Page 1

User Manual

SmartGuard 600 Controllers

Catalog Numbers 1752-L24BBB, 1752-L24BBBE

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, CompactLogix, ControlLogix, FactoryTalk, Guard I/O, GuardLogix, MicroLogix, PanelBuilder, PanelView Plus, PLC-5, POINT I/O, Rockwell Software, RSLinx, R SLogix 5000, RSNetWorx, RSView, SLC

and SmartGuard are trademarks of Rockwell Automation, Inc.

EtherNet/IP and DeviceNet are trademarks of the ODVA

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Summary of Changes

The information below summarizes the changes to this manual since the last

printing.

To help you find new and updated information in this release of the manual, we

have included change bars as shown to the right of this paragraph.

Top ic Pag e

Updated the procedure for handling forgotten passwords 48

Updated DeviceNet driver information 50

Rockwell Automation Publication 1752-UM001E-EN-P - June 2014 3

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication 1752-UM001E-EN-P - June 2014

Page 5

Summary of Changes

Table of Contents

Preface

Overview

Table of Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Purpose of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Common Techniques Used in This Manual . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

About the SmartGuard 600 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Configuration and Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Status and Error Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Safety Concept of the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Additional Resource. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Installing and Wiring the SmartGuard

600 Controller

Chapter 2

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

General Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Understanding Node Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Set the Node Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Setting the Communication Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

DeviceNet Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Ethernet Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Mount the SmartGuard Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Grounding the SmartGuard Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Connecting a Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Making Communication Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Connect to the DeviceNet port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Connecting to USB Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Connecting to the Ethernet port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Wiring the SmartGuard 600 Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Wire Output Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Wiring Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Chapter 3

Set Up Your DeviceNet Network

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Connecting a Computer to the DeviceNet Network . . . . . . . . . . . . . . . . 41

Configure a Driver for the Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Make Sure the Driver Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Commission All Nodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Browse the Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Rockwell Automation Publication 1752-UM001E-EN-P - June 2014 5

Page 6

Table of Contents

Configuration Signature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Safety Reset (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Setting Passwords (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Set or Change a Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Forgotten Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Chapter 4

Set Up Your EtherNet/IP Network

Manage the Safety Network Number

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Connecting a Computer to the EtherNet/IP Network . . . . . . . . . . . . . . 49

Configure a Driver for the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Make Sure the Driver Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Connecting the SmartGuard 600 Controller to the EtherNet/IP

Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Setting the IP Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Using BOOTP to Set the IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Use the Rockwell BOOTP Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Use RSLinx Software to Set the IP Address . . . . . . . . . . . . . . . . . . . . . 54

Bridging across Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

EtherNet/IP Network to a DeviceNet Network. . . . . . . . . . . . . . . . . 57

USB Port to the EtherNet/IP Network. . . . . . . . . . . . . . . . . . . . . . . . . 59

Chapter 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Safety Network Number (SNN) Formats. . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Time-based Safety Network Number (recommended) . . . . . . . . . . . 62

Manual Safety Network Number (SNN) . . . . . . . . . . . . . . . . . . . . . . . 62

Assignment of the Safety Network Number (SNN) . . . . . . . . . . . . . . . . . 62

Automatic (time-based) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Set the Safety Network Number (SNN) in All Safety Nodes . . . . . . . . . 63

Safety Network Number (SNN) Mismatch . . . . . . . . . . . . . . . . . . . . . . . . . 65

Safety Network Number (SNN) and Node Address Changes . . . . . . . . 65

Chapter 6

Configure Local I/O

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Configure Local Safety Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Example: Input Channel as Test Pulse from Test Output . . . . . . . . 70

Automatic Adjustment of On- and Off-delay Times . . . . . . . . . . . . . 71

Configure Local Test Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Configure Local Safety Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Chapter 7

Configure Your Controller for

DeviceNet Communication

6 RockwellJune Automation Publication 1752-UM001E-EN-P - June 2014

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Setting Up the Controller as a Safety Master. . . . . . . . . . . . . . . . . . . . . . . . 77

Configure CIP Safety I/O Targets on the DeviceNet Network . . . 78

Page 7

Table of Contents

Configure Safety I/O Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Change an I/O Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Setting Up the Controller as a Safety Slave . . . . . . . . . . . . . . . . . . . . . . . . . 87

Create Safety Slave I/O Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Use the Safety Generic Profile in RSLogix 5000 Software . . . . . . . . 90

SmartGuard Controller to SmartGuard Controller Safety

Interlocking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Setting Up the Controller as a DeviceNet Standard Slave . . . . . . . . . . . . 95

Create Standard Slave I/O Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Adding the SmartGuard Standard Slave to the Standard Master’s

Scanlist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Reading and Writing to and from the SmartGuard Controller to a

PanelView Plus Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Read BOOLs from the SmartGuard Controller and Display Them on

the PanelView Plus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Configure the Scanlist of the PanelView Scanner. . . . . . . . . . . . . . . 103

Configure the RN10C DeviceNet Scanner . . . . . . . . . . . . . . . . . . . . 104

Read and Write from and to the SmartGuard Controller from the

PanelView Plus Interface Concurrently . . . . . . . . . . . . . . . . . . . . . . . 110

Configure the Scanlist of the PanelView Scanner. . . . . . . . . . . . . . . 113

Configure the RN10C DeviceNet Scanner . . . . . . . . . . . . . . . . . . . . 115

Configure the Data that is Written from the PanelView Plus Interface

to the SmartGuard Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

COS versus Polled. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Maximum Connection Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Configure Your Controller for

EtherNet/IP Communication

Set Controller Modes

Create Your Application Program

Chapter 8

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Multicast Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Configure Target I/O in RSNetWorx for DeviceNet Software. . . . . . 126

Set Up Your Controller as a Slave by Using RSLogix 5000 Software

Generic Profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Configure Communication between a Standard PanelView Terminal and

a SmartGuard 600 Controller over an EtherNet/IP Network . . . . . . . 132

Chapter 9

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Set Automatic Execution Mode (optional) . . . . . . . . . . . . . . . . . . . . . . . . 135

Set Standalone Communication Mode (optional). . . . . . . . . . . . . . . . . . 136

Change Controller Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Chapter 10

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

The Logic Editor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Programming Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Logic Functions and Function Blocks . . . . . . . . . . . . . . . . . . . . . . . . . 141

Rockwell Automation Publication 1752-UM001E-EN-P - June 2014 7

Page 8

Table of Contents

Input Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Output Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

I/O Comment Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Programming Restrictions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Creating a Function Block Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Add an Input or Output Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Add a Function Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Connect the Tags to the Function Block. . . . . . . . . . . . . . . . . . . . . . . 145

Edit Function Block Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

In/Out Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Optional Output Point Selections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Find Function Blocks with Open Connections . . . . . . . . . . . . . . . . . . . . 148

Program on Multiple Pages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Save the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Update the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Monitor the Program Online. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Program Execution Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

User-defined Function Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Create User-defined Function Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . 153

Password Protect User-defined Function Blocks. . . . . . . . . . . . . . . . 154

Reuse User-defined Function Block Files . . . . . . . . . . . . . . . . . . . . . . 155

Precautions for Reusing User-defined Function Blocks. . . . . . . . . . 157

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Download and Verify

Monitor Status and Handle Faults

Chapter 11

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Download the DeviceNet Network Configuration . . . . . . . . . . . . . . . . . 159

Verifying Your DeviceNet Safety Configuration . . . . . . . . . . . . . . . . . . . 161

Start the Safety Device Verification Wizard. . . . . . . . . . . . . . . . . . . . . . . . 161

Determine if Devices Can Be Verified . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Select Devices to Verify . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Review the Safety Device Verification Reports . . . . . . . . . . . . . . . . . . . . . 164

Lock Safety Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

View the Safety Device Verification Wizard Summary . . . . . . . . . . . . . . 167

Chapter 12

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Alphanumeric Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Monitoring I/O Power Supply Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Monitoring I/O Maintenance Information . . . . . . . . . . . . . . . . . . . . . . . . 172

Contact Operation Counter Monitoring . . . . . . . . . . . . . . . . . . . . . . 172

Total On-time Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Configure a Maintenance Monitoring Mode. . . . . . . . . . . . . . . . . . . 173

Clear the Maintenance Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

8 RockwellJune Automation Publication 1752-UM001E-EN-P - June 2014

Page 9

Table of Contents

Viewing I/O Status Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

General Status Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Local Input Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Local Output Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Test Output or Muting Lamp Status . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Controller Connection Status (safety slave function). . . . . . . . . . . . . . . 177

Error Categories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Error History Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Error History Memory Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Display the Error History Table for the 1752-L24BBB

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Display the EtherNet/IP Error History Table for the 1752-L24BBBE

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Ethernet Error History Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Error History Messages and Corrective Actions. . . . . . . . . . . . . . . . . . . . 183

Download Errors and Corrective Actions . . . . . . . . . . . . . . . . . . . . . . . . . 185

Reset Errors and Corrective Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Mode Change Errors and Corrective Actions. . . . . . . . . . . . . . . . . . . . . . 188

Controller Specifications

Status Indicators

Logic Functions Command Reference

Appendix A

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Appendix B

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Module Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Identifying Errors Using Module Status Indicators and Alphanumeric

Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Identifying EtherNet/IP Errors Using Status Indicators and

Alphanumeric Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Appendix C

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

NOT Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

NOT Instruction Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

NOT Instruction Truth Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

AND Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

AND Instruction Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

AND Instruction Truth Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

OR Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

OR Instruction Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

OR Instruction Truth Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Exclusive OR Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Exclusive OR Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Rockwell Automation Publication 1752-UM001E-EN-P - June 2014 9

Page 10

Table of Contents

Exclusive OR Truth Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Exclusive NOR Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Exclusive NOR Instruction Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Exclusive NOR Instruction Truth Tables. . . . . . . . . . . . . . . . . . . . . . 210

Routing Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Routing Instruction Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Routing Instruction Truth Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Reset Set Flip-flop (RS-FF) Instruction. . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Reset Set Flip-flop Instruction Diagram . . . . . . . . . . . . . . . . . . . . . . . 211

Reset Set FIip-flop Error Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

RS Flip-flop Instruction Timing Chart . . . . . . . . . . . . . . . . . . . . . . . . 212

Multi-connector Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Multi-connector Instruction Diagram . . . . . . . . . . . . . . . . . . . . . . . . . 212

Multi-connector Instruction Truth Table . . . . . . . . . . . . . . . . . . . . . 213

Comparator Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Comparator Instruction Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Comparator Instruction Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Comparator Instruction Truth Table . . . . . . . . . . . . . . . . . . . . . . . . . 215

