Page 1

Installation Instructions

SmartGuard 600 Controllers

Catalog Numbers 1752-L24BBB, 1752-L24BBBE

Topic Page

Important User Information 2

North American Hazardous Location Approval 3

General Safety Information 3

About the SmartGuard 600 Controller 5

Before You Begin 7

Set the Node Address 7

Setting the Communication Rate 7

Set the IP Address for Ethernet Communication 8

Install the SmartGuard 600 Controller 9

Mount the SmartGuard 600 Controller 9

Grounding the SmartGuard 600 Controller 10

Connecting a Power Supply 11

Wiring the SmartGuard 600 Controller 12

Making Communication Connections 15

Interpreting the Status Indicators 17

Alphanumeric Status Display 18

Status Indicators 18

Specifications 24

Additional Resources 28

Page 2

2 SmartGuard 600 Controllers

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication

available from your local Rockwell Automation sales office or online at

SGI-1.1

http://literature.rockwellautomation.com

equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

) describes some important differences between solid state

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances that can cause an explosion in

a hazardous environment, which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful application and understanding of

the product.

Identifies information about practices or circumstances that can lead to personal injury

or death, property damage, or economic loss. Attentions help you identify a hazard,

avoid a hazard and recognize the consequences.

Labels may be on or inside the equipment, for example, a drive or motor, to alert

people that dangerous voltage may be present.

Labels may be on or inside the equipment, for example, a drive or motor, to alert

people that surfaces may reach dangerous temperatures.

Publication 1752-IN001C-EN-P - January 2009

Page 3

SmartGuard 600 Controllers 3

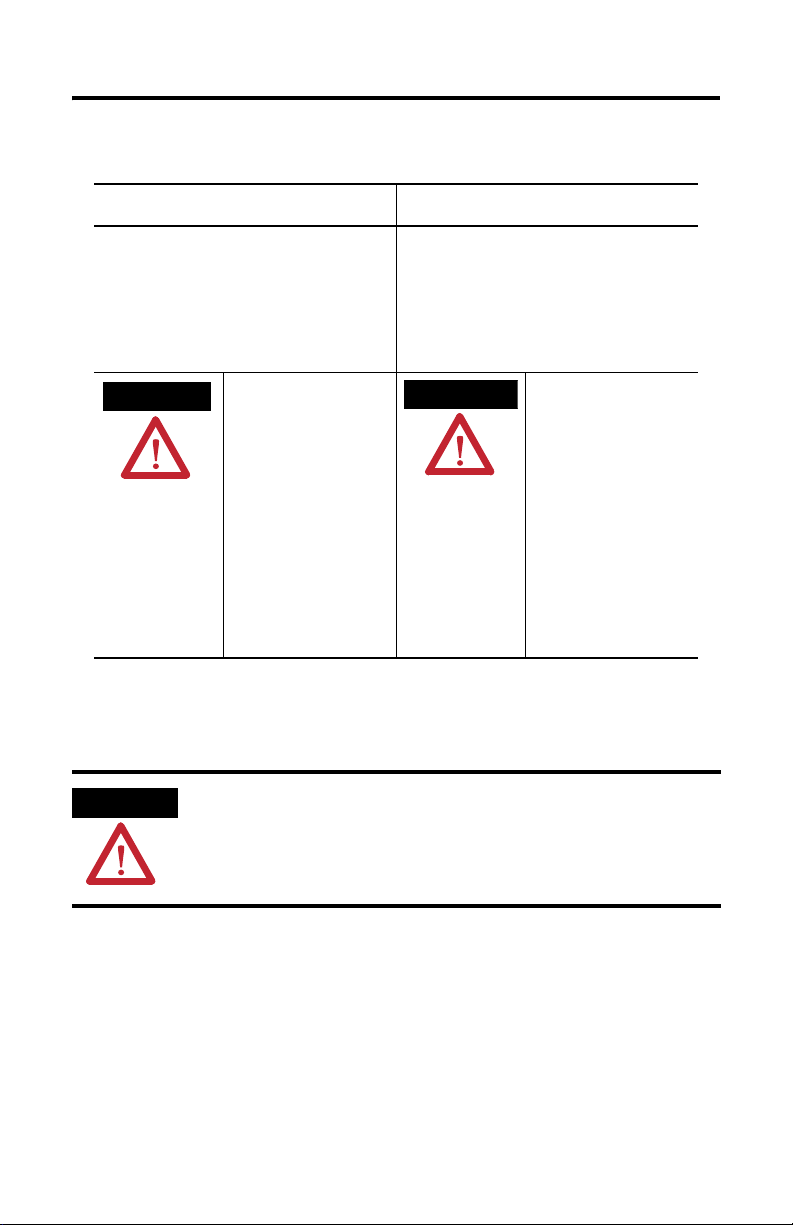

North American Hazardous Location Approval

The following information applies when operating

this equipment in hazardous locations.

Products marked "CL I, DIV 2, GP A, B, C, D" are suitable for use in

Class I Division 2 Groups A, B, C, D, Hazardous Locations an d

nonhazardous locations only. Each product is su pplied with

markings on the rating nameplate indicatin g the hazardous

location temperature code. When combinin g products within a

system, the most adverse temperature code (lowest "T" number)

may be used to help determine the overa ll temperature code of

the system. Combinations of equipment in your system are subject

to investigation by the local Authorit y Having Jurisdiction at the

time of installation.

WARNING

EXPLOSION HAZARD -

• Do not disconnect equipment

unless power has been removed

or the area is known to be

nonhazardous.

• Do not disconnect connections to

this equipment unless power has

been removed or the area is

known to be nonhazardous.

Secure any external connections

that mate to this equipment by

using screws, sliding latches,

threaded connectors, or other

means provided with this product.

• Substitution of components may

impair suitability for Class I,

Division 2.

• If this product contains batteries,

they must only be changed in an

area known to be nonhazardous.

General Safety Information

Informations sur l’utilisation de cet équipement en

environnements dangereux.

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne conviennent

qu'à une utilisation en environnement s de Classe I Division 2

Groupes A, B, C, D dangereux et non dangereu x. Chaque produit

est livré avec des marquages sur sa plaque d'identification q ui

indiquent le code de température pour les en vironnements

dangereux. Lorsque plusieurs produits sont combi nés dans un

système, le code de température le plus défavorable (code de

température le plus faible) peut ê tre utilisé pour déterminer le

code de température global du système. Les combinaisons

d'équipements dans le système sont sujettes à inspection par les

autorités locales qualifiées au moment de l'installation .

AVERTISSEMENT

RISQUE D’EXPLOSION –

• Couper le courant ou s'assurer

que l'environnement est classé

non dangereux avant de

débrancher l'équipement.

• Couper le courant ou s'assurer

que l'environnement est classé

non dangereux avant de

débrancher les connecteurs. Fixer

tous les connecteurs externes

reliés à cet équipement à l'aide

de vis, loquets coulissants,

connecteurs filetés ou autres

moyens fournis avec ce produit.

• La substitution de composants

peut rendre cet équipement

inadapté à une utilisation en

environnement de Classe I,

Division 2.

• S'assurer que l'environne ment est

classé non dangereux avant de

changer les piles.

