Page 1

Installation Instructions

GuardPLC 1753-IF8XOF4 Analog I/O Module

Catalog Number 1753-IF8XOF4

Inside ................................................................................................page

Related Documentation ............................................................................3

Description................................................................................................4

General Safety..........................................................................................4

Mount the Module....................................................................................6

Wire the Module....................................................................................... 7

Reset Pushbutton....................................................................................14

Troubleshoot with LED Indicators...........................................................15

Specifications .........................................................................................16

Publication 1753-IN013A-EN-P - September 2005

Page 2

2 GuardPLC 1753-IF8XOF4 Analog I/O Module

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (Publication

SGI-1.1 available from your local Rockwell Automation sales office or online at

http://www.ab.com/manuals/gi) describes some important differences between solid state equipment and

hard-wired electromechanical devices. Because of this difference, and also because of the wide variety of

uses for solid state equipment, all persons responsible for applying this equipment must satisfy themselves

that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc. is prohibited.

Throughout this manual, when necessary we use notes to make you aware of safety considerations.

WARNING

Identifies information about practices or circumstances that can cause an explosion in a

hazardous environment, which may lead to personal injury or death, property damage,

or economic loss.

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information that is critical for successful application and understanding of the

product.

Identifies information about practices or circumstances that can lead to personal injury

or death, property damage, or economic loss. Attentions help you:

• identify a hazard

• avoid a hazard

• recognize the consequence

Labels may be located on or inside the equipment (e.g., drive or motor) to alert people

that dangerous voltage may be present.

Labels may be located on or inside the equipment (e.g., drive or motor) to alert people

that surfaces may be dangerous temperatures.

Publication 1753-IN013A-EN-P - September 2005

Page 3

GuardPLC 1753-IF8XOF4 Analog I/O Module 3

Related Documentation

The table below provides a listing of publications that contain important

information about GuardPLC Controller systems.

For Read this document Publication

number

Detailed information regarding the safety certification

of the GuardPLC System.

Detailed information on installing, wiring, configuring,

operating, maintaining, and troubleshooting GuardPLC

systems.

Information on programming with RSLogix Guard PLUS!

software

Information on installing GuardPLC 1600 controllers GuardPLC 1600 Controller

Information on installing GuardPLC 1800 controllers GuardPLC 1800 Controller

Information on installing GuardPLC 1753-IB20XOB8

Digital Input/Output Modules

Information on installing GuardPLC 1753-IB16 Digital

Input Modules

Information on installing GuardPLC 1753-OB16 Digital

Output Modules

Information on installing GuardPLC 1753-IB8XOB8

Digital Input/Output Modules

Information on installing GuardPLC 1753-IB16XOB8

Digital Input/Output Modules

Information on installing GuardPLC 1753-OW8 Relay

Output Modules

GuardPLC Controller Systems

Safety Reference Manual

GuardPLC Controller Systems User

Manual

Using RSLogix Guard PLUS!

Software with GuardPLC

Controllers

Installation Instructions

Installation Instructions

GuardPLC Digital Input/Output

Module

GuardPLC Digital Input Module

Installation Instructions

GuardPLC Digital Output Module

Installation Instructions

GuardPLC 8-Digital Inputs and

8-Digital Outputs Module

Installation Instructions

GuardPLC16-Digital Inputs and

8-Digital Outputs Module

Installation Instructions

GuardPLC 8-Relay Output Module

Installation Instructions

1753-RM002

1753-UM001

1753-PM001

1753-IN001

1753-IN002

1753-IN003

1753-IN004

1753-IN005

1753-IN010

1753-IN011

1753-IN012

If you would like a manual, you can:

• download a free electronic version from the internet at

www.rockwellautomation.com/literature

• purchase a printed manual by contacting your local distributor or Rockwell

Automation representative)

IMPORTANT

For planning information, see the Industrial Automation Wiring

and Grounding Guidelines, publication 1770-4.1.