Comparator Instruction Timing Chart . . . . . . . . . . . . . . . . . . . . . . . . 216

Function Blocks Command Reference

Appendix D

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Reset Function Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Reset Function Block Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Reset Function Block Timing Charts. . . . . . . . . . . . . . . . . . . . . . . . . . 219

Restart Function Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Restart Function Block Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Restart Function Block Timing Charts . . . . . . . . . . . . . . . . . . . . . . . . 221

Emergency Stop (ESTOP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

ESTOP Function Block Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

ESTOP Function Block Truth Tables . . . . . . . . . . . . . . . . . . . . . . . . . 222

ESTOP Function Block Error Handling. . . . . . . . . . . . . . . . . . . . . . . 223

ESTOP Function Block Timing Chart . . . . . . . . . . . . . . . . . . . . . . . . 223

Light Curtain (LC) Function Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Light Curtain Function Block Parameters . . . . . . . . . . . . . . . . . . . . . 224

Light Curtain Function Block Truth Tables . . . . . . . . . . . . . . . . . . . 224

Light Curtain Function Block Error Handling . . . . . . . . . . . . . . . . . 224

Light Curtain Function Block Timing Chart . . . . . . . . . . . . . . . . . . 225

Safety Gate Monitoring Function Block . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Safety Gate Monitoring Function Block Optional Outputs . . . . . 226

Safety Gate Monitoring Function Block Fault Present Output

Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Safety Gate Monitoring Function Block Function Tests . . . . . . . . 226

Safety Gate Monitoring Function Block Parameters . . . . . . . . . . . . 227

Safety Gate Monitoring Function Block Truth Tables . . . . . . . . . . 227

Safety Gate Monitoring Function Block Error Handling . . . . . . . . 228

Safety Gate Monitoring Function Block Timing Charts. . . . . . . . . 229

10 RockwellJune Automation Publication 1752-UM001E-EN-P - June 2014

Page 11

Table of Contents

Two-hand Control Function Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Two-hand Control Function Block Optional Outputs . . . . . . . . . 230

Two-hand Control Function Block Fault Present Output

Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Two-hand Control Function Block Parameters . . . . . . . . . . . . . . . . 230

Two-hand Control Function Block Truth Table. . . . . . . . . . . . . . . 231

Two-hand Control Function Block Error Handling. . . . . . . . . . . . 231

Two-hand Control Function Block Timing Chart . . . . . . . . . . . . . 232

OFF-delay Timer Function Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

OFF-delay Timer Function Block Timing Chart. . . . . . . . . . . . . . . 233

ON-delay Timer Function Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

ON-Delay Timer Function Block Timing Chart. . . . . . . . . . . . . . . 234

User Mode Switch Function Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

User Mode Switch Function Block Optional Outputs . . . . . . . . . . 234

User Mode Switch Function Block Fault Present Output Setting 235

User Mode Switch Function Block Truth Table . . . . . . . . . . . . . . . 235

User Mode Switch Function Block Error Handling . . . . . . . . . . . . 235

User Mode Switch Function Block Timing Chart . . . . . . . . . . . . . . 236

External Device Monitoring (EDM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

EDM Function Block Optional Outputs . . . . . . . . . . . . . . . . . . . . . . 236

EDM Function Block Fault Present Output Setting. . . . . . . . . . . . 237

EDM Function Block Parameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

EDM Function Block Error Handling . . . . . . . . . . . . . . . . . . . . . . . . 237

EDM Function Block Timing Chart . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Muting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Muting Function Block Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Muting Function Block Optional Outputs . . . . . . . . . . . . . . . . . . . . 239

Muting Function Block Fault Present Output Setting . . . . . . . . . . 240

Muting Function Block Error Handling. . . . . . . . . . . . . . . . . . . . . . . 240

Muting Function Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Example: Parallel Muting with Two Sensors . . . . . . . . . . . . . . . . . . . 241

Example: Position Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Example: Override Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Enable Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Enable Switch Function Block Parameters . . . . . . . . . . . . . . . . . . . . . 255

Optional Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Fault Present Output Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

able Switch Function Block Error Handling. . . . . . . . . . . . . . . . . 256

En

Enable Switch Function Block Timing Charts . . . . . . . . . . . . . . . . . 256

Pulse Generator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Pulse Generator Function Block Parameters . . . . . . . . . . . . . . . . . . . 257

Pulse Generator Function Block Timing Chart . . . . . . . . . . . . . . . . 257

Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Counter Function Block Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Reset Condition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Count Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Counter Function Block Timing Charts . . . . . . . . . . . . . . . . . . . . . . 259

Rockwell Automation Publication 1752-UM001E-EN-P - June 2014 11

Page 12

Table of Contents

Appendix E

Explicit Messages

Application and Configuration

Examples

Glossary

Index

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Receiving Explicit Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Command Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Response Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Error Response Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Example Read Message from a GuardLogix Controller . . . . . . . . . . 263

Send Explicit Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Restrictions on Sending Explicit Messages . . . . . . . . . . . . . . . . . . . . . 265

Accessing Controller Parameters By Using DeviceNet Explicit

Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Appendix F

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Emergency Stop Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Safety Gate Application with Automatic Reset. . . . . . . . . . . . . . . . . . . . . 273

Dual Zone Safety Gate Application Using Emergency Stop Switch with

Manual Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Safety Mat Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Light Curtain Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

12 RockwellJune Automation Publication 1752-UM001E-EN-P - June 2014

Page 13

Preface

Read this preface to familiarize yourself with the rest of the manual. It provides

information concerning:

• who should use this manual.

• the purpose of this manual.

• additional resources.

• conventions used in this manual.

Who Should Use This Manual

Purpose of This Manual

Additional Resources

Use this manual if you are responsible for designing, installing, programming, or

troubleshooting control systems that use SmartGuard™ 600 controllers.

You must have a basic understanding of electrical circuitry and familiarity with

relay logic. You must also be trained and experienced in the creation, operation,

and maintenance of safety systems.

This manual is a guide for using SmartGuard 600 controllers. It describes the

specific procedures you use to configure, operate, and troubleshoot your

SmartGuard 600 controller.

The table provides a listing of publications that contain important information

about SmartGuard 600 controller systems.

Resource Description

SmartGuard 600 Controller Installation Instructions,

publication 1752-IN001

SmartGuard Controllers Systems Safety Reference Manual,

publication 1752-RM001

DeviceNet Safety I/O Installation Instructions, publication

1791DS-IN001

Guard I/O DeviceNet Safety Modules User Manual,

publication 1791DS-UM001

DeviceNet Media Design Installation Guide, publication

DNET-UM072

Information on installing the SmartGuard 600 controller

Detailed requirements for achieving and maintaining SIL

3 with the SmartGuard controller system

Information on installing Guard I/O™ DeviceNet Safety

modules

Information on using Guard I/O DeviceNet Safety modules

Information on planning your EtherNet/IP™ network

You can view or download publications at http://

www.rockwellautomation.com/literature. To order paper copies of technical

documents, contact your local Allen-Bradley® distributor or Rockwell

Automation sales representative.

Rockwell Automation Publication 1752-UM001E-EN-P - June 2014 13

Page 14

Preface

Common Techniques Used in This Manual

These conventions are used throughout this manual:

• Bulleted lists, such as this one, provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical information.

14 Rockwell Automation Publication 1752-UM001E-EN-P - June 2014

Page 15

Overview

Chapter 1

Introduction

About the SmartGuard 600 Controller

Top ic Pag e

About the SmartGuard 600 Controller 15

Safety Concept of the Controller 21

Additional Resource 21

The SmartGuard 600 controller (catalog numbers 1752-L24BBB and 1752L24BBBE) are programmable electronic systems featuring 16 digital inputs, 8

digital outputs, 4 test pulse sources, and connections for USB and DeviceNet™

communication. In addition, the 1752-L24BBBE controller offers EtherNet/IP

connectivity.

The SmartGuard 600 controller supports both standard and CIP Safety

communication over DeviceNet networks, and supports standard CIP

communication over EtherNet/IP networks.

The SmartGuard 600 controller is certified for use in safety applications up to

and including Safety Integrity Level (SIL) 3, according to IEC 61508,

Performance Level PL(e) according to ISO 13849-1, and Category (CAT) 4,

according to EN 954-1.