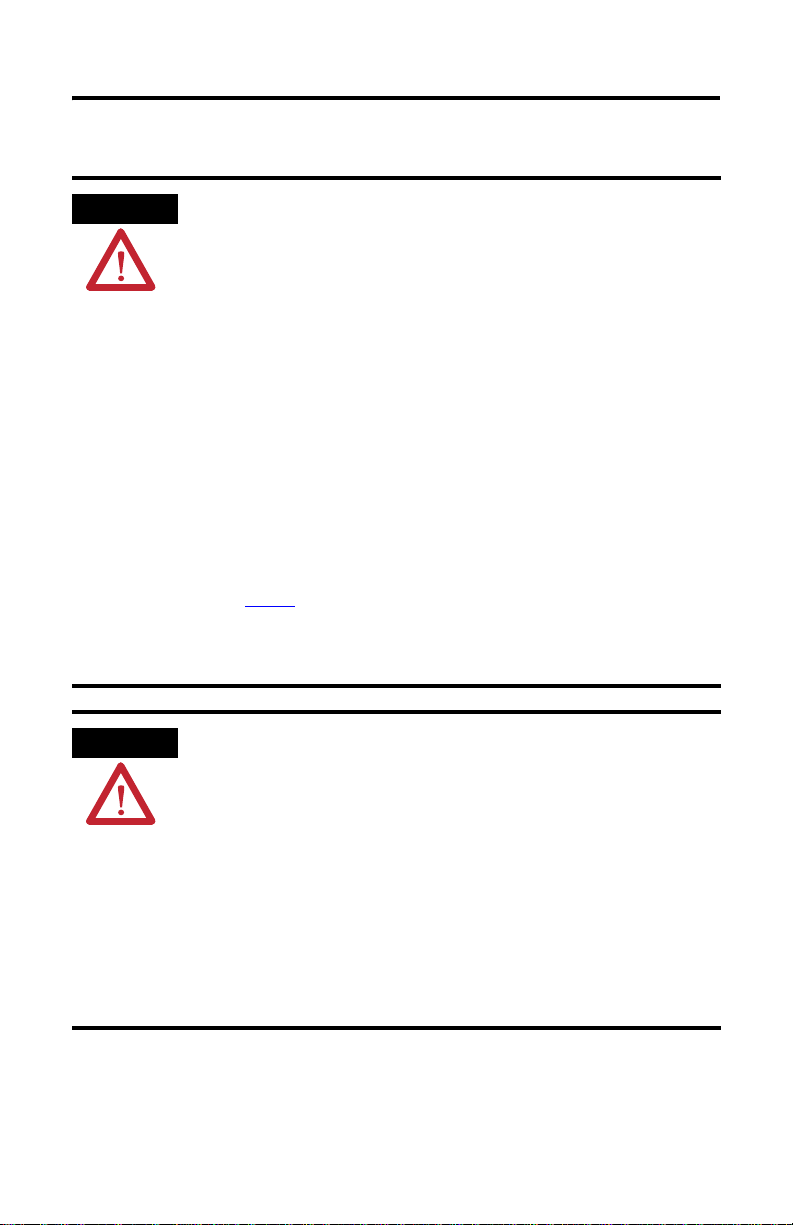

ATTENTION

Safety Programmable Electronic Systems (PES)

Personnel responsible for the application of safety-related programmable electronic

systems (PES) shall be aware of the safety requirements in the application of the system

and shall be trained in using the system.

Publication 1752-IN001C-EN-P - January 2009

Page 4

4 SmartGuard 600 Controllers

ATTENTION

ATTENTION

Environment and Enclosure

This equipment is intended for use in Pollution Degree 2 Industrial environment, in

Overvoltage Category II applications (as defined in IEC publication 60664-1), at altitudes

up to 2000 m (6562 ft) without derating.

This equipment is considered Group 1, Class A industrial equipment according to

IEC/CISPR Publication 11. Without appropriate precautions, there may be potential

difficulties ensuring electromagnetic compatibility in other environments due to

conducted as well as radiated disturbance.

This equipment is supplied as open type equipment. It must be mounted within an

enclosure that is suitably designed for those specific environmental conditions that will

be present and appropriately designed to prevent personal injury resulting from

accessibility to live parts. The enclosure must have suitable flame-retardant properties to

prevent or minimize the spread of flame, complying with flame spread rating or 5VA, V2,

V1, V0 (or equivalent) if non-metallic. The interior of the enclosure must be accessible

only by the use of a tool. Subsequent sections of this publication may contain additional

information regarding specific enclosure type ratings that are required to comply with

certain product safety certifications.

In addition to this publication, see:

• Industrial Automation Wiring and Grounding Guidelines, Allen-Bradley publication

• NEMA Standards publication 250 and IEC publication 60529, as applicable, for

Prevent Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which can cause internal damage

and affect normal operation. Follow these guidelines when you handle this equipment:

• Touch a grounded object to discharge potential static.

.

1770-4.1

explanations of the degrees of protection provided by different types of enclosure.

• Wear an approved wrist grounding strap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation, if available.

• Store the equipment in appropriate static-safe packaging when not in use.

Publication 1752-IN001C-EN-P - January 2009

Page 5

SmartGuard 600 Controllers 5

ATTENTION

T

ATTENTION

Protective Debris Strip

Do not remove the protective debris strip until after the controller and all the other

equipment near the controller is mounted and wiring is complete.

Once wiring is complete, remove the protective debris strip. Failure to remove the strip

before operating can cause overheating.

Serious injury may occur due to the loss of required safety function.

• Do not use test outputs as safety outputs.

• Do not use DeviceNet standard I/O data or explicit message data as safety data.

• Do not use the safety indicators for safety operations.

• Do not connect loads beyond the rated value to safety outputs or test outputs.

• Wire the controller properly so that the 24V DC line does not accidentally touch the

outputs.

• Ground the 0V line of the power supply for external output devices so that the

devices do not turn on when the safety output line or test output line is grounded.

• Do not dismantle, repair, or modify the controller. Doing so may impair the safety

functions.

