Page 1

QUICK START

SMC™ FLEX

BULLETIN 150

This guide provides you with the basic information required to start up your SMC Flex controller. When reading

this document, look for this symbol “Step x” to guide you through the four basic steps required to install, start-up,

and program the SMC Flex.

The information provided in this Qu

downloaded by visiting www.ab.com. The Quick Start guide assumes the installer is a qualified person with

previous experience and basic understanding of electrical terminology, configuration procedures, required

equipment, and safety precautions.

For safety of maintenance personnel as well as other

maintenance activities, follow all local safety related work practices (for example, the NFPA 70E, Part II in the

United States). Maintenance personnel must be trained in the safety p ra ctices, procedures, and requirements that

pertain to their respective job assignments.

For detailed SMC Flex information including set-up, programming, precautions, and a

refer to the following documentation.

For product technical support:

ick Start guide does not replace the User Manual which can be ordered or

s who might be exposed to electrical hazards associated with

pplication considerations,

Title Publication Number Availability

SMC Flex User Manual 150-UM008* www.ab.com/literature

SMC Flex Application Guide 150-AT002* www.ab.com/literature

Online Support www.ab.com/support

Telephone Support 440-646-5800 (option 2, option 4 or use

direct dial code 804)

Page 2

2 SMC™ Flex Quick Start

!

WARNING

Step 1 - Read the General Precautions

• Only personnel familiar with the controller and associated machinery should plan or implement the

installation, start-up, and subsequent maintenance of the system. Failure to do this may result in personal injury

and/or equipment damage.

• Hazardous voltage is present in the motor circuit ev

hazard, disconnect main power before working on the controller , motor, and control devices such as Start-Stop

push buttons. Procedures that require parts of the equipment to be energized during troubleshooting, testing,

etc., must be performed by properly qualified personnel, using appropriate local safety work practices and

precautionary measures.

• Failure of solid state power switching components can cause

motor. To prevent injury or equipment damage, the use of an isolation contactor or shunt trip type circuit

breaker on the line side of the SMC is recommended. This device should be capable of interrupting the motor’s

lock rotor current.

• Hazardous voltages that can cause shock, burn, or death

Power terminal covers for units rated 108…480 A can be installed to prevent inadvertent contact with

terminals. Disconnect the main power before servicing the motor controller, motor, or associated wiring.

en when the SMC-Flex controller is off. To avoid shock

ov

erheating due to a single-phase condition in the

are present

on L1, L2, L3, T1, T2, T3, T4, T5, and T6.

Page 3

SMC™ Flex Quick Start 3

NOTICE

• The controller contains ESD- (electrostatic discharge) sensitive parts and assemblies. Static control precautions

are required when installing, testing, servicing, or repairing the assembly. Component damage may result if

ESD control procedures are not followed. If you are not familiar with static control procedures, refer to

applicable ESD protection handbooks.

sed

• Stopping modes are not intended to be u

as an emergency stop. The user is responsible for determining

which stopping mode is best suited to the application. Refer to the applicable standards for emergency stop

requirements.

• Pump Stopping may cause motor heating depending on the me

chanical dynamics of the pumping system.

Therefore, select the lowest stopping time setting that will satisfactorily stop the pump.

ed fo

• Slow Speed running is not intend

r continuous operation due to reduced motor cooling.

• The fan jumpers have been factory installed for 110/120V AC input. Refer to page 9 for 220/240V AC fan

wiring (5…480 A devices only).

• Tw o peripheral devices can be connected to the DPI port. The maximum output

current through the DPI port

280 mA.

that th

• When installing or inspecting protective modules, make su re

e controller has been disconnected from the

power source. The protective module should be inspected periodically for damage or discoloration. Replace if

necessary.

• An incorrectly applied or installed contro

ller can damage components or reduce product life. Wiring or

application errors such as under sizing the motor, over sizing the controller , incorrect or inadequate A C supply,

excessive ambient temperatures, or power quality may result in malfunction of the system.

• The Motor Overload parameter must be

programmed by the installer to prov

ide proper protection. Overload

configuration must be properly coordinated with the motor.

• This product has been designed and tested as Class A equipment for

EMC compatibility . Use of the product in

domestic environments may cause radio interference, in which case, the installer may need to employ

additional mitigation methods.

is

• Disconnect the controller from the mot

or before measuring insulation resistance (IR) of the mot

or windings.

Voltages used for insulation resistance testing can cause SCR failure. Do not make any measurements on the

controller with an Insulation Resistance (IR or Megger) tester.