Rockwell Automation Publication 1752-UM001E-EN-P - June 2014 15

Page 16

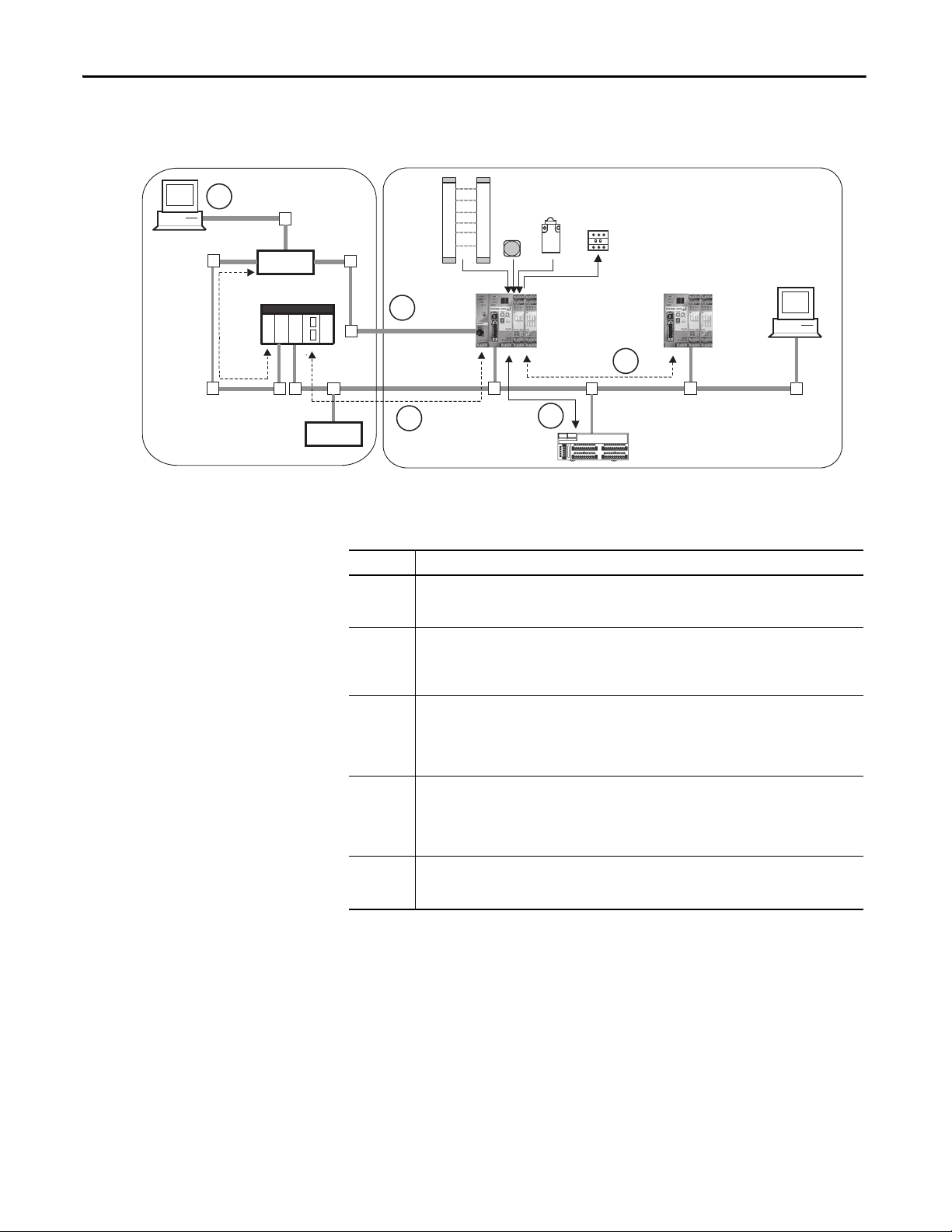

Chapter 1 Overview

Programming

Standard Controller

Standard Slave

DeviceNet

Network

SmartGuard

Control ler

1752-L24BBB

Safety Control

RSNetWorx™ for

DeviceNet Software

DeviceNet Safety I/O

Safety Slave

Ethernet

Switch

Ethernet

Network

SmartGuard

Control ler

1752-L24BBBE

Figure 1 - SmartGuard 600 Controller Safety Control System Example

5

4

2

3

Number Description

1 As a DeviceNet safety master, the SmartGuard 600 controller can control up to 32 Guard I/O modules.

2 As a DeviceNet safety slave, the SmartGuard 600 controller looks like distributed safety I/O to a safety

3 As a DeviceNet standard slave, the SmartGuard 600 controller can look like a standard distributed I/O

4 As an E therNet/IP standard target, the SmartGu ard 600 controller comm unicates with an Ethernet/ IP

5 As a limited EtherNet/IP bridge device, the SmartGuard 600 controller lets programming tools bridge

These 1791DS and 1732DS modules are the same distributed safety I/O modules used with

GuardLogix® controllers.

master. A GuardLogix or another SmartGuard safety master can read and write safety data to the

SmartGuard slave controller. This lets you per form distrib uted safety control through the interlocking

of multiple controllers via CIP Safety on DeviceNet networks.

module and respond to explicit messages so that standard DeviceNet masters like ControlLogix®, SLC™

500, or PLC-5® controllers or an HMI can read and write information to and from the SmartGuard 600

controller. This facilitates coordination with your standard PLC application, including displaying safety

system information on an HMI.

standard originator, such as a CompactLogix™ or MicroLogix™ controller or an HMI device. The

SmartGuard controller does not support CIP Safety on EtherNet/IP communication. As a result, the

SmartGuard controller cannot control 1791ES safety modules. All safety control must be do ne over the

DeviceNet network as shown in numbers 1 and 2 above.

to DeviceNet to view and program the SmartGuard 600 controller and configure other DeviceNet

devices.

1

16 Rockwell Automation Publication 1752-UM001E-EN-P - June 2014

Page 17

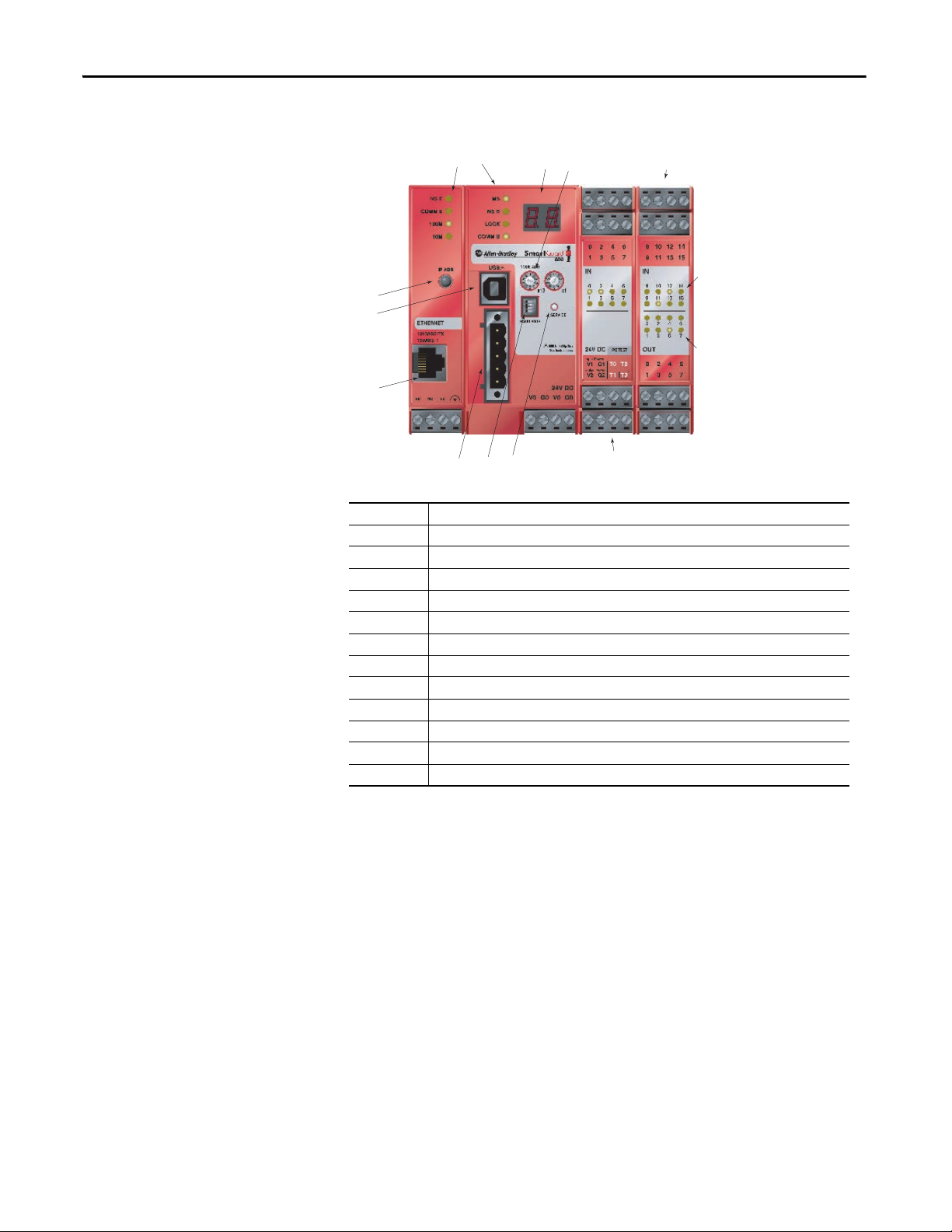

Overview Chapter 1

1

3

4

6

10

5

2

7

8

9

7

Hardware

The SmartGuard 600 controller (catalog numbers 1752-L24BBB and 1752L24BBBE) features 16 digital inputs, 8 digital outputs, 4 pulse test sources, and

connections for USB and DeviceNet Safety protocol. In addition, the 1752L24BBBE controller offers EtherNet/IP connectivity.

Figure 2 - SmartGuard 600 Controller (catalog number 1752-L24BBB) Features

Number Feature

1 Module status Indicators

2 Alphanumeric display

3 Node address switches

4 Baud rate switches

5USB port

6 DeviceNet communication connector

7 Terminal connectors

8 Input status indicators

9 Output status indicators

10 Service switch

Rockwell Automation Publication 1752-UM001E-EN-P - June 2014 17

Page 18

Chapter 1 Overview

SmartGuard 600 Controller (catalog number 1752-L24BBBE) Features

1

10

5

11

12

46

Number Feature

1 Module status indicators

2 Alphanumeric display

3 Node address switches

4 Baud rate switches

5USB port

6 DeviceNet communication connector

7 Terminal connectors

8 Input status indicators

9 Output status indicators

10 IP address display switch

11 Ethernet connector

12 Service switch

27

3

8

9

7

18 Rockwell Automation Publication 1752-UM001E-EN-P - June 2014

Page 19

Overview Chapter 1

Safety Inputs

The controller has 16 local safety inputs, which support the features described

below.

• Input circuit diagnosis — Test pulse sources can be used to monitor

internal circuits, external devices, and external wiring.

• Input on- and off-delays — You can set input time filters of 0…126 ms in

multiples of the controller cycle time. Setting input on- and off-delays

helps reduce the influence of chattering and external noise.

• Dual Channel mode — You can set Dual Channel mode for pairs of

related local inputs. When Dual Channel mode is set, time discrepancies in

changes in data or input signals between two paired, local inputs can be

evaluated.

Safety Outputs

The controller has eight local safety outputs, which support the features

described below.

• Output circuit diagnosis — Test pulses can be used to diagnose the

controller’s internal circuits, external devices, and external wiring.

• Overcurrent detection and protection — To protect the circuit, an output

is blocked when an overcurrent is detected.

• Dual Channel mode — Both of two paired outputs can be set into a safety

state without depending on the user program when an error occurs in

either of the two paired local outputs.

Test Pulse Sources

Four independent test outputs are normally used in combination with safety

inputs. They can also be set for use as standard signal output terminals. The test

pulse outputs support the following features.

• Overcurrent detection and protection — To protect the circuit, an output

is blocked when an overcurrent is detected.

• Current monitoring for muting lamp — Disconnection can be detected

for the T3 terminal only.

Rockwell Automation Publication 1752-UM001E-EN-P - June 2014 19

Page 20

Chapter 1 Overview

Communication

The controller can act as a DeviceNet safety master or slave, as a DeviceNet

standard slave, or as a standalone controller when DeviceNet communication is

disabled. A single controller can function simultaneously as a safety master, safety

slave, and standard slave.

