Page 1

Installation Instructions

AC (24V) Output Module

Cat. No. 1771-OND Series B

To The Installer

Preinstallation

Considerations

European Union Directive Compliance

This document provides information on:

• important pre-installation considerations

• power supply requirements

• installing the module

• setting the fault mode

• using the indicators for troubleshooting

• replacing the fuses

• module specifications

This module must be used with a 1771-A1B thru -A4B or later I/O

chassis. If you are using a 1771-ASB remote I/O adapter you may

use any combination of I/O modules. Otherwise, make sure no other

output module or single card block transfer module is placed in the

same I/O group.

If this product has the CE mark it is approved for installation within

the European Union and EEA regions. It has been designed and

tested to meet the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards,

in whole or in part, documented in a technical construction file:

• EN 50081-2EMC – Generic Emission Standard, Part 2 –

Industrial Environment

• EN 50082-2EMC – Generic Immunity Standard, Part 2 –

Industrial Environment

This product is intended for use in an industrial environment.

Publication 17715.41 - May 1996

Page 2

AC (24V) Output Module2

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC

Low Voltage, by applying the safety requirements of EN 61131–2

Programmable Controllers, Part 2 – Equipment Requirements and

Tests.

For specific information required by EN 61131-2, see the appropriate

sections in this publication, as well as the following Allen-Bradley

publications:

• Industrial Automation Wiring and Grounding Guidelines For

Noise Immunity, publication 1770-4.1

• Guidelines for Handling Lithium Batteries, publication AG-5.4

• Automation Systems Catalog, publication B111

Power Requirements

Initial Handling

Your module receives its power through the 1771 I/O chassis

backplane from the chassis power supply. The module requires

700mA from the output of this supply. Add this to the requirements

of all other modules in the I/O chassis to prevent overloading the

chassis backplane and/or backplane power supply.

The ac output module is shipped in a static-shielded bag to guard

against electrostatic discharge damage. Observe the following

precautions when handling the module.

Electrostatic Discharge Damage

ATTENTION: Under some conditions, electrostatic

discharge can degrade performance or damage the

!

module. Observe the following precautions to guard

against electrostatic damage.

• Wear an approved wrist strap grounding device, or touch a

grounded object to discharge yourself before handling the

module.

• Do not touch the backplane connector or connector pins.

• If you configure or replace internal components, do not touch

other circuit components inside the module. If available, use a

static-free work station.

• When not in use, keep the module in a static-shielded bag.

Publication

17715.41 - May 1996

Page 3

AC (24V) Output Module 3

Installing Your Module

In this section we tell you how to set the fault mode selection plug,

key your I/O chassis, install your module and make your wiring

connections.

Fault Mode Selection

You may select one of two output-failure configurations (last state or

reset) by positioning a configuration plug on the bottom edge of the

printed circuit board. This configuration plug is independent of the

last state switch on the I/O chassis backplane.

To set the fault mode selection, proceed as follows:

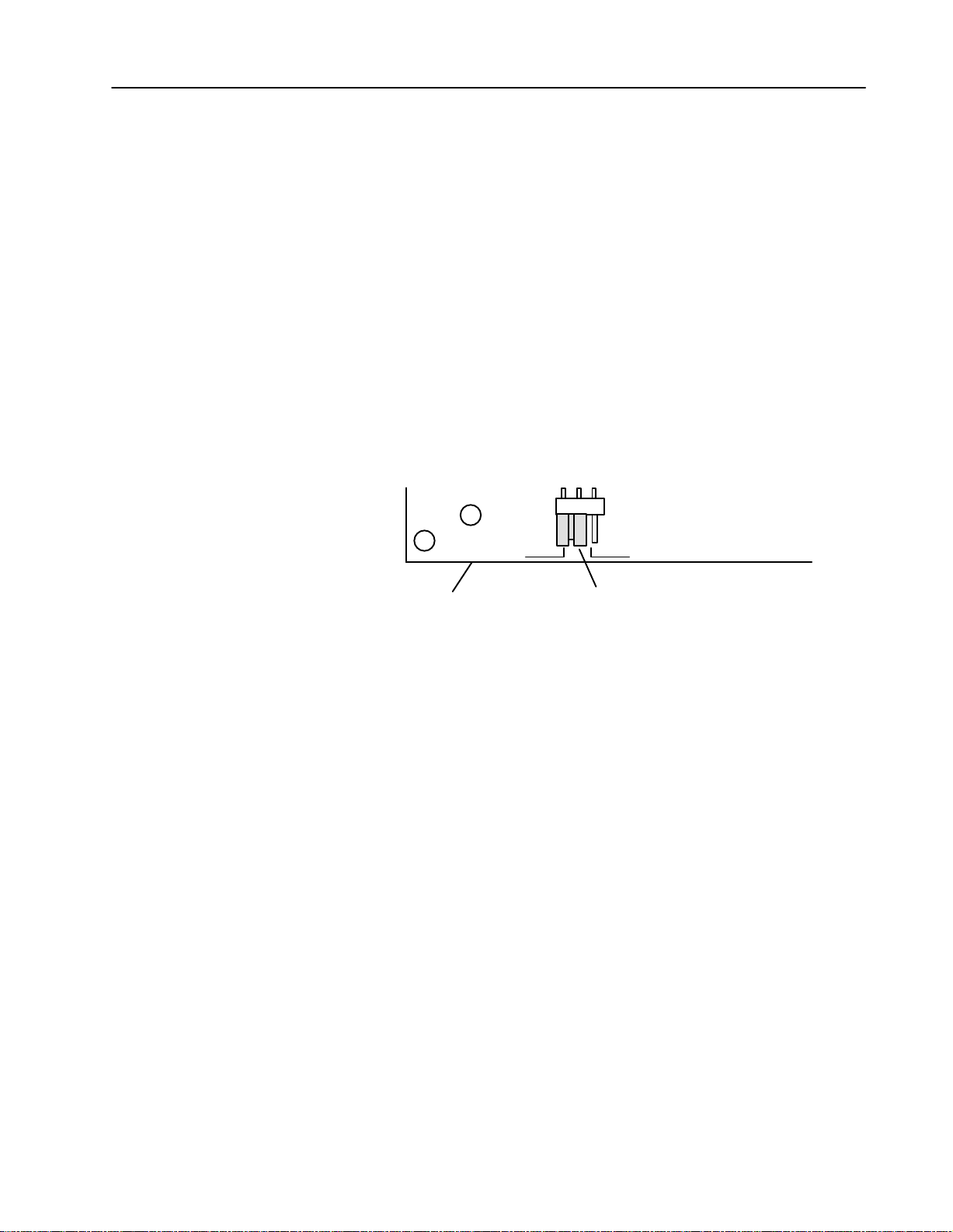

1. Locate the fault mode selection plug at the bottom edge of the

module circuit board (Figure 1).

Figure 1

Mode Selection Plug

Fault

LS RESET

Bottom edge of circuit board

Fault Mode Selection Plug

(shown in last state position)

10673-I

2. Using your finger, slide the plug off the two posts.,

3. Carefully position the plug on two of the three posts that

correspond to your requirement.

Keying Your I/O Chassis

Use the plastic keying bands, shipped with each I/O chassis, to key

the I/O slots to accept only this type of module.

The module circuit board is slotted in two places on the rear edge.

The position of the keying bands on the backplane connector must

correspond to these slots to allow insertion of the module. You can

key any connector in an I/O chassis to receive this module except for

the left-most connector reserved for adapter or processor modules.

Place keying bands between the following numbers labeled on the

backplane connector:

• Between 20 and 22

• Between 32 and 34

You can change the position of these keys if system redesign and

rewiring makes insertion of a different module necessary.