Publication 1753-IN013A-EN-P - September 2005

Page 4

4 GuardPLC 1753-IF8XOF4 Analog I/O Module

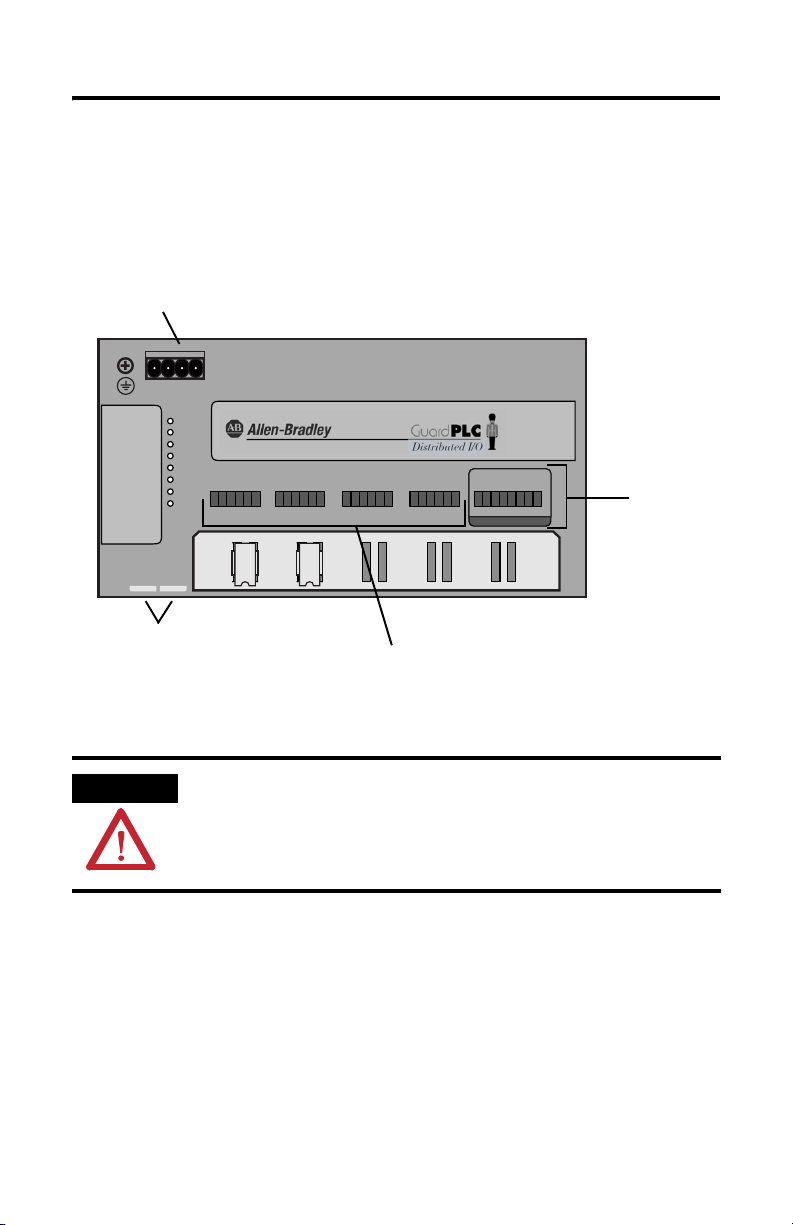

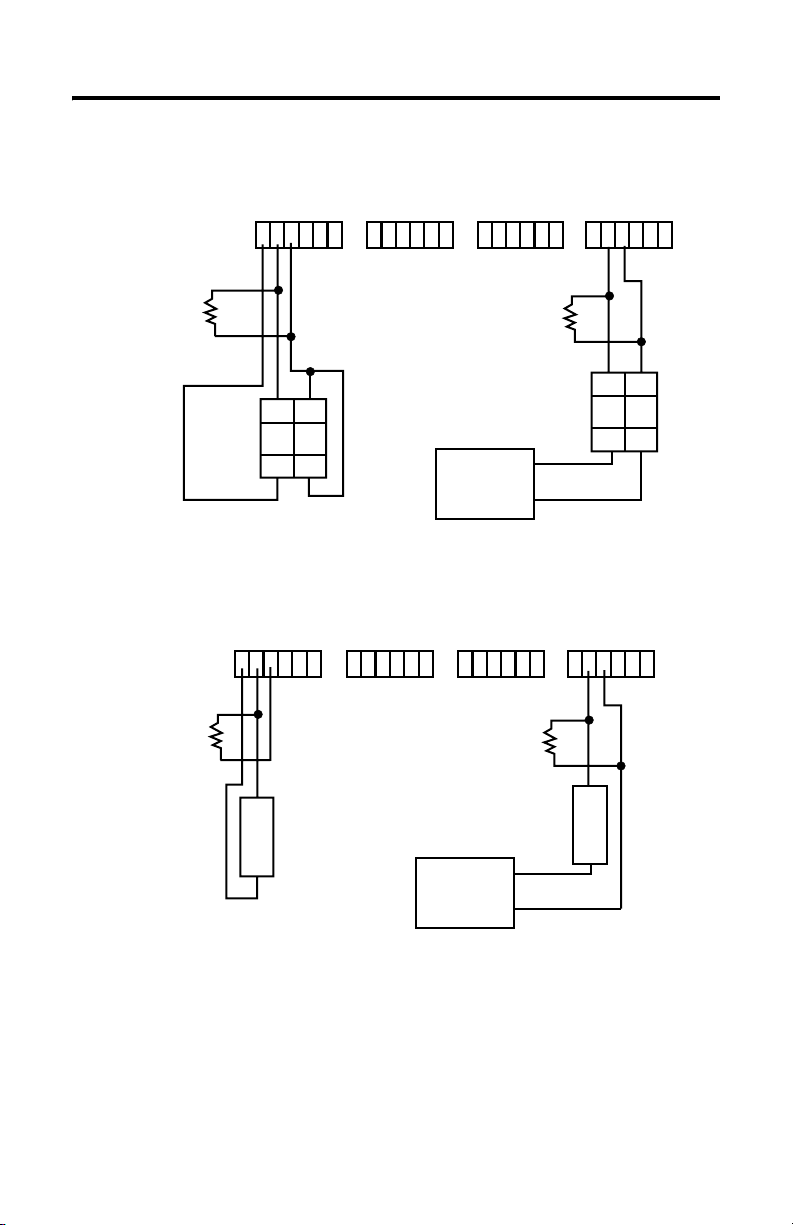

Description

The 1753-IF8XOF4 module is a distributed safety I/O module for use with

GuardPLC controllers. The module features 8 safety analog inputs and 4 standard

analog outputs. The module communicates with the GuardPLC controller via

GuardPLC Ethernet.

Voltage Supply Connection

L-L- L+ L+

24V DC

GuardPLC Ethernet

10/100 BaseT

<—>2<—>

1

24 V DC

RUN

ERROR

PROG

FORCE

AI

FAULT

T1 I1 L- T2 I2 L-AIT3 I3 L- T4 I4 L-AIT5 I5 L- T6 I6 L-AIT7 I7 L- T8 I8 L-

OSL

BL

1 2 34 56 7 8 9101112 13 1415161718 192021222324

1753-IF8XOF4

8 Analog Inputs

4 Analog Outputs

AO

O1 O2 O3 O4

+-+-+-+-

25 26 27 28 29 30 31 32

STD ANALOG OUTPUTS

Standard

Analog

Outputs

Ethernet Ports

(on bottom of controller)

Safety Analog Inputs

General Safety

ATTENTION

Publication 1753-IN013A-EN-P - September 2005

Personnel responsible for the application of safety-related

Programmable Electronic Systems (PES) shall be aware of the

safety requirements in the application of the system and shall be

trained in using the system.