Explicit messages can be used to read controller status information. The user

program can be configured to send explicit messages from the user program. The

messages can be routed between DeviceNet and EtherNet/IP networks.

The USB port can be used to program the SmartGuard controller and to

configure devices on the DeviceNet network. The SmartGuard provides some

limited pass-through capability from USB to DeviceNet, for programming and

configuration purposes. When used in Standalone mode, the controller

communicates with the configuration software via USB communication.

Configuration and Programming

Use RSNetWorx for DeviceNet software, version 8.0 (minimum) or later

(version 9.1 is recommended), to configure, program, and monitor the status of

the 1752-L24BBB controller. Use RSNetWorx for DeviceNet software, version

9.1 or later, to configure, program, and monitor the status of the 1752-L24BBBE

controller. With RSNetWorx for DeviceNet software, you can configure the

controller by using the SmartGuard controller’s USB port or via the DeviceNet

network or EtherNet/IP network.

You also need RSLinx® software, version 2.55 or later, which lets you configure a

1752-L24BBBE controller on EtherNet/IP.

The logic editor is launched from within RSNetWorx for DeviceNet software.

Basic logic operations, such as AND and OR, and function blocks, such as

ESTOP and light curtain, are supported. A maximum of 254 logic functions and

function blocks can be used in a maximum of 32 programming pages. You can

password-protect both configuration data and project files.

Status and Error Monitoring

The controller’s internal status information and I/O data can be monitored

online by using RSNetWorx for DeviceNet software with either a USB,

DeviceNet network connection or EtherNet/IP network connection.

The status indicators and alphanumeric display on the controller provide status

and error information. When the service switch on the front of the controller is

pressed, the alphanumeric display shows the controller’s safety configuration

signature two digits at a time for a total of ten pairs of numbers.

20 Rockwell Automation Publication 1752-UM001E-EN-P - June 2014

Page 21

Overview Chapter 1

When the IP Address display switch is pressed for 1 second or longer, the display

shows the EtherNet/IP address that is set.

Errors detected by the controller are recorded in an error history log and an

EtherNet/IP history log, along with the time the error occurred. (The time is

shown as total operating time since the controller was powered up.)

Safety Concept of the Controller

The SmartGuard 600 controller is certified for use in safety applications up to

and including Safety Integrity Level (SIL) 3, according to IEC 61508,

Performance Level PL(e) according to ISO 13849-1, and Category (CAT) 4,

according to EN 954-1, in which the de-energized state is the safety state. Safety

application requirements include evaluating the probability of failure rates (PFD

and PFH), system reaction-time calculations, and functional verification tests

that fulfill SIL 3 criteria. You must read, understand, and fulfill these

requirements prior to operating a SmartGuard 600 controller-based SIL 3 or

CAT 4 safety system.

The controller uses the following mechanisms to support the integrity of safety

data.

• Safety network number (SNN) — A unique number that identifies the

safety network. CIP safety nodes must have a unique SNN and DeviceNet

network address.

• Configuration signature — The combination of an ID number, date, and

time that uniquely identifies a specific configuration for a safety device.

• Configuration lock (or safety-lock) — After the configuration data has

been downloaded and verified, you can lock the controller’s configuration

to prevent it from being modified.

• Password protection — The controller’s configuration can be protected by

the use of an optional password. If you set a password, download, locking,

unlocking, resetting, and changing the status of the controller requires a

password to perform.

Additional Resource

You must create and document a clear, logical, and visible distinction between the

safety and any standard portions of the application.

Refer to the SmartGuard Controllers Safety Reference Manual, publication

1752-RM001, for information on SIL 3 and CAT 4 safety system requirements,

including functional verification test intervals, system reaction time, and PFD/

PFH values.

Rockwell Automation Publication 1752-UM001E-EN-P - June 2014 21

Page 22

Chapter 1 Overview

Notes:

22 Rockwell Automation Publication 1752-UM001E-EN-P - June 2014

Page 23

Chapter 2

Installing and Wiring the SmartGuard 600

Controller

Introduction

General Safety Information

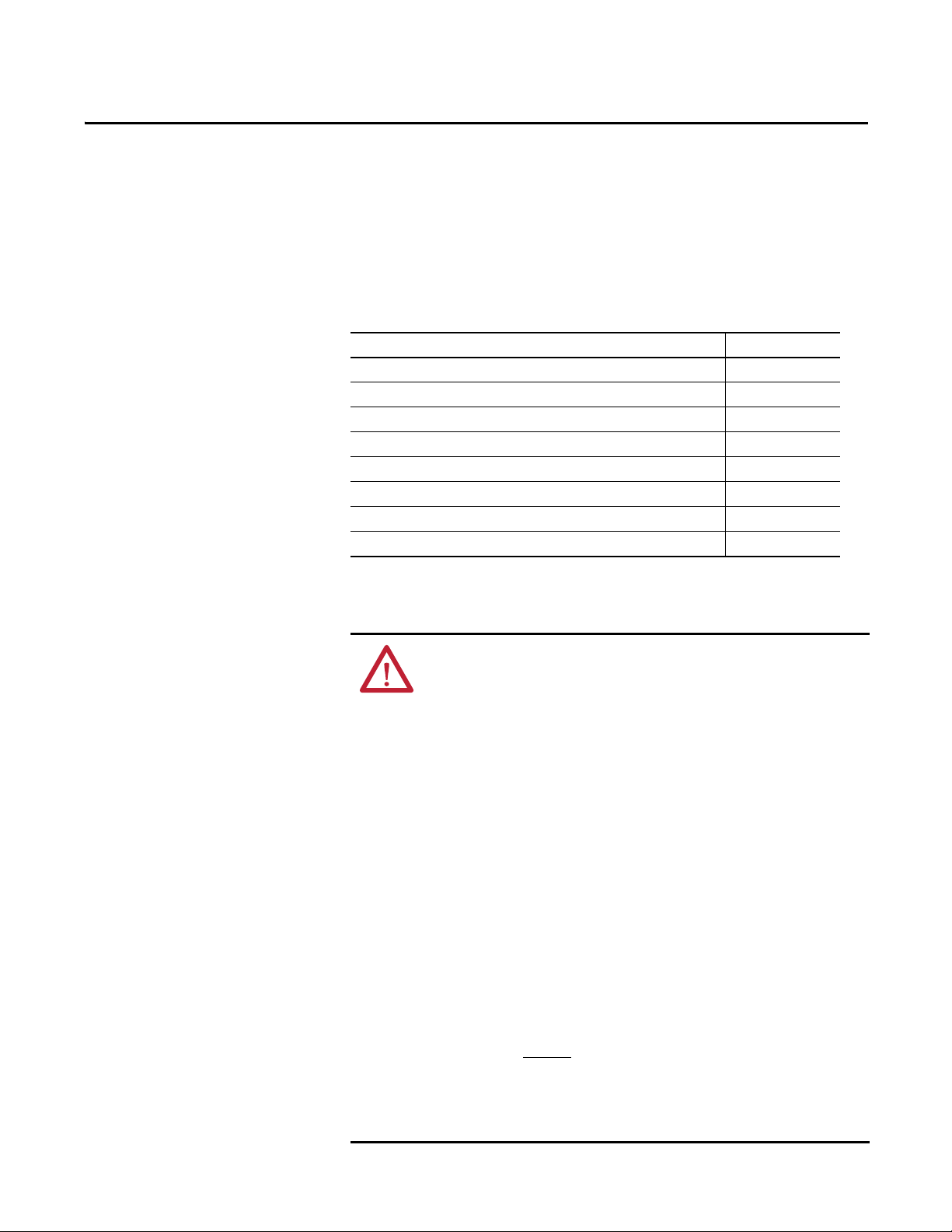

Top ic Pag e

General Safety Information 23

Understanding Node Addressing 25

Set the Node Address 26

Setting the Communication Rate 26

Mount the SmartGuard Controller 29

Grounding the SmartGuard Controller 30

Connecting a Power Supply 30

Wiring the SmartGuard 600 Controller 34

ATTENTION: Environment and Enclosure

This equipment is intended for use in Pollution Degree 2 Industrial environment, in

Overvoltage Category II applications (as defined in IEC publication 60664-1), at

altitudes up to 2000 m (6562 ft) without derating.

This equipment is considered Group 1, Class A industrial equipment according to

IEC/CISPR Publication 11. Without appropriate precautions, there may be potential

difficulties ensuring electromagnetic compatibility in other environments due to

conducted as well as radiated disturbance.

This equipment is supplied as open type equipment. It must be mounted within an

enclosure that is suitably designed for those specific environmental conditions that

will be present and appropriately designed to prevent personal injury resulting

from accessibility to live parts. The enclosure must have suitable flame-retardant

properties to prevent or minimize the spread of flame, complying with flame

spread rating or 5VA, V2, V1, V0 (or equivalent) if non-metallic. The interior of the

enclosure must be accessible only by the use of a tool. Subsequent sections of this

publication may contain additional information regarding specific enclosure type

ratings that are required to comply with certain product safety certifications.

In addition to this publication, see:

· Industrial Automation Wiring and Grounding Guidelines, Allen-Bradley

publication 1770-4.1

.

· NEMA Standards publication 250 and IEC publication 60529, as applicable, for

explanations of the degrees of protection provided by different types of

enclosure.

Rockwell Automation Publication 1752-UM001E-EN-P - June 2014 23

Page 24

Chapter 2 Installing and Wiring the SmartGuard 600 Controller

Table 1 - North American Hazardous Location Approval

The following information applies when operating this equipment in

hazardous locations

Products marked CL I, DIV 2, GP A, B, C, D are suitable for use in Class I Division 2 Groups

A, B, C, D, Hazardous Locations and nonhazardous locations only. Each product is

supplied with markings on the rating nameplate indicating the hazardous location

temperature code. When combining products within a system, the most adverse

temperature code (lowest T number) may be used to help determine the overall

temperature code of the system. Combinations of equipment in your system are subject

to investigation by the local Authority Having Jurisdiction at the time of installation.

EXPLOSION HAZARD

·Do not disconnect equipment unless power has been

removed or the area is known to be nonhazardous.

·Do not disconnect connections to this equipment unless

power has been removed or the area is known to be

nonhazardous. Secure any external connections that mate

to this equipment by using screws, sliding latches,

threaded connectors, or other means provided with this

product.

·Substitution of components may impair suitability for

Class I, Division 2.

