Page 1

Installation Instruction

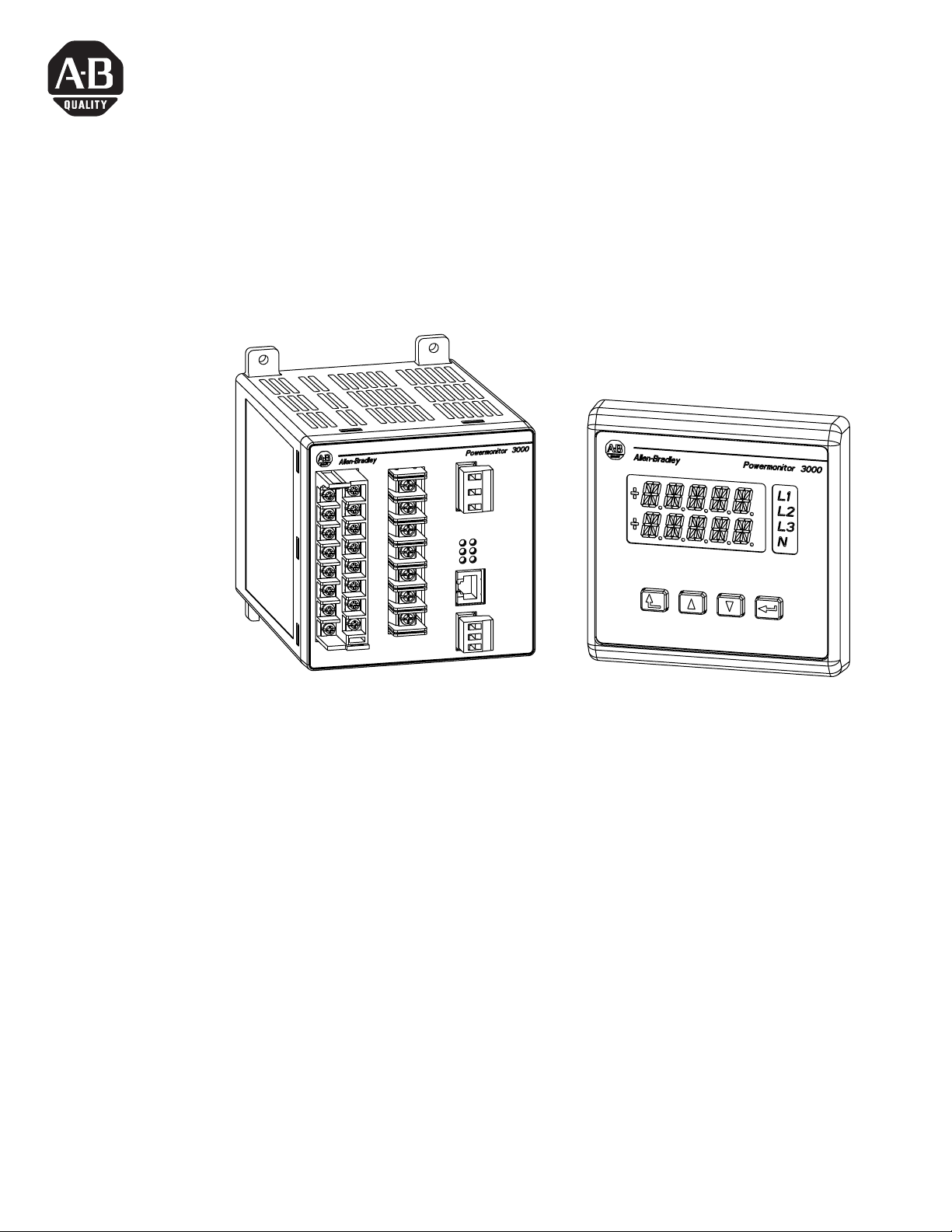

Powermonitor 3000

(Catalog Numbers: 1404-M4, 1404-M5, 1404-M6, 1404-M8)

Inside. . .

Important User Information............................................................... 2

European Communities (EC) Directive Compliance ........................3

Using This Installation Instruction ....................................................4

Safety Considerations.........................................................................6

Product Description...........................................................................7

Master Module....................................................................................8

Display Module ................................................................................ 10

LED Indicators.................................................................................. 11

Quick Start Guidelines.....................................................................15

Installation........................................................................................15

System Accuracy Considerations.....................................................17

Wiring ............................................................................................... 19

Wiring Diagrams ..............................................................................23

Communication Wiring....................................................................38

Maintenance .....................................................................................51

Catalog Number Explanation .......................................................... 55

Dimension Drawings ....................................................................... 56

Product Approvals ........................................................................... 57

Technical Specifications................................................................... 59

1 Publication 1404-IN007D-EN-P - October 2004

Page 2

2 Powermonitor 3000

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (Publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://www.ab.com/manuals/gi) describes some important differences

between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for

solid state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is

acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

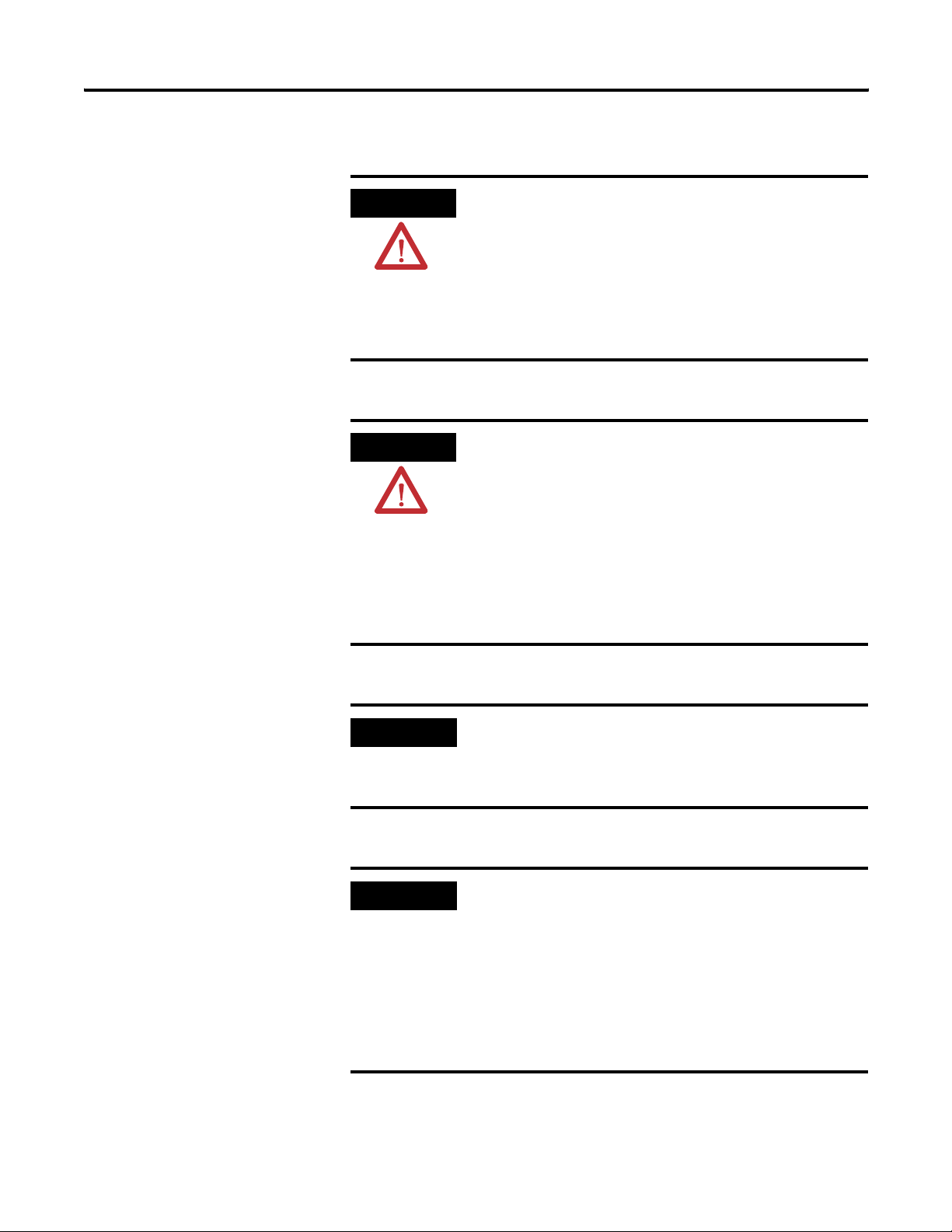

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances

that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful

application and understanding of the product.

Identifies information about practices or circumstances

that can lead to personal injury or death, property

damage, or economic loss. Attentions help you:

• identify a hazard

• avoid a hazard

• recognize the consequence

Labels may be located on or inside the drive to alert

people that dangerous voltage may be present.

Labels may be located on or inside the drive to alert

people that surfaces may be dangerous temperatures.

Publication 1404-IN007D-EN-P - October 2004

Page 3

Powermonitor 3000 3

European Communities (EC) Directive Compliance

If this product has the CE mark, it is approved for installation within

the European Union and EEA regions. It has been designed and tested

to meet the following directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) by applying the following

standards, in whole or in part, documented in a technical construction

file:

This product is intended for use in an industrial environment.

• EN 50081-2 EMC — Generic Emission Standard, Part 2 —

Industrial Environment

• EN 50082-2 EMC — Generic Immunity Standard, Part 2 —

Industrial Environment

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low

Voltage, by applying the safety requirements of IEC 1010-1, Safety

Requirements for Electrical Equipment for Measurement, Control, and

Laboratory Use.

This equipment is classified as an open style device. Open style

devices must be provided with environmental and safety protection

by proper mounting in enclosures designed for specific application

conditions. See NEMA Standards publication 250 and IEC publication

529, as applicable, for explanations of the degrees of protection

provided by different types of enclosure.

Publication 1404-IN007D-EN-P - October 2004

Page 4

4 Powermonitor 3000

Using This Installation Instruction

What This Manual Doesn’t Contain

This manual does not contain the following information. Except as

noted, refer to the Powermonitor 3000 User Manual, Publication

1404-UM001 for detailed information on the topics in this list.

• Information on metering functionality and measurements

• Use of the Display Module for configuration, monitoring and

commands

• Discussion of communications options, functionality,

configuration and operation

• Setpoint configuration and operation

• Discrete I/O configuration and operation

• Data logging including Event Log, Trend Log, Min/Max Log,

Load Factor Log

• Advanced features including Oscillography, Harmonic Analysis

and Transient Detection

• Powermonitor 3000 data tables

• Sample ladder diagrams for communicating with the

Powermonitor 3000 using various communications options

• Display module installation instructions (refer to Publication

1404-IN005)

