Page 1

Installation Instructions

Bulletin 1405 (M620) Operating Instructions

Overview

The MiniPowermonitor (1405-M620) measures all the important

parameters of 3-phase power lines in low-voltage AC power

applications. The measurements are indicated on a 3-line display, one

parameter at time, either by auto-sequencing or by manual access.

There are 6 parameter groups:

• Line-to-line voltages

• Line-to-neutral voltages

• Instantaneous, time-averaged and peak currents

• Real power per phase, apparent power per phase, total real and

apparent power, and 3-phase power factor

• Power factor (Cos φ) per phase

• Net real energy: per phase and total for all 3 phases

Phase voltages are monitored continuously for under- and

over-voltage conditions, and when such a condition is detected, an

alarm relay is activated. Energy units are also transmitted as relay

pulses. Relay contacts are connected via rear panel terminal points.

Measured values for each of the 3 phases are indicated simultaneously

on bright red 7-segment LED displays, 14 mm high, arranged in 3

horizontal lines of 5 digits each. The displayed values can be easily

read even in high ambient light conditions, at substantial viewing

distances, and at acute viewing angles.

The left-most 7-segment digit on each of the three lines functions as a

limited alphanumeric indicator. These digits, along with the LED status

lamps on the right of the instrument front panel, indicate either which

measurement parameter is being displayed at any instant, or the

set-up status.

The instrument is operated through three key-switches (‘-’, ‘F’, and ‘+’)

arranged in a row at the bottom right of the front panel. These keys

are used for instrument set-up, and for manual selection of displayed

measurements. Different functions are selectable using the function

(‘F’) key-switch, by keeping it pressed for varying lengths of time. The

left-most character of the lowest display line indicates the selected

function.

1 Publication 1405-IN002C-EN-P - November 2004

Page 2

2 Bulletin 1405 (M620) Operating Instructions

External connections to the instrument are terminated on plug-in

connector blocks with spring-clamp wire terminals, at the rear of the

instrument. Phase voltage connections are terminated on a 7-pin

connector block. Another 12-pin connector block is used for the

current transformer inputs, and alarm and energy pulse relay outputs.

The instrument’s operating power supply is drawn from a separate

120V or 240V ac power supply input, through an additional 3-pin

connector block. An optional 400V or 480V version of the unit is

available with operating power drawn from two of the phase voltage

input lines (L1 - L2). Therefore the M620 can be used with either

3-wire (3 phase) or 4-wire (3 phase and neutral) power systems.

The M620 is a compact instrument, with a 96 x 96 mm front panel,

and a depth of approximately 85 mm.

Installation

Only qualified personnel should install and wire this equipment. Refer

to the following safety guidelines prior to installation.

ATTENTION

Only qualified personnel, following accepted safety

procedures, should install and wire the

MiniPowermonitor. Before beginning any work,

disconnect all sources of power and verify that they

are de-energized and locked out. Failure to follow

these instructions may result in personal injury or

death, property damage or economic loss.

ATTENTION

Never open a current transformer (CT) secondary

circuit with primary current applied. Wiring between

the CTs and the MiniPowermonitor should include a

shorting terminal block in the CT secondary circuit.

Shorting the secondary with primary current present

allows other connections to be removed if needed.

An open CT secondary with primary current applied

produces a hazardous voltage, which can lead to

personal injury, death, property damage or economic

loss.

Publication 1405-IN002C-EN-P - November 2004

Page 3

Bulletin 1405 (M620) Operating Instructions 3

1. Install your module within a suitable enclosure. Make sure the

enclosure provides adequate clearance for ventilation and wiring

of the module.

Refer to Dimensions on page 20 for dimensions and spacing

guidelines for the MiniPowermonitor.

2. Determine your wiring mode and install wiring between the

MiniPowermonitor and your power system.

Refer to Electrical Connections on page 3 for more information.

3. Configure the instrument settings to match those used in your

power system connections.

Refer to Instrument Set-Up on page 14 for more information.

Grounding

Electrical Connections

MiniPowermonitors do not need to be grounded because of the

isolated enclosures. Follow all local requirements for grounding of PT

and CT secondaries.