·If this product contains batteries, they must only be

changed in an area known to be nonhazardous.

ATTENTION: Safety Programmable Electronic Systems (PES)

Personnel responsible for the application of safety-related programmable

electronic systems (PES) shall be aware of the safety requirements in the

application of the system and shall be trained in using the system.

Informations sur l’utilisation de cet équipement en environnements dangereux

Les produits marqués CL I, DIV 2, GP A, B, C, D ne conviennent qu’à une utilisation en

environnements de Classe I Division 2 Groupes A, B, C, D dangereux et non dangereux. Chaque

produit est livré avec des marquages sur sa plaque d’identification qui indiquent le code de

température pour les environnements dangereux. Lorsque plusieurs produits sont combinés

dans un système, le code de température le plus défavorable (code de température le plus

faible) peut être utilisé pour déterminer le code de température global du système. Les

combinaisons d’équipements dans le système sont sujettes à inspection par les autorités

locales qualifiées au moment de l’installation.

RISQUE D’EXPLOSION

·Couper le courant ou s’assurer que l’environnement est classé

non dangereux avant de débrancher l'équipement.

·Couper le courant ou s'assurer que l’environnement est classé

non dangereux avant de débrancher les connecteurs. Fixer tous

les connecteurs externes reliés à cet équipement à l'aide de vis,

loquets coulissants, connecteurs filetés ou autres moyens

fournis avec ce produit.

·La substitution de composants peut rendre cet équipement

inadapté à une utilisation en environnement de Classe I,

Division 2.

·S’assurer que l’environnement est classé non dangereux avant

de changer les piles.

ATTENTION: Prevent Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which can cause internal

damage and affect normal operation. Follow these guidelines when you handle

this equipment.

· Touch a grounded object to discharge potential static.

· Wear an approved wrist grounding strap.

· Do not touch connectors or pins on component boards.

· Do not touch circuit components inside the equipment.

· Use a static-safe workstation, if available.

· Store the equipment in appropriate static-safe packaging when not in use.

ATTENTION: Protective Debris Strip

Do not remove the protective debris strip until after the controller and all the other

equipment near the controller is mounted and wiring is complete.

Once wiring is complete, remove the protective debris strip. Failure to remove the

strip before operating can cause overheating.

24 Rockwell Automation Publication 1752-UM001E-EN-P - June 2014

Page 25

Installing and Wiring the SmartGuard 600 Controller Chapter 2

ATT EN TI ON : Serious injury may occur due to the loss of required safety

function.

· Do not use test outputs as safety outputs.

· Do not use DeviceNet standard I/O data or explicit message data as safety data.

· Do not use status indicators for safety operations.

· Do not connect loads beyond the rated value to safety outputs or test outputs.

· Wire the controller properly so that the 24V dc line does not accidentally touch

the outputs.

· Ground the 0V line of the power supply for external output devices so that the

devices do not turn on when the safety output line or test output line is

grounded.

· Do not dismantle, repair, or modify the controller. Doing so may impair the

safety functions.

Understanding Node Addressing

To communicate on the DeviceNet network, each device requires its own

address. Follow the recommendations below when assigning addresses to the

devices on your network.

Table 2 - Node Address Recommendations

Give this device This address Notes

Scanner 0 If you have multiple scanners, give them the lowest

Any device on your network, except

the scanner

RSNetWorx for DeviceNet

workstation

No device 63 Leave address 63 open. This is where a non-

1…61 Gaps between addresses are allowed and have no

62 If you connect a computer directly to the DeviceNet

addresses in sequence.

effect on system performance. Leaving gaps gives you

more flexibility as you develop your system.

network, use address 62 for the computer or

bridging/linking device.

commissioned node typically enters the network.

The standard DeviceNet network assigns communication priority based on the

device’s node number. The lower the node number, the higher the device’s

communication priority. This priority becomes important when multiple nodes

are trying to communicate on the network at the same time.

DeviceNet safety nodes have additional priority on the network, regardless of

node number. DeviceNet safety communication from devices with lower node

numbers have priority over DeviceNet safety communication from devices with

higher node numbers.

Rockwell Automation Publication 1752-UM001E-EN-P - June 2014 25

Page 26

Chapter 2 Installing and Wiring the SmartGuard 600 Controller

IMPORTANT

IMPORTANT

IMPORTANT

Set the Node Address

Set the node address before you mount the controller.

Turn off power to the controller before setting the node address or

communication rate via the switches.

Do not change the switch settings while the power supply is on. The controller

will detect this as a change in the configuration and will switch to the ABORT

mode.

Use a small flathead screwdriver to set the node address by using the two rotary

switches on the front panel of the controller. Use care not to scratch the switches.

Values from 00…63 are valid. The default setting is 63.

Follow these steps to set the node address.

1. Set the tens digit of the node address (decimal) by turning the left rotary

switch.

2. Set the ones digit by turning the right rotary switch.

3. To allow the node address to be set by using RSNetWorx for DeviceNet

software, set the rotary switches to a value from 64…99.

Setting the Communication Rate

A node address duplication error will occur if the same node address is set for

more than one node.

Set the communication rate before you mount the controller.

Turn off power to the controller before setting the node address or

communication rate via the switches.

Do not change the switch settings while the power supply is on. The controller

will detect this as a change in the configuration and will switch to the ABORT

mode.

DeviceNet Communication

The default communication rate for a DeviceNet network is 125 Kbps.

26 Rockwell Automation Publication 1752-UM001E-EN-P - June 2014

Page 27

Installing and Wiring the SmartGuard 600 Controller Chapter 2

If you choose to use a different communication rate, the length of the trunkline

and types of cable determine which communication rates your application can

support.

