinking and sourcing wiring.

Input and Output wiring use up to 14AWG (2mm

inch insulation.

WARNING

Use supply wires suitable for 30°C above surrounding

ambient.

2

) stranded (Cu) with 3/64

Publication

1791P-IN002B-EN-P - October 2003

Page 10

10 CompactBlock Distributed I/O on PROFIBUS DP Series D

Output Wiring Diagram for 1791P-0B16P and 1791D-0B16PX

Modules

V

DC

OUT 0 OUT 2

OUT 4

OUT 8OUT 6

OUT 10

V

DC

OUT 12 OUT 14

Not

Used

GND

OUT 1 OUT 3

OUT 5 OUT 7

GND

OUT 9

OUT 11 OUT 15OUT 13

+

Load

-

41669

Input Wiring Diagram for 1791P-16B0 and 1791D-16B0X Modules

V

DC

GND

IN 0 IN 2

IN 1 IN 3

IN 4

IN 5 IN 7

V

IN 8IN 6

IN 10

DC

IN 9

IN 12 IN 14

IN 11 IN 15IN 13GND

-

+

Not

Used

41671

Wiring Diagram for the 1791P-8B8P Module

V

DC

GND

IN 0 IN 2

IN 1 IN 3

IN 4

IN 5 IN 7

OUT 0IN 6

OUT 2

V

DC

GND

OUT 1

OUT 4 OUT 6

OUT 3 OUT 7OUT 5

Not

Used

-

+

Publication

+

Load

-

1791P-IN002B-EN-P - October 2003

41672

Page 11

CompactBlock Distributed I/O on PROFIBUS DP Series D 11

Wiring Diagram for the 1791P-4B4P Module

V

DC

IN 0 V

IN 2

DC

DC

OUT 0V

V

DC

GND

OUT 2 GND

Not

Used

GND

IN 1 V

IN 3 V

DC

+

-

GND

OUT 1

DC

+

GND GNDOUT 3

Load

-

Wiring Diagram for the 1791P-8V8P Module

V

IN 0 IN 2 OUT 0IN 6

DC

GND GND

IN 1 IN 3

+

-

IN 4

IN 5 IN 7

OUT 2

V

DC

OUT 1

-

OUT 4 OUT 6

OUT 3 OUT 7OUT 5

Load

+

Output Wiring Diagram for 1791D-0V16PX Modules

OUT 0 OUT 2

V

DC

GND

OUT 1 OUT 3

OUT 4

OUT 5 OUT 7

OUT 8OUT 6

OUT 10

V

DC

GND

OUT 9

OUT 12 OUT 14

OUT 11 OUT 15OUT 13

Not

Used

42344

Not

Used

42346

-

Load

+

Publication

1791P-IN002B-EN-P - October 2003

41726

Page 12

12 CompactBlock Distributed I/O on PROFIBUS DP Series D

Input Wiring Diagram for 1791D-16V0X Modules

V

DC

IN 0 IN 2

GND

IN 1 IN 3

IN 4

IN 5 IN 7

IN 8IN 6

IN 10

V

DC

GND

IN 9

IN 12 IN 14

IN 11 IN 15IN 13

Not

Used

+

-

41670

Connect the PROFIBUS DP Terminal Connector

Refer to the following information when connecting the PROFIBUS DP

terminal connector to the 1791P block I/O.

WARNING

If you connect or disconnect the PROFIBUS cable

with power applied to this module or any device on

the network, an electrical arc can occur. This could

cause an explosion in hazardous location installations.

Be sure that power is removed or the area is

nonhazardous before proceeding.

Publication

1791P-IN002B-EN-P - October 2003

Page 13

CompactBlock Distributed I/O on PROFIBUS DP Series D 13

1. Connect the PROFIBUS DP female 9-pin D-sub connector to the

terminal connector as shown below.

Module

Status

Network

Status

Profibus DP

Profibus DP

Allen-Bradley

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

Compact

8 INPUTS / 8 OUTPUTS . DC POWER

Block I/O

1791P-8V8P

31337-m

2. Connect the terminal connector to the Block. Use the side screws on

the terminal connector to fasten it to the Block.

