Page 1

SMC™-Flex

BULLETIN 150

USER MANUAL FOR SERIES B

Page 2

Important User Information

ATTENTION

!

IMPORTANT

Because of the variety of uses for the products described in this publication,

those responsible for the application and use of this control equipment must

satisfy themselves that all necessary steps have been taken to assure that

each application and use meets all performance and safety requirements,

including any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in

this guide are intended solely for purposes of example. Since there are many

variables and requirements associated with any particular installation,

Allen-Bradley does not assume responsibility or liability (to include

intellectual property liability) for actual use based upon the examples shown

in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application,

Installation and Maintenance of Solid-State Control (available from your

local Allen-Bradley office), describes some important differences between

solid-state equipment and electromechanical devices that should be taken

into consideration when applying products such as those described in this

publication.

Reproduction of the contents of this copyrighted publication, in whole or

part, without written permission of Rockwell Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

Identifies information about practices or circumstances

that can lead to personal injury or death, property damage

or economic loss

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

Identifies information that is critical for successful

application and understanding of the product.

Trademark List

Accu-Stop, Allen-Bradley Remote I/O, RSNetworx, PLC, PowerFlex, SLC, SMC, SMC-2,

SMC-Flex, SMC PLUS, SMC Dialog Plus, SMB, and STC are trademarks of Rockwell

Automation. ControlNet is a trademark of ControlNet International, Ltd. DeviceNet and the

DeviceNet logo are trademarks of the Open Device Vendors Association (ODVA). Ethernet is a

registered trademark of Digital Equipment Corporation, Intel, and Xerox Corporation. Modbus is

a trademark or registered trademark of Schneider Automation Inc. Profibus is a registered

trademark of Profibus International.

Page 3

European Communities (EC)

Directive Compliance

If this product has the CE mark it is approved for installation within the

European Union and EEA regions. It has been designed and tested to meet

the following directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC

Electromagnetic Compatibility (EMC) per EN/IEC 60947-4-2.

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage,

per EN/IEC 60947-4-2.

This equipment is classified as open equipment and must be mounted in an

enclosure during operation to provide safety protection.

Page 4

Notes

Page 5

Table of Contents

Chapter 1

Product Overview

Other Related Documents ........................................................................... 1-1

Description .................................................................................................1-1

Operation ....................................................................................................1-2

Modes of Operation (Standard) ....................................................................1-2

Soft Start ..............................................................................................1-2

Selectable Kickstart ..............................................................................1-3

Current Limit Start ................................................................................1-3

Dual Ramp Start ...................................................................................1-4

Full Voltage Start ..................................................................................1-4

Preset Slow Speed ...............................................................................1-5

Linear Speed Acceleration.....................................................................1-6

Soft Stop ..............................................................................................1-7

Control Options ...........................................................................................1-8

Modes of Operation (Pump Control) .............................................................1-8

Pump Control Option ............................................................................1-8

Modes of Operation (Braking Control) ..........................................................1-9

SMB Smart Motor Braking Option .........................................................1-9

Accu-Stop Option ...............................................................................1-10

Slow Speed with Braking Option .........................................................1-10

Protection and Diagnostics ........................................................................1-11

Overload ............................................................................................1-11

Underload ...........................................................................................1-11

Undervoltage ......................................................................................1-13

Overvoltage ........................................................................................1-13

Unbalance ..........................................................................................1-13

Stall Protection and Jam Detection .....................................................1-14

Ground Fault ......................................................................................1-15

Ground Fault Trip ...............................................................................1-16

Ground Fault Alarm ............................................................................1-16

Thermistor/PTC Protection ..................................................................1-17

PTC Trip .............................................................................................1-17

Excessive Starts/Hour .........................................................................1-18

Overtemperature ................................................................................1-18

Open Gate ..........................................................................................1-18

Line Faults .........................................................................................1-18

Metering ...................................................................................................1-19

I/O ............................................................................................................1-19

Communication .........................................................................................1-20

Programming ............................................................................................1-20

Status Indication .......................................................................................1-21

Chapter 2

Installation

Degree of Protection ...................................................................................2-1

Receiving ....................................................................................................2-1

Unpacking ...................................................................................................2-1

Inspecting ...................................................................................................2-1

Storing ........................................................................................................2-1

Page 6

Lifting .........................................................................................................2-2

General Precautions .................................................................................... 2-3

Heat Dissipation ..........................................................................................2-3

Enclosures ..................................................................................................2-4

Mounting ....................................................................................................2-5

Power Factor Correction Capacitors .......................................................... 2-12

Protective Modules ................................................................................... 2-13

Motor Overload Protection .........................................................................2-13

Two-speed Motors .............................................................................2-13

Multi-motor Protection .......................................................................2-13

Electromagnetic Compatibility (EMC) ......................................................... 2-14

Enclosure ...........................................................................................2-14

Wiring ................................................................................................2-14

Additional Requirements ....................................................................2-14

Chapter 3

Wiring

Terminal Locations .....................................................................................3-1

Power Structure .......................................................................................... 3-3

Power Wiring .......................................................................................3-3

Line Connected ....................................................................................3-4

Delta Connected ..................................................................................3-4

Power Lugs ................................................................................................3-5

Control Power .............................................................................................3-7

Control Wiring ......................................................................................3-7

Controllers rated 5…480 A ..................................................................3-7

Controllers rated 625…1250 A ............................................................3-7

Control Wire Specifications ................................................................3-11

Fan Power ................................................................................................3-11

Fan Terminations ...............................................................................3-11

Control Terminal Designations ..................................................................3-12

Standard Controller Wiring Diagrams ........................................................ 3-13

Soft Stop, Pump Control, and SMB Smart Motor Braking ...........................3-24

Preset Slow Speed .................................................................................... 3-28

Slow Speed with Braking ..........................................................................3-30

Sequence of Operation ..............................................................................3-31

Special Application Considerations ............................................................3-36

Use of Protective Modules ..................................................................... 36

Multi-motor Applications ........................................................................... 3-38

SMC-Flex Controller as a Bypass to an AC Drive .......................................3-39

SMC-Flex Controller with a Bulletin 1410 Motor Winding Heater ...............3-40

Chapter 4

Programming

Overview ....................................................................................................4-1

Keypad Description .....................................................................................4-1

Programming Menu ....................................................................................4-1

Password ....................................................................................................4-5

Parameter Management .............................................................................4-6

Random Access Memory (RAM) ...........................................................4-6

Read-only Memory (ROM) ....................................................................4-6

Electrically Erasable Programmable Read-only Memory (EEPROM)....... 4-6

Parameter Modification................................................................................ 4-7

Soft Start .................................................................................................... 4-8

Page 7

Current Limit Start ......................................................................................4-8

Dual Ramp Start ..........................................................................................4-9

Full Voltage Start .......................................................................................4-10

Linear Speed .............................................................................................4-10

Programming Parameters .........................................................................4-11

Standard ............................................................................................4-11

Pump Control .....................................................................................4-12

Braking Control ..................................................................................4-12

Basic Set Up .............................................................................................4-14

Motor Protection .......................................................................................4-15

Example Settings ......................................................................................4-16

Undervoltage ......................................................................................4-16

Overvoltage ........................................................................................4-16

Jam ...................................................................................................4-16

Underload ..........................................................................................4-16

Chapter 5

Metering

Chapter 6

Optional HIM Operation

Chapter 7

Communications

Overview .....................................................................................................5-1

Viewing Metering Data ................................................................................5-1

Overview .....................................................................................................6-1

Human Interface Module .............................................................................6-1

Standard .............................................................................................. 6-1

Pump Control .......................................................................................6-2

Braking Control ....................................................................................6-2

Overview .....................................................................................................7-1

Communication Ports ..................................................................................7-1

Human Interface Module............................................................................. 7-2

Keypad Description .............................................................................. 7-2

Connecting the Human Interface Module to the Controller ....................7-4

HIM Control Enable ...............................................................................7-4

Control Enable .............................................................................................7-6

Loss of Communication and Network Faults ................................................7-6

SMC-Flex Specific Information ....................................................................7-6

Default Input/Output Configuration ..............................................................7-7

Variable Input/Output Configuration .............................................................7-7

SMC — Flex Bit Identification ..................................................................... 7-8

Reference/Feedback ...................................................................................7-9

Parameter Information ................................................................................7-9

Scale Factors for PLC Communication .........................................................7-9

Read Example ......................................................................................7-9

Write Example ......................................................................................7-9

Display Text Unit Equivalents ....................................................................7-10

Configuring DataLinks ...............................................................................7-10

Rules for Using DataLinks ..................................................................7-10

Updating Firmware ....................................................................................7-10

Chapter 8

Diagnostics

Overview .....................................................................................................8-1

Protection Programming .......................................................................8-1

Page 8

Fault Display ...............................................................................................8-1

Clear Fault ..................................................................................................8-2

Fault Buffer .................................................................................................8-2

Fault Codes ..........................................................................................8-3

Fault and Alarm Auxiliary Indication for Fault or Alarm ................................8-3

Fault Definitions .......................................................................................... 8-4

Chapter 9

Troubleshooting

Appendix A

Specifications

Appendix B

Parameter Information

Appendix C

Renewal Parts

Appendix D

Accessories

Introduction ................................................................................................9-1

Power Module Check ..................................................................................9-7

Shorted SCR Test .................................................................................9-7

Functional Design Specifications .................................................................A-1

Electrical Ratings ........................................................................................A-2

Short Circuit Protection ...............................................................................A-3

Environmental .............................................................................................A-5

Mechanical .................................................................................................A-5

Other ..........................................................................................................A-6

Approximate Dimensions and Shipping Weights ..........................................A-6

Open Type Controllers ..........................................................................A-6

Enclosed Type Line-Connected Controllers ...........................................A-7

Parameter Information................................................................................ B-1

Renewal Parts ............................................................................................C-1

Contactor Replacement Installation Instructions for

625…1250 A units

...................................................................................... D-1

Appendix E

Accessories

Appendix F

Renewal Parts Cross Reference

Accessories ................................................................................................ E-1

Renewal Part Cross Reference ....................................................................F-1

Page 9

Product Overview

Chapter 1

Other Related Documents • Quick Start — Publication 150-QS001_

• Renewal Part Instructions — 41053-277-01 (5…85 A)

41053-328-01 (108…135 A)

41053-228-01 (201…480 A)

41053-367-01 (625…1250 A)

• Selection Guide — Publication 150-SG009_

• Application Guide — Publication 150-AT002_

①

-EN-P

①

-EN-P

①

-EN-P

Description The SMC™-Flex controller offers a full range of starting modes as

standard:

• Soft Start with Selectable Kickstart

• Current Limit with Selectable Kickstart

• Dual Ramp Start with Selectable Kickstart

• Full Voltage Start

• Preset Slow Speed

• Linear Speed Acceleration with Selectable Kickstart (requires

Tach feedback)

• Soft Stop

Other features that offer further user benefit include:

• Expanded protective features

• Metering

•I/O

• Communication capability

Innovative starting and stopping options provide enhanced

performance:

• Pump Control

• Braking Control

• Smart Motor Braking (SMB™)

• Accu-Stop™

• Slow Speed with Braking

These modes, features, and options are further described in this

chapter.

➀ Latest revision

Page 10

1-2 Product Overview

Percent Voltage

100%

Initial

Torque

Time in Seconds

Start

Run

Ramp Time

Current Limit

Operation The SMC-Flex controller can operate standard squirrel-cage

induction motors rated 1…1250 A or Star-delta (wye-delta) type

motors rated 1.8…1600 A; up to 690V AC, 50/60 Hz. Depending

upon the controller type ordered, the control power input can range

from 100…240V AC to 24V AC/DC. Please verify voltage on

product, before applying power.