Page 4

4 SMC™ Flex Quick Start

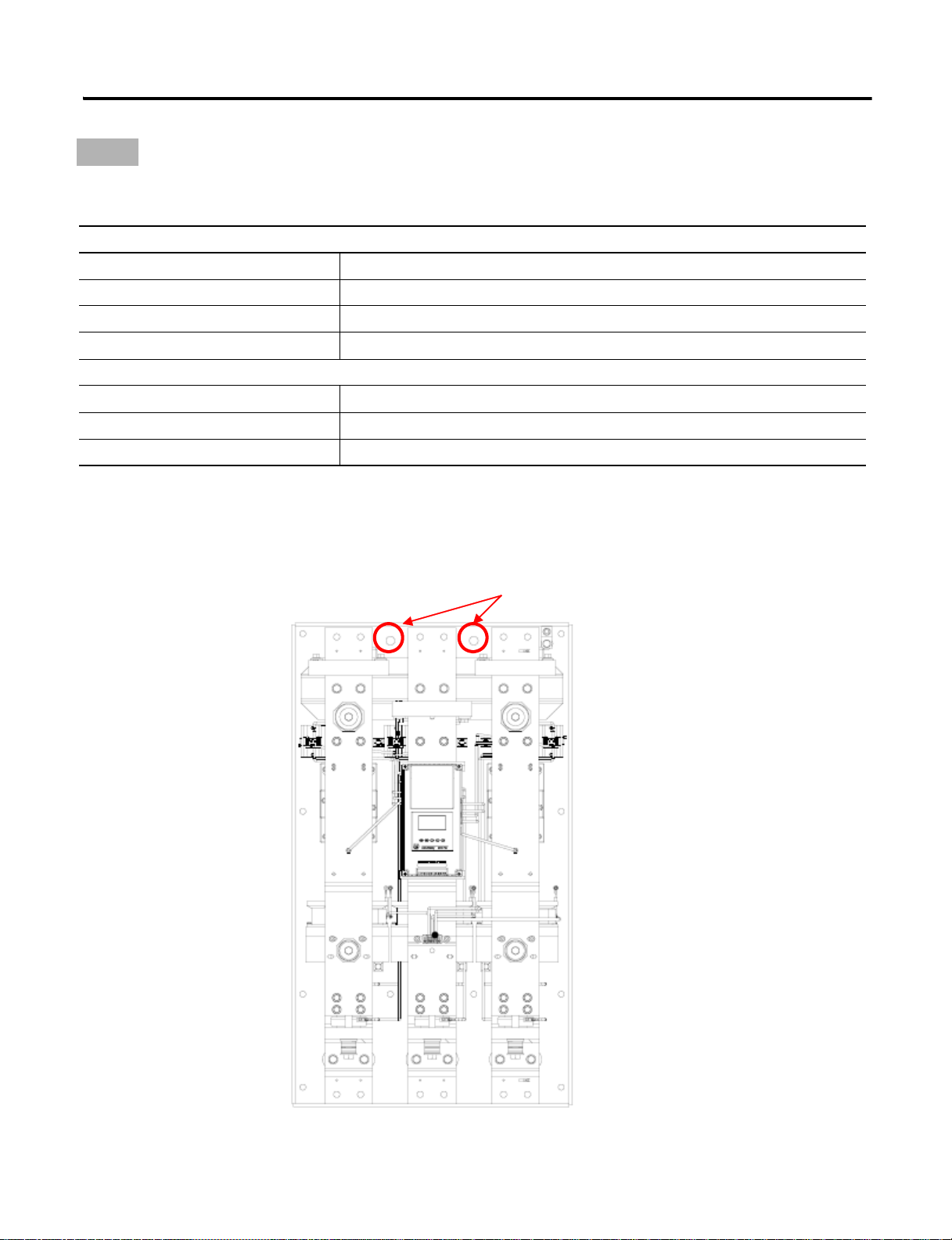

Lifting Points

Step 2 - Installation

Mounting

Enclosure Ratings

Standard Device Rating IP00 (NEMA Open Type)

Minimum Required Enclosure IP23 (NEMA Type 1)

Recommended Enclosure IP54 (NEMA Type 12), sizing guide in User Manual

Enclosure Internal Temperature -5…50 °C (23…122 °F)

Orientation and Clearance

Mounting Orientation Vertical

Minimum horizontal clearance 0 cm (0 in.)

Minimum vertical clearance 15 cm (6 in.)

Controllers rated 625…1250 A

Device must be lifted only at the designated lift points identified with labels.