Publication

17715.41 - May 1996

Page 4

AC (24V) Output Module4

Installing the Output Module

To install the ac output module in your 1771 I/O chassis, follow the

steps listed below.

ATTENTION: Remove power from the 1771 I/O

chassis backplane and wiring arm before removing or

!

installing the module.

• Failure to remove power from the backplane or field

wiring arm could cause module damage, degradation

of performance, or injury.

• Failure to remove power from the backplane could

cause injury or equipment damage due to possible

unexpected operation.

1. Turn off power to the I/O chassis.

2. Place the module in the plastic tracks on the top and bottom of the

slot that guides the module into position.

3. Do not force the module into its backplane connector. Apply firm,

even pressure on the module to seat it properly.

4. Snap the chassis latch over the top of the module to secure its

position.

5. Connect the wiring arm to the module.

6. Make wiring connections to the field wiring arm as indicated in

Figure 2.

Publication

17715.41 - May 1996

Page 5

AC (24V) Output Module 5

Connecting Wiring to the Output Module

Connections to the output module are made to the field wiring arm

(cat. no. 1771-WH) shipped with the module. An optional fused

wiring arm is available (cat. no. 1771-WHF) which provides

individual fusing for each circuit. Attach the wiring arm to the pivot

bar on the bottom of the I/O chassis. The wiring arm pivots upward

and connects with the module so you can install or remove the

module without disconnecting the wires.

You must supply ac (L1) at terminals A through D on the wiring

arm. You need four ac connections to accommodate the total

required surge rating on the module without overstressing any single

connection on the field wiring arm. Jumper all ac (L1) connections

together to prevent module damage.

Figure 2

Connection

Diagram

Terminal A

Terminal B

Terminal C

Terminal D

Output 00

Output 01

Output 02

Output 03

Output 04

Output 05

Output 06

Output 07

Output 10

Output 11

Output 12

Output 13

Output 14

Output 15

Output 16

Output 17

Terminal E

A

B

C

D

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

E

(Actual wiring runs in this direction.)

L1

24V ac

Output

Device

L2

ac Low

10674I

Publication

17715.41 - May 1996

Page 6

AC (24V) Output Module6

Important: You can use an AC (24V) Output Module (cat. no.

1771-OND) to directly drive terminals on an AC (24V)

Input Module (cat. no. 1771-IND) (Figure 3). You can

also use a 1771-OND Output module to drive an AC

(24V) Input Module (cat. no. 1771-IN) but you must

connect a 250 ohm, 5W resistor between the output

terminal and L2 (common) as shown in Figure 3. Use

the same ac power source to power both modules to

ensure proper phasing and prevent module damage.

Figure 3

an Input Module with an Output Module

Driving

AC (24V)

Output Module

(Cat. No. 1771OND)

L1

24V ac High

AC (24V)

Input Module

(Cat. No. 1771IND)

AC (24V)

Output Module

(Cat. No. 1771OND)

AC (24V)

Input Module

(Cat. No. 1771IN)

L1

24V ac High

250 ohm 5W

resistor

Publication

ac Low

Note: 1771OND output voltage

range is 1060V ac. However, the

onstate voltage range of the

1771IND is 1929V ac.

17715.41 - May 1996

L2

L2

L2

ac Low

Note: 1771OND output voltage

range is 1060V ac. However, the

onstate voltage range of the

1771IN is 1228V ac.