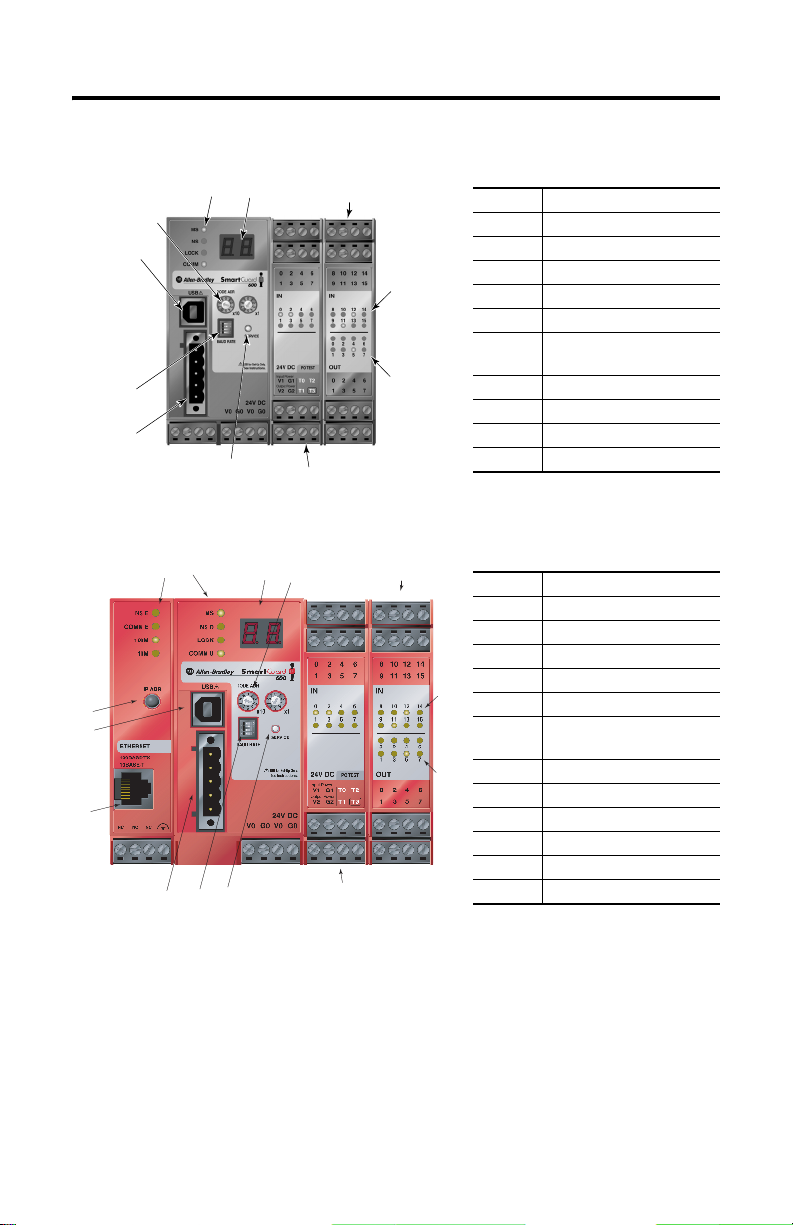

About the SmartGuard 600 Controller

SmartGuard 600 controllers, catalog numbers 1752-L24BBB and 1752-L24BBBE, are

programmable electronic systems featuring 16 digital inputs, 8 digital outputs, 4 test

pulse sources, and connections for USB and DeviceNet safety communication. In

addition, the 1752-L24BBBE controller offers EtherNet/IP connectivity.

SmartGuard 600 controllers are certified for use in safety applications up to and

including Safety Integrity Level (SIL) 3, according to IEC 61508,

Performance Level PL(e) according to ISO 13849-1, and Category (CAT) 4,

according to EN 954-1.

Publication 1752-IN001C-EN-P - January 2009

Page 6

6 SmartGuard 600 Controllers

1752-L24BBB Controller

2

1

3

5

4

6

10

1752-L24BBBE Controller

1

10

5

11

46

27

12

7

8

9

Number Feature

1 Module status indicators

2 Alphanumeric display

3 Node address switches

4 Baud rate switches

5 USB port

6 DeviceNet communication

connector

7 Terminal connectors

8 Input status indicators

9 Output status indicators

10 Service switch

7

3

7

Number Feature

1 Module status indicators

2 Alphanumeric display

3 Node address switches

4 Baud rate switches

8

5 USB port

6 DeviceNet communication

connector

7 Terminal connectors

9

8 Input status indicators

9 Output status indicators

10 IP address display switch

11 Ethernet connector

12 Service switch

Publication 1752-IN001C-EN-P - January 2009

Page 7

SmartGuard 600 Controllers 7

Before You Begin

Before you install the controller, set its DeviceNet node address and communication

rate.

IMPORTANT

Turn off power to the controller before setting the node address or communication rate

via the switches.

Do not change the switch settings while the power supply is on. The controller will detect

this as a change in the configuration and will switch to the ABORT mode.

Set the Node Address

Use a small screwdriver to set the DeviceNet node address by using the two rotary

switches on the front panel of the controller. Use care not to scratch the switches.

Values from 00…63 are valid. The default setting is 63.

Follow these steps to set the node address.

1. Set the tens digit of the node address (decimal) by turning the left rotary

switch.

2. Set the ones digit by turning the right rotary switch.

3. To set the node address by using RSNetWorx for DeviceNet software, set the

rotary switches to a value from 64…99.

IMPORTANT

A node address duplication error will occur if the same node address is set for more than

one node.

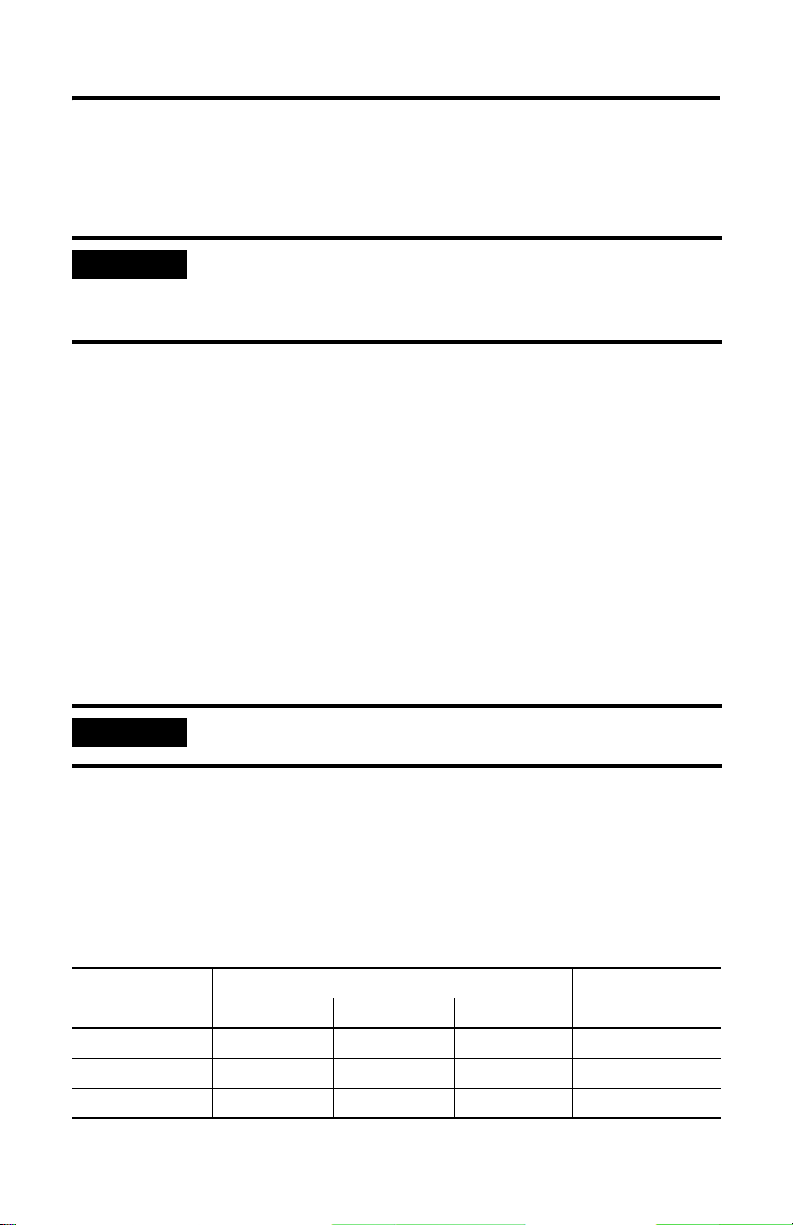

Setting the Communication Rate

The default communication rate for a DeviceNet network is 125 Kbps.