Page 5

GuardPLC 1753-IF8XOF4 Analog I/O Module 5

Open style devices must be provided with environmental and safety protection by

proper mounting in enclosures designed for specific application conditions.

ATTENTION

Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2 industrial environment, in

overvoltage Category II applications (as defined in IEC publication 60664-1), at altitudes up to

2000 meters without derating.

This equipment is considered Group 1, Class A industrial equipment according to IEC/CISPR

Publication 11. Without appropriate precautions, there may be potential difficulties ensuring

electromagnetic compatibility in other environments due to conducted as well as radiated

disturbance.

This equipment is supplied as "open type" equipment. It must be mounted within an

enclosure that is suitably designed for those specific environmental conditions that will be

present and appropriately designed to prevent personal injury resulting from accessibility to

live parts. The interior of the enclosure must be accessible only by the use of a tool.

Subsequent sections of this publication may contain additional information regarding

specific enclosure type ratings that are required to comply with certain product safety

certifications.

See NEMA Standards publication 250 and IEC publication 60529, as applicable, for

explanations of the degrees of protection provided by different types of enclosure. Also, see

the appropriate sections in this publication, as well as the Allen-Bradley publication 1770-4.1

("Industrial Automation Wiring and Grounding Guidelines"), for additional installation

requirements pertaining to this equipment.

Preventing Electrostatic Discharge

ATTENTION

This equipment is sensitive to electrostatic discharge, which can

cause internal damage and affect normal operation. Follow these

guidelines when you handle this equipment:

• Touch a grounded object to discharge static potential.

• Wear an approved wrist-strap grounding device.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• If available, use a static-safe workstation.

• When not in use, store the equipment in appropriate static

safe packaging.

Publication 1753-IN013A-EN-P - September 2005

Page 6

6 GuardPLC 1753-IF8XOF4 Analog I/O Module

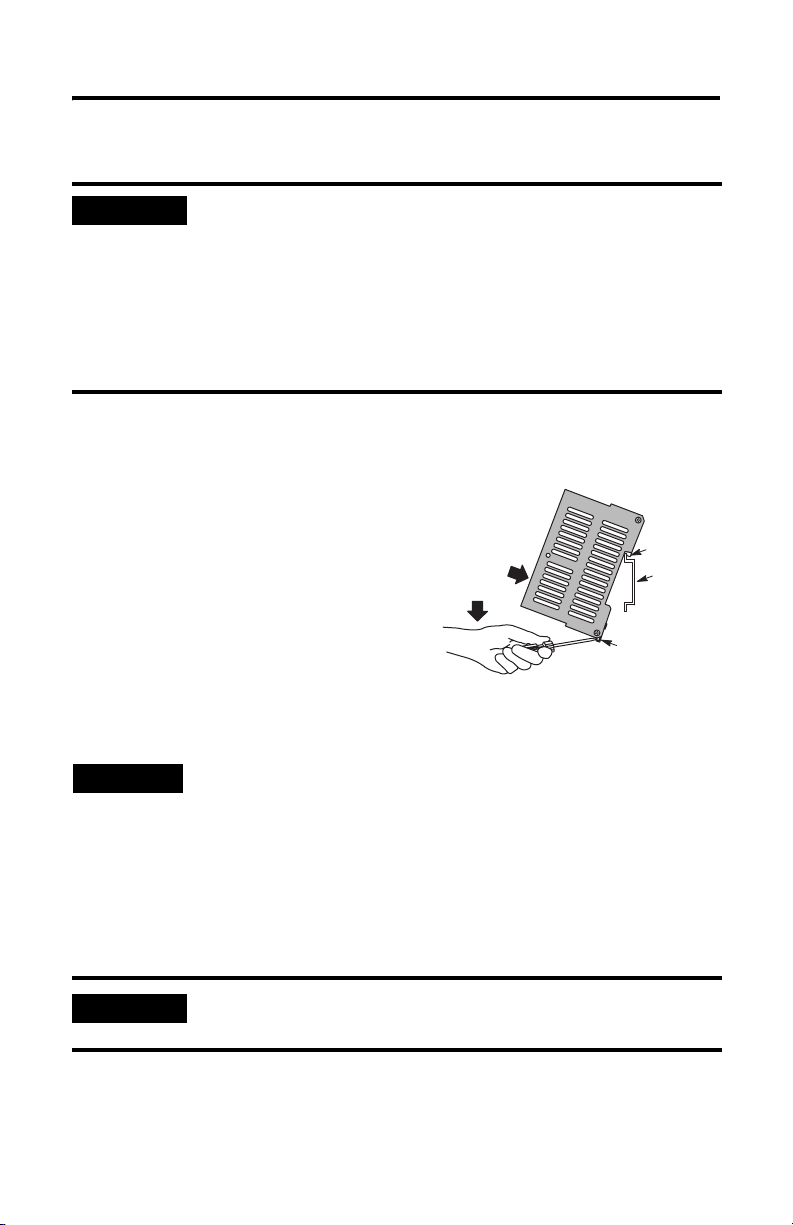

Mount the Module

IMPORTANT

The module cannot be panel-mounted. Mount the module to a DIN rail by

following the steps below.

1. Hook the top slot over the DIN rail.

2. Insert a flathead screwdriver into the

gap between the housing and the latch

and pull the latch downward.

3. Hold the latch down as you push the

housing back onto the DIN rail.

4. Release the latch to lock the module

onto the rail.

TIP

For effective cooling:

• Mount the module horizontally.