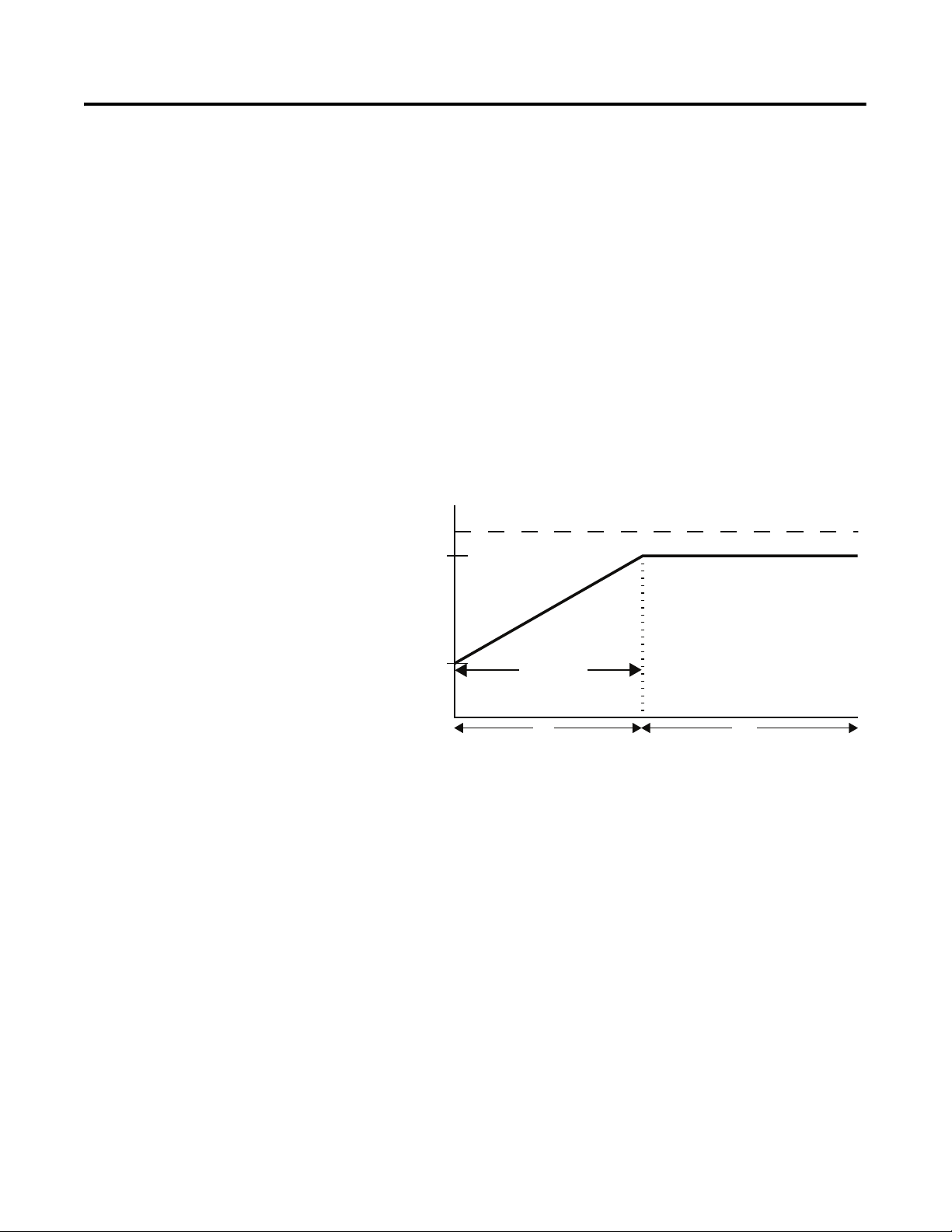

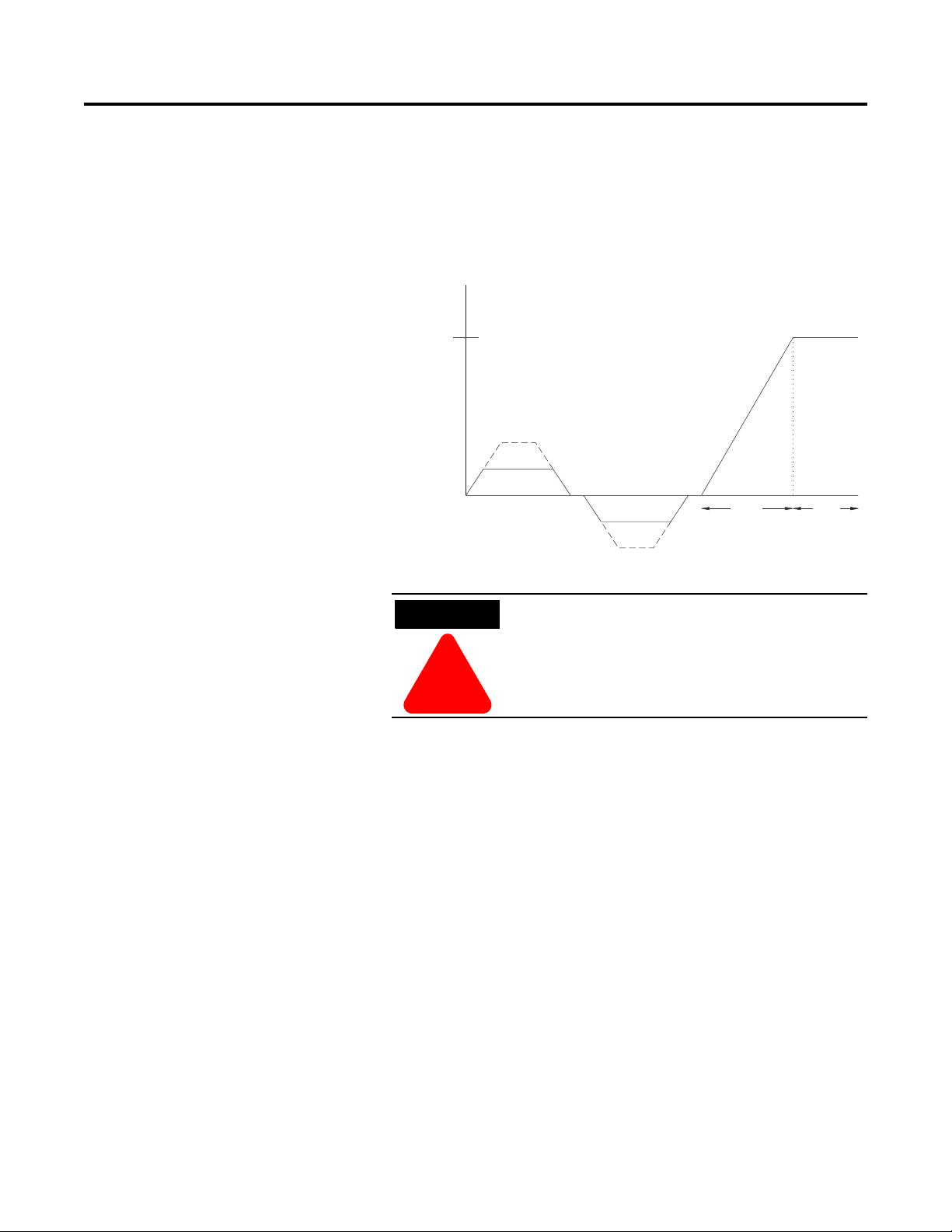

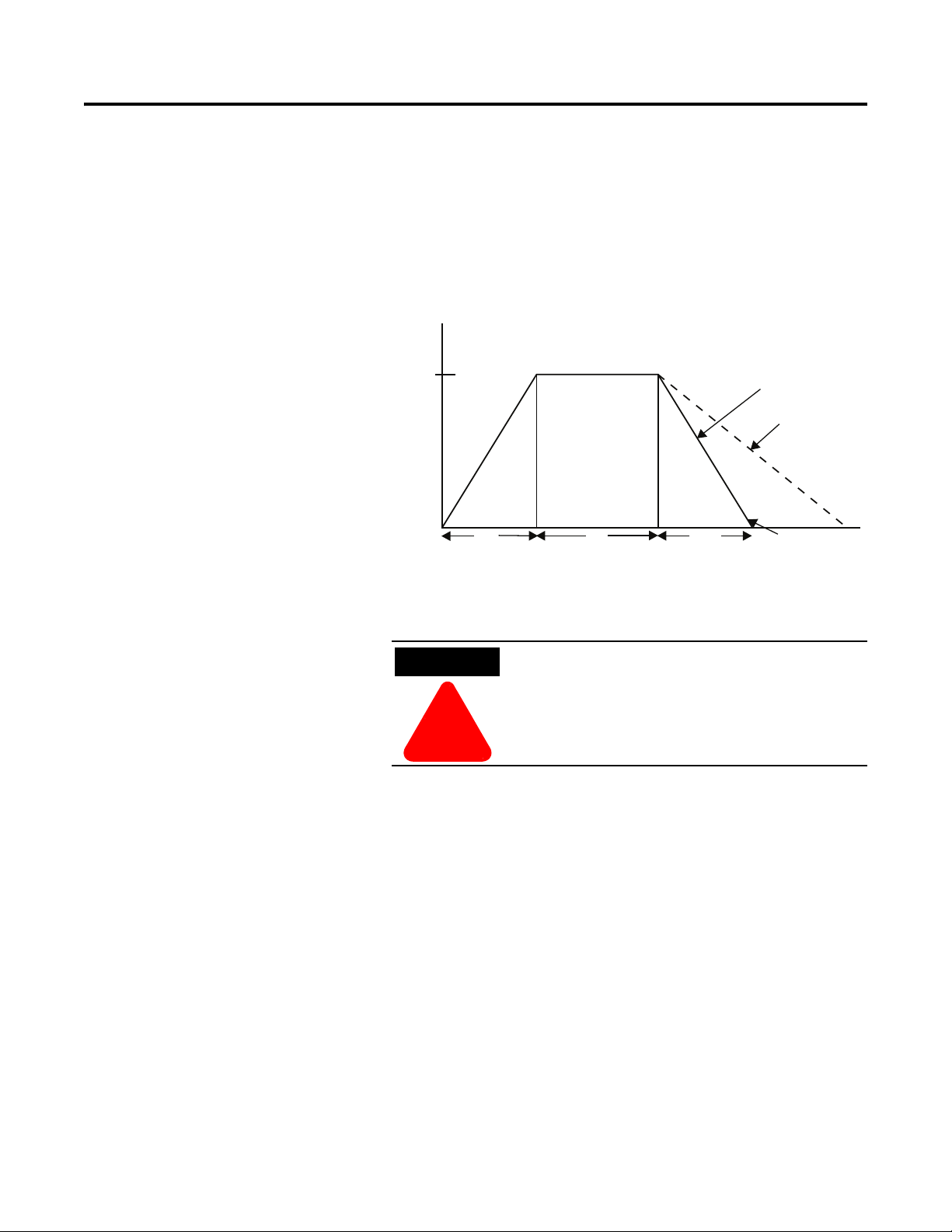

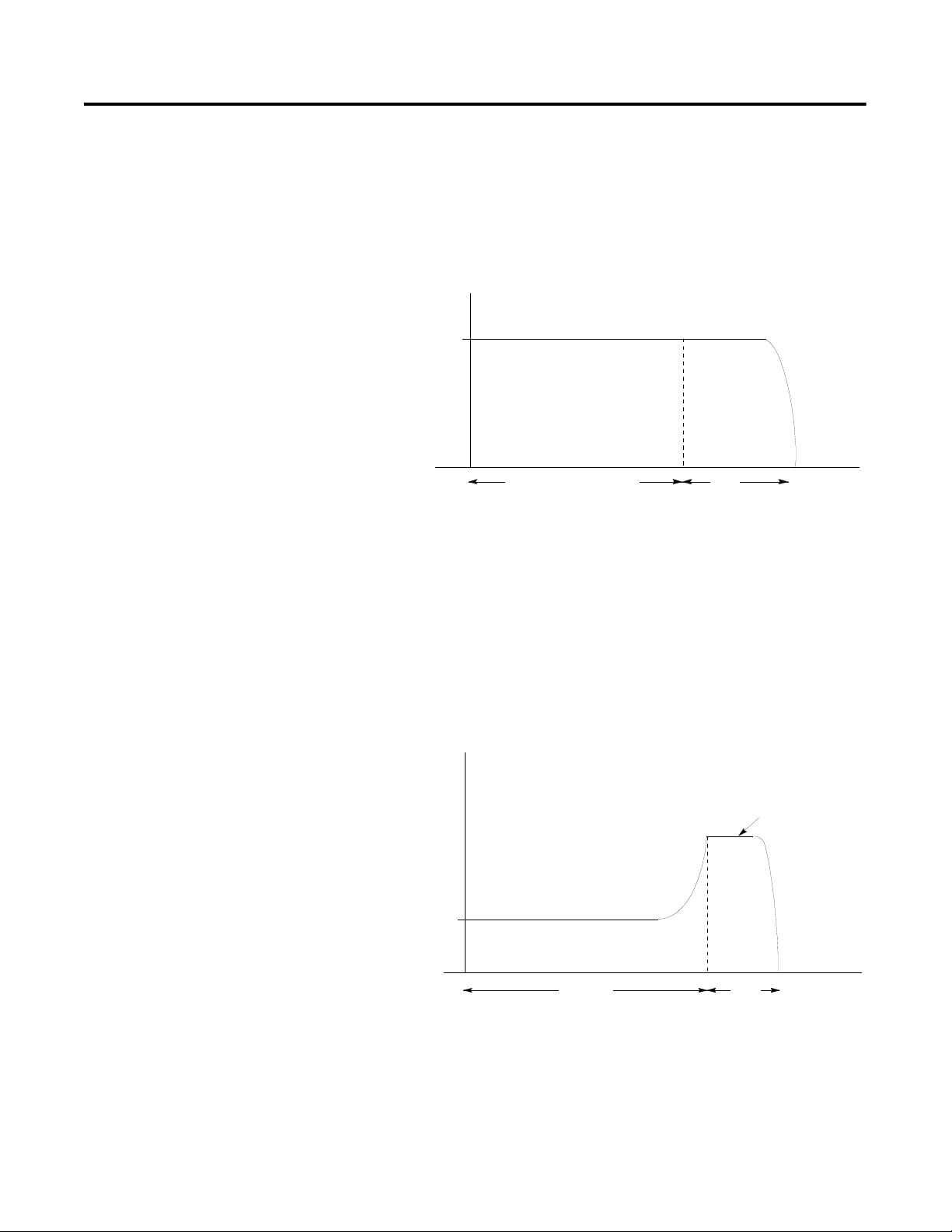

Modes of Operation (Standard) Soft Start

This mode has the most general application. The motor is given an

initial torque setting, which is user-adjustable from 0…90% of locked

rotor torque. From the initial torque level, the output voltage to the

motor is steplessly increased during the acceleration ramp time. The

acceleration ramp time is user-adjustable from 0…30 seconds. If the

SMC-Flex controller senses that the motor has reached the up-tospeed condition during the voltage ramp operation, the internal

bypass contactor will be pulled in.

Figure 1.1 Soft Start

①

➀ Kickstart is also available with Soft Start.

Page 11

Product Overview 1-3

S

t

un

00%

que

ge

)

S

t

p

C

t

p

S

t

600%

50%

C

t

)

Selectable Kickstart

This feature provides a boost at startup to break away loads that

require a pulse of high torque to get started. This is intended to

provide a pulse of current that is selectable from 0…90% of locked

rotor torque. Selectable kickstart is user-adjustable from

0.0…2.0 seconds.

Figure 1.2 Selectable Kickstart

Percent

Volta

1

Initial

Tor

electable Kickstar

oast-to-res

Soft Sto

tar

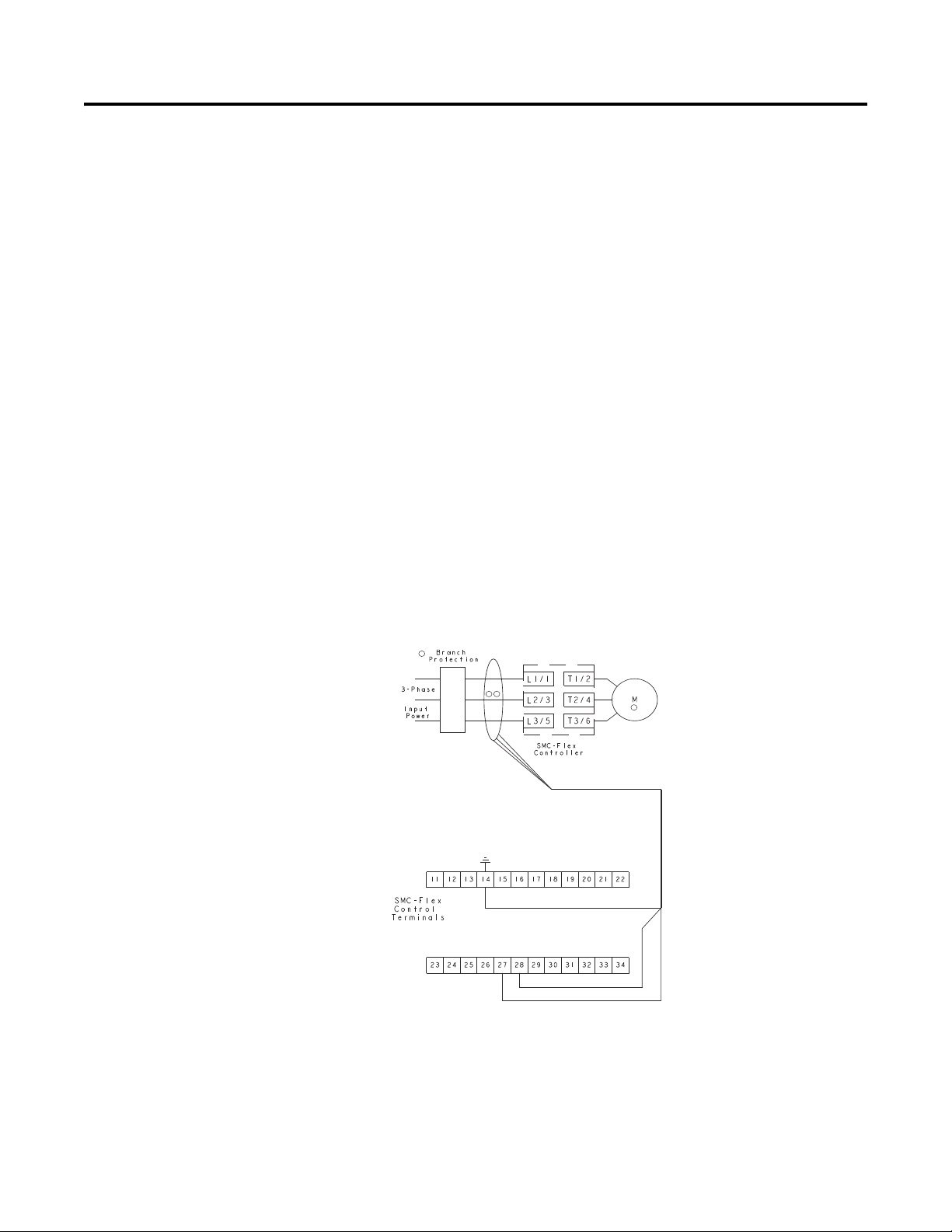

Current Limit Start

R

Time (seconds

➀

Soft Sto

This starting mode provides a true current limit start; it is used when

limiting maximum starting current is necessary. The Current Limit

level is user-adjustable from 50…600% of the motor full load ampere

rating; and the current limit time is user-adjustable from 0…30

seconds. If the SMC-Flex controller senses that the motor has reached

the up-to-speed condition during the current limit starting mode, the

internal bypass contactor will be pulled in.