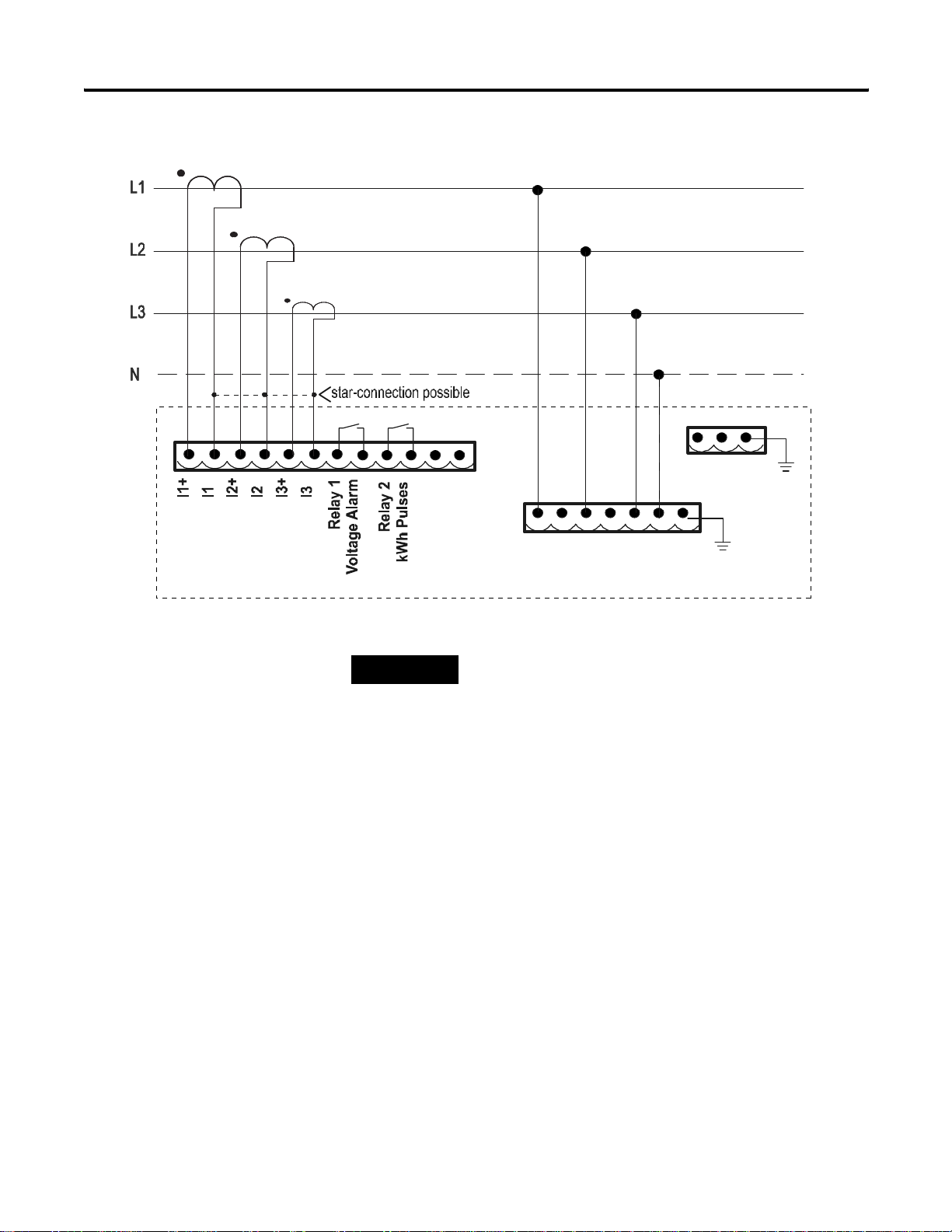

Electrical connections are terminated on two plug-in connector blocks

with spring-clamp wire terminals, at the rear of the instrument. These

connector blocks, 7- and 12-pin respectively, can accept wire sizes

from 28 to 14 AWG (0.08 to 2.5 sq.mm).

Publication 1405-IN002C-EN-P - November 2004

Page 4

4 Bulletin 1405 (M620) Operating Instructions

-

Current Inputs

M620

-

-

L1

GND

Aux. Supply

(120V or 240V only)

L2

NCNCL3

NNGND

TIP

L1

Voltage Inputs

Pins 2 and 4 (counting from the left side) of the 7-pin

connector are not used: no external wires should be

connected to these terminals!

CT Connection: Careful consideration should be given when

connecting the secondary of the CT to the current inputs of the

MiniPowermonitor. Extended lengths of connection wire will cause

the VA rating of the CT to increase and will create higher common

mode input voltage. It is recommended that the wire size be selected

to limit the impedance to 200 milliohms. Exceeding this limit may

cause current readings to become less accurate when using a star

connection.

Publication 1405-IN002C-EN-P - November 2004

Aux Supply: With this option, instrument power is supplied by a

separate 120V or 240V line, independent of the measured power lines.

A third connector block (3-pin, spring-clamp terminals type) is added

at the rear with this option.

Page 5

Bulletin 1405 (M620) Operating Instructions 5

IMPORTANT

Units are rated 120V or 240V but not both. A 120V

unit will not accept 240V, and a 240V unit will not

accept 120V.

A unit with the 120V supply option is not designed to operate on

240V or any other voltage. Likewise, a unit with the 240V supply

option is not designed to operate on 120V or any other voltage. Units

designed for 400V and 480V operation do not have an auxiliary

supply connection and receive power from the measurement line.

Ensure that each unit is properly supplied with a power source that

matches the voltage designation of your unit.

Relay Output Connections

Alarm and energy pulse relay contact connections are made to the

spring-clamp wire terminals on the 12-pin connector block, as

follows:

Table 1 Alarm and Energy Pulse Relay Contact Connections

Measurement Operations

Alarm: Terminals 7 - 8

Energy pulses: Terminals 9 - 10

Immediately after the instrument is switched on, the software version

is first displayed for 8 seconds, after which the measured values are

displayed. The measured parameter that is displayed when the

instrument is switched on will be the main displayed parameter group

that was on display when the instrument was switched off. This will

happen regardless of whether the instrument was in the “constant

parameter” or auto-sequencing display mode at that time the

instrument was switched off.

In the “constant parameter” display mode, any one of the 6 parameter

groups can be manually selected, by forward or backward sequential

stepping, using the “+” or “-“keys. Only that parameter will be

displayed, until another parameter is manually selected, or the

instrument is switched to auto-sequencing display mode. Some of the

parameter groups (current, power, and energy) have a main displayed

parameter and also additional parameters within the same group. The

additional parameters can be accessed when the instrument is

displaying the main parameter of that group. For example, when the

instrument is displaying current measurements, the main parameter

Publication 1405-IN002C-EN-P - November 2004

Page 6

6 Bulletin 1405 (M620) Operating Instructions

displayed is instantaneous phase currents, while the additional

parameters are time-averaged phase currents and peak phase currents.