Page 7

AC (24V) Output Module 7

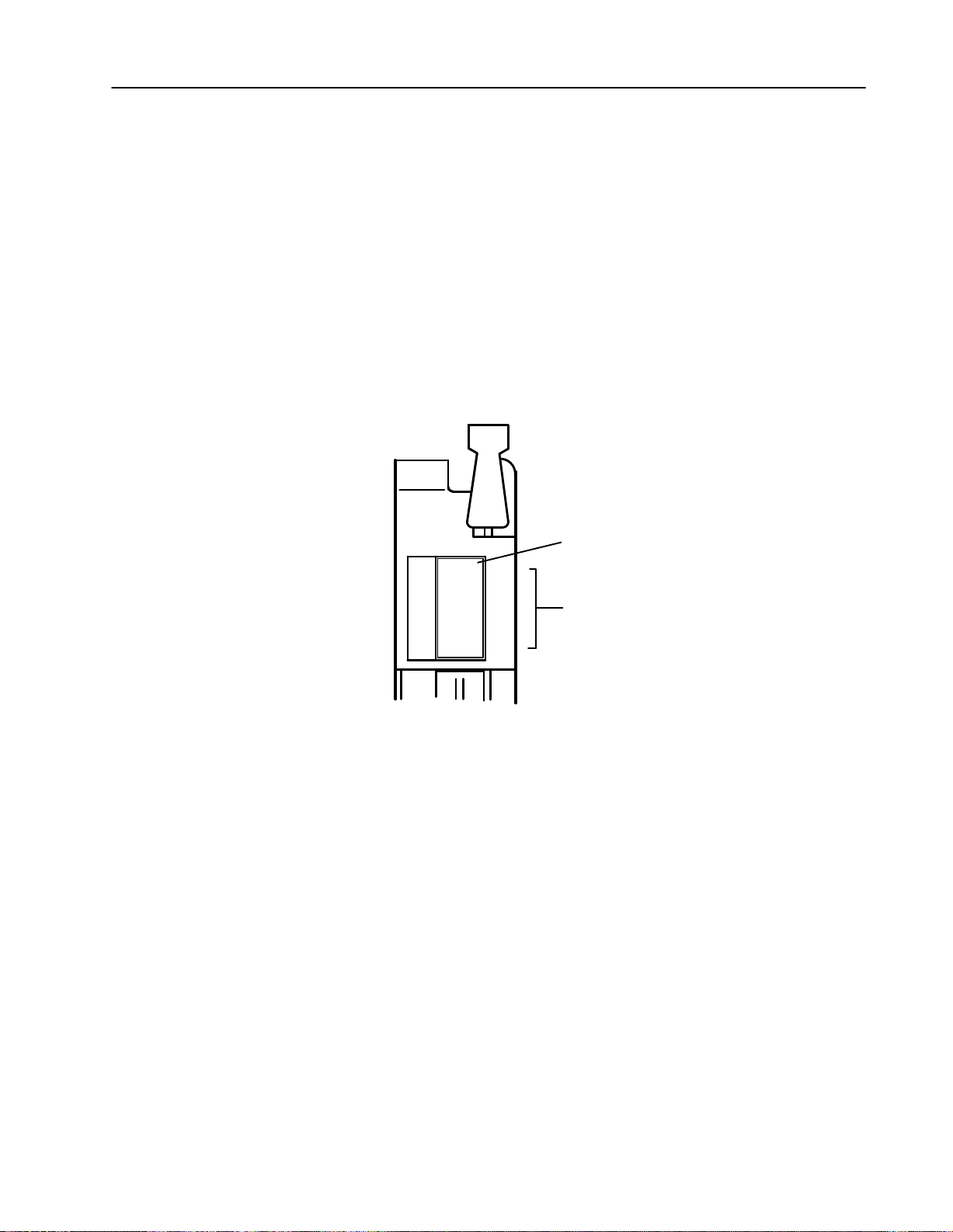

Interpreting the Status Indicators

The front panel of your module contains one green, module active

indicator, and 16 red status indicators (Figure 4). The 1771-OND

performs diagnostics in a handshaking mode when first powered up.

Upon successful completion of the diagnostics, the green module

active indicator lights. It turns off if a fault occurs in the data paths

or the opto-isolators.

The red status indicators are provided for system logic side

indication of individual inputs. When a red indicator lights, voltage

is present on the terminal. The module transfers this information to

the backplane for the processor to read.