Pin

Name: Description:

Number:

1 shield Shield, Protective Ground

2 M24V Minus 24V Output Voltage (Not used)

3 RxD/TxD-P Receive/Transmit-Data-P

4 CNTR-P Control-p

5 DGND Data Ground

6 VP Voltage-Plus

7 P24V Plus 24V Output Voltage (Not used)

8 RxD/TxD-N Receive/Transmit-Data-N

9 CNTR-N Control-N (Not used)

Publication

1791P-IN002B-EN-P - October 2003

Page 14

14 CompactBlock Distributed I/O on PROFIBUS DP Series D

Select Termination for the Module

The terminator resistor is provided in the connector. Use the DIP switches in

the connector to select termination for the module. Refer to the illustration

below.

VP (6)

390 ohm

SW in the connector

RxD/TxD-P (3)

RxD/TxD-N (8)

DGND (5)

220 ohm

390 ohm

Switch SW in the Connector

ON Terminator Connector

OFF No Terminator

43109

Base Module to Expansion Interface

The base module is linked to the expansion module with an 8-bit parallel bus,

control lines, Vcc and ground connections, a reset/initialization line, and an

expansion presence line. The 8-bit bus is multiplexed so that 16 bits of data (1

for each I/O point) can be transmitted/received with two transfers. The

reset/initialization line is used during initialization of the module. The

presence line is used for the detection of an expansion module at power up

and for a period of each data transfer. Module ID is read over this bus at

power up.

1791P modules supply expansion power via expansion bus as follows:

Expansion power voltage 5Vdc

Expansion power current 100mA

Publication

1791P-IN002B-EN-P - October 2003

Page 15

CompactBlock Distributed I/O on PROFIBUS DP Series D 15

Connect Power to the Module

To apply power to the 1791P module, refer to the illustration below.

Module power

connector

COM

GND

+24V

Pin Number Name

1 Com (24V dc return)

2 Gnd (Field ground)

3 +24V dc

43108

Remove the Terminal Block

WARNING

When you connect or disconnect the Removable

Terminal Block (RTB) with field side power applied,

an electrical arc can occur. This could cause an

explosion in hazardous location installations.

Be sure that power is removed or the area is

nonhazardous before proceeding.

Follow the directions below to remove the CompactBlock terminal block.

1. Unscrew the two retaining screws on the side of the terminal block.

Publication

1791P-IN002B-EN-P - October 2003

Page 16

16 CompactBlock Distributed I/O on PROFIBUS DP Series D

2. Lift the terminal block out of the base.

Retaining Screw

VDC

IN0

IN2

Retaining Screw

IN4

IN1

GND

IN6

IN3

IN5

VDC

IN8

IN7

IN10

IN12

GND

IN9

IN14

IN11

Not

IN13

Used

IN15

43111

Insert the Terminal Block

To in s e r t the C o m p a c t Block terminal block:

1. Insert the terminal block by aligning it and pushing it back until it

rests against the back of the module.

2. Tighten the retaining screws on each side of the terminal block until

the terminal block is firmly in place.

Communicate With the 1791P Module

Determine the Baud Rate for Your PROFIBUS Connection

All 1791P CompactBlock PROFIBUS I/O modules contain the autobaud

feature. Autobaud lets the modules automatically detect the baud rate for the

network upon connection to the live network.

Publication

1791P-IN002B-EN-P - October 2003

Page 17

CompactBlock Distributed I/O on PROFIBUS DP Series D 17

Refer to the following table for baud rate specifications.

Baud Rate Cable Length

9.6KBPS 1000m

19.2KBPS 1000m

45.45KBPS 1000m

93.75KBPS 1000m

187.5KBPS 1000m

500KBPS 400m

1.5MBPS 200m

3MBPS 100m

6MBPS 100m

12MBPS 100m

*Specified in PROFIBUS

Standard as 22AWG shielded

twisted pair cable.