Figure 1.3 Current Limit Start

Percent Full

urren

Load

tar

Time (seconds

➀ Kickstart is also available with Current Limit Start.

Page 12

1-4 Product Overview

Ramp #2

Ramp #1

Time in Seconds

Percent Voltage

100%

Initial

Torque #2

Initial

Torque #1

Start #1

Start #2

Run #1

Run #2

Current Limit 2

Current Limit 1

100%

Percent Voltage

Time in Seconds

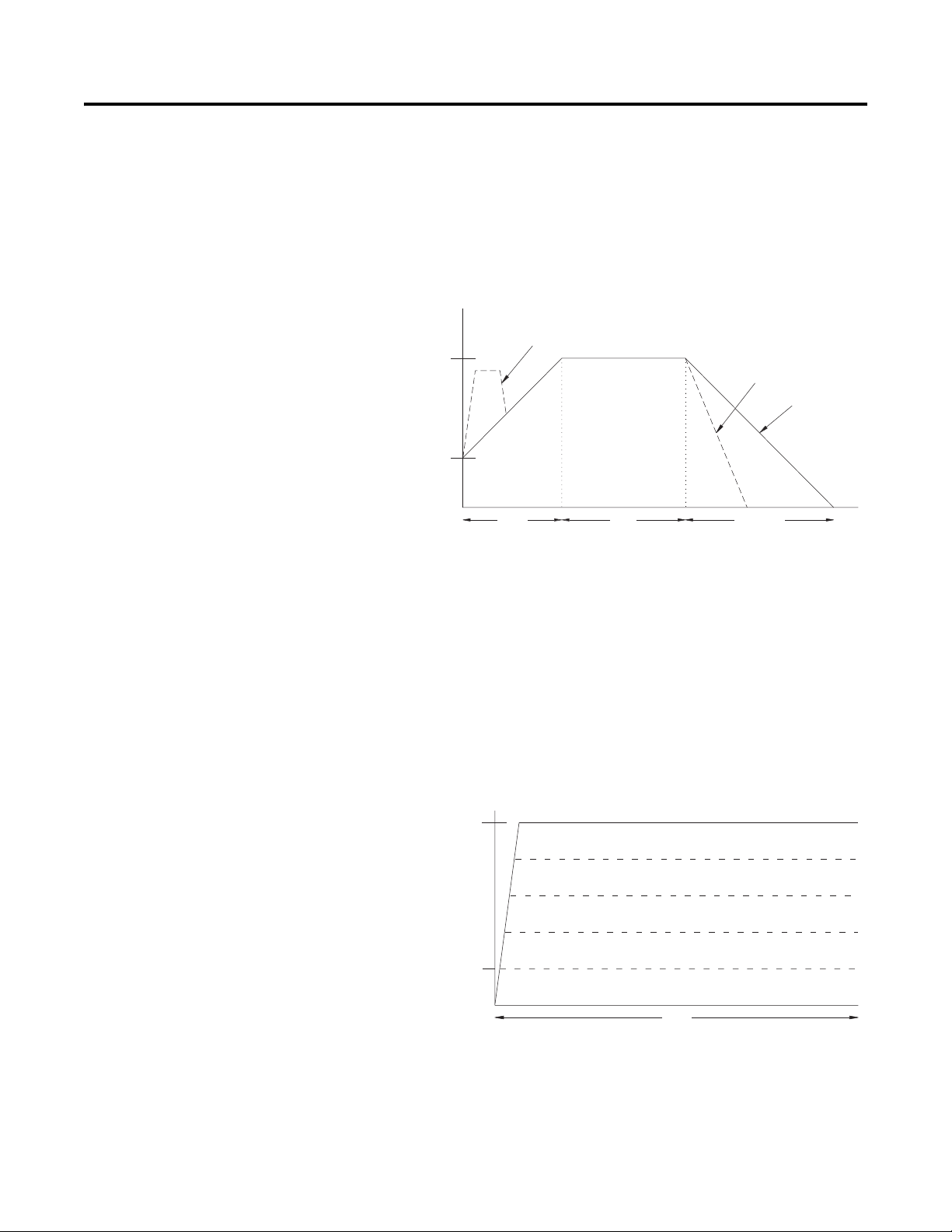

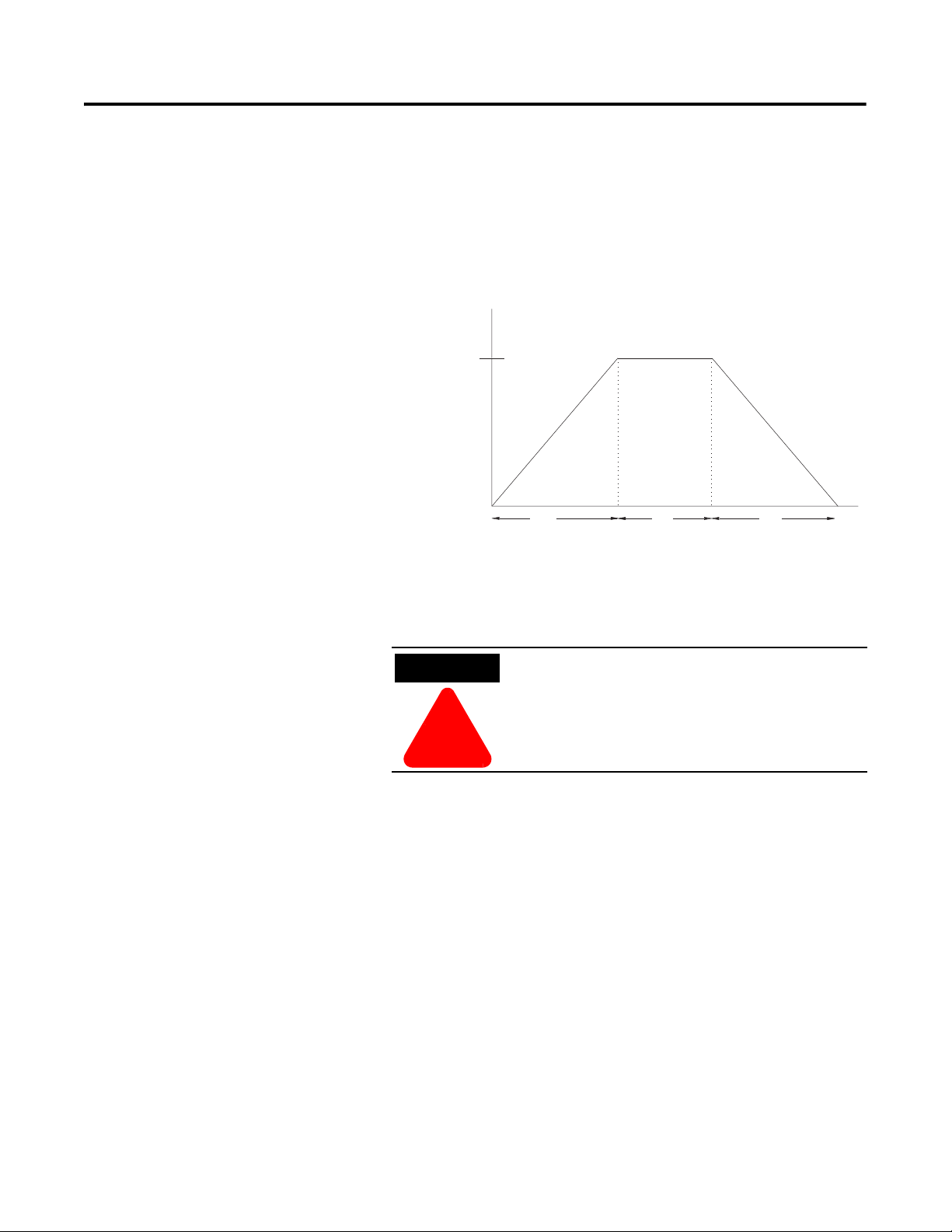

Dual Ramp Start

➀

This starting mode is useful on applications that have varying loads

(and therefore varying starting torque requirements). Dual Ramp Start

allows the user to select between two separate start profiles with

separately adjustable ramp times and initial torque settings.

Figure 1.4 Dual Ramp Start

➀ Dual Ramp Start is available only with the standard controller.

Full Voltage Start

This starting mode is used for applications requiring across-the-line

starting. The output voltage to the motor will reach full voltage within

1/4 second.

Figure 1.5 Full Voltage Start

Page 13

Product Overview 1-5

S

t

un

00%

peed

)

gh

w

w

gh

d

se

ATTENTION

!

Preset Slow Speed

This option can be used in applications that require a slow speed jog

for general purpose positioning. Preset Slow Speed provides either

7% of base speed (low) or 15% of base speed (high) settings in the

forward direction. Reverse can also be programmed and offers 10%

of base speed (low) and 20% of base speed (high) settings.

Figure 1.6 Preset Slow Speed

1

Motor

S

Forwar

15% - Hi

7% - Lo

10% - Lo

20% - Hi

Time (seconds

Rever

tar

R

Slow speed running is not intended for continuous

operation due to reduced motor cooling.

Page 14

1-6 Product Overview

S

t

00%

peed

)

un

Stop

ATTENTION

!