Page 5

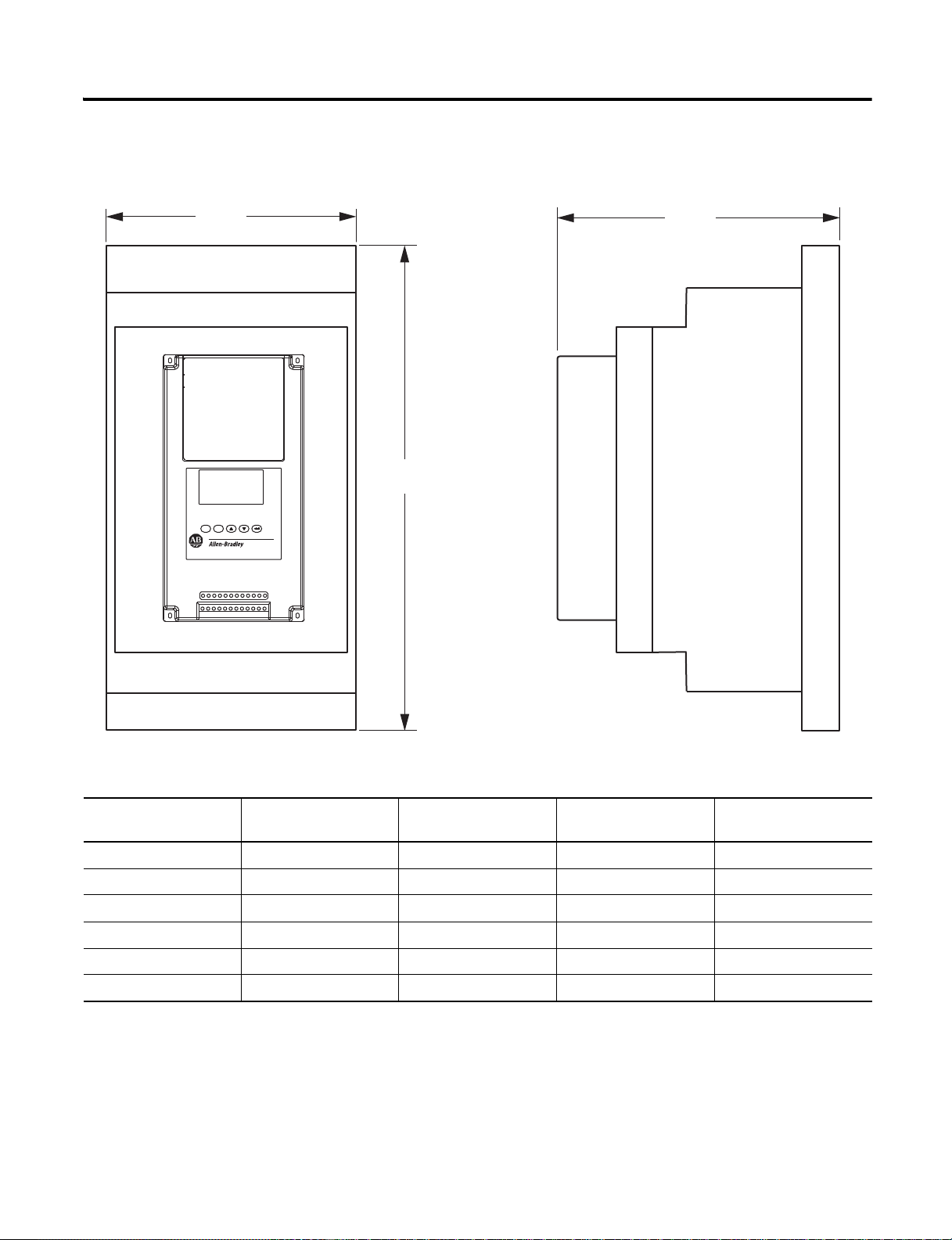

Dimensions

23 24 25 26 27 28 29 30 31 32 33 34

11 12 13 14 15 16 17 18 19 20 21 22

SMC-Flex

Lang

TM

Esc

Sel

C

A

B

For detailed dimensions, please refer to the SMC Flex User Manual.

SMC™ Flex Quick Start 5

Dimensions are in millimeters (inches).

Controller Rating [A] Height (B) Width (A) Depth (C) Approximate Shipping

Weight

5…85 321.0 (12.60) 150.0 (5.90) 203.0 (8.00) 5.7 kg (12.5 lb)

108…135 443.7 (17.47) 196.4 (7.74) 212.2 (8.35) 15.0 kg (33.0 lb)

201…251 560.0 (22.05) 225.0 (8.86) 253.8 (9.99) 30.4 kg (67.0 lb)

317…480 600.0 (23.62) 290.0 (11.42) 276.5 (10.89) 45.8 kg (101 lb)

625…780 1041.1 (41.00) 596.9 (23.50) 346.2 (13.63) 179 kg (395 lb)

970…1250 1041.1 (41.00) 596.9 (23.50) 346.2 (13.63) 224 kg (495 lb)

Page 6

6 SMC™ Flex Quick Start

23

24

25

26

27

28

29

30

31

32

33

34

11

12

13

14

15

16

17

18

19

20

21

22

Power Wiring

Refer to the product nameplate or the SMC Flex User Manual for device specific information.

SMC Rating

[A]

Lug Kit

Cat. No.