For More Information on Additional Power Quality Products

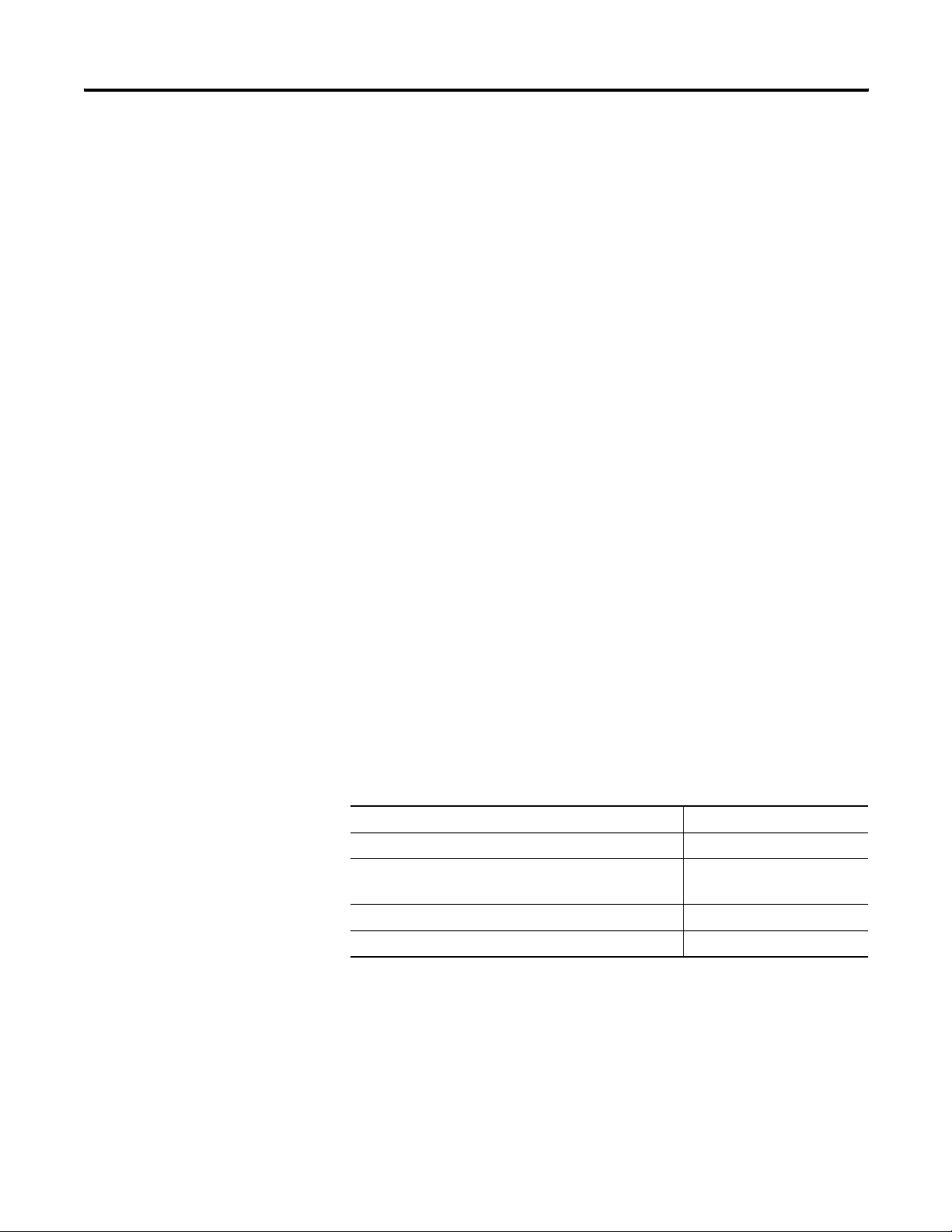

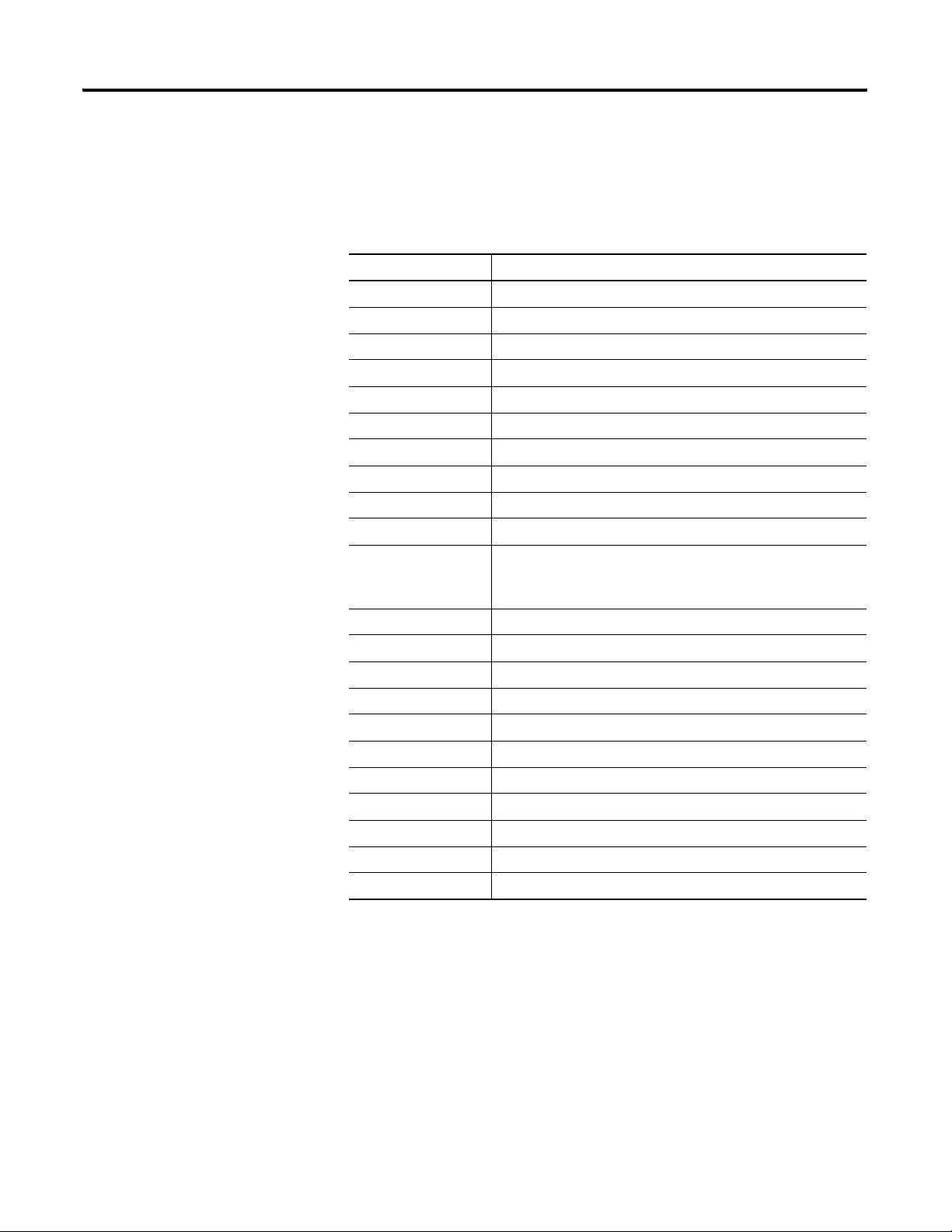

Table 1 Related Documentation

For this information: Refer to Publication:

Powermonitor 3000 User Manual 1404-UM001

Powermonitor 3000 Display Module Installation

Instructions

Bulletin 1403 Powermonitor II Tutorial 1403–1.0.2

Ethernet Series B Release Note 1404-RN008

1404-IN005

Publication 1404-IN007D-EN-P - October 2004

Page 5

Powermonitor 3000 5

Terms and Conventions

In this manual, the following terms and conventions are used:

Table 2

Abbreviation Term

AWG American Wire Gage

CSA Canadian Standards Association

CT Current Transformer

DM Display Module

EMI Electromagnetic Interference

ID Identification

IEC International Electrotechnical Commission

LED Light Emitting Diode

NEMA National Electrical Manufacturers Association

PLC Programmable Logic Controller

PT Potential Transformer

(Also known as VT in some countries)

RAM Random Access Memory

RFI Radio Frequency Interference

R I/O Remote Input/Output

RMS Root–mean–square

SLC Small Logic Controller

SPDT Single Pole Double Throw

UL Underwriters Laboratories

VA Volt–ampere

VAR Volt–ampere Reactive

CIP Control and Information Protocol

NAP Network Access Port

Publication 1404-IN007D-EN-P - October 2004

Page 6

6 Powermonitor 3000

Safety Considerations

ATTENTION

ATTENTION

Only qualified personnel, following accepted safety

procedures, should install, wire and service the

Powermonitor 3000 and its associated components.

Before beginning any work, disconnect all sources of

power and verify that they are de-energized and

locked out. Failure to follow these instructions may

result in personal injury or death, property damage

or economic loss.

Never open a current transformer (CT) secondary

circuit with primary current applied. Wiring between

the CTs and the Powermonitor 3000 should include a

shorting terminal block in the CT secondary circuit.

Shorting the secondary with primary current present

allows other connections to be removed if needed.

An open CT secondary with primary current applied

produces a hazardous voltage, which can lead to

personal injury, death, property damage or economic

loss.

IMPORTANT

IMPORTANT

The Powermonitor 3000 is not designed for nor

intended for use as a circuit protective device. Do

not use this equipment in place of a motor overload

relay or circuit protective relay.

The relay output contacts and solid-state KYZ output

contacts on the Powermonitor 3000 may be used to

control other devices through setpoint control or

communications. The response of these outputs to a

communications failure is configurable by the user.

Refer to Publication 1404-UM001 for information on

configuring the outputs. Be sure to evaluate the

safety impact of the output configuration on your

plant or process.

Publication 1404-IN007D-EN-P - October 2004

Page 7

Other Warnings

Powermonitor 3000 7

Product Description

ATTENTION

The Bulletin 1404 Powermonitor 3000 is uniquely designed and

developed to meet the needs of both producers of and users of

electric power. A Powermonitor 3000 system consists of:

• Master Module which provides metering and native RS-485

communications

• Optional Display Module for configuration, commands and data

display

• Optional communications port to serve data to other devices

using a choice of networks

• Optional external devices and applications that display and

utilize data for reporting, control and management of power and

energy usage

Electrostatic discharge can damage integrated circuits

or semiconductors. Follow these guidelines when

you handle the module.

• Touch a grounded object to discharge static

potential.

• Wear an approved wrist strap-grounding device.

• Do not open the module or attempt to service

internal components.

• If available, use a static safe workstation.

• When not in use, keep the module in its static

shield bag.

The Powermonitor 3000 is a microprocessor-based monitoring and

control device ideally suited for a variety of applications including:

• Load Profiling - Using the configurable trending utility to log

power parameters such as real power, apparent power and

demand, for analysis of power usage by loads over time.

• Demand Management - Understanding when and why demand

charges occur allows you to make informed decisions that

reduce your electrical power costs.

• Cost Allocation - Knowing your actual energy costs promotes

manufacturing efficiencies.

Publication 1404-IN007D-EN-P - October 2004

Page 8

8 Powermonitor 3000

• Distribution System Monitoring - Using power parameters to

show power flow, system topology and distribution equipment

status.

• Emergency Load Shedding - Monitoring power usage to

preserve system stability in the event of sudden utility outage.

• Power System Control - Managing system voltage, harmonic

distortion and power factor.

The Powermonitor 3000 is a sophisticated modern alternative for

traditional electro-mechanical metering devices. A single

Powermonitor 3000 can replace many individual transducers and

meters. The Powermonitor 3000 is operator-friendly and provides the

user with easy to understand, accurate information in a compact

economical package.

Master Module

The Master Module contains the main microprocessor-based

monitoring functions, including terminations for power system

connections, status inputs, control outputs, a native RS-485

communications port and a port for the Display Module

Configuration

Although the Powermonitor 3000 ships from the factory with default

settings, you will need to configure it for your particular requirements.

You may configure the Powermonitor 3000 using the optional Display

Module. Alternately, you may use an external device or application to

write configuration, operational parameters and commands to the

Master Module through its native or optional communications port.

Refer to the Powermonitor 3000 User Manual, publication

1404-UM001 for additional detail.

Optional external applications that you may use for Powermonitor

3000 configuration include RSPower32™ and RSEnergyMetrix™

software operating on a personal computer. Contact your local

Rockwell Automation sales office or distributor, or visit

http://www.software.rockwell.com/ for more information on available

software packages.

Publication 1404-IN007D-EN-P - October 2004

Page 9

Powermonitor 3000 9

Communications

Every Powermonitor 3000 comes with a native RS-485

communications port. The RS-485 port may be configured to use the

Allen-Bradley DF1 half-duplex slave protocols or Modbus

slave. The native port is suitable for communicating to master devices

including:

• PLC-5, SLC 500 and ControlLogix processors

• RSLinx software with DDE/OPC server functionality

• Modbus RTU Master devices

• Other third-party devices

• Software that you develop

You may also specify Powermonitor 3000 units with optional

communications ports including:

• Serial RS-232 (DF1 half-duplex or Modbus RTU slave)

• Remote I/O

• DeviceNet

• EtherNet/IP

• ControlNet

RTU

A Powermonitor 3000 may be easily integrated into a programmable

controller or computer based control and monitoring system, using

any of the communications methods listed above.