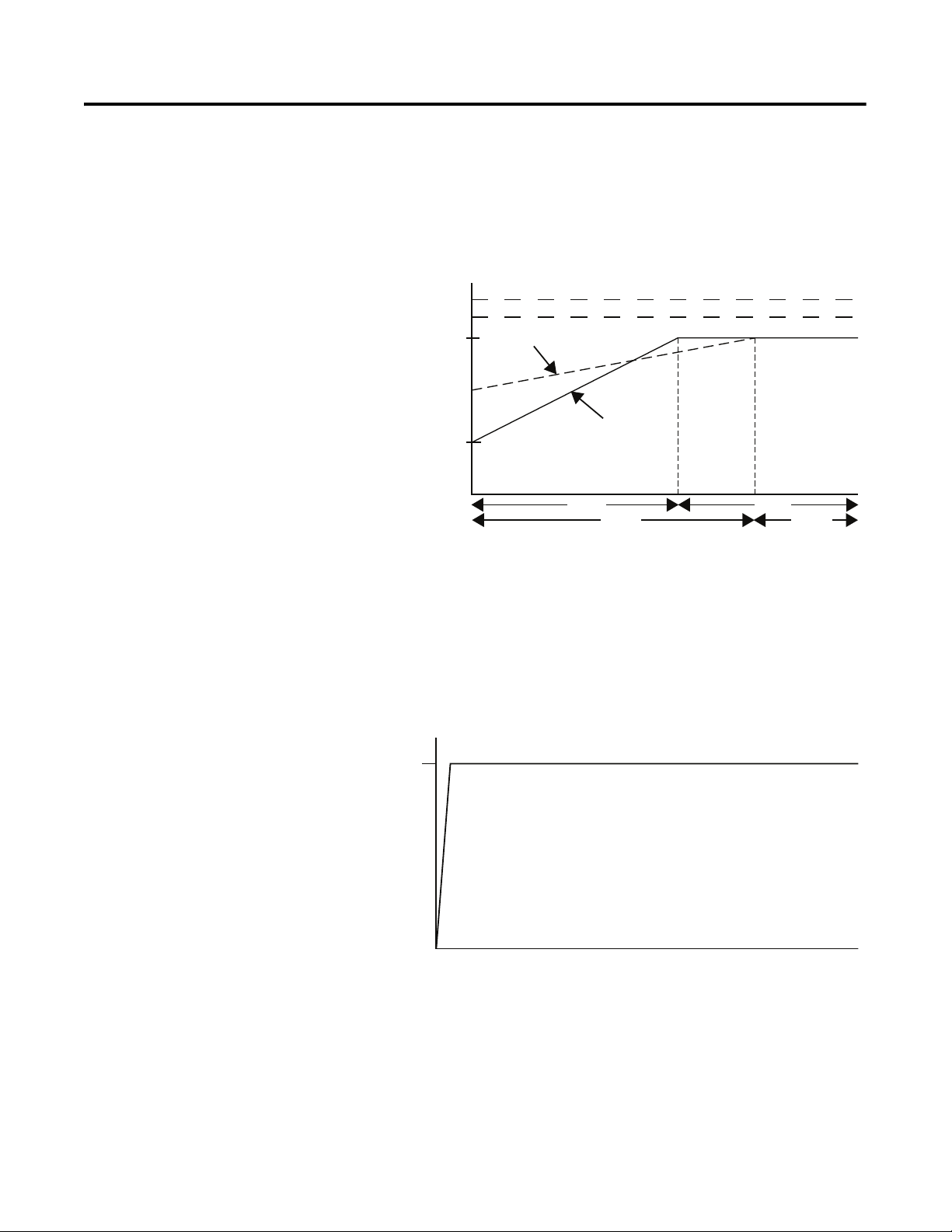

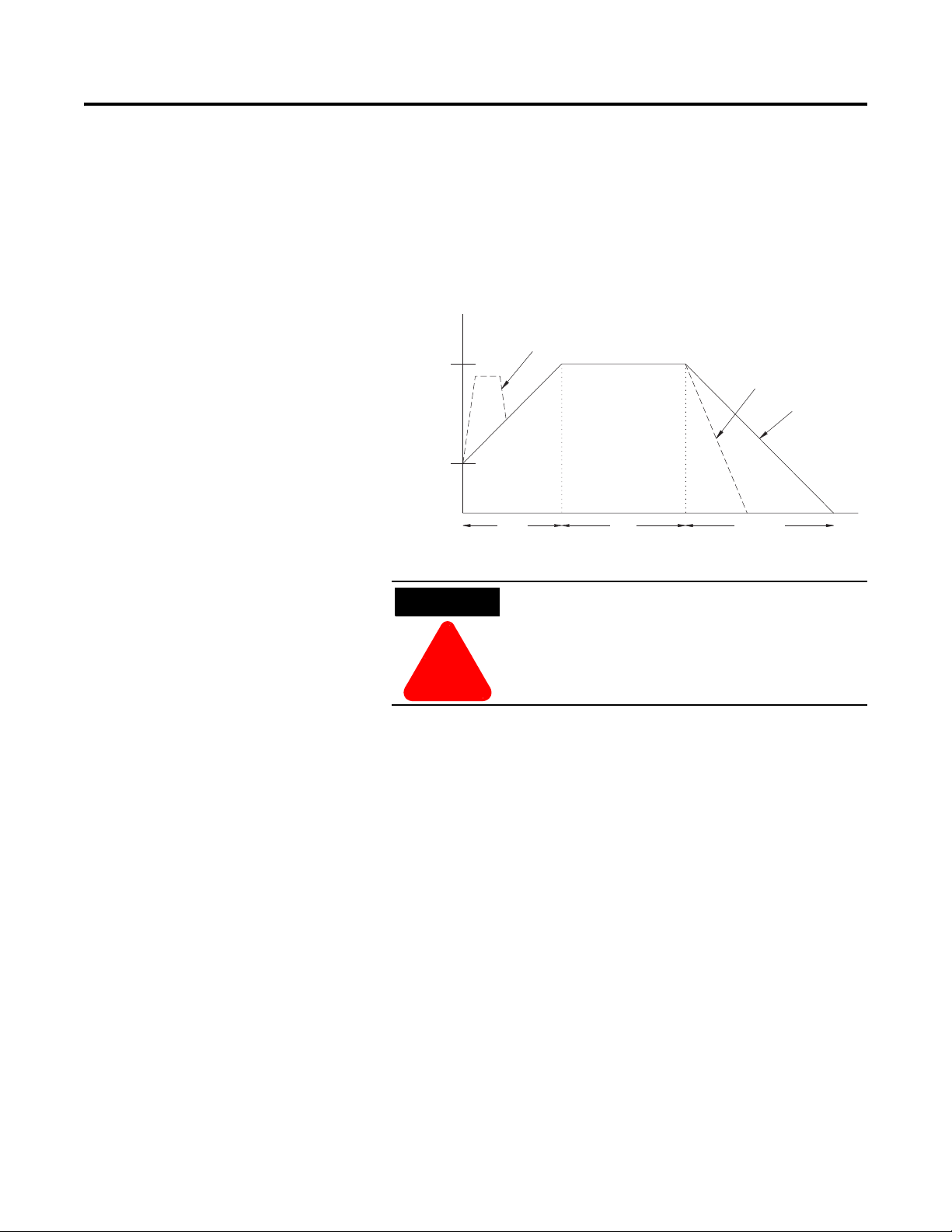

Linear Speed Acceleration

➀

The SMC-Flex has the ability to control the motor speed during

starting and stopping maneuvers. A tach input (0…5V DC) is

required to perform this start mode. The start time is selectable from

0…30 seconds and determines the time the motor will ramp from 0

speed to full speed. Kickstart is available with this option.

Figure 1.7 Linear Speed Acceleration

Percent

S

1

tar

R

Time (seconds

➀ Kickstart is also available with Linear Speed Acceleration.

Linear Stop is not intended to be used as an

emergency stop. Refer to the applicable standards

for emergency stop requirements.

The Linear Stop does not need to be set up even if the linear start has

been programmed. The Linear Stop can not brake the motor/load and

reduce the stopping time.

Page 15

Product Overview 1-7

S

t

un

00%

que

ge

)

S

t

p

C

t

p

ATTENTION

!

Soft Stop

This option can be used in applications that require an extended stop

time. The voltage ramp down time is user-adjustable from

0…120 seconds and is adjusted independently from the starting time.

The load will stop when the output voltage drops to a point where the

load torque is greater than the developed motor torque.

Figure 1.8 Soft Stop

Percent

Volta

1

Initial

Tor

electable Kickstar

oast-to-res

Soft Sto

tar

R

Time (seconds

Soft Sto

Soft Stop is not intended to be used as an emergency

stop. Refer to the applicable standards for

emergency stop requirements.

Page 16

1-8 Product Overview

100%

Motor Speed

Time in Seconds

Pump Start

Ramp Time

Run

Pump Stop

Stop Time

ATTENTION

!

ATTENTION

!

Control Options The SMC-Flex controller offers the control options described below.

Important: The options listed in this section are mutually exclusive

and must be specified when ordering. An existing

controller may be upgraded to another control option by

replacing the control module. Consult your local

Allen-Bradley distributor.

Modes of Operation

(Pump Control)

Pump Control Option

This option reduces surges during the starting and stopping of a

centrifugal pump by smoothly accelerating and decelerating the

motor. The microprocessor analyzes the motor variables and

generates commands that control the motor and reduce the possibility

of surges occurring in the system.

The starting time is programmable from 0…30 seconds, and the

stopping time is programmable from 0…120 seconds.

Figure 1.9 Pump Control Option

➀

➀ Kickstart is also available with Pump Control.

Pump stopping is not intended to be used as an

emergency stop. Refer to the applicable standard for

emergency stop requirements.

Pump stopping may cause motor heating depending

on the mechanical dynamics of the pumping system.

Therefore, select the lowest stopping time setting

that will satisfactorily stop the pump.

Page 17

Product Overview 1-9

100%

Motor Speed

Smart Motor

Braking

Coast-to-Rest

Time in Seconds

Automatic Zero

Speed Shut-Off

Start

Run

Brake

Stop

Time

ATTENTION

!

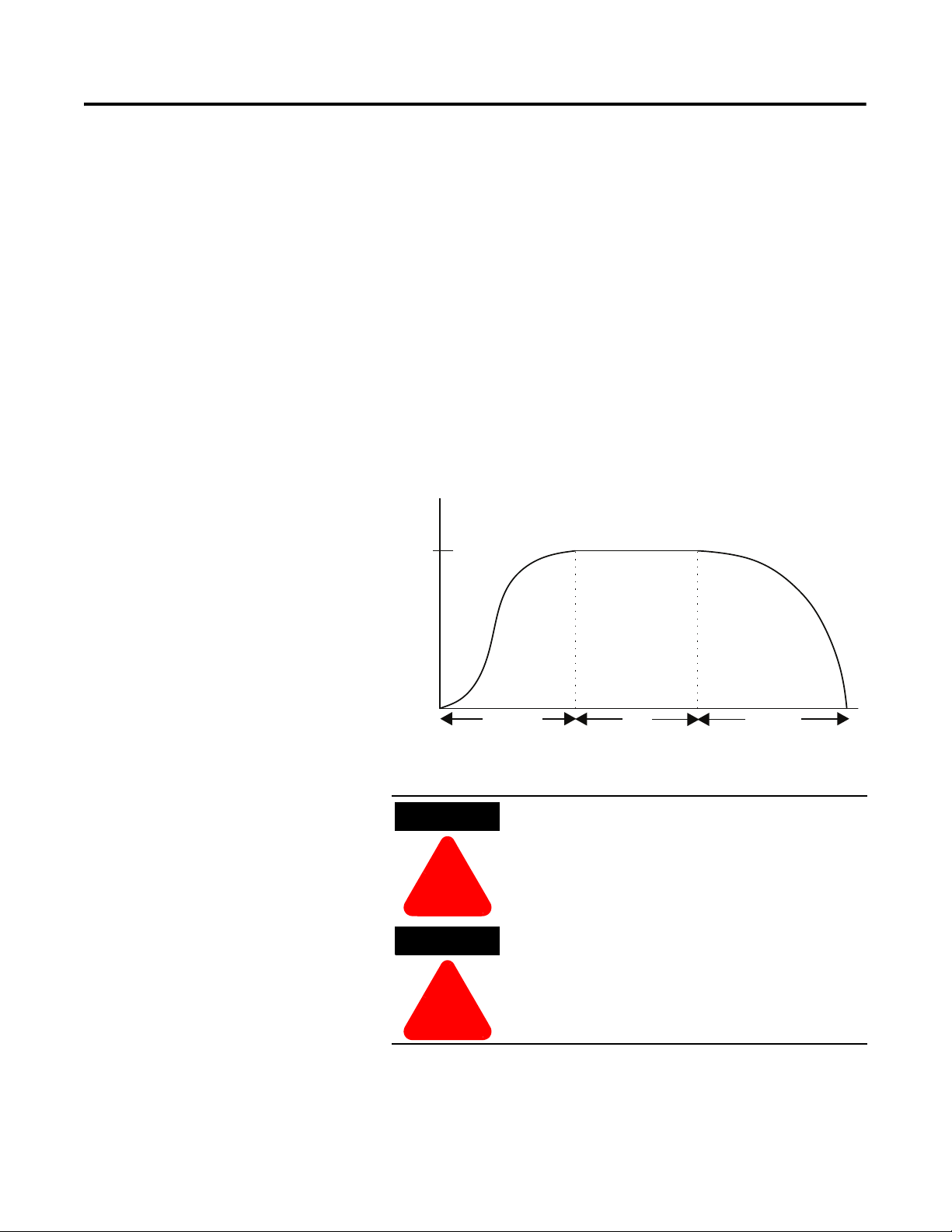

Modes of Operation

(Braking Control)

SMB™ Smart Motor Braking Option

This option can be used in applications that require reduced stopping

times. The SMC-Flex controller incorporates a microprocessor-based

system that applies braking current to a motor without any additional

equipment. This option offers a user-adjustable braking current

setting from 0% to 400% of the motor’s full load current rating.

Further, it provides automatic shut-off at zero speed detection.

Figure 1.10 SMB Smart Motor Braking Option

Note: All braking current settings in the range of 1…100% will

provide 100% braking current to the motor.

SMB Smart Motor Braking is not intended to be used

as an emergency stop. Refer to applicable standards

for emergency stop requirements.

Page 18

1-10 Product Overview

ATTENTION

!

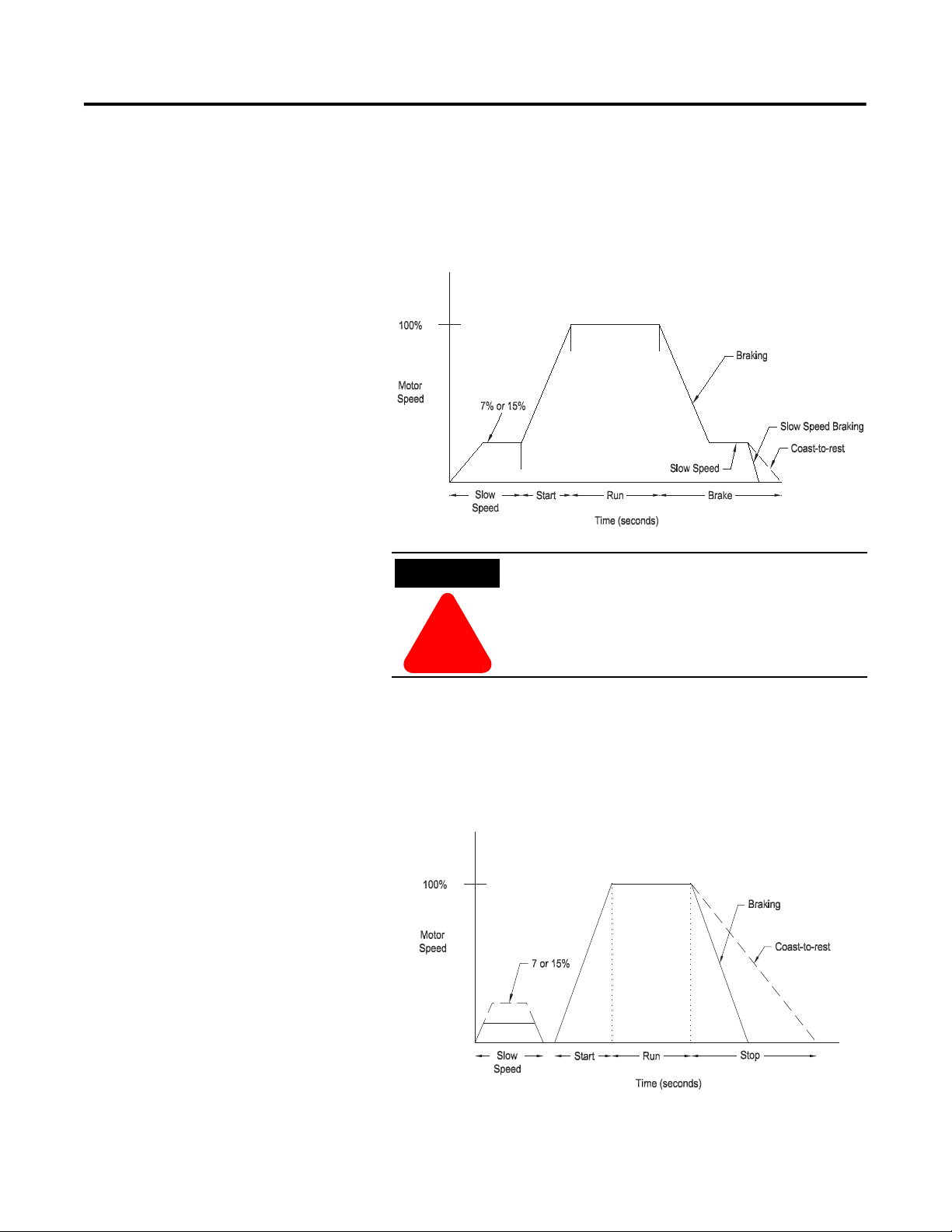

Accu-Stop™ Option

This option combines the benefits of the SMB Smart Motor Braking

and Preset Slow Speed options. For general purpose positioning, the

Accu-Stop option provides a brake from full speed to the preset slow

speed setting, then brakes to stop.

Figure 1.11 Accu-Stop Option

Accu-Stop and Slow Speed with Braking are not

intended to be used as an emergency stop. Refer to

applicable standards for emergency stop

requirements.

Slow Speed with Braking Option

The Slow Speed with Braking option provides a jog speed for process

set-up and braking-to-stop at the end of the cycle.