Figure 4

Indicators

Status

Module Active Indicator (green)

ACTIVE

00

10

01

11

02

12

03

13

04

14

05

15

06

16

07

17

00 to 17 Status Indicators (red)

10676I

Publication

17715.41 - May 1996

Page 8

AC (24V) Output Module8

Replacing the Fuse

The module’s output circuitry is protected from overload or shorts by

a fuse. You can replace the fuse as outlined below.

1. Turn off all power to the I/O chassis and all output device power

to the field wiring arm.

ATTENTION: Remove power from the 1771 I/O

chassis backplane and wiring arm before removing or

!

installing the module.

• Failure to remove power from the backplane or field

wiring arm could cause module damage, degradation

of performance, or injury.

• Failure to remove power from the backplane could

cause injury or equipment damage due to possible

unexpected operation.

2. Pivot the wiring arm away from the module and remove the

module from the chassis.

3. Replace the blown fuse with a 10A, 250V rectifier fuse (1/4 x

1-1/4 inch), Littelfuse part number 322010.

4. Replace the module in the chassis and attach the field wiring arm.

Publication

17715.41 - May 1996

Page 9

AC (24V) Output Module 9

Troubleshooting

If a problem occurs, follow the procedure listed below.

Modules with Internal Fuses Only

1. Turn off all power to the I/O chassis and all output device power

to the field wiring arm.

ATTENTION: Remove power from the 1771 I/O

chassis backplane and wiring arm before removing or

!

installing the module.

• Failure to remove power from the backplane or field

wiring arm could cause module damage, degradation

of performance, or injury.

• Failure to remove power from the backplane could

cause injury or equipment damage due to possible

unexpected operation.

2. Pivot the wiring arm away from the module and remove the

module from the chassis.

3. Replace the blown fuse with a 10A, 250V rectifier fuse (1/4 x

1-1/4 inch), Littelfuse part number 322010.

4. Replace the module in the chassis and attach the field wiring arm.

5. Turn OFF all outputs to the module.

6. Turn ON power to the I/O chassis only.

7. Check that the red status indicators on the front of the module

(Figure 4) are off (no outputs on). Make sure the red fuse blown

indicator is off.

8. Turn on output device power to the field wiring arm.

9. Start with bit 00 and turn on individual outputs one at a time.

Turn off the previous output before turning on the next output.

10.If the red fuse blown indicator turns on, note which output is

faulty and trace the output wiring to the faulty device.

After correcting the fault problem, return to step 1 and begin again.

If you cannot locate a faulty output, return to step 9 and turn on 2 or

more outputs at the same time. Total output current should not

exceed 2A per output, or 8A total per module.

Publication

17715.41 - May 1996

Page 10

AC (24V) Output Module10

Modules with External Fuses Only

1. Turn off all power to the I/O chassis and all output device power

to the field wiring arm.

2. Pivot the wiring arm away from the module.

3. Use a continuity checker (meter in low ohms setting) to check

fuses for an open (high resistance) reading.

4. Note if fuse is open and trace the output wiring back to the output

device.

5. Check the remaining fuses (refer to step 3).

6. After all faulty fuses are replaced and any wiring problems

solved, reposition the wiring arm on the module.

7. Turn off all outputs to the module.

8. Turn on power to the I/O chassis.

9. Check that the red status indicators on the front of the module are

off (no outputs on). Make sure the red fuse blown indicator is off.

10.Turn on output device power to the wiring arm.

11. Start with bit 00 and turn on individual outputs one at a time.

Turn off last output before turning on the next output.

12.If the red fuse blown indicator lights, note which output is faulty

and trace the output wiring to the faulty device.

After correcting the fault problem, return to step 1 and begin again.

If you cannot locate a faulty output, return to step 8 and turn on 2 or

more outputs at the same time. Total output current should not

exceed 2A per output, or 8A per module.