If you choose to use a different communication rate, the length of the trunkline and

types of cable determine which communication rates your application can support.

DeviceNet Communication Rates and Cable Lengths

Communication

Rate

125 Kbps 420 m (1378 ft) 500 m (1640 ft) 100 m (328 ft) 156 m (512 ft)

250 Kbps 200 m (656 ft) 250 m (820 ft) 100 m (328 ft) 78 m (256 ft)

500 Kbps 75 m (246 ft) 100 m (328 ft) 100 m (328 ft) 39 m (128 ft)

Distance, Max Cumulative Drop

Flat Cable Thick Cable Thin Cable

Line Length

Publication 1752-IN001C-EN-P - January 2009

Page 8

8 SmartGuard 600 Controllers

Set the communication rate by using the DIP switch on the front of the controller.

DIP Switch Settings

DIP Switch

Pin

IMPORTANT

1 2 3 4 Communication Rate

OFF OFF OFF OFF 125 Kbps

ON OFF OFF OFF 250 Kbps

OFF ON OFF OFF 500 Kbps

ON ON OFF OFF Set by software

ON or OFF ON or OFF ON OFF Set by software

ON or OFF ON or OFF ON or OFF ON Automatic baud-rate detection

If you change the communication rate of your network, make sure that all devices change

to the new communication rate. Mixed communication rates produce communication

errors.

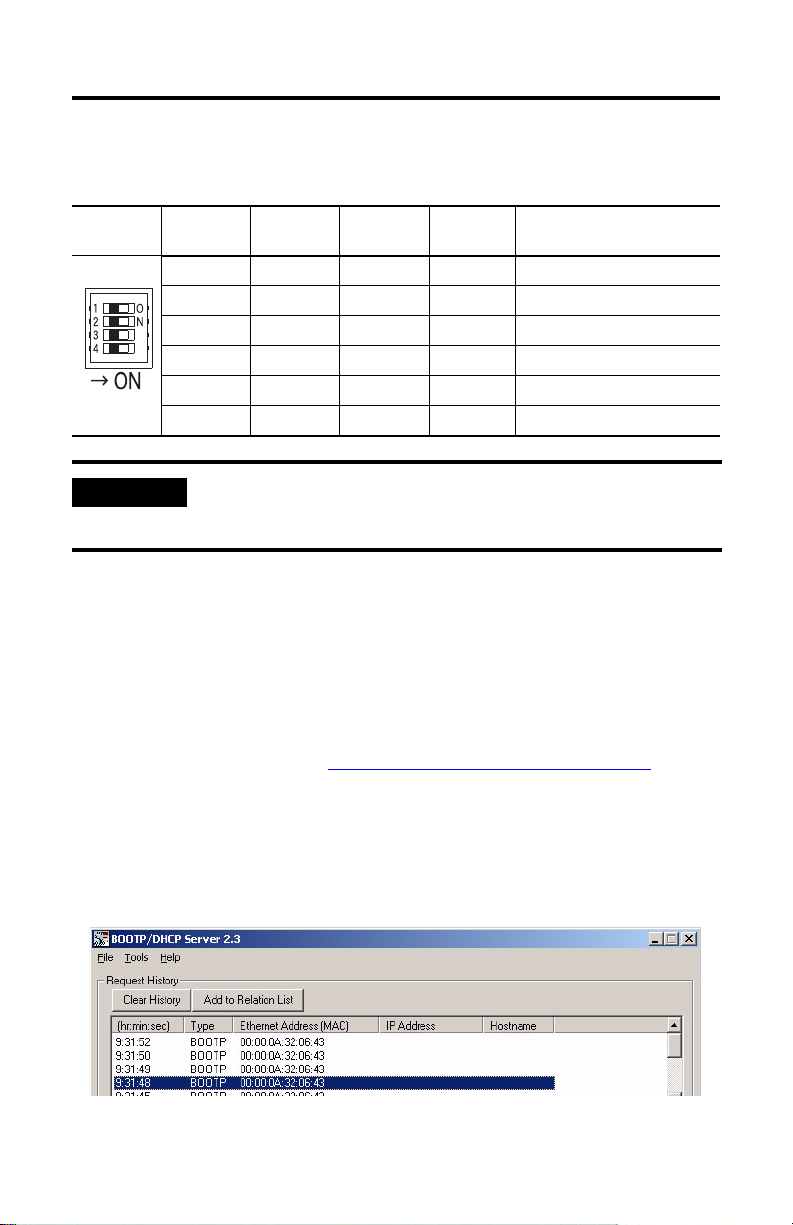

Set the IP Address for Ethernet Communication

Connect the 1752-L24BBBE controller to the network via a 100 Mbps Ethernet

switch, which will help reduce collisions and lost packets, and increase bandwidth.

The 1752-L24BBBE controller is shipped with BOOTP enabled for setting the IP

address. You can use any commercially available BOOTP server. If you do not have

BOOTP Server capabilities on your network, download the free Rockwell

Automation BOOTP server from http://www.ab.com/networks/bootp.html

To set the IP address by using the Rockwell Automation BOOTP utility, follow

these steps.

.