Figure 1.12 Slow Speed with Braking Option

Page 19

Product Overview 1-11

Protection and Diagnostics The SMC-Flex controller provides the protective and diagnostic

features described below.

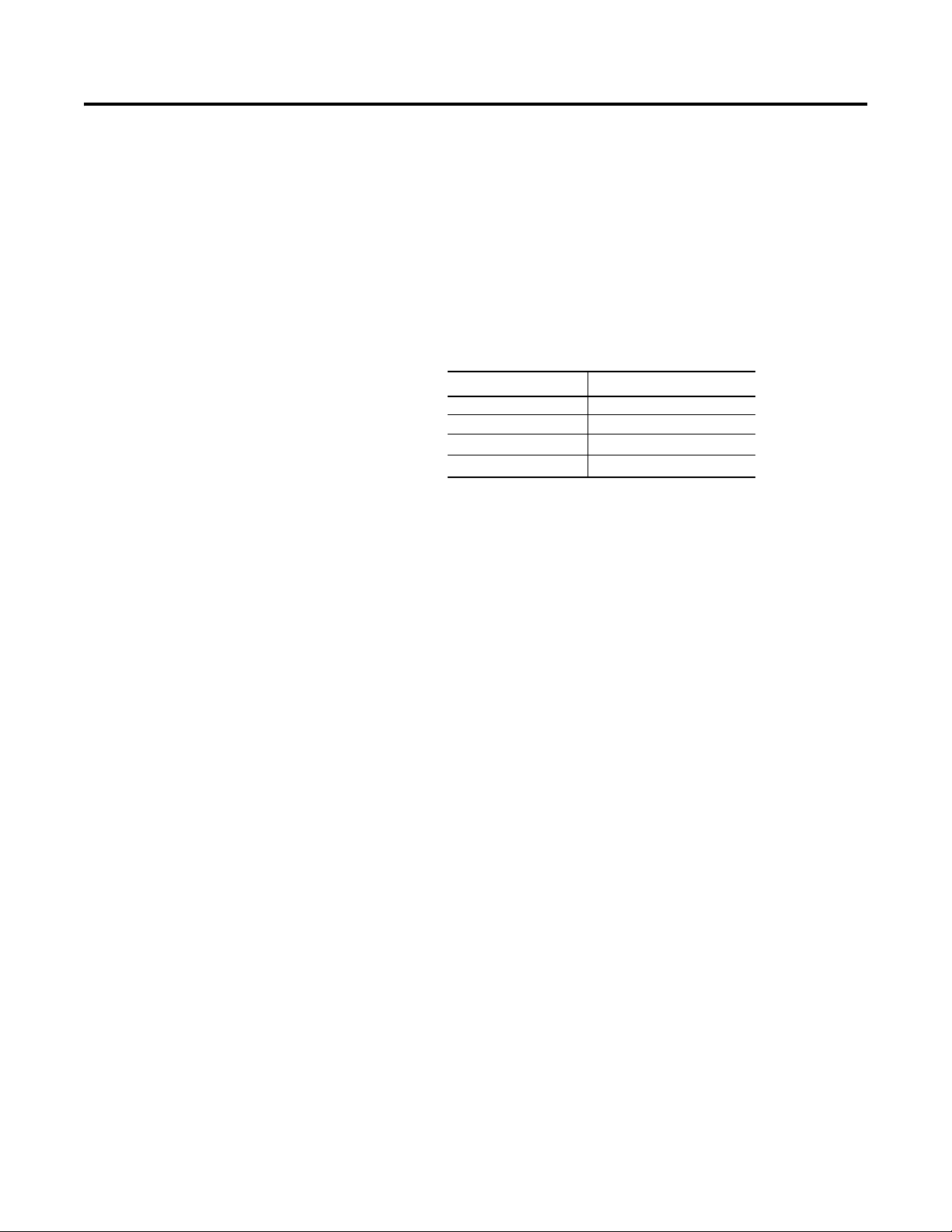

Overload

The SMC-Flex controller meets applicable requirements as a motor

overload protective device. Thermal memory provides added

protection and is maintained even when control power is removed.

The built-in overload controls the value stored in Parameter 12, Motor

Thermal Usage; an Overload Fault will occur when this value reaches

100%. The programming parameters below provide application

flexibility and easy setup.

Parameter Range

Overload Class Off, 10, 15, 20, 30

Overload Reset Manual – Auto

Motor FLC

Service Factor

Notes: (1) The factory default setting for Overload Class, which is

10, enables overload protection. The motor’s full load

current rating must be programmed to properly set

overload protection.

(2) Automatic reset of an overload fault requires the start

input to be cycled in a 2-wire control scheme.

1.0

…2200 A

0.01…1.99

The trip rating is 117% of the programmed FLC.

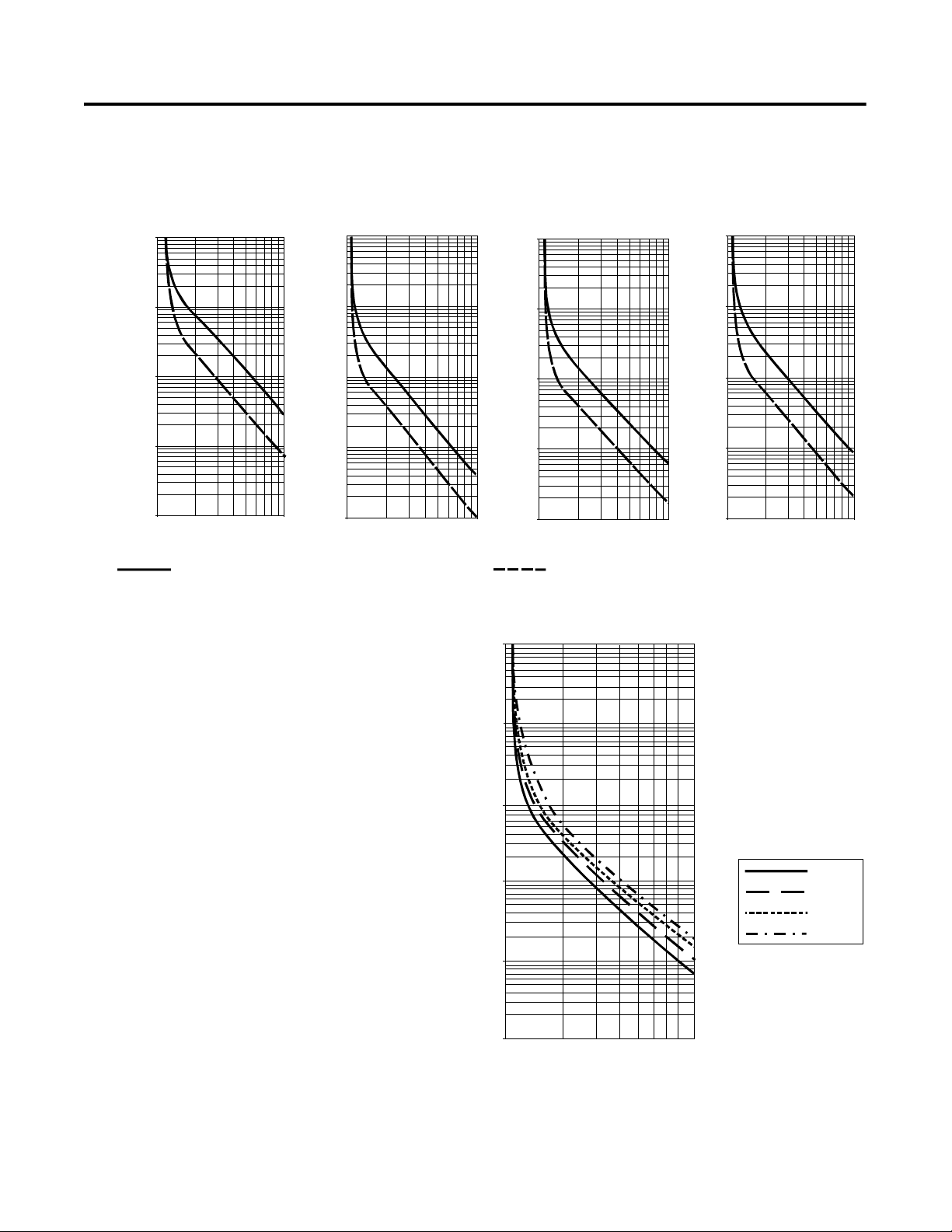

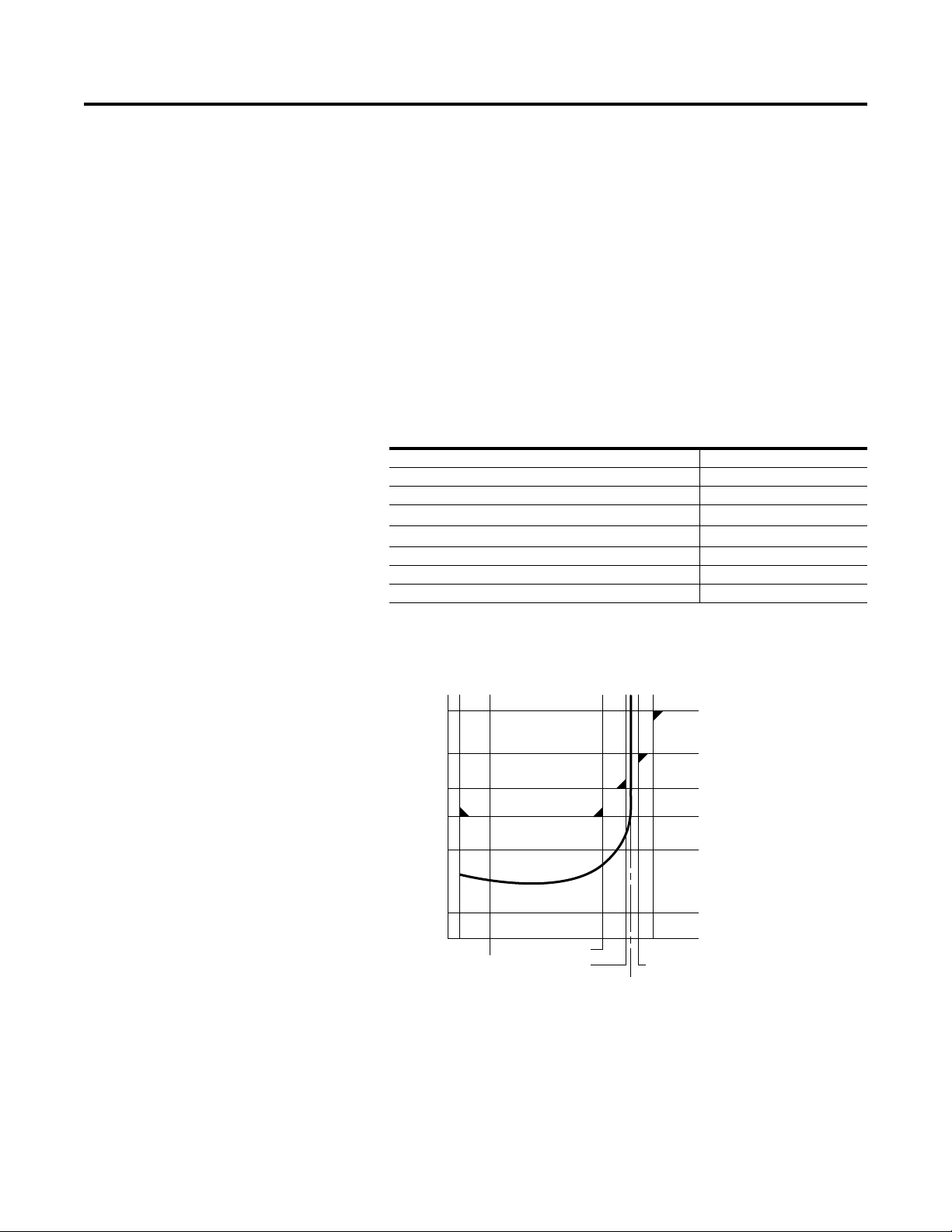

Figure 1.13 and Figure 1.14 provide the overload trip curves for the

available trip classes.

Underload

➀

Utilizing the underload protection of the SMC-Flex controller, motor

operation can be halted if a sudden drop in current is sensed.

The SMC-Flex controller provides an adjustable underload trip

setting from 0…99% of the programmed motor full load current

rating. Trip delay time can be adjusted from 0…99 seconds.

➀ Underload protection is disabled during slow speed and braking operations.

Page 20

1-12 Product Overview

Approximate trip time for 3-phase balanced

Approximate trip time for 3-phase balanced

1.0

10.0

100.0

1000.0

10000.0

1 10 2 3 9 8 7 6 5 4

0.1

1.0

10.0

100.0

1000.0

1 10 2 3 9 8 7 6 5 4

10.0

100.0

1000.0

10000.0

1

2 3 9 8 7 6 5 4

10.0

100.0

1000.0

10000.0

1 10 2 3 9 8 7 6 5 4

Approximate trip time for 3-phase balanced

condition from cold start.

Approximate trip time for 3-phase balanced

condition from hot start.

100%

0

1

10

100

1000

100000

Percent Full Load Current Setting

Class 10

Class 15

Class 20

Class 30

Auto Reset Times:

Class 10 = 90s

Class 15 = 135s

Class 20 = 180s

Class 30 = 270s

Class 10 Class 15 Class 20 Class 30

Figure 1.13 Overload Trip Curves

Approximate Trip Time (seconds)

Approximate Trip Time (seconds)

Approximate Trip Time (seconds)

1.0

Approximate Trip Time (seconds)

1.0

10

Multiples of FLC Multiples of FLC Multiples of FLC Multiples of FLC

condition from cold start.

condition from cold start.

Figure 1.14 Restart Trip Curves after Auto Reset

Seconds

1000%

Page 21

Product Overview 1-13

Undervoltage

➀

Utilizing the undervoltage protection of the SMC-Flex, motor

operation can be halted if a sudden drop in voltage is detected.

The SMC-Flex controller provides an adjustable undervoltage trip

setting from 0…99% of the programmed motor voltage. Trip delay

time can be adjusted from 0…99 seconds.

An alarm (pre-fault) indication level can be programmed to indicate

the unit is getting close to faulting. The alarm modification

information is displayed through the LCD, HIM, Communication (if

applicable) and alarm contact closing.

Overvoltage

➀

Utilizing the overvoltage protection of the SMC-Flex, motor

operation can be halted if a sudden increase in voltage is detected.

The SMC-Flex controller provides an adjustable overvoltage trip

setting from 0…199% of the programmed motor voltage. Trip delay

time can be adjusted from 0…99 seconds.

An alarm (pre-fault) indication level can be programmed to indicate

the unit is getting close to faulting. The alarm modification

information is displayed through the LCD, HIM, Communication (if

applicable) and alarm contact closing.

Unbalance

➀

The SMC-Flex is able to detect an unbalance in line voltages. Motor

operation can be halted if the unbalance is greater than the desired

range.