• Provide a gap of at least 100 mm (3.94 in.) above and below

the module.

• Select a location where air flows freely or use an additional

fan.

• Do not mount the module over a heating device.

(3)

(2)

Latch

To remove the module from the DIN rail, insert a flathead

screwdriver into the gap between the housing and the latch and

pull the latch downward as you lift the module off of the rail.

(1) Top Slot

DIN Rail

IP Address Label

A transparent label shipped with the module can be used to note the IP address

and system ID (SRS).

IMPORTANT

Publication 1753-IN013A-EN-P - September 2005

If you attach the label to the module, make sure you do not cover

any of the ventilation slots.

Page 7

GuardPLC 1753-IF8XOF4 Analog I/O Module 7

Wire the Module

Ground the Module

You must provide an acceptable grounding path for each device in your

application. For more information on proper grounding guidelines, refer to the

Industrial Automation Wiring and Grounding Guidelines, publication number

1770-4.1.

The I/O module is functionally grounded through its DIN rail connection. A

protective earth ground connection is required and is provided by a separate

grounding screw, located on the upper left of the housing and marked with the

grounding symbol .

ATTENTION

This product is grounded through the DIN rail to chassis ground.

Use zinc plated yellow-chromate steel DIN rail to assure proper

grounding. The use of other DIN rail materials (e.g. aluminum,

plastic, etc.) that can corrode, oxidize, or are poor conductors,

can result in improper or intermittent grounding.

Connections for Safety-Related Communications

Ethernet Switch

The module has two 10/100BaseT, RJ-45 connectors, located on the bottom of the

unit, that provide communications to the GuardPLC controller via GuardPLC

Ethernet. Because this is an Ethernet switch, you can daisy-chain connections from

the GuardPLC to other distributed I/O blocks. The switch is auto-detect. Either

cross-over or straight-through shielded Ethernet cabling can be used.

Star or line configurations are available. Make sure that a network loop is not

generated. Data packets must only be able to reach a node via a single path. Ring

topology is not supported.

MAC Address

The Media Access Control (MAC) Address of the module can be found on the label

positioned over both lower RJ-45 connections.

Publication 1753-IN013A-EN-P - September 2005

Page 8

8 GuardPLC 1753-IF8XOF4 Analog I/O Module

Connect the Voltage Supply

The 24V dc voltage supply must feature galvanic isolation (in accordance with EN

60950 or UL 1950) since inputs and outputs are not electrically isolated from the

internal processor. In order to comply with CE Low Voltage Directives (LVD), you

must use either a NEC Class 2, a Safety Extra Low Voltage (SELV) or a Protected

Extra Low Voltage (PELV) power supply to power this module. A SELV supply

cannot exceed 30V rms, 42.4V peak or 60V dc under normal conditions and under

single fault conditions. A PELV supply has the same rating and is connected to

protected earth.

IMPORTANT

The supply voltage is connected via a 4-pin connector.. You only need to connect

one wire to L+ and one wire to L-. Both L+ and L- terminals are internally

connected, so you can daisy-chain 24V dc power from the GuardPLC to other

devices in the panel using the remaining terminal. See the wire size and terminal

torque specifications on page 16

ATTENTION

Protect the module with a 10 A slow-blow fuse.

Do not reverse the L+ and L- terminals or damage to the module

will result. There is no reverse polarity protection.

Safety Analog Inputs

The module has 8 analog inputs with sensor supplies for the unipolar measurement

of voltages from 0 to 10V. A 10 kΩ shunt is used for single-ended voltage signals.

With a 500 Ω shunt resistor, currents from 0 to 20 mA can also be measured.

Publication 1753-IN013A-EN-P - September 2005

Page 9

GuardPLC 1753-IF8XOF4 Analog I/O Module 9

Analog cabling should be no more than 300 m (984 ft) in length and must be

shielded, twisted-pair cables for each measurement input. The shields must be

connected at one end.

IMPORTANT

Short-circuit unused input channels to the reference pole by

connecting wire jumpers.

AI

T1 I1 L- T2 I2 L-

123456

wire jumpers

wire jumpers

Analog Input Values

The following input values are available:

Input Channels Polarity Current or Voltage Range Safety Accuracy

0…+10V 0…2000

8unipolar

(1) with external 250 Ω shunt

(2) with external 500 Ω shunt

0…20 mA / 4…20 mA

0…1000

0…2000

(1)

(2)

2%

Voltage Measurment

If an open-circuit fault occurs during voltage measurement, unpredictable input

signals are received on the high resistance inputs. Values resulting from this

fluctuating input voltage are not reliable. Because the module does not feature

circuit monitoring, you must terminate input channels with a 10 kΩ resistor when

measuring voltage. Consider the internal resistance of the source as well.

Current Measurement

To measure current, connect a 500 Ω external shunt in parallel to the input.

Accuracy of the shunt must be included in accuracy calculations of the input signal.

Terminating resistors are not required for current measurement with the external

shunt connected in parallel.