Publication 1404-IN007D-EN-P - October 2004

Page 10

10 Powermonitor 3000

wermonitor 3000

wermonitor 3000

wermonitor 3000

wermonitor 3000

wermonitor 3000

wermonitor 3000

Terminal Blocks

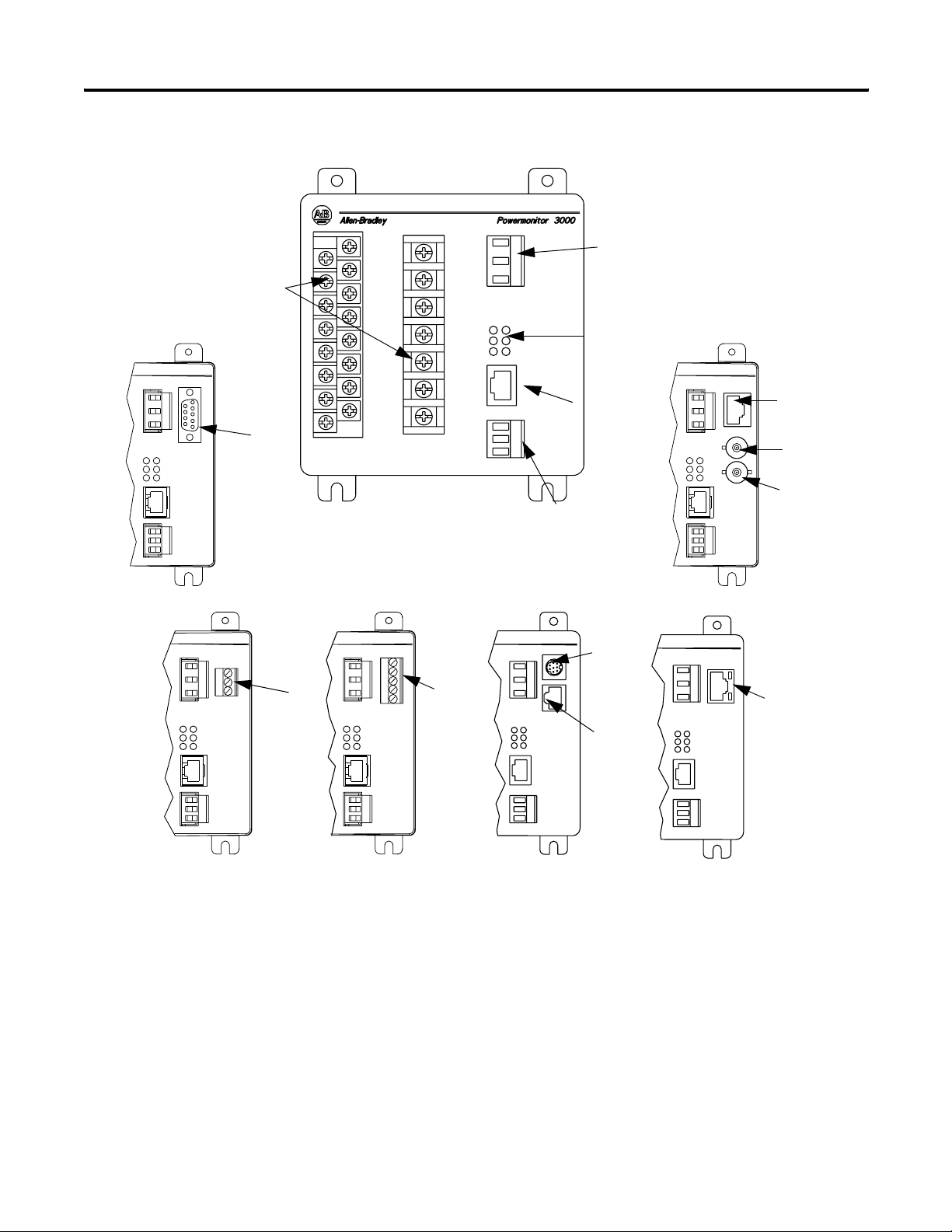

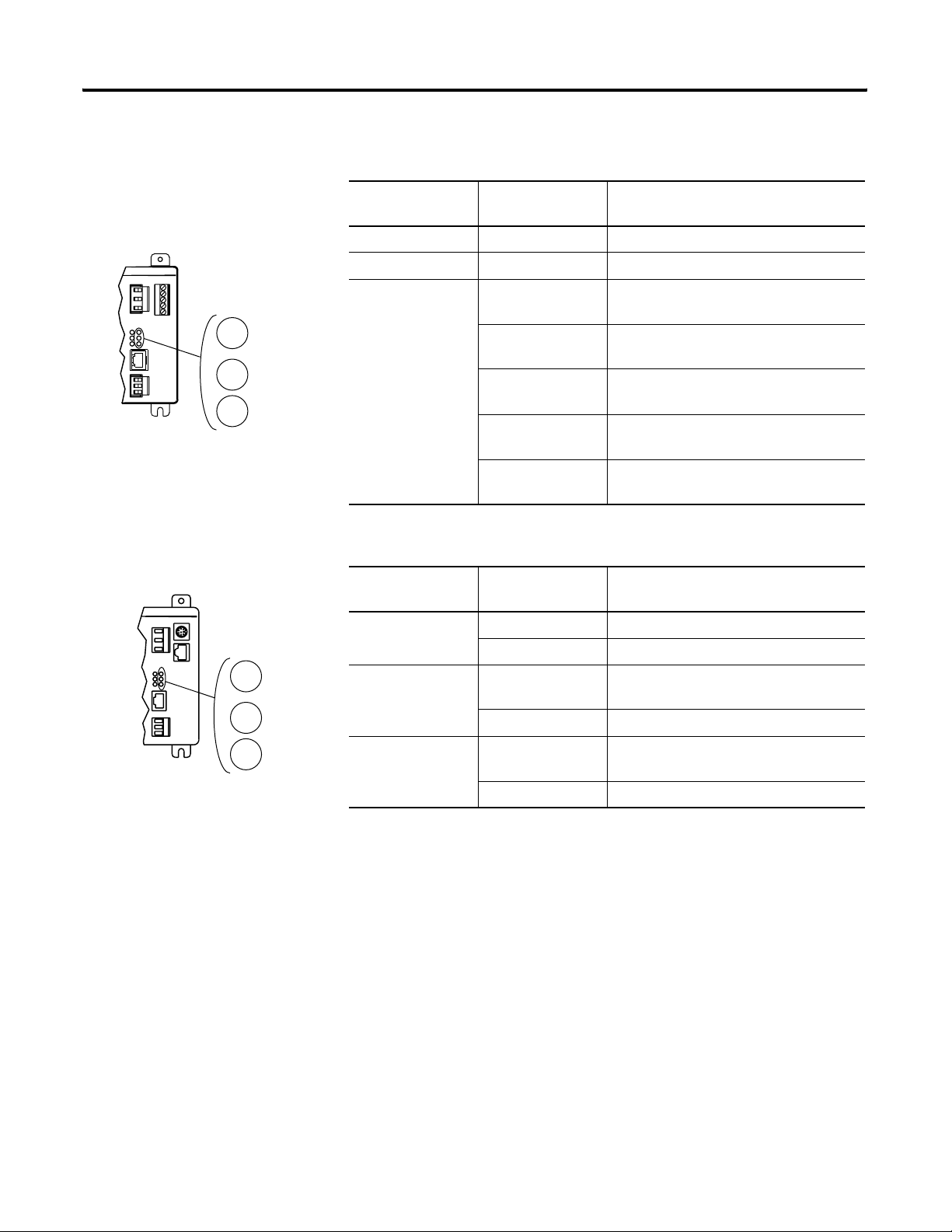

Figure 3 Master Module with Communication Options

Removable Status Input

Connector

LED Indicators

Powermonitor 3000

Powermonitor 3000

Optional

RS-232 Port

Optional

Remote I/O

Port

Powermonitor 3000

Optional

DeviceNet

Port

Display Module Port

RS-485 (Native)

Communications Port

Powermonitor 3000

Auxiliary

Port (not

used)

Optional

Ethernet

10BaseT

Port

(Series A)

Powermonitor 3000

NAP Port

ControlNet

Channel A

ControlNet

Channel B

Powermonitor 3000

Optional

Ethernet

10BaseT

Port

(Series B)

Display Module

Publication 1404-IN007D-EN-P - October 2004

The Bulletin 1404 Display Module is an optional user interface device.

The Display Module provides the most economical and simplest

method for setting up and configuring the Master Module for

operation.

The Display Module has a highly visible, two-line LED display and

four operator buttons with tactile feedback. Use the buttons and

display to navigate through a series of menus for configuration,

commands and data display.

Page 11

Powermonitor 3000 11

Powermonitor 3000

RX

TX

RS-485

The Display Module is shipped with a 3-meter (10 ft) long, shielded

4-pair cable that provides power and serial communications between

the Master Module and the Display Module. The Display Module fits

into a standard ANSI four inch analog meter cutout for panel

mounting. Only one Display Module may be connected to a Master

Module, although you may use one Display Module to configure and

monitor any number of Master Modules; one at a time.

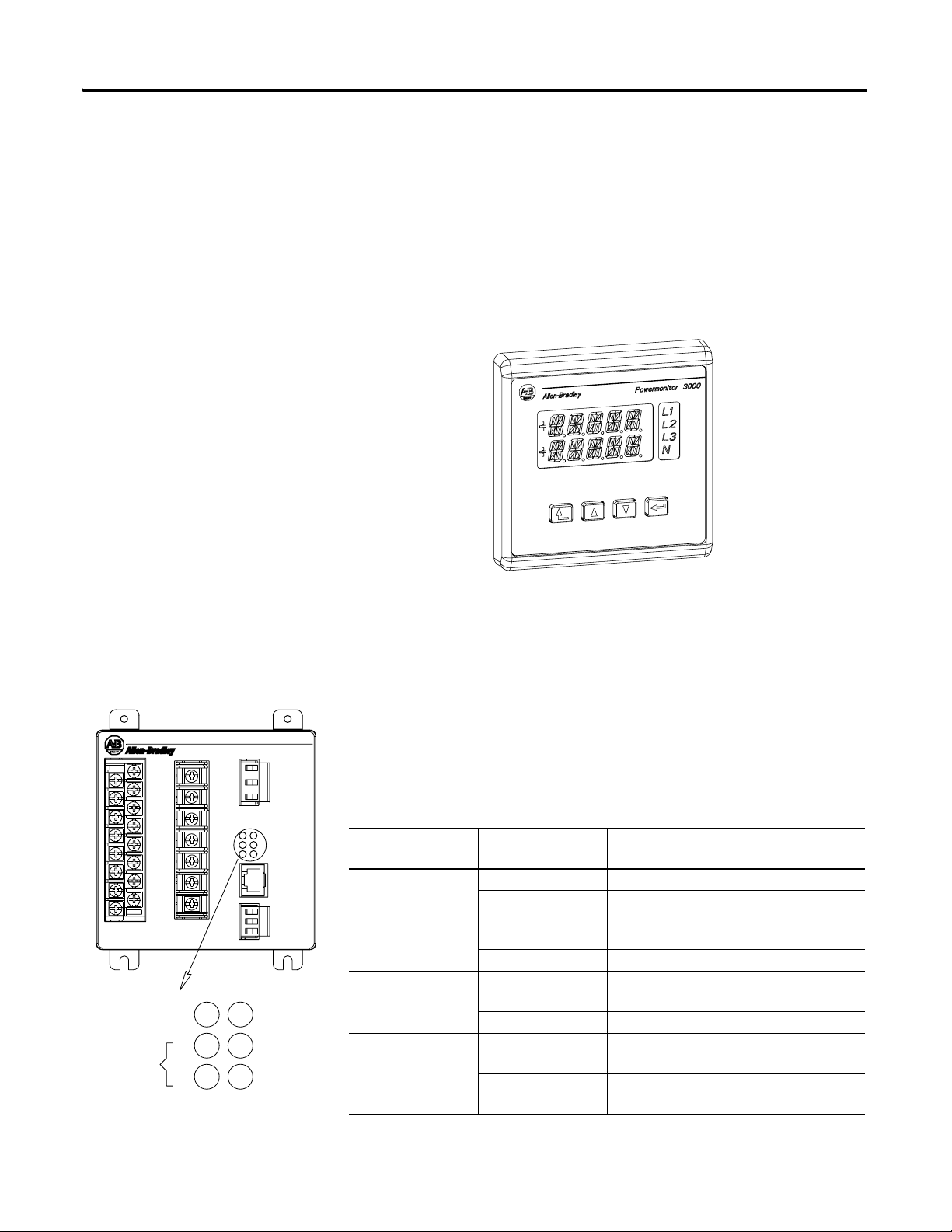

Figure 4 Display Module

LED Indicators

Figure 5 LED Indicators

MODULE

STATUS

The Powermonitor 3000 is equipped with six bi-color light emitting

diodes (LED’s) arranged as shown in

Figure 5.

The three LED’s on the left display the same information on

Powermonitor 3000 modules with any communication option

including native RS-485 communications only. The three LED’s on the

right have different labels and different indications depending on the

communications option selected, as shown in the charts below.

Table 6 LED Indicators All Powermonitor 3000 Models

LED LED Color LED State and Communications

Condition

Module Status Off Control power is off or insufficient

Steady Red Major fault; internal self-test has failed. If a

power cycle does not correct the problem,

call customer support

Steady Green Powermonitor 3000 is operating normally

RS-485 RX Off The RS-485 bus is idle; no active data is

present

Flashing Green Active data is present on the RS-485 bus

RS-485 TX Off Powermonitor 3000 is not transmitting data

onto the RS-485 bus

Flashing Green Powermonitor 3000 is transmitting data

onto the RS-485 bus

Publication 1404-IN007D-EN-P - October 2004

Page 12

12 Powermonitor 3000

Powermonitor 3000

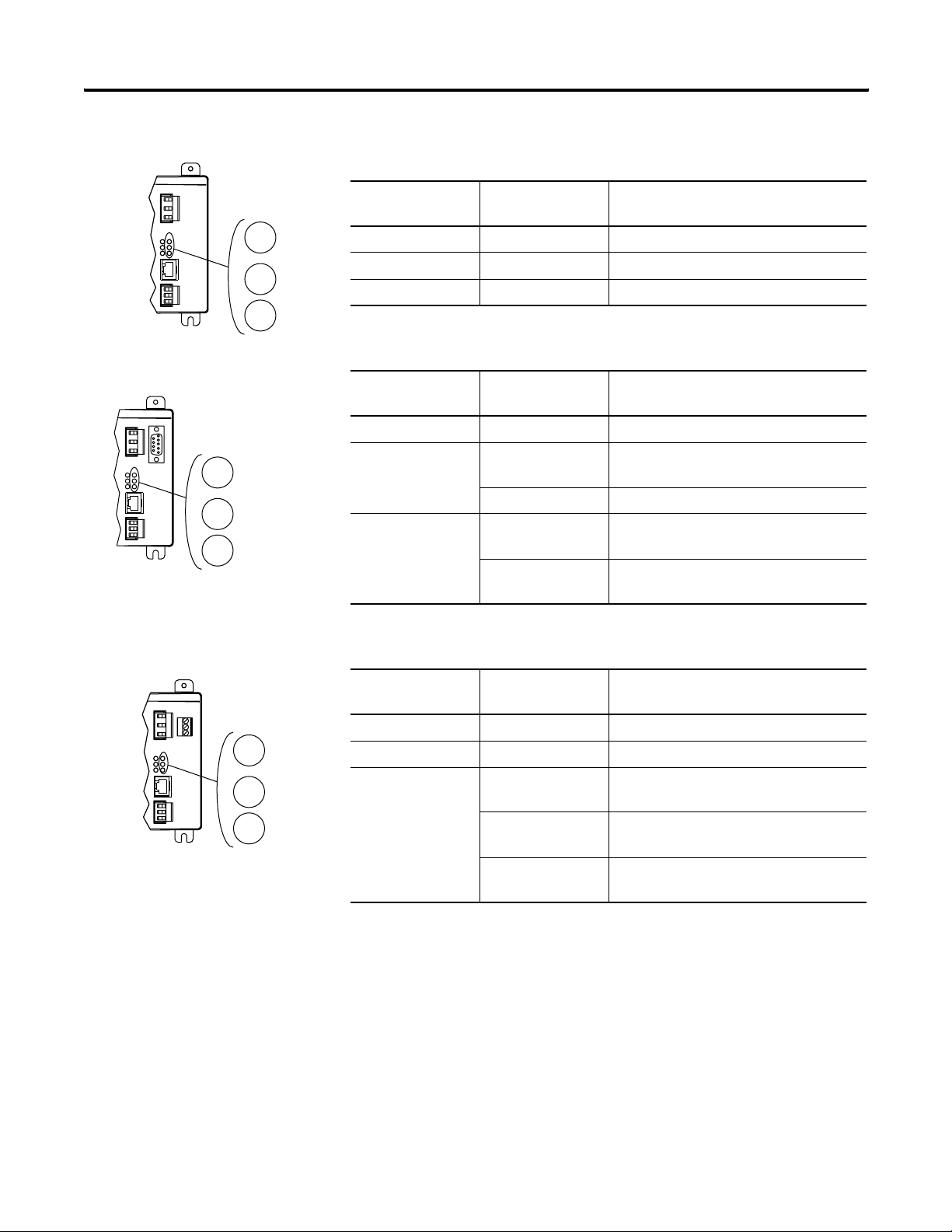

Table 7 Native RS-485 Communications only (catalog numbers ending in -000)

LED LED Color LED State and Communications

Condition

Powermonitor 3000

Powermonitor 3000

F1

RX

TX

}

F1

F1

F2

F3

RS-232

F1 Off Not Used

F2 Off Not Used

F3 Off Not Used

Table 8 RS-232 Optional Communications (catalog numbers ending in -232)

LED LED Color LED State and Communications

Condition

F1 Off Not Used

RS-232 RX Off The RS-232 bus is idle; no active data is

present

Flashing Green Powermonitor 3000 is receiving data.

RS-232 TX Off The Powermonitor 3000 is not transmitting

any data onto the RS-232 bus

Flashing Green The Powermonitor 3000 is transmitting

data.

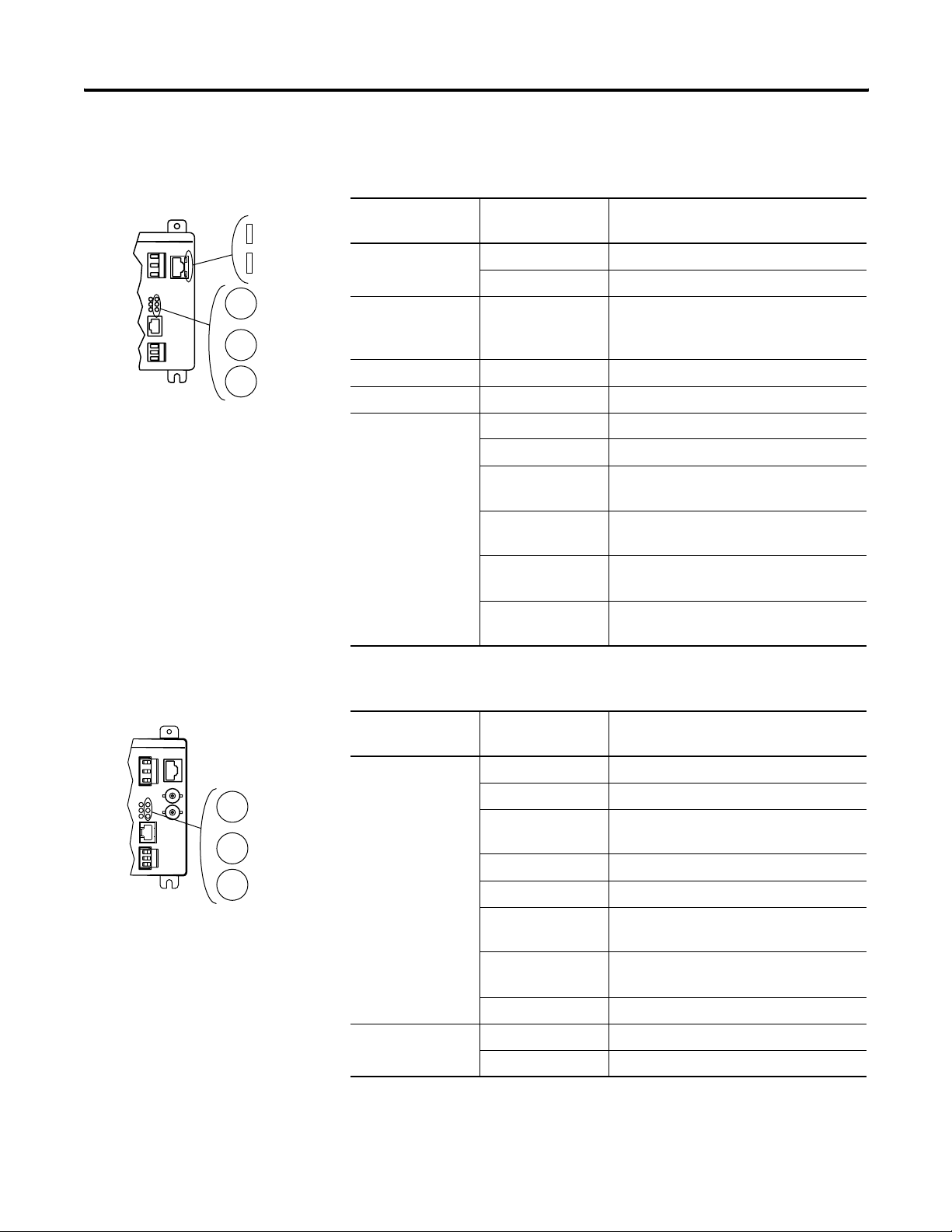

Table 9 Remote I/O Optional Communications (catalog numbers ending in -RIO)

LED LED Color LED State and Communications

Condition

F1 Off Not Used

F2 Off Not Used

F2

R I/O

Publication 1404-IN007D-EN-P - October 2004

R I/O Off Remote I/O communications has not been

established

Flashing Green Remote I/O communications has been

established but there are errors

Steady Green Remote I/O communications has been

established

Page 13

Powermonitor 3000

F1

F2

NETWORK

STATUS

Powermonitor 3000 13

Table 10 DeviceNet Optional Communications (catalog numbers ending in -DNT)

LED LED Color LED State and Communications

Condition

F1 Off Not Used

F2 Off Not Used

NETWORK STATUS Off Power is off or the Powermonitor 3000 is

not online

Flashing Green Network status is OK, no connections

established

Steady Green Network status is OK, connections

established

Flashing Red Recoverable communications failure; port is

restarting

Steady Red Non-recoverable communications error;

check wiring and configuration parameters

Powermonitor 3000

LINK

RX

TX

Table 11 Ethernet Optional Communications (Series A catalog numbers ending in

-ENT)

LED LED Color LED State and Communications

Condition

LINK Off Ethernet connection is inactive

Steady Green Ethernet connection is active

RX Off Ethernet is idle, no active data present on

port

Flashing Red Active data is present on Ethernet port

TX Off Powermonitor 3000 is not transmitting any

data through the Ethernet port

Flashing Red Powermonitor 3000 is transmitting data

Publication 1404-IN007D-EN-P - October 2004

Page 14

14 Powermonitor 3000

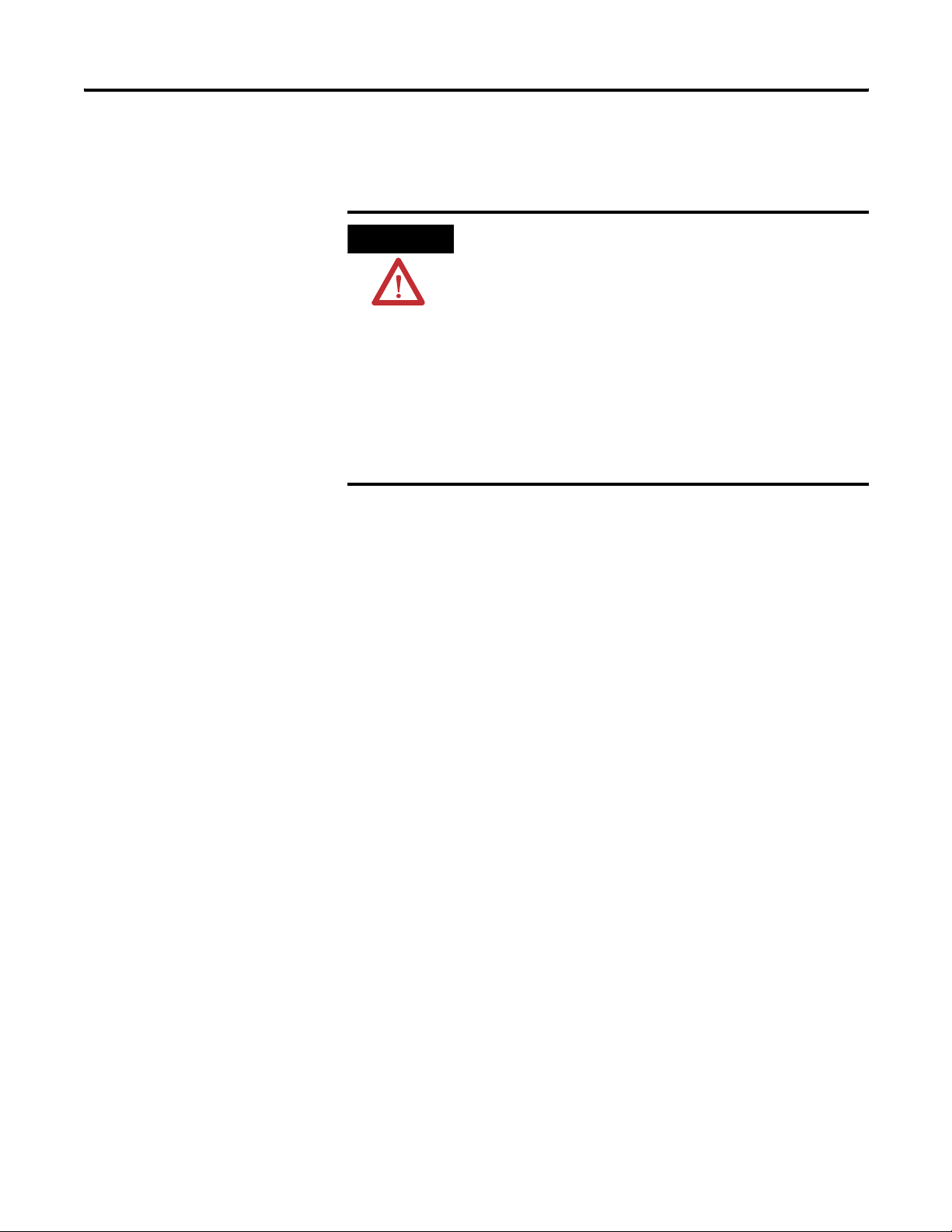

Powermonitor 3000

LNK

ACT

F1

F2

NETWORK

STATUS

Table 12 Ethernet/IP Optional Communications (Series B catalog numbers ending

in -ENT)

LED LED Color LED State and Communications

Condition

LNK Off No valid physical Ethernet connection

Steady Green Valid physical Ethernet connection

ACT Strobing or

Solid Yellow

F1 Off Not Used

F2 Off Not Used

NETWORK STATUS Off No power

Flashing Green No established connections

Steady Green Connected; has at least one established

Flashing Red Connection timeout; one or more

Steady Red Duplicate IP; the IP address assigned to this

Flashing Green/Red Selftest; this device is performing a

Powermonitor 3000 transmitting onto

Ethernet

connection

connections to this device has timed-out

device is already in use

power-up self test

Powermonitor 3000

CHAN A

CHAN B

NETWORK

STATUS

Table 13 ControlNet Optional Communications (catalog numbers ending in -CNT)

LED LED Color LED State and Communications

Condition

CHAN A and

CHAN B

Status Off Normal operation

Off No power or Channel disabled

Steady Red Faulted unit

Alternating

red/green

Alternating red/off Incorrect node configuration

Steady green Normal operation

Flashing green/off Temporary errors or node is not configured

Flashing red/off Media fault or no other nodes present on

Flashing red/green Incorrect network configuration

Flashing green Communication card power-up self-test

Self-test

to go on-line

network

Publication 1404-IN007D-EN-P - October 2004

Page 15

Powermonitor 3000 15

Quick Start Guidelines

The Powermonitor 3000 may be used in many electric power

monitoring and control systems. Whether your Powermonitor 3000 is

a complete power and energy monitor or a component in a plant- or

enterprise-wide energy management system, there are a few basic

steps to follow to make your unit operational.

1. Install your Powermonitor 3000 master module within a suitable

enclosure.

2. Install your optional Display Module. Refer to the Installation

Instructions included with the Display Module, publication

1404-IN005.

3. Determine your Wiring Mode and install wiring between the

Powermonitor 3000 and your power system. Connect control

power wiring, preferably from a separate source of control

power. If used, connect wiring to the status inputs, Form C

control relay, and KYZ solid-state outputs.

Master Module on page 20.

4. Configure the potential transformer (PT) and current transformer

(CT) ratios to match those used in your power system

connections. Configure the Voltage Mode of the Powermonitor

3000 to match your power system configuration.

Refer to Installation on page 15.

Refer to Wiring of

Installation

5. Configure Powermonitor 3000 communications. This step varies

depending upon the communications option you have selected.

6. Configure other optional performance features such as Setpoint

Control, Data Logging, etc.

Refer to the Powermonitor 3000 User Manual, publication

1404-UM001, for complete information on configuring and operating

your Powermonitor 3000.

Only qualified personnel should install, wire, service and maintain this

equipment. Refer to and follow the safety guidelines found starting at

page 6 and pay attention to all warnings and notices in these

instructions.

Publication 1404-IN007D-EN-P - October 2004

Page 16

16 Powermonitor 3000

Prevent Electrostatic Discharge

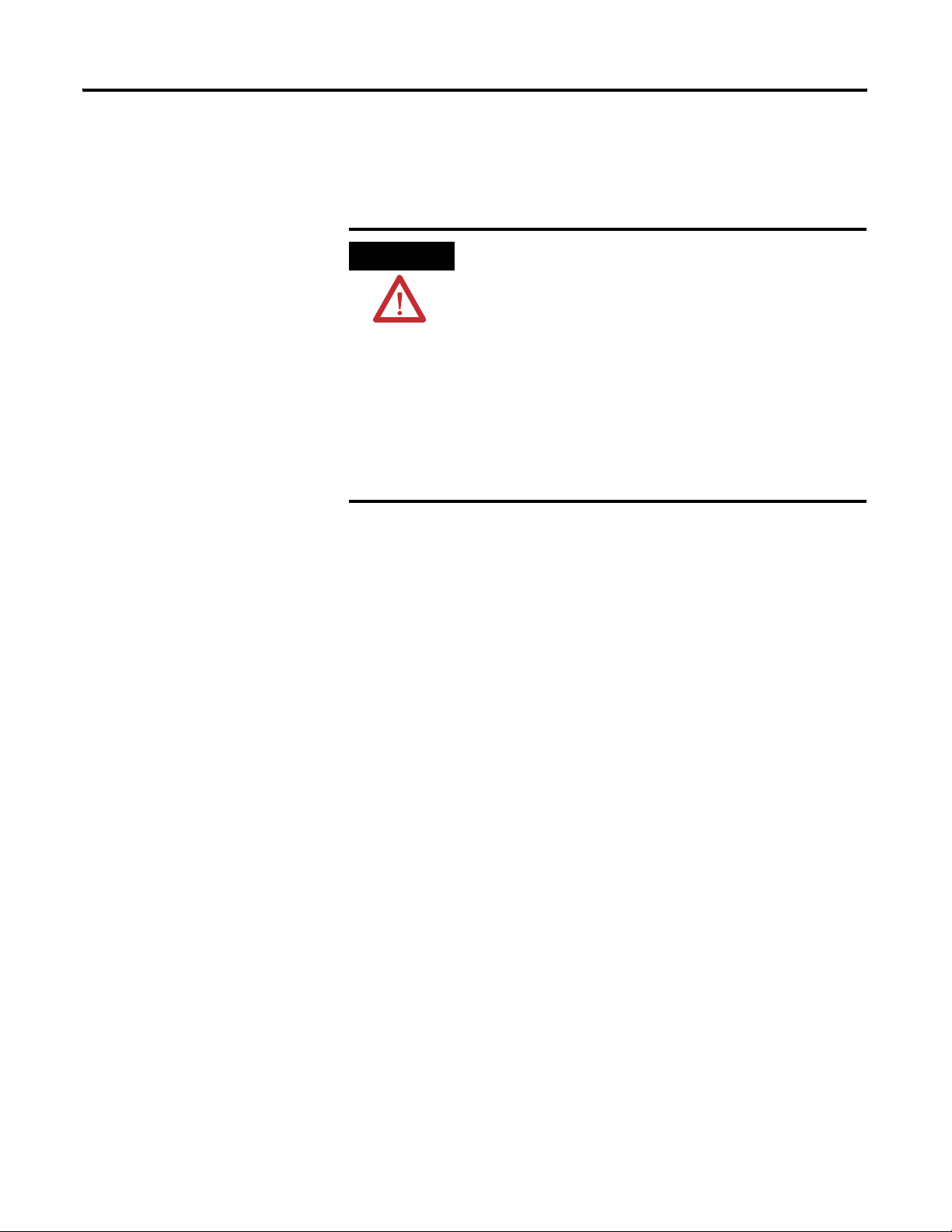

ATTENTION

Electrostatic discharge can damage integrated circuits

or semiconductors. Follow these guidelines when

you handle the module.

• Touch a grounded object to discharge static

potential.

• Wear an approved wrist strap grounding device.

• Do not open the module or attempt to service

internal components.

• If available, use a static safe work station.

• When not in use, keep the module in its static

shield bag.

Mounting of Master Module

Mount the Powermonitor 3000 Master Module in a suitable protective

enclosure. Select an enclosure that will protect the Master Module

from atmospheric contaminants such as oil, water, moisture, dust

corrosive vapors and other harmful airborne substances. The

enclosure should also protect against personnel contact with

energized circuits. The ambient temperature within the enclosure must

remain within the limits listed in the Specifications,

page 61.

Publication 1404-IN007D-EN-P - October 2004

Select an enclosure that will provide adequate clearance for

ventilation and wiring for the Powermonitor 3000 and other

equipment to be installed within the enclosure.

Figure 42 for dimensions and spacing guidelines for the

Powermonitor 3000.

Mount the Master Module so that the metal grounding clips on the

bottom of the mounting feet make direct contact with the enclosure

mounting panel. If the mounting panel is painted, scrape or sand the

paint down to bare metal. Use star washers to assure good long-term

electrical contact with the mounting panel. Ensure that the mounting

panel is properly connected to a low-impedance earth ground.

Mount the enclosure in a position that allows full access to the

Powermonitor 3000 Master Module. Install the Master Module with the

ventilation slots in the bottom and top of the unit unobstructed to

assure adequate free convection cooling of its internal electronic

components.

See Figure 41 and

Page 17

Powermonitor 3000 17

System Accuracy Considerations

IMPORTANT

See Figure 41 on page 56 for mounting hole dimensions. Mount the

Master Module with four (4) No. 8-32 UNC or M4 screws with flat

washers and lock washers.

User supplied potential transformers (PTs) and current transformers

(CTs), as well as wiring from the CTs to the Powermonitor, may

reduce the accuracy of your Powermonitor 3000 system. The quality

of the Powermonitor 3000’s measurements can be no better than the

quality of the signals presented to its input terminals. It is the user’s

responsibility to select transformers that are adequate for the desired

metering accuracy.

ANSI/IEEE C57.13, Requirements for Instrument Transformers, defines

three classes of transformer accuracy: class 1.2, class 0.6, and class 0.3.

The application should dictate the transformer accuracy class to be

used.

Use caution not to block the ventilation slots of the

Master Module. All wiring and other obstructions

must be a minimum of 50 mm (2.0 inches) from the

top and bottom of the unit.

PTs and CTs may introduce errors in three areas: ratio errors, phase

errors, and bandwidth errors.

Ratio Errors

The voltage ratio of a PT is the number of primary turns of wire

divided by the number of secondary turns. Manufacturing tolerances

may cause the ratio to be slightly different than the design specifies,

causing an error affecting the voltage input to the Powermonitor 3000.

Likewise, the current ratio of a CT is a function of the ratio of the

number of turns of wire on the primary and secondary. Some error in

this ratio is quite common in commercial grade PTs and CTs.

Other errors include magnetic core losses, winding impedance, and

the burden, or load, on the transformer secondary. The combination

of these errors is known as “Ratio Error”. You may compensate for

Ratio Error, if known, by adjusting the Basic Configuration entries for

PT and CT primary or secondary voltages.

Publication 1404-IN007D-EN-P - October 2004

Page 18

18 Powermonitor 3000

For a PT the Ratio Error increases as the transformer’s load current

increases, so its total load impedance should be as high as possible.

Conversely, a CT’s Ratio Error increases as the voltage supported by

the transformer secondary increases, so its total load impedance,

including the impedance of the wire connecting the CTs to the

metering device, should be as low as possible. This is why #12 AWG

or larger is usually recommended for wiring CTs with a 5 amp

secondary rating.

Phase Error

Phase shift between the primary to secondary signals is another

source of inaccuracy introduced by the user-supplied PTs and CTs.

Phase shift is generally not of concern for simple voltage or current

measurements. When these signals are combined, for instance when

calculating line to line voltage or phase power, the effect of phase

shift can become significant. The difference in phase error among

different transformers causes measurement errors. If all the PTs and

CTs introduced a five-degree phase shift, there would be no error in

the measured quantities. If on the other hand the PTs had a phase

error of one degree and the CTs had a phase error of six degrees,

there would be a five-degree phase error in the power calculation.

This would show up as power factor and reactive power (VAR) errors.

Phase errors can not be corrected by adjusting the Powermonitor 3000

configuration since the errors change based on varying conditions of

the power system.

Publication 1404-IN007D-EN-P - October 2004

A typical PT phase error varies from ±1° to ±0.25° depending on the

PT’s accuracy class. Applying higher than rated voltage increases the

phase error and may saturate the transformer and cause even larger

errors.

The phase error in a CT increases as its current decreases, and is

lowest when the current is greater than 80% of the CT rating. Because

significant phase error can occur when CT current is less than 20% of

rated current, CTs sized for protection do not perform well when used

for metering.

The phase error of both PTs and CTs are also affected by the power

factor of the load on the secondary. For best accuracy, loads should

be resistive, with PT loads as high as possible and CT loads as low as

possible.

Page 19

Powermonitor 3000 19

Bandwidth Error

For fundamental 50 Hz or 60 Hz measurements, bandwidth error has

no affect on accuracy. However, for waveforms with significant

harmonic content, the user-supplied PTs and CTs may attenuate

higher harmonics. Most instrument quality PTs have a flat frequency

response out to 3 kHz, or the 50th harmonic on a 60 Hz system.

Current transformers, especially older, existing units, tend to be less

linear, with a flat response only out to 300 Hz, or the fifth (60 Hz)

harmonic. Wide-band instrument CTs are available for improved

frequency response. Bandwidth error cannot be corrected by

adjusting the Powermonitor 3000 configuration.

In addition, operation of either the PTs or CTs at extremely low

frequencies may also cause saturation and resulting magnitude and

phase errors.

For more detailed information on instrument transformer accuracy and

power measurement, refer to publication 1403-1.0.2, “Bulletin 1403

Powermonitor II Tutorial”.

Wiring

ATTENTION

Wiring of the Powermonitor 3000 includes the following steps:

• Connection of voltage and current signals from PTs and CTs

• Connection of control power

• Connection of status inputs and status/control outputs

• Communications wiring

Please follow these guidelines to help assure reliable, trouble-free

operation of your Powermonitor 3000.

Only qualified personnel, following accepted safety

procedures, should install, wire and service the

Powermonitor 3000 and its associated components.

Before beginning any work, disconnect all sources of

power and verify that they are de-energized and

locked out. Failure to follow these instructions may

result in personal injury or death, property damage

or economic loss.

Publication 1404-IN007D-EN-P - October 2004

Page 20

20 Powermonitor 3000

• Install and connect all wiring in a neat and workmanlike

manner. Use wire tags to identify connections. Bundle wiring

neatly and maintain a minimum of 50 mm (2.0 inches) clearance

from the Master Module ventilation slots to avoid a buildup of

heat within the unit

• Furnish and install properly-selected fuses for voltage signals

and control power

• Use 600 volt wiring rated at 75°C (167°F) or higher. We strongly

recommend the use of flame-retardant wire rated VW-1 by

Underwriters Laboratories

• Use a shorting terminal block (provided by customer) for CT

wiring, to permit servicing connected equipment such as the

Powermonitor 3000 Master Module without de-energizing the

power system

• Use ring lugs or locking spade lugs for voltage and current

connections to provide additional wiring security and safety

• Pay careful attention to correct phasing and polarity for proper

operation

• Connect the Master Module to a low-impedance earth ground

using its grounding terminal and a dedicated grounding wire at

least as large as the largest current-carrying wire connected to

the Master Module. Keep grounding wiring as short as possible.

To obtain maximum EMI immunity, the Master Module

mounting feet should make electrical contact with the mounting

panel. Refer to Mounting of Master Module on page 16 for

additional information.

• Connect all equipment ground terminals (Master Module, PT

and CT secondary) to a single point, low impedance earth

ground

Publication 1404-IN007D-EN-P - October 2004

For information on wire sizes and types for grounding electrical

equipment, refer to publication 1770-4.1, Industrial Automation Wiring

and Grounding Guidelines for Noise Immunity or the National Electric

Code published by National Fire Protection Association (NFPA).

Wiring of Master Module

Terminal Blocks Wire Sizes and Screw Torques - Observe all wire lug

sizes and screw torques.

Refer to Technical Specifications on page 59.

Page 21

Powermonitor 3000 21

Voltage and Current Inputs

Voltage Input and PT Selection

The Powermonitor 3000 is designed to connect directly to power

system rated up to 600 volts line-to-line (347 volts line-to-neutral).

Higher system voltages require the use of user-supplied PTs. Typical

secondary voltage on a PT is 120V ac. Select the PT primary voltage to

match the nominal voltage of your power system.

Connect user-furnished short circuit protection between the power

system and the Powermonitor 3000. If PTs are used, install the

user-furnished short circuit protection on the high-voltage side of the

PTs.

Current Inputs and Current Transformer (CT) Selection

The current input on the Powermonitor 3000 is designed for a 5 amp

nominal current signal. User-supplied CTs are required to connect

your power system to the input of the Powermonitor 3000. Select the

CT primary current to match the nominal current of your power

system.

ATTENTION

Never open a current transformer secondary circuit

with primary current applied. Wiring between the

CTs and the Powermonitor 3000 should include a

shorting terminal block in the CT secondary circuit.

Shorting the secondary with primary current present

allows other connections to be removed if needed.

An open CT secondary with primary current applied

produces a hazardous voltage, which can lead to

personal injury, death, property damage of economic

loss.

The shorting terminal block should be located adjacent to the

Powermonitor 3000 Master Module so that it is readily accessible

2

should service be needed. Use #14 AWG (2.5 mm

) wire for the short

run between the Powermonitor 3000 and the shorting terminal block.

2

Use wiring of #12 AWG (4 mm

) or larger between the shorting

terminal block and the CT so that the additional load of the wiring

does not overload the CT and reduce its accuracy.

Publication 1404-IN007D-EN-P - October 2004

Page 22

22 Powermonitor 3000

IMPORTANT

You may install either two or three CTs for any of the

Delta or Open Delta wiring or voltage modes. Refer

to

Figure 21, Figure 23, or Figure 26 for wiring of a 2

CT configuration. Whether there are two or three CTs

in a circuit does not affect the voltage wiring. Refer

to the User Manual, publication 1404-UM001.

Do not install fuses or other overcurrent protection in the secondary

circuit of a CT.

Refer to System Accuracy Considerations on page 17 for guidelines on

PT and CT selection.

Refer to Technical Specifications on page 59 for information on

voltage isolation levels and wire termination recommendations.

The wiring diagrams depict wiring methods for a variety of power

system configurations. You will need to configure your Powermonitor

3000 to match the power system configuration for correct operation.

Refer to the Powermonitor 3000 User Manual, publication

1404-UM001, for detailed instructions on unit configuration.

Publication 1404-IN007D-EN-P - October 2004

Page 23

Powermonitor 3000 23

Wiring Diagrams

L1

L2

Figure 14 Single Phase Direct Connection Wiring Diagram

(Systems < 600 Volts Nominal L-L)

Line

N

Fuse

Fuse

Customer Supplied

CT Shorting Switch or

Test Block

Voltage Mode = Single Phase

R14

R11

R12

N/C

I1-

I2-

I3-

I4-

Y

K

Z

N/C

I1+

I2+

I3+

I4+

Powermonitor 3000

MASTER

MODULE

L1

(+)

L2

(-)

GRD

V1

V2

V3

N

Load

Customer

Chassis

Ground

KZR14 R11

Y

R12

Publication 1404-IN007D-EN-P - October 2004

Page 24

24 Powermonitor 3000

L1

L2

Figure 15 Single Phase with PTs Wiring Diagram

Line

N

Fuse

Fuse

Customer Supplied

CT Shorting Switch or

Voltage Mode = Single Phase

Test Block

R14

R11

R12

N/C

I1-

I2-

I3-

I4-

Y

K

Z

N/C

I1+

I2+

I3+

I4+

R12

Powermonitor 3000

MASTER

MODULE

L1

(+)

L2

(-)

GRD

V1

V2

V3

N

KZR14 R11

Y

Load

Publication 1404-IN007D-EN-P - October 2004

Customer

Chassis

Ground

Page 25

Figure 16 3-Phase 4-Wire Wye Direct Connect Wiring Diagram

(Systems < 600 Volts Nominal L-L)

Powermonitor 3000 25

Line

NL1 L2 L3

Fuse

Fuse

Fuse

Customer Supplied

CT Shorting Switch or

Test Block

Voltage Mode = Wye

R14

R11

R12

N/C

I1-

I2-

I3-

I4-

Y

K

Z

N/C

I1+

I2+

I3+

I4+

Powermonitor 3000

MASTER

MODULE

L1

(+)

L2

(-)

GRD

V1

V2

V3

N

YKZR14 R11 R12

Load

Customer

Chassis

Ground

Publication 1404-IN007D-EN-P - October 2004

Page 26

26 Powermonitor 3000

Figure 17 3-Phase 4-Wire with PT’s Wiring Diagram

Line

NL1 L2 L3

Fuse

Fuse

Fuse

Customer Supplied

CT Shorting Switch or

Voltage Mode = Wye

Test Block

R14

R11

R12

N/C

I1-

I2-

I3-

I4-

Y

K

Z

N/C

I1+

I2+

I3+

I4+

R12

Powermonitor 3000

MASTER

MODULE

L1

(+)

L2

(-)

GRD

V1

V2

V3

N

KZR14 R11

Y

Load

Publication 1404-IN007D-EN-P - October 2004

Customer

Chassis

Ground

Page 27

Line

L1 L2 L3

Powermonitor 3000 27

Figure 18 3-Phase 3-Wire Grounded Wye Direct Connection Wiring Diagram

(Systems < 600 Volts Nominal L-L)

Voltage Mode = Wye

Fuse

Fuse

Fuse

Powermonitor 3000

Customer Supplied

CT Shorting Switch or

Test Block

R14

R11

R12

N/C

I1-

I2-

I3-

I4-

Y

K

Z

N/C

I1+

I2+

I3+

I4+

R12

KZR14 R11

Y

MASTER

MODULE

L1

(+)

L2

(-)

GRD

V1

V2

V3

N

Load

Customer

Chassis

Ground

Publication 1404-IN007D-EN-P - October 2004

Page 28

28 Powermonitor 3000

Line

L1 L2 L3

Figure 19 3-Phase 3-Wire Grounded Wye with PT’s Wiring Diagram

Voltage Mode = Wye

Fuse

Fuse

Fuse

Powermonitor 3000

Customer Supplied

CT Shorting Switch or

Test Block

R14

R11

R12

N/C

I1-

I2-

I3-

I4-

Y

K

Z

N/C

I1+

I2+

I3+

I4+

R12

L1

(+)

L2

(-)

GRD

V1

V2

V3

KZR14 R11

Y

MASTER

MODULE

N

Load

Publication 1404-IN007D-EN-P - October 2004

Customer

Chassis

Ground

Page 29

Powermonitor 3000 29

Figure 20 3-Phase 3-Wire Delta with Three PT’s and Three CT’s Wiring Diagram

Line

L1 L2 L3

Fuse

Fuse

Fuse

Customer Supplied

CT Shorting Switch or

Test Block

Voltage Mode = Delta 3 CT

R14

R11

R12

N/C

I1-

I2-

I3-

I4-

Y

K

Z

N/C

I1+

I2+

I3+

I4+

Powermonitor 3000

MASTER

MODULE

L1

(+)

L2

(-)

GRD

V1

V2

V3

N

Load

Customer

Chassis

Ground

KZR14 R11

Y

R12

Publication 1404-IN007D-EN-P - October 2004

Page 30

30 Powermonitor 3000

Figure 21 3-Phase 3-Wire Delta with Three PT’s and Two CT’s Wiring Diagram

Line

L1 L2 L3

Fuse

Fuse

Fuse

Customer Supplied

CT Shorting Switch or

Test Block

Voltage Mode = Delta 2 CT

R14

R11

R12

N/C

I1-

I2-

I3-

I4-

Y

K

Z

N/C

I1+

I2+

I3+

I4+

Powermonitor 3000

MASTER

MODULE

L1

(+)

L2

(-)

GRD

V1

V2

V3

N

Load

Publication 1404-IN007D-EN-P - October 2004

Customer

Chassis

Ground

R12

KZR14 R11

Y

Page 31

Powermonitor 3000 31

Figure 22 3-Phase 3-Wire Open Delta with Two PT’s and Three CT’s Wiring Diagram

Line

L1 L2 L3

Fuse

Fuse

Customer Supplied

CT Shorting Switch or

Test Block

Voltage Mode = Open Delta 3 CT

R14

R11

R12

N/C

I1-

I2-

I3-

I4-

Y

K

Z

N/C

I1+

I2+

I3+

I4+

Powermonitor 3000

MASTER

MODULE

L1

(+)

L2

(-)

GRD

V1

V2

V3

N

Load

Customer

Chassis

Ground

KZR14 R11

Y

R12

Publication 1404-IN007D-EN-P - October 2004

Page 32

32 Powermonitor 3000

Figure 23 3-Phase 3-Wire Open Delta with Two PT’s and Two CT’s Wiring Diagram

Line

L1 L2 L3

Fuse

Fuse

Customer Supplied

CT Shorting Switch or

Test Block

Voltage Mode = Open Delta 2 CT

R14

R11

R12

N/C

I1-

I2-

I3-

I4-

Y

K

Z

N/C

I1+

I2+

I3+

I4+

Powermonitor 3000

MASTER

MODULE

L1

(+)

L2

(-)

GRD

V1

V2

V3

N

Load

Publication 1404-IN007D-EN-P - October 2004

Customer

Chassis

Ground

R12

KZR14 R11

Y

Page 33

Powermonitor 3000 33

Figure 24 3-Phase 3-Wire Grounded L2(B) Phase Open Delta Direct Connect with

Three CT’s Wiring Diagram(Systems

< 600 Volts Nominal L-L)

Distribution

Ground

Line

L1 L3

Voltage Mode = Open Delta 3 CT

Fuse

Fuse

Voltage must not

exceed 347 Volts L-L

(otherwise, step down

transformers are required).

Customer Supplied

CT Shorting Switch or

Test Block

R14

R11

R12

N/C

I1-

I2-

I3-

I4-

Y

K

Z

N/C

I1+

I2+

I3+

I4+

Powermonitor 3000

MASTER

MODULE

L1

(+)

L2

(-)

GRD

V1

V2

V3

N

Load

Customer

Chassis

Ground

KZR14 R11

Y

R12

Publication 1404-IN007D-EN-P - October 2004

Page 34

34 Powermonitor 3000

Figure 25 3-Phase 3-Wire Delta Direct Connect with Three CT’s Wiring Diagram

(Systems < 600 Volts Nominal L-L)

Line

L1 L2 L3

Fuse

Fuse

Fuse

Customer Supplied

CT Shorting Switch or

Test Block

Voltage Mode = Direct Delta 3 CT

R14

R11

R12

N/C

I1-

I2-

I3-

I4-

Y

K

Z

N/C

I1+

I2+

I3+

I4+

Powermonitor 3000

MASTER

MODULE

L1

(+)

L2

(-)

GRD

V1

V2

V3

N

Load

Publication 1404-IN007D-EN-P - October 2004

Customer

Chassis

Ground

R12

KZR14 R11

Y

Page 35

Line

L1 L2 L3

Powermonitor 3000 35

Figure 26 3-Phase 3-Wire Delta Direct Connect with Two CT’s Wiring Diagram

(Systems < 600 Volts Nominal L-L)

Voltage Mode = Direct Delta 2 CT

Fuse

Fuse

Fuse

Powermonitor 3000

Customer Supplied

CT Shorting Switch or

Test Block

R14

R11

R12

N/C

I1-

I2-

I3-

I4-

Y

K

Z

N/C

I1+

I2+

I3+

I4+

R12

KZR14 R11

Y

MASTER

MODULE

L1

(+)

L2

(-)

GRD

V1

V2

V3

N

Load

Customer

Chassis

Ground

Publication 1404-IN007D-EN-P - October 2004

Page 36

36 Powermonitor 3000

Figure 27 Control Power

L1

N/L2

Local

Frame

Ground

Powermonitor 3000

MASTER MODULE

Y

R14

R14

R11

R12

N/C

I1-

I2-

I3-

I4-

R11

K

Z

N/C

I1+

I2+

I3+

I4+

R12 Y

L1

(+)

L2

(-)

GRD

V1

V2

V3

N

Z

K

S1

S2

SCOM

DISPLAY

MODULE

SHLD

RS-485

Control Power

The Powermonitor 3000 draws a nominal 15VA control power. Catalog

numbers 1404-MxxxA-xxx require nominal control power of 120 to

240V ac or 125 to 250V dc. The power supply is self-scaling. Catalog

number 1404-MxxxB-xxx require nominal control power of 24V dc.

Refer to Technical Specifications on page 59 for acceptable control

voltage ranges and wiring termination information.

We strongly recommend the use of a separate source of control power

from the power system being monitored. For applications where

power system information is critical, consider the use of a

user-supplied uninterruptible power supply so that the Powermonitor

3000 continues to operate during power system events such as

significant sags, swells, and transient disturbances.

It is required to connect your Powermonitor 3000 control power

through user-supplied disconnecting means and overcurrent

protection.

Status Inputs

ATTENTION

Do not apply an external voltage to a Status Input.

These inputs have an internal source and are

intended for dry contact input only. Applying a

voltage may damage the associated input or internal

power supply.

All Status Inputs are common to an internal 24VDC source on the

SCOM terminal. Status input terminals S1 and S2 are positive polarity

and SCOM is negative polarity.

For optimal EMC performance, we recommend wiring the status

inputs using shielded cable, Belden™ 8771 or equivalent, with the

cable shield grounded at both ends where possible.

See Figure 28.

Publication 1404-IN007D-EN-P - October 2004

Page 37

Figure 28 Status Input Connections

Powermonitor 3000

MASTER MODULE

+

R14

R11

R12

N/C

N/C

I1-

I1+

I2-

I2+

I3-

I3+

I4-

I4+

Y

K

Z

R14

R11

R12 Y

K

Z

L1

(+)

L2

(-)

GRD

V1

S1

S2

SCOM

V2

V3

N

DISPLAY

MODULE

SHLD

RS-485

N.O.

Contact

N.O.

Contact

Powermonitor 3000 37

R14

Figure 30 Control Relay Connections

10A

Fuse

L1 N

Y

R14

K

R11

Z

R12

N/C

N/C

I1+

I1-

I2+

I2-

I3+

I3-

I4+

I4-

R12 Y

R11

R14

K

L1

(+)

L2

(-)

GRD

V1

V2

V3

N

Z

Powermonitor 3000

MASTER MODULE

S1

S2

SCOM

DISPLAY

MODULE

SHLD

-

+

RS-485

Table 29

Parameter Condition 1 Condition 2

Applied resistance verses

3.5K Ohms or less = ON 5.5K Ohms or greater = Off

status state

Isolation Voltage 500V status input to case; 500V status input to

internal digital circuitry.

TIP

Status Input S2 can be configured for external

demand pulse input. See Powermonitor 3000 User

Manual, publication 1404-UM001, for more

information.

Relay and KYZ Outputs

Figure 30 shows the Form C relay output connections and an example

of customer wiring to a supply voltage and two loads. Terminal R11 is

the common connection, R14 is the normally-open connection and

R12 is the normally-closed connection. You must supply the wetting

voltage and overcurrent protection for the circuit connected to the

relay output.

information.

The KYZ output is a solid-state relay designed for low-current

switching and long life. Its normal application is to provide a pulse

based on energy usage (or one of five other parameters) to an

external pulse accumulator. Terminal K is common, Y is

normally-open, and Z is normally-closed.

Refer to Technical Specifications on page 59 for further

Refer to Powermonitor 3000 User Manual, publication 1404-UM001,

for further information on the application and operation of relay and

KYZ outputs.

Publication 1404-IN007D-EN-P - October 2004

Page 38

38 Powermonitor 3000

Communication Wiring

Methods for connecting communications wiring vary from option to

option. This section provides guidelines for installing dependable

communications wiring for your Powermonitor 3000 system for each

communications option including the native RS-485 communications

port that is part of every Powermonitor 3000.

ATTENTION

IMPORTANT

The user must supply and install special high level

isolation when the possibility of high ground

potential differences exists. This may occur when

communicating with a unit connected to a power

ground mat. Failure to install such isolation may lead

to personal injury or death, property damage or

economic loss.

You will need to configure communications for each

communications option. Refer to the Powermonitor

3000 User Manual, publication 1404-UM001, for

detailed communications configuration instructions.

Native RS-485 Communications Wiring

Every Powermonitor 3000 Master Module is equipped with a native

RS-485 communications port. The RS-485 communications standard

supports multi-drop communications among as many as 32 stations or

nodes. The RS-485 port supports Allen-Bradley DF1 half-duplex slave

and Modbus RTU slave communications at data rates of 1200 to 19.2k

baud.

RS-485 port is also used for Master Module firmware upgrades in the

field.

The native RS-485 communications wiring should be installed in a

daisy-chain configuration. We recommend the use of Belden 9841

2-conductor shielded cable or equivalent. The maximum cable length

is 1,219 meters (4,000 feet). Use of a star or bridging topology is not

recommended and will result in signal distortion unless impedance is

matched for each spur (star topology) or network (bridge topology).

Publication 1404-IN007D-EN-P - October 2004

Page 39

Powermonitor 3000 39

If required, install suitable terminating resistors at the ends of the

daisy-chain cable. For RS-485, install a 150 ohm, 1/4 watt terminating

resistor (refer to the wiring diagram). Note that some RS-485

conversion devices are equipped with internal terminating resistors.

Contact the manufacturer of the converter for additional information.

At each end of each cable segment, connect the cable shields to the

SHLD terminal of the Master Module RS-485 port or the converter. The

SHLD connection provides a low-impedance ground for

high-frequency noise while attenuating DC or line-frequency signals.

The RS-485 port in the Master Module presents a standard load

impedance to the RS-485 network, allowing the standard 32 nodes on

a network.

Configuration options for the native RS-485 port include the protocol,

device address and the data rate. Defaults are:

• Auto-detect protocol

• Device address = the Device ID assigned at the factory in the

range 1 to 254

• Baud rate = 9600

Use of RS-232 to RS-485 converter

You need a user-supplied RS-232 to RS-485 converter for

communication between the Powermonitor 3000 native RS-485 port

and an external device such as a computer or programmable

controller RS-232 port. Examples of these include:

• B&B Electronics, Inc. part number 485SD9TB (DB-9 connection)

• Allen-Bradley catalog number 1761-NET-AIC

Publication 1404-IN007D-EN-P - October 2004

Page 40

40 Powermonitor 3000

IBM Compatible PC

PLC Processor

SLC Processor

Figure 31 RS-485 Connections

Shield Connection

(See Note 4)

External

RS-232C to RS-485

Converter

(See Note 3)

Or

Powermonitor 3000 Device #1

Or

RS-485

SHLD

SHLD

_

+

A

B

150

Ω

Terminating

Resistor

(See Note 2)

Or

ControlLogix Processor

Notes:

1) 3-device network portrayed. Up to 31 DF1

Slave Devices can be connected to a

DF1 Master without the use of a repeater

2) Terminating resistors may be required for

networks with long distances or high noise

environments. Consult the RS-232 to RS-485

converter manufacturer for more information.

3) Examples:

B & B Electronics

Part Number 485SD9TB (DB9).

Allen-Bradley Cat. 1761-NET-AIC.

4) Shields should be connected at

one end only to avoid ground loops.

Powermonitor 3000 Device #2

RS-485

Powermonitor 3000 Device #3 (Last)

RS-485

SHLD

_

+

SHLD

_

+

Publication 1404-IN007D-EN-P - October 2004

150

Ω

Terminating

Resistor

(See Note 2)

Page 41

Powermonitor 3000 41

Optional RS-232 Communications

Powermonitor 3000 units with a catalog number ending in -232 are

equipped with an RS-232 serial communications port in addition to

the native RS-485 port. The RS-232 communications standard supports

point-to-point communications among two stations or nodes. The

RS-232 port supports Allen-Bradley DF1 half-duplex slave and Modbus

RTU slave communications at data rates of 1200 to 19.2k baud. You

must select either optional RS-232 communications or native RS-485

communications. The two ports do not operate at the same time.

The optional RS-232 communications port is a DCE (data

communications equipment) type device. It requires a straight-through

RS-232 cable to connect with personal computers, programmable

controller serial ports, and other DTE (data terminal equipment)

devices. It requires a crossover cable for connection to a modem or

other DCE devices. No terminating resistor is required.

The maximum cable length is 15.24 meters (50.0 feet). Refer to the

following wiring diagrams for cable pinout information for

constructing your own cable using DB-9 and/or DB-25 connectors.

Publication 1404-IN007D-EN-P - October 2004

Page 42

42 Powermonitor 3000

Powermonitor 3000

IBM Compatible

PC

Or PLC Processor

Figure 32 Connecting Powermonitor 3000 to Computer Communications Port

DB9 Female

5

1

6

RS-232

(See Note 3)

no connect

TXD

RXD

no connect

GND

DSR (See Note 2)

RTS (See Note 1)

CTS (See Note 1)

no connect

Notes:

1) Required only if user has

enabled hardware handshaking.

2) Internally pulled active in this DCE

device - function not supported.

3) Straight-through RS-232 cable required.

9

1

2

3

4

5

6

7

8

9

–

output

input

–

ground

output

input

output

–

Or SLC Processor

Or ControlLogix Processor

Powermonitor 3000 IBM PC IBM PC -

DB9 Female

5

TXD

RXD

CTS (See Note 1)

RTS (See Note 1)

GND

1

6

9

2

3

8

7

5

SLC 500 Ch 0 PLC-5 Ch 0 - DB-25 Male

DB9 Female

5

1

13

6

9

2

3

8

7

5

25

DB-25 Female

3

2

5

4

7

1

14

RXD

TXD

CTS (See Note 1)

RTS (See Note 1)

GND

Optional Remote I/O Communications

Powermonitor 3000 units with a catalog number ending in -RIO are

equipped with a Remote I/O port in addition to the native RS-485

port. Allen-Bradley Remote I/O is a robust, widely used industrial data

network that uses twinaxial cable as its physical media. The

Powermonitor 3000 emulates a logical quarter rack and supports both

polled I/O and block transfer communications. The Remote I/O port

and the native RS-485 port may be used simultaneously, although

overall data throughput may be reduced.

Publication 1404-IN007D-EN-P - October 2004

Remote I/O communications wiring should be installed in a

daisy-chain configuration. We recommend the use of Belden 9463

twinaxial cable or equivalent. The maximum cable length is shown in

Page 43

Powermonitor 3000 43

Table 33 and varies with the data rate. Use of a star or bridging

topology is not recommended and will result in signal distortion

unless impendance is matched for each spur (star topology) or

network (bridge topology).

Ensure that all devices on your Remote I/O network are capable of

operation at the desired baud rate. Certain legacy devices may not

support a 230.4k baud rate.

Table 33 Remote I/O Capabilities

Baud Rate Maximum Distance Terminating Resistor

57.6k 3048m (10,000 ft) 150 ohm, 1/4 watt

115.2k 1524m (5,000 ft) 150 ohm, 1/4 watt

230.4k 762m (2,500 ft) 84 ohm, 1/4 watt

Install suitable terminating resistors at the ends of the Remote I/O

network.

TIP

Some Remote I/O devices are equipped with internal

terminating resistors.

At each end of each cable segment, connect the cable shields to the

SHLD terminal of the Remote I/O port connector. The SHLD

connection provides a low-impedance ground for high-frequency

noise while attenuating dc or line-frequency signals. We recommend

that you follow the standard blue/shield/clear color scheme for

Remote I/O to differentiate it from Data Highway Plus

(clear/shield/blue).

Configuration options for optional Remote I/O communications

include the logical rack address and module group (the Powermonitor

3000 is always one-quarter rack), and data rate. Defaults are rack 1,

group 0, 57.6k baud. Refer to the Powermonitor 3000 User Manual,

publication 1404-UM001.

Refer to the note at the beginning of Communication Wiring page 38.

Publication 1404-IN007D-EN-P - October 2004

Page 44

44 Powermonitor 3000

IBM Compatible

PC With R I/O

Interface Card

Or

PLC Processor/

PLC R I/O Scanner

Or

SLC R I/O Scanner

Figure 34 Connecting Powermonitor 3000 to Remote I/O Scanner

82 ohm

Terminating

Resistor

(See Note 2)

1

SHLD

2

Powermonitor 3000 Device #1

R I/O

Blue

Shield

Clear

2

SHLD

1

ControlLogix R I/O Scanner

Or

Notes:

1) 3-Device Network portrayed.

Up to 32 slave devices can

be connected per master

R I/O channel.

2) Terminating Resistors

must be connected

to each end of the

R I/O network. Omit the

terminating resistor(s)

if the device(s) already

are equipped with internal

terminating resistors.

Powermonitor 3000 Device #2

R I/O

Powermonitor 3000 Device #3 (Last)

R I/O

2

SHLD

1

2

SHLD

1

82 ohm

Terminating

Resistor

(See Note 2)

Publication 1404-IN007D-EN-P - October 2004

Page 45

Powermonitor 3000 45

Optional DeviceNet Communications

Powermonitor 3000 units with a catalog number ending in -DNT are

equipped with a DeviceNet port in addition to the native RS-485 port.

DeviceNet is an open-standard, multi-vendor, industrial device data

network that uses a variety of physical media. DeviceNet also

provides 24V dc power to devices connected to the network. The

DeviceNet port and the native RS-485 port may be used

simultaneously, although overall data throughput may be reduced.

For detailed DeviceNet system installation information, including

cable lengths, the placement of terminating resistors, power supplies

and other media components, refer to publication DN-6.7.2,

DeviceNet cable System Planning and Installation Manual.

Refer to the note at the beginning of Communication Wiring page 38.

Install suitable terminating resistors at the ends of the DeviceNet

cable.

TIP

IMPORTANT

Some DeviceNet devices are equipped with internal

terminating resistors.

You must install and wire a suitable 24V dc power

supply to the V+ and V- conductors in the DeviceNet

cable. The Powermonitor 3000 consumes less than

100 mA from the DeviceNet 24V dc supply.

Configuration options for optional DeviceNet Communications

include the node address (MAC ID) and data rate. Defaults are node

63 and 125k baud. Refer to the Powermonitor 3000 User Manual,

publication 1404-UM001.

Table 35 DeviceNet Terminal Block Wiring Connections

Term in al Signal Function Color

1 COM (V-) Common Black

2 CAN_L Signal Low Blue

3 SHIELD Shield Uninsulated

4 CAN_H Signal High White

5 VDC+ (V+) Power Supply Red

Publication 1404-IN007D-EN-P - October 2004

Page 46

46 Powermonitor 3000

Figure 36 Connecting Powermonitor 3000 to other DeviceNet Devices

Powermonitor 3000 Device

IBM Compatible PC With

1784 PCDPCMCIA Interface Card

Or

1770-KFD Interface Box

Or

PLC With

1771-SDN Scanner

Or

SLC With

1747-SDN Scanner

Or other DeviceNet

scanner devices

V-

CAN_L

SHLD

CAN_H

V+

V-

CAN_L

SHLD

CAN_H

V+

V-

CAN_L

SHLD

CAN_H

V+

V-

CAN_L

SHLD

CAN_H

V+

121 ohm

Terminating

Resistor

(See Note 2)

Cabling:

Allen-Bradley catalog number:

1485C-P1-C

(thin cable - DeviceNet)

Notes:

1) Example network protrayed.

For detailed DeviceNet

installations, including

cable requirements, refer to

Publication DN-6.7.2.

2) Terminating Resistors

must be connected

to each end of the

DeviceNet network. Omit the

terminating resistor(s)

if the device(s) already

are equipped with internal

terminating resistors.

121 ohm

Terminating

Resistor

(See Note 2)

Publication 1404-IN007D-EN-P - October 2004

DeviceNet

+

24V dc

Power Supply

-

Optional Ethernet Communications

Powermonitor 3000 units with catalog numbers ending in -ENT are

equipped with an industry standard Ethernet 10baseT port. Your

Powermonitor 3000 may contain one of two hardware versions of the

Ethernet port. The catalog number series determines which hardware

version the product contains.

differences.

Table 37 below indicates the

Page 47

Powermonitor 3000 47

Table 37 Ethernet Hardware Versions

Series A Series B

Data Rate 10M Bit only 10/100M bit

Protocol Supported EtherNet/IP and CSP EtherNet/IP

Built-in Web Page Yes, fixed Yes, configurable

Supports CIP Class 1

Connnection (I/O Data)

Supports Control FLASH No Yes

No Yes

The Powermonitor 3000 is designed to connect easily to

industry-standard Ethernet hubs and switches using standard UTP

(unshielded twisted-pair) cables with RJ-45 connectors.

Table 38

shows the cable and connector pin assignments and Figure 39 shows

a typical star network topology.

Table 38 Ethernet Wiring Connections

Term in al Signal Function

1 TX+ TX+

2 TX- TX-

3 RX+ RX+

4

5

6 RX- RX-

7

8

Publication 1404-IN007D-EN-P - October 2004

Page 48

48 Powermonitor 3000

Figure 39 Powermonitor 3000 Ethernet Network Example

Ethernet Switch

LAN

Powermonitor 3000

Master Module #1

PC w/RSLinx and

RSPower 32 or

RSEnergyMetrix

PLC 5 Controller

SLC 500 Controller

Powermonitor 3000

Master Module #2

ControlLogix Controller

Refer to the note at the beginning of Communication Wiring page 38.

Configuration options for optional Ethernet communications include

the IP (Internet Protocol) address, subnet mask, default gateway IP

address and protocol.

Defaults are:

• IP address: 128.1.1.xxx where xxx is the Device ID assigned at

the factory in the range 1 to 254.

• Subnet mask: 255.255.0.0

• Default gateway IP address: 128.1.1.1

• Protocol: CSP (PCCC)/CIP (EtherNet/IP) dual stack (Series A),

CIP (EtherNet/IP) (Series B)

Publication 1404-IN007D-EN-P - October 2004

Page 49

Powermonitor 3000 49

Optional ControlNet Communications

Powermonitor 3000 units with catalog numbers ending in -CNT are

equipped with a ControlNet communications interface. The

ControlNet Powermonitor 3000 can be connected in a single media or

redundant media network.

network using redundant media.

Figure 40 Powermonitor 3000 ControlNet Network Example

1756-CNBR

(in 1756-A4 chassis)

Figure 40 shows an example ControlNet

Powermonitor 3000 Device

ControlNet

node

redundant media

(optional)

Refer to the following documentation for ControlNet network wiring

requirements and general ControlNet information.

ControlNet link

Powermonitor 3000 Device

ControlNet

node

• ControlNet Cable System Planning and Installation Manual,

publication 1786-6.2.1

• ControlNet Coax Tap Installation Instructions, publication

1786-5.7

• ControlNet Coax Media Planning and Installation Guide,

publication CNET-IN002.

Publication 1404-IN007D-EN-P - October 2004

Page 50

50 Powermonitor 3000

Connecting a Programming Terminal to the Network Using

1786-CP Cable

To connect a programming terminal to the network using a 1786-CP

cable, you have the following options:

1. Using a 1784-KTC, -KTCx, or -PCC communication card and a

1786-CP cable:

1784-KTC, KTCx,

Powermonitor 3000 Device

1786-CP Cable

PCIC, or PCC card

ControlNet link

2. Using a 1770-KFC communication interface, a serial or parallel

connection, and a 1786-CP cable:

Powermonitor 3000 Device

ControlNet link

1786-CP

Cable

(1)

1770-KFC

Serial or parallel

connections

The 1786-CP cable can be plugged into any ControlNet product’s NAP

to provide programming capability on the ControlNet network. A

programming terminal connected through this cable is counted as a

node and must have a unique network address.

Publication 1404-IN007D-EN-P - October 2004

Page 51

Powermonitor 3000 51

Maintenance

ATTENTION

Use a 1786-CP cable when connecting a

programming terminal to the network through NAPs.

Using a commercially available RJ-style cable could

result in network failure.

Accessing Self-test/Diagnostic Data using Display Module

You can access valuable diagnostic information using the optional

Display Module. Connect the Display Module to the Master Module

using the Display Module cable. Using the four control keys, navigate

through the menus to “Display” - “Status” and select using the Enter

key. The Display Module then displays the following data. Use the up

and down arrow keys to step through the status data.

• - the unit catalog number and series revision letter.

• - displays the revenue meter accuracy class.

• - the unit’s unique Warranty Identification Number

(needed for service and optional firmware enhancements).

• - displays details of the digital board, analog board,

and ASIC revisions.

• - shows the Master Module

firmware revision.

• - shows the units device ID number

assigned at the factory. This number is also used in the default

address for native RS-485, and optional RS-232 and Ethernet

communications.

• - displays a status code bitfield

as a hex number. A non-zero value indicates a problem.

• - indicates the health of the flash memory

code area.

• - indicates the health of the random-access memory.

• - indicates the health of the flash memory

data area.

• - indicates the health of the super-cap backed

non-volatile random access memory.

• - indicates the data acquisition system health.

• - indicates the system watchdog timer status.

• - indicates the health of the real-time clock.

• - displays the firmware revision of the optional

communications card (if applicable).

• - displays the optional communication card type.

Publication 1404-IN007D-EN-P - October 2004

Page 52

52 Powermonitor 3000

• - displays the optional communications status bitfield

as a hex number (0000 hex is normal for -232 and -RIO units,

and 9001 hex is normal for -DNT and -ENT units).

• - displays the Display Module status bitfield as a hex

number. A non-zero value may indicate a problem, although a

non-zero value may appear if a Display Module is connected to

an operating Master Module.

• - indicates the Display Module firmware revision.

• - displays the current Date.

• - displays the current Time.

• - shows the status of the Form 4C relay.

• - shows the status of the KYZ output.

• - shows the status of Status Input 1.

• - shows the accumulated value of Status Input

1 counter, since last cleared.

• - shows the status of Status Input 2, since

last cleared.

• - shows the accumulated value of Status Input

2 counter.

• - displays the output word bitfield as a hex number.

Refer to the Powermonitor 3000 User Manual, publication

1404-UM001 for information on using the Display Module.

Calibration

To meet general operating requirements, regular recalibration is not

necessary.

For special customer requirements, contact your Rockwell Automation

representative for calibration or service information.

Publication 1404-IN007D-EN-P - October 2004

Page 53

Cleaning Instructions

Powermonitor 3000 53

ATTENTION

Electrostatic discharge can damage integrated circuits

or semiconductors. Follow these guidelines when

you handle the module.

• Touch a grounded object to discharge static

potential.

• Wear an approved wrist strap grounding device.

• Do not open the module or attempt to service

internal components.

• If available, use a static safe work station.

• When not in use, keep the module in its static

shield bag.

• Disconnect and lock out all power sources and

short all current transformer secondaries before

servicing. Failure to comply with these

precautions can lead to personal injury or death,

property damage or economic loss.

1. Turn off all electrical power supplied to the Master Module.

2. If necessary, clean the Master Module with a dry, anti-static,

lint-free cloth. Remove all dust and any obstructions from the

cooling air vents on the upper, lower, and ends of the module.

Ensure that the nameplate is clean and in good condition.

3. If necessary, clean the Display Module with a dry, anti-static,

lint-free cloth. Remove all dust and any foreign material(s) from

the exterior of the module. Ensure that the graphic front panel

overlay and back nameplate are clean and in good condition.

Publication 1404-IN007D-EN-P - October 2004

Page 54

54 Powermonitor 3000

Field Service Considerations

If the Powermonitor 3000 requires servicing, please contact your

nearest Allen-Bradley Sales Office. To minimize your inconvenience,

the initial installation should be performed in a manner which makes

removal easy.

1. A CT shorting block should be provided to allow the

Powermonitor 3000 Master Module current inputs to be