Publication

17715.41 - May 1996

Page 11

AC (24V) Output Module 11

CSA Hazardous Location Approval Approbation d'utilisation dans des emplacements dangereux par la

CSA certifies products for general use as well as for use in

hazardous locations. Actual CSA certification is indicated by the

product label as shown below, and not by statements in any user

documentation.

Example of the CSA certification product label Exemple d'étiquette de certification d'un produit par la CSA

To comply with CSA certification for use in hazardous locations, the

following information becomes a part of the product literature for

CSAcertified AllenBradley industrial control products.

• This equipment is suitable for use in Class I, Division 2,

Groups A, B, C, D, or nonhazardous locations only.

• The products having the appropriate CSA markings (that is, Class

I Division 2, Groups A, B, C, D), are certified for use in other

equipment where the suitability of combination (that is, application

or use) is determined by the CSA or the local inspection office

having jurisdiction.

Important: Due to the modular nature of a PLC control system, the

product with the highest temperature rating determines the overall

temperature code rating of a PLC control system in a Class I,

Division 2 location. The temperature code rating is marked on the

product label

as shown.

CSA

La CSA certifie les produits d'utilisation générale aussi bien que ceux qui

s'utilisent dans des emplacements dangereux. La certification CSA en

vigueur est indiquée par l'étiquette du produit et non par des

affirmations dans la documentation à l'usage des utilisateurs.

Pour satisfaire à la certification de la CSA dans des endroits dangereux,

les informations suivantes font partie intégrante de la documentation des

produits industriels de contrôle AllenBradley certifiés par la CSA.

• Cet équipement convient à l'utilisation dans des emplacements de

Classe 1, Division 2, Groupes A, B, C, D, ou ne convient qu'à

l'utilisation dans des endroits non dangereux.

• Les produits portant le marquage approprié de la CSA (c'est à dire,

Classe 1, Division 2, Groupes A, B, C, D) sont certifiés à l'utilisation

pour d'autres équipements où la convenance de combinaison

(application ou utilisation) est déterminée par la CSA ou le bureau local

d'inspection qualifié.

Important: Par suite de la nature modulaire du système de contrôle PLC),

le produit ayant le taux le plus élevé de température détermine le taux

d'ensemble du code de température du système de contrôle d'un PLC

dans un emplacement de Classe 1, Division 2. Le taux du code de

température est indiqué sur l'étiquette du produit.

Temperature code rating

Look for temperature code

rating here

The following warnings apply to products having CSA certification for

use in hazardous locations.

ATTENTION: Explosion hazard

• Substitution of components may impair suitability

!

for Class I, Division 2.

• Do not replace components unless power has

been switched off or the area is known to be

nonhazardous.

• Do not disconnect equipment unless power has

been switched off or the area is known to be

nonhazardous.

• Do not disconnect connectors unless power has

been switched off or the area is known to be

nonhazardous. Secure any usersupplied

connectors that mate to external circuits on an

AllenBradley product using screws, sliding

latches, threaded connectors, or other means

such that any connection can withstand a 15

Newton (3.4 lb.) separating force applied for a

minimum of one minute.

Taux du code de température

Le taux du code de

température est indiqué ici

Les avertissements suivants s'appliquent aux produits ayant la

certification CSA pour leur utilisation dans des emplacements dangereux.

AVERTISSEMENT: Risque d'explosion

• La substitution de composants peut rendre ce matériel

!

inacceptable pour lesemplacements de Classe I,

Division 2.

• Couper le courant ou s'assurer quel'emplacement est

désigné non dangereux avant de remplacer

lescomposants.

• Avant de débrancher l'équipement, couper le courant

ou s'assurer que l'emplacement est désigné non

dangereux.

• Avant de débrancher les connecteurs, couper le

courant ou s'assurer que l'emplacement est reconnu

non dangereux. Attacher tous connecteurs fournis par

l'utilisateur et reliés aux circuits externes d'un appareil

AllenBradley à l 'aide de vis, loquets coulissants,

connecteurs filetés ou autres moyens permettant aux

connexions de résister à une force de séparation de 15

newtons (3,4 lb. 1,5 kg) appliquée pendant au moins

une minute.