Copper Cable*

The module produces 1 byte for every 8 inputs. Similarly, the module

consumes 1 byte for every 8 outputs.

IMPORTANT

When installing an expansion module, refer to the table

below to see how many bytes are produced and

consumed by the modules.

Remember, though, when configuring your CompactBlock I/O application,

these values are entered as bytes received (R

) and bytes transmitted (Tx) by

x

the scanner.

For example, a Base Input module produces 2 bytes and consumes 0 bytes. In

such a case, the scanner connected to the Base Input module will receive (Rx)

2 bytes and transmit (T

) 0 bytes.

x

Publication

1791P-IN002B-EN-P - October 2003

Page 18

18 CompactBlock Distributed I/O on PROFIBUS DP Series D

Word/Bit Definitions

The following table lists the combination of input and output modules and

the input and output bytes produced and consumed.

Digital Expander

Base Expansion I/O Points Produced

16 input 16 in 2 0

16 output 16 out 0 2

8 in / 8 out 8 in / 8 out 1 1

4 in / 4 out 4 in / 4 out 1 1

16 input 16 input 32 input 4 0

16 input 16 output 16 in / 16 out 2 2

16 output 16 input 16 in / 16 out 2 2

16 output 16 output 32 out 0 4

8 in / 8 out 16 input 24 in /8 out 3 1

8 in / 8 out 16 output 8 in / 24 out 1 3

4 in / 4 out 16 input 20 in / 4 out 3 1

4 in / 4 out 16 output 4 in / 20 out 1 3

Analog Expander

Base Expansion I/O Points Produced

16 input analog 16 input digital

16 output analog 16 output digital

8 in / 8 out analog 8 in / 8 out digital

4 in / 4 out analog 4 in / 4 out digital

4 in / 2 out analog

4 in / 2 out analog

4 in / 2 out analog

4 in / 2 out analog

(input bytes)

(input bytes)

12 4

10 6

12 6

12 6

Consumed

(output bytes)

Consumed

(output bytes)

Publication

1791P-IN002B-EN-P - October 2003

Page 19

CompactBlock Distributed I/O on PROFIBUS DP Series D 19

The following table is an example of the word/bit definitions for an

8 in/8 out combination module.

Bit 07 06 05 04 03 02 01 00

Produces I7 I6 I5 I4 I3 I2 I1 I0

Consumes O7 O6 O5 O4 O3 O2 O1 O0

The following table is an example of the word/bit definitions for an

8 in/8 out combination module that uses a 16 input expansion module.

Bit 07 06 05 04 03 02 01 00

Produces 0 I7 I6 I5 I4 I3 I2 I1 I0

Produces1 I15 I14 I13 I12 I11 I10 I9 I8

Produces 2 I23 I22 I21 I20 I19 I18 I17 I16

Consumes 0 O7 O6 O5 O4 O3 O2 O1 O0

The following table describes input and output bits used in both the example

tables above.

Byte Bit Description

Produces 0-2 00-07 Input Status bits - when the bit is set (1), the input is on.

Consumes 0 00-07 Output bits - when the bit is set (1), the output will be

Bit 00 corresponds to input I0, bit 01 corresponds to

input I1, bit 02 corresponds to input I2, and so forth.

turned on. Bit 00 corresponds to output O0, bit 01

corresponds to output O1, bit 02 to output O2, and so

forth.

The PROFIBUS configuration tools require a GSD file in order to configure

the module’s parameters. The GSD file can be found at the Web site

www.ab.com/networks/gsd/.

Publication

1791P-IN002B-EN-P - October 2003

Page 20

20 CompactBlock Distributed I/O on PROFIBUS DP Series D

Following are data tables for internal usage between base and expansion

modules.