For power measurements, the main parameters displayed are real

power for each phase. The additional parameters in this group are

apparent power of each phase, total real and apparent power, and

3-phase power factor. When the instrument is displaying the main

parameter of a group, the additional parameters within that group can

be scrolled using the “F” key.

Measurement Modes

The functions of the instrument are accessed as follows:

Table 2

Key Function

Indication

“+” Skip to the next measured parameter Short

Auto-sequencing display mode: enable /

disable

Re-set average and peak values - “c” Very long

“F” Sequentially display one parameter type: e.g.,

current

Enter set-up mode Very long

“-“ Go back to the previous displayed parameter

- “r” Long

Key Press

Duration

Short

The instrument measures voltage and current for each of three phases

in an alternating sequence of 2 seconds each. This corresponds to the

integrating time of the A/D converter circuits. At the same time, the

values of power, power factor (Cos f), and energy consumption are

computed. The energy value is computed for each phase over the

integration period, and the accumulated values are stored in memory.

The measured voltage values are continuously evaluated for over- and

under-voltage occurrences, and the energy transfer rate is converted

to an output pulse rate. Voltage limit alarms and energy unit pulses

are transmitted by relay contacts.

Publication 1405-IN002C-EN-P - November 2004

In the auto-sequencing displayed mode, the displayed parameter

change every 6 seconds. The user can halt the auto-sequencing of

displayed parameters, so that one desired parameter is displayed

continuously. Independent of the sequencing mode, the measured

values are updated and displayed in 2-second intervals.

Page 7

Bulletin 1405 (M620) Operating Instructions 7

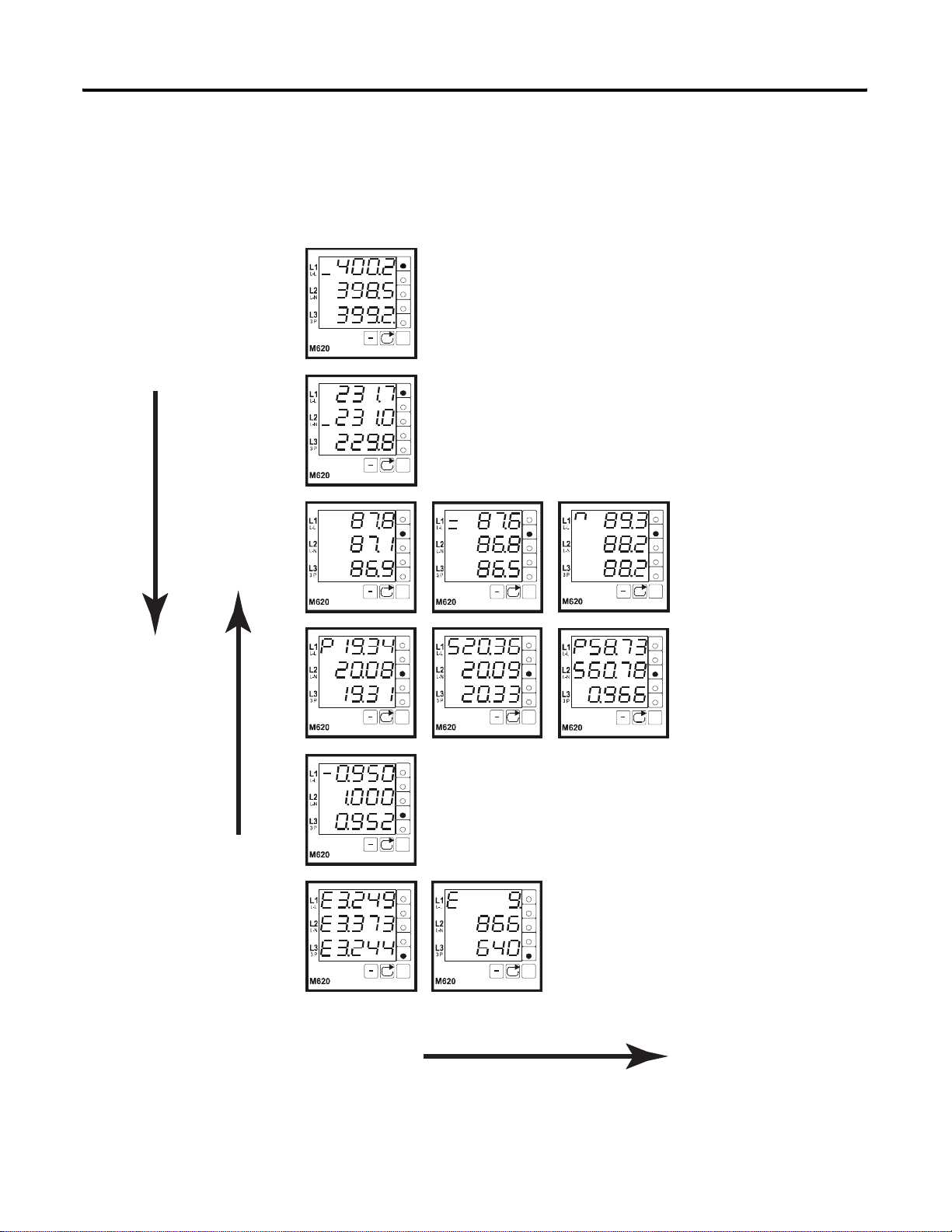

The measured values of the electrical parameters are available with six

analog retransmission outputs (4-20 mA) (optional). Details of these

analog outputs are found on

V

Line-to-line voltage

A

L1-L2

P

L2-L3

cos

ϕ

L1-L3

E

F

+

page 22.