CSA

logo is a registered trademark of the Canadian Standards Association.

Publication

17715.41 - May 1996

Page 12

AC (24V) Output Module12

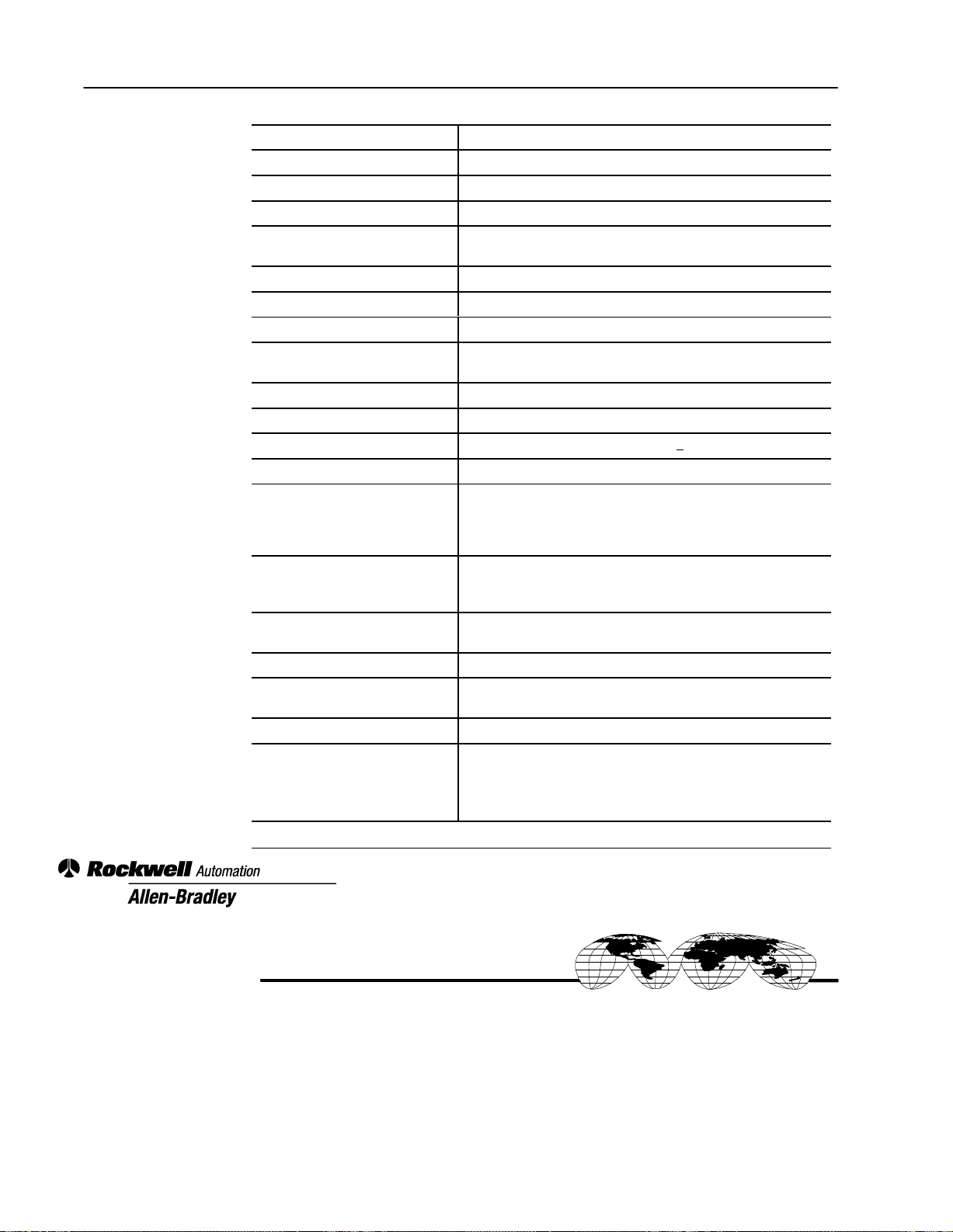

Specifications

Outputs per Module 16

Module Location 17711A1B thru A4B or later I/O chassis; 1771AM1, AM2

Output Voltage Range 10 to 60V ac @ 47 63Hz

Output Current Rating 2A per output not to exceed 8A per module

Surge Current (maximum) 25A per output for 100ms, repeatable every 1 second

25A per module for 100ms, repeatable every 1 second

Minimum Load Current 50mA per output @ 24V ac, 60Hz

On State Voltage Drop (max.) 1.6V at 2A

Off State Leakage Current (max.) 3mA per output @ 24V ac

Signal Delay Off to On

On to Off

1.0ms;

8.3 to 9.1ms @ 60Hz

Power Dissipation 16.5 Watts (max.), 3.7 Watts (min.)

Thermal Dissipation 56.2 BTU/hr (max.), 12.6 BTU/hr (min.)

Backplane Current 700mA @ 5V dc +5%

Isolation Voltage Tested at 1500V ac (rms) for 1s

Environmental Conditions

Operational Temperature

Storage Temperature

Relative Humidity

Conductors Wire Size

Category

0o to 60oC (32o to 140oF)

o

40

to 85oC (40o to 185oF)

5 to 95% (without condensation)

14 gauge (2mm2) stranded maximum

3/64 inch (1.2mm) insulation maximum

1

1

Keying Between 20 and 22

Between 32 and 34

Fuse 10A, 250V rectifier fuse (1/4 x 11/4 inch), Littelfuse PN 322010

Field Wiring Arm Standard

Optional

Catalog Number 1771WH

Catalog Number 1771WHF (fused)

Wiring Arm Screw Torque 79 inchpounds

Agency Certification

(when product or packaging is

marked)

• CSA certified

• CSA Class I, Division 2, Groups A, B, C, D certified

• UL listed