Publication 1753-IN013A-EN-P - September 2005

Page 10

10 GuardPLC 1753-IF8XOF4 Analog I/O Module

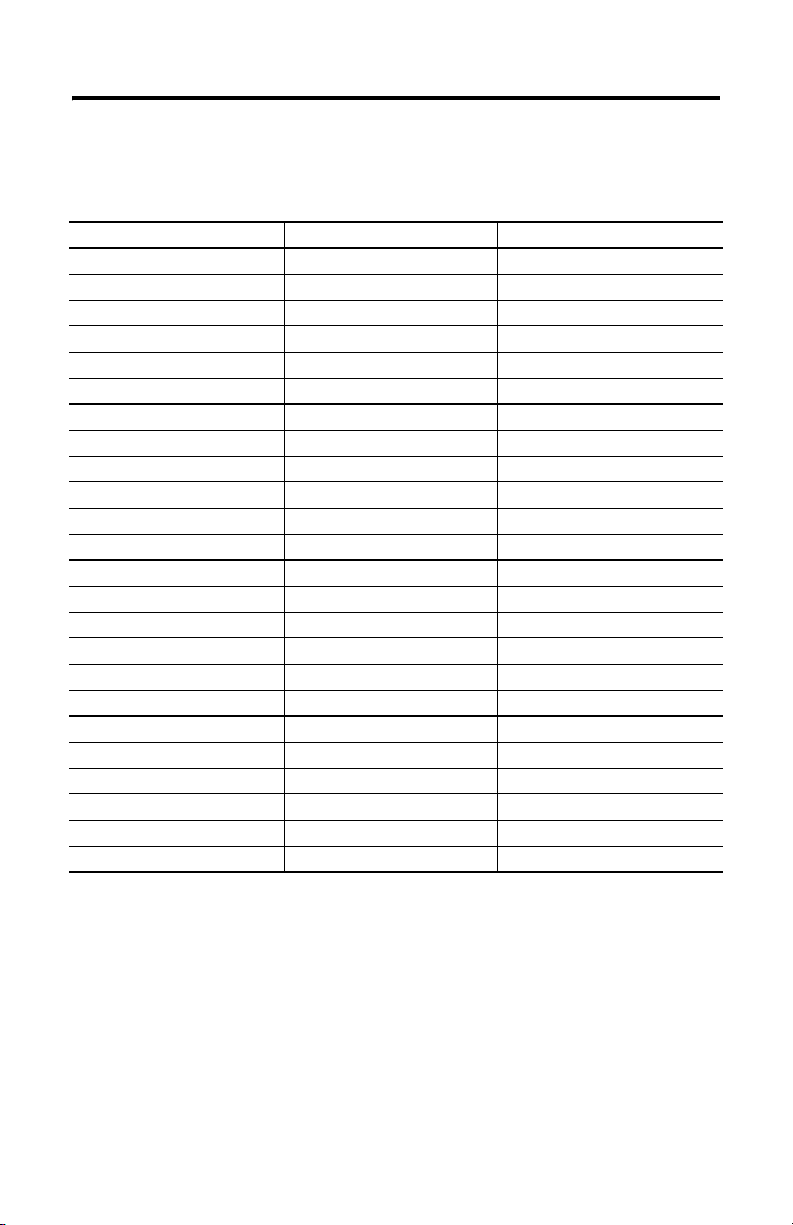

1753-IF8XOF4 with

Wiring Examples

1753-IF8XOF4 with a 4-wire device:

AI

I1T1 L-

L- T2 I2 I3T3 L-L- T4 I4 I5T5 L-L- T6 I6 I7T7 L-L- T8 I8

AI AI AI

7891011121 2 3 4 5 6 13 14 15 16 17 18 19 20 21 22 23 24

10 KΩ for Voltage

500 Ω for Current

10 KΩ for Voltage

500 Ω for Current

10 KΩ for Voltage

500 Ω for Current

++-

++-

-

-

4-wire Device with Power Source from GuardPLC 4-wire Device with External Power Source

a 2-wire device:

AI

I1T1 L-

L- T2 I2 I3T3 L-L- T4 I4 I5T5 L-L- T6 I6 I7T7 L-L- T8 I8

AI AI AI

7891011121 2 3 4 5 6 13 14 15 16 17 18 19 20 21 22 23 24

24V dc

Power

Supply

10 KΩ for Voltage

500 Ω for Current

-

+

2-wire Device with Power

Source from GuardPLC

24V dc

Power

Supply

2-wire Device with External Power Source

+

COM

-

+

+

COM

Publication 1753-IN013A-EN-P - September 2005

Page 11

GuardPLC 1753-IF8XOF4 Analog I/O Module 11

Analog Input Terminals

Analog inputs (AI) are connected to the following terminals:

Terminal Number Designation Function

1 T1 Sensor supply 1

2 I1 Analog input 1

3 L- Reference pole input 1

4 T2 Sensor supply 2

5 I2 Analog input 2

6 L- Reference pole input 2

7 T3 Sensor supply 3

8 I3 Analog input 3

9 L- Reference pole input 3

10 T4 Sensor supply 4

11 I4 Analog input 4

12 L- Reference pole input 4

13 T5 Sensor supply 5

14 I5 Analog input 5

15 L- Reference pole input 5

16 T6 Sensor supply 6

17 I6 Analog input 6

18 L- Reference pole input 6

19 T7 Sensor supply 7

20 I7 Analog input 7

21 L- Reference pole input 7

22 T8 Sensor supply 8

23 I8 Analog input 8

24 L- Reference pole input 8

Connect the Wires

See the wire size and terminal block torque specifications on page 16. The cables

are connected to the front plate of the module using pluggable terminals. Shielded

cabling is fed in from below so that the shielding can be connected to the shield

contact plate using a clip. Remove about 2 cm (3/4 in) of the outer cable insulation

so that the mesh is exposed at the point where the cable is clipped to the plate.

Publication 1753-IN013A-EN-P - September 2005

Page 12

12 GuardPLC 1753-IF8XOF4 Analog I/O Module

51 5241 42 43 44 45

Position the clip over the uninsulated cable shielding and push it into the slots of

the shield contact plate until it fits firmly in place, as shown below.

mesh

shielded cable

IMPORTANT

Make sure that the mesh comes in direct contact with the shield

contact plate. If the mesh does not touch the plate, the cable is

cable clip

not grounded.

Standard Analog Outputs

The module has 4 analog outputs, which are not safety-rated outputs. However, in

the event of an internal error, they can be shut down safely through configuration

via the user program.