"+" Key

Scrolls Down

"-" Key

Scrolls Up

Line-to-neutral voltage

V

A

L1-N

P

L2-N

cos

ϕ

L1-N

E

F

+

V

A

P

cos

ϕ

E

F

+

V

A

P

cos

ϕ

E

F

+

V

A

P

cos

ϕ

E

F

+

V

A

P

cos

ϕ

E

F

+

V

Left:

A

Instantaneous current

P

Middle:

cos

ϕ

Time-averaged current

E

+

V

A

P

cos

ϕ

E

+

Right:

Peak current

Left:

Real power

Middle:

Apparent power

Right:

Total real power

F

F

Total apparent power

V

A

Power factor (Cos φ)

P

L1

cos

ϕ

L2

E

F

L3

+

3-phase power factor

V

A

P

cos

ϕ

E

F

+

V

A

P

cos

ϕ

E

F

+

"F" Key Scrolls Right

Left

Net real energy

L1

L2

L3

Right:

Total net real energy

Publication 1405-IN002C-EN-P - November 2004

Page 8

8 Bulletin 1405 (M620) Operating Instructions

Auto-Sequencing Display Mode

In this display mode, the instrument automatically switches the

displayed values from one parameter group to the next, at intervals of

6 seconds, cycling continuously through all 6 parameter groups.

Any of the additional parameters can be selected instead of the main

parameter. Thereafter only the selected additional parameter will be

displayed when the turn of that parameter group comes up during

display sequencing. For example, if time-averaged phase currents are

selected in the current (I) parameter group, only these values will be

displayed when it is the turn of this group during auto-sequencing.

Irrespective of the specific parameter selected for display within each

group, the total period of the display cycle for the 6 parameter groups

remains constant.

Line-to-neutral voltages and line-to-line voltages are treated as

separate parameter groups, so that both these parameters are always

displayed during auto-sequencing.

Analog Outputs

Examples of all the parameter displays, and parameters grouping, are

illustrated on the next page.

The M620 is also available with six analog retransmission outputs.

These outputs can be user programmed for 0-20 mA or 4-20 mA, and

assigned to any of the measured power-line measured variables.

These outputs are electrically isolated from the rest of the instrument’s

circuits. Each output has a positive polarity. A common return line at 0

V potential is used for all analog outputs. Each output can drive a load

of up to 250 ohms, with output voltage of up to 5V dc. These outputs

may be connected in parallel.

Configure the analog outputs during instrument setup. The following

key sequences and indications apply during setup.

The “-” key scrolls through the parameters that may be assigned as a

0 to 20 mA output:

VVoltage P-P

nVoltage P-N

I Current instantaneous

= Current time average

Preal power

S apparent power

C cos phi (power factor)

Publication 1405-IN002C-EN-P - November 2004

Page 9

Bulletin 1405 (M620) Operating Instructions 9

If you continue scrolling the list repeats with a “4” appearing in the

line above the parameter indicator to designate a 4 to 20 mA output.

Analog Output Connections

Connections to all analog outputs (1 to 6, depending on the option)

are made via a 9-pin D-sub connector. The female socket is on the

rear panel. A matching male connector with a patch cable is used for

external connections. Pin assignments are as follows:

Table 3

Output Pin Output Pin

Output 1 Pin 1 Output 2 Pin 2

Output 3 Pin 3 Output 4 Pin 4

Output 5 Pin 5 Output 6 Pin 6

Output GND Pins 7, 8, 9

Scaling of Measured Parameters

Analog outputs selected as voltages (‘V’ or ‘n’) provide a linear

measurement range centered around the nominal value of the

line-to-line (V

nominal

) or line-to-neutral 3V

respectively. This diagram depicts the scaling of line-to-line voltage.

Max

50%

Output current

Min

50% 75% 100% 125% 150%

Voltage, per cent of V

nominal

•() voltage,

nominal

Publication 1405-IN002C-EN-P - November 2004

Page 10

10 Bulletin 1405 (M620) Operating Instructions

Analog outputs selected as ‘I’, ‘=’, ‘P’ or ‘S’ provide a linear

measurement scaled from zero to the full-scale value as configured by

the V

nominal

and I

nominal

settings.

Refer to Table 4 and Table 5 for more information.

With the output range set to 0 to 20 mA, the relationships are:

Table 4

Line-to-line voltages (V

L-L

)

10 mA V V

⁄()1–()4 10 mA••+

nom

for 0 to 20 mA Range

Line-to-neutral voltages (V

for 0 to 20 mA Range

Currents

Power (per phase)

Total power

Power factor

)

L-N

10 mA 3() VV

20 mA I I

20 mA PX V

20 mA P V

10 mA 10 mA 1 Cos f–()0.5 (capacitive⁄()•+

10 mA 10 mA 1 Cos f–()0.5 (inductive⁄()•–

ڥ

⁄()1–()4 10 mA•••+

nom

nominal

nominal

nominalInominal

3I

•⁄()⁄•

nominal

3••()⁄•

With the output range set to 4 to 20 mA, the relationships are:

Table 5

Line-to-line voltages (V

Line-to-neutral voltages (V

L-L

)

4 mA 8 mA V V

)

L-N

4 mA 8 mA 3() VV

⁄()1–()48 mA••++

nom

⁄()1–()48 mA•••++

nom

Publication 1405-IN002C-EN-P - November 2004

Currents

Power (per phase)