• CE marked for all applicable directives

1

Refer

to publication 17704.1, Programmable Controller Wiring and Grounding Guidelines.

AllenBradley, a Rockwell Automation Business, has been helping its customers improve

productivity and quality for more than 90 years. We design, manufacture and support a broad

range of automation products worldwide. They include logic processors, power and motion

control devices, operator interfaces, sensors and a variety of software. Rockwell is one of the

world's leading technology companies.

Worldwide representation.

Argentina •

Denmark • Ecuador

Ireland

Philippines •

Sweden

AllenBradley Headquarters, 1201 South Second Street, Milwaukee, WI 53204 USA, Tel: (1) 414 3822000 Fax: (1) 414 3824444

Publication

Australia • Austria • Bahrain

• Israel • Italy • Jamaica •

• Switzerland • T

17715.41 - May 1996

Publication

• Egypt • El Salvador • Finland • France •

Poland • Portugal • Puerto Rico • Qatar • Romania • Russia-CIS • Saudi Arabia • Singapore

aiwan

17715.41 - May 1996

• Belgium • Brazil •

Japan • Jordan • Korea • Kuwait • Lebanon

• Thailand • T

urkey • United Arab Emirates • United Kingdom • United States • Uruguay

Bulgaria • Canada

Germany • Greece • Guatemala • Honduras • Hong Kong • Hungary

• Chile •

China, PRC • Colombia

• Malaysia • Mexico •

• Costa Rica •

Netherlands

• New Zealand •

• Slovakia • Slovenia •

Croatia • Cyprus

Norway

South Africa, Republic

• V

enezuela

Copyright

1995 AllenBradley Company

• Iceland •

• Yugoslavia

• Czech Republic •

India • Indonesia

• Pakistan •

•

Peru

•

• Spain •

PN955124-34

, Inc. Printed in USA

Loading...

Loading...