Wire Strip

Length

5…85 — 18…20 mm

108…135 199-LF1 18…20 mm

201…251 199-LF1 18…20 mm

317…480 199-LG

1 18…25 mm

625…780 100-DL630 32 mm/64 mm

970 100-DL860 26 mm/48 mm

100-DL630 32 mm/64 mm

1250

100-DL860 26 mm/48 mm

Control Terminals

Conductor

Range

2.5…85 mm

2

(#14…3/0 AWG)

16…120 mm

2

(#6…250 MCM)

16…120 mm

2

(#6…250 MCM)

25…240 mm

2

(#4…500 MCM)

70…240 mm

2

(2/0…500 MCM)

120…240 mm

(4/0…500 MCM)

70…240 mm

2

(2/0…500 MCM)

120…240 mm

(4/0…500 MCM)

Max. No. Lugs/Pole Tightening Torque

Line Side Load Side Wire - Lug Lug - Busbar

— —

1 1

2 2

2 2

2 2

2

1 1

1 1

2

1 1

11.3 N•m

(100 lb•in)

31 N•m

(275 lb•in)

31 N•m

(275 lb•in)

42 N•m

(375 lb•in)

45 N•m

(400 lb•in)

45 N•m

(400 lb•in)

45 N•m

(400 lb•in)

—

23 N•m

(200 lb•in)

23 N•m

(200 lb•in)

28 N•m

(250 lb•in)

68 N•m

(600 lb•in)

68 N•m

(600 lb•in)

68 N•m

(600 lb•in)

Terminal Description Termina l Description Footnotes

➂➃ Control Power Input (+) 23➀ PTC Input

11

12➂➃ Control Power Common 24➀ PTC Input

➀ Controller Enable Input 25 Tachometer Input

13

➀ Do not connect any additional loads to these

14 Ground 26 Tachometer Input

➀➂ Option Input #2 27➀ Ground Fault Transformer Input

15

➀➂ Option Input #1 28➀ Ground Fault Transformer Input

16

➀➂ Start Input 29➁➂ Aux Contact #2

17

➀➂ Stop Input 30➁➂ Aux Contact #2

18

➁➂ Aux Contact #1 31➁➂ Aux Contact #3

19

➁➂ Aux Contact #1 32➁➂ Aux Contact #3

20

21 Not Used 33

22 Not Used 34

➁➂ Aux Contact #4

➁➂ Aux Contact #4

➁ When set for External Bypass mode, the SMC

➂ RC Snubbers are required on inductive type

➃ Control power on units rated 625…1250 A is

terminals. These “parasitic” loads may cause

incorrect operation.

Flex can be used to control a properly sized

external contactor and overload once the motor

reaches full speed. The SMC-Flex overload

functionality is disabled in this mode.

loads connected to auxiliary contacts.

pre-wired internally, from terminal block CP1.

Page 7

SMC™ Flex Quick Start 7

Control Wiring

Refer to the product nameplate for additional details. Depending on the specific application, additional control

circuit transformer VA capacity may be required.

Controllers rated 5…480 A

Control power is connected to the product through terminals 11 and 12.

Conductor Range

Torque 0.6 N•m (5 lb•in)

Maximum Number of Wires per Terminal 2

AC Control Voltage Input 100…240V AC or 24V AC (+10/-15%)

Supply Type 1-phase, 50/60 Hz

24V AC Power Requirement 130VA

100…240V AC Power Requirement 75VA

DC Control Voltage Input 24V DC (+10/-15%)

Inrush Current 5 A

Inrush Time 250 ms

Transient Watts 60 W

Transient Time 500 ms

Staedy State Watts 24 W

Recommended Supply 1606-XLP50E

Fan Power Input (AC only) separately wired

F5…F135 20VA

F201…F251 40VA

F317…F480 60VA

0.75…2.5 mm

2

(18…14 AWG)

Controllers rated 625…1250 A

Control power is connected to the product through terminal block CP1, at terminals 1 and 4.

Conductor Range

Torque 0.6 N•m (5 lb•in)

Maximum Number of Wires per Terminal 2

Control Voltage Input 110/120V AC or 230/240V AC, (+10/-15%)

Supply Type 1-phase, 50/60 Hz

Control Power Input 800VA (includes controller, bypass, and fans)

0.75…2.5 mm

2

(18…14 AWG)

Page 8

8 SMC™ Flex Quick Start

L1 L2 L3

T1 T2 T3

Motor

T6

T4

T5

K1

L1 L2 L3

T1 T2 T3

Motor

K1

Diagrams per NEMA Symbology

Delta Connection with

Isolation Contactor

(Optional Mode)

Line Connection with

Isolation Contactor

(Default Mode)

2

1

4

3

6

5

L1 L2 L3

M

3

2

U

K1

2

1

1

4

V

4

3

3

6

W

6

5

5

M

3

L1

2

K1

1

2

1

L2

4

3

4

3

L3

6

2

143

6

5

5

6

5

U1V1W

1

W

2

U

2

V

2

Diagrams per IEC Symbology

L1 L2 L3

T1 T2 T3

Motor

T6

T4 T5

Delta Connection with

Shorted SCR Protection

(Optional Mode)

K1

Delta Connection with

Isolation Contactor

(Optional Mode)

Line Connection with

Isolation Contactor

(Default Mode)

Delta Connection with

Shorted SCR Protection

(Optional Mode)