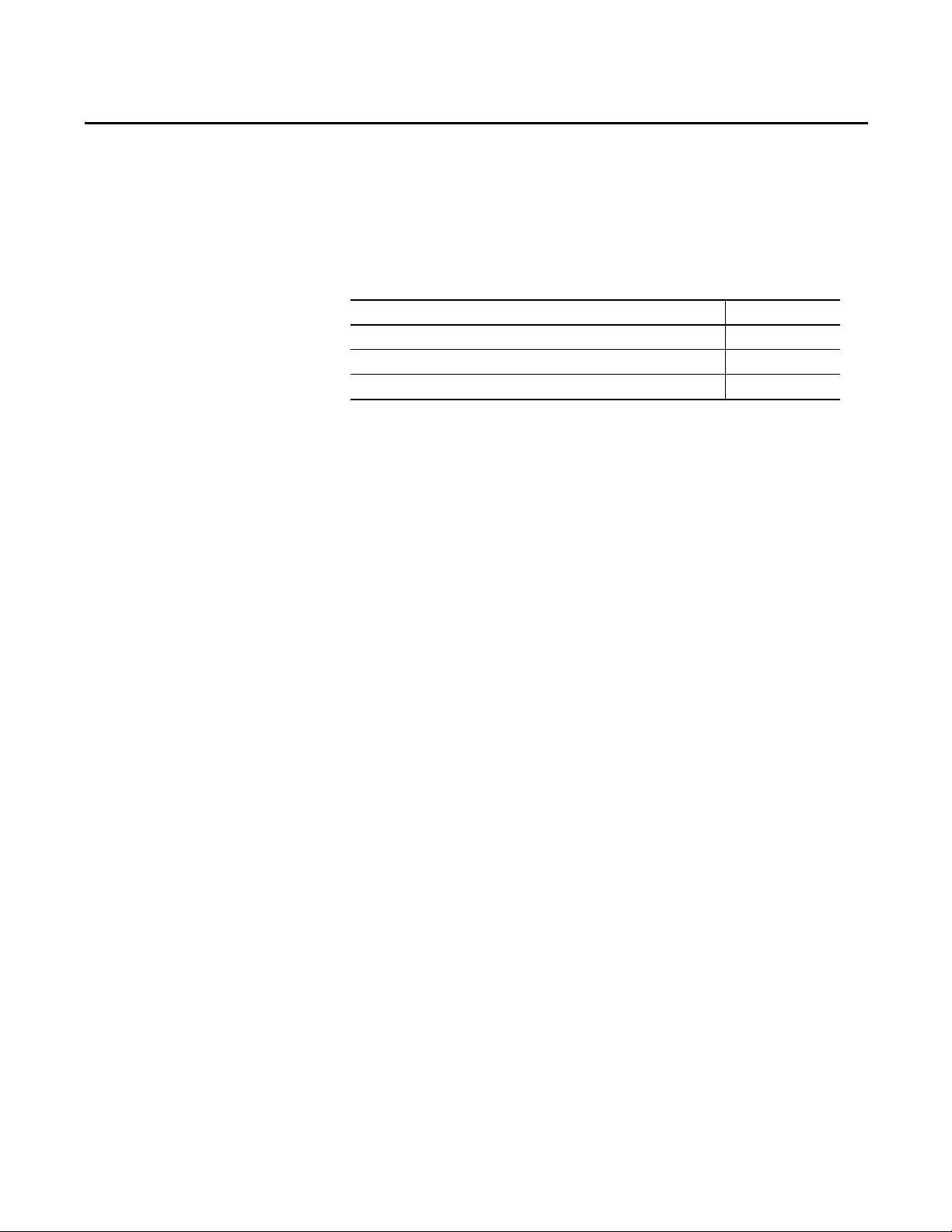

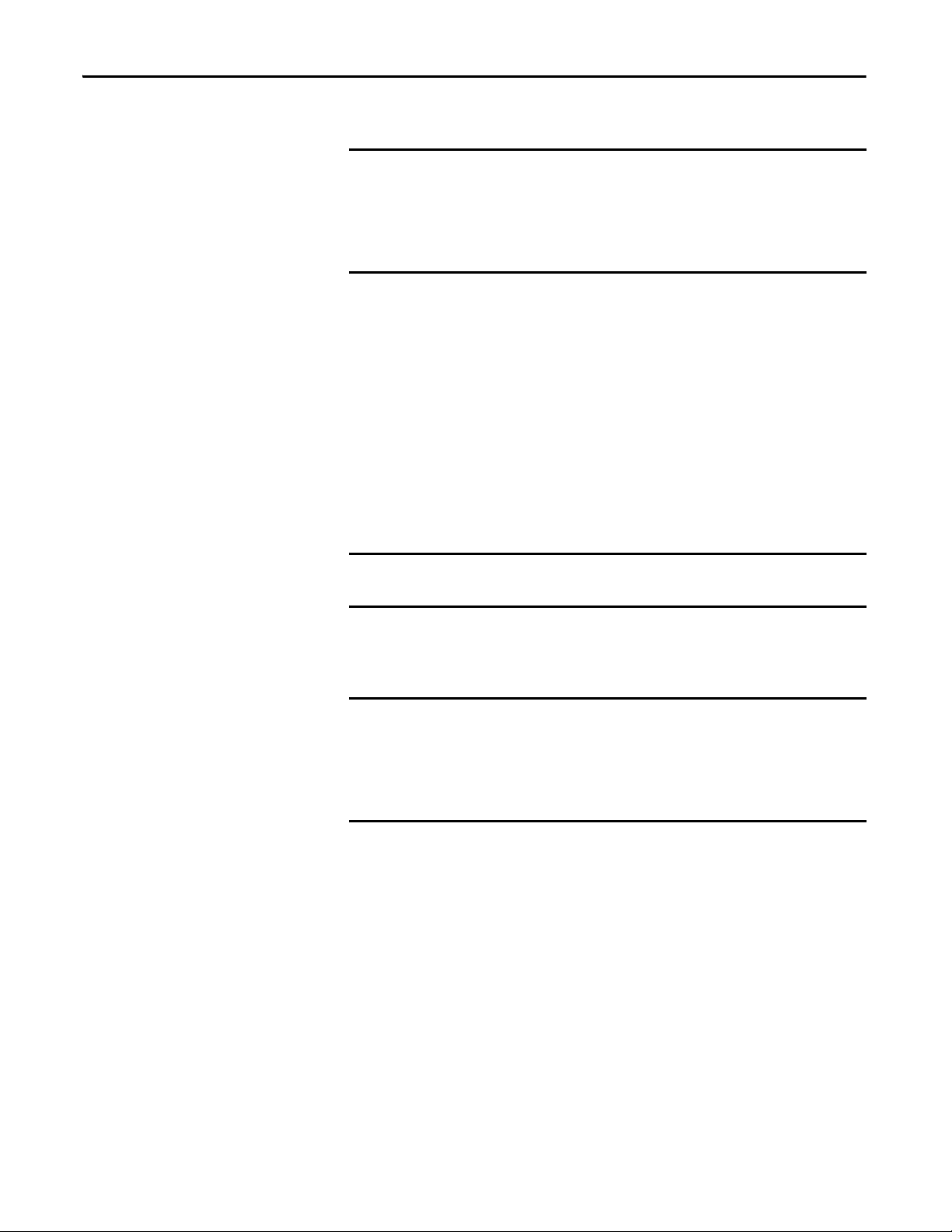

Table 3 - DeviceNet Communication Rates and Cable Lengths

Communication Rate Distance, max Cumulative Drop

Flat Cable Thick Cable Thin Cable

125 Kpbs 420 m (1378 ft) 500 m (1640 ft) 100 m (328 ft) 156 m (512 ft)

250 Kpbs 200 m (656 ft) 250 m (820 ft) 100 m (328 ft) 78 m (256 ft)

500 Kpbs 75 m (246 ft) 100 m (328 ft) 100 m (328 ft) 39 m (128 ft)

Line Length

Rockwell Automation Publication 1752-UM001E-EN-P - June 2014 27

Page 28

Chapter 2 Installing and Wiring the SmartGuard 600 Controller

IMPORTANT

1

2

3

4

O

N

ON

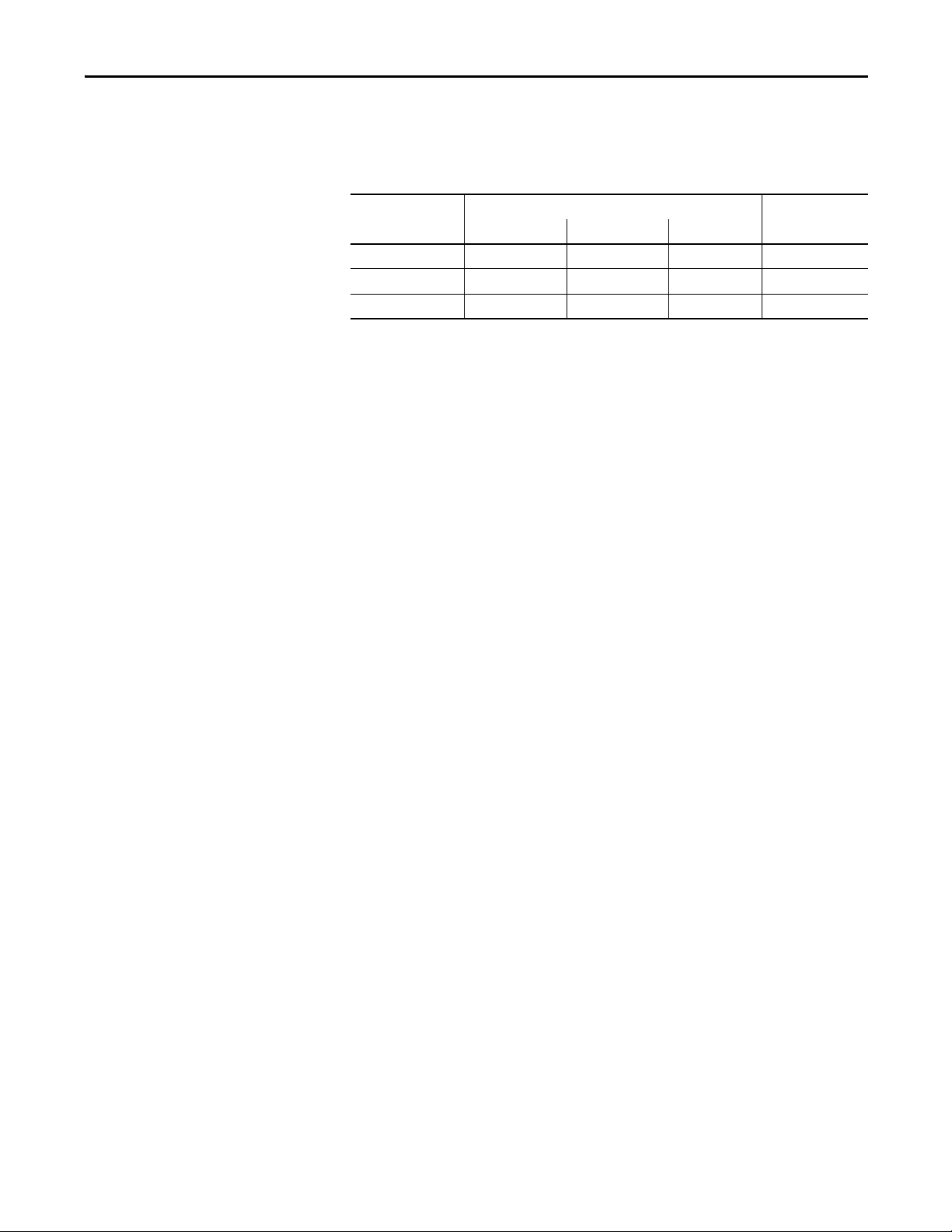

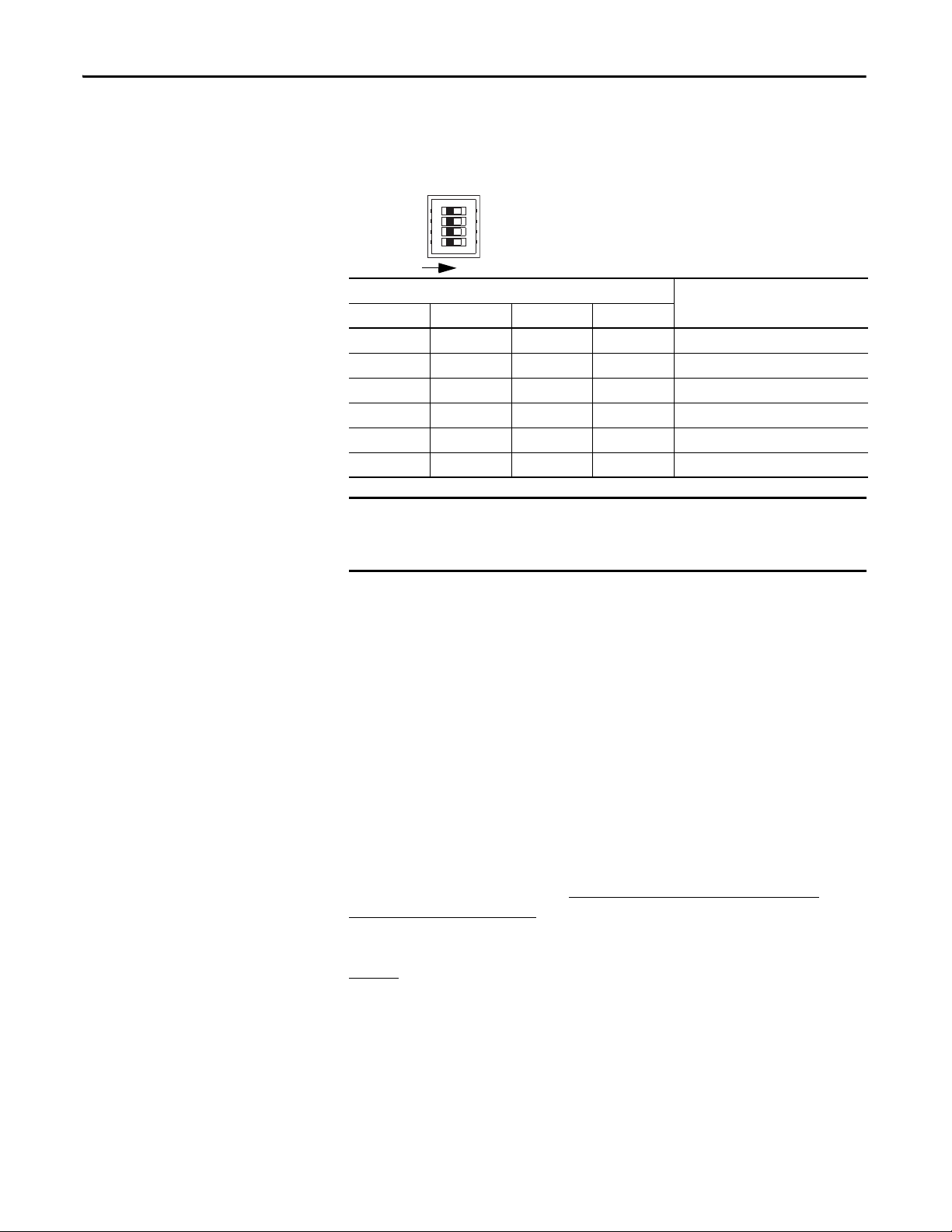

Set the communication rate by using the DIP switch on the front of the

controller.