1. Run the BOOTP utility.

2. Double-click the hardware address of the device you want to configure.

Publication 1752-IN001C-EN-P - January 2009

Page 9

SmartGuard 600 Controllers 9

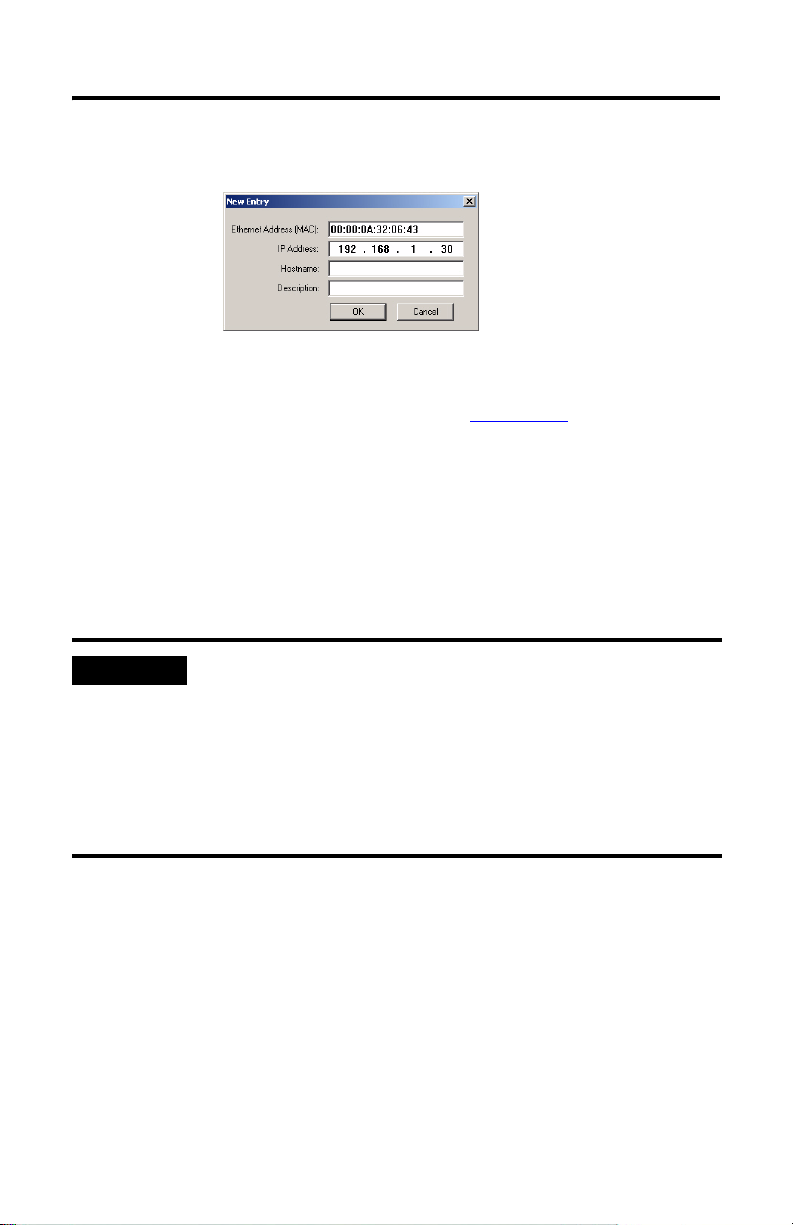

3. In the the New Entry pop-up dialog box, type the IP address you want to

assign to the device, and click OK.

The controller appears in the Relation List.

For detailed information on EtherNet/IP communication, refer to the EtherNet/IP

Performance and Application Solution, publication ENET-AP001.

Install the SmartGuard 600 Controller

To install the SmartGuard 600 controller, you must mount it on the DIN rail, wire

the terminals, and make communication connections.

Mount the SmartGuard 600 Controller

IMPORTANT

For effective cooling:

• mount the controller on a horizontal DIN rail. Do not mount the controller vertically.

• provide a gap of at least 50 mm (2.0 in.) above and below the controller and 5 mm

(0.20 in.) on each side.

• select a location where air flows freely or use an additional fan.

• do not mount the controller over a heating device.

Publication 1752-IN001C-EN-P - January 2009

Page 10

10 SmartGuard 600 Controllers

Mount the controller only to a DIN rail. Follow these steps to mount the controller

to an EN 50022-35x7.5 or EN 50022-35x15 DIN rail.

1. Hook the top slot over the DIN rail.

2. Snap the bottom of the controller into position while pressing the controller

down against the top of the rail.

Top Slot

DIN Rail

Latch

3. Attach end plates to each end of the DIN rail.

To remove the controller from the DIN rail, use a screwdriver to pull down the

latch and lift the controller off of the rail. The 1752-L24BBB controller has one latch

and the 1752-L24BBBE controller has two latches on the bottom of the controller.

Grounding the SmartGuard 600 Controller

ATTENTION

You must provide an acceptable grounding path for each device in your

application. Functionally ground the controller through its V0/G0 power

connection.

In addition, if you are using the 1752-L24BBBE controller, you should connect the

Ethernet ground terminal to an acceptable ground.

Publication 1752-IN001C-EN-P - January 2009

This product is grounded through the DIN rail to chassis ground. Use zinc plated

yellow-chromate steel DIN rail to assure proper grounding. The use of other DIN rail

materials (for example, aluminum or plastic) that can corrode, oxidize, or are poor

conductors, can result in improper or intermittent grounding. Secure DIN rail to mounting

surface approximately every 200 mm (7.8 in.) and use end anchors appropriately.

Page 11

SmartGuard 600 Controllers 11

Ethernet Ground

Refer to the Industrial Automation Wiring and Grounding Guidelines, publication

1770-4.1, for additional information.

Connecting a Power Supply

Power for the controller is provided via an external 24V DC power source. The

output hold time must be 20 ms or longer.

To comply with the CE Low Voltage Directive (LVD), DeviceNet connections and

I/O must be powered by a DC source compliant with safety extra low voltage

(SELV) or protected extra low voltage (PELV).

To comply with UL restrictions, DeviceNet connections and I/O must be powered

by DC sources whose secondary circuits are isolated from the primary circuit by

double insulation or reinforced insulation. The DC power supply must satisfy the

requirements for Class 2 circuits or limited voltage/current circuits defined in

UL 508.

TIP

R

The following Rockwell Automation 1606 power supplies are Class 2, SELV- and

PELV-compliant, and they meet the isolation and output hold-off time requirements of the

SmartGuard 600 controller:

•1606-XLP30E

•1606-XLP50E

•1606-XLP50EZ

• 1606-XLP72E

• 1606-XLP95E

• 1606-XLDNET4

• 1606-XL60DR

• 1606-XLSDNET4

The SmartGuard controller has three V/G terminal pairs that require a power

connection. There are two V0/G0 pairs, but because they are internally connected,

you need to only connect one V0/G0 pair. You can use the other pair to distribute

power to other devices.

Publication 1752-IN001C-EN-P - January 2009

Page 12

12 SmartGuard 600 Controllers

Power Supply Connections

+-

+-

+-

Wiring the SmartGuard 600 Controller

See page 24 for appropriate wire size and torque specifications.

Controller Terminal Descriptions

Terminal Designation Description

V0 Power terminal for internal circuit (logic).

G0 Power terminal for internal circuit (logic).

V1 Power terminal for input circuits and test outputs.

G1 Power terminal for input circuits and test outputs.

V2 Power terminal for safety outputs.

G2 Power terminal for safety outputs.

IN0…IN15 Terminals for safety inputs.

T0…T3 These are test output terminals that can provide pulse test sources for safety

inputs IN0...IN15. T3 can also support wire off detection and burned out bulb

detection for a load such as a muting lamp.

OUT0…OUT7 Terminals for safety outputs.

WARNING

If you connect or disconnect wiring while the field-side power is applied, an electrical arc

can occur. This could cause an explosion in hazardous location installations. Be sure that

power is removed or the area is nonhazardous before proceeding.

Publication 1752-IN001C-EN-P - January 2009

Page 13

SmartGuard 600 Controllers 13

WARNING

IMPORTANT

If you connect or disconnect the removable terminal block (RTB) while the field-side

power is applied, an electrical arc can occur. This could cause an explosion in hazardous

location installations. Be sure that power is removed or the area is nonhazardous before

proceeding.

Prepare stranded wires by attaching ferrules with plastic insulation covers (compliant

with the DIN 46228-4 standard). Ferrules similar in appearance but not compliant may not

match the terminal block on the controller.

Wiring Input Devices

ATTENTION

Input devices with mechanical contact outputs, such as emergency stop buttons

and safety limit switches, use both a safety input terminal and a test output

terminal. This enables the circuit to reach a Category 4 rating.

When safety devices are connected via test outputs to an input circuit on the

SmartGuard controller, we recommend the length of the wire to be 30 m (98.4 ft) or

less.

Applying an inappropriate DC or any AC voltage may result in a loss of safety function,

product damage, or serious injury. Properly apply only the specified voltage to controller

inputs.

Input Devices with Mechanical Contact Outputs

V1

4.5 mA Typical

Tx

SmartGuard 600

Controller

INx

24V DC

G1

Publication 1752-IN001C-EN-P - January 2009

Page 14

14 SmartGuard 600 Controllers

Devices, such as light curtains, with current-sourcing PNP semiconductor outputs

send a signal to the SmartGuard 600 controller safety-input terminal and do not use

a test output.