Maximum Input Data Format (Base Modules -16B0 or -16V0)

Bit Position

Wor d 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 In15 In14 In13 In12 In11 In10 In9 In8 In7 In6 In5 In4 In3 In2 In1 In0 Base

1 Reserved Analog Input Data Channel 0

2 Reserved Analog Input Data Channel 1

3 Reserved Analog Input Data Channel 2

4 Reserved Analog Input Data Channel 3

5 URo1 URo0 ORo1 ORo0 OW3 OW2 OW1 OW0 ORi3 ORi2 ORi1 ORi0 Reserved RF UF

UF Module Unrecoverable Fault Set “0”: No Error Set “1”: Error

RF Module Recoverable Fault Set “0”: No Error Set “1”: Error

ORi x Over Range Input Channel Set “0”: No Over Range Set “1”: Over Range

OW x Input Open Wire (@ 4-20mA Range) Set “0”: No Open Wire Set “1”: Open Wire

ORo x Output Data Over Range Set “0”: No Over Range Set “1”: Over Range

URo x Output Data Under Range (@4-20mA Range) Set “0”: No Under Range Set “1”: Under Range

Maximum Output Data Format (Base Modules -0B16P or -0V16P)

Wor d

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 O15 O14 O13 O12 O11 O10 O9 O8 O7 O6 O5 O4 O3 O2 O1 O0 Base

1 Reserved Analog Output Data Channel 0

2 Reserved Analog Output Data Channel 1

3 OE HLS R IF IR3 IR2 IR1 IR0 IM3 IM2 IM1 IM0 OR1 OR0 OM1 OM0

OM x Output Mode Selection Set “0”: Voltage Mode Set “1”: Current Mode

OR x Output Range Selection on Current Mode Set “0”: 4-20mA Set “1”: 0-20mA

IM x Input Channel Mode Select Set “0”: Voltage Mode Set “1”: Current Mode

IR x Input Range Select on Current Mode Set “0”: 4-20mA Set “1”: 0-20mA

IF Input Filter Selection Set “0”: 50Hz Set “1”: 60Hz

R Reserved;

HLS HLS/OFF Set “0”: Output Reset Set “1”: Hold Last State

OE Output Enable Set “0”: Output Disabled Set “1”: Output Enabled

Bit Position

(Output is 0mA at 0-20mA mode and 4-20mA mode

and 0V at 0-10V mode wh en this bit is 0)

Publication

1791P-IN002B-EN-P - October 2003

Page 21

CompactBlock Distributed I/O on PROFIBUS DP Series D 21

Following are data tables on RSLogix500.

Maximum Input Data Format (Base Modules -16B0)

Bit Position

Wor d 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 In15 In14 In13 In12 In11 In10 In9 In8 In7 In6 In5 In4 In3 In2 In1 In0 Base

1 Reserved Analog Input Data Channel 0

2 Reserved Analog Input Data Channel 1

3 Reserved Analog Input Data Channel 2

4 Reserved Analog Input Data Channel 3

5 URo1 URo0 ORo1 ORo0 OW3 OW2 OW1 OW 0 ORi3 ORi2 OR i1 ORi0 Reserved RF UF

UF Module Unrecoverable Fault Set “0”: No Error Set “1”: Error

RF Module Recoverable Fault Set “0”: No Error Set “1”: Error

ORi x Over Range Input Channel Set “0”: No Over Range Set “1”: Over Range

OW x Input Open Wire (@ 4-20mA Range) Set “0”: No Open Wire Set “1”: Open Wire

ORo x Output Data Over Range Set “0”: No Over Range Set “1”: Over Range

URo x Output Data Under Range (@4-20MA Range) Set “0”: No Under Range Set “1”: Under Range

Bit 12-15 are not used to display correct data on the tool at decimal data type

Maximum Output Data Format (Base Modules -16B0)

Bit Position

Wor d 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 Reserved Analog Output Data Channel 0

1 Reserved Analog Output Data Channel 1

Maximum Input Data Format (Base Modules -0B16P)

Bit Position

Wor d 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 Reserved Analog Input Data Channel 0