ATTENTION

The following output values are available:

Value Range in the Application Output Current

00 mA

2000 20 mA

To achieve SIL 3, the output values must be read back via safety

analog inputs and evaluated in the RSLogix Guard PLUS! user

program. Otherwise, they may not be used as safety outputs.

Publication 1753-IN013A-EN-P - September 2005

Page 13

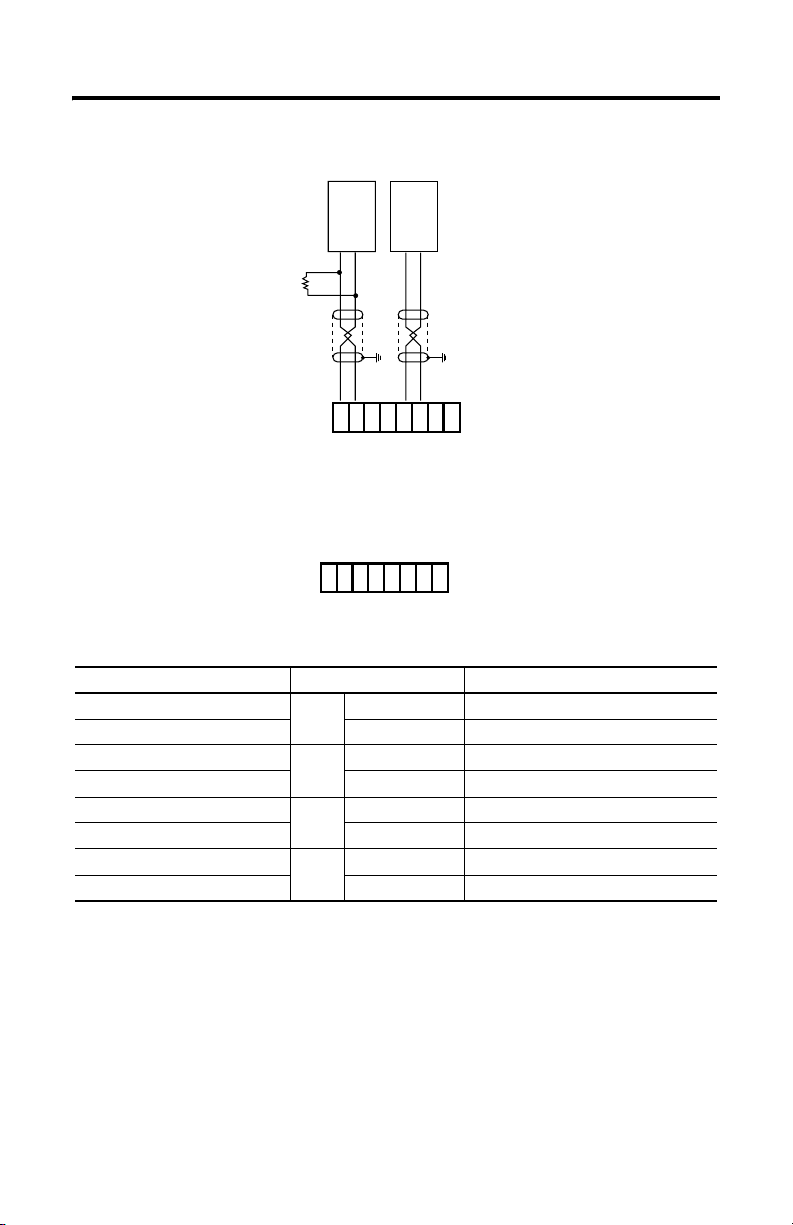

Wiring Example

GuardPLC 1753-IF8XOF4 Analog I/O Module 13

output

voltage

+- +-

current

output

500 Ω

Ground cable shields

at the shield plate.

AO

O1 O2 O3 O4

-+-+-+ - +

25 26 27 28 29 30 31 32

Analog Output Terminals

AO

01 02 03 04

-+-+-+ - +

25 26 27 28 29 30 31 32

Analog outputs (AO) are connected to the following terminals:

Terminal Number Designation Function

25

26 - Reference pole output 1

27

28 - Reference pole output 2

29

30 - Reference pole output 3

31

32 - Reference pole output 4

+ Analog output 1

O1

+ Analog output 2

O2

+ Analog output 3

O3

+ Analog output 4

O4

See the wire size and terminal block torque specifications on page 16.

Publication 1753-IN013A-EN-P - September 2005

Page 14

14 GuardPLC 1753-IF8XOF4 Analog I/O Module

Reset Pushbutton

You can use the reset button if you forget the password for connecting the

programming software. The pushbutton is accessible through a small round hole at

the top of the housing, approximately 4 to 5 cm (1.6 to 2.0 in.) from the left rim and

recessed approximately 9.5 mm (0.375 in.).

IMPORTANT

To reset, press and hold the pushbutton for 20 seconds while rebooting the device

by cycling power. Pressing the Reset pushbutton during operation has no affect.

With activation of the reset button:

• All accounts are deleted except for the default account.

• IP address and system ID (SRS) are set to default values.

At the next power cycle, these settings will be restored to the last values stored into

Flash. This means that either:

• the settings prior to the reset will be restored, or

• if any settings were changed after the reset, these new settings will still be in

effect.

Activate the reset pushbutton using an insulated pin to prevent

short-circuits.