Input Devices with PNP Semiconductor Outputs

4.5 mA Typical

V1

24V DC

Tx

Wiring Output Devices

ATTENTION

Serious injury may occur due to a loss of required safety functions.

Do not connect loads beyond the rated value of safety or test outputs.

Do not use test outputs as safety outputs.

Wire the controller properly so that the 24V DC lines do not touch the safety or test

outputs.

Do not apply the power supply to the test output terminals.

Ground the 0V line of the power supply for external output devices so that the devices do

not turn on when the safety output line or the test output line is grounded.

Separate I/O cables from high voltage or high current lines.

OSSDx

24V DC

GND

INx

G1

SmartGuard 600

Controller

Publication 1752-IN001C-EN-P - January 2009

Page 15

Output Device Wiring

SmartGuard 600 Controllers 15

SmartGuard

600 Controller

V2

OUTx

24V DC

0.5 A Max

Load

G2

Making Communication Connections

WARNING

You can configure the network and controller on the DeviceNet network by using a

1784-PCD card inside your personal computer and RSNetWorx for DeviceNet

software. You can also configure the network and controller by using the

controller’s USB port and RSNetWorx for DeviceNet software.

In addition, you can communicate via the EtherNet/IP network. The EtherNet/IP

address and subnet mask are configured with the RSLinx module configuration. The

1752-L24BBBE controller is shipped with BOOTP enabled for setting the

IP Address. See page 8

Do not connect or disconnect the communication cable with power applied to this

controller or any device on the network, because an electrical arc can occur. This could

cause an explosion in hazardous location installations. Be sure that power is removed or

the area is nonhazardous before proceeding.

for details.

Publication 1752-IN001C-EN-P - January 2009

Page 16

16 SmartGuard 600 Controllers

Connect to the DeviceNet Port

Follow these steps to connect to the DeviceNet port.

1. Wire the connector according to the colors on the connector.

Wire No. Wire Color Connects to

1Red V+

2WhiteCAN H

3— Drain

4Blue CAN L

5BlackV-

D

D

D

D

D

2. Attach the connector to the DeviceNet port.

3. Tighten the screws to 0.25…0.3 N•m (2.21…2.65 lb•in).

For detailed DeviceNet connection information, refer to the DeviceNet Media

Design Installation Guide, publication DNET-UM072

. Also refer to the Industrial

Automation Wiring and Grounding Guidelines, publication 1770-4.1.

1

2

3

4

5

Connecting to the USB Port

Connect the USB communication connector to your personal computer when you

want to configure the network and controller by using RSNetWorx for DeviceNet

software. Use a commercially available USB-A to USB-B male/male cable to make

the connection.

ATTENTION

WARNING

Publication 1752-IN001C-EN-P - January 2009

The USB cable length must be less than 3 m (10 ft).

The USB port is intended for temporary programming purposes only and is not intended for

permanent connection.

If you connect or disconnect the USB cable with power applied to this module or any

device on the USB network, an electrical arc could occur. This could cause an explosion in

hazardous location installations. Be sure that power is removed or the area is

nonhazardous before proceeding.

Page 17

SmartGuard 600 Controllers 17

Connecting to the Ethernet Port

Use an RJ45 connector to connect the controller to the EtherNet/IP network.

ATTENTION

WARNING

The cable length must be less then 100 m (328 ft) between hub and nodes.

If you connect or disconnect the Ethernet cable with power applied to this controller or any

other device on this network, an electrical arc can occur. This could cause an explosion in

hazardous location installations. Be sure that power is removed or the area is

nonhazardous before proceeding.

Ethernet Pin Placement

Pin No. Pin Name Pin Placement

8 Not used

7 Not used

6RD5 Not used

4 Not used

3RD+

2TD1TD+

8

1

Interpreting the Status Indicators

The SmartGuard 600 controller features status indicators for module, DeviceNet and

EtherNet/IP network status, lock, USB and EtherNet/IP communication, individual

input and output status, as well as an alphanumeric status display for DeviceNet

error codes, DeviceNet node address, and EtherNet/IP address information.

Publication 1752-IN001C-EN-P - January 2009

Page 18

18 SmartGuard 600 Controllers

Alphanumeric Status Display

The controller’s alphanumeric display provides information about the module’s

status. Under normal operating conditions, the display shows the node address of

the module, 00…63 in decimal format. If the controller is operating in a standalone

configuration (not networked), the display shows ‘nd’. The display flashes when

the controller is self-testing, configuring, or in Idle mode. If a fault exists, the

display alternates between the error code and the node address where the error

occurred. If a fatal error has occurred, the display shows the error code only.

When the service switch is pressed, the display shows the controller’s

safety-configuration signature two digits at a time. The configuration signature can

also be viewed on the Safety tab of the Controller Properties dialog box in

RSNetWorx for DeviceNet software. You can use the configuration signature to

verify that the program and configuration of the controller has not been changed.

When the IP address display switch is pressed for 1 second or longer, the display

shows the EtherNet/IP address that is set. The error code ‘n4’ is displayed if an error

occurs in the EtherNet/IP configuration.

Status Indicators

Use these tables to interpret the color and status combinations of the status

indicators and take recommended actions where applicable.

Module Status (MS) Indicator Descriptions

If the Module Status

(MS) indicator is

Off No power. Refer to the corrective action following this

Green, on The controller is operating in Run

Green, flashing The controller is idle.

Red, flashing A recoverable fault exists. Refer to the corrective action following this

Red, on An unrecoverable fault exists.

Red/green flashing Self-test in progress. Or, the

If your Module Status indicator is off, follow these steps.

1. Cycle the power supply.

2. Take corrective actions for noise.

Publication 1752-IN001C-EN-P - January 2009

It means Take this action

table.

No action required.

mode and under normal conditions.

table.

controller’s configuration is being

downloaded or is incomplete or

incorrect.

Page 19

SmartGuard 600 Controllers 19

3. Contact Rockwell Automation.

If your Module Status indicator is flashing red, follow these steps.

1. Configure the switches properly.

2. Reset the configuration data.

If your Module Status indicator is solid red (on), follow these steps.

1. Cycle the power supply.

2. Check external wiring.

3. Take corrective actions for noise.

4. Contact Rockwell Automation.

If your Module Staus indicator is flashing red and green, follow these steps.

1. Configure the switches properly.

2. Set the safety network number.

3. Reconfigure the device.

DeviceNet Network Status (NS D) Indicator Descriptions

If the DeviceNet

Network Status

(NS D) indicator is

Off The controller is not online or may not

Green, on The controller is online; connections

Green, flashing The controller is online; no

Red, on Communication failure due to

Red, flashing Communication timeout.

Red/green flashing The Safety Network Number (SNN) is

It means Take this action

Refer to the corrective action following this

have power from the DeviceNet

network.

are established.

connections are established.

duplicate MAC ID (error code F0) or

Bus OFF (error code F1).

being set.

table.

No action required.

Refer to the corrective action following this

table

No action required.

Publication 1752-IN001C-EN-P - January 2009

Page 20

20 SmartGuard 600 Controllers

If your Network Status indicator is off, follow these steps.

1. Cycle the power supply.

2. Check external wiring.

3. Take corrective actions for noise.

4. Contact Rockwell Automation.

If your Network Status indicator is on or flashing red, follow these steps.

1. View the Alphanumeric display for the node address of the error and error

code.