1 Reserved Analog Input Data Channel 1

2 Reserved Analog Input Data Channel 2

3 Reserved Analog Input Data Channel 3

4 URo1 URo0 ORo1 ORo0 OW3 OW2 OW1 OW0 ORi3 ORi2 ORi1 ORi0 Reserv ed RF UF

UF Module Unrecoverable Fault Set “0”: No Error Set “1”: Error

RF Module Recoverable Fault Set “0”: No Error Set “1”: Error

ORi x Over Range Input Channel Set “0”: No Over Range Set “1”: Over Range

OW x Input Open Wire (@ 4-20mA Range) Set “0”: No Open Wire Set “1”: Open Wire

ORo x Output Data Over Range Set “0”: No Over Range Set “1”: Over Range

URo x Output Data Under Range (@4-20MA Range) Set “0”: No Under Range Set “1”: Under Range

Publication

1791P-IN002B-EN-P - October 2003

Page 22

22 CompactBlock Distributed I/O on PROFIBUS DP Series D

Maximum Output Data Format (Base Modules -0B16P)

Bit Position

Wor d 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 O15 O14 O13 O12 O11 O10 O9 O8 O7 O6 O5 O4 O3 O2 O1 O0 Base

1 Reserved Analog Output Data Channel 0

2 Reserved Analog Output Data Channel 1

Maximum Input Data Format (Base Modules -8B8P or -8V8P)

Bit Position

Wor d 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 Reserved In7 In6 In5 In4 In3 In2 In1 In0 Base

1 Reserved Analog Input Data Channel 0

2 Reserved Analog Input Data Channel 1

3 Reserved Analog Input Data Channel 2

4 Reserved Analog Input Data Channel 3

5 URo1 URo0 ORo1 ORo0 OW3 OW2 OW1 OW 0 ORi3 ORi2 OR i1 ORi0 Reserved RF UF

UF Module Unrecoverable Fault Set “0”: No Error Set “1”: Error

RF Module Recoverable Fault Set “0”: No Error Set “1”: Error

ORi x Over Range Input Channel Set “0”: No Over Range Set “1”: Over Range

OW x Input Open Wire (@ 4-20mA Range) Set “0”: No Open Wire Set “1”: Open Wire

ORo x Output Data Over Range Set “0”: No Over Range S et “1”: Over Range

URo x Output Data Under Range (@4-20MA Range) Set “0”: No Under Range Set “1”: Under Range

Maximum Output Data Format (Base Modules -8B8P or -8V8P)

Bit Position

Wor d

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 Reserved O7 O6 O5 O4 O3 O2 O1 O0 Base

1 Reserved Analog Output Data Channel 0

2 Reserved Analog Output Data Channel 1

Publication

1791P-IN002B-EN-P - October 2003

Page 23

CompactBlock Distributed I/O on PROFIBUS DP Series D 23

Maximum Input Data Format (Base Modules -4B4P)

Bit Position

Wor d 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 Reserved In3 In2 In1 In0 Base

1 Reserved Analog Input Data Channel 0

2 Reserved Analog Input Data Channel 1

3 Reserved Analog Input Data Channel 2

4 Reserved Analog Input Data Channel 3

5 URo1 URo0 ORo1 ORo0 OW3 OW2 OW1 OW 0 ORi3 ORi2 OR i1 ORi0 Reserved RF UF

UF Module Unrecoverable Fault Set “0”: No Error Set “1”: Error

RF Module Recoverable Fault Set “0”: No Error Set “1”: Error

ORi x Over Range Input Channel Set “0”: No Over Range Set “1”: Over Range

OW x Input Open Wire (@ 4-20mA Range) Set “0”: No Open Wire Set “1”: Open Wire

ORo x Output Data Over Range Set “0”: No Over Range Set “1”: Over Range

URo x Output Data Under Range (@4-20MA Range) Set “0”: No Under Range Set “1”: Under Range

Maximum Output Data Format (Base Modules -4B4P)

Bit Position

Wor d

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 Reserved O3 O2 O1 O0 Base

1 Reserved Analog Output Data Channel 0

2 Reserved Analog Output Data Channel 1

Publication

1791P-IN002B-EN-P - October 2003

Page 24

24 CompactBlock Distributed I/O on PROFIBUS DP Series D

Troubleshoot with the Indicators

The 1791P I/O module has the following indicators:

• Module Status indicator - base only

• Network Status indicator - base only

• I/O Status indicators - base and expansion

Module Status Indicator

Indication: Status:

Off No power

Green Module operating correctly

Red Hardware or software error

Flashing Red Communication failure

Flashing Red/Orange Expansion error

Network Status Indicator

Indication: Stat us:

Off Network offline

Yellow Network online

I/O Status Indicators

Function Indicator Module

Outputs Each output:

Inputs Each Input:

Publication

Yellow

Yellow

1791P-IN002B-EN-P - October 2003

Illumination

None

Yellow

None

Yellow

Condition

Output not energized

Output energized

No valid input

Valid input

Page 25

CompactBlock Distributed I/O on PROFIBUS DP Series D 25

Specifications

Sinking or Sourcing Input Specifications

Inputs per block groups of 4 or 8

Off-state Voltage 5V dc maximum

On-state Voltage 30V dc @ 40×C maximum

Off-state Current 1.5mA minimum

On-state Current 11mA @ 30V dc maximum

Sinking or Sourcing Output Specifications

Outputs per block groups of 4 or 8

On-state Voltage Range 10 - 30V dc

On-state Voltage Drop 0.5V dc @ rated current

On-state Current 0.5A maximum

Off-state Leakage 1.0mA maximum

Module Current (per output) 0.5A maximum

Surge Current - for 10 mS

repeatable every 2 S

PROFIBUS DP Specifications

Network Protocol PROFIBUS-DP (EN50170)

Redundancy Not supported

Repeater Control Signal RS485 signal

Implementation Type DPC31

Freeze Mode Supported

Sync Mode Supported

Auto Baud Rate Supported

25V dc @ 60×C maximum

10V dc minimum

2mA @ 10V dc minimum

1.0A maximum

• Communication of the slave with a Class 1 master

• Communication of the slave with a Class 2 master

Publication

1791P-IN002B-EN-P - October 2003

Page 26

26 CompactBlock Distributed I/O on PROFIBUS DP Series D

PROFIBUS DP Specifications (continued)

Fail Safe Mode

Station Type Slave

FMS Support Not supported

Number of nodes 125 maximum

Network Length/

Communication rate

General Specifications

Indicators Module status - red/green/orange

Isolation

Auxiliary I/O power to PROFIBUS

I/O group-to-group

I/O group-to-PROFIBUS

PROFIBUS DP Power Voltage

Expansion Power Voltage

Auxiliary Power Inputs

Voltage

Current

Auxiliary Power Outputs

Voltage

Current

Base Module Dimensions 150mm X 50mm X 38mm

Expansion Module Dimensions 115mm X 50mm X 38mm

Current

Current

1

Supported

9.6KBPS @ 1000m (3280ft)

19.2KBPS @ 1000m (3280ft)

45.45KBPS @ 1000m (3280ft)

93.75KBPS @ 1000m (3280ft)

187.5KBPS @ 1000m (3280ft)

500KBPS @ 400m (1312ft)

3MBPS @ 100m (328ft)

6MBPS @ 100m (328ft)

12MBPS @ 100m (328ft)

Network status - yellow

I/O status - yellow

Type tested to 500V ac for 60 seconds

Type tested to 500V ac for 60 seconds

Type tested to 500V ac for 60 seconds

18 - 26.4V dc

250mA maximum (with expansion)

5V dc

100mA

10-30V dc

88mA each group of 8

10-30V dc

4A each group of 8

5.91in X 1.97in X 1.5in

4.4in X 1.97in X 1.5in

Publication

1791P-IN002B-EN-P - October 2003

Page 27

CompactBlock Distributed I/O on PROFIBUS DP Series D 27

General Specifications (continued)

Operating Temperature IEC 60068-2-1 (Test Ad, Operating Cold),

Field Wiring Tightening Torque 5-7lb-in. (0.5-0.6 Nm)