The SMC-Flex controller provides an adjustable unbalance setting

from 0…25% of the line voltages. Trip delay time can be adjusted

from 0…99 seconds.

An alarm (pre-fault) indication level can be programmed to indicate

the unit is getting close to faulting. The alarm modification

information is displayed through the LCD, HIM, Communication (if

applicable) and alarm contact closing.

➀ Undervoltage, overvoltage, and voltage unbalance protection are disabled during braking operation.

Page 22

1-14 Product Overview

Stall

600%

Percent

Full

Load

Current

Time (seconds)

Programmed Start Time

100%

Running Jam

Percent

Full

Load

Current

Time (seconds)

User Programmed Trip Level

Stall Protection and Jam Detection

The SMC-Flex controller provides both stall protection and jam

detection for enhanced motor and system protection.

• Stall protection is user-adjustable from 0.0…10.0 seconds (in

addition to the ramp time programmed).

Figure 1.15 Stall Protection

• An alarm (pre-fault) indication level can be programmed to

indicate the unit is getting close to faulting. The alarm

modification information is displayed through the LCD, HIM,

Communication (if applicable) and alarm contact closing.

• Jam detection allows the user to determine the jam level (up to

1000% of the motor’s FLC rating) and the delay time (up to

99.0 seconds) for application flexibility.

Figure 1.16 Jam Detection

➀➁

➀ Jam detection is disabled during slow speed and braking operation.

➁ Unit will self-protect in a jam condition.

Page 23

Product Overview 1-15

Ground Fault

In isolated or high impedance-grounded systems, core-balanced

current sensors are typically used to detect low level ground faults

caused by insulation breakdowns or entry of foreign objects.

Detection of such ground faults can be used to interrupt the system to

prevent further damage, or to alert the appropriate personnel to

perform timely maintenance.

The SMC-Flex’s ground fault detection capabilities require the use of

external sensor. Installation of this sensor allows the option of

enabling Ground Fault Trip, Ground Fault Alarm, or both.

For the 5…480 Amp devices, the recommended sensor is a Cat. No.

825-CBCT core balance current transformer for 1…5 A corebalanced ground fault protection.

For the 625…1250 A devices, the recommended sensor is shown

below and provides 5…25 A core-balanced ground fault protection.

• Manufacturer: Allen-Bradley

• Description: 600 Volt-Rated Current Transformer

• Catalog Number: 1411-126-252

• Ratio: 2500:5

Figure 1.17

1

2

1

BLACK

WHITE

SHIELD

SHIELD

BLACK

WHITE

➀ Customer supplied.

➁ Cat. No. 825-CBCT or Flex-Core Cat. No. 126-252

1

Note: When connecting the ground fault sensors, the secondary of

the CT should be shorted until the connection to the Flex

control module is completed.

Page 24

1-16 Product Overview

Ground Fault Trip

The SMC-Flex will trip with a ground fault indication if:

• No other fault currently exists

• Ground fault protection is enabled

• GF Inhibit Time has expired

• GF Current is equal to or greater than the GF Trip Level for a

time period greater than the GF Trip Delay

Parameter 75, Gnd Flt Inh Time, allows the installer to inhibit a

ground fault trip from occurring during the motor starting sequence

and is adjustable from 0…250 seconds.

Parameter 74, Gnd Flt Delay, allows the installer to define the time

period a ground fault condition must be present before a trip occurs. It

is adjustable from 0.1…250 seconds.

Parameter 73, Gnd Flt Level, allows the installer to define the ground

fault current at which the SMC-Flex will trip. It is adjustable from

1.0…5.0 A or 5.0…25 A, depending on the service size.

Important: The ground fault inhibit timer starts after the maximum

phase of load current transitions from 0 A to 30% of the

device’s minimum FLA Setting or the GF Current is

greater than or equal to 0.5 A. The SMC-Flex does not

begin monitoring for a ground fault condition until the

Gnd Flt Inh Time expires.

Ground Fault Alarm

The SMC-Flex will indicate a Ground Fault Alarm if:

• No warning currently exists

• Ground fault alarm is enabled

• GF Inhibit Time has expired

• GF Current is equal to or greater than the Gnd Flt A Lvl

Parameter 77, Gnd Flt A Lvl, allows the installer to define the ground

fault current at which the SMC-Flex will indicate a warning. It is

adjustable from 1.0…5.0 A or 5.0…25 A, depending on the service

size.

Parameter 78, Gnd Flt A Dly, allows the installer to define the time

period a ground fault alarm condition must be present before a trip

occurs. It is adjustable from 0…250 seconds.

Page 25

Product Overview 1-17

10

20

100

250

550

1330

4000

-20°C TNF-20K

0°C TNF- 5K

TNF+15K

TNF+ 5K

TNF

Thermistor/PTC Protection

The SMC-Flex provides terminals 23 and 24 for the connection of

positive temperature coefficient (PTC) thermistor sensors. PTC

sensors are commonly embedded in motor stator windings to monitor

the motor winding temperature. When the motor winding temperature

reaches the PTC sensor’s temperature rating, the PTC sensor’s

resistance transitions from a low to high value. Since PTC sensors

react to actual temperature, enhanced motor protection can be

provided to address such conditions as obstructed cooling and high

ambient temperatures.

The following table defines the SMC-Flex PTC thermistor input and

response ratings:

Table 1.A PTC Input Ratings

Response resistance 3400 Ω ±150 Ω

Reset resistance 1600 Ω ±100 Ω

Short-circuit Trip Resistance 25 Ω ±10 Ω

Maximum Voltage at PTC Terminals (R

Maximum Voltage at PTC Terminals (R

Maximum Number of Sensors 6

Maximum Cold Resistance of PTC Sensor Chain 1500 Ω

Response Time 800 ms

= 4kΩ) < 7.5V

PTC

= open) 30V

PTC

The following figure illustrates the required PTC sensor

characteristics, per IEC-34-11-2.

Figure 1.18 PTC Sensor Characteristics per IEC-34-11-2

PTC Trip

The SMC-Flex will trip with a PTC indication if:

• No other fault currently exists

• PTC protection is enabled

Page 26

1-18 Product Overview

• The resistance across terminals 23 and 24 is either greater than

the relay’s response resistance or less than the short-circuit trip

resistance.

Excessive Starts/Hour

The SMC-Flex controller allows the user to program the allowed

number of starts per hour (up to 99). This helps eliminate motor stress

caused by repeated starting over a short time period.

Overtemperature

The SMC-Flex controller monitors the temperature of the SCRs and

Bypass by using internal thermistors. When the power poles’

maximum rated temperature is reached, the unit will shut down and

restart is inhibited.

An overtemperature condition can indicate inadequate ventilation,

high ambient temperature, overloading, or excessive cycling. After

the temperature is reduced to allowable levels, the fault can be

cleared.

Open Gate

An open gate fault indicates that improper SCR firing, typically

caused by an open SCR gate, has been detected on one of the power

poles. Before the controller shuts down, it will attempt to start the

motor a total of three times.

Line Faults

The SMC-Flex controller continually monitors line conditions for

abnormal factors. Pre-start protection includes:

• Line Fault (with phase indication)

– Line voltage loss

– Missing load connection

– Shorted SCR

Running protection includes:

• Line Fault (no phase indication)

– Line voltage loss

– Missing load connection

Phase Reversal

➀

protection can be toggled either On or Off.

➀ Phase Reversal protection is functional only at pre-start.

Page 27

Metering Power monitoring parameters include:

• Three-phase current

• Three-phase voltage

•Power in kW

• Power usage in kWH

•Power factor

• Motor thermal capacity usage

• Elapsed time

Notes: (1) Voltage measurement is not available during the braking

operation of the SMB Smart Motor Braking, Accu-Stop,

and Slow Speed with Braking control options.

(2) The elapsed time and kWH values are automatically

saved to memory every 12 hours.

(3) Motor thermal capacity usage is determined by the built-

in electronic thermal overload. An overload fault occurs

when this value reaches 100%.

Product Overview 1-19

I/O The SMC-Flex has the ability to accept up to two (2) inputs and

four (4) outputs controlled over a network. The two inputs are

controlled at terminal 16 (Option Input #1), and terminal 15

(Option Input #2). For these two inputs, see Chapter 4 for the

parameter settings and see Chapter 7 for the bit identification.

By using these two terminals as inputs, the Stop Input will need to be

programmed to meet the desired stop functionality.

The four (4) outputs are Aux #1, Aux #2, Aux #3, and Aux #4. All

auxiliary contacts are programmable to the function found on

page 4-14. If programmed to Network or Network NC, they can be

controlled over a Network. Please see Table 7.H that defines the

Logic Command Word (Control).

Page 28

1-20 Product Overview

DPI

ATTENTION

!

Port 5 — DPI

Communications

Port 2

Ports 2 and 3 when two

HIMs are connected with

a splitter

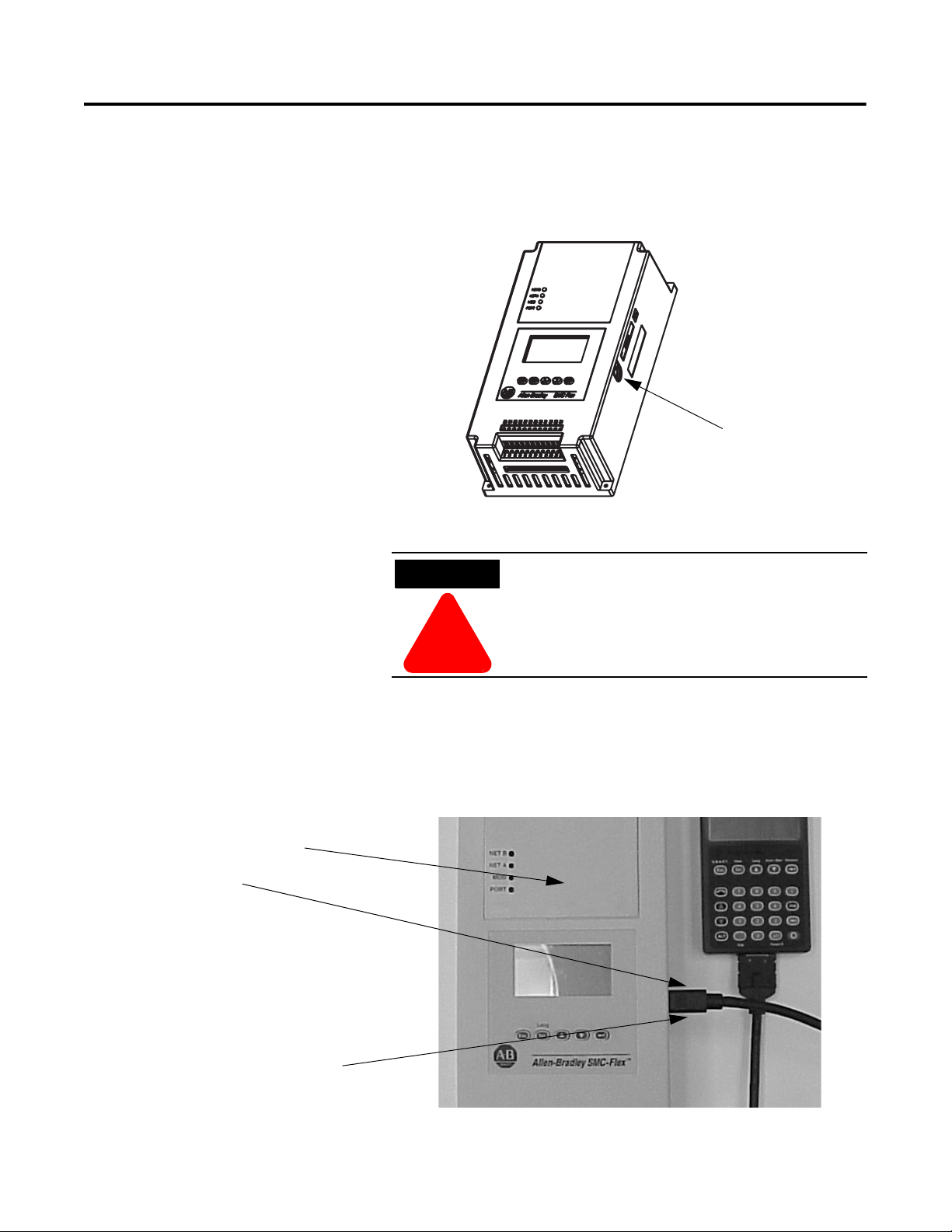

Communication A serial interface port (DPI) is provided as standard, which allows

connection to the Bulletin 20-HIM LCD interface modules.

Figure 1.19 DPI Location

Two peripheral devices can be connected to the DPI.

The maximum output current through the DPI is

280 mA.

Programming Setup is easy with the built-in keypad and three-line, sixteen character

backlit LCD. Parameters are organized in a three-level menu

structure, using a text format for straightforward programming.

Figure 1.20 Built-in Keypad and LCD

Page 29

Product Overview 1-21

11 12

13

14

15 16

17

18 19 20

21

23

24

25 26

27

28 29

30 31 32 332234

Aux #3

Aux #2

Aux #4

Aux #1

SMC-Flex

Control Terminals

PTC

Input

TACH

Input

Ground

Fault

Stop

Input

Start

Input

Opt

Input #2

Opt

Input #1

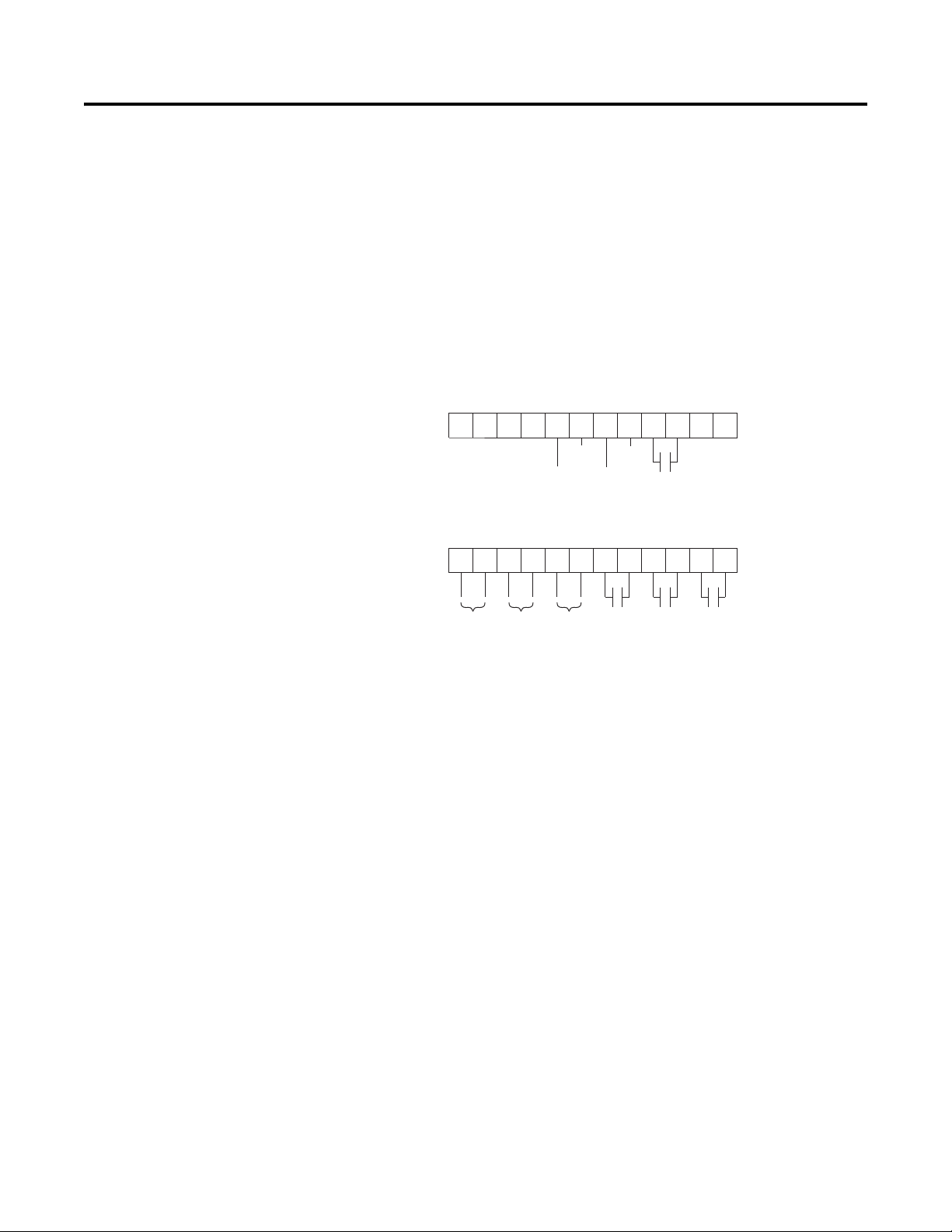

Status Indication Four programmable hard contact outputs are provided as standard. All

auxiliary contacts are programmable for the following states:

• Normal (N.O./N.C.)

• Up-to-Speed (N.O./N.C.)

• Alarm (N.O./N.C.)

• Fault (N.O./N.C.)

• Network Control (N.O./N.C.)

• External Bypass (N.O.)

Figure 1.21 Control Terminals

Network inputs can be obtained through proper programming of

Option Input #1 and Option Input #2.

Page 30

1-22 Product Overview

Notes

Page 31

Chapter 2

Installation

Degree of Protection The SMC-Flex soft starters have an IP00 or IP2X protection rating,

depending on the size. Taking into account the ambient conditions,

the device must be installed in IP54 (Type 2) switchgear cabinets.

Make sure that no dust, liquids, or conductive parts can enter the soft

starter. Soft starter operation produces waste heat (heat loss). See

Table 2.A or Specifications on page A-9, for details.

Receiving It is the user’s responsibility to thoroughly inspect the equipment

before accepting the shipment from the freight company. Check the

item(s) received against the purchase order. If any items are damaged,

it is the responsibility of the user not to accept delivery until the

freight agent has noted the damage on the freight bill. Should any

concealed damage be found during unpacking, it is again the

responsibility of the user to notify the freight agent. The shipping

container must be left intact and the freight agent should be requested

to make a visual inspection of the equipment.

Unpacking Remove all packing material, wedges, or braces from within and

around the controller.

Inspecting After unpacking, check the item(s’) nameplate catalog number

against the purchase order.

Storing The controller should remain in its shipping container prior to

installation. If the equipment is not to be used for a period of time, it

must be stored according to the following instructions in order to

maintain warranty coverage.

• Store in a clean, dry location.

• Store within an ambient temperature range of –20°C to +75°C

(–4°F to +167°F).

• Store within a relative humidity range of 0% to 95%,

noncondensing.

• Do not store equipment where it could be exposed to a corrosive

atmosphere.

• Do not store equipment in a construction area.

Page 32

2-2 Installation

Lifting Points

Lifting For controllers rated 625…1250 A, the device should only be lifted

from designated lifting points. The lifting points are designed to

accept a ½ -13 threaded hoist ring capable of lifting 2500 pounds.

These points are identified in Figure 2.1.

Figure 2.1 Lifting Points

Page 33

Installation 2-3

ATTENTION

!

ATTENTION

!

ATTENTION

!

ATTENTION

!

General Precautions In addition to the precautions listed throughout this manual, the

following statements, which are general to the system, must be read

and understood.

The controller contains ESD- (electrostatic

discharge) sensitive parts and assemblies. Static

control precautions are required when installing,

testing, servicing, or repairing the assembly.

Component damage may result if ESD control

procedures are not followed. If you are not familiar

with static control procedures, refer to applicable

ESD protection handbooks.

An incorrectly applied or installed controller can

damage components or reduce product life. Wiring

or application errors, such as undersizing the motor,

incorrect or inadequate AC supply, or excessive

ambient temperatures, may result in malfunction of

the system.

Only personnel familiar with the controller and

associated machinery should plan or implement the

installation, start-up, and subsequent maintenance

of the system. Failure to do this may result in

personal injury and/or equipment damage.

Hazardous voltages that can cause shock, burn, or

death are present on L1, L2, L3, T1, T2, T3, T4, T5,

and T6.

Power terminal covers can be installed to prevent

inadvertent contact with terminals. Disconnect the

main power before servicing the motor controller or

associated wiring.

Heat Dissipation The following table provides the maximum heat dissipation at rated

current for the controllers. For currents lower than rated value, heat

dissipation will be reduced.

Table 2.A Maximum Heat Dissipation

SMC

Rating

5 A 25 A 43 A 60 A 85 A 108 A 135 A 201 A 251 A 317 A 361 A 480 A 625 A 700 A 970 A 1250 A

Max.

Watts

70 70 81 97 129 91 104 180 198 225 245 290 446 590 812 1222

Page 34

2-4 Installation

Enclosures The open-style design of the SMC-Flex controller requires that it be

installed in an enclosure. The internal temperature of the enclosure

must be kept within the range of 0…50°C.

For Type 12 (IP54) enclosures, the following guidelines are

recommended to limit the maximum controller ambient temperature.

There should be a clearance of at least 15 cm (6 in.) above and below

the controller. This area allows air to flow through the heatsink.

Table 2.B Minimum Enclosure Size ➊

Controller

Rating (A)

5 610 (24) 406 (16) 254 (10)

25 610 (24) 406 (16) 254 (10)

43 610 (24) 406 (16) 254 (10)

60 610 (24) 406 (16) 254 (10)

85 610 (24) 406 (16) 254 (10)

108 762 (30) 610 (24) 305 (12)

135 762 (30) 610 (24) 305 (12)

201 965 (38) 762 (30) 356 (14)

251 965 (38) 762 (30) 356 (14)

317 1295 (51) 914 (36) 356 (14)

361 1295 (51) 914 (36) 356 (14)

480 1295 (51) 914 (36) 356 (14)

625 2286 (90) 889 (35) 508 (20)

780 2286 (90) 889 (35) 508 (20)

5 610 (24) 406 (16) 254 (10)

25 610 (24) 406 (16) 254 (10)

43 610 (24) 406 (16) 254 (10)

60 610 (24) 406 (16) 254 (10)

85 610 (24) 406 (16) 254 (10)

108 965 (38) 762 (30) 356 (14)

135 965 (38) 762 (30) 356 (14)

201 965 (38) 762 (30) 356 (14)

251 965 (38) 762 (30) 356 (14)

317 1524 (60) 965 (38) 356 (14)

361 1524 (60) 965 (38) 356 (14)

480 ➊ 1524 (60) 965 (38) 356 (14)

480 ➋ 2286 (90) 889 (35) 508 (20)

625 2286 (90) 1397 (55) 508 (20)

780 2286 (90) 1397 (55) 508 (20)

5 610 (24) 406 (16) 254 (10)

25 610 (24) 406 (16) 254 (10)

43 610 (24) 406 (16) 254 (10)

60 610 (24) 406 (16) 254 (10)

85 610 (24) 406 (16) 254 (10)

108 965 (38) 762 (30) 356 (14)

135 965 (38) 762 (30) 356 (14)

201 965 (38) 762 (30) 356 (14)

251 965 (38) 762 (30) 356 (14)

317 1295 (51) 914 (36) 356 (14)

361 1295 (51) 914 (36) 356 (14)

480 1295 (51) 914 (36) 356 (14)

625 2286 (90) 1397 (55) 508 (20)

780 2286 (90) 1397 (55) 508 (20)

➊ Larger enclosure may be required based on options selected. Consult your local Rockwell

Automation Sales office or Allen-Bradley distributor.

➋ Use this row for 460V -58 and 575V -59.

➌ Use this row for 460V -59 and 575V -60 and -61.

B Height A Width C Depth

Non-Combination Controller [mm (in.)]

Combination Controllers with Fusible Disconnect

Combination Controllers with Circuit Breaker

IP65 (Type 4/12)

Page 35

Installation 2-5

Mounting All units are fan cooled. It is important to locate the controller in a

position that allows air to flow vertically through the power module.

The controller must be mounted in a vertical plane and have a

minimum of 15 cm (6 in.) free space above and below the

controller.

When drilling or installing near the softstarter, make sure that

adequate measures are taken to protect the device from dust and

debris. See Figure 2.2.

Figure 2.2 SMC-Flex Mounting Protection

Page 36

2-6 Installation

C

F

B

E

A

D

H

Figure 2.3 Dimensions: 5…85 A Controllers

5…85 A

Controller

Unit

mm 150.1 307 203.1 120 291 119.8 14.1 5.7 kg

A

WidthBHeightCDepth

DEFH

in. 5.91 12.09 8.00 4.72 11.46 4.72 0.56 12.6 lb.

All dimensions are approximate and are not intended for manufacturing purposes. Consult your

local Allen-Bradley distributor for complete dimension drawings.

Approx.

Ship. Wt.

Page 37

Figure 2.4 Dimensions: 108…135 A Controllers

A

B

C

D

E

F

G

Installation 2-7

Unit

108…135 A

Controller

mm 196.4 443.7 212.2 166.6 367 129.5 26 15 kg

in. 7.74 17.47 8.35 6.56 14.45 5.10 1.02 33 lb.

A

Width

B

Height

C

Depth

All dimensions are approximate and are not intended for manufacturing purposes. Consult your

local Allen-Bradley distributor for complete dimension drawings.

DEFG

Approx.

Ship. Wt.

Page 38

2-8 Installation

157.25

(6.2)

6.4

(.250)

253.8

(9.992)

40.9

(1.6)

C

1.000

13.5

(.531)

50.8

(2.0)

24.9

(.980)

25

(.984)

48

(1.890)

SCALE

#8-32 UNC-2B

M10 X 1.5

560

(22.047)

225

(8.858)

504.1

(19.847)

150

(5.906)

Ø

13

(.513)

Ø

11.5

(.453)

Ø

27.5

(1.083)

19.7

(.776)

91.189

(3.59)

164.126

(6.46)

152.749

(6.01)

44.311

(1.74)

79.811

(3.14)

245.689

(9.67)

80

(3.15)

SEE DETAIL AA

G

Figure 2.5 Dimensions: 201…251 A Controllers

201…251 A

Controller

Unit

A

WidthBHeightCDepth

DEFGHI

Approx.

Ship. Wt.

mm 225 560 253.8 150 504.1 157.25 91.189 44.311 79.811 30.4 kg

in. 8.858 22.047 9.992 5.906 19.847 6.2 3.59 1.74 3.14 67 lb.

All dimensions are approximate and are not intended for manufacturing purposes. Consult your

local Allen-Bradley distributor for complete dimension drawings.

Page 39

40.9

(1.6)

276.5

(10.89)

182.25

(7.18)

C

63.5

(2.50)

17

(.67)

22.5

(.89)

#8 - 32 UNC - 2B

12.522

(.49)

32.74

(1.29)

48

(1.89)

M12 x 1.75

30.5

(1.20)

Figure 2.6 Dimensions: 317…480 A Controllers

Installation 2-9

Unit

A

WidthBHeightCDepth

DEFGH I

Ship. Wt.

Approx.

317…480 A

Controller

mm 290 600 276.5 200 539.18 182.25 104.5 55.5 103.5 45.8 kg

in. 11.42 23.62 10.89 7.87 21.23 7.18 4.11 2.19 4.07 101 lb.

All dimensions are approximate and are not intended for manufacturing purposes. Consult your

local Allen-Bradley distributor for complete dimension drawings.

Page 40

2-10 Installation

23.5023.50

596,9596,9

[ ]

41.0041.00

1041,41041,4

[ ]

2.002.00

50,850,8

[ ]

4.004.00

101,6101,6

[ ]

1.201.20

30,530,5

[ ]

21.6921.69

550,9550,9

[ ]

1.641.64

41,641,6

[ ]

7.897.89

200,4200,4

[ ]

23.3923.39

594,1594,1

[ ]

38.4538.45

976,6976,6

[ ]

.90.90

2323

[ ]

13.6313.63

346,2346,2

[ ]

2X 2X .2525

6,46,4

[ ]

.

7878

19,819,8

[ ]

3.623.62

92,192,1

[ ]

8.468.46

214,9214,9

[ ]

3X 3X .2525

.05.05

[ ]

.39.39

1010

[ ]

13.8613.86

351,9351,9

[ ]

14.5414.54

369,4369,4

[ ]

19.5419.54

496,3496,3

[ ]

29.0229.02

737737

[ ]

Ø

.500.500

12,712,7

[ ]

Ø

.531.531

13,4913,49

[ ]

7.357.35

186,6186,6

[ ]

14.3514.35

364,4364,4

[ ]

8.258.25

209,5209,5

[ ]

7.007.00

177,8177,8

[ ]

4X 4X 2.752.75

69,869,8

[ ]

4X 4X 3.003.00

76,276,2

[ ]

Ø

.734.734

18,6418,64

[ ]

1.001.00

25,425,4

[ ]

SEE DETAIL ASEE DETAIL A

3X DETAIL A3X DETAIL A

#8-32 UNC-2B#8-32 UNC-2B

C

F

B

E

G

A

D

Figure 2.7 Dimensions: 625…780 A Controllers

625…780 A

Controller

A

Width

B

Height

C

Depth

DEFG

Approx.

Ship. Wt.

Unit

mm 596.9 1041.4 346.2 550.9 594.1 214.9 200.4 179 kg

in. 23.5 41.0 13.63 21.69 23.39 8.46 7.89 395 lb.

All dimensions are approximate and are not intended for manufacturing purposes. Consult your

local Allen-Bradley distributor for complete dimension drawings.

Page 41

41.0041.00

1041,41041,4[ ]

23.3923.39

594,1594,1[ ]

7.897.89

200,4200,4[ ]

1.641.64

41,641,6[ ]

.90.90

2323[ ]

21.6921.69

550,9550,9[ ]

23.5023.50

596,9596,9[ ]

3X 3X .15.15

3,83,8[ ]

13.8613.86

351,9351,9[ ]

14.5414.54

369,4369,4[ ]

19.5419.54

496,3496,3[ ]

29.0229.02

737737[ ]

4.574.57

116,2116,2[ ]

8.468.46

214,9214,9[ ]

2X 2X .25.25

6,46,4[ ]

13.6313.63

346,2346,2[ ]

Ø

.500.500

12,712,7[ ]

2.502.50

63,563,5[ ]

5.005.00

127127[ ]

.74.74

18,818,8[ ]

1.201.20

30,530,5[ ]

.28.28

7,27,2[ ]

Ø

.531.531

13,4913,49[ ]

38.4538.45

976,6976,6[ ]

4X 4X 2.252.25

57,157,1[ ]

4X 4X 2.002.00

50,850,8[ ]

Ø

.734.734

18,6418,64[ ]

8.258.25

209,5209,5[ ]

7.007.00

177,8177,8[ ]

7.357.35

186,6186,6[ ]

14.3514.35

364,4364,4[ ]

1.251.25

31,831,8[ ]

SEE DETAIL ASEE DETAIL A

3X DETAIL A3X DETAIL A

#8-32 UNC-2B#8-32 UNC-2B

C

F

B

E

G

A

D

Installation 2-11

Figure 2.8 Dimensions: 970…1250 A Controllers

970…1250 A

Controller

Unit

A

Width

B

Height

C

Depth

DEFG

Approx.

Ship. Wt.

mm 596.9 1041.4 346.2 550.9 594.1 214.9 200.4 224 kg

in. 23.5 41.0 13.63 21.69 23.39 8.46 7.89 495 lb.

All dimensions are approximate and are not intended for manufacturing purposes. Consult your

local Allen-Bradley distributor for complete dimension drawings.

Page 42

2-12 Installation

/1

3/5

/3

3/6

/4

/2

3

e

r

ec

n

SMC

C

r

r

s

➀

➀ Customer Supplied

➁

➀

➀

➁ Overload protection is included as a

standard feature of the SMC-Flex controller.

L1/1

L3/5

L2/3

T3/6

T2/4

T1/2

M

3-Phase

Input Power

Branch

Protection

SMC-Flex

Controller

Power Factor

Correction Capacitors

➀

➀ Customer Supplied

➁

➀

➀

➁ Overload protection is included as a standard feature of the SMC-Flex controller.

➂ Energize 1/2 second before start command to SMC.

➂

➃ Open contactor after stopping method is complete.

➂ Energize contactor after up-to-speed.

➃ Open contactor before initiating a stop.

Alternate

➃

Power Factor

Correction Capacitors

The controller can be installed on a system with power factor

correction (PFC) capacitors. The capacitors must be located on the

line side of the controller. This must be done to prevent damage to the

SCRs in the SMC-Flex controller.

When discharged, a capacitor essentially has zero impedance. For

switching, sufficient impedance should be connected in series with

the capacitor bank to limit the inrush current. One method for limiting

the surge current is to add inductance in the capacitor’s conductors.

This can be accomplished by creating turns or coils in the power

connections to the capacitors.

• 250V — 15 cm (6 in.) diameter coil, 6 loops

• 480…690V — 15 cm (6 in.) diameter coil, 8 loops

Take care in mounting the coils so that they are not stacked directly

on top of each other; stacking will cause a cancelling effect. Also,

mount the coils on insulated supports away from metal parts so they

will not act as induction heaters. If an isolation contactor is used, put

capacitors in front of contactor.

Note: For further instructions, consult the PFC capacitor vendor.

Figure 2.9 Typical Wiring Diagram for Power Factor Correction Capacitors

-Phas

Input Powe

Prot

Branch

L1

L2

L

tio

Power Facto

Correction Capacitor

ontrolle

T1

T2

T

-Flex

Figure 2.10 Typical Wiring Diagram for Power Factor Correction Capacitors

and Contactor

Page 43

Installation 2-13

ATTENTION

!

ATTENTION

!

Protective Modules Protective modules containing metal oxide varistors (MOVs) can be

installed on controllers rated 5…1250 A and 200…600V, to protect

the power components from electrical transients. The protective

modules clip voltage transients generated on the lines to prevent such

surges from damaging the SCRs.

When installing or inspecting the protective module,

make sure that the controller has been disconnected

from the power source. The protective module

should be inspected periodically for damage or

discoloration. Replace if necessary.

Motor Overload

Protection

Thermal motor overload protection is provided as standard with the

SMC-Flex controller. If the overload trip class is less than the

acceleration time of the motor, nuisance tripping may occur.

Overload protection should be properly coordinated

with the motor.

Two applications require special consideration: two-speed motors,

and multi-motor protection.

Two-speed Motors

The SMC-Flex controller has overload protection available for single

speed motors. When the SMC-Flex controller is applied to a twospeed motor, the Overload Class parameter must be programmed to

OFF and separate overload relays must be provided for each speed.

Multi-motor Protection

If the SMC-Flex controller is controlling more than one motor,

individual overload protection is required for each motor.

Page 44

2-14 Installation

ATTENTION

!

Electromagnetic Compatibility (EMC)

This product has been designed for Class A

equipment. Use of the product in domestic

environments may cause radio interference, in

which case, the installer may need to employ

additional mitigation methods.

The following guidelines are provided for EMC installation

compliance.

Enclosure

Install the product in a grounded metal enclosure.

Wiring

Wire in an industrial control application can be divided into three

groups: power, control, and signal. The following recommendations

for physical separation between these groups is provided to reduce the

coupling effect.

• Different wire groups should cross at 90° inside an enclosure.

• Minimum spacing between different wire groups in the same tray

should be 16 cm (6 in.).

• Wire runs outside an enclosure should be run in conduit or have

shielding/armor with equivalent attenuation.

• Different wire groups should be run in separate conduits.

• Minimum spacing between conduits containing different wire

groups should be 8 cm (3 in.).

• For additional guidelines, please refer to Wiring and Ground

guidelines, publication DRIVES-IN001A-EN-P.

Additional Requirements

• If linear acceleration is used, a separate conduit or wire way

should be used for the tachometer leads.

• Wire earth ground to control terminal 14.

• Use shielded wire for PTC, Tachometer, and ground fault input.

• Terminate shielded wires to terminal 14.

• Ground fault CT must be inside or within 3 m of metal enclosure.

To meet product susceptibility requirements, ferrite cores need to be

added to the communication lines. When using an external HIM (or

DPI interface), a core should be added to the HIM cable near the

SMC-Flex control module. The recommended core is Fair-Rite

no. 0431167281 or equivalent. When using a DeviceNet circuit, two

cores need to be added to the DeviceNet cable near the SMC-Flex

control module. The recommended cores are TDK ZCAT2023 0930H

and TDK ZCAT2035 0930 or equivalent. All cores specified are the

split type cores and can be added to existing connections.

Page 45

Chapter 3

4

1

5

3

2

3

3

➀

➀

Wiring

Terminal Locations The SMC-Flex controller wiring terminal locations are shown in

Figure 3.1 and Figure 3.2. Make wiring connections as indicated in

the typical connection diagrams. Incoming three-phase power

connections are made to terminals L1/1, L2/3, and L3/5. Load

connections to Line motors are made to T1/2, T2/4, and T3/6, while

load connections to Wye-Delta motors are made to T1/2, T2/4, T3/6,

T4/8, T5/10, and T6/12.

Figure 3.1 Wiring Terminal Locations (5…85 A)

Table 3.A Wiring Terminal Locations

1 Incoming Line Termination

2 Line Motor Connections

3 Delta Motor Connections

4 Control Terminations

5 Fan Terminations

IP20 protective covers on Delta termination must be removed when connecting in a Delta

➀

configuration.

Page 46

3-2 Wiring

4

1

5

3

2

3

3

Figure 3.2 Wiring Terminal Locations (108…480 A)

Table 3.A Wiring Terminal Locations

1 Incoming Line Termination

2 Line Motor Connections

3 Delta Motor Connections

4 Control Terminations

5 Fan Terminations

Page 47

Figure 3.3 Wiring Terminal Locations (625…1250 A)

3

1

2

Wiring 3-3

Table 3.B Wiring Terminal Locations

1 Incoming Line Terminations

2 Line Motor Connections

3 Terminal Block CP1 - Common Control Power Connections

(Fans, Contactors, and Control Modules)

Power Structure The SMC-Flex product has an integrated mechanical run contactor on

each phase of the motor to minimize heat generation during run time.

These contacts are pulled in sequentially in the 108…1250 A units. In

the 5…85 A units, these contacts are pulled in, all at once. The

SMC-Flex product also has a Current Transformer (CT), built in on

each phase of the motor to provide current readings.

Power Wiring

Refer to the product nameplate or User Manual for power lug

termination information including:

• Lug wire capacity

• Tightening torque requirements

• Lug kit catalog numbers (108…1250 A)

Page 48

3-4 Wiring

ATTENTION

!

Use of an isolation contactor or shunt trip type circuit breaker on the line side of the SMC. This

device should be capable of interrupting the motor’s lock rotor current.

Connection of this isolation device to an auxiliary contact on the SMC-Flex. The auxiliary contact

should be programmed for the “normal” condition. See Chapter 4 for additional information on

programming.

Failure of solid state power switching components can cause overheating due to a single-phase

condition in the motor. To prevent injury or equipment damage, the following is recommended:

Line Connected

The SMC-Flex by default is programmed to be connected to a line

controlled motor as shown in Figure 3.4. These motors typically have

3 leads and must be rated between 1…1250 amps. An optional

isolation contactor can be added to the circuit to provide galvanic

isolation of the motor and final electro-mechanical removal of power.

Figure 3.4

SMC-Flex

IC

5/L3

6/T3

10/T5

IC

3/L2

IC

1/L1

4/T2

8/T4

2/T1

12/T6

M

3~

Delta Connected

The SMC Flex can be programmed and connected to a delta

controlled motor as shown in Figure 3.5. These motors typically have

6 or 12 leads and must be rated between 1.8…1600 amps. It is

recommended that an isolation contactor be added to the circuit to

provide galvanic isolation of the motor and final electro-mechanical

removal of power.

Figure 3.5

Page 49

Wiring 3-5

2/T1

4/T2

6/T3

12/T6

8/T4

10/T5

M

3~

1/L1

5/L3

3/L2

IC

IC

IC

SMC-Flex

ATTENTION

!

Power Lugs Power lugs are required for devices rated 108..1250 A. In some cases

these lugs are sold in kits. Each kit contains three lugs. The number

and type of lugs required is listed in the following tables.

Table 3.C lists the recommended lugs for the SMC when configured

as a line connection. Table 3.D lists the recommended lugs when

using the SMC Flex with a delta connection. Note that devices rated

625…1250 A require the use of a power distribution block when used

with a delta connection.

Terminal covers are available for units rated

108…480 A which can make the product deadfront

(IP2X) safe. See Appendix D for the appropriate

catalog numbers for ordering.

Page 50

3-6 Wiring

Table 3.C SMC-Flex 5…1250 A, Line Connection Lug Information

SMC

Rating

Lug Kit

Cat. No.

Wire Strip

Length

5…85 A — 18…20 mm

108…135 A 199-LF1 18…20 mm

201…251 A 199-LF1 18…20 mm

317…480 A 199-LG1 18…25 mm

625…780 A 100-DL630 32 mm / 64 mm

970 A 100-DL860 26 mm / 48 mm

100-DL630 32 mm / 64 mm

1250 A

➀

100-DL860 26 mm / 48 mm

Conductor

Range

2.5…85 mm

(#14…3/0 AWG)

16…120 mm

(#6…250 MCM)

16…120 mm

(#6…250 MCM)

25…240 mm

(#4…500 MCM)

70…240 mm

(2/0…500 MCM)

120…240 mm

(4/0…500 MCM)

70…240 mm

(2/0…500 MCM)

120…240 mm

(4/0…500 MCM)

The 1250 A device requires one (1) each of the 100-DL630 and 100-DL860.

➀

Max. No. Lugs/Pole Tightening Torque

Line Side Load Side Wire — Lug Lug — Busbar

2

— — 11.3 N•m

(100 lb.-in.)

2

11 31 N•m

(275 lb.-in.)

2

22 31 N•m

(275 lb.-in.)

2

22 42 N•m

(375 lb.-in.)

2

22 45 N•m

(400 lb.-in.)

2

11 45 N•m

(400 lb.-in.)

2

11

45 N•m

2

11

(400 lb.-in.)

—

23 N•m

(200 lb.-in.)

23 N•m

(200 lb.-in.)

28 N•m

(250 lb.-in.)

68 N•m

(600 lb.-in.)

68 N•m

(600 lb.-in.)

68 N•m

(600 lb.-in.)

SMC

Rating

Suggested Lug

Cat. No.

108…135 A 1494R-N15

201…251 A 1494R-N14

317…480 A 150-LG5MC

625…780 A

970…1250 A

➀

➀

—

—

Table 3.D SMC-Flex 108…1250 A, Delta Connection Lug Information (for

Inside-the-Delta applications)

Conductor

Pole

Range

Line Side ➁ Wire — Lug Lug — Busbar

Max. No. Lugs/

25…240 mm

2

1 42 N•m

(#4…500 MCM)

50…120 mm

2

2 31 N•m

(1/0…250 MCM)

95…240 mm

2

1 33.9 N•m

(3/0…500 MCM)

25…240 mm

2

2 42 N•m

(#4…500 MCM)

25…240 mm

2

4 42 N•m

(#4…500 MCM)

For 625

➀

➁ Load side lug information for inside-the-delta applications is contained in Table 3.C.

…1250 A inside-the-delta connections, terminal blocks are required for line side

connections. Required terminal blocks are as follows:

- Allen-Bradley Part# 1492-BG (625…780 A: 2 per phase, 970…1250 A: 4 per phase). Short-Circuit

Protection = Fuses

- Cooper Bussmann Part# 16504-2 (625…780 A: 1 per phase, 970…1250 A: 2 per phase). ShortCircuit Protection = Circuit breaker

Tightening Torque

(375 lb.-in.)

(275 lb.-in.)

(300 lb.-in.)

(375 lb.-in.)

(375 lb.-in.)

23 N•m

(200 lb.-in.)

23 N•m

(200 lb.-in.)

28 N•m

(250 lb.-in.)

N/A

N/A

Page 51

Control Power Control Wiring

Refer to the product nameplate for control terminal wire capacity and

tightening torque requirements. Each control terminal will accept a

maximum of two wires. Refer to the product nameplate prior to

applying control power. Depending on the specific application,