2. Check that node addresses have not been duplicated.

3. Make sure the communication rate is the same for all nodes.

4. Check that cables are not loose, disconnected or too long.

5. Verify that terminating resistors have been installed only at both ends of the

main line.

6. Take corrective action for noise.

7. Make sure target devices are configured, verified, and in normal operating

state.

Lock Configuration (Lock) Status Indicator Descriptions

If the Lock

Configuration (Lock)

status indicator is

Yellow, on A locked valid configuration exists. No action required.

Yellow, flashing An unlocked valid configuration exists. Lock the configuration before operating the

Off The configuration is invalid. Reconfigure the controller.

Publication 1752-IN001C-EN-P - January 2009

It means Take this action

safety system.

Page 21

SmartGuard 600 Controllers 21

USB Communication (COMM U) Status Indicator Descriptions

If the USB

Communication

(COMM U) status

indicator is

Yellow, flashing The controller is communicating. No action required.

Off The controller is not communicating.

It means Take this action

I/O (inputs 0...15, outputs 0...7) Status Indicators Descriptions

If the I/O status

indicators are

Red, on A failure has been detected in the

Red, flashing A failure has been detected in the

Off The input or output signal is off.

Yellow, on The input or output signal is on. No action required.

It means Take this action

Refer to the corrective action following this

input or output circuit or a discrepancy

error has occurred in the I/O set for

Dual-channel mode.

associated I/O circuit’s dual channel

configuration.

table.

If your I/O Status indicator is on or flashing red, follow these steps.

1. Check that the signal wire:

• is not making contact with the power source (positive side).

• does not have an earth fault.

• is not disconnected.

2. Make sure there is not a short-circuit between signal wires.

3. Check that there is no overcurrent for the output.

4. Make sure there is no failure in the connected devices.

5. Verify that the Discrepancy Time settings are valid.

If your I/O Status indicator is off, follow these steps.

1. Check that the power supply voltage is set within the specified range.

2. Make sure a cable or wire is not disconnected.

Publication 1752-IN001C-EN-P - January 2009

Page 22

22 SmartGuard 600 Controllers

EtherNet/IP Network Status (NS E) Indicator Descriptions

If the EtherNet/IP

Network Status

(NS E) indicator is

Off The controller does not have an IP

Green, flashing The controller has no established

Green, on The controller has at least one

Red, flashing One or more of the connections in

Red, on The controller has detected that its IP

If your EtherNet/IP Status indicator is off, follow these steps.

1. Apply power to the controller.

It means Take this action

address or is not turned on.

connections but has obtained an IP

address.

established connection (even to the

message router).

which this device is the target has

timed out. This shall be left only if all

timed out connections are

reestablished or if the device is reset.

address is already in use.

Refer to the corrective action following this

table.

No action required.

Refer to the corrective action following this

table.

Reset the IP address.

2. Set the IP address.

If your EtherNet/IP Status indicator is flashing green, follow these steps.

1. Check the wiring to the controller.

2. Configure the originator to connect to the target.

If your EtherNet/IP Status indicator is flashing red, follow these steps.

1. Check external wiring.

2. Check the endpoints.

3. Check the switches.

Publication 1752-IN001C-EN-P - January 2009

Page 23

SmartGuard 600 Controllers 23

EtherNet/IP Communication (COMM E) Status Indicator Descriptions

If the EtherNet/IP

Communication

(COMM E) status

indicator is

Green, on The controller is communicating on

Off The controller is not communicating

It means Take this action

No action required.

the Ethernet network.

on the Ethernet network.

Ethernet Network Speed (100) Status Indicator Descriptions

If the Ethernet

Network Speed (100)

status indicator is

Yellow, on The communication rate is 100 Mbps. No action required.

(1)

Off

(1) If this indicator is Off along with the Network Speed (10) indicator, check your Ethernet connection.

It means Take this action

The communication rate is 10 Mbps. Check that the Network Speed (10) indicator

is on.

Ethernet Network Speed (10) Status Indicator Descriptions

If the Ethernet

Network Speed (10)

status indicator is

Yellow, on The communication rate is 10 Mbps. No action required.

(1)

Off

(1) If this indicator is Off along with the Network Speed (100) indicator, check your Ethernet connection.

Refer to the SmartGuard 600 Controller User Manual, publication 1752-UM001

more information on recovering from I/O errors.

ATTENTION

It means Take this action

The communication rate is 100 Mbps. Check that the Network Speed (100) indicator

is on.

Status indicators are not reliable indicators for safety functions. They should be used

only for general diagnostics during commissioning and troubleshooting. Do not use

status indicators as operational indicators.

Publication 1752-IN001C-EN-P - January 2009

, for

Page 24

24 SmartGuard 600 Controllers

Specifications

SmartGuard 600 Controllers - 1752-L24BBB, 1752-L24BBBE

Attribute 1752-L24BBB 1752-L24BBBE

Dimensions (HxWxD), approx.

(4)

x 99.4 x 131.4 mm

99.0

(4)

(3.90

x 3.91 x 5.18

Weight, approx. 460 g (1.23 lb) 575 g (1.54 lb)

DeviceNet current load, max 15 mA @ 24V DC

Supply voltage

(1)

20.4…26.4V DC (24V DC, -15…10%)

Inrush current - unit power supply 4.8 A peak for 600 μs @ V0/G0

Inrush current - safety input power

2.6 A peak for 3 ms @ V1/G1

supply

DeviceNet voltage range 11…25V DC

Current consumption

230 mA @ 24V DC 280 mA @ 24V DC

(V0 - internal logic circuit)

Overload protection Shut down of the affected output with cyclic reconnecting

Isolation voltage 50V, Functional insulation type

Tested at 600V AC for 60 s, between all groups

Wire type Copper

Wiring category

Wire size

(2)

2 - on power, signal, and

communication ports

For power supply and I/O, use 0.2…2.5 mm

or 0.34…1.5 mm

connecting, prepare standard wires by attaching ferrules with plastic

insulation collars (DIN 46228-4 standard compatible)

For Ethernet connections:

RJ45 connector according to IEC 60603-7, 2 or 4 pair Category 5e

minimum cable according to TIA 569-B.1 or Category 5 cable according

to ISO/IEC 24701

I/O terminal screw torque 0.56…0.79 N•m (5…7 lb•in)

North American temperature code T4A

Input type Current sinking

Voltage, on-state input, min 11V DC

Voltage, off-state input, max 5V DC

Current, off-state input, max 1 mA

Input current 4.5 mA

Input impedance 2.6 kΩ

(5)

(5)

in.)

(4)

99.0

x 113.0 x 131.4

(4)

(3.90

x 4.48 x 5.18

2 - on power, 1 - on signal, 1 communication ports

2

2

(16…22 AWG) standard flexible wire. Before

(12…24 AWG) solid wire,

(5)

mm

(5)

in.)

Publication 1752-IN001C-EN-P - January 2009

Page 25

SmartGuard 600 Controllers 25

SmartGuard 600 Controllers - 1752-L24BBB, 1752-L24BBBE

Attribute 1752-L24BBB 1752-L24BBBE

Test output type Current sourcing

Pulse test output current

(3)

Test output surge current 0.7 A

Pulse test off-state voltage, max 1.2V

Pulse test output leakage current,

max

Muting lamp output current (T3)

• More than 25 mA

• Less than 5 mA

Output type Current sourcing

Output current 0.5 A

Output surge current 0.5 A

Voltage, off-state output max 1.2V

Leakage current, off-state output,

max

Heat dissipation 9.3 W under max load

Ethernet Communication

CIP connections Not applicable 2

Auto negotiation Not applicable Supported

Data rate Not applicable 10/100 Mbps

Duplex Not applicable Full/half

Allowable unit

communication bandwidth

Explicit message

communication

(1) V0/G0 for internal logic circuit; V1/G1 for external input devices and test outputs; V2/G2 for external output devices.