Total power

Power factor

4 mA 16 mA I I

4 mA 16 mA PX V

20 mA P V

4 mA 8 mA 8 mA 1 Cos f–()0.5 (capacitive)⁄•++

4 mA 8 mA 8 mA 1 Cos f–()0.5 (inductive)⁄•–+

ڥ+

nominal

nominalInominal

nominal

3I

•⁄()⁄•+

3••()⁄•

nominal

Page 11

Bulletin 1405 (M620) Operating Instructions 11

Modbus Communications

The M620 is available with an RS-485 half-duplex communications

port which supports Modbus RTU slave protocol version 1.0. The

following Modbus commands are supported:

03 (0x03) Read Holding Registers

16 (0x10) Write Multiple Registers

43 (0x2B) Read Device Identification

The port may be configured during instrument setup. The baud rate

may be set to 9.6 K or 19.2 K bits per second. The Modbus address

may be set in the range 1 to 257.

The M620 equipped with Modbus includes 2 LEDs which display

Modbus status and Network status.

Modbus Port Connections

Connections to the Modbus port are made via a 3-pin connector as

shown below:

1

2

3

IMPORTANT

Rx Tx-

Grd

Rx Tx+

Terminating resistors are not included in the M620. If

needed, terminating resistors must be provided and

installed by the user.

Modbus Memory Map

The tables below provide a cross-reference of Modbus register

address to metered value along with data type.