Publication 1753-IN013A-EN-P - September 2005

Page 15

GuardPLC 1753-IF8XOF4 Analog I/O Module 15

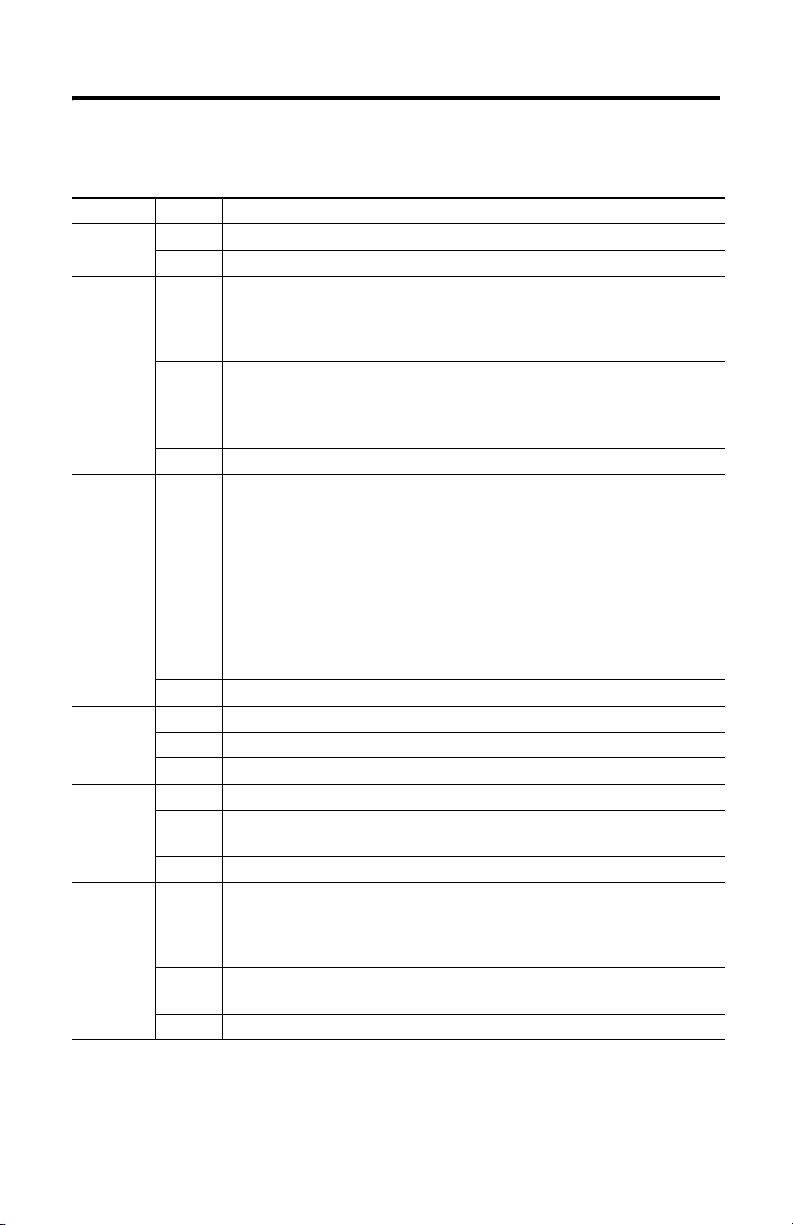

Troubleshoot with LED Indicators

Indicator State Condition

24V dc On 24V dc operating voltage present.

Off No operating voltage.

RUN On This is the normal status of the module.

A routine, which has been loaded into the controller, is executed.

The controller processes input and output signals, carries out communication, and

performs hardware and software tests.

Flashing The controller is in STOP mode and is not executing a routine.

Off The controller is in ERROR_STOP (see ERROR).

ERROR On • A hardware error has been detected by the controller. The controller goes

Off No errors are detected.

PROGress On The upload of a new controller configuration is in progress.

Flashing The upload of a new operating system into the Flash ROM is in progress.

Off No upload of controller configuration or operating system in progress.

FORCE On The controller is executing a routine (RUN) and FORCE mode is activated by the user.

Flashing The controller is in STOP, but Forcing has been initiated and will be activated when

Off Forcing is OFF.

FAULT On • The routine (logic) has caused an error.

Flashing An error has occurred during a Flash ROM write cycle.

Off None of the above errors has occurred.

All system outputs are reset.

STOP mode can be triggered by setting the Emergency stop system variable to TRUE

in the routine, or by direct command from the programming software.

to ERROR_STOP and the execution of the routine is halted. Hardware

errors are errors in the controller, errors in one or more of the digital input

and output modules, or errors in the counters.

• A software error in the operating system has been detected by the

controller.

• The watchdog has reported an error due to exceeded cycle time.

All system outputs will be reset and the controller ceases all hardware and software

tests. The controller can only be restarted by a command from the programming

software.

the controller is started.

• The controller configuration is faulty.

• The upload of a new operating system was not successful and the

operating system is corrupted.

One or more I/O errors have occurred.

Publication 1753-IN013A-EN-P - September 2005

Page 16

16 GuardPLC 1753-IF8XOF4 Analog I/O Module

Indicator State Condition

OSL Flashing Emergency Operating System Loader is active.

BL Flashing Boot Loader unable to load operating system or unable to start COMM operating

Controller status can be interrogated through the programming software. For more information, refer to the

GuardPLC™ Controller Systems User Manual (1753-UM001).

system loader.