(2) Use this Conductor Category information for planning conductor routing. Refer to Industrial Automation Wiring and

Grounding Guidelines, publication 1770-4.1

(3) T0...T3 total current at the same time: 1.4 A.

(4) Height includes terminal connectors.

(5) Depth includes DeviceNet connector.

(6) PPS is packets per second. It indicates the number of send or receive packets that can be processed per second.

(7) The maximum message length for class 3 connection and UCMM connection.

0.7 A

0.1 mA

• Normal operation (to avoid fault when used as a muting lamp

output)

• Fault (a fault indication is generated when used as a muting

lamp output)

0.1 mA

Not applicable

Not applicable

.

3000 pps

502 Bytes

(6)

(7)

Publication 1752-IN001C-EN-P - January 2009

Page 26

26 SmartGuard 600 Controllers

Environmental Specifications

Attribute 1752-L24BBB 1752-L24BBBE

Temperature, storage IEC 60068-2-1 (Test Ab, Unpackaged Nonoperating Cold),

IEC 60068-2-2 (Test Bb, Unpackaged Nonoperating Dry Heat),

IEC 60068-2-14 (Test Na, Unpackaged Nonoperating Thermal Shock):

-40…70 °C (-40…158 °F)

Temperature, operating IEC 60068-2-1 (Test Ad, Operating Cold),

IEC 60068-2-2 (Test Bd, Operating Dry Heat),

IEC 60068-2-14 (Test Nb, Operating Thermal Shock):

-10…55 °C (14…131 °F) (surrounding air temperature)

Relative humidity IEC 60068-2-30

(Test Db, Unpackaged Nonoperating Damp Heat):

10…95% noncondensing

Vibration IEC 60068-2-6 (Test Fc, Operating):

0.35 mm @ 10…57 Hz

5 g @ 57…150 Hz

Shock, operating IEC 60068-2-27 (Test Ea, Unpackaged Shock): 15 g

Shock, nonoperating IEC 60068-2-27 (Test Ea, Unpackaged Shock): 30 g

Enclosure type rating Meets IP20

Emissions CISPR 11: Group 1, Class A

ESD immunity IEC 61000-4-2:

• 4 kV contact discharges

• 8 kV air discharges

Radiated RF immunity IEC 61000-4-3:

• 10 V/m with 1 kHz

sine-wave 80% AM from

80…1000 MHz

• 10 V/m with 1 kHz

sine-wave 80% AM from

1.4…2.0 GHz

• 10 V/m with 200 Hz 50%

Pulse 100% AM at 900 MHz

• 10 V/m with 200 Hz 50%

Pulse 100% AM at 1200

MHz

• 3 V/m with 1 kHz sine-wave

80% AM from 2000…2700

MHz

IEC 60068-2-6 (Test Fc, Operating):

5 g @ 10…500 Hz

IEC 61000-4-2:

• 6 kV contact discharges

• 8 kV air discharges

IEC 61000-4-3:

• 10 V/m with 1 kHz

sine-wave 80% AM from

80…1000 MHz

• 10 V/m with 1 kHz

sine-wave 80% AM from

1.4…2.0 GHz

• 20 V/m with 200 Hz 50%

Pulse 100% AM at 800, 900,

1200 MHz

• 3 V/m with 1 kHz sine-wave

80% AM from 2000…2700

MHz

Publication 1752-IN001C-EN-P - January 2009

Page 27

SmartGuard 600 Controllers 27

Environmental Specifications

Attribute 1752-L24BBB 1752-L24BBBE

EFT/B immunity IEC 61000-4-4:

• ±2 kV @ 5 kHz on power

ports

• ±2 kV @ 5 kHz on signal

ports

• ±2 kV @ 5 kHz on

communication ports

Surge transient immunity IEC 61000-4-5:

• ±1 kV line-line (DM) and ±2

kV line-earth (CM) on power

ports

• ±1 kV line-line (DM) and ±2

kV line-earth (CM) on signal

ports

• ±1 kV line-earth (CM) on

communication ports

Conducted RF immunity IEC 61000-4-6:

• 10V rms with 1 kHz sine-wave 80% AM from 150 kHz…80 MHz

IEC 61000-4-4:

• ±2 kV @ 5 kHz on power

ports

• ±1 kV @ 5 kHz on signal

ports

• ±1 kV @ 5 kHz on

communication ports

IEC 61000-4-5:

• ±500V line-line (DM) and ±1

kV line-earth (CM) on power

ports

• ±1 kV line-earth (CM) on

signal ports

• ±1 kV line-earth (CM) on

communication ports

Certifications

Certification

(when product is marked)

c-UL-us UL Listed for Class I, Division 2 Group A,B,C,D Hazardous Locations, certified

CE European Union 2004/108/EEC EMC Directive, compliant with:

C-Tick Australian Radiocommunications Act, compliant with:

TÜV TÜV Certified for Functional Safety

UL UL Certified for Functional Safety. See UL File E256621.

(1)

Valu e

for US and Canada. See UL File E194810.

• EN 61000-6-4; Industrial Emissions

• EN 61131-2; Programmable Controllers (Clause 8, Zone A & B)

• EN 61326-1; Meas./Control/Lab., Industrial Requirements

• EN 61000-6-2; Industrial Immunity

AS/NZS CISPR 11; Industrial Emissions

Functional Safety: SIL 1 to 3, according to IEC 61508; Performance Level PL(e)

according to ISO 13849-1, Category 1 to 4, according to EN954-1; NFPA79;

when used as described in the SmartGuard Controllers Safety Reference

Manual, publication 1752-RM001

.

Publication 1752-IN001C-EN-P - January 2009

Page 28

(1) See the Product Certification link at http://ab.com for Declarations of Conformity, Certificates, and other certifications

details.

Additional Resources

These documents contain additional information concerning related Rockwell

Automation products.

Resource Description

SmartGuard 600 User Manual, publication

1752-UM001

SmartGuard 600 Safety Reference Manual,

publication 1752-RM001

Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

Product Certifications website,

http://ab.com

You can view or download publications at

http://literature.rockwellautomation.com

documentation, contact your local Rockwell Automation distributor or sales

representative.

Information on wiring, configuring, operating, and

troubleshooting a SmartGuard 600 controller.

Information on the safety concept of the SmartGuard 600

controller, as well as PFD and PFH values and reaction time

calculations.

Provides general guidelines for installing a Rockwell

Automation industrial system.

Provides declarations of conformity, certificates, and other

certification details.

. To order paper copies of technical

Allen-Bradley, Rockwell Automation, SmartGuard, RSNetWorx for DeviceNet, and RSLinx are trademarks of Rockwell

Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication 1752-IN001C-EN-P - January 2009 PN 28964

Supersedes Publication 1752-IN001B-EN-P - October 2006 Copyright © 2009 Rockwell Automation, Inc. All rights reserved. Printed in Japan.

Loading...

Loading...