Storage Temperature IEC 60068-2-1 (Test Ab, Un-packaged Non-operating

Relative Humidity IEC 60068-2-30 (Test Db, Un-packaged Non-operating

Shock IEC60068-2-27 (Test Ea, Unpackaged Shock):

Vibration IEC60068-2-6 (Test Fc, Operating):

Conductors Wire Size

Category

ESD Immunity IEC 61000-4-2:

Radiated RF Immunity IEC 61000-4-3:

EFT/B Immunity IEC 61000-4-4:

Surge Transient Immunity IEC 61000-4-5:

Conducted RF Immunity IEC 61000-4-6:

Emissions CSPR 11:

IEC 60068-2-2 (Test Bd, Operating Dry Heat),

IEC 60068-2-14 (Test Nb, Operating Thermal Shock):

0 to 60°C (32 to 140°F)

Cold),

IEC 60068-2-2 (Test Bb, Un-packaged Non-operating Dry

Heat),

IEC 60068-2-14 (Test Na, Un-packaged Non-operating

Thermal Shock):

–40 to 85°C (–40 to 185°F)

Damp Heat):

5-95% non-condensing

Operating 30g

Non-operating 50g

5g @ 10-500Hz

14 gauge (2mm2) stranded maximum

3/64 inch insulation maximum

2, 3

2

6kV contact discharge

8kV air discharge

10V/m with 1kHz sine-wave 80%AM from 80MHz to

1000MHz

10V/m with 200Hz 50% Pulse 100%AM at 900Mhz

±2kV at 5kHz on signal ports

±2kV at 5kHz on communications ports

±1kV line-line(DM) and ±2kV line-earth(CM) on signal

ports

±2kV line-earth(CM) on shielded ports

10Vrms with 1kHz sine-wave 80%AM from 150kHz to

80MHz

Group 1, Class A

Publication

1791P-IN002B-EN-P - October 2003

Page 28

28 CompactBlock Distributed I/O on PROFIBUS DP Series D

General Specifications (continued)

Enclosure Meets IP20

Certifications:

(when product is marked)

1. Dependant upon the scanner module being used. For example, the SST Scanner (cat. no.

SST-PFB-SLC) does not fully support Fail Safe Mode, as it only resets outputs to 0. You

cannot define behavior such as Hold Last State or Fault Value with the SST scanner.

2. You use this conductor category information for planning conductor routing as described in

the system level installation manual.

3. See pub. 1770-4.1, Programmable Controller Wiring and Grounding Guidelines

4. See the Product Certification link at www.ab.com for Declarations of Conformity,

Certificates, and other certification details.

IMPORTANT

c-UL-us UL Listed Industrial Control Equipment,

certified for US and Canada

c-UL-us UL Listed for Class I, Division 2 Group

A,B,C,D Hazardous Locations, certified

for U.S. and Canada

4

CE

Directive, compliant with:

C-Tick4Australian Radiocommunications Act,

compliant with:

European Union 89/336/EEC EMC

EN 61000-6-4; Industrial Emissions

EN 50082-2; Industrial Immunity

EN 61326; Meas./Control/Lab.,

Industrial Requirements

61000-6-2; Industrial Immunity

AS/NZS CISPR 11; Industrial Emissions

Input and output wiring must be in accordance with

Class 1, Division 2 wiring methods and in accordance

with the authority having jurisdiction.

Publication

1791P-IN002B-EN-P - October 2003

Page 29

CompactBlock Distributed I/O on PROFIBUS DP Series D 29

T

North American Hazardous Location Approval

The following information applies when

operating this equipment in hazardous

locations:

Products marked “CL I, DIV 2, GP A, B, C, D”

are suitable for use in Class I Division 2 Groups

A, B, C, D, Hazardous Locations and

nonhazardous locations only. Each product is

supplied with markings on the rating nameplate

indicating the hazardous location temperature

code. When combining products within a system,

the most adverse temperature code (lowest “T”

number) may be used to help determine the

overall temperature code of the system.