M

3

L1

2

1

L2

4

3

L3

2

143

6

5

6

5

U1V1W

1

W2U

2

V

2

2

K1

143

6

5

Typical Wiring Diagrams

Typical Power Wiring Examples

Page 9

Typical Control Wiring Examples

11 12 13 14 15 16 17 18 19 20 21 22

23 24 25 26

SMC Flex Control Terminals

Aux#1

Aux#4

27 28 29 30 31 32 33 34

Aux#3Aux#2

Hold In

11 12 13 14 15 16 17 18 19 20 21 22

23 24 25 26

SMC Flex Control Terminals

Aux#1

Aux#4

27 28 29 30 31 32 33 34

Aux#3Aux#2

Hold In

2 Wire

Device

Up-to-Speed

Indication

Fault

Indication

L1 (L+)

N (L-)

Programming Notes:

Aux#4 – Set for Fault

Parameter#132 – Set for Diable

Programming Notes:

Aux#1 – Set for Normal

Aux#4 – Set for Up to Speed

FAN

Start

L1 (L+)

N (L-)

FAN

K1

A1

A2

Stop

Connection Required

for DPI Control

Fig 1.x

3 Wire Control (With or Without DPI control), Isolation Contactor (K1),

and Up-to-Speed Indication

Fig 1.x

2 Wire Control (No DPI control or Option Stopping) with Fault Indication

Fan Power Terminations Example

(Separately Wired for F5...F480 Devices)

1

2

3

4

Factory Default Position

110/120 VAC

Optional Configuration

220/240 VAC

Jumpers

Supply

1

2

3

4

Supply

Jumper

SMC™ Flex Quick Start 9

Page 10

10 SMC™ Flex Quick Start

Typical Control Wiring Examples, Continued

Fig 1.x

3 Wire Control with Option Stopping, DPI control, Isolation Contactor (K1),

and Alarm Indication

L1 (L+)

Option Stop

Stop

Programming Notes:

Aux#1 – Set for Normal

Aux#4 – Set fot Alarm

Start

FAN

11 12 13 14 15 16 17 18 19 20 21 22

Hold In

Aux#1

SMC Flex Control Terminals

K1

23 24 25 26

Aux#4

27 28 29 30 31 32 33 34

Aux#3Aux#2

Alarm

Indication

N (L-)

Fig 1.x

Start and Stop Control via DPI Communication ONLY with Isolation

Contactor (K1)

A1

A2

L1 (L+)

N (L-)

Programming Notes:

Aux#1 – Set for Normal

Parameter

#87 - Logic Mask must be set for DPI Control.

- Value of 4 enables HIM control only

- Value of 32 enables Communication Port control only

- Value of 44 enables ALL DPI ports for control

FAN

11 12 13 14 15 16 17 18 19 20 21 22

SMC Flex Control Terminals

23 24 25 26

Hold In

Aux#1

Aux#4

27 28 29 30 31 32 33 34

Aux#3Aux#2

K1

A1

A2

Page 11

SMC™ Flex Quick Start 11

Parameters

Diagnostics

Preferences

Memory

Storage

Log In *

See File Structure Below for

additional details

Alarms

Faults

Device Revision

Change Password

User Dspl Line

User Dspl Time

User Dspl Video

Reset User Display

Reset to Defaults

Enter Password

(* - Only Active when a password is used)

Main Menu

Monitoring

Volts Phase A-B

Volts Phase B-C

Volts Phase C-A

Current Phase A

Current Phase B

Current Phase C

Watt Meter

Kilowatt Hours

Elapsed Time

Meter Reset

Power Factor

Mtr Thermal Usage

Set Up

Motor Protection

Communications

Utility

Linear List

Basic

SMC Option

Motor Connection

Line Voltage

Starting Mode

Ramp Time

Initial T orque

Cur Limit Lvl

Kickstart Time

Kickstart Level

Stop Input

Option 1 Input

Option 2 Input

Stop Mode

Stop Time

Overload Class

Service Factor

Motor FLC

Overload Reset

Aux1 Config

Aux2 Config

Aux3 Config

Aux4 Config

Parameter Mgt

Metering

Overload

Underload

Undervoltage

Overvoltage

Unbalance

Jam

Stall

Ground Fault

PTC

Phase Reversal

Restart

Overload Class

Service Factor

Motor FLC

Overload Reset

Overload A Lvl

Parameter Mgmt

Underload F Lvl

Underload F Dly

Underload A Lvl

Underload A Dly

Parameter Mgmt

Undervoltage F Lvl

Undervoltage F Dly

Undervoltage A Lvl

Undervoltage A Dly

Parameter Mgmt

Overvoltage F Lvl

Overvoltage F Dly

Overvoltage A Lvl

Overvoltage A Dly

Parameter Mgmt

Unbalance F Lvl

Unbalance F Dly

Unbalance A Lvl

Unbalance A Dly

Parameter Mgmt

Jam F Lvl

Jam F Dly

Jam A Lvl

Jam A Dly

Parameter Mgmt

Stall Delay

Parameter Mgmt

Gnd Flt Enable

Gnd Flt Lvl

Gnd Flt Dly

Gnd Flt Inh Time

Gnd Flt A Enable

Gnd Flt A Lvl

Gnd Flt A Dly

Parameter Mgmt

PTC Enable

Parameter Mgmt

Phase Reversal

Parameter Mgmt

Starts Per Hour

Restart Attempts

Restart Delay

Parameter Mgmt

Comm Masks

Data Links

Logic Mask

Parameter Mgmt

Data In A1

Data In A2

Data In B1

Data In B2

Data In C1

Data In C2

Data In D1

Data In D2

Data Out A1

Data Out A2

Data Out B1

Data Out B2

Data Out C1

Data Out C2

Data Out D1

Data Out D2

Parameter Mgmt

Language

Motor Data

Language

Parameter Mgmt

Motor FLC

Motor ID

Parameter Mgmt

Linear List

All Parameters

Menu Structure Hierarchy

Stopped

---

0.0

0.0

0.0

Amps

Volt

%MTU

Power Up and Status Display

Note:

•Depending on the SMC option, additional

parameters may appear in some menus

•The external HIM has similar programming

operation to the built-in HIM, however some

differences do exist.

•The built-in HIM can not be used to program

other DPI devices (i.e. Device Select)

Step 3 - Basic Programming

The SMC-Flex controller can be programmed with the built-in keypad and LCD display or with an optional

Bulletin 20-HIM-xx LCD human interface module.

Page 12

12 SMC™ Flex Quick Start

Access the Basic set up group by selecting the Parameters menu from the Main Menu and then Set Up.This

programming group provides a limited parameter set, allowing quick start-up with minimal adjustment.

Parameter Name and Description Values Default

Parameter # 14 - SMC Option

Displays the type of controller. This is factory set and not

Parameter # 15 - Motor Connection

Displays the motor type to which the device is being connected.

Parameter # 16 - Line Voltage

Displays the system line voltage to which the

Parameter # 17 - Starting Mode

Allows the user to program the SMC-Flex controller for the type of sta

Parameter # 18 - Ramp Time

This sets the time period during which the

Parameter # 19 - Initial Torque

When the Soft Start mode is selected, this parameter

voltage ramp.

Parameter # 20 - Current Limit Level

When Current Limit mode is selected, this parameters sets level of cu

programmed Ramp Time.

Parameter # 22 - Kickstart Time

A boost current is provided to the motor for the programmed time period.

rameter # 23 - Kickstart Level

Pa

Adjusts the amount of current applied to the motor during kickstart.

Parameter # 133 - Stop Input

Allows the user to select the operation of terminal 18, Stop Input.

Parameter # 132 - Option Input 1

Allows the user to select the operation of terminal 16, Option

Parameter # 24 - Option Input 2

Allows the user to select the operation of terminal 15, Option

Parameter # 32 - Stop Mode

Allows the user to program the SMC Flex controller for the type of sto

Parameter # 33 - Stop Time

This sets the time period which the controller will ramp th

Parameter # 44 - Overload Class

Allows the user to enter the desired Overload trip class for

Parameter # 45 - Service Factor

Allows the user to enter the Service Factor of

Parameter # 46 - Motor FLC

This is a user entered value that is needed so the device

Parameter # 47 - OL Reset Mode

This value allows the user to define how the overload can reset.

rameter # 107 - Aux1 Config

Pa

Auxiliary 1 contact is located at terminals 19 and 20 and

contact.

Parameter # 110 - Aux2 Config

Auxiliary 2 contact is located at terminals 29 and 30 and

contact.

Parameter # 108 - Aux3 Config

Auxiliary 3 contact is located at terminals 31 and 32 and

contact.

Parameter # 109 - Aux4 Config

Auxiliary 4 contact is located at terminals 33 and 34 and

contact.

Parameter # 115 - Parameter Mgmt

Allows the user the ability to recall all Factor

unit is connected.

controller will ramp the output voltage.

the motor. For IEC motors the typical value is 1.0. For NEMA

y default parameter values.

adjustable.

rting that best fits the application.

sets the initial reduced voltage output level for the

rrent that is applied for the

Input #1.

Input #2.

pping that best fits the application.

e voltage during a stopping maneuver.

the motor.

can provide proper motor Overload protection.

allows the user to configure the operation of the

allows the user to configure the operation of the

allows the user to configure the operation of the

allows the user to configure the operation of the

Standard, Pump Control, Brake Read Only

Line or Delta Line

0…10000 480

Soft Start, Current Limit, Full

Voltage, Linear Speed, Pump

Control

0…30 s 10

0…90% of locked rotor torque 70

50…600% FLC 350

0.0…2.0 s 0

of locked rotor torque 0

0…90%

Coast, Stop

Disable, Coast, Stop Option,

Fault, Fault NC, Network

Disable, Slow Speed, Dual Ramp,

Fault, Fault NC, Network, Clear

Fault

Soft Stop, Linear Speed, SMB,

Accu-Stop, Pump

0.0…120 s 0.0

Disable, 10, 15, 20, 30 10

0.01…1.99 1.15

1.0…2200 1.0

Auto, Manual Manual

Normal, Up-to-speed, Fault,

Alarm, Network Control, External

Bypass: (N.O./N.C.)

