Page 1

DataSite Configured Panel

Installation Instructions

1748 DataSite Configured Panel

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines for the

Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1 available from your local Rockwell Automation sales

office or online at http://literature.rockwellautomation.com

hard-wired electromechanical devices. Because of this difference, and also because of the wide variety of uses for solid state equipment, all

persons responsible for applying this equipment must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or

application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements

associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the

examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software described in

this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

) describes some important differences between solid state equipment and

WARNING

Identifies information about practices or circumstances that can cause an explosion in a

hazardous environment, which may lead to personal injury or death, property damage, or

economic loss.

IMPORTANT

ATTENTION

Identifies information that is critical for successful application and understanding of the product.

Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and

recognize the consequence

SHOCK HAZARD

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

Allen-Bradley, DataSite, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication 1748-IN001B-EN-P - May 2009

Page 3

Table of Contents

Preface

Overview

Install and Wire the Panel

Who Should Use this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Common Techniques Used in this Manual. . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Nameplate Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

cULus Marking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Environmental Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Panel Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Receiving, Handling, and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 2

Environment and Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Hazardous Location Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Panel Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Panel Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Control Panel Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Over-current Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Incoming/Outgoing Wire Installation . . . . . . . . . . . . . . . . . . . . . . . . . 20

Install Conduit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Install Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Antenna and Antenna Cable Installation . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 3

Final Checklist Before Energizing

Perform a Pre-energizing Check Procedure . . . . . . . . . . . . . . . . . . . . . 23

Pre-energizing Check Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Chapter 4

Energizing and Commissioning

Energizing Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Energizing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

DataSite Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Radio Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Software Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Chapter 5

Maintaining the DataSite

Configured Panel

3 Publication 1748-IN001B-EN-P - May 2009

Maintenance Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Maintenance after a Fault Condition. . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Page 4

4 Table of Contents

Troubleshooting

Chapter 6

Field Repairs and Replacement Procedures . . . . . . . . . . . . . . . . . . . . . 33

Troubleshooting the DataSite Configured Panel . . . . . . . . . . . . . . . . . 34

Troubleshooting the Solar Controller of the DataSite Configured

Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Step 1: Check environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Step 2: Check solar panel output. . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Step 3: Check condition of batteries . . . . . . . . . . . . . . . . . . . . . . . . 37

Step 4: Test condition of power transistors in solar controller . . . 38

Step 5: Test condition of blocking diode in solar controller . . . . . 38

Step 6: Test temperature compensation cable . . . . . . . . . . . . . . . . 39

Troubleshooting the Human-machine Interface (HMI) . . . . . . . . . . . 40

Step 1: Test the condition of ’ON’ push button for the HMI. . . . 40

Step 2: Test the HMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Common Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Improper End Connections for Antennas . . . . . . . . . . . . . . . . . . . 41

Moisture Penetration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Renewal Parts

DataSite Configured Panel Battery

Solar Panel

Configuring the ‘ON’ Push Button

for the Human-machine Interface

Chapter 7

Renewal Parts Stocking Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Order Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Appendix A

Environmental Effects on Charge Capacity . . . . . . . . . . . . . . . . . . . . . 45

Charging and Discharging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Operating Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Battery Life Expectancy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Temperature Effects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Rate of Discharge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Deep-cycling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Energy Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Appendix B

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Sizing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Appendix C

Programming the ‘ON’ Push Button . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Publication 1748-IN001B-EN-P - May 2009

Page 5

Preface

Read this preface to familiarize yourself with the rest of the manual. It provides

information concerning:

• who should use this manual

• the purpose of this manual

• related documentation

• conventions used in this manual

Who Should Use this

Use this manual if you are responsible for designing, installing, programming,

or troubleshooting DataSite configured panels.

Manual

You should have a basic understanding of electrical circuitry and familiarity

with relay logic. If you do not, obtain the proper training before using this

product.

Purpose of this Manual

Related Documentation

Related publications for DataSite configured panel

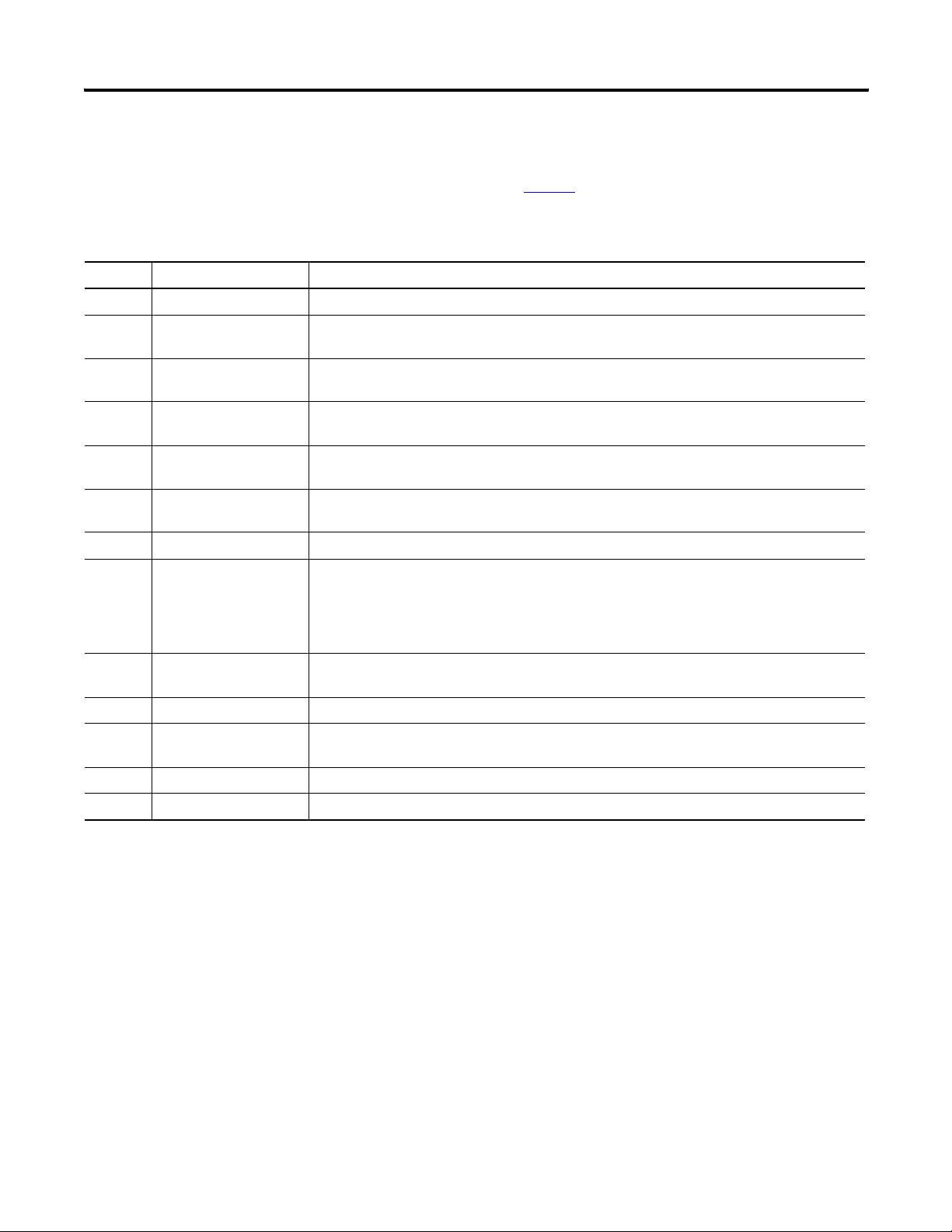

Pub. Title Pub. Number Description

DataSite Accelerator Toolkit Quick Start IASIMP-QS008

DataSite Electronic Flow Meter and Remote Terminal Unit

Installation Instructions

DataSite Electronic Flow Meter and Remote Terminal Unit

Hardware User Manual

This publication is an installation manual for the DataSite configured panel. It

describes the procedures you use to install, wire, and troubleshoot the panel.

The publications listed in this table contain more information on the DataSite

configured panel and other related devices.

Information on how to set up functional DataSite

configurations to work with a ControlLogix L63 controller, a

PanelView Plus terminal, and an industrial computer

running FactoryTalk View.

1758-IN001

1758-UM001

Information on how to install a DataSite controller.

Information on how to install and wire a DataSite controller.

DataSite Electronic Flow Meter and Remote Terminal Unit

Software User Manual

DataSite Customized Function Blocks Reference Manual 1758-RM001

Advanced Interface Converter (AIC+) User Manual 1761-UM004

DeviceNet Interface User Manual 1761-UM005

DF1 Protocol and Command Set Reference Manual 1770-6.5.16

5 Publication 1748-IN001B-EN-P - May 2009

1758-UM002

Information on how to install and use the software tools,

DS Settings, DS FloConfig, and DS DNP3 to configure and

monitor DataSite controllers.

Description of the customized function blocks used for

programming DataSite controllers using ISaGRAF software.

A description on how to install and connect an AIC+.

This manual also contains information on network wiring.

Information on how to install, configure, and commission a

DNI.

Information on DF1 open protocol.

Page 6

6 Preface

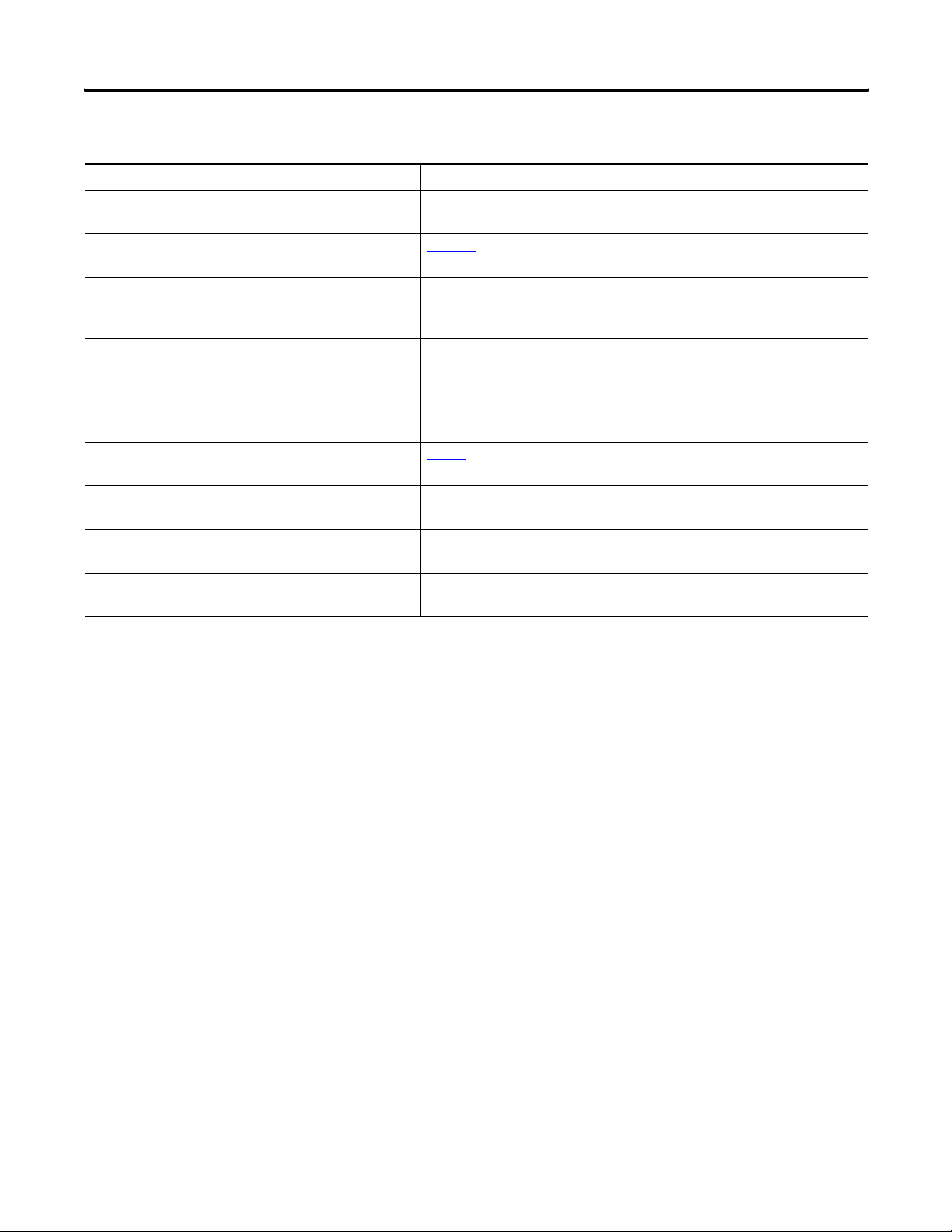

Related publications for DataSite configured panel (Continued)

Pub. Title Pub. Number Description

Modbus Protocol Specifications Available from

www.modbus.org

Allen-Bradley Programmable Controller Grounding and

Wiring Guidelines

— Information about the Modbus protocol.

1770-4.1

In-depth information on grounding and wiring Allen-Bradley

programmable controllers.

Application Considerations for Solid-State Controls SGI-1.1

National Electrical Code - Published by the National Fire

Protection Association of Boston, MA.

Allen-Bradley Publication Index SD499 — A complete listing of current documentation, including

Allen-Bradley Industrial Automation Glossary AG-7.1

Prosoft User Manual — Technical documentation on ProSoft radio. Shipped with

DataLinc User Manual — Technical documentation on DataLinc radio. Shipped with

Antenna and Cable manual — Technical documentation on antenna and antenna cable.

Common Techniques Used in this Manual

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not procedural steps.

— An article on wire sizes and types for grounding electrical

A description of important differences between solid-state

programmable controller products and hard-wired

electromechanical devices.

equipment.

ordering instructions. Also indicates whether the

documents are available on CD-ROM or in multi-languages.

A glossary of industrial automation terms and

abbreviations.

DataSite configured panel.

DataSite configured panel.

Shipped with DataSite configured panel.

• Numbered lists provide sequential steps or hierarchical information.

• Italic type is used for emphasis.

Publication 1748-IN001B-EN-P - May 2009

Page 7

Overview

Chapter

1

Introduction

Allen-Bradley industrial control panels consist of a metal or polycarbonate

enclosure that house a wide variety of factory-wired industrial control

equipment such as motor controllers, switches, relays, auxiliary devices and

programmable logic controllers. The panels may also include a disconnecting

means and motor branch circuit protective devices.

These enclosures can be wall-mounted or free-standing (pole mounted) to

meet varying application requirements. These industrial control panels have

been designed to meet the requirements of IP 66/UL Type 4X/NEMA Type

4X (outdoor) when applying proper installation techniques suitable for the

environment.

Panel dimensions vary based on the application and equipment being used.

Panels can range in size from very small 20.32 x 15.24 x 8.89 cm

(8 x 6 x 3.5 in.) operator boxes to large 228.6 x 50.8 x 50.8 cm

(90 x 20 x 20 in.) enclosures. Panels are cULus Listed to UL 508A for

Industrial Control panels or UL 1604 for Hazardous Locations.

Power can be distributed to the panel via incoming cables provided by the site

electrical system. Cables leave the control panel to power motors and other

devices and also to send analog and digital control signals.

7 Publication 1748-IN001B-EN-P - May 2009

Page 8

8 Overview

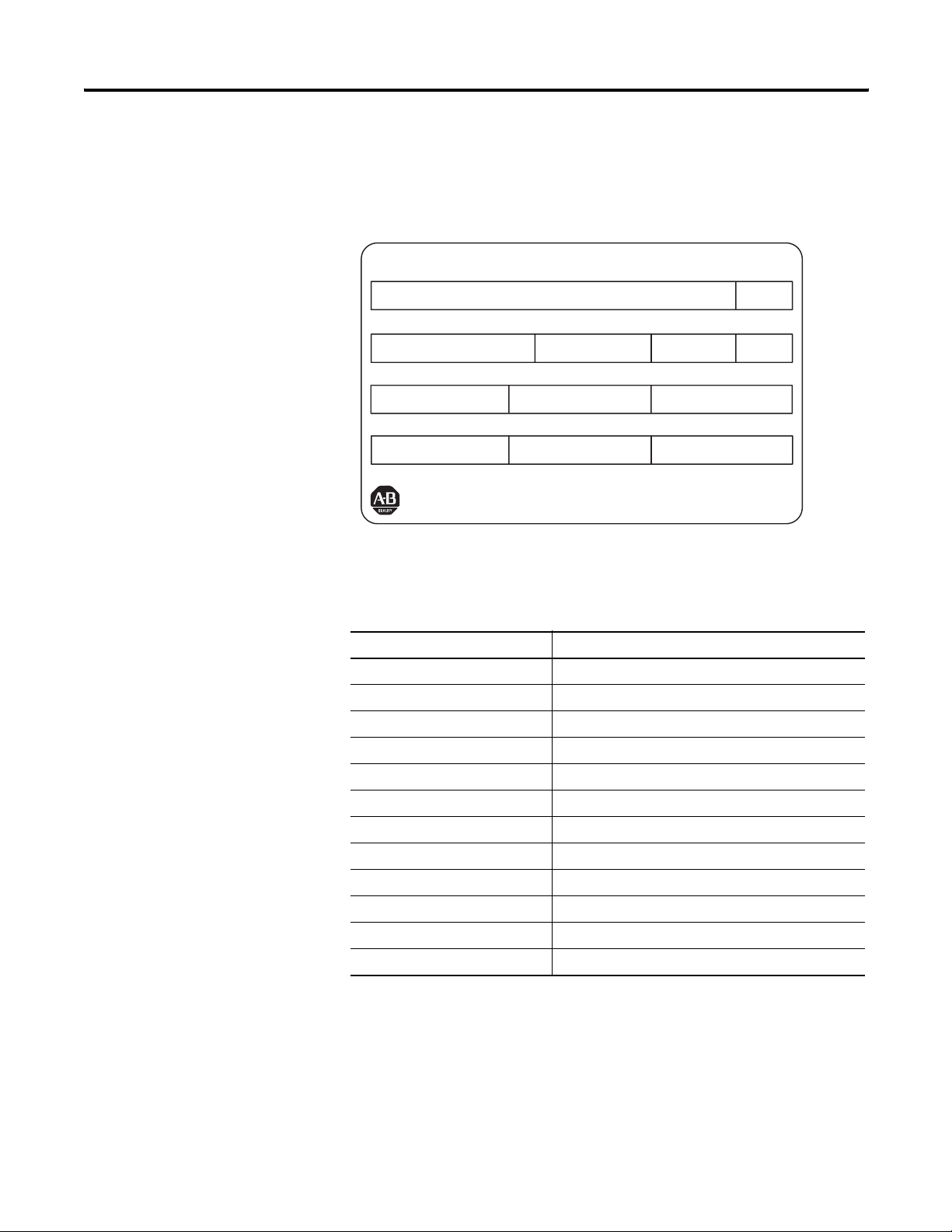

Nameplate Data

Each control panel has a nameplate located on the enclosure or enclosure

door.

Unit Nameplate

DATASITE CONFIGURED PANEL

CATALOG NO. SERIES

PHASESHZ.LINE [V]A-B SERIAL NO.

ENCL. TYPE.

WIRING DIAGRAM

Allen-Bradley

FULL LOAD [A] LARGEST LOAD [A]

HAZ. LOC TEMP. CODE

MADE IN ____________

The following product information is provided on the panel nameplate.

44743

Information Fields on Panel Nameplate

Field Description

CATALOG NO. Catalog number

SERIES Series letter of product

A-B SERIAL NO. Product serial number

LINE [V] Line voltage (V)

HZ Frequency (Hz)

PHASES Number of phases

ENCL. TYPE. UL enclosure type

FULL LOAD [A] Maximum panel amperage

LARGEST LOAD [A] Largest component current load

WIRING DIAGRAM Schematic number

HAZ. LOC Hazardous (Classified) location code

TEMP. CODE Operating temperature code

Publication 1748-IN001B-EN-P - May 2009

Page 9

Overview 9

cULus Marking

Environmental Ratings

Each industrial control panel, where applicable, will bear a cULus Listing

Mark. Panels that do not meet cULus Listing will not bear a label.

ATTENTION

The panel is rated for IP 66/UL Type 4X/NEMA Type 4X applications;

enclosures constructed for either indoor or outdoor use that provide a degree

of protection to personnel against incidental contact with the enclosed

equipment. They provide a degree of protection against falling dirt, rain, sleet,

snow, windblown dust, splashing water, and hose-directed water, will be

undamaged by the external formation of ice on the enclosure and will provide

corrosion protection.

The unit is rated to function within a temperature range of -30 °C to 50 °C

(-22 °F to 122 °F) and 0 °C to 50 °C (32 °F to 122 °F) with the

human-machine interface (HMI).

Suitable for use in Class I Division 2, Groups A, B, C, and D

Hazardous Locations, or Nonhazardous Locations only.

Battery life is reduced at lower temperatures. For battery derating information,

see Appendix A

.

Publication 1748-IN001B-EN-P - May 2009

Page 10

10 Overview

Components

This table provides a list of the main components in the DataSite configured

panel and their descriptions. The numbers in the Number column refer to the

components as shown on page 11

DataSite Configured Panel Components (All Options Shown)

Number Component Description

1 DataSite controller Low power logic device used for calculation and storing of field attached measuring devices.

2 Radio Wireless communication device designed for sending data output from the DataSite configured

panel back to a central location.

3 Solar charge controller This device is designed to regulate the charging of the backup batteries of the DataSite

configured panel by using a solar panel as an external power source.

4 Backup batteries These batteries serve as a backup in the event that there is no output from the solar panel or

when there is no solar power available.

5 DC-DC converter

(optional)

6 Surge suppressor This device is designed to help protect the solar charge controller from high transient voltages

7 On/Off switch Primary power disconnect for the panel. May be locked in the ‘On’ or ‘Off’ position.

8 Human-machine

interface (optional)

9 ‘ON’ push button for the

HMI (optional)

This device outputs 24V DC for use with components requiring higher input than the 12V DC

supplied from the solar panel and backup batteries.

caused by lightning strikes to the connected solar panel.

The human-machine interface (HMI) allows the user to see different parameters that are

programmed into the DataSite controller.

The HMI and the DataSite controller do not come programmed from the factory. In order for them

to work together properly, they must be programmed. For more information, refer to the IDEC and

DataSite user manuals.

This push button will turn on the HMI for a configurable amount of time. The push button serves

as a power saving component by turning on the HMI only when necessary.

.

10 Fuse blocks Fuse holder for FU1, FU2 and FU3 fuses.

11 Lightning suppressor

(optional)

12 Terminal blocks (optional) Provided for ease of wiring to the DataSite controller.

13 Enclosure vents These provide pressure equalization and cooling of the DataSite configured panel enclosure.

This device helps protect the radio in the event of a lightning strike.

Publication 1748-IN001B-EN-P - May 2009

Page 11

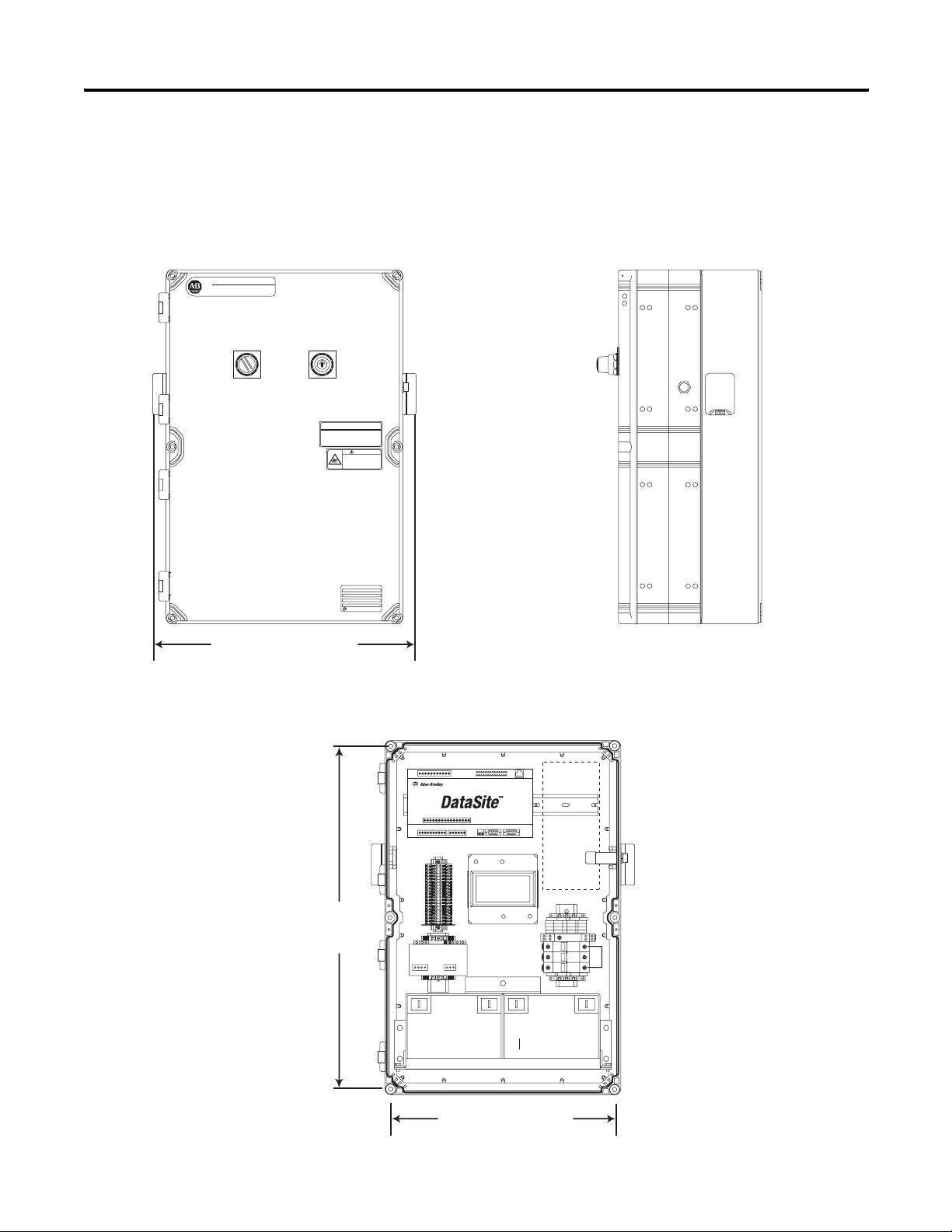

DataSite Configured Panel Components

Front view (with door closed) Side view (with door closed)

Allen-Bradley

97

WARNING

CAUTION

Overview 11

13

Allen-Bradley

Mounting Holes

Mounting Holes

44746

Inside view

1

2

12

11

8

Note:

3

(3) is located beneath (8) and

is not visible in this drawing.

6

10

5

4

44747

Mounting Holes

44748

Publication 1748-IN001B-EN-P - May 2009

Page 12

12 Overview

Panel Layout

This figure shows a typical layout of the DataSite configured panel.

Typical DataSite Configured Panel Layout

Publication 1748-IN001B-EN-P - May 2009

Page 13

Overview 13

Receiving, Handling, and Storage

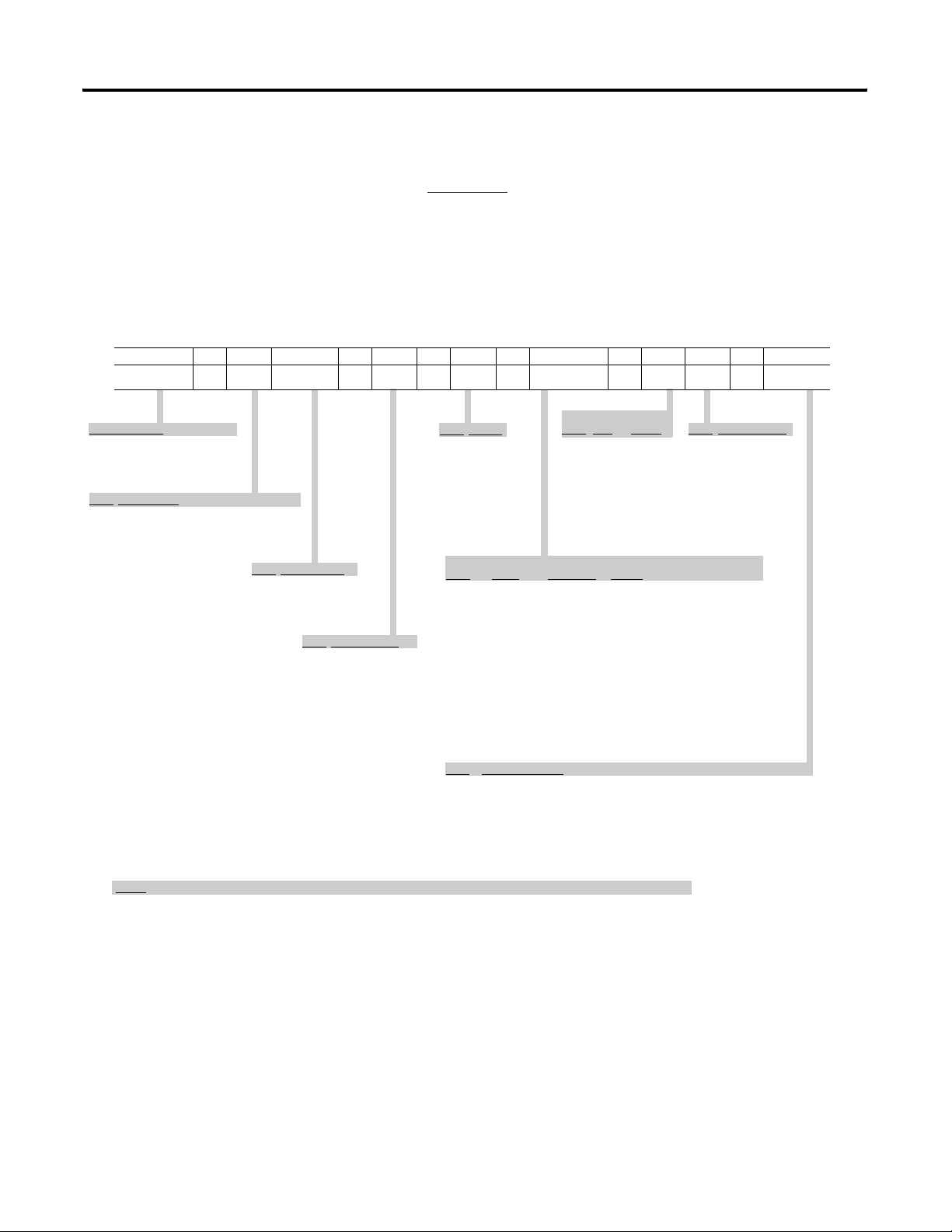

Catalog Number Explanation

1-4 5 6 7-8 9 10 11 12-13 14 15-18 19 20-21 22 23 24-25

1748 - F DC - P - 14 - PS9E - 10 Y - TB

Bulletin Number

1748 DataSite Enclosure in

UL Type 4X polycarbonate

Code Product Type

F Enclosed with Flow Measurements (AGA)

R Enclosed, RTU only

Code Analog Inputs

DC 0…10V DC

MA 4…20 mA

Code Mounting Type

W Wall mounting kit

P Pipe mounting kit

For a complete list of receiving, handling and storage instructions, please refer

to "Receiving, Handling, and Storage Industrial Control Panels Instructions",

publication 1000-IN001

.

The following chart describes the parts that make up the catalog number for a

DataSite configured panel.

Antenna Cable Length

Code Battery

14 14 Ah

28 28 Ah

56 56 Ah

Radio

Code Brand Frequency Comm.

NR None None None Space for radio included.

PS9E Prosoft 900 MHz Ethernet

PS9S Prosoft 900 MHz Serial

PS24E Prosoft 2.4 GHz Ethernet

PS24S Prosoft 2.4 GHz Serial

DL9E Datalinc 900 MHz Ethernet

DL9S Datalinc 900 MHz Serial

DL24E Datalinc 2.4 GHz Ethernet

DL24S Datalinc 2.4 GHz Serial

FW9E FreeWave 900 MHz Ethernet

FW9S FreeWave 900 Mhz Serial

FW24E FreeWave 2.4 GHz Ethernet

FW24S FreeWave 2.4 GHz Serial

Code Feet Meters

NC None None

10 10 3.1

25 25 7.6

50 50 15.2

100 100 30.5

Cable length between panel

and antenna must not be

longer than 30.5m (100 ft).

Code Antenna Brand

Y Yagi

OOmni

NA No antenna

Code Enclosed Options

Blank No options

AL Aluminum NEMA 4X enclosure, 60.96 x 50.8 x 25.4 cm (24 x 20 x 10 in.).

See note 6.

TB RTU wired to control terminals. If not selected, no terminals provided.

HMI IDEC display unit HG1X-222. See note 5.

24V 24V system voltage. This means 24V is available for field devices, but the

DataSite panel, radio and batteries remain at 12V DC. See note 8.

Notes:

1. Unit is UL Class I Division 2 certified only when FreeWave 900 MHz radios are selected (options FW9E and FW9S).

2. Solar panels are available from local RA authorized distributors.

Please see DataSite Configured Panel Application Techniques, publication 1748-AT001A-EN-P for proper sizing and selection.

Solar panels must meet UL Class I Division 2 if required.

3. Standard system voltage is 12V DC.

4. Radio surge suppressor included when a radio is specified.

5. Human-machine interface (HMI) option includes:

2-line, 16-character or 4-line, 20 character backlit LCD HG1X-222 is 24V DC and supports RS232 or RS485 communications.

A 12V/24V voltage converter is included.

6. Replaces NEMA 4X polycarbonate enclosure.

7. DC-DC converter included for voltage conversion from 12…24 V DC.

8. If a radio is not selected, antennas and cables cannot be selected.

Publication 1748-IN001B-EN-P - May 2009

Page 14

14 Overview

Notes:

Publication 1748-IN001B-EN-P - May 2009

Page 15

Chapter

2

Install and Wire the Panel

This chapter provides you with an overview of the installation and wiring of

the DataSite configured panel.

Environment and Enclosure

Hazardous Location Considerations

Most applications require installation in an industrial enclosure to reduce the

effects of electrical interference and environmental exposure. Locate your

controller as far as possible from power lines, load lines, and other sources of

electrical noise such as hard-contact switches, relays, and AC motor drives. For

more information on proper grounding guidelines, see the Industrial

Automation Wiring and Grounding Guidelines, publication 1770-4.1

ATTENTION

The DataSite configured panel is UL Listed for use in hazardous locations

Class I Division 2, groups A, B, C, and D, or non-hazardous locations only.

Proper installation must be considered for the panel to be used in these

locations. Installation of the panel should be done only after ensuring the

location is free of any hazardous gases or substances. For proper installation

refer to articles 500, 504 and 505 of the National Electric Code, NFPA 70,

2005.

Be careful of metal chips when drilling mounting holes for your

controller or other equipment within the enclosure or panel.

Drilled fragments that fall into the controller could cause

damage. Do not drill holes above a mounted controller if the

protective debris strips have been removed.

.

The following WARNING statement applies to use in hazardous locations.

WARNING

15 Publication 1748-IN001B-EN-P - May 2009

Explosion Hazard

• Substitution of any component may impair suitability for Class I

Division 2.

• Do not disconnect equipment while the circuit is live or unless

the area is known to be free of ignitable concentrations.

•

Batteries must only be changed in an area known to be

non-hazardous.

Page 16

16 Install and Wire the Panel

Panel Dimensions

Front view (with door closed) Side view (with door closed)

Allen-Bradley

Depending on the options chosen, the dimensions for the DataSite configured

panel are 59.69 x 41.28 x 26.67 cm (23.5 x 16.25 x 10.5 in.) or

59.69 x 41.28 x 20.96 cm (23.5 x 16.25 x 8.25 in.).

WARNING

CAUTION

45.72 cm (18.00 in.)

57.98 cm

(22.83 in.)

Allen-Bradley

44751

Inside view

44752

Note: Depending on options chosen, the panel depth

is 26.67 cm (10.50 in.) or 20.96 cm (8.25 in.).

Publication 1748-IN001B-EN-P - May 2009

37.99 cm (14.96 in.)

44753

Page 17

Install and Wire the Panel 17

Panel Weights

Mounting

The weight of the DataSite configured panel depends on the battery included.

The following are the approximate weights of the panel for each battery

option:

• With a 14 Ah battery: 9.07 kg (20 lb)

• With a 28 Ah battery: 13.61 kg (30 lb)

• With a 56 Ah battery: 20.41 kg (45 lb)

When planning the location for your DataSite configured panel, be sure to

consider the following:

• Conduits

• Installation type and requirements for mounting

• Connection to other equipment

• Future needs

• Ambient considerations: The environment must be compatible with the

enclosure rating of the equipment.

When your panel was purchased, an option was available to purchase a pole or

wall-mounting kit. In addition to properly mounting your control panel, other

items such as radios, solar panels, auxiliary devices, sensors and

incoming/outgoing cables will have to be installed to complete the installation

of your DataSite configured panel.

The pole or wall mounting kit provided with the DataSite configured panel

includes instructions on how to use those kits to properly mount the panel.

Refer to those instructions for clear directions on how to mount the panel.

Publication 1748-IN001B-EN-P - May 2009

Page 18

18 Install and Wire the Panel

The following figures show a typical DataSite controller system installation

and a typical pole-mounted arrangement.

Typical DataSite Controller System

Solar Cell Serial or Ethernet Comms

Controller

12V DC

Battery Bank

IMPORTANT

Cable length between panel and antenna must not exceed

30.5m (100 ft).

Typical DataSite Configured Panel Pole Mounting

Antenna

Radio

44744

Publication 1748-IN001B-EN-P - May 2009

Note: Picture may not match actual product.

Page 19

Install and Wire the Panel 19

Control Panel Wiring

Over-current Protection

Wiring details for the control panel can be found on the schematics shipped

with your panel. The selector switch on the door serves as a disconnecting

device to energize or de-energize power to the unit.

When installing field devices, over-current protection must be considered.

Refer to NEC 2005 article 240 regarding the use of over-current protection for

field installed devices.

IMPORTANT

Over-current protection is provided by the fuses already provided as part of

the panel assembly.

IMPORTANT

Due to the limited energy storage of the DataSite configured

panel, installation of field devices will affect the number of

hours of backup energy the panel may have.

Replacement or removal of these fuses must be done in a safe

environment free of any combustible substances and by

certified field maintenance personnel as described in

NEC/NFPA guidelines.

ATTENTION

Replace over-current protection fuses with class CC, 250V type

ATQR or equivalent fuses only.

Replacement of fuses with any other type may result in damage

to the DataSite configured panel.

Publication 1748-IN001B-EN-P - May 2009

Page 20

20 Install and Wire the Panel

Incoming/Outgoing Wire Installation

Allowable incoming and outgoing voltages can range from 0V DC to 24V DC.

IMPORTANT

For details about field wiring apparatus, refer to the control drawing in the

DataSite Hardware User Manual, publication 1758-UM001

Any conduit or cable entering or leaving the DataSite

configured panel which is not deemed non-incendive must be

held in conduit to maintain the UL Class I Division 2 Listing of

that control panel.

.

Install Conduit

When installing conduit, make sure it is installed according to all applicable

codes and standards. This is to ensure that water and moisture cannot enter or

accumulate in the DataSite controller enclosure.

Conduits must be installed so they are compatible with the UL rating of the

DataSite controller. It is recommended that the conduit be positioned to

minimize cable bending and maintain relative vertical alignment to incoming

connections.

ATTENTION

When installing the DataSite configured panel within a Class I

Division 2, hazardous location, special installation of conduit

and cable must be considered. Refer to NEC 2005 article 501 for

details on proper installation of the conduit, cable, and box

fittings.

Install Cable

Install cable when the ambient temperature is above freezing (0 °C or 32 °F),

unless it is suitable for installation at temperatures below freezing. This will

help prevent cable insulation from cracking or splitting.

DataSite controllers are rated for use with 75 °C (167 °F) cable. Cable must be

sized using 75 °C (167 °F) column in NEC Table 310–16 (NEC 2005 Edition).

TIP

To verify field wiring connection points, refer to the wiring

diagrams in the DataSite Hardware User Manual, publication

1758-UM001

.

Publication 1748-IN001B-EN-P - May 2009

Page 21

Install and Wire the Panel 21

Antenna and Antenna Cable Installation

Use only antennas approved by radio manufacturers.

The following are some common types of antennas:

Gain is specified in dBd or dBi and achieved by directing (focusing) radio

frequency (RF) emission. Emission patterns must be considered such that

other sites are within the focused area.

Antenna cables should be selected to match required length. Coiling of excess

cables can increase dB loss and should be avoided. To help prevent installation

issues, it is recommended that you purchase pre-fabricated cables.

Lightning arrestors are always recommended for outdoor applications and

should be installed near the radio. A lightning arrestor is supplied when a radio

is purchased.

For more details on antenna or antenna cable installation, visit

http://www.prosoft-technology.com

Typical Antenna Mounting Installation

• Directional (yagi, parabolic)

• Omni-directional (dipole)

.

Antenna coax to

lightning arrestor

Ground

N Type male connector

RF signal direction

Antenna coax to

lightning arrestor

Mounting

hose clamps

N Type male

connector

Ground

44745

Publication 1748-IN001B-EN-P - May 2009

Page 22

22 Install and Wire the Panel

Notes:

Publication 1748-IN001B-EN-P - May 2009

Page 23

Chapter

3

Final Checklist Before Energizing

This chapter provides guidance for the start-up of a newly installed DataSite

configured panel.

It is recommended to make an itemized list including the following

information:

• Serial number

• Number of units and their locations

• System voltage

• Other important data.

This itemized list should be saved in a file along with other data for the

installation of the DataSite controller, such as component manuals, radio

manuals, and wiring diagrams.

Perform a Pre-energizing Check Procedure

The following procedures should be performed by a “qualified person” as

defined by Standards Publication NFPA 70E, 2004, “Standard for Electrical

Safety in the Workplace” Article 110 “Qualified Person”:

“A qualified person shall be trained and knowledgeable of the

construction and operations of equipment or a specific work method

and be trained to recognize and avoid the electrical hazards that might

be presented with respect to that equipment or work method.

a. Such person shall also be familiar with the proper use of the special

precautionary techniques…

b. An employee who is undergoing on-the-job training and who, in the

course of such training, has demonstrated the ability to perform

duties safely at his or her level of training…

c. Such persons permitted to work within the Limited Approach

Boundary of exposed live parts operating at 50 volts or more…”

23 Publication 1748-IN001B-EN-P - May 2009

Page 24

24 Final Checklist Before Energizing

Pre-energizing Check Procedure

1. Remove all blocks or temporary holding means used for shipping all

component devices.

2. Inspect the enclosure and units for damage. If structural damage is

present, contact Rockwell Automation Technical Support.

3. Check and verify that the panel is properly installed, as described in

Chapter 2

(if necessary or required).

. Inspect and verify that it is level, supported, and anchored

ATTENTION

To ensure the safety of personnel performing the pre-energizing

check, make sure that the power source(s) of the DataSite

controller is disconnected and locked in the “OFF” / “O”

position.

Use a voltmeter to verify that the panel remote power source(s)

is disconnected.

4. Check the integrity of the cable/conduit connections.

Recommended torque values can be found on the schematic that was

shipped with the DataSite configured panel.

5. Check and verify that all ground connections are made properly, based

on local standards. Make sure that the DataSite configured panel is

connected to provide a continuous ground path.

6. Check field wiring:

a. Check the field wiring for proper conductor sizing. Field conductors

should be sized using the National Electrical Code (NEC) 75 °C

(167 °F) wire tables.

b. Removal of barrier(s) may have been required for field wiring.

Make sure that all barriers and parts that may have been removed

during installation have been reinstalled.

c. Make sure that all incoming and outgoing power wiring is secure and

braced. Make sure that conduit and/or cabling are well supported.

d. Check the integrity of all field connections. Recommended torque

values not found on individual devices can be found on the unit

wiring diagrams.

e. Check that field wired connections made to the panel agree with

wiring diagrams and verify proper spacing.

Publication 1748-IN001B-EN-P - May 2009

7. Make sure that the voltage ratings on the system correspond with the

unit ratings of the DataSite controller.

Page 25

Final Checklist Before Energizing 25

8. For applications requiring power fuses, install the fuses in the fusible

switches in accordance with the NEC application requirements.

All fuses must be completely inserted in the fuse clips. Fuses may only

be inserted after the location has been determined to be non-hazardous.

9. Component devices may require unique start-up procedures. For

specific start-up guidance, refer to the DataSite Hardware User Manual,

publication 1758-UM001

. Set and verify adjustable current, voltage and

other settings, according to device instructions or wiring diagrams.

10. Manually exercise all switches, including control auxiliary switches,

circuit breakers, their respective operators, and any other operating

mechanisms to verify proper operation.

11. Check timing relay settings as required.

12. Recheck and ensure that all barriers and parts that may have been

removed during installation have been reinstalled.

13. Before closing the enclosure and/or individual units, remove all tools,

metal chips, scrap wire and other debris from the interior of the

DataSite configured panel. If there is an accumulation of dust or dirt,

clean out the DataSite configured panel using a brush, vacuum cleaner

or clean, lint-free rag. Do not use compressed air. Doing so will

redistribute contaminants on other surfaces.

ATTENTION

When conducting an electrical insulation resistance test,

isolate equipment sensitive to high test voltages, such as

meters, solid state devices, motor winding heaters, and

capacitor units.

14. Make sure all unit latches are secure.

15. Close and latch all doors, making sure that no wires are pinched.

Publication 1748-IN001B-EN-P - May 2009

Page 26

26 Final Checklist Before Energizing

Notes:

Publication 1748-IN001B-EN-P - May 2009

Page 27

Chapter

Energizing and Commissioning

This chapter provides you with instructions for energizing the DataSite

configured panel.

4

Energizing Equipment

This procedure is provided as a general guidance for energizing a newly

installed DataSite configured panel.

IMPORTANT

ATTENTION

Perform this procedure after the Final Check procedure has

been completed. See Chapter 3,

Energizing.

Energizing a DataSite controller for the first time is potentially

dangerous. Serious damage and/or personal injury can result

when the power is turned on. Therefore, only qualified

personnel should energize the equipment.

Final Checklist Before

Energizing Procedure

1. Review any additional instructions supplied for the proper operation of

special units with appropriate and qualified personnel.

IMPORTANT

27 Publication 1748-IN001B-EN-P - May 2009

Ensure that there is no load on the DataSite controller when it

is energized. Also, make sure any associated remote devices

are de-energized.

Page 28

28 Energizing and Commissioning

2. Energize the remote power source of the DataSite controller.

3. Energize the main devices followed by the feeder devices and the

branch circuit devices. Always energize from the source of the system,

working toward the loads.

ATTENTION

After all of the disconnect devices have been closed, loads may

be energized.

DataSite Commissioning

For information regarding the commissioning of the DataSite controller, refer

to the DataSite Hardware User Manual, publication 1758-UM001

.

Radio Commissioning

When the DataSite configured panel is equipped with a factory supplied radio

(optional), refer to the radio manufacturer’s user manual supplied with the

DataSite configured panel. The radio user manual can also be found by

contacting the Rockwell Help Desk at 414-382-1616.

Publication 1748-IN001B-EN-P - May 2009

Software Commissioning

For information regarding the commissioning of the DataSite software, refer

to the DataSite Software User Manual, publication 1758-UM002

.

Page 29

Chapter

5

Maintaining the DataSite Configured Panel

A periodic maintenance program should be established for the DataSite

configured panel to avoid unnecessary downtime. The frequency of service to

your DataSite configured panel will depend upon the equipment usage and the

environment in which it operates. The following is a suggested checklist and

can be used to establish a maintenance program.

Maintenance Checklist

ATTENTION

Use this checklist to perform maintenance on the DataSite configured panel.

1. Inspect the DataSite configured panel once per year or per established

maintenance program.

2. Carefully inspect the door and enclosure sides for evidence of excessive

heat.

3. Check for moisture or any signs of dampness or drippings inside the

DataSite configured panel. Condensation in the conduit or dripping

from an outside source is a common cause of failure. Eliminate any

source of moisture.

a. Seal off conduit, cracks and openings that have allowed and/or could

allow moisture to enter the DataSite configured panel enclosure.

b. Dry or replace and clean insulating material that is damp or wet or

shows signs of moisture.

c. Check devices for wetness or signs of moisture, corrosion or

contamination.

d. Replace damaged or malfunctioning parts.

e. Make sure the source or cause of wetness or moisture contamination

is identified and eliminated.

De-energize the DataSite configured panel before servicing.

29 Publication 1748-IN001B-EN-P - May 2009

Page 30

30 Maintaining the DataSite Configured Panel

4. Check for the proper function and freedom of movement (no sticking

or binding) for the disconnect switch (800H), and defeater mechanisms.

Replace broken, deformed, malfunctioning or badly worn parts or

assemblies.

WARNING

Follow NFPA 70E, 2004 safety guidelines when working on

energized equipment. To prevent injury or death to personnel

lubricating disconnect switch contacts, make sure DataSite

configured panel power source(s) is disconnected and the

respective disconnect(s) is locked in the OFF/O position. To

prevent personal injury or damage to equipment, make sure

that the unit handle operator is in the OFF/O position before

working on the unit.

5. Inspect current carrying parts such as fuse clips, knife blades of

disconnects and line and load terminals of devices for discoloration,

corrosion or other signs of wear or possible failure.

6. Check locking or interlocking devices for proper working condition.

Adjust, repair or replace any device if necessary.

7. Check for loose wire connections on power and control circuit

terminals. Loose connections can cause overheating, hot spots or arcing

faults that could lead to equipment malfunction or failure. Replace any

damaged parts or wiring.

Publication 1748-IN001B-EN-P - May 2009

8. Check relay coils for evidence of overheating, such as cracking, melting

or burning of insulation. If there is evidence of overheating, the coil

must be replaced. When replacing a coil, check and correct the

over-voltage or under-voltage conditions that may have caused the coil

failure. Be sure to clean any residue of melted coil insulation from other

parts of the device and replace as necessary.

9. Check battery terminals for excessive corrosion. If corrosion is present

clean or replace batteries or terminals as needed.

Batteries should be replaced at recommended intervals. The table,

Recommended Battery Replacement Schedule

on page 31, shows the

recommended intervals between battery replacements based on ambient

temperatures.

ATTENTION

Failure to replace batteries may lead to a loss in backup power

resulting in the loss of function of the DataSite configured

panel.

Page 31

Maintaining the DataSite Configured Panel 31

Battery intervals may vary with the addition of external loads to the

system or rapid changes in ambient temperature. Periodic maintenance

and measurement of battery life should be done to ensure system

reliability.

10. Check all fuses. If replacing fuses, install the same type and rated fuse

that was originally furnished with the DataSite configured panel.

11. Remove accumulated dust and dirt from structure and individual units

by vacuuming. Do not use compressed air, as it may contain moisture

and blow debris within the enclosure.

12. Refer to individual user policies, NFPA 70B, Recommended Practice for

Electrical Equipment Maintenance for Servicing Guidelines.

This table was developed with the assumption that batteries are maintained

properly without additional loads connected to system. Replacement schedules

for additional loads may vary depending on size of load connected. Also, this

table is based on temperature only as the load on the battery will only affect

the battery life if the load is greater than or equal to 1 W continuous.

Recommended Battery Replacement Schedule

Average summer

temperature

-40 °C (-40 °F) Not recommended Not recommended 1.25 years

-30 °C (-22 °F) Not recommended 9 months 2 years

-20 °C (-4 °F) Not recommended 1 year 3 years

-10 °C (14 °F) 6 months 1.5 years 3 years

0 °C (32 °F) 9 months 2.25 years 3 years

10 °C (50 °F) 9 months 2.25 years 3.5 years

20 °C (68 °F) 9 months 2.5 years 3.5 years

30 °C (86 °F) 1 year 2.5 years 2.5 years

40 °C (104 °F) 1 year 1.5 years 1.5 years

50 °C (122 °F) 9 months 9 months 9 months

60 °C (140 °F) 6 months 6 months 6 months

70 °C (158 °F) 3 months 3 months 3 months

Suggested battery replacement intervals

14 Ah battery 28 Ah battery 56 Ah battery

Publication 1748-IN001B-EN-P - May 2009

Page 32

32 Maintaining the DataSite Configured Panel

Maintenance after a Fault Condition

Ensure the location is free of any hazardous gasses then disconnect all power

sources to the DataSite configured panel before diagnosing the cause of a fault

condition. For more details, refer to NFPA 70E, 2004 “Safety Related Work

Practices”.

Fault conditions (lightning strike, over-current situation) can cause damage to

control equipment. When a fault occurs, de-energize the DataSite configured

panel, investigate the cause of the fault and inspect all equipment thoroughly

per Standards Publication NFPA 70E, 2004 “Standard for Electrical Safety in

the Workplace” Section 235 “Maintenance for Hazardous (Classified)

Locations”.

Make necessary repairs to units, components and structures as required, prior

to re-energizing the equipment. Be sure that replacement parts are suitably

rated for the application. Before re-energizing, refer to NFPA 70E, 2004

Section 440, Hazardous (Classified) Locations.

Publication 1748-IN001B-EN-P - May 2009

Page 33

Chapter

6

Troubleshooting

You can use this chapter as a diagnostic tool to aid in the troubleshooting of

the DataSite configured panel. A table and a step-by-step guide are provided.

The assumption has been made that the DataSite configured panel had been

properly installed and operating prior to the occurrence of a fault.

Field Repairs and Replacement Procedures

ATTENTION

Troubleshooting requires a clear definition of the problem based upon the

system fault symptoms. Defining the problem clearly and knowing the system

status or operating conditions prior to the problem will narrow the scope of

the troubleshooting. For example, ask questions such as the following:

• Was the system operating normally before the fault occurred?

• Were the batteries charged?

• Was there adequate sunlight for the solar panel?

IMPORTANT

Troubleshooting in a hazardous location must be done by a

qualified field personnel. Additional procedures may be

required depending on the location and the presence of a

hazardous atmosphere. Refer to NFPA 70B, Recommended

Practice for Electrical Equipment Maintenance for Servicing

Guidelines.

Replacement of DataSite configured panel parts must be

completed by a qualified person. Installation of a replacement

component other than those specified is not recommended and

will violate the Class I Div. 2 panel listing. For proper

functionality, components should only be replaced with

Rockwell approved replacement components.

Before servicing the DataSite configured panel, remove all power sources and

ensure the environment is clear of all hazards including explosive gases.

Service on the DataSite configured panels should be performed by personnel

familiar with the DataSite configured panel and its functionality. Read the

DataSite Installation Instructions, publication 1758-IN001

before servicing the panel or field supplied components connected to it.

33 Publication 1748-IN001B-EN-P - May 2009

, in its entirety

Page 34

34 Troubleshooting

Troubleshooting the

The following table covers a brief technical approach to verifying the

functionality of the following components:

DataSite Configured Panel

It is recommended that troubleshooting of the DataSite configured panel

begin with the use of the following troubleshooting table for a more systematic

and modular approach. The numbers in parentheses ( ) refer to the

components as shown on page 11

For troubleshooting information on the DataSite controller or its associated

software, refer to the related publications listed in the table,

Related publications for DataSite configured panel on page 5

If additional information on the DataSite configured panel operation is

needed, contact Rockwell Automation Technical Support.

Troubleshooting the DataSite Configured Panel

• DataSite controller

• Human-machine interface (HMI)

• Transmit radio

• Batteries

• Solar charge controller

.

.

Problem Component Possible Cause Check Action

No power at the

DataSite controller

(1)

Wire Wire fault Make sure that all connections

are tight and that there is

continuity in the wires.

Fuse Fuse blown Check to see that the fuse has

not opened.

Batteries No charge in

battery

Battery terminal Corrosion on

Terminal

Solar controller Short in solar

panel

Shorted battery If there is light reaching the solar

Shorted solar

controller

Perform load test

condition of the battery.

Check if the integrity of the

battery terminal has been

compromised, and if there are

loose or corroded terminals

If there is light reaching the solar

panel, disconnect the solar panel

from the controller and ensure

that there is voltage at the solar

panel terminals.

panel and there is voltage at the

solar panel terminals, ensure that

the battery output terminals read

11.5V or greater.

Check the solar panel and

battery.

(1)

to confirm the

If the wire is faulty, tighten the terminal

or replace the wire as necessary.

Replace the fuse if it is open.

If battery test fails, replace battery with

Rockwell approved replacement part.

If compromised, replace battery with

Rockwell approved replacement part.

If no voltage is present, ensure that

there is not a short at the solar panel or

a bad connection at the solar panel

junction box. Replace the solar panel if

there is no voltage at the panel output.

If the reading is lower than 11.5V, the

battery may be shorted or possibly

deep-cycled. Charge the battery, and

then recheck the system. If necessary,

replace the battery.

If after checking the solar panel and

battery, the charge light still does not

illuminate, contact Rockwell

Automation Technical Support.

Publication 1748-IN001B-EN-P - May 2009

Page 35

Troubleshooting the DataSite Configured Panel

Problem Component Possible Cause Check Action

HMI (8) does not

power on

Display Wire fault Check all wiring associated with

the HMI. Ensure that the

protective fuse has not blown and

that the DC-DC converter is

Check wiring. Contact Rockwell

Automation Technical Support if the

HMI or a related component needs to

be replaced.

working properly.

Radio (2) will not

send data

Radio Wire fault Check radio to ensure 12V DC is

at the input terminals.

Check wiring and fuse associated with

device.

Troubleshooting 35

Antenna Lightning strike Lightning suppressor (11) may

have shorted antenna.

Contact Rockwell Automation Technical

Support for replacement lightning

suppressor.

Adjust antenna height and position to

ensure signal integrity. Refer to user

manual that came with the antenna for

more information.

For details on configuration, refer to the

radio user manual.

Re-adjust or move solar panel to ensure

light is reaching the panel.

System has

shortened battery

backup.

Poor signal

strength

Ensure that no obstacles are in

the path of the antenna and that

all connections in the antenna

wire are tight.

Radio Configuration Ensure that the radio is

configured correctly.

Solar panel Poor light quality Ensure that sunlight is striking

the solar panel and that no

obstructions are in the way of the

light path.

Battery Battery life

depleted

Perform load test

condition of the battery.

(1)

to confirm the

If battery test fails, replace battery with

Rockwell Automation approved

replacement part. Make sure that the

battery is not getting too hot by

checking the internal temperature of

the DataSite configured panel

enclosure. High temperatures will

shorten the life expectancy of a battery.

Batteries should be replaced according

to the table, Recommended Battery

Replacement Schedule on page 31.

Batteries should be replaced when

capacity is less than 60% of the rated

value.

No 24V DC output

at terminal blocks

24V DC+ and

24V DC Com (when

equipped)

(1)

Use a battery load tester designed for Lead Acid Batteries. Follow the instructions of the load tester to check the condition of the battery.

Fuse Fuse blown Check to see that fuse has not

opened.

DC-DC converter Fault Check to see that the status LED

indicator is green.

Replace fuse if it is open.

If the indicator is not illuminated,

contact Rockwell Automation Technical

Support.

Publication 1748-IN001B-EN-P - May 2009

Page 36

36 Troubleshooting

Troubleshooting the Solar Controller of the DataSite Configured Panel

Depending on the system it will be normal for the solar controller to go a long

period of time with or without charging. The function of the solar controller is

to regulate the charging of the batteries in the DataSite configured panel.

After a long period without sunlight, the solar controller will allow the solar

panel to charge the batteries of the DataSite configured panel for an extended

period of time. The charging LED on the solar controller may remain lit for an

extended period of time. The opposite will also occur when there is minimal

use of the DataSite configured panel batteries for an extended period of time.

The charge light may not illuminate when there is sunlight striking the solar

panel. This is because the batteries are fully charged and adding additional

charge can cause an overcharge condition of the battery.

ATTENTION

Since batteries will not store their full charge in extreme cold

environments, the DataSite configured panel batteries supplied

may not contain sufficient charge to keep the system running

for extended periods without sunlight.

To view a derating table, see DataSite Configured Panel Battery

Derating on page 46.

Perform the following to check the solar controller for correct functionality.

• Step 1: Check environment

• Step 2: Check solar panel output

• Step 3: Check condition of batteries

• Step 4: Test condition of power transistors in solar controller

• Step 5: Test condition of blocking diode in solar controller

• Step 6: Test temperature compensation cable

The numbers in parentheses ( ) refer to the components as shown on page 11

.

Publication 1748-IN001B-EN-P - May 2009

Page 37

Troubleshooting 37

Step 1: Check environment

Ensure that the environment is clear of all hazards including explosive gases

before opening the DataSite configured panel. Refer to NFPA 70E, 2004

Safety Guidelines when servicing the DataSite configured panel equipment.

Step 2: Check solar panel output

Check the solar panel output to ensure that the solar array is connected and

working properly.

• Disconnect the solar panel from the DataSite configured panel and

measure the voltage of the solar panel while sunlight is striking the

panel. In sunny conditions the open voltage of the solar panel should

read between 18…24V DC. A lower value could indicate a problem with

the solar panel array.

Step 3: Check condition of batteries

Check the condition of the batteries.

1. Check the connections for the battery and make sure that all terminals

are torque to their specified ratings and that no wires are cut or frayed.

(1)

2. Create a load on the battery by using a battery load tester

battery test fails, replace the battery.

If the battery is working properly, move onto Step 4: Test condition of

power transistors in solar controller.

. If the

(1)

Use a battery load tester designed for Lead Acid Batteries. Follow the instructions of the load tester to check

the condition of the battery.

Publication 1748-IN001B-EN-P - May 2009

Page 38

38 Troubleshooting

Step 4: Test condition of power transistors in solar controller

Test the condition of the power transistors in the solar controller.

1. With the solar controller completely disconnected from the DataSite

configured panel, make these connections.

a. Use a variable power supply set to 20V DC, 0.5 mA.

b. Connect the + VDC Power Supply terminal to the ARRAY(+) input

terminal of the solar charge controller (3).

c. Connect the Common Power Supply terminal to the ARRAY (-)

input terminal of the solar charge controller (3).

2. Measure the voltage at BATT (+) and BATT (-) terminals of the solar

charge controller (3). The reading should be approximately 14.3V.

• If the reading is high (16…20V), the power transistor has failed

short.

• If the reading is low (0…5V), the power transistor has failed open.

• If the transistor is open or shorted, replace the solar controller.

Step 5: Test condition of blocking diode in solar controller

Test the condition of the blocking diode in the solar controller.

1. With the solar controller completely disconnected from the DataSite

configured panel, make these connections.

a. Use a variable power supply set to 20V DC, 0.5 mA.

b. Connect the + VDC Power Supply terminal to the ARRAY (+) input

terminal of the solar controller.

c. Connect the Common Power Supply terminal to the BATT (+) input

terminal of the solar controller.

2. Measure the voltage at ARRAY (+) and BATT (+).

The reading should be around 0.3…0.6V.

• A very high reading (16…20V) indicates an open blocking diode.

• A very low reading (0…0.2V) indicates a shorted blocking diode.

• If the diode is open or shorted, replace the solar controller.

Publication 1748-IN001B-EN-P - May 2009

Page 39

Troubleshooting 39

Step 6: Test temperature compensation cable

Test the temperature compensation cable which is affixed to the side of the

backup batteries ((4) on page 11

1. With the solar controller completely disconnected from the DataSite

configured panel, make these connections.

a. Use a variable power supply set to 20V DC, 0.5 mA.

b. Connect the + VDC Power supply terminal to ARRAY (+) input

terminal of the solar controller.

c. Common Power supply terminal to ARRAY (-) input terminal of the

solar controller.

2. Measure the voltage at BATT (+) and BATT (-) terminals.

The reading should be about 14.3V when the temperature sensor is at

room temperature.

.)

• When you place the sensor onto the outside of a hot cup of water

(37.8 °C/100 °F), the voltage should rise.

• When you place the sensor onto the outside of a cold cup of water

(4.44 °C/40 °F), the voltage should fall.

• If the measured voltage does not change, there is a problem with the

voltage compensation and the solar controller and compensation

cable should be replaced.

Publication 1748-IN001B-EN-P - May 2009

Page 40

40 Troubleshooting

Troubleshooting the Human-machine Interface (HMI)

When equipped, the HMI (8) will display information programmed to read the

different parameters of the DataSite. The default program in the HMI is

empty. The units must be programmed before use.

This section gives an overview of troubleshooting when the HMI is not

working.

Step 1: Test the condition of ’ON’ push button for the HMI

With the main power switch in the ON position, conduct the following test:

1. Press the ‘ON’ push button for the HMI.

The DataSite configured panel is wired so that when the ‘ON’ push

button is pressed, the LED indicating D0 lights up. If D0 does not light

up, check the push button wiring and the sealed switch contacts and

replace as necessary.

2. The push button input must be programmed to trigger the output to the

24V DC relay.

The DataSite controller is not pre-programmed to turn on this relay. For

information on programming of the ‘ON’ push button, see Appendix C

Step 2: Test the HMI

With the main power switch in the ON position, conduct the following test:

1. Press and hold the ‘ON’ push button of the HMI and verify 24V DC at

the power input terminals of the HMI. If 24V DC is present, replace the

HMI.

2. If 24V DC is not present at the power input terminals of the HMI,

check the following:

a. Check the status light of the DC-DC converter to see if it is switched

on. If the light is not illuminated green, make sure that it has 12V DC

on the input side. If 12V DC is present, the DC-DC converter may

be faulty and should be replaced or checked first.

.

Publication 1748-IN001B-EN-P - May 2009

Page 41

Troubleshooting 41

b. If 12V DC is not present at the DC-DC converter, check the

following:

– Check to see that the fuse 3FU has not opened.

– If the fuse has opened, inspect the wiring for cuts or frays and

replace if necessary. Contact Rockwell Technical Support for more

details.

3. Check all cables and wires associated with the HMI.

a. The HMI communicates with the DataSite controller via a serial

communication RS232 cable. If this cable is frayed or kinked, the

communication may be halted. Inspect the cable for any damage and

replace if necessary.

b. The HMI requires 24V DC. If the device receives less than 20V DC,

it may not power up. Check the voltage at the HMI inputs and

replace the power wiring if necessary.

Common Problems

Two common problems with outdoor panel applications are improper end

connections for antennas, and moisture penetration.

Improper End Connections for Antennas

When installing a radio communication device in the DataSite configured

panel, it is suggested to use precut manufactured antenna cables. A majority of

the signal loss in a cable is often attributed to the improper crimping and

soldering of the antenna end connectors. It is suggested that when installing

antenna cables that a manufactured cable be used to eliminate the effects of

improper installation of the end connectors. Additional cable may be coiled up

when not used without concerning the loss of signal strength.

IMPORTANT

When an antenna cable longer than 30.5 m (100 ft) is used, the

signal loss may be large due to the impedance of the antenna

cable. It is not suggested to coil wire up in excess of 30.5 m

(100 ft) as this could cause a loss of signal. In applications

where long distances of cable are required, it is suggested that

a trained technician should install the antenna cable.

Publication 1748-IN001B-EN-P - May 2009

Page 42

42 Troubleshooting

Moisture Penetration

Moisture is the leading cause of faults associated with outdoor panel

applications. The introduction of moisture or condensate in the DataSite

configured panel may cause components in the panel to wear out prematurely.

Moisture in the panel will cause corrosion of some of the components, making

the DataSite configured panel unreliable. In the event that moisture or

condensate is found within the panel, check all conduit connections as well as

the main gasket seal of the DataSite configured panel. If any seals are broken

or leaking, replace or fix these seals to ensure that no moisture accumulation

occurs within the panel.

Publication 1748-IN001B-EN-P - May 2009

Page 43

Renewal Parts

Chapter

7

Renewal Parts Stocking Program

A Renewal Parts Stocking Program for your DataSite configured panel is

recommended in conjunction with a maintenance program. This is important

for minimizing expensive downtime and facilitating critical repairs.

The following are factors to consider when developing an effective Renewal

Parts Stocking Program:

1. Frequency of “ON-OFF” cycling,

2. Duration of “ON” or operating time,

3. Need for continuous operation, inherent design limitations,

environmental considerations, and the like,

4. Total number of similar devices supplied as original equipment within

the DataSite configured panel, and

5. Individual user policies governing spare parts.

Consideration should also be given to stocking complete units when the job

site is in an area remote from a distributor or district sales office or when it is

critical to maintain continuous operation of a system.

Order Information

43 Publication 1748-IN001B-EN-P - May 2009

The following information is required when ordering renewal parts:

• Part or catalog number

• Description of part or unit

• Series letter

• Serial number

• Quantity

• Shipping address

(1)

Can be found on the nameplate label of your DataSite configured panel.

(1)

(1)

(1)

Page 44

44 Renewal Parts

Replacement Parts

This table lists the replacement parts available, the manufacturers, and the

corresponding Rockwell part numbers.

Replacement Part Manufacturer Rockwell Part

Number

DataSite controller, with AGA flow calculation,

0…10V DC analog inputs

DataSite controller, with AGA flow calculation,

4…20 mA analog inputs

DataSite controller, 0…10V DC analog inputs Allen-Bradley 1758-RTU201

DataSite controller, 4…20 mA analog inputs Allen-Bradley 1758-RTU202

Display power relay Allen-Bradley 700-HLT1Z24-EX

On/Off selector switch Allen-Bradley 800H-HR2

’ON’ push button for the human-machine

interface

Contact block for selector switch or display ’ON’

push button

Selector switch locking mechanism Allen-Bradley 800T-NX446

Solar charge controller module ASC 31034-328-05

Single-pole fuse holder Littelfuse 31034-328-03

14 Ah replacement battery Power Sonic 31034-328-01

Allen-Bradley 1758-FLO301

Allen-Bradley 1758-FLO302

Allen-Bradley 800H-AR2

Allen-Bradley 800T-XD1P

28 Ah replacement battery Power Sonic 31034-328-02

900 MHz frequency surge suppressor Prosoft 31034-328-07

2.4 GHz frequency surge suppressor Prosoft 31034-328-08

Enclosure vent Stahlin 31034-328-09

12V to 24V DC-to-DC converter Weidmuller 31034-328-06

Publication 1748-IN001B-EN-P - May 2009

Page 45

Appendix

DataSite Configured Panel Battery

This appendix provides the following information:

A

Environmental Effects on Charge Capacity

• Environmental Effects on Charge Capacity

• Battery Life Expectancy

Battery capacity is a function of ambient temperature and the rate of discharge.

The batteries supplied for the DataSite configured panels are rated at a 100%

capacity at 20 °C (68 °F). As shown in the installation section, the increase in

ambient temperature will increase the available capacity of the battery.

Conversely, as the ambient temperature increases, the battery life (usually

measured in months) decreases. The effects of ambient temperature should be

considered when sizing the batteries.

For the DataSite configured panel application, measures have been taken to

reduce the power consumption and the rate of discharge of the batteries.

Additional loads such as lights, displays or measuring equipment on the

DataSite configured panel may cause the capacity of the batteries to decrease

depending on the size of the loads involved.

This figure shows the effect of temperature and rate of discharge on the

charge capacity of the batteries.

Temperature Effects on Battery Capacity and Expected Life

Temperature (°F)

-40 -31 -22 -13 -4 5 14 23 32 41 50 59 68 77 86 95 104 113 122 131 140 149 158

70

60

50

40

30

20

Battery Life Expectancy (Months)

10

Optimal operating range

0

-40 -35 -30 -25 -20 -15 -10 -5 0 5 10 15 20 25 30 35 40 45 50 5 5 60 65 70

45 Publication 1748-IN001B-EN-P - May 2009

Temperature (°C)

Life Expec tanc y

Battery Capacity

100

90

80

70

60

50

40

30

(% of Rated Ah)

Maxim um Battery Cap acity

Page 46

46 DataSite Configured Panel Battery

Charging and Discharging

The batteries supplied with the DataSite configured panel are designed for

discharge in temperatures ranging from -40 °C to 60 °C (-40 °F to 140 °F) and

to be charged in temperatures ranging from -20 °C to 50 °C (-4 °F to 122 °F).

Charging or discharging of these batteries outside of the specified ranges can

cause reduced battery life.

Operating Temperature

When installing the DataSite configured panel in regions where the ambient

temperature could fall below 16 °C (60.8 °F), derating the DataSite configured

panel backup time is necessary to ensure reliable use of the system. The battery

capacity of the DataSite configured panel should be derated as the temperature

decreases.

See the table, DataSite Configured Panel Battery Derating

, for derated hours

of backup based on ambient temperature. This table assumes the battery can

be charged to 100% capacity. For details on battery capacity, see

Recommended Battery Replacement Schedule

DataSite Configured Panel Battery Derating

Average summer

temperature

-40 °C (-40 °F) 8 hours 16 hours 32 hours

-30 °C (-22 °F) 11 hours 22 hours 45 hours

-20 °C (-4 °F) 14 hours 28 hours 57 hours

-10 °C (14 °F) 18 hours 36 hours 72 hours

0 °C (32 °F) 21 hours 42 hours 84 hours

10 °C (50 °F) 23 hours 46 hours 92 hours

20 °C (68 °F) 24 hours 48 hours 97 hours

30 °C (86 °F) 25 hours 50 hours 101 hours

40 °C (104 °F) 25 hours 51 hours 103 hours

Maximum duration without sunlight

14 Ah battery 28 Ah battery 56 Ah battery

on page 31.

Publication 1748-IN001B-EN-P - May 2009

50 °C (122 °F) 26 hours 52 hours 105 hours

60 °C (140 °F) 26 hours 52 hours 105 hours

70 °C (158 °F) 26 hours 52 hours 105 hours

Page 47

DataSite Configured Panel Battery 47

Battery Life Expectancy

The life expectancy of the battery, also referred to as the number of charge

cycles, is a function of both the discharge rate as well as the depth of discharge.

Just as the temperature affects the capacity of the battery, it also affects the

number of charge cycles available from the battery.

Life expectancy is determined as the number of charge cycles before the

battery can no longer hold an adequate charge. End of life for a battery is

defined as the ability of the battery to hold in capacity, less than 60% of its

original rated capacity when fully charged at 20 °C (68 °F). This means that if a

battery had a rated capacity of 100 AH, but the maximum charge capacity of

the battery is now only 60 AH at 20 °C (68 °F), the battery is at the end of its

life.

Although the battery life is determined by the amount of charge capacity, it is

not dependent on temperature. The determination of a battery at end of life

can only be done by testing the overall capacity of the battery against its rated

capacity from the factory at the rated ambient temperature which is 20 °C

(68 °F).

Temperature Effects

On average every 10 °C (18 °F) increase in temperature above 20 °C (68 °F)

will decrease the battery life by one half. See Temperature Effects on Battery

Capacity and Expected Life for expected battery life based on ambient

temperature.

Rate of Discharge

As the rate of discharge increases the overall life expectancy of the battery

decreases. High discharge rates should be avoided to ensure proper battery life

expectancy. To eliminate the possibility of high discharge rates, it is

recommended that no external loads be connected to the DataSite configured

panel in excess of 1 W.

Publication 1748-IN001B-EN-P - May 2009

Page 48

48 DataSite Configured Panel Battery

Deep-cycling

Deep-cycling is referred to as the discharging of a battery more than 80% of its

expected capacity. This form of discharging should be avoided as it will cause a

decrease in the battery’s life expectancy. The DataSite configured panel has

been designed and rated to a depth of discharge at 80% of its rated capacity at

20 °C (68 °F).

The table, DataSite Configured Panel Battery Derating

for multiple temperatures along the suggested operating temperature. If the

DataSite configured panel uses more than the rated number of hours backup

energy, battery life will be reduced due to deep cycling. When necessary to

deep cycle the DataSite configured panel batteries on a normal basis, a larger

size battery should be considered or a battery specific for the application

should be used to help ensure reliability of the DataSite configured panel.

, shows the rated values

Energy Storage

Over the lifetime of the battery, the actual capacity of stored energy will

decrease. The number of cycles, depth of discharge and ambient temperature