Figure 3 - Communication Rate Dip Switch

DIP Switch Pin Communication Rate

1234

OFF OFF OFF OFF 125 Kbps

ON OFF OFF OFF 250 Kbps

OFF ON OFF OFF 500 Kbps

ON ON OFF OFF Set by software

ON or OFF ON or OFF ON OFF Set by software

ON or OFF ON or OFF ON or OFF ON Automatic baud rate detection

If you change the communication rate of your network, make sure that all

devices change to the new communication rate. Mixed communication rates

produce communication errors.

If you set other devices to autobaud, at least one device on the network must have

a communication rate established. If you set all devices on the network to

autobaud, they will not be able to establish a communication rate and will not

communicate with each other.

Ethernet Communication

We recommend connecting the module to the network via a 100 Mbps Ethernet

switch, which will help reduce collisions and lost packets and increase bandwidth.

The 1752-L24BBBE controller is shipped with BOOTP enabled for setting the

IP address. You can use any commercially available BOOTP server. If you do not

have BOOTP Server capabilities on your network, download the free Rockwell

Automation BOOTP server from http://www.rockwellautomation.com/

rockwellsoftware/download/.

To set the IP address by using the Rockwell Automation BOOTP utility, refer to

page 51

.

The following table provides additional EtherNet/IP information.

28 Rockwell Automation Publication 1752-UM001E-EN-P - June 2014

Page 29

Mount the SmartGuard

IMPORTANT

Latch

Top Sl ot

DIN Rail

Controller

Installing and Wiring the SmartGuard 600 Controller Chapter 2

For detailed information on EtherNet/IP communication, refer to the EtherNet/

IP Performance and Application Solution, publication ENET-AP001

Attribute Value

Number of CIP packets 2

Allowable Unit communication bandwidth 3000 pps

Explicit message communication 502 B

(1) PPS is packets Per second. It indicates the number of send or receive packets that can be processed per second.

(2) The maximum message length for class 3 connection and UCMM connection.

(1)

(2)

.

For effective cooling:

· mount the controller on a horizontal DIN rail. Do not mount the controller

vertically.

· provide a gap of at least 50 mm (2.0 in.) above and below the controller

and 5 mm (0.20 in.) on each side.

· select a location where air flows freely or use an additional fan.

· do not mount the controller over a heating device.

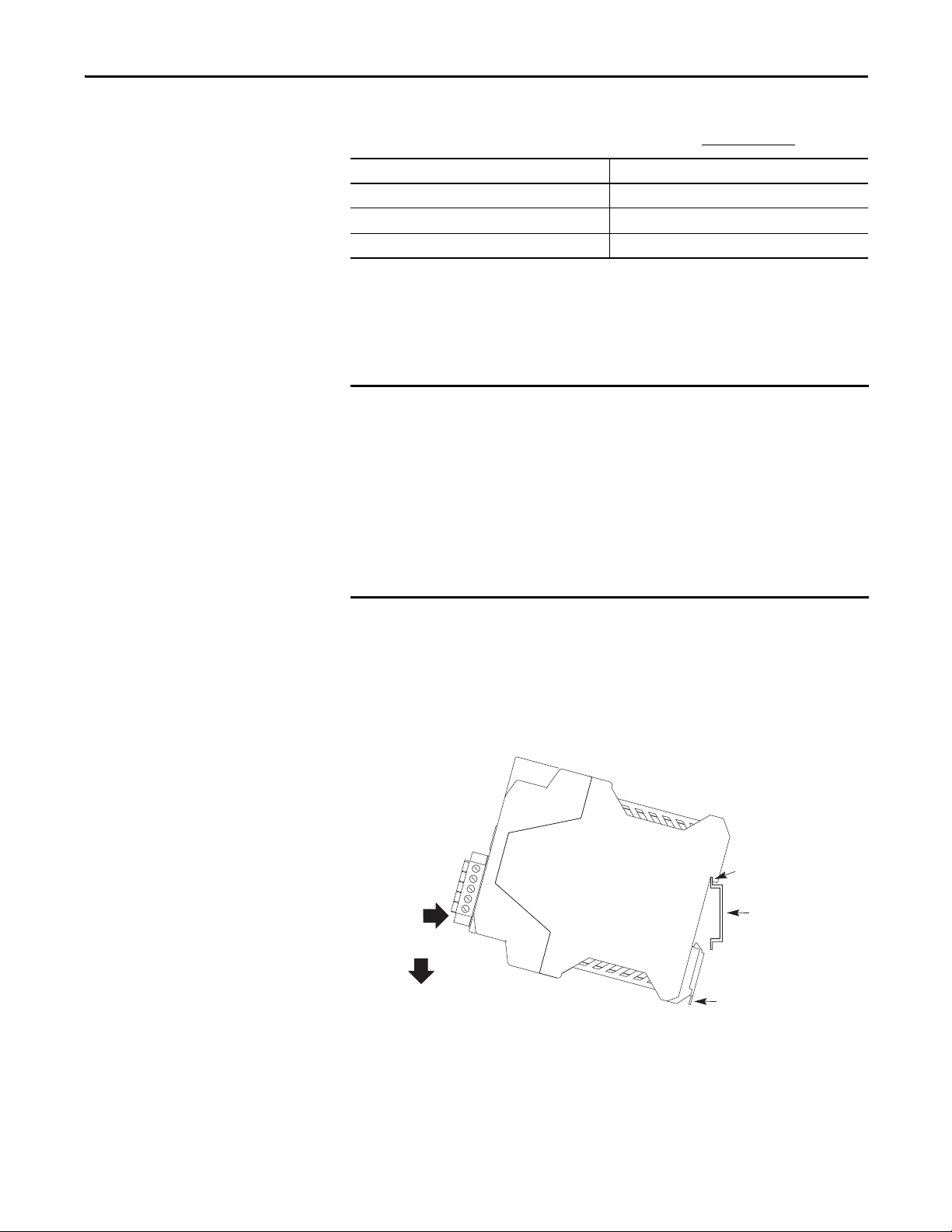

The controller cannot be panel-mounted. Follow these steps to mount the

controller to an EN50022-35x7.5 or EN50022-35x15 DIN rail.

1. Hook the top slot over the DIN rail.

2. Snap the bottom of the controller into position while pressing the

controller down against the top of the rail.

3. Attach end plates to each end of the DIN rail.

To remove the controller from the DIN rail, use a flathead screwdriver to pull

down the latch and lift the controller off of the rail. The 1752-L24BBB

controller has one latch and the 1752-L24BBBE controller has two latches on the

bottom of the controller.

Rockwell Automation Publication 1752-UM001E-EN-P - June 2014 29

Page 30

Chapter 2 Installing and Wiring the SmartGuard 600 Controller

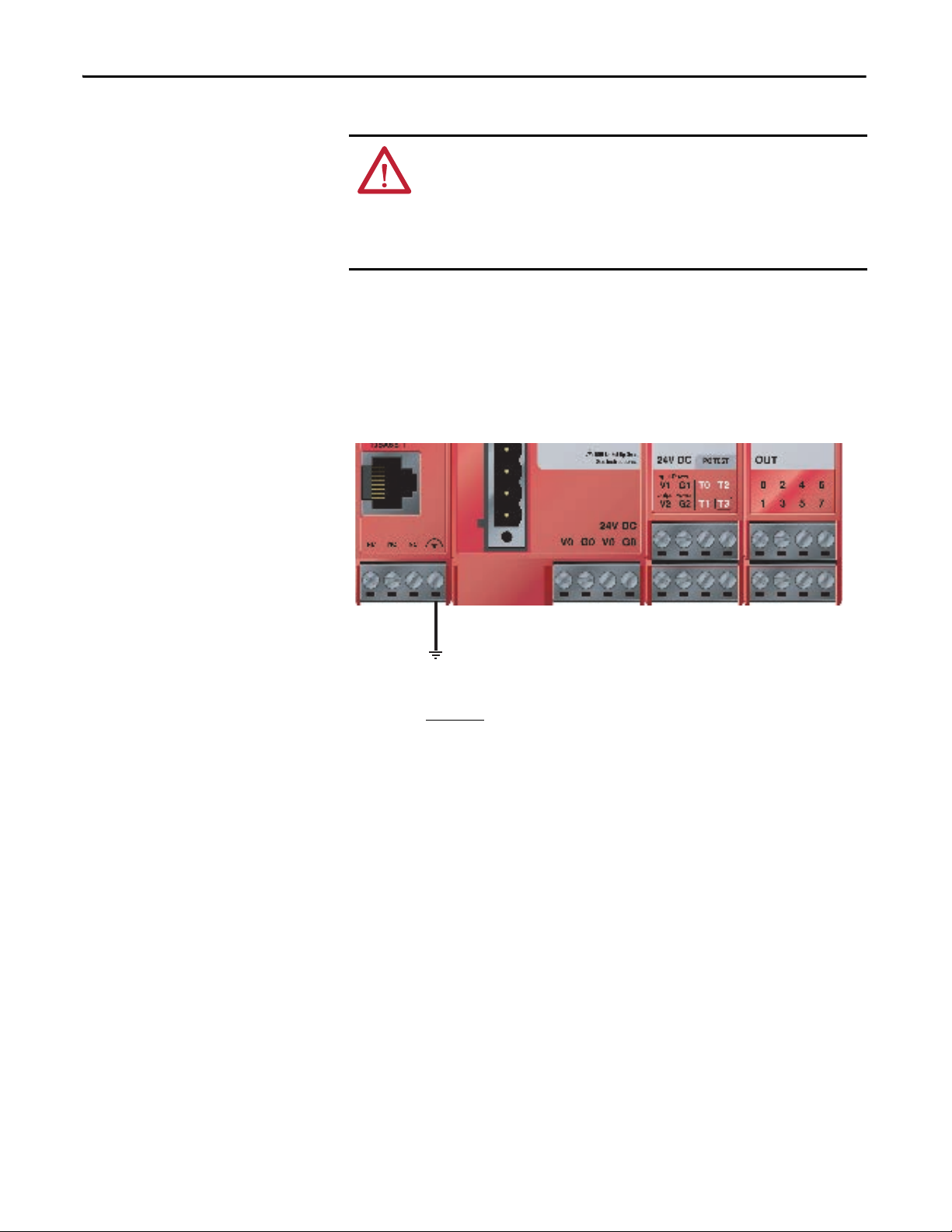

Grounding the SmartGuard Controller

You must provide an acceptable grounding path for each device in your

application. Functionally ground the controller through its V0/G0 power

connection.