Combinations of equipment in your system are

subject to investigation by the local Authority

Having Jurisdiction at the time of installation.

The following information applies when

operating this equipment in hazardous

locations:

WARNING

EXPLOSION HAZARD

• Do not disconnect

equipment unless power

has been removed or the

area is known to be

nonhazardous.

• Do not disconnect

connections to this

equipment unless power

has been removed or the

area is known to be

nonhazardous. Secure any

external connections that

mate to this equipment by

using screws, sliding

latches, threaded

connectors, or other

means provided with this

product.

• Substitution of

components may impair

suitability for Class I,

Division 2.

• If this product contains

batteries, they must only

be changed in an area

known to be

nonhazardous.

Informations sur l’utilisation de cet équipement en

environnements dangereux :

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne

conviennent qu’à une utilisation en environnements de

Classe I Division 2 Groupes A, B, C, D dangereux et non

dangereux. Chaque produit est livré avec des marquages

sur sa plaque d’identification qui indiquent le code de

température pour les environnements dangereux.

Lorsque plusieurs produits sont combinés dans un

système, le code de température le plus défavorable

(code de température le plus faible) peut être utilisé pour

déterminer le code de température global du système.

Les combinaisons d’équipements dans le système sont

sujettes à inspection par les autorités locales qualifiées

au moment de l’installation.

Informations sur l’utilisation de cet équipement en

environnements dangereux :

AVERTISSEMEN

RISQUE D’EXPLOSION

• Couper le courant ou

• Couper le courant ou

• La substitution de

• S’assurer que

s’assurer que

l’environnement est classé

non dangereux avant de

débrancher l'équipement.

s'assurer que

l’environnement est classé

non dangereux avant de

débrancher les

connecteurs. Fixer tous les

connecteurs externes reliés

à cet équipement à l'aide de

vis, loquets coulissants,

connecteurs filetés ou

autres moyens fournis avec

ce produit.

composants peut rendre cet

équipement inadapté à une

utilisation en

environnement de Classe I,

Division 2.

l’environnement est classé

non dangereux avant de

changer les piles.

Publication

1791P-IN002B-EN-P - October 2003

Page 30

30 CompactBlock Distributed I/O on PROFIBUS DP Series D

Notes:

Publication

1791P-IN002B-EN-P - October 2003

Page 31

Notes:

CompactBlock Distributed I/O on PROFIBUS DP Series D 31

Publication

1791P-IN002B-EN-P - October 2003

Page 32

Rockwell Automation Support

Rockwell Automation provides technical information on the web to assist you in using

our products. At http://support.rockwellautomation.com, you can find technical

manuals, a knowledge base of FAQs, technical and application notes, sample code and

links to software service packs, and a MySupport feature that you can customize to

make the best use of these tools.

For an additional level of technical phone support for installation, configuration and

troubleshooting, we offer TechConnect Support programs. For more information,

contact your local distributor or Rockwell Automation representative, or visit

http://support.rockwellautomation.com.

Installation Assistance

If you experience a problem with a hardware module within the first 24 hours of

installation, please review the information that's contained in this manual. You can also

contact a special Customer Support number for initial help in getting your module up

and running:

United States 1.440.646.3223 Monday – Friday, 8am – 5pm EST

Outside United States Please contact your local Rockwell Automation representative for any

New Product Satisfaction Return

Rockwell tests all of our products to ensure that they are fully operational when shipped

from the manufacturing facility. However, if your product is not functioning and needs

to be returned:

United States Contact your distributor. You must provide a Customer Support case

Outside United States Please contact your local Rockwell Automation representative for

CompactBlock is a trademark of Rockwell Automation, Allen-Bradley, Inc.

technical support issues.

number (see phone number above to obtain one) to your distributor in

order to complete the return process.

return procedure.

Publication 1791P-IN002B-EN-P - October 2003 PN 957831-15

Supersedes Publication 1791P-IN002A-EN-P - June 2003 Copyright © 2003 Rockwell Automation, Inc. All rights reserv ed. Printed in the U.S.A.

Loading...

Loading...