Publication 1405-IN002C-EN-P - November 2004

Page 12

12 Bulletin 1405 (M620) Operating Instructions

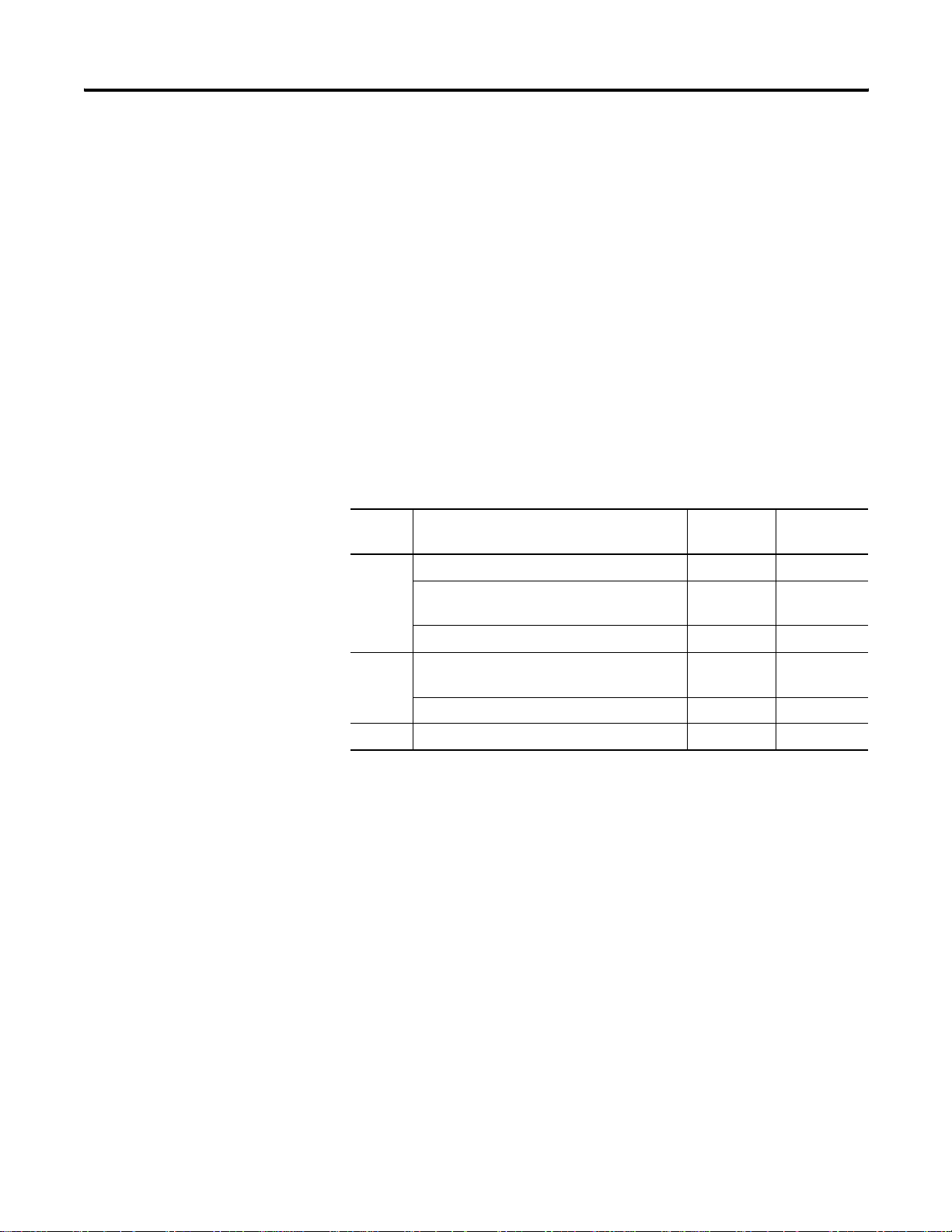

Table 6 Modbus Memory Map

Register Byte Low Metered Value Data Type

0 0 L1-N voltage WORD

1 2 L2-N voltage WORD

2 4 L3-N voltage WORD

3 6 L1-L2 voltage WORD

4 8 L2-L3 voltage WORD

5 10 L3-L1 voltage WORD

6 12 I1 WORD

7 14 I2 WORD

8 16 I3 WORD

9 18 I1 peak WORD

10 20 I2 peak WORD

11 22 I3 peak WORD

12 24 I1 average WORD

13 26 I2 average WORD

14 28 I3 average WORD

15 30 Cos1 (power factor) WORD

16 32 Cos2 WORD

17 34 Cos3 WORD

18 36 P1 real power DWORD

19 38

20 40 P2 real power DWORD

21 42

22 44 P3 real power DWORD

23 46

24 48 S1 apparent power DWORD

25 50

26 52 S2 apparent power DWORD

27 54

28 56 S3 apparent power DWORD

29 58

30 60 E1 real energy DWORD

31 62

32 64 E2 real energy DWORD

Publication 1405-IN002C-EN-P - November 2004

33 66

Page 13

Bulletin 1405 (M620) Operating Instructions 13

Table 6 Modbus Memory Map

Register Byte Low Metered Value Data Type

34 68 E3 real energy DWORD

35 70

36 72 Total Power DWORD

37 74

38 76 Total Energy DWORD

39 78

40 80 Status/Alarm WORD

41 82 Baud/Address WORD

42 84 Diagnostic 0 WORD

43 86 Diagnostic 1 WORD

44 88 Diagnostic 2 WORD

45 90 Diagnostic 3 WORD

46 92 Diagnostic 4 WORD

47 94 Diagnostic 5 WORD

48 96 Diagnostic 6 WORD

49 98 Diagnostic 7 WORD

80 100 Under Voltage WORD

81 102 Over Voltage WORD

82 104 Control WORD

Notes:

• Registers 0 to 35 contain the named measured values.

• Registers 18 to 39 represent values as 32 bit DWORD.

• Registers are organized as “big-Endian”, with first the high-Byte

and then the low-Byte. The transferred bytes are not in a rising

sequence, but the higher register follows after the lower register.

• Register 40 returns the status of device M620 and status

over/under voltage alarm.

• Register 41 returns the node address and baud rate.

• Registers 42 to 49 return diagnostic registers per the Modbus

specifications.

• Registers 80 and 81 are read/write registers for over/under

voltage parameter.

• Register 82 is a read/write register for control of M620 functions:

reset I peak, reset E-Counter.

Publication 1405-IN002C-EN-P - November 2004

Page 14

14 Bulletin 1405 (M620) Operating Instructions

Instrument Set-Up

For instrument set-up, numeric values are entered in one of two ways.

For some setting, a continuously variable value is to be entered. In

this case, the right-most digit of the display line blinks when a

numeric value is to be altered. The value of each digit is changed in

succession.

Table 7

Key Description

“+” key: Scrolls a value of the currently

blinking digit, from 0 through 9

“-“key: Shifts to the next digit

“F” key: Leaves the currently displayed

value, and skips to the next setting

For other settings, a specific value is to be selected from a

pre-programmed list of values. Digits do not blink, in this case.

Table 8

Key Description

“+” key: Scrolls to the next higher value, of a

list of fixed values

“-“key: Scrolls to the next lower value, of a

list of fixed values

“F” key: Leaves the currently displayed

value, and skips to the next setting

To enter into setting mode, the “F” key is kept pressed for 2.4

seconds, while the instrument is switched on. When this is done, the

displays are initially unlit for a few seconds, and then the setting mode

prompt (“PArA”), and the software version number are displayed.

When the “F” key is released, the prompt for the first setting

parameter appears: “Uno”, which is the prompt for nominal voltage

range selection.

Publication 1405-IN002C-EN-P - November 2004

Page 15

Bulletin 1405 (M620) Operating Instructions 15

V

A

P

cos

E

F

+

V

A

P

cos

E

F

+

Begin settings

Indicates software version

ϕ

Select nominal voltage

ϕ

Repeatedly pressing the “F” key causes the prompts for the other

parameters to be displayed in succession. If the settings are to be

selected from a limited number of fixed values (e.g. the initial values

of the energy counters, or the analog retransmission output ranges)

only index characters are displayed.

Publication 1405-IN002C-EN-P - November 2004

Page 16

16 Bulletin 1405 (M620) Operating Instructions

V

Set undervoltage alarm voltage limit

A

Range: 000.0 to 650.0 volts

P

cos

ϕ

E

F

+

Set overvoltage alarm voltage limit

V

A

Range: 000.0 to 650.0 volts

P

cos

ϕ

E

F

+

Select primary current transformer value.

V

A

Selectable values: 1, 2.5, 5, 10, 15, 20,

P

25, 30, 40, 50, 60, 75, 80, 100, 125, 150,

cos

ϕ

200, 250, 300, 400, 500, 600, 750, 800,

E

F

1000, 1200, 1250, 1500, 1600, 1800,

+

2000, 2500, 3000, 4000 amperes

V

Select current transformer output

A

range 1A or 5A

P

cos

ϕ

E

F

+

V

A

P

cos

ϕ

E

F

+

V

Select the energy pulse output rate

A

Selectable values: 0.00, 0.01, 0.10,

P

cos

ϕ

1.00, 10.0, 100 kWh/pulse

E

No pulse output if vale 0.00 is

selectable

F

+

V

A

P

cos

ϕ

E

F

+

V

A

P

cos

ϕ

E

F

+

V

Similarly for analog

A

outputs A3 through

P

cos

ϕ

A6s

E

F

+

V

Set initial energy counter values

A

Range: 0000.000 to 0999.999 Mwh

P

cos

ϕ

When the value reaches 1000.000 Mwh,

E

the energy counter resets to zero. Overflow

F

+

condition is indicated by “c”.