In addition, if you are using the 1752-L24BBBE controller, you should connect

the Ethernet ground terminal to an acceptable ground.

Figure 4 - Ethernet Ground

ATT EN TI ON : This product is grounded through the DIN rail to chassis ground.

Use zinc plated yellow-chromate steel DIN rail to assure proper grounding. The

use of other DIN rail materials (for example, aluminum or plastic) that can

corrode, oxidize, or are poor conductors, can result in improper or intermittent

grounding. Secure DIN rail to mounting surface approximately every 200 mm

(7.8 in.) and use end anchors appropriately.

Connecting a Power Supply

Refer to the Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Power for the controller is provided via an external 24V dc power source. The

output hold time must be 20 ms or longer.

To comply with the CE Low Voltage Directive (LVD), DeviceNet connections

and I/O must be powered by a dc source compliant with Safety Extra Low

Voltage (SELV) or Protected Extra Low Voltage (PELV).

To comply with UL restrictions, DeviceNet connections and I/O must be

powered by dc sources whose secondary circuits are isolated from the primary

circuit by double insulation or reinforced insulation. The dc power supply must

satisfy the requirements for Class 2 circuits or limited voltage/current circuits

defined in UL 508.

, for additional information.

30 Rockwell Automation Publication 1752-UM001E-EN-P - June 2014

Page 31

Installing and Wiring the SmartGuard 600 Controller Chapter 2

TIP

+-

+-

+-

The following Allen-Bradley 1606 power supplies are SELV- and PELVcompliant, and they meet the isolation and output hold-off time requirements

of the SmartGuard 600 controller:

· 1606-XLP30E

· 1606-XLP50E

· 1606-XLP50EZ

The SmartGuard controller has three V/G terminal pairs that require a power

connection. There are two V0/G0 pairs, but because they are internally

connected, you only need to connect one V0/G0 pair. You can use the other pair

to distribute power to other devices.

Figure 5 - Power Supply Connections

· 1606-XLP72E

· 1606-XLP95E

· 1606-XLDNET4

· 1606-XLSDNET4

Making Communication Connections

ATT EN TI ON : Do not connect or disconnect the communication cable with

power applied to this controller or any device on the network, because an

electrical arc can occur. This could cause an explosion in hazardous location

installations. Be sure that power is removed or the area is nonhazardous before

proceeding.

You can configure the network and controller on the DeviceNet network by

using a 1784-PCD card inside your personal computer and RSNetWorx for

DeviceNet software. You may also configure the network and controller by using

the controller’s USB port and RSNetWorx for DeviceNet software. In addition,

you can configure the controller using RSNetWorx for DeviceNet software by

connecting to the EtherNet/IP port and routing down to DeviceNet network.

Connect to the DeviceNet port

Follow these steps to connect to the DeviceNet port.

Rockwell Automation Publication 1752-UM001E-EN-P - June 2014 31

Page 32

Chapter 2 Installing and Wiring the SmartGuard 600 Controller

D

D

D

D

D

1

2

3

4

5

Wire No. Wire Color Connects to

V+ Red V+

CAN H White CAN H

Drain — Drain

CAN L Blue CAN L

V- Bl ack V-

For detailed DeviceNet connection information, refer to the DeviceNet Media

Design Installation Guide, publication DNET-UM072

Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

1. Wire the connector according to the colors on the connector.

2. Attach the connector to the

DeviceNet port.

3. Tighten the screws to 0.25…0.3 N•m (2.21…2.65 lb•in).

. Also refer to the

.

32 Rockwell Automation Publication 1752-UM001E-EN-P - June 2014

Page 33

Installing and Wiring the SmartGuard 600 Controller Chapter 2

IMPORTANT

Connecting to USB Port

Connect the USB communication connector to your personal computer when

you want to configure the network and controller by using RSNetWorx for

DeviceNet software. Use a commercially available USB-A to USB-B male/male

cable to make the connection.

ATT EN TI ON : To reduce the potential for electromagnetic interference, the USB

cable length must be less than 3 m (10 ft).

The USB port is intended for temporary programming purposes only and is not

intended for permanent connection.

ATT EN TI ON : If you connect or disconnect the USB cable with power applied to

this module or any device on the USB network, an electrical arc could occur. This

could cause an explosion in hazardous location installations. Be sure that power

is removed or the area is nonhazardous before proceeding.

Connecting to the Ethernet port

Depending on where you plan to route your cable you must select the correct

cable for the environment. Shielded cable performs better than non shielded

cable in industrial environments. In particular, if your application is in a high

noise environment or your cable must be run in close proximity to noise radiating

sources then you should plan to use shielded cables.

You should consider shielded cables if your application includes one or more of

the following:

• spot welding control

• Motor Control Centers

• drives greater than 10 Hp

• induction welding processes

• proximity to high-power RF radiation

• electrostatic processes

• high current devices (greater than 100 A)

Shields play an important role in providing noise immunity for your system.

However, an improperly installed shielded cable can cause problems due to

voltage offsets in your grounding system. To help minimize the effects of

ground offsets you will need to isolate the shield at one end of the cable. In this

case the shield should be isolated at the deice, not at the switch.

Use an RJ45 connector to connect the controller to the EtherNet/IP network.

When connecting to the SmartGuard controller to a switch or a hub, use a

Rockwell Automation Publication 1752-UM001E-EN-P - June 2014 33

Page 34

Chapter 2 Installing and Wiring the SmartGuard 600 Controller

standard Ethernet cable. When connecting the SmartGuard controller directly to

your personal computer or a NIC card, use a cross-over (null modem) cable.

Pin No. Pin Name Pin placement

8 Not used

7 Not used

6RD-

5 Not used

4 Not used

3RD+

2TD-

1TD+

ATT EN TI ON : The cable length must be less then 100 m (328 ft) between hub

and nodes.

WARNING: If you connect or disconnect the Ethernet cable with power applied

to this controller or any other device on this network, an electrical arc can occur.

This could cause an explosion in hazardous location installations. Be sure that

power is removed or the area is nonhazardous before proceeding.

8

1

Wiring the SmartGuard 600 Controller

Use cables of 30 m (98 ft) or less.

Attribute Value

Wire t ype Coppe r

Wiring c ategor y

Wire size For power supply and I/O, use 0.2…2.5 mm2 (12…24 AWG) solid wire, or

I/O Terminal Screw Torque 0.56…0.79 N•m (5…7 lb•in)

(1) Use this Conductor Category information for planning conductor routing. Refer to Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

Terminal Designation Description

(1)

V0 Power terminal for internal circuit (logic).

G0 Power terminal for internal circuit (logic).

V1 Power terminal for input circuits and test outputs.

G1 Power terminal for input circuits and test outputs.

V2 Power terminal for safety outputs.

G2 Power terminal for safety outputs.

2 - on power, signal, and communication ports

0.34…1.5 mm2 (16…22 AWG) stranded flexible wire. Before connecting,

prepare stranded wires by attaching ferrules with plastic insulation collars

(DIN 46228-4 standard compatible).

.

34 Rockwell Automation Publication 1752-UM001E-EN-P - June 2014

Page 35

Installing and Wiring the SmartGuard 600 Controller Chapter 2

IMPORTANT

SmartGuard 600

Control ler

V1

Tx

INx

G1

24V dc

4.5 mA Typical

IN0…IN15 Terminals for safety inputs.

T0…T3 These are test output terminals that can provide pulse test sources for safety inputs

OUT0…OUT7 Terminals for safety outputs.

IN0…IN15. T3 can also support wire off detection and burned out bulb detection for a

load such as a muting lamp.

ATT EN TI ON : If you connect or disconnect wiring while the field-side power is

applied, an electrical arc can occur. This could cause an explosion in hazardous

location installations. Be sure that power is removed or the area is

nonhazardous before proceeding.

ATT EN TI ON : If you connect or disconnect the removable terminal block (RTB)

while the field-side power is applied, an electrical arc can occur. This could

cause an explosion in hazardous location installations. Be sure that power is

removed or the area is nonhazardous before proceeding.

Prepare stranded wires by attaching ferrules with plastic insulation covers

(compliant with the DIN 46228-4 standard). Ferrules similar in appearance but

not compliant may not match the terminal block on the controller.

When safety devices are connected via test outputs to an input circuit on the

SmartGuard controller, we recommend the length of the wire to be 30 m (98.4 ft)

or less.

Figure 6 - Input Devices with Mechanical Contact Outputs

Devices, such as light curtains, with current-sourcing PNP semiconductor

outputs send a signal to the SmartGuard 600 controller safety input terminal and

do not use a test output.

Rockwell Automation Publication 1752-UM001E-EN-P - June 2014 35

Page 36

Chapter 2 Installing and Wiring the SmartGuard 600 Controller

SmartGuard 600

Control ler

V1

Tx

INx

G1

24V dc

24V dc

OSSDx

GND

4.5 mA Typical

SmartGuard 600

Control ler

V2

G2

24V dc

OUTx

0.5 A Max

Load

Figure 7 - Input Devices with PNP Semiconductor Outputs

Wire Output Devices

ATT EN TI ON : Serious injury may occur due to a loss of required safety functions.

Do not connect loads beyond the rated value of safety or test outputs.

Do not use test outputs as safety outputs.

Wire the controller properly so that the 24V dc lines do not touch the safety or test

outputs.

Do not apply the power supply to the test output terminals.

Ground the 0V line of the power supply for external output devices so that the

devices do not turn on when the safety output line or the test output line is

grounded.

Separate I/O cables from high voltage or high current lines.

Figure 8 - Output Device Wiring

36 Rockwell Automation Publication 1752-UM001E-EN-P - June 2014

Page 37

Wiring Examples

E1 and E2: 24V dc Power Supplies

S1: Emergency Stop Switch

S2: Reset Switch (N.O. Contact)

KM1 and KM2: Contactors

Connect a 24V dc power supply to terminals V0 and G0, the power supply terminals for internal circuits.