Normal, Up-to-speed, Fault,

Alarm, Network Control, External

Bypass: (N.O./N.C.)

Normal, Up-to-speed, Fault,

Alarm, Network Control, External

Bypass: (N.O./N.C.)

Normal, Up-to-speed, Fault,

Alarm, Network Control, External

Bypass: (N.O./N.C.)

Ready, Load Default Ready

Option Coast

Stop

Soft Start

Stop Op

Disable

Soft Stop

Normal

Fault

Alarm

Normal

tion

Page 13

SMC™ Flex Quick Start 13

Step 4 - Operation and Troubleshooting

Start Up Check List

1. Verify Input Supply voltage and wiring

2. Chec k output wiring

3. Chec k control wiring

4. App l y control power

5. Test local start/stop control

Monitoring

The SMC Flex controller has built in diagnostics and metering functions which can be accessed through a local or

remote LCD display.

Step Action

1 From any menu, Press Esc to get to the MAIN Device display.

2 If using the built in display, Press Enter and continue to step #3.

If using a remote HIM, first make sure that the SMC Flex is displayed by going to

MAIN MENU / DEVICE SELECT / SMC FLEX Press Enter and continue to step #3.

3 To View or Review the Metering Information

- Access the metering parameters by selecting PARAMETER / MONITORING / and then METERING. Press enter to view

any selected v

alue.

Viewing and Clearing Faults

Step Action

1 Press Esc to acknowledge the fault. The fault information will be removed so that you can use the HIM.

2 To View or Review the fault information

- Go to MAIN MENU / DIAGNOSTICS / FAULTS / VIEW FAULT QUEUE.

- Or look at parameters 124…128.

3 Address the condition that caused the fault. The cause mus

4 After corrective action has been taken, clear the fault by one of these methods:

- Press and Hold the ESC key for 3 seconds.

- Cycle control power to the device.

- Press Stop key on an External HIM.

- Program the SMC-Flex controller for a CLEAR FAULT, which can be found in MAIN MENU / DIAGNOSTICS / F

- Option Input #2 (terminal 15) can be configured to clear faults with the us

t be c

orrected before the fault can be cleared.

e of N.O. push button.

AUL

TS.

Page 14

14 SMC™ Flex Quick Start

Troubleshooting - Abbreviated Listing

For a complete list of fault codes and troubleshooting tips, refer to the SMC Flex User Manual.

Display Fault Fault Code Enabled Possible Causes Possible Solutions

Line Fault with

Phase Indication

Shorted SCR

Phas

e

with

indication

Open Gate with

Phase Indication

PTC Power Pole

and SCR

Overtemp

Motor PTC 12 running Motor ventilation blocked

Open Bypass

e

phas

with

indication

No Load Fault 16, 17, 18, 40 prestart

Line Unbalance 19 running Supply unbalance is greater than the user-programmed value

Overvoltage 20 running Supply voltage is greater than user programmed value

Undervoltage 21 running Supply voltage is less than user programmed value

Overload 22 running Motor overloaded

Underload 23

Jam 24 running Motor current has exceeded the user programmed jam level Correct source of jam or excessive loading

Stall 25 running Motor did not reach full speed by the end of the programmed

Phase Reversal 26 prestart

Network and

's Loss

Comm

Ground Fault 33 running Ground fault current level has exceeded programmed value

Power Loss with

phase indication

Line Loss with

phase indication

Internal 24V and

System Faults

1, 2, 3 prestart

4, 5, 6 all Shorted power module Check for shorted SCR, replace power module if necessary

7, 8, 9 start or

10, 11 Controller ventilation blocked

13, 14, 15 running Control voltage is low

running Broken motor shaft, belts, toolbits, etc..

30, 31, 32

27, 28, 29

35, 36, 37 start or

41, 42, 43 start or

44, 45, 46,

128…209

Missing supply phase

only

Motor not connected properly

Incoming 3-phase voltage instability

Open gate circuitry

op

Loose gate lead

st

Controller duty cycle exceeded

Fan failure

Ambient temperature limit exceeded

Failed thermistor

Motor duty cycle exceeded

PTC open or shorted

Inoperable power module bypass

Loss

ly

on

ly

on

all DPI network loss

op

st

op

st

all Low line c

of load side power wiring

Start command cycled unexpectedly with motor rotating

The delay time is too short for the application

The delay time is too short for the application

The delay time is too short for the application

Overload parameters are not matched to the motor

Pump cavitation

Incorrect user setting

ramp time

Incorrect user setting

Incoming

supply voltage is not in the expected ABC sequence Check power wiring, correct if necessary

Communication disconnection at the serial port

The delay time is too short for the application

Missing supply phase (as indicated)

Internal CT problem

Incoming 3-phase voltage instability or distortion

High impedance connection

ondition

Excessive load on

Check for open line (i.e., blown fuse)

Check for open load lead

Verify power quality

Perform resistance check; replace power module if necessary

Check gate lead connections to the control module

Check for proper ventilation

Check application duty cycle

Wait for motor to cool or provide external cooling

Replace power module or control module as needed

Replace fan

Check for proper ventilation

Check application duty cycle

Wait for motor to cool or provide external cooling

Check resistance of PTC

Check control voltage power supply

Replace power module

Check control module TB2…TB4 and TB5…TB7 for securness

Check Aux 1, 2, 3, 4 configurations are not set to External

Bypass

Check all load side power connections

Check motor windings

Check power system and correct if necessary

Extend the delay time to match the application requirements

Check power system and correct if necessary

Correct the user-programmed value

Extend the delay time to match the application requirements

Check power system and correct if necessary

Correct the user-programmed value

Extend the delay time to match the application requirements

Check motor overload condition

Check values for overload class and motor FLC

Verify current draw of the motor

Check pump system, machine drive components, and loading

Check settings

Repair or replace motor

Check programmed time value

Correct source of stall or excessive loading

Adjust SMC starting parameters to compensate for load

Check communication adapters and verify connection to SMC

Reconnect each DPI connected device

Check power system and motor; correct if necessary

Check programmed ground fault levels to match application

requirements

the delay time to match the application requirements

Extend

Check for open line (i.e., blown line fuse)

Replace power pole as indicated

Check supply voltage for capability to start/stop motor

Check for loose connections on line side or motor s

power wires

Verify and correct input power quality

Check the control power, verify it is within the specification

Check connections and grounding to the SMC control

terminals

Replace control module

ide of

Page 15

SMC™ Flex Quick Start 15

Repair Parts

Description SMC Rating

Part No.

For units rated 200…600V AC

➀

For units rated 690V

AC

100…240V AC 24V AC/DC 100…240V AC

Control Modules Standard All 41391-454-01-S1FX 41391-454-02-S2FX 41391-454-05-S1FZ

Pump All 41391-454-01-B1FX 41391-454-02-B2FX 41391-454-05-B1FZ

Braking 5…85 A 41391-454-01-D1AX 41391-454-02-D2AX 41391-454-05-D1AZ

108…251 A 41391-454-01-D1BX 41391-454-02-D2BX 41391-454-05-D1BZ

317…480 A 41391-454-01-D1CX 41391-454-02-D2CX 41391-454-05-D1CZ

625…780 A 41391-454-01-D1DX N/A 41391-454-05-D1DZ

970…1250 A 41391-454-01-D1EX N/A 41391-454-05-D1EZ

Part No. ➀

Description SMC Rating Series

Line Voltage

200…480V 200…600V 230…690V

Power Poles 5 A B 150-FPP5B ➁ 150-FPP5C ➁ N/A

25 A B 150-FPP25B ➁ 150-FPP25C ➁ N/A

43 A B 150-FPP43B ➁ 150-FPP43C ➁ N/A

60 A B 150-FPP60B ➁ 150-FPP60C ➁ N/A

85 A B 150-FPP85B ➁ 150-FPP85C ➁ N/A

108 A A 41391-800-01

135 A A 41391-800-03

➂ 41391-800-02 ➂ N/A

➂ 41391-800-04 ➂ N/A

108 A B 150-FPP108B ➁ 150-FPP108C ➁ 150-FPP108Z ➁

135 A B 150-FPP135B ➁ 150-FPP135C ➁ 150-FPP135Z ➁

201 A B

150-FPP201B 150-FPP201C 150-FPP201Z ➂

251 A B 150-FPP251B 150-FPP251C 150-FPP251Z

317 A B 150-FPP317B 150-FPP317C 150-FPP317Z

361 A B 150-FPP361B 150-FPP361C 150-FPP361Z

480 A B 150-FPP480B 150-FPP480C 150-FPP480Z

625 A B 150-FPP625B 150-FPP625C 150-FPP625Z

780 A B 150-FPP780B 150-FPP780C 150-FPP780Z

970 A B 150-FPP970B 150-FPP970C 150-FPP970Z ➂

1250 A B 150-FPP1250B 150-FPP1250C 150-FPP1250Z

Heatsink Fans 5…85 A B 41391-801-03

108…135 A B 41391-801-03

201…251 A B 41391-801-01

317…480 A B 41391-801-02

625

110/120V AC

ower

Control P

230/240V AC

…1250 A B 41391-801-04

…1250 A B 41391-801-05

625

Control Power

Base Plate 201…251 A B 41391-803-01

317…480 A B 41391-803-02

By-Pass

Contactor ➃

110/120V AC

Control Power

230/240V AC

Control Power

625…780 A B 100-D180ED11

970…1250 A B 100-D420ED11

…780 A B 100-D180EA11

625

970…1250 A B 100-D420EA11

➂

➂

➂

➂

➂

➂

➂

One piece provided per part number.

➀

➁ Three-phase power pole structure provided per part no.

➂ One-phase power pole provided per part no.

➃ Refer to Appendix D in the SMC Flex User Manual, for installation instructions.

Page 16

Publication 150-QS001G-EN-P — August 2008 40055-217-01 (7)

Superecedes Publication 150-QS001F-EN-P — November 2006 Copyright ©2008 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.

Loading...

Loading...