Assign optional analog outputs to

measure parameters:

“-” key: V, n, l, =, c

“+” key: V, n, I, +, P, S, c

“F” key: A1 to Ax

Analog output range:

Left: 0 to 20 mA

Right: 4 to 20 mA

Publication 1405-IN002C-EN-P - November 2004

Page 17

Bulletin 1405 (M620) Operating Instructions 17

V

A

P

cos

ϕ

E

F

+

V

A

P

cos

E

F

+

Address: 1 to 257

Baud Rate: 9.6 or 19.2

kbaud

ϕ

The changed setting values are stored only when a password code is

entered. The default password code is “3136”. After all the setting

parameters are stepped through, the prompt “PASS” is displayed. If no

password code or a wrong password code is entered, the instrument

will exit the setting mode without storing any changes to the previous

settings.

V

Enable storage of changed settings

A

P

cos

ϕ

Enter the password code

E

F

+

V

Store the changed settings

A

P

cos

ϕ

E

F

+

Display Functions

V

Settings done

A

P

cos

ϕ

E

F

+

The following display related functions are described below.

• Version indication

• Under- and overvoltage alarm indication

• Enabling / disabling the auto-sequencing display mode

• and re-setting peak values

• Re-set energy counters

Version indication: The software version of the instrument is

indicated by this display, which determines the features and functions

Publication 1405-IN002C-EN-P - November 2004

Page 18

18 Bulletin 1405 (M620) Operating Instructions

built into the instrument. This number should be stated if and when

information or technical assistance is requested relating to this

instrument.

V

Version number displayed at start

A

P

cos

ϕ

E

F

+

Under- and overvoltage alarm indication: If any of the phase

voltages cross either of the user-programmed undervoltage or

overvoltage limits, not only is the alarm relay activated, but also the

alarm condition is indicated on the instrument display panel. An

undervoltage condition causes the character “u” to blink in the

left-most digit position to the left of the corresponding phase voltage

display. An overvoltage condition is similarly indicated by the blinking

character “o”. These alarm indications are independent of the

measuring range.

V

A

P

cos

ϕ

E

F

+

F

Under and overvoltage alarm

V

indication

A

P

cos

ϕ

E

+

Enabling / disabling the auto-sequencing display mode and

re-setting peak values: The “+” key has three functions, depending

on the duration for which this key is pressed, and indicated by a

function character at in the bottom left digit position. These functions

are selected sequentially when this key is kept pressed for different

durations.

Publication 1405-IN002C-EN-P - November 2004

Page 19

Table 9

Bulletin 1405 (M620) Operating Instructions 19

Key

Function Function

Key Press Duration

Indication

Switch

“+” Skip to the next measured parameter Approx. 0 to 2 seconds

Auto-sequencing display mode: enable / disable - “r” Approx. 2 to 4 seconds

Re-set peak current values - “c” Approx. 4 to 8

seconds

V

A

P

cos

E

F

+

Auto-sequencing display

enabled/disabled

ϕ

The display can be manually skipped to the next measured parameter

in the sequence, regardless of whether the auto-sequencing display

mode is enabled or disabled. Similarly, the stored peak current values

can be deleted at any time.

V

A

P

cos

E

F

+

Reset peak current value

ϕ

The setting of the initial values of the energy counters can be used for

simply resetting any of them to zero, while the instrument is in set-up

mode. To do this, first the “-“key is used to shift the digit to the

left-most position. Then the “+” key is pressed to scroll the digit from

0 upward, until the function character “c” appears in the bottom left

digit position. Since the counter capacity is limited to 0999.999 MWh,

when it reaches 1000.000 MWh, it causes the counter to overflow,

automatically resetting it to 0000.000 MWh. This value is then locked

and stored by pressing the “F” key. Energy counting then starts from

0000.000 MWh. This setting is to be done for all three energy counters

separately.

Publication 1405-IN002C-EN-P - November 2004

Page 20

20 Bulletin 1405 (M620) Operating Instructions

Reset energy counter

V

A

P

cos

ϕ

E

F

+

Dimensions

Specifications

Panel cut-outs should be 92 x 92 mm (3.6 x 3.6 in).

Table 10 Measured Parameters

Parameter Value

Voltage, RMS (Vrms) V

Instantaneous current

Average current (15 min.)

Peak current

/ V

L1-L2

L2-L3

V

/ V

L1-N

L2-N

IL1, IL2, I

L3

IL1=, IL2=, I

L3

IL1^, IL2^, IL3^

/ V

=

/ V

L3-L1

L3-N

Publication 1405-IN002C-EN-P - November 2004

Real power PL1, PL2, P

Apparent power SL1, SL2, S

L3

L3

Total power (P, S, 3-Phase Power Factor) PS, SS, PS/SS (power factor)

Power factor (Cos φ) Cos

Net real energy, per phase energy, total

, CosL2, Cos

L1

EL1, EL2, EL3, E

L3

S

energy

Energy counter range per phase 1000.000 MWh

Measuring rate Approx. 0.5 measurements / second

Update time 2 seconds

Page 21

Table 11 General Parameters

Parameter Value

Bulletin 1405 (M620) Operating Instructions 21

Input impedance Voltage input, per

2 Mohm

phase

Input load Current, 1A and 5A 0.02 ohm

Nominal voltage per catalog number version

Units with separate 120V or 240V supply: 600V

Units powered from 400V measurement line: 400V

Units powered from 480V measurement line: 480V

Nominal current input 1 A or 5 A

Overload current rating Nominal

2 x, continuous

current input 5A

Temperature coefficient < 0.01% / K

Temperature - Operating +5 to +50°C (+41 to +122°F) (ambient)