Specifications

General

Interfaces: GuardPLC Ethernet 2 x RJ-45, 10/100BaseT (with 100 Mbps) with integrated switch

Operating Voltage 24V dc, -15% to +20%, w

separation, conforming to IEC 61131-2 requirements, as well as either

of the following:

• EN 60950 - SELV (Safety Extra Low Voltage)

• EN 60204 - PELV (Protective Extra Low Voltage)

Response Time ≥ 20 ms

Battery Backup none

Current Consumption max. 0.8 A (with max. load), idle current 0.4 A @24V

Isolation Voltage No isolation between circuits

Wiring Category

Wire Size

(1)

category 2 on communications ports, signal ports, and power ports

I/O – 16 AWG (1.5 mm

wire rated at 75 °C (167 °F) or greater with 3/64 inch (1.2 mm) insulation

maximum

15% from a power supply with protective

ss

2

) to 26 AWG (0.14 mm2) solid or stranded copper

Power – 14 AWG (2.5 mm

copper wire rated at 75 °C (167 °F) or greater with 3/64 inch (1.2 mm)

insulation maximum

Terminal Block Torque 0.51 Nm (4.5 in-lb)

Publication 1753-IN013A-EN-P - September 2005

2

) to 22 AWG (0.34 mm2) solid or stranded

Page 17

GuardPLC 1753-IF8XOF4 Analog I/O Module 17

Analog Inputs

Number of Inputs 8 (not electrically isolated)

Input Signal Range, Nominal Voltage: 0 to +10V dc

Current: 0 to +20 mA

Input Signal Range, Service Voltage: -0.1 to +11V dc

Current: -0.4 to +23 mA

Shunt Resistor, External 500 Ω (for current input)

Impedance, Analog Input >2 MΩ

Analog Input Signal, Source

≤ 500 Ω

Impedance

Input Resolution 12 bits

Effective Resolution 9 bits @ 10V

Sensor Supply selectable 26V/8.2V

200 mA, short-circuit-proof

Accuracy 0.5%

Safety Accuracy 2%

Calibration Error Zero Point ±1%

Calibration Error Terminal Point ±0.4%

Channel Error ±0.5%

Temperature Error Zero Point ±0.5%/10 K

Temperature Error Terminal Point ±0.5%/10 K

Linearity Error ±0.5%

Long-term Drift ±0.5%

Analog Outputs

Number of Outputs 4 (not electrically isolated)

non-safety with common safety switch off

Output Signal Range 4…20 mA nominal

0…20 mA full range

Resolution of Software 12 bits

Impedance, Current Output 600 Ω max.

Calibration Error Zero Point ±1%

Calibration Error Terminal Point ±1%

Channel Error ±1%

Temperature Error Zero Point ±1%/10 K

Temperature Error Terminal Point ±1%/10 K

Linearity Error ±1%

(3)

(3)

Publication 1753-IN013A-EN-P - September 2005

Page 18

18 GuardPLC 1753-IF8XOF4 Analog I/O Module

Environmental Conditions

Storage Temperature IEC 60068-2-1 (Test Ab, Un-packaged Non-operating Cold),

Operating Temperature IEC 60068-2-1 (Test Ad, Operating Cold),

Vibration IEC60068-2-6 (Test Fc, Operating): 1 g @ 10…150 Hz

Shock, Operating IEC60068-2-27 (Test Ea, Unpackaged Shock):15 g

Relative Humidity IEC 60068-2-30 (Test Db, Un-packaged Non-operating Damp Heat):

Emissions Group 1, Class A

ESD Immunity IEC 61000-4-2:

Radiated RF Immunity IEC 61000-4-3:

EFT/B Immunity IEC 61000-4-4:

Surge Transient Immunity IEC 61000-4-5:

Conducted RF Immunity IEC 61000-4-6:

Enclosure Type Rating meets IP20

Mechanical Dimensions

Width 207 mm (8.16 in.) including housing screws

Height 114 mm (4.49 in.) including latch

Depth 97 mm (3.82 in.) including grounding bolt

Weight 0.95 kg (2.09 lb)

IEC 60068-2-2 (Test Bb, Un-packaged Non-operating Dry Heat),

IEC 60068-2-14 (Test Na, Un-packaged Non-operating Thermal Shock):

-40°C to +85°C (-40°F to +185°F) without backup battery

IEC 60068-2-2 (Test Bd, Operating Dry Heat),

IEC 60068-2-14 (Test Nb, Operating Thermal Shock):

0°C to +60°C (+32°F to +140°F)

10 to 95% non-condensing

6 kV contact discharges

8 kV air discharges

10V/m with 1kHz sine-wave 80% AM from 80 Hz to 2000 MHz

±2 kV @ 5 kHz on power ports

±1 kV @ 5 kHz on signal ports

±1 kV @ 5 kHz on communication ports

±500V line-line (DM) and ±500 line-earth (CM) on DC power ports

±1 kV line-earth (CM) on shielded ports

±1 kV line-earth (CM) on communication ports

10V rms with 1 kHz sine-wave 80% AM from 150 kHz to 80 MHz

Publication 1753-IN013A-EN-P - September 2005

Page 19

GuardPLC 1753-IF8XOF4 Analog I/O Module 19

Certifications (when product is marked)

(2)

c-UL-us UL Listed Industrial Control Equipment, certified for US and Canada

CE European Union 89/336/EEC EMC Directive, compliant with:

• EN 61000-6-4; Industrial Emissions

• EN 61000-6-2; Industrial Immunity

C-Tick Australian Radiocommunications Act, compliant with:

AS/NZS CISPR 11; Industrial Emissions

TÜV TÜV Certified for Functional Safety

(1) Use this Conductor Category information for planning conductor routing. Refer to Publication 1770-4.1, Industrial

Automation Wiring and Grounding Guidelines.

(2) See the product certification link at www.ab.com for Declarations of Conformity, Certificates, and other certification details.

(3) with external shunt resistor

Publication 1753-IN013A-EN-P - September 2005

Page 20

GuardPLC is a trademark of Rockwell Automation, Inc.

All other trademarks are the property of their respective holders and are hereby acknowledged.

Publication 1753-IN013A-EN-P - September 2005 PN 40071-201-01(1)

Copyright © 2005 Rockwell Automation, Inc. A ll rights reserved. Printed in t he U.S.A.

Loading...

Loading...