Temperature - Storage -20 to +70°C (-4 to +158°F)

Frequency range 47 to 63 Hz

Power consumption Approx. 3 W

Weight Approx. 0.3 kg

Front dimensions 96 x 96 mm

Breakdown rating Per DIN 41700

Panel insertion depth 85 mm

Panel mounting fasteners Screw clamps

Panel cutout dimensions 92 mm x 92 mm +/- 0.8 mm

Spacing between cutouts 4 mm (minimum), 20 mm (typical)

Protection class Enclosure IP 20

(IP 65 with optional protective hood

(1)

)

Terminals IP 00

Agency Certifications UL, CE

(1)

The optional hood, catalog number 1405-PRO, can be ordered separately. Contact your Rockwell Automation

distributor for additional information.

Table 12 Digital Displays

Typ e 7-segment LED, red

Lines x characters 3 x 5

Character height 14 mm

Publication 1405-IN002C-EN-P - November 2004

Page 22

22 Bulletin 1405 (M620) Operating Instructions

Table 13 Relay Outputs

Alarm Logic: contacts open on alarm

Energy pulses Contacts close: 128 ms / 128 ms

Energy pulse output rate Selectable: 0.01, 0.10, 1.00, 10.0, 100

kWh/pulse (0.0 disables)

Contacts rating Voltage 250Vac; 220V dc

Load: 60 VA; 60 W

Table 14 Measurement Accuracy and Range

Parameter Percent of Reading Nominal Value Operating Range Maximum Limit

Volts ±1% 240V rms 10V rms to 347V rms L-N or

17V rms to 600V rms L-L

Current ±1% 5 Amps 0.1 Amps to 8 Amps 10 Amps

Power and Energy ±2% n/a n/a n/a

Power Factor ±0.2% n/a n/a n/a

400V rms L-N or

690V rms L-L

Product Approvals

Table 15 Modbus Communications

Port specifications RS-485, 2-wire, half-duplex

Protocol Modbus RTU slave

Data Rate 9.6 or 19.2 Kbaud, selectable

Isolation 500 Vac, tested 1 kV ac

UL/CUL

cULus Listed, File E96956, per UL508, the Standard for Industrial

Control Equipment.

CE Certification

If this product bears the CE marking, it is approved for installation

within the European Union and EEA regions. It has been designed to

meet the following directives.

Publication 1405-IN002C-EN-P - November 2004

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards, in

whole, documented in a technical construction file:

Page 23

Bulletin 1405 (M620) Operating Instructions 23

• EN 50081-2 - Generic Emission Standard, Part 2 - Industrial

Environment

• EN 61000-6-2 - Generic Immunity Standard, Part 2 - Industrial

Environment.

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low

Voltage, by applying the safety requirements of EN/IEC 61010-1.

This equipment is classified as open equipment and must be installed

(mounted) in an enclosure during operation as a means of providing

safety protection.

International Standard IEC 529 / NEMA / UL 508 Degree of

Catalog Number Explanation

Protection

The MiniPowermonitor is rated as IP10 degree of protection per

International Standard IEC 529. It is considered an open device per

NEMA and UL 508.

1405-M620-400-420

Bulletin Number

1405 = MiniPowermonitor

1

- 120V and 240V connections are via a separate

connection

2

- 400V and 480V connections are via the measurement line

3 - M620 current is 1A / 5A programmable

Device Category

M620 = Power and

Energy Meter

Power Supply

Voltage

No Designator =

120V 60 Hz

120 = 120V 60 Hz

240 = 240V 60 Hz

480 = 480V 60 Hz

400 = 400V 50 Hz

Data Output

420 = Analog Output

Option (480V model 2

1

outputs, all others have

6 outputs)

1

485 = RS485 port with

2

Modbus protocol

2

No Designator = Relay

and Pulse Output only

3

Publication 1405-IN002C-EN-P - November 2004

Page 24

Rockwell Automation Support

Rockwell Automation provides technical information on the web to assist you in using our products. At

http://support.rockwellautomation.com, you can find technical manuals, a knowledge base of FAQs, technical and

application notes, sample code and links to software service packs, and a MySupport feature that you can customize

to make the best use of these tools.

For an additional level of technical phone support for installation, configuration and troubleshooting, we offer

TechConnect Support programs. For more information, contact your local distributor or Rockwell Automation

representative, or visit http://support.rockwellautomation.com.

Installation Assistance

If you experience a problem with a hardware module within the first 24 hours of installation, please review the

information that's contained in this manual. You can also contact a special Customer Support number for initial help

in getting your module up and running:

United States 1.440.646.3223

Monday – Friday, 8am – 5pm EST

Outside United States Please contact your local Rockwell Automation representative for any technical support issues.

New Product Satisfaction Return

Rockwell tests all of our products to ensure that they are fully operational when shipped from the manufacturing

facility. However, if your product is not functioning and needs to be returned:

United States Contact your distributor. You must provide a Customer Support case number (see phone number

above to obtain one) to your distributor in order to complete the return process.

Outside United States Please contact your local Rockwell Automation representative for return procedure.

Publication 1405-IN002C-EN-P - November 2004 24 PN 40055-220-01(3)

Supersedes Publication 1405-IN002A-EN-P - July 2003 Copyright © 2004 Rockwell Automation, In c. All rights reserved. Printed in the U.S.A.

